Page 1

PAMS Technical Documentation

NSE 8/9 Series Transceivers

Service Software

Instructions

Issue 1 07/99

Page 2

NSE 8/9

PAMS

Service Software Instructions

Technical Documentation

CONTENTS

Installing the Software 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hardware requirements for Windows 3.1x 5. . . . . . . . . . . . . . . . . . . . . . . .

Hardware requirements for Windows 95 5. . . . . . . . . . . . . . . . . . . . . . . . . .

Software Environment of the Support Modules 5. . . . . . . . . . . . . . . . . . . .

Required Servicing Equipment 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Equipment Setup 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the Software on PC Hard Disk 8. . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Software with a Hard Drive 8. . . . . . . . . . . . . . . . . . . . . . . . .

Equipment Setup for Tuning a Phone without Removing Covers 9. . . . .

Flash Concept for NSE–8/9 (covers on) 10. . . . . . . . . . . . . . . . . . . . . . . . . .

Flash Concept for NSE–8/9 (covers off) 11. . . . . . . . . . . . . . . . . . . . . . . . . .

Tuning With Covers Off 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warranty Transfer 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tuning Steps 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1. RX Calibration (AGC + AFC) 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. Alignment of Transmitter Power Levels 15. . . . . . . . . . . . . . . . . . . . . . . .

3. I/Q Modulator Alignments 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. Energy Management Calibration 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Common User Interface 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

NSE–8 Features 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Product 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

New command 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Open... command 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Initialise... command 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Normal Mode 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Local Mode 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Band command 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GSM 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PCN 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Faultlog command 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 2

Activate Faultlog 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Edit Faultlog 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FastNAM command 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FLS–1 Remote Update command 23. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exit command 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tuning 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RX Calibration... command 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Issue 1 07/99

Page 3

PAMS

NSE 8/9

Technical Documentation

Tx Power... command 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tx I/Q... command 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Energy Management Calibration... command 32. . . . . . . . . . . . . . . . . .

DC/DC Tuning Command 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T esting 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RF Controls... command 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RSSI Reading... command 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Self Tests... command 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Supported Self Tests 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ADC Readings... command 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Audio... command 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Internal Audio Loops 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

User Interface... command 46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Call Simulation... command 46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Software Instructions

Noise Sensitivity... command 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Vibra test....command 49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Software 50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Product Profile... command 50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Start Up Self–tests... command 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Set Factory Values... command 52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Phone Identity... command 53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warranty State... command 55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Production Data Edit... command 56. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dealer 57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

User Settings... command 57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Short Code Memory... command 58. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SCM & User Settings... command 59. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Restore User Defaults... command 61. . . . . . . . . . . . . . . . . . . . . . . . . . .

Set UI/DEV Default Values... command 62. . . . . . . . . . . . . . . . . . . . . . .

Flash PPM... command 63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operator Settings.......command 64. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IWR Swap data ......command 64. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Flash Phone... command 65. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

View 66. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Quick/RF Info... command 66. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Phone Identity... command 67. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix 1, Vocabulary 68. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Issue 1 07/99

Page 3

Page 4

NSE 8/9

PAMS

Service Software Instructions

[This page intentionally left blank]

Technical Documentation

Page 4

Issue 1 07/99

Page 5

PAMS

NSE 8/9

Technical Documentation

Installing the Software

To run the After Sales SW, a parallel port software protection device

(PKD–1) has to be connected. TDF–4 box must be connected to the PC

for flashing purposes. The user can use PC–locals functions in modules

for testing NSE–8 mobile stations (MS).The test functions send test

messages from PC to MS and receive results and show them in the PC

display. The messages can be sent via M2BUS or FBUS.

Note: if this software is to be run on laptops, the power saving feature MUST be switched

off.

Hardware requirements for Windows 3.1x

The recommended minimum hardware standard to run Service Software

is any computer which is 386 33 MHz or greater with at least 4 MB of

memory and VGA type display (640 x 480). This assumes that only the

WinTesla with After Sales Support Modules is active, i.e. other Windows

packages are not running in the background.

Service Software Instructions

Hardware requirements for Windows 95

The recommended minimum hardware standard to run Service Software

is any computer which has a Pentium processor, memory of 8 MB and

meets HW requirements recommended by Microsoft.

Software Environment of the Support Modules

The Service Software user interface is intended for the following

environments: Microsoft Windows 3.1x (enhanced mode) and Windows 95

environment running in enhanced mode. Support for Microsoft NT may be

added, if required. Detailed information about Windows and application

usage can be found from the Microsoft Windows Version 3.1 Users Guide

chapter one (Windows Basics) and chapter two (Application Basics).

As an ordinary Windows application, the main idea in the user interface is

that selections are made with menus, push buttons and shortcut keys.

Selections can be done by using keyboard and/or mouse. There is always

a status bar displayed at the bottom of the main window which contains

information about current actions.

Issue 1 07/99

Page 5

Page 6

NSE 8/9

PAMS

Service Software Instructions

Required Servicing Equipment

– Computer: At least IBM 80386 or compatible with one unused serial

*)

port (COM1 or COM2)

mended

– Operating System: DOS Version 3.2 or later

– If PCLStart in use: DOS 6.22 and IBM 80486 or compatible

– Display: Any 80–character text display

– Service software version for 3.5” disk (product code: 0774080)

– Software protection key PKD–1 (product code: 0750018)

– Service MBUS Cable DAU–9S (product code: 0730108)

– Audio cable ADS–1 (product code: 0730011)

– Modular T–adapter (product code: 4626134)

– Service Box JBU–5 (product code: 0770120)

, one parallel port (LPT1), hard disk recom-

Technical Documentation

– PC with service software; see separate section for instructions on

installation and use.

– Service accessories; see equipment setup pictures.

– Multimeter or DVM.

– GSM radio telephone test station or separate measuring equipment as

follows:

– RF generator

– pulse power meter

– spectrum analyzer

– attenuator and branching unit

Page 6

Issue 1 07/99

Page 7

PAMS

NSE 8/9

Technical Documentation

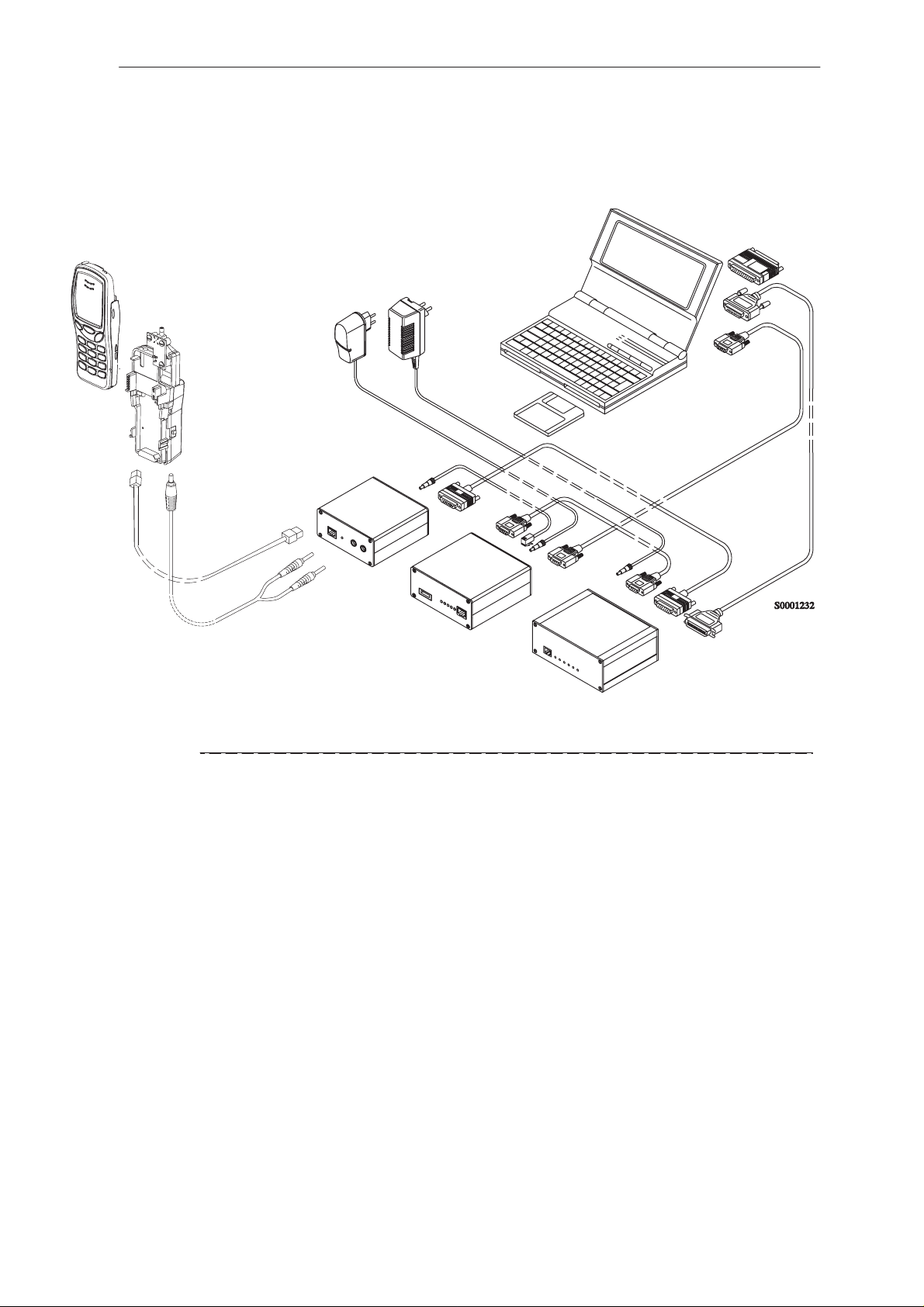

Equipment Setup

Caution: Make sure that you have switched off the PC and the printer

before making connections !

Caution: Do not connect the PKD–1 key to the serial port. You may

damage your PKD–1 !

Attach the protection key PKD–1 to parallel port one (25–pin female

D–connector) of the PC. When connecting the PKD–1 to the parallel port

be sure that you insert the PC end of the PKD–1 to the PC (male side). If

you use a printer on parallel port one, place the PKD–1 between the PC

and your printer cable.

Next connect the M2BUS service cable, DAU–9P, to the serial port

(RS–232) of the computer. Attach one end of the service cable to the PC

serial port and the other end to TDS–7 or MJS–13.

When the phone covers are removed the jigs should be used.

Service Software Instructions

For audio measurements connect the audio cable, SCB–5 from the

bottom connector on the phone, or MJS–13, to service box JBA–4.

For JBA–4 and ADS–1 connect as follows:

– EAR line to AF INPUT of test equipment

– MIC line to MOD GEN OUTPUT of test equipment

Issue 1 07/99

Page 7

Page 8

NSE 8/9

PAMS

Service Software Instructions

Installing the Software on PC Hard Disk

The program is delivered on a diskette and is copy protected with a

dongle PKD–1. It must be present in parallel port when using Service

software.

The program can also be installed on the hard disk, which is

recommendable to obtain a maximum data access rate.

Keep the original diskette safe to enable re–installing of the program !

If you plan to use PCL Start service software, you must install it before

installing Service software, see PCL Start installation instructions.

To install the new Service software program, follow the steps below:

1. Insert the new Service software diskette into drive A

2. Start Windows, open File Manager, select drive A

Technical Documentation

3. Start INSTALL.EXE and

Using the Software with a Hard Drive

Windows 3.x

Windows 95

Open Programs group:

Double Click:

WinTesla Service Software

Press Start, Programs,

Service Software

Service Software, WinTesla Service Software

Page 8

Issue 1 07/99

Page 9

PAMS

NSE 8/9

Technical Documentation

Service Software Instructions

Equipment Setup for Tuning a Phone without Removing Covers

6

4.

1

5.

2

Item: Service accessory: Product

code:

1 Service Interface Cable TDS–7 0770160

2 DC Cable PCS–1 0730012

3 Service MBUS Cable DAU–9S 0730108

4 Software Protection Key PKD–1 0750018

5 Service SW Disk 3.5 0774080

3.

6 RF Coaxial Test Cable 4626009

Note: Nominal operating voltage range for TDS–7 is 9–15VDC

Issue 1 07/99

Page 9

Page 10

NSE–8/9

PAMS

Service Software

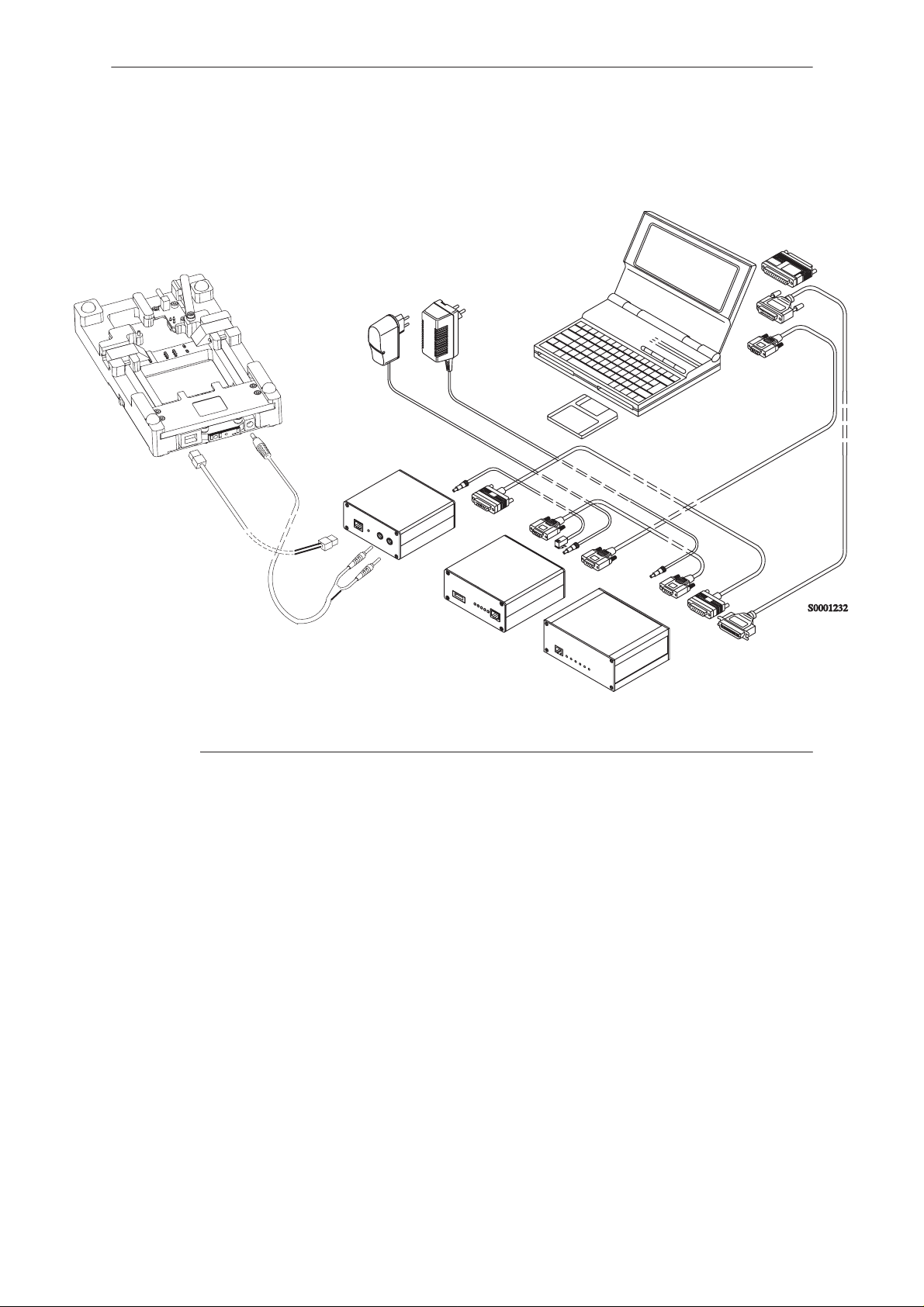

Flash Concept for NSE–8/9 (covers on)

13.

