Olympus CHA-F, CHA-F-3 Repair Manual

OLYMPUS SYSTEM MICROSCOP

MODEL

CH

REPAIR

MANUA

OLYMPUS

CONTENTS

1.

REPAIR TOOLS

AND

GREASE

..

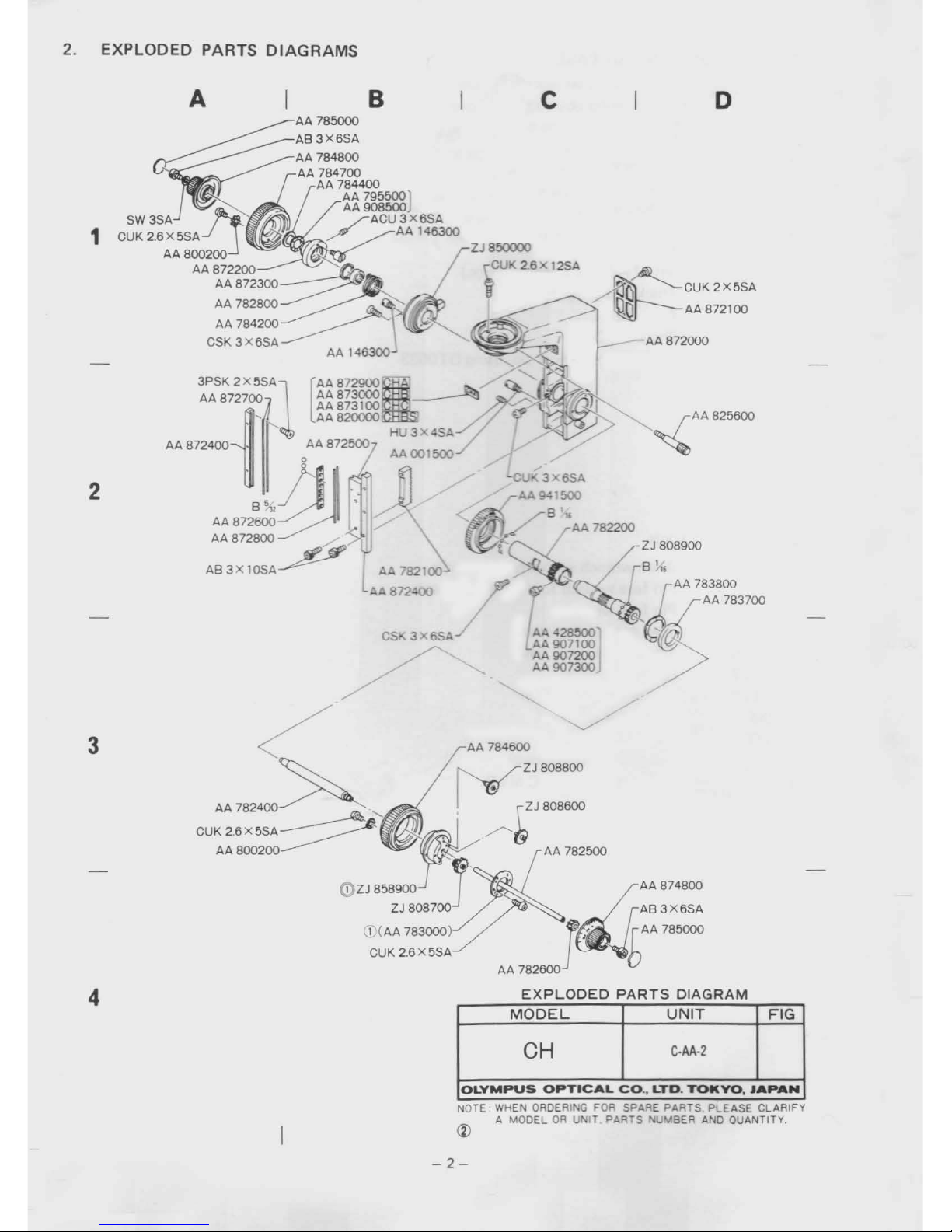

