Oliver 600-R35 Installation Manual

Grand Rapids, Michigan, U.S.A. 49504-5298

USER’S OPERATING AND INSTRUCTION MANUAL

MODEL 600-R3 SERIES

DOUGH MOULDERS

600-R3S20000-CV

THIS PAGE WAS INTENTIONALLY

LEFT BLANK.

GEN020319

SAFETY INSTRUCTIONS

Various safety devices and methods of guarding have been provided on this machine. It

is essential, however, that machine operators and maintenance personnel observe the

following safety precautions. Improper installation or operation of this equipment may

cause injury to personnel or damage to equipment.

1. Read this manual before attempting to operate your machine. Never allow an

untrained person to operate or service this machine.

2. Connect the machine to a properly grounded electrical supply that matches the

requirements shown on the electrical specification plate and follow specifications of

local electrical codes.

3. Disconnect and lock-out the machine from the power supply before cleaning or

servicing.

4. Check and secure all guards before starting the machine.

5. Observe all caution and warning labels affixed to the machine.

6. Use only proper replacement parts.

7. Do not wear loose fitting clothing or loose hair. Shirt tails should be tucked in.

8. Wear proper personal safety equipment.

9. Keep Hands away form the moving parts of this machine while it is in operation.

10. In addition to these general safety instructions, also follow the more specific safety

instructions given for the different areas of the machine in the operating instructions.

WARNING

DO NOT USE FOR OTHER THAN ORIGINALLY INTENDED PURPOSE

REV. 12-15-95 GEN951215

600-R3

MODEL 600-R3 SERIES DOUGH MOULDERS

INDEX

SECTION

1.0 DESCRIPTION/SPECIFICATIONS .............................................................. 1-1

1.1 Description

1.2 Dimensional Specifications

1.3 Electrical Specifications

1.4 Wiring Diagram

2.0 MACHINE INSTALLATION .......................................................................... 2-1

2.1 Electrical Requirements

2.2 Machine Running Direction

3.0 OPERATING INSTRUCTIONS .................................................................... 3-1

3.1 Machine Preparation

3.2 Establishing Settings

4.0 CLEANING/MAINTENANCE ....................................................................... 4-1

4.1 Cleaning

4.2 Changing the Felt Under the Heavy Mat

4.3 Changing the V-belt

4.4 Replacing the Motor

4.5 Removing Rear Chamber Assembly and Belt

4.6 Removing the Sheeting Rollers

4.6.1 Removing the Upper Sheeting Roller

4.6.2 Removing the Lower Sheeting Roller

4.7 Replacing the Front Triangular Belt

4.7.1 Removing the Front Triangular Belt

4.7.2 Installing the Front Triangular Belt

5.0 REPLACEMENT PARTS ............................................................................. 5-1

5.1 Assembly Drawings

5.2 Parts List

5.3 Recommended Spare Parts

WARRANTY ................................................................................................

WARRANTY PROCEDURE ………………………………………………….....

RETURNED PARTS POLICY ......................................................................

PAGE N0.

0600S20005.doc Rev. 2/25/04

THIS PAGE WAS INTENTIONALLY

LEFT BLANK.

