Page 1

D. REPAIR PROCEDURE

C-40ZOOM/D-40ZOOM

D. REPAIR PROCEDURE

[1] TROUBLESHOOTING GUIDE .................................................................................. D-2

TAKING INOPERATIVE .......................................................................................... D-2

POWER LOSS INOPERATIVE ............................................................................... D-2

NO PICTURE .......................................................................................................... D-2

D-1 Ver. 1

Page 2

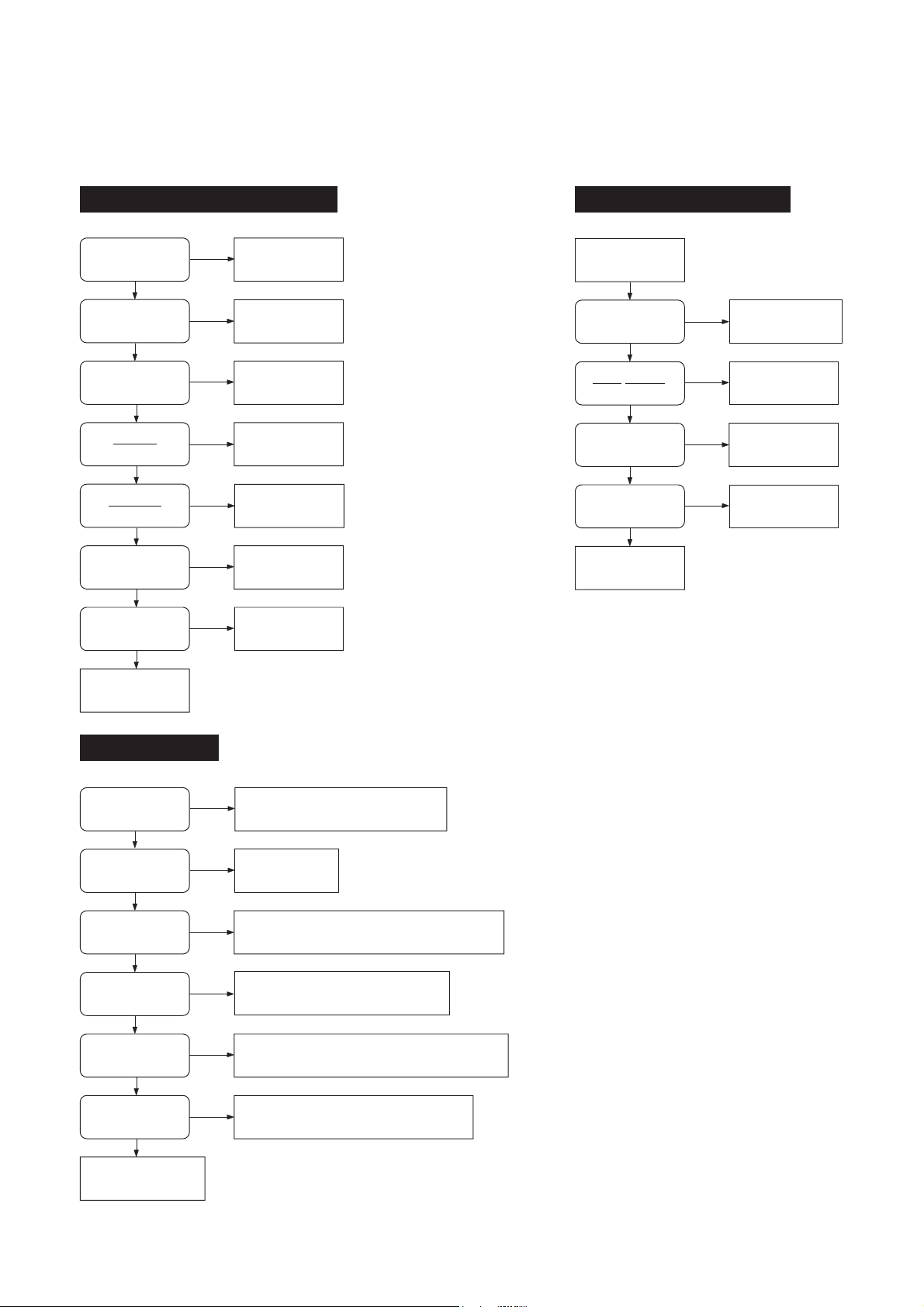

[1] TROUBLESHOOTING GUIDE

D. REPAIR PROCEDURE

C-40ZOOM/D-40ZOOM

POWER LOSS INOPERTIVE

CHECK PFC include

IC301-90 (SCAN IN 5)

