Oliver 625-DR Installation Manual

Grand Rapids, Michigan, U.S.A. 49504-5298

USER’S OPERATING AND INSTRUCTION MANUAL

MODEL 625-DR & 625-S

DOUGH DIVIDER / ROUNDERS

0625S20000-CVR

MODEL 625 DOUGH DIVIDER - ROUNDERS

INDEX

DEFINITIONS …………………………………………………………………..… GEN93118

SAFETY INSTRUCTIONS.......................................................................... 0625S20001

DESCRIPTION/SPECIFICATIONS............................................................. 0625S20002

SETUP & OPERATION ..…....................................................................... 0625S25003

Removing the Divider Rounder from the Skid ........................….... 0625S20003-1/3

Adjusting the Main Plate Stop ....................................................... 0625S20003-2/3

Operation ……………….................…............................................ 0625S20003-2/3

MAINTENANCE.......................................................................................... 0625S20004

Cleaning................................................................................…….. 0625S20004-1/4

Lubrication............................................................................…..... 0625S20004-2/4

Tightening of V-Belts .....………………….............…...................... 0625S20004-3/4

Replacing the V-Belts ..........................................................…...... 0625S20004-4/4

REPLACEMENT PARTS SECTION

Base Unit Assembly Drawing (Model 625-DR Shown)..... .............. 0625F10000-1/2

Base Unit Assembly Drawing (Model 625-DR Shown).................... 0625F10000-2/2

Base Replacement Parts List ...........…...............................……... 0625S20009-1/2

Base Replacement Parts List ...........…...................................…... 0625S20009-2/2

Arch Assembly Drawing (Model 625-DR Shown)........................……... 0625F10001

Arch Replacement Parts List ...........…...............................….…... 0625S20010-1/2

Arch Replacement Parts List ...........…....................................…... 0625S20010-2/2

Electrical Replacement Parts List ........................................……... 0625S20011-1/2

RECOMMENDED SPARE PARTS LIST.................................................... 0625S20007

WIRING DIAGRAMS ................................................................................. 0625S20008

3/4 HP, 1-60-115 VAC ...........................................................…….. 0625S20008-1/2

3/4 HP, 1-60-208 VAC ...........................................................…..... 0625S20008-1/2

3/4 HP, 1-60-230 VAC ...........................................................…..... 0625S20008-2/2

3/4 HP, 3-60-230 VAC ....………………….............…...................... 0625S20008-2/2

WARRANTY............................................................................................... GEN040225

WARRANTY PROCEDURE…................................................................... GEN040226

RETURNED PARTS POLICY…………………………………………………. GEN 040227

Rev. 4-26-04

0625S20000

GENERAL

DEFINITIONS

The use of the words WARNING, CAUTION, and NOTE in this manual should be guided

by the following.

WARNING

AN OPERATING PROCEDURE, TECHNIQUE, ETC., WHICH MAY

RESULT IN PERSONAL INJURY IF NOT CAREFULLY FOLLOWED.

CAUTION

AN OPERATING PROCEDURE, TECHNIQUE, ETC., WHICH MAY

RESULT IN DAMAGE TO EQUIPMENT IF NOT CAREFULLY FOLLOWED.

NOTE

AN OPERATING PROCEDURE, TECHNIQUE, ETC., WHICH IS CONSIDERED

ESSENTIAL TO EMPHASIZE.

GEN931118

MODEL 625 DOUGH DIVIDER-ROUNDERS

SAFETY INSTRUCTIONS

Every effort has been made by Oliver Products Company to provide you with a safe

machine. It is essential, however, that machine operators and maintenance personnel

observe the following safety precautions. Improper installation or operation of this

equipment may cause personal injury or damage to the equipment.

1. Read this manual before attempting to operate your machine. Never allow an

untrained person to operate or service this machine.

2. Connect the machine to a properly grounded electrical supply that matches the

requirements shown on the electrical specification plate and follow specifications of

local electrical codes.

3. Disconnect and lock-out the machine from the power supply before cleaning or

servicing.

4. Check and secure all guards before starting the machine.

5. Observe all caution and warning labels affixed to the machine.

6. Use only proper replacement parts.

7. Do not wear loose fitting clothing or loose hair. Shirt tails should be tucked in.

8. Wear proper personal safety equipment.

9. Keep Hands away form the moving parts of this machine while it is in operation.

10. In addition to these general safety instructions, also follow the more specific safety

instructions given for the different areas of the machine in the operating instructions.

WARNING

DO NOT USE FOR OTHER THAN ORIGINALLY INTENDED PURPOSE.

Rev. 3-29-02

0625S20001

MODEL 625 DOUGH DIVIDER-ROUNDERS

DESCRIPTION/SPECIFICATIONS

DESCRIPTION

The Model 625 Series of Dough Divider Rounders will divide a pre-weighed amount of

dough into either 15 or 36 equal parts. The same machine will then shape each of the

parts into a convenient ball shape for stamping or baking.

