North Star DIMENSION Service Manual

North

Star

DIMENSIONTM

Service Manual

•.nr^

...^s

NOTICE

North Star Computers

,

Inc. makes no representations or warranties with

respect to this manual

.

Further, North Star Computers

,

Inc. reserves the

right to make changes in the specifications of the product described in

,^ this manual at any time without notice and without obligation of North

Star Computers

,

Inc. to notify any person of such revision or changes. All

technical information

,

statements and recommendations in this document

and in any manuals or related documents are believed to be reliable, but

the accuracy or completeness thereof is not guaranteed.

DISCLAIMER

OF WARRANTY

North Star Computers

,

Inc. makes no representations or warranties

,

either

expressed or implied

,

by or with respect to hardware, software, or

anything in this manual

,

and shall not be liable for any implied warranties

of merchantability or fitness for a particular purpose or for any indirect,

special or consequential damages

.

Some states do not allow the exclusion

of incidental or consequential damages, so this exclusion may not apply to

you.

COPYRIGHT NOTICE

All rights reserved

.

No part of this publication may be reproduced

,

stored

in a retieval system, or transmitted

,

in any form or by any means,

mechanical

,

photocopying

,

recording or otherwise

,

without the prior written

consent of North Star Computers

,

Inc. No patent liability is assumed with

respect to the use of the information

'

contained herein

.

While every

precaution has been taken in the preparation of this manual, North Star

Computers

,

Inc. assumes no responsibility for errors or omissions.

Furthermore

,

this publication and features described herein, are subject to

change without notice.

DIMENSION

Service Manual i

TRADEMARKS

c North

Star

DIMENSION

is a trademark

of North Star Computers, Inc.

North

Star

NetWare is

a trademark

of North Star Computers, Inc.

NetWare

is a trademark

of Novell Inc.

MS-DOS is a trademark of Microsoft Corporation.

IBM, IBM PC, and IBM XT are registered trademarks of International

Business

Machines

^t 80186

,

8254

, 2732A, 2764,

8274, 8255A-5 and 8259A are registered

trademarks of Intel Corporation

SCN2682 is a trademark of Signetics Corporation

uPD765A

is a trademark

of NEC Electronics USA Incorporated

WDIO10-00/01 is a trademark of Western Digital Corporation

ti MC6845 and MC146818 are trademarks of Motorola Semiconductor

Products

Copyright 1985 by North Star Computers, Inc.

All rights reserved.

FEDERAL COMMUNICATIONS COMMISSION

RADIO FREQUENCY INTERFERENCE STATEMENT

Warning: This equipment has been certified to comply with the limits for a

Class A computing device

,

persuant to Subpart J of Part 15

of FCC rules.

Only peripheral devices

(

computer devices, terminals

,

printers, etc.)

certified to comply with the Class B limits may be attached to this

computer

.

Operation with non-certified peripheral devices may result in

interference to radio and television reception.

ii DIMENSION Service Manual

Instructions

To Users: This equipment generates and uses radio frequency

energy and if not installed and used properly

, i.e., in

strict accordance

with the operating instructions and reference manuals, may cause

interference to radio and television reception.

,,.•., If this equipment does cause interference to radio or television reception,

the user is encouraged to try to correct the problem by employing one or

more of the following measures:

0400-

r Reorient the receiving antenna.

• Relocate the equipment with respect to the receiver.

* Move the equipment away from the receiver.

* Plug the equipment into a different electrical outlet so that the

equipment and receiver are on different branch circuits.

* Ensure that workstation circuit board mounting screws, peripheral

device attachment screws, and ground wires are properly fastened.

* Ensure that workstation circuit board sheet-metal covers are in

place when no workstation circuit boards are installed.

If necessary, consult your dealer for additional suggestions.

North Star Computers, Inc. is not responsible for radio or television

interference caused by unauthorized modifications to this equipment. It is

the responsibility of the user to correct such interference.

Caution

: This equipment is equipped with a UL listed and CSA certified

plug. It is to be used in conjunction with a properly grounded, 115VAC

receptacle to avoid electrical shock.

DIMENSION

Service Manual iii

iv DIMENSION Service Manual

INTRODUCTION TO THE

DIMENSION

SERVICE MANUAL

The North Star DIMENSION is a versatile, fast, and reliable computer

system that incorporates contemporary system design, imaginative use of

electronic circuitry and components, and rigid manufacturing quality

control. This service manual attempts to follow in these traditions.

A service manual that attempts to be all things to all people is asking for

trouble. There are computer users who simply want to install their own

systems; technicians who have only the responsibility of maintaining the

equipment; engineers who need to understand the host-system in order to

design hardware peripherals; and programmers who may wish to create

alternative operating systems or application packages. This manual is not

written for all of you.

If you are a system owner

/

user who wants to install your own equipment,

we recommend reading the

DIMENSION

System Manual. It contains

abbreviated hardware and operating system installation instructions that

are tailored especially for you.

If you are a technician who needs a manual to help speed your

troubleshooting, diagnosis, and repair of problems, this manual is for you.

The manual is specifically designed for the field technician who must get

in, fix the problem, and leave quickly. The manual contains no theories of

operation, specifications, extensive parts lists or schematics. It does

contain diagnostic charts, troubleshooting steps, and

removal/replacement/adjustment procedures. The DIMENSION Service

Manual is the field-accompaniment to the DIMENSION Technical Manual.

If you are an engineer who needs to know anything and everything about

DIMENSION

hardware, we recommend

that you refer to the DIMENSION

Technical

Manual

.

It contains specifications

,

theories of operation,

schematic diagrams

,

timing diagrams

,

and parts lists related to the system

and each of its components.

If you are a programmer

,

and your task is to create alternative operating

systems or application programs for our computer

,

we recommend reading

the DIMENSION Programmer's Notebook

.

This manual contains only the

very specialized information required by a programmer.

DIMENSION

Service Manual v

INTRODUCTION TO THE DIMENSION SERVICE MANUAL (cont.)

If you are still in doubt about the appropriateness of this manual to your

area of interest, refer to the following paragraphs for a more in-depth

discussion of the contents of the North Star DIMENSION Service Manual.

Chapter 1 - Hardware

Installation

discusses procedures used for installing

all system hardware. This includes installation procedures for the

central module and workstations as well as procedures and

requirements for attaching shared and local printers, modems and

local mouse devices.

Chapter 2 - Troubleshooting discusses the processes used for locating

faults within the DIMENSION system. The chapter is comprised of

in-depth discussions about the auto-boot diagnostic aid and power

supply and central board troubleshooting procedures. An expanded

troubleshooting chart that covers both hardware and software

symptoms is also included.

Chapter 3 -

Diagnostics

discusses the four diagnostic aids that are

provided with the DIMENSION system. These include:

r Self tests that checks critical central module hardware

x^ Service Diskette #1 that provides a further test of central module

hardware

^t Service Diskette #2 that tests and formats the diskette and fixed

disk drives

^Y Service Diskette #3 that tests and evaluates the tape drive

system

Chapter

4 - Subassembly Removal

provides procedures used for removing

all system hardware. The chapter is a shorthand device that

explains in a concise manner all the steps necessary to remove any

major subassembly from the central module.

Appendix A - Parts Lists contains parts lists for system subassemblies.

Appendix B - I/O Ports

contains information about the four DIMENSION

I/O ports.

vi DIMENSION Service Manual

DIMENSION SERVICE MANUAL TABLE OF CONTENTS

INTRODUCTION TO THE DIMENSION SERVICE MANUAL

CHAPTER 1 - HARDWARE INSTALLATION

Physical Location of the System Modules

Central Module Installation and Configuration

Opening the Central Module

Central Board Expansion RAM Installation

Workstation Board Expansion RAM Installation

8087 Board Installation

Workstation Board Installation

OMNINET Board

Installation

Tape Drive and Tape Drive Interface Board Installation

Second Fixed Disk Drive Installation

Checking the Power Supply

Checking the Selectable Power Line Receptacle

Central Module Final Setup

Workstation

Installation

Workstation

Installation

Tilt and Swivel Installation

Shared Printer Installation

Shared Parallel Printer Installation

Shared Serial Printer Installation

Local Printer Installation

Local Modem

Installation

Local Mouse

Installation

CHAPTER 2 - TROUBLESHOOTING

Auto-Boot Diagnostics

Preliminary Troubleshooting (Boot Sequence)

v

1-2

1-5

1-7

1-8

1-10

1-12

1-15

1-17

1-19

1-25

1-31

1-33

1-37

1-39

1-40

1-43

1-45

1-47

1-48

1-49

1-53

1-56

2-2

2-2

DIMENSION

Service Manual vii

TABLE OF CONTENTS (

cont.)

