Page 1

C. ADJUSTMENT METHOD C-120/D-380

C. ADJUSTMENT METHOD

[1] TABLE FOR SERVICING TOOLS .......................................................................... C-2

[2] EQUIPMENT ..........................................................................................................C-2

[3] ADJUSTMENT ITEMS AND ORDER ..................................................................... C-2

[4] SETUP....................................................................................................................C-2

[5] CONNECTING THE CAMERA TO THE COMPUTER ............................................ C-3

[6] USB STORAGE INFORMATION REGISTRATION ................................................. C-4

[7] ADJUST SPECIFICATIONS ................................................................................... C-4

1. IC501 Oscillation Frequency Adjustment ......................................................... C-4

2. 5.1 V (A) VOLTAGE ADJUSTMENT .................................................................... C-4

3. AWB ADJUSTMENT ............................................................................................ C-5

4. COLOR ADJUSTMENT ....................................................................................... C-5

5. CCD WHITE POINT DEFECT DETECT ADJUSTMENT ....................................C-5

6. CCD BLACK POINT DEFECT DETECT ADJUSTMENT .................................... C-5

7. LCD PANEL ADJUSTMENT .............................................................................. C-6

7-1. LCD H AFC ADJUSTMENT ...................................................................... C-6

7-2. LCD RGB OFFSET ADJUSTMENT .......................................................... C-6

7-3. LCD GAIN ADJUSTMENT ....................................................................... C-6

7-4. LCD BLUE BRIGHTNESS ADJUSTMENT .............................................. C-6

7-5. LCD RED BRIGHTNESS ADJUSTMENT ................................................ C-7

7-6. LCD VCOMPP ADJUSTMENT................................................................. C-7

[8] Lens ADJUSTMENT............................................................................................... C-7

[9] ADJUSTMENT ITEMS ............................................................................................C-8

SIMENS STAR CHART ................................................................................................... C-9

