Oliver 619-24RA Installation Manual

Grand Rapids, Michigan, U.S.A. 49504-5298

USER’S OPERATING AND INSTRUCTION MANUAL

MODEL 619-16A

MODEL 619-20A

MODEL 619-24RA

DOUGH DIVIDERS

0619S20000-CV1

INDEX |

|

|

Section Description |

Document No. |

Page No. |

SAFETY INSTRUCTIONS ------------------------------- |

0619S20047 --------------------- |

1-1 |

DESCRIPTION/SPECIFICATIONS -------------------- |

0619S20058---------------------- |

2-1 |

Description -------------------------------------------------------------------------------------- |

|

2-1 |

Physical Specifications----------------------------------------------------------------------- |

|

2-1 |

Electrical Specifications---------------------------------------------------------------------- |

|

2-2 |

Electrical Wiring Diagrams------------------------------------------------------------------- |

|

2-2 |

OPERATING INSTRUCTIONS ------------------------- |

0619S20048 --------------------- |

3-1 |

Before You Start ------------------------------------------------------------------------------ |

|

3-1 |

Basic Operation ------------------------------------------------------------------------------- |

|

3-1 |

MAINTENANCE -------------------------------------------- |

0619C20049 --------------------- |

4-1 |

Cleaning ----------------------------------------------------------------------------------------- |

|

4-1 |

Lubrication -------------------------------------------------------------------------------------- |

|

4-1 |

Hydraulic Oil Specification ------------------------------------------------------------------ |

|

4-2 |

Hydraulic Filter Replacement -------------------------------------------------------------- |

|

4-2 |

Removing The Lid ---------------------------------------------------------------------------- |

|

4-2 |

Replacing A Plastic Floor ------------------------------------------------------------------- |

|

4-2 |

Changing The Blades ------------------------------------------------------------------------ |

|

4-3 |

Replacing The Thrust Plate ---------------------------------------------------------------- |

|

4-3 |

Replacing The Hydraulic Cylinder -------------------------------------------------------- |

|

4-4 |

Removing The Motor ------------------------------------------------------------------------- |

|

4-4 |

Changing The Pump Or Coupling -------------------------------------------------------- |

|

4-5 |

Replacing The Control Valve -------------------------------------------------------------- |

|

4-5 |

Adjusting The Pressure Relief On The Control Valve ------------------------------- |

4-6 |

|

TROUBLESHOOTING ------------------------------------ |

0619S20050 --------------------- |

5-1 |

The “End of Stroke Light” Does Not Come On |

---------------------------------------- |

5-1 |

The Motor “Hums” But Will Not Start ---------------------------------------------------- |

|

5-1 |

The Motor Runs But “Stalls” During The Cylinder’s Stroke ------------------------ |

5-1 |

|

The Motor Has “Stalled” And Cannot Be Restarted --------------------------------- |

5-2 |

|

The Divider Is Not Cutting Properly ------------------------------------------------------ |

|

5-2 |

RECOMMENDED SPARE PARTS -------------------- |

0619S20051 --------------------- |

6-1 |

REPLACEMENT PARTS SECTION |

|

|

MAIN FRAME PARTS ----------------------------------- |

0619S20052 --------------------- |

7-1 |

Drawing ------------------------------------------------------------------------------------- |

|

7-1 |

Parts List ----------------------------------------------------------------------------------- |

|

7-2 |

|

|

Continued |

REV. 2-26-04 |

|

|

|

|

|

|

|

|

0619S20046 |

|

0-1 |

INDEX (Continued)

REPLACEMENT PARTS SECTION (Continued)

