Page 1

INSTRUCTIONS FOR O.S. TYPE 7B. 5B.4BK-4D & 4E AUTOMATIC CARBURETTOR

This new carburettor incorporates an automatic mixture control device which ensures that the engine receives a

correctly balanced mixture of fuel and air at all throttle settings. The device progressively reduces the effective

size of the fuel jet orifice as the throttle is closed, thereby preventing the engine from running too rich at low

speeds. This also means that an airbleed is no longer required and, with its elimination, maximum suction is maintained at the fuel jet at all times. This is a most important factor where manoeuvres have to be executed at low engine

speeds and through wide variations of fuel level within the fuel tank.

Under

average

normally function satisfactorily as factory set. Simply start the

engine in the normal way and adjust the needle-valve for

maximum r.p.m. On closing the throttle, the engine should idle

at between 2,000 and 2,500 r.p.m. and also run steadily at all

intermediate speeds. However, different fuels and/or climatic

conditions, may require minor readustments for optimum

results.

operating

conditions,

the

carburettor

will

MAX-60FSR

ADJUSTING THE CARBURETTOR

Three adjustable controls are provided on this carburettor:

(1) The Needle-Valve (located on left-hand side of

carburettor).

(2) The Mixture Control Valve (recessed screw on right-hand

side).

(3) The Throttle Rotor Set-Screw (angled at rear of body).

I.

The Needle-Valve is used in the same way as on all model

engines, i.e., for adjusting the high-speed mixture strength.

Start the engine and, with the throttle fully open, gradually

close the Needle-Valve until it is running at its maximum

speed. Caution: Do not close Needle-Valve to too "lean" a

setting as this will cause the engine to overheat and slow up.

Set the Needle-Valve very slightly

peak r.p.m. setting. Make sure that the engine is fully

"broken-in" (about 1 hour of total running time in short runs)

before operating it continuously at full throttle.

II. The Mixture Control Screw is for adjusting fuel mixture

strength at part-throttle and idling speeds. Having set the

Needle-Valve as detailed above, close the throttle. The engine

should idle continuously and steadily without further

adjustment.

(a) If, however, the engine begins to idle unevenly, open the

throttle. If the engine then hesitates before picking up to full

speed, it is probable that the idling mixture is too rich. Check

this by closing the throttle again and letting the engine idle for

a little longer before again opening up. If the engine now puffs

out a good deal of smoke and hesitates or even stops, it will

be necessary to close the Mixture Control Screw. Do this by

inserting a small screwdriver into the recessed screw on the

right-hand side and turning it clockwise. About a quarter turn

should be sufficient.

to

the

"rich"

side of

the

Page 2

(b) If instead of being set too rich, the Mixture Control

Screw is set too lean, the engine will stop when the throttle is

closed, or will lose speed while idling and then cut-out

abruptly (without smoking) when the throttle is opened again.

In this case, turn the Mixture Control Screw about one-half

turn counter-clockwise.

Mixture Control Screw adjustment is not critical and by

remembering the symptoms of rich and lean running quoted

above, it is a very simple matter to establish the best setting.

III. The Throttle Rotor Set-Screw is for establishing the

minimum idling speed. If the engine runs too fast with the

throttle closed, the Rotor Set-Screw should be turned

counter-clockwise to allow the throttle opening to be reduced.

CARBURETTOR INSERT

A muffler pressurised fuel system should be used with the Type

7B carburettor for best results. If, however, ordinary suction

feed is to be used, it is advisable to fit the carburettor insert,

which is supplied, as follows:

(1) Unscrew rotor set-screw and remove

(2) Remove the mixture control screw.

(3) Insert the carburettor insert into the throttle rotor throat.

(4) Reassemble carburettor.

SUBSEQUENT OPERATION AND CARE

Once the required settings have been established it should be

unnecessary to alter them. Such slight needle-valve alterations

as may be necessary to cope with differences in atmospheric

conditions or fuels, do not affect the other two adjustments.

The engine should start readily with the throttle in the idle

position.

It is important that the carburettor operates under clean

conditions. Make sure that fuel is properly filtered before use.

We advise fitting a filter to your fuel can and another filter in

the delivery tube between tank and engine, to reduce the risk

of the carburettor jet becoming partially clogged and upsetting

running adjustments.

rotor.

