Page 1

Nokia Mob er Care E&A

Technical Services, Repair Concepts

ile Phones Custom

PAGE 1 (21)

Confidential

Approved 2.0

SQX 00451-en MWy

27.05.2002

Nokia 3310 Nokia 3330 Nokia 3410

NHM-5 NHM-6 NHM-2

Service Manual

Service Level 1

Copyright © Nokia Corporation. This material, including documentation and any related computer

programs, is protected by copyright controlled by Nokia Mobile Phones. All rights are reserved.

Copying, including reproducing, storing, adapting or translating, any or all of this material requires

the prior written consent of Nokia Mobile Phones. This material also contains confidential

information, which may not be disclosed to others without the prior written consent of Nokia Mobile

Phones.

Service Manual 3310/3330/3410 Level 1 Copyright 2002 © Nokia Corporation

Page 2

Nokia Mobile Phones Customer Care E&A

Technical Services, Repair Concepts Confidential 27.05.2002

PAGE 2 (21) Approved 2.0

SQX 00451-en MWy

Introduction

The purpose of this document is to give Nokia service level 1 workshops aids to carry out

service for 3310/3330/3410. The picture material is based on 3410 and is exemplary for

3310 and 3330. The use of this Service Manual is only for Nokia authorized service

partners additionally to other service documentation like Service Bulletins.

While every endeavor has been made to ensure the accuracy of this document, some

errors may exist. If you find any errors or if you have further suggestions, Nokia should

be notified. Please keep in mind also that this documentation is continuously being

updated and modified, so watch always out for the newest version.

Warnings and Cautions

Please refer to the phone’s user guide for instructions relating to operation, care and maintenance

including important safety information. Note also the following:

Warnings:

1. CARE MUST BE TAKEN ON INSTALLATION IN VEHICLES FITTED WITH ELECTRONIC ENGINE

MANAGEMENT

SYSTEMS AND ANTI–SKID BRAKING SYSTEMS. UNDER CERTAIN FAULT CONDITIONS, EMITTED RF

ENERGY CAN AFFECT THEIR OPERATION. IF NECESSARY, CONSULT THE VEHICLE

DEALER/MANUFACTURER TO DETERMINE THE IMMUNITY OF VEHICLE ELECTRONIC SYSTEMS TO RF

ENERGY.

2. THE HANDPORTABLE TELEPHONE MUST NOT BE OPERATED IN AREAS LIKELY TO CONTAIN

POTENTIALLY EXPLOSIVE ATMOSPHERES EG PETROL STATIONS (SERVICE STATIONS), BLASTING AREAS

ETC.

3. OPERATION OF ANY RADIO TRANSMITTING EQUIPMENT, INCLUDING CELLULAR TELEPHONES, MAY

INTERFERE WITH THE FUNCTIONALITY OF INADEQUATELY PROTECTED MEDICAL DEVICES. CONSULT A

PHYSICIAN OR THE MANUFACTURER OF THE MEDICAL DEVICE IF YOU HAVE ANY QUESTIONS. OTHER

ELECTRONIC EQUIPMENT MAY ALSO BE SUBJECT TO INTERFERENCE.

Cautions:

1. Servicing and alignment must be undertaken by qualified personnel only.

2. Ensure all work is carried out at an anti–static workstation and that an anti–static wrist strap is

worn.

3. Ensure solder, wire, or foreign matter does not enter the telephone as damage may result.

4. Use only approved components as specified in the parts list.

5. Ensure all components, modules screws and insulators are correctly re–fitted after servicing and

alignment. Ensure all cables and wires are repositioned correctly.

6. All PC’s used with NMP Service Software for this produce must be bios and operating system ”Year

2000 Compliant”.

Service Manual 3310/3330/3410 Level 1 Copyright 2002 © Nokia Corporation

Page 3

Nokia Mobile Phones Customer Care E&A

Technical Services, Repair Concepts Confidential 27.05.2002

PAGE 3 (21) Approved 2.0

SQX 00451-en MWy

Table of content

1. EXPLODED VIEW.................................................................................................................................... 5

2. BILL OF REPAIR...................................................................................................................................... 6

3. SW-UPDATE ............................................................................................................................................11

4. GENERAL REPAIR INFORMATION ................................................................................................. 12

5. DISASSEMBLY INSTRUCTIONS ........................................................................................................13

6. MAIN PARTS........................................................................................................................................... 16

7. QUICK TROUBLE SHOOTER PART1 ............................................................................................... 17

8. QUICK TROUBLE SHOOTER PART2 ............................................................................................... 18

9. ESD PROTECTION REQUIREMENTS............................................................................................... 19

10. SERVICE NOTES................................................................................................................................ 20

11. GONOGO TESTER............................................................................................................................. 21

12. BATTERYTESTER ............................................................................................................................. 21

