Panasonic DMREZ-25-EB Service manual

DMR-EZ25EB

Vol.1

Colour

(S).......................Silver Type

ORDER NO.MAD0606015CE

DVD Recorder

© 2006 Matsushita Electric Industrial CO., Ltd. All

rights reserved. Unauthorized copying and

distribution is a violation of law.

DMR-EZ25EB

CONTENTS

Page Page

1 SAFETY PRECAUTIONS 3

1.1. GENERAL GUIDELINES

2 WARNING

2.1. PREVENTION OF ELECTROSTATIC DISCHARGE (ESD)

TO ELECTROSTATIC SENSITIVE (ES) DEVICES

2.2. PRECAUTION OF LASER DIODE

2.3. SERVICE CAUTION BASED ON LEGAL RESTRICTIONS

3 SERVICE NAVIGATION

3.1. SERVICE INFORMATION

4 SPECIFICATION

5 NEW FEATURE

5.1. HDAVI CONTROL (HDMI LINK)

6 LOCATION OF CONTROLS AND COMPONENTS

7 OPERATING INSTRUCTIONS

7.1. TAKING OUT THE DISC FROM DVD-DRIVE UNIT WHEN

THE DISC CANNOT BE EJECTED BY OPEN/CLOSE

BUTTON

8 SERVICE MODE

8.1. SELF-DIAGNOSIS AND SPECIAL MODE SETTING

9 SERVICE FIXTURE AND TOOLS

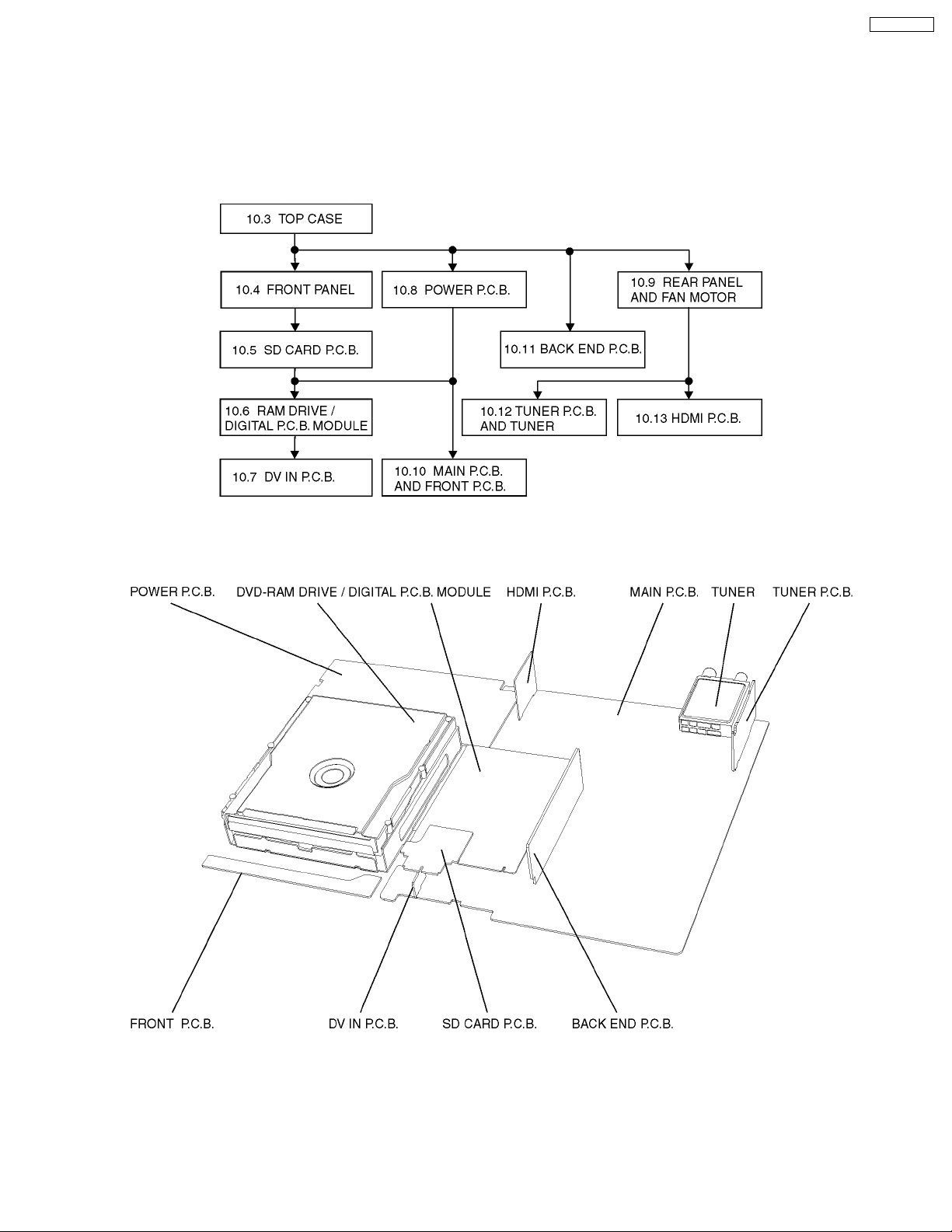

10 ASSEMBLIN G AND DISASSEMB LING

10.1. DISASSEMBLY FLOW CHART

10.2. P.C.B. POSITIONS

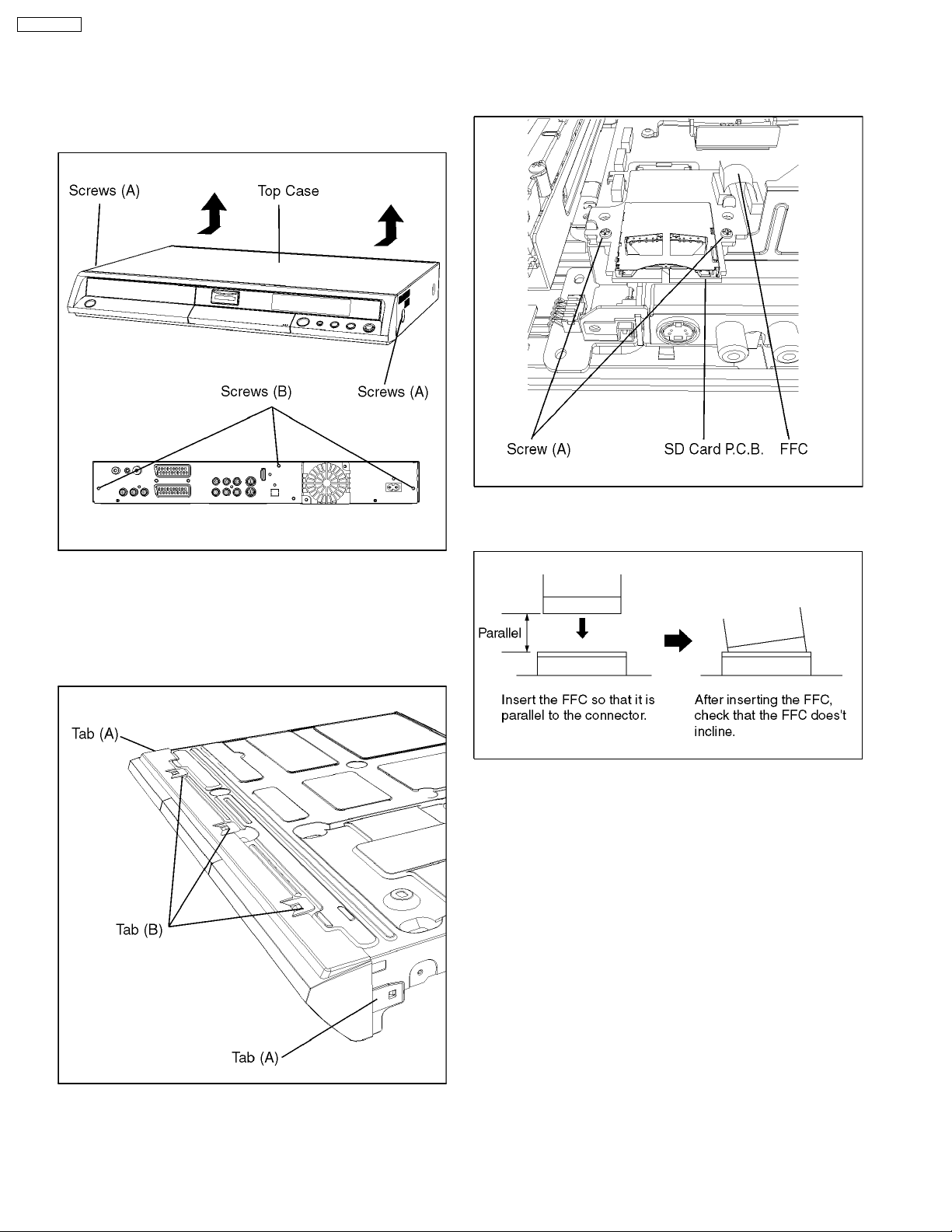

10.3. TOP CASE

10.4. FRONT PANEL

10.5. SD CARD P.C.B.

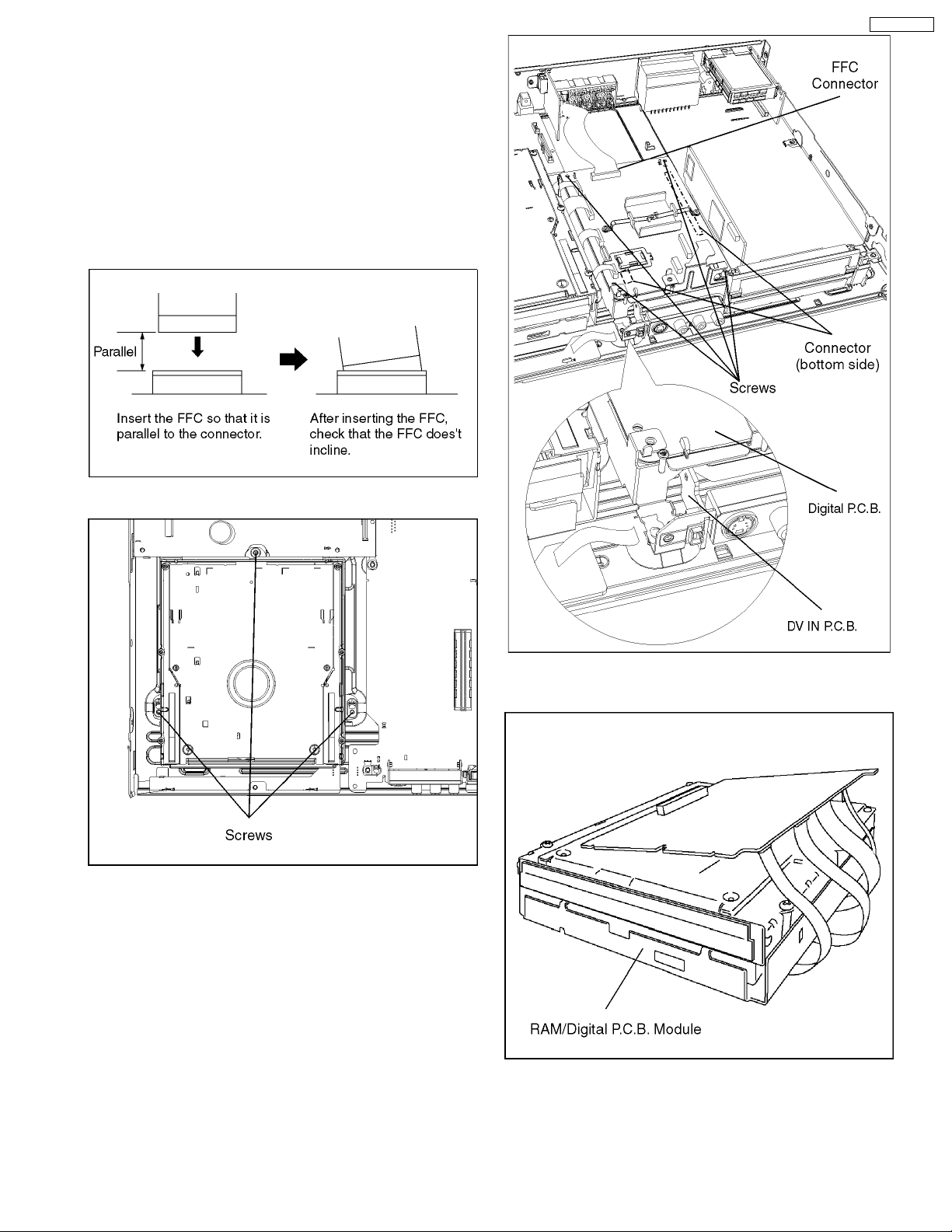

10.6. RAM DRIVE / DIGITAL P.C.B. MODULE

10.7. DV IN P.C.B.

10.8. POWER P.C.B.

10.9. REAR PANEL

10.10. MAIN P.C.B. AND FRONT P.C.B.

10.11. BACK END P.C.B.

10.12. TUNER P.C.B. AND TUNER

10.13. HDMI P.C.B.

11 MEASUREM ENTS AND ADJUSTMENTS

11.1. SERVICE POSITION

11

12

12

13

13

22

23

23

23

24

24

24

25

26

27

27

28

28

28

29

30

30

3

4

4

5

6

7

7

8

9

9

11.2. CAUTION FOR REPLACING PARTS

11.3. STANDARD INSPECTION SPECIFICATIONS AFTER

MAKING REPAIRS

11.4. ABBREVIATIONS

12 BLOCK DIAGRAM

12.1. POWER BLOCK DIAGRAM

12.2. ANALOG VIDEO BLOCK DIAGRAM

12.3. ANALOG AUDIO BLOCK DIAGRAM

12.4. TIMER BLOCK DIAGRAM

12.5. HDMI BLOCK DIAGRAM

13 SCHE MATIC DIAGRAM

13.1. INTERCONNECTION

13.2. POWER SCHEMATIC DIAGRAM

13.3. MAIN AV IO

13.4. MAIN TIMER

13.5. MAIN DECODER

13.6. MAIN NET

13.7. SD CARD / FRONT / DV IN

13.8. HDMI

13.9. TUNER

14 PRINT ED CIRCUIT BOARD

14.1. POWER P.C.B.

14.2. MAIN P.C.B.

14.3. TUNER P.C.B. / DV IN P.C.B.

14.4. SD CARD P.C.B. / FRONT P.C.B.

14.5. HDMI

15 APPENDIX FOR SCHEMATIC DIAGRAM

15.1. VOLTAGE AND WAVEFORM CHART

16 EXPLO DED VIEWS

16.1. CASING PARTS AND & MECHANISM SECTION

16.2. PACKING & ACCESSORIES SECTION

17 REPL ACEMENT PARTS LIST

17.1. CASING PARTS & PRINTED CIRCUIT BOARDS

17.2. PACKING & ACCESSORIES PARTS

17.3. ELECTRICAL PARTS

17.4. SERVICE FIXTURE AND TOOLS

18 DIAGRAMS FOR PRINTING WITH A4

33

34

35

37

37

39

40

41

42

43

43

44

45

46

47

48

49

50

51

53

53

54

56

57

58

59

59

63

63

64

65

65

65

65

74

75

2

DMR-EZ25EB

1 SAFETY PRECAUTIONS

1.1. GENERAL GUIDELINES

1. Be careful during removing metal parts, sharp edges.

2. When servicing, observe the original lead dress. If a short circuit is found, replace all parts

which have been overheated or damaged by the short circuit.

3. After servicing, see to it that all the protective devices such as insulation barriers,

insulation papers shields are properly installed.

4. After servicing, make the following leakage current checks to prevent the customer from being exposed to shock hazards.