The Model 625 Series of dough Divider Rounders are built of heavy gauge steel and

cast iron. All contact parts are either electroless nickel plated or plastic.

The standard Divider Rounder is driven by a 3/4 HP, TEFC, single phase, capacitor start

motor.

SPECIFICATIONS

Weight (Approx.)--------------------------------------------------------------- 715 lbs.

Shipping Weight --------------------------------------------------------------- 800 lbs.

Electrics:

• Standard-------------------- 3/4 hp, 1 ph, 60 hz, 115 volts, 11.4 amps.

• Optional----------------------- 3/4 hp, 1 ph, 60 hz, 208 volts, 5.7 amps.

• Optional------------------------ 3/4 hp,1 ph, 60 hz, 230 volts, 5.7 amps.

• Optional---------------------- 3/4 hp, 3 ph, 60 hz, 230 volts, 2.6 amps.

• Others-------------------------------------------------------- Consult Factory

Product Weight Range (Approx.)

• 36-Part ---------------------------------------------------------- 1 to 3-1/2 oz.

• 15-Part ----------------------------------------------------- 2-1/2 to 8-1/4 oz.

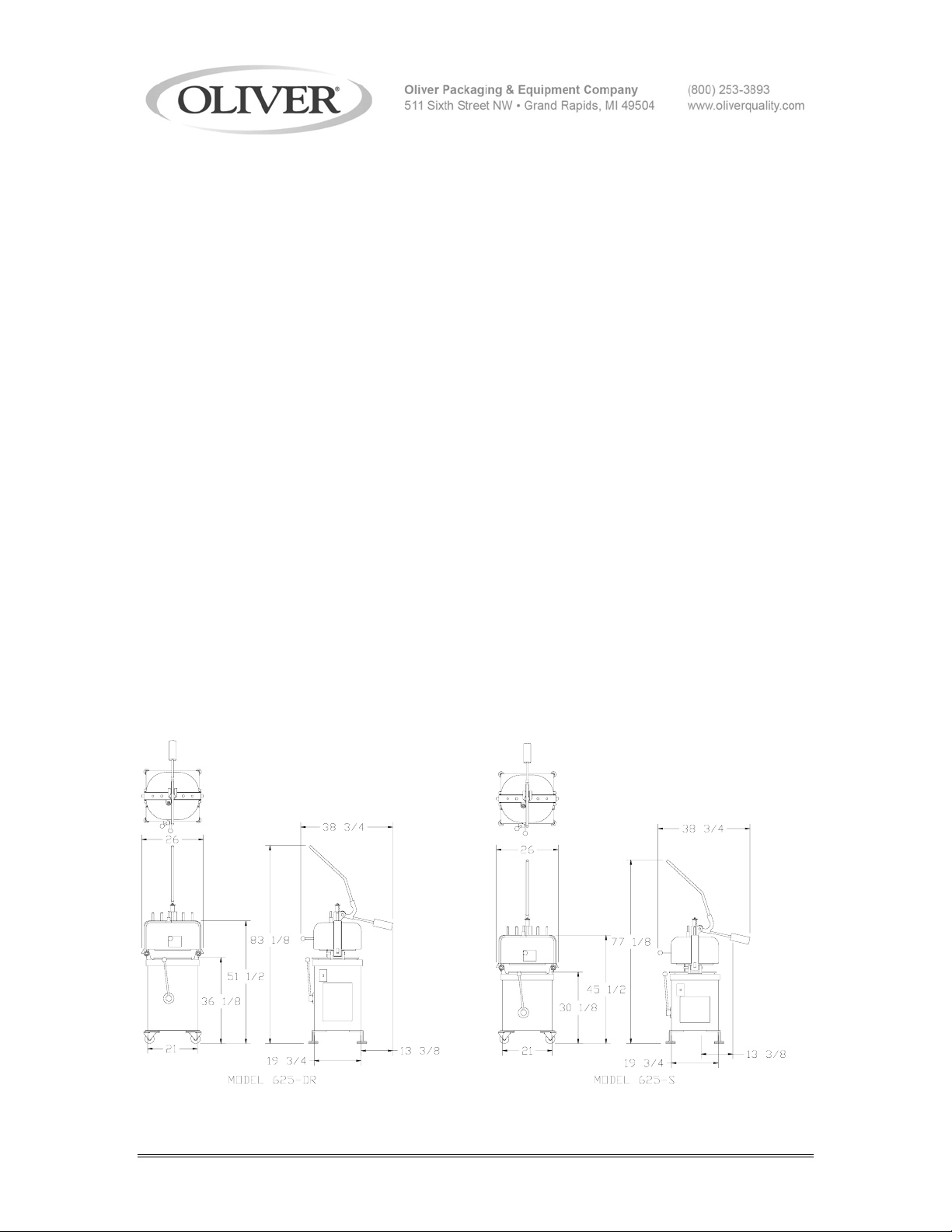

Physical Size of Machine (plus/minus

1/2"):

Rev. 6-11-02

0625S20002

MODEL 625 DOUGH DIVIDER-ROUNDERS

SETUP & OPERATION

SETUP

Removing the Divider Rounder from the Skid

The first thing to do is to pick a location where the machine will be used. It should have

a grounded power outlet of the same rating as that of the machine and be capable of

carrying the load that the Divider Rounder will put on it. As the Divider Rounder weighs

over 715 pounds we suggest that you next move the crate as near as possible to this

area.

