Omron ZEN Communications Manual

Authorized Distributor:

Man. No. Z212-E1-01 Note: Specifications subject to change without notice. Printed in Japan

0206-?M(0206

(?)

Man. No. Z212-E1-01

Preface

OMRON products are manufactured for use according to proper procedures by a qualified operator and

only for the purposes described in this manual.

The ZEN is a compact and highly functional controller that can be used to easily automate small-scale

applications. Its development has drawn on OMRON's advanced control technology and expertise in

manufacturing various types of controllers.

Version 2 of the ZEN includes Economy-type CPU Units and Communications-type CPU Units. Twin timer

operation and operation between days for weekly timers have been added. Pulse output operation and 8digit counters with high-speed counting have also been added, and Expansion I/O Units have been

downsized to half the width.

This manual describes the communications functions of Communications-type CPU Units. When using a

Communications-type CPU Unit, read this manual and be sure to use the communications functions

correctly. Keep the manual close at hand so that you can refer to it whenever necessary.

● Intended Audience

This manual is intended for the following readers.

• Persons in charge of introducing FA devices

• Persons who design FA systems

• Persons who install or connect FA devices

• Persons who manage working FA installations

Persons who use this product must have sufficient knowledge of electrical systems (i.e., an electrical

engineer or the equivalent).

ii

Warranty and Application Considerations

Read and Understand this Manual

Please read and understand this manual before using the product. Please consult your OMRON

representative if you have any questions or comments.

Warranty and Limitations of Liability

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and

workmanship for a period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED,

REGARDING NON-INFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR

PURPOSE OF THE PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE

BUYER OR USER ALONE HAS DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET

THE REQUIREMENTS OF THEIR INTENDED USE. OMRON DISCLAIMS ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL

DAMAGES, LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH

THE PRODUCTS, WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY,

NEGLIGENCE, OR STRICT LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the

product on which liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER

CLAIMS REGARDING THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT

THE PRODUCTS WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED

AND NOT SUBJECT TO CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE

MODIFICATION OR REPAIR.

iii

Application Consideration

SUITABILITY FOR USE

THE PRODUCTS CONTAINED IN THIS DOCUMENT ARE NOT SAFETY RATED. THEY ARE

NOT DESIGNED OR RATED FOR ENSURING SAFETY OF PERSONS, AND SHOULD NOT BE

RELIED UPON AS A SAFETY COMPONENT OR PROTECTIVE DEVICE FOR SUCH

PURPOSES. Please refer to separate catalogs for OMRON's safety rated products.

OMRON shall not be responsible for conformity with any standards, codes, or regulations that

apply to the combination of products in the customer’s application or use of the product.

At the customer’s request, OMRON will provide applicable third party certification documents

identifying ratings and limitations of use that apply to the products. This information by itself is not

sufficient for a complete determination of the suitability of the products in combination with the

end product, machine, system, or other application or use.

The following are some examples of applications for which particular attention must be given.

This is not intended to be an exhaustive list of all possible uses of the products, nor is it intended

to imply that the uses listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or

conditions or uses not described in this document.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems,

medical equipment, amusement machines, vehicles, safety equipment, and installations subject

to separate industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE

OR PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN

DESIGNED TO ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT IS PROPERLY

RATED AND INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR

SYSTEM.

iv

Disclaimers

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and

other reasons.

It is our practice to change model numbers when published ratings or features are changed, or

when significant construction changes are made. However, some specifications of the products

may be changed without any notice. When in doubt, special model numbers may be assigned to

fix or establish key specifications for your application on your request. Please consult with your

OMRON representative at any time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even

when tolerances are shown.

PERFORMANCE DATA

Performance data given in this manual is provided as a guide for the user in determining

suitability and does not constitute a warranty. It may represent the result of OMRON's test

conditions, and the users must correlate it to actual application requirements. Actual performance

is subject to the OMRON Warranty and Limitations of Liability.

