Page 1

Order Number: MGCS040402C0

H21

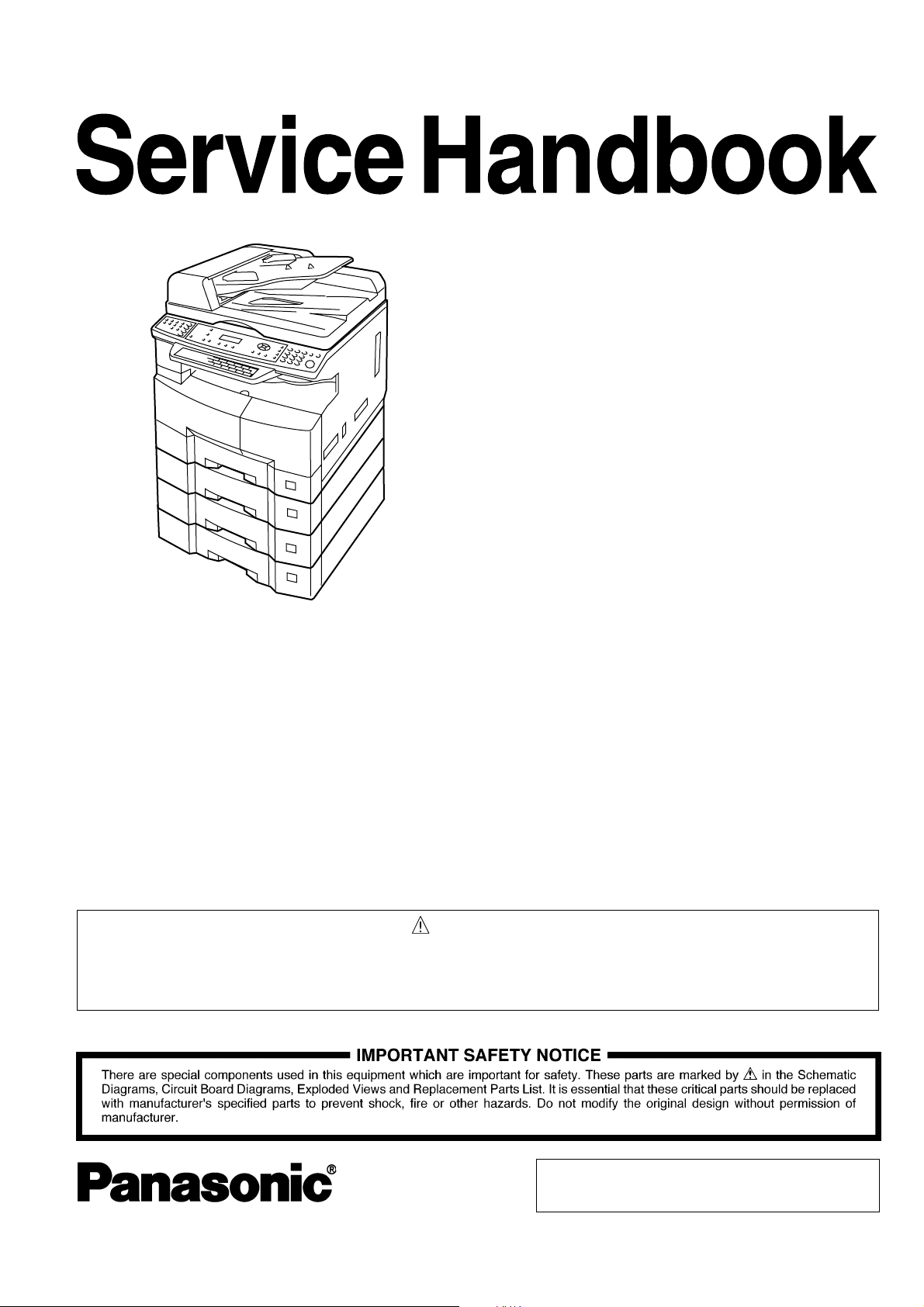

Digital Imaging Systems

DP-1520P/1820P/1820E

[ Version 1.0 ]

WARNING

Thisserviceinformationisdesignedforexperiencedrepairtechniciansonlyandisnotintendedforusebythegeneralpublic.

Itdoesnotcontainwarningsorcautionstoadvisenon-technicalindividualsofpotentialdangersinattemptingtoserviceaproduct.

Productspoweredbyelectricityshouldbeservicedorrepairedonlybyexperiencedprofessionaltechnicians.Anyattempttoservice

orrepairtheproductorproductsdealtwithinthisserviceinformationbyanyoneelsecouldresultinseriousinjuryordeath.

© 2004 Panasonic Communications Co., Ltd.

All rights reserved. Unauthorized copying and distribution is

a violation of law.

Page 2

This Product Uses Lead (Pb) Free Solder Printed Circuit

Boards (PCBs).

Information regarding Lead-Free (PbF) solder:

Distinction of PbF PCB:

PCBs (manufactured) using lead free solder will have a mark following

the PCB part numbers in a label on the PCB.

Caution:

Pb free solder has a higher melting point than standard solder; typically

the melting point is 50 - 70 F (30 - 40 C) higher. Please use a soldering iron

with temperature control and adjust it to 700 20 F (370 10 C). Exercise care

while using higher temperature soldering irons, do not heat the PCB for too long

to prevent solder splash or damage to the PCB.

Pb free solder will tend to splash when heated too high (about 1100 F/600 C).

ECO SOLDER M705 (available from Senju Metal Industry Co., Ltd.:

URL: http://www.senju-m.co.jp) is recommended when repairing PbF PCBs.

The contents of this Service Manual and the Specifications are subject to change

without notice.

Panasonic Communications Co., Ltd. reserves the right to make improvements in

the product design without reservation and without notice.

Published in Japan.

2

Page 3

ImportantNotice

PleasereadthisnoticecompletelyBEFOREinstallinganyoptional

accessories.Asfailuretoproperlyinstalltheadditionalboardor

connectorwiththepowerONcoulddamagethemachine'sSPCor

SCboard.

Pleasefollowtheinstructionsbelow:

1.ItisessentialthatyouturnOFFtheMainPowerSwitchlocated

ontheRightSideofthemachine.

2.ItisessentialthatyouunplugtheACPowerCordfromthewall

outlet.(DuringaLightningStorm,topreventelectrocution

disconnecttheTelephoneLineCablefirstbeforeunpluggingthe

ACPowerCord,iftheFaxoptionisinstalled.)

3.Pleasereadtheinstallationinstructionscarefullyandfolloweach

step.

<Example:DP-1820E>

Note:

O=PowerOFF,l=PowerON

Note:

IftheHardDiskDriveUnitisinstalled,topreventaScanDiskFunctionfrombeing

performed(similartoWindowsOSwhenthepowerisabruptlyinterrupted),itis

importanttofollowthestepsequencebelowwhenturningOFFthePowerSwitchonthe

machine.

1.Ifthemachineisinthe"ENERGYSAVER(ShutdownMode)",youmayturnthePowerSwitchonthe

RightSideofthemachinetotheOFFposition.Ifitisnotinthe"ENERGYSAVER(ShutdownMode)",

continuetostep2below.

2.Press"FUNCTION"and"ENERGYSAVER"keyssimultaneouslyfirst.

3.Waitapproximately10secondswhilethemachinewritestheclosingstatusontotheHardDiskDrive

Unitandadvancesinto"ENERGYSAVERMODE".

4.TurnthePowerSwitchontheRightSideofthemachinetotheOFFposition.

5.UnplugtheACPowerCord.(DuringaLightningStorm,topreventelectrocutiondisconnectthe

TelephoneLineCablefirstbeforeunpluggingtheACPowerCord,iftheFaxoptionisinstalled.)

*Thespecificationsaresubjecttochangewithoutnotice.PanasonicCommunicationsCo.,Ltd.reserves

therighttomakeimprovementsintheproductdesignwithoutreservationandwithoutnotice.

3

Page 4

Important

Before installing optional Paper Tray(s), ensure the two (2)

Brackets located on the Rear of the Copier and each

preceding Paper Tray is removed first.

MainUnit

2ndPaperTray

3rdPaperTray

4thPaperTray

Donotremovethesebrackets

fromthebottomPaperTrayof

yourconfiguration.

Note: It is not necessary to remove these brackets from

the bottom Paper Tray of your configuration or the

Copier if it is being placed on a Plain Stand.

4

Page 5

Caution:

Dependingonyourmachine'smodel,itmayweightapproximately93.26-98.33

lb(42.3-44.6kg)withoutanyoptions.

Topreventinjuries,usetheappropriatenumberofpersonnelandliftormove

themachineasillustrated.

DonotliftthemachinebythePaperTrayasitmaycausedamageand/orbodily

injury.

Note:

RefertotheInstallationInstructionswheninstallingthemachine.

5

Page 6

P

e

t

F

T

m

P

T

I

e

P

recautions

or Your Safety

o prevent severe injury and loss of life, read this section carefully before servicing the Panasonic

achine to ensure proper and safe operation.

lease ensure that the machine is installed near a wall outlet and is easily accessible.

his section explains the graphic symbols used in the machine and/or this manual.

WARNING:

Denotes a potential hazard that could result in serious injury or death.

CAUTION:

Denotes hazards that could result in minor injury or damage to the machine.

This section also explains the graphic symbols used in the machine and/or this manual.

These symbols are used to alert operators to a specific operating procedure

that must not be performed.

These symbols are used to alert operators to a specific operating procedure

that must be emphasized in order to operate the machine safely.

nstallation and Relocation Cautions

CAUTION

Do not place the machine near heaters or volatile, flammable, or combustible materials

such as curtains that may catch fire.

Do not place the machine in a hot, humid, dusty or poorly ventilated environment.

Prolonged exposure to these adverse conditions can cause fire or electric shocks.

Place the machine on a level and sturdy surface that can withstand.

If tilted, the machine may tip-over and cause injuries.

When relocating the machine, remove the toner and/or developer, and pack the machin

with proper packing materials for shipping.

When moving the machine, be sure to unplug the power cord from the outlet. If the

machine is moved with the power cord attached, it can cause damage to the cord which

could result in fire or electric shock.

ower and Ground Connection Cautions

WARNING

Ensure that the plug connection is free of dust. In a damp environment, a contaminated

connector can draw a significant amount of current that can generate heat and

eventually cause fire over an extended period of time.

Always use the power cord provided with your machine. When an extension power cord

is required, always use a properly rated cord.

120 V/15 A or AC 220 - 240V/10 A

If you use a cord with an unspecified current rating, the machine or plug may emit smok

or become hot to the touch externally.

Do not attempt to rework, pull, bend, chafe or otherwise damage the power cord. Do no

place a heavy object on the cord. A damaged cord can cause fire or electric shocks.

6

Page 7

Never touch a power cord with wet hands. Danger of electric shock exists.

y.

O

O

If the power cord is broken or insulated wires are exposed, replace immediately with a specified cord onl

Using a damaged cord can cause fire or electric shocks.

Stop operation immediately if your machine produces smoke, excessive heat, unusual noise, or smell,

or if water is spilt onto the machine. These conditions can cause fire. Immediately switch Off and

unplug the machine.

Do not disconnect or reconnect the machine while it is on. Disconnecting a live connector can deform

the plug and cause fire.

When disconnecting the machine, grasp the plug instead of the cord. Forcibly pulling on a cord can

damage it and cause fire or electric shock.

When the machine is not used over an extended period of time, switch it Off and unplug it. If an unused

machine is left connected to a power source for a long period, degraded insulation can cause electric

shocks, current leakage or fire.

Be sure to switch Off and unplug the machine before accessing the interior of the machine for cleaning,

maintenance or fault clearance. Access to a live machines interior can cause electric shock.

Be sure to switch Off and unplug the machine before accessing the interior of the machine for

accessing interface cables, maintenance or fault clearance. Access to a live machines interior can

cause electric shock.

Once a month, unplug the machine and check the power cord for the following. If you notice any

unusual condition.

The power cord is plugged firmly into the receptacle.

The plug is not excessively heated, rusted, or bent.

The plug and receptacle are free of dust.

The cord is not cracked or frayed.

thers

The machine has a built-in circuit for protection against lightning-induced surge current. If lightning strikes in your

neighborhood, switch Off the machine. Disconnect the telephone line cable first, then unplug the power cord from

the machine and reconnect only when the lightning storm has stopped.

If you notice flickering or distorted images or noises on your audio-visual units, your machine may be causing

radio interference. Switch it Off and if the interference disappears, the machine is the cause of the radio interference. Perform the following procedure until the interference is corrected.

Move the machine and the TV and/or radio away from each other.

Reposition or reorient the machine and the TV and/or radio.

Unplug the machine, TV and/or radio, and replug them into outlets that operate on different circuits.

Reorient the TV and/or radio antennas and cables until the interference stops.

For an outdoor antenna, ask your local electrician for support.

Use a coaxial cable antenna.

perating Safeguards

WARNING

Do not touch areas where these caution labels are attached to the surface may be very hot, and cause

server burns.

Do not place any liquid container such as a vase or coffee cup on the machine. Spilt water can cause

fire or shock hazard.

Do not place any metal parts such as staples or clips on the machine. If metal and flammable parts get

into the machine, they can short-circuit internal components, and cause fire or electric shocks.

If debris (metal or liquid) gets into the machine, switch Off and unplug the machine.

Operating a debris-contaminated machine can cause fire or electric shock.

Do not try to alter the machine configuration or modify any parts. An unauthorized modification can

cause smoke or fire.

7

Page 8

t

n

s

CAUTION

C

e

Do not place a magnet near the safety switch of the machine. A magnet can activate the

machine accidentally resulting in injuries.

Do not use a highly flammable spray or solvent near the machine. It can cause fire.

When copying a thick document, do not use excessive force to press it against the

document glass. The glass may break and cause injuries.

Never touch a labeled area found on or near the heat roller. You can get burnt. If a shee

of paper is wrapped around the heat roller, do not try to remove it when it is hot, to avoid

injuries or burns. Switch Off the machine immediately, and wait until it cools down.

Do not use conductive paper, e.g. folding paper, carbonic paper and coated paper. Whe

a paper jam occurs, they can cause a short circuit and fire.

Do not place any heavy object on the machine. An off-balance machine can tip-over or

the heavy object can fall, causing damage and/or injuries.

Keep the room ventilated when using the machine for an extended period of time to

minimize the ozone density in the air.

When copying with the document cover open, do not look directly at the exposure lamp.

Direct eye exposure can cause eye fatigue or damage.

Pull out paper trays slowly to prevent injuries.

When removing jammed paper, make sure that no pieces of torn paper are left in the

machine. A piece of paper remaining in the machine can cause fire. If a sheet of paper i

wrapped around the heat roller, or when clearing a jammed paper that is difficult or

impossible to see, do not try to remove it by yourself. Doing so can cause injuries or

burns. Switch Off the machine immediately, and wait until it cools down.

onsumable Safeguards

WARNING

Never throw a toner bottle into an open flame. Toner remaining in the bottle can

cause an explosion and you can get burnt.

Never throw toner or a waste toner container or a toner bottle into an open flame. It

can cause an explosion and you can get burnt.

Keep button batteries out of the reach of children. If a button battery is swallowed

accidentally, get medical treatment immediately.

CAUTION

Never heat the drum cartridge, or scratch its surface. A heated or scratched drum can b

hazardous to your health.

Do not mix new and old batteries together. Otherwise, batteries can burst or leak,

causing fire or injuries.

Be sure to use the specified type of batteries only.

Ensure that batteries are installed with correct polarity. Incorrectly installed batteries can

burst or leak, resulting in spillage or injuries.

