Panasonic SA-HT530GCP Schematic

A

A

A

ORDER NO. MD0503084C3

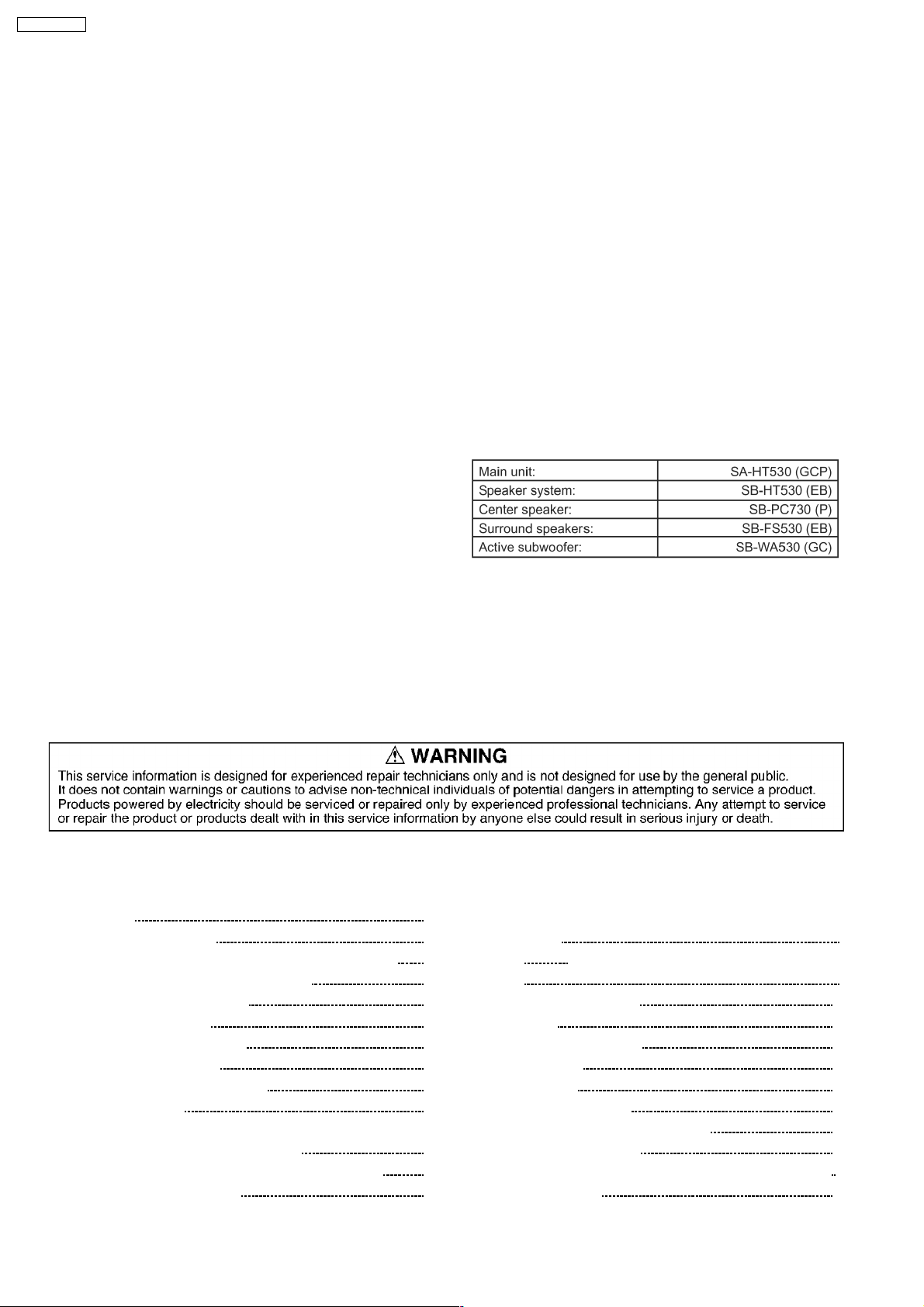

DVD Home Theater Sound System

SA-HT530GCP

Colour

(S)...Silver Type

Specification

n Amplifier Section

RMS Output Power: Dolby Digital Mode

Front Ch

55 W per channel (6 Ω ), 1 kHz, 10% THD

Surround Ch

55 W per channel (6 Ω ), 1 kHz, 10% THD

Center Ch

160 W per channel (6 Ω ), 1 kHz, 10% THD

Subwoofer Ch

220 W per channel (4 Ω ), 100 Hz, 10% THD

Total RMS Dolby Digital Mode Power 600 W

DIN Output Power: Dolby Digital Mode

Front Ch

40 W per channel (6 Ω ), 1 kHz, 1% THD

Surround Ch

40 W per channel (6 Ω ), 1 kHz, 1% THD

Center Ch

120 W per channel (6 Ω ), 1 kHz, 1% THD

Subwoofer Ch

150 W per channel (4Ω ), 100 Hz, 1% THD

Total DIN Dolby Digital Mode Power 430 W

n FM/AM Tuner, Terminals Section

Preset station FM 15 stations

AM/MW 15 stations

Frequency Modulation (FM)

Frequency Range

87.50-108.00 MHz (50-kHz step)

Sensitivity 2.5 µV (IHF)

S/N 26 dB 2.2 µV

ntenna terminals 75 Ω (unbalanced)

mplitude Modulation (AM/MW)

Frequency Range 522-1629 kHz (9-kHz step)

520-1630 kHz (10-kHz step)

M Sensitivity S/N 20 dB at 999 kHz 560 µV/m

Phone Jack

Terminal Stereo, 3.5 mm jack

Mic Jack

Sensitivity 0.7mV,1.2kΩ

Terminal Mono, 6.3 mm jack (2 systems)

n Disc Section

Disc played [8 cm or 12 cm]

1. DVD-RAM (DVD-VR compatible, JPEG formatted disc)

2. DVD-Audio

3. DVD-Video

4. DVD-R, DVD-RW (DVD-Video compatible) + R, + RW (Video

compatible)

5. CD-Audio (CD-DA)

6. Video CD

7. SVCD (Conforming to IEC62107)

8. CD-R/RW (CD-DA, Video-CD, SVCD, MP3, WMA, JPEG formatted

disc)

9. MP3/WMA*1

© 2005 Matsushita Electric Industrial Co. Ltd.. All

rights reserved. Unauthorized copying and

distribution is a violation of law.

A

SA-HT530GCP

· Compatible compression rate:

MP3: between 32 kbps and 320 kbps

WMA: between 48 kbps and 320 kbps

10. JPEG*1

· Exif Ver 2.1 JPEG Baseline files

· Picture resolution: between 320 x 240 and 6144 x 4096 pixels

(sub sampling is 4:2:2 or 4:2:0)

11. HighMAT Level 2 (Audio and Image)

*1 The total combined maximum number of recognizable audio and

picture contents and groups: 4000 audio and picture contents and 400

groups.

Pick up

Wavelength CD 785 nm

DVD 662 nm

Laser power CLASS 2/CLASS 3A

udio output (Disc)

Number of channels 5.1ch (FL, FR, C, SL, SR, SW)

n Video Section

Video System

Signal system PAL625/50, PAL525/60, NTSC

Composite video output

Output level 1Vp-p(75Ω)

Terminal Pinjack(1system)

S-video output

Y output level 1Vp-p(75Ω)

C output level PAL; 0.3 Vp-p (75 Ω )

NTSC; 0.286 Vp-p (75 Ω )

Terminal S terminal (1 system)

Component Video Output (480p/480i)

Y output level 1Vp-p(75Ω)

PBoutput level 0.7 Vp-p (75 Ω)

PRoutput level 0.7 Vp-p (75 Ω )

Terminal

Pin jack (Y: green, PB:blue,PR:red)(1system)

n General

Power Supply

AC 110/127/220-230/240 V, 50/60 Hz

Power consumption 25 W (SA-HT530),

250 W (SB-WA530)

Dimensions (W x H x D) 430 x 60 x 348.3 mm

Mass 2.7 kg (SA-HT530)

Operating temperature range +5 °C to +35 °C

Operating humidity range

5 % to 90 % RH (no condensation)

Power consumption in standby mode: approx. 0.9 W

*2Rating with low cut filter equipped amplifier

n System

SC-HT530 (GCP)

Note:

1. Specifications are subject to change without notice. Mass and

dimensions are approximate.

2. Total harmonic distortion is measured by the digital spectrum

analyzer.

CONTENTS

Page Page

1 Before Use

2 Use of Active Subwoofer

2.1. Checking Main Unit when Active Subwoofer is Used

2.2. Checking Main Unit Using Power Jig

3 Before Repair and Adjustment

4 SAFETY PRECAUTIONS

4.1. GENERAL GUIDELINES

5 Handling the Lead Solder

5.1. About lead free solder (PbF)

6 Protection Circuitry

7 Prevention of Electro Static Discharge (ESD) to

Electrostatically Sensitive (ES) Devices

8 Cautions to Be Taken When Handling Optical Pickup

8.1. Handling Optical Pickup

3

4

4

5

5

5

5

6

6

6

7

8

8

8.2. Cautions to Be Taken During Replacement of Optical

Pickup

8.3.

9 Precaution of Laser Diode

10 Accessories

11 Remote Control Reference

12 Disc information

13 About HighMAT

13.1. What 痴 HighMAT?

13.2. Why take advantage of HighMat?

13.3. Benefits of HighMat?

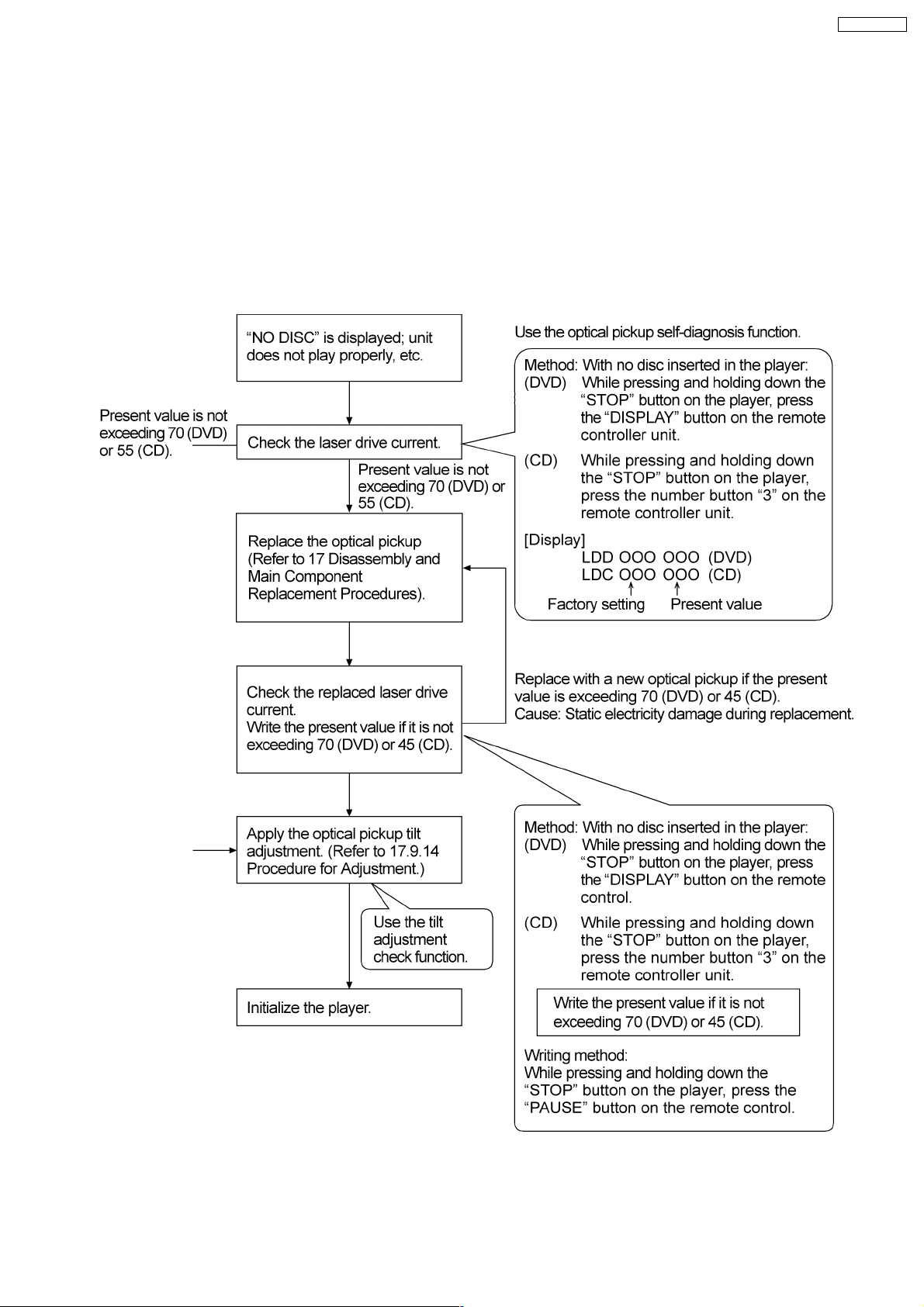

14 Optical Pickup Self-Diagnosis and Replacement Procedure

14.1. Self-diagnosis

Grounding for Preventing Electrostatic Destruction

2

9

9

10

11

12

13

17

17

18

18

21

21

SA-HT530GCP

14.2. Cautions to Be Taken During Replacement of Optical

Pickup and Spindle Motor

15 Self-Diagnosis Function

15.1. Automatic Displayed Error Codes

15.2. Memorized Error Codes

15.3. Service Mode Table 1

15.4. DVD/CD Self-Diagnosis Error Code Description

15.5. Mode Table 2

15.6. Lock Function

15.7. Things to Do After Repair

16 Service precautions

16.1. Recovery after the player is repaired

16.2. DVD Player Firmware Version Upgrade Process

16.3. Firmware Version Upgrade Process by Using Recovery

Disc

17 Disassembly and Main Component Replacement Procedures

17.1. Disassembly flow chart

17.2. P.C.B. Locations

17.3. Disassembly of Top Cabinet

17.4. Disassembly of Front Panel Unit

17.5. Disassembly of Panel P.C.B., Headphone P.C.B. & MIC

P.C.B.