Section Description |

Document No. |

Page No. |

COVERS ----------------------------------------------------- |

0619S20053 --------------------- |

8-1 |

Drawing ------------------------------------------------------------------------------------- |

|

8-1 |

Parts List ----------------------------------------------------------------------------------- |

|

8-2 |

HYDRAULIC PARTS ------------------------------------- |

0619S20054 --------------------- |

9-1 |

Drawing ------------------------------------------------------------------------------------- |

|

9-1 |

Parts List ----------------------------------------------------------------------------------- |

|

9-2 |

LID PARTS -------------------------------------------------- |

0619S20055 -------------------- |

10-1 |

Drawing ------------------------------------------------------------------------------------ |

|

10-1 |

Parts List ---------------------------------------------------------------------------------- |

|

10-2 |

ELECTRICAL PARTS ------------------------------------ |

0619S20056 -------------------- |

11-1 |

Drawing ------------------------------------------------------------------------------------ |

|

11-1 |

Parts List ---------------------------------------------------------------------------------- |

|

11-2 |

PUSHER PARTS ------------------------------------------ |

0619S20057 -------------------- |

12-1 |

Drawing ------------------------------------------------------------------------------------ |

|

12-1 |

Parts List ---------------------------------------------------------------------------------- |

|

12-2 |

WARRANTY ------------------------------------------------ |

GEN 040225 |

|

WARRANTY PROCEDURE ---------------------------- |

GEN 040226 |

|

RETURNED PARTS POLICY -------------------------- |

GEN 040227 |

|

REV. 2-26-04

0619S20046 |

0-2 |

SAFETY INSTRUCTIONS

WARNING

VARIOUS SAFETY DEVICES AND METHODS OF GUARDING HAVE BEEN PROVIDED ON THIS MACHINE. IT IS ESSENTIAL HOWEVER THAT THE MACHINE OPERATORS AND MAINTENANCE PERSONNEL OBSERVE THE FOLLOWING SAFETY PRECAUTIONS. IMPROPER INSTALLATION, MAINTENANCE, OR OPERATION OF THIS EQUIPMENT COULD CAUSE SERIOUS INJURY OR DEATH.

1.Before attempting to operate your divider read this manual. Never allow an untrained person to operate this machine.

2.Make sure that the machine is only connected to a properly grounded electrical supply source of sufficient capacity for the load the divider will put on it. Always unplug the machine when it is not in use.

3.Always make sure the machine has been disconnected from the power supply before cleaning or servicing.

4.All guards must be in place before starting the machine.

5.Keep your hands away from the moving parts of the machine.

6.Use only proper replacement parts.

7.Do not wear loose fitting clothing. Shirt tails should be tucked in.

8.In addition to these general safety instructions, also follow the more specific safety instructions given for the different areas of the machine in the operating instructions.

WARNING

DO NOT USE FOR OTHER THAN ORIGINALLY INTENDED PURPOSE.

0619S20047 |

1-1 |

THIS PAGE WAS INTENTIONALLY

LEFT BLANK.

GEN020319

DESCRIPTION/SPECIFICATION

Description

The Oliver divider consists of a hopper which can be loaded with dough from a minimum of ten and one half pounds up to forty-five pounds. The lid and hopper are made of heavy cast aluminum. The moveable hydraulic floor of the hopper is made of a collection of food grade plastic plates which, when moved upward, will compress the dough until it completely fills the remaining area. At this point a group of stainless steel knives come between the plates cutting the dough into equal weight, easy to use pieces.

This machine is ideal for pizza and bakery operations and is mounted on four casters for easy movement about the work area. The divider can divide pieces as small as seven ounces, on a 24 part divider, to as large as forty five ounces, on the 16 part divider. See below for specific maximums.

The hydraulic pump is powered by a two horse power, totally enclosed motor. The system has a built-in four and one half gallon hydraulic oil tank making the machine totally self contained.