GEN020319

600-R3

MODEL 600-R3 SERIES DOUGH MOULDER

1.0 DESCRIPTION / SPECIFICATION

1.1 Description

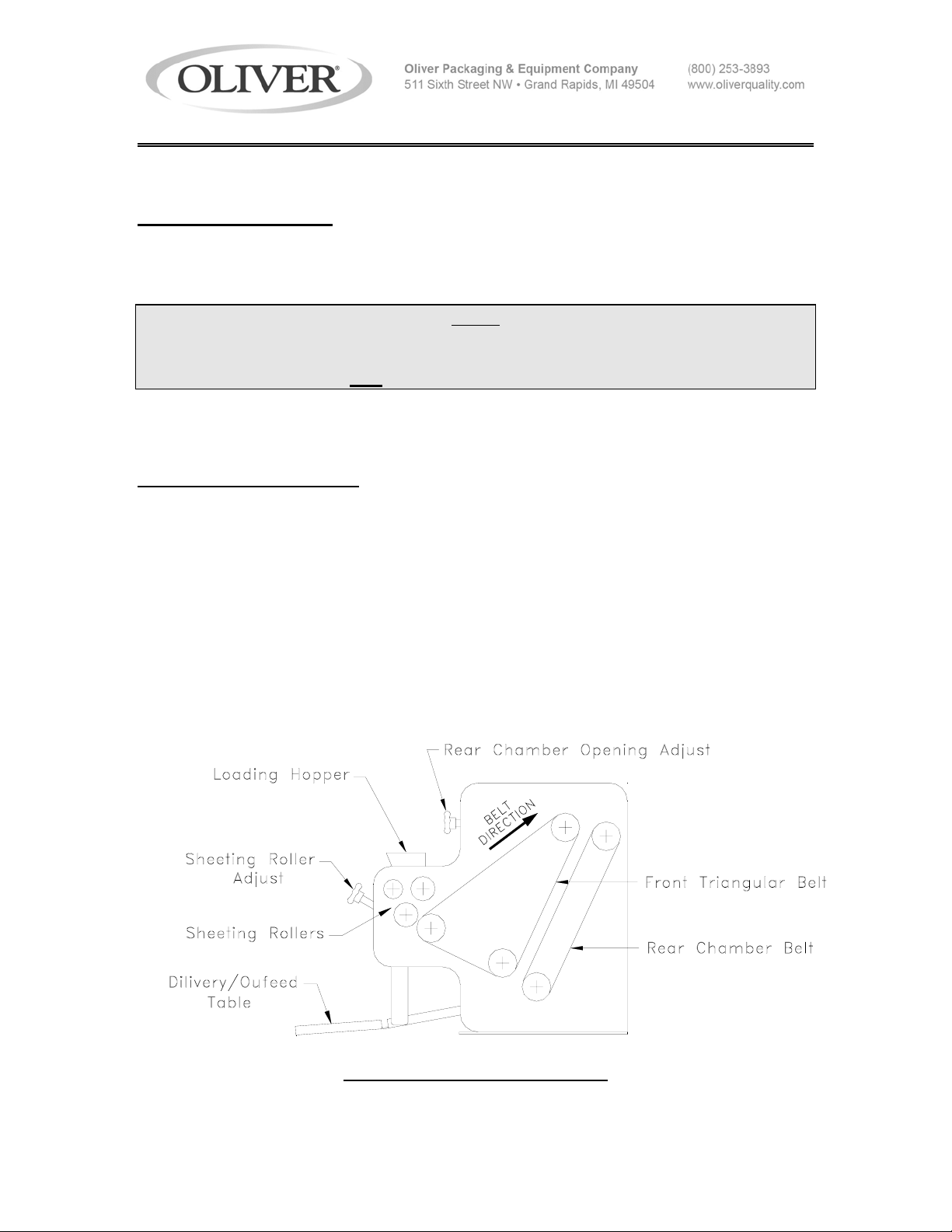

The moulder stretches dough gently and gradually between two belts revolving in

opposite directions and at different speeds. The dough is inserted in a hopper located

approximately 54" from the floor (when mounted on the Oliver Moulder stand with

casters), which feeds it between three plastic coated sheeting rollers. The sheeting and

stretching operations are controlled manually with two levers with easy to read scales.

The moulded dough is delivered below the hopper on a felt covered retractable shelf

approximately 32" above the floor (when mounted on the Oliver Moulder stand with

casters).

All driving cylinders are mounted on sealed bearings which are lubricated at the factory

and need no further lubrication. The front belt rotates on three cylinders positioned in a

triangular pattern while the rear belt rotates in the opposite direction on two cylinders.

The three plastic coated sheeting rollers, (of which the lower one is adjustable), flatten

the dough after it is inserted in the hopper.

The moulder is driven by a 3/4 HP open drip proof motor which is easily adjustable for

tightening the V-belt drive. The revolving belts are driven by a noiseless gear belt

system which never needs lubrication.