C-1 Ver.1

Page 2

C. ADJUSTMENT METHOD C-120/D-380

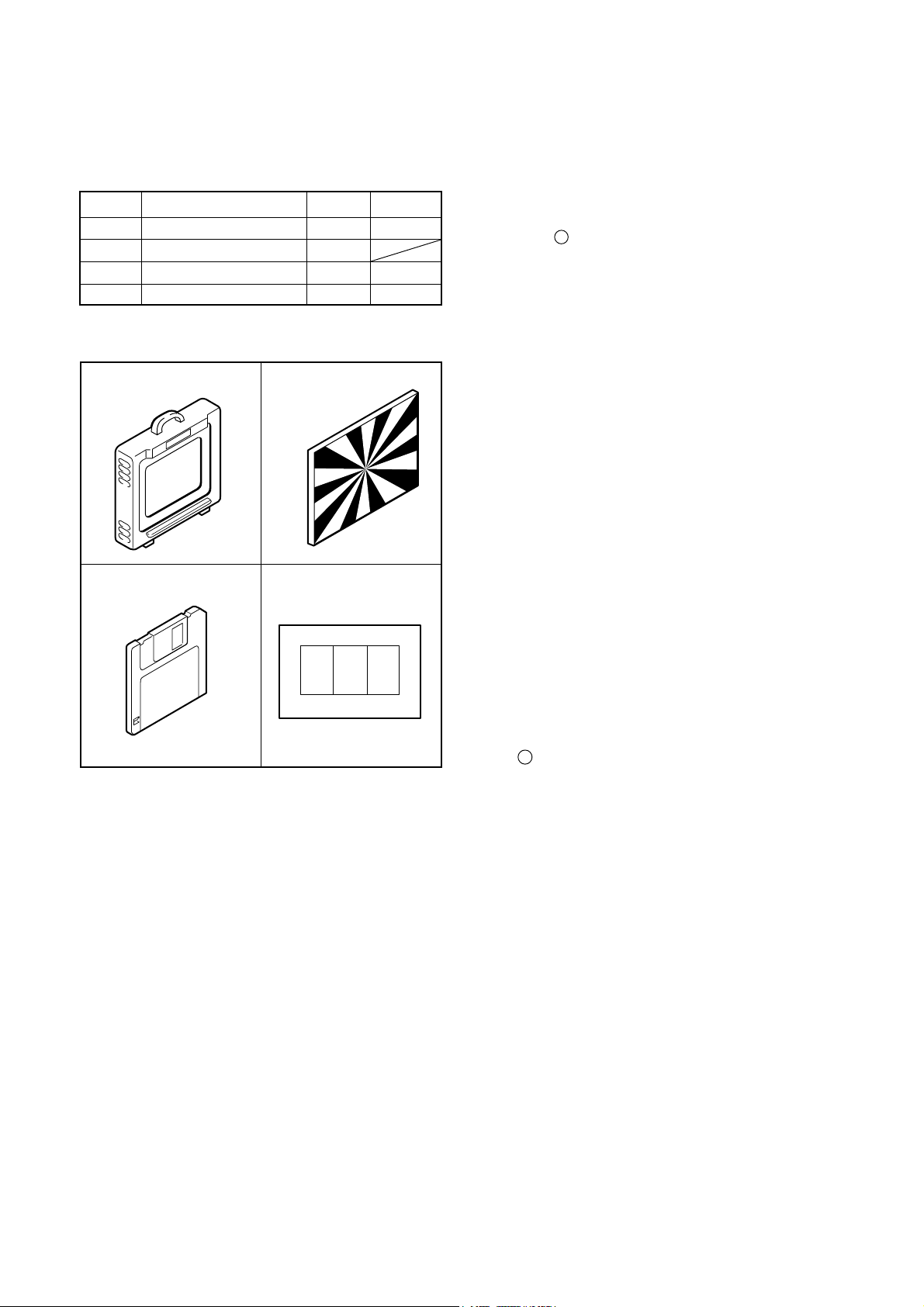

[1] Table for Servicing Tools

Ref. No. Name Part code

J-1

J-2

J-3

J-4

Note: J-1 color viewer is 100 - 110 VAC only.

Color viewer 5,100 K

Siemens star chart

Calibration software

Chart for color adjustment

Number

1

1

1

1

VJ8-0007

VJ8-0189

VJ8-0155

J-1 J-2

J-3

J-4

[2] Equipment

1. Oscilloscope

2. Digital voltmeter

3. AC adaptor

4. PC (IBM R -compatible PC, Pentium processor, Win dow 98 or Me or 2000)

[3] Adjustment Items and Order

1. IC501 Oscillation Frequency Adjustment

2. 5.1 V (A) Voltage Adjustment

3. AWB Adjustment

4. Color Adjustment

5. CCD White Point Defect Detect Adjustment

6. CCD Black Point Defect Detect Adjustment

7. LCD Panel Adjustment

7-1. LCD H AFC Adjustment

7-2. LCD RGB Offset Adjustment

7-3. LCD Gain Adjustment

7-4. LCD Blue Brightness Adjustment

7-5. LCD Red Brightness Adjustment

7-6. LCD VcomPP Adjustment

8. Lens Adjustment

Note:

1. If the lens, CCD, board and changing the part in item 36 replace, it is necessary to adjust again. 3-5 adjust-

ments other than these should be carried out in se quence. Item 6 adjustment should be carried out after

item 3.

[4]. Setup

1. System requirements

Windows 98 or Me or 2000

IBM R -compatible PC with pentium processor

CD-ROM drive

3.5-inch high-density diskette drive

USB port

40 MB RAM

Hard disk drive with at least 15 MB available

VGA or SVGA monitor with at least 256-color display

2. Installing calibration software

1. Insert the calibration software installation diskette into

your diskette drive.

2. Open Explorer.

3. Copy the DscCalDI_128c folder on the floppy disk in

the FD drive to a folder on the hard disk.

3. Installing USB drive

Install the USB drive with camera or connection kit for PC.