ERRORS AND OMISSIONS

The information in this document has been carefully checked and is believed to be accurate;

however, no responsibility is assumed for clerical, typographical, or proofreading errors, or

omissions.

Copyright and Copy Permission

Copyright and Copy Permission

COPYRIGHT AND COPY PERMISSION

This document shall not be copied for sales or promotions without permission.

This document is protected by copyright and is intended solely for use in conjunction with the

product. Please notify us before copying or reproducing this document in any manner, for any

other purpose. If copying or transmitting this document to another, please copy or transmit it in its

entirety.

v

Precautions

This section provides precautions for using the ZEN Programmable Relays.

This information contained in this section is important for the safe and reliable application of the ZEN. You must read

this section and understand the information before attempting to set up for a ZEN.

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .viii

Precautions for Safe Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

Precautions for Correct Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xii

vii

Precautions

Safety Precautions

Definition of Precautionary Information

The following notation is used in this manual to provide precautions required to ensure safe usage of the product.

The safety precautions that are provided are extremely important to safety. Always read and heed the information

provided in all safety precautions.

The following notation is used.

Indicates a potentially hazardous situation which, if not avoided, will result in minor or

WARNING

moderate injury, or may result in serious injury or death. Additionally, there may be significant

property damage.

CAUTION

Symbols

Caution

Prohibition

Mandatory

Caution

Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury or in property damage.

Symbol Meaning

General Caution

Indicates non-specific general cautions, warnings, and dangers.

Electrical Shock Caution

Indicates possibility of electric shock under specific conditions.

Explosion Caution

Indicates possibility of explosion under specific conditions.

Disassembly Prohibition

Indicates prohibitions when there is a possibility of injury, such as from electric shock,

as the result of disassembly.

General Caution

Indicates non-specific general cautions, warnings, and dangers.

viii

Precautions

WARNIN G

Serious human hazard may occasionally occur due to ignition or rupture of the lithium battery used in

the Battery Unit. Do not short the battery terminals or charge, disassemble, deform under pressure,

or incinerate the battery.

Never use any battery that has been dropped on the floor or otherwise

subjected to excessive shock.

CAUTION

Electric shock, fire, or malfunction may occur. Do not disassemble, modify, or repair the ZEN or touch

any of the internal parts.

Electrical shock may occur. Never touch the I/O terminals, computer connector, Expansion Unit

connector, or Battery Unit connector while power is being supplied.

Electrical shock may occur. Do not remove the Expansion Unit connector cover unless an Expansion

I/O Unit will be permanently installed.

Fires may occasionally occur. Tighten the terminal block screws to the specified torque (0.5 to 0.6

N·m) so that they do not become loose.

Precautions

ix

Precautions

Precautions for Safe Use

Please observe the following precautions for safe use of this products.

Circuit Design

1. All interface connectors and battery connector are live parts, they may not be directly connected to Softy Extra

Low Voltage (SELV) circuit or to accessible conductive parts.

For the programming units and Personal Computers use only the ZEN-CIF01 Connecting Cable (optional

accessory) manufactured by OMRON.

ZEN-CIF01 provides safe (reinforced) insulation between Personal Computers and ZEN.

2. Provide emergency stop circuits, external interlock circuits, limit circuits, and other safety circuits in addition to

any provided within the ZEN control circuits to ensure safety of the overall system in the event of ZEN failure or

external factors.

3. If the ZEN discovers an error during self-diagnosis, operation will be stopped and all outputs will be turned OFF.

As a countermeasure for such problems, external safety measures must be provided to ensure safety in the

overall system.

4. Outputs from the ZEN may remain ON or OFF due to faults in internal circuits such as output relay fusing or

burning, or output transistor destruction. As a countermeasure for such problems, external safety measures

must be provided to ensure safety in the overall system.

5. Fail-safe measures must be taken by the user to ensure overall system safety in the event of broken signal lines

or momentary power interruptions.