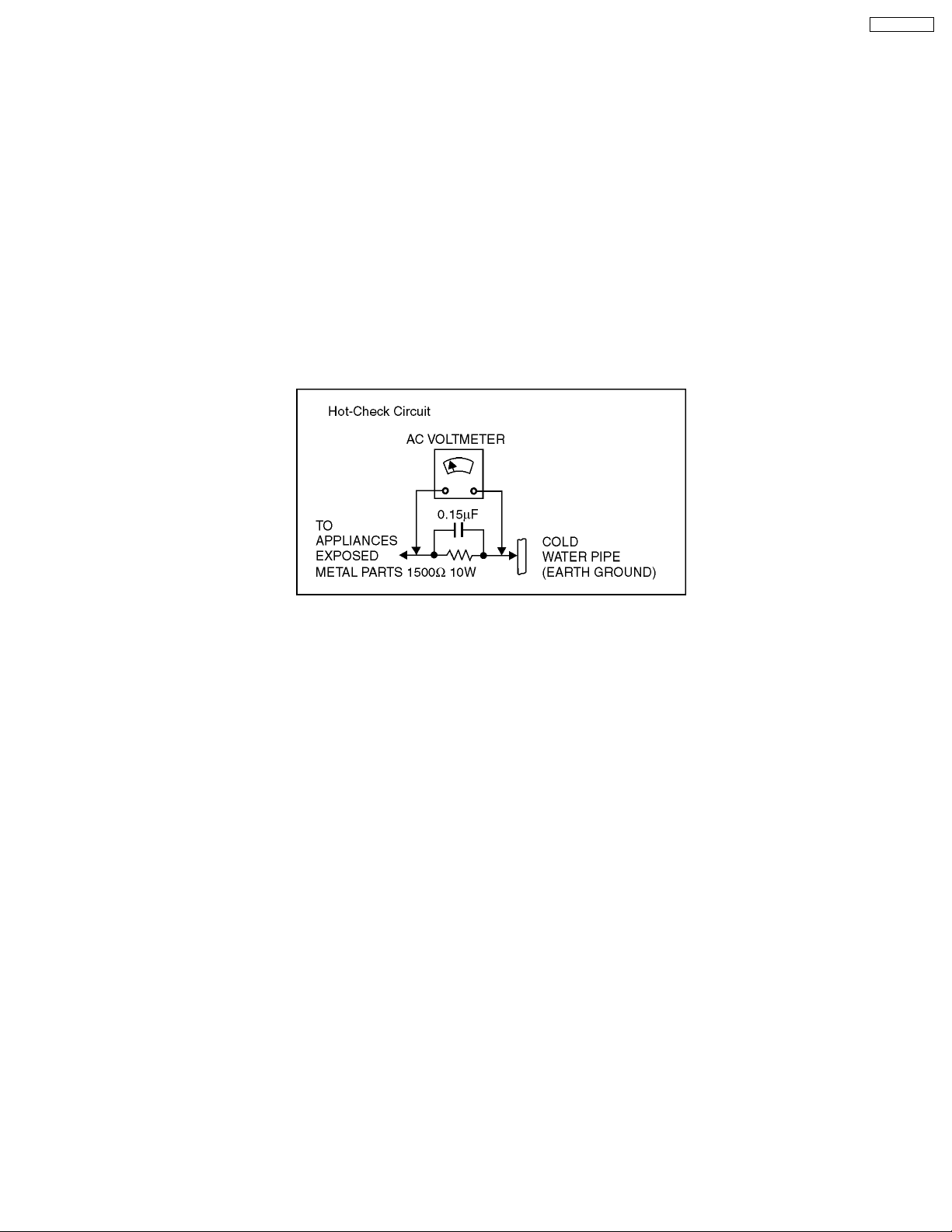

1.1.1. LEAKAGE CURRENT COLD CHECK

1. Unplug the AC cord and connect a jumper between the two prongs on the plug.

2. Measure the resistance value, with an ohmmeter, between the jumpered AC plug and each exposed metallic cabinet part on

the equipment such as screw heads, connectors, control shafts, etc. When the exposed metallic part has a return path to the

chassis, the reading should be between 1MΩ and 5.2MΩ.

When the exposed metal does not have a return path to the chassis, the reading must be infinity.

Figure 1

1.1.2. LEAKAGE CURRENT HOT CHECK

1. Plug the AC cord directly into the AC outlet. Do not use an isolation transformer for this check.

2. Connect a 1.5kΩ, 10 watts resistor, in parallel with a 0.15µF capacitors, between each exposed metallic part on the set and a

good earth ground such as a water pipe, as shown in Figure 1.

3. Use an AC voltmeter, with 1000 ohms/volt or more sensitivity, to measure the potential across the resistor.

4. Check each exposed metallic part, and measure the voltage at each point.

5. Reverse the AC plug in the AC outlet and repeat each of the above measurements.

6. The potential at any point should not exceed 0.75 volts RMS. A leakage current tester (Simpson Model 229 or equivalent) may

be used to make the hot checks, leakage current must not exceed 1/2 milliampere. In case a measurement is outside of the

limits specified, there is a possibility of a shock hazard, and the equipment should be repaired and rechecked before it is

returned to the customer.

3

DMR-EZ25EB

2 WARNING

2.1. PREVENTION OF ELECTROSTATIC DISCHARGE (ESD) TO

ELECTROSTATIC SENSITIVE (ES) DEVICES

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are called

Electrostatic Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some field-effect transistor-sand

semiconductor "chip" components. The following techniques should be used to help reduce the incidence of component damage

caused by electrostatic discharge (ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any ESD on your

body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap,

which should be removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly on a conductive surface such as

aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder

or unsolder ES devices.

4. Use only an anti-static solder removal device.

Some solder removal devices not classified

as "anti-static (ESD protected)" can generate electrical charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminum foil or comparable

conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be installed.

Caution

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpacked replacement ES devices. (Otherwise harmless motion such as the brushing

together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity sufficient to damage

an ES device).

4

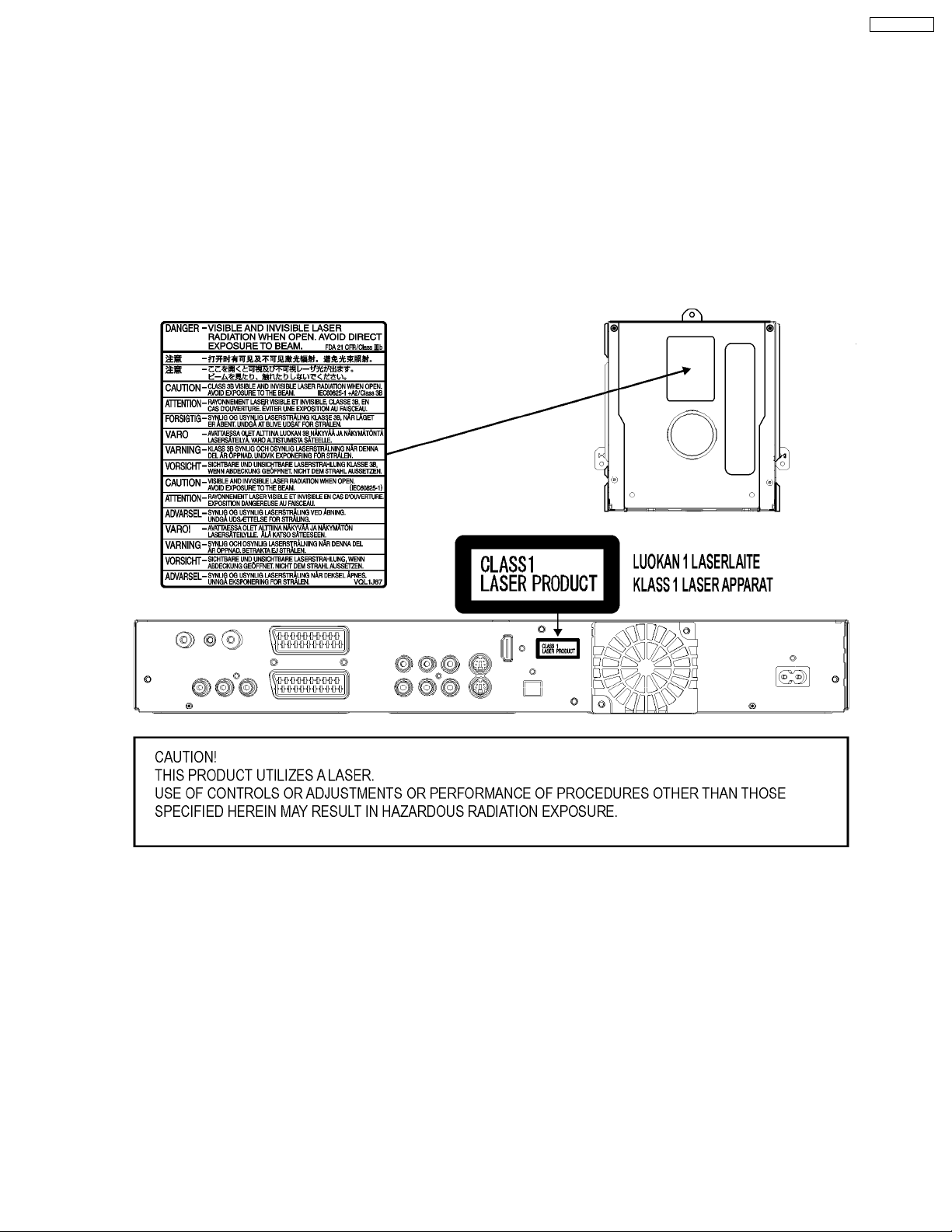

2.2. PRECAUTION OF LASER DIODE

CAUTION: ACHTUNG:

This product utilizes a laser diode with the unit turned “on”,

invisible laser radiation is emitted from the pickup lens.

Wave length: 662 nm/795 nm

Maximum output radiation power from pickup: 100µ W/VDE.

Laser radiation from the pickup lens is safety level, but be sure

the followings:

1. Do not disassemble the optical pickup unit, since radiation

from exposed laser diode is dangerous.

2. Do not adjust the variable resistor on the pickup unit.

It was already adjusted.

3. Do not look at the focus lens using optical instruments. 3. Nicht in die Fokussierlinse blicken.

4. Recommend not to look at pickup lens for a long time. 4. Auch nicht mit optischen Instrumenten in die Fokussierlinse blicken.

Dieses Produkt enthält eine Laserdiode.

Im eingeschalteten Zustand wird unsichtbare Laserstrahlung von der

Lasereinheit ausgestrahlt.

Wellenlänge: 662 nm/795 nm

Maximale Strahlungsleistung der Lasereinheit: 100µ W/VDE.

Die Strahlung der eingeschalteten Lasereinheit ist ungefährlich, wenn

folgende Punkte beachtet werden:

1. Die Lasereinheit nicht zerlegen, da die Strahlung an der freigelegten

Laserdiode gefährlich ist.

2. Den werksseitig justierten Einstellregler der Lasereinheit nicht

verstellen.

DMR-EZ25EB

5

DMR-EZ25EB

2.3. SERVICE CAUTION BASED ON LEGAL RESTRICTIONS

General description about lead free Solder (PbF)

· The lead free solder has been used in the mounting process of all electrical components on the printed circuit boards used

for this equipment in considering the globally environmental conservation.

· The normal solder is the alloy of tin (Sn) and lead (Pb). On the other hand, the lead free solder is the alloy mainly consists

of tin (Sn), silver (Ag) and Copper (Cu), and the melting point of the lead free solder is higher approx. 30 degrees C (86°F)

more than that of the normal solder.

Service caution for repair work using Lead Free Solder (PbF)

· The lead free solder has to be used when repairing the equipment for which the lead free solder is used.

· To put lead free solder, it should be well molten and mixed with the original lead free solder.

· Remove the remaining lead free solder on the PCB cleanly for soldering of the new IC.

· Since the melting point of the lead free solder is higher than that of the normal lead solder, it takes the longer time to melt

the lead free solder.

· Use the soldering iron (more than 70W) equipped with the temperature control after setting the temperature

at 350±30 degrees C (662±86°F). When soldering or unsoldering, please completely remove all of the solder

on the pins or solder area and be sure to heat the soldering points with the Pb free solder until it melts enough.

Definition of PCB Lead Free Solder being used

· The letter of “Pbf is printed either foil side or component side using the lead free solder.

Recommended Lead Free Solder (Service Parts Route.)

· The following 3 types of lead free solder are available through the service parts route.

RFKZ03D01K-----------(0.3mm 100g Reel)

RFKZ06D01K-----------(0.6mm 100g Reel)

RFKZ10D01K-----------(1.0mm 100g Reel)

Note

· Ingredient: tin (Sn), 96.5%, silver (Ag) 3.0%, Copper (Cu) 0.5%, Cobalt (Co) / Germanium (Ge) 0.1 to 0.3%

6

DMR-EZ25EB

3 SERVICE NAVIGATION

3.1. SERVICE INFORMATION

This service manual contains technical which will alow service personnel’s to understand and service this model.

Please place orders using the parts list and not the drawing reference numbers.

If the circuit is changed or modified, this information will be followed by supplement service manual to be filed with original service

manual.

1. This service manual does not contain the following information, because of the impossibility of sevicing at component level.

· Schematic Diagram, Block Diagram and P.C.B. layout of Digital P.C.B. and Back End P.C.B.

· Parts List for individual parts of Digital P.C.B. and Back End P.C.B.

· Exploded View and Parts List for individual parts of RAM drive.

2. The following category are recycle module part. Please send them to Central Repair Center.

· RAM/DIGITAL P.C.B. Module: RFKNEZ25EBS

· Back End P.C.B.: REPD0031B

7

DMR-EZ25EB

4 SPECIFICATION

Power supply: AC220-240 V, 50/60 Hz

Power consumption: 24 W ±1,3 W

Power save mode 2 W ±0,4 W

Dimensions and Mass: 430 (W) x 329 (D) x 58 (H) mm

(excluding protrusions) / 3.3 kg

Operating temperature range: +5 to +40 °C

Operating humility range: 10 to 80 % RH (no condensation)

Pickup Laser power: CLASS1

Pickup Wave length: DVD 662 nm / CD 780 nm

No hazardous radiation is emitted

with the safety protection

Recording system: MPEG2 (Hybrid VBR)

Audio: Dolby Digital 2CH

Signal system: PAL 625/50, NTSC 525/60

DVD Region number: Region No. 2

DVD Recording / Playable discs: DVD-RAM (12 cm 4.7 GB)

DVD-RAM (12 cm 9.4 GB)

DVD-RAM (8 cm 2.8 GB)

DVD-R (12 cm 4.7 GB)

DVD-R (8 cm 1.4 GB)

DVD-RW (12 cm 4.7GB)

DVD+R (12 cm 4.7 GB)

DVD+RW (12 cm 4.7 GB)

DVD-R DL (12 cm 8.5 GB)

DVD+R DL (12 cm 8.5 GB)

DVD approximate Recording time: XP: 10 MBps (60 min)

SP: 5 MBps (120 min)

LP: 3 MBps (240 min)

EP: 1.7 / 1.2 MBps (360 -480min)

Video input AV1 / AV2: 21 pin connector (1.0 Vp-p 75 Ω )

Video input AV3 / AV4: pin jack connector (1.0 Vp-p 75 Ω)

S-Video input AV1 / AV2: 21 pin connector

(Y: 1.0 Vp-p, C: 0.3 Vp-p 75 Ω)

S-Video input AV3 / AV4: pin jack connector

(Y: 1.0 Vp-p, C: 0.3 Vp-p 75 Ω)

RGB Video input AV3 (PAL): 21 pin connector (0.7 Vp-p 75 Ω)

DV input: IEEE 1394 Standard 4 pin

Video output AV1 / AV2: 21 pin connector (1.0 Vp-p 75 Ω)

FBAS Video output (composit): pin jack connector (1.0 Vp-p 75 Ω)

S-Video output AV1: 21 pin connector (1.0 Vp-p 75 Ω)

S-Video output (cinch): pin jack connector (1.0 Vp-p 75 Ω)

S-Video output: S connector (1.0 Vp-p 75 Ω)

RGB Video output AV1: 21 pin connector (0.7 Vp-p 75 Ω)

Component Video output: Y pin jack (1.0 Vp-p 75 Ω)

PB pin jack (0.7 Vp-p 75 Ω)

PR pin jack (0.7 Vp-p 75 Ω)

HDMI output (19 pin type A): Version 1.2a (EDID Vers. 1.3)

Audio input AV1 / AV2: 21 pin connector (-6 dBV 500 mV)

Audio input AV3 / AV4: pin jack (-6 dBV 500 mV)

Audio output (cinch): pin jack (-6 dBV 500 mV)

Optical output: PCM, Dolby Digital, DTS, MPEG

Note:

Specifications are subject to change without notice.