8

Page 9

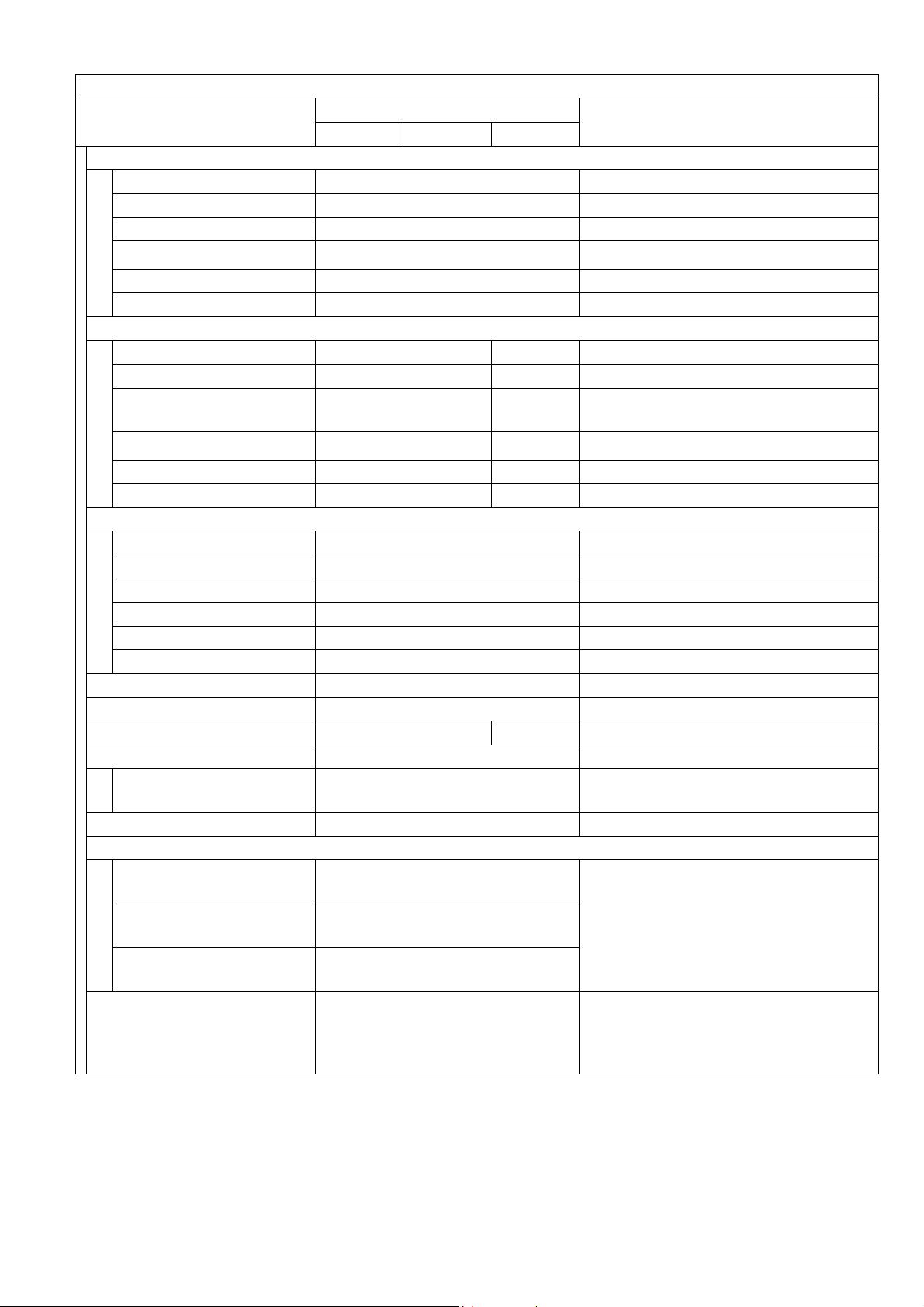

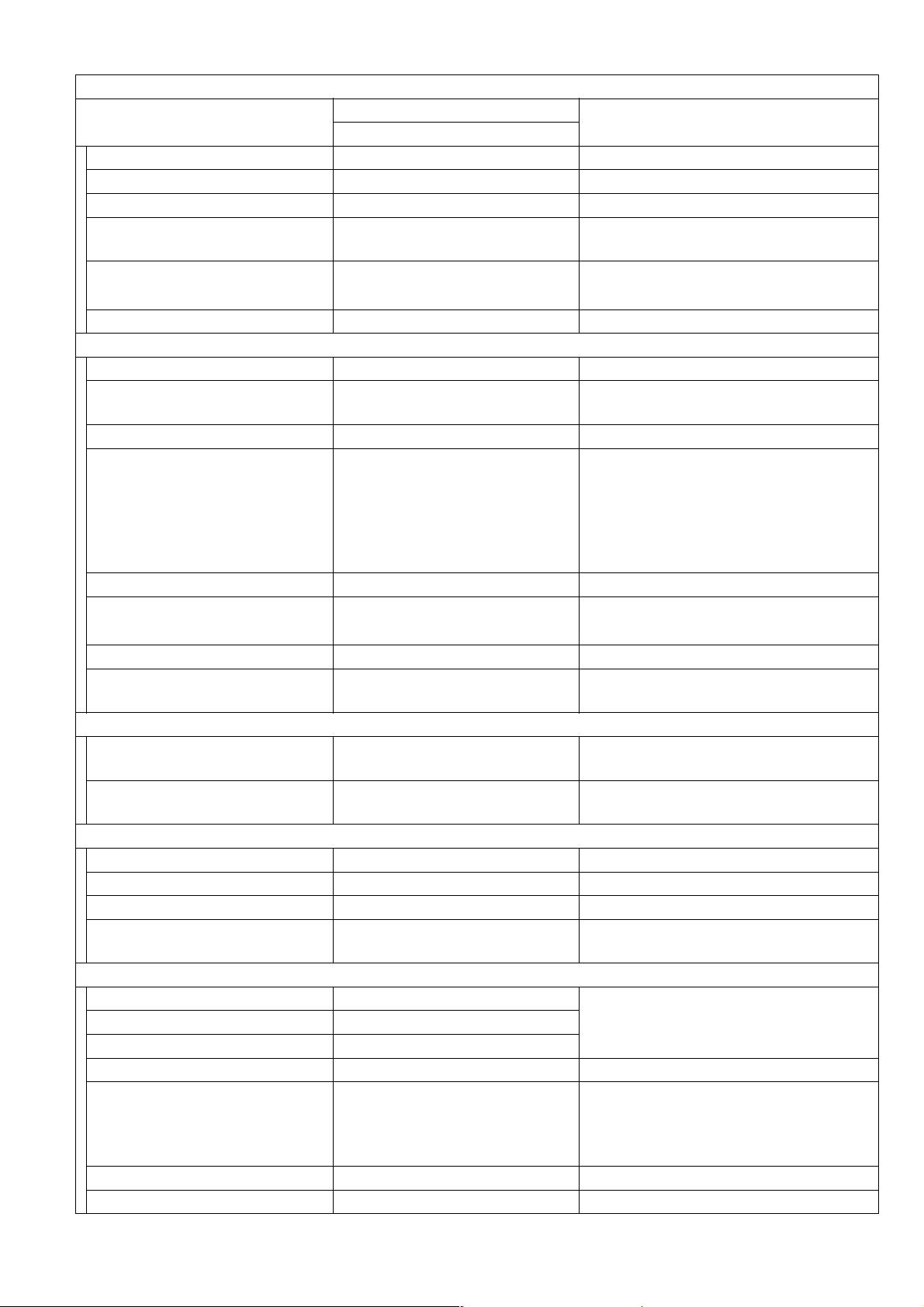

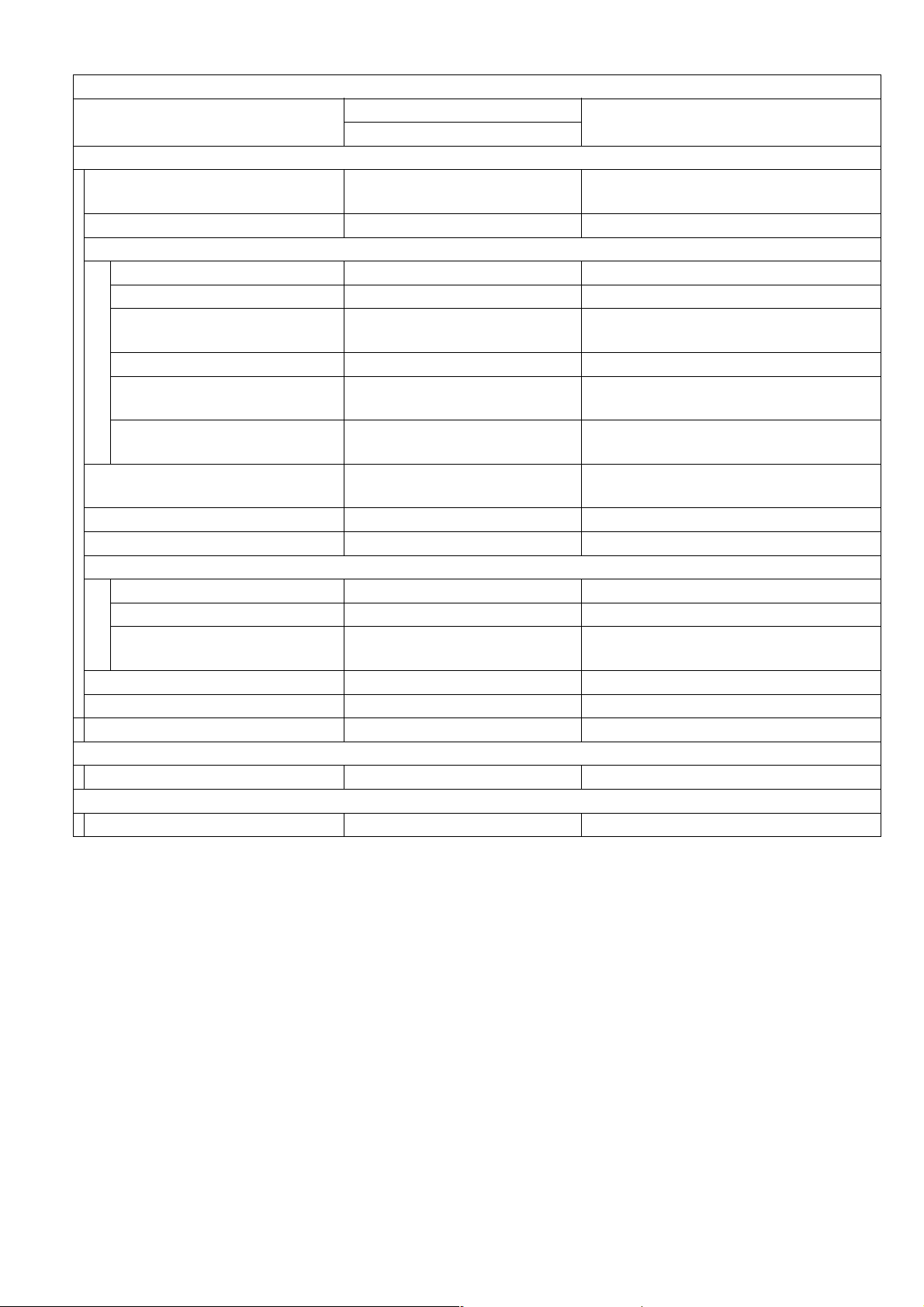

Table of Contents

Specifications Table................................. 10

1.1. Copy Function.........................................10

1.2. Fax, Printer and Internet

Fax Functions .........................................20

1.3. System Combination...............................30

1.4. Options List.............................................31

Maintenance, Adjustments and

Check Points............................................ 32

2.1. Preventive Maintenance .........................32

2.2. Required Tools .......................................34

2.3. Preventive Maintenance Points ..............35

2.4. Preventive Maintenance

Check List ...............................................37

2.5. Resetting the P/M

(Preventive Maintenance) Counter .........39

2.6. Lubrication Point List ..............................40

2.7. Updating the Firmware ...........................41

2.8. Copy Quality Adjustment

Procedure (Order)...................................50

2.9. Adjusting the Printer Registration,

LSU Image Side to Side .........................53

Troubleshooting .......................................57

3.1. Error Codes (For Copier) ........................57

3.2. Information Codes Table

(For Facsimile)........................................67

5.16. Inverting Automatic Document

Feeder (For DP-1820E) ....................... 188

5.17. PC Boards/Harnesses.......................... 204

5.18. 2nd/4th Paper Tray .............................. 210

5.19. 3rd Paper Tray ..................................... 216

5.20. Packing and Accessories ..................... 222

5.21. Printer Controller Module

for PCL6 ............................................... 226

5.22. Printer Controller Module

for PS/PCL6 ......................................... 228

5.23. Network Scanner Module..................... 230

5.24. Internet Fax/E-Mail Module .................. 232

5.25. Fax Communication Board................... 234

5.26. Keyboard Option .................................. 236

5.27. Hard Disk Drive Unit............................. 238

5.28. Accounting Software ............................ 240

5.29. i-ADF Packing and Accessories........... 242

5.30. ADF Packing and Accessories ............. 244

5.31. 2nd/4th Paper Tray and

3rd Paper Tray Packing and

Accessories.......................................... 246

5.32. Dehumidifier Heater Kit

(For Main Unit) ..................................... 248

5.33. Dehumidifier Heater Kit

(For Optional Paper Tray(s)) ................ 250

5.34. Key Counter Harness Kit ..................... 252

5.35. Hardware Identification Template ........ 254

Service Modes .........................................73

4.1. Service Modes (For Copier)....................73

4.2. Service Modes (For Facsimile) .............100

Exploded View & Parts List.................... 130

5.1. Destination Codes ................................131

5.2. Cover Assembly....................................132

5.3. Scanner Unit .........................................136

5.4. Control Panel Unit.................................140

5.5. Paper Transportation ............................144

5.6. Automatic Duplex Unit ..........................148

5.7. Electrical Parts......................................152

5.8. Frame Parts ..........................................156

5.9. Fuser Unit .............................................160

5.10. Hopper Unit...........................................164

5.11. Developer Unit ......................................166

5.12. Drum Unit..............................................170

5.13. Drive Unit ..............................................174

5.14. Paper Tray ............................................178

5.15. Automatic Document Feeder ................180

Alphanumerical Parts List...................... 257

9

Page 10

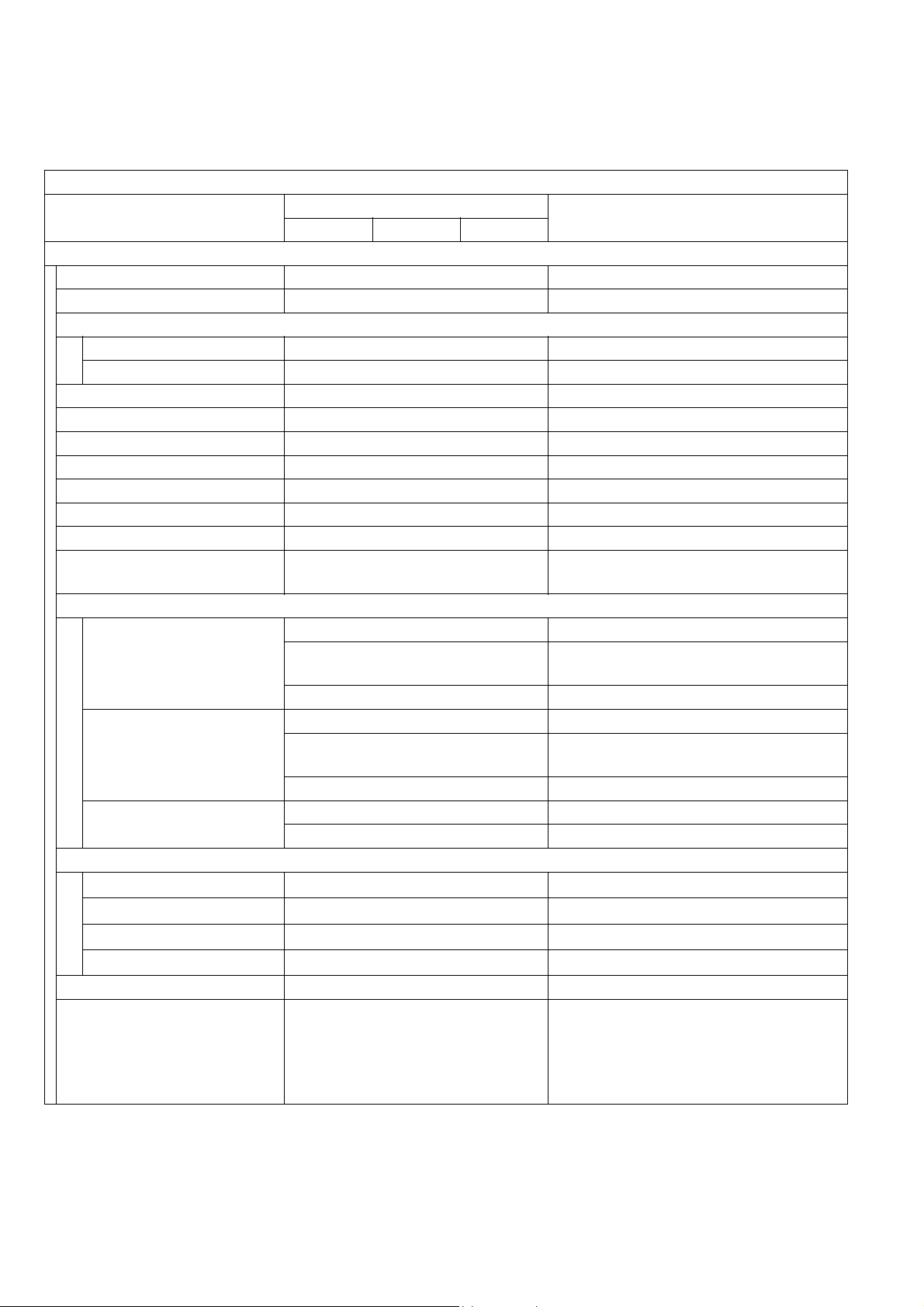

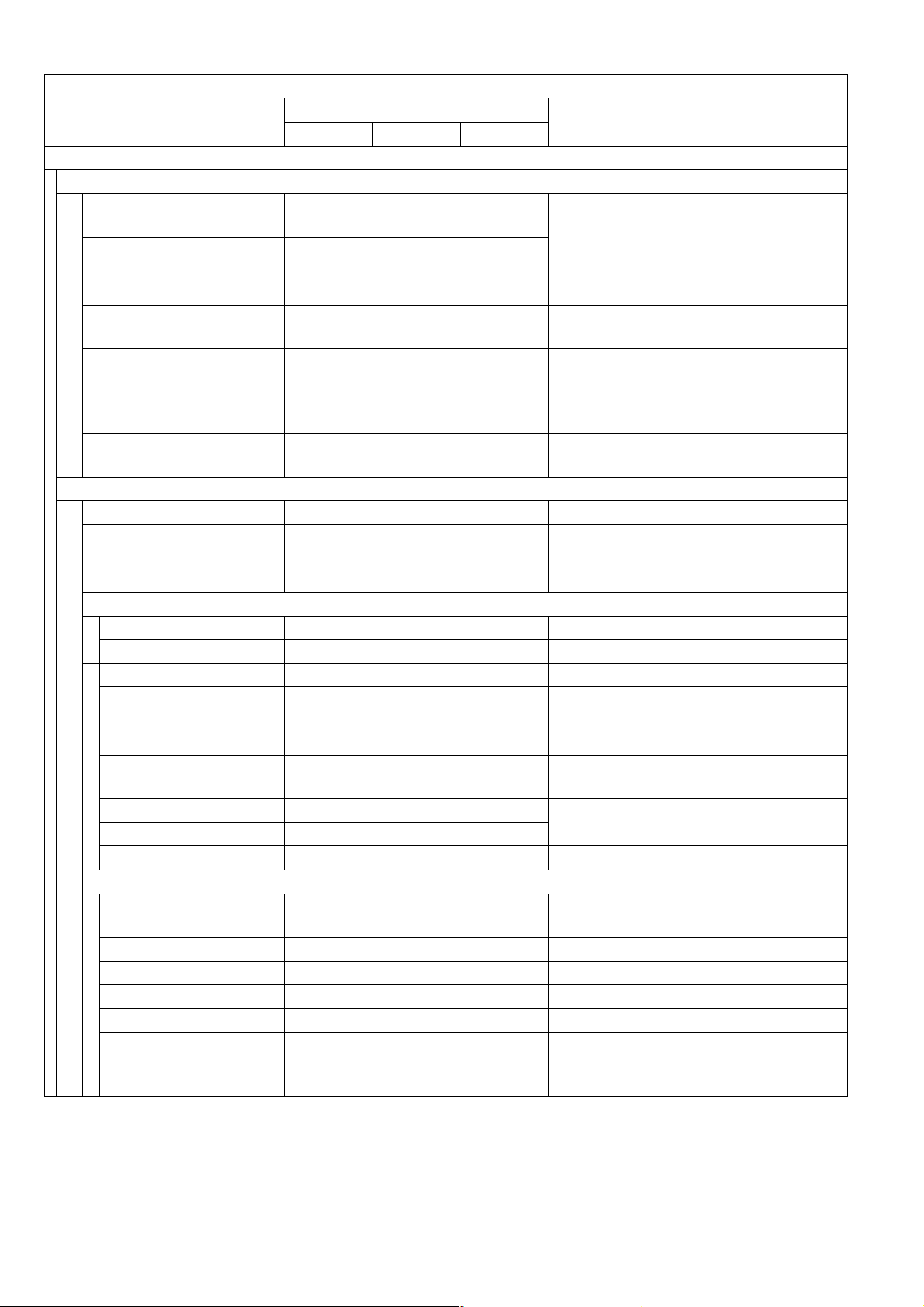

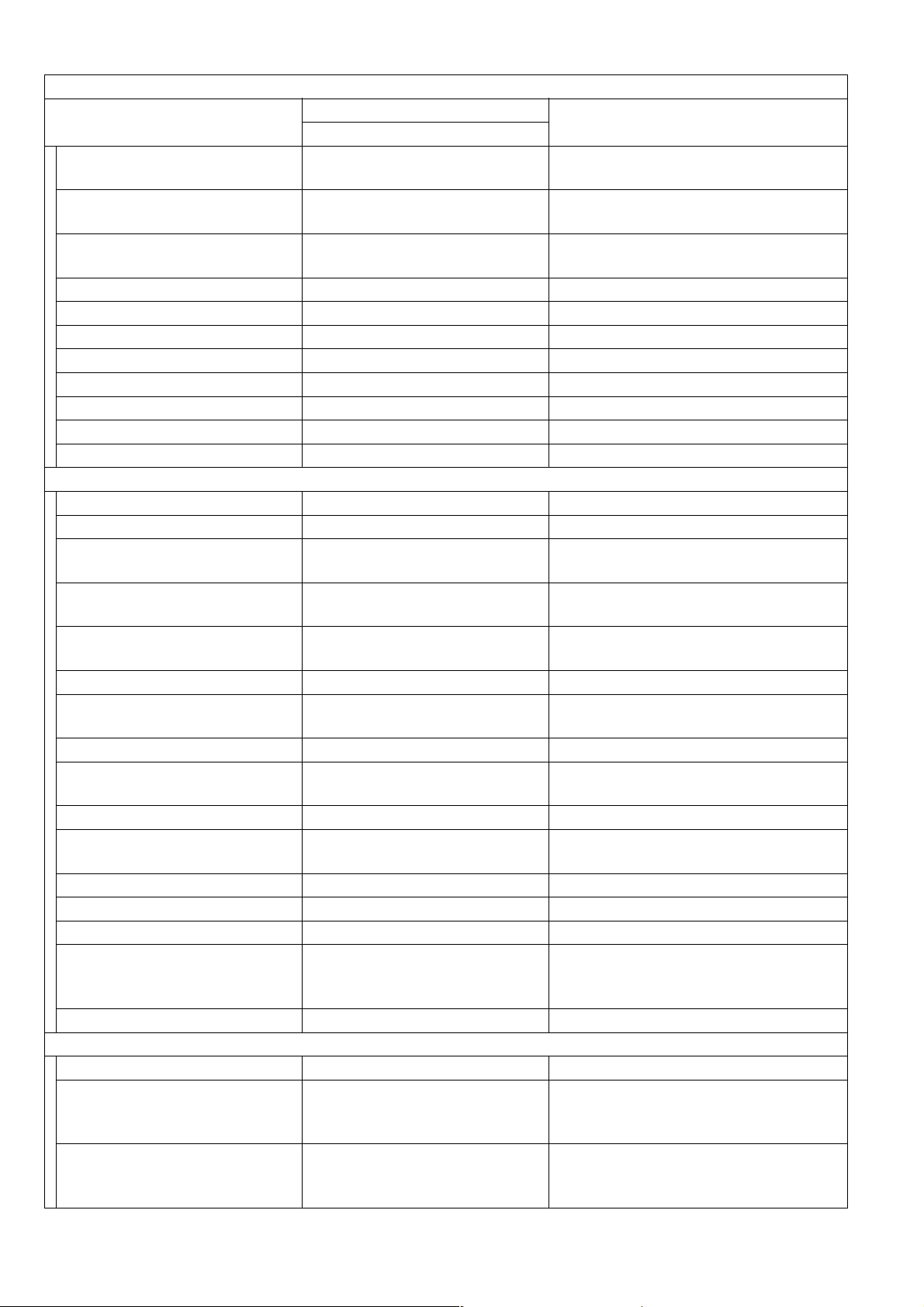

1 Specifications Table

1.1. Copy Function

Copy Function

Items

DP-1520P DP-1820P DP-1820E

Basic Specifications

1 Type Desktop

2 Platen Fixed

3 Original Position

Platen Left / Rear

ADF / i-ADF Left / Center

4 Recording Paper Path Center

5 Face Up / Face Down Face Down

6 Drum Organic Photo Conductor (OPC)

7 Copy Process Dry Electrostatic System

8 Developing Process Dry Dual Components

9 Toner Recycle No

10 Fusing System Heat & Pressure

11 Max Original Size

12 Paper Size

LDR, LGL, LTR, LTR-R, INV-R For USA and Canada

Paper Tray

A3, A4, A4-R, A5, A5-R, B4, FLS

A3, A4, A4-R, B4, B5, B5-R For Other Destinations

LDR, LGL, LTR, LTR-R, INV-R For USA and Canada

Bypass Tray

A3, A4, A4-R, A5-R, B4, FLS

A3, A4, A4-R, B4, B5, B5-R For Other Destinations

Bypass Tray (Envelope)