PULSE INPUT

YES

IC302-7 (UNREG)

HIGH

IC301-81

(VDD)

HIGH

IC301-84

(RESET)

HIGH

IC301-85

(BAT OFF)

HIGH

IC301-80

OSCILLATION

YES

IC301-82

OSCILLATION

YES

NO

POWER SW, CN304,

LOW

CHECK PW1, CA2

LOW

LOW

LOW

NO

NO

CHECK IC302

CHECK IC302, R3006

CHECK R3007

CHECK X3001

CHECK X3002,

R3011, C3009, C3010

R3021

TAKING INOPERATIVE

PUSH SHUTTER

BUTTON

IC301-6, 89

(SCAN IN 2, 3)

PULSE INPUT

YES

CN306-6, 8

(P ON, P(A) ON)

HIGH

CN306-30, 31, 33

HIGH

YES

SERIAL

COMMUNICATION

OK

CHECK CA2

CHECK PFC include

NO

CN303, R3004, RB301

LOW

NO

IC301, CA2, PW1

NG

CHECK IC301, CA2

SHUTTER SW,

CHECK IC301,

R3025, PW1

CHECK

CHECK IC301

NO PICTURE

CLK (96 MHz)

INPUT TO

IC102-283 (CLK IN 1)

NO

CLK (36 MHz)

INPUT TO

IC101-132 (CLK IN 1)

OK

IC101-61 (ZAS)

OK

IC101-52

(ZBREQ)

OK

IC101-56

(ZBGRNT)

OK

IC101-118, 119

(IRL1, 2)

