Page 1

D. REPAIR PROCEDUREC-40ZOOM/D-40ZOOM

C-40ZOOM

DOCUMENT

CA-2 EXCHANGE PROCEDURE

※ Refer to the service manual for each adjustment.

Ver.1/Rev.4

D-3

Page 2

PAGEDATEDCHANG DAYDRAWN

D. REPAIR PROCEDURE

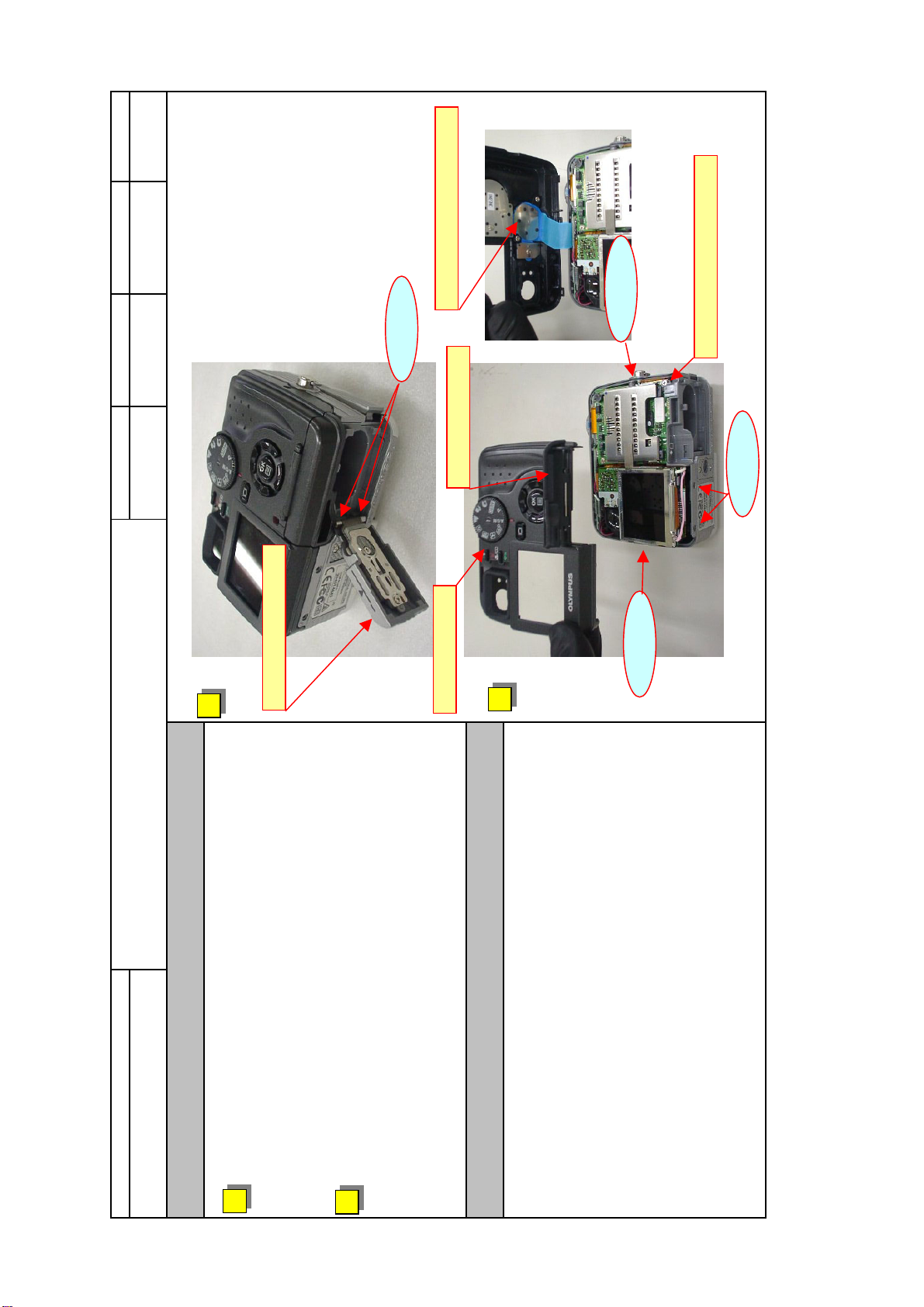

UNIT CONTROL BACK

C-40ZOOM/D-40ZOOM

SCREW_c

SCREW_a

A2002.07.30 2002.07.24 1

COVER CARD

COVER BATTERY

1

CABI BACK

2

SCREW_b

COVER CARD SW

SCREW_d

ASSEMBLE INSTRUCTION

SCREW : b SHLPN174R0SM- 1

・ Remove FPC of UNIT CONTROL BACK fron SY-1.

