Oliver 732-N Installation Manual

Grand Rapids, Michigan, U.S.A. 49504-5298

USER’S OPERATING AND INSTRUCTION MANUAL

MODEL 732-N

BREAD SLICER

0732S20000-CV

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

732-N Front Load Slicer

INDEX

Section Description

SAFETY INSTRUCTIONS -------------------------------------- 0732S20002 --------------------------- 1-1

DESCRIPTION/SPECIFICATIONS --------------------------- 0732S20003---------------------------- 2-1

Description -------------------------------------------------------------------------------------------------- 2-1

Specifications----------------------------------------------------------------------------------------------- 2-1

INSTALLATION INSTRUCTIONS ---------------------------- 0732S20004 --------------------------- 3-1

Slicer Installation ------------------------------------------------------------------------------------------ 3-1

OPERATING INSTRUCTIONS -------------------------------- 0732S20005 --------------------------- 4-1

TROUBLESHOOTING ------------------------------------------- 0732S20006 --------------------------- 5-1

The Slicer Will Not Start (Motor is Not Humming) ------------------------------------------------ 5-1

The Slicer Will Not Start (Motor is Humming) ------------------------------------------------------ 5-2

The Slicer Stops Before Slicing is Complete ------------------------------------------------------- 5-2

The Slicer Does Not Automatically Stop Upon Completion of Slicing ----------------------- 5-2

Bread Slices Vary in Thickness ------------------------------------------------------------------------ 5-3

The Blade Frames are Knocking ---------------------------------------------------------------------- 5-3

The Slicer Vibrates Excessively ----------------------------------------------------------------------- 5-3

The Hand Lever Pulls Hard ----------------------------------------------------------------------------- 5-3

The Bread is Cutting Slowly or is Being Damaged ----------------------------------------------- 5-4

MAINTENANCE --------------------------------------------------- 0732S20007 --------------------------- 6-1

Removing the Blade Frames --------------------------------------------------------------------------- 6-1

Replacing the Blade Frames --------------------------------------------------------------------------- 6-4

Changing the Blades ------------------------------------------------------------------------------------- 6-5

Tightening the Belt ---------------------------------------------------------------------------------------- 6-7

Replacing the Belt ---------------------------------------------------------------------------------------- 6-8

Replacing the Gas Spring ------------------------------------------------------------------------------ 6-9

Adjusting the Gas Spring ------------------------------------------------------------------------------ 6-12

Adjusting the Blade Frames When Slices Vary in Thickness -------------------------------- 6-13

Adjusting the Clearance Between the Blade Frames ------------------------------------------ 6-14

Lubrication ------------------------------------------------------------------------------------------------- 6-15

Cleaning ---------------------------------------------------------------------------------------------------- 6-15

RECOMMENDED SPARE PARTS -------------------------- 0732S20008 --------------------------- 7-1

REPLACEMENT PARTS SECTION

MAIN FRAME ---------------- ------------------------------------- 0732S20009 --------------------------- 8-1

Drawing ------------------------------------------------------------------------------------------------- 8-1

Parts List ----------------------------------------------------------------------------------------------- 8-2

Continued

Document No. Page No.

0732S20001 0-1

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

732-N Front Load Slicer

INDEX (Continued)

REPLACEMENT PARTS SECTION (Continued)

Section Description

COVERS ------------------------------------------------------------ 0732S20010 --------------------------- 9-1

Drawing ------------------------------------------------------------------------------------------------ 9-1

Parts List ----------------------------------------------------------------------------------------------- 9-2

PUSHER ------------------------------------------------------------ 0732S20011 -------------------------- 10-1

Drawing ----------------------------------------------------------------------------------------------- 10-1

Parts List ---------------------------------------------------------------------------------------------- 10-2

ROCKER ----------------------------------------------------------- 0732S20012 -------------------------- 11-1

Drawing ----------------------------------------------------------------------------------------------- 11-1

Parts List ---------------------------------------------------------------------------------------------- 11-2

DRIVEN PULLEY ------------------------------------------------- 0732S20013 -------------------------- 12-1

Drawing ----------------------------------------------------------------------------------------------- 12-1