17.6. Disassembly of Main P.C.B.

17.7. Disassembly of CD/ DVD Mechanism

17.8. Disassembly and Assembly Mechanism Unit

18 Service Position

18.1. Checking the Main P.C.B.

18.2. Checking the Main P.C.B., Panel P.C.B., MIC P.C.B. and

22

19 Adjustment Procedure

23

23

20 Block Diagram

23

24

21 Schematic Diagram

24

25

27

27

28

28

28

22 Printed Circuit Board

28

30

30

31

23 Wiring Connection Diagram

24 Illustration of IC 痴, Transistors and Diodes

32

32

25 Terminal Function of IC 痴

33

33

26 Parts Location and Replacement Parts List

34

34

42

42

Headphone P.C.B.

19.1. Required Tools and Equipment

21.1. Optical Pickup Unit Circuit

21.2. (A) DVD Module (DV2) Circuit

21.3. (B) Main Circuit

21.4. (C) Panel Circuit

21.5. (D) Microphone Circuit

21.6. (E) Headphone Circuit & (F) CD Tray Loading Circuit

22.1. (A) DVD Module P.C.B. (Side A & B)

22.2. (B) Main P.C.B.

22.3. (C) Panel P.C.B., (D) Mic P.C.B. & (E) Headphone P.C.B.

22.4. (F) CD Tray Loading P.C.B.

25.1. IC2018(C2CBHG000168): Microprocessor

25.2. IC8001 (MN2DS0003APH) DV2.1 IC

26.1. DVD Loading Mechanism

26.2. Cabinet

26.3. Component Parts List

26.4. Packing Materials & Accessories Parts List

26.5. Packaging

43

44

44

46

54

55

56

63

70

71

72

73

73

75

77

79

80

82

83

83

83

87

88

90

92

100

101

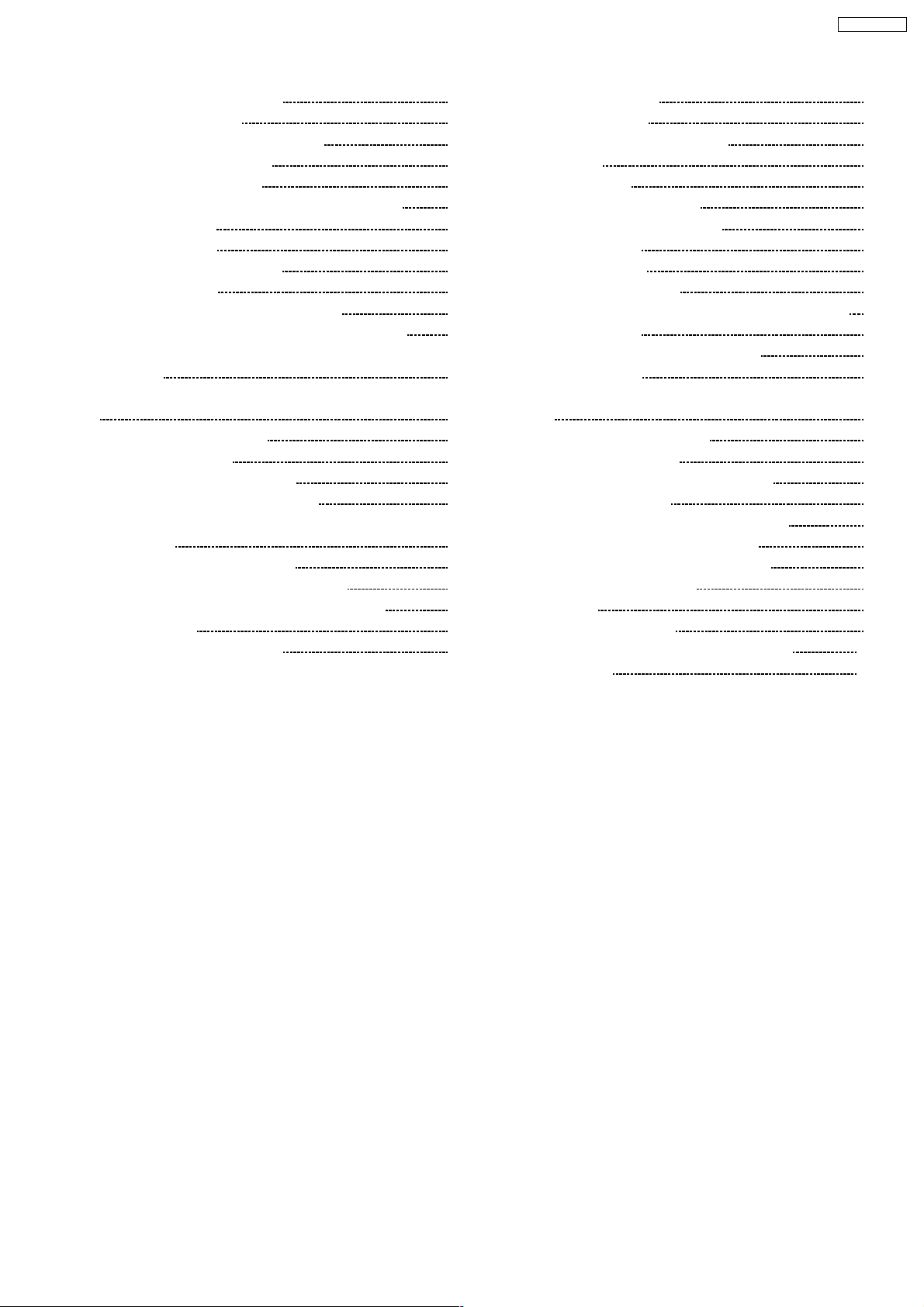

1 Before Use

Be sure to disconnect the mains cord before adjusting the voltage selector.

Use a minus(-) screwdriver to set the voltage selector (on the rear panel) to the voltage setting for the area in which the unit will

be used. (If the power supply in your area is 117V or 120V, set to the “127V” position.)

Note that this unit will be seriously damaged if this setting is not made correctly. (There is no voltage selector for some countries,

the correct voltage is already set.)

3

SA-HT530GCP

2 Use of Active Subwoofer

2.1. Checking Main Unit when Active Subwoofer is Used

4

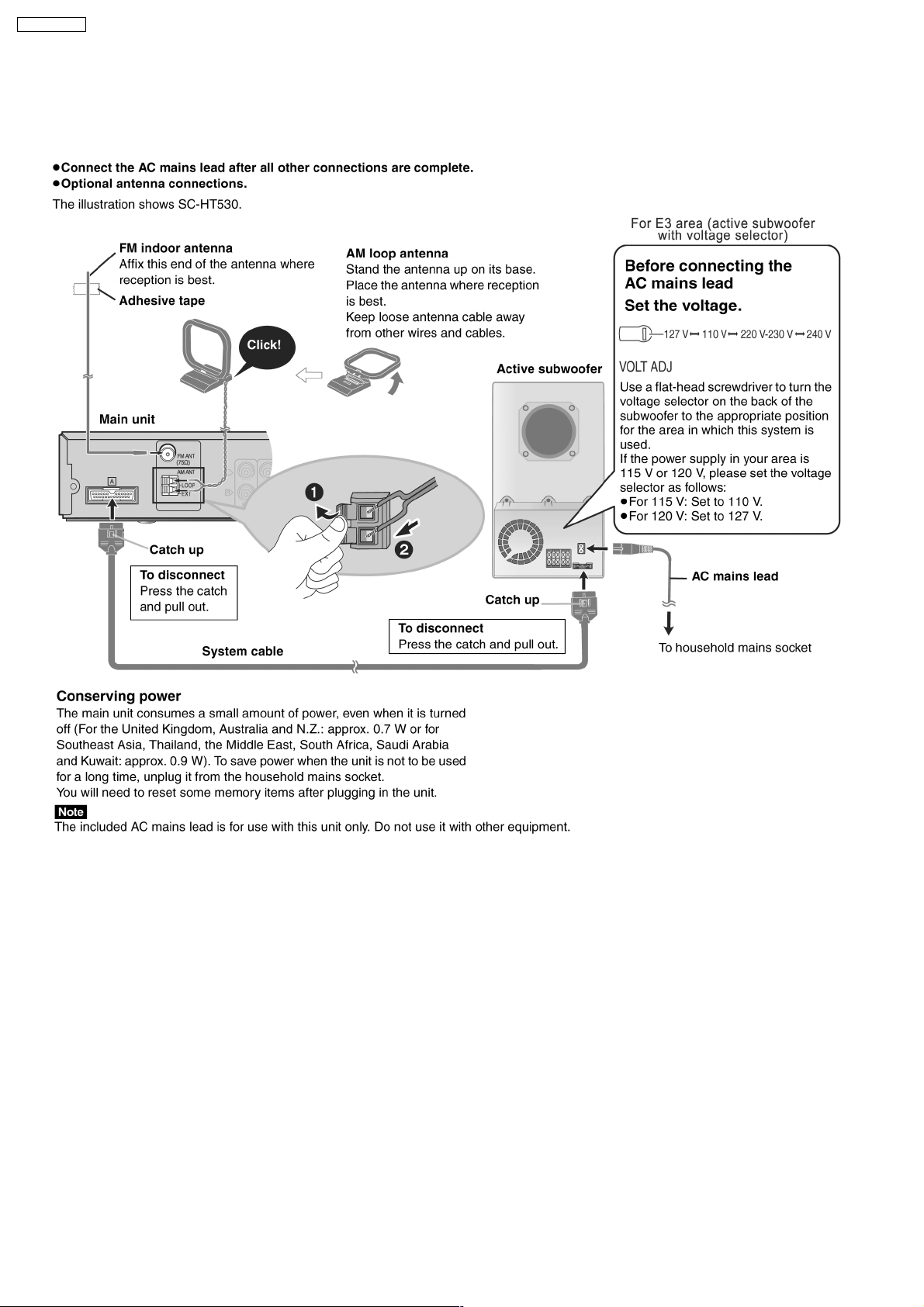

2.2. Checking Main Unit Using Power Jig

If the active subwoofer is not available during time of repair to the unit, the following equipment could be used.

Jig product number

RFKZ0182 (110V , 127V, 220V, 230V - 240V for with voltage selector overseas domestic use).

SA-HT530GCP

3 Before Repair and Adjustment

Disconnect AC power, discharge Power Supply Capacitors C2080 through a 10Ω, 10 W resistor to ground.

DO NOT SHORT-CIRCUIT DIRECTLY (with a screwdriver blade, for instance), as this may destroy solid state devices.

After repairs are completed, restore power gradually using a variac, to avoid overcurrent.

Current consum ption at AC 110V, 50/60Hz in NO SIGNAL mode should be

Current consum ption at AC 230V - 240V, 50Hz in NO SIGNAL mode should be ~420 mA (Active Subwoofer).

~835 mA (Active Subwoofer).

4 SAFETY PRECAUTIONS

4.1. GENERAL GUIDELINES

1. When servicing, observe the original lead dress. If a short circuit is found, replace all parts which have been overheated or

damaged by the short circuit.

2. After servicing, ensure that all the protective devices such as insulation barriers, insulation papers shields are properly installed.

3. After servicing, make the following leakage current checks to prevent the customer from being expose d to shock hazards.

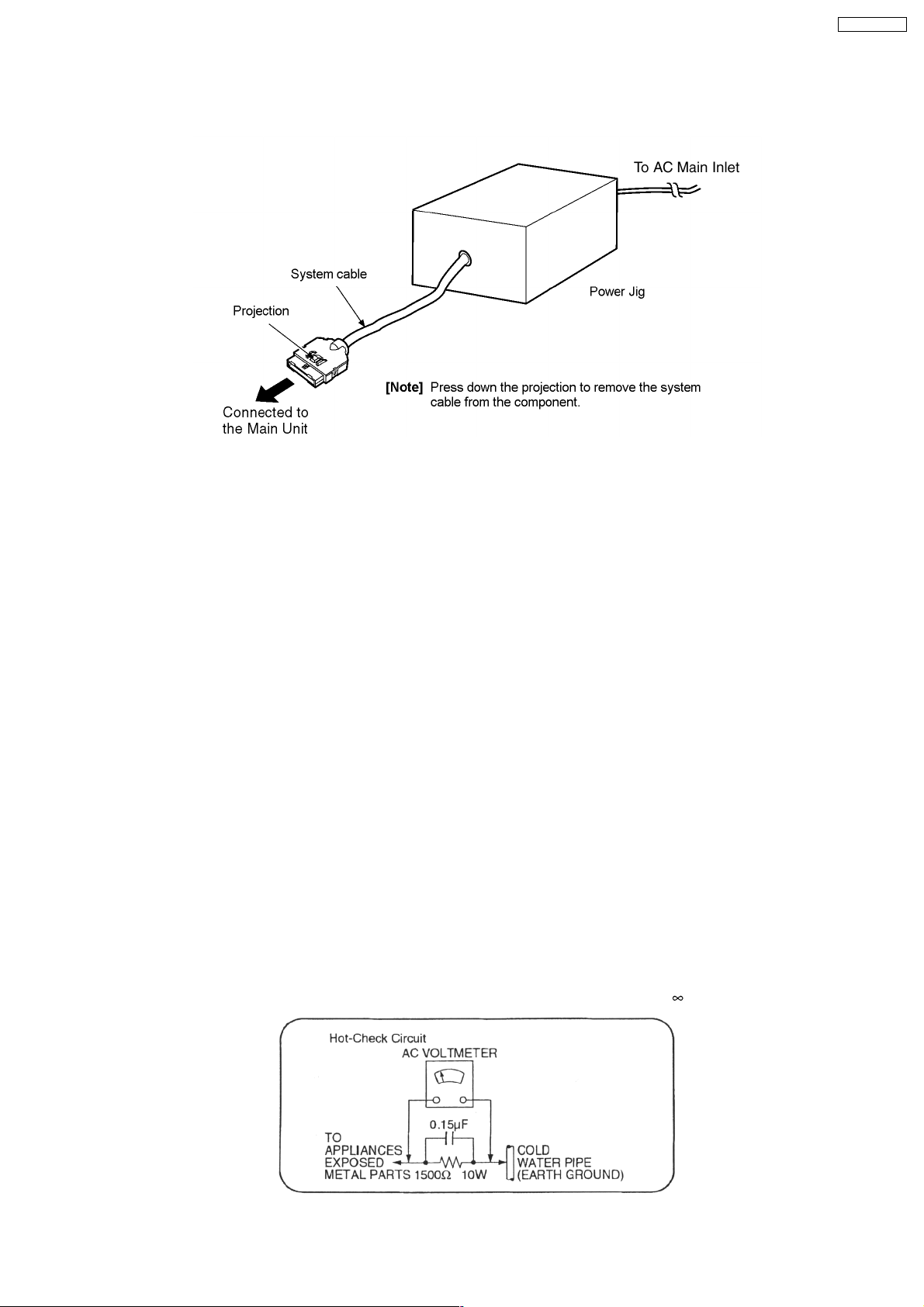

4.1.1. LEAKAGE CURRENT COLD CHECK (FOR ACTIVE SUBWOOFER)

1. Unplug the AC cord and connect a jumper between the two prongs on the plug.

2. Measure the resistance value, with an ohmmeter, between the jumpered AC plug and each exposed metallic cabine t part on

the equipment such as screwheads, connectors, control shafts, etc. When the exposed metallic part has a return path to the

chassis, the reading should be between 1MΩ and 5.2Ω.