13 Paper Weight

Paper Tray

Bypass Tray

ADU

ADF / i-ADF

14

Warm-up Time Less than 30 sec 68 °F (20 °C)

0.13 - 0.20 lb (60 - 90 g/m

0.12 - 0.29 lb (55 - 133 g/m

0.14 - 0.20 lb (64 - 90 g/m

0.11 - 0.24 lb (50 - 110 g/m

15

First Copy Time Less than 6.9 sec

Description

Ledger (11 x 17 in) /

A3 (297 x 420 mm)

For EU

FLS = 8 x 13 in, 8.5 x 13 in

For EU

FLS = 8 x 13 in, 8.5 x 13 in

#10 (4.1 x 9.5 in) For USA and Canada

DL (4.3 x 8.7 in) For EU

2

)

2

)

2

For DP-1820E only

)

2

)

From Platen, Letter/ A4 Portrait, 1st

Paper Tray. Period between Start Key

is pressed and Paper ejected to the

Exit Tray.

When LSU is ready.

DP-1520P/1820P/1820E

Remarks

Ver. 1. 0

10

JUN 2004

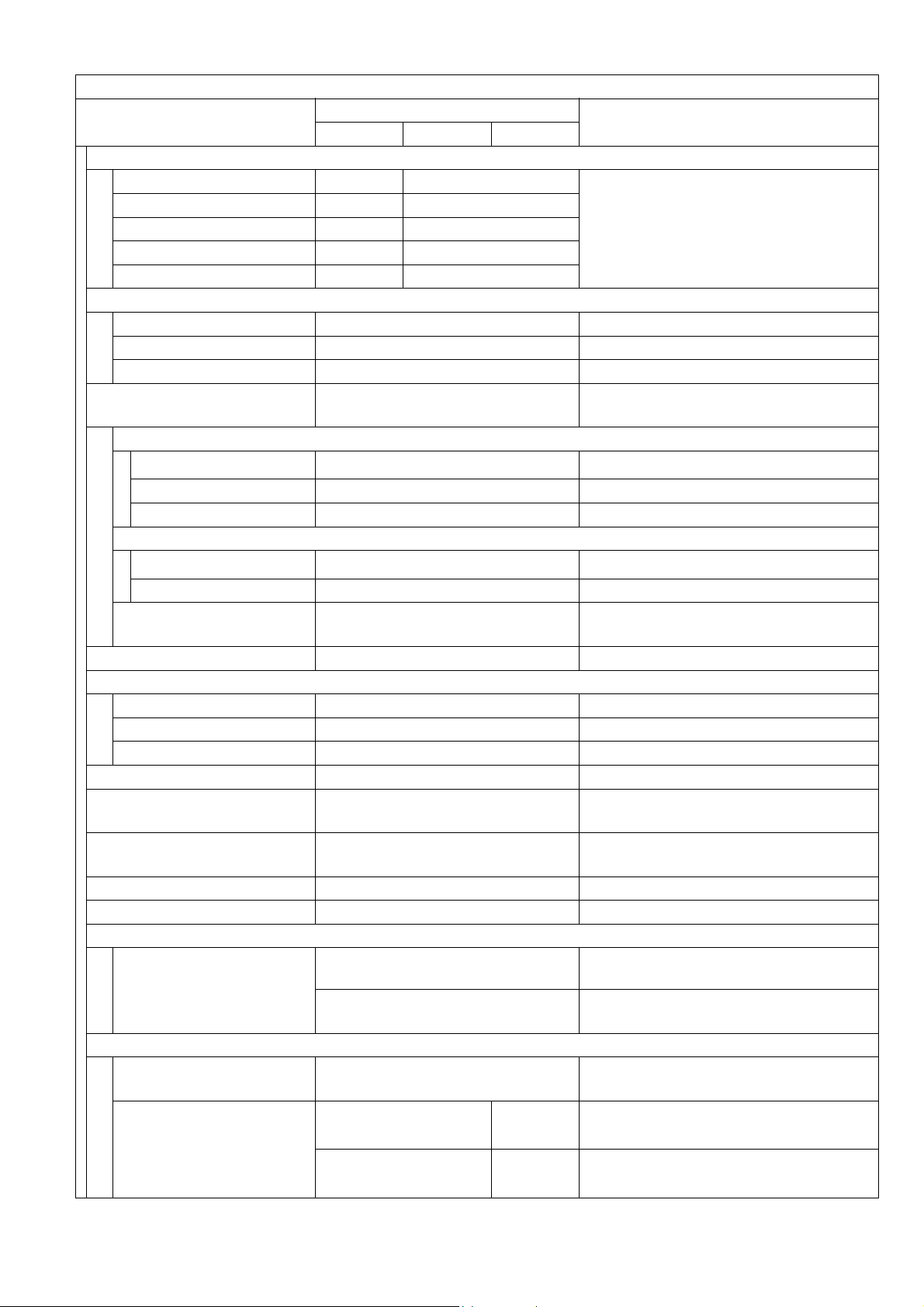

Page 11

Copy Function

Items

Description

Remarks

DP-1520P DP-1820P DP-1820E

16 Copy Speed

Ledger / A3 9 cpm 11 cpm

Legal / B4 / FLS 10 cpm 12 cpm

Letter-R / A4-R 12 cpm 15 cpm / 14 cpm

Letter / A4 15 cpm 18 cpm

From Platen, Letter/A4 Portrait, 1st

Paper Tray, and Paper ejected to the

Exit Tray, LSU is ready, and

Continuous Copy.

Invoice-R / A5-R 15 cpm 18 cpm

17

Zoom

Enlargement Selected Original size / Copy size

Reduction Selected Original size / Copy size

Zoom 50 - 200% 1% Step

18 Paper Feed

Front Loading Universal Paper

Tray

Paper Tray

Capacity

550 sheets x 1

LTR / A4 : 20 lb (75 g/m

Auto Size Setting No Control Panel Selectable

Low Level Warning Empty Only

Bypass Paper Tray

Capacity 50 sheets

LTR / A4 : 20 lb (75 g/m

Auto Size Setting Yes

Paper Capacity

(Std. Configuration)

600 sheets

Paper Tray 1 (Std) +

Bypass Paper Tray

19 Multi Copy Range 999 sheets

20 Gradation

Te xt B i- Le ve l

Text / Photo 256 steps Halftone by Error Diffusion

Photo 256 steps

21

Resolution 600 dpi Scanning and Printing.

Standard Sorting Memory

22

Size

Standard Page Memory

23

Size

Exit Tray Capacity

24

Standard: 250 sheets

16 MB

32 MB

25 Color No

26 Dimensions

(W x D x H)

22.0 x 21.9 x 18.1 in

(558 x 557 x 460 mm)

33.2 x 24.6 x 24.5 in

(844 x 624 x 623 mm)

H: To Platen Glass.

Includes ADF / Bypass Paper Tray.

27 Operating Space

(W x D)

93.26 lb (42.3 Kg)

33.2 x 22.2 in

(844 x 565 mm)

95.46 lb

(43.3 Kg)

Includes Bypass Paper Tray.

For USA and Canada

Weight

96.12 lb (43.6 Kg)

98.33 lb

(44.6 Kg)

For EU and Other Destinations

DP-1520P/1820P/1820E

2

)

2

)

Ver. 1. 0

11

JUN 2004

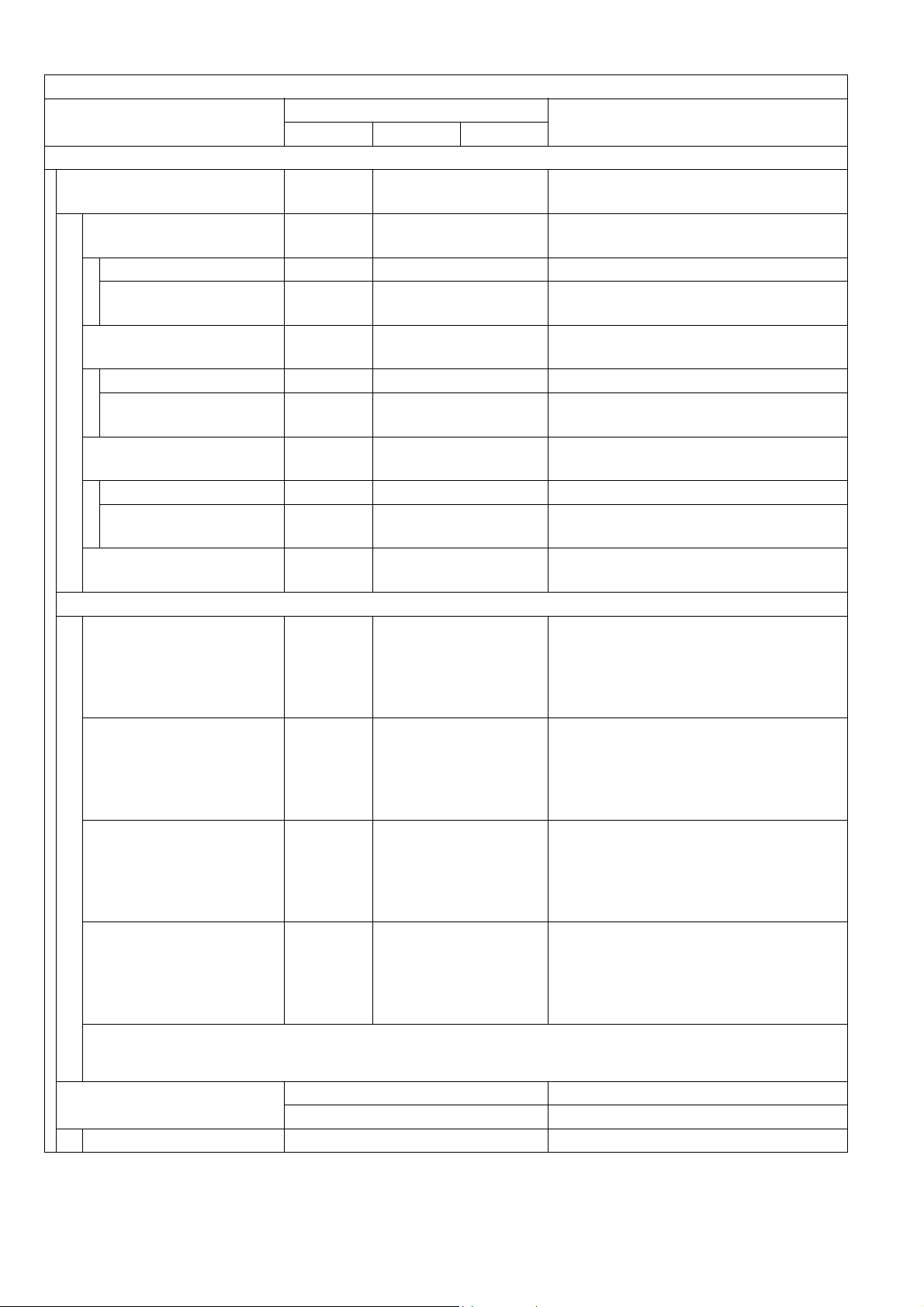

Page 12

Copy Function

Items

Description

DP-1520P DP-1820P DP-1820E

Options

1 Paper Feed System

550 sheets 2nd

Paper Tray

550

sheets x 1

550 sheets x 3

Yes Yes Motor is not mounted.

Paper Size Detection Manual Manual Control Panel Selectable

Low Level Paper

Warning

550 sheets 3rd

Paper Tray

Empty

Only

No

Empty Only

Yes Motor is mounted.

Paper Size Detection - Manual Control Panel Selectable

Low Level Paper

Warning

550 sheets 4th

Paper Tray

-

No

Empty Only

Yes Motor is not mounted.

Paper Size Detection - Manual Control Panel Selectable

Low Level Paper

Warning

Max. Paper Capacity

-

1,150

sheets

Empty Only

2, 250 sheets

LTR / A4 : 20 lb (75 g/m

2Stand

Low Stand with Casters

Stand for

4*-Paper Tray

Configuration

No Option

DA1D18C : For USA and Canada

DA-DA191-PE : For Other

Low Stand with Casters

Stand for

3*-Paper Tray

Configuration

No Option

DA1D18C : For USA and Canada

DA-DA190-PE : For Other

Mid Stand with Casters

Stand for

2-Paper Tray

Configuration

Option Option

DA1D18B : For USA and Canada

DA-DA189-PE : For Other

High Stand with Casters

Stand for

1-Paper Tray

Configuration

Option Option

DA1D18A : For USA and Canada

DA-DA188-PE : For Other

Note:

The same Stand (DA1D18C) is used for either 3 or 4 Paper Tray Configuration for USA and

Canada.

3Platen Cover

Option

Standard

For USA and Canada

For EU and Other Destinations

Free Stop Yes From 30 to 70 degrees.

DP-1520P/1820P/1820E

Remarks

2

)

Only

Destinations

Only

Destinations

Only

Destinations

Only

Destinations

Ver. 1. 0

12

JUN 2004

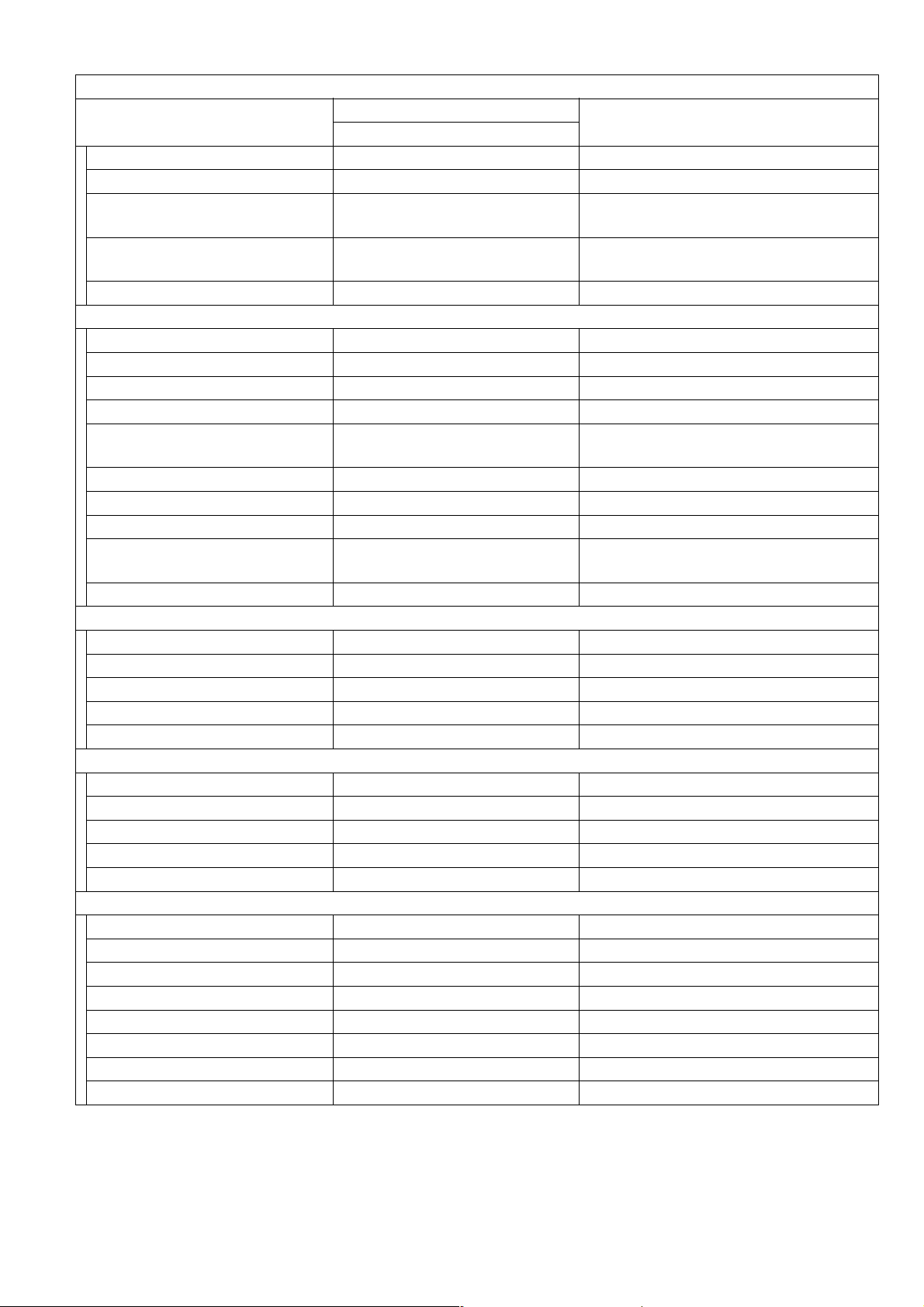

Page 13

DP-1520P/1820P/1820E

Copy Function

Items

Description

Remarks

DP-1520P DP-1820P DP-1820E

4ADF

Single Side Type Option

Original Set Face Up

Scanning Method Sheet Through

Capacity (Originals) 50 sheets

LTR / A4 : 20 lb (75 g/m

2

)

SADF Mode Yes

Free Stop Yes From 30 to 70 degrees.