System Troubleshooting

Boot Problems

Hang Problems

Printer Problems

Printer Problems in MAINT

Application Installation Problems

Asynchronous Communications Problems

TPA (Workstation Memory

)

Problems

dBase II Problems

Miscellaneous Application Problems

Fixed Disk Problems

Monitor Problems

Keyboard Problems

Miscellaneous Problems

Tape Drive Problems

Testing the Central Module Power Supply

Power Supply Troubleshooting Chart

Testing the Central Board

CHAPTER 3

-

DIAGNOSTICS

Supplemental Tools

Self-tests

Service Diskettes

Loading Service Diskettes

Service Diskette #1

Test Options

Test Data Pointer Screen

Central Board Test Analysis Screen

Workstation Board Test Failure Screen

Communications Port Testing

2-6

2-7

2-19

2-22

2-28

2-30

2-33

2-35

2-37

2-39

2-42

2-47

2-49

2-51

2-55

2-57

2-59

2-63

3-2

3-3

3-5

3-6

3-7

3-10

3-13

3-14

3-15

3-16

Iftow

viii DIMENSION Service Manual

(cont.) TABLE OF CONTENTS

Service Diskette #2

3-17

Test Options

3-18

Diskette Drive Test

3-23

Fixed Disk Format and Label Writer

3-25

Test Fixed Disk Drives

3-26

Park Fixed Disk Drive Heads

3-28

Using Fixed Disk Drive Extension Cables

3-29

Error Screens and Codes

3-31

Error Code Matrix

3-39

Service Diskette #3

3-45

Loading Service Diskette #3

3-46

Tape

Diagnostic

Main Menu

3-48

Test Options

3-49

Technician Menu

3-52

Test Options

3-53

Interpreting

Drive Status Bytes

3-58

Error

Message Interpretation

3-59

CHAPTER 4 - SUBASSEMBLY REMOVAL

Workstation Board

4-3

8087 Board

4-4

OMNINET Board

4-5

Tape Drive

Interface Board

4-6

Workstation 128K/384K

Expansion

RAM Board

4-7

Power Supply

4-8

Central Board Expansion RAM

4-10

Bus Board

4-1 1

Central Board

4-12

Diskette Drive

4-14

Fixed Disk Drive

4-16

Tape Drive

4-17

Installing

a New

Central Board

4-19

Installing a New Bus Board

4-21

DIMENSION

Service Manual ix

TABLE OF CONTENTS

(

cont.)

APPENDIX A - PARTS LISTS

Central Module

A-2

Miscellaneous Parts

A-2

Circuit Boards

A-4

Harnesses and Cables

A-5

Workstation

A-6

Miscellaneous Workstation Parts

A-6

APPENDIX

B - I/O PORTS

Serial Ports Si and S2

Serial Port Pinouts

Parallel Port P1

Parallel Port Pinouts

Workstation Interconnect Box Serial Port

Serial Port Pinouts

B-2

B-3

B-5

B-6

B-8 ....^

B-8

x DIMENSION

Service Manual

CHAPTER 1

HARDWAREINSTALLATION

Overview

This chapter explains how to install DIMENSION

computer system hardware including the central

module, its workstations and peripheral devices

such as printers.

DIMENSION computer systems may vary significantly

in complexity. A simple system might contain two

workstations and' a shared printer; a complex sys-

tem might contain as many as-twelve-workstations

with shared and local printers and modems, and

local mouse devices. Simple and complex systems

use the installation procedures found on the

following pages.

Because of the number of power cords and cables

used to connect the components of the system, you

should position the equipment before attaching

cords and cables. Begin the installation by

sketching your office area and determining where

you plan to locate the central module, worksta-

tions and peripheral equipment. Then unpack and

move the components to the locations suggested by

your sketch. After you've finished positioning

the equipment, begin using the installation

procedures to connect the components.

You'll need a small slotted

screwdriver and a

medium Phillips screwdriver to complete the

installation

procedures.

Technical Manual 1-1

SYSTEM HARDWARE INSTALLATION

Physical Location of the System Modules

General

Before you begin positioning the components of

Requirements

your computer system, consider the following

requirements:

o The central module and the video displays

receive their power from standard 115VAC (U.S.)

or 230VAC (international) three-conductor,

grounded power outlets.

The central module and any peripheral devices

attached to the central module must share power

outlets that are part of a commonly fused and

grounded electric circuit.

o The length of the central module and video

display power cables is fixed, so placement of

these components is determined by power cable

length and power outlet location. You may be

able to install three-conductor, grounded

extension cords if they are rated for at least

10 amps (115VAC) or 5 amps (230VAC).

o A standard workstation cable is 25 feet long;

100-foot extensions are also available. Three

100-foot extensions may be used in conjunction

with a standard 25-foot cable to create a

maximum central module-to-workstation cable

length of 325 feet.

When you are determining workstation cable

lengths, take into account that cable placement

should not stress cable connectors.

1-2 Technical Manual

SYSTEM HARDWARE INSTALLATION

(cont.) Physical Location of the System Modules

General

o Consider local fire, electrical and building

Requirements

codes as you are setting up your computer

(cont.) system. For example:

- Don't allow cables to cross aisles--they may

pose a safety hazard and might be accidentally

disconnected.

- Don't cover power cables with carpeting--this

may create a fire hazard.

- Don't use extension cords unless you are

familiar with local electrical codes governing

their use in office environments.

Make sure you follow local codes. Speak with

someone knowledgeable (a building electrician

or contractor) before you begin connecting the

equipment.

Technical Manual 1-3

SYSTEM HARDWARE INSTALLATION

Physical Location of the System Modules (cont.)

