Omron Z300 DATASHEET

High-precision Visual Displacement Measurement System

Z300

2-Dimensional CCD is Built in. A New Type of

Displacement Sensor Utilizing the Best and Most

Up-to-date Image Processing Technologies.

Z300

Features

Stable measurement of a transparent object or a glass.

A wide variety of sensor heads for enhanced detection possibilities.

OMRON's Z300 makes the notion that displacement sensors cannot perform stable measurement of a transparent object

or a glass a thing of the past. The newly-developed 2-dimensional CCD (S-CCD) incorporated in the Z300, combined with

upgraded performance of the controller, provides enhanced stability and accuracy in measurement of a transparent object.

The latest algorithm employed by the Z300 enables optimal sensitivity even if there is a big difference between the amount

of reflected light from the surface and that from the bottom of a glass.

Enhanced measurement area and a variety of high-resolution,

long-distance sensor heads greatly expand the range of

applications.

The Z300 is just another example of OMRON's ongoing

challenge to the limits of sensing possibilities.

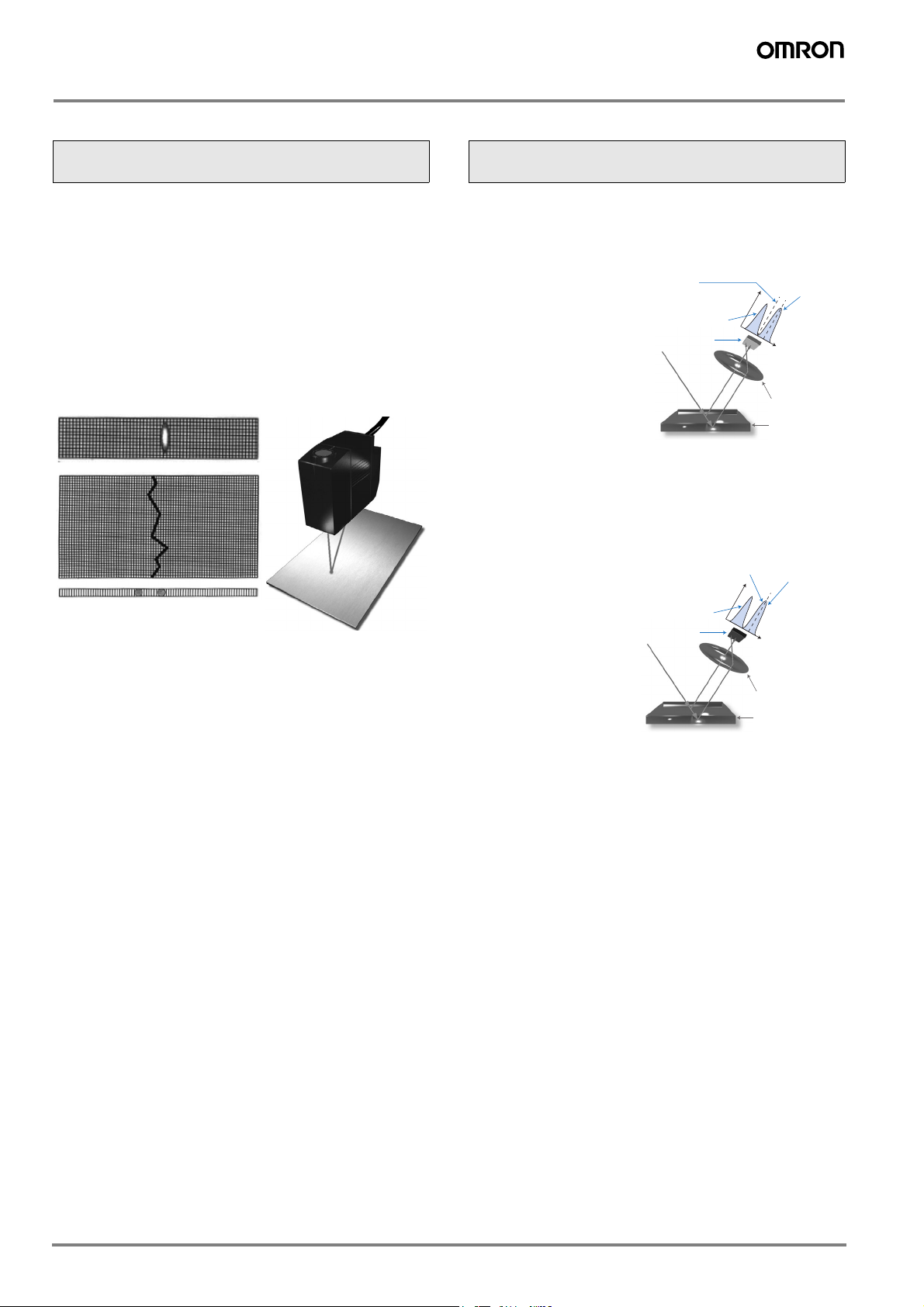

Z300-S60

Super Long-range Model

Detection distance of 600

± 350 mm

Z300-S10

Long-range Model

Detection distance of

100 ± 20 mm

Z300-S5T

High-precision Model

Detection distance of

50 ± 5 mm

Z300-S2T

Super-precision Model

Detection distance of

20 ± 1 mm

B-31Z300

The innovative 2-dimensional CCD (S-CCD) is the key to the sensing performance.

The 2-dimensional CCD enables stable, high-speed

measurement.

A conventional displacement sensor using a 1-dimensional

CCD cannot deal with flutter influence to the output. Therefore, the sensor requires increased number of measurements

for signal averaging, which leads to slow response time. The

S-CCD with a 2-dimensional CCD has solved this disadvantage, by splitting the measurement point into 60 lines for measurement in finer detail. The value per each pixel is then

averaged to produce a reliable output, free from flutter influence caused by the object's surface condition. Stable detection and high-speed processing is thus possible with the Z300.

CCD makes a difference in measurement of a

transparent object.

PSD sensor

A PSD sensor using diffuse reflection is virtually

prevented from performing measurement due to

insufficient reflection distribution from the surface.

A sensor using the mirror

PSD output

(position of the reflected

light output from PSD)

Reflected light

from the bottom

PSD

reflection method, on the

other hand, receives reflective light from the bottom or background of the

object, which causes an

error in determining the

target position, impeding

accurate measurement.

CCD sensor

A CCD using the mirror reflection method is a solution. It can extract only the

light reflected off the surface of the target. Accu-

Reflected light from the surface

Reflected light

from the bottom

CCD

Light gain

rate measurement of a

transparent object is possible without being affected by reflected light from

the bottom or background

of the object.