When the exposed metal does not have a return path to the chassis, the reading must be

.

Fig. 1

5

SA-HT530GCP

4.1.2. LEAKAGE CURRENT HOT CHECK (See Figure 1.)

1. Plug the AC cord directly into the AC outlet. Do not use an isolation transformer for this check.

2. Connect a 1.5kΩ, 10 watts resistor, in parallel with a 0.15µF capacitor, between each exposed metallic part on the set and a

good earth ground such as a water pipe, as shown in Figure 1.

3. Use an AC voltmeter, with 1000 ohms/volt or more sensitivity, to measure the potential across the resistor.

4. Check each exposed metallic part, and measure the voltage at each point.

5. Reverse the AC plug in the AC outlet and repeat each of the above measurements.

6. The potential at any point should not exceed 0.75 volts RMS. A leakage current tester (Simpson Model 229 or equivalent) may

be used to make the hot checks, leakage current must not exceed 1/2 milliamp. In case a measurement is outside of the limits

specified, there is a possibility of a shock hazard, and the equipment should be repaired and rechecked before it is returned to

the customer.

5 Handling the Lead Solder

5.1. About lead free solder (PbF)

Distinction of PbF P.C.B. :

P.C.B.s (manufactured) using lead free solder will have a PbF stamp on the P.C.B.

Caution:

· Pb free solder has a higher melting point that standard solder; Typically the melting point is 50 - 70°F (30 - 40°C) higher.

Please use a high temperature soldering iron. In case of the soldering iron with temperature control, please set it to 700 ± 20°F

(370 ± 10°C).

· Pb free solder will tend to splash when heated too high (about 1100°F/600°C).

· W hen soldering or unsoldering, please completely remove all of the solder on the pins or solder area, and be sure to heat the

soldering points with the Pb free solder until it melts enough.

6 Protection Circuitry

The protection circuitry may have operated if either of the following conditions are noticed:

· No sound is heard when the power is turned on.

· Sound stops during a performance.

The function of this circuitry is to prevent circuitry damage if, for example, the positive and negative speake r connection wires are

“shorted”, or if speaker systems with an impedance less than the indicated rated impedance of the amplifier are used.

If this occurs, follow the procedure outlines below:

1. Turn off the power.

2. Determine the cause of the problem and correct it.

3. Turn on the power once again after one minute.

Note :

When the protection circuitry functions, the unit will not operate unless the power is first turned off and then on again.

6

SA-HT530GCP

7 Prevention of Electro Static Discharge (ESD) to

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by electricity. Such components commonly are called

Electrostatically Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some field-effect transistors and

semiconductor “chip” components. The following techniques should be used to help reduce the incidence of component damage

caused by electro static discharge (ESD).

1. Immediately before handling any semiconductor component or semiconductor-equiped assembly, drain off any ESD on your

body by touchin g a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap,

which should be removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equiped with ES devices, place the assembly on a conductive surface such as aluminium

foil, to prevent electrostatic charge build up or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder remover device. Some solder removal devices not classified as “anti-static (ESD protected)” can

generate electrical charge to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminium foil or

comparable conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be installed.

Caution

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise harmless motion such as the

brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD)

sufficient to damage an ES device).

7

SA-HT530GCP

8 Cautions to Be Taken When Handling Optical Pickup

· The laser diode used inside the optical pickup could be destroyed due to static electricity (potential difference is caused by

electrostatic load discharged from clothes and human body). Handle the parts carefully to avoid electrostatic destruction during

repair & during replacement.

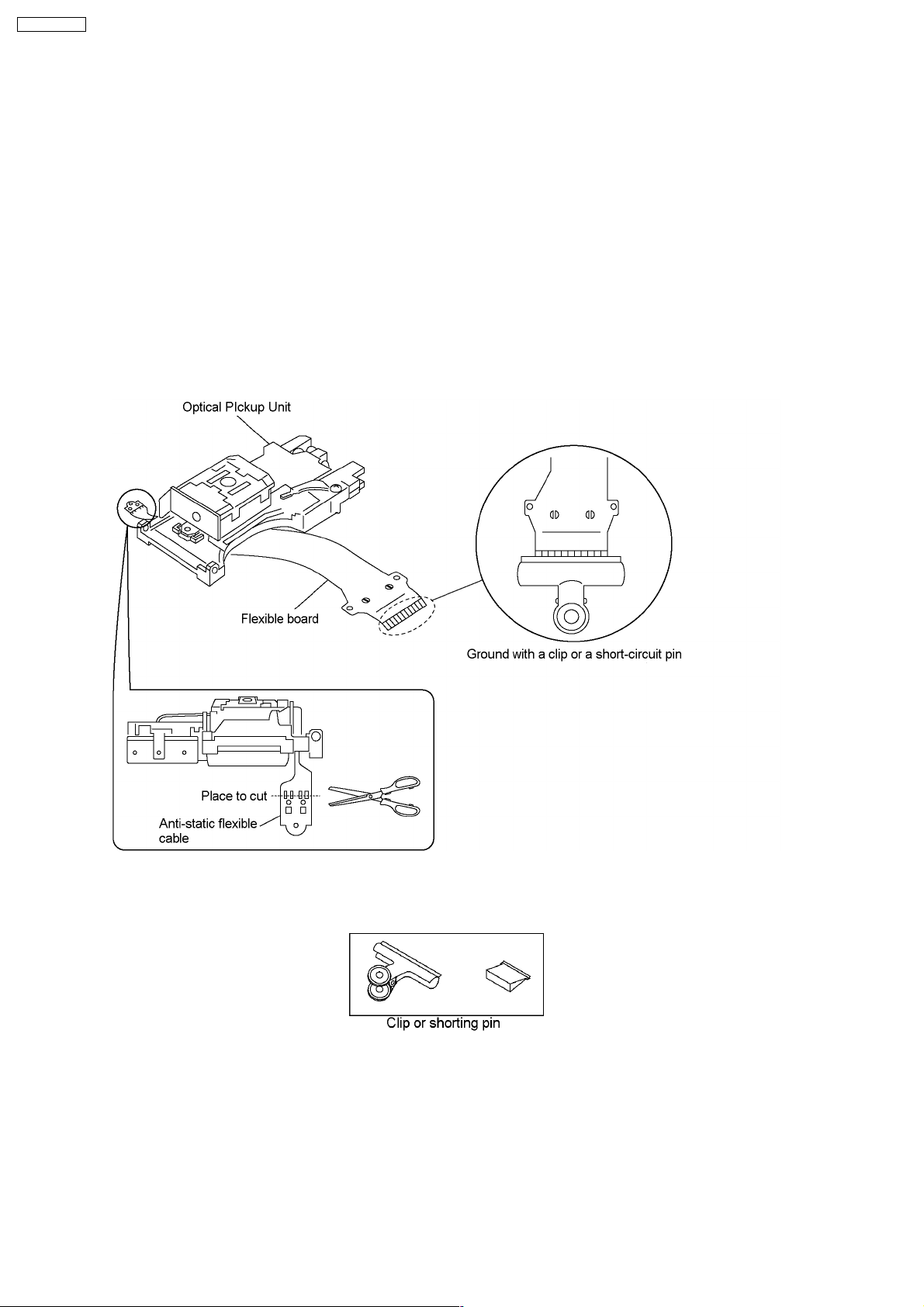

8.1. Handling Optical Pickup

1. Do not cause any strong impact on optical pickup as the unit structurally uses an extremely precise technology.

2. Short-circuit the flexible cable of optical pickup removed from the circuit board using a short-circuit pin or clip in order to prevent

laser diode from electrostatic destruction. (Refer to Fig. 8-1 and Fig. 8-2.)

3. Do not handle flexible cables forcibly as this may cause snapping. Handle the parts carefully. (Refer to Fig. 8-1)

4. A new optical pickup is equipped with an anti-static flexible cable. After replacing and connecting to the flexible board, cut the

anti-static flexible cable. (Refer to Fig. 8-1)

Fig. 8-1

Fig. 8-2

8

SA-HT530GCP

8.2. Cautions to Be Taken During Replacement of Optical Pickup

Supplied optical pickup is equipped with a short clip found at the end of flexible cable in order to prevent electrostatic destruction

of laser diode. Before connection, remove the short clip, and check that the short land is opened (remove solder if the part is shortcircuited). Also ensure human body is properly ground (Refer Section 8.3)

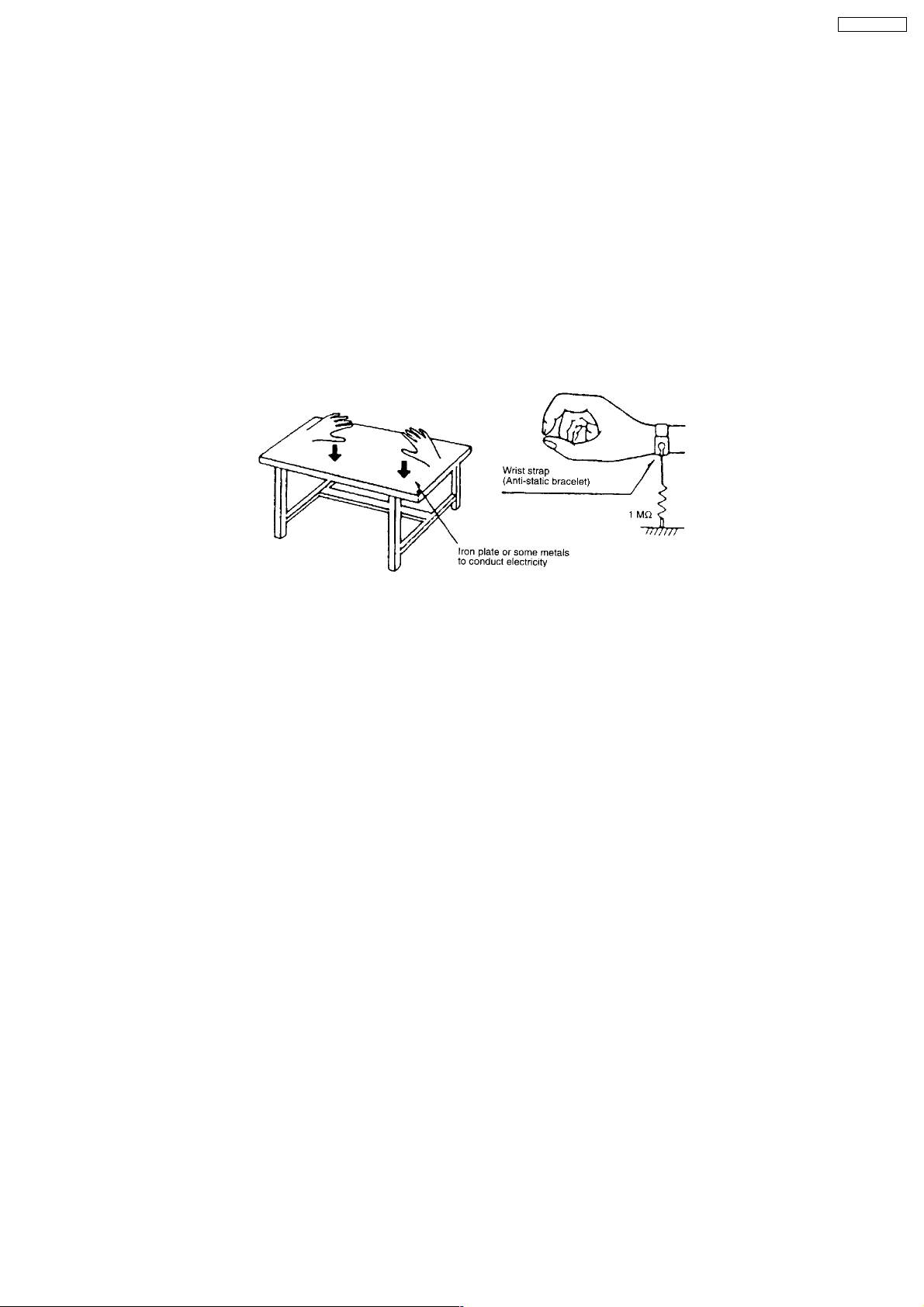

8.3. Grounding for Preventing Electrostatic Destruction

1. Human body grounding

Use an anti-static wrist strap to release static electricity accumulated in your body. (Refer to Fig. 8-3)

2. Workplace grounding

Place a conductive material (conductive sheet) or iron board where optical pickup is placed . (Refer to Fig. 8-3)

Note:

Keep your clothes away from optical pickup as wrist strap does not release the static electricity charged in clothes.