Physical specifications

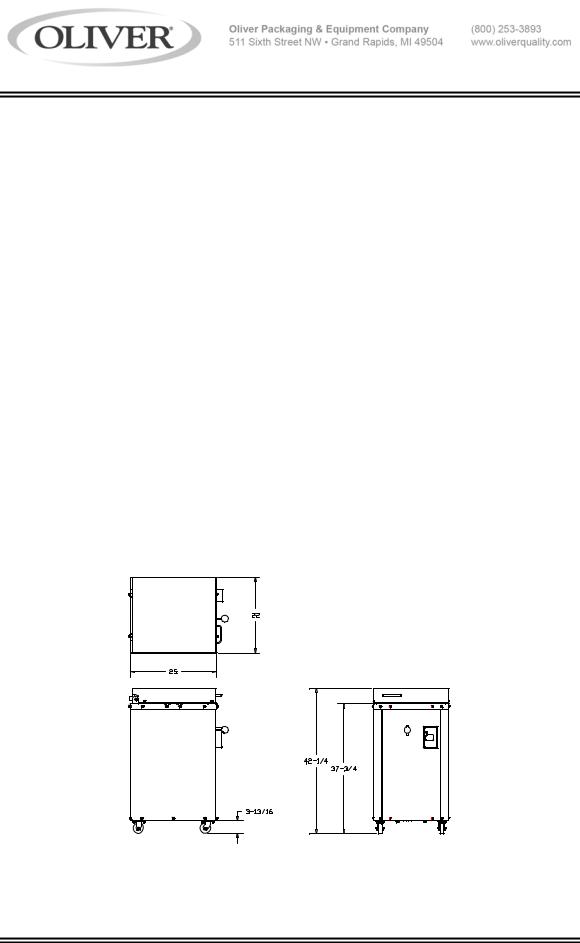

OVERALL MACHINE DIMENSIONS

0619S20058 |

2-1 |

Physical specifications (continued)

Net Weight:

Approximately 455 pounds.

Shipping Weight:

Approximately 500 pounds.

Product Capacities:

Fill Capacity (approximate) = 10-1/2 to 45 pounds

Divided piece Size (approximate):

16 part dividers = 10-1/2 to 45 ounces 20 part dividers = 8-1/2 to 36 ounces 24 part dividers = 7 to 30 ounces