C-2 Ver. 1

Page 3

C. ADJUSTMENT METHODC-120/D-380

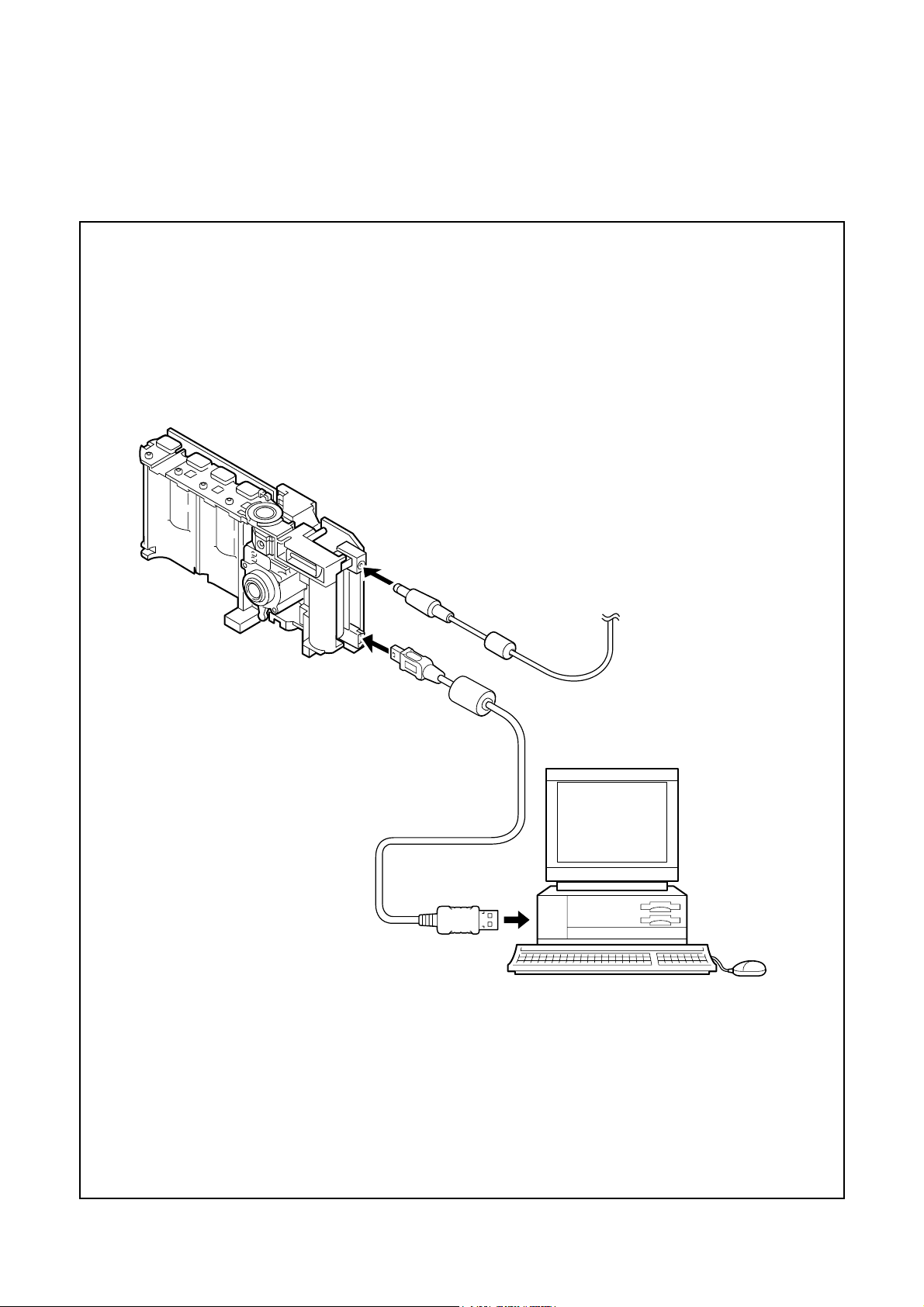

[5] Connecting the camera to the computer

1. Line up the arrow on the cable connector with the notch on the camera's USB port. Insert the connector.

2. Locate a USB port on your computer.

USB cable

To USB port

AC adaptor

C-3 Ver. 1

Page 4

C. ADJUSTMENT METHOD C-120/D-380

[6] USB Storage Information Registration

USB storage data is important for when the camera is connected to a computer via a USB connection.

If there are any errors in the USB storage data, or if it has

not been saved, the USB specification conditions will not be

satisfied, so always check and save the USB storage data.

Preparation:

POWER switch: ON

Adjustment method:

1. Connect the camera to a computer. (Refer to [5] Connecting the camera to the computer on the page C-3.)

2. Double-click on the DscCalDi128c.

3. Click on the Get button in the USB storage window and

check the USB storage data.