5 Inverting ADF (i-ADF)

Duplex Type

No

Option

Original Set - Face Up

Scanning Method -

Capacity (Originals)

SADF Mode

-

-

Sheet

Through

50 sheets

Yes

LTR / A4 : 20 lb (75 g/m

2

)

Available for single side scanning only.

Free Stop - Yes From 30 to 70 degrees.

6 Exit Tray (Inner)

Tray Position Inner

Number of Bins 1

Face Up / Face Down Face Down

Bin Capacity 250 sheets

Multi Tray Function

No

Shift Tray Function No

7 Finisher No

8 Exit Tray (Outer) No

11 Automatic Duplex Unit No Standard

12 Counter

Key Counter Capability

Option

The Harness Kit contains only

Harnesses, Bracket and a Screw.

13 Dehumidifier Option Supplied as a Service Part.

14 Sorting Image Memory

Optional Image Memory 1

(16MB)

Optional Image Memory 2

(64MB)

Optional Image Memory 3

(128MB)

Yes

Yes

Yes

Unit comes standard with 16 MB.

1-Slot available for an Optional Image

Memory module.

Additional Optional Sorting Image

15 Hard Disk Drive Option

Memory (Minimum 16 MB) is required

for the Hard Disk Drive to function.

(For Tandem, Remote Copy, etc.)

Ver. 1. 0

13

JUN 2004

Page 14

Copy Function

Items

Description

DP-1520P DP-1820P DP-1820E

Features

1 Automatic Features

Auto Magnification

Selection

Yes

Auto Paper Selection Yes

Auto Paper Tray

Selection

Yes

Auto Start Yes

Remote Diagnostic

Machine Stops when Out

of Toner

Yes

Yes PPC Function

2 Additional Features

Low Level Paper Warning Empty Only

Photo Mode Yes 256 steps

Original Detection

Release

No

Edit / Effects

Book Mode Yes

Edge Mode Yes

Margin Mode Yes

X-Y Zoom No

Stamping /

Page Numbering

Inverse Mode

(Negative / Positive)

No

No

Centering Mode Yes

Image Repeat Yes

Mirror Mode No

Others (Inverting ADF & ADU)

2-Page Copy Mode Yes

2 in 1 Yes

4 in 1 Yes

6 in 1 No

8 in 1

Booklet Mode

No

No

DP-1520P/1820P/1820E

Remarks

Using ADF only

Reservation while Power On

Initializing.

Requires the Fax Communication

Board (DA-FG180) option or the

Internet Fax / E-MAIL Module

(DA-NF180) option.

Manually overridden when using the

Original Size keys.

With Digital Sky Shot

LDR → LTR x 2

(A3 → A4 x 2, B4 → B5 x 2)

Copy from four 1-Sided

pages to 1 Booklet Mode

sheet.

Ver. 1. 0

14

JUN 2004

Page 15

Copy Function

Items

Description

DP-1520P DP-1820P DP-1820E

Duplex Copy

1→2No

2→1

Yes Yes

2→2No

Book→2No

Yes

Yes

Yes

Scanning twice by turning the original.

1st Page BLANK No 1 → 2/2 → 1/2 → 2

1st Page IMAGE No Book → 2

Image Rotation (90 or

270 °)

Yes

Electronic Sorting Yes

Rotation Sorting Yes

Insertion Job

Cover Mode No

Page Insertion Mode No

OHP Interleave Mode No

Presentation Mode No

Department Counter Yes 300 Departments

ADF

Multi Size Feed

JOB Build and SADF

Mode

No

Yes

Original Counter No

Job Memory Yes 2 Jobs in Memory

Job Time Display Yes

Concurrent Copy

Yes 12 Concurrent Copy Jobs

Tandem Copy Mode No

Remote Copy Mode No

Scan Once Print Many

Mode

Yes

Job Complete Notice No

Trial Copy Mode No

Weekly Timer No

Function Mode Yes

Interrupt Yes

Electronic Counter Yes

Digital Sky Shot Mode Yes

Double Exposure Yes

3 Control Panel

Display LCD 20 digits x 2 lines

GREEN : Scanning /

Status Lamp Yes

RED : Alarm / Warning

DP-1520P/1820P/1820E

Remarks

Printing

Ver. 1. 0

15

JUN 2004

Page 16

Copy Function

Items

Description

Remarks

DP-1520P DP-1820P DP-1820E

Key

Original Size Yes

Copy Size Yes

Keypad Yes

Clear Yes

Stop Yes

Start Yes

Energy Saver Yes

Multi Size Feed No

Sort Yes

Function Mode Yes

Original Detection

Release

No

Interrupt Yes

Reset Yes

One-Touch key Yes With Keyboard Option

Mode Change No Yes

Copier / Printer / NW Scanner / Fax

and Internet Fax Mode

LCD Main Indication

Message Language

(Default)

Original Size / Image

Indication

Paper Size / Image

Indication

English (American) For USA and Canada

Specified Language

For EU and Other Destinations

Yes

(without Image)

Yes

(without Image)

Paper Tray Selection Yes

Selected Paper Tray /

Tray Status

Original Mode

Selection

Yes

Yes

Text / Text-Photo / Photo

Copy Density Selection Yes

Setting Confirmation Yes

Function Classification Yes

Zoom Magnification Yes

Number of Copies Yes

JOB Build and SADF /

Multi Size Feed Mode

Yes

Error Code Yes

Finishing

No

Warning Indicators Yes

Add Toner Yes

Toner Waste

Container Full

Add Paper (No

Yes

Yes

Paper)

Add Paper

(Under 50 sheets)

No

DP-1520P/1820P/1820E

Ver. 1. 0

16

JUN 2004

Page 17

Copy Function

Items

Description

Remarks

DP-1520P DP-1820P DP-1820E

Paper Jam Indication Yes

Paper Jam Location Yes

Service Alert Call Yes

User Error Yes

Machine Error Yes

History of Jam Errors Yes

4 Main Unit

Total Counter

Electronic Yes

Standard for EU.

Mechanical Yes

Available as a Service Part for Other

Destinations.

Max. Weight of

Documents on the Platen

11.02 lb (5 kg)

Glass

ADF with Document

Guide

Yes

Clip Pocket Yes

Operating Instructions

Pocket

No

Warning / Caution Label Specified Language

5 Optical System

Original Detection

Method

Reflective Photo Sensor Type

Scanning Method 600 dpi CCD

Dehumidifier Yes Supplied as a Service Part

Mechanical Multi Copy

Mode

No

6 Process System

Type

Toner 10 K

Separate OPC Unit and

Developer Unit Type

User replacement

Toner Waste Container 10 K

Drum Life 60 K

Developer Life 60 K

Dehumidifier Yes Supplied as a Service Part

Manual Add Toner Yes

Manually adds toner to the developer

(up to TDC threshold)

Efficiency

1 Productivity

ADF Productivity (LTR /

A4)

ADU Copy Productivity

(LTR / A4)

100%

Throughput when the LSU is ready;

-55%

Paper is fed from the 1st Paper Tray

and is ejected to the Exit Tray.

DP-1520P/1820P/1820E

Ver. 1. 0

17

JUN 2004

Page 18

DP-1520P/1820P/1820E

Copy Function

Items

Description

Remarks

DP-1520P DP-1820P DP-1820E

PM Cycle

1PM Cycle

Major PM 120 K

Minor PM (Cleaning) 60 K

Packing Configuration

1 Packing Dimension

2 Packing Weight

28.5 x 28.6 x 34.1 in

(724 x 727 x 866 mm)

28.4 x 28.4 x 29.5 in

(722 x 722 x 750 mm)

121.25 lb

(55 kg)

127.87 lb

(58 kg)

112.44 lb

(51 kg)

123.46 lb

(56 kg)

130.07 lb

(59 kg)

114.64 lb

(52 kg)

For USA, Canada and China

For EU and Other Destinations

For USA and Canada

For China

For EU and Other Destinations

3 Accessories

Process Unit Yes

Developer No

To ne r No

Toner Waste Container No

Operating Instructions Yes

Power Supply

1 Power Requirement

99 - 132 VAC 47 - 63 Hz

Single phase

180 - 264 VAC 47 - 63 Hz

Single phase

120 VAC

220 - 240 VAC

2 Power Consumption

Max.Power Consumption

100 VAC PS Less than 1.3 KW

220 VAC PS Less than 1.3 KW

Standby

100 VAC PS 120 W

220 VAC PS 120 W

Turns On the Heater Power.

Energy Saver Automatically enters the Sleep or

Power Saver Mode

100 VAC PS 19.0 W

220 VAC PS 19.5 W

Sleep Mode

100 VAC PS 8.5 W

220 VAC PS 9.5 W

Shutdown Mode after 10 minutes from

the Standby or Energy Saver Mode.

Manually enters the Energy Saver

Mode by pressing the Energy Saver

key.

Sleep or Shutdown mode is controlled

by the General Functions setting.

Shutdown Mode

100 VAC PS 1.4 W

Network Function not available

220 VAC PS 1.6 W

Ver. 1. 0

18

JUN 2004

Page 19

Copy Function

Items

Description

DP-1520P DP-1820P DP-1820E

Ambient Conditions

1 Temperature 50 - 80 °F / 10 - 30 °C

2 Relative Humidity 30 - 80%

3 Safety

UL1950-1 / CSA C22.2 No.950 For USA and Canada

EN60950-1

4 Energy Saver Energy Star Compliant

Class A computing device in FCC

Rules Part 15

5EMI

Class B

EN55022, EN55024,

EN61000-32, EN61000-3-3

6 Lead Free Solder (PbF)

This Product uses Lead Free

(PbF) PCBs

DP-1520P/1820P/1820E

Remarks

For EU and Other Destinations

For USA and Canada

For EU

Refer to the Parts Manual for details

Ver. 1. 0

19

JUN 2004

Page 20

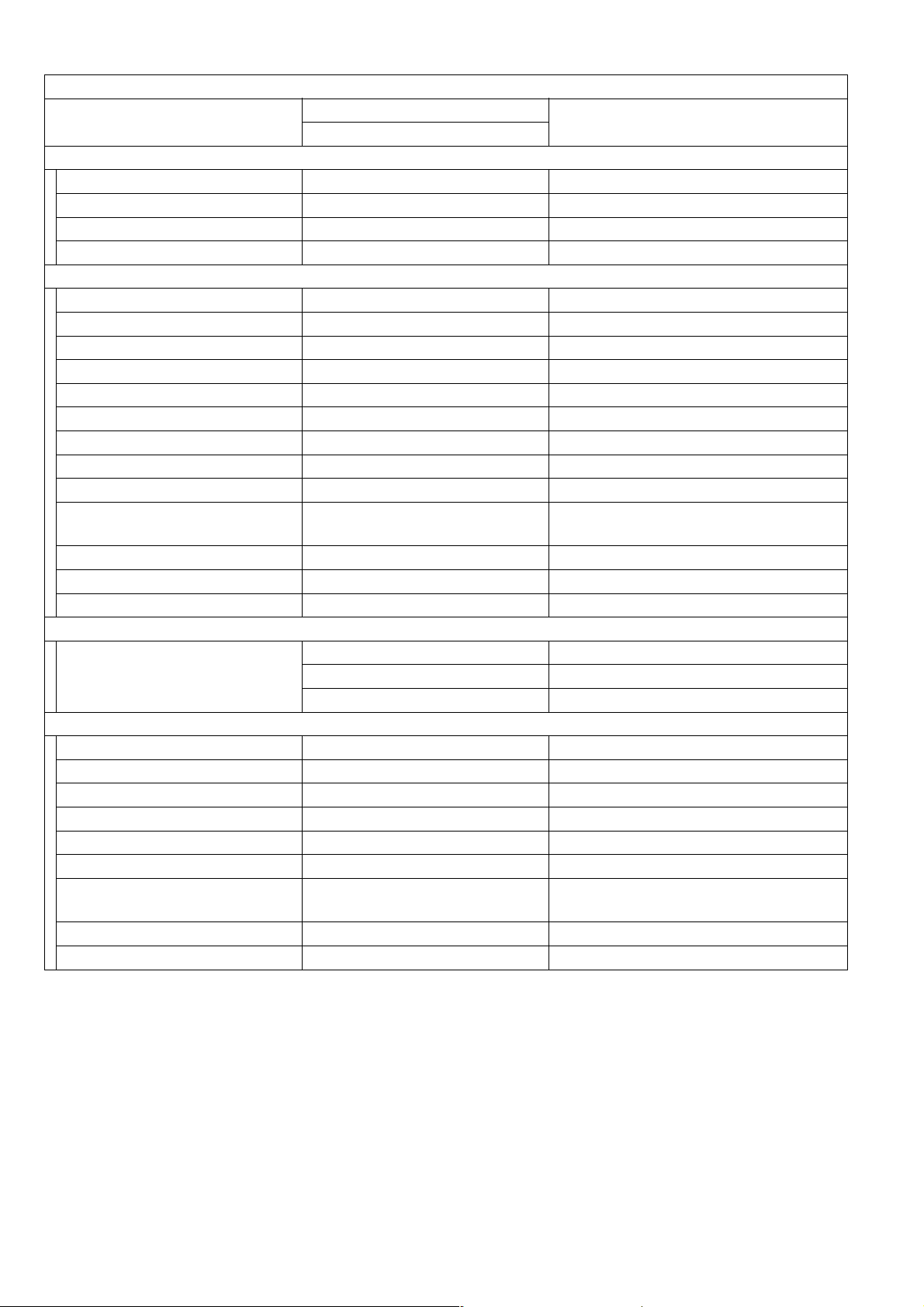

DP-1520P/1820P/1820E

1.2. Fax, Printer and Internet Fax Functions

1.2.1. Fax Function

Fax Function

Items

Main Specifications

1 Compatibility G3 ITU-T Std & Non-Std

2 PSTN Line Port Yes 1-Line Only

3 Leased Line Port No

4 V.24 Line Port No

5 Modem Speed 33.6 - 2.4 kbps T.30/V.34/V.17/V.29/V.27ter

6 Coding Scheme JBIG/MMR/MR/MH

7 ECM Yes Conforms to ITU-T Rec. T.30 ECM

8 Short Protocol Yes (B, D)

9 Transmission Speed

Transmission

Std. : 203 x 98 (8 x 3.85)

Fine : 203 x 196 (8 x 7.7)

S-Fine : 203 x 391 (8 x 15.4)

Communication Resolution

10

dpi x lpi (pels/mm x lines/

mm)

600dpi : 600 x 600 dpi

Reception

Std. : 203 x 98 (8 x 3.85)

Fine : 203 x 196 (8 x 7.7)

S-Fine : 203 x 391 (8 x 15.4)

600dpi : 600 x 600 dpi

Scanner Mechanism

1 Scanning Device CCD (ADF / Platen)

2 Scanning Speed (ADF)

Resolution Vertical Horizontal

Std: 203 x 98 (8 x 3.85)

dpi x lpi (pels/mm x lines/

mm)

0.9 / 1.0 sec 0.7 sec

Fine: 203 x 196 (8 x 7.7)

dpi x lpi (pels/mm x lines/

mm)

S-Fine: 406 x 391 (16 x

15.4) dpi x lpi (pels/mm x

1.8 / 2.0 sec 1.4 sec

lines/mm)

600dpi: 600 x 600 2.8 sec 2.1 sec

3 Scanning Speed (Platen)

Resolution Vertical Horizontal

600dpi: 600 x 600 2.8 sec 2.1 sec

Std. : 203 x 98 (8 x 3.85)

Scanning Resolution

4

dpi x lpi (pel/mm x lines/

Fine : 203 x 196 (8 x 7.7)

S-Fine : 203 x 391 (8 x 15.4)

mm)

600dpi : 600 x 600 dpi

Description

DP-1820P / 1820E

Approx. 2.9 sec

406 x 391 (16 x 15.4)

406 x 391 (16 x 15.4)

406 x 391 (16 x 15.4)

Remarks

ITU-T Image No. 1

(A4, Std Resolution)

600 dpi communication is only

possible between T.30 Compliant

Panafax, WORKiO, and other T.30

compliant machines.

LTR / A4, Scanned in Vertical or

Horizontal Direction.

Excluding Initializing Time and ADF

slipping factor.

Ver. 1. 0

20

JUN 2004

Page 21

Fax Function

Items

Description

Remarks

DP-1820P / 1820E

5 Document Size (Max.) ADF: LDR / A3

6 Effective Scanning Width LDR (11.5 in) / A3 (292 mm)

7 A3 size TX/RX Yes Conforms to ITU-T A3

8 Reduction XMT Yes

9 ADF Capacity 50 sheets

LDR to LTR / A3 to B4 / A3 to A4

/ B4 to A4

Face-Up, feed from top page

LTR / A4 (20 lb / 75 g/m

10 Collation Stack Yes Face Down

Printer Mechanism

1 Recording Method LP

2 Recording Speed

23 / 30 ppm

(A4 Horizontal)

Recording Speed attained after the 1st

copy.

3 Recording Resolution Fax 600 x 600 dpi

Invoice : Not supported.

Ledger size is transmitted as A3 size

4 Recording Paper Size

Ledger / Legal / Letter /

A3 / B4 / A4 / A5

for N. American models. If A3 is

received, approx. 1" of image on both

edges are not printed on Ledger size

paper.

5 Effective Printing Width 11.4 in (289 mm) Conforms to ITU-T A3

6 Recording Paper Capacity 600 sheets

Optional max. 2250 sheets

LTR / A4 : 20 lb (75 g/m

7 Collation Stack Yes Face Down

8 Consumable

Toner Bottle, Developer,

OPC Drum

Fax Memory

1 Standard Memory 2 MB (120 pages)

Optional Memory

2

4 MB

8 MB

Flash ROM, ITU-T Image No.1

(A4, Std Resolution)

Expansion Flash Memory Card, using

ITU-T Image No.1 (A4, Std Resolution)

Dual Operation

1 Multi Task Operation Yes

2 Direct XMT Reserve Yes

3 Memory XMT Reserve Yes

Number of Memory Job

4

Files

Yes Max. 50 files

Dialing/Telephone Features

1 One-Touch Keys 28

Requires Optional Keyboard.2 One-Touch / Program Keys 4

3 One-Touch Auto Dialers 32

4 Abbr. Auto Dialers 200

Plus an additional 800 stations

5 Total Auto Dialers 232

available to select from, when the

optional Hard Disk Drive (DA-HD18) is

installed.

6 Directory Search Dialing

7

Max. Tel Number Digits 36

Yes

DP-1520P/1820P/1820E

2

)

2

)

Ver. 1. 0

21

JUN 2004

Page 22

DP-1520P/1820P/1820E

Fax Function

Items

Description

Remarks

DP-1820P / 1820E

8 Max. Station Name

Characters

Full Number Dialing

9

(Buffered Dialing)

10 Direct Dialing

(Monitor Dialing)

15

Yes Max. 50 stations

Yes Voice mode

11 Automatic Redialing Yes Up to 15 times at 0 to 15 min. intervals

12 Manual Redialing Yes Pressing the REDIAL/PAUSE button

13 Line Monitor Speaker Yes

14 Chain Dialing (Hybrid Dial) Yes In Monitor Dialing mode only

15 Pulse / Tone Dialing Yes 10 pps / DTMF

16 Pulse to Tone Change No

17 Flash Key Yes

18 Handset No

Transmission Features

1 Direct Transmission Yes

2 Memory Transmission Yes Page Retransmission

Quick Memory

3

Transmission

Multi-Station Transmission

4

(Sequential Broadcasting)

Direct Deferred

5

Transmission

Yes

Yes Max. 250 stations

No ADF Deferred Transmission

6 Deferred Transmission Yes Max. 50 timers

Deferred Multi-Station

7

Transmission

Yes

8 Priority Direct Transmission Yes Priority ADF Transmission

Priority Memory

9

Transmission

No

10 Batch Transmission Yes Real Time (up to 5 Files)

90 Degree Rotation

11

Transmission

Yes

12 Cover Sheet Yes

13 Confidential Mail Box No

14 Multi-Copy Transmission No

FAX : Back-up with Flash Memory.