Service Manual 3310/3330/3410 Level 1 Copyright 2002 © Nokia Corporation

Page 4

Nokia Mobile Phones Customer Care E&A

PAGE 4 (21) Approved 2.0

SQX 00451-en MWy

Technical Services, Repair Concepts Confidential 27.05.2002

Change History

Originator Status Version No. Date Comments

MWy Draft 0.1 04.04.2002 Initial draft

MWy Approved 1.0 03.05.2002 approval

MWy Approved 2.0 27.05.20002 3310 and 3330 added

Service Manual 3310/3330/3410 Level 1 Copyright 2002 © Nokia Corporation

Page 5

Nokia Mobile Phones Customer Care E&A

Technical Services, Repair Concepts Confidential 27.05.2002

PAGE 5 (21) Approved 2.0

SQX 00451-en MWy

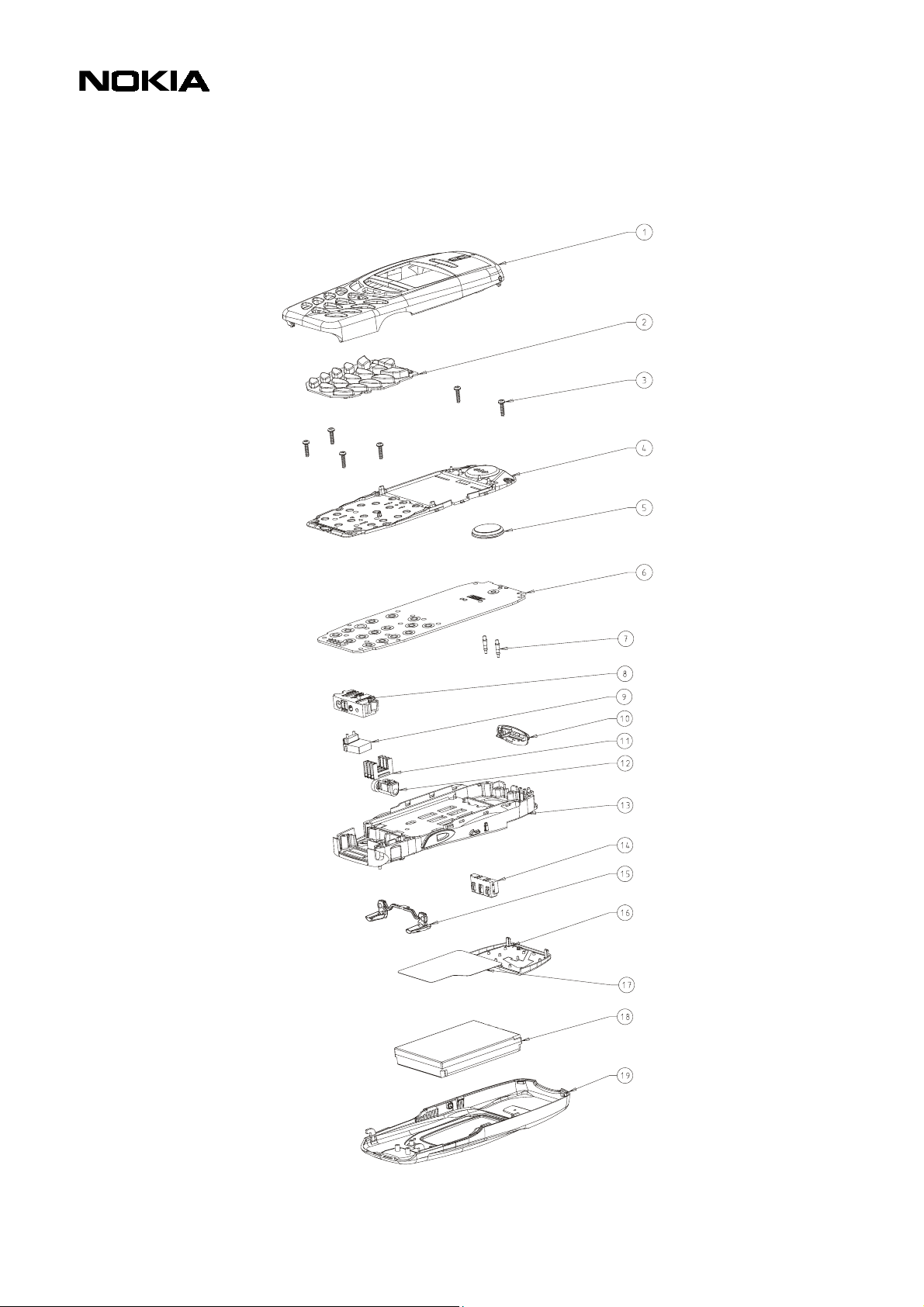

1. EXPLODED VIEW

Description: See corresponding ITEM/CIRCUIT REF of the BOR (Bill Of Repair)

