Oliver 641 Installation Manual

Grand Rapids, Michigan, U.S.A. 49504-5298

USER’S OPERATING AND INSTRUCTION MANUAL

MODEL 641

DOUGH ROLLER

0641S20000-CV

641 DOUGH ROLLER

INDEX

Section Description

Document No. Page No.

SAFETY INSTRUCTIONS -------------------------------------- 0641S20003 --------------------------- 1-1

DESCRIPTION/SPECIFICATIONS --------------------------- 0641S20004---------------------------- 2-1

Description -------------------------------------------------------------------------------------------------- 2-1

Specifications----------------------------------------------------------------------------------------------- 2-1

INSTALLATION INSTRUCTIONS ---------------------------- 0641S20005 --------------------------- 3-1

Dough Roller Installation ---------------------------------------------------------------------------------3-1

OPERATING INSTRUCTIONS -------------------------------- 0641S20006 --------------------------- 4-1

TROUBLESHOOTING ------------------------------------------- 0641S20007 --------------------------- 5-1

The Dough Roller Will Not Start (Motor is Not Humming) --------------------------------------- 5-1

The Dough Roller Will Not Start (Motor is Humming) -------------------------------------------- 5-1

Lines or Marks in Finished Crust ---------------------------------------------------------------------- 5-2

The Dough is Not Feeding ------------------------------------------------------------------------------ 5-2

The Dough is Sticking to Rollers -----------------------------------------------------------------------5-3

MAINTENANCE --------------------------------------------------- 0641S20008 --------------------------- 6-1

Cleaning ----------------------------------------------------------------------------------------------------- 6-1

Removing Scrapers -------------------------------------------------------------------------------------- 6-1

General Notes on Disassembly ----------------------------------------------------------------------- 6-2

Lubrication -------------------------------------------------------------------------------------------------- 6-2

Service ------------------------------------------------------------------------------------------------------- 6-2

RECOMMENDED SPARE PARTS -------------------------- 0641S20009 --------------------------- 7-1

REPLACEMENT PARTS SECTION

MAIN FRAME ------------------------------------------------------ 0641S2

Drawing ------------------------------------------------------------------------------------------------- 8-1

Parts List ----------------------------------------------------------------------------------------------- 8-2

ROLLERS ---------------------------------------------------------- 0641S20011 --------------------------- 9-1

Drawing ------------------------------------------------------------------------------------------------- 9-1

Parts List ----------------------------------------------------------------------------------------------- 9-2

TABLES ------------------------------------------------------------- 0641S20012 ---------------------------10-1

Drawing ----------------------------------------------------------------------------------------------- Parts List -----------------------------------------------------------------------------------------------10-2

COVERS ------------------------------------------------------------ 0641S20013 ---------------------------11-1

Drawing ----------------------------------------------------------------------------------------------- Parts List -----------------------------------------------------------------------------------------------11-2

0010 --------------------------- 8-1

10-1

11-1

Continued

0641S20002 0-1

INDEX (Continued)

Section Description

Document No. Page No.

DRIVE --------------------------------------------------------------- 0641S20014 ---------------------------12-1

Drawing ----------------------------------------------------------------------------------------------- Parts List -----------------------------------------------------------------------------------------------12-2

ELECTRICAL PARTS ------------------------------------------- 0641S20015 ---------------------------13-1

Drawing ----------------------------------------------------------------------------------------------- Parts List -----------------------------------------------------------------------------------------------13-2

OPTIONAL STAND ---------------------------------------------- 0641S20016 ---------------------------14-1

Drawing ----------------------------------------------------------------------------------------------- Parts List -----------------------------------------------------------------------------------------------14-2

WIRING DIAGRAMS -------------------------------------------- 0641S20017 ---------------------------15-1

WARRANTY ---------------------------------------------------- --- GEN 040225

WARRANTY PROCEDURE------------------------------------ GEN 040226

RETURNED PARTS POLICY --------------------------------- GEN 040227

12-1

13-1

14-1

0641S20002 0-2

641 DOUGH ROLLER

SAFETY INSTRUCTIONS

WARNING

VARIOUS SAFETY DEVICES AND METHODS OF GUARDING HAVE BEEN

PROVIDED ON THIS MACHINE. IT IS ESSENTIAL HOWEVER THAT THE MACHINE

OPERATORS AND MAINTENANCE PERSONNEL OBSERVE THE FOLLOWING

SAFETY PRECAUTIONS. IMPROPER INSTALLATION, MAINTENANCE, OR

OPERATION OF THIS EQUIPMENT COULD CAUSE SERIOUS INJURY OR DEATH.