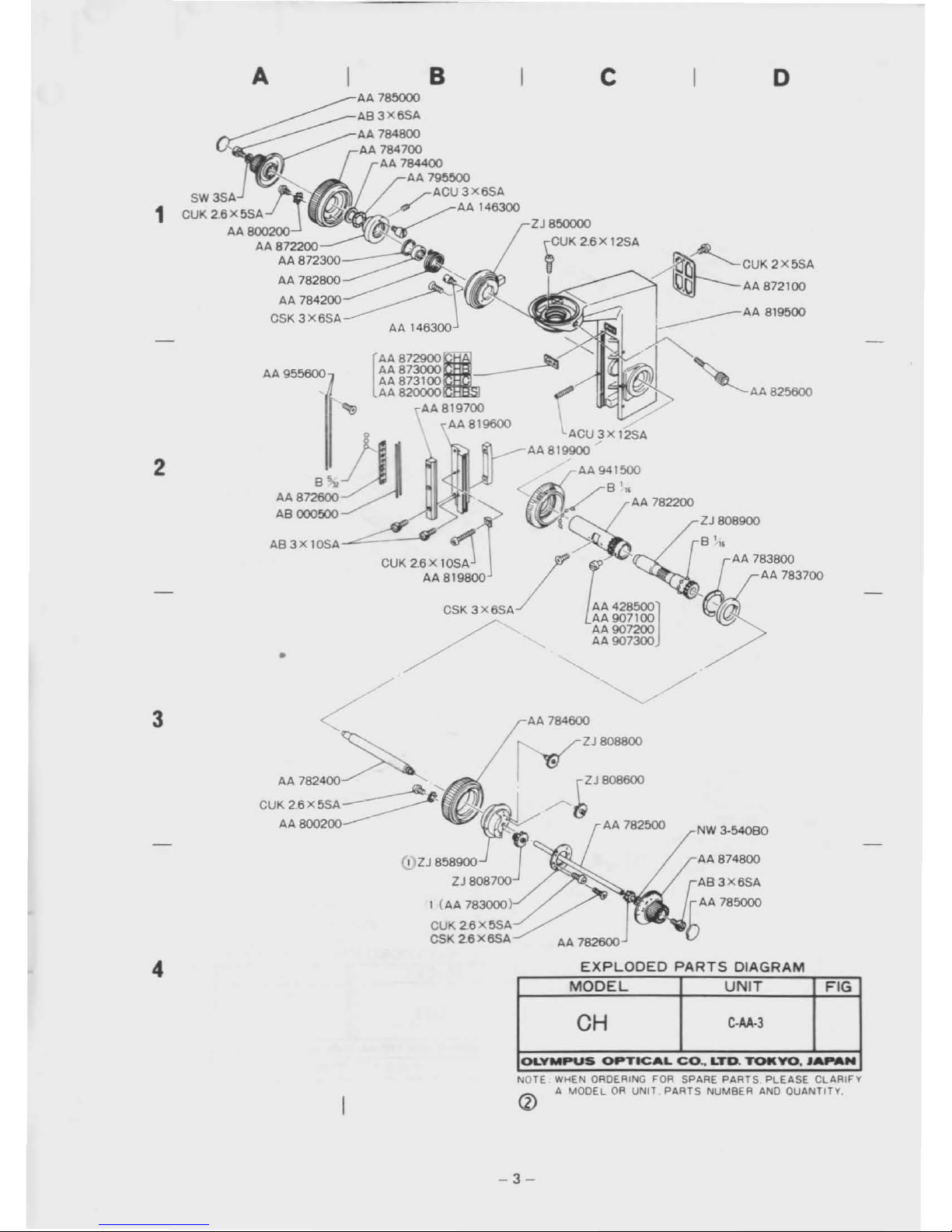

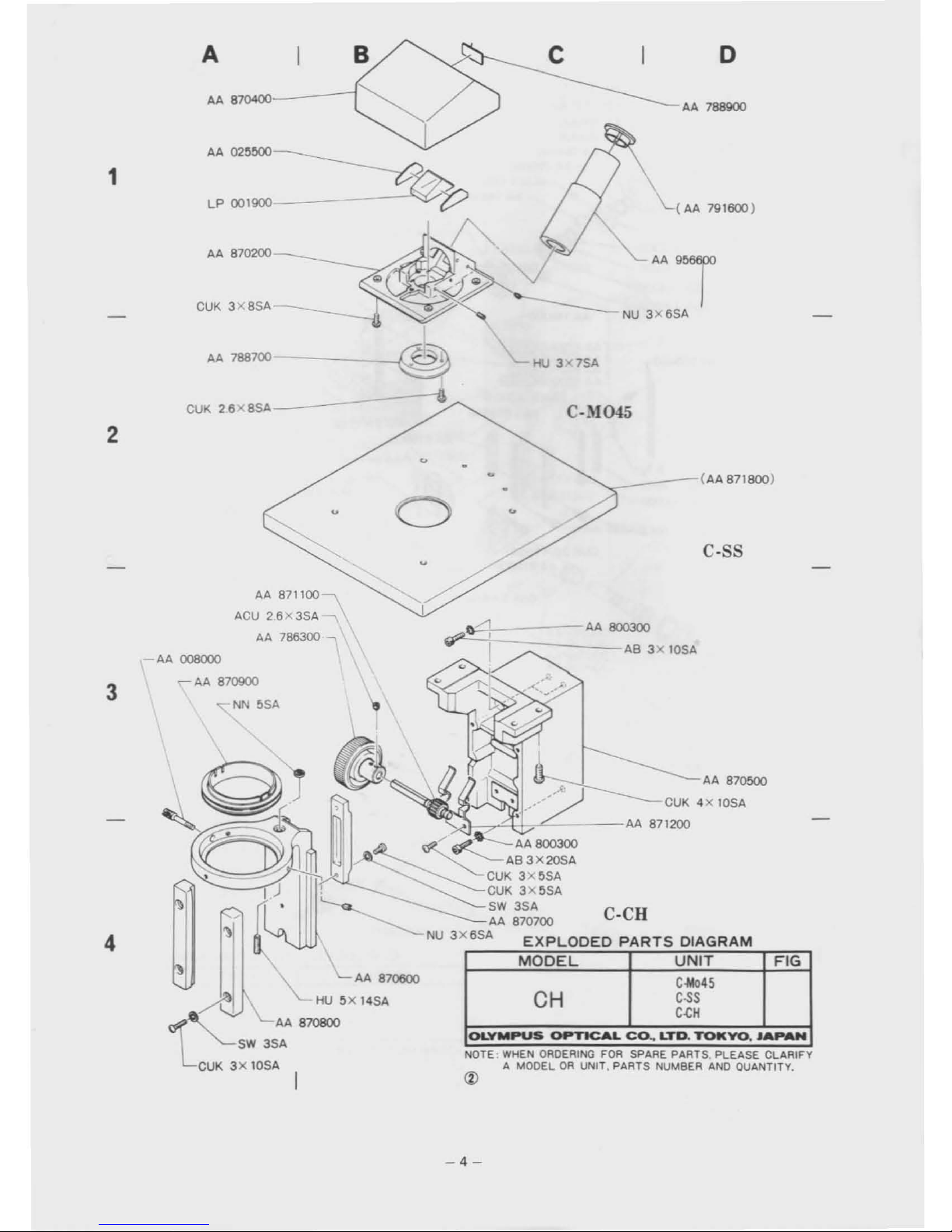

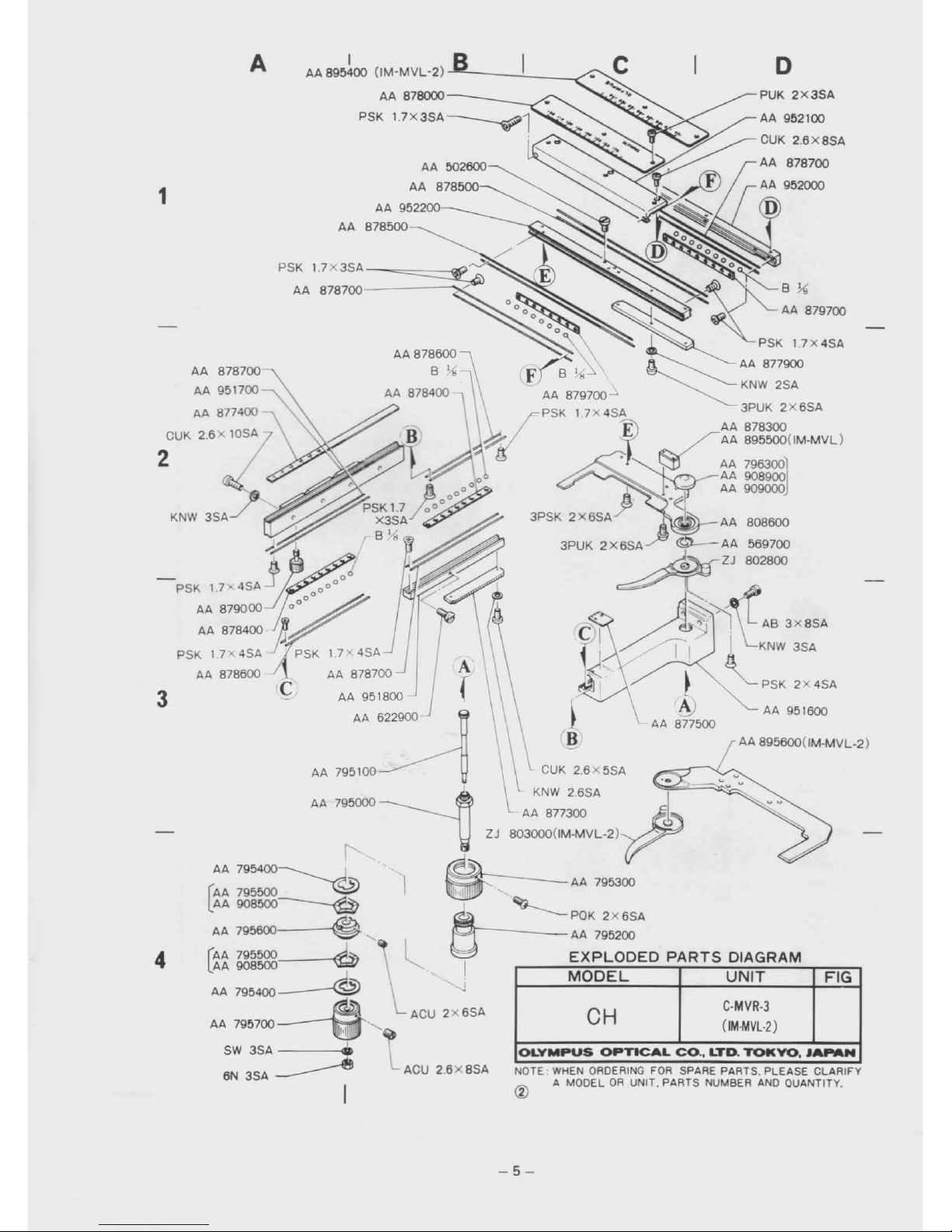

2. EXPLODED PARTS

DIAGRAMS

....................•......•.....•.....

