Page 1

OPERATING INSTRUCTIONS FOR THE O.S. TYPE 86 CARBURETTOR

The O.S. Type 86 carburettor has been designed exclusively for use with the O.S. PD-02 fuel pump unit. These two

components, with appropriate plumbing, form the O.S. PA-102 Pump System. The O.S. Pump Systems offer the twin

advantages

The Type 86 carburettor has an extra large throat, which improves breathing and increases power. With normal suction fuel

feed, or low-pressure (exhaust gas) assisted fuel feed, such a large choke area would be impracticable, but the special pump

unit

tive of fuel tank location or the aircraft's attitude.

These qualities are especially valuable for international

where it may be difficult to locate the fuel tank close to the engine.

The

available.

ensures

Type

of

increased

that

86

carburettor

fuel

power

is

delivered

is

and

not

the

virtual elimination

to

the carburettor at

suitable

for

engines

of

the

variation

pressure

in fuel

required

"head"

to

maintain

at the carburettor.

optimum

mixture strength,

class pattern aerobatic flying and in models (including scale aircraft)

not

equipped

with a pump:

for

these

the

O.S.

Type

7L

irrespec-

carburettor

is

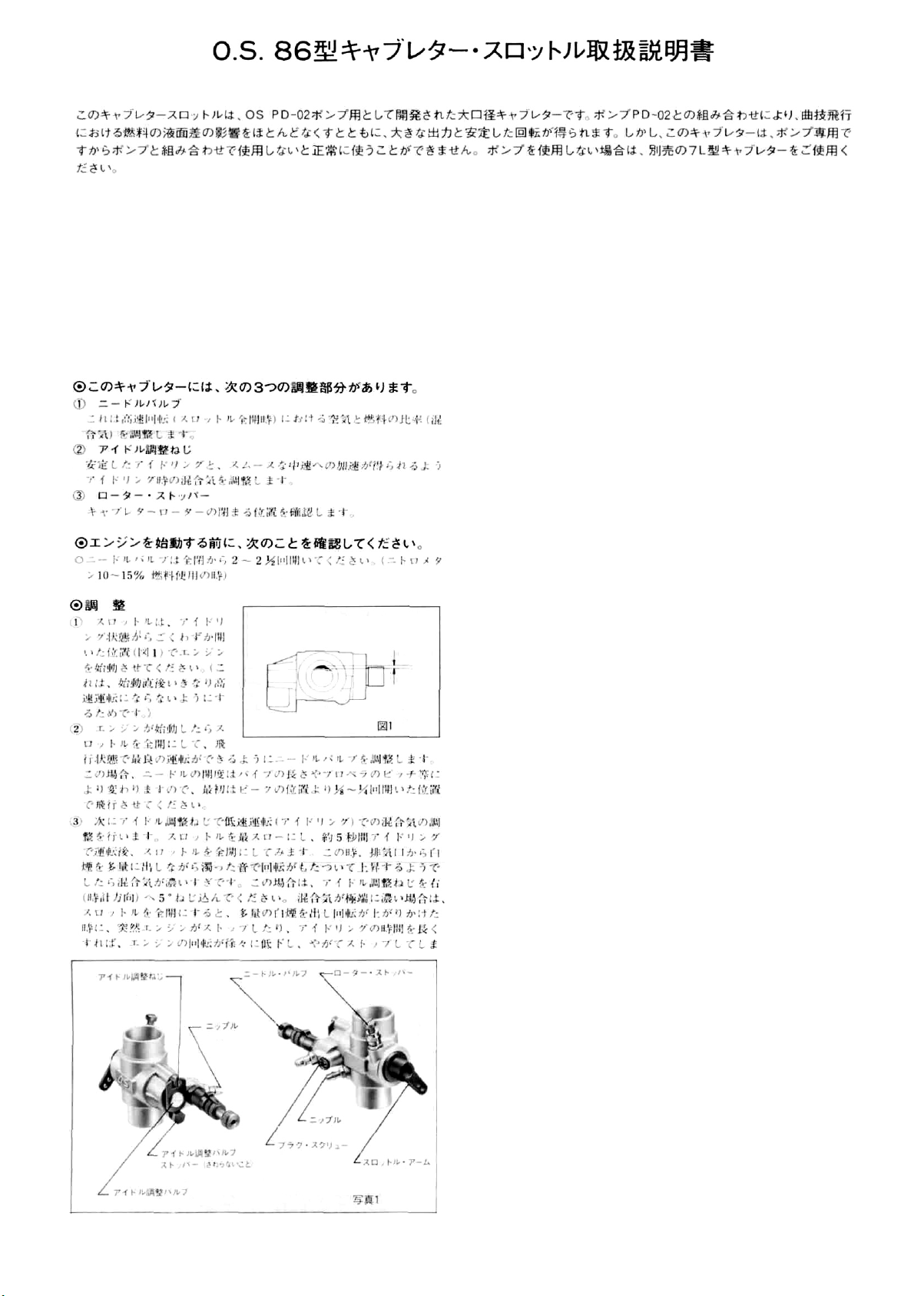

Idle Mixture

Control Screw

Mixture Control Valve Stopper

Mixture Control Valve

Nipple

Needle Valve

Plug Screw

Throttle Stop Screw

Nipple

Throttle Lever

1.5~2.0mm

Fig

Photo-1

Three adjustable controls are provided on the Type

86

carburettor. (See photo below.)