12.

6.

5.

4.

11.

Technical Documentation

10.

9A.

7.

9B.

8.

1.

14

2.

3.

Item: Service accessory: Product code:

1 Flash Loading Adapter FLA–5 0080178

2 Flash Security Box TDF–4 0770106

3 Prommer FPS–4S 0085095

4 Service Interface Cable TDS–7 0770160

5 Modular Cable XMS–3 0730174

6 DC Cable PCC–1B 0730053

7 D15 – D15 Cable AXS–5 0730091

(Included in FLA–5 sales pack)

8 Printer Cable (Included in FPS–4 sales pack) 0730029

9A D9 – D9 Cable AXS–4 0730090

(Included in FPS–4 sales pack)

9B D9 – D9 Cable AXS–4 0730090

10 Software protection key PKD–1 0750018

11 Service SW diskette 3.5” 0774080

12 Travel Charger ACH–6E (Euro) 0270381

Travel Charger ACH–6U (USA/Japan) 0270382

Travel Charger ACH–6X (UK) 0270380

13 AC Charger ACL–3E (part of FPS–4 kit) 0680015

14 DC Cable PCS–1 0730012

Page 10

Issue 1 07/99

Page 11

PAMS

NSE–8/9

Technical Documentation

Flash Concept for NSE–8/9 (covers off)

4.

5.

12.

13.

6.

11.

Service Software

9A.

7.

9B.

10.

8.

1.

14

Item: Service accessory: Product code:

1 Flash Loading Adapter FLA–5 0080178

2 Flash Security Box TDF–4 0770106

3 Prommer FPS–4S 0085095

4 Service Interface Cable MJS–13 0770158

5 Modular Cable XMS–3 0730174

6 DC Cable PCC–1B 0730053

7 D15 – D15 Cable AXS–5 0730091

(Included in FLA–5 sales pack)

8 Printer Cable (Included in FPS–4 sales pack) 0730029

9A D9 – D9 Cable AXS–4 0730090

(Included in FPS–4 sales pack)

9B D9 – D9 Cable AXS–4 0730090

10 Software protection key PKD–1 0750018

11 Service SW diskette 3.5” 0774080

12 Travel Charger ACH–6E (Euro) 0270381

Travel Charger ACH–6U (USA/Japan) 0270382

Travel Charger ACH–6X (UK) 0270380

13 AC Charger ACL–3E (part of FPS–4 kit) 0680015

14 DC Cable PCS–1 0730012

2.

3.

Issue 1 07/99

Page 11

Page 12

NSE 8/9

PAMS

Service Software Instructions

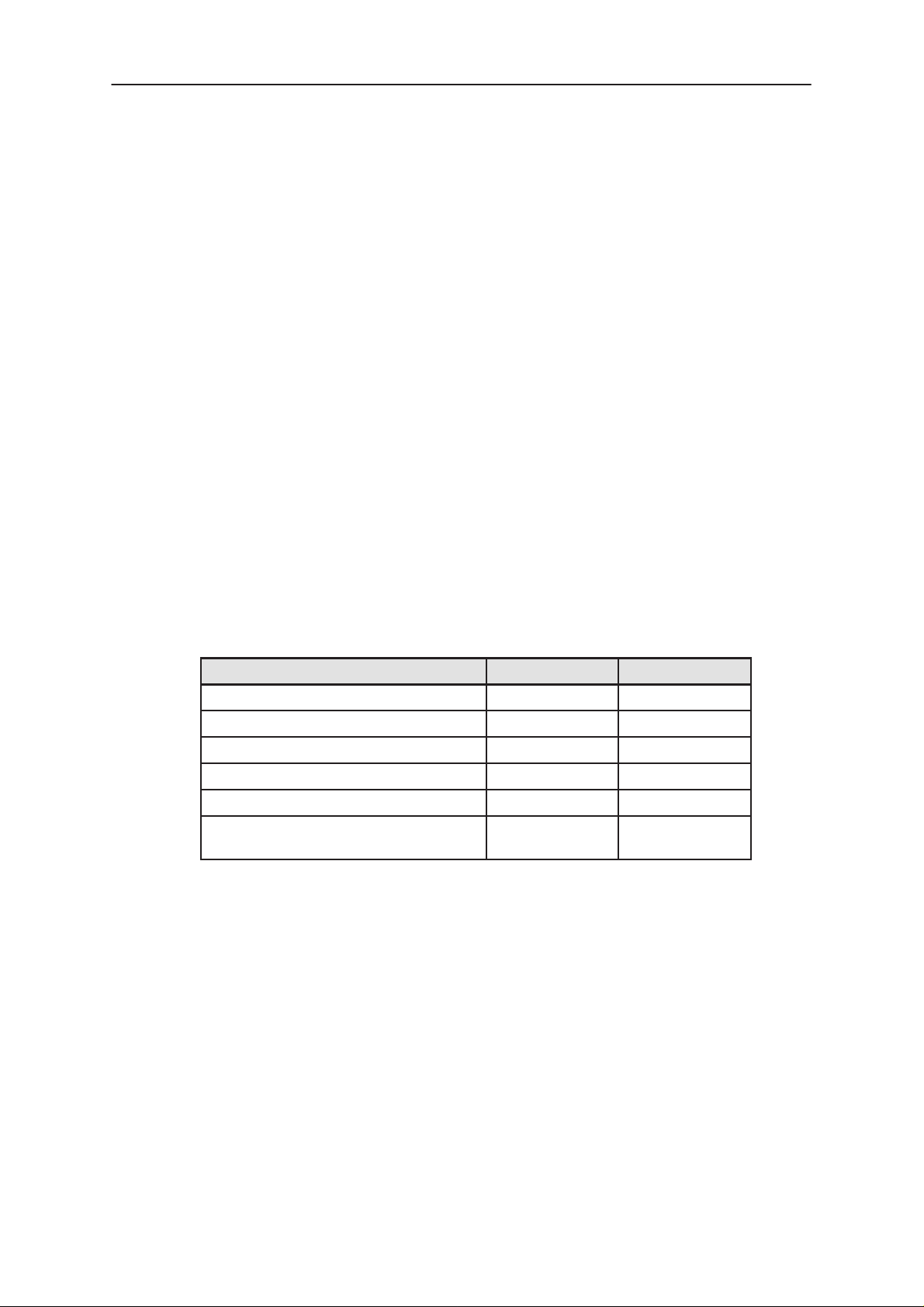

Tuning With Covers Off

4

1.

Technical Documentation

8.

9.

3.

6.

7.

5.

2.

Item: Service accessory: Product code:

1 Module Jig MJS–13 0770158

2 Service Audio Box JBA–4 0770094

3 DC Cable PCS–1 0730012

4 RF Coaxial Test Cable 4626009

5 Audio Test Cable SCB–5 0775211

6 Service MBUS Cable DAU–9S 0730108

7 Audio Cable ADS–1 0730011

Page 12

8 Software Protection Key PKD–1 0750018

9 Service SW diskette 3.5 0774080

Note The nominal operating voltage for MJS–13 is 9–15VDC

Issue 1 07/99

Page 13

PAMS

NSE 8/9

Technical Documentation

Warranty Transfer

Service Software Instructions

2

1

Item: Service accessory: Product code:

1 Warranty Transfer Tool SCW–1 0770161

(2pcs reqd.)