Parts List ---------------------------------------------------------------------------------------------- 12-2

SLICE PARTS ----------------------------------------------------- 0732S20014 -------------------------- 13-1

Drawing ----------------------------------------------------------------------------------------------- 13-1

Parts List ---------------------------------------------------------------------------------------------- 13-2

ELECTRICAL ------------------------------------------------------ 0732S20015 -------------------------- 14-1

Drawing ----------------------------------------------------------------------------------------------- 14-1

Parts List ---------------------------------------------------------------------------------------------- 14-2

WIRING DIAGRAM 1-60-115/230 --------------------------- 0732S20016 -------------------------- 15-1

WARRANTY ------------------------------------------------------- GEN 040225

WARRANTY PROCEDURE------------------------------------ GEN 040226

RETURNED PARTS POLICY --------------------------------- GEN 040227

Document No. Page No.

0732S20001 0-2

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

732-N Front Load Slicer

SAFETY INSTRUCTIONS

WARNING

VARIOUS SAFETY DEVICES AND METHODS OF GUARDING HAVE BEEN

PROVIDED ON THIS MACHINE. IT IS ESSENTIAL HOWEVER THAT THE MACHINE

OPERATORS AND MAINTENANCE PERSONNEL OBSERVE THE FOLLOWING

SAFETY PRECAUTIONS. IMPROPER INSTALLATION, MAINTENANCE, OR

OPERATION OF THIS EQUIPMENT COULD CAUSE SERIOUS INJURY OR DEATH.

1. Read this manual before attempting to operate your machine. Never allow an

untrained person to operate or service this machine.

2. Connect the machine to a properly grounded electrical supply that matches the

requirements shown on the electrical specification plate and follow all specifications

of local electrical codes.

3. Disconnect and lock-out the machine from the power supply before cleaning or

servicing.

4. Check and secure all guards before starting the machine.

5. Observe all caution and warning labels affixed to the machine.

6. Use only proper replacement parts.

7. Do not wear loose fitting clothing or loose hair when working near this machine.

Shirt tails should be tucked in.

8. Wear proper, personal, protective, safety equipment.

9. Keep Hands away from the moving parts of this machine while it is in operation.

10. In addition to these general safety instructions, please follow the more specific safety

instructions in the rest of this operating instruction manual.

WARNING

DO NOT USE FOR OTHER THAN ORIGINALLY INTENDED PURPOSE.