• The Needle Valve: For adjusting the mixture strength

when the throttle is fully open.

• The Mixture Control Screw:

For adjusting the mixture

strength at part-throttle and idling speeds to obtain

steady idling and smooth acceleration.

• The Throttle Stop Screw: For establishing the

minimum

idling speed.

PROVISIONAL SETTING

Before starting the engine, open the Needle-Valve three full

turns from the fully closed position.

ADJUSTING THE CARBURETTOR

1) Set the throttle very slightly open from the idle position

(see Fig. 1) and start the engine in the usual way. It is

preferable to have the throttle only slightly open, to

avoid unnecessarily high revolutions when the engine

starts.

2) Now open the throttle fully and gradually close the

Needle-Valve until the engine is running at its maximum

1

speed.*

* Warning:

(a) Do not close the Needle-Valve to too lean a setting,

as this will cause overheating which may result in

internal damage and reduced engine life. Set the

Needle-Valve approximately 1/8 to 1/4 turn open

(i.e. "rich") from the peak r.p.m. setting, even

though this will slightly reduce r.p.m. on the

ground.

(b)

Make sure

that

the

engine

is

fully

"run-in"

before

operating it continuously at full power. (See engine

instruction leaflet.)

3) Having set the Needle-Valve as described above, close the

throttle. The engine should idle steadily and continuously. (If it stops immediately, first try turning the Throttle

Stop Screw clockwise a few degrees to raise the idling

speed a little.)

(a) If, however, the engine idles unevenly and smokes a

good deal when the throttle is re-opened, before

picking up speed, it is probable that the idling mixture is too rich. In this case it will be necessary to

turn the Mixture Control Screw clockwise about 5

degrees.

(b) Alternatively, if the Mixture Control Screw is set

too lean, the engine may stop when the throttle is

closed, or it may idle for a few moments, then speed

up very slightly before coming to a stop. Re-opening

the throttle under these conditions will usually

result in the engine cutting out abruptly, without

smoking. Corrective action is to turn the Mixture

Control Screw about 5 degrees counter-clockwise.