Fig. 8-3

9

SA-HT530GCP

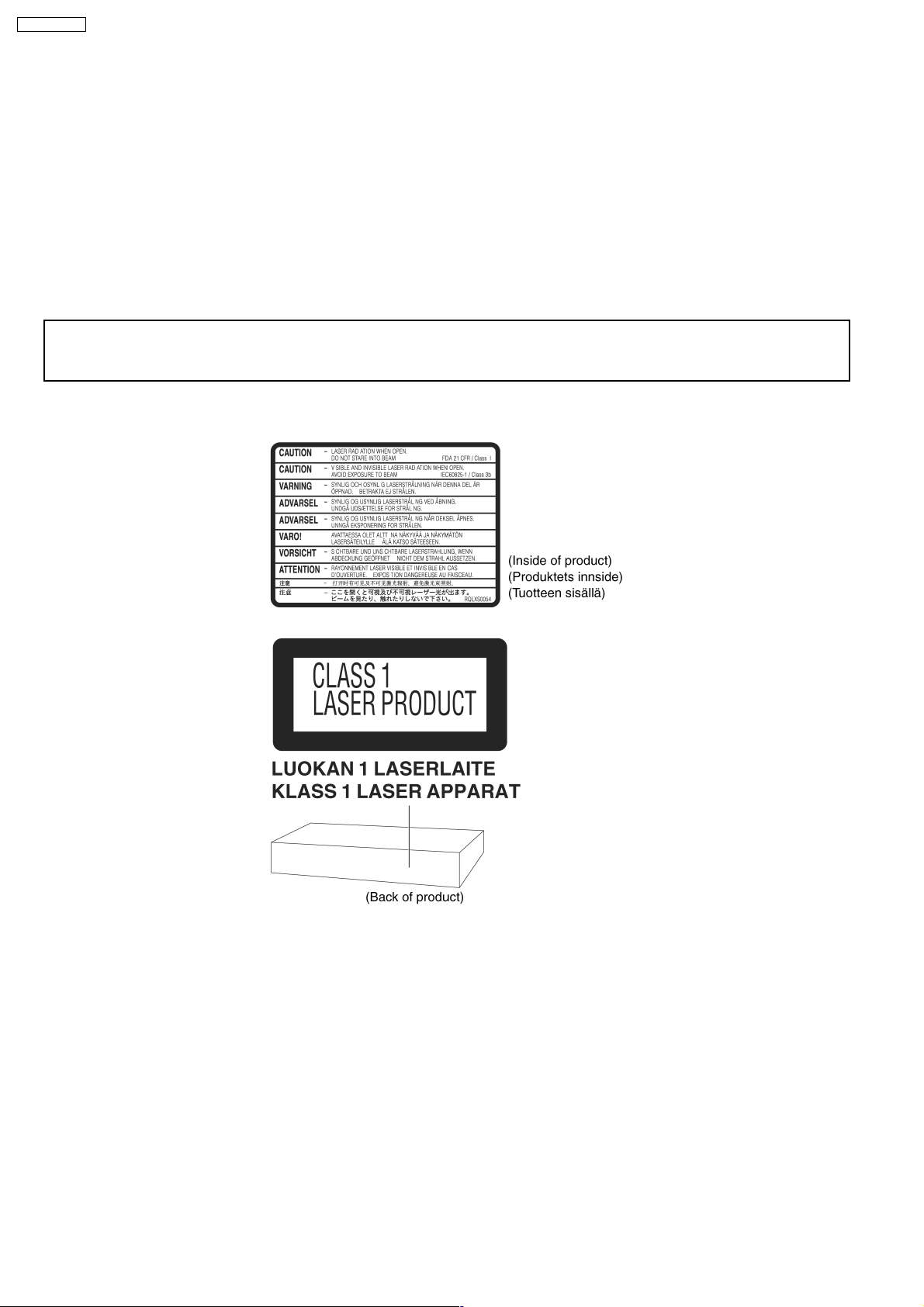

9 Precaution of Laser Diode

CAUTION :

This product utilizers a class 1 laser. Invisible laser radiation is emitted from the optical pick up lens.

When the unit is turned on:

Wavelenght : 662nm/785nm

Maximum output radiation power from pick up : 100µW/VDE

1. Do not disassemble the optical pick up unit, since radiation from exposed laser diode is dangerous.

2. Do not adjust the variable resistor on the pick up unit. It was already adjusted.

3. Do not look at the focus lens using optical instruments.

4. Recommend not to look at pick up lens for a long time.

CAUTION!

THIS PRODUCT UTILIZES A LASER.

USE OF CONTROLS OR ADJUSTMENTS OR PERFORMANCE OF PROCEDURES OTHER THAN THOSE SPECIFIED HEREIN MAY RESULT

IN HAZARDOUS RADIATION EXPOSURE.