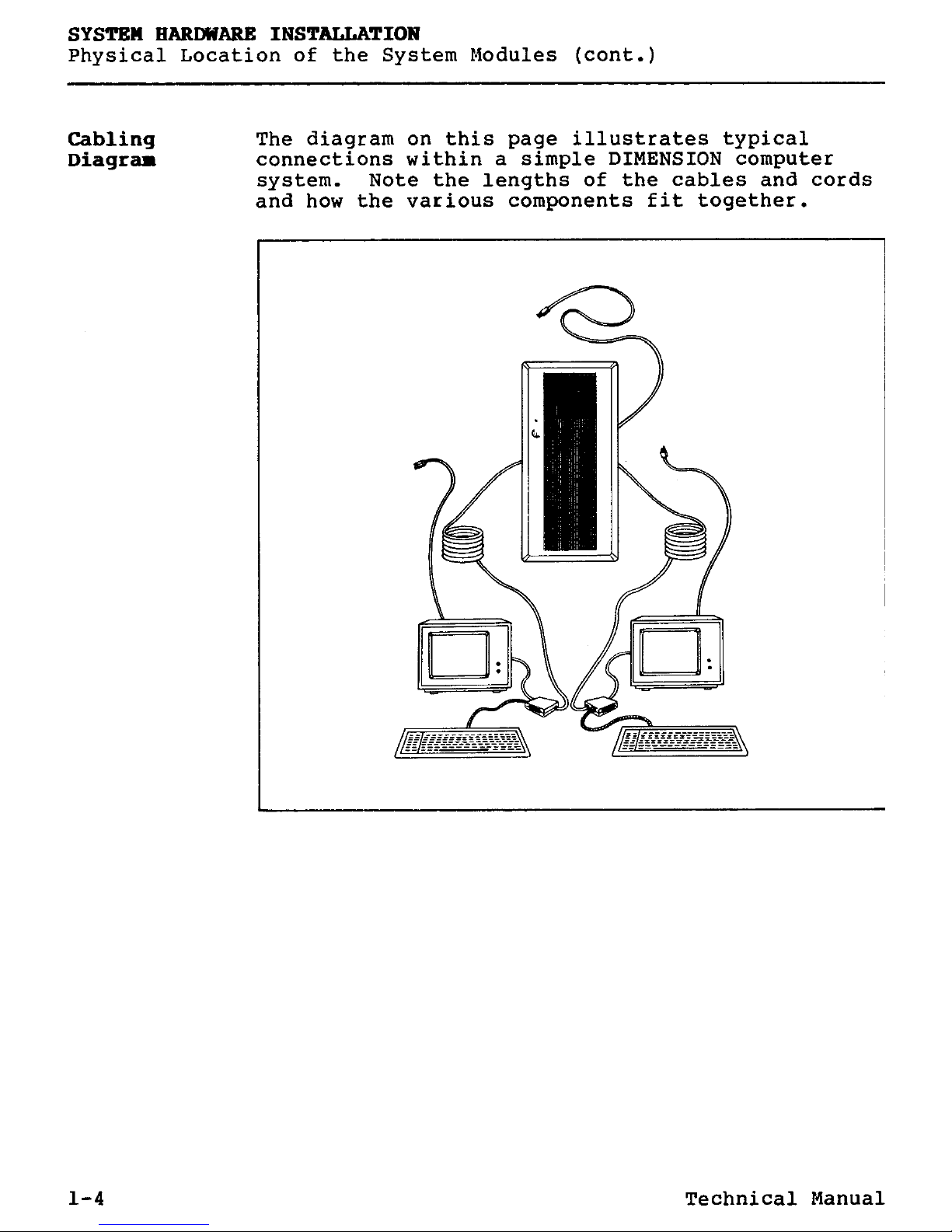

Cabling The diagram on this page illustrates typical

Diagram

connections within a simple DIMENSION computer

system. Note the lengths of the cables and cords

and how the various components fit together.

1-4 Technical Manual

SYSTEM HARDWARE INSTALLATION

(cont.) Physical Location of the System Modules

Cable

and

The following list of cord and cable lengths

Cord Lengths

details physical constraints you should consider

when locating the system components.

o

Central module power cord =

8 feet

o

Video display power cords =

6 feet

o

Keyboard cable (extended) =

6 feet

o

Workstation cable =

25 feet

o

Workstation extension cable =

100 feet

Technical Manual 1-5

SYSTEM HARIMARE

INSTALLATION

Central Module

Procedure

After you have positioned the system components,

Sugary

the next step in the hardware installation

procedure is to install and configure the central

module. The procedures on the following pages

describe how to:

o Place the central module on

its side and remove

the cover.

o Install the workstation circuit boards.

o Set the thumbwheel switches of the workstation

circuit boards.

o Connect the workstation cables to the

workstation circuit boards.

o Install the workstation

expansion

RAM circuit

boards. (Optional)

o Install the central

module expansion RAM

circuit boards. (Optional)

o Replace the cover.

o Check the selectable power line receptacle for

correct orientation of the voltage selection cam

and proper fuse.

o Install rubber feet to protect the base of the

central module.

o Return the central module to an upright

position.

o Install the power cord.

1-6 Technical Manual

SYSTEM HARDWARE INSTALLATION

(cont.) Central Module

Procedure

:

Central Module Installation and Configuration

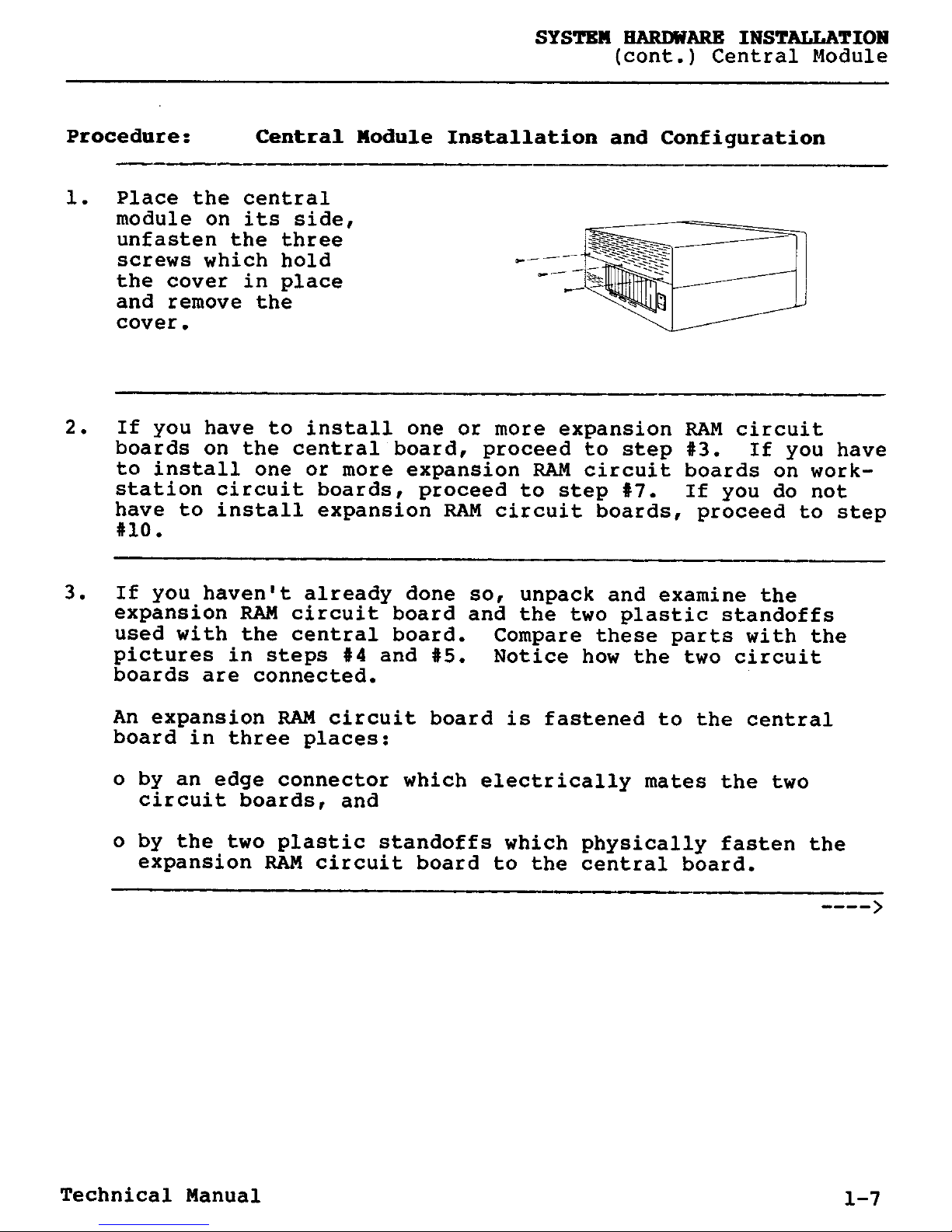

1. Place the central

module on its side,

unfasten the three

screws

which hold

the cover in place

and remove the

cover.

2. If you have to install

one or more expansion

RAM circuit

boards on

the central board, proceed to step #3. If you have

to install

one or more expansion

RAM circuit boards on work-

station circuit boards,

proceed

to step V. If you do not

have to install

expansion

RAM circuit

boards

, proceed to step

#10.

3. If you haven't already done so, unpack and examine the

expansion RAM circuit board and the two plastic standoffs

used with the central board. Compare these parts with the

pictures in steps #

4 and

#5. Notice how the two circuit

boards are connected.

An expansion RAM circuit board is fastened to the central

board in three places:

o by an

edge connector

which electrically mates the two

circuit

boards, and

o by the two plastic standoffs which physically fasten the

expansion

RAM circuit board to the central board.

Technical Manual 1-7

SYSTEM HARDWARE INSTALLATION

Central Module (cont.)