Reflected light from

the surface

Light gain

Position

Receiver lens

Transparent object

Position

Receiver lens

Transparent object

Detecting reflect

light from the

surface

B-32 Displacement sensors / Width-measuring Sensors

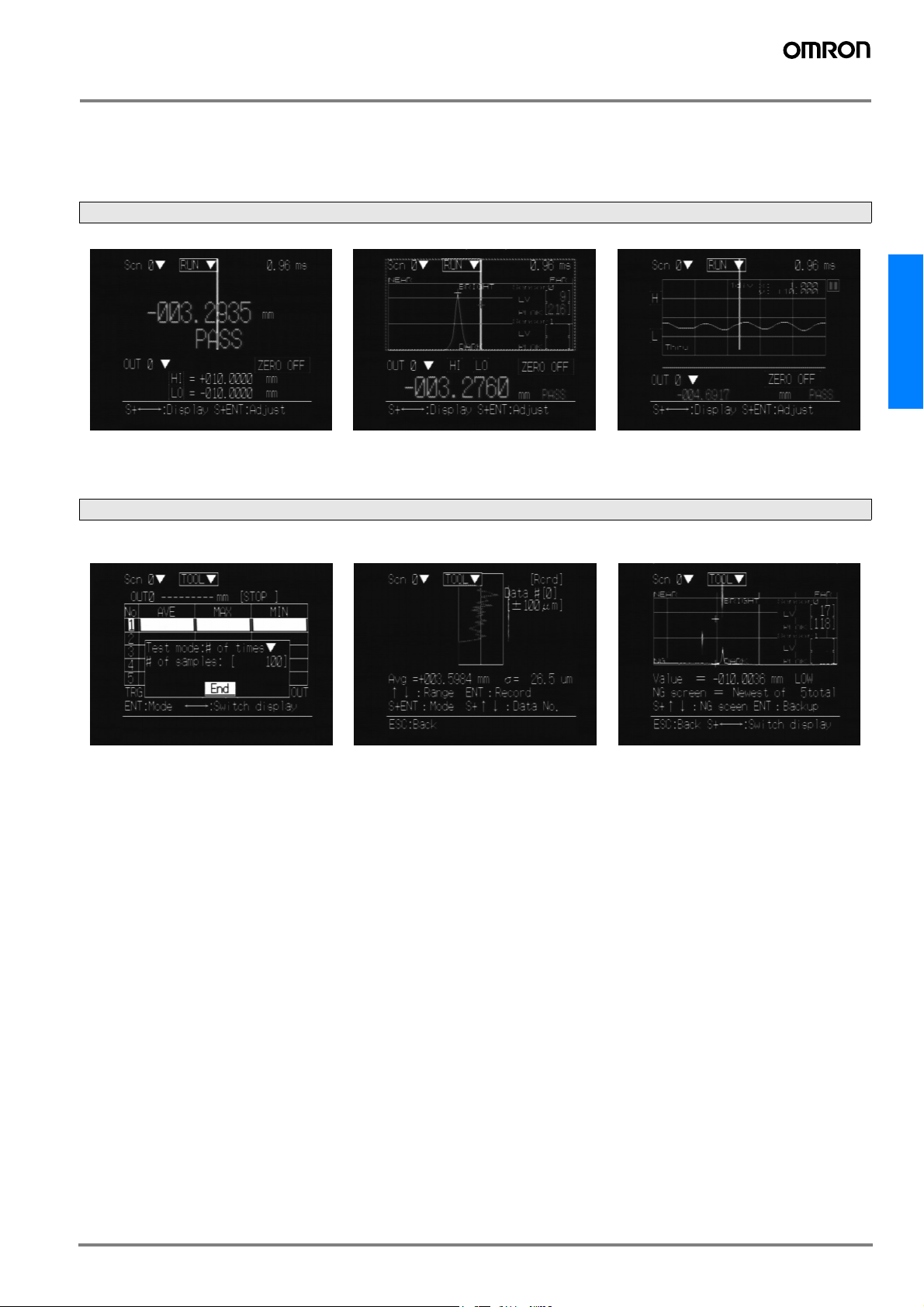

Monitoring as the object is being measured.

Measurement data can be recorded and played back.

Easy-to-see color display is another great feature of the Z300 (when connected to a color monitor). Monitoring at each key stage

including test and adjustment, operation, or maintenance greatly facilitates efficient, error-free measurement.

Real-time monitoring

Digital monitor Image monitor Trend monitor

Z300

The measured value is displayed. The use of two

colors: green for "Pass" judgement, and red for

"High/Low," enhances visual recognition of the

measurement result.

Displays the position of measurement point as well as

intensity of the reflected light.

Conveniently checks whether optimum measurement

is taking place.

Monitoring during recording and playback

Test mode Conditions during Test mode can be

recorded and played back

Any desired number of measurement data can be

stored for testing with a workpiece.

Test measurement data obtained off-line can be

saved for reference for actual in-line measurement.

Continuous measurement values during a certain

period of time are shown in chronological order.

Changes in the measured values of a moving or

rotating object can be checked at a glance.

NG (High/Low) judgement status is

recorded and played back.

Up to 20 in-line NG data (information including

reflected light condition and measurement data) can

be recorded for workpiece analysis as well as for

troubleshooting.