OK

CHECK SOLDERING OF

EACH CPU AND

MEMORY PIN

MAIN CLOCK FOR SYSTEM OPERATION

YES

NO OPERATION IF ABSENT

CHECK X1101 OSCILLATOR AND IC111

NG

BASIC CPU BLOCK

CHECK IC102-272

ALWAYS APPEARS WHEN CPU, ETC. IS ACCESSED

NG

CHECK IF CPU IS READKING PROGRAM, AND

CHECK ADDRESS AND DATA BUS OF IC121

REQUEST FOR USE OF DATA BUS FROM

NG

ASIC TO CPU NO DMA TRANSMISSION

IF ABSENT

RECEIVES ZBREQ SIGNAL AND GIVES PERMISSION

NG

TO ASIC FOR USE OF DATA BUS

NO DMA TRANSMISSION IF ABSENT

INCORRECT HANDSHAKING BETWEEN 8-BIT

NG

CPU AND RS-232C

CHECK EACH INTERFACE

D-2 Ver. 1

Page 3

D. REPAIR PROCEDUREC-40ZOOM/D-40ZOOM

2002.08.20

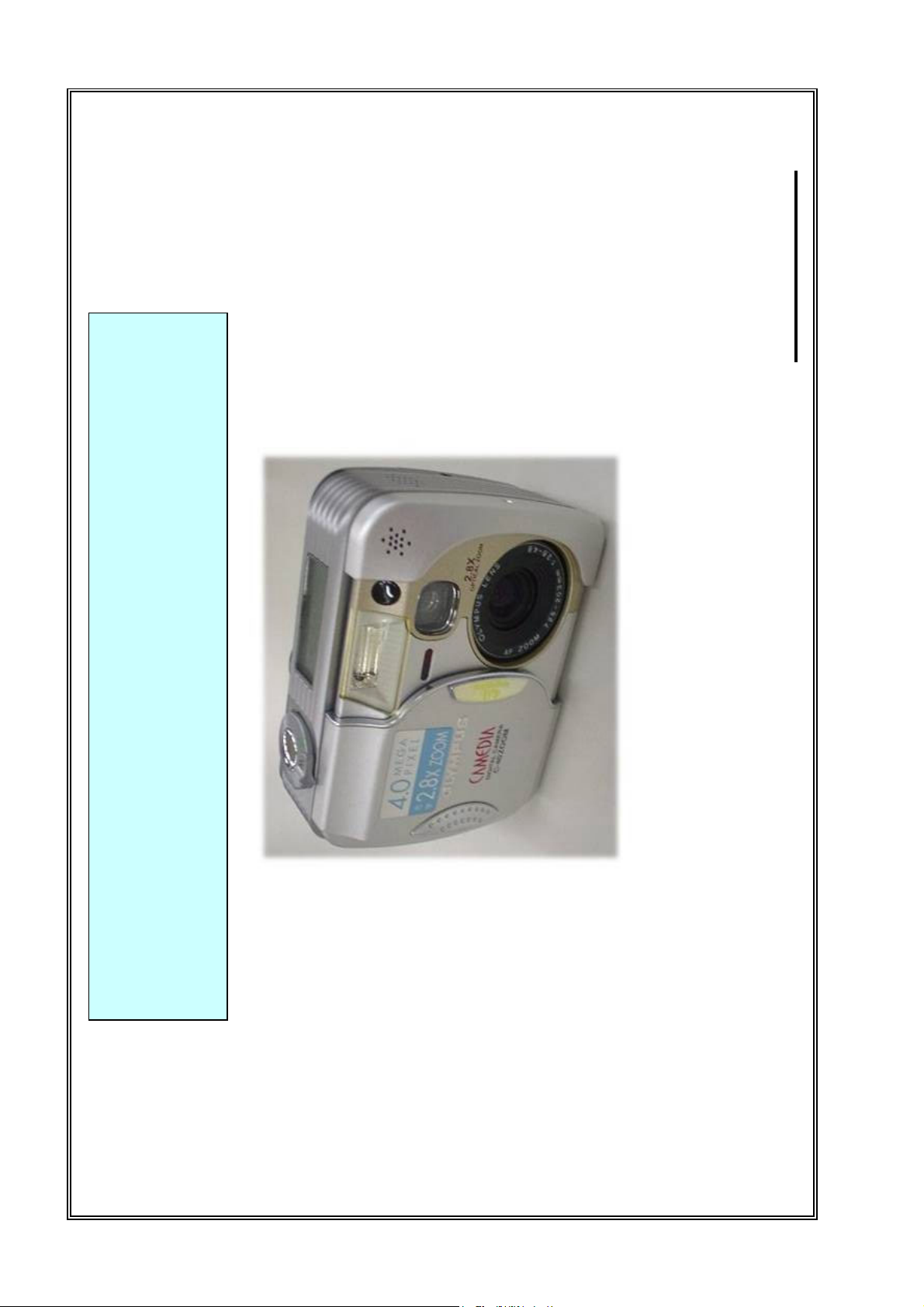

C-40ZOOM

DOCUMENT

CA-2 EXCHANGE PROCEDURE

※ Refer to the service manual for each adjustment.