2

3. DISASSEMBLING PROCEDURES FOR CHA·F-3 6

4. REASSEMBLING PROCEDURES FOR CHA·F-3

17

5. DISASSEMBLING PROCEDURES FOR C·CH CONDENSER

HOLDER

31

6. REASSEMBLING PROCEDURES FOR C·CH CONDENSER

HOLDER

34

7. DISASSEMBLING PROCEDURES FOR C-CL

LIGHT

EXiT

37

8. REASSEMBLING PROCEDURES FOR C-CL

LIGHT

EXiT

38

9.

OVERALL

REASSEMBLY

AND

ADJUSTMENT

38

10. DISASSEMBLING

AND

REASSEMBLING PROCEDURES FOR CHA-F

40

11. DISASSEMBLING

AND

REASSEMBLING PROCEDURES FOR C-MVR -45

TO

OLYMPUS

MICROSCOPE

SERVICING

PERSONNEL

CH Series Microscopeiswidely

used

throughout

the

world

for

training

students and inspecting various

specimens. Since

this

microscopeisfrequently

operated

for

routine

microscopy,itistobe

often

repaired

at

your

shop.

Accordingly,

this

manual shouldbehighly

helpful

for

servicing personnel.

As

you

know,

the coarse and fine adjustment mechanismofCH Seriesisnearly the

sameasthatofthe

preceding BH Series.

The

servicing personnel having experience in repairofBH Series

can

therefore easily

repair CH Series.

However,

attention

mustbepaidtothe

fact

that

CH Series

has

undergone

modificationofits coarse adjust-

ment

guide, and accordingly

this

series

currently

uses

new and

old

typesofcoarse adjustment guides.

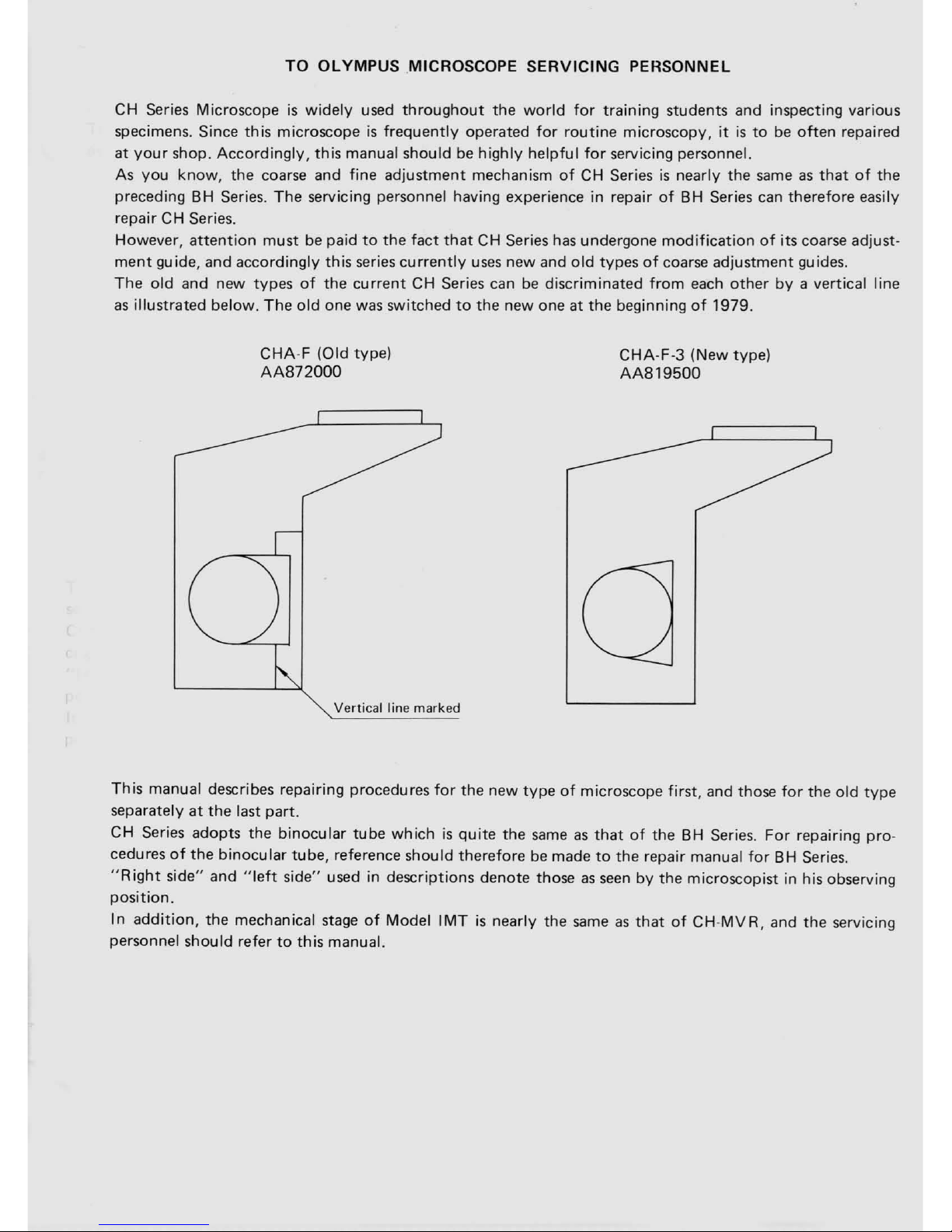

The

old and new typesofthe

current

CH Series can

be

discriminated

from

each

other

by

a vertical line

as

illustrated below.

The

old

one was switchedtothe

new one at

the

beginningof1979.

CHA-F

(Old type)

AA872000

Vertical

line marked

CHA-F-3

(New type)

AA819500

This

manual describes repairing procedures

for

the new

typeofmicroscope

first,

and those

for

the

old

type

separatelyatthe

last part.

CH Series adopts

the

binocular

tube

whichisquite

the

sameasthatofthe BH Series.

For

repairing pro-

cedures

of

the

binocular

tube, reference should thereforebemadetothe

repair manual

for

BH Series.

"R

ight

side" and

"left

side" used in descriptions denote thoseasseenbythe

microscopist in his observing

position.

In

addition,

the mechanical stageofModel

IMTisnearly the

sameasthatofCH-MVR,

and

the

servicing

personnel should refer

to

this

manual.

Requisites

for

repairs:

1. First

of

all, ascertain

what

partsofthe

microscope

the

.userorownerofwhich wishes youtorepair.

2. Never fail

to

check

the

entire

functionofthe

microscope before you commence its repair.

a)

Find

out

what

prts are defective and

how

much

they

are damaged.

b)

Prior

to

repair,

think

of

the

best possible

orderofdisassembling

the

defective partsina most

efficicent way.