6. The durability of the output relays is largely affected by the switching conditions. Confirm the operation of the

system under actual operating conditions and set the switching frequency to ensure that adequate performance

will be provided. Insulation faults and burning in the ZEN may result if relays are used after their performance

has deteriorated.

Connecting Expansion I/O Units

1. Supply power to both the CPU Unit and Expansion I/O Units from the same power supply and turn them ON

and OFF at the same time.

2. When connecting Expansion I/O Units with DC inputs to a CPU Unit with an AC power supply, the burst noise

immunity will be 1 kV (IEC 61000-4-4).

3. Expansion I/O Units with AC inputs (ZEN-8E1AR) cannot be connected to a CPU Unit with a DC power supply.

System Startup and Program Changes

1. Check the user program for proper execution before actually running it on the Unit.

2. Disconnect the output lines from the system before testing operation in any system in which incorrect operation

can result in injury or equipment damage.

3. Confirm safety before attempting any of the following operations.

• Changing the operating mode (RUN/STOP).

• Using the button switches.

• Changing bit status or parameter settings.

4. Double-check all wiring before turning ON the power supply.

5. Refer to Cycle Time Calculation Method on page 130 in the ZEN Programmable Relay Operation Manual (Cat.

No. Z211) and confirm that the increase in the cycle time will not affect operation. If the cycle time is too long,

it may become impossible to read input signals accurately. The increase in the cycle time will be particularly

noticeable when set values are written in RUN mode for a CPU Unit with communications (ZEN-10C4@R-@-

V2).

Installation and Wiring

1. Do not allow the ZEN to fall during installation.

2. Be sure that the DIN Track mounting levers, Expansion I/O Units, Memory Cassettes, Battery Units, cable

connectors, and other items with locking devices are properly locked into place. Improper locking may result in

malfunction.

3. When mounting the ZEN to the surface of the control panel, tighten mounting screws to the following torques.

CPU Units: 1.03 N⋅m max.

Expansion I/O Units: 0.46 N⋅m max.

4. Use wires with cross-sectional areas of 0.2 to 2.5 mm

them for 6.5 mm. If using stranded wires, always connect straight crimp terminals (0.25 to 2.5 mm

Handling

1. The environment of use of ZEN is “Pollution degree 2” and “Overvoltage category II” specified in IEC60664-1.

2

(equivalent to AWG24 to AWG14) for wiring and strip

2

).

x

Precautions

2. Always use the ZEN within the rated ambient operating temperature and humidity. The rated ambient operating

temperature is 0 to 55°C for LCD-type CPU Units and –25 to 55°C for LED-type CPU Units. If the ZEN is used

near sources of heat, such as a power supply, the internal temperature of the ZEN may increase, lowering the

durability of the ZEN.

3. Discharge static electricity from your body, e.g., by touching a grounded metal plate, before touching any Unit.

4. The exterior of the Units will be damaged if it comes into contact with organic solvents (e.g., benzene or paint

thinner), strong alkalies, or strong acids. Never allow such substances to come into contact with the Units.

5. Do not apply voltages exceeding the rated voltages. Internal elements may be destroyed.

6. Short failures or open failures may result from the destruction of output elements. Do not use loads that exceed

the rated output current.

Maintenance

When replacing a CPU Unit, transfer to the new Unit and confirm all settings for clock data, internal holding bits,

holding timers, and counters before starting operation again.

Transportation and Storage

1. Use special packaging boxes when transporting the ZEN and do not subject it to excessive shock or vibration

or drop it during shipment.

2. Store the ZEN at an ambient temperature of −40 to 75°C for LED-type CPU Units and −20 to 75°C for all other

types of CPU Units. If the ZEN has been stored at −10°C or lower, allow it to stand at room temperature for 3

hours or longer before turning ON the power supply.

xi

Precautions

Precautions for Correct Use

Installation Environment

1. Do not install the ZEN in the following locations.

• Locations subject to radical changes in temperature

• Location with high humidity subject to condensation

• Locations subject to excessive dust or dirt

• Locations subject to corrosive gas

• Locations subject to direct sunlight

2. Do not install the ZEN in locations subject to shock or vibration. Extended use in such location may cause

damage from stress.