2 Modular T Adapter 4626134

Issue 1 07/99

Page 13

Page 14

NSE 8/9

PAMS

Service Software Instructions

Tuning Steps

1. RX Calibration (AGC + AFC)

Procedure

Follow the steps described in chapter ”Service Software Instructions”

section ”RX calibration... command”.

Software reports the following:

AFC init value

AFC slope

PSW slope

AGC DAC values and the corresponding voltages for each gain step (0 57 dB)

Technical Documentation

Limits for the reported values

If everything went well the reported values should approximately be the

following:

Parameter Low limit High limit

AFC init value –80 80

AFC slope 130 230

PSW slope 250 350

AGC 0 dB 400 640

AGC 57 dB 100 300

Difference between the two neighbour

AGC steps

10 20

Troubleshooting

If the calibration does not succeed the software normally reports ”Unable

to read data from phone” or ”Failed to set high reference” or ”Failed to set

low reference”.

Page 14

In this case check first the basic functionality of the receiver chain: RF

generator frequency set as in the calibration and level for example to the

high reference value.

Then go to the RSSI reading menu (under RF controls). If the reading is

very low there is something broken in the receiver and must be found by

measuring voltages and signal levels at different places (information of

these can be found elsewhere in this manual).

Issue 1 07/99

Page 15

PAMS

NSE 8/9

Technical Documentation

If the RSSI reading seems to be within 5 - 10 dB the same as the RF input

level check that the VCTCXO (G650) frequency is close enough the

wanted frequency. This is most easiest done by measuring the UHF VCO

(G550) frequency because the absolute value of the deviation is biggest

there. In the GSM mid channel the UHF–VCO frequency should be 2040.0

MHz. If the deviation is bigger than about +/–20 kHz it is probable that the

VCTCXO is not operating correctly.

If both of these (RSSI reading and the frequency) seem to be correct and

calibration still fails the most probable reason is that there is a little lack of

gain somewhere or the AGC gain control slope in N600 is out of the limits.

This can be verified by changing the generator reference levels from the

demanded ones in the calibration procedure in 1 dB steps up and down. If

the calibration goes through with some reference levels the corrective

action is most probably changing N500 or N600.

Service Software Instructions

2. Alignment of Transmitter Power Levels

Equipment:

– Pulsed power meter or spectrum analyzer and 10 dB attenuator.

– MSJ–13 voltage source within 9–15VDCV.

The following settings for the spectrum analyzer are recommended when

aligning the power levels: zero span, resolution and video bandwidths 1

MHz, input attenuation 40 dB, sweep time 1 ms, video triggering.

Procedure:

Follow the instructions given in chapter ”Service Software Instructions”

section ”TX power... command”.

For GSM the alignment channel is 60 (902 MHz) and for PCN 700

(1747.8 MHz).

Issue 1 07/99

Page 15

Page 16

NSE 8/9

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

PAMS

Service Software Instructions

Targets in dBm:

Power level GSM PCN

0

ÁÁÁÁ

1

2

3

4

5

6

7

8

9

ÁÁÁÁ

10

11

Technical Documentation

ББББББÁББББББ

32.5

31

29

27

ББББББ

25

ББББББ

23

21

29.5

28

26

24

22

20

18

16

14

12

10

8

12

13

14

15

16

17

18

ÁÁÁÁ

19

ÁÁÁÁ

Base

ББББББ

ББББББ

0.06 below lowest

power coefficient

19

17

15

13

11.5

10

8.5

7

6.5

5

3.5

2

ББББББ

ББББББ

0.06 below lowest

power coefficient

– Align the three levels.

– Switch off base level calculation and re–calculate.

– Set baselevel coefficient to 0.06 below the lowest coefficient.

– Check that the power is within 0.5dB from target, adjust if not.

Page 16

Issue 1 07/99

Page 17

PAMS

NSE 8/9

Technical Documentation

3. I/Q Modulator Alignments

I/Q modulator alignments are performed in PCN band. If GSM band has

been selected and I/Q alignment is started, the service software asks to

change to PCN band. If the user wants to continue in GSM, the adjusted

values can only be saved to PC memory, not to phone’s EEPROM. After

changing to PCN band values from PC memory are available, and if the

modulator adjustment is good, also the values can be saved to phone’s

EEPROM. See chapter ”Service Software Instructions” and section ”TX

I/Q... command” for further information.

Procedure:

Connect the spectrum analyzer to the phone antenna connector. The

recommended spectrum analyzer settings are: span 200 kHz, resolution

BW 10 kHz, video BW 1 kHz, sweep 500 ms, input attenuation 30 dB.

– From

– Go to

(1747.8 MHz).

RF controls

TX I/Q tuning

menu make sure that TX data type is 1.

menu. The alignment channel for PCN is 700

Service Software Instructions

– Select the ”TX I DC offset” option and adjust the level of the centre fre-

quency (CHF) to minimum.

– Select the ”TX Q DC offset” option and adjust the level of the CHF

again to minimum.

– After finding both minima change ”TX I DC offset” by step or two from

the current value to both directions to see, whether better minimum

can be found for CHF.

– Select the ”Amplitude Difference” option and adjust the level of the un-

wanted sideband CHF + 67.71 kHz to minimum.

– Select the ”Phase Difference” option and dajust the level of CHF +

67.71 kHz again to minimum.

– After all the minima have been found press ”Save” button to store the

values to phone EEPROM.

Targets:

The level of the centre frequency CHF should be at least 30 dB down to

the wanted sideband CHF - 67.71 kHz.

The level of the unwanted sideband CHF + 67.71 kHz should be at least

35 dB down to the wanted sideband CHF - 67.71 kHz.

Issue 1 07/99

Page 17

Page 18

NSE 8/9

PAMS

Service Software Instructions

Alignment verification in GSM band:

– Go to

Product ––> Initialize ––> Normal mode

a SW reset for the phone. Which in turn is needed to get the aligned

I/Q values in use.

– Go to

– Go to

Product ––> Band ––> GSM

RF controls

level 10, TX data type 1.

– Check the levels of CHF and CHF + 67.71 kHz. Both the levels

should be at least 30 dB down to the wanted sideband CHF - 67.71

kHz. If both or either of the specifications is not met adjust the required

values (I and Q DC offsets for CHF and amplitude and phase for CHF

+ 67.71kHz) to meet the specifications.