3. After completing

the

repair, check

the

functionsofnot

only

the

re-assembled parts

but

also

the

entire

microscope

to

make

sure no

defect

shouldbeleft unremedied.

4.

Be

carefu I

not

to

deform repair

parts

during

the

assembly; make it practicetouse tools and jigs

specified

for

purpose.

5. Make repairs

promptly

and accurately.

1.

REPAIR

TOOLS

AND

GREASE

1-1

Regular Tools

OTOOll

OT0015

OT0016

OT0017

OT0023

OT0035

OT0044

OT0216

OT0317

OT1027

OTl131

OTl141

1-2 Grease

OT2006

OT2008

OT2010

OT2012

Setofscrewdrivers (6 pes.)

Phillips screwdriver (medium size)

Phillips screwdriver (large size)

Screwdriver (small size)

Handle

of

small sizeofPhillips screwdriver

Tweezers (special made)

Torque

screwdriver

Set

of

Allen

wrenches (8 pes.)

Thickness

gauge

Alon

Alpha

Shellac (20

g)

Phillips screwdriver tiP. using

OT0023

1-3 Special Jigs and Tools

KKACU2.5

Allen

wrench

with

straight handle

KKAA7828

Pin face wrench

for

fine adjustment

K

KAA8716

Pin face wrench

KC-2010

Tool

for

holding

gear

8-KC0026

Jig

for

receptacle balls

8-KC0027

Spoon

for

balls

B-KC0028 Jig

for

receptacle balls

SKN0003

Gauge

for

checking

stage

tilt

alignment

CHKC0001 Jig

for

adjusting movementofC-MVR

CHKC0002

Jig

for

adjusting movementofC-MVR

CHKC0003

Support

frame

for

C-MVR

-1-

2.

PARTS

DIAGRAMS

EXPLODED

CSK 3 6SA

/'

/

~AA825800

o

~

CUK2X5SA

~G

AA 872100

lO

AA 872000

l~~~

AA907200

AA 907300J

--CU

...

3X6SA

A.>

941500

~ .

h(

B.

82200

r

AA

7

ZJ

808900

• -

/B'"

r

AA

783800

AA 783700

ZJ850000

CUK 2.6 x 12SA

i

c

AA

782100"

AA872

3PSK

2X5SA

AA872700

[

AA

8729003000

AA87

AA

873100

AA 820000

• AA 872500

U"'~.~~

AA872800

~

AB3X

10SA

I B

A AA 785000

~

AB3X6SA

AA

784800

84700

Q

AA

~A

7844OO795500J

AA

500

AA~U3X6SA

/

AAI46300

;:~~.!f~/~

AA8002OO2200~~

AA87

AA872300

AA 782800

AA 784200

CSK

3X6SA

2

1

NOTE:MODELORUN

~

AA 7

PARTS

DIA

~

EXPLODED

UNIT

FIG

I

MODEL

C-AA·2

CH

YO

JAPAN

TOk

.

ICAL

CO..LTD.

EASE CLARIFY

OLYMPUS

OPT

FOR SPARE

P~~~SA~~

OUANTITY.

HEN ORDERING

IT

PARTS

filUM

AA 784600

ZJ

808800

~ZJ808600

(;

AA

782500

""""'!l4::

::

82600

GRAM

4

3

-2-

o

NW

3-54080

'AA825600

~~CUK2X5SA

~AA872100

AA 819500

------

c

2J

808600

/"~

AA 782500

2J850000

~CUK

2.B

X 12SA

AA

784600

2J808800

B

•

lACUjX12SA

AA 819900

J

AA941500

,,",~gJ

<

K/"~

:"7~~

AB 000500

~

,~

AA 783700

AB3X10SA

CUK2.BX10SA

/

l:

AA 819800

AA

428500]

AA

907100

CSK 3XBSA

AA

907200

/'

AA907300

/

AA955600

AA

782400

CUK 2.BX5SA

AA800200

~

AA78~

~

AB3X6SA

AA 784800

~

AA

~~4i~400

AA

795500 XBSA

ACU3

/.

AAI46300

O:~;:~~?f

~!~

AA800200

~~

AA872200

AA

872300

"-

AA782800~

~

AA 784200

_______

CSK

3 XBSA

AA14B3OO

[

AA

8729003000.

AA87

AA8=

AA 8 AA 819700

~

AA819600

2

1

3

4

FIG

TICAL

CO.,

LT.

PLEASE

CLARIFY

CH

yo

........

D

TOt(

•

toLYMPUS

OP

G FOR SPARE

PAB~~S

AND

QUANTITY,

QRDERIN

PARTS

NUM

NOTE

WHEN

OR

UNIT

A

MODEL

-3-

OLYMPUS

OPTICAL

Co..

lro.

TOKYO.

JAPAN

NOTE:

WHEN

ORDERING

FDA SPARE PARTS. PLEASE CLARIFY

A MODELORUNIT. PARTS NUMBER

AND

QUANTITY,

FIG

C-Mo45

C-SS

C<:H

C-CR

CH

AA

87ססoo

CUK4X10SA

~~-r'*l/~C-_--

AA

871200

<

fIZ...~AA

800300

____

-z::::--

AS

3X 20SA

CUK

3X5SA

CUK3X5SA

SW

3SA

AA

870700

NU

3X6SA

EXPLODED

PARTS

DIAGRAM

MODEL

UNIT

\.

L

AA

870600

"-

HU5X14SA

AA 870800

SW

3SA

CUK

3X

10SA

4

-4-

o

PUK

2x3SA

NOTE

WHEN

ORDERING FOR SPARE PARTS, PLEASE CLARIFY

<Z)

A MODELORUNIT. PARTS NUMBER

AND

QUANTlTV,

MODEL

UNIT

FIG

CH

C·MVR-3

(IM-MVL-2)

OLYMPUS

OPTICAL

CO.•LTD.

TOKYO.

JA

....

N

ACU

2.6X8SA

I

AA 895400

(IM-MVL

-2)

--'--_--..!..

__

-.<

AA

878000-

---/

PSK

PSK

1.7

X3SA

-~==::::5Il

AA

878700-------,'"

A

AA 878700

AA

951700

AA 877400

CUK 2.6x 10SA

2

3

3PSK 2X

6SA.J

AA

808600

3PUK

2X6SA~

AA

569700

-_.

~ZJ

802600

-PSK

17'

4SA j

000000

;:---

~

~-

~

AA

879000

~oo"

/ I

-d~,).n.

AS

3x8SA

AA

878400

J~~

/~~

PSK

17x4SA

J'i

PSK

17<4SA

II

I

KNW

3SA

AA

878600 C

AA

878700

A(

\ l

.g

r

'-

PSK2X4SA

AA

951800

~

AA

951600

AA

622900

AA

877500

AA 895600(IM-MVL-2)

AA

795100 \ \

K~~\:::5SA~

.•

AA

79!iOOO

~

AA

877300

ZJ

803000(lM-MVL-2) -

f'

AA795400~

~

'1

----

AA

795300

[:

AA

795600

A""

I

AA

908600"'<=l7

I

~

. a POK

2x6SA

AA 795600

~

AA

795200

(AA

795600·.L

l

EXPLODED

PARTS

DIAGRAM

lAA

908600 g I

AA

795400

--®

--J

~

'-ACU

2X6SA

AA

795700~·'

SW

3SA

..