n Use of Caution Labels

10

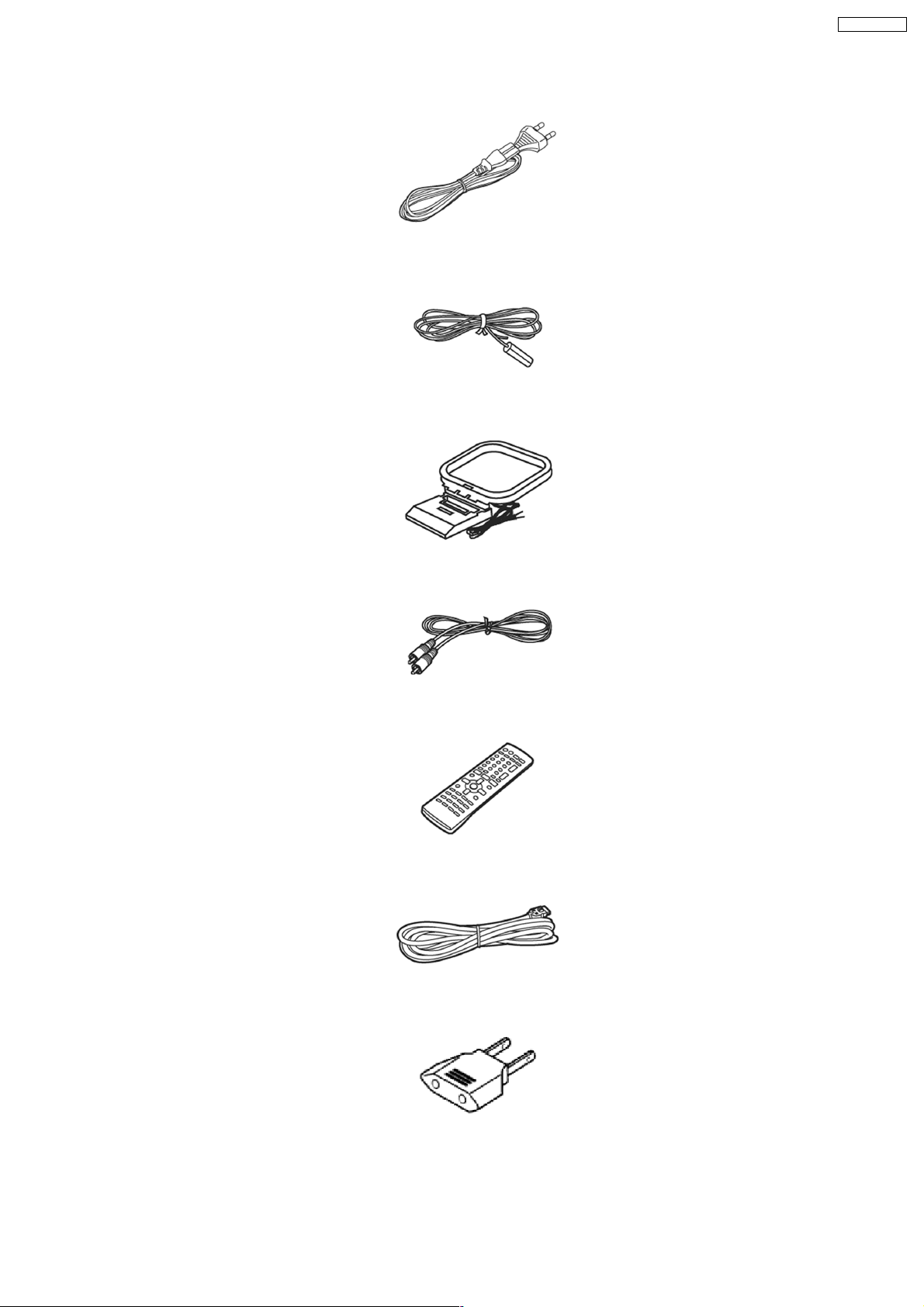

10 Accessories

SA-HT530GCP

AC cord

FM indoor antenna

AM loop antenna

Video cable

Remote control

System cable

Antenna plug

adapter

11

SA-HT530GCP

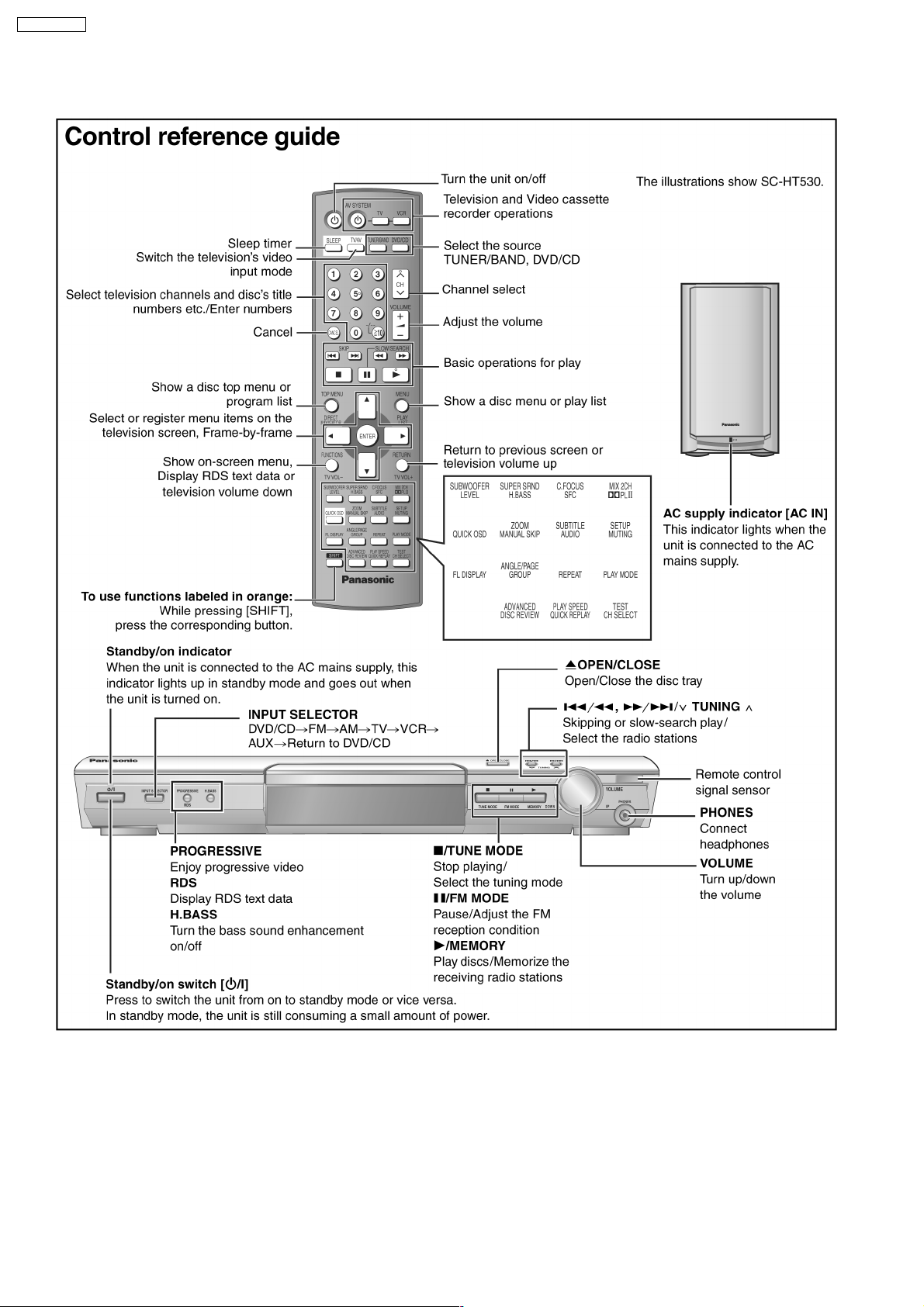

11 Remote Control Reference

12

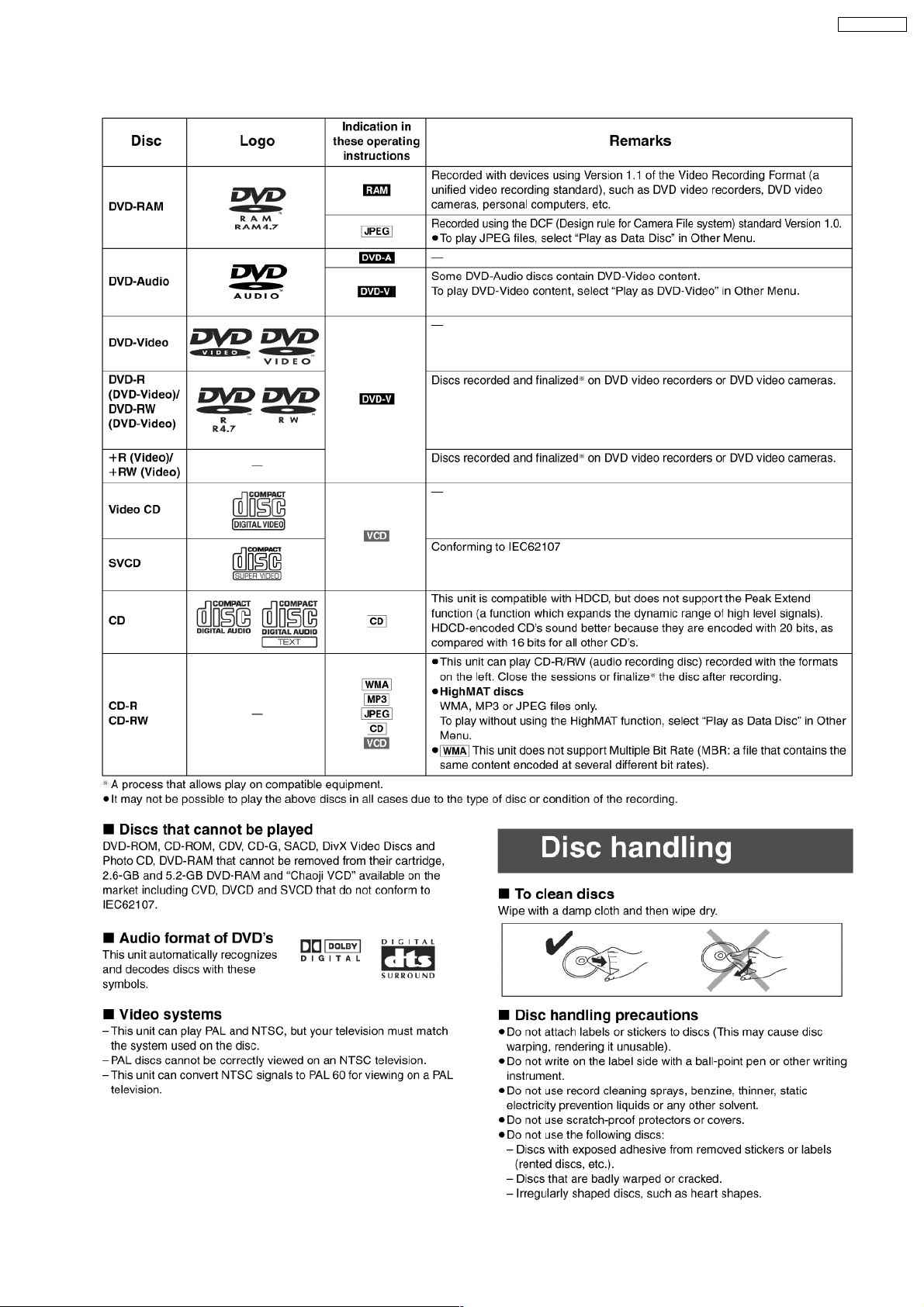

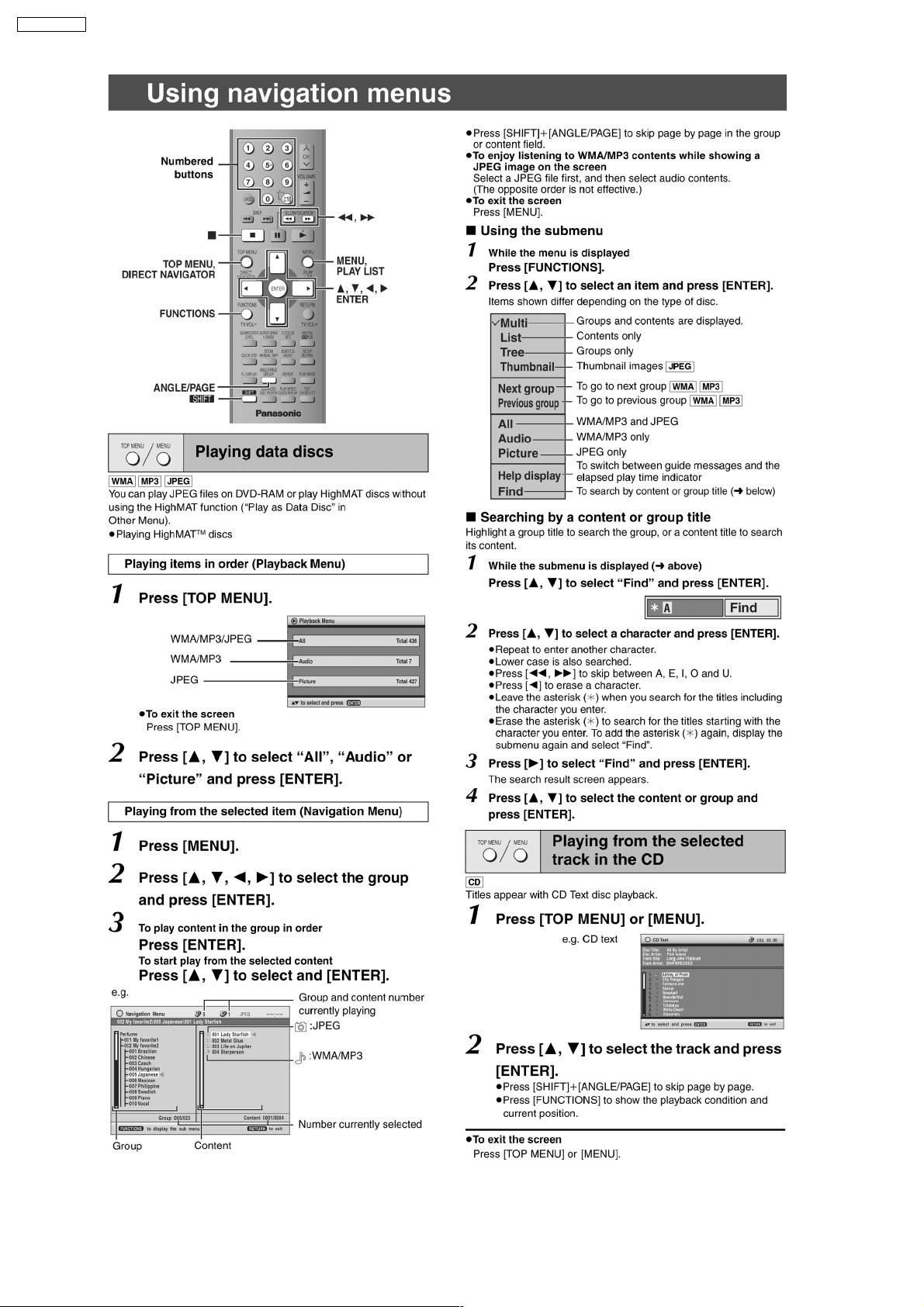

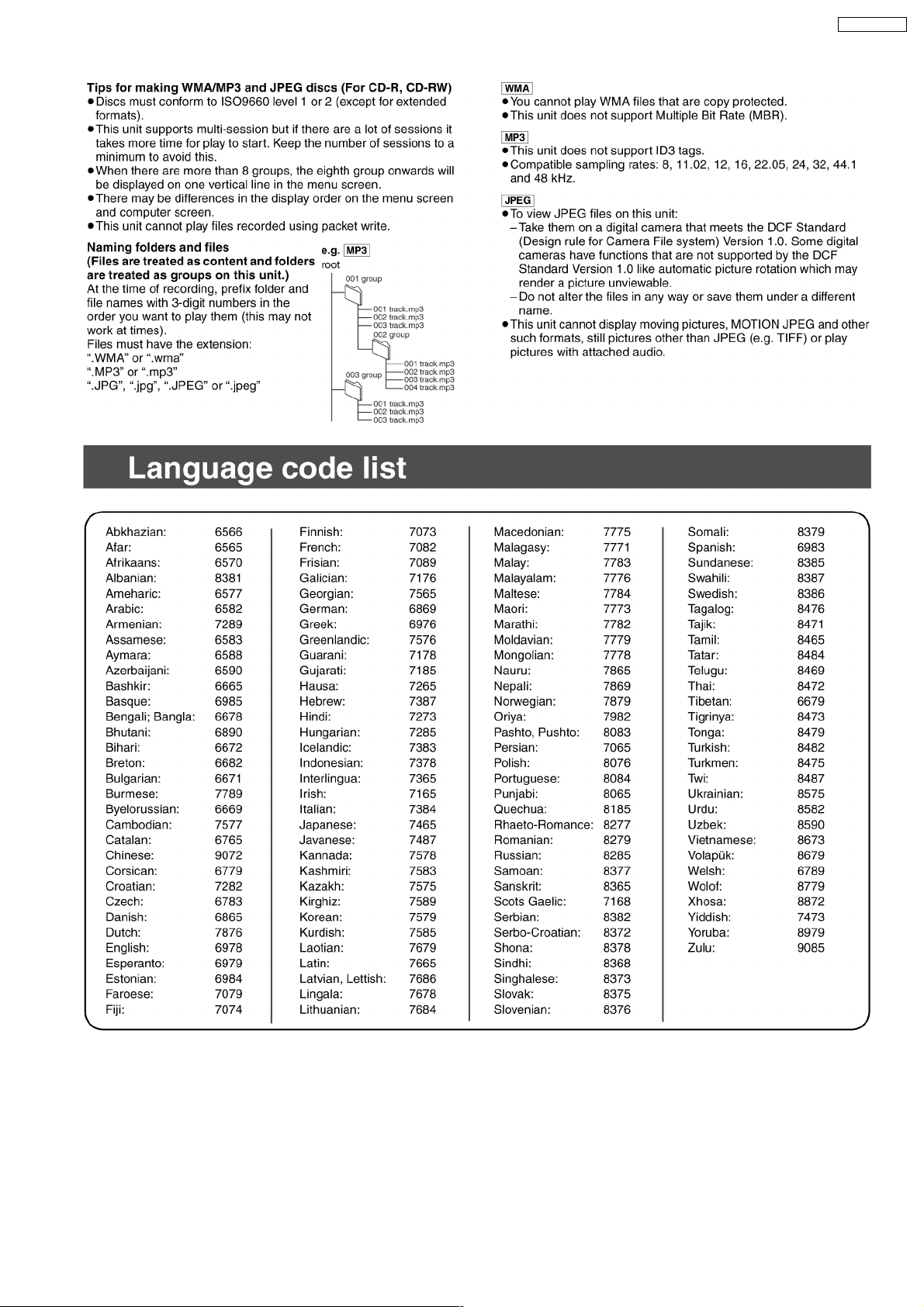

12 Disc information

SA-HT530GCP

13

SA-HT530GCP

14

SA-HT530GCP

15

SA-HT530GCP

16

SA-HT530GCP

13 About HighMAT

13.1. What’s HighMAT?

Consumers worldwide are using PCs to create their own collections of music, photos and even video by burning them onto CDs.

But how these collections can be experienced across different devices can be confusing to navigate, time consuming to access for

a DVD player, and be incomplete in terms of music information available to the customer.

HighMAT offers a solution to this growing consumer problem. HighMAT dramatically improves the digital media experience on

consumer electronic devices by delivering a simple, standardized approach that allows consumers who have created personal

collections of digital music, photography and video on their PC to:

· Create a HighMAT CD or DVD which can be easily played back on consum er electronics devices such as CD and DVD players,

and car stereos.

· Move digital media files (using recordable media such as CD-R and CD-RW) between the PC and various playback devices

such as CD and DVD players.

A new standard for creating personal media on consumer electronic devices, HighMAT enable easier and more seamless

interoperability between Windows PCs and devices designed for your living room, or the car.

17

SA-HT530GCP

13.2. Why take advantage of HighMat?

A Problem Defined:Toda y, when consumers create their own digital audio, video or photo collections on CD-R or other physical

formats, there are numerous, inconsistent ways that devices read the data. For the consumer, the playba ck experie nce can be

confusing:

A Solution Created: HighMat delivers a better digital media access experience by creating a standard approach for PCs to structure

digital media on various physical formats and for playback devices to read the data.

13.3. Benefits of HighMat?

Conventional HighMat

Even though DVD player is CD-R/RW compatible, the inconsistent

ways that various DVD players can read the music or photos files often

leads to a confusing and inconsistant playback experince.

HighMAT compatible products play content back with consistent

interface. This includes products which are JPEG compatible products

without HighMAT support.

18

Conventional HighMat

SA-HT530GCP

19

SA-HT530GCP

HighMAT is now available for CD Burning and in Leadin g DVD Players.HighMAT is a new technology that is now available in

leading software and consumer electronic devices to dramatically improve the digital media experience when you create

homemade CDs.

HighMAT™ delivers a simple, standardized way for PC software and consumer electronics devices to talk to each other and work

better together.

When you create your homemade CDs with software that supports HighMAT CD burning, and then play them back on a DVD

player that supports HighMAT, you get better, easier navigation. You get folders you can access with a single click of your DVD

player´s remote control. You can view important information about your music like full song names, artist titles, album names and

genre. And you can get faster startup on your home entertainment device.

To enjoy the benefits of HighMAT, all you need is software that supports HighMAT for CD burning of music or photos, as well as

a home entertainment device like a DVD player that supports HighMAT for playback. Always look for the HighMAT logo on your

software or home entertainment device to ensure it supports the HighMAT experience.

20

SA-HT530GCP

14 Optical Pickup Self-Diagnosis and Replacement

Procedure

14.1. Self-diagnosis

This unit is equipped with the optical pickup self-diagnosis function and the tilt adjustment check function. Follow the procedure

described below during repair in order to perform self-diagnosis and tilt adjustment effectively. Especially when “NO DISC” is

displayed, be sure to apply the self-diagnosis function before replacing with an optical pickup. Replacement of optical pickup

generally requires when the present value of laser drive exceeds 70 (DVD) or 55 (CD).

Note:

Start diagnosis within three minutes after turning on the power (as diagnosis fails when the unit becomes warm).

21

SA-HT530GCP

14.2. Cautions to Be Taken During Replacement of Optical Pickup and

Spindle Motor

Before replacing the optical pickup and spindle motor, check the total usage time respectively. Follow the checking method

described as below.