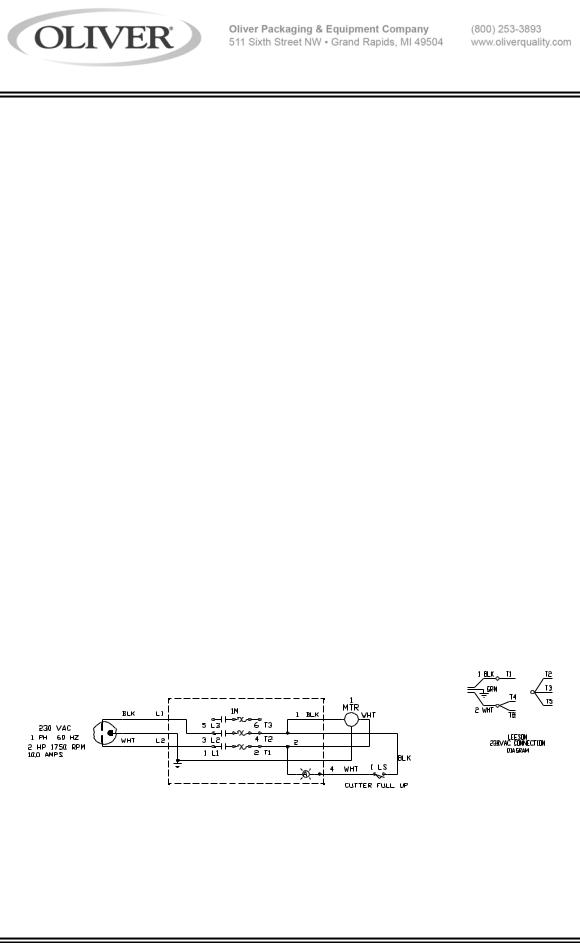

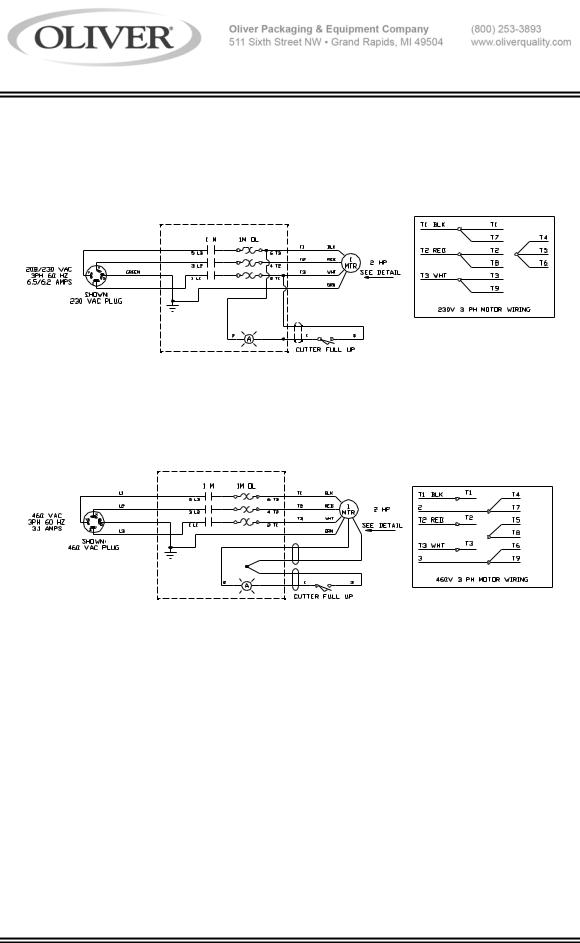

Electrical Specifications

2 Horse Power, 1 phase, 60 hertz, 230 Volts AC, 10 Amps. 2 Horse Power, 3 phase, 60 hertz, 208 Volts AC, 6.5 Amps. 2 Horse Power, 3 phase, 60 hertz, 230 Volts AC, 6.2 Amps. 2 Horse Power, 3 phase, 60 hertz, 460 Volts AC, 3.1 Amps. Others consult factory

Electrical Wiring Diagrams

1 ph, 60 hz, 230 VAC

Continued

0619S20058 |

2-2 |

Electrical Wiring Diagrams (Continued) 3 ph, 60 hz, 208/230 VAC

3 ph, 60 hz, 460 VAC

0619S20058 |

2-3 |

OPERATING INSTRUCTIONS

Before You Start

CAUTION

THE DIVIDER SHOULD ONLY BE PLUGGED INTO AN OUTLET

WITH THE SAME VOLTAGE AS STATED ON THE NAMEPLATE

Before starting a new divider with THREE PHASE electrical power for the first time you should check to see if the motor is running in the correct direction. Remove the front cover by removing the four thumbscrews which secure it; you will also have to remove the handle from the directional control lever before removing the front cover. Once the cover has been removed you should be able to see the fan end of the motor on your divider, this fan MUST rotate in a clockwise direction.

CAUTION

EXTENDED RUNNING OF A DIVIDER WITH THE MOTOR ROTATING IN THE INCORRECT DIRECTION WILL SEVERELY DAMAGE THE HYDRAULIC PUMP OF YOUR DIVIDER.

If the motor is rotating in the incorrect direction turn the machine off, disconnect it from the power supply and have a qualified electrician reverse two of the three power wires in the plug at the end of the power cord. DO NOT move the ground, (green), wire.

WARNING

ALWAYS HAVE ELECTRICAL WORK DONE BY QUALIFIED ELECTRICIANS.

Recheck the divider making sure that it is now running in the correct direction, (clockwise looking at the fan end of the motor).

CAUTION

MOTOR ROTATION SHOULD BE CHECKED EVEN IF THE

DIVIDER IS ONLY MOVED TO A DIFFERENT POWER OUTLET

IN THE SAME ROOM

Basic Operation

•Start by weighing out a piece of dough, which, when divided by the number of compartments available on your divider, will provide you with the desired end weight. For example: a thirty pound piece of dough after division on a twenty-four part divider will yield twenty-four, twenty ounce pieces, perfect for molding into one and a quarter pound loaves of bread.

0619S20048 |

3-1 |

Basic Operation (Continued)

•Lower the floor of the hopper before attempting to open the lid of the divider.

•Open the lid and load the preweighed dough into the hopper. Spread the dough over the floor of the hopper making it approximately the same height, this is done to eliminate large air pockets and to insure equal division of the dough.

•Close and hold the lid down until dough compression has been started, (see the next step).

•With the machine running grasp the control valve handle and lift it to start the floor of the hopper up. Hold it in this position until the light on the starter switch box comes on, this means that the upward stroke has stopped and that division is complete. Let loose of the valve handle when you see the light come on.