0732S20002 1-1

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

732-N Front Load Slicer

DESCRIPTION/SPECIFICATIONS

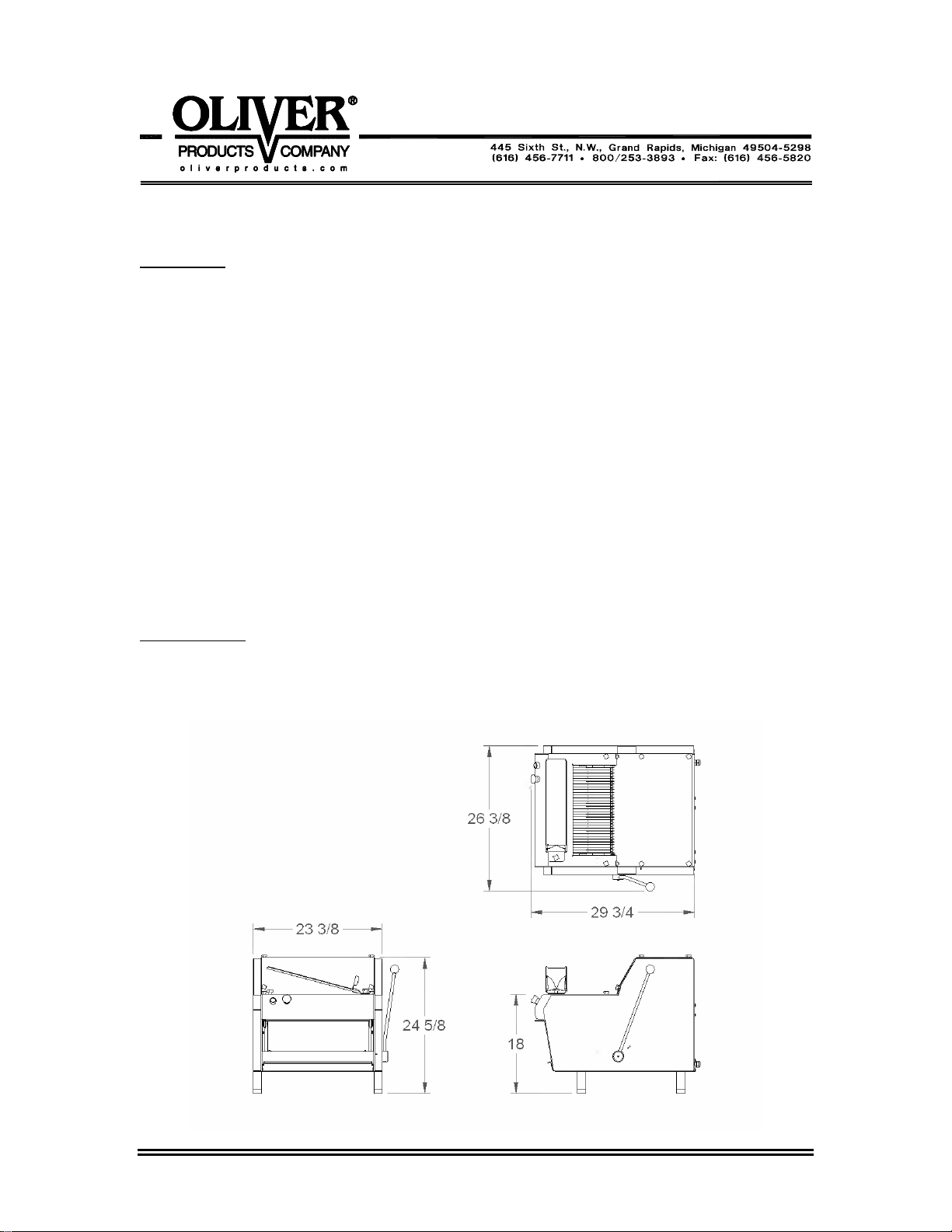

Description

The Oliver Model 732-N Counter Top Bread Slicer is of a compact, sturdy, time tested

design, which has been used in bakeries worldwide for many years. The machine is

easy to operate and can be loaded and unloaded from the front of the machine. It is

capable of slicing either hard crusted breads or soft-textured sandwich loaves with ease

and precision. After slicing, the bread can be easily packaged with the use of its

convenient front mounted bagging scoop. Its design will provide years of efficient,

trouble-free operation requiring a minimum of maintenance.

The Model 732-N Bread Slicer is of stainless, plated, and painted steel construction for

easy cleaning and maintenance. As with other Oliver slicers it is so easy to change the

blades, when that becomes necessary, that most operators will feel comfortable enough

to do it themselves eliminating the need of a service call.

Oliver Products Company, who has a reputation of serving the Baking Industry for over

70 years, backs these slicers.

Specifications

Space Requirements:

Model 732-N (All Dimensions are Approximate)

0732S20003 2-1

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

732-N Front Load Slicer

Product Capacities:

Length 16 Inches

Width 5-1/2 inches (See Note)

Height 5-1/2 inches (See Note)

NOTE

WIDTH AND HEIGHT DIMENSIONS ARE FOR A SQUARE PRODUCT. LOWER AND

WIDER PRODUCTS MAY ALSO BE SLICED BY TAKING CARE IN LOADING THE

PRODUCT. INDIVIDUAL DETERMINATIONS WOULD HAVE TO BE MADE.

Standard Electrical Options: (Others consult factory).

1 phase, 60 hz, 115VAC, 7 Amps.

1 phase, 60 hz, 230VAC, 3.5 Amps.

1 phase, 50 hz, 220VAC, 3.5 Amps.

Standard Slice Spacings,

7/16, 1/2, 9/16 (inches)

Optional Slice Spacings, (At additional cost). (Specials available -- consult factory).