Procedure:

Central Module Installation and Configuration

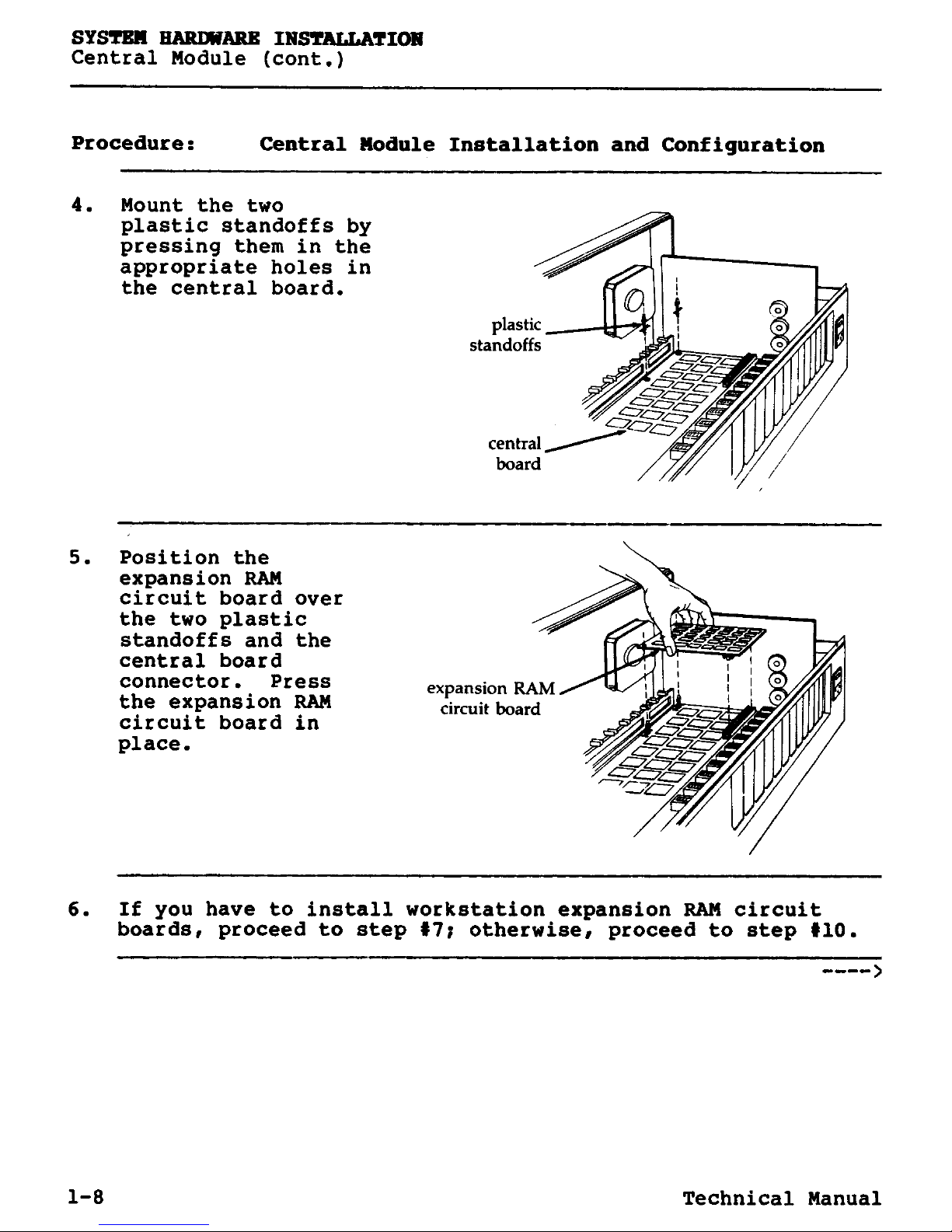

4. Mount the two

plastic standoffs by

pressing them in the

appropriate holes in

the central board.

5. Position the

expansion RAM

circuit board over

the two plastic

standoffs and the

central board

connector. Press

the expansion RAM

circuit board in

place.

6. If you have to install workstation expansion RAM circuit

boards, proceed to step

#

7; otherwise

,

proceed to step #10.

1-8 Technical Manual

SYSTEM HARD19ARE INSTALLATION

(cont.) Central Module

Procedure

:

Central Module Installation and Configuration

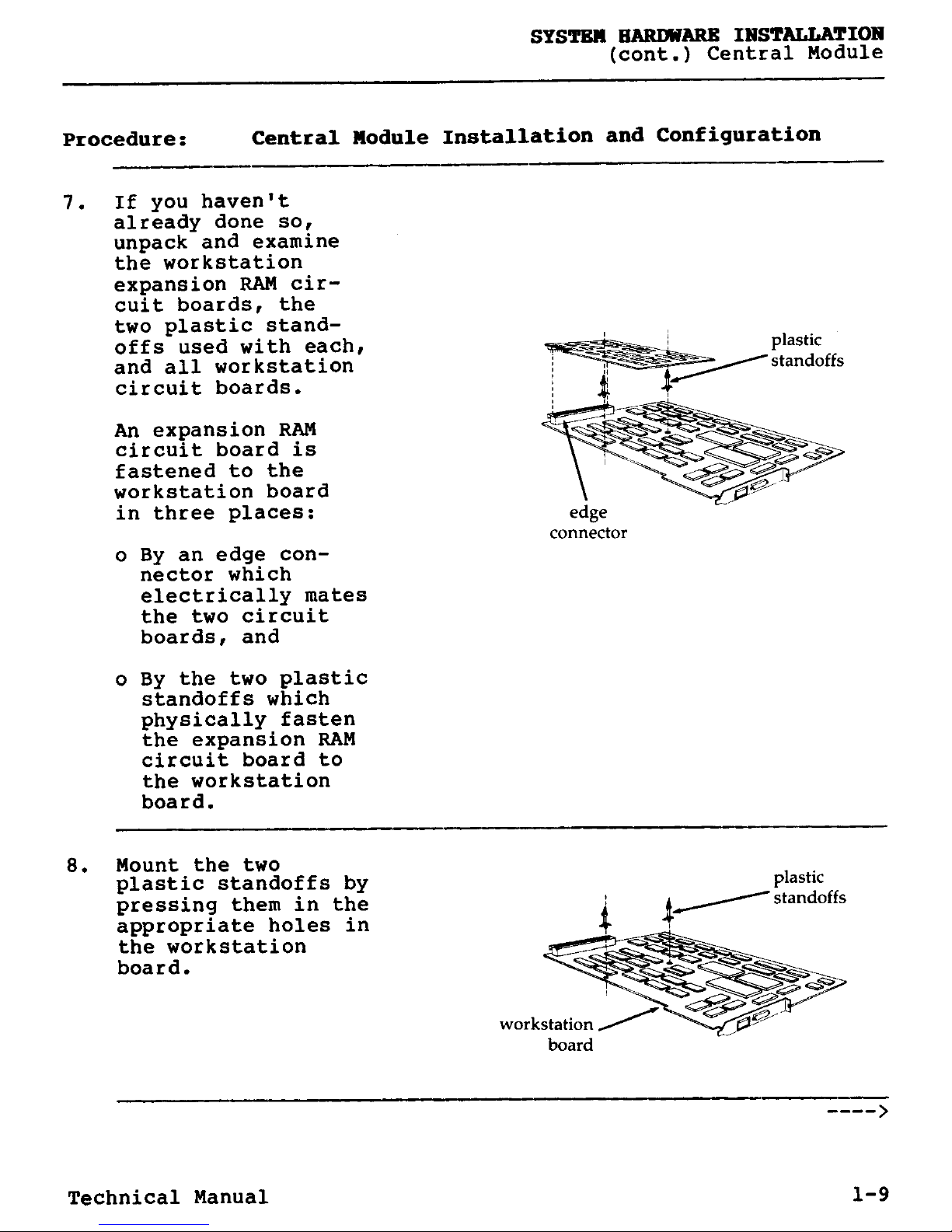

7. If you haven't

already done so,

unpack and examine

the workstation

expansion RAM circuit boards, the

two plastic standoffs used with each,

and all workstation

circuit boards.