Service Manual 3310/3330/3410 Level 1 Copyright 2002 © Nokia Corporation

Page 6

Nokia Mobile Phones Customer Care E&A

Technical Services, Repair Concepts Confidential 27.05.2002

PAGE 6 (21) Approved 2.0

SQX 00451-en MWy

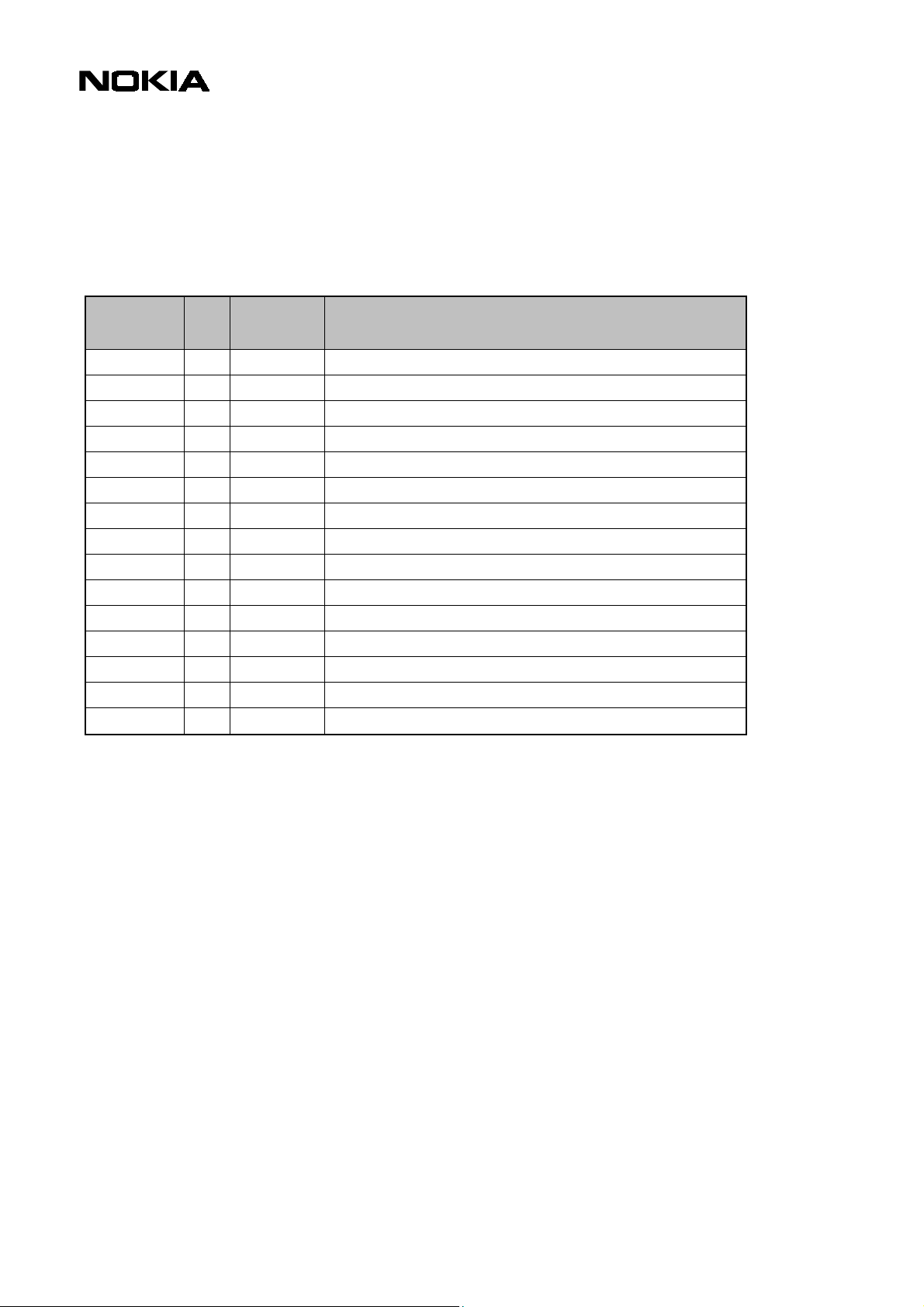

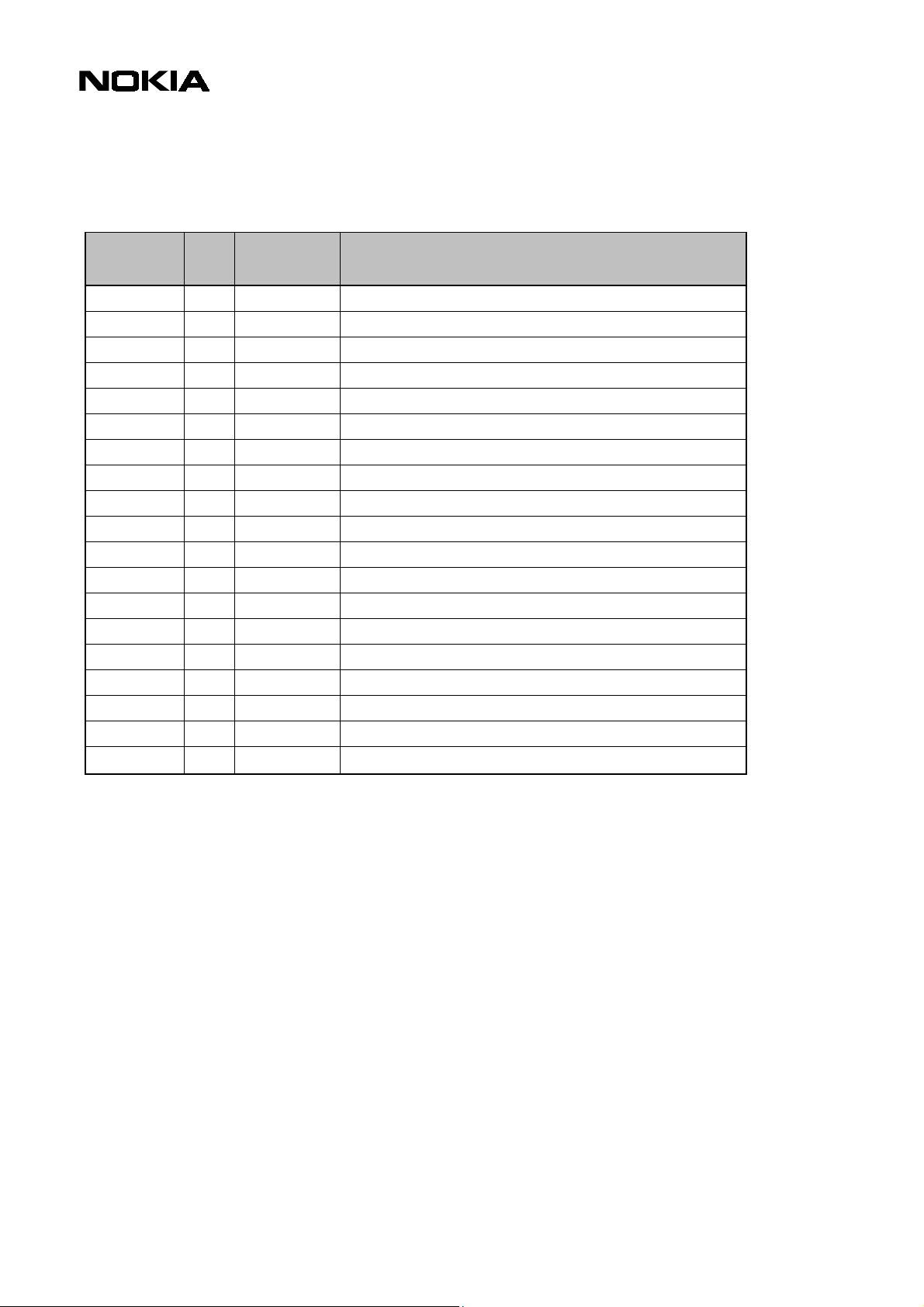

2. BILL OF REPAIR

SPARE PARTS

ITEM/

CIRCUIT REF.