15 Memory Back-Up Yes

Copy / Printer : No Back-up with DRAM

16 Duplex Scanning Yes With Inverting ADF (i-ADF)

Reception Features

1 Substitute Reception Yes

LTR/A4/LGL: 70 - 100%

2 Fixed Reduction Yes

(in 1% Steps),

Top & Left Alignment

LTR/A4/LGL: 70 - 100%

3 Auto Reduction Yes

(in 1% Steps),

Top & Left Alignment

Ver. 1. 0

22

JUN 2004

Page 23

DP-1520P/1820P/1820E

Fax Function

Items

Description

Remarks

DP-1820P / 1820E

4 Overlap Printing Yes Page End Approx. 0.51 in (13 mm)

5 Receive to Memory Yes

Distinctive Ring Detector

6

(DRD)

90 Degree Rotation

7

Reception

No

Yes

8 Duplex Printing Yes

Polling

1 Polling Yes

2 Turnaround Polling No

3 Multi-Station Polling Yes

Max. 250 stations

4 Deferred Polling Yes Max. 50 timers

Deferred Multi-Station

5

Polling

Yes Max. 50 timers / 250 stations

6 Direct Polling Tx No

7 Memory Polling Tx Yes 1 File

8 Preset Polling Password Yes

Temporary Polling

9

Password

Yes

10 Continuous Polling Yes

Convenience

1 Panel Display LCD

2 Voice Contact No

3 Edit File Mode Yes With View Mode

4 Incomplete File Save Yes With View Mode

5 Automatic Cover Sheet Yes

Certainty

1 Verification Stamp Yes

2 Header / Total Page Print Yes

3 Transaction Journal Yes 200 Transactions / with View Mode

4 Comm. Journal Yes With Image Data

5 Last Ind. XMT Journal Yes

List Printouts

1 One-Touch List 2 ABBR. No. List 3 Program List Yes

4 Address Book Search List Yes Auto Dialer List

5 Fax Parameter List Yes

6 File List Yes With View Mode

7 Ind. XMT Journal Yes

8Directory Sheet No

Ver. 1. 0

23

JUN 2004

Page 24

DP-1520P/1820P/1820E

Fax Function

Items

Description

Remarks

DP-1820P / 1820E

Identifications

1 Logo Yes 25 Characters

2 Multiple Logo No

3 Character ID Yes 16 Characters

4 Numeric ID Yes 20 Digits

Special Communications

1 Password XMT / RCV No

2 Selective Reception No TSI Check

3 Relay XMT Request No

4 Relay XMT Center No

5 Confidential XMT / Polling No

6 Confidential Center No

7 Mailbox XMT / Polling No

8 Mailbox Center No

9File XMT No

10 Fax Forward Yes

Received File Transfer

(Only with Internet Fax Option)

11 Sub-Address XMT Yes T. Routing

12 Sub-address RCV No

13 OMR-XMT No

Standards

FCC Part 68 For USA

1 PSTN

Industry Canada CS-03 For Canada

TBR 21 For EU

Others

1 Fax Access Code Yes

2 PIN Code Access Yes For USA and Canada only

3 Intelligent Redial (AI) Yes 5 Files

4 Department Code Yes 300 Departmental Codes

5 Power Saver Mode Yes

6 Self Diagnostic Function Yes

Remote Diagnostic

7

Function

Yes

8 Check & Call Function Yes

9 V.24 / Encryption Interface No

Ver. 1. 0

24

JUN 2004

Page 25

DP-1520P/1820P/1820E

1.2.2. Printer Function

Printer Function

Items

DP-1520P / 1820P / 1820E

Interface

1

Centronics Parallel I/F No

2LAN (Network)

3 USB Port Yes USB

4 IEEE-1394 No

Printer Function

LDR, LGL, LTR, LTR-R, INV-R For USA and Canada

1 Printing Size

A3, A4, A4-R, A5, A5-R, B4, FLS For EU

A3, B4, A4, A4-R, B5, B5-R For Other Destinations

2 Bypass Paper Tray Yes

3 Stapling No

4 Printing Resolution (dpi)

Max. 1200 (Equivalent) x 600 dpi

5 Interface

6OS

7 Printer Work Memory Size 20 MB Not expandable

8GDI Yes

9

PDL (PCL6) Yes Requires Optional PCL6 Emulation Kit.

10 PDL (PS3) Yes

11

Duplex Printing Yes

12 Collation Stack Yes

13 Status Monitor

Network Yes

USB No

14 Network Printing Yes

15 Smoothing Yes

16 Applicable PC IBM PC, AT or Compatible, MAC MAC is PS only.

17 Multi-Task Operation

Printing while Fax-XMT

from Memory

Printing while Fax-RCV

into Memory

Fax-XMT from Memory

while Printing

Fax-RCV into Memory

while Printing

Output to separate tray for

18

Printing, Fax, Copy

Description

Ethernet 10Base-T/

100Base-TX

USB / Ethernet

Win 98 / Win Me /

Win NT 4.0 / Win 2000 /

Win XP / MAC 8.6-10.1

Yes

Yes

Yes

Yes

No

Remarks

Selectable 600 dpi, with Smoothing,

the results are similar to PS3 / PCL6

Printers (1200 dpi Equivalent).

MAC 8.6-10.1 is PS only.

Requires Optional PS / PCL6

Emulation Kit

DP-1820E only.

Custom Size/Post Card Size is not

available.

Ver. 1. 0

25

JUN 2004

Page 26

Printer Function

Items

Description

DP-1520P / 1820P / 1820E

19 Font Yes

20 Mailbox Yes

21 Secure Mailbox Yes

DP-1520P/1820P/1820E

Remarks

Requires Optional PCL6 or PS / PCL6

Emulation Kit

Requires Optional HDD Unit.

Max. 100 Users.

Max. 20 mailboxes for each User ID

Requires Optional HDD Unit.

Max. 100 Users.

Max. 20 mailboxes for each User ID

Ver. 1. 0

26

JUN 2004

Page 27

DP-1520P/1820P/1820E

1.2.3. Network Scanner Function

Network Scanner Function

Items

Interface

1 Centronics Parallel I/F No

2 LAN (Network)

3 USB Port No

4 IEEE-1394 No

Network Scanning Function

1 Scanning Device CCD (i-ADF / ADF / Platen)

Scanning Speed

2

(ADF / I-ADF)

3 Halftone 256 Halftone shades With Error Diffusion

4

Max. Document Size Ledger, A3

Scanning Resolution

5

(dpi)

6OS

Win NT 4.0 / Win 2000 / XP

7 2-Sided Scanning Yes With i-ADF.

8 File Format Mult-page TIFF / PDF

9 Completion Notice Yes

10 Protocol TCP/IP, Non-Std

Network Address Features

1 One Touch Address Keys

2 Abbr. Address Numbers 60 Independent for Network Scanner

Description

DP-1820P / 1820E

Ethernet 10Base-T/

100Base-TX

600 x 600 : 2.1 sec

300 x 300 : 1.1 sec

150 x 150 : 1.1 sec

600 x 600

300 x 300

150 x 150

Win 98 / Me /

32

Remarks

Letter / A4

Selectable, 600 dpi Optical Scanner

TIFF can also be converted to PDF

with the PDMS Software

Auto Pop-up on the PC Screen

(requires WEB Status Monitor)

Requires Optional Keyboard.

Shared with Fax/Internet Fax

One Touch Address, 32 in Total

Ver. 1. 0

27

JUN 2004

Page 28

1.2.4. Internet Fax Function

Internet Fax Function

Items

Main Specifications

1 Communication Protocols SMTP / POP3 / MIME

2 Max. Modem Speed NA

3 Coding Scheme JBIG/MMR/MR/MH

4 File Format TIFF / PDF

5 Line Interface RJ-45 Ethernet LAN

Scanner Mechanism

1 Max. Document Size Ledger, A3

2 Effective Scanning Width 11.4 in (289 mm)

Std. : 203 x 98 (8 x 3.85)

Scanning Resolution

3

dpi x lpi (pel/mm x lines/mm)

Fine : 203 x 196 (8 x 7.7)

S-Fine : 203 x 391 (8 x 15.4)

600dpi : 600 x 600 dpi

Printer Mechanism

1 Printing Resolution 600 dpi

2 Effective Recording Width 11.4 in (289 mm)

Transmission Features

1 Multi-Task Operation Yes

2 Memory Transmission Yes

Sequential Multi-Station

3

Transmission

Simultaneous Multi-Station

4

Transmission

5 Sender Selection Yes

G3 / Email Mixed

6

Broadcasting

7 Deferred Transmission Yes

8 Fax Forward Yes

9 Sub-address RCV Yes

10 Mail Header

Email Header Print Selection Yes All or From / To / Subject only

Subject Line Random Entry

Description

DP-1820P / 1820E

406 x 391 (16 x 15.4)

Yes

Yes

Yes

Remarks

Selectable

PDF file is only available if sending to

PC (Network Scanner).

LAN: 600 dpi, 16 x 15.4 Scanning

Resolution is available with

Parameter setting

Simultaneous operation of G3 Fax and

LAN is available.

Max. 250 stations

(200 Address Book + 50 Full Number

Dialing)

Received File Transfer, only with

Internet Fax Option

Inbound Routing, only with Internet

Fax Option

DP-1520P/1820P/1820E

Ver. 1. 0

28

JUN 2004

Page 29

DP-1520P/1820P/1820E

Internet Fax Function

Items

Description

Remarks

DP-1820P / 1820E

LAN Features

1 Internet Fax Communication Yes

A3 Communication is available with

Parameter setting.

2 Internet Mail Reception Yes

3 Internet Fax Server Features

Internet Fax Relay XMT Yes Internet Fax → Internet Fax → G3FAX

Email Relay MXT Yes PC → Internet Fax → G3FAX

Received Fax / Email

Forward

Yes Local print available

PC to FAX Transmission No

Inbound Routing Yes

Phone Book Registration from

PC

Internet Fax Parameters

4

Registration via Email

Yes Via E mai l

Yes

Using Sub-Address.

Local print available

5 Internet Delivery Confirmation Yes With MDN

6 Network Scanning Yes 600 dpi

7 Network Printing

LPR / LPD Yes 600 dpi

GDI Yes 600 dpi

PDL Yes

Requires Optional PCL6 or PS

Emulation Kit

8 DHCP Client Yes

9 LDAP Yes Lightweight Directory Access Protocol

10 TIFF Viewer Yes Selectable, PDMS / TIFF Viewer

Certainty

1 Comm. Journal (w / Image) Yes

ID

1 Email Address Yes

Ver. 1. 0

29

JUN 2004

Page 30

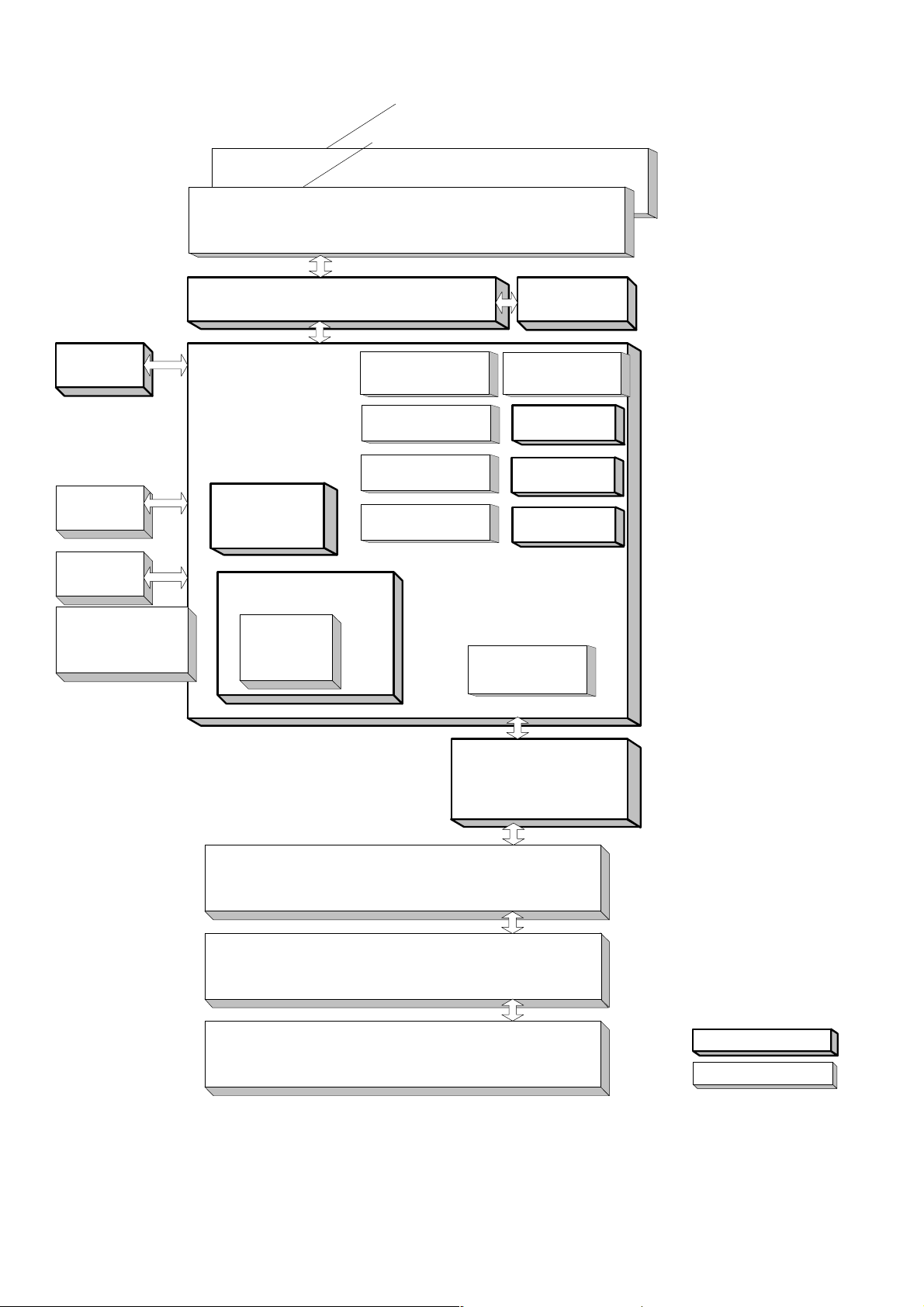

1.3. System Combination

ADF PC Board

DP-1520P/1820P/1820E

ADF

Inverting ADF (DP-1820E only)

Panel

(PNL PC Board)

Key Counter

Harness Option

Dehumidifier

Heater Kit

Expansion Flash

Memory Card

4 or 8M

Scanner Unit

(SPC PC Board)

Main PC Board

(SC PC Board)

Automatic

Duplex Unit

(DP-1820E only)

Electronic Sorting Memory

Image Memory

16, 64, 128MB

Either Option

PCL6

Emulation Option

PS/PCL6

Emulation Option

Network

Scanner Option

Internet Fax/

E-Mail Option

Document Sensor

Motor

Fax Communication

Option (FXB/MJR)

Printer

USB

Interface

10/100 Ethernet

Interface

Hard Disk

Drive Option

2nd Paper Tray (CST2 PC Board)

3rd Paper Tray (CST3 PC Board)

4th Paper Tray (CST2 PC Board)

SPC PC Board

Standard Configuration

Option

Ver. 1. 0

30

JUN 2004

Page 31

DP-1520P/1820P/1820E

1.4. Options List

■ Options

Option Name Option Number Remarks

Printer Controller Module (PCL) DA-PC180 Printer Controller for PCL6*

Multi Page Description Language

Controller Module (PCL/PostScript)

Network Scanner Module DA-NS180 For Network Scanning

Internet Fax / E-Mail Module DA-NF180 Internet Fax/Email Communication

Fax Communication Board DA-FG180 G3 Fax Communication

Keyboard Option DA-KB180

Hard Disk Drive Unit DA-HD18

Expansion Board DA-EM600 F-ROM Board (8 MB)

Expansion Flash Memory Card, 4 MB UE-410047

Expansion Flash Memory Card, 8MB UE-410048

Image Memory (16MB) DA-SM16B

Image Memory (64 MB) DA-SM64B

Image Memory (128MB) DA-SM28B

Accounting Software DA-WA10 For Accounting Function

Platen Cover DA-UC200 Available in Specified Destinations

Automatic Document Feeder DA-AS181

Inverting Automatic Document Feeder DA-AR202

2nd / 4rd Paper Tray DA-DS184

3rd Paper Tray DA-DS185

Deluxe Stand (High) DA1D18A For USA and Canada

Deluxe Stand (Mid) DA1D18B

Deluxe Stand (Low) DA1D18C

Stand (1-Paper Tray Configuration) DA-DA188-PE

Stand (2-Paper Tray Configuration) DA-DA189-PE

Stand (3-Paper Tray Configuration) DA-DA190-PE

Stand (4-Paper Tray Configuration) DA-DA191-PE

Key Counter Harness Kit DA-KH180

DA-MC180

Printer Controller for PCL6/PS3*

Additional Optional Sorting Image Memory

(Minimum 16 MB) is required for the Hard

Disk Drive to function.

(For additional 800 address book, etc.)

Additional Memory for Fax / Internet Fax

For Electronic Sorting

4th Paper Tray is for DP-1820P/1820E

only.

3rd Paper Tray is for DP-1820P/1820E

only.

Note:

The same Deluxe Stand (DA1D18C) is

used for either 3 or 4 Paper Tray

Configuration.

Available in Specified Destinations

■ Supplies

Part Name Part Number Remarks

Toner DQ-TU10J 10K

OPC Drum DQ-H60J 60K

Developer DQ-Z60J 60K

Note:

PCL6 is a Page Description Language of the Hewlett-Packard Company.

PS3 is a Page Description Language of the Adobe Systems Company.

31

Ver. 1. 0

JUN 2004

Page 32

2 Maintenance, Adjustments and Check Points

2.1. Preventive Maintenance

Preventive maintenance is performed at specific intervals and consists of machine

cleaning and parts replacement.

It is essential to perform these service activities properly and at the specified intervals

for customer satisfaction.

The purpose of this service is to maintain machine performance and image quality.

- You should prepare the replacement parts, and cleaning tools beforehand.

- After completing the preventive maintenance, discard the used parts and

packaging in accordance with local regulations and clean the surrounding

area.

- Before servicing the equipment, disconnect the power cord from the wall outlet.

- Before using solvents such as IPA (Isopropyl alcohol), put on rubber gloves

and eye protection.

1 Timing

- Perform the preventive maintenance in accordance with the Preventive

Maintenance Check List. (refer to 2.4.)

DP-1520P/1820P/1820E

2 Cleaning the Rollers

- Rollers should be cleaned with water and cloth.

- Use the IPA (Isopropyl Alcohol) sparingly.

3 Disassembly and Adjustment Precautions

CAUTION!

Turn the Power Switch on the Right Side of the machine to the OFF

position, and then unplug the AC Power Cord from the wall outlet

before disassembling the machine. (During a Lightning Storm, to

prevent electrocution disconnect the Telephone Line Cable first

before unplugging the AC Power Cord.)

- After taking the unit apart, do not attempt to operate the machine.

- When operating the machine with covers removed, be careful and avoid clothing

from being caught by moving components.

-

While the electricity is applied to the unit, do not connect nor disconnect the

connectors on any PC Board.

- Ensure to use correct screws.

- Use toothed lock washers for the installation of ground wires to ensure electrical

continuity.