Ver.1/Rev.4

D-3

Page 4

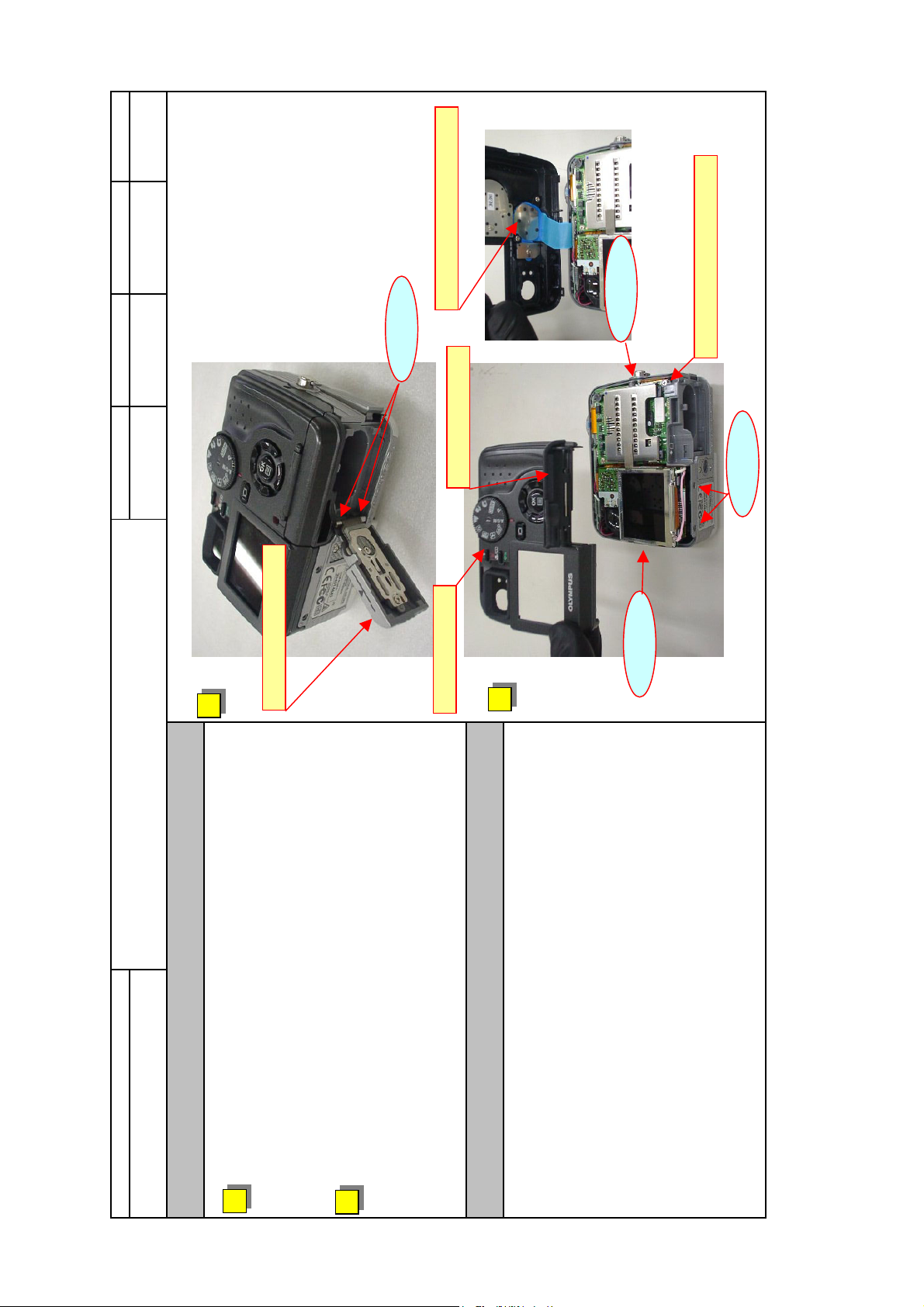

PAGEDATEDCHANG DAYDRAWN

D. REPAIR PROCEDURE

UNIT CONTROL BACK

C-40ZOOM/D-40ZOOM

SCREW_c

SCREW_a

A2002.07.30 2002.07.24 1

COVER CARD

COVER BATTERY

1

CABI BACK

2

SCREW_b

COVER CARD SW

SCREW_d

ASSEMBLE INSTRUCTION

SCREW : b SHLPN174R0SM- 1

・ Remove FPC of UNIT CONTROL BACK fron SY-1.

ASSEMBLE PROCEDURES

MODEL NAME

C-40ZOOM

SCREW : a SHLPN174R0SA- 2

the main part.

Remove 2 screws , and remove COVER BATTERY from

1

the main part.