1. Read this manual before attempting to operate your machine. Never allow an

untrained person to operate or service this machine.

2. Connect the machine to a properly grounded electrical supply that matches the

requirements shown on the electrical specification plate and follow all specifications

of local electrical codes.

3. Disconnect and lock-out the machine from the power supply before cleaning or

servicing.

4. Check and secure all guards before starting the machine.

5. Observe all caution and warning labels affixed to the machine.

6. Use only proper replacement parts.

7. Do not wear loose fitting clothing or loose hair when working near this machine.

Shirt tails should be tucked in.

8. Wear proper, personal, protective, safety equipment.

9. Keep Hands away from the moving parts of this machine while it is in operation.

10. In addition to these general safety instructions, please follow the more specific safety

instructions in the rest of this operating instruction manual.

WARNING

DO NOT USE FOR OTHER THAN ORIGINALLY INTENDED PURPOSE.

0641S20003 1-1

641 DOUGH ROLLER

DESCRIPTION/SPECIFICATIONS

Description

The Oliver Model 641 Dough Roller is engineered to exacting standards. It’s designed to

provide maximum performance in minimal space. The machine is easy to operate, crusts

of uniform thickness are made quickly and easily.

Parts to be cleaned are quickly removed without the use of tools.

Available in 14”, 17” and 21” capacities.