Mass and dimensions are approximate.

■ Build-in decoders: You can play discs with following symbols

Additional playable discs: DVD-RAM (VR format)

DVD-RW (VR format)

DVD-R (MP3, JPG)

DVD-R DL, DVD+R DL

DVD-Video, DVD-Audio

CD-Audio (CD-DA), Video CD

SVCD (IEC62107)

CD-R, CD-RW

(CD-DA, MP3, JPG, VCD)

TV tuner system (PAL): UHF: CH21-CH68 (analog/DVB-T)

RF Converter Output: not provided

SD Card Slot: JPEG (Still Picture DCF Standard)

TIFF (uncompressed)

MPEG2 (rec. by Panasonic cam)

Campatible Cards: SD Card, Multimedia Card

miniSD™ Card (with adapter)

Card format: FAT12, FAT16

Card picture pixels: 34x34 to 6144x4096

8

5 NEW FEATURE

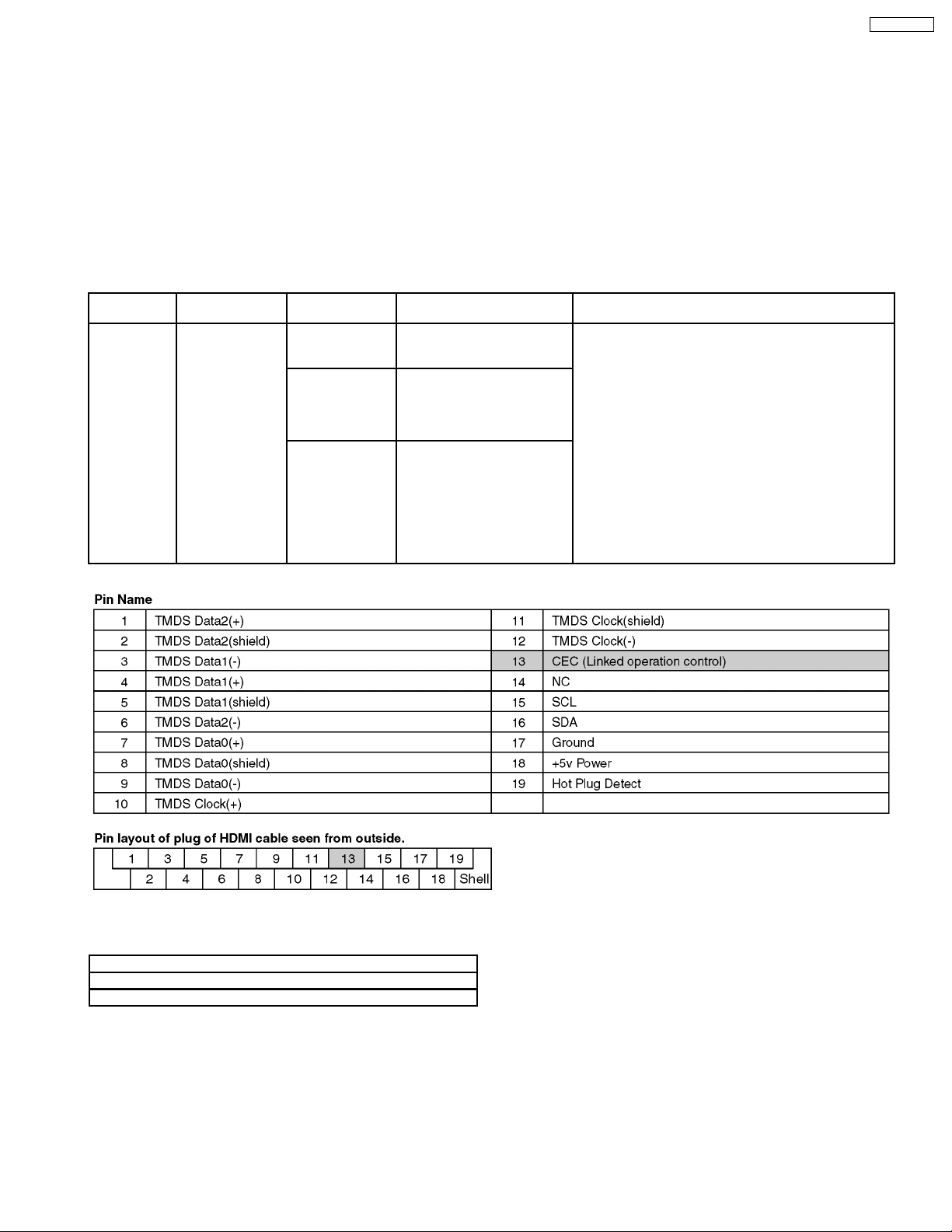

5.1. HDAVI CONTROL (HDMI LINK)

Linked operations by HDAVI Control (HDMI Link)

5.1.1. WHAT IS HDMI

HDMI is abbreviation of [High-Definition Multimedia Interface], and is digital interface standard for next generation TV

corresponding to follows.

1. Non-compressing high quality digital image

2. Digital transmission of multi channel digital audio.

3. Two way communication of control signal of control straightening between equipments.

Cable Transmission

HDMI

Cable

method

Digital

(~4.455Gbps)

Directionality Transmission

signal

One-way Digital image

(none-compression highdefinition television image)

One-way Digital Audio

(6ch/24 bit high sound quality

PCM of DVD audio/Bit stream

of surround to 8ch of DVD

video)

Interactive Digital control signal

(Advanced control between

equipments)

Feature

Clock line in one system and data line in three systems

can high-speed communicate high reliability because of

balance communication that uses three respectively

every one system.

Moreover, because high-speed data line in three system

can be used at same time, it has ten of other digital

cables times or more transmission ability.

And can transmit high-definition television image of noncompression, 24 bit high sound quality PCM voice of

multi-CH of DVD audio (to 6ch) and Bit stream signal of

surround to 8ch of DVD video (5.1ch, 6.1ch, and 7.1ch,

etc.) as a digital signal of no deterioration.

It has power supply line and a interactive control signal

line communication independent of AV signal, a Cd can

an advanced control between equipments. Therefore it

can correspond to making of AV equipment in the future

highly a network.

DMR-EZ25EB

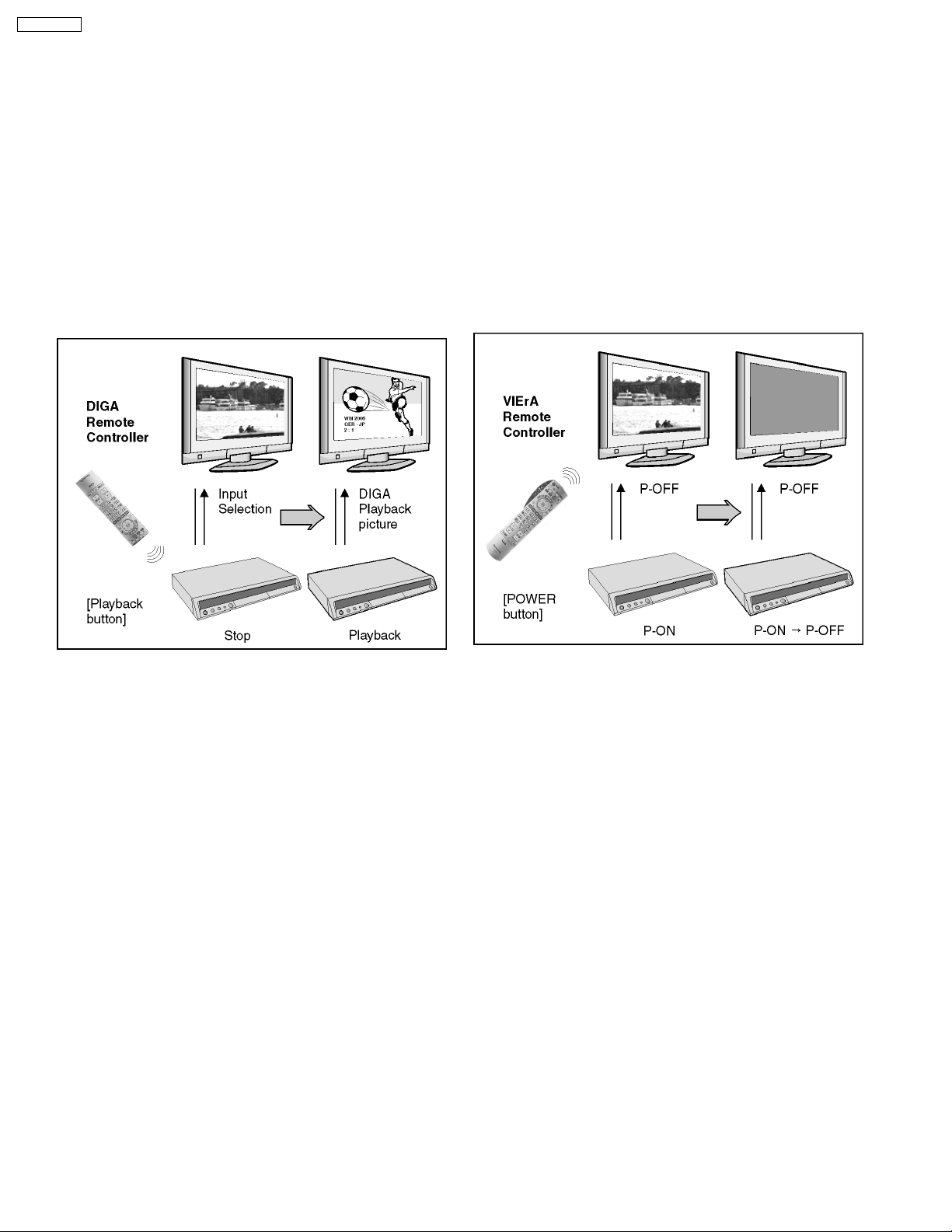

5.1.2. LINK FUNCTIONS

Functions

(1) Automatic Input switch

(2) Link of Power

9

DMR-EZ25EB

5.1.3. OUTLINE OF EQUIPMENTS

LINKED FUNCTIONS

1. Automatic Input switch

At starting of playback / GUI (Graphical User Interface)

display by DIGA, it turn on power of VIErA, and it displays

picture of DIGA onto screen of VIErA.

a. Starting of playback:

It includes automatic playback of DVD-Video and so on.

And it includes picture of screen saver too.

b. GUI display:

FUNCTIONS, DIRECT NAVIGATOR, TV PROGRAM,

PROG/CHECK, Timer Recording, G-code, Initial setting,

Playback setting, Play list, SD/DVD guide, Warning

messages that user can select and so on.

2. Power Link

Power of DIGA is turned off linking to POWER OFF of

VIErA.

· Power not turned on linking to POWER ON of VIErA.

· It is limited in following cases that DIGA links to POWER

OFF of VIErA.

· During EE display (While Timer recording is being

executed/Functions is being displayed are included.)

However except cases below.

· During EE display, but manual recording is being

executing/during EXT_Link recording.

· During Tray is being opened.

· Case that DIGA is in status that power cannot turn off

(during dubbing, during finalize).

10

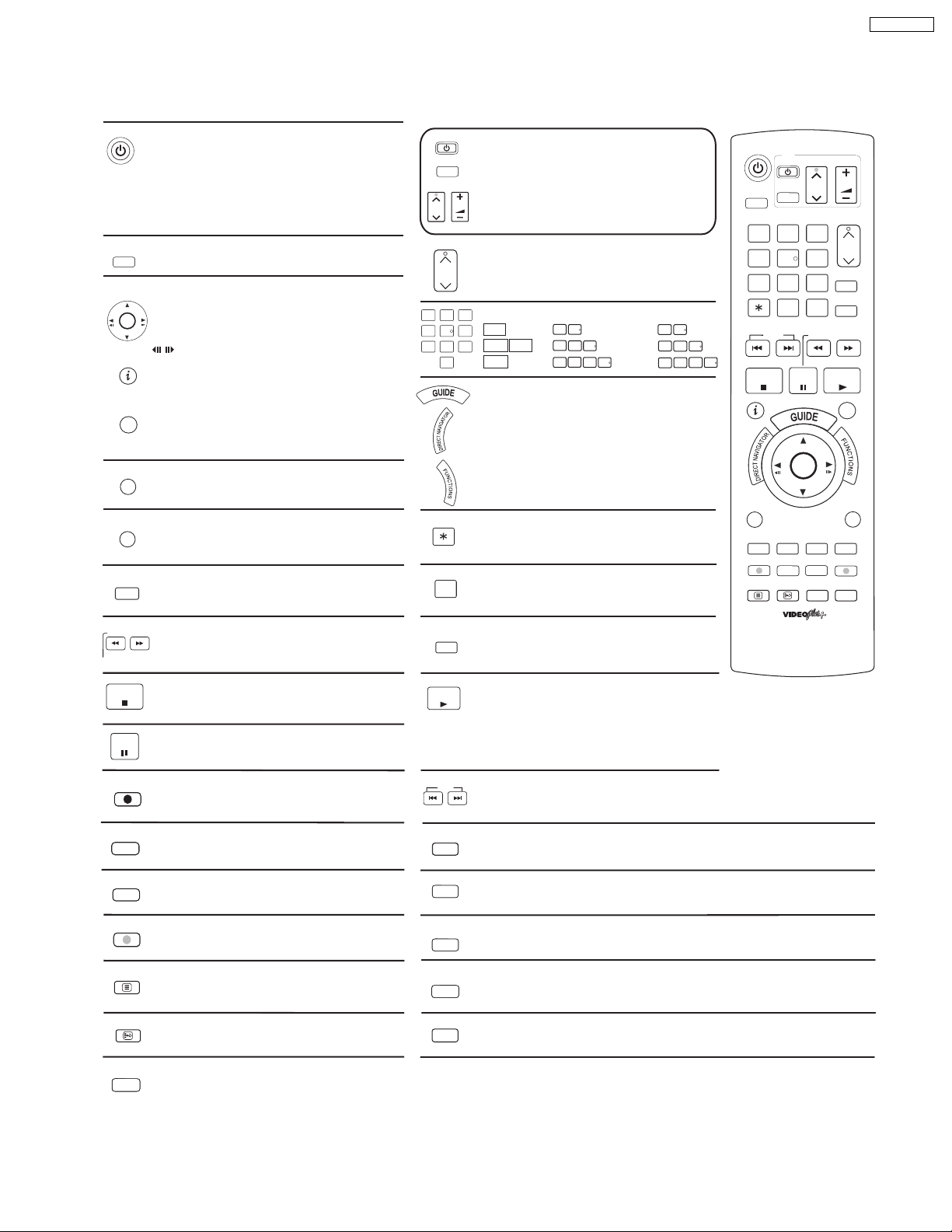

6 LOCATION OF CONTROLS AND COMPONENTS

Remote Control

DVD

Stand-by/on switch

Press to switch the unit from on to stand-by mode

or vice versa. In stand-by mode, the unit is still consuming

a small amount of power.

Switching this unit into standby mode does not

disconnect it from the mains.

DRIVE

SELECT

Select the DVD or SD drive.

Direction buttons in the menu guide.

Select groups or titles.

ENTER

OK

ENTER: Select or save a setting.

Still picture or slow motion playback.

Display the programme information from

the TV GUIDE or the Banner.

PROG/CHECK

Check / Change a Timer recording.

SUB MENU

Launch sub menus.

S

RETURN

Return to the previous menu.

VIDEO Plus+

VIDEO Plus+ menu (for analogue stations)

4

TV

Turn the television set on and off.

AV

Select the AV input on the television set.

CH: Select the channel on the television set.

VOLUME

CH

VOLUME: Volume control of the television set.

PAGE

CH: Select the channel on the Recorder.

CH

PAGE: Scroll in the electronic TV Guide.

Number buttons - direct input

3

2

5

6

VCD

9

JPEG

0

JPEG

MP3

0

5

5:

0

0

5:

5:

5

0

0

0

5

GUIDE: Launch the TV Guide menu.

DIRECT NAVIGATOR: title view

TOP MENU: Main menu of DVD-video.

FUNCTION selection menu.

Cancel a function.