ASSEMBLE PROCEDURES

MODEL NAME

C-40ZOOM

SCREW : a SHLPN174R0SA- 2

the main part.

Remove 2 screws , and remove COVER BATTERY from

1

the main part.

Remove 4 screws , and remove CABINET BACK from

2

c SHLPN175R0SM- 1

d SHLPN175R0SA- 2

CAUTIONS

open COVER CARD.

(In order to prevent COVER CARD SW breaking.)

・ The time of removing CABI BACK -- surely -- You have to

D-4

reinforcement board.

・ Be sure to perform FPC extraction and insertion by having a

Ver.1/Rev.4

Page 3

PAGEDATEDCHANG DAYDRAWN

A2002.07.30 2002.07.24 2

D. REPAIR PROCEDUREC-40ZOOM/D-40ZOOM

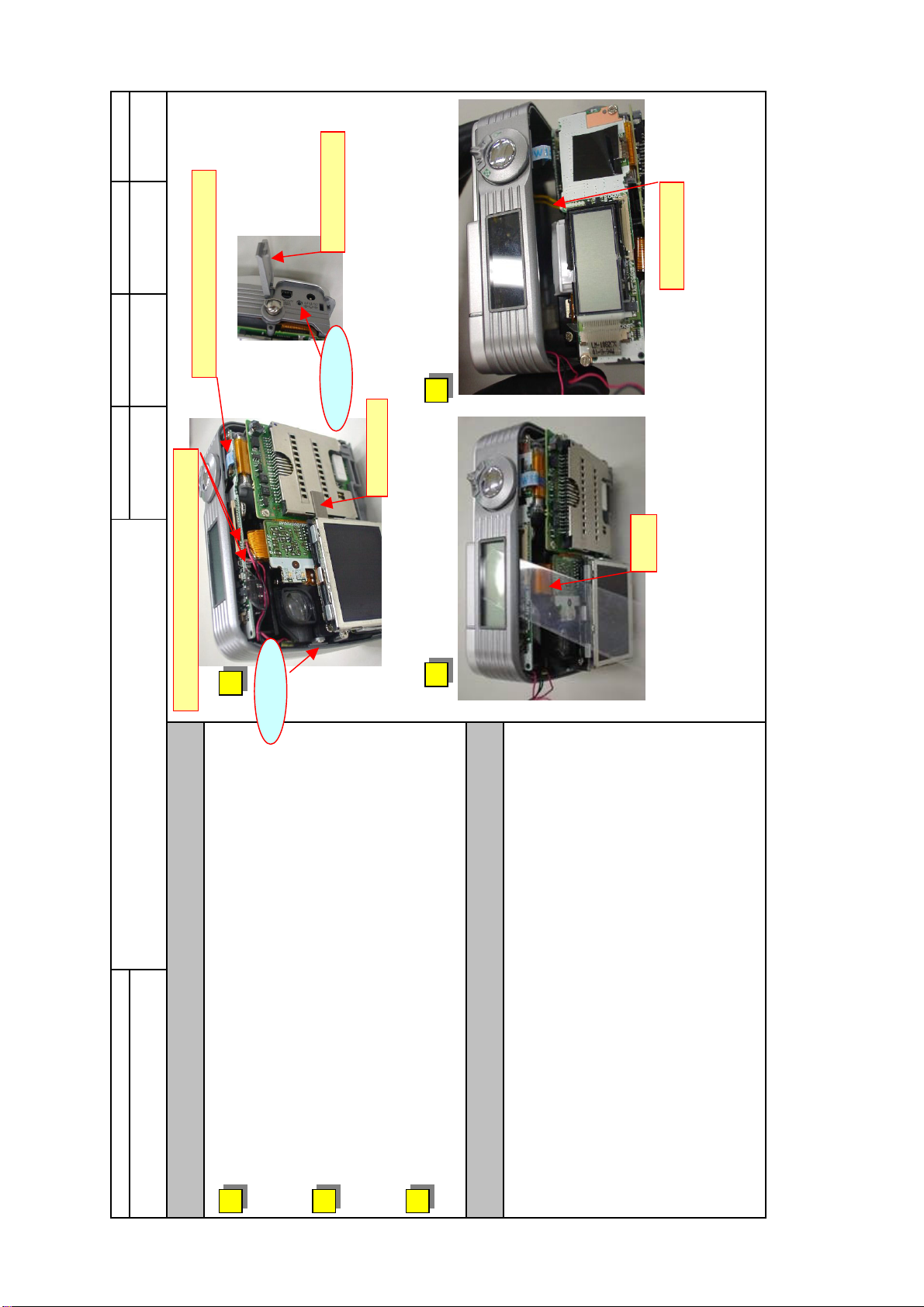

COVER JACK

LEAF SW

FPC of UNIT CONTROL

SCREW_a

PAD L=12

1

CONNECTOR of MIC , SPEAKER

SCREW_a

2 3

ASSEMBLE INSTRUCTION

JIG

MODEL NAME

Ver.1/Rev.4

SCREW : a SHLPN174R0SA- 2

ASSEMBLE PROCEDURES

C-40ZOOM

Remove 2 screws, connector of MIC, connector of SPEAKER,

FPC of UNIT CONTROL TOP, and PAD on card socket.

1

as right photograph.

Remove CABI FRONT from the main part using JIG as shown

2

Remove connector of LEAF SW from SY-1.

3

D-5

CAUTIONS

open COVER JACK.

・ The time of removing CABI BACK -- surely -- You have to

reinforcement board.