3/8, 5/8, 11/16, 3/4, 13/16, 7/8, 1, 1-1/4 (inches)

Shipping Weight

300 lbs. (approximate)

Net Weight

250 lbs. (approximate)

0732S20003 2-2

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

732-N Front Load Slicer

INSTALLATION INSTRUCTIONS

Slicer Installation:

Before starting the Installation process make sure you observe the following three

caution notes.

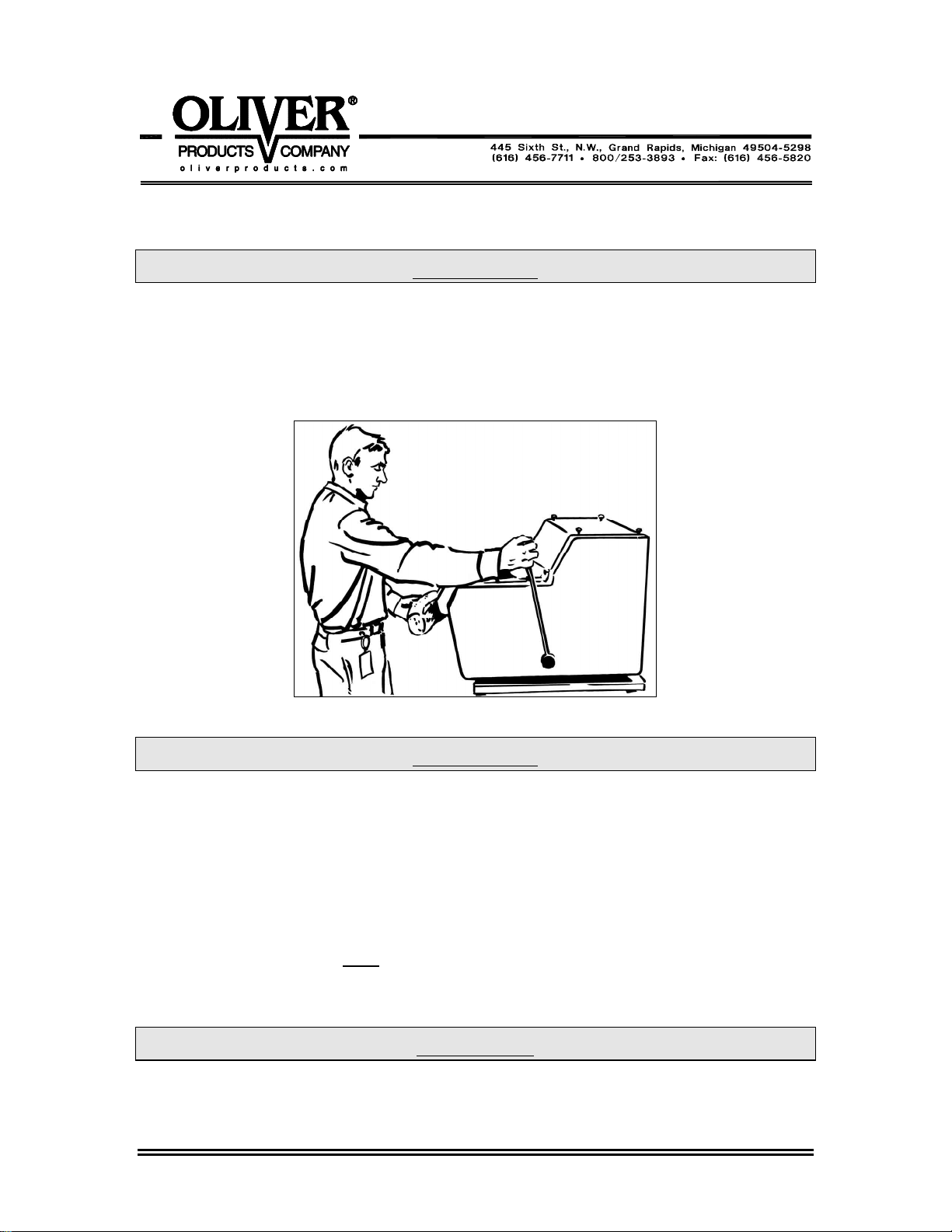

CAUTION

THE SLICER IS HEAVY, USE PROPER TECHNIQUE WHEN LIFTING.