An expansion RAM

circuit board is

fastened to the

workstation board

in three places:

o By an edge con-

nector which

electrically mates

the two circuit

boards, and

o By the two plastic

standoffs which

physically fasten

the expansion RAM

circuit board to

the workstation

board.

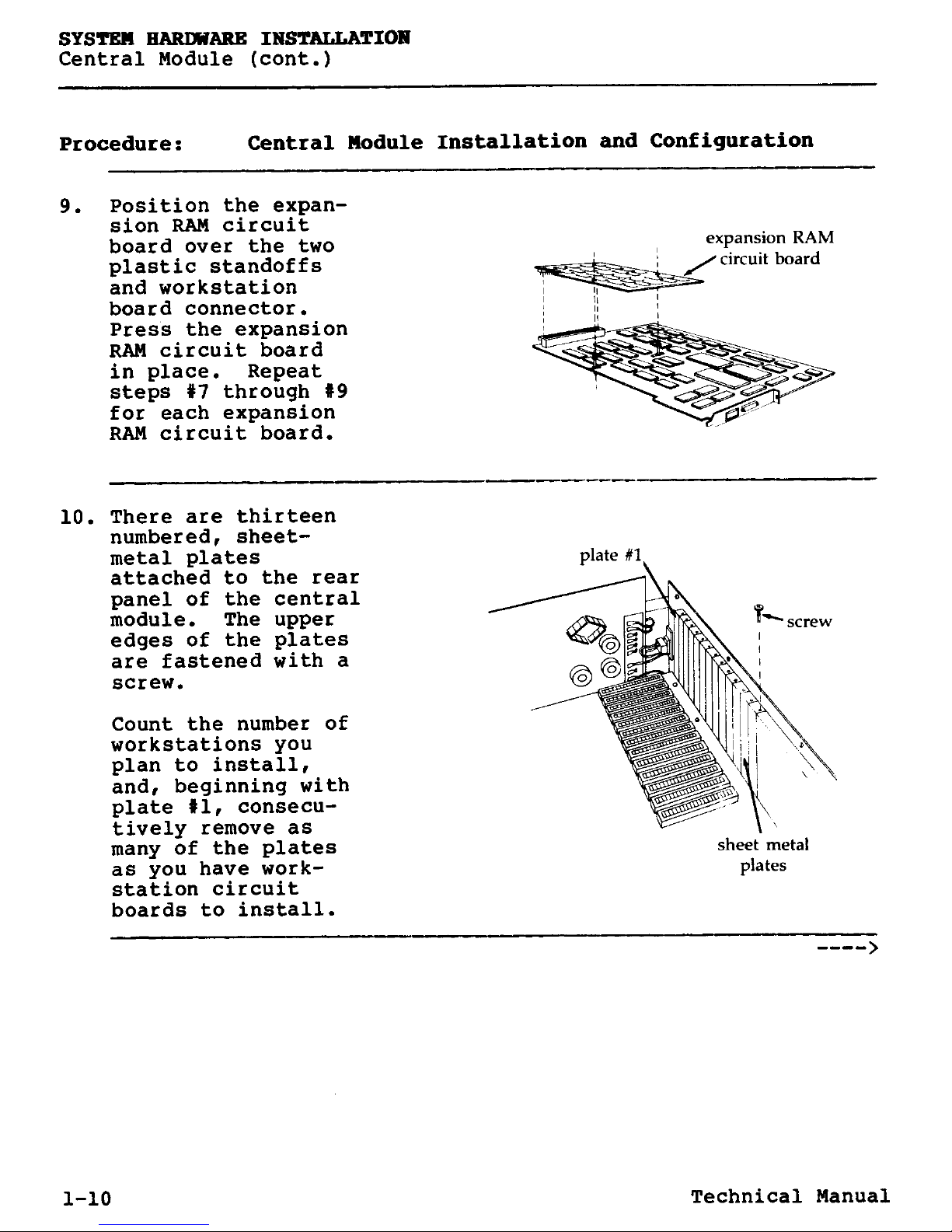

8. Mount the two

plastic standoffs by

pressing them in the

appropriate holes in

the workstation

board.

plastic

standoffs

Technical Manual 1-9

SYSTEM HARDWARE INSTALLATION

Central Module (cont.)

Procedure

:

Central Module Installation and Configuration

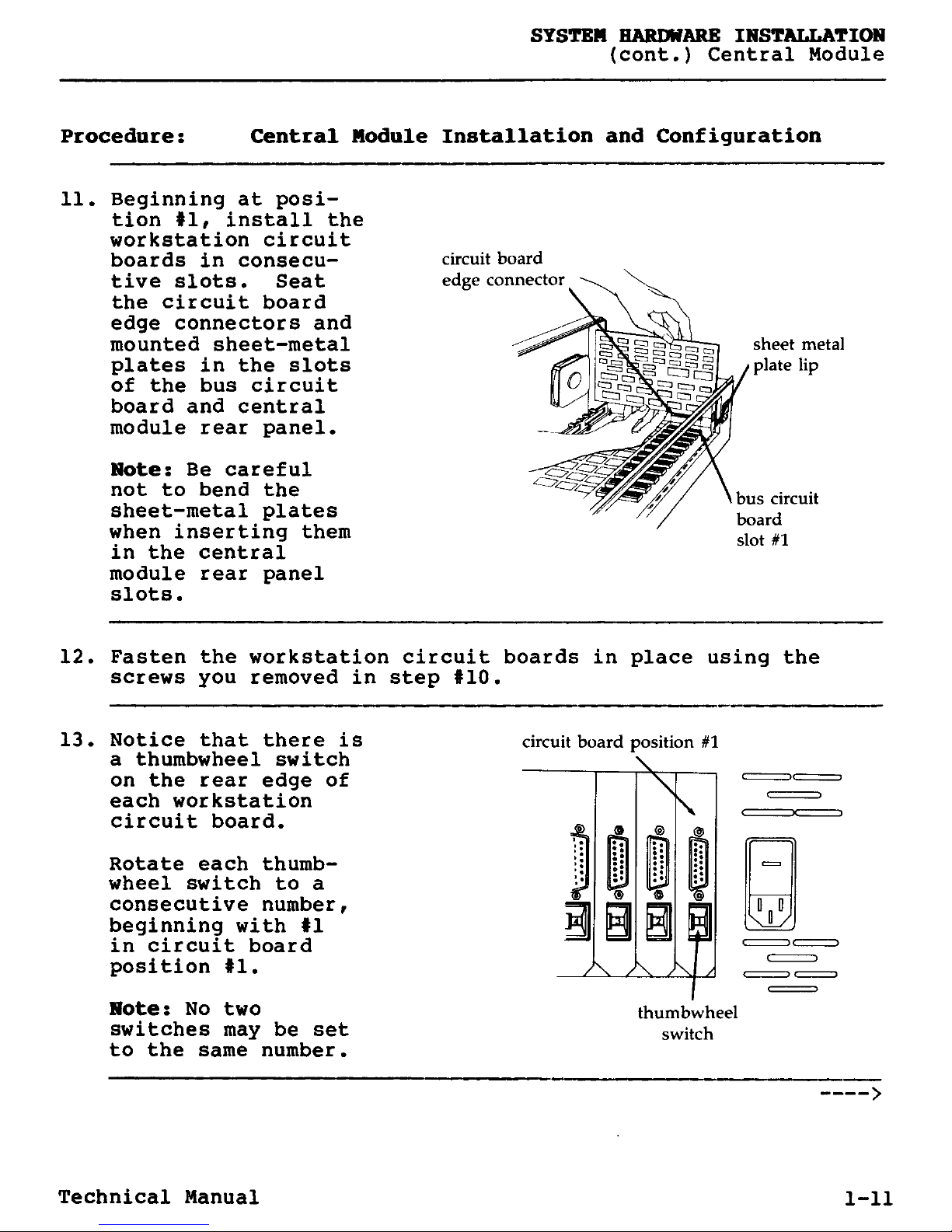

9. Position the expan-

sion RAM

circuit

board over the two

plastic standoffs

and workstation

board connector.