•Press the control valve handle down slightly before opening the lid.

•The dough may be ejected by lifting the control valve handle to bring the plastic floors of the dough compartments level with the top of the hopper.

•We suggest that the cut pieces of dough be removed as soon as possible to prevent them from sticking together.

•Return the floor of the hopper to its lowest position by pushing down on the control valve handle. When complete this will allow filling of the machine for the next cycle.

•The above process may now be repeated.

WARNING

NEVER LEAVE DOUGH IN THE MACHINE; RISING DOUGH MAY CAUSE EXPLOSIVE PRESSURES TO DEVELOP.

0619S20048 |

3-2 |

MAINTENANCE

WARNING

ALWAYS MAKE SURE THE MACHINE HAS BEEN DISCONNECTED FROM THE POWER SUPPLY BEFORE CLEANING OR SERVICING.

Cleaning

Remove- all scraps from lower pan. Open side doors and brushing out all scraps. Wash all interior surfaces; Knives, pusher plates, hopper, lid surface with a damp rag and mild soap solution. The exterior and contact surfaces should be cleaned daily using common cleaners. The knives should be extended for easier cleaning. This can be done by placing the cleaning separator, furnished with the machine, IN THE CENTER OF THE HOPPER straddling the knives. Close the lid and bring the floor of the hopper up until the light on the manual starter is on, lower the floor slightly. Open the lid and disconnect the divider from the power supply. Clean the knives and plastic compartment floors of all dough build-up. Rinse all interior surfaces with a damp rag and clean water. Sanitize all interior surfaces with a damp rag and sanitizing solution. Air Dry, leave divider lid open and allow interior to air dry before using.

CAUTION

IF NOT CLEANED A BUILD-UP OF DRIED DOUGH BETWEEN THE PLASTIC FLOORS AND THE KNIVES COULD DAMAGE THE DIVIDER.

In addition to the general cleaning discussed above, it is important that you check for and remove scraps of dried dough from between the blade holder and the bottom thrust plate. This can be done by first extending the knives as described above and then by removing the front and rear covers from the machine by removing the eight thumb screws and the control valve handle knob. This will allow access to the blade holder area, which can then be cleaned of all dried scraps of dough. When finished replace the covers and knob.

CAUTION

FAILURE TO CLEAN DRIED DOUGH FROM THE BLADE HOLDER AND THRUST PLATE COULD RESULT IN SEVERE PUSHER DRIVE DAMAGE.

Occasionally, as required, you should also remove the build up of flour and dough particles in the base of the machine around the motor.

0619S20049 |

4-1 |

Lubrication

The machine requires no lubrication but the oil level in the hydraulic system should be checked periodically. To check the oil level remove the rear cover by removing the four knobs which secure it to the divider, then remove the tank breather/cap and determine where the top of the oil is in relation to the top surface of the tank. Fill with oil to within approximately one inch of the top surface. If necessary add HYDRAULIC OIL to return it to the proper level, DO NOT OVERFILL. In addition to the above we advise replacing the hydraulic oil in the system approximately every three years.

Hydraulic Oil Specification

The hydraulic oil used in your divider should be made of good quality base stocks compounded with the following additives: antiwear, antioxidation, antifoaming, and antirust. In addition it should be an “ISO” viscosity grade No. 32.

Hydraulic Filter Replacement

At least once a year the throw-away filter on the hydraulic system should be replaced, more often when under heavy use. To replace the filter remove the front cover, unscrew the old filter and replace it with a new one. The filter is located on the return line near the front of the tank.

Removing The Lid

•Remove the lid cover by removing the four screws, which secure it in position.

•Open the lid as far as it will go.

•Release the tension on the two large torsion springs by moving the long leg of the spring to the side and out from behind the bracket.

WARNING

USE CARE AS THE LID WILL DROP ONCE THE SPRING TENSION

HAS BEEN REMOVED.

•Close the lid and remove the right hand snap ring from the lid hinge pin and push the pin to the left to remove it.

•Reassemble by reversing the above steps.

0619S20049 |

4-2 |

Loading...

Loading...