I003 6 6290107 SCREWS

I004 1 4850123

I004 1 4850221

I005 1 5140067 SPEAKER

I005 1 9480588 SPEAKER GASKET

I007 2 5400171 ANTENNA POGO PIN DMS02722 SPR

I008 1 5460039 SYS CONN ASSY SPR. 5AF+5DC+MIC

I009 1 5140191 BUZZER ASSY DMC02718 HDA12

I010 1 9790437 POWERKEY DMD05798-EN HDA12

I011 1 5400169 SIM CONN 2X3POL P2.54 SPR 15V 1A

I012 1 6800049 VIB MOT ASSY 1.3V 115MA 9500RPM

I014 1 5409153 SM BATT CONN 4POL SPR 200V 2A

I015 1 9460355 BATTERY LOCK DMD05789 HDA12

I016 1 0660212 INT. PIFA EGSM/PCN (ANTENNA)

QTY PART NO PART NAME

DISPLAY ASSEMBLY 3310/3330

DISPLAY ASSEMBLY 3410

Service Manual 3310/3330/3410 Level 1 Copyright 2002 © Nokia Corporation

Page 7

Nokia Mobile Phones Customer Care E&A

Technical Services, Repair Concepts Confidential 27.05.2002

PAGE 7 (21) Approved 2.0

SQX 00451-en MWy

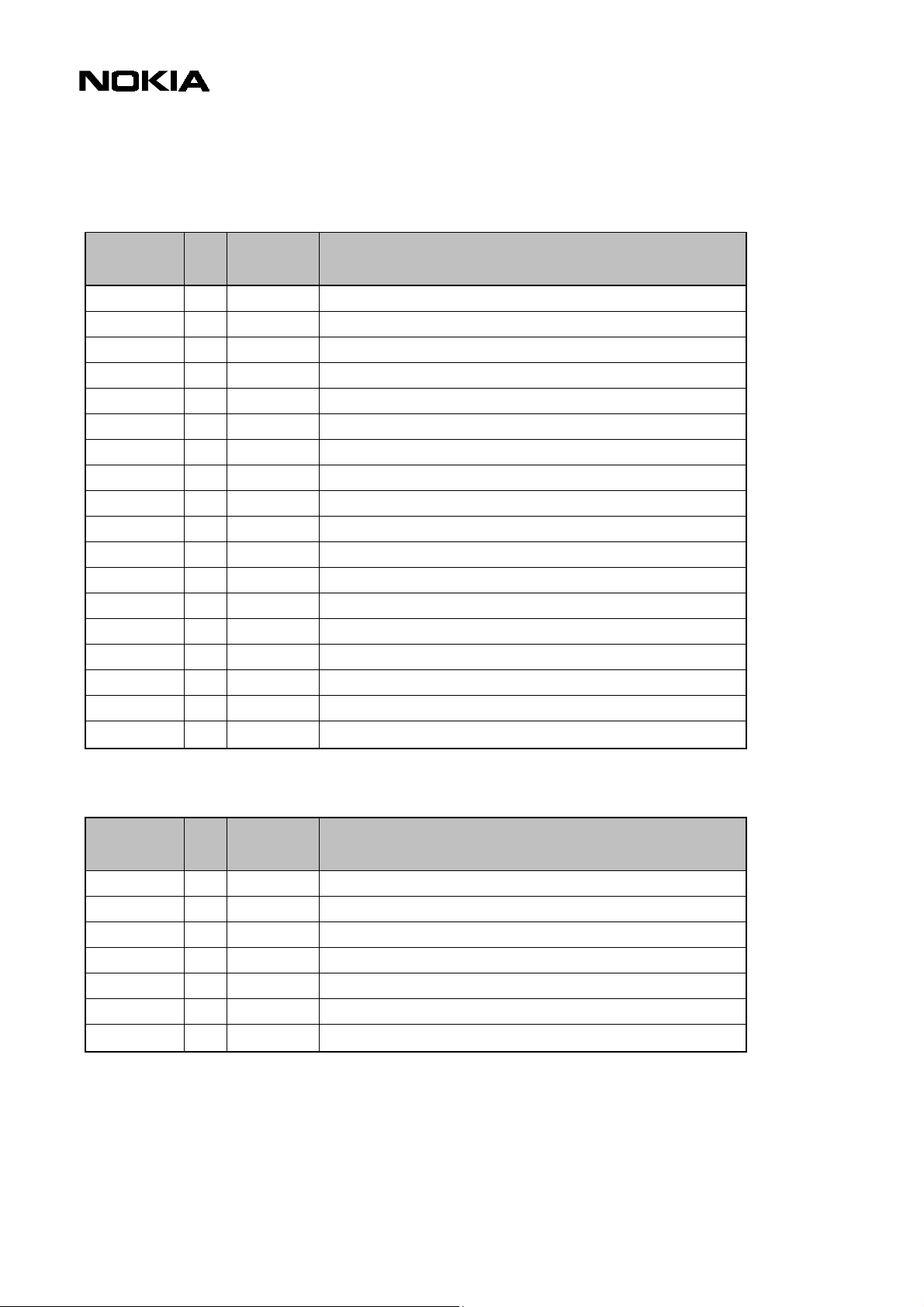

VARIANT PARTS 3310

ITEM/

CIRCUIT REF.

I001 1 9451807 A-COVER ASSEMBLY NAVY BLUE

I001 1 9451822 A-COVER ASSEMBLY POLAR BLUE

I001 1 9451830 A-COVER ASSEMBLY VESUVIUS RED

I001 1 9451835 A-COVER ASSEMBLY HIMALAJA WHITE

I001 1 9451833 A-COVER ASSEMBLY SAHARA YELLOW

I001 1 9451839 A-COVER ASSEMBLY ICEBER GREY

I001 1 9451911 A-COVER ASSEMBLY ARCTIC SILVER

I002 1 9790420 KEYMAT ENGLISH

I002 1 9790576 KEYMAT CYRILLIC

I002 1 9790466 KEYMAT HEBREW

I002 1 9790465 KEYMAT ARABIC

I019 1 9451797 B-COVER ASSEMBLY NAVY BLUE

I019 1 9451821 B-COVER ASSEMBLY POLAR BLUE

I019 1 9451836 B-COVER ASSEMBLY VESUVIUS RED

I019 1 9451834 B-COVER ASSEMBLY HIMALAJA WHITE

I019 1 9451832 B-COVER ASSEMBLY SAHARA YELLOW

I019 1 9451841 B-COVER ASSEMBLY ICEBER GREY

I019 1 9451915 B-COVER ASSEMBLY ARCTIC SILVER

QTY PART NO PART NAME

Service Manual 3310/3330/3410 Level 1 Copyright 2002 © Nokia Corporation

Page 8

Nokia Mobile Phones Customer Care E&A

Technical Services, Repair Concepts Confidential 27.05.2002

PAGE 8 (21) Approved 2.0

SQX 00451-en MWy

VARIANT PARTS 3330

ITEM/

CIRCUIT REF.