3. In environments subject to static electricity (e.g., close to pipes conveying forming materials, powders, or fluid

materials), separate the ZEN as far as possible from the source of static electricity.

4. The ZEN is neither waterproof nor oil-proof. Do not use it in locations subject to water or oil.

5. Use the ZEN within the allowable power supply voltage range. Be particularly careful in locations with bad power

supply conditions, e.g., large fluctuations in the power supply voltage.

6. Do not install the ZEN in locations subject to excessive noise, which may cause the ZEN to fail.

7. Take appropriate and sufficient countermeasures when installing systems in the following locations:

• Locations subject to strong electromagnetic fields

• Locations subject to possible exposure to radioactivity

Power Supply

1. Always turn OFF the power supply to the ZEN (CPU Unit and Expansion I/O Units) before attempting any of the

following.

• Assembling the ZEN

• Attaching or removing Expansion I/O Units

• Connecting or disconnecting any cables or wiring

• Attaching or removing the Memory Cassette

• Attaching or removing the Battery Unit

2. If the power supply is interrupted for 2 days or more (at 25°C), the internal capacitor will discharge and internal

bit status and the contents of PV areas will be lost or corrupted and dates and times will be reset. When

restarting operation after the power supply has been interrupted for an extended period of time, check the

system in advance to confirm that no errors will occur.

Handling

1. Connect connectors only after confirming that the direction or polarity is correct.

2. Failures could result if dust or dirt enters the ZEN. Always connect the connector cover to the computer

connector whenever it is not being used.

3. Do not remove the label from the left side of the CPU Unit if a Battery Unit is not mounted.

EEPROM Write Life

The EEPROM has a limited write life. The write life may be exceeded if communications are used frequently to

write settings. Consider this in the system design.

Other

1. The execution of the ladder program in the ZEN is different from that for other PLCs. Refer to Appendix B Ladder

Program Execution in the ZEN Programmable Relay Operation Manual (Cat. No. Z211) when writing the ladder

program.

2. Abide by all local ordinances and regulations when disposing of the ZEN.

3. The Battery Unit (ZEN-BAT01, sold separately) contains a lithium battery. Observe all applicable legal

requirements for your area when disposing of the lithium battery.

xii

Conventions Used in This Manual

This user's manual describes the communications functions of CPU Units with communications. For information on using other functions, refer to the ZEN Programma-

ble Relay Operation Manual.

