O.S. Engines FS-52S User Manual

It is of vital importance, before attempting to operate your engine, to read the general

'SAFETY INSTRUCTIONS AND WARNINGS' section on pages 2-6 of this booklet and to strictly adhere to the advice contained therein.

●Also, please study the entire contents of this instruction manual, so as to familiarize yourself with the controls and other features of the engine.

●Keep these instructions in a safe place so that you may readily refer to them whenever necessary.

●It is suggested that any instructions supplied with the aircraft, radio control equipment, etc., are accessible for checking at the same time.

CONTENTS

SAFETY INSTRUCTIONS AND WARNINGS |

2~6 |

RUNNING -IN |

15~16 |

|

ABOUT YOUR O.S. ENGINE |

|

IDLING MIXTURE ADJUSTMENT |

16~17 |

|

|

|

|||

INTRODUCTION,BASIC ENGINE PARTS |

7 |

VALVE ADJUSTING |

17~20 |

|

|

|

|||

INSTALLATION |

8 |

CARE AND MAINTENANCE |

20~21 |

|

|

|

|||

EXHAUST HEADER PIPE AND SILENCER, |

|

ENGINE EXPLODED VIEW |

22 |

|

THROTTLE LINKAGE, NEEDLE-VALVE EXTENSION |

9 |

|||

PROPELLERS, FUEL |

10 |

ENGINE PARTS LIST |

23 |

|

GLOWPLUG |

11 |

CARBURETTOR EXPLODED |

|

|

|

|

VIEW & PARTS LIST |

24 |

|

FUEL AND PRESSURE LINES, |

|

GENUINE PARTS & ACCESSORIES |

25 |

|

PROPELLER AND SPINNER ATTACHMENT |

12 |

|||

|

|

|||

TYPE 40N CARBURETTOR, |

|

THREE VIEW DRAWING |

26 |

|

|

|

|

||

CONTROL LOCATIONS |

13 |

|

|

|

STARTING |

14~15 |

|

|

1

SAFETY INSTRUCTIONS AND WARNINGS ABOUT YOUR O.S. ENGINE

Remember that your engine is not a "toy", but a highly efficient internalcombustion machine whose power is capable of harming you, or others, if it is misused.

As owner, you, alone, are responsible for the safe operation of your engine, so act with discretion and care at all times.

If at some future date, your O.S. engine is acquired by another person, we would respectfully request that these instructions are also passed on to its new owner.

The advice which follows is grouped under two headings according to the degree of damage or danger which might arise through misuse or neglect.

The advice which follows is grouped under two headings according to the degree of damage or danger which might arise through misuse or neglect.

WARNINGS

WARNINGS

These cover events which might involve serious (in extreme circumstances, even fatal) injury.

NOTES

NOTES

These cover the many other possibilities, generally less obvious sources of danger, but which, under certain circumstances, may also cause damage or injury.

2

WARNINGS

WARNINGS

•Never touch, or allow any object to come into contact with, the rotating

propeller and do not crouch over the engine when it is running.

•A weakened or loose propeller may disintegrate or be thrown off and, since propeller tip speeds with powerful engines may exceed 600 feet(180 metres) per second, it will be understood that such a failure could result in serious injury, (see 'NOTES' section relating to propeller safety).

•Model engine fuel is poisonous. Do not allow it to come into contact with the eyes or mouth. Always store it in a

clearly marked container and

out of the reach of children.

•Model engine fuel is also highly flammable. Keep it away from open flame, excessive heat, sources of sparks, or anything else which might

ignite it. Do not smoke or allow anyone else to smoke, near to it.

•Never operate your engine in an enclosed space. Model engines, like automobile engines, exhaust deadly carbonmonoxide. Run your engine only in an open area.

•Model engines generate considerable heat. Do not touch any part of your engine until it has cooled. Contact with the muffler (silencer),

cylinder head or exhaust header pipe, in particular, may result in a serious burn.

3

NOTES

•This engine was designed for model aircraft. Do not attempt to use it for any other purpose.

•Mount the engine in your model securely, following the manufacturers' recommendations, using appropriate screws and locknuts.

•Be sure to use the silencer (muffler) supplied with the engine. Frequent exposure to an open exhaust may eventually impair your hearing.

Such noise is also likely to cause annoyance to others over a wide area.

•If you remove the glowplug from the engine and check its condition by connecting the battery leads to it, do not hold the plug with bare fingers.Use an appropriate tool or a folded piece of cloth.

•Fit a top-quality propeller of the diameter and pitch specified for the engine and aircraft. Locate the propeller on the shaft so that the curved face of the blades faces forward-i.e. in the direction of flight. Firmly tighten the propeller nut, using the correct size wrench.

4

NOTES

•Always check the tightness of the propeller nut and retighten it, if necessary, before restarting the engine, particularly in the case of four-stroke-cycle engines. If a safety locknut assembly is provided with your engine, always use it. This will prevent the propeller from flying off in the event of a "backfire", even if it loosens.