INPUT

Switch button of the AV input between AV1,AV2

SELECT

AV3 (front), AV4 and DV in.

15:

15:

15:

DVD

DRIVE

SELECT

5

1

0

5

1

5

0

1

0

SUB MENU

S

TV

AV

112

4

5

77889

0

SKIP

PAUSE

STOP

ENTER

OK

REC

REC MODE

STTL

TEXT

CH

3

6

VIDEO Plus+

DELETE

INPUT

SELECT

SLOW/SEARCH

PLAY/ x1.3

PROG/CHECK

CREATE

MANUAL SKIP

CHAPTER

EXT LINK

DIRECT TV REC

DISPLAY

TIME SLIP

DMR-EZ25EB

VOLUME

PAGE

CH

RETURN

SLOW/SEARCH

Search or slow motion playback.

STOP

Stops recording, replay or forward / reverse action

PAUSE

Pause a recording or playback.

REC

Start the recording.

REC MODE

Record mode button XP, SP, LP, EP

EXT LINK

Record with external recording control.

DIRECT TV REC

Direct TV recording.

TEXT

Launch the Digital Text Service.

STTL

Displays subtitles

DISPLAY

Show on screen menu.

DELETE

Delete items.

PLAY/ x1.3

Starts playback.

RAM - You can increase the playback speed.

Hold PLAY during playback.

SKIP

Skip chapters, titles, or pictures.

Menu guide ed button(r ): Profile, Guide, Digital Text, Manual Tuning

Menu guide button(green ): Profile, Guide, Digital Text

CREATE

Menu guide button(yellow ): Profile, Guide, Digital Text

CHAPTER

CREATE CHAPTER: Deviding a recording into chapters.

MANUAL SKIP

Menu guide button(blue ): Profile, Guide, Digital Text

MANUAL SKIP: Jump forwards 30 seconds.

TIME SLIP

Select the time frame.

Panasonic

DVD/TV

11

DMR-EZ25EB

7 OPERATING INSTRUCTIONS

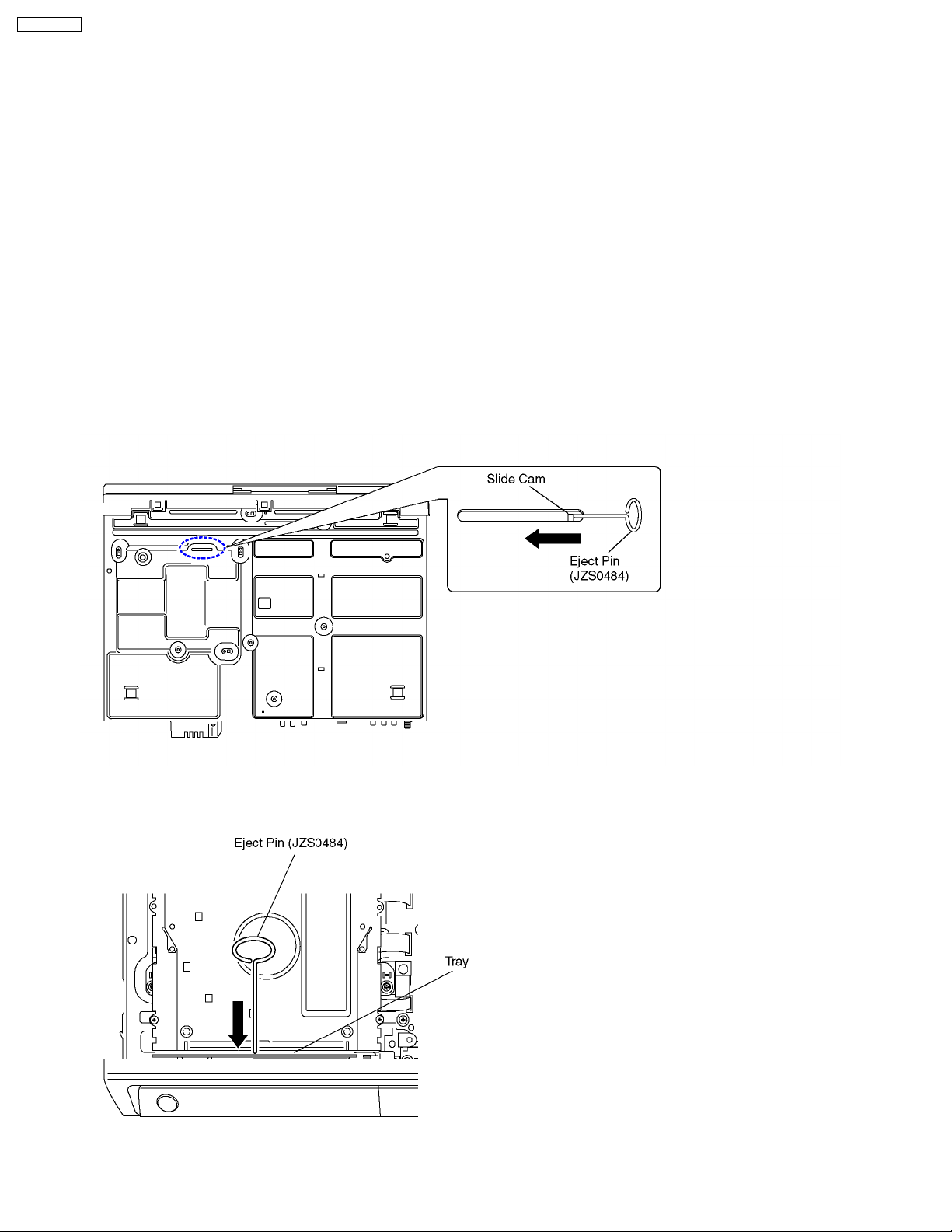

7.1. TAKING OUT THE DISC FROM DVD-DRIVE UNIT WHEN THE DISC

CANNOT BE EJECTED BY OPEN/CLOSE BUTTON

7.1.1. FORCIBLE DISC EJECT

7.1.1.1. WHEN THE POWER CAN BE TURNED OFF

1. Turn off the power and press [STOP], [CH UP] keys on the front panel simultaneously for 5 seconds.

7.1.1.2. WHEN THE POWER CAN NOT BE TURNED OFF

1. Press [POWER] key on the front panel for over 10 seconds to turn off the power forcibly and press [STOP] [CH UP] keys on

the front panel simultaneously for 5 seconds.

7.1.2. WHEN THE FORCIBLE DISC EJECT CAN NOT BE DONE

1. Turn off the power and pull out AC cord.

2. Remove the Top Case.

3. Put deck so that bottom can be seen.

4. Push SLIDE CAM by Eject Pin (JZS0484) or minus screw driver (small) in the direction of arrow to eject tray slightly.

5. Put deck upward and push out Tray by Eject Pin (JZS0484) or minus screw driver (small).

12

DMR-EZ25EB

8 SERVICE MODE

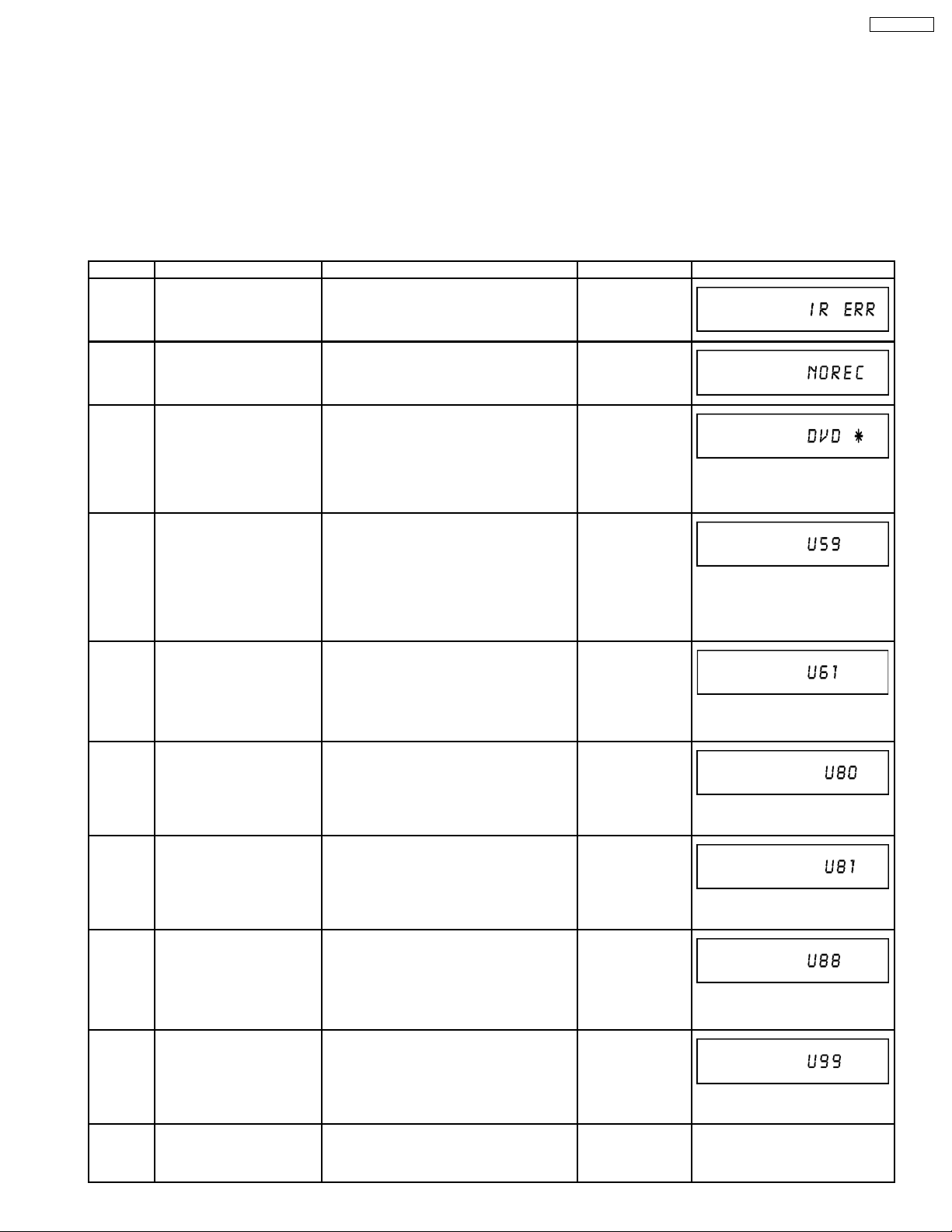

8.1. SELF-DIAGNOSIS AND SPECIAL MODE SETTING

8.1.1. SELF-DIAGNOSIS FUNCTIONS

Self-Diagnosis Function provides information for errors to service personnel by “Self-Diagnosis Display” when any error has

occurred.

U**, H** and F** are stored in memory and held.

You can check latest error code by transmitting [0] [1] of Remote Controller in Service Mode.

Automatic Display on FL will be cancelled when the power is turned off or AC input is turned off during self-diagnosis display is ON.

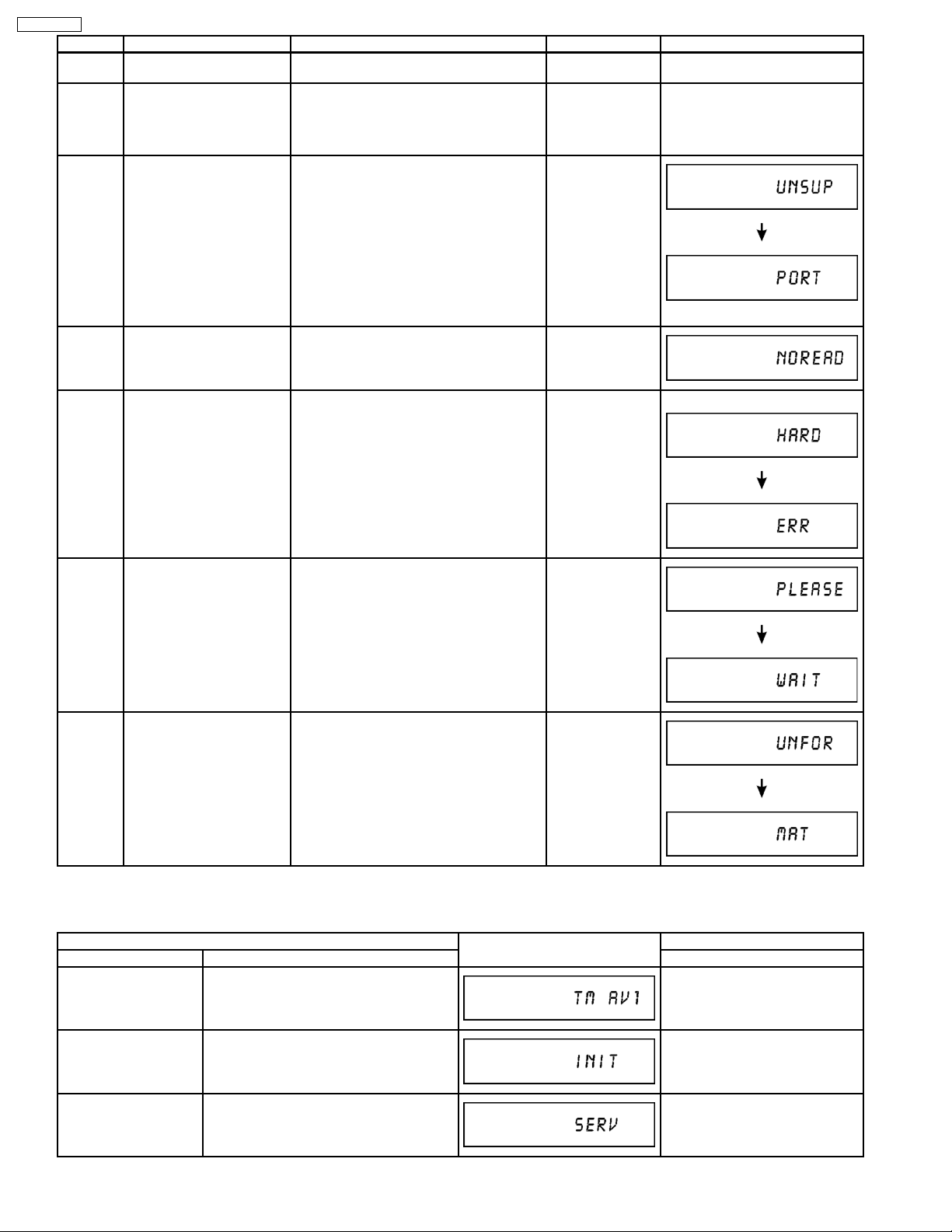

Error Code Diagnosis contents Description Monitor Display Automatic FL display

IR ERR IR communication error [IR ERR] is displayed when communication

between Timer microprocessor and IR

microprocessor fails.

No display

No REC Recording is impossible [No REC] is displayed when recording is

U30 Remote control code error Display appears when main unit and remote

U59 Abnormal inner temperature

detected

U61 The unit is carrying out its

recovery process (with no

disc in the disc tray).

U80 ST Microprocessor

Communication Error on

Timer Bus

impossible due to the defect, dirt or wound

of media.

controller codes are not matched.

Display appears when the drive temperature

exceeds 70°C.

The power is turned off forcibly.

For 30 minutes after this, all key entries are

disabled. (Fan motor operates at the highest

speed for the first 5 minutes. For the

remaining 25 minutes, fan motor is also

stopped.) The event is saved in memory as

well.

* The unit detected an error while recording

or playing with with no disc in the disc

tray.

The unit is carrying out its recovery process.

This process restores the unit to normal

operation. The unit is not broken. Wait until

the message disappears.

Displayed appears when ST Microprocessor

Communication Error on Timer Bus occurs.

No display

No display

“*” is remote controller code of the

main unit.

Display for 5 seconds.

No display

“U59 is displayed for 30 minutes.

No display

No display

U81 ST Microprocessor

Communication Error on

UART

U88 The unit is carrying out its

recovery process (with no

disc in the disc tray).

U99 Hang-up Displayed when communication error has

F00 No error information Initial setting for error code in memory

Displayed appears when ST Microprocessor

Communication Error on UART occurs.

* The unit detected an error while recording

or playing with with no disc in the disc

tray.

The unit is carrying out its recovery process.