KEEP BACK STRAIGHT, KNEES BENT, AND LIFT WITH LEGS.

USE GLOVES TO PROTECT HANDS.

CAUTION

NEVER LIFT THE SLICER BY ITS SIDE COVERS.

CAUTION

BEFORE PLACING THE SLICER ON THE TABLE OR COUNTER MAKE SURE THAT

IT CAN SUPPORT THE SLICER’S WEIGHT WHICH IS APPROX. 250 POUNDS.

Select a location for your slicer which has a substantial mounting surface, (see the

caution note above), and which has electrical service compatible with the load the

machine will place on it as indicated on the electrical data plate of the machine.

Position the machine while it is still in its packaging as close as possible to the desired

end location. Expose the machine by removing the outer packaging and remove its

crumb tray. Using at least two people, (one in the front and one at the back of the

machine), lift the slicer from the resting surface of the packaging and set the machine

onto the counter or table as close as possible to the desired end location. Make final

location adjustments by sliding the machine to its desired location.

0732S20004 3-1

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

732-N Front Load Slicer

OPERATING INSTRUCTIONS

WARNING

ALWAYS USE CARE WHENEVER WORKING NEAR THE CUTTING KNIVES.

To operate the slicer, stand in front of the machine and grasp the lever with your right

hand. Pull the lever all the way down and hold it in that position. Using your left hand

load the product into the machine.

WARNING

NEVER START THE MACHINE BEFOE LOADING THE PRODUCT.

Make sure that the product does not hang over either edge of the cradle. While holding

the lever completely forward, (the machine will not start unless this is done), push the

Green “Start” button with your left hand.

After starting the machine restrain the hand lever slightly allowing it to return slowly until

the knives have contacted AND

the lever to return at its own speed.

penetrated the crust on the product. At this point allow

CAUTION

NEVER PUSH THE HAND LEVER.

0732S20005 4-1

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

732-N Front Load Slicer

Operating Instructions (Continued)

When the slicing operation is complete the machine will automatically stop. Once

stopped, remove the product from the cradle. Use of the standard front mounted

bagging scoop will ease packaging of your product.

The bagging scoop’s bread stop is adjustable to accommodate various size loaves. To

adjust, apply pressure to the outside edges of the bread stop and slide it along the scoop

to the desired position.

0732S20005 4-2

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

732-N Front Load Slicer

TROUBLE SHOOTING

WARNING

ALWAYS DISCONNECT THE SLICER FROM THE POWER SUPPLY BEFORE

ATTEMPTING ANY TYPE OF MAINTENANCE TASK, INCLUDING

TROUBLESHOOTING.

The Slicer Will Not Start (Motor Is Not Humming)

• The machine is not plugged in.

• There is no power at the outlet. (Check by plugging in a small working appliance,

like a lamp. Check to see if a circuit breaker has tripped. If the circuit breaker has

not tripped and the circuit is still not working have a qualified electrician check the

circuit.)

• The Emergency “Stop” button has been pushed. Twist the Red button in the

direction of the arrow on the button to release it to its run position.

• The lever is not being HELD

• There are bread crumbs beneath the cradle bracket or in the cradle guide tracks at

each side of the cradle bracket preventing it from going all the way down, which it

must do before the lower limit switch can be tripped.

• The lower limit switch is not adjusted properly. (Have a qualified service agent

adjust the switch.)

• The lower limit switch is defective. (Have a qualified electrician check and replace

the switch if required.)

• The problem is somewhere else in the electrical system of the machine. (Have a

qualified electrician find and repair the problem.)

Continued

in the forward most position.

0732S20006 5-1

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

732-N Front Load Slicer

Trouble Shooting (Continued)

The Slicer Will Not Start (Motor Is Humming)

CAUTION

DO NOT ALLOW THE MOTOR TO HUM WITHOUT STARTING.