Technical Documentation

. This is needed to give

menu and start transmission on channel 60, power

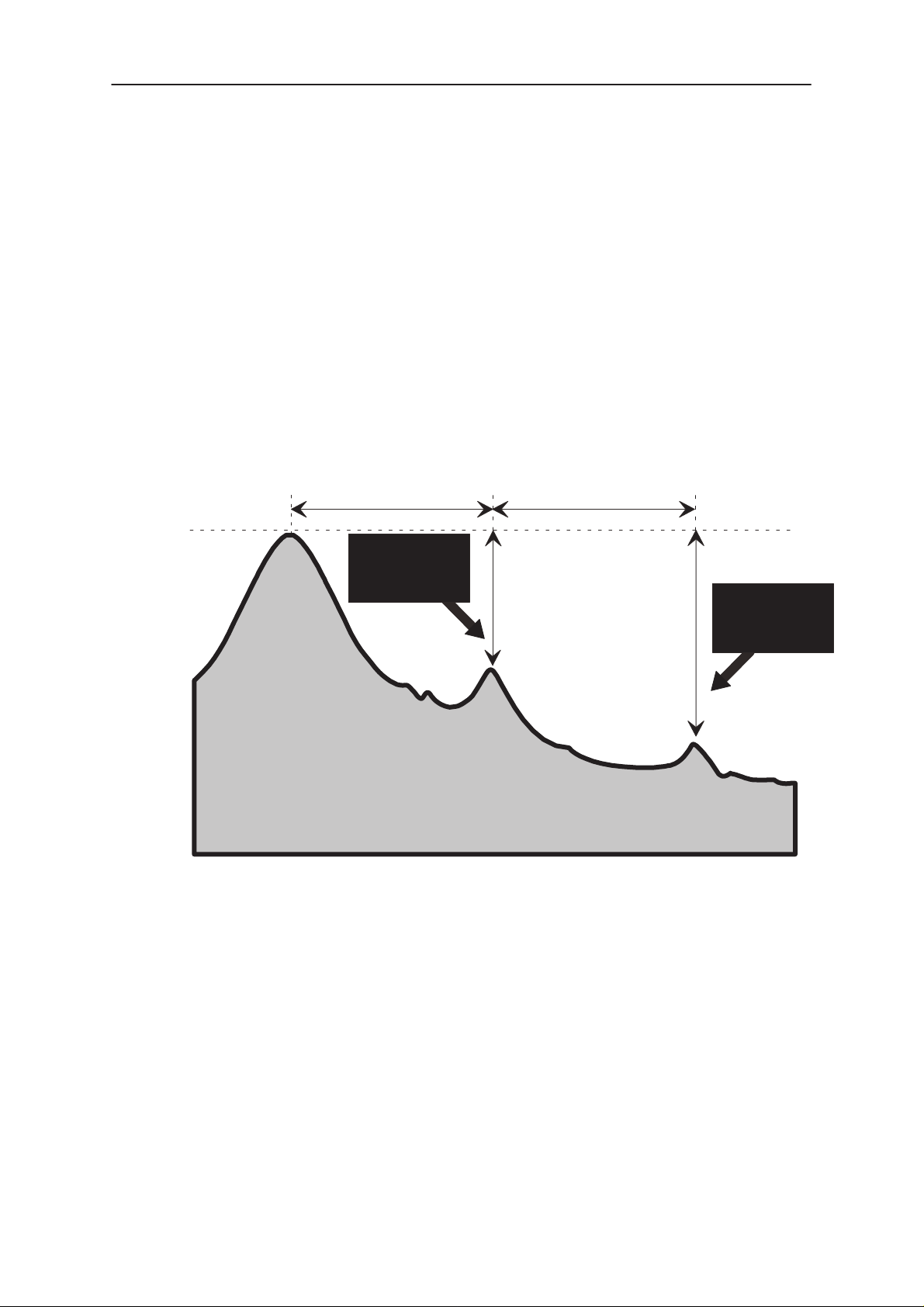

–67.71 kHz +67.71 kHz

D.C. offset

tunings:

Set this value

to minimum

CHF

> 30 dB

> 35 dB

Amplitude &

phase difference:

Set this value

to minimum

Page 18

– Store the results in PC memory.

– Go to

Product ––> Band ––> PCN

and then to

TX I/Q Tuning

to check

the alignment with the values which are in PC memory. If the specifications are not met in PCN the solution is to find compromise values

which are not optimum for either bands but still meet the specifications.

– If the PCN band alignment is good with the values from PC memory,

the TX I/Q tuning procedure can be stopped by pressing the ”Save”

button.

Issue 1 07/99

Page 19

PAMS

NSE 8/9

Technical Documentation

4. Energy Management Calibration

Equipment

– Voltage source – within 9–15VDC range.

– MJS–13 Module Repair Jig.

Procedure

– Connect power supply to MJS–13.

– Start up WinTesla.

– Set switch on MSJ–13 to ( local position)*

– Choose

– Select no.2

– Press

– Press OK to save

Tuning

Battery Voltage

Run.

menu and then

and no.3

Battery Voltage.

Service Software Instructions

Energy Management Calibration.

Charger Voltage.

– Press OK to save

* MJS–13 supplies the system board with 8.4VDC via X5 pin 11, when the

test switch is in (local position).

Charger Voltage.

Issue 1 07/99

Page 19

Page 20

NSE 8/9

PAMS

Service Software Instructions

Common User Interface

All WinTesla files share a common interface which are detailed in the

WinTesla help files once the software is installed. A typical example is

shown in the figure below.

Technical Documentation

Page 20

Issue 1 07/99

Page 21

PAMS

NSE 8/9

Technical Documentation

NSE–8 Features

Product

New command

Activation Status Bar Text

Alt, P, N Rescan a new phone

Ctrl+R

If phone is changed (with same phone type only serial number is

changed) phone will be initialised. If phone is changed to different phone

type the current DLLs are unloaded and new ones are loaded for that

phone.

If the Quick/RF Info view is open, window will be automatically updated. If

Phone Information view is open, it will be automatically updated.

Service Software Instructions

pen... command

O

Activation Status Bar Text

Alt, P, O Force load phone specific functionality

Phone is set to normal mode.

I

nitialise... command

Activation Status Bar Text

Alt, P, I

Opens a submenu

Normal Mode

Activation Status Bar Text

Alt, P, N Initialises phone to normal mode

F5

When normal mode has been activated or program has been started,

self–test results will be asked from MCU. If any fault was found in the

tests, an error message is shown. If normal mode has been set

successfully (no self test error has been found), and paging listening has

been started, the used AFC value is requested from MS. Initialisation

routine checks phone’s cellular type and if unsupported phone is detected,

application unloads the DLLs.

Issue 1 07/99

Page 21

Page 22

NSE 8/9

PAMS

Service Software Instructions

The After Sales SW sets automatically the MS state to local mode when

needed. If phone identification view is open, window will be automatically

updated. Also if RF Information Window is open it will be updated to quick

info view.

ocal Mode

L

Activation Status Bar Text

Alt, P, L Initialises phone to local mode

Shift+F5

Selection will change the MS state to

Testing or Tuning menus, the After Sales SW software will change

automatically the MS state to local.

The After Sales SW sets automatically the MS state to local mode when

needed.

Technical Documentation

local

. When user selects item from

Also if quick info view is open it will be updated to RF Information view.

and command

B

Activation Status Bar Text

Alt, P, B

Opens a submenu

SM

G

Activation Status Bar Text

Alt, P, B, G

Selects the GSM band on the MS

CN

P

Activation Status Bar Text

Alt, P, B, P

Selects the PCN band on the MS

aultlog command

F

Activation Status Bar Text

Alt, P, F

Opens a submenu. Only enabled when a user has logged in.

Page 22

Issue 1 07/99

Page 23

PAMS

NSE 8/9

Technical Documentation

Activate Faultlog

Activation Status Bar Text

Alt, P, F, A

F9

Activates the faultlog. Only enabled when a user has logged in.

dit Faultlog

E

Activation Status Bar Text

Alt, P, F, A

Allows user to edit faultlog entries. Only enabled when a user has logged

in.

FastNAM command

Service Software Instructions

Activation Status Bar Text

Alt, P, N

F8

This menu is only enabled when FastNAM functionality is included in Win

Tesla.

FLS–1 Remote Update command

Activation Status Bar Text

Alt, P, 1

This menu is only shown if the FLS–1 License Update Control Centre

program has been installed into the WinTesla directory.

With this program it is possible to request and update the number of flash

licenses in the FLS device.

it command

Ex

Activation Status Bar Text

Alt, P, X

Exits the WinTesla application.

Issue 1 07/99

Page 23

Page 24

NSE 8/9

PAMS

Service Software Instructions

Tuning

The tuning menu offers functions for ME adjustments.

R

X Calibration... command

Activation Status Bar Text

Alt, T,R Open RX Calibration dialog box

Starts RX calibration.

When calibrating the RX it is nessessary to first calibrate in GSM and then

in PCN. WinTesla will automatically change to GSM if the calibration is

started in PCN.

Technical Documentation

The next automatic selections are made when this tuning function is

activated:

• Phone is set to local mode

• Update RF information window

The measurement is started automatically when RX calibration is entered.

The measurement is done in five steps:

1. User is requested to put signal generator to high input level (read from

Tesla .INI file).

2. Measurement with high input level is executed

3. User is requested to put signal generator to low input level (read from

Tesla .INI file).

4. Measurement with low input level is executed

Page 24

Issue 1 07/99

Page 25

PAMS

NSE 8/9

Technical Documentation

5. The RX Calibration dialog will be updated when previous steps are

done.