I001 1 9452043 A-COVER ASSEMBLY NAVY BLUE

I001 1 9452038 A-COVER ASSEMBLY POLAR BLUE

I001 1 9452039 A-COVER ASSEMBLY VESUVIUS RED

I001 1 9452040 A-COVER ASSEMBLY HIMALAJA WHITE

I001 1 9452041 A-COVER ASSEMBLY SAHARA YELLOW

I001 1 9452042 A-COVER ASSEMBLY ICEBER GREY

I001 1 9452037 A-COVER ASSEMBLY ARCTIC SILVER

I002 1 9790420 KEYMAT ENGLISH

I002 1 9790576 KEYMAT CYRILLIC

I002 1 9790466 KEYMAT HEBREW

I019 1 9451797 B-COVER ASSEMBLY NAVY BLUE

I019 1 9451821 B-COVER ASSEMBLY POLAR BLUE

I019 1 9451836 B-COVER ASSEMBLY VESUVIUS RED

I019 1 9451834 B-COVER ASSEMBLY HIMALAJA WHITE

I019 1 9451832 B-COVER ASSEMBLY SAHARA YELLOW

I019 1 9451841 B-COVER ASSEMBLY ICEBER GREY

I019 1 9451915 B-COVER ASSEMBLY ARCTIC SILVER

QTY PART NO PART NAME

VARIANT PARTS 3410

ITEM/

CIRCUIT REF.