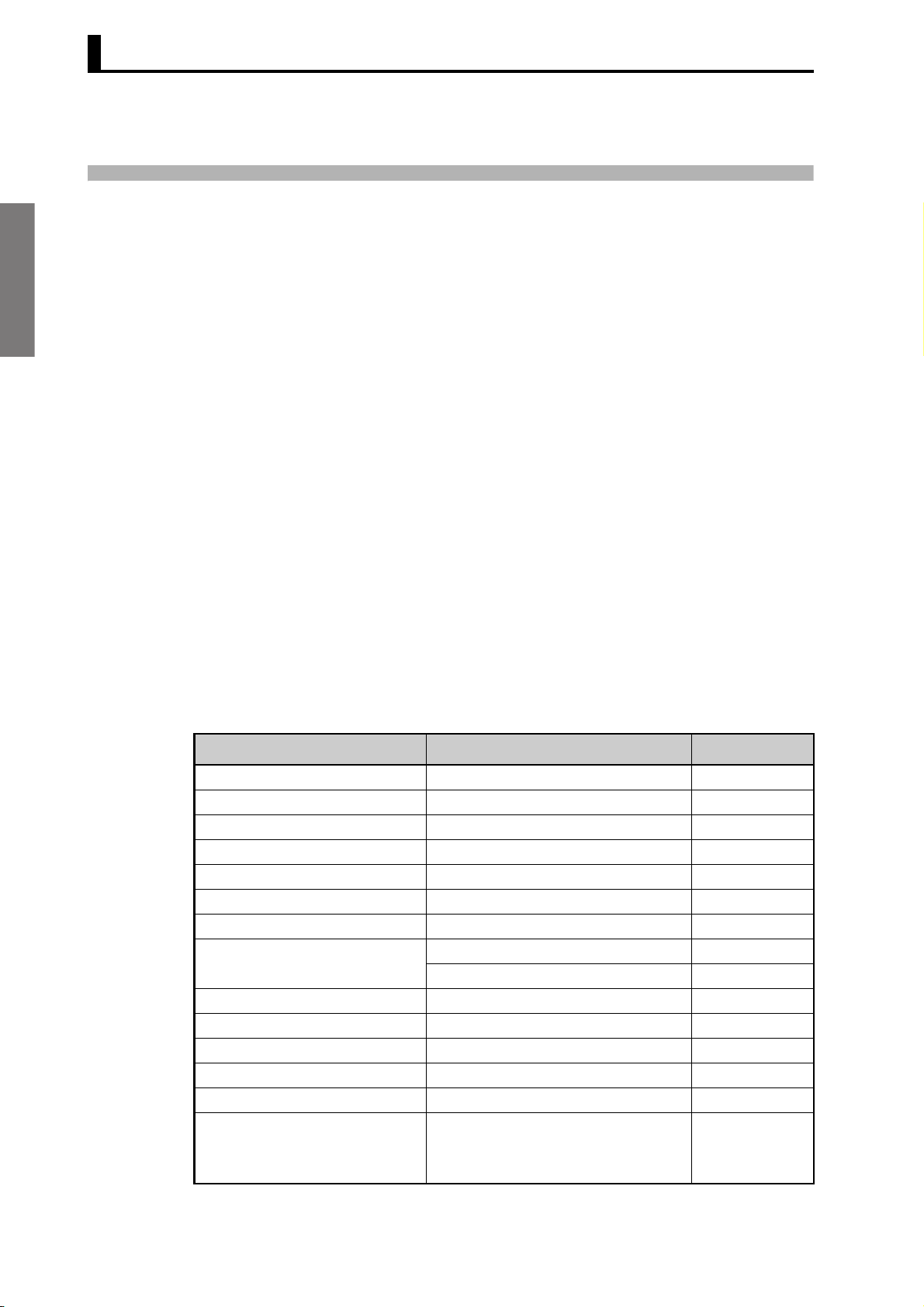

■ Manual Contents

Item Description

SECTION 1

Communications Methods

SECTION 2

CompoWay/F

Communications Protocol

SECTION 3

Communications Data

Appendix ASCII list

■ Related Manuals

ZEN Programmable Relay Operation Manual (Z211)

ZEN Support Software Operation Manual (Z184)

This section briefly describes the supported

communications methods and how to wire

equipment. Refer to this section before setting up equipment.

This section describes the protocol for

communications using the CompoWay/F

format.

This section lists the details of the

communications data in the CompoWay/F

communications protocol.

xiii

Revision History

■ Manual Revision Code

A manual revision code appears as a suffix to the catalog number on the front and

back cover of the manual.

Man. No. Z212-E1-01

■ Revision History

The following table outlines the changes made to the manual during each revision.

Page numbers refer to the previous version.