Service Software Instructions

Dialog mode: modal

RX Calibration dialog has the following items:

AFC information box:

Shows AFC init value, AFC slope and PSW slope values.

AGC List box (ALT+A):

Issue 1 07/99

Page 25

Page 26

NSE 8/9

PAMS

Service Software Instructions

AGC, DAC, Voltage and Difference. The difference column shows the

difference between tuned DAC values and mean straight line calculated

from part slopes in dBs (see /1/). This can be calculated when all

measurement results have been received from phone.

Repeat button (ALT+R):

The measurement can be started again by pressing this button.

Save button (ALT+S):

Dialog is closed and tuning

Cancel button (ESC):

Dialog is closed and tuning

When calibration is ended, the DAC value checking is made and if it is not

succeeded, error message is shown.

When exit is made, the next selections are set to the values which were

selected before this adjustment.

is saved

to phone.

is not saved

Technical Documentation

to phone.

The exit and the use of AGC–control values is done same way as exit

from power level tuning and power coefficient use:

ower... command

Tx P

Activation Status Bar Text

Alt, T,P Open TX Power Tuning dialog box

Starts TX power tuning.

Before the TX power tuning starts the DC/DC converter is set to the mode

specified in TESLA.INI in the section:

[NSE–8TXPOW]

DC2DC_Startup=2 ;0=Auto Mode 1=Abs Mode and 2=Max

Mode

Max Mode is the default mode set at installation time and is recommended

because it will ensure, that the phone will not shut down due to too big

supply voltage drops when tuning the higher power levels.

Operation Mode

Update RF Information window

Page 26

Issue 1 07/99

Page 27

PAMS

NSE 8/9

Technical Documentation

Then the user is requested to select in the Start Tuning dialog which

tuning values to use. If the Start Tuning dialog is not shown the tuning will

use the EEPROM values directly.

Start Tuning dialog has following items:

Start Tuning With list box (ALT+S):

Current Values in PC memory

Service Software Instructions

Tuning values are load from program’s internal memory.

EEPROM Values

Tuning values are load from ME’s EEPROM.

Factory Default Values

Tuning values are load from ME’s flash.

The next automatic selections are made when this tuning function is

activated:

the lowest power level is selected

Operation mode = TX pulsed

Issue 1 07/99

Page 27

Page 28

NSE 8/9

PAMS

Service Software Instructions

The TX Power Tuning dialog will be activated automatically after value

selection.

Technical Documentation

Dialog mode: modal

TX Power Tuning dialog has following items:

Power Level & Coefficients list box (ALT+L):

The power is presented in GSM or PCN values. The test value is not

saved to the EEPROM. The test value can be changed during tuning as

other power coefficients and the program remembers its value when

tuning function is activated later again.

If there is more power levels in the phone that can fit into window the

window is scrollable. When phone is initialised the program asks the

number of power levels used in the phone.

Only three power coefficients (highest, third smallest and lowest) are

needed to tune (left justified Coefficients) and the rest of them are

calculated.

The highlighted tuning position can be tuned with +/– keys or left/right

cursor keys.

Calculate button (ALT+C):

The calculation is activated with this button. The power coefficients which are

calculated from the tuned coefficients are displayed.

Page 28

Issue 1 07/99

Page 29

PAMS

NSE 8/9

Technical Documentation

Base level calculation check box:

If this box is checked the base level is calculated.

+/– buttons (+/– and left/right cursor keys):

+ and – buttons will cause power changing by 0.25dB steps. When these

keys are used the coefficient value is updated on the tuning window.

Save button (ENTER):

Dialog is closed and tuned values are

Cancel button (ESC):

Dialog is closed and tuning

When selections are used, the power value checking is made and if it is

not succeeded, error message is shown. The test checks that all power

coefficients are in descending order (same order than power levels).

Service Software Instructions

saved

is not saved

to phone.

to phone.

If the power tuning function is ended and EEPROM values are not

received or EEPROM fault is noticed, an error message is shown.

When all power coefficients have such values that they don’t cause any

error messages, save can be made. The last used tuning power is in use

after exit.

The next automatic selection is made when this tuning function is ended:

Operation Mode = RX pulsed

When the tuning dialog is closed the DC/DC converter is set to the mode

specified specified in TESLA.INI in the section:

[NSE–8TXPOW]

DC2DC_Exit=0 ;0=Auto Mode 1=Abs Mode and 2=Max

Mode

Auto Mode is the default mode set at installation time.

Issue 1 07/99

Page 29

Page 30

NSE 8/9

PAMS

Service Software Instructions

Tx I/Q... command

Activation Status Bar Text

Alt, T,Q Open TX I/Q Tuning dialog box

This function is used for tuning TX I and Q branch DC offset, amplitude

difference and phase difference.

It is not possible to tune TX I/Q in GSM. WinTesla will automatically

change to PCN if the calibration is started in GSM.

Technical Documentation

Then the user is requested to select in the Start Tuning dialog which

tuning values to use. If the Start Tuning dialog is not shown the tuning will

use the EEPROM values directly.

The next automatic selections are made when this function is activated:

Operation Mode = TX pulsed

Update RF Information window

The TX I/Q Tuning dialog is opened.

Page 30

Issue 1 07/99

Page 31

PAMS

NSE 8/9

Technical Documentation

Dialog mode: modal

TX I/Q Tuning has following items:

Tune TX I

Tune TX Q

Tune A

DC Offset scroll bar (ALT+I):

The DC Offset is shown as percents (%) from the ± maximum

value. 0% means that there is no DC. The value range is

–100%...100%. The value is rounded to the nearest integer

value.

DC Offset scroll bar (ALT+Q):

The operation of this function is the same as one above, except

with this selection the Q branch DC Offset is tuned. The value

range is –100%...100%. The value is rounded to the nearest

integer value.

mplitude Difference scroll bar (ALT+A):

Service Software Instructions

When this selection is made user can increase or decrease the

amplitude difference within 0.1 dB steps. The value range is

–1...1.

Tune P

Save button (ENTER):

Cancel button (ESC):

After each value change the new value is sent to the phone.

The next automatic selection is made when TX I / Q tuning function is

ended:

hase Difference scroll bar (ALT+P):

When this selection is made user can increase or decrease the

phase difference within 0.5° steps. The current phase difference

is shown on the tuning window with numbers and bar figure.

The value range is –85...90.

Dialog is closed and tuning

Dialog is closed and tuning

Operation Mode = RX pulsed

is saved

is not saved

to phone.

to phone.

Issue 1 07/99

Update RF Information window

Page 31

Page 32

NSE 8/9

PAMS

Service Software Instructions

Energy Management Calibration... command

Activation Status Bar Text

Alt, T,E Energy Management Calibration

This command opens the Energy Management Calibration dialog box:

Technical Documentation

Page 32

The Energy Management Calibration dialog box contains the following

options:

Run button (ALT+R):

The selected energy management calibrations are performed,

Close button (ENTER):

The dialog box is closed without performing energy

management calibration.

Help button (ALT + H):

Displays context sensitive help.

Issue 1 07/99

Page 33

PAMS

NSE 8/9

Technical Documentation

The settings to be selected are:

1. Run battery & charger default values checkbox (ALT+1):

Loads battery & charger default values to phone when selected.

2. Battery voltage checkbox (ALT+2):

Calibrates battery voltage A/D value.

3. Charger voltage checkbox (ALT+3):

Calibrates charge voltage A/D value.

The user is asked to connect the correct charging voltage and current

limit.

4. VDC Out (DC/DC) checkbox (ALT+7)

Calibrates the VDC Out voltage from the DC/DC converter.

This calibration is special for the NSE–8 phone. When this calibration is

executed a VDC Out input field is shown. The voltage must be measured

and entered into this field and then the Calibrate button completes the

calibration.

Service Software Instructions

Issue 1 07/99

Page 33

Page 34

NSE 8/9

PAMS

Service Software Instructions

DC/DC Tuning Command

Activation Status Bar Text

Alt, T,D DC/DC (Vdc_out) tuning

This command opens the DC/DC Tuning dialog box.