1-1

0600S20006.doc Rev. 5/02/02

600-R3

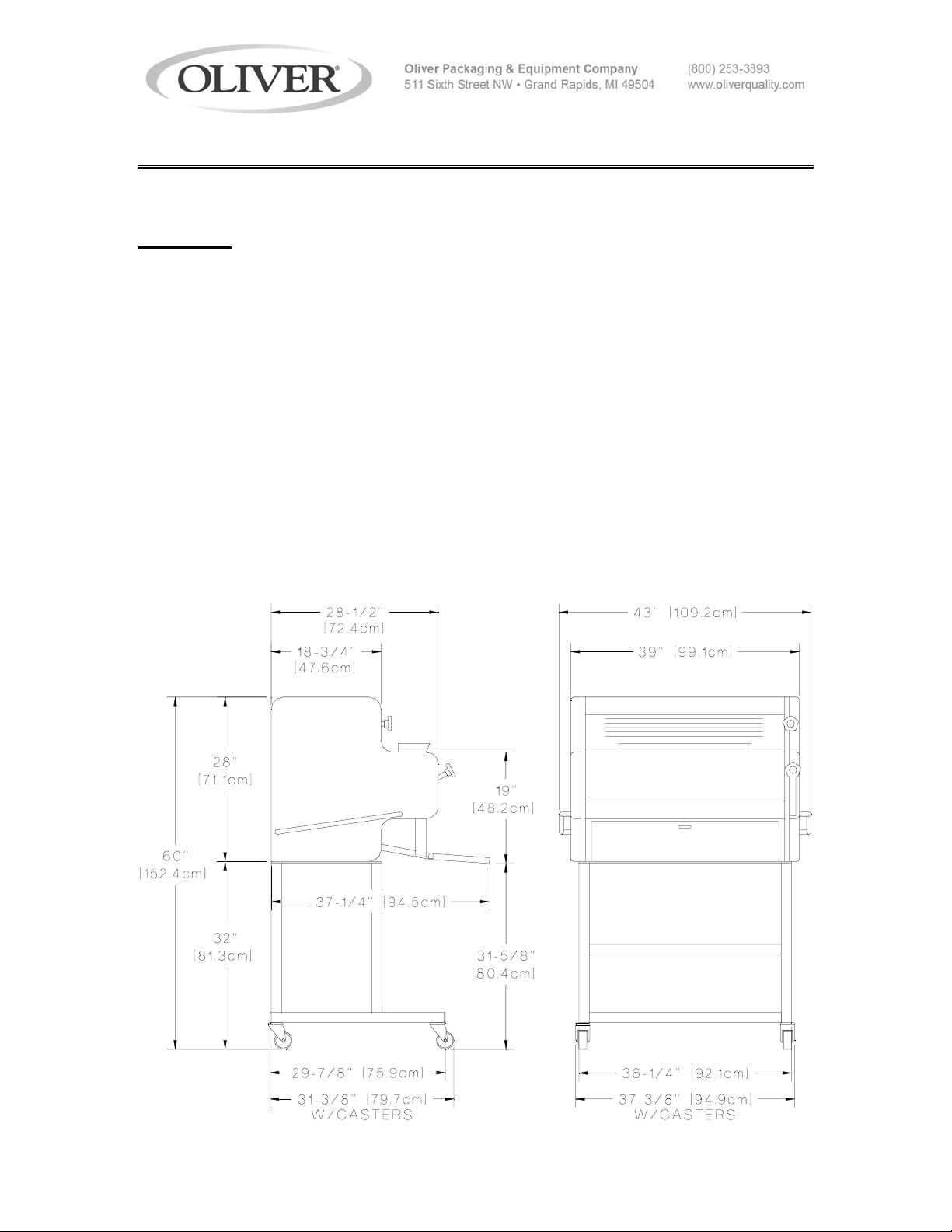

1.2 Dimensional Specifications

Product Capacities: Machine size:

2 ounces (0.1kg) to 6 pounds (3.0kg) Width = 43 inches

Height = 28 inches,

Net Weight: Height OA = 60 inches

Approximately 380 pounds Depth = 28-1/2 inches,

425 pounds with stand Depth OA = 37-1/4 inches

Shipping Weight:

Approximately 575 pounds

1.3 Electrical Specifications

208-220/440 Volts AC

3 Phase, 50/60 Hz,

3/4 Horse Power

3.1-3.1/1.5 AMPS.