Remove 4 screws , and remove CABINET BACK from

2

c SHLPN175R0SM- 1

d SHLPN175R0SA- 2

CAUTIONS

open COVER CARD.

(In order to prevent COVER CARD SW breaking.)

・ The time of removing CABI BACK -- surely -- You have to

D-4

reinforcement board.

・ Be sure to perform FPC extraction and insertion by having a

Ver.1/Rev.4

Page 5

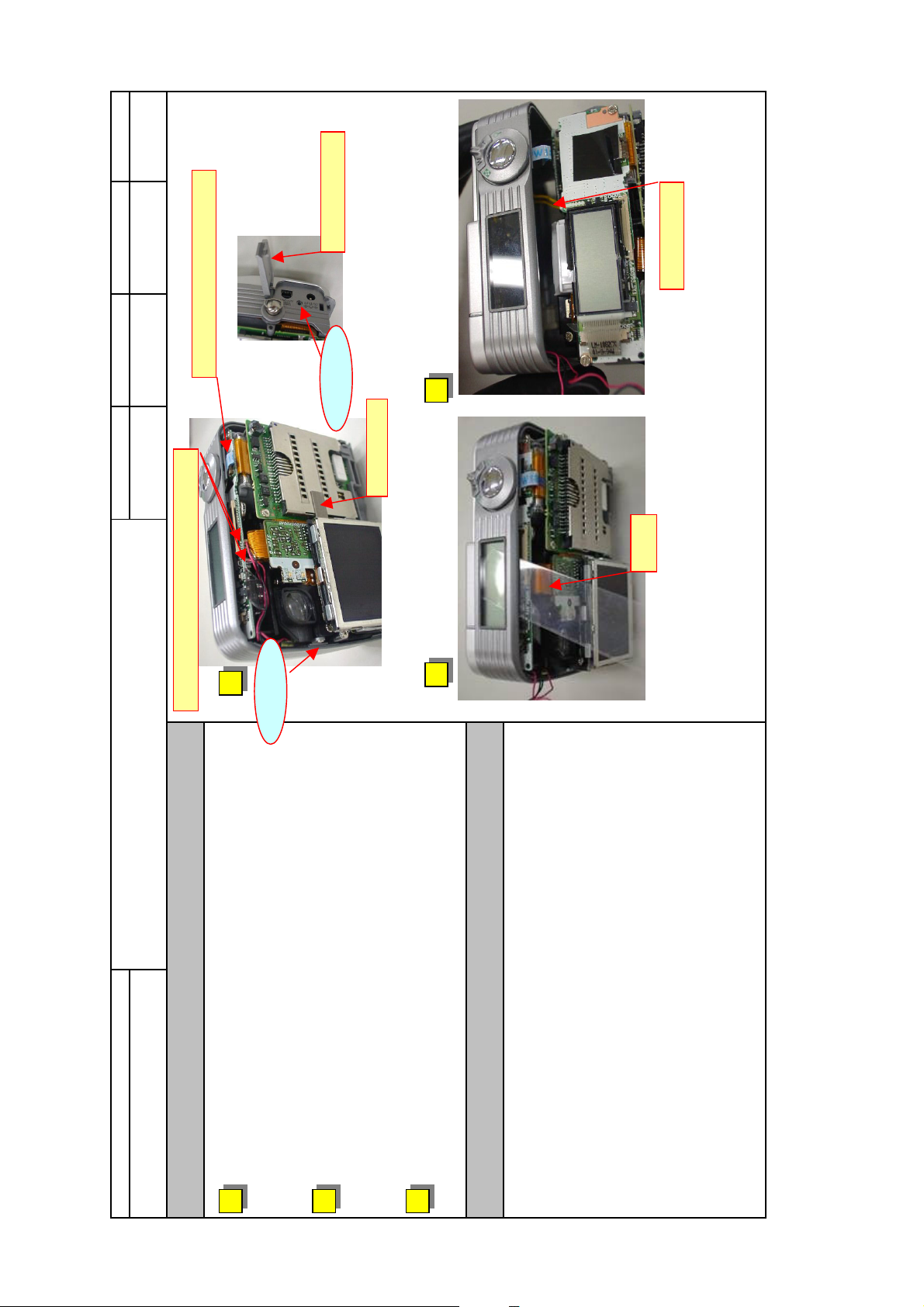

PAGEDATEDCHANG DAYDRAWN

A2002.07.30 2002.07.24 2

D. REPAIR PROCEDUREC-40ZOOM/D-40ZOOM

COVER JACK

LEAF SW

FPC of UNIT CONTROL

SCREW_a

PAD L=12

1

CONNECTOR of MIC , SPEAKER

SCREW_a

2 3

ASSEMBLE INSTRUCTION

JIG

MODEL NAME

Ver.1/Rev.4

SCREW : a SHLPN174R0SA- 2

ASSEMBLE PROCEDURES

C-40ZOOM

Remove 2 screws, connector of MIC, connector of SPEAKER,

FPC of UNIT CONTROL TOP, and PAD on card socket.

1

as right photograph.

Remove CABI FRONT from the main part using JIG as shown

2

Remove connector of LEAF SW from SY-1.

3

D-5

CAUTIONS

open COVER JACK.

・ The time of removing CABI BACK -- surely -- You have to

reinforcement board.

・ Be sure to perform FPC extraction and insertion by having a

Page 6

PAGEDATEDCHANG DAYDRAWN

D. REPAIR PROCEDURE

C-40ZOOM/D-40ZOOM

2002.07.25 3

MODE LCD

1

SY-1

4

FLEXIBLE REMOCON

SCREW

3

TB-1

2

HOLDER FLASH

ASSEMBLE INSTRUCTION

ASSEMBLE PROCEDURES

MODEL NAME

C-40ZOOM