This dialog box allows you to set the DC/DC mode used and to check the

different voltage levels for the all power levels when in Auto mode.

The tuning is done for the currently selected band (GSM/PCN).

The modeless RF Information window is opened.

OK button:

The dialog is closed and the selected mode will be preserved.

Cancel button:

Technical Documentation

The dialog is closed and the mode used before starting the

DC/DC tuning is restored.

Page 34

The DC/DC converter can be set to 3 different modes. When opening the

DC/DC tuning dialog the currently used mode is shown.

1) Auto mode.

The Auto mode is the default mode and is active when the phone powers

up and after a reset. When the phone is in automatic mode the DC/DC

output voltage is changed by the phone itself.

Issue 1 07/99

Page 35

PAMS

NSE 8/9

Technical Documentation

This is done to save power. In standby, idle and the lower power levels the

voltage is low and only when transmitting on the higher power levels, the

vibrator is on or the buzzer is on is a high output voltage required.

When Auto mode is selected the phone is set to the TX power level

highlighted in the listbox. The phone will set the DC/DC output voltage

according to the VDC Out value shown.

Changing the selected power level can test the DC/DC converter in Auto

Mode.

2) Max mode

In maximum output voltage mode the DC/DC converter constantly

supplies the highest possible voltage. Only changing mode or resetting

the phone will change the voltage level.

3) Abs mode

In absolute output voltage mode the DC/DC converter constantly supplies

the voltage level requested by the user. Only changing the requested

voltage level, mode or resetting the phone will change the voltage level.

Service Software Instructions

The voltage level can be entered directly and is limited to the range from

3volt to 4.49volt. The phone set the DC/DC output voltage to the nearest

possible value when clicking on the Apply button.

Issue 1 07/99

Page 35

Page 36

NSE 8/9

PAMS

Service Software Instructions

Testing

The Testing sub menu offers functions for ME testing.

R

F Controls... command

Activation Status Bar Text

Alt, E,R Open RF Controls dialog box

This function is used for RF testing.

Command opens RF Controls dialog, which contains data for testing and

adjustments.

Technical Documentation

Page 36

Dialog mode: modal

RF Controls dialog has following items:

Active Unit group:

RX radio button (ALT+R):

RX

When

is selected, the next functions are made:

Data transmission is deactivated

TX power is deactivated

If operation mode is continuous,

– AGC is controlled

– RX continuous mode channel is activated

Issue 1 07/99

Page 37

PAMS

NSE 8/9

Technical Documentation

RF Information window is updated

The RX value is always given as default.

Note! Function is activated immediately, Apply is not needed.

TX radio button (ALT+T):

TX

When

is selected, the next functions are made:

Data transmission is activated

If operation mode is continuous,

– Operation mode is set to burst

RF Information window is updated

Continuous mode radio button is disabled.

Note! Function is activated immediately, Apply is not needed.

Service Software Instructions

Operation Mode group:

Continuous radio button (ALT+C):

When

continuous

selection is used,

synthesiser is set to constant frequency

synthesiser channel number is as given with Continuous Mode

Channel selection

transmitter power is not connected

if Active Unit is RX, AGC is controlled

Note! Function is activated immediately, Apply is not needed.

Issue 1 07/99

Page 37

Page 38

NSE 8/9

PAMS

Service Software Instructions

Burst radio button (ALT+B):

burst

When

selection is used,

synthesiser is controlled by using

receiving/transmission/measuring synthesiser control sequence

synthesiser channel numbers are as given with

Channel/Monitoring Channel selections

if Active Unit is TX, data (selected with TX Data Type) is sent

and the TX power is connected

Note! Function is activated immediately, Apply is not needed.

TX Data Type drop list (ALT+D):

TX Power Level edit box (ALT+T):

It is possible to change the transmission power in TX mode. The user can

select the needed power value or select the test value, which is tuned with

TX power tuning function. The test value is found at the end of the list.

Technical Documentation

TX Power have value

and is disabled (

greyed

) when active unit is

OFF

RX. When the TX power is tuned with test value (smallest value) the TX

TEST

Power has value

.

Continuous Mode Channel edit box (ALT+C):

Here the user can enter the continuous mode channel which may have all

channel numbers. The used frequency depends on the Active Unit. If

Active Unit is RX, then RX frequency is used, else TX frequency. The

frequency of the selected channel is shown after selection.

annel edit box (ALT+H):

Ch

Here the user can enter the channel number that is used for both

transmission and receiving. The frequency of the selected channel is

shown.

Monitoring Channel edit box (ALT+M):

This field selects the neighbour monitoring channel. The frequency of the

selected channel is shown.

AGC A

bsolute edit box (ALT+A):

Page 38

This selection allows user to edit AGC absolute value (value from A/D

converter). When AGC Absolute value is changed the AGC dB value will

be calculated depending on the AGC Absolute value.

Front End On check box:

This selection allows user to change whether the Front End amplifier is On

or Off.

Issue 1 07/99

Page 39

PAMS

NSE 8/9

Technical Documentation

AGC edit box (ALT+G):

This selection allows user to edit the AGC dBvalue. The AGC value is

shown only when its value is controlled by PC. When Active Unit has

value RX and Operation Mode is continuous, AGC is controlled by PC

except when next adjustment functions are activated:

RSSI Calibration

AFC Diagram

Apply button (ALT+A):

Accepts entered values and validates them. After validation all values are

sent to ME and the RF information window is updated.

Note! Active Unit and Operation mode are not included because they are activated

immediately.

Set Defaults button (ALT+S):

Service Software Instructions

Sets current values shown as default RF Controls values. Stores the

values in

Tesla.ini

Get Defaults button (ALT+G):

Gets default RF Controls values from the

Tesla.ini

file and shows them.

The next automatic selection is made when Quick testing function is

ended:

Active Unit = RX

Update RF Information window

The next table shows the dialog’s properties on different situations:

ACTIVE UNIT = TX:

TX Data Type: Updated

AGC values: Greyed

Monitoring Channel: Greyed

OPERATION MODE = BURST:

ACTIVE UNIT = RX:

Issue 1 07/99

TX Power Level: Updated

Continuous Mode Channel: Greyed

Channel: Updated

TX Data Type: Greyed

TX Power Level: OFF, Greyed

Page 39

Page 40

NSE 8/9

PAMS

Service Software Instructions

OPERATION MODE = BURST:

AGC values: Greyed

Continuous Mode Channel: Greyed

Channel: Updated

Monitoring Channel: Updated

OPERATION MODE = CONT:

AGC values: Updated

Continuous Mode Channel: Updated

Channel: Greyed

Monitoring Channel: Greyed

RSSI Re

ading... command

Technical Documentation

Activation Status Bar Text

Alt, E,R read continuously RSSI value

Command opens RSSI Reading dialog:

Dialog mode: modal

RSSI value is read continuously until user presses ESC–key or Close

button to cancel reading.

Page 40

RSSI Reading dialog has following items:

Close (ENTER) button:

Closes the RSSI Reading dialog. Does not send anything to

phone.

H

elp button:

Context sensitive help.

Issue 1 07/99

Page 41

PAMS

NSE 8/9

Technical Documentation

Self Tests... command

Activation Status Bar Text

Alt, E,S Open MCU Self–tests dialog box

Command is used for reading self test results and running self tests.

When the selection is made, the test result is read from ME. The test

result will be shown to the user within MCU Self–test dialog.

Service Software Instructions

Dialog mode: modal

MCU Self–test dialog has following items:

Tests list box (ALT+T):

The field ”(p)” in the screen example means that the test is also run in

power up. The field “(/s)” means that this test is selectable one.

Test states are updated according to results received from the phone.

Possible test states will be one of the next:

Passed

Failed

No response

Not executed

Issue 1 07/99

Page 41

Page 42

NSE 8/9

PAMS

Service Software Instructions

Not valid

RUNNING....