This process restores the unit to normal

operation. The unit is not broken. Wait until

the message disappears.

occurred between Main microprocessor and

Timer microprocessor.

(Error code Initialization is possible with error

code initialization and main unit

initialization.)

13

“U80” is displayed till Power Key is

pressed.

No display

“U81” is displayed till Power Key is

pressed.

No display

No display

Displayed is left until the [POWER]

key is pressed.

No display No display

DMR-EZ25EB

Error Code Diagnosis contents Description Monitor Display Automatic FL display

F58 Drive hardware error When drive unit error is detected, the event

F34 Initialization error when main

UNSUPPORT

NO READ Disc read error *A disc is flawed or dirty.

microprocessor is started up

for program recording

Unsupported disc error *An unsupported format disc was played,

is saved in memory.

When initialization error is detected after

starting up main microprocessor for program

recording, the power is turned off

automatically.

The event is saved in memory.

although the drive starts normally.

*The data format is not supported, although

the media type is supported.

*Exceptionally in case of the disc is dirty.

*A poor quality failed to start.

*The track information could not be read.

No display No display

No display No display

“This disc is

incompatible.”

Display for 5 seconds.

“Cannot read.

Please check the

disc.”

HARD

ERR

PLEASE

WAIT

UNFORMAT

Drive error The drive detected a hard error. “DVD drive error.” Display for 5 seconds.

Unit is in termination process Unit is in termination process now.

“BYE” is displayed and power will be turned

off.

In case “Quick Start” of setup menu is ON, it

is displayed in restoration operation for AC

off.

Unformatted disc error You have inserted an unformatted DVD-

RAM or DVD-RW that is unformatted or

recorded on other equipment.

No display

Format:

This disc is not

formatted properly.

Format the disc in

DISK

MANAGEMENT?

8.1.2. SPECIAL MODES SETTING

Item FL display Key operation

Mode name Description Front Key

TEST Mode *All the main unit’s parameters (include

Rating password The audiovisual level setting password is

Service Mode Setting every kind of modes for servicing.

tuner) are initialized.

initialized to “Level 8”.

*Details are described in “

Service Mode

”.

14

Press [STOP], [CH UP] and

[OPEN/CLOSE] keys

simultaneously for five seconds

when power is off.

Open the tray, and press [REC]

and [PLAY] simultaneously for 5

seconds.

When the power is off, press [CH

UP], [OPEN/CLOSE] and [REC]

keys simultaneously for 5 seconds.

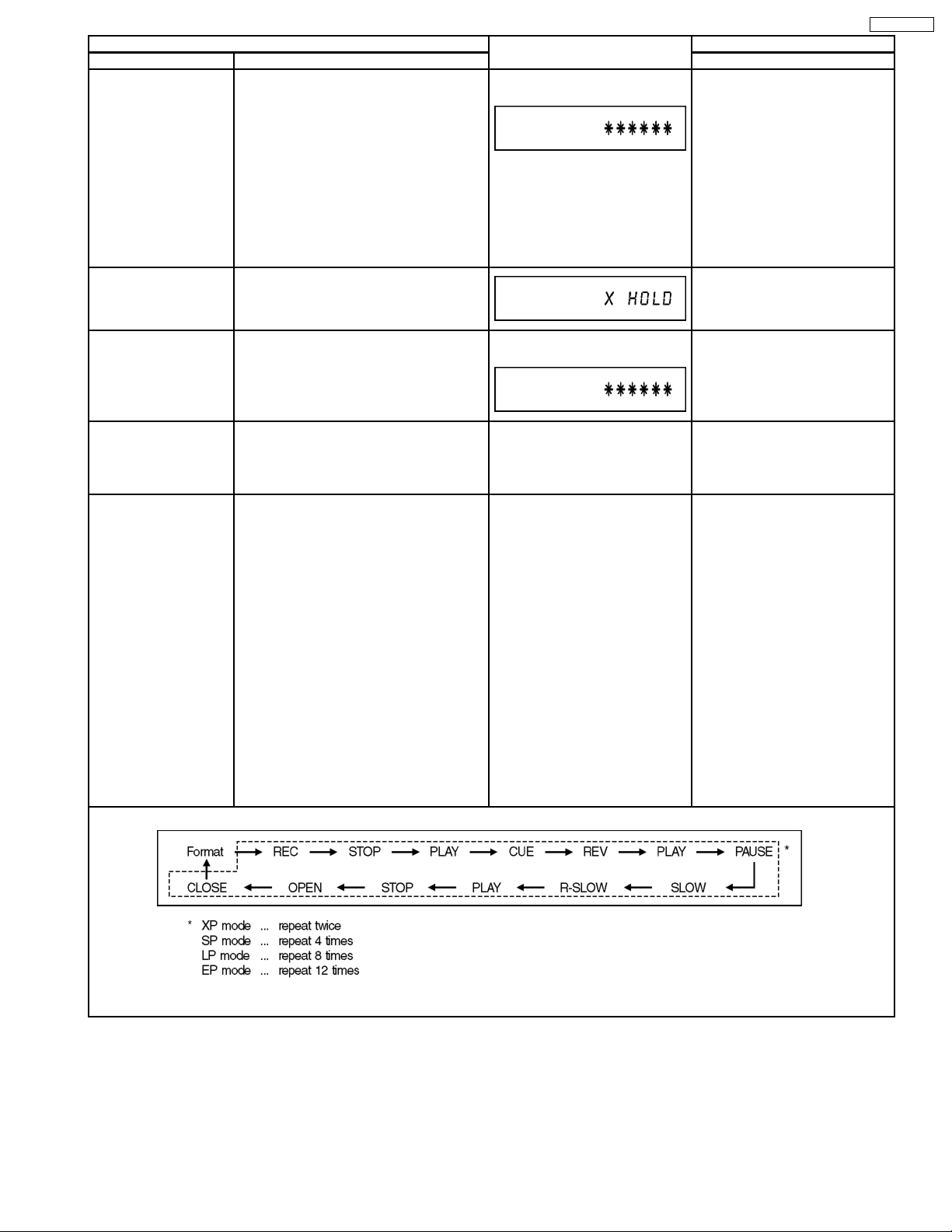

Item FL display Key operation

Mode name Description Front Key

Forced disc eject Removing a disc that cannot be ejected.

The tray will open and unit will shift to P-off

mode.

*When Timer REC is ON or EXT-LINK is

ON, execute " Forced disc eject " after

releasing Timer REC or EXT-LINK.

*This command is not effective during "Child

lock" is ON.

While Demonstration Lock is being set, this

Forced disc eject function is not accepted.

If this command was executed while

TIMER REC is being set, TIMER REC

setting will turn to OFF.

Child lock/unlock Set or release “Child Lock”. Press [ENTER] and [RETURN] by

The display before execution

leaves.

When the power is off, press

[STOP] and [CH UP] keys

simultaneously for 5 seconds.

remote controller simultaneously

until [X-HOLD] is displayed.

DMR-EZ25EB

NTSC/PAL system select To switch PAL/NTSC altemately. The display before execution

Forced power-off When the power button is not effective while

power is ON, turn off the power forcibly.

*When Timer REC is ON or EXT-LINK is

ON, execute “Forced Power-off” after

releasing Timer REC or EXT-LINK.

Aging Perform sequence of modes as * Aging

Description shown below continually.

Caution:

All programs in DVD-RAM disc will be

deleted because Formatting is done once

in Aging process.

leaves.

Display in P-off mode. Press [Power] key over than 10

Display following the then mode. When the power is ON, press

Aging Contents (Example):

While the power is on (E-E mode),

press [STOP] and [OPEN/CLOSE]

simultaneously for 5 seconds.

seconds.

[STOP], [POWER] and

[OPEN/CLOSE] simultaneously for

over 5 seconds and less than 10

seconds.

NOTE1:

If Unit has not turned into Aging

mode by operations shown above,

execute TEST MODE once and reexecute operation shown above.

(*All the main unit’s parameters

include tuner are initialized by

TEST mode.)

NOTE2:

If the unit has hung-up because of

pressing keys for over 10 seconds,

once turn off the power, and reexecute this command.

*When releasing Aging mode,

press [POWER] key.

15

DMR-EZ25EB

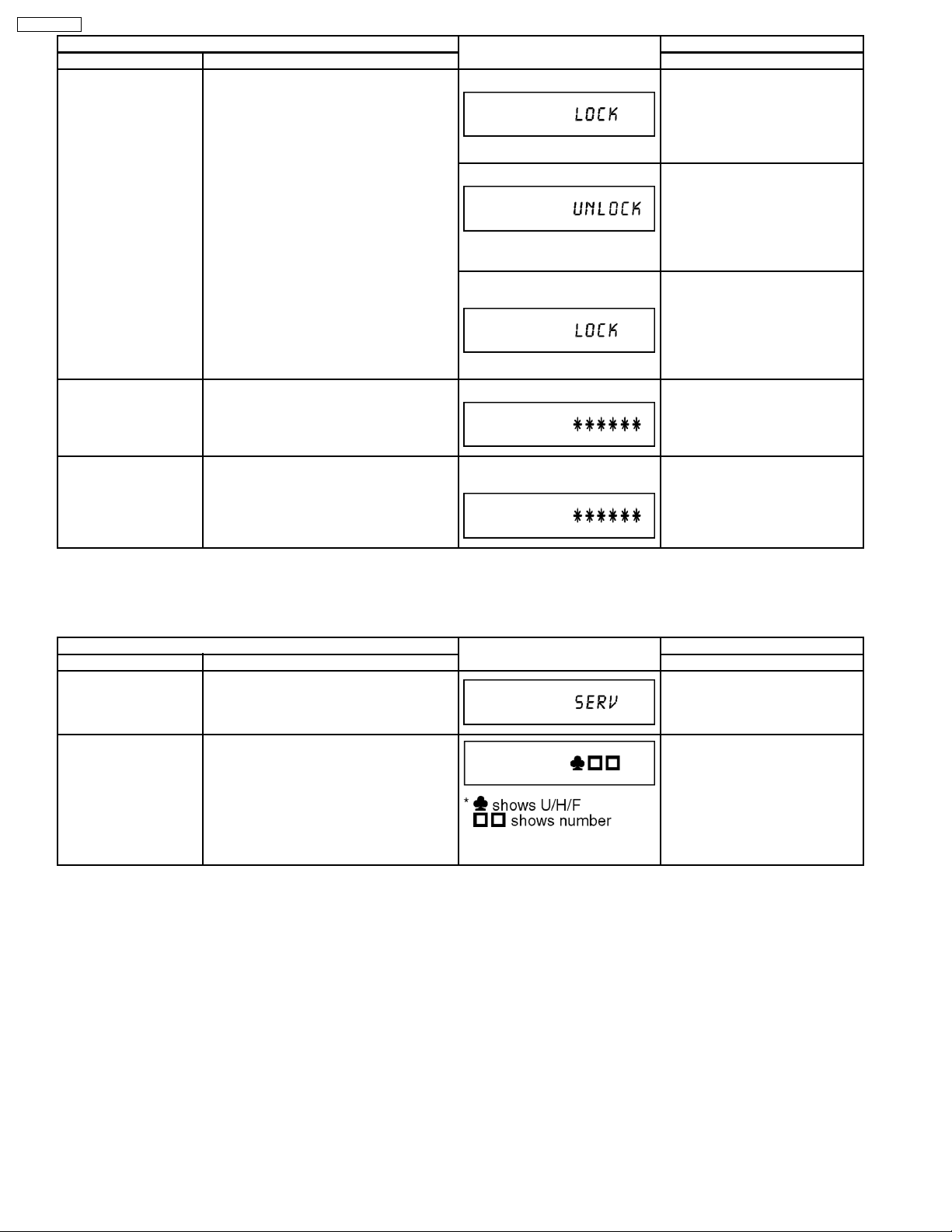

Item FL display Key operation

Mode name Description Front Key

Demonstration

lock/unlock

ATP re-execution Re-execute ATP. Display at ATP executing. When the power is on (E-E mode),

Ejection of the disc is prohibited.

The lock setting is effective until unlocking

the tray and not released by “Main unit

initialization” of service mode.

*When lock the tray.

“LOCK” is displayed for 3 seconds.

*When unlock the tray.

“UNLOCK” is displayed for 3

seconds.

*When press OPEN/CLOSE key

while the tray being locked.

Display “LOCK” for 3 seconds.

When the power is on, press

[STOP] and [POWER] keys

simultaneously for 5 seconds.

When the power is on, press

[STOP] and [POWER] keys

simultaneously for 5 seconds.

Press [OPEN/CLOSE] key while

the tray being locked.

press [CH UP] and [CH DOWN]

simultaneously for 5 seconds.

Progressive initialization The progressive setting is initialized to

Interlace.

The display before execution

leaves.

When the power is on (E-E mode),

press [STOP] and [PLAY]

simultaneously for 5 seconds.

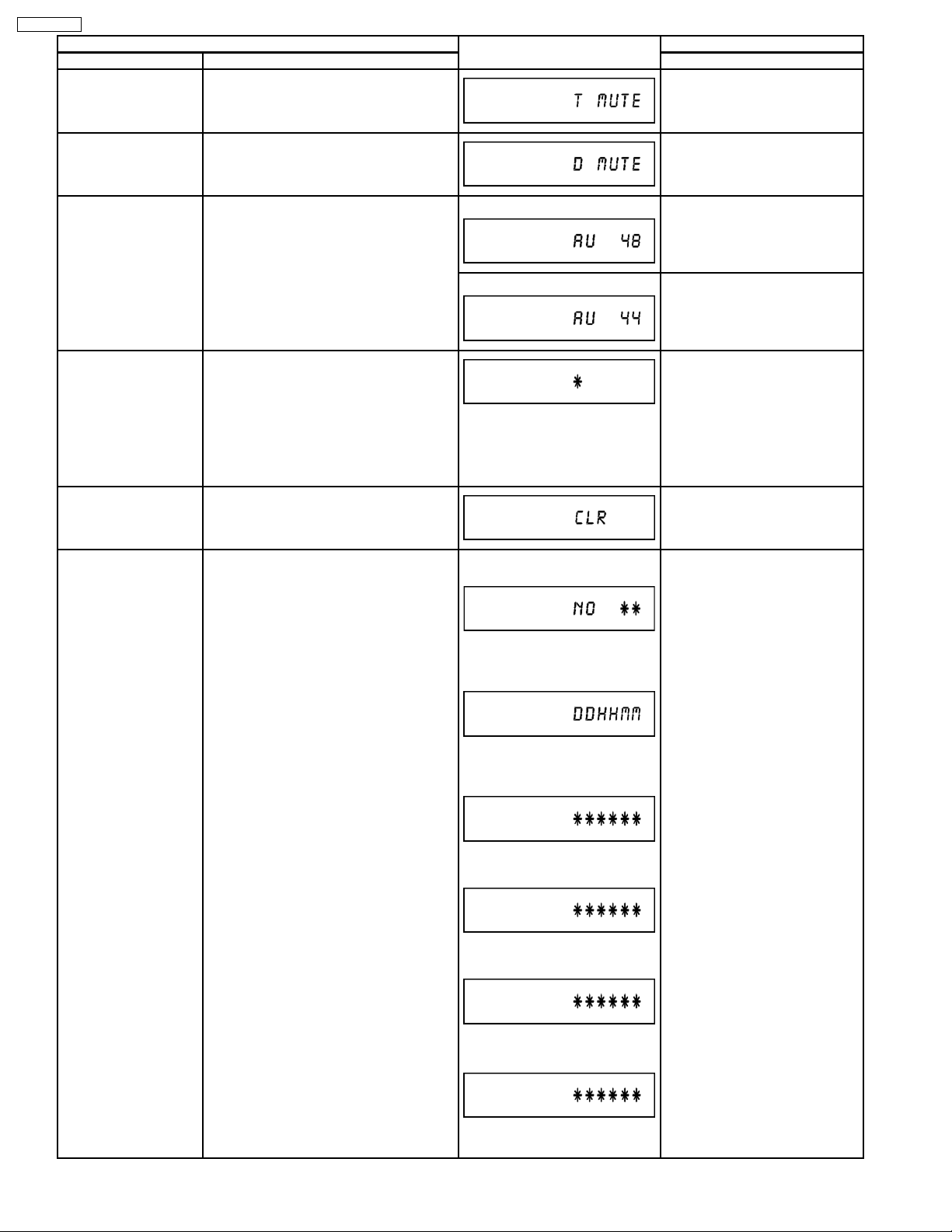

8.1.3. SERVICE MODES AT A GLANCE

Service mode setting: While the power is off, press [REC], [CH UP] and [OPEN/CLOSE] simultaneously for five seconds.