Extract FPC of MODE LCD , and remove MODE LCD from

SY-1.

Remove TB-1.

1

2

SCREW : SHMPN174R0SA- 1

Remove a screw , and remove HOLDER FLASH from

the main part.

3

CAUTIONS

Remove FPC of FLEXIBLE REMOCON from SY-1.

4

D-6

reinforcement board.

・ Be sure to perform FPC extraction and insertion by having a

Ver.1/Rev.4

Page 7

PAGEDATEDCHANG DAYDRAWN

2002.07.25 4

D. REPAIR PROCEDUREC-40ZOOM/D-40ZOOM

SCREW_a

1

ASSEMBLE INSTRUCTION

2

PW-1

FPC CA2-SY1

3

SCREW_b

MODEL NAME

Ver.1/Rev.4

SCREW : a SHMPN174R0SA- 2

ASSEMBLE PROCEDURES

C-40ZOOM

Remove 2 screws , and remove SY-1 from the main part.

1

Remove FPC CA2-SY1 , and remove SY-1.

2

CAUTIONS

SCREW : b SHMPN174R0SA- 1

Remove a screw from PW-1.

3

D-7

reinforcement board.

・ Be sure to perform FPC extraction and insertion by having a

Page 8

5

PAGEDATEDCHANG DAY

D. REPAIR PROCEDURE

C-40ZOOM/D-40ZOOM

5

2002.07.25

DRAWN

1

CA-2

EARTH CA2-ST1

SCREW_a

2

COVER TACT SW

SCREW_b

FPC CA2-PW1

FPC of CA1

FPC CA2-SY1

3

4

FPC of LCD

ASSEMBLE INSTRUCTION

b SHMPN175R0SA- 1

SCREW : a SHMPN174R0SA- 1

ASSEMBLE PROCEDURES

MODEL NAME

C-40ZOOM

Remove 2 screws from CA-2.

1

Remove EARTH CA2-ST1and COVER TACT SW.

2

Remove FPC CA2-PW1from CA2.

3

CAUTIONS

Remove FPC of CA1 and FPC of LCD from CA2.

4

Remove FPC CA2-SY1 from CA2.

5

D-8

reinforcement board.