I001 1 9458276 A-COVER ASSEMBLY

I002 1 9790657 KEYMAT LATIN

I002 1 9790658 KEYMAT CYRILLIC

I002 1 9790695 KEYMAT HEBREW

I002 1 9790698 KEYMAT ARABIC

I019 1 9458278 B-COVER ASSEMBLY

QTY PART NO PART NAME

Service Manual 3310/3330/3410 Level 1 Copyright 2002 © Nokia Corporation

Page 9

Nokia Mobile Phones Customer Care E&A

Technical Services, Repair Concepts Confidential 27.05.2002

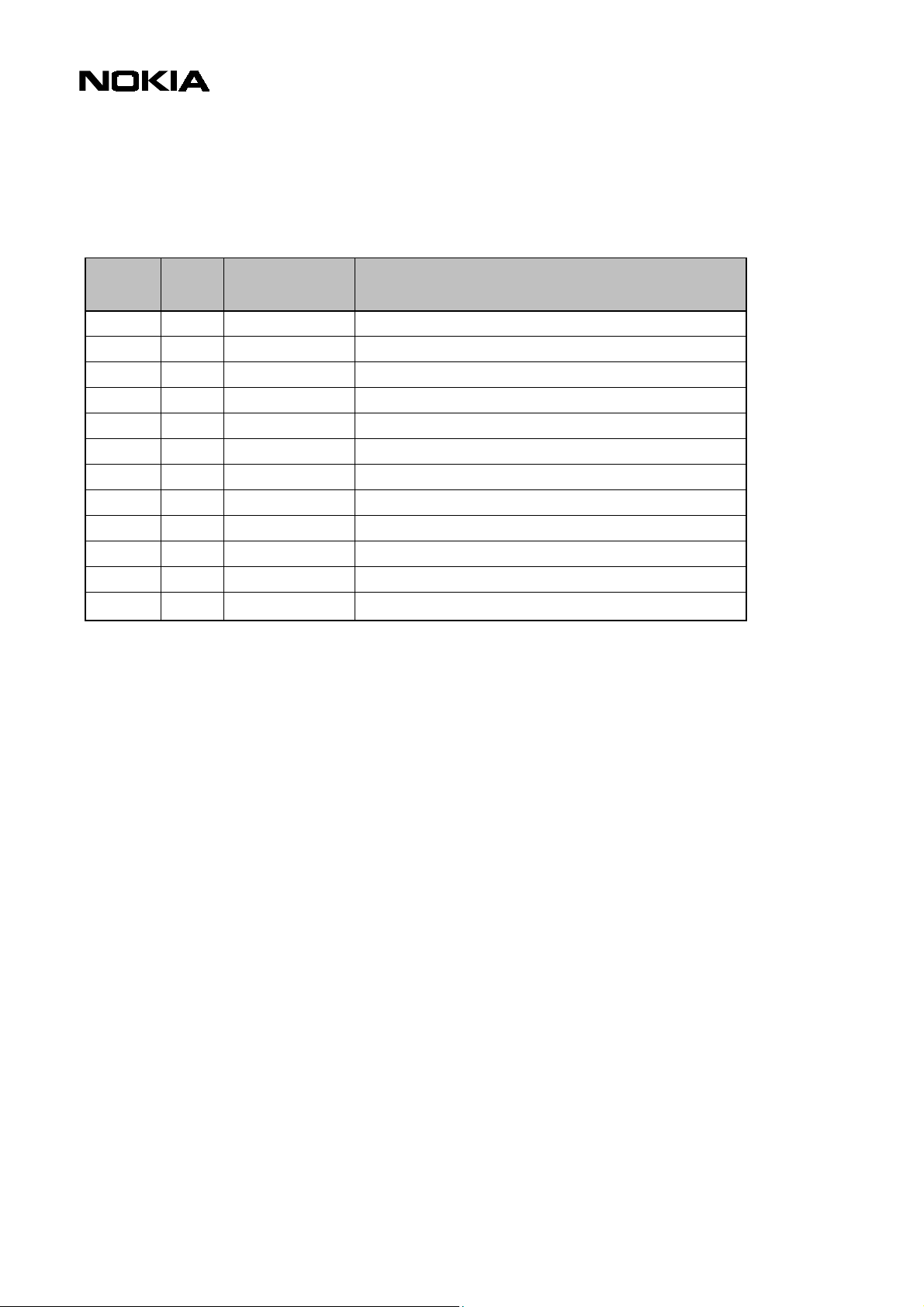

SWAP UNITS 3310

QTY PART NO PART NAME

1 0073642 NHM-5NX N3310 SWAP ENGINE

1 0073643 NHM-5NX N3310 SWAP ENGINE PL

1 0073644 NHM-5NX N3310 SWAP ENGINE RU

1 0073645 NHM-5NX N3310 SWAP ENGINE FR

SWAP UNITS 3330

QTY PART NO PART NAME

PAGE 9 (21) Approved 2.0

SQX 00451-en MWy

1 0071631 NHM-6NX N3330 SWAP ENGINE

1 0071729 NHM-6NX N3330 SWAP ENGINE RU

1 0071730 NHM-6NX N3330 SWAP ENGINE PL

1 0071731 NHM-6NX N3330 SWAP ENGINE FR

SWAP UNITS 3410

QTY PART NO PART NAME

0074068 NHM-2NX N3410 SWAP ENGINE PL

0074069 NHM-2NX N3410 SWAP ENGINE CS

0074070 NHM-2NX N3410 SWAP ENGINE RU

0074071 NHM-2NX N3410 SWAP ENGINE TR

0074072 NHM-2NX N3410 SWAP ENGINE FR

0074073 NHM-2NX N3410 SWAP ENGINE E&A

Service Manual 3310/3330/3410 Level 1 Copyright 2002 © Nokia Corporation

Page 10

Nokia Mobile Phones Customer Care E&A

Technical Services, Repair Concepts Confidential 27.05.2002

SERVICE TOOLS

TYPE QTY PART NO PART NAME

0080541 FLS-4S SALES PACK E&A

0670403 BLC-2 BATTERY PACK

0630262 FLP-2 POS FLASH ADAPTER

0730218 XCS-1 SERVICE CABLE

0271582 DCV-10 DESKTOP STAND

0272169 AC TRAVEL CHARGER ACP-8E (EUR)

0272172 AC TRAVEL CHARGER ACP-8X (UK)

0271467 HDC-5 HEADSET

0774071 WINTESLA 3,5 DISKETTE

0770269 SERVICE SW

0770431 SRT-6 OPENING TOOL 5510

PAGE 10 (21) Approved 2.0

SQX 00451-en MWy

Service Manual 3310/3330/3410 Level 1 Copyright 2002 © Nokia Corporation

Page 11

Nokia Mobile Phones Customer Care E&A

Technical Services, Repair Concepts Confidential 27.05.2002

PAGE 11 (21) Approved 2.0

SQX 00451-en MWy

3. SW-UPDATE

To use FLS-4S Flash Dongle you have to follow the user guide inside the sales package. Please

check always the latest version of flash software, which is available on Partner Website.

Flash Concept – (Point of Sales)

Note that ACF-8 charger is inside FLS-4S sales pack and cannot be ordered separately.

Description: See corresponding ITEM/CIRCUIT REF of the BOR (Bill Of Repair)

Service Manual 3310/3330/3410 Level 1 Copyright 2002 © Nokia Corporation

Page 12

Nokia Mobile Phones Customer Care E&A

Technical Services, Repair Concepts Confidential 27.05.2002

PAGE 12 (21) Approved 2.0

SQX 00451-en MWy

4. GENERAL REPAIR INFORMATION

In this section you will get some general hints how to carry out repairs:

o Before starting the repair you must take care of ESD precautions like being in your ESD-area and

connecting your wristband.

o Use gloves to avoid corrosion and fingerprints.

o Protect windows and displays with a foil to avoid dust and scratches.

o When cleaning the pads you have to use a soft cloth and isopropanol. It is not allowed to use a

glass fiber pencil because it scratches the surface and will lead later on to corrosion.

o Mechanical parts, which didn’t repair the failure, can be reused, if they are not soldered.

o Use always original Nokia parts or accessories.

o Meet the torque requirements when assembling the unit (see also the document “torques for

transceiver assembly” on Partner Websites).

o Always use your own equipment for testing where you are sure that it works. E.g. if the customer

complains about charger function, please test the phone with your own charger to be sure if

phone or charger causes the malfunction.

Following General Service Bulletins have to be followed:

SB-055: Common notice for good ventilation

SB-089: Don’t try to repair prototypes (indicated on Typelabel).

SB-107: Be sure that you have minimum hardware requirements in place.

SB-115: Handling of liquid damages.

SB-121: If one of your service tools cause malfunction, return the defective part.

SB-124 Service Policy for packaging serviced products

SB-131: Check these guidelines when refurbishing products.

SB-132: You need a

Please check Partner Websites (PWS) for latest news and files on a regular basis.

Golden Phone

for inspecting your measuring equipment.