WARNING

THE MACHINE MUST BE

CONNECTED TO A PROPERLY GROUNDED

ELECTRICAL SOURCE OF THE SAME RATING AS THE MACHINE.

If you haven't already removed the upper crate do so now. You will find that the Divider

Rounder is bolted to the skid and that the Pressure lever, counter weight, and the four

leveling pads and other components have been shipped loose. Remove the four bolts

from the feet of the machine freeing the Divider Rounder from the skid. Also set to one

side those parts which have been shipped loose.

Carefully raise the machine and remove the skid, or gently slide the machine from the

skid, using care not to tip it over. Locate the machine as near as possible to its

permanent location. Install the legs between the feet of the machine and the cast pads.

Following the installation of the legs and pads, attach the pressure lever and the counter

weight and connect the machine to the power source. After reading the instruction

manual you will be ready to start your machine.

CAUTION

BEFORE ATTEMPTING TO OPERATE THE MACHINE MAKE SURE

THAT ALL OPERATORS HAVE READ THIS MANUAL.

Rev. 6-11-02

0625S20003-1

OPERATING INSTUCTIONS

Adjusting the Main Plate Stop

The only adjustment on the Divider Rounder is the adjustment of the stop for the Main

Plate.

When rounding the divided dough the Main plate is elevated above the Molding Plate to

create a rolling space for the dough. This is done by releasing the Main Plate from the

Gear Shaft using the Releasing Lever. Spring Tension will move the Main Plate above

the Molding Plate to a position set by a stop located on top of the machine. This

distance or stop setting, is determined by the volume of the individual pieces of dough.

More space is required to round a large piece of dough than is required to round a small

piece. Once these settings have been determined we suggest that they be recorded for

future use.

The actual adjustment is made by loosening the large knurled hand locking nut at the

top of the machine and then turning the index screw counter clockwise to raise the plate,

(larger pieces of dough), or clockwise to stop the plate lower for smaller pieces of dough.

After each adjustment, before running the machine, make sure that the index screw has

been secured by tightening the knurled locking nut.

Improper or incomplete rounding can occur either because not enough space has been

allowed or that too much space has been provided. When improper rounding occurs

check this adjustment.

Operation

1. The first step is to weigh a piece of dough which when divided will provide you with

pieces of the desired size. The large piece of dough should weigh either 36 or 15

times, (depending on the option you have chosen), as much as you wish the divided

piece to weigh.

Example: 2-1/4 pounds of dough = 36 one ounce pieces.

4-1/2 pounds of dough = 36 two ounce pieces.

6-3/4 pounds of dough = 36 three ounce pieces.

2.4 pounds of dough = 15 two and a half ounce pieces.

7-3/4 pounds of dough = 15 eight and a quarter ounce pieces.

Place one of the plastic molding plates on a work surface with the circular pockets

facing upward. Place the large piece of weighed dough in the center of the molding

plate and spread it over the plate by hand. The dough should not be spread so that it

lies outside of the large containment ring of the Divider Rounder.

Rev. 3-29-02

0625S20003-2

Operation (Cont’d.)

2. Take the Molding Plate with the dough and place it on the Working Plate of the

machine against the stops in the back and over the alignment pin in the front.

3. Using the Pressure Lever compress the dough firmly to fill the containment ring and to

remove all air.

4. Reduce pressure on the Lever and release the spring loaded Main Plate by actuating

the releasing lever with one hand while maintaining slight pressure on the Pressure

Lever with the other hand.

5. Increase the pressure on the large Pressure Lever and bring it down firmly to the limit

of its travel. This movement will now cut the single large flattened piece of dough into

equal pieces.

6. Again reduce the pressure on the handle but keep it at the bottom of its travel. Turn

the power switch to the "ON" position. Start the rounding action by grasping the

Molding Lever and moving it in a counter clockwise direction as far as it will go. Hold

it in this position for 3 to 5 seconds.

7. Allow the Pressure Lever to return to its normal position. Turn the machine off and

remove the Molding Plate with the rounded pieces of dough. If the pieces are not

rounded properly see the adjustment section of this manual.

Rev. 3-29-02

0625S20003-3

Loading...

Loading...