VID: OLYMPUS

PID: C-120/D-380

Serial:

Rev. : 1.00

4. Check the “Serial” in the above USB storage data. If the

displayed value is different from the serial number printed

on the base of the camera, enter the number on the base

of the camera. Then click the Set button.

5. Next, check VID, PID and Rev. entries in the USB storage data. If any of them are different from the values in

3. above, make the changes and then click the corresponding Set button.

[7] Adjust Specifications

[CP1 board (Side B)]

S3001

CL310

VR503

VR501

(side A)

CL526

(side A)

CL423

CL425

CL309

CL568

CL415

CL424

(side A)

CL428

Note:

1. Carry out the voltage adjustment with LCD through display mode.

Preparation:

1. Shorten the pin 1 and pin 2 of S3001 (card switch).

2. Shorten the CL309 and CL310 (connection parts of power

switch wires).

3. Insert the smart media.

4. Connect the power, and turn on the LCD switch.

1. IC501 Oscillation Frequency Adjustment

Calibration

AWB

Focus

UV Matrix

Cal Mode

OK

Cal Data

OK

USB storage

VID

Get

PID

Set

Upload

Firmware

Image

Initialize

EVF

LCD Type

LCD

R Bright

RGB Offset

Tint

VCO

H AFC Test

Serial

Set

Set

Rev.

B Bright

Gain

Phase

Set

Set

VCOMDC

VCOMPP

Setting

Language

Video Mode

Measuring Point

Measuring Equipment

ADJ. Location

ADJ. Value

CL526

Frequency counter

VR503

501.5 ± 1 kHz

Adjustment method:

1. Adjust with VR503 to 501.5 ± 1 kHz.

2. 5.1 V (A) Voltage Adjustment

Measuring Point

Measuring Equipment

ADJ. Location

ADJ. Value

Adjustment method:

1. Adjust with VR501 to 5.10 ± 0.05 V.

CL568

Digital voltmeter

VR501

5.10 ± 0.05 V

C-4 Ver. 1

Page 5

3. AWB Adjustment

C. ADJUSTMENT METHODC-120/D-380

W

1/4 H

Camera

All white pattern

Color viewer

Preparation:

POWER switch: ON

Macro switch: normal position

Adjusting method:

1. When setting the camera in place, set it to an angle so

that nothing appears in any part of the color viewer except the white section. (Do not enter any light.)

2. Double-click on the DscCalDi128c.

3. Click the “AWB”, and click the “Yes”.

4. AWB adjustment value will appear on the screen.

5. Click the OK.

4. Color Adjustment

H

Ye

R

1/8 W

Preparation:

POWER switch: ON

Macro switch: normal position

Adjustment method:

1. Set the color adjustment chart to the color viewer, and fix

the camera. (Do not enter any light.) This above chart

shows Ye (yellow) and R (red) portion should apart 1/4

high from edge, and should apart 1/8 width from edge.

2. Double-click on the DscCalDi128c.

3. Click the “UV Matrix”, and Click the “Yes”.

4. Color adjustment values will appear on the screen.

5. Click the OK.

5. CCD White Point Defect Detect Adjustment

Preparation:

POWER switch: ON

Adjustment method:

1. Double-click on the DscCalDi128c.

2. Select “CCD Defect” on the LCD “Test”, and click the

“Yes”.

3. After the adjustment is completed, the number of defect

will appear.

Camera

All white pattern color

viewer and color matrix

adjustment chart

C-5 Ver . 1

Page 6

C. ADJUSTMENT METHOD C-120/D-380

6. CCD Black Point Defect Detect Adjustment 7-1. LCD H AFC Adjustment

Preparation:

POWER switch: ON

Adjusting method:

1. Double-click on the DscCalDi128c.

2. Select 0 on the LCD “H AFC”.

3. While watching the LCD monitor, adjust “H AFC” so that

the edge of the LCD adjustment frame are the same distance from the left and right edge of the LCD screen.

(A = B)

Camera

LCD screen

All white pattern

Color viewer

A

FPC

LCD

adjustment

B

frame

Preparation:

POWER switch: ON

Macro switch: macro position

Adjusting method:

1. When setting the camera in place, set it to an angle so

that nothing appears in any part of the color viewer except the white section. (Do not enter any light.)

2. Double-click on the DscCalDi128c.

3. Select “CCD Black” on the LCD “Test”, and click the

“Yes”.