・ Be sure to perform FPC extraction and insertion by having a

Page 4

PAGEDATEDCHANG DAYDRAWN

D. REPAIR PROCEDURE

C-40ZOOM/D-40ZOOM

2002.07.25 3

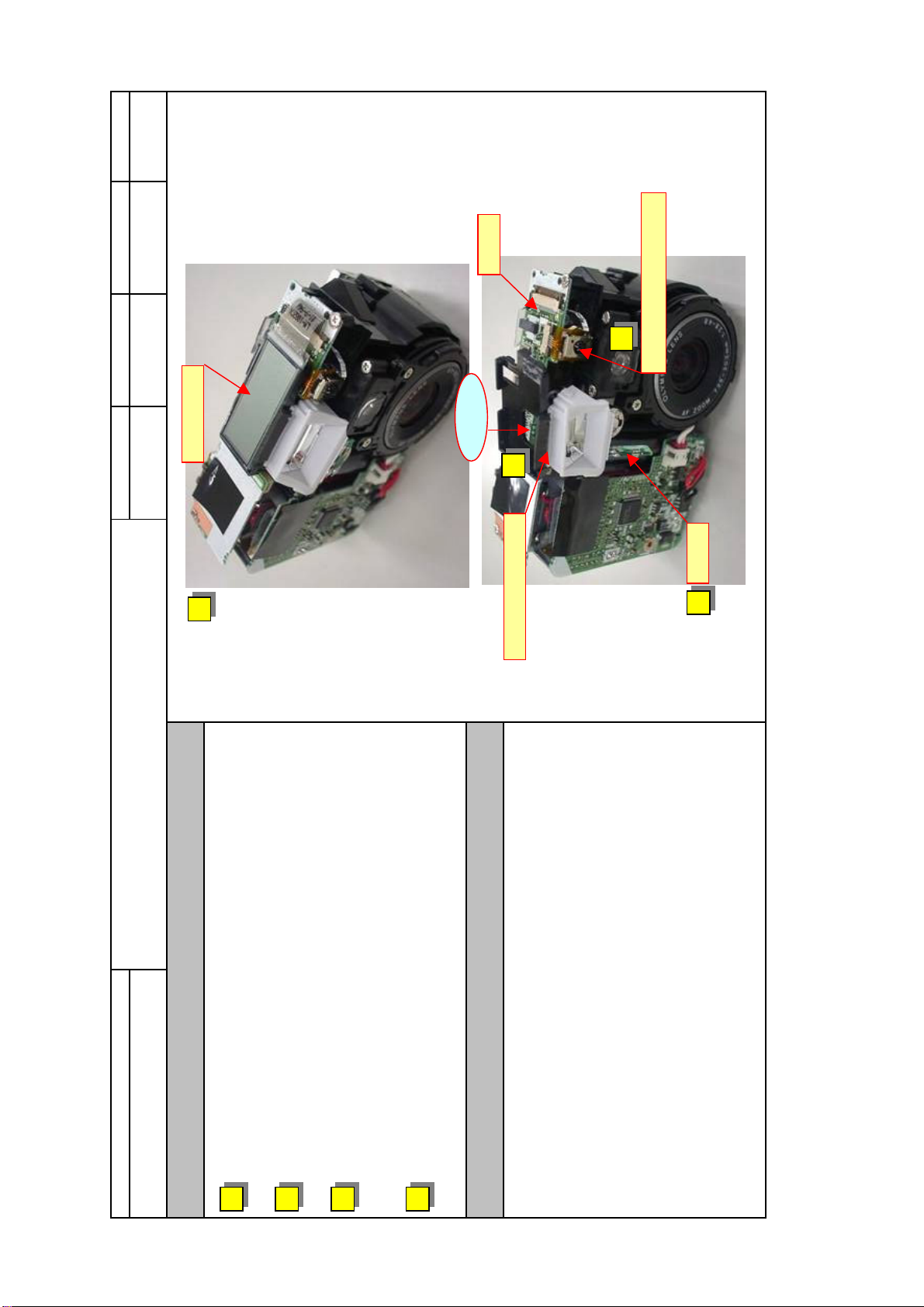

MODE LCD

1

SY-1

4

FLEXIBLE REMOCON

SCREW

3

TB-1

2

HOLDER FLASH

ASSEMBLE INSTRUCTION

ASSEMBLE PROCEDURES

MODEL NAME

C-40ZOOM

Extract FPC of MODE LCD , and remove MODE LCD from

SY-1.

Remove TB-1.

1

2

SCREW : SHMPN174R0SA- 1

Remove a screw , and remove HOLDER FLASH from

the main part.

3

CAUTIONS

Remove FPC of FLEXIBLE REMOCON from SY-1.

4

D-6

reinforcement board.

・ Be sure to perform FPC extraction and insertion by having a

Ver.1/Rev.4

Page 5

PAGEDATEDCHANG DAYDRAWN

2002.07.25 4

D. REPAIR PROCEDUREC-40ZOOM/D-40ZOOM

SCREW_a

1

ASSEMBLE INSTRUCTION

2

PW-1

FPC CA2-SY1

3

SCREW_b

MODEL NAME

Ver.1/Rev.4

SCREW : a SHMPN174R0SA- 2

ASSEMBLE PROCEDURES

C-40ZOOM

Remove 2 screws , and remove SY-1 from the main part.

1

Remove FPC CA2-SY1 , and remove SY-1.

2

CAUTIONS

SCREW : b SHMPN174R0SA- 1

Remove a screw from PW-1.

3

D-7

reinforcement board.