Press the

expansion

RAM circuit board

in place. Repeat

steps

#7 through #9

for each

expansion

RAM circuit board.

10. There are thirteen

numbered

,

sheet-

metal plates

attached to the rear

panel of the central

module. The upper

edges of the plates

are fastened with a

screw.

Count the number of

workstations you

plan to install,

and, beginning with

plate #1, consecutively remove as

many of the plates

as you have work-

station circuit

boards

to install.

1-10 Technical Manual

SYSTEM HARDWARE INSTALLATION

(cont.) Central Module

Procedure

:

Central Module Installation and Configuration

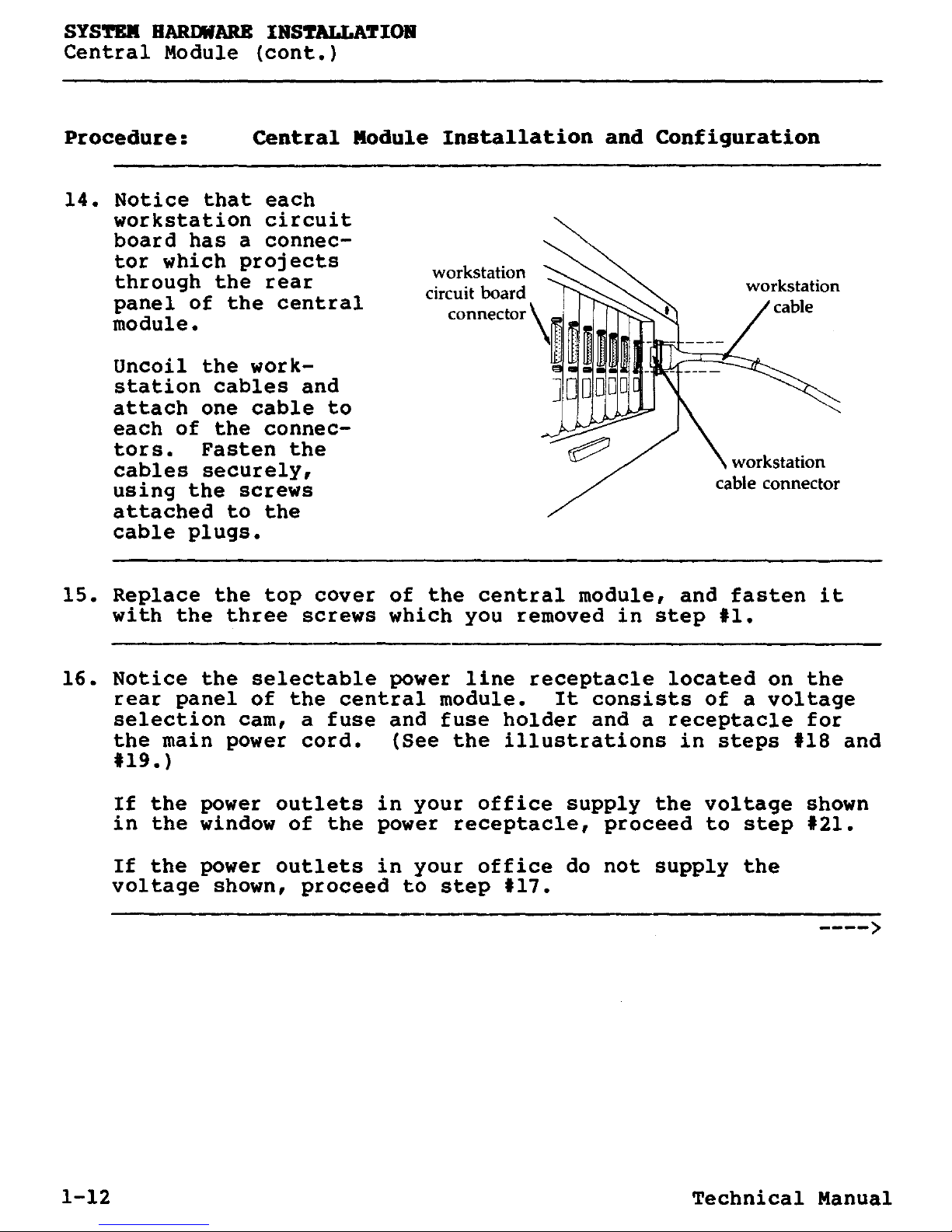

11. Beginning at position#1, install the

workstation circuit

boards in consecu-

tive slots. Seat

the circuit board

edge connectors and

mounted sheet-metal

plates in the slots

of the bus circuit

board and central

module rear panel.

Note

: Be careful

not to bend the

sheet-metal plates

when inserting them

in the central

module rear panel

slots.

12. Fasten the workstation circuit boards in place using the

screws

you removed in step #10.

13. Notice that there is

a thumbwheel switch

on the rear edge of

each workstation

circuit board.

Rotate each thumbwheel switch to a

consecutive number,

beginning with #1

in circuit board

position #1.

Note: No two

switches may be set

to thesame number.

circuit board position #1

thumbwheel

switch

00

Technical Manual 1-11

SYSTEM HARDWARE INSTALLATION

Central Module (cont.)

Procedure

:

Central Module Installation and Configuration

14. Notice that each

workstation

circuit

board has a connec-

tor which

projects

through the rear

panel of the

central

module.

Uncoil the workstation cables and

attach one cable to

each of the connectors. Fasten the

cables securely,

using the screws

attached to the

cable plugs.

workstation

circuit board

connector

15. Replace the top cover of the central module

,

and fasten it

with the three screws which you removed in step #1.

16. Notice the selectable power line receptacle located on the

rear panel of the central module. It consists of a voltage

selection cam, a fuse and fuse holder and a receptacle for

the main power cord.

(

See the illustrations in steps #18 and

#19.)

If the power outlets in your office supply the voltage shown

in the window of the power receptacle

,

proceed to step #21.

If the power outlets in your office do not supply the

voltage shown, proceed to step #17.

1-12 Technical Manual

SYSTEM HARDWARE INSTALLATION

(cont.) Central Module

Procedure

:

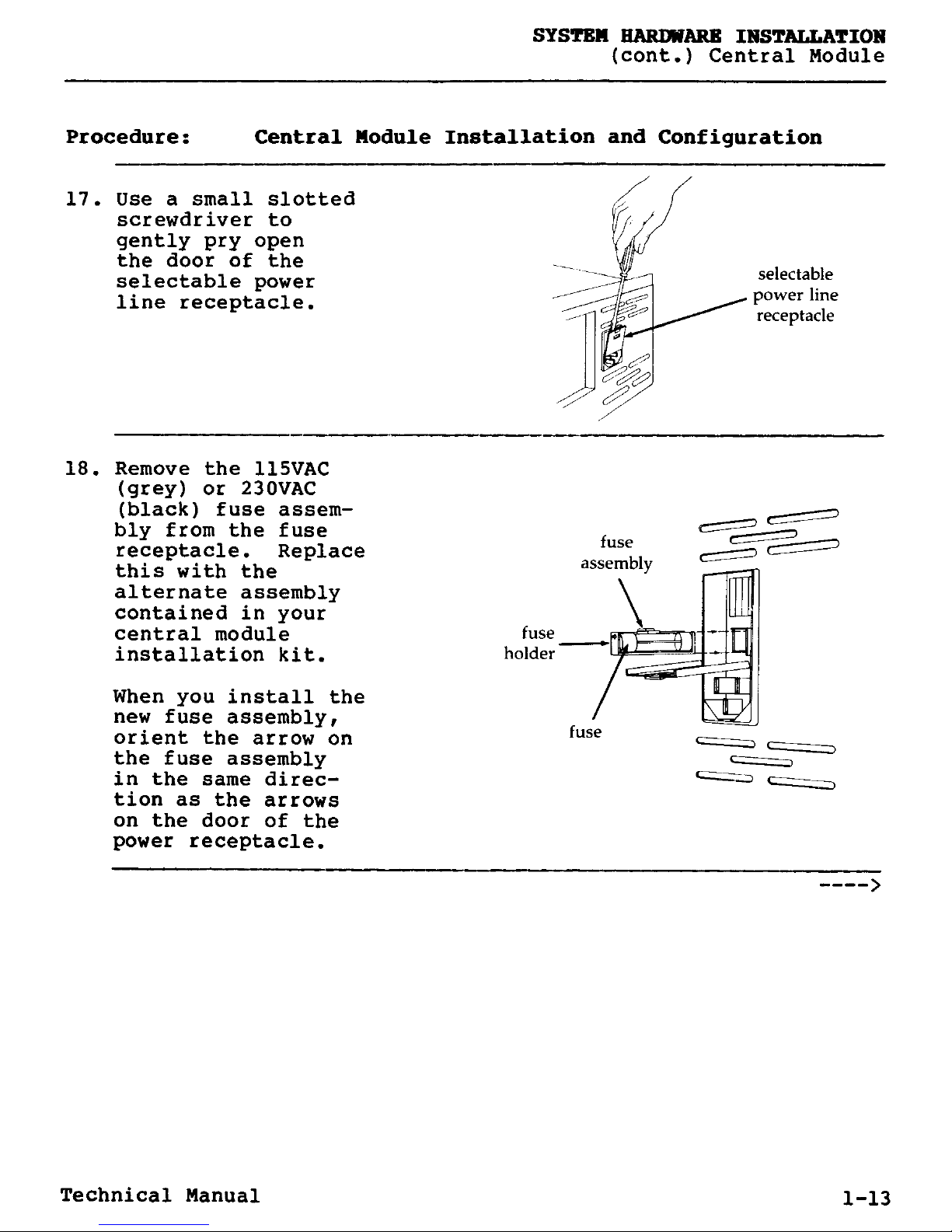

Central Module Installation and Configuration

17. Use a small slotted

screwdriver to

gently pry open

the door of the

selectable power

line receptacle.

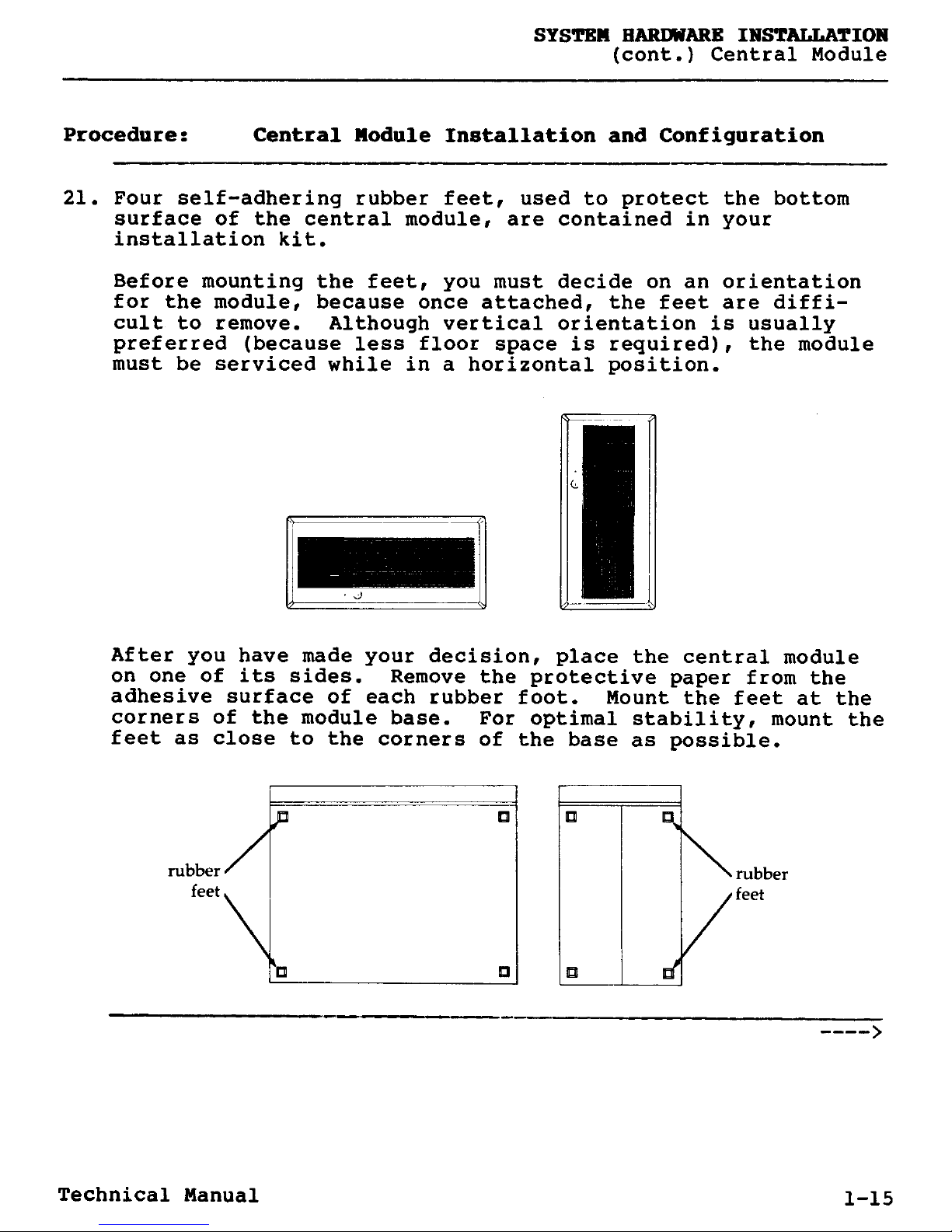

18. Remove the 115VAC

(grey) or 230VAC

(black)

fuse assem-

bly from the fuse

receptacle. Replace

this with the

alternate assembly

contained in your

central module fuse

installation

kit. holder

When you install the

new fuse assembly,

orient the arrow on

the fuse assembly

in the same direc-

tion

as the arrows

on the door of the

power receptacle.

selectable

power line

receptacle

C-

fuse

assembly

== O

fuse

Technical Manual 1-13

SYSTEM HARDWARE

INSTALLATION

Central Module (cont.)

Procedure

:

Central Module Installation and Configuration

19. Remove the voltage

selection cam from

the selectable power

line receptacle.

Rotate the cam

appropriately and

replace it so the

correct voltage sign

(either 115VAC or

230VAC)

appears

when the door of the

power receptacle is

closed.

20. Close the door of the selectable power line receptacle.

1-14 Technical Manual

SYSTEM HARDWARE INSTALLATION

(cont.) Central Module

Procedure

:

Central Module Installation and Configuration

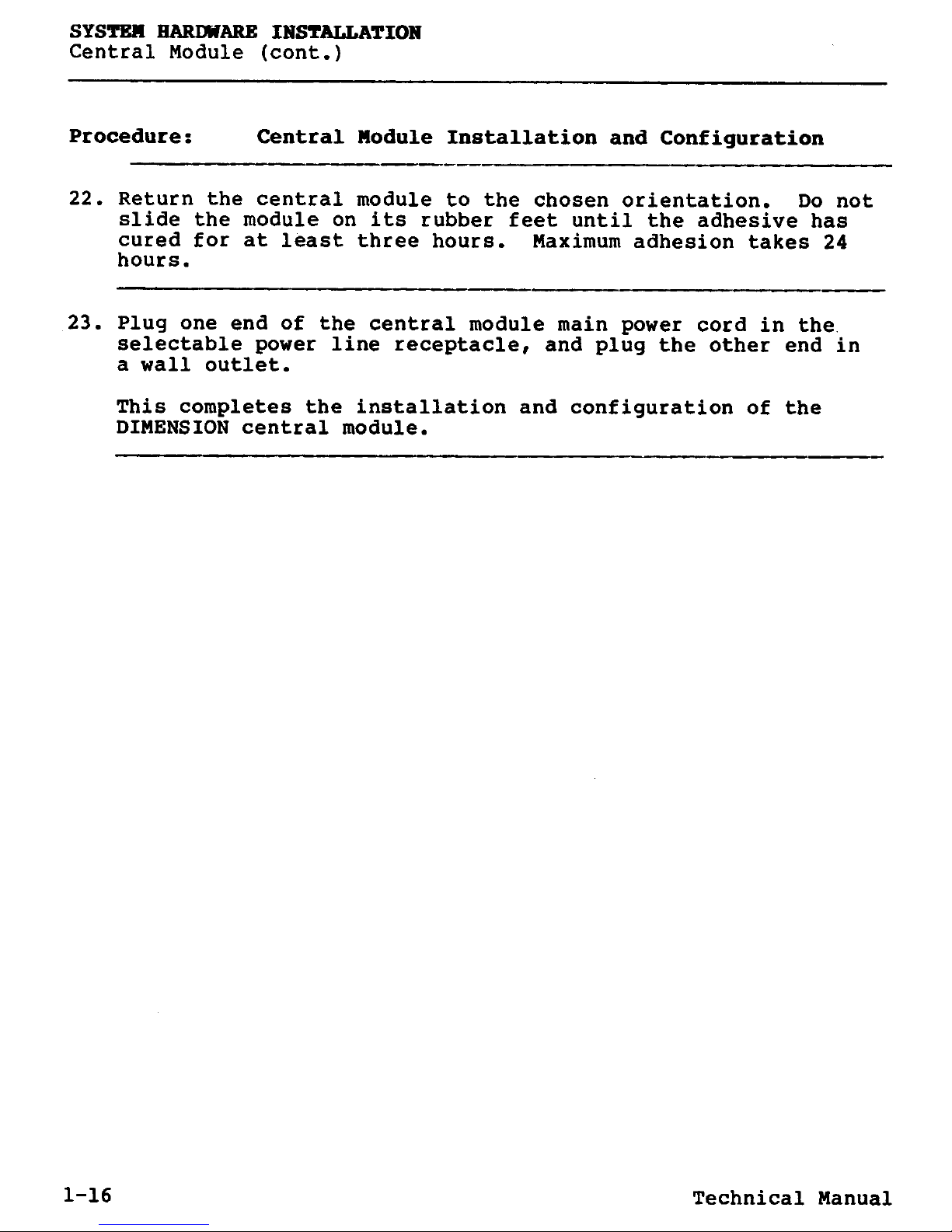

21. Four self-adhering rubber feet, used to protect the bottom

surface of the central module, are contained in your

installation kit.

Before mounting the feet, you must decide on an orientation

for the module, because once attached, the feet are diffi-

cult to remove. Although vertical orientation is usually

preferred (because less floor space is required), the module

must be serviced while in a horizontal position.

C

J

After you have made your decision, place the central module

on one of its sides. Remove the protective paper from the

adhesive surface of each rubber foot. Mount the feet at the

corners of the module base. For optimal stability, mount the

feet as close to the corners of the base as possible.

rubber

feet

Technical Manual 1-15

SYSTEM HARDWARE INSTALLATION

Central Module (cont.)

Procedure: Central Module Installation and Configuration

22. Return the central module to the chosen orientation. Do not

slide the module on its rubber feet until the adhesive has

cured for at least three hours

.

Maximum adhesion takes 24

hours.

23. Plug one end of the central module main power cord in the.

selectable power line receptacle, and plug the other end in

a wall outlet.

This completes the installation and configuration of the

DIMENSION central module.

1-16 Technical Manual

SYSTEM HARDWARE INSTALLATION

Workstation

Procedure

After you have installed and configured the

Summary

central module, the next step in the hardware

installation procedure is to install and configure

the workstations. The procedures on the following

pages describe how to:

o Plug the keyboard cable into the connector box.

o Plug the video cable into the video display.

o Mount the connector box.

o Mount the workstation label.

o Plug in the video display power cord.

o Adjust the tilt-and-swivel mechanism.

Technical Manual 1-17

SYSTEM HARDWARE INSTALLATION

Workstation (cont.)

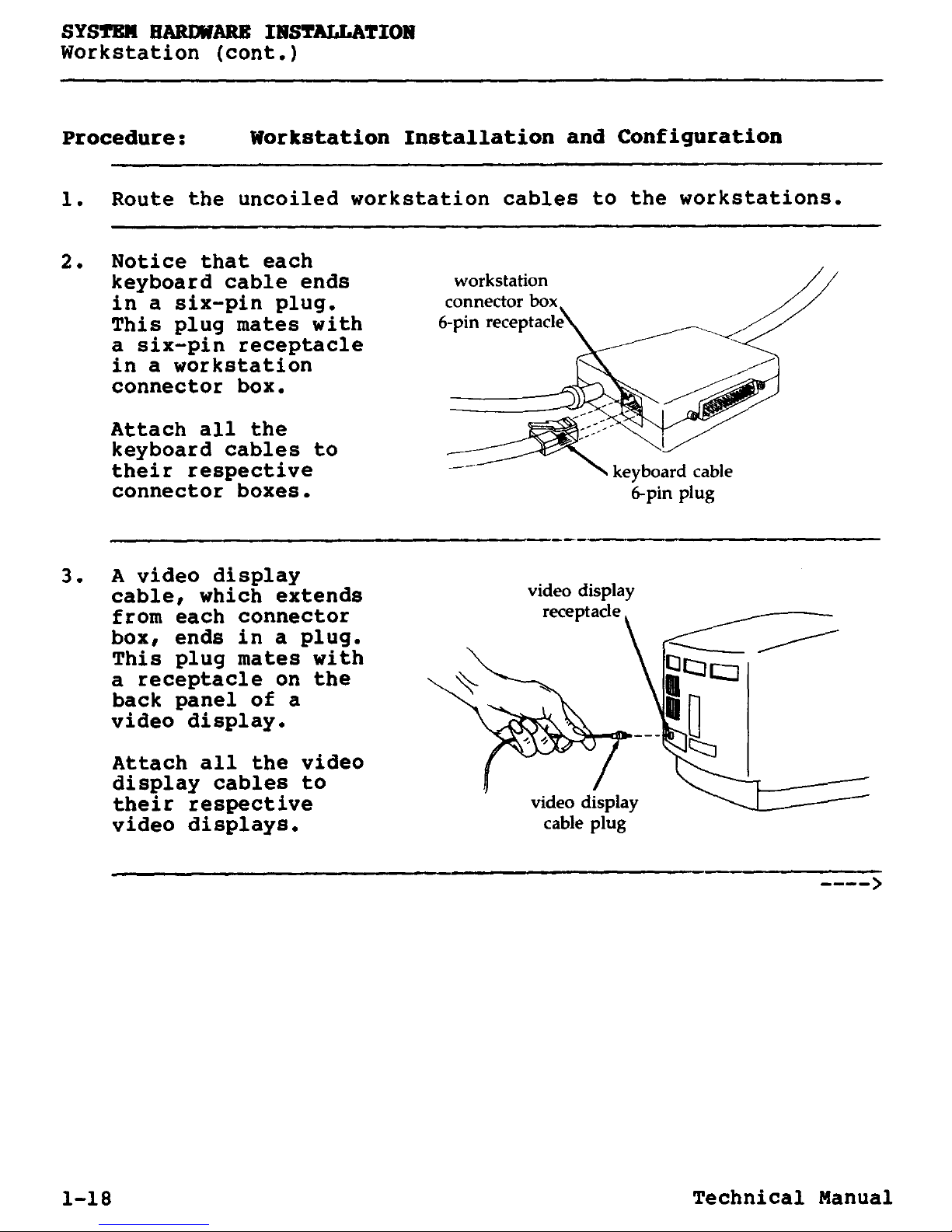

Procedure: Workstation Installation and Configuration

1. Route the

uncoiled workstation cables to the workstations.

2. Notice that each

keyboard

cable

ends

workstation

in a six-pin

plug. connector box

This plug mates with

6-pin receptacle

a six-pin receptacle

in a workstation

connector box.

Attach all the

keyboard cables to

their respective

connector boxes.

3. A video display

cable,

which extends

from each connector

box, ends in a plug.

This plug

mates with

a receptacle on the

back panel of a

video display.

Attach all

the video

display cables to

their respective

video display

video displays

. cable plug

1-18 Technical Manual

Loading...

Loading...