6N

3SA

--------e

I

1

4

-5-

3.

DISASSEMBLING

PROCEDURES FOR CHA-F-3

Fig. 3-1

",--

..

~

C-AA

C-BDA

C-AA:

C-CH:

C-CL:

C-BDA:

Arm

Condenser holder

Light

exit

Electrical

base

plate

Fig. 3-2

Fig. 3-3

AB4x16SA

SW4SA

C-BDA

CUK3x6SA

CUK3x6SA

3- Detaeh Electrical

base

plate C-BDA

from

the

m croscope stand.

3-

-1

Set the microscope stand upside

down

and

en

remove

four

fixing

Screws

AB4x16SA

from

the

base

plate.

(See

Fig. 3-2)

3-'-2

Remove Screw

CUK3x6SA

from

the ground-

,ng line.

(See

Fig. 3-2)

3-1-3

Detaeh

the

electrical

base

platebylihing

it.

3-2

By

removing three Screws

CUK3x6SA,

dis-

mount

Light

exit

C-CL.

(See

Fig. 3-3)

-6-

Fig.34

Fig. 3-5

AA819800

. .

j-

, '

'1'

..

•

..

'

...

Fig. 3-6

3-3 Disassemble Condenser holder C-CH

by

remov·

ing three Screws

AB3xlOSA

and three

Washers

AA800300.

3-3-1 Rack

up

the condenser holder

to

its upper

limit.

Remove Screw

AB3xl0SA

which

is

visible through the notch formed under

Holder

AA870600.

(See

Fig. 3-4)

3-3-2 Rack

down

the condenser holdertoits lower

limit

and then remove

two

Screws

AB3x1OSA.

(See

Fig. 3-5)

3-4 Disassembling procedures

for

coarse adjustment

guide.

NOTE:

For disassembling procedures

of

the coarse

adjustment guide

of

CHA-F (old type),

see

10-1

ofthis

manual.

3-4-1 Detach

two

Fixing pieces

AA819800

by

removing

two

ScrewsCUK2.6x10SA.

(See

Fig. 3-6)

-7-

AA819700

AB3xl0SA

3-4-2 Remove three Screws

AB3x1OSA

from

Inner

gu

ide

AA819700.

(See

Fig. 3-7)

,

-~-

-

.'

-.

-

•.•

. 1 .

J .

~

.,

"

Fig, 3-7

Fig.

3-8

3-4-3 Loosen

two

Screws

AB3x10SA

on Rack

AA819900_

(See

Fig. 3-8)

3-4-4 Disassemble Inner guide

AA819700.

Eight

Bal.s B 5/32 and Casing

AA872600

are

isassembled together

with

the inner guide.

-8-

I

· ,

'-"'"

-,~..

'

,..

,

Fig. 3-9

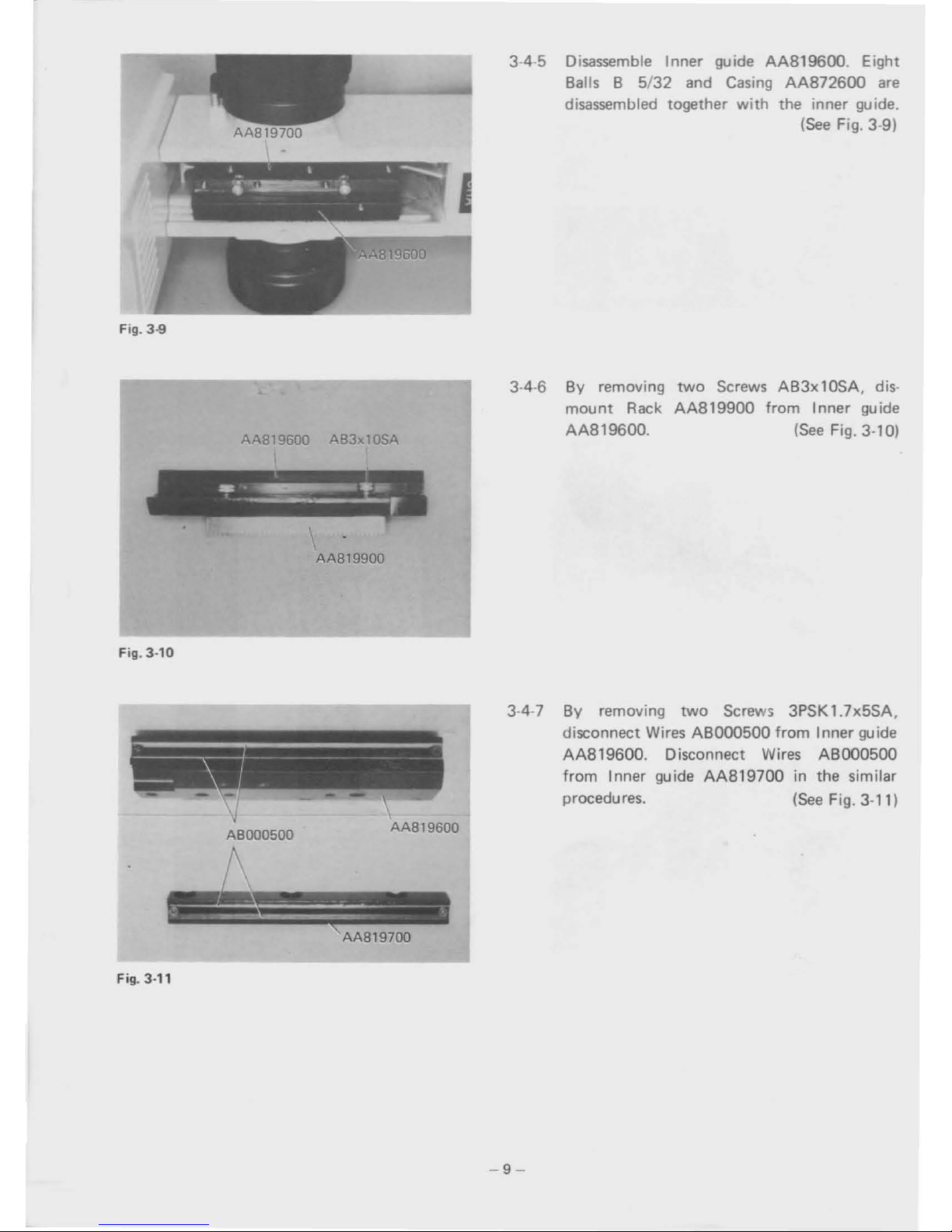

3-4-5 Disassemble Inner guide AA819600. Eight

8alls 8 5/32 and

Casing

AA872600

are

disassembled together

with

the inner guide.

(See

Fig. 3-9)

AA819600

AB3xl0SA

AAB19900

Fig. 3-10

3-4-6

By removing

mount

Rack

AA819600.

two

Screws AB3x10SA. dis·

AA819900

from Inner guide

(See

Fig. 3-10)

3·4-7 By removing

two

Screws 3PSK 1.7x5SA.

disconnect Wires

ABOOO500

from Inner guide

AA819600. Disconnect Wires ABOO0500

from Inner guide

AA819700

in the similar

procedures.