・ Be sure to perform FPC extraction and insertion by having a

Page 6

5

PAGEDATEDCHANG DAY

D. REPAIR PROCEDURE

C-40ZOOM/D-40ZOOM

5

2002.07.25

DRAWN

1

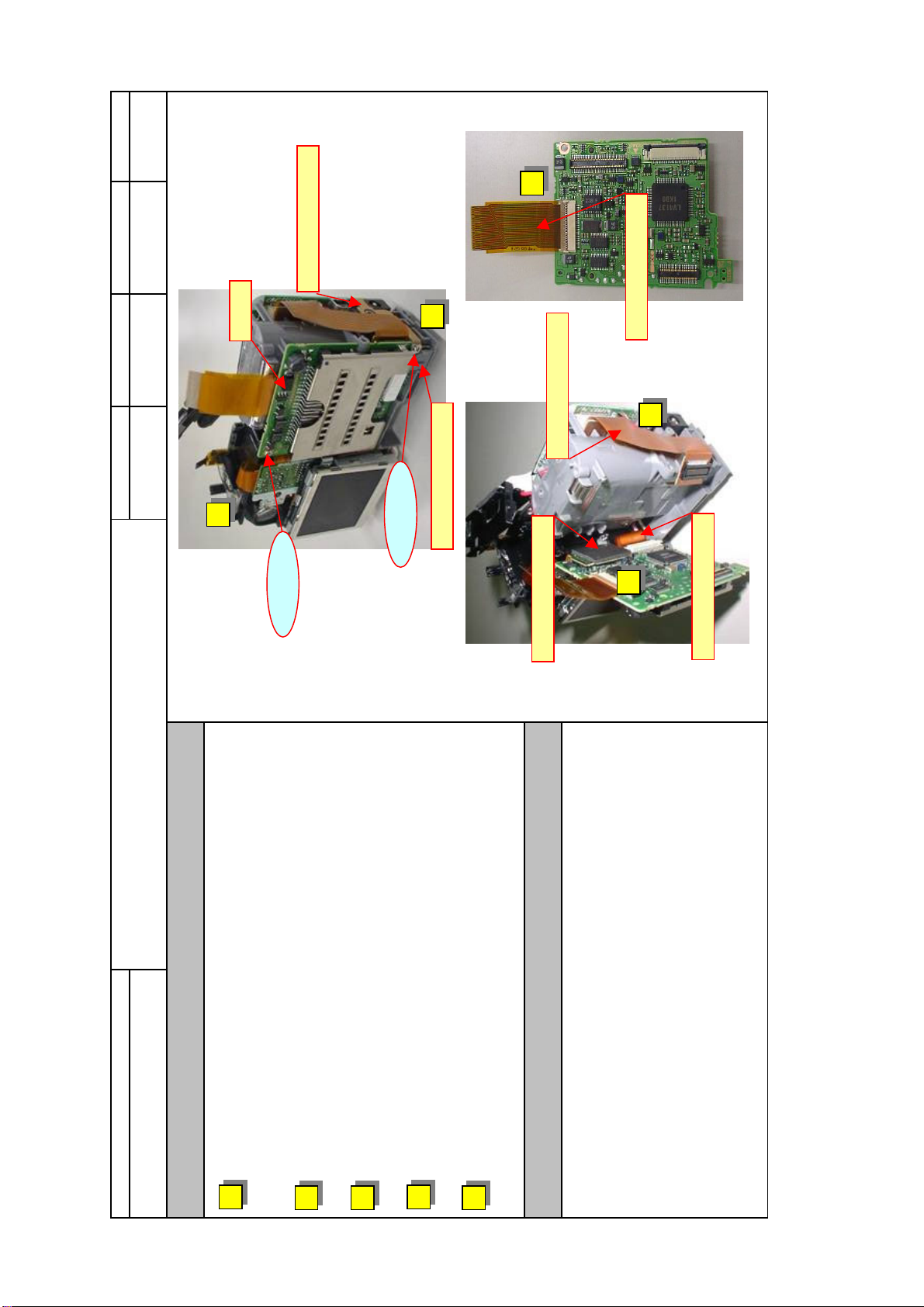

CA-2

EARTH CA2-ST1

SCREW_a

2

COVER TACT SW

SCREW_b

FPC CA2-PW1

FPC of CA1

FPC CA2-SY1

3

4

FPC of LCD

ASSEMBLE INSTRUCTION

b SHMPN175R0SA- 1

SCREW : a SHMPN174R0SA- 1

ASSEMBLE PROCEDURES

MODEL NAME

C-40ZOOM

Remove 2 screws from CA-2.

1

Remove EARTH CA2-ST1and COVER TACT SW.

2

Remove FPC CA2-PW1from CA2.

3

CAUTIONS

Remove FPC of CA1 and FPC of LCD from CA2.