- To reassemble, reverse the sequence of disassembly, unless otherwise specified.

- Blown fuses should only be replaced with fuses of the same specified rating.

Ver. 1. 0

32

JUN 2004

Page 33

DP-1520P/1820P/1820E

4

y

t

r

5

a

n

Laser Handling Precautions

The optical laser system employed by this photocopier is completely sealed b

a protective housing and an external cover. Therefore, the laser beam will no

stray or leak during photocopying operation.

However, when servicing the photocopier, take the following precautions:

1. Do not insert any screwdrivers or other tools that have high reflective

properties into the laser's path.

.

2. Before servicing the photocopier, remove watches, rings, or other metallic

objects that you may be wearing. (This is to avoid the danger of the lase

striking the eye by reflecting off the metallic objects being worn.)

Since the laser beam cannot be seen with the naked eye, for maximum

safety, please follow the above precautions.

Safety Interlock Switches

- The service technician may defeat the safety interlock switches by inserting

interlock cheater into the opening of the switch cover.

- Ensure to remove the interlock cheater from the switch cover after completio

of service.

33

Ver. 1.0

JUN 2004

Page 34

2.2. Required Tools

No. Tools No. Tools

1 Soft Cloth 7 Pliers

2 Isopropyl Alcohol 8 Cotton Swab

3 Phillips Screwdriver (#2) 9 Brush

KS-660 - Conductive Grease

4 Stubby Phillips Screwdriver (#2) 10

5 Slotted Screwdriver (3/32 in) 11

6Tweezer

2.2.1. Preventive Maintenance Method

(Available from Shin-Etsu Silicones of America, Inc.

URL: http://www.shinetsusilicones.com)

Molykote EM-50L Grease

(Available from Dow Corning,

URL: http://www.dowcorning.com)

DP-1520P/1820P/1820E

No. Part Description

Important

Action

Comments

1 Memory Data Check 1. Print the RAM DATA for reference and as a precaution.

2. After completing the task(s), print and compare the RAM

DATA with the previously printed one.

2 Auto Document

Feeder (ADF)

Check &

Clean

1. Clean the Rollers and Separation Rubber with Wet soft

cloth (Water).

Note:

For stubborn toner accumulation, wipe with a soft cloth

saturated with Isopropyl Alcohol first, then follow up with

a soft cloth saturated with water.

3 Scanner Unit Check &

Clean

4 Transmitter Unit Check &

Clean

5 Mirrors Check &

Clean

1. Clean the Scanning Glass or White Reference Sheet with

Isopropyl Alcohol when required.

1. Remove any foreign obstacles.

2. Clean the Rollers with Wet soft cloth (Water).

1. Do not touch the surface of the Mirrors with your bare

hands. Clean any dirt or fingerprints with a soft cloth,

saturated with Isopropyl Alcohol.

6 Inspection Items Check 1. Check the Harnesses.

2. Check the Connectors.

3. Check the Screws. If required, replace consumable parts.

7 Gears, Rollers Shafts Check &

1. Check and grease the required Gears and Shafts.

Grease

8 Timing Belts Check &

Clean

1. Check for belt looseness or abrasion.

2. Adjust the Idle Pulley.

Ver. 1. 0

34

JUN 2004

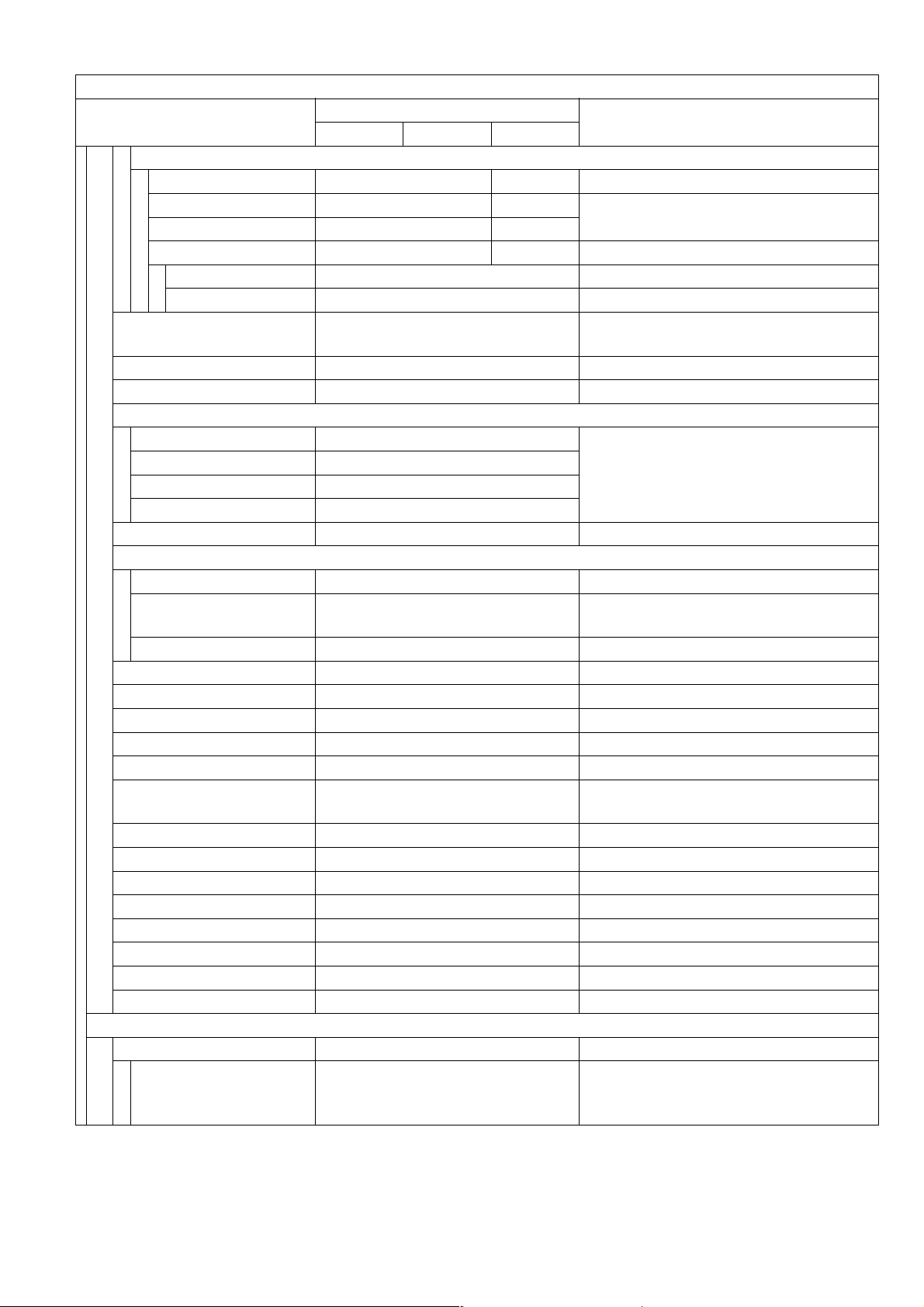

Page 35

2.3. Preventive Maintenance Points

i-ADF

2

5

4

1 2543

DP-1520P/1820P/1820E

15

13

14

43

42

37 39

36 38 41

27

26

27

25

20

22

17

8 11 109

6

ADF

12

16

4

DETAILA

4

18 19

3 24

21

20

17

18 19

21

20

17

18 19

21

20

17

18 19

35

Ver. 1.0

JUN 2004

Page 36

28

3

35

2 33 34

31

DP-1520P/1820P/1820E

3029

DETAIL A

36

Ver. 1. 0

JUN 2004

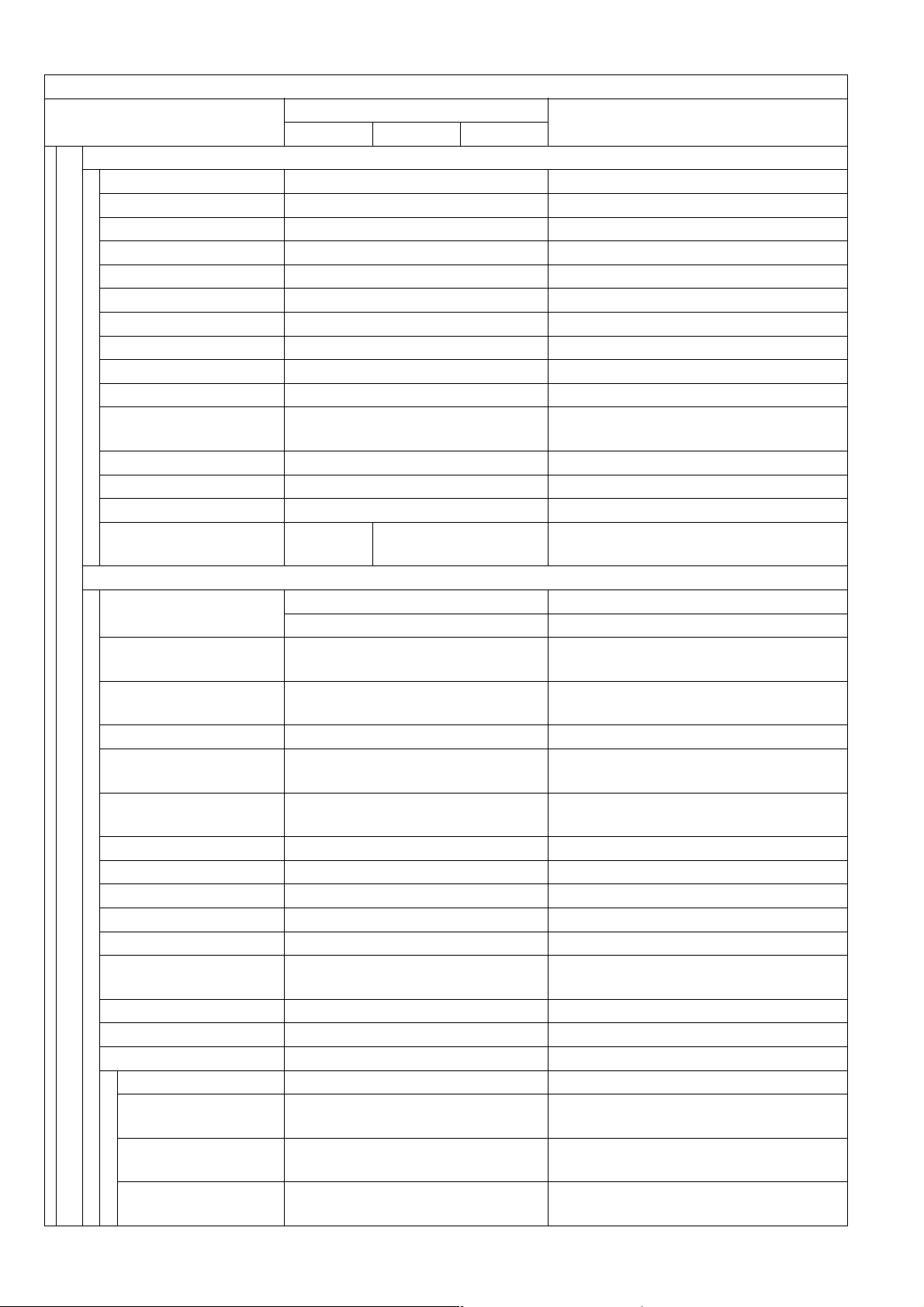

Page 37

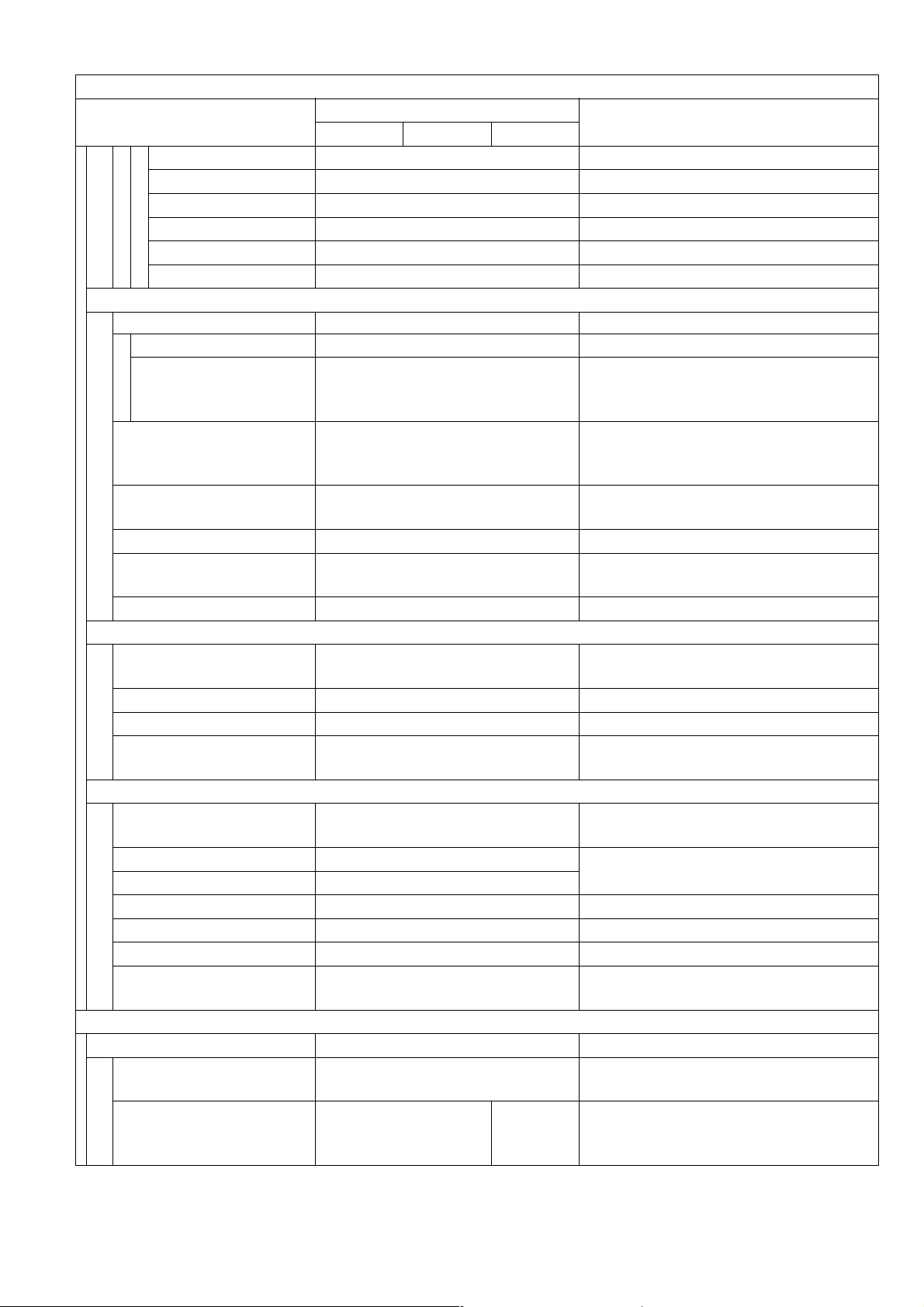

2.4. Preventive Maintenance Check List

The chart outlined below is a general guideline for maintenance.

DP-1520P/1820P/1820E

Cleaning Replacement/Adjustment

Cycle

Method

Cycle

(Sheet)

Procedure

Counter

No.

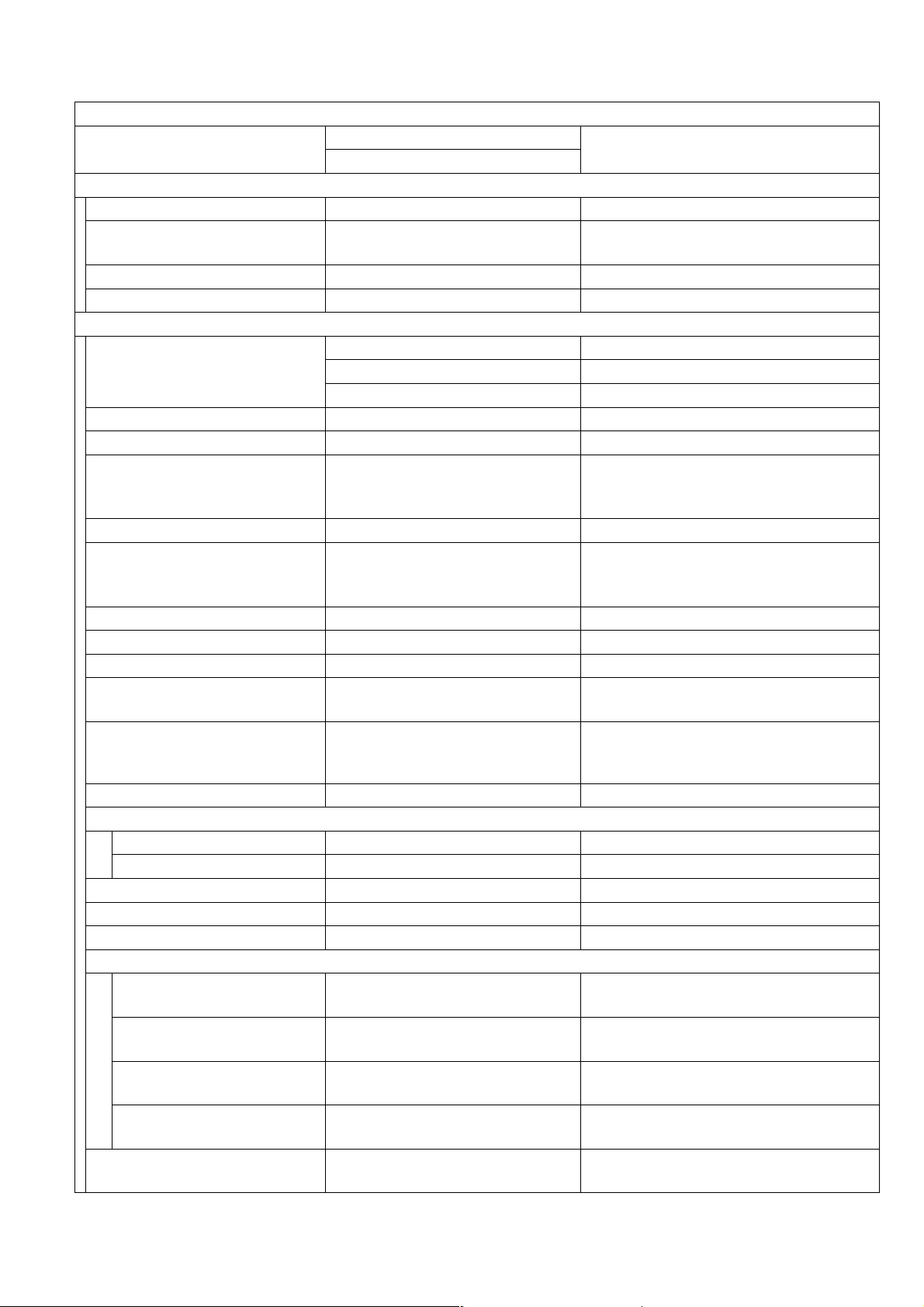

Mechanical Parts

Ref.

No.