Specifications

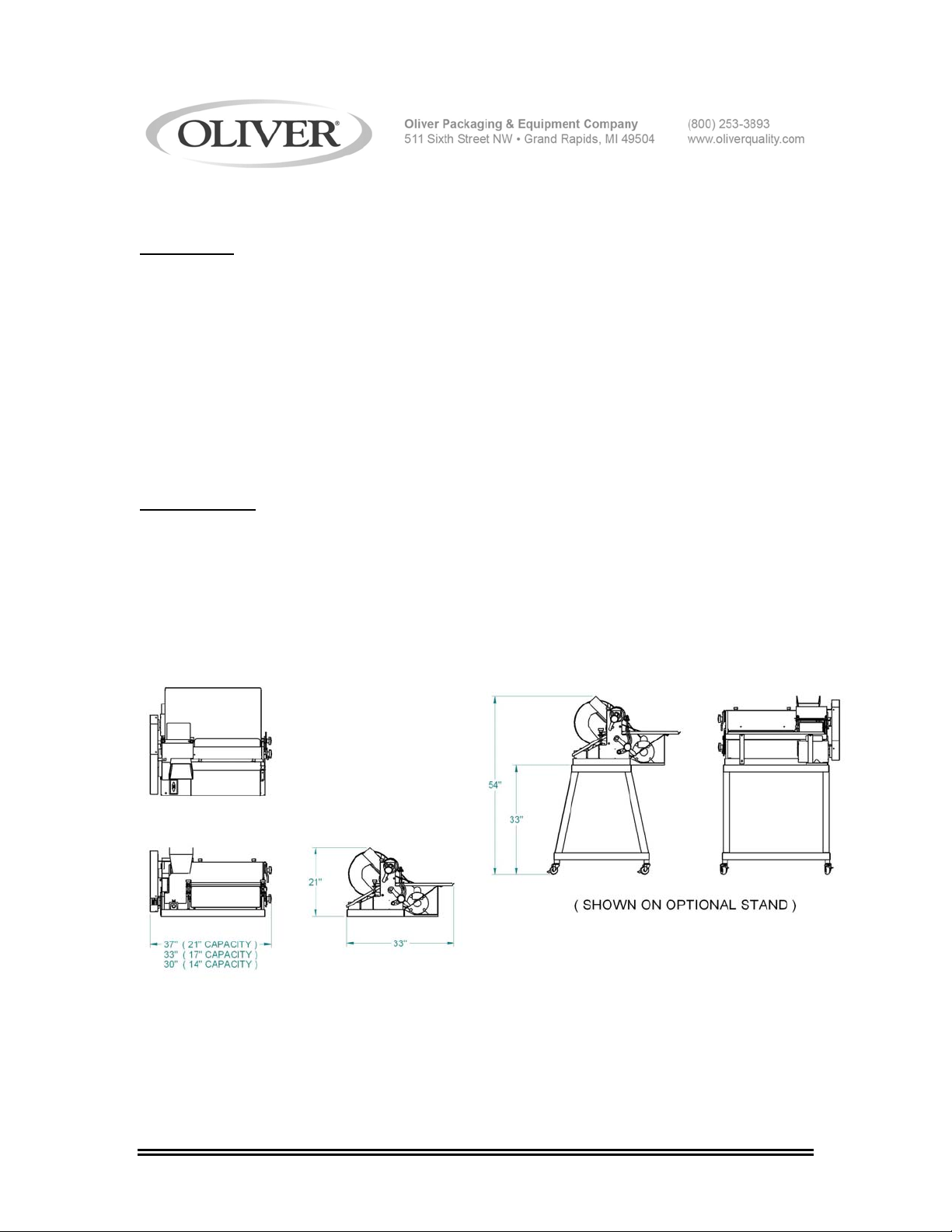

Space Requirements:

Model 641 (All Dimensions are Approximate)

Continued

0641S20004 2-1

DESCRIPTION/SPECIFICATIONS (Continued)

NOTE

Standard Electrical Options: (Others consult factory).

½ HP, 1 phase, 60 hz, 115VAC, 7 Amps.

½ HP, 1 phase, 60 hz, 230VAC, 3.5 Amps.

½ HP, 1 phase, 50 hz, 220VAC, 3.5 Amps.

Standard Product Width Capacity

14”, 17”, & 21”

Shipping Weight

14”: 212 lbs. (95 kg) (approximate)

17”: 227 lbs. (102 kg) (approximate)

21”: 257 lbs. (116 kg) (approximate)

Height

Bench Top: 21” (533 mm), (all widths) (approximate)

On Optional Stand: 54” (1372 mm), (all widths) (approximate)

Bench Space (All Dimensions are Approximate)

14”: 30” (762 mm) X 33” (838 mm)

17”: 33” (838 mm) X 33” (838 mm)

21”: 37” (940 mm) X 33” (838 mm)

Options

33” High Metal Stand with 3” Casters.

Above specifications subject to change without notice.

0641S20004 2-2

641 DOUGH ROLLER

INSTALLATION INSTRUCTIONS

Dough Roller Installation:

Before starting the Installation process make sure you observe the following three

caution notes.

CAUTION

THE DOUGH ROLLER IS HEAVY, USE PROPER TECHNIQUE WHEN LIFTING.

KEEP BACK STRAIGHT, KNEES BENT, AND LIFT WITH LEGS.

USE GLOVES TO PROTECT HANDS.

CAUTION

NEVER LIFT THE DOUGH ROLLER BY ITS COVERS OR GUARDS.

CAUTION

BEFORE PLACING THE DOUGH ROLLER ON THE TABLE OR COUNTER MAKE

SURE THAT IT CAN SUPPORT THE DOUGH ROLLER’S WEIGHT WHICH IS

APPROX. 260 POUNDS (21”).

Bench Mounted

Select a location for your dough roller which has a substantial mounting surface, (see

the caution note above), and which has electrical service compatible with the load the

machine will place on it as indicated on the electrical data plate of the machine.

Position the machine while it is still in its packaging as close as possible to the desired

end location. Expose the machine by removing the outer packaging. Remove any

straps or fasteners securing machine to crate. Using at least two people, (one in the

front and one at the back of the machine), lift the dough roller from the resting surface of

the packaging and set the machine onto the counter or table as close as possible to the

desired end location. The machine must be sealed to the counter using the included

neoprene rubber under machine edges. Plastic Hole plugs are included to close any

unused holes in machine base.

Continued

0641S20005 3-1

INSTALLATION INSTRUCTIONS (Continued)

Optional Stand Mounted

Note:

One bottom guard bolt will have to be removed to mount machine to stand.

Select a location for your dough roller which has a level surface, and which has electrical

service compatible with the load the machine will place on it as indicated on the

electrical data plate of the machine.

Position the machine while it is still in its packaging as close as possible to the desired

end location. Expose the machine and stand by removing the outer packaging.

Remove any straps or fasteners securing machine and stand to crate. Machine will only

go on the stand one way. Using at least two people, (one in the front and one at the

back of the machine), lift the dough roller from the resting surface of the packaging and

set the machine onto the stand. Secure to stand using the provided fasteners.