Revision code Date Revised content

01 January 2006 Original production

xiv

Table of Contents

Precautions vii

SECTION 1

Communications Methods

1.1 Overview of Communications Methods ......................................................... 2

Introduction ............................................................................................ 2

Communications Specifications ............................................................. 2

Transmission Procedure ........................................................................ 3

Interface ................................................................................................. 3

Wiring ..................................................................................................... 3

Communications Parameters ................................................................. 4

Setting Communications Parameters .................................................... 5

SECTION 2

CompoWay/F Communications Protocol

2.1 Data Format ................................................................................................ 10

Command Frame ................................................................................. 10

Response Frame ................................................................................. 11

Communications Data .......................................................................... 12

2.2 Structure of Command Text ........................................................................ 14

PDU Structure ...................................................................................... 14

Addresses ............................................................................................ 14

Number of Elements ............................................................................ 14

List of Services ..................................................................................... 15

2.3 Detailed Description of the Services ........................................................... 16

Read Variable Area .............................................................................. 16

Variable Type and Read Start Address ............................................... 16

Bit Position ........................................................................................... 16

Number of Elements ............................................................................ 16

Response Code ................................................................................... 16

Reading Timers, Counters, and Comparators ..................................... 17

Reading Work Bits and HR Bits ........................................................... 20

Write Variable Area .............................................................................. 21

Writing Timer and Counter Set Values ................................................ 22

Writing Work Bits and HR Bits ............................................................. 26

Read Controller Attributes .................................................................... 26

Read Controller Status ......................................................................... 27

Read Time Data ................................................................................... 28

Write Time Data ................................................................................... 29

Echoback Test ..................................................................................... 31

Operation Command ............................................................................ 32

2.4 Response Code List .................................................................................... 34

SECTION 3

Communications Data

3.1 Variable Area (Data Range) List ................................................................. 36

Appendix 41

ASCII List .............................................................................................................. 42

Preface - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ii

Warranty and Application Considerations - - - - - iii

Conventions Used in This Manual - - - - - - - - - - xiii

Revision History - - - - - - - - - - - - - - - - - - - - - - xiv

xv

xvi

SECTION 1 Communications Methods

This section briefly describes the supported communications methods and

how to wire equipment. Refer to this section when setting up equipment.

1.1 Overview of Communications Methods ........................... 2

Introduction................................................................. 2

Communications Specifications.................................. 2

Transmission Procedure............................................. 3

Interface...................................................................... 3

Wiring ......................................................................... 3

Communications Parameters ..................................... 4

Setting Communications Parameters ......................... 5

1

Overview

SECTION 1 Communications Methods

1.1 Overview of Communications Methods

■ Introduction

A host computer (see note 1) can communicate with the ZEN using the

CompoWay/F communications protocol. The host computer is

programmed to monitor and set ZEN settings. This manual is thus

written from the viewpoint of the host computer. Up to 32 nodes

including host computers can be connected via CompoWay/F.

CompoWay/F is an integrated protocol for OMRON general-purpose

serial communications. Consistent frame formats and commands that

are compliant with FINS (see note 2), which is widely used with

OMRON Programmable Controllers (PLCs), enable easy communications between a host computer and components.

Note 1:Host computers include personal computers.

Note 2:FINS (Factory Interface Network Service) is a message service

used between controllers on OMRON FA networks.

The ZEN supports the following communications functions.

• Reading/writing of parameters

• Operation instructions

Note: RS-485 communications are not possible when a computer

running ZEN Support Software is online with the CPU Unit.

■Communications Specifications

Item Details Default settings

Transmission line connection Multi-drop None

Communications method RS-485 (2-wire, half-duplex) None

Synchronization method Start-stop synchronization None

Communications baud rate 4800, 9600, or 19200 bps 9600 bps

Communications code ASCII None

Communications data bits 7 or 8 bits 7 bits

Communications stop bits 1 or 2 bits 2 bits

Error detection Vertical parity (none, even, or odd) Even

BCC (Block Check Character) None

Flow control None ---

Interface RS-485 ---

Retry function None ---

Communications buffer 36 bytes ---

Communications protocol CompoWay/F None

Number of nodes 1:1 connection:

1:N connections:

1 node

None

32 nodes max. including host computer

2

Loading...

Loading...