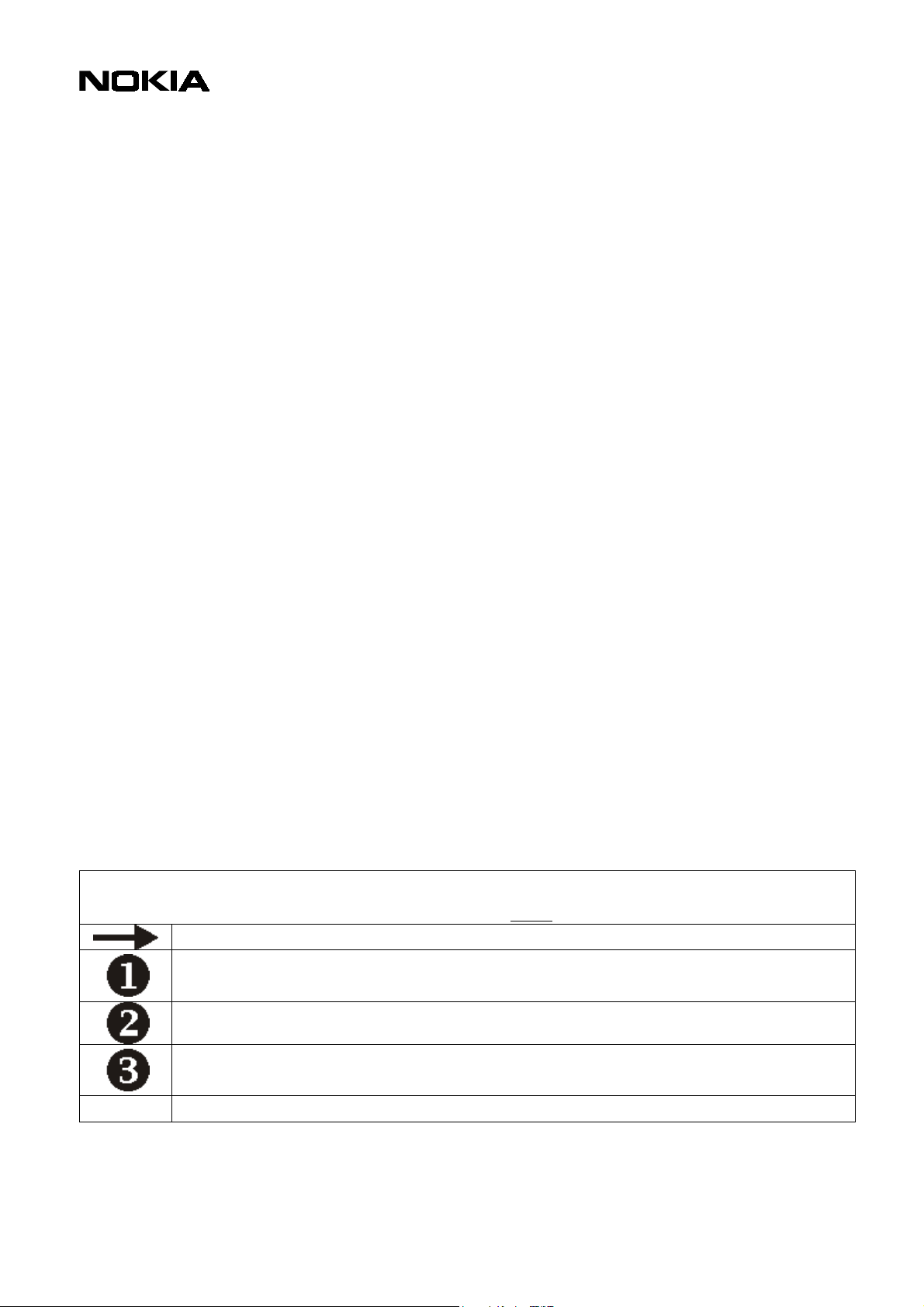

Legend for Quick Trouble Shooter:

This legend is valid for all parts of the

Quick Trouble Shooter

Follow the steps until the problem is solved. If this doesn’t help, you are not authorized

to go forward. Only underlined components ( e.g

Follow the arrows step by step

. I007

) can be changed.

Pads or contacts: Check optical and mechanical condition as well as corrosion.

Clean if necessary.

Measure component for electrical functionality and change, if needed.

No more action possible, send product to the

appropriate service partner with higher service level.

4, 5

Superscript numbers are for additional comments or instructions

Service Manual 3310/3330/3410 Level 1 Copyright 2002 © Nokia Corporation

Page 13

Nokia Mobile Phones Customer Care E&A

Technical Services, Repair Concepts Confidential 27.05.2002

PAGE 13 (21) Approved 2.0

SQX 00451-en MWy

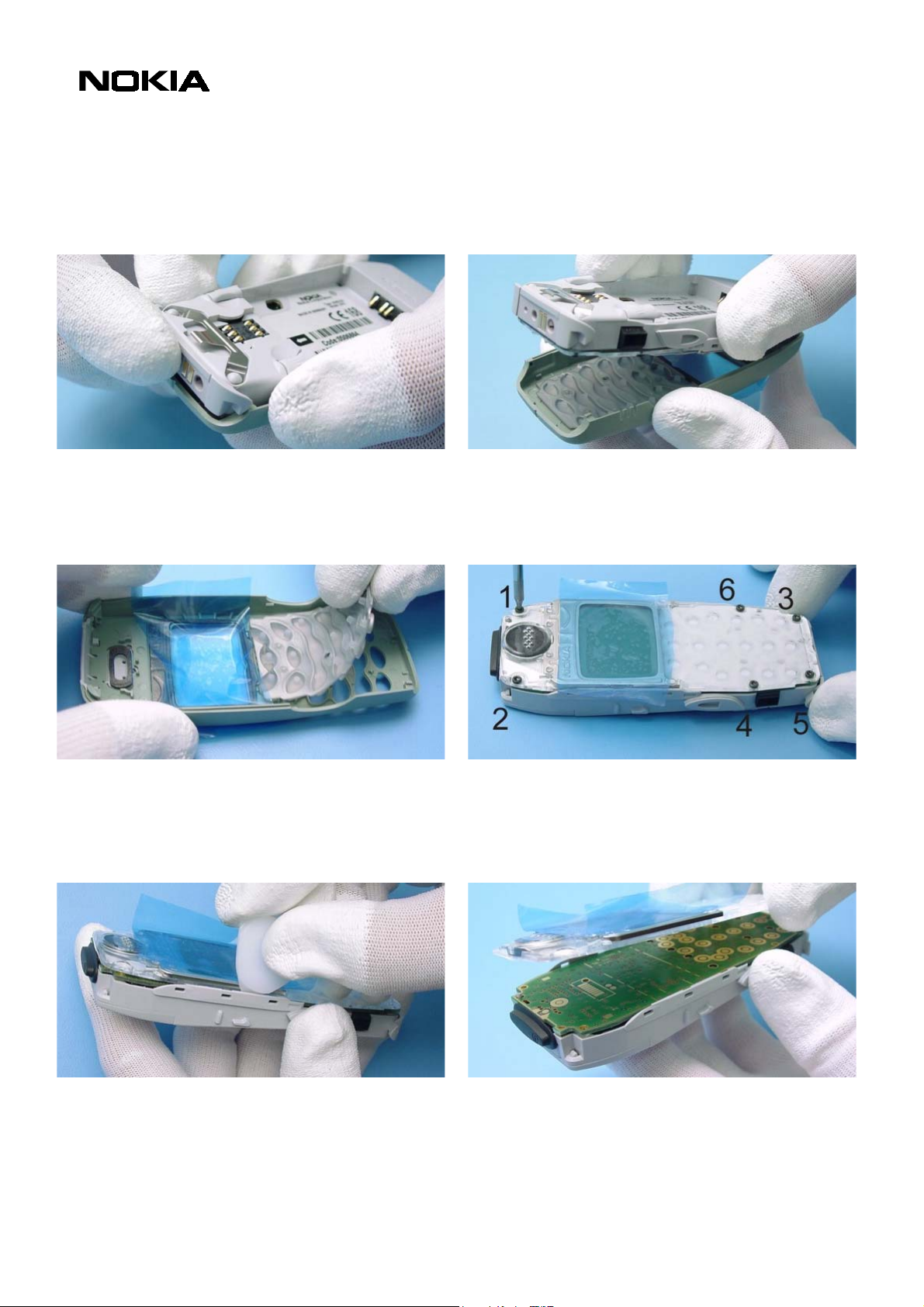

5. DISASSEMBLY INSTRUCTIONS

Take care that your workbench is always clean and

protect the Window with a foil against dust and

scratches. Release the A-Cover from the bottom side

of the unit.