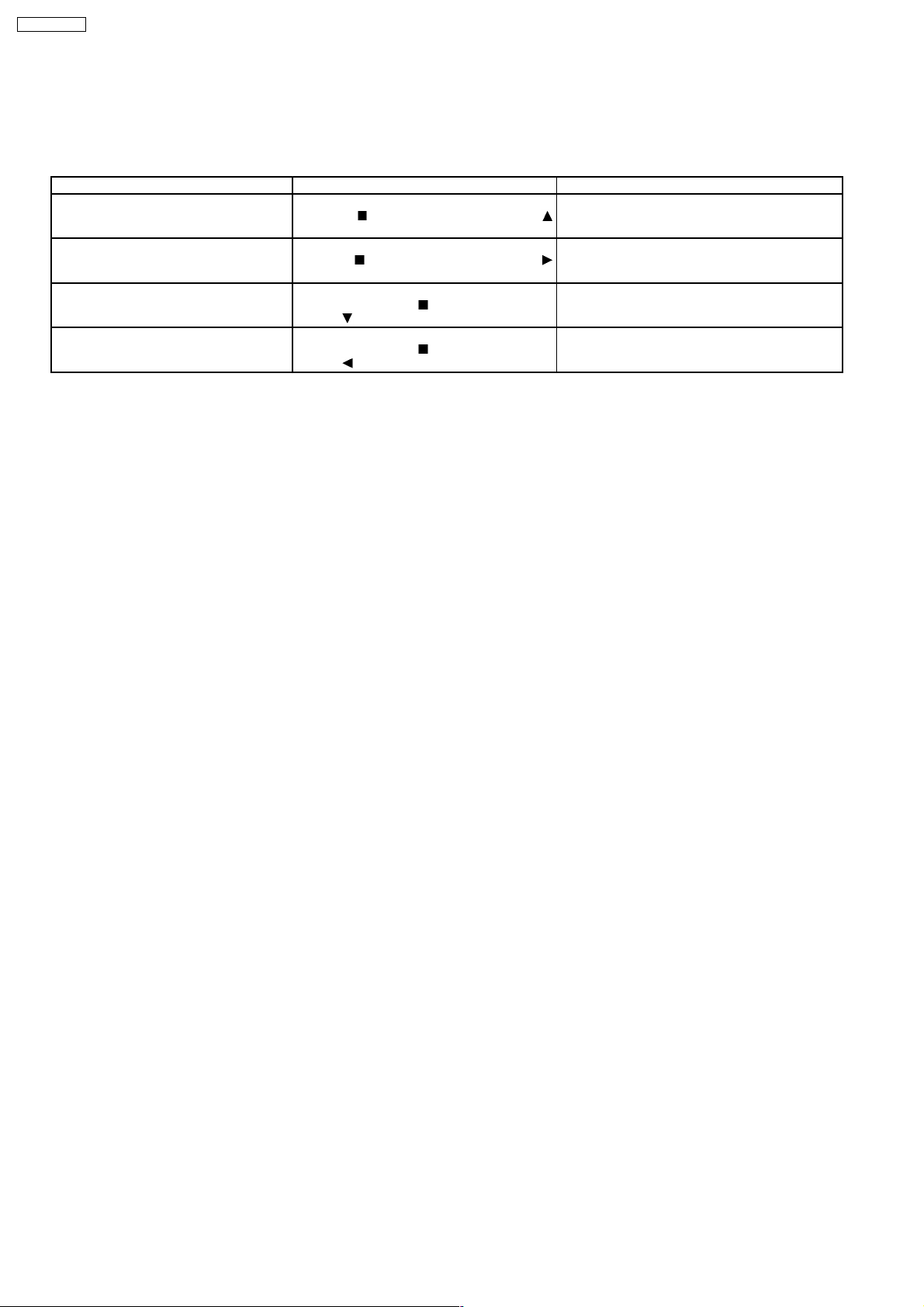

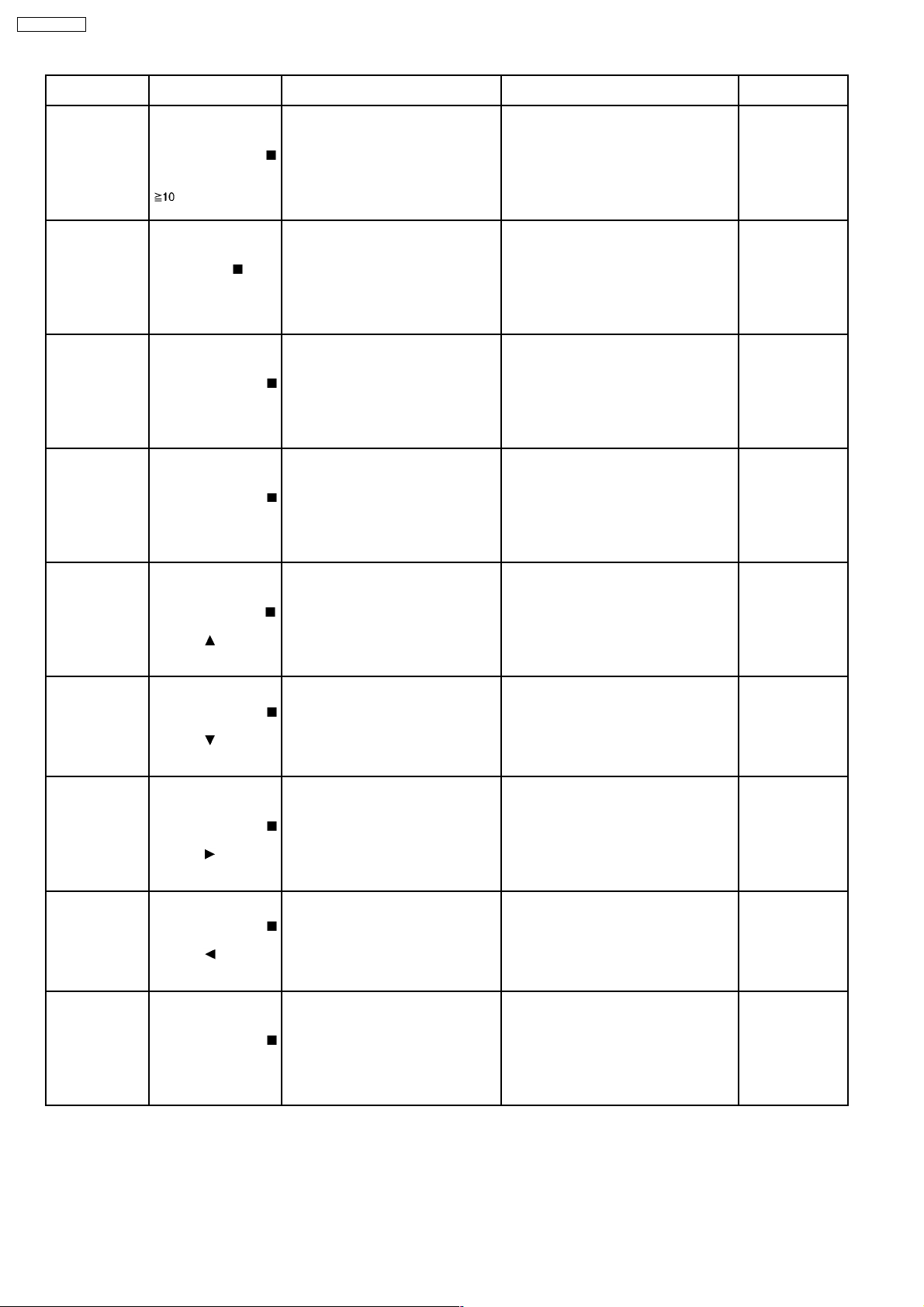

Item Status and Key Function Display

Checking DVD, CD laser usage time With the unit stopped and no disc inserted,

press the.

button on the remote controller unit.

Checking spindle motor usage time With the unit stopped and no disc inserted,

press the

button on the remote controller unit.

Resetting DVD, CD laser usage time While the DVD and CD laser usage times are

displayed, press the

and the

Resetting spindle motor usage time While the spindle motor usage time is

displayed, press the

and the

button on the player and the

button on the player and the

button on the player

button on the remote controller unit.

button on the player

button on the remote controller unit.

T1_xxxx_yyyy

xxxx(DVD), yyyy(CD): total time is displayed with a

four-digit number by the ten hours.

T2_xxxx

xxxx: total time is displayed with a four-digit number

by the ten hours.

T1_0000_0000

T2_0000

22

15 Self-Diagnosis Function

SA-HT530GCP

This unit is equipped with the self-diagnosis function, which

displays an error when it occurs, for use during servicing.

15.1. Automatic Displayed Error

Codes

15.1.1. Automatic Display Function

For a power unit error, the code is automatically display ed.

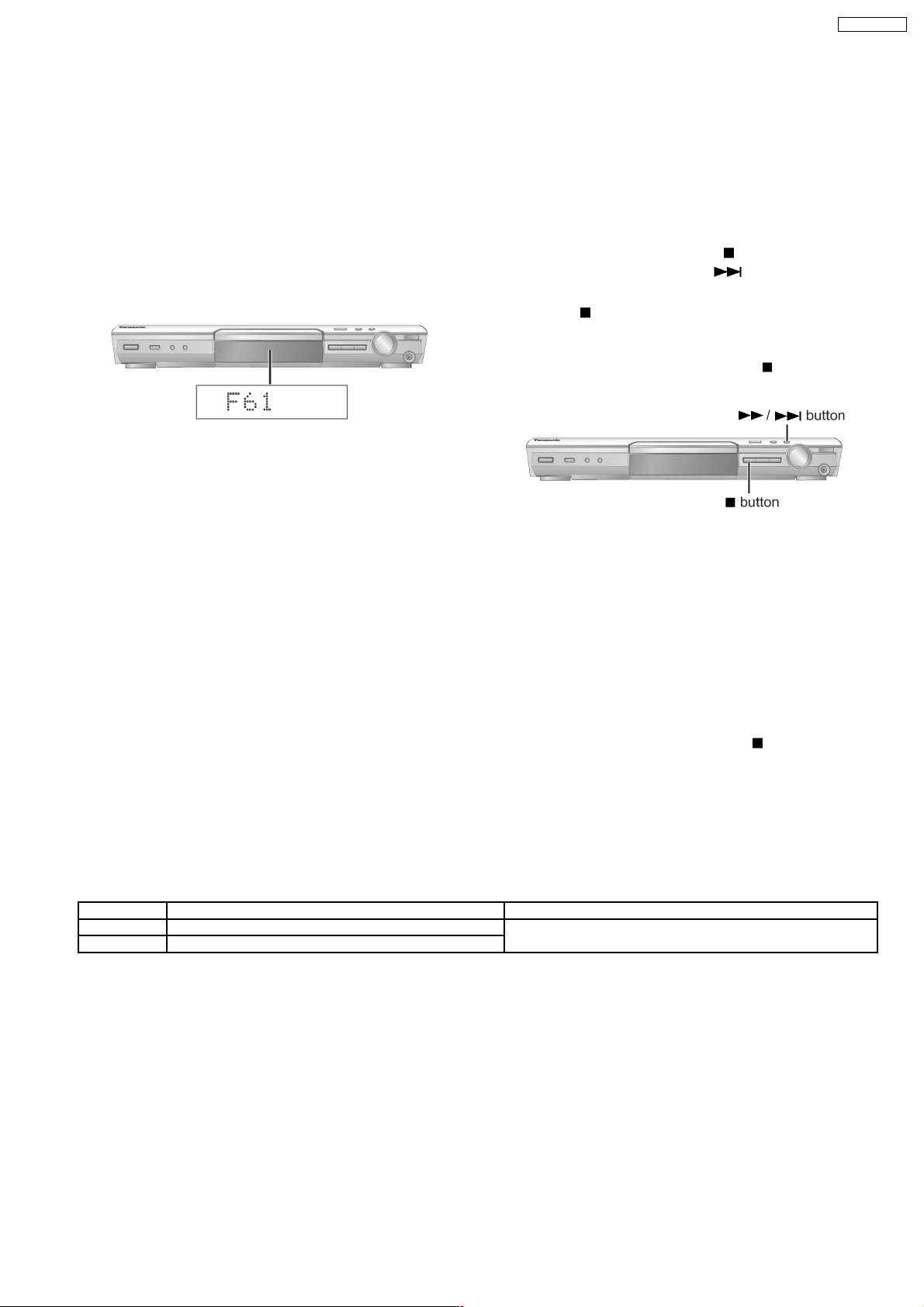

F61: Automatically displayed on the LCD of

the player.

Fig. 15-1

15.1.2. Re-Display

· For F61 Display

−

− When the code, F61 is displayed, the power is

− −

automatically turned off.

−

− The code, F61 is displayed for three seconds, and then

− −

the current time appears.

−

− To retrieve the code, turn on the power button so that

− −

the code F61 appears, however, is switched to time

display after three seconds, and the power is

automatically turned off.

15.1.3. Description of Error Code

15.1.3.1. F61

· State, Condition

When the power is turned on, the unit is automatically

turned off. The power does not turn on.

· Cause, Troubleshooting

Power circuit system failure and/or direct current flown to

speaker terminal

Identify the cause and replace with new parts.

15.2. Memorized Error Codes

15.2.1. Activating Self-Diagnosis Function

and Displaying Method

1. Turn on the power.

2. Select DVD/CD function. With no DVD/CD inserted in the

player, press and hold down the

seconds, and press the F_SKIP

seconds in order to display “T___________”.

3. Press the

result of self diagnosis is display ed. (Ex.: T H15) (See table

below)

If several errors are detected, press the

each.

button. If a memorized error is detected, the

Fig. 15-2

15.2.2. Re-Display

· Press the power button to turn off the power, and then turn

on the power.

· The details of self diagnosis are stored in the unit memory.

To retrieve them, follow the procedure described the above,

“Activating Self-Diagnosis Function and Displaying

Method”.

15.2.3. Deleting Details of Self Diagnosis

· After repair, press and hold down the

five second s, “T___ --- __” appears for a second and then

“T________” appears. (Deleting the details of self

diagnosis)

· After repairing errors, be sure to delete the details of self

diagnosis.

button for at least two

button for at least two

button to display

button for at least

Error Code State, Conditon Cause, Troubleshooting

H15 The disc tray cannot be opened: it closes spontaneously. Disc tray open/close detection switch (S901, S902) failure.

H16 The disc tray cannot be closed: it opens spontaneously.

(Check and replace)

23

SA-HT530GCP

15.3. Service Mode Table 1

Following modes are available with combinations of the pressed buttons on the player and on the remote controller unit.

Player Remote controller

button

unit

0 Error code display (Refer to the item, 15.4. DVD Error Code Description)

5 Tilt adjustment

6 Area number and broadcasting system check

7 MICRO - P & Firmware Version.

DISPLAY DVD laser drive current check

3 CD laser drive current check

PAUSE Writing of laser drive current value after replacement of optical pickup

(Do use this function only when optical pickup is replaced.)

Initialization of the player (factory setting is restored.)

Used after replacement of micro-computer and its peripherals and printed circuit board.

Usage

15.4. DVD/CD Self-Diagnosis Error Code Description

Error Code Meaning Details

U. H. Error

U11 Focus servo failure

H01 Tray loading failure

H02 Spindle servo failure (Spindle servo, DSC, SP motor, CLV servo failure)

H03 Traverse motor failure

H04 Tracking servo error

H05 Seek timeout failure

DSC system

F500 DSC failure DSC stops due to servo failure.

F501 DSC not Ready failure Communication failure between DSC and system computer

F502 DSC Time out failure See F500.

F503 DSC communication failure Communication failure (Result failure occurs after communication

F505 DSC Attention Error See F500.

F506 Invalid media Disc is placed upside down; TOC is unreadable or invalid disc is inserted.

ODC system

F600 Unable to obtain control information due to form

recovery failure

F601 Illegal sector ID requested Operation stops because access of illegal ID data is requested.

F602 Unable to obtain LEAD IN due to form recovery

failure

F603 Unable to obtain KEY DET due to form recovery

failure

F610 ODC failure No permission of command issue

F611 No CRC OK appearing for a certain time Unable to obtain seek address at CD system

F612 No CRC OK appearing for a certain time Unable to obtain ID data at DVD system

Disc Code

F103 Ilegal highlight position Disc standard is possibly illegal when highlight is displayed.

IIC Error

F4FF Forced initialization failure (Time out)

Micro-computer Error

F700 MBX overflow When replying a message to Disc Manager

F701 Unable to complete a message command A message is issued before replying to Disc Manager.

F702 Change in a message command A message is issued before replying to Disc Manager.