4

Remove FPC CA2-SY1 from CA2.

5

D-8

reinforcement board.

・ Be sure to perform FPC extraction and insertion by having a

Ver.1/Rev.4

Page 7

D. REPAIR PROCEDUREC-40ZOOM/D-40ZOOM

PAGEDATEDCHANG DAYDRAWN

2002.07.26 6

FPC of LCD

2

3

FPC of CA1

FPC CA2-PW1

4

1

FPC CA2-SY1

ASSEMBLE INSTRUCTION

ASSEMBLE PROCEDURES

JIG for CA-2

CAUTIONS

MODEL NAME

Ver.1/Rev.4

C-40ZOOM

Put CA-2 on an even field and fix FPC CA2-SY1to CA-2.

1

Set MAIN PART to JOG and fix FPC of LCD to CA-2.

2

※ You may use tweezers etc., If you required it.

Fix FPC of CA1 to CA-2.

3

Fix FPC CA2-PW1 to CA-2.

4

D-9

from the back.

・ Be careful of handling enough for stress not to join CA-2.

・ When you attach a connector in CA2, be sure to press down

・ You have to use JIG ,when attaching CA-2.

Page 8

PAGEDATEDCHANG DAYDRAWN

D. REPAIR PROCEDURE

C-40ZOOM/D-40ZOOM

Move to an advance end.

B2002.08.19 2002.07.26 7

Move to an advance end.

1

CA-2 is made to slide to the left,

CA2 is certainly hung on a hook so

3

taking care that a hook does not

2

that a shock may not join it.

The position relation between CA2

and rib has become like this

photograph.

4

HOOK

The position of a boss hole is

united with a boss.

ASSEMBLE INSTRUCTION

ASSEMBLE PROCEDURES

MODEL NAME

C-40ZOOM

Set main part to JIG like a right photograph.

CA-2 is hooked on a hook so that a shock may not join it.

Taking care that a hook does not separate, CA-2 is

made to slide to the left and it puts on a rib.

The boss of the chassis of the lower right of a main part and

the position of the boss hole of CA-2 check certainly

matching. After that CA-2 is attached.

1

2

3

4

CAUTIONS

・ Be careful of handling enough for stress not to join CA-2.

・ Set to JIG certainly.

・ It warns against giving a crack to stroboscope parts.

D-10

Ver.1/Rev.4

Page 9

PAGEDATEDCHANG DAYDRAWN

A2002.07.30 2002.07.26 8

D. REPAIR PROCEDUREC-40ZOOM/D-40ZOOM

EARTH CA2-ST1

Move to an advance end.

2

SCREW_a

1

SCREW_b

PAD L=12

COVER TACT SW

HOLDER MONITOR

ASSEMBLE INSTRUCTION

3

SCREW

MODEL NAME

Ver.1/Rev.4

b SHMPN175R0SA- 1

SCREW : a SHMPN174R0SA- 1

ASSEMBLE PROCEDURES

C-40ZOOM

Fix EARTH CA2-ST1 and COVER TACT SW

to main part, its fix with 2 screws.

1

PAD is stuck ranging over HOLDER MONITOR and S/M.

2

CAUTIONS

SCREW : SHMPN174R0SA- 1

Main part is put and changed to JIG like a right photograph,

and fix with a screw.

3

D-11

Tightening torque : 0.14±0.02N・m

: 1.40±0.20kgf・cm

・ Be careful of handling enough for stress not to join CA-2.

・ Set to JIG certainly.

・ It warns against giving a crack to stroboscope parts.

Page 10

PAGEDATEDCHANG DAYDRAWN

2002.07.29 9

D. REPAIR PROCEDURE

SCREW

C-40ZOOM/D-40ZOOM

3

FLEXIBLE REMOCON

1

FPC CA2-SY1

ASSEMBLE INSTRUCTION

2

CAUTIONS

ASSEMBLE PROCEDURES

MODEL NAME

C-40ZOOM

Insert FPC CA2-SY1 to SY-1certainly.

1

SCREW : SHMPN174R0SA- 2

Tightening torque : 0.14±0.02N・m

: 1.40±0.20kgf・cm

Fix SY-1 to main part with 2 screws.