4. After the adjustment is completed, the number of defect

will appear.

7. LCD Panel Adjustment

[CP1 board (Side A/B)]

S3001

CL310

VR503

VR501

(side A)

CL526

(side A)

CL423

CL425

CL309

CL568

CL415

CL424

(side A)

CL428

7-2. LCD RGB Offset Adjustment

Adjusting method:

1. Adjust LCD “RGB Offset” so that the amplitude of the

CL424 waveform is 3.5 V ± 0.1 Vp-p.

3.5 V

± 0.1Vp-p

CL424 waveform

7-3. LCD Gain Adjustment

Adjusting method:

1. Adjust LCD “Gain” so that the amplitude of the CL424

waveform is 1.9 V ± 0.1 Vp-p.

Note:

7-2. LCD RGB Offset adjustment should always be carried

out first.

1.9 V

± 0.1 Vp-p

CL424 waveform

C-6 Ver. 1

Page 7

C. ADJUSTMENT METHODC-120/D-380

7-4. LCD Blue Brightness Adjustment

Adjusting method:

1. Adjust LCD “B Bright” so that the amplitude of the CL425

waveform is VG ± 0.1 Vp-p with respect to the CL424

(VG) waveform.

Note:

7-2. LCD RGB Offset adjustment and 7-3. LCD Gain adjustment should always be carried out first.

VG

CL424 waveform

VG ±

0.1 Vp-p

7-6. LCD VcomPP Adjustment

Adjusting method:

1. Adjust LCD “VCOMPP” so that the amplitude of the

CL415 waveform is 5.6 V ± 0.1 Vp-p.

5.6 V

± 0.1 Vp-p

CL415 waveform

8. Lens Adjustment

Adjusting method:

1. LH Plate is exchanged for LH Plate2 (VE383000) for the

adjustment with the mark. (It is cut at 10°.)

2. A FC ring should be pressure in the CCD direction by

about 150g. A chart is 1.2m from the front of the lens.

As for the chart, Large Siemens star chart (KC0324) is

used.

CL425 waveform

7-5. LCD Red Brightness Adjustment

Adjusting method:

1. Adjust LCD “R Bright” so that the amplitude of the CL423

waveform is VG ± 0.1 Vp-p with respect to the CL424

(VG) waveform.

Note:

7-2. LCD RGB Offset adjustment and 7-3. LCD Gain adjustment have done.

VG

CL424 waveform

VG ±

0.1 Vp-p

CL423 waveform

3. It turns it until a FC ring is seen from the front of the lens

and put in the CW direction and stuck and it stops.

4. One of the mountains of Roulette of the FC ring is de cided as the mark. (The side of the gate)

5. It hints in the CW direction, and a FC ring is turned in

CCW from the condition with making TFT on condition

and confirming an image in TTL. Then, anabbreviation

peak is found in TTL, and marking is done in LH Plate2.

6. It is returned by five in the CW direction from the mark ing position. That is decided with the start position, and

turning it one indication toward CCW, and shoot one

photography.Repeating this ten times and shoot it

ten photography.

7. An image is confirmed with the PC, and a FC ring is

checked with the best, and screw of LH Plate2 is fas tened and fixed. (A FC ring is always turned in the CCW

direction from the CW direction and checked.)

C-7 Ver. 1

Page 8

[9] Adjustment Items

CCD

LENS

CP1

1. IC501 Oscillation Frequency Adjustment

2. 5.1V(A) Voltage Adjustment

3. AWB Adjustment

4. Color Adjustmen

5. CCD White Point Defect Detect Adjustment

6. CCD Black Point Defect Detect Adjustment

7-1. LCD H AFC Adjustment

7-2. LCD RGB Offset Adjustment

7-3. LCD Gain Adjustment

7-4. LCD Blue Brightness Adjustment

7-5. LCD Red Brightness Adjustment

7-6. LCD VcomPP Adjustment

8. Lens Adjustment

Changed repair parts

Adjustment items

C. ADJUSTMENT METHOD C-120/D-380

○

○

○ ○ ○

○ ○ ○

○ ○ ○

○ ○ ○

○

○

○

○

○

○

○ ○ ○

C-8 Ver. 1

Page 9

C. ADJUSTMENT METHOD C-120/D-380

C-9 Ver. 1

Loading...

Loading...