F880 Unsuitable task number When a message arrives from not existing task

F890 A message is sent during AV task transmission During transmission of a message to AV task

F891 Unable to transmit a message to AV task When transmission of a message to AV task starts

F893 FROM altered

F894 EEPROM failure

F8A0 Unsuitable message command When transmission of a message to AV task starts

(Startup, focus failure, etc.)

(No communication because DSC does not move)

command is transmitted.)

Operation stops because navigation data cannot be obtained due to form

recovery system failure.

Unable to read LEAD IN data

Unable to obtain CSS data

24

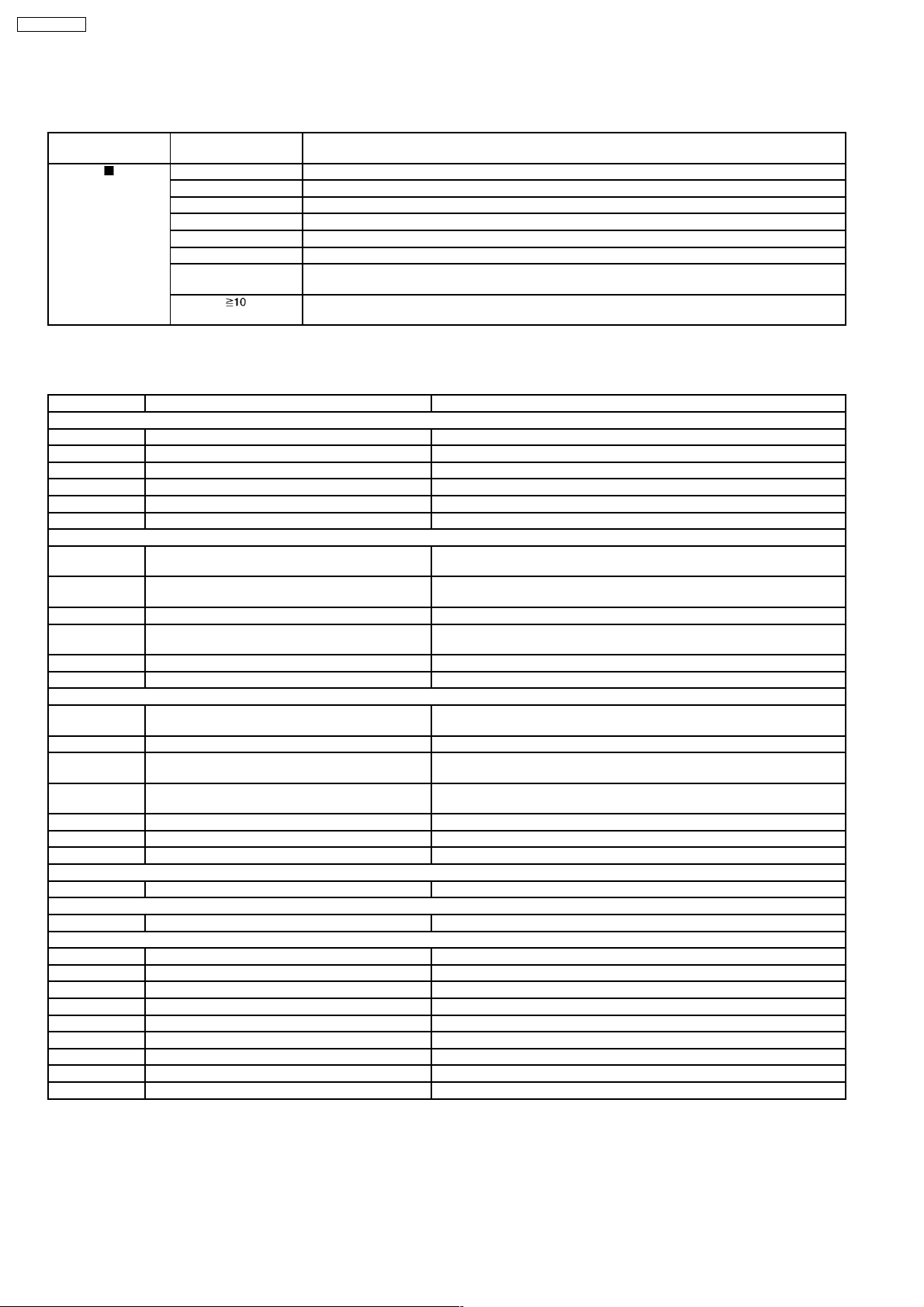

15.5. Mode Table 2

Following modes are available with combinations of the pressed buttons on the player and on the remote controller unit.

Item Operational Condition

and Key Function

Jitter display While the player is

stopped and no disc is

inserted, press and

hold down the

button on the player

and the number

button, “5” on the

remote controller unit.

Error code

display

While the player is

stopped and no disc is

inserted, press and

hold down the

button on the player

and the number

button, “0” on the

remote controller unit.

Measurement of

laser current

electricity

initialization value

While the player is

stopped and no disc is

inserted, press and

hold down the

button on the player

and the

button on

the remote controller

unit.

Measurement of

DVD laser current

electricity

While the player is

stopped and no disc is

inserted, press and

hold down the

button on the player

and the DISPLAY

button on the remote

controller unit.

ADSC internal

RAM display

While the player is

stopped and no disc is

inserted, press and

hold down the

button on the player

and the number button

“1” or “2” on the remote

controller unit.

Measurement of

CD laser current

electricity

While the player is

stopped and no disc is

inserted, press and

hold down the

button on the player

and the number button

“3” on the remote

controller unit.

Jitter display

Measures and displays jitter.

Measurement is repeated every

second. Read error counter starts at 0

at the mode setting, and increased by

one as data read fails at target block. A

small defect is allowed to correct by

retry. Any possibility is counted as one

increment. Repetitive errors after retry

increase by two levels or more.

Error code display

Displays the latest error code stored in

EEPROM.

Measurement of laser current

electricity initialization value

Memorizes each initialization value of

DVD and CD in EEPROM.

Measurement of DVD laser current

electricity

Measures DVD laser current electricity

and displays the result together with

the initialization value stored in

EEPROM. After measurement, DVD

laser is lit till the power is turned off (or

goes off when the primary power is

turned off).

ADSC internal RAM display

Reads and displays the RAM value

inside ADSC. The address is renewed

when the CLEAR key is pressed so

that the values at eleven points appear.

Measurement of CD laser current

electricity

Measures CD laser current electricity

and displays the result together with

the initialization value stored in

EEPROM. After measurement, CD

laser is lit till the power is turned off (or

goes off when the primary power is

turned off).

Details Display To Exit Mode

J*1xxx*2_yyy*3_zz

*1

: Jitter display mode

*2

: Jitter measurement value

*3

: Read error counter

*4

: Focus driving value

*4

Press the STOP or

OPEN button.

Values are shown to one decimal place

in the decimal digit.Focus driving value is

displayed in the hexadecimal digit.

DVDnn_F---

*nn: Error history

*--: Error number

DO*1_034*2_028

*1

: Laser current electricity measurement

mode

*2

: DVD current electricity value

*3

: CD current electricity value

*3

Automatically exits

the mode after five

seconds.

Automatically exits

the mode after five

seconds.

Values are shown in the decimal digit.

The above example indicates that the

current electricity initialization value is

34mA at DVD laser and 28mA at CD

laser when laser is turned on.

DD*1_034*2_032

*1

: DVD laser current electricity

measurement mode

*2

: Current electricity initialization value

stored in EEPROM

*3

: Present value of current electricity

*3

Automatically exits

the mode after five

seconds.

Values are shown in the decimal digit.

The above example indicates that the

current electricity initialization value is

34mA and its present value is 32mA.

A*1_0FA*2_6901

*1

:ADSC internal RAM display mode

*2

: Address

*3

: RAM value at displayed address

*3

Press the STOP or

OPEN button.

Values are shown in the hexadecimal

digit. The above example indicates that

ADSC value at the address, 0FAh is

6901h.

DC*1_028*2_026

*1

: CD laser current electricity

measurement mode

*2

: Current electricity initialization value

stored in EEPROM

*3

: Present value of current electricity

*3

Automatically exits

the mode after five

seconds.

SA-HT530GCP

25

Values are shown in the decimal digit.

The above example indicates the current

electricity initialization value is 28mA and

its present value is 26mA when laser is

turned on.

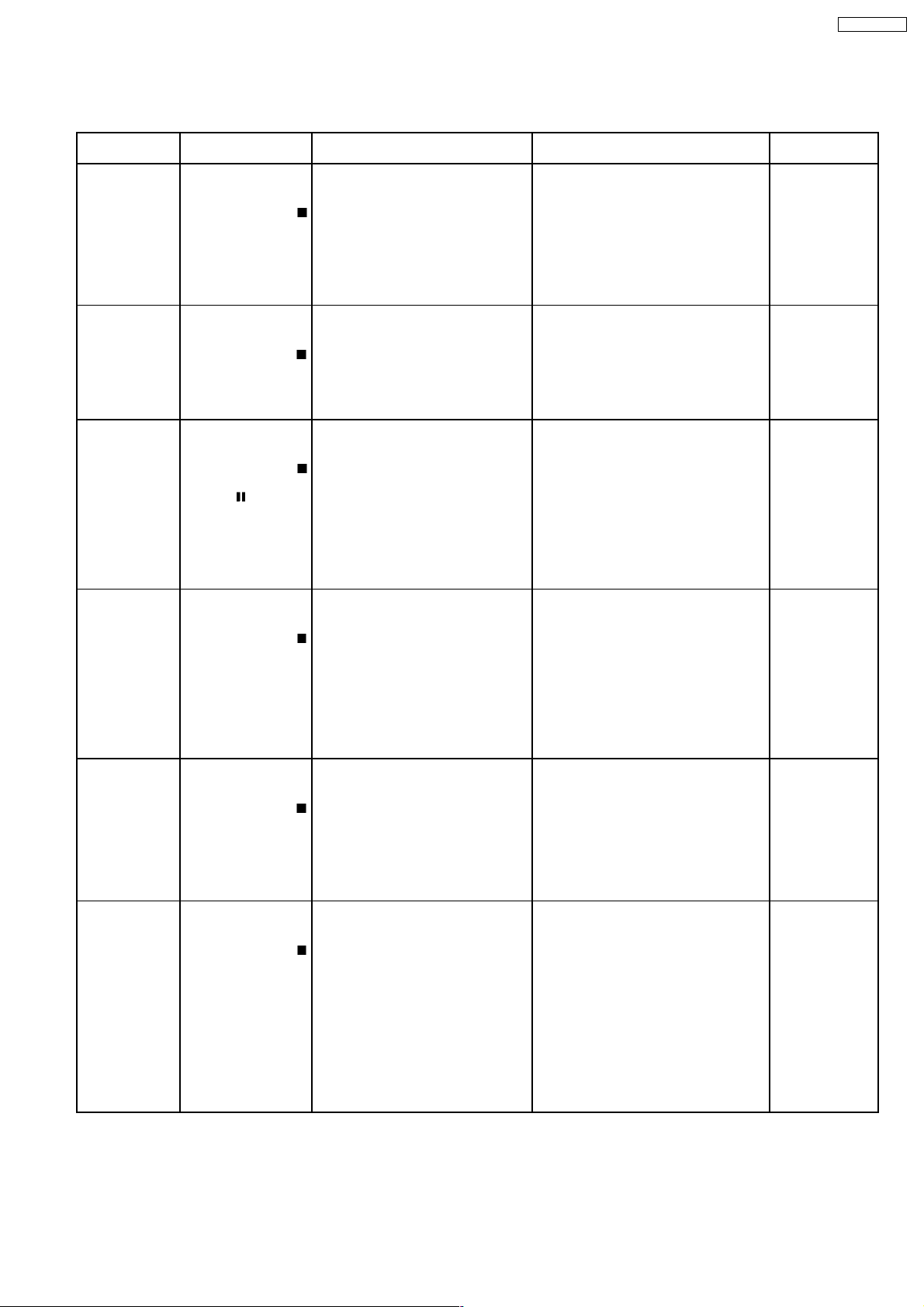

SA-HT530GCP

Item Operational Condition

and Key Function

User initialization While the player is

stopped and no disc is

inserted, press and

hold down the

button on the player

and the number button

on the remote

controller unit.

Region display While the player is

stopped and no disc is

inserted, press and

hold down the

button on the player

and the number

button, “6” on the

remote controller unit.

Firm version

display

While the player is

stopped and no disc is

inserted, press and

hold down the

button on the player

and the number

button, “7” on the

remote controller unit.

Region and firm

version display

While the player is

stopped and no disc is

inserted, press and

hold down the

button on the player

and the number

button, “8” on the

remote controller unit.

Usage time 1 While the player is

stopped and no disc is

inserted, press and

hold down the

button on the player

and the

button on

the remote controller

unit.

Usage time 1

reset

While the usage time 1

is displayed, press and

hold down the

button on the player

and the

button on

the remote controller

unit.

Usage time 2 While the player is

stopped and no disc is

inserted, press and

hold down the

button on the player

and the

button on

the remote controller

unit.

Usage time 2

reset

While the usage time 2

is displayed, press and

hold down the

button on the player

and the

button on

the remote controller

unit.

Communication

error display

While the player is

stopped and no disc is

inserted, press and

hold down the

button on the player

and the MENU button

on the remote

controller unit.

Details Display To Exit Mode

User initialization

“INITIALIZED” None

The user setting recovers the factory

setting.

Region display __w*1_x*2y*3_zzz

*1

: Region number

*2

: N; no PAL/P; PAL

*3

: N; NTSC/6; PAL60

*4

: Panel computer jumper information

Firm version display rrr*1_xx*2y*3zzz

*1

: Panel computer release number

*2

: System computer generation

*3

: System computer model type

*4

: System computer release number

Region and firm version display _r*1__xx*2y*3zzz

*1

: Region number

*2

: System computer generation

*3

: System computer model type

*4

: System computer release number

Usage time 1

T1_1234_5678

Laser usage time

Measures each for DVD and CD

respectively.

The numbers in the left show usage time

for DVD laser and those in the right for

CD laser. The four-digit number is shown

by the ten hours in the decimal digit. The

number after 0000 is 9999.

Usage time 1 reset

T1_0000_0000 Automatically exits

Laser usage time‘

Resets both for DVD and CD at once.

Usage time 2

T2_1234

Spindle motor usage time

The four-digit number is shown by the ten

hours in the decimal digit. The number

after 0000 is 9999.