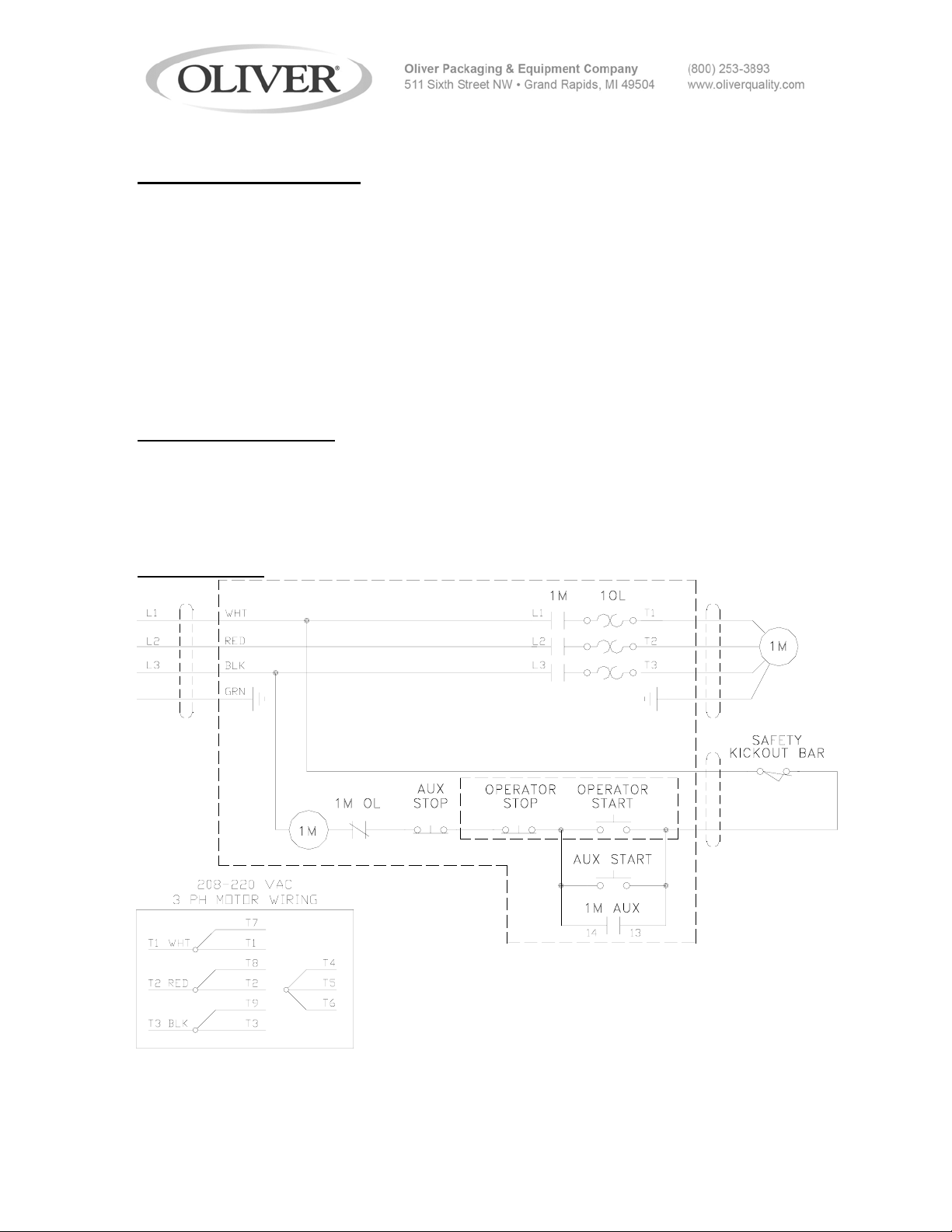

1.4 Wiring Diagram

1-2

0600S20006.doc Rev. 5/02/02

600-R3

MODEL 600-R3 SERIES DOUGH MOULDER

2.0 MACHINE INSTALLATION

2.1 Electrical Requirements

First, check the wall receptacle to be sure it is a three phase, 230 volt receptacle. If not,

one must be installed. Attach a three phase, 230 volt plug to the end of the power cord.

Be sure the pattern of the wall receptacle and pattern of the plug are matching.