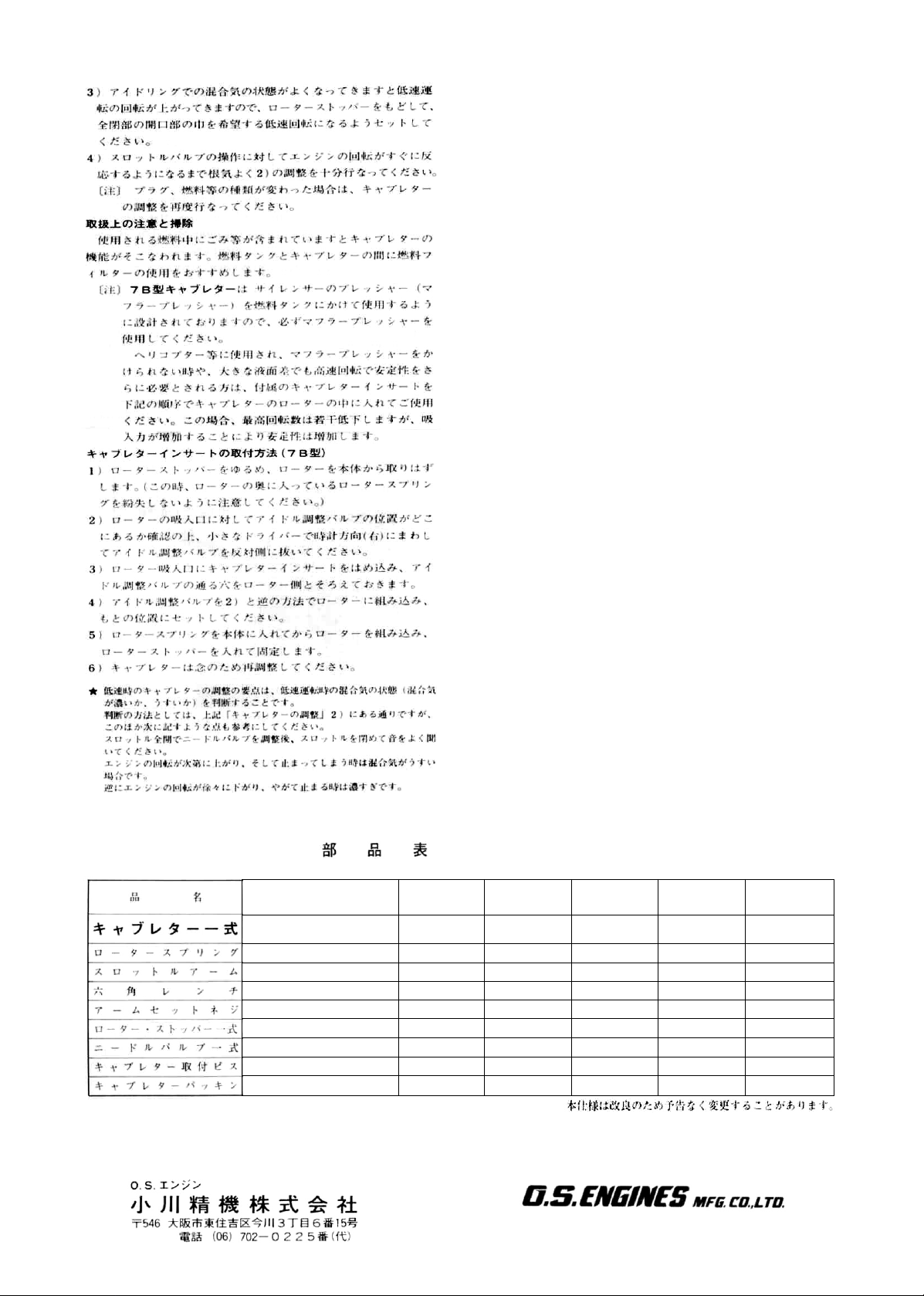

Description

Carburettor Complete

Rotor spring

Throttle lever

Hex key wrench

Throttle lever set-screw

Rotor set-screw Assembly

Needle valve Assembly

Throttle

fixing

screw

Carburettor gasket

PARTS LIST

7B Code No.

26781008

26781506

26781402

26381548

26381501

26781619

26881931

25081700

22115002

The specification is subject to alteration for improvement without notice.

5B Code No.

25181009

26781506

26781402

26381548

26381501

2678161 9

24981930

25081700

22115002

6-15 3-chome Imagawa Higashisumiyoshi-ku

Osaka 546, Japan. TEL. Osaka (06) 702-0225

4BK Code No.

24981029

26781506

24981405

26381548

26381501

26781619

26781938

25081700

22115002

4D Code No.

25381006

26781506

24981405

26381 548

26381501

26781619

24981930

25081700

2211 5002

4E Code No.

25383000

26781506

24981405

26381 548

26381501

26781619

26781938

Loading...

Loading...