OVERHEATING CAN PERMANENTLY DAMAGE THE MOTOR.

NOTE

A SPECIAL NON-VENTILATED MOTOR MUST BE USED WITH THIS SLICER.

• The drive system is binding. (Have a qualified service agent check for defective

bearings or other restrictions to free movement.)

• There is mechanical interference between other parts of the slicer. (Have a qualified

service agent evaluate the machine for adjustment or replacement of defective

parts.)

• The motor has failed. (Have it checked by a qualified electrician.)

The Slicer Stops Before Slicing is Complete

• The upper limit switch is not adjusted properly. (Have a qualified service agent

adjust the switch.)

The Slicer Does Not Automatically Stop Upon Completion of Slicing

• The upper limit switch is not adjusted properly. (Have a qualified service agent

adjust the switch.)

• The upper limit switch is defective. (Have a qualified electrician check and replace

the switch if required.)

• A bread crust or other foreign object is preventing the cradle from returning to the top

of its travel.

Continued

0732S20006 5-2

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

732-N Front Load Slicer

Trouble Shooting (Continued)

Bread Slices Vary in Thickness

• The blade frames are out of adjustment. (See the “Maintenance” section of this

manual under “Adjusting the Blade Frames When Slices Vary in Thickness” on how

to correct this problem.)

The Blade Frames Are Knocking

• The blade frames are out of adjustment. (See the “Maintenance” section of this

manual under “Adjusting the Clearance Between the Blade Frames” on how to

perform this adjustment.)

The Slicer Vibrates Excessively

• The drive belt is loose or worn. (See the “Maintenance” section of this manual under

“Tightening the Belt” or “Replacing the Belt” on how to make these corrections.)

• One or more of the bearings on the machine are failing. (Have a qualified service

agent check for defective bearings and replace them as required.)

• The pins, (two eccentrics and two regular), and links at the top of the blade frames

are worn. We suggest that these be replaced together. Mixing worn parts with new

will shorten the life of the replacement parts. Remember, after replacing the pins

and links the clearance between the blade frames must be re-adjusted. (See the

“Maintenance” section of this manual under “Adjusting the Clearance Between the

Blade Frames” on how to perform this adjustment.)

The Hand Lever Pulls Hard

• Check the Cradle guide tracks at each end of the cradle bracket for a build-up of

foreign material.

Continued

0732S20006 5-3

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

732-N Front Load Slicer

Trouble Shooting (Continued)

The Bread is Cutting Slowly or is Being Damaged

• The product you are attempting to slice is below the minimum height capacity of the

machine.

• You are pushing the lever of the machine in an attempt to speed slicing. This may

not only damage the product but may also damage the machine.

• If only certain products are cutting slowly the cutting speed you are experiencing may

be normal for that particular product.

• The knives of the machine have become worn, (dull). (See the “Maintenance” section

of this manual under “Changing the Cutting Knives”). Most owners can perform this

item of maintenance without calling a service company.

• The blades are not aligned properly. (See the “Maintenance” section of this manual

under “Adjusting the Clearance Between the Blade Frames” on how to perform this

adjustment.)

• The Gas spring may require adjustment or replacement. (See the Maintenance

section of this manual under “Gas Spring Replacement” on how to perform this task.)