Item FL display Key operation

Mode name Description (Remote controller key)

Release Items Item of Service Mode executing is cancelled. Press [0] [0] or [Return] in service

Error Code Display Last Error Code of U/H/F held by Timer is

displayed on FL.

*Details are described in “Self-Diagnosis

Functions”.

If any error history dose not exist,

[F00] is displayed.

mode.

Press [0] [1] in service mode

16

Item FL display Key operation

Mode name Description (Remote controller key)

ROM Version Display 1. Region code

1.

Press [0] [2] in service mode

(displayed for 5 sec.)

2. Main firm version

(displayed for 5 sec.)

3. Timer firm version

2.

(displayed for 5 sec.)

4. Drive firm version

(displayed for 5 sec.)

3.

5. ROM correction version

(left displayed)

4.

5.

‘’ ’’ are version displays.

White Picture Outpu t White picture is output as component Output

*Initial mode is “Interlace”. Press [1] [1] in service mode.

from AV Decoder.

*White picture

(Saturation rate : 100%)

*It is enable to switch Interlace/Progressive

by “I/P switch: [1] [4]”

Switch Interlace/Progressive Press [1] [4] in White Picture

Output mode.

*I/P are switched alternately.

DMR-EZ25EB

Magenta Picture Output Magenta picture is output with Component

Output from AV Decoder.

*Magenta picture

(Saturation rate: 100%)

*It is enable to switch Interlace/Progressive

by “I/P switch: [1] [4]”

RTSC Return in XP

(A & V)

AV1 input signal is encoded (XP), decoded

(XP) and output decoded signal to external

without DISC recording and DISC playback.

I/P Switch Switch Interlace and Progressive in EE

mode.

*Initial setting is “Interlace”.

*This command is effective during executing

“White Picture Outpu t”, “Magenta Picture

Output” and “RTSC Return in XP (A & V)”

modes.

*Initial mode is “Interlace”. Press [1] [2] in service mode.

Switch Interlace/Progressive Press [1] [4] in Magenta Picture

Output mode.

*I/P are switched alternately.

Initial mode: EE2/ Interlace/ XP/

Press [1] [3] in service mode.

Audio 48kHz

Switch Interlace/Progressive Press [1] [4] in RTSC Return XP

mode.

*I/P are switched alternately.

Audio 44.1 kHz/ 48 kHz Switch Press [2] [4] in RTSC Return XP

mode.

*48 kHz / 44.1 kHz are switched

alternately.

Initial mode is Interlace

Press [1] [4] in I/P Switch mode.

*I/P are switched alternately.

Switch Interlace/Progressive

17

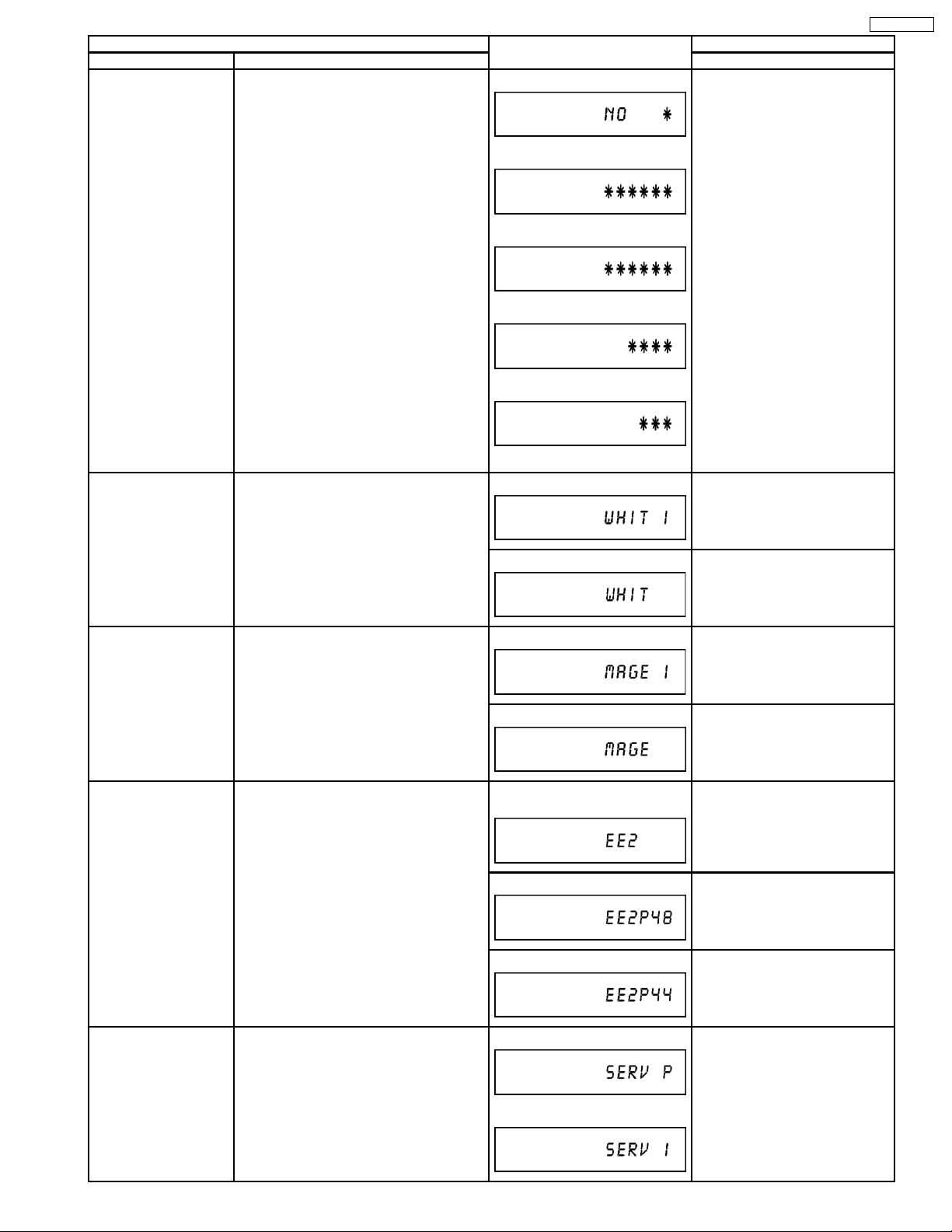

DMR-EZ25EB

Item FL display Key operation

Mode name Description (Remote controller key)

Audio Mute (XTMUTE) Check whether mute is applied normally by

the timer microprocessor.

Press [2] [1] in service mode.

Audio Mute (XDMUTE) Check whether mute is applied normally by

the Digital P.C.B..

Audio Pattern Output The audio pattern stored in the internal

memory is output

(Lch: 1kHz/-18dB)

(Rch: 400Hz/-18dB)

*Audio sound clock switching operation of

DAC can be confirmed by sub command [2]

[4].

Laser Used Time

Check laser used time (hours) of drive.

Indiction

Delete the Laser Used

Time

Laser used time stored in the memory of the

unit is deleted.

RAM Drive Last Error RAM Drive error code display.

*For details about the drive error code, refer

to the Service Manual for the specific RAM

Drive.

Press [2] [2] in service mode.

Initial mode (Audio 48kHz) Press [2] [3] in service mode.

Audio 44.1kHz/48kHz switching Press [2] [4] in Audio Pattern

Output mode.

*48 kHz / 44.1 kHz are switched

alternately.

Press [4] [1] in service mode.

●(*****) is the used time display in

hour.

●Laser used time of DVD/ CD in

Playback/Recording mode is

counted.

Press [9] [5] in service mode.

1. Error Number is displayed for 5

seconds.

Press [4] [2] in service mode.

When “INFO******” is being

displayed, past 19 error histories

can be displayed by pressing [0]

[1] - [1] [9]

2. Time when the error has

occurred is displayed for 5

seconds.

DD: Day / HH: Hour / MM: Minute

3. Last Drive Error (1/2) is

displayed for 5 seconds.

4. Last Drive Error (2/2) is

displayed for 5 seconds.

5. Error occurring Disc type is

displayed for 5 seconds.

6. Disc Maker ID is displayed for 5

seconds.

In case that the maker cannot be

identified, display is black out.

7. Factor of Drive Error occurring is

left displayed

18

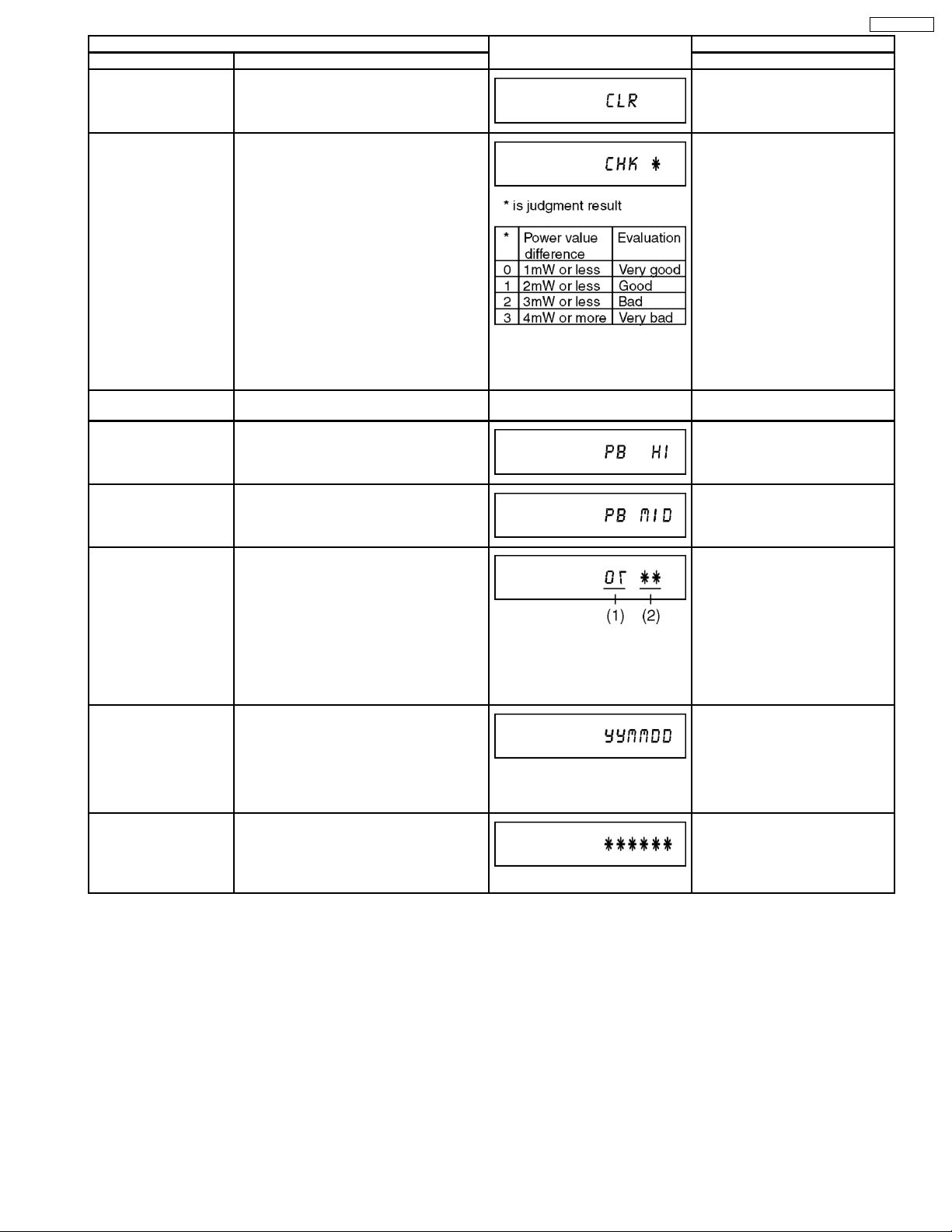

Item FL display Key operation

Mode name Description (Remote controller key)

Delete the Last Drive

Error

Delete the Last Drive Error information

stored on the DVD RAM-Drive.

Press [9] [6] in service mode.

DMR-EZ25EB

Laser power confirmation Drive state is judged based on difference

between laser power value at shipping and

present laser power value.

Turn on all FL/LEDs All segments of FL and all LEDs are turned

on.

PB HIGH Signal Output 8 pin of AV 1 Jack (PB HIGH terminal) is

High (approx. 11V DC).

PB MIDDLE Signal

Output

Front connection

inspection

8 pin of AV 1 Jack (PB HIGH terminal) is

Middle (approx. 5.5V DC)

Press all front keys and check the

connection between Main P.C.B. and Front

key Switches.

1.

Insert DVD-RAM disc

into RAM Drive in service

mode. (Other media are

assumed to be noncorrespondence.)

2. Press [4] [4].

If DVD-RAM disc in not inserted,

[NO DISC] is displayed.

If power value study was filed,

[ERROR] is displayed.

All segments are turned on. Press [5] [1] in service mode.

Press [5] [2] in service mode.

Press [5] [3] in service mode.

Press [5] [4] in service mode.

Production Date Display Display the date when the unit was produced.

Display the accumlated

Display the accumulated unit’s working time.

working time

(1) Each time a key is pressed,

segment turned on increases one

by one.

(2) Total umber of keys that have

been pressed.

Press [6] [1] in service mode.

YY: Year

MM: Month

DD: Day

Press [6] [4] in service mode.

(Indicating unit: Second)

19

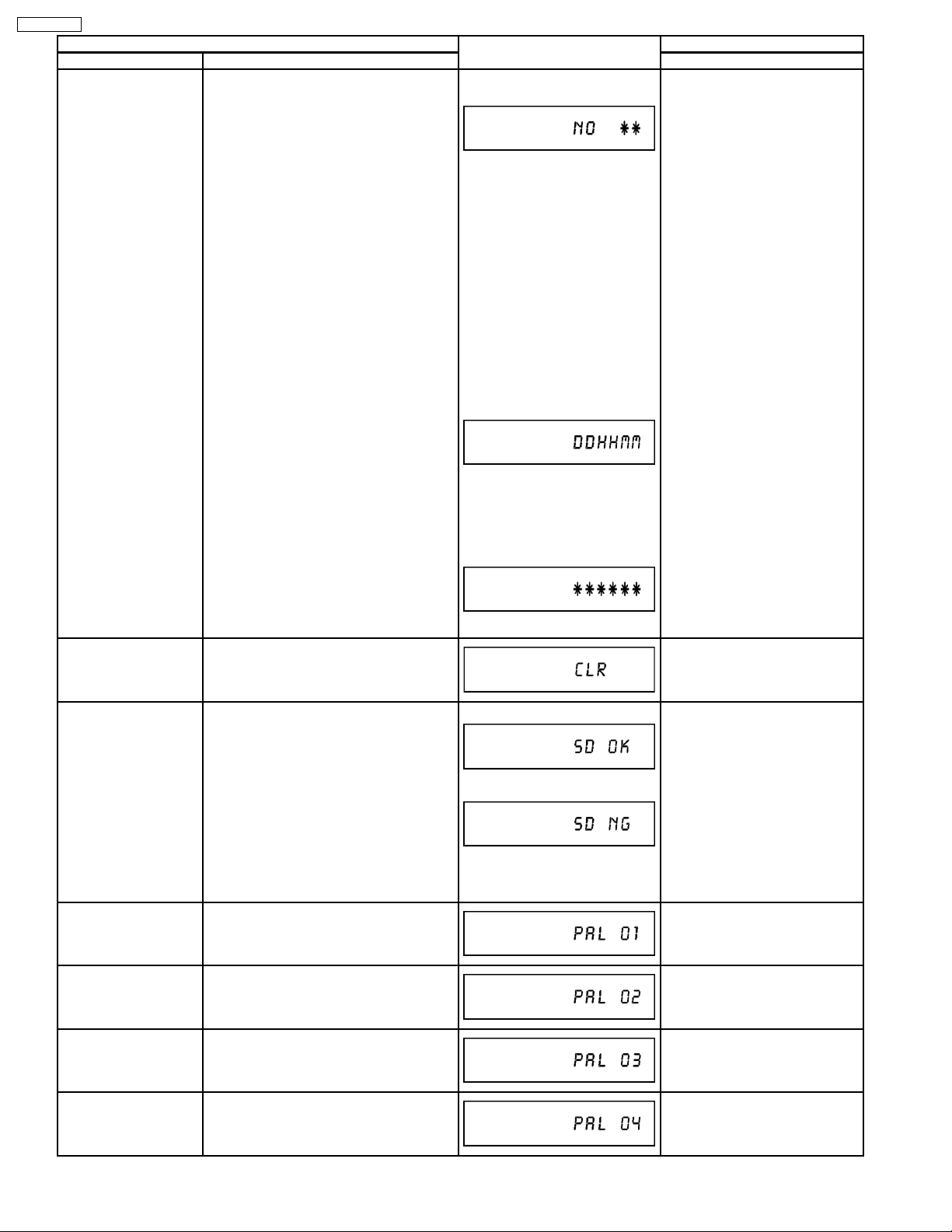

DMR-EZ25EB

Item FL display Key operation

Mode name Description (Remote controller key)

Display the Error History Display the Error History stored on the unit. Display reason of error for

5 seconds.