B-33Z300

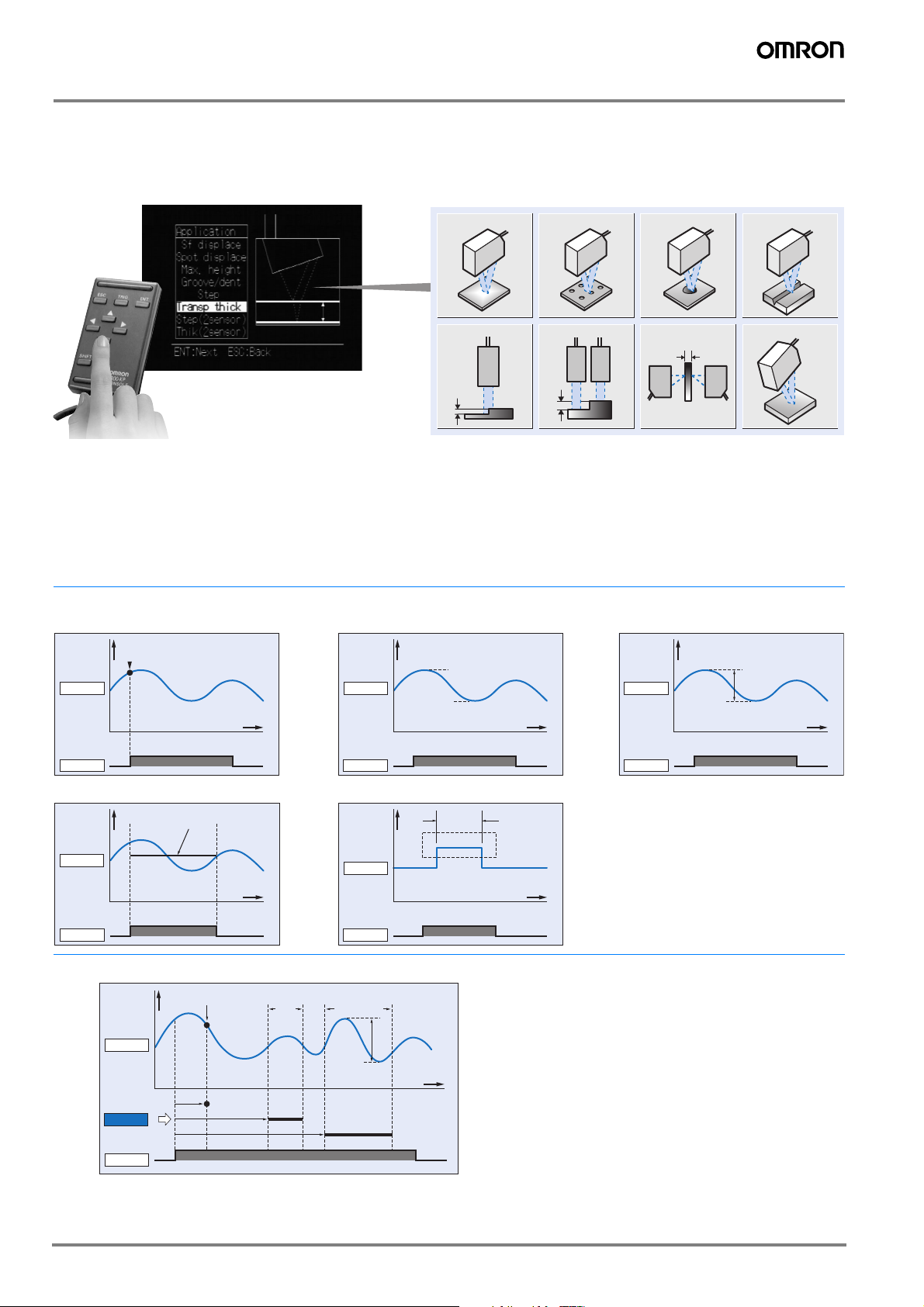

Interactive menus provide a variety of measurement functions.

Application menu

Settings for measurement methods are easily performed using the menu.

Just follow the guidance of the monitor screen.

Surface displacement Spot displacement Maximum height

Level difference

Level difference (2 sensors)

Thickness (2 sensors)

Groove/indentation

Transparent object thickness

Expert menu

Expert menu is available for more advanced measurement. Detailed setting conditions can be conveniently programmed using

the menu.

Enhanced hold functions widen the scope of application.

With discrete hold functions equipped within the controller, the Z300 provides a variety of trigger (measurement timing) functions,

making otherwise difficult applications a reality — with ease.

Hold functions

Sampling hold

Displacement

amount

Displacement

amount

Peak hold (bottom)

Displacement

amount

Displacement

amount

Bottom value

Peak value

Peak to peak hold

Displacement

amount

Displacement

amount

Peak to peak

Direction/Time

Measurement

trigger

Measurement

trigger

Average hold Length hold

Average value

Displacement

amount

Average

displacement amount

Measurement

trigger

Direction/

Time

Displacement

amount

Measurement

trigger

Displacement

amount

Selectable trigger function

Displacement

amount

Optional trigger

function

Measurement

trigger

Displacement

amount

Sampling

Peak to peakPeak

Direction/

Time

Direction/Time

Length

Direction/Time

Measurement

trigger

Direction/Time

Measurement trigger can be set to the controller for

desired measurement timing.

B-34 Displacement sensors / Width-measuring Sensors

Application

Measuring the thickness of transparent film

Measuring the thickness of sheet

Measurement of electrode position in the display module

Z300

Measurement of warping in transparent plastic

Inspecting the surface uniformity of a hard disk

Measuring tire or black rubber thickness

Shape measurement for welding robot control

Grinding measurement of a whetstone

B-35Z300

Loading...

Loading...