(Sheet)

i-ADF Unit

1 ADF Roller 2314 60K Alcohol 120K Refer to

2 Pre Feed Roller 2018 60K Alcohol 120K

3 Separation Roller 2509 60K Alcohol 120K

4 Torque Limiter

2510 60K Alcohol 120K

2.2.1. of the

Service

Manual

F7-08

Bushing

5 Torque Limiter

2511 60K Alcohol 120K

Spring

ADF Unit

6 Exit 1 Roller 1812 60K Alcohol - Refer to

7 White Sheet 1814 60K Alcohol 8 Feed Roller 2010 60K Alcohol 9 Pre Feed Roller 2018 60K Alcohol 120K

2.2.2. of the

Service

Manual

F7-08

10 Separation Rubber 2024 - - 60K

11 Paper Feed Roller 2001 60K Alcohol 120K

12 Scanning Pad 1822 60K Dry soft cloth -

Scanner Unit

13 Mirror 1 415 60K - - Refer to

14 Mirror 2 421 60K - 15 Platen (L) Glass 106 60K - 16 Scanning (S) Glass 110 60K - -

2.2.4. of the

Service

Manual

F7-04

2nd, 3rd & 4th Paper Trays

17 Pickup Roller 619 60K Alcohol 120K Refer to

18 Separation Roller 629 60K Alcohol 120K

19 Torque Limiter 1 690 - - 120K

20 Feed Roller 623 60K Alcohol 120K

2.2.10. of the

Service

Manual

F7-12/-13/14/-15

21 Intermediate Roller 3104 60K Alcohol -

Sheet Bypass

22 Feed Roller 689 60K Alcohol 120K Refer to

23 Separation Roller 658 60K Alcohol 120K

24 Torque Limiter 2 691 - - 120K

25 Registration Roller 601 60K - -

2.2.9. of the

Service

Manual

F7-11

Bias Transfer Unit

26 Bias Transfer Roller

(BTR)

27 Duplex Feed Roller 735 60K -

711 60K Dry soft cloth 120K Refer to

2.2.8. of the

Service

F7-02

Manual

Process Unit

- Developer - - - 60K Refer to

28 OPC Drum 1403 - - 60K F7-06

2.2.5. of the

F7-10

Service

Manual

Ref.

Ver. 1.0

37

JUN 2004

Page 38

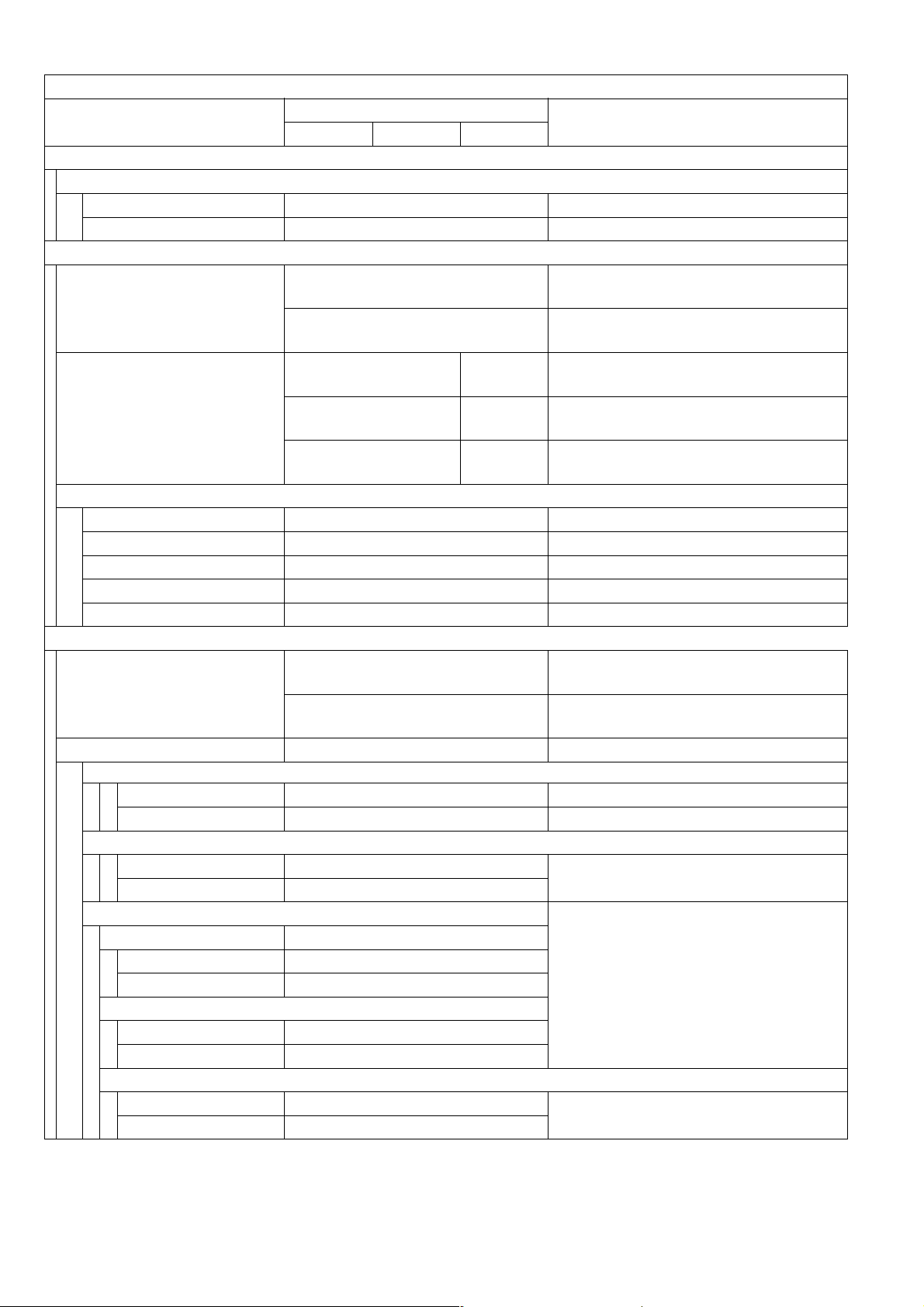

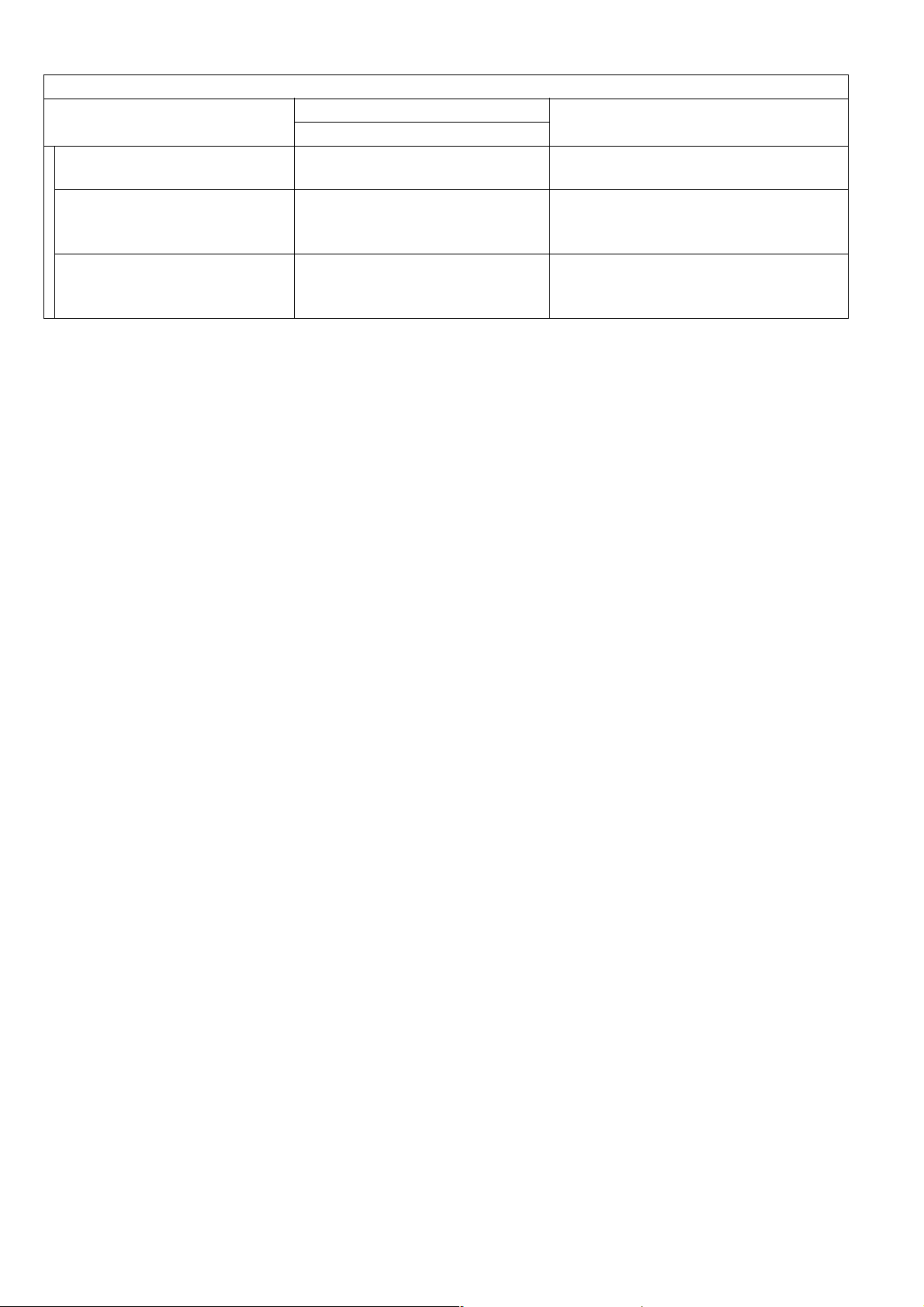

DP-1520P/1820P/1820E

Cleaning Replacement/Adjustment

Cycle

Method

Cycle

(Sheet)

Procedure

Mechanical Parts

No.

Ref.

No.

(Sheet)

29 Charge Corona Case 1444 60K - - Refer to

30 Charge Wire 1443 10K

- 60K

By Customer

31 Cleaning Blade 1408 - - 60K

2.2.5. of the

Service

Manual

32 Front Cleaning Felt 1410 - - 60K

33 Rear Cleaning Felt 1411 - - 60K

34 Cleaning Sponge 1412 - - 60K

35 Sheet Scoop 1415 - - 60K

Fuser Unit

36 Fuser Roller 1115 60K Alcohol 120K Refer to

37 Pressure Roller 1021 60K Alcohol 240K

38 Fuser Roller Busing 1114 - - 120K

39 Pressure Roller

1020 - - 240K

2.2.6. of the

Service

Manual

Busing

40 Thermistor

1125 60K Dry soft cloth 120K

Assembly

41 Fuser Lamp 1116 - - 240K

42 Separator 1109 60K Alcohol 120K

43 Exit 2 Roller 1104 60K - -

Main Unit

44 Ozone Filter 825 - - 240K Refer to

45 Toner Spill Tray 1202 60K - -

2.2.13. of the

Service

Manual

Ref.

Counter

F7-07

F7-02

F7-02

Note:

1. Wet Cloth represents a soft cloth saturated with water.

For stubborn toner accumulation, wipe with a soft cloth saturated with Isopropyl Alcohol first, then

follow up with a soft cloth saturated with water.

2. The Maintenance Cycle is based on the Counter Information for each individual module.

To verify the counter information, print the Total Counter List using the Service Mode: F7 - Electronic

Counter - 00 (List Print).

3. Cleaning, Replacement and Adjustment Cycle (Sheet) are based on using Panasonic's recommended

standard paper and supplies. These cycles may vary with the kind of paper used, Paper size,

orientation, print duty, continuous/interval print and/or ambient conditions.

• Total Counter View Mode on the LCD

The Total Counter can be displayed on the Panel Display by pressing "COPY SIZE" and "PAPER TRAY"

keys simultaneously in Standby mode for quick reference.

TOTAL COUNTER

1234

• LCD Contrast Adjustment

Press holding the “CLEAR” key and press “ORIGINAL SIZE” key for Lighter or “COPY SIZE” key for

Darker.

Ver. 1. 0

38

JUN 2004

Page 39

DP-1520P/1820P/1820E

2.5. Resetting the P/M (Preventive Maintenance) Counter

When the machine reaches the preset P/M Cycle, it will show "Call for P/M" or "Replace The Toner Waste

Container" on the LCD Display. The PM Counter can be reset by following the procedures below.

2.5.1. "Call for P/M" (Default: 120K)

1. Perform the P/M (Preventive Maintenance). Refer to Section 2.3 and 2.4.

2. Press “FUNCTION”, “ORIGINAL SIZE”, and “3” keys sequentially to enter the Service Mode.

3. Enter the Copy Service Mode F5-70 (PM Cycle) and change to the desired value.

4. Press “FUNCTION” and “CLEAR” keys simultaneously to exit the Service Mode.

2.5.2. "Call for P/M ADF" (Default: Not Set)

1. Perform the P/M (Preventive Maintenance). Refer to Section 2.3 and 2.4.

2. Press “FUNCTION”, “ORIGINAL SIZE”, and “3” keys sequentially to enter the Service Mode.

3. Enter the Copy Service Mode F5-87 (ADF PM Cycle) and change to the desired value.

4. Press “FUNCTION” and “CLEAR” keys simultaneously to exit the Service Mode.

2.5.3. U14 "Replace The Toner Waste Container"

A. Blinking Maintenance and Toner Waste Container Indicators

Upon detecting that the Toner Waste Container is full, the machine will complete the current job, and

stop operating.

A blinking Maintenance and Toner Waste Container Indicators will appear on the display.

To continue using the machine temporarily while waiting for the Service Technician, press any key

(up to 100 additional copies can be made).

B. Steady Maintenance and Toner Waste Container Indicators

Upon reaching the 100 copies, the machine stops and will not allow further operation until the Toner

Waste Container is replaced.

Replace the Toner Waste Container. (Refer to Section 2.2.5. of the Service Manual)

Ver. 1.0

39

JUN 2004

Page 40

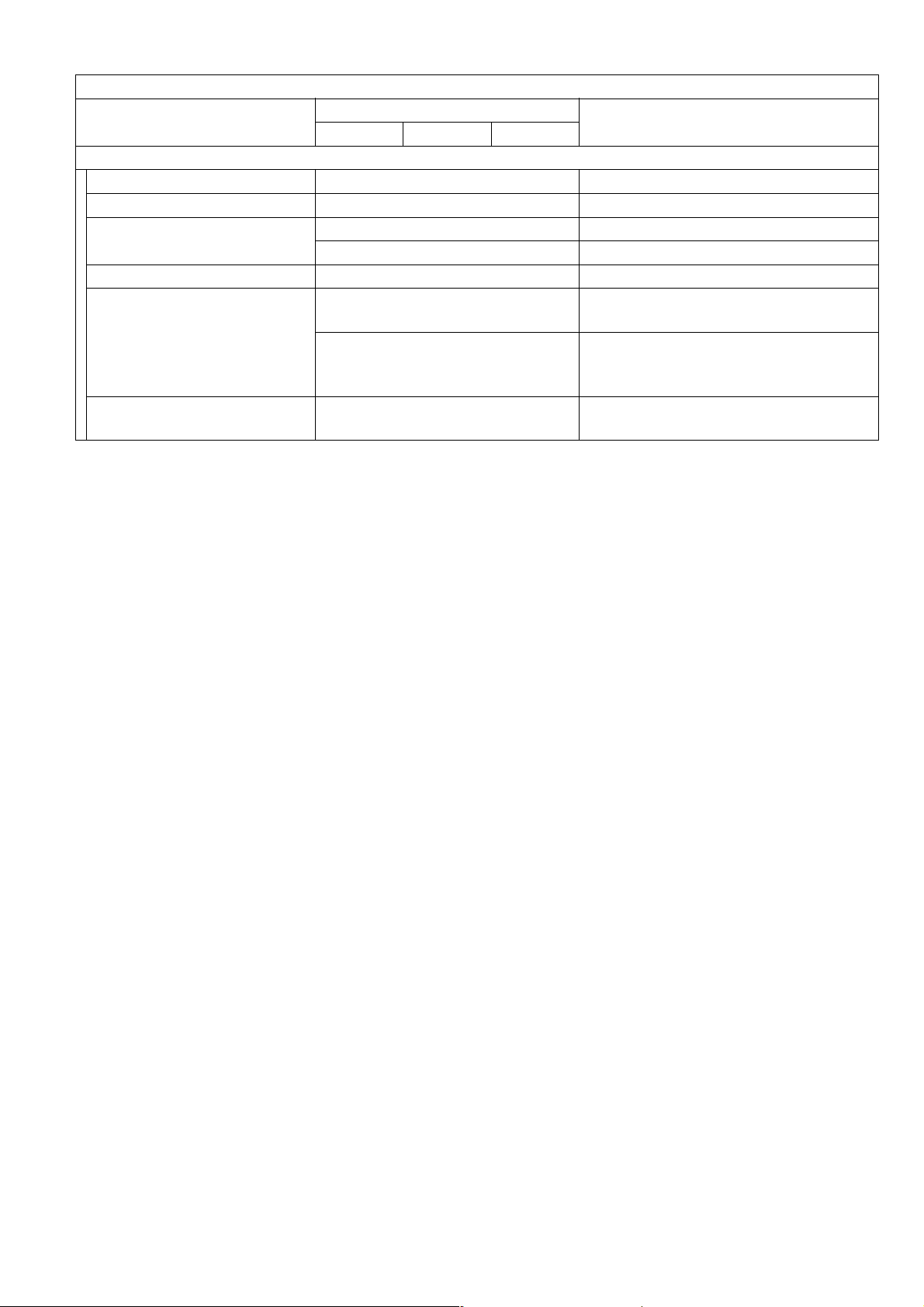

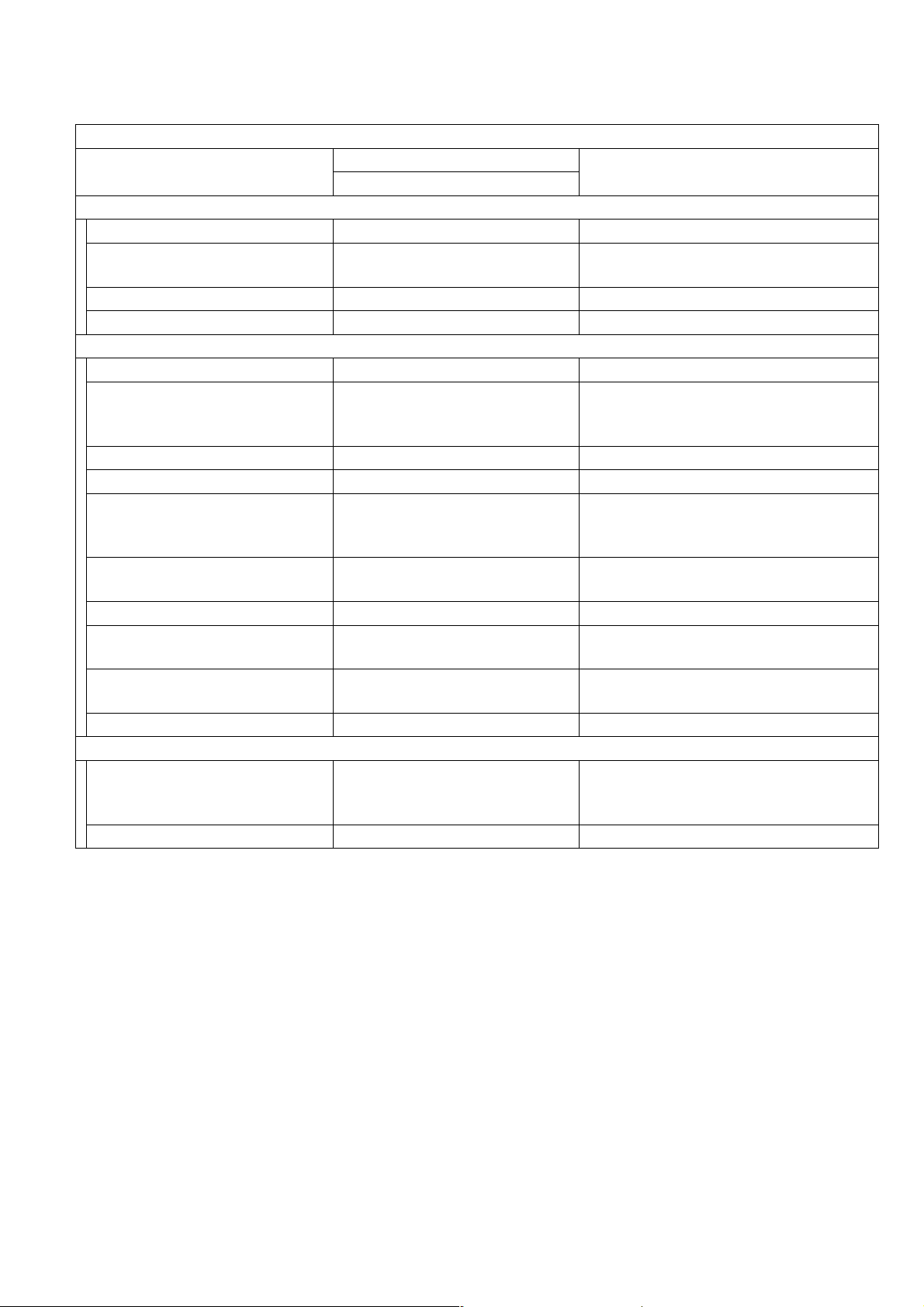

DP-1520P/1820P/1820E

2.6. Lubrication Point List

This information is used for routine Preventive Maintenance (PM) calls to ensure the highest degree of

reliability. Inspect the following areas and lubricate as required. The inspection interval is usually 120K

copies or more, however the interval may be reduced due to environmental conditions.