・ Be sure to perform FPC extraction and insertion by having a

Ver.1/Rev.4

Page 9

D. REPAIR PROCEDUREC-40ZOOM/D-40ZOOM

PAGEDATEDCHANG DAYDRAWN

2002.07.26 6

FPC of LCD

2

3

FPC of CA1

FPC CA2-PW1

4

1

FPC CA2-SY1

ASSEMBLE INSTRUCTION

ASSEMBLE PROCEDURES

JIG for CA-2

CAUTIONS

MODEL NAME

Ver.1/Rev.4

C-40ZOOM

Put CA-2 on an even field and fix FPC CA2-SY1to CA-2.

1

Set MAIN PART to JOG and fix FPC of LCD to CA-2.

2

※ You may use tweezers etc., If you required it.

Fix FPC of CA1 to CA-2.

3

Fix FPC CA2-PW1 to CA-2.

4

D-9

from the back.

・ Be careful of handling enough for stress not to join CA-2.

・ When you attach a connector in CA2, be sure to press down

・ You have to use JIG ,when attaching CA-2.

Page 10

PAGEDATEDCHANG DAYDRAWN

D. REPAIR PROCEDURE

C-40ZOOM/D-40ZOOM

Move to an advance end.

B2002.08.19 2002.07.26 7

Move to an advance end.

1

CA-2 is made to slide to the left,

CA2 is certainly hung on a hook so

3

taking care that a hook does not

2

that a shock may not join it.

The position relation between CA2

and rib has become like this

photograph.

4

HOOK

The position of a boss hole is

united with a boss.

ASSEMBLE INSTRUCTION

ASSEMBLE PROCEDURES

MODEL NAME

C-40ZOOM

Set main part to JIG like a right photograph.

CA-2 is hooked on a hook so that a shock may not join it.

Taking care that a hook does not separate, CA-2 is

made to slide to the left and it puts on a rib.

The boss of the chassis of the lower right of a main part and

the position of the boss hole of CA-2 check certainly

matching. After that CA-2 is attached.

1

2

3

4

CAUTIONS

・ Be careful of handling enough for stress not to join CA-2.

・ Set to JIG certainly.

・ It warns against giving a crack to stroboscope parts.

D-10

Ver.1/Rev.4

Page 11

PAGEDATEDCHANG DAYDRAWN

A2002.07.30 2002.07.26 8

D. REPAIR PROCEDUREC-40ZOOM/D-40ZOOM

EARTH CA2-ST1

Move to an advance end.

2

SCREW_a

1

SCREW_b

PAD L=12

COVER TACT SW

HOLDER MONITOR

ASSEMBLE INSTRUCTION

3

SCREW

MODEL NAME

Ver.1/Rev.4

b SHMPN175R0SA- 1

SCREW : a SHMPN174R0SA- 1

ASSEMBLE PROCEDURES

C-40ZOOM

Fix EARTH CA2-ST1 and COVER TACT SW

to main part, its fix with 2 screws.

1

PAD is stuck ranging over HOLDER MONITOR and S/M.

2

CAUTIONS

SCREW : SHMPN174R0SA- 1

Main part is put and changed to JIG like a right photograph,

and fix with a screw.

3

D-11

Tightening torque : 0.14±0.02N・m

: 1.40±0.20kgf・cm

・ Be careful of handling enough for stress not to join CA-2.

・ Set to JIG certainly.

・ It warns against giving a crack to stroboscope parts.

Page 12

PAGEDATEDCHANG DAYDRAWN

2002.07.29 9

D. REPAIR PROCEDURE

SCREW

C-40ZOOM/D-40ZOOM

3

FLEXIBLE REMOCON

1

FPC CA2-SY1

ASSEMBLE INSTRUCTION

2

CAUTIONS

ASSEMBLE PROCEDURES

MODEL NAME

C-40ZOOM

Insert FPC CA2-SY1 to SY-1certainly.

1

SCREW : SHMPN174R0SA- 2

Tightening torque : 0.14±0.02N・m

: 1.40±0.20kgf・cm

Fix SY-1 to main part with 2 screws.