Usage time 2 reset

T2_0000 Automatically exits

Spindle motor usage time

Displays frequency of communication

ERR_00_/30 Automatically exits

errors between system computer firm

IC and mechanical computer IC during

DVD module.

*4

Automatically exits

the mode after five

seconds.

*4

Automatically exits

the mode after five

seconds.

*4

Automatically exits

the mode after five

seconds.

Automatically exits

the mode after five

seconds.

the mode after five

seconds.

Automatically exits

the mode after five

seconds.

the mode after five

seconds.

the mode after five

seconds.

26

SA-HT530GCP

15.6. Lock Function

This function prohibits removal of disc and some disc operations to prevent loss of disc at a shop during sales promotion or

equivalent occasions.

While this function is activated, the player display s “___LOCKED_” if any button is touched.

The lock function can be used in two ways.

15.6.1. Setting

· LOCK MODE A/LOCK MODE B

1. While the player is set to SELECTOR DVD/CD and POWER ON, press and hold down the

[POWER] button on the remote controller for at least three seconds so that the player display s "___LOCKED_" for three

seconds to indicate that LOCK MODE A is activated and the currently loaded disc is played.

2. The following button is invalid during LOCK MODE A.

OPEN/CLOSE

button are invalid and the player displays “___LOCKED_” while the lock function mode is entered.

3. While LOCK MODE A is activated and the player is locked, press and hold down the

[POWER] button on the remote controller for at least three seconds so that the player display s "_UNLOCKED_" to indicate

the function is deactivated.

4. While the player is set to SELEC TOR DVD/CD and POWER ON, press and hold down the

[POWER] button on the remote controller for at least three seconds so that the player display s "___LOCKED_" for three

seconds to indicate that LOCK MODE B is activated and the currently loaded disc in played.

5. The following buttons are invalid, based on the "selector or disc related", during LOCK MODE B.

Player , , , SELECTOR, , , VOL. JOG

Remote

controller unit

SLEEP, REPEAT, D.MIX (REPEAT holding down), 0~9, ,RETURN, FL DISPLAY, TEST ( FL DISPLAY holding

down), DISPLAY, SCREEN, CH SELECT,

TUNER/BAND, TV, VCR/AUX

, , , , , , SET UP, GROUP, MUTING, P MEMORY,

button on the player and the

button on the player and the

button on the player and the

6. The keys prohibited during PLAY and LOCK MODE B need not to correspond each other. The keys related to sound quality

and shown on the DVD screen are not prohibited. Following buttons are always valid:

Player POWER, DVD/CD>, PROGRESSIVE, VOL. JOG

Remote

controller unit

POWER, PLAY MODE, CANCEL, SFC, B. B LEVEL, VOL-, VOL+, DVD/CD>, MENU, TOP MENU, , , , ,

ENTER, DPL, SSS,C.F, CSM, ZOOM

7. While LOCK MODE B is activated and the player is locked, press and hold down the button on the player and the

[POWER] button on the remote controller for at least three seconds so that the player display s "_UNLOCKED_" for three

seconds to indicate that the function is deactivated.

8. The tray lock function is deactivated by "AC Prohibition".

9. LOCK MODE A or B is an exclusive control over whichever is activated first.

10. While the player is set to a lock mode and POWER OFF, the auto power on function can be controlled by the DVD/CD

button on the remote controller. The auto power on function is invalid by the other selector buttons (such as TUNER/BAND

button).

11. While a lock mode is turned on and the prohibition button is pressed, "___LOCKED_" appears on FL.

12. While a lock mode is turned on and set to POWER OFF, the OPEN/CLOSE button is invalid to control the auto power on

function.

15.7. Things to Do After Repair

Follow the procedure described below after repair.

1. While the power is on, press the

2. Press the power button to turn off the power.

3. Unplug the power cable.

Note:

It is prohibited to unplug the power cable while the tray is opene d and to close the tray manually.

button to close the tray.

27

SA-HT530GCP

16 Service precautions

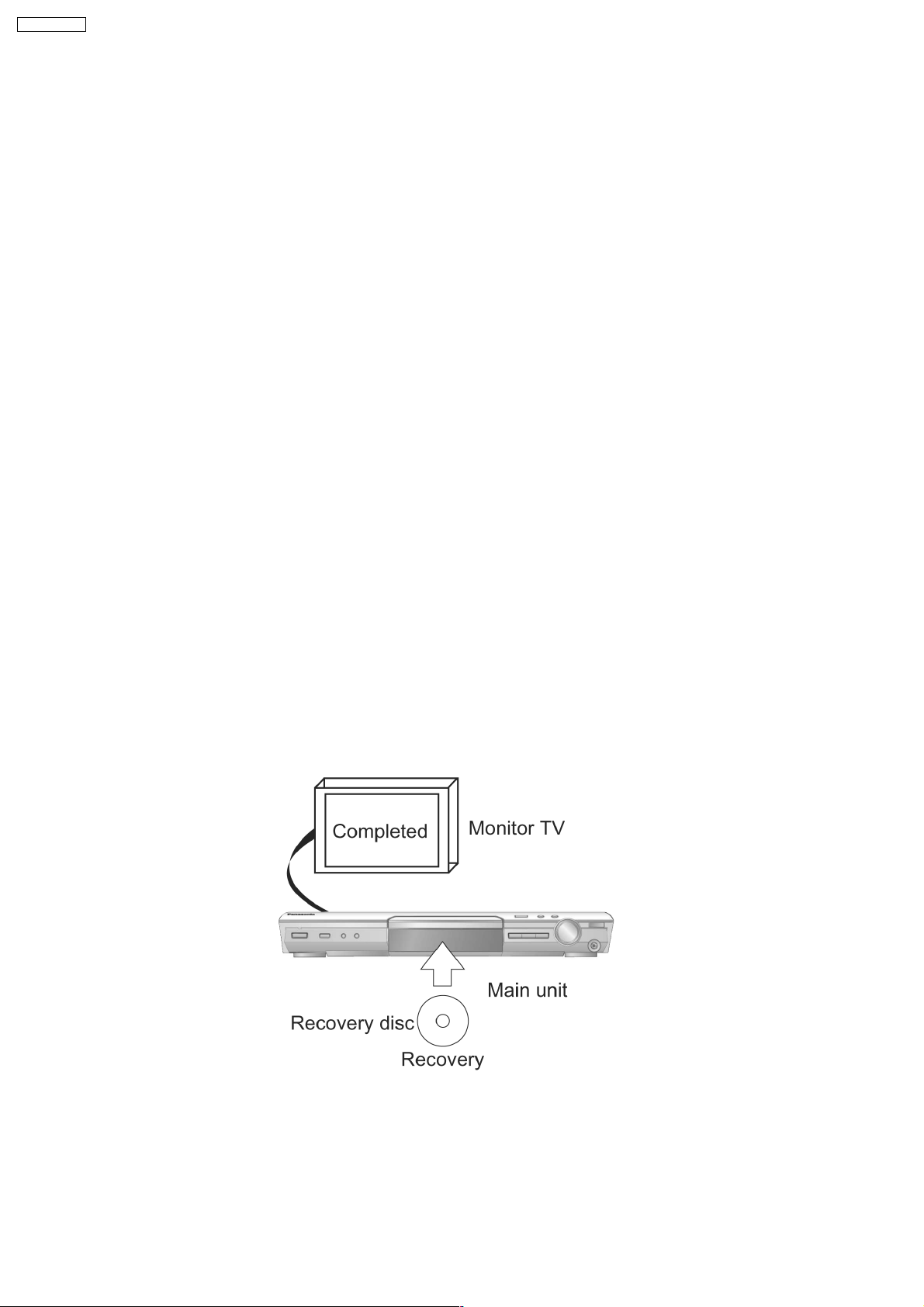

16.1. Recovery after the player is repaired

· W hen FLASH ROM IC or DVD Module P.C.B. is replaced, carry out the recovery processing to optimize the drive. Playback the

recovery disc to process the recovery automatically.

· Recovery disc (Product number=RFKZD03R005)

· Performing recovery

1. Load the recovery disc (Product number: RFKZD03R005) to the player and run it.

2. Recovery is performed automatically . When it is finished, a message appears on the screen.

3. Remove the recovery disc.

4. Turn off the power.

Note:

This unit requires no initialization process carried out after the traditional DVD players were repaired. When the recovery

measures are taken, the customer setting will return to the factory setting as same as the procedure described in item

“Initialization” in 13.6 is carried out. Write down the contents of the setting before recovery processing and reset the player.

16.2. DVD Player Firmware Version Upgrade Process

Firmware of DVD player may upgrade to conform to improvement of its performance and quality including operational range,

playability of non-standardized discs, etc. The version upgrade disc contains the recovery function, and the recovery disc is not

necessary.

Note:

Version upgrade process cannot be complete if the AC power is cut off due to power failure and other occasions during the

process. If this occurs, replace FLASH ROM IC and restart version upgrade. Version upgrade disc number is informed when

ordered.

16.3. Firmware Version Upgrade Process by Using Recovery Disc

· Recovery process

· Firmware version upgrade process

Both of the above procedures automatically start when the recovery disc is replayed.General CD-R disc allows version upgrade

process and recovery process, making version upgrade through disc simple.

Recovery process: Optimization process of player after replacement of FLASH ROM IC, EEPROM IC, or DVD Module Circuit board

Version upgrade process: Renewal of firmware for improvement of operational range and performance

16.3.1. Version Upgrade Process

1. Insert the recovery disc to the player to replay.

2. The version of player is automatically checked and prompts if necessary.

3. Select version upgrade process using the cursor keys on the remote controller unit. (Select YES or NO)

4. a. If YES is selected, the process starts.

28

b. If NO is selected, only the recovery process is applied.

5. a. When the version upgrade process is complete, a message of completion appears on the screen. Remove the disc.

b. Follow the instruction appearing on the screen, and remove the disc.

6. Turn off the power.

SA-HT530GCP

29

SA-HT530GCP

17 Disassembly and Main Component Replacement

Procedures

“ATTENTION SERVICER”

Some chassis components may have sharp edges.

Be careful when disassembling and servicing.

1. This section describes procedures for checking the operation of the major printed circuit boards and replacing the main

components.

2. For reassembly after operation checks or replacement, reverse the respective procedures.

Special reassembly procedures are described only when required.

3. Select items from the following index when checks or replacement are required.

Warning:

This product uses a laser diode. Refer to caution statement Precaution of Laser Diode.

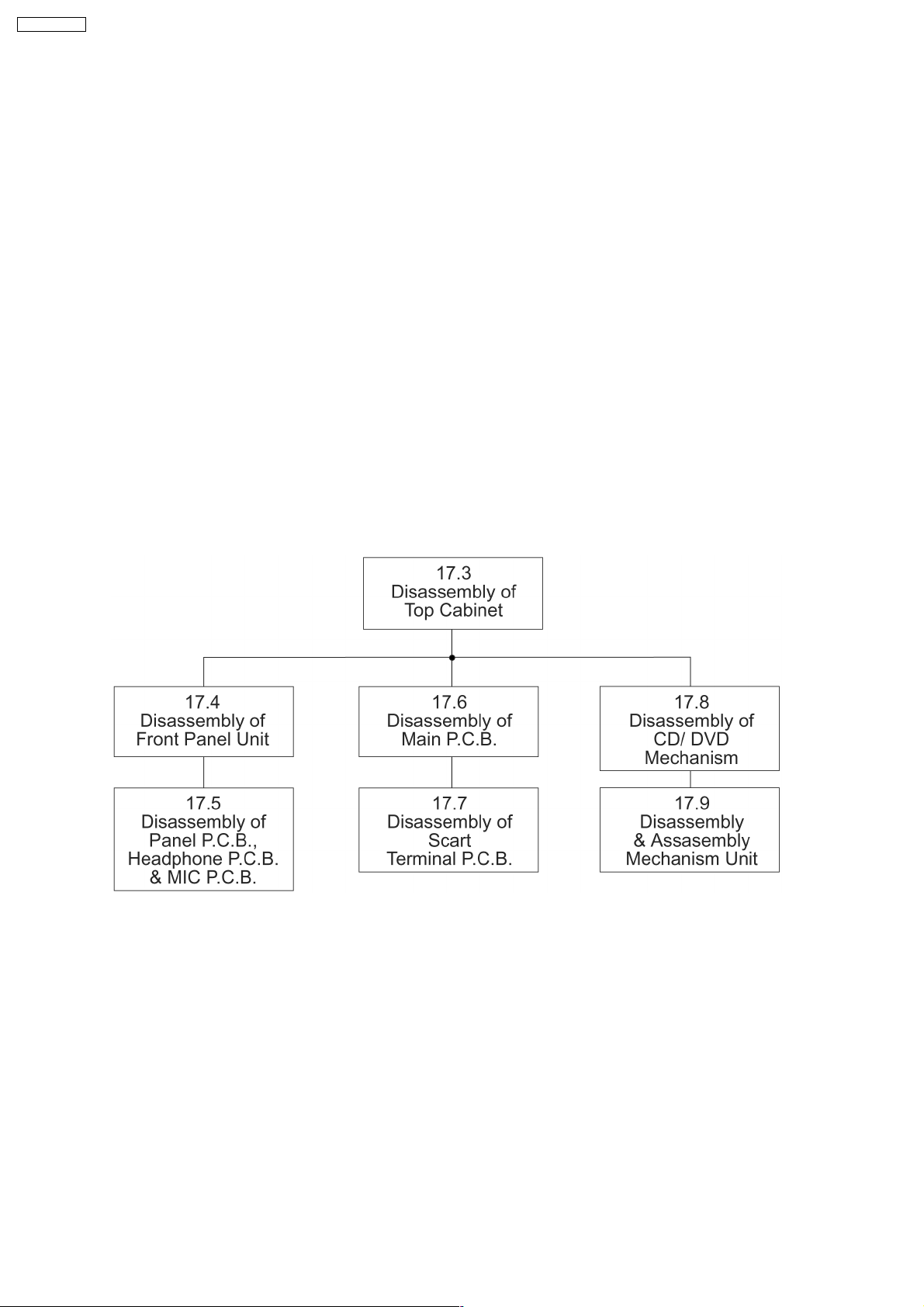

17.1. Disassembly flow chart

The following chart is the procedure for disassembling the casing and inside parts for internal inspection when carrying out the

servicing

To assemble the unit, reverse the steps shown in the chart below.

30

Loading...

Loading...