Mechanical Parts

Ref.

No.

Automatic Duplex Unit

Pinch Timing Roller 712

Bias Transfer

Bushing

709

Grease Lubrication Point

KS-660

Ver. 1. 0

40

JUN 2004

Page 41

DP-1520P/1820P/1820E

g

2.7. Updating the Firmware

The Quickest and Most Easiest Method of Updating the Firmware is to use the Network Firmware

Tool (FUP) using Ethernet LAN Port and a Crossover Cable.

The Network FUP Tool version must be 3.XX or higher, and it can be found on the Panasonic Document

Management System CD-ROM included with the main unit or on the CD-ROM included with the PCL or

PS/PCL options.

Refer to the Firmware Update Operation Instructions, Service Notes (8.1.) for additional details.

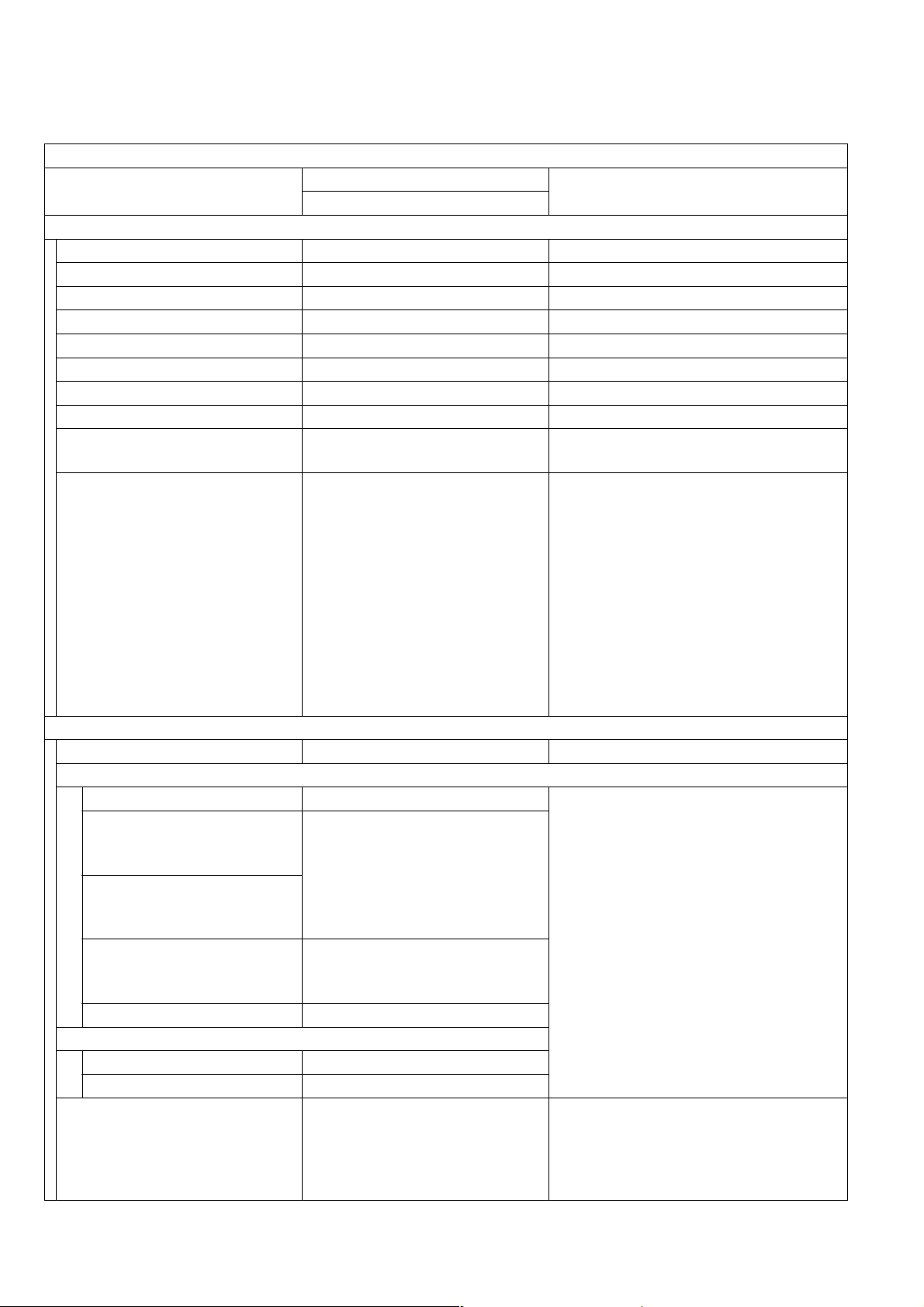

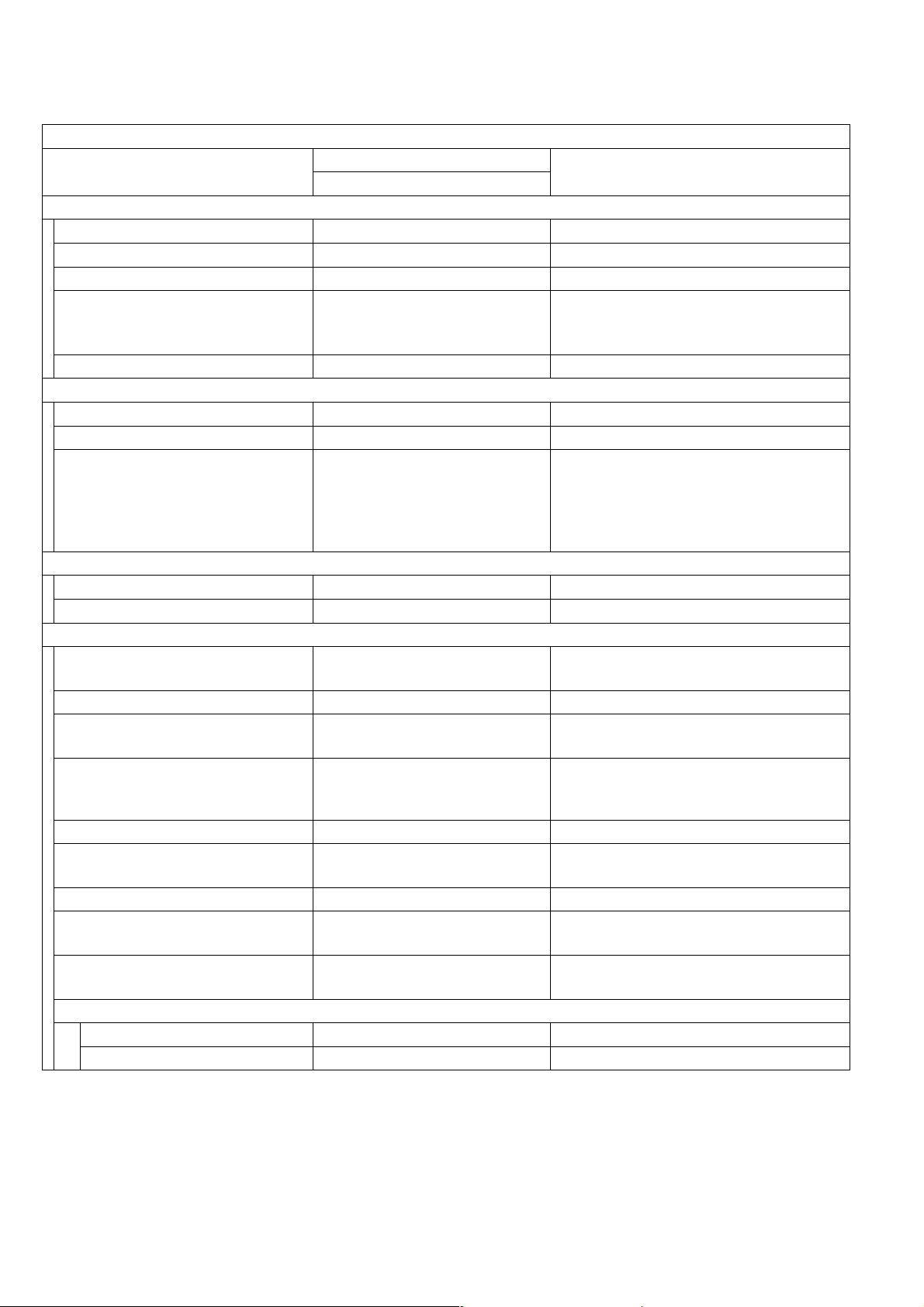

2.7.1. Firmware Configuration

A. Hardware Configuration

This machine is controlled by three (3) CPUs which are located on the System Control (SC) PC Board

and the Scanner Printer Control (SPC) PC Board.

SC PC Board

Standard

Confi

uration

With PCL Option

Configuration

With PS Option

Configuration

PC

Ethernet Port

PC

USB Port Slot 1 (C) 8MB (E) 8MB

Flash Memory

Card

4 MB or 8 MB

CPU

SPC PC Board

On Board (A)

F-ROM

4 MB

FRM

PCB

8 MB

Slot 2

Not

Used

(1) (2) (5)

Program Program Program

4 MB

(B)

4 MB

(3) (6)

Program

2 MB

(a)

(4) (7)

Font

(b)

4 MB

(D)

4 MB

Program

4 MB

Font

4 MB

(a)

(b)

CPU

F-ROM

512 KB

Scanner Control Program

Printer Control Program

B. SC PC Board Firmware

The 4 MB Program Memory (F-ROM) is integrated on the SC PCB. An Optional Expansion 8 MB

Program Memory (FRM8 PCB) can be installed into SLOT 1.

The Firmware to be written into the 4 MB onboard and the 8 MB of SLOT 1 depends upon the

configuration of the Standard, PCL or PS Options.

(1) Standard

The Standard Program (1) is only written into the 4 MB onboard, which is assigned as ROM

Code (A).

(2) For PCL Option

The PCL Control Program (2) must be written into the 4 MB onboard, which is assigned as ROM

Code (B). The PCL Control Program (3) and PCL Font data (4) are written into the 8 MB in the

SLOT 1. The Firmware (3) and (4) are assigned as ROM Code (C).

When using 8 MB Flash Memory Card, the 8 MB Program (C) can be written onto one card.

41

Ver. 1.0

JUN 2004

Page 42

DP-1520P/1820P/1820E

When using 4 MB Flash Memory Card, the 8 MB program (C) must be divided onto 2 cards, one 4

MB card for the PCL Control Program (3) and one 4 MB card for the PCL Font data (4).

(3) For PS Option

The PS Control Program must be written into the 4 MB onboard, which is assigned as ROM Code

(D). The PS Control Program (6) and (7) are written into the 8 MB in the SLOT 1.

Both Firmwares (6) and (7) are assigned as ROM Code (E).

When using 4 MB Flash Memory Card, the 8 MB program (E) must be divided onto 2 cards, one 4

MB card for the PS Control Program (6) and one 4 MB card for the PS Control Program (7).

C. SPC PC Board Firmware

The 512 KB Program Memory (F-ROM) is integrated on the SPC PCB. The Programs for Scanner

Control and Printer Control are saved on the Board. The Firmware is transferred as Serial Data from

the SC PCB.

D. Firmware Updating Ports

Three (3) types of Ports are available for updating the firmware.

(1) Ethernet LAN Port (The Quickest and Most Easiest Method)

The machine's Firmware can be updated from a PC via Local Area Network (LAN). Refer to the

Firmware Update Operation Instructions, Service Notes (8.1.) for additional details.

(2) USB Port (Alternate)

The machine's Firmware can be updated from a PC via USB Port. The Master Firmware Card can

also be created from a PC using the USB Port. Refer to the Firmware Update Operation

Instructions, Service Notes (8.1.) for additional details.

(3) Flash Memory Card (Alternate)

The machine's Firmware can be updated using the Master Firmware Card. The Master Firmware

Card can be created by copying the Firmware from an existing machine's SC PCB using a 4 MB or

8 MB Flash Memory Card.

To update the SC, SPC and PNL PCB, 3 Flash Memory Cards are required for the Standard

configuration or 5 Flash Memory Cards for the PCL or PS/PCL configuration.

Ver. 1. 0

42

JUN 2004

Page 43

DP-1520P/1820P/1820E

2.7.2. Updating through a LAN Port (The Quickest and Most Easiest Method)

The firmware code can be easily updated when the main unit is connected to a LAN.

The Network Firmware Update Tool can also be used by connecting to the machine using a crossover

cable, if the unit is not connected to a LAN.

1) Install the Network Firmware Update Tool to your PC

The option CD-ROM includes the Network Firmware Update Tool and the Main Unit Firmware Code.

Please refer to the following Operating Instructions to install the Network Firmware Update Tool.

The installation password is "workio".

Operating Instructions:

\xFirmware\Tools\NwFirmup\NwFirmup OI.pdf (Refer to the Network Firmware Update Tool OI

CD)

Setup:

\xFirmware\Tools\NwFirmup\Setup\Setup.exe

2) Preparing the Firmware Code

Double click the appropriate Destination Shortcut Batch File and copy the Firmware Code File on the

CD-ROM to the Firmware Data Folder in your PC. Note that the files in the Archive will be extracted

automatically into the designated folder when the Archived file (.exe) is Double-clicked.

Example:

From:

Destination Shortcut Batch File: D:(CD-ROM Drive) \ xFirmware \ USA.bat

Firmware Code File: DP-1520_1820_PU_xxxxxx.exe

To:

Firmware Data Folder: C:\ Panasonic \ Panasonic-FUP \ Data

on the

3) Preparing the Main Unit for the Firmware Upgrade

Make sure the unit's Key Operator Password is the same as the tool's password.

Make sure the unit is in an idle state (e.g. not making copies, not printing, etc.).

4) Upgrading the Main Unit's Firmware Code

Start the Network Firmware Update Tool and select the following Firmware Code Folders in the

C:\Program Files\Panasonic\Panasonic-FUP\Data folder, and then follow the display instructions to

upgrade the Main Unit's Firmware Codes.

Parent Firmware File Folder Sub Firmware File Folder

\ DP-1520_1820_PU_xxxxxx \ SC_STD \ DP-LLNewAxVxxxxx-xx 1

\ SC_PCL \ DP-LLNewBxVxxxxx-xx 1

\ SC_PS \ DP-LLNewDxVxxxxx-xx 1

\ SPC \ DP-LLNewSPCAxVxxxxxx 2

Transferring Order

When you select the Parent Folder, the following

Firmware Type window appears. Proper Sub File Folders

are selected automatically by selecting the Firmware

Type.

The transferring order is set up automatically.

Ver. 1.0

43

JUN 2004

Page 44

DP-1520P/1820P/1820E

Note:

1. Manual mode must be used, when updating the designated version of the firmware or changing

the type of the firmware.

Please refer to the Section 2.2, "Setting up the Network Firmware Update Tool, File Selection

Tab" of the Operating Instructions.

2. While updating the firmware code, the display may become garbled, however, it will return to

normal upon completion of the firmware update.

3. If the firmware update fails and the unit does not boot up, the Network Firmware Update Tool will

not be able to transfer the firmware code. If this occurs, please refer to the next section "Updating

through the USB Port" and use the Local Firmware Update Tool to recover the unit.

4. The suffix "_xx" for the Folder Name or File Name may not exist depending on the destination

location.

5) After the Firmeware Update is completed, enter the F5 & F6 Parameters according to the lists printed

in step (3) above.

2.7.3. Updating through USB Port (Alternate method)

If the device is not connected to the LAN, upgrade the firmware code using the USB Port.

1) Install the Local Firmware Update Tool to your PC

The option CD-ROM includes the Local Firmware Update Tool and the Main Unit Firmware Code.

Please refer to the following Operating Instructions to install the Local Firmware Update Tool.

Operating Instructions:

\xFirmware\Tools\Firmup\FIRMUP OI.pdf (Refer to the Local Firmware Update Tool OI

Setup:

\xFirmware\Tools\Firmup\Setup\Setup.exe

on the CD)

2) Preparing the Firmware Code

Double click the appropriate Destination Shortcut Batch File and copy the Firmware Code File on the

CD-ROM to the Firmware Data Folder in your PC. Note that the files in the Archive will be extracted

automatically into the designated folder when the Archived file (.exe) is Double-clicked.

Example:

From:

Destination Shortcut Batch File: D:(CD-ROM Drive) \ xFirmware \ USA.bat

Firmware Code File: DP-1520_1820_PU_xxxxxx.exe

To:

Firmware Data Folder: C:\ Panasonic \ Panasonic-FUP \ Data

3) Preparing the Main Unit for the Firmware Upgrade

Important: DO NOT connect the USB Cable yet.

Print the F5/F6 Parameters List (Copier Service Mode F9-03-00).

Enter into Test Mode F9-07-01 to enable the unit to accept the programming code from the USB Port.

If the unit does not boot up, follow the procedure below:

a. Turn the power Off (use the power switch on the right side of the unit).

b. Turn the power On while holding the “ENERGY SAVER” key.

c. When the unit's front panel green lamp (DATA lamp) turns On, release the “ENERGY SAVER” key, it

is now ready to accept the firmware code from the USB Port.

Now connect the USB Cable between the Unit and PC.

Ver. 1. 0

44

JUN 2004

Page 45

DP-1520P/1820P/1820E

4) Upgrading the Main Unit's Firmware Code

Start the Local Firmware Update Tool and select the following Firmware Code Parent File Folder in

the C:\Panasonic\Panasonic-FUP\Data folder, and select the Firmware Code Type then follow the

display instructions to upgrade the Main Unit's Firmware Codes.

You must process each firmware file separately in this manner and sequence.

Parent Firmware File Folder Sub Firmware File Folder Firmware File

\ DP-1520_1820_PU_xxxxxx \ SC_STD \ DP-LLNewAxVxxxxx-xx DP-LLNewAxVxxxxx-xx.bin 1

\ SC_PCL \ DP-LLNewBxVxxxxx-xx DP-LLNewBxVxxxxx_xx.bin

DP-LLNewCxVxxxxxa_xx.bin

DP-LLNewCxVxxxxxb.bin

\ SC_PS \ DP-LLNewDxVxxxxx-xx DP-LLNewDxVxxxxx_xx.bin

DP-LLNewExVxxxxxa_xx.bin