0732S20006 5-4

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

732-N Front Load Slicer

MAINTENANCE

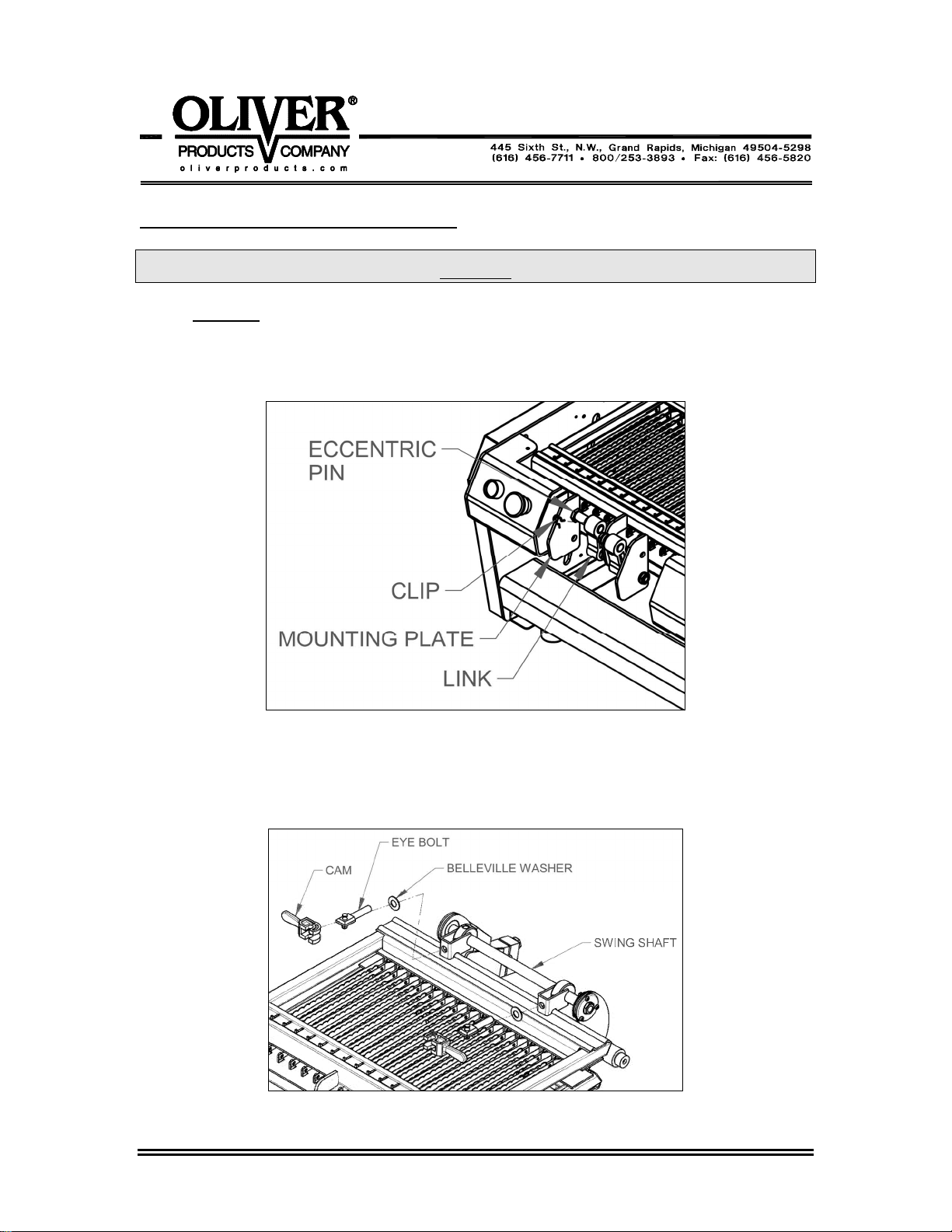

Removing The Blade Frames

WARNING

ALWAYS UNPLUG THE SLICER BEFORE PERFORMING

ANY TYPE OF MAINTENANCE TASK.