(See

Fig. 3-11)

ABOO0500

AA819600

AA819700

Fig. 3-11

-9-

Fig. 3-12

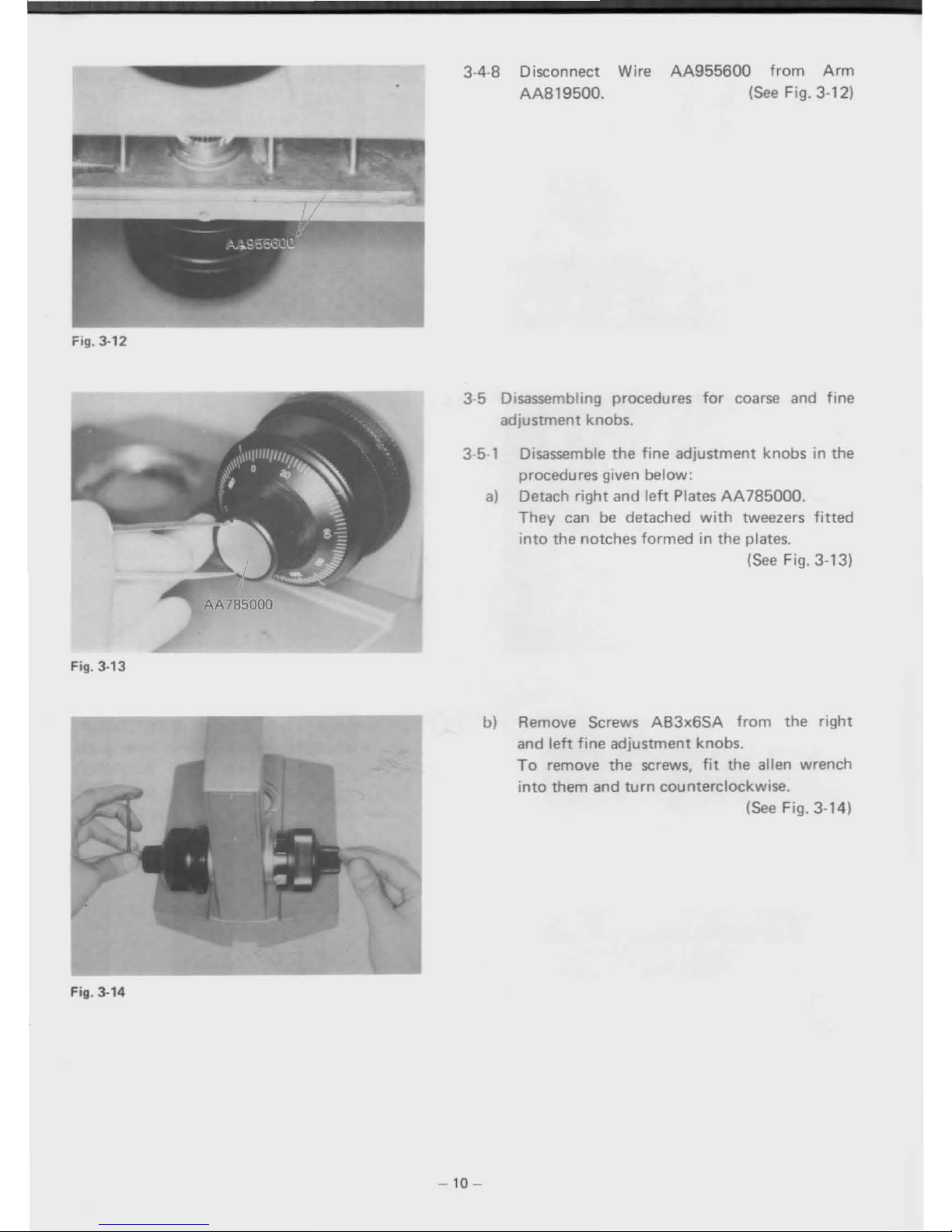

3-4-8 Disconnect Wire

AA955600

from

Arm

AA819500.

(See

Fig. 3-12)

Fig. 3-13

AA785000

3-5 Disassembling procedures

for

coarse and fine

adjustment knobs.

3-5-1 Disassemble

the

fine

adjustment knobs in the

procedures given below:

a)

Detach

right

and

left

PlatesAA785000.

They

can

be

detached

with

tweezers

fitted

into

the

notches

formed

in the plates.

(See

Fig. 3-13)

Fig. 3-14

b) Remove Screws

AB3x6SA

from

the

right

and

left

fine

adjustment knobs.

To

remove

the

screws,

fit

the alien wrench

into

them and

turn

counterclockwise.

(See Fig. 3-14)

-10

-

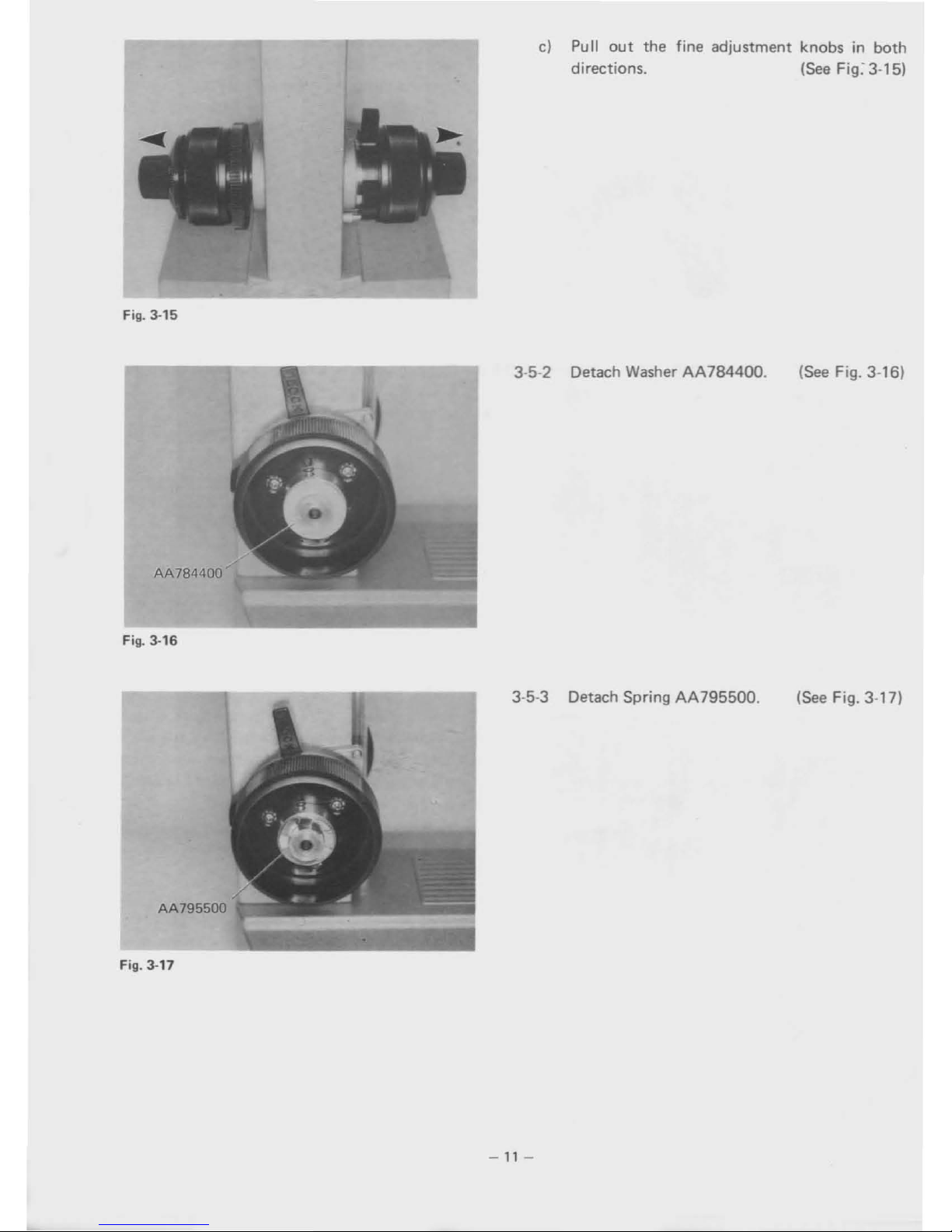

Fig.