2

Insert FPC of FLEXIBLE REMOCON to SY-1.

3

reinforcement board.

・ Be sure to perform FPC extraction and insertion by having a

D-12

Ver.1/Rev.4

Page 11

PAGEDATEDCHANG DAYDRAWN

D. REPAIR PROCEDUREC-40ZOOM/D-40ZOOM

MODE LCD

HOLDER FLASH BASE

B2002.08.19 2002.07.29 10

SCREW

1

HOLDER FLASH

3

Minus pole lead wire

LINE

REFERENCE

BOSS

TB-1

MODEL NAME

Ver.1/Rev.4

ASSEMBLE INSTRUCTION

SCREW : SHMPN174R0SA- 1

ASSEMBLE PROCEDURES

C-40ZOOM

Fix HOLDER FLASH to BASE with a screw.

1

Stick TB-1 to main part like a right photograph.

2

FPC of Mode LCD is inserted in a socket and Mode LCD

is stuck on HOLDER FLASH.

3

D-13

CAUTIONS

a minus pole lead wire.

・ When fixing HOLDER FLASH to BASE, it warns against inserting

Tightening torque : 0.14±0.02N・m

: 1.40±0.20kgf・cm

Page 12

PAGEDATEDCHANG DAYDRAWN

A2002.07.30 2002.07.29 11

D. REPAIR PROCEDURE

1

FPC of UNIT CONTROL TOP

The lead of Leaf SW makes it move in the

direction of an arrow so that it may not

put between HOLDER FLASH.

C-40ZOOM/D-40ZOOM

SCREW

COVER JACK

3

LEAF SW LEAD WIRE

CABI FRONT

ASSEMBLE INSTRUCTION

3

4

2

SCREW

REFRECTOR IR

CONNECTOR of MIC , SPEAKER

Dress lead wire of MIC

and SPEAKER as shown.

HOLDER LENS

ASSEMBLE PROCEDURES

MODEL NAME

C-40ZOOM

SCREW : SHLPN174R0SA- 2

※ Please check the notes in a figure.

Insert connector of MIC and SPEAKER to SY-1, and insert

FPC of UNIT CONTROL TOP to SY-1.

Insert leaf SW connector of CABI FRONT to SY-1, and

fix CABI FRONT to main part.

1

2

Fix CABINET FRONT to main part with 2 screws.

3

CAUTIONS

Tightening torque : 0.14±0.02N・m

: 1.40±0.20kgf・cm

Dress lead wire of MIC and SPEAKER.

4

D-14

open COVER JACK.

・ The time of fixing CABI BACK -- surely -- You have to

reinforcement board.

・ Be sure to perform FPC extraction and insertion by having a

・ Be careful of handling enough for stress not to join CA-2.

Ver.1/Rev.4

Page 13

PAGEDATEDCHANG DAYDRAWN

D. REPAIR PROCEDUREC-40ZOOM/D-40ZOOM

SCREW_b

A2002.07.30 2002.07.29 12

COVER CARD

CABI BACK

1

2

SCREW_a

UNIT CONTROL BACK

COVER CARD SW

SCREW_c

SCREW

3

COVER BATTERY

MODEL NAME

Ver.1/Rev.4

ASSEMBLE INSTRUCTION

b SHLPN175R0SM- 1

c SHLPN175R0SA- 2

ASSEMBLE PROCEDURES

C-40ZOOM

Insert FPC of UNIT CONTROL BACK to SY-1, and fix

CABINET BACK to main part.

1

screws are fastened in order of a b c.

2

SCREW : a SHLPN174R0SM- 1

SCREW : SHLPN174R0SA- 2

Fix COVER BATTERY to main part with 2 screws.

3

D-15

CAUTIONS

open COVER CARD.

・ The time of fixing CABI BACK -- surely -- You have to

Tightening torque : 0.14±0.02N・m

: 1.40±0.20kgf・cm

(In order to prevent COVER CARD SW breaking.)

reinforcement board.

・ Be sure to perform FPC extraction and insertion by having a

Loading...

Loading...