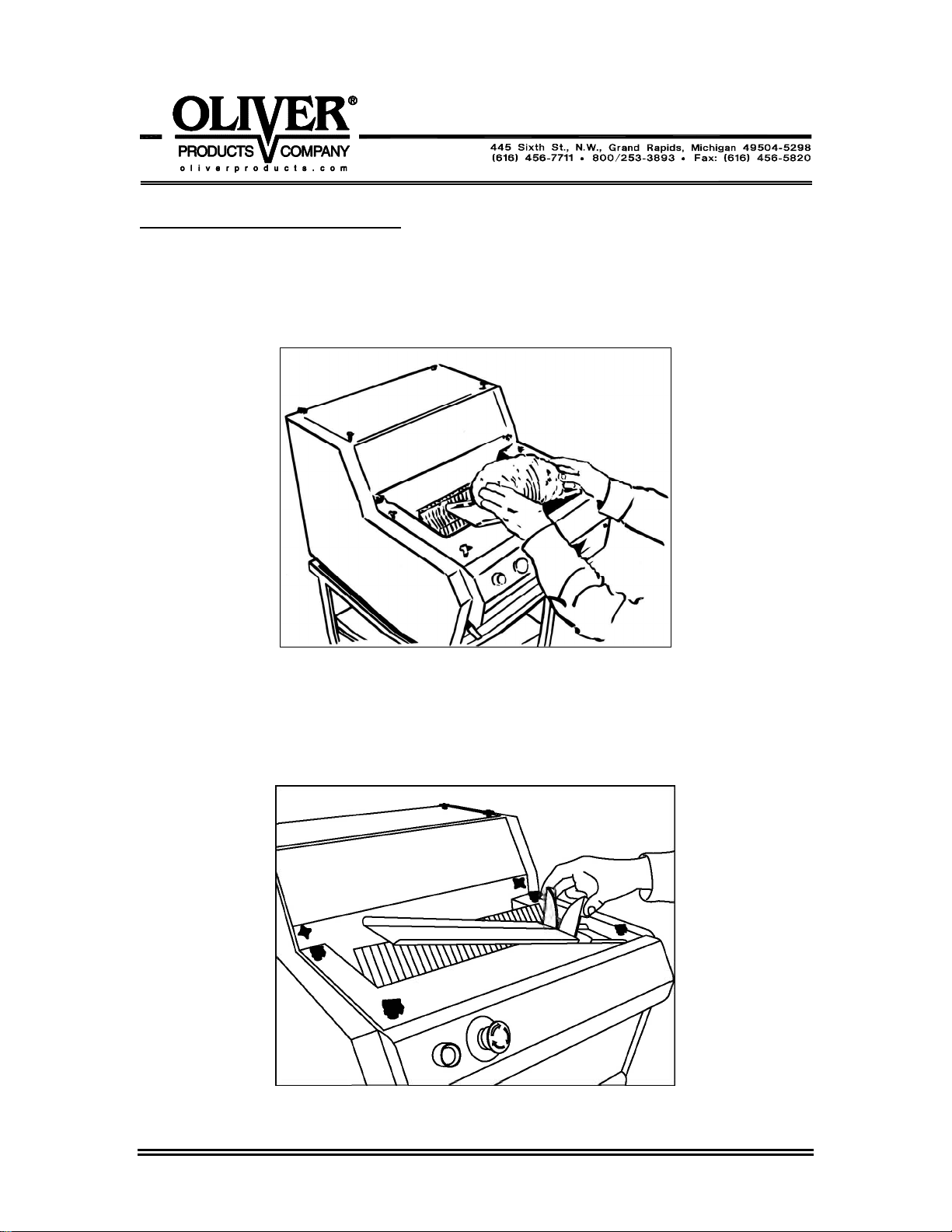

Remove the bagging scoop, the top and front covers by removing the ten knobs which

secure them. Only remove the infeed table in the event that you MUST

lower blade frame. See the note below.

remove the

NOTE

REMOVAL OF THE LOWER BLADE FRAME IS NOT

TO CHANGE ITS BLADES

Should it be necessary to remove the lower blade frame you must first remove the infeed

table by removing the two knobs which secure it in place and then by pulling the table

down out of the clips and out through the infeed opening. See above illustration.

Continued

0732S20007 6-1

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

REQUIRED

732-N Front Load Slicer

Removing The Blade Frames (Continued)

NOTE

DO NOT

Pull the clip from the eccentric pin and slide the link toward the eccentric pin mounting

plate. See the illustration below.

LOOSEN THE NUTS WHICH SECURE THE ECCENTRIC PINS.

After removing the pair of locking cams, eyebolts and Belleville washers, (which secure

each blade frame to the rocker’s swing shaft), the blade frame can be lifted from the

machine. The eyebolts and Belleville washers can be removed by turning them counter

clockwise once the cams have been removed.

Continued

0732S20007 6-2

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Loading...

Loading...