2

Insert FPC of FLEXIBLE REMOCON to SY-1.

3

reinforcement board.

・ Be sure to perform FPC extraction and insertion by having a

D-12

Ver.1/Rev.4

Page 13

PAGEDATEDCHANG DAYDRAWN

D. REPAIR PROCEDUREC-40ZOOM/D-40ZOOM

MODE LCD

HOLDER FLASH BASE

B2002.08.19 2002.07.29 10

SCREW

1

HOLDER FLASH

3

Minus pole lead wire

LINE

REFERENCE

BOSS

TB-1

MODEL NAME

Ver.1/Rev.4

ASSEMBLE INSTRUCTION

SCREW : SHMPN174R0SA- 1

ASSEMBLE PROCEDURES

C-40ZOOM

Fix HOLDER FLASH to BASE with a screw.

1

Stick TB-1 to main part like a right photograph.

2

FPC of Mode LCD is inserted in a socket and Mode LCD

is stuck on HOLDER FLASH.

3

D-13

CAUTIONS

a minus pole lead wire.

・ When fixing HOLDER FLASH to BASE, it warns against inserting

Tightening torque : 0.14±0.02N・m

: 1.40±0.20kgf・cm

Page 14

PAGEDATEDCHANG DAYDRAWN

A2002.07.30 2002.07.29 11

D. REPAIR PROCEDURE

1

FPC of UNIT CONTROL TOP

The lead of Leaf SW makes it move in the

direction of an arrow so that it may not

put between HOLDER FLASH.

C-40ZOOM/D-40ZOOM

SCREW

COVER JACK

3

LEAF SW LEAD WIRE

CABI FRONT

ASSEMBLE INSTRUCTION

3

4

2

SCREW

REFRECTOR IR

CONNECTOR of MIC , SPEAKER

Dress lead wire of MIC

and SPEAKER as shown.

HOLDER LENS

ASSEMBLE PROCEDURES

MODEL NAME

C-40ZOOM

SCREW : SHLPN174R0SA- 2

※ Please check the notes in a figure.

Insert connector of MIC and SPEAKER to SY-1, and insert

FPC of UNIT CONTROL TOP to SY-1.

Insert leaf SW connector of CABI FRONT to SY-1, and

fix CABI FRONT to main part.

1

2

Fix CABINET FRONT to main part with 2 screws.

3

CAUTIONS

Tightening torque : 0.14±0.02N・m

: 1.40±0.20kgf・cm

Dress lead wire of MIC and SPEAKER.

4

D-14

open COVER JACK.

・ The time of fixing CABI BACK -- surely -- You have to

reinforcement board.

・ Be sure to perform FPC extraction and insertion by having a

・ Be careful of handling enough for stress not to join CA-2.

Ver.1/Rev.4

Page 15

PAGEDATEDCHANG DAYDRAWN

D. REPAIR PROCEDUREC-40ZOOM/D-40ZOOM

SCREW_b

A2002.07.30 2002.07.29 12

COVER CARD

CABI BACK

1

2

SCREW_a

UNIT CONTROL BACK

COVER CARD SW

SCREW_c

SCREW

3

COVER BATTERY

MODEL NAME

Ver.1/Rev.4

ASSEMBLE INSTRUCTION

b SHLPN175R0SM- 1

c SHLPN175R0SA- 2

ASSEMBLE PROCEDURES

C-40ZOOM

Insert FPC of UNIT CONTROL BACK to SY-1, and fix

CABINET BACK to main part.

1

screws are fastened in order of a b c.

2

SCREW : a SHLPN174R0SM- 1

SCREW : SHLPN174R0SA- 2

Fix COVER BATTERY to main part with 2 screws.

3

D-15

CAUTIONS

open COVER CARD.

・ The time of fixing CABI BACK -- surely -- You have to

Tightening torque : 0.14±0.02N・m

: 1.40±0.20kgf・cm

(In order to prevent COVER CARD SW breaking.)

reinforcement board.

・ Be sure to perform FPC extraction and insertion by having a

Loading...

Loading...