A TWIST-LOCK TYPE PLUG MUST BE USED ON THE 600-R3 SERIES OF

DOUGH MOULDERS POWER CORD TO KEEP IN COMPLIANCE WITH

Before putting machine into operation, check to see if the machine is running in the

correct direction. (See Section 2.2).

2.2 Machine Running Direction

To check for proper running direction you must first disengage the heavy mat, (Item

#808, Assembly Drawing 5.1.1) by removing the left and right heavy mat support springs

(Item #809, Not Shown) from their posts located towards the top. Lay the heavy mat

and under lying felt over the front of machine. Then switch the machine on briefly and

observe the direction in which the front triangular belt is moving. If the belt is moving

upward the belt rotation is correct. If the belt is moving downward the machine’s running

direction must be reversed. Unplug the machine from the power receptacle. Reverse

the black and white wires in the plug at the end of the power cord.

When the running direction of the machine is correct reinstall the heavy mat.

NOTE

ETL SAFETY REQUIREMENTS.

Proper Running Direction

2-1

0600S20007.doc Rev. 5/2/02

600-R3 SERIES DOUGH MOULDER

3.0 OPERATING INSTRUCTIONS

3.1 Machine Preparation

Always flour the delivery outfeed table felt generously and thoroughly. You should also

flour the dough as thickly as possible, all around. Also, when preparing to run the

moulder we recommend that you first weigh as many pieces of dough as possible in

advance.

3.2 Establishing Settings

NOTE

ADJUSTMENTS SHOULD BE MADE WHILE THE MACHINE IS RUNNING.

Gently drop a piece of dough in the hopper and observe its shape after moulding.

• If the loaf is too compact, open the sheeting rollers.

• If the loaf is not compact enough, close the sheeting rollers.

• If the loaf is too short, close the rear chamber.

• If the loaf is too long, open the rear chamber.

• If the loaf is too fat in the center, close the sheeting rollers while sheeting, or, the

dough may be too stiff.

• If the ends twist, open the rear chamber.

We recommend that all settings be recorded for later use once they are established.

Remember, results may vary depending on dough condition. If required, make

adjustments gradually starting with the original established setting.

ESTABLISHED SETTINGS

FOR SHEETING ROLLERS & REAR CHAMBER OPENINGS

LOAF TYPE SHEETING STRETCHING

_____________________________ ______ ______

_____________________________ ______ ______

_____________________________ ______ ______

_____________________________ ______ ______

_____________________________ ______ ______

_____________________________ ______ ______

_____________________________ ______ ______

_____________________________ ______ ______

3-1

0600S20008.doc Rev. 5/2/02

600-R3 SERIES DOUGH MOULDER

WARNING

ALWAYS MAKE SURE THE MACHINE HAS BEEN DISCONNECTED FROM THE

POWER SUPPLY BEFORE CLEANING OR SERVICING.

4.0 CLEANING / MAINTENANCE

4.1 Cleaning

The machine should receive general cleaning at regular intervals with special attention

given to the following:

WEEKLY:

• The belts and felt pad on the delivery outfeed table should be thoroughly brushed.

• The upper scraper should be removed and cleaned to eliminate scraps of dried

In general the moulder requires little additional maintenance other than that which is

specified below. Most of the drives are supplied by either gear belt or V-belt, neither

should be lubricated.

4.2 Changing the Felt Under the Heavy Mat

1. Remove the intake cover, (Item #738, Drawing 5.1.1).

2. Remove the two upper scraper tension springs, (Item #816, Drawing 5.1.1), and then

3. Unhook the heavy mat, (Item #808, Drawing 5.1.1), by removing the heavy mat

4. When replacing the felt under the heavy mat, make sure that the seam is on top and

Do NOT

dough which might scratch the roller, (section 4.2, procedure 2), for removal of the

scraper.

disengage the upper scraper, (Item #807, Drawing 5.1.1), by pushing it to the left

and lifting it out. Note, the lower scraper is pushed to the right to be remove.

support springs (Item #809, Not Shown), from their post’s located towards the top.

Lift the heavy mat assembly and under lying felt from their brackets, (Items #813 and

#813-1).

not against the front triangular belt.

use a metal dough cutter.

4-1

0600S20009.doc Rev. 5/2/02

Loading...

Loading...