•If you fit a spinner, make sure that it is a precision made product and that the slots for the propeller blades do not cut into the blade roots and weaken them.

•Preferably, use an electric starter. The wearing of safety glasses is also strongly recommended.

•Discard any propeller which has become split, cracked, nicked or otherwise rendered unsafe. Never attempt to repair such a propeller: destroy it. Do not modify a propeller in any way, unless you are highly experienced in tuning propellers for specialized competition work such as pylon-racing.

•Take care that the glow plug clip or battery leads do not come into contact with the

propeller. Also check the linkage to the throttle arm. A disconnected linkage could also foul the propeller.

•After starting the engine, carry out any needle-valve readjustments from a safe

position behind the rotating propeller. Stop the engine before attempting to make other adjustments to the carburettor.

5

NOTES

•Adjust the throttle linkage so that the engine stops when the throttle stick and trim lever on the transmitter are fully retarded. Alternatively, the engine may be stopped by cutting off the fuel supply. Never try to stop the engine physically.

•Take care that loose clothing (ties, shirt sleeves, scarves, etc.)do not come into contact with the propeller.Do not carry loose objects (such as pencils, screwdrivers, etc.) in a shirt pocket from where they could fall through the propeller arc.

•Do not start your engine in an area containing loose gravel or sand.

The propeller may throw such material in your face and eyes and cause injury.

•For their safety, keep all onlookers (especially small children) well back (at least 20 feet or 6 meters) when preparing your model for flight. If you have to carry the model to the take-off point with the engine running, be especially cautious. Keep the propeller pointed away from you and walk well clear of spectators.

•Warning! Immediately after a glowplugignition engine has been run and is still warm, conditions sometimes exist whereby it is just possible for the engine to abruptly restart if the propeller is casually flipped over compression WITHOUT the glowplug battery being reconnected. Remember this if you wish to avoid the risk of a painfully rapped knuckle!

6

INTRODUCTION

Having pioneered the development of fourstroke cycle model aircraft engines in 1976, O.S. has maintained a continuing program of technological advancement, examples of which, would include the line of beautiful multi-cylinder engines, with many new engine designs continually under development. One of the latter is this new FS52S model. Closely resembling the FS-48S externally, the FS-52S combines increased performance and improved durability at virtually no increase in overall dimensions or weight.

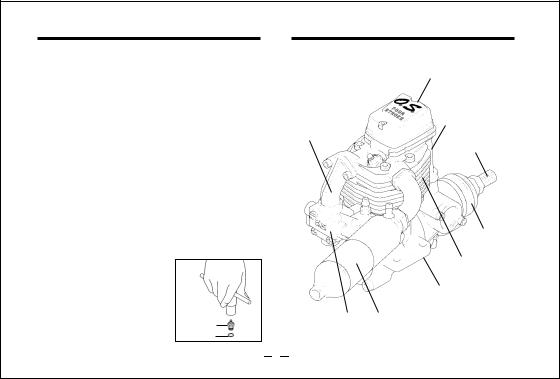

INSTALLING THE GLOWPLUG

Fit washer to glowplug and |

|

insert carefully into cylinder- |

|

head, making sure that it is |

|

not cross-threaded |

|

before tightening firmly. |

Glow plug |

|

Washer |

BASIC ENGINE PARTS

Rocker Cover

Push Rod Cover

Intake Pipe

Crankshaft

Drive Hub

Crankcase

Beam Mount

Carburettor Silencer

7

INSTALLATION

Installation in the model

A typical method of beam |

O.S. radial motor mount |

|

(Available as an optional extra part. |

||

mounting is shown below,left. |

||

See parts list) |

||

|

|

Rigid hardwood |

|

|

(e.g. maple) |

|

At least |

At least |

|

15mm(19/32") |

||

15mm(19/32") |

Make sure that the mounting beams are parallel and that their top surfaces are in the same plane.

CORRECT |

INCORRECT |

||

Front view |

Side view |

Top surfaces are not |

|

in the same plane. Opposite beam |

|||

|

|

|

Top surfaces |

|

|

Re-align the surfaces |

are not in the |

|

|

as necessary |

same plane. |

Engine does

Top surfaces are in the same plane.

not rest firmly.

How to fasten the mounting screws.

|

Tighten second nut firmly |

|

|

down onto first nut. |

|

3.5mm steel nuts |

Tighten this nut first. |

|

Spring washer or |

||

|

||

lock washer |

|

|

15mm min. |

Hardwood such as |

|

cherry or maple. |

||

|

||

15mm min. |

Steel washer |

3.5mm steel screw

Hardwood mounting beams

3.5mm steel Allen screw

O.S. radial motor mount (cast aluminum)

8

Loading...

Loading...