3·15

c)

Pull

out

the fine adjustment knobs in both

directions.

(See

Fig:

3-15)

AA784400

Fig.

3·16

3-5-2 Detach

Washer

AA784400.

(See

Fig. 3-16)

Fig.

3·17

3-5-3 Detach Spring AA795500.

-

11

-

(See

Fig. 3-17)

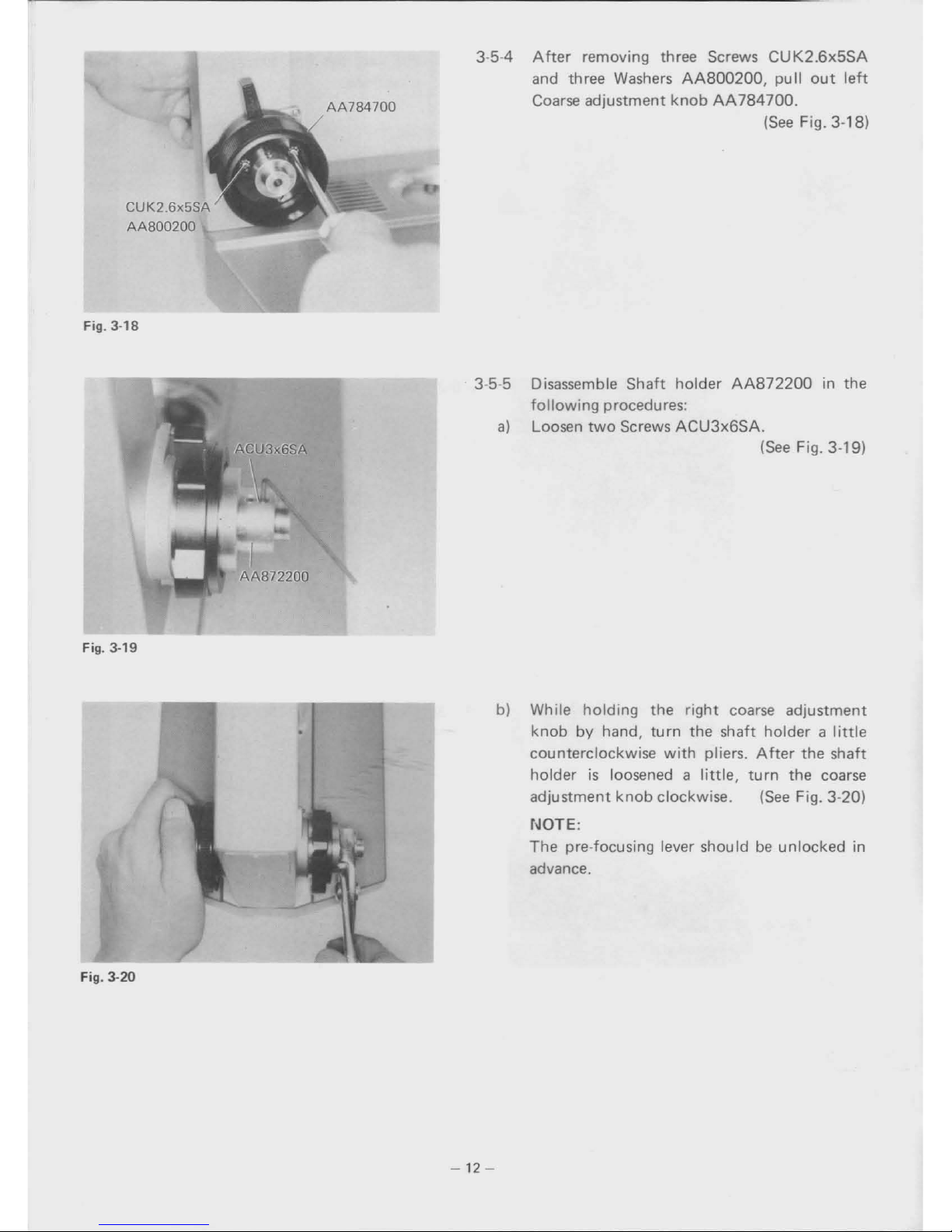

CUK2_6x5SA

AA800200

Fig.

3·18

AA784700

3-5-4

Aher

removing three Screws

CUK2.6x5SA

and three Washers

AA800200,

pull

out

leh

Coarse adjustment

knob

AA784700.

(See

Fig. 3-18)

Fig. 3-19

3-5-5 Disassemble Shaft

holder

AA872200

in the

following

procedures:

a)

Loosen

two

Screws

ACU3x6SA.

(See

Fig. 3-19)

Fig. 3-20

•

b) While

holding

the

right

coarse adjustment

knob

by hand,

turn

the shaft holder a

little

counterclockwise

with

pliers.

After

the shaft

holder

is

loosened a

little,

turn

the coarse

adjustment

knob

clockwise.

(See

Fig. 3-20)

NOTE:

The

pre-focusing lever shouldbeunlocked in

advance.