01:

Defect of Digital P.C.B.

(AV DEC / MAIN CPU)

02:

Defect of RAM Drive.

03:

Defect of Disc.

04:

Defect of Digital P.C.B. or

Communication Error.

05:

Defect of Digital P.C.B.

(AV DEC / MAIN CPU)

06:

Defect of HDD.

Display the time when the error

has occurred for 5 seconds.

Press [6] [5] in service mode.

Then press [0] [1] ~ [1] [9], the

past 19 error histories are

displayed.

Delete the Error History Delete Error History information stored on

SD card WRITE check Check SD card WRITE function with SD

AV4(V)/AV1(RGB) I/O

Setting

the unit.

slot.

Set input to AV4 (V) and set output to AV1

(RGB) for I/O checking

DD: Day

hh: Hour

mm: Minute

Accumulated working time till

occuring of the error is left

displayed.

(Indicating unit: Second)

When the WRITE check is OK.

When the WRITE check is NG.

*Note:

The image stored in the SD

card will be erased.

Press [9] [7] in service mode.

Insert a SC card to SD card slot,

and press [7] [4] in service mode.

* Insert SD card while the power is

off.

* Check for [CARD SD] display on

the FL display and go on the

procedure.

Press [8] [0] in service mode.

AV2(Y/C)/AV1(V) I/O

Setting

AV2(V)/AV1(Y/C) I/O

Setting

AV2(RGB)/AV1(V) I/O

Setting

Set input to AV2 (Y/C) and set output to

AV1 (V) for I/O checking

Set input to AV2 (V) and set output to AV1

(Y/C) for I/O checking

Set input to AV2 (RGB) and set output to

AV1 (V) for I/O checking

Press [8] [1] in service mode.

Press [8] [2] in service mode.

Press [8] [3] in service mode.

20

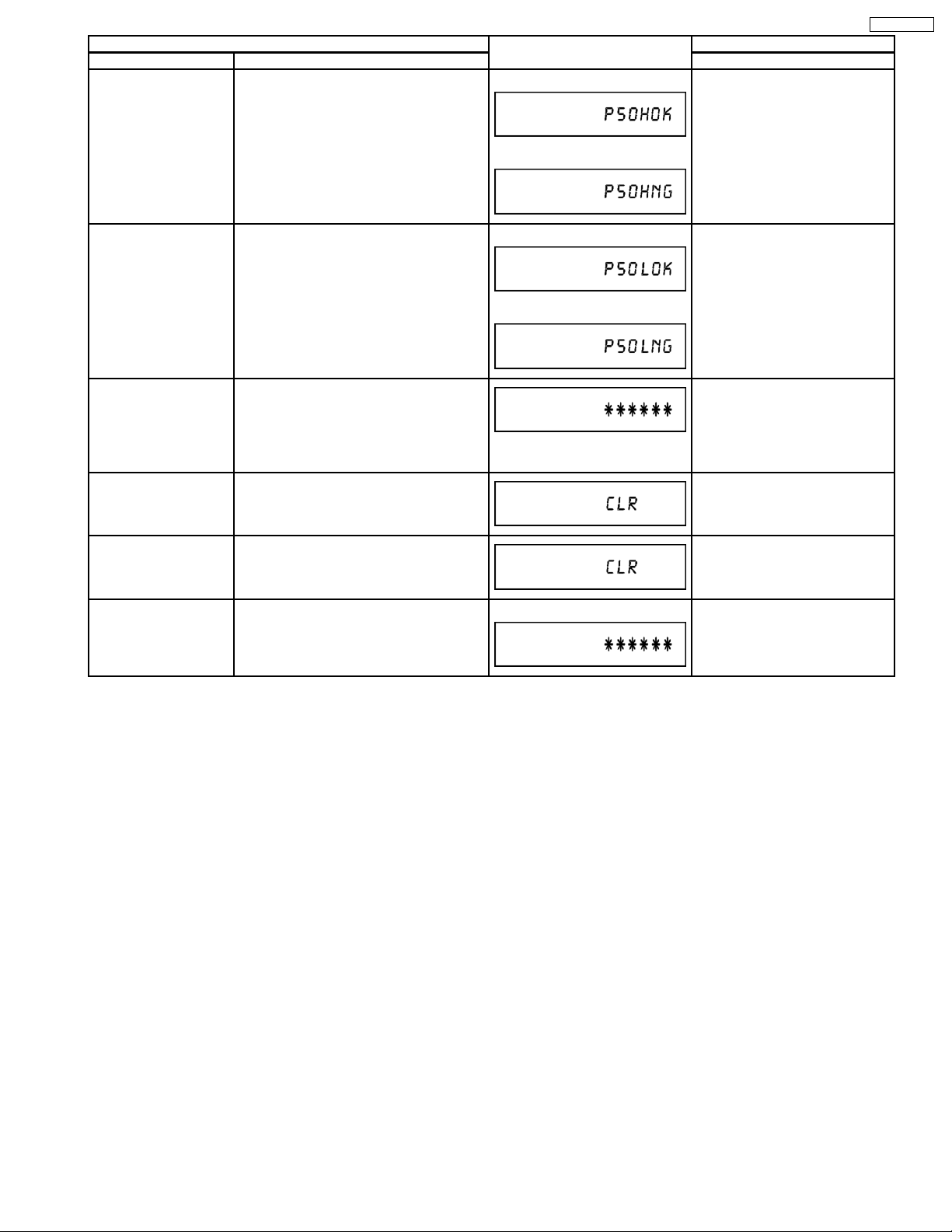

Item FL display Key operation

Mode name Description (Remote controller key)

P50(H) Output Timer Microprocessor IC7501-76 output

When OK.

Press [8] [4] in service mode.

High signal for AV1-pin 10 passing through

inverter (approx. 0V DC at AV1-pin 10).

When NG.

DMR-EZ25EB

P50(L) Output Timer Microprocessor IC7501-76 output Low

When OK.

Press [8] [5] in service mode.

signal for AV1-pin 10 passing through

inverter (approx. 4.4V DC at AV1-pin 10).

When NG.

Tray OPEN/CLOSE Test The RAM drive tray is opened and closed

repeatedly.

Press [9] [1] in service mode

*When releasing this mode, press

the [POWER] button of Remote

Controller more than 10 seconds.

“*” is number of open/close cycle

times.

Error code initialization Initialization of the last error code held by

Press [9] [8] in service mode.

timer (Write in F00)

Initialize Service Last Drive Error, Error history and Error

Press [9] [9] in service mode.

Codes stored on the unit are initialized to

factory setting.

Finishing service mode Release Service Mode. Display in STOP (E-E) mode. Press power button on the front

panel or Remote controller in

service mode.

21

DMR-EZ25EB

9 SERVICE FIXTURE AND TOOLS

Part Number Description Compatibility

RFKZ0260 Extension Cable (Main P.C.B. - RAM/Digital P.C.B. / 88 Pin) Same as EH50 Series

RFKZ0216 Extension Cable (Main P.C.B. - Power P.C.B. / 23 Pin) Same as E55 Series

RFKZ0366 Extension FFC (HDMI P.C.B. - RAM/Digital P.C.B. / 40 Pin / 500 mm) Same as EH55 / EH56 Series

RFKZ0168 Extension Cable (Power P.C.B. - Fan Motor / 3 Pin) Same as E50 / E55 Series

JZS0484 Eject Pin Same as ES15

RFKZ03D01K Lead Free Solder (0.3 mm / 100 g Reel) Same as ES15

RFKZ06D01K Lead Free Solder (O.6 mm / 100 g Reel) Same as ES15

RFKZ010D01 Lead Free Solder (1.0 mm / 100 g Reel) Same as ES15

RFKZ0316 Solder Remover (Lead free 10 W temperature Solder / 180 g) Same as ES15

RFKZ0328 Flux Same as ES15

RFKZ0329 Bottle of Flux Same as ES15

22

DMR-EZ25EB

10 ASSEMBLING AND DISASSEMBLING

Caution: Oringal screws shoul be used.

10.1. DISASSEMBLY FLOW CHART

This chart is the procedure for disassembling the casing and inside parts for internal inspection when carrying out the servicing.

To assemble the unit, reverse the steps shown in the chart below.

10.2. P.C.B. POSITIONS

23

DMR-EZ25EB

10.3. TOP CASE

10.5. SD CARD P.C.B.

1. Remove the 2 screws (A) and 3 screws (B).

2. Slide Top Case rearward and open the both ends at rear

side of the Top Case a little and lift the Top Case in the

direction of the arrows.

1. Release FFC

2. Remove 2 Screws (A) to remove SD Card P.C.B.

Caution:

When replacing P.C.B., pay attention as below.

10.4. FRONT PANEL

1. Unlock 2 tabs (A) and 3 tabs (B) in this order to remove

Front Panel.

The tab (A) and (B) should be unlocked at the same time,

respectively.

24

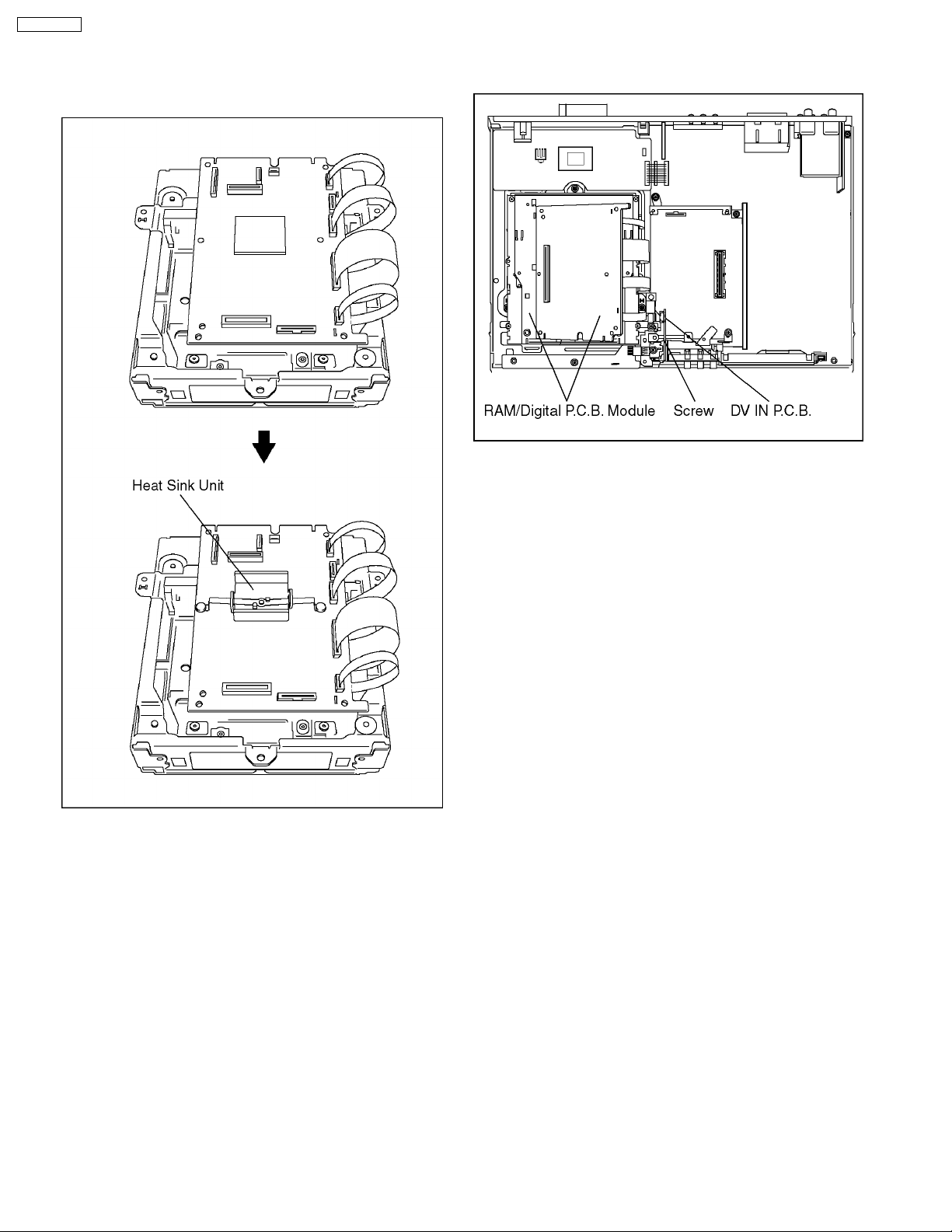

10.6. RAM DRIVE /

DIGITAL P.C.B. MODULE

Caution 1:

The DVD-RAM Drive and the Digital P.C.B. have to be

replaced together as one Module.

If the Module is changed the DVD-RAM Drive has to be realigned because the aligment data for the DVD-RAM Drive

is stored in the Digital P.C.B.

Caution 2:

When replacing Digital P.C.B., pay attention as below.

DMR-EZ25EB

1. Remove 3 Screws on DVD-RAM Drive.

2. Remove HDMI FFC from Digital P.C.B.

3. Lift up Digital P.C.B. slightly to disconnect Main P.C.B.

Connector and DV IN P.C.B. Connector on the bottom side.

4. Put Digital P.C.B. on DVD-RAM Drive and remove

RAM/DIGITAL P.C.B. Module.

25

DMR-EZ25EB

Note:

RAM/Digital P.C.B. Module as service part has no heat sink

unit. Before returning to customer, heat sink unit should be

installed on to Digital P.C.B.