(see page 14-1)

For all Machines

1. Be sure machine is clean and dry.

2. Make sure power switch is in “Off” position.

3. Check machine nameplate for correct voltage and frequency.

4. Connect machine to a power source that matches nameplate requirements.

5. Switch power “On” and check for proper operation of the machine.

0641S20005 3-2

641 DOUGH ROLLER

OPERATING INSTRUCTIONS

WARNING

ALWAYS USE CARE WHENEVER WORKING NEAR THE ROLLERS.

KEEP HANDS CLEAR OF DOUGH CHUTE.

Machine Preparation

1. Make sure the dough chute and trays are dry.

2. Dust the transfer tray (Item 200, page 10-1) with flour, Leave a little extra flour in the

tray to dust the bottom side of the dough before it is sent through the second set of

rollers.

3. Make your initial setting of the roller adjustment levers. Loosen knob, move handle,

then tighten knob. Dial numbers are for reference only.

Dough Preparation

1. Size and shape of the dough ball affects size and shape of the finished crust. For

round pies make a dough piece a fat sausage shape and flatten slightly.

2. Dust the dough pieces with flour before putting them in the machine.

Making a Crust

1. Place the dough piece in the top hopper chute (Item 206, page 10-1) end first.

2. When the dough piece comes out in the transfer tray it should be a little longer than

the diameter of the pie.

3. Dust the top of the dough with flour. There should be sufficient flour in the transfer tray

to dust the bottom of the dough.

4. Turn the dough piece a quarter of a turn in the transfer tray and slide it sideways into

the second pass rollers.

WARNING

NEVER PUSH THE DOUGH WITH THE TIPS OF YOUR FINGERS.

5. The second pass rollers should produce a crust of the proper thickness and about

round in shape. If the crust is too thin, open the lower rollers. If the crust is to thick, close

the lower rollers. If the thickness is right but the crust is too short, make the initial dough

piece bigger and open the upper rollers. If it is too long, make the initial dough piece

smaller and close the upper rollers. When you get the results you want, it is a good idea

to write down the setting numbers if the adjustment levers for future reference.

0641S20006 4-1

641 DOUGH ROLLER

TROUBLESHOOTING

WARNING

ALWAYS DISCONNECT THE DOUGH ROLLER FROM THE POWER SUPPLY

BEFORE ATTEMPTING ANY TYPE OF MAINTENANCE TASK, INCLUDING

TROUBLESHOOTING.

The Dough Roller Will Not Start (Motor Is Not Humming)

• The machine is not plugged in.

• There is no power at the outlet. (Check by plugging in a small working appliance,

like a lamp. Check to see if a circuit breaker has tripped. If the circuit breaker has

not tripped and the circuit is still not working have a qualified electrician check the

circuit.)

• The thermal overload on dough roller power switch has tripped – turn machine off,

allow to cool then push switch further “Off” to reset.

• The problem is somewhere else in the electrical system of the machine. (Have a

qualified electrician find and repair the problem.)

The Dough Roller Will Not Start (Motor Is Humming)

CAUTION

DO NOT ALLOW THE MOTOR TO HUM WITHOUT STARTING.

OVERHEATING CAN PERMANENTLY DAMAGE THE MOTOR.

NOTE

A SPECIAL NON-VENTILATED MOTOR MUST BE USED WITH THIS DOUGH

ROLLER.

• The drive system is binding. (Have a qualified service agent check for defective

bearings or other restrictions to free movement.)

• There is mechanical interference between other parts of the Dough Roller. (Have a

qualified service agent evaluate the machine for adjustment or replacement of

defective parts.)

Continued

0641S20007 5-1

TROUBLESHOOTING (Continued)

• Broken belt or chain. (Have a qualified service agent evaluate the machine for

adjustment or replacement of defective parts.)

• The motor has failed. (Have it checked by a qualified electrician.)

Lines or Marks in Finished Crust

• The rollers need to be cleaned. (see Maintenance section of this manual)

The Dough is Not Feeding

• Too much flour on dough surface. Dust dough with less flour.

• Dough piece is too thin for current roller setting.

The Dough is Sticking to Rollers

• Dough needs more flour on surface. Dust dough with more flour.

• The rollers need to be cleaned. (see Maintenance section of this manual)

• Missing or improperly installed scrapers. (see Maintenance section of this manual)

0641S20007 5-2

Loading...

Loading...