-12-

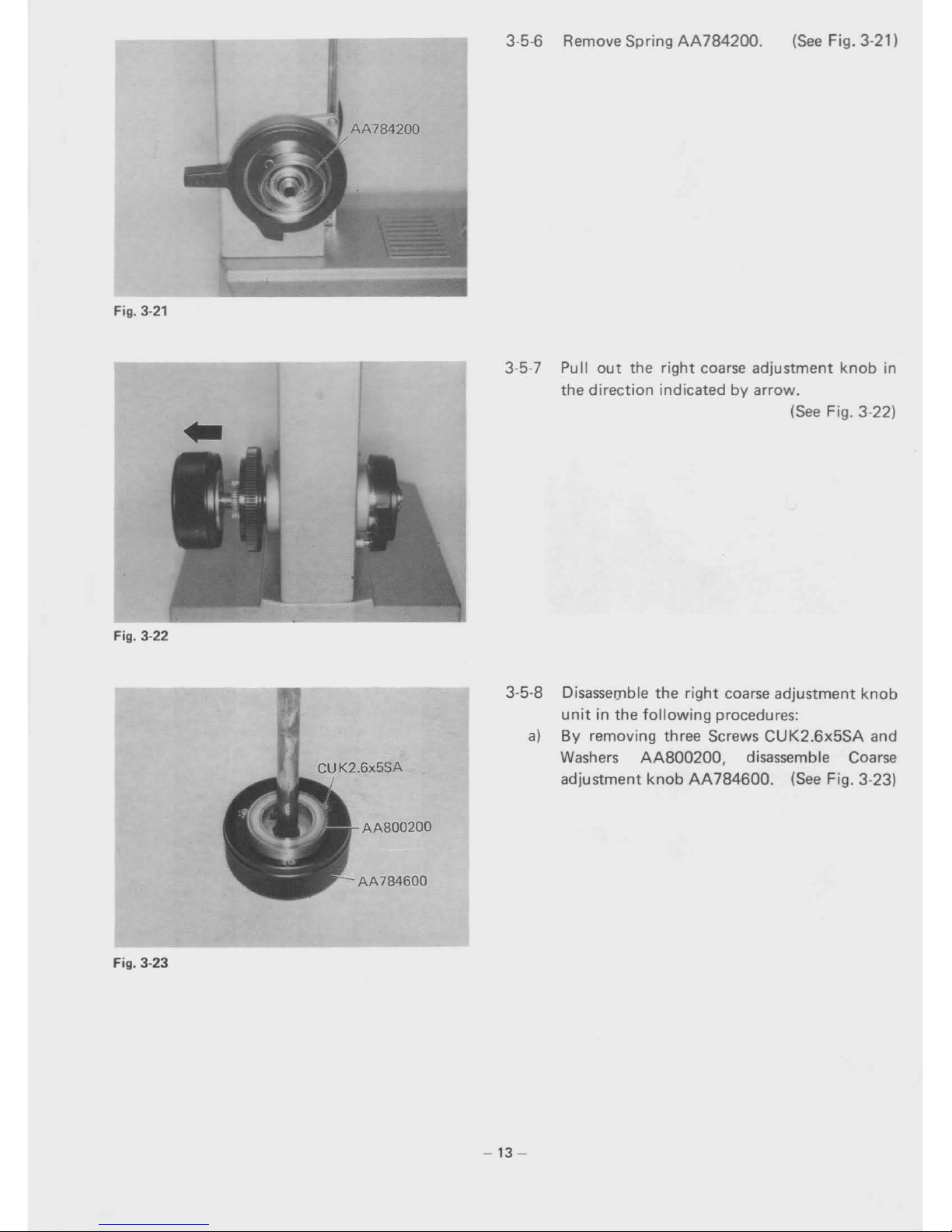

Fig. 3-21

3-5-6 Remove Spring

AA784200.

(See

Fig. 3-21)

Fig. 3-22

AA800200

AA784600

Fig. 3-23

3-5-7

Pullout

the right coarse adjustment

knob

in

the direction indicated

by

arrow.

(See

Fig. 3-22)

3-5-8 Disassel]lble the

right

coarse adjustment

knob

unit

in the

following

procedures:

a)

8y

removing three Screws

CUK2.6x5SA

and

Washers

AA800200,

disassemble Coarse

adjustment

knob

AA784600.

(See

Fig. 3-23)

-13

-

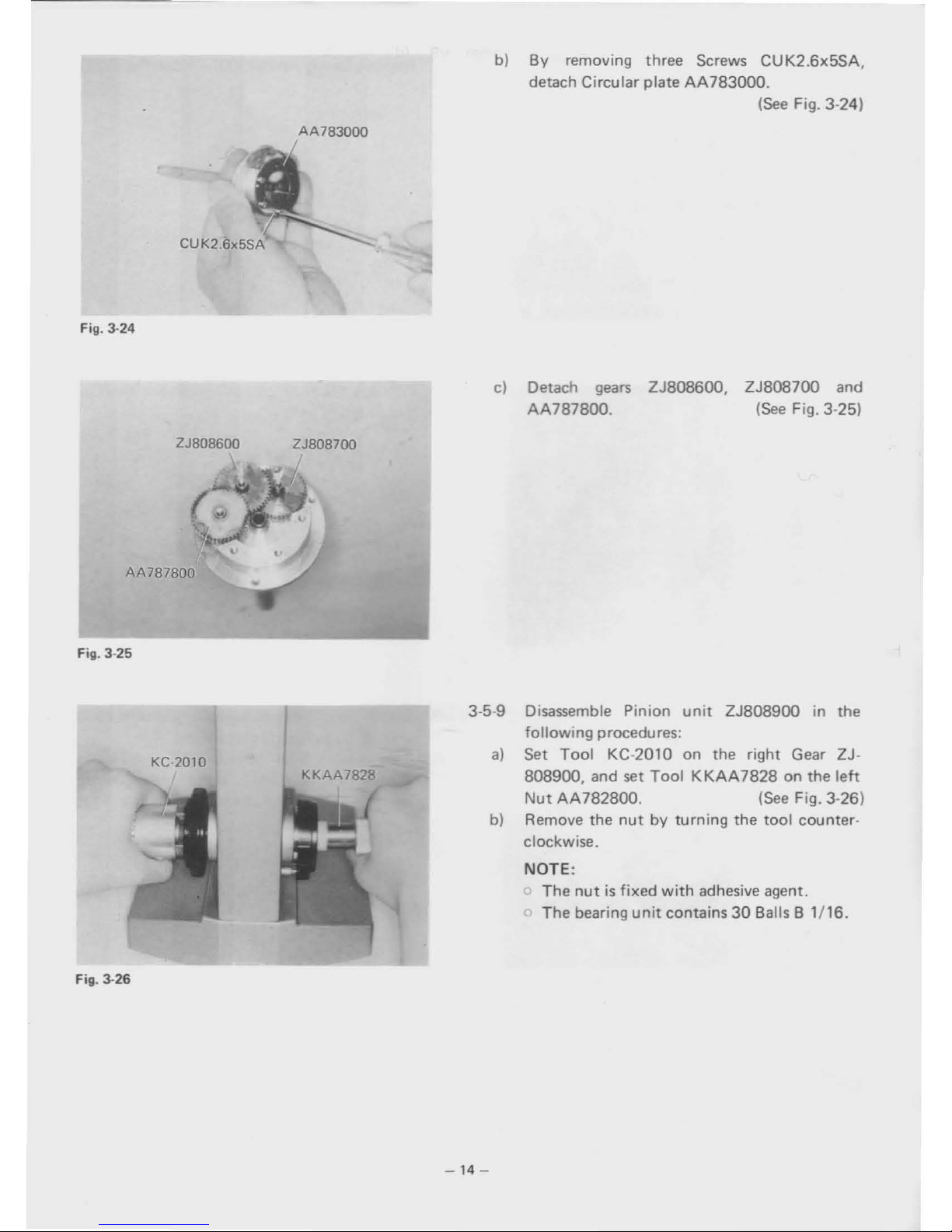

AA783000

Fig. 3-24

b)

By

removing three Screws CUK2.6x5SA,

detach Circular plate

AA783000.

(See

Fig. 3-24)

ZJ808600

AA787800

Fig.

3·25

ZJ808700

c)

Detach

gears

AA787800.

ZJ808600, ZJ808700 and

(See

Fig. 3-25)

KC-2010

Fig.

3·26

3·5-9 Disassemble Pinion

unit

ZJ808900 in the

following procedures:

a)

Set

Tool

KC-2010 on the right Gear ZJ·

808900, and set

Tool

KKAA7828

on the

left

Nut

AA782800.

(See

Fig. 3-26)

b)

Remove the

nut

by

turning the

tool

counter·

clockwise.

NOTE:

The

nutisfixed

with

adhesive agent.

The bearing

unit

contains308alls B

1/16.

-14

-

Loading...

Loading...