10.7. DV IN P.C.B.

1. Remove the Screw to remove DV IN P.C.B.

26

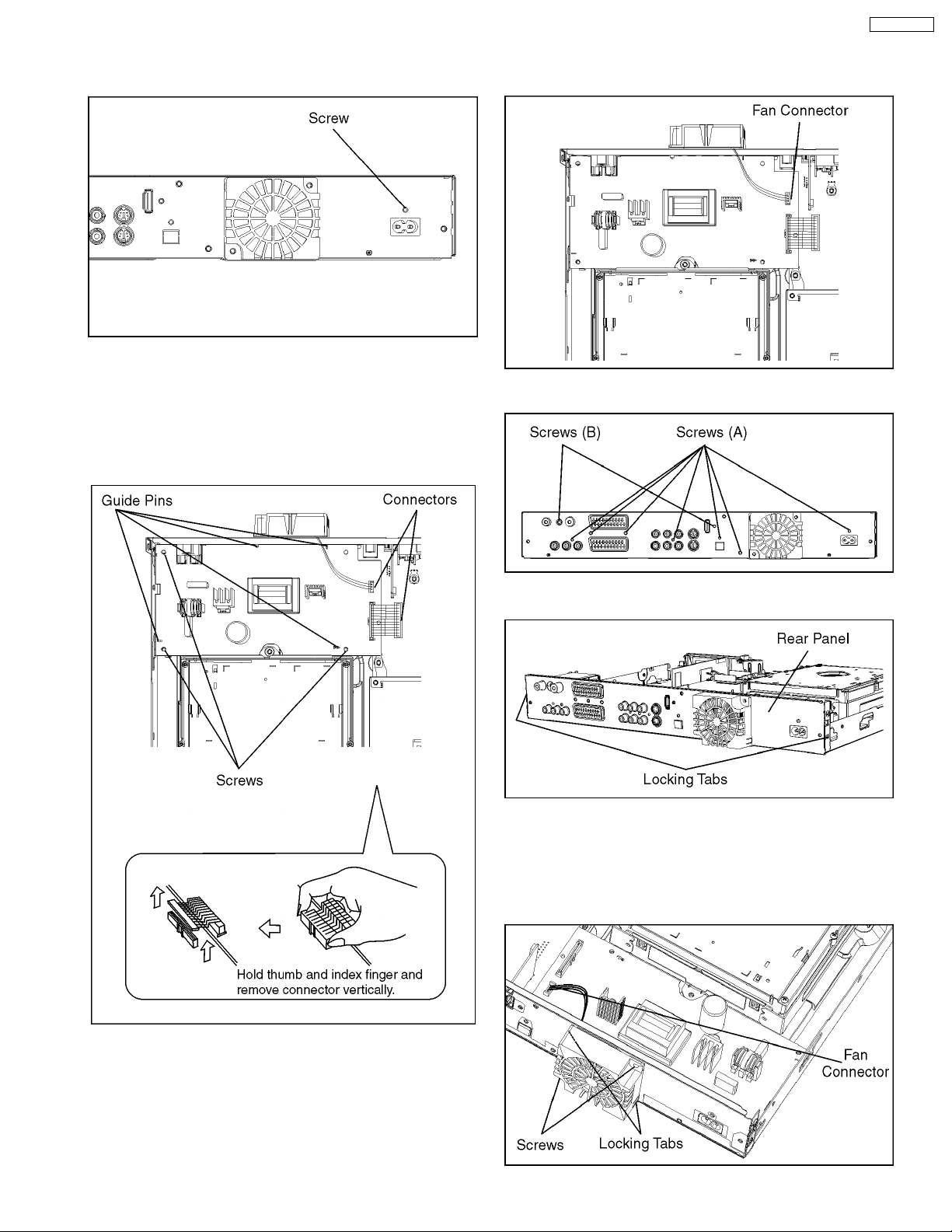

10.8. POWER P.C.B.

DMR-EZ25EB

10.9. REAR PANEL

1. Remove the Screw.

2. Remove 3 Screws and disconnect the 2 Connectors.

3. Lift up Power P.C.B. a little upwards and remove the P.C.B.

sideways out of the Guide Pins.

Note:

When inserting P.C.B. confirm correct positions

of Guide Pins.

1. Disconnect Fan Connector.

2. Remove 7 Screws (A) and 2 Screws (B).

3. Unlock 2 Locking Tabs to remove Rear Panel.

10.9.1. FAN MOTOR

1. Disconnect Fan Connector.

2. Remove the 2 Screws.

3. Push and unlock 2 locking Tabs to remove Fan Motor.

27

DMR-EZ25EB

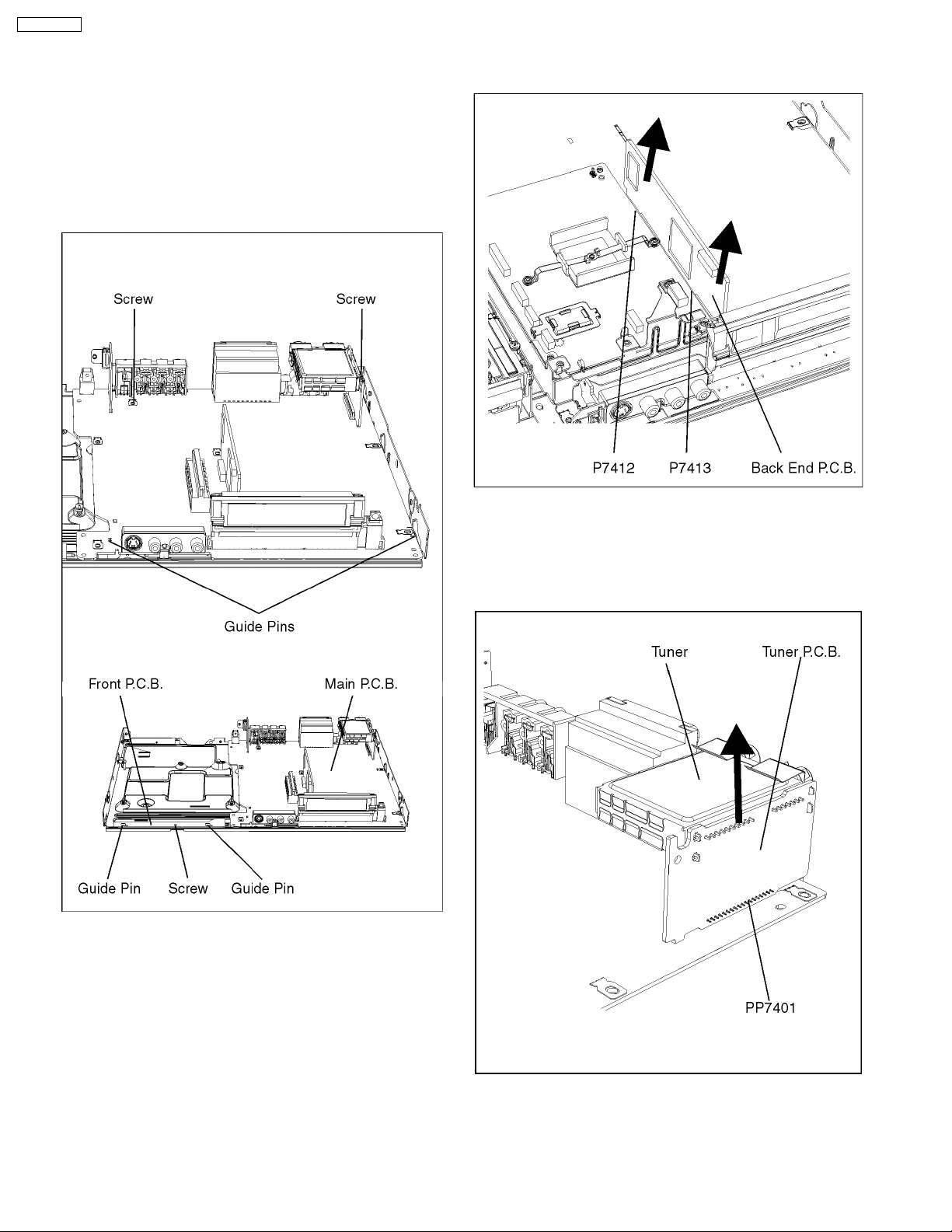

10.10. MAIN P.C.B. AND FRONT

P.C.B.

1. Remove 2 Screws from Main P.C.B.

2. Remove 1 Screw from Front P.C.B.

3. Pull out Main P.C.B. together with Front P.C.B. .

Note:

When inserting P.C.B. confirm correct positions

of Guide Pins.

10.11. BACK END P.C.B.

1. Pull out the Back End P.C.B. in the direction to the arrow.

10.12. TUNER P.C.B.

AND TUNER

1. Pull out the Tuner P.C.B. in the direction of the arrow.

2. Remove Solder and pull out Tuner from Tuner P.C.B.

28

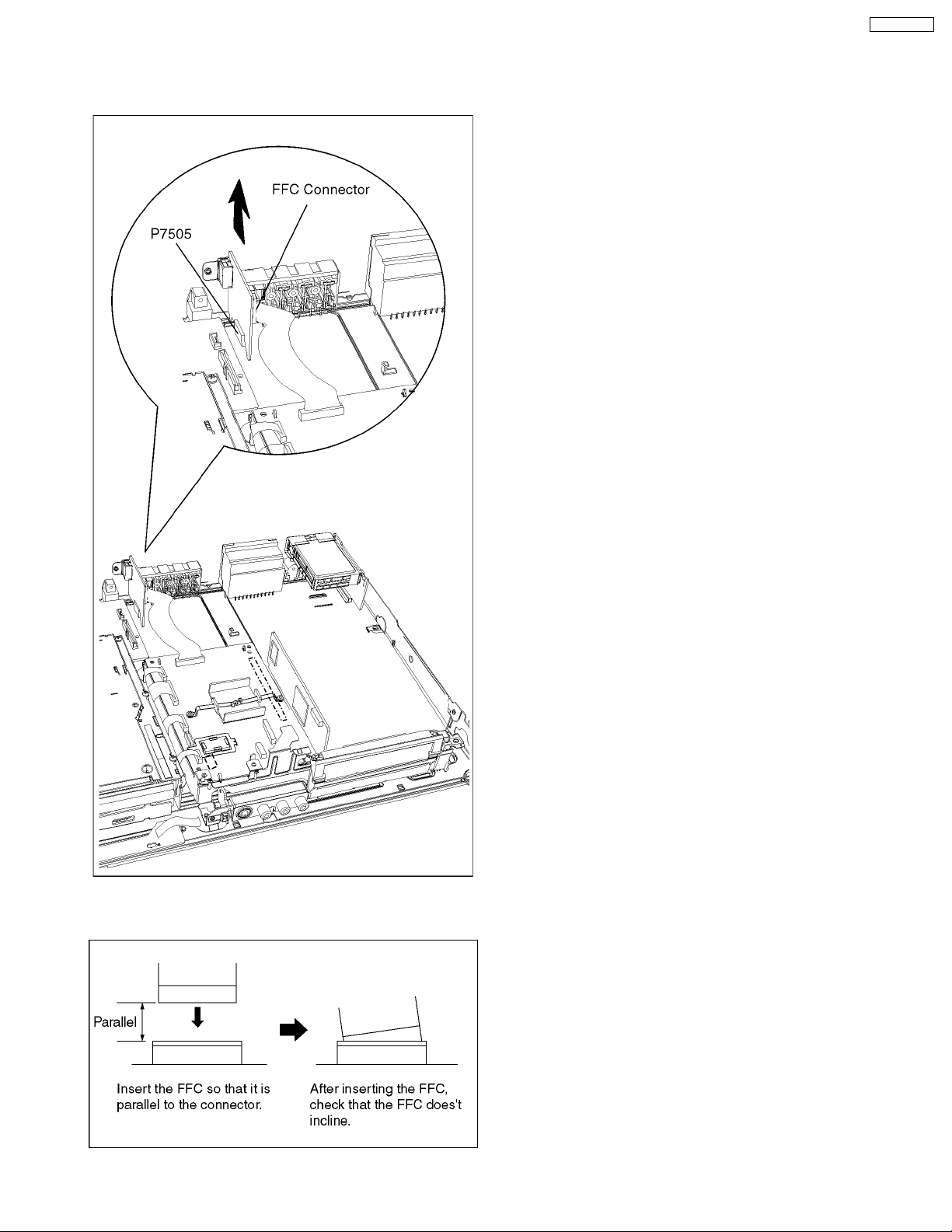

10.13. HDMI P.C.B.

1. Disconnect FFC Connector.

2. Pull out the HDMI P.C.B. in the direction of the arrow.

DMR-EZ25EB

Caution:

When replacing P.C.B., pay attention as below.

29

DMR-EZ25EB

11 MEASUREMENTS AND ADJUSTMENTS

11.1. SERVICE POSITION

Note:

For description of the disassembling procedure, see the section ASSEMBLING AND DISASSEMBLING

(DISASSEMBLY FLOW CHART).

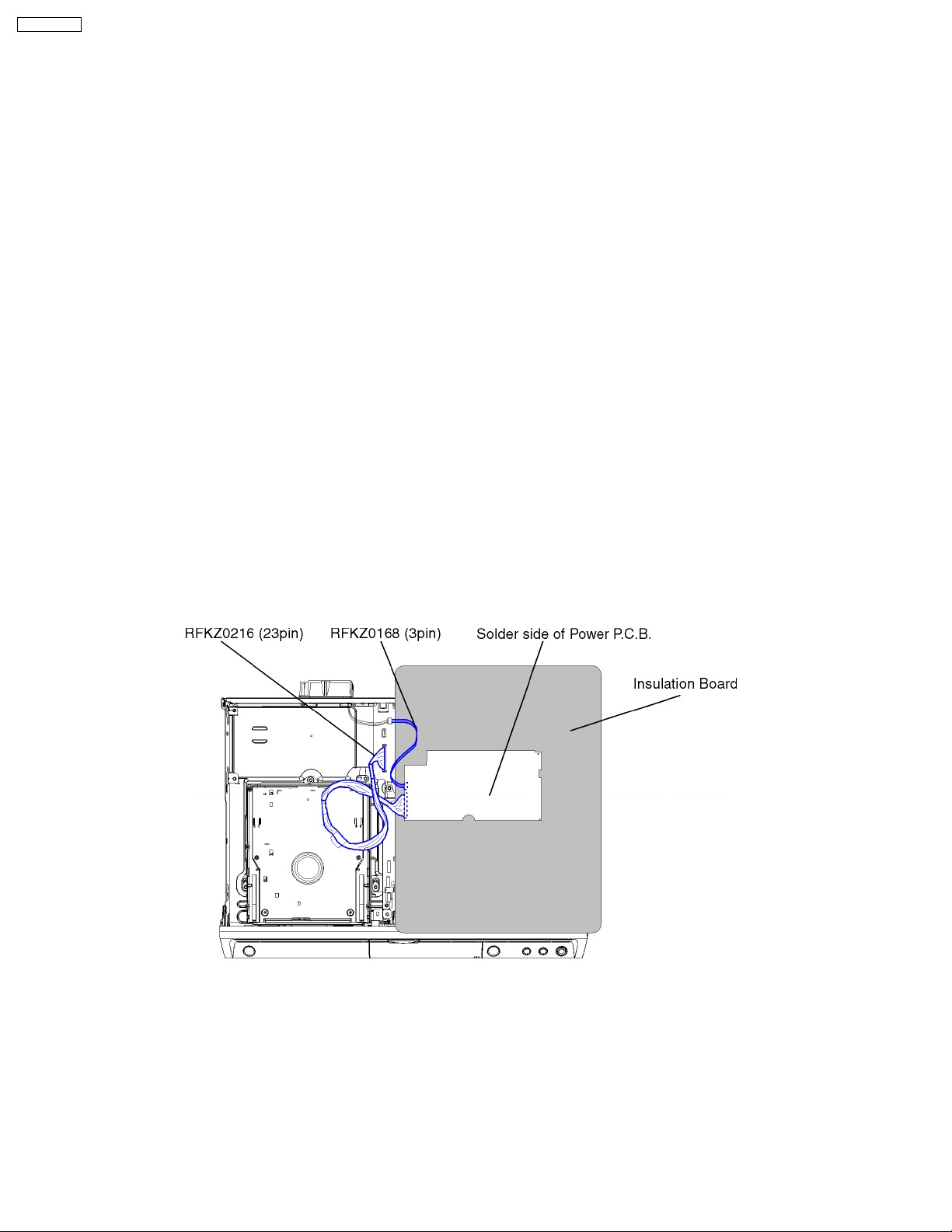

11.1.1. CHECKING AND REPAIRING OF POWER P.C.B.

1. Top Case

· Remove 2 Screws (A) on side

· Remove 3 rear Screws (B) on rear

· Remove Top Case

2. Power P.C.B.

· Remove 1 Screw for AC Inlet fixing

· Remove 3 Screws fixing Power P.C.B.

· Remove 1 Connector to Main P.C.B.

· Remove 1 Connector to Fan P.C.B.

· Lift up Power P.C.B. sideways out of the Guide Pins.

· Connect Extension Cable:

− between Main P.C.B. and Power P.C.B. with RFKZ0216

− between Fan Motor and Power P.C.B. with RFKZ0168

· Put Power P.C.B. on Insulation Board so that it’s solder side faces top

Caution 1

Red wire in the extension cable should be connected to pin 1

Caution 2

Orginal screws should be used

30

Loading...

Loading...