Take away the A-Cover

.

Also, protect the inner part of the window with a

foil. The Keymat is loose inside the cover.

When releasing the side clips of the D-Cover you can

use plastic tweezers or the opening tool from 5510

(SRT-6, 0770431), as shown in the picture.

Open the six screws in the predefined order with a

Torx 6 driver.

order has to be taken with a torque of 30 Ncm.

Take away the Display Assembly (UI module) and

avoid touching the pads with your fingers.

When re-assembling, the reverse

Service Manual 3310/3330/3410 Level 1 Copyright 2002 © Nokia Corporation

Page 14

Nokia Mobile Phones Customer Care E&A

Technical Services, Repair Concepts Confidential 27.05.2002

If you need to remove the Speaker with Gasket, do

not take it from the spring contacts.

PAGE 14 (21) Approved 2.0

SQX 00451-en MWy

Lifting up the radio module UW5 is also very easy

now.

The Vibra Motor with its rubber housing is pressed

into the D-Cover.

Remove the SIM Connector by hand. Note the right

direction, when replacing the SIM connector. It only

No special tools are needed to remove t

he System

Connector. Note that the Microphone cannot be

changed separately (like in other products), because

it is one unit with the System Connector.

The Buzzer can be taken away with tweezers.

Service Manual 3310/3330/3410 Level 1 Copyright 2002 © Nokia Corporation

Page 15

Nokia Mobile Phones Customer Care E&A

Technical Services, Repair Concepts Confidential 27.05.2002

Remove the Power Key.

PAGE 15 (21) Approved 2.0

SQX 00451-en MWy

There are different ways to remove the Battery

Connector. One way is, to press it from the backside

of the D-Cover. The other way is to take it with

fingers from the front side of the D-Cover.

The SRT-6 opening tool is also very helpful, when

opening the Antenna.

You need some power to press the Antenna Pogo

Pins from the D-Cover.

When assembling the phone, screws must be

tightened with a torque of 30 Ncm!

The GoNoGo test verifies that the electrical

specifications will be fulfilled.

Take away the Antenna from the D-Cover.

If you need to change the Battery Lock, you first

have to press the retaining clips before rotating the

straight bladed screwdriver.

Service Manual 3310/3330/3410 Level 1 Copyright 2002 © Nokia Corporation

Page 16

Nokia Mobile Phones Customer Care E&A

Technical Services, Repair Concepts Confidential 27.05.2002

PAGE 16 (21) Approved 2.0

SQX 00451-en MWy

6. MAIN PARTS

SIM Connector

I011

Speaker

Buzzer

I005

I009

Microphone not changeable

System Connector

Vibra Motor

I012

Keymat

I008

I002

Antenna Pogo Pins

Battery Connector

Battery Lock

I007

I014

I015

A-Cover

Service Manual 3310/3330/3410 Level 1 Copyright 2002 © Nokia Corporation

I001

D-Cover, not changeable

Display Assembly

I004

Page 17

7. QUICK TROUBLE SHOOTER PART1

Service Manual 3310/3330/3410 Level 1 Copyright 2002 © Nokia Corporation

Page 18

8. QUICK TROUBLE SHOOTER PART2

Service Manual 3310/3330/3410 Level 1 Copyright 2002 © Nokia Corporation

Page 19

Nokia Mobile Phones Customer Care E&A

Technical Services, Repair Concepts Confidential 27.05.2002

PAGE 19 (21) Approved 2.0

SQX 00451-en MWy

9. ESD PROTECTION REQUIREMENTS

Electrostatic discharge can easily damage the sensitive components of

electronic products. Therefore every Service Partner has to take care of

at least some precautions like ESD restricted area, floor, table, covering,

chair(s), shoes or arm wrist.

Please refer to the Partner Website document

ESD protection requirements for NMP Service Level 1/2 Service Suppliers

example configuration of an epa-area

source: www.armeka.com

example workbench and testers

source: http://www.armekaengineering.com

example configuration of a workbench

source: www.warmbier.com

Service Manual 3310/3330/3410 Level 1 Copyright 2002 © Nokia Corporation

Page 20

Nokia Mobile Phones Customer Care E&A

Technical Services, Repair Concepts Confidential 27.05.2002

PAGE 20 (21) Approved 2.0

SQX 00451-en MWy

10. SERVICE NOTES

We recommend using Service Notes when shipping phones to other Service Partners. It

prevents the product from scratches, it is ESD-neutral and has the possibility to give

valuable feedback of the fault symptom through a structured form.

Please refer to the document

Service Notes for faulty NMP transceiver

on Partner

Website to get further information.

Service Manual 3310/3330/3410 Level 1 Copyright 2002 © Nokia Corporation

Page 21

Nokia Mobile Phones Customer Care E&A

Technical Services, Repair Concepts Confidential 27.05.2002

PAGE 21 (21) Approved 2.0

SQX 00451-en MWy

11. GONOGO TESTER

The Acterna/Wavetek GoNoGo Tester

has to be used to carry out the final

test after your service action to

guarantee the functionality of the

phone.

Please refer to the actual

information in the Nokia Care

Point Extranet within the Partner

Website.

12. BATTERYTESTER

The Astratec battery tester

lets you test the capacity

of Nokia batteries.

Please refer to the actual

information in the Nokia

Care Point Extranet

within the Partner

Website.

Service Manual 3310/3330/3410 Level 1 Copyright 2002 © Nokia Corporation

Loading...

Loading...