Mixture Control Screw adjustment is not unduly critical,

but do not turn it more than 5 degrees at a time. Carry

Page 2

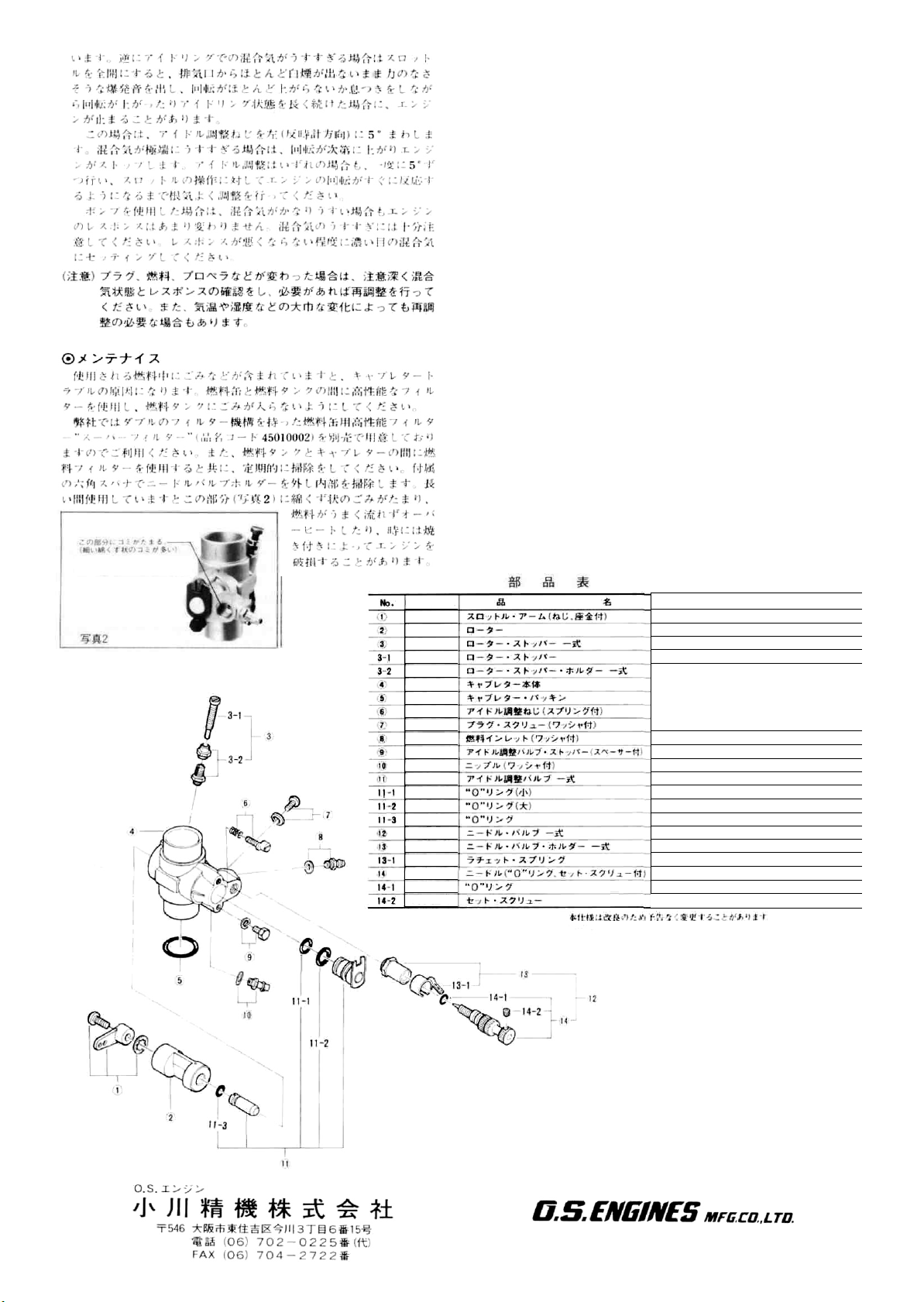

Dirand fibrous matter

mostly accumulate here

Photo 2

Code No.

27881400

27881200

27181600

27181620

27181610

27881100

29015019

27881330

27881120

22681953

27681340

22681953

27881300

27881800

27881810

27881820

27681900

27381940

26711305

27681970

24981837

26381501

out readjustments progressively and patiently, remembering the symptoms of rich and lean running,

quoted above, until the engine responds quickly and

positively to the throttle.

4) The Throttle Stop Screw is for fixing the minimum

idling speed. If, after carrying out mixture adjustments,

the idling speed is found to be too high, the Throttle

Stop Screw should be turned counter-clockwise until

the desired idling speed is obtained.

Note: Once the correct carburettor settings have been

established, it should be unnecessary to alter them.

Such slight needle-valve readjustments as may be

required to compensate for variations in atmospheric

conditions will not normally affect the other two

controls. Slight readjustments may be necessary for

optimum performance if different types of fuel,

glowplugs or propellers are used.

CARBURETTOR CLEANLINESS

The correct functioning of the carburettor depends on its

small fuel orifices remaining clear. The minute particles of

foreign matter that are present in any fuel can easily partially obstruct these orifices and upset mixture strength so that

engine performance becomes erratic and unreliable.

It is recommended that fuel is passed through a filter when

the tank is filled and that a good in-line filter is installed

between the fuel tank and carburettor and, furthermore,

that this filter is frequently cleaned to remove dirt and lint

that accumulates on the filter screen. Finally, occasionally

remove the needle-valve holder from the carburettor and

extract any remaining foreign matter that may have lodged

inside the carburettor.

PARTS LIST

Description

Throttle Lever Assembly (with screw 8 lock washer)

Carburettor Rotor

Throttle Stop Screw Assembly

Throttle Stop Screw

Throttle Stop Screw Holder Ass'y

Carburettor Body

Carburettor Rubber Gasket

Mixture Control Screw (with spring)

Plug Screw (with washer)

Fuel Inlet (with washer)

Mixture Control Valve Stopper (with spacer)

Nipple (with washer)

Mixture Control Valve Assembly

"0" Ring (S)

"0" Ring (L)

"0" Ring

Needle Valve Assembly

Needle Valve Holder Assembly

Ratchet Spring

Needle (with "0" ring & set-screw)

"0" Ring

Set-screw

The specifications are subject to alteration for improvement without notice

©

Copyright

1986

by

O.S. Engines Mfg. Co., Ltd. All rights reserved Printed in

6-15 3-chome Imagawa Higashisumiyoshi-ku

Osaka 546,Japan. TEL (06)702-0225

Japan

39007

FAX.

(06) 704-2722

Loading...

Loading...