Note that power–off test have no values, because if test has been passed, power has

been turned off. If power–off test fails a special error message window is shown. If no

response is received to power off test message in a few seconds, the user is informed by

special info window, where user is asked to turn the power on and then press the return

key.

Note also that power–off test (if passed) turns power off and power should be

reconnected by using the phones keypad after the successful test. After the power has

been connected to phone, the normal start–up routines are made and the self–test

results are shown in the MCU self–tests menu (i.e. all other than power–up self–tests are

in Not executed state after the power–up routines).

Run button (ALT+R):

User can select desired test from list and hit Run button. When user

selects test to be run the text

test is run. When results are received the test state field is updated

according to the result.

RUNNING...

Technical Documentation

is shown in test state field and

If no response was received in the defined time, a

be shown and the test state is changed to

local mode if it is not already there.

Run A

ll button (ALT+A):

User can run all listed tests. The text

field and test is run. When results are received the test state field is

updated according to the result. When state field is updated application

moves to next test and repeats previous cycle. Phone is set to local mode

if it is not already there.

Supported Self Tests

The following tests are available:

1 MCU ROM Checksum................

2 MCU RAM Interface...............

3 MCU RAM Component...............

4 MCU EEPROM Interface............

5 MCU EEPROM Component............

No response

RUNNING...

error message box

will

. Phone is set to

is shown in test state

Page 42

6 Not Used.....................

7 CCONT Interface.................

8 A/D Converter...................

9 SW Reset........................

A Power Off.......................

Issue 1 07/99

Page 43

PAMS

NSE 8/9

Technical Documentation

B Security Data...................

C EEPROM Tune Checksum............

D PPM Checksum....................

E MCU Download DSP................

F DSP Alive.......................

G COBBA Serial.......................

H COBBA Parallel.....................

I EEPROM Sec Checksum................

J PPM Validity..................................

K Warranty State..............................

A

DC Readings... command

Service Software Instructions

Activation Status Bar Text

Alt, E,A Open ADC Readings dialog box.

Command is used to read and show A/D values from phone.

Command opens ADC Readings dialog.

Dialog mode: modal

The ADC Readings are updated every second.

ADC Readings dialog has following items:

Close (ENTER) button:

Closes the ADC Readings dialog. Does not send anything to phone.

Help button: Context sensitive help.

Following A/D values are measured:

Issue 1 07/99

Page 43

Page 44

NSE 8/9

PAMS

Service Software Instructions

Battery Voltage.........:

Battery Temperature.....:

Charge Voltage..........:

Charge Current..........:

PSCC Voltage............:

Acessory Detection......:

VDC Out...................:

VCXO Temperature........:

Hook Informaton........:

dio... command

Au

Activation Status Bar Text

Alt, E,U

Technical Documentation

Opens a submenu which contains following options:

Internal Audio Loops

Activation Status Bar Text

Alt, E,U,I Open Internal Audio loops dialog box.

Command is used for making internal audio loop tests in Internal Audio

Loops dialog.

Page 44

Issue 1 07/99

Page 45

PAMS

NSE 8/9

Technical Documentation

Dialog mode: modal

Internal Audio Loops dialog has following items:

Buzzer group:

Next three different values can be selected for Buzzer:

Volume On radio button (ALT+V):

Turns buzzer on.

Volume O

Level drop down list (ALT+L):

Frequency edit box

ff radio button (ALT+O):

Turns buzzer off.

Sets level of a buzzer. Allowed range 0...127

Sets the sound frequency

Service Software Instructions

Internal Audio Loop group:

Input group:

Next three different values can be selected for input:

Internal radio button (ALT+I):

Turns internal input.

External radio button (ALT+I):

Turns external input.

dset radio button (ALT+A):

Hea

Turns headset input.

Output group:

Next two different values can be selected for output:

ernal radio button (ALT+T):

Int

Turns internal output.

ternal radio button (ALT+X):

Ex

Headset radio button (ALT+D):

Issue 1 07/99

Turns external output.

Turns headset output.

Page 45

Page 46

NSE 8/9

PAMS

Service Software Instructions

Loop group:

Next two different values can be selected for loop:

Off

radio button (ALT+F):

Turns audio loop off.

On

radio button (ALT+N):

Turns audio loop on.

When the dialog is closed, the Buzzer Volume is always switched off. Also

internal audio loop is turned off.

User Interface... command

Activation Status Bar Text

Alt, E,T Open User Interface Tests dialog box

Technical Documentation

Command is used for making display tests in Display Tests dialog.

Dialog mode: modal

Display Tests dialog has following items:

1. Test Pattern radio button (ALT+1):

In test display 1 the display is filled with chessboard letters.

2. Test Pattern radio button (ALT+2):

In test display 2 the display is filled with inverse chessboard letters.

When dialog is closed the phone LCD display is cleared.

C

all Simulation... command

Activation Status Bar Text

Alt, E,C Open Call Simulation dialog box

Command is used for making call simulation. Function opens Call

Simulation dialog.

Page 46

Issue 1 07/99

Page 47

PAMS

NSE 8/9

Technical Documentation

Dialog mode: modal

Service Software Instructions

Call Simulation dialog has following items:

TX Power Level edit box (ALT+T):

All power levels can be selected. This updates same parameter as TX

Power Level in the RF Controls dialog. Note that TEST value cannot be

selected. If TEST value was in use when Call simulation menu selected,

power level is changed to smallest value.

Channel edit box (ALT+C):

This tells the normal operating RF channel number. Normal GSM/PCN

channel numbers can be selected. Same channel is used both for

transmission and receiving. This updates same parameter as Channel in

the RF–Controls dialog.

Channel 1

Channels for monitoring are specified with these six selections. All

GSM/PCN channel numbers can be used. If more than one selection has

same number, the monitoring channel list (neighbour list) will have less

than 6 selected channels. The minimum number of monitoring channels is

one (all channels have same value). The monitoring channel can also

have same value as normal operating channel.

,2,3,4,5,6 edit box (ALT+1,2,...):

The first monitoring channel updates same parameter as Monitoring

Channel in the RF–Controls dialog.

Apply button (ALT+A):

Validates and sends entered data to ME.

Set Defaults button (ALT+S):

Sets current values as default Call Simulation values.

Issue 1 07/99

Page 47

Page 48

NSE 8/9

PAMS

Service Software Instructions

Get Defaults button (ALT+G):

Gets default Call Simulation values as current values.

Noise Sensitivity... command

Activation Status Bar Text

Alt, E,N Opens Noise sensitivity dialog box

Command is used for noise sensitivity measurement.

The next automatic selections are made when this tuning function is

activated:

– Operation mode = RX cont

– AGC = 81 dB

Before function opens Noise Sensitivity dialog application prompts:

Technical Documentation

Then application opens Noise Sensitivity dialog:

Dialog mode: modal

Noise Sensitivity dialog has following items:

Measurements group:

Page 48

Issue 1 07/99

Page 49

PAMS

NSE 8/9

Technical Documentation

Clipping distance is the difference to the signal clipping value. SNR is

measured in AD converter.

The last value on the display is signal power difference between I and Q

branch. The numbers are shown in 0.1dB accuracy. The error messages,

”OUT OF RANGE”, are shown only if the SNR and/or amplitude difference

values are not acceptable.

Signal/Noise radiobutton (ALT+S/ALT+N):

When buttons are pressed, the RX I and Q burst data is asked, text

”SIGNAL MEASURING...” or ”NOISE MEASURING...” will come to the

measurement group window. The power level value should be –92 dBm

during signal measurement.

When signal data is received, distance to clipping signal level is shown as

dBs on the display. When either signal or noise measurement results are

received ”MEASURING” text is removed and measurements are updated

to screen. When both measurements (signal and noise) are done at least

once, the signal to noise relation and difference are also shown on the

display.

Service Software Instructions

When exit is made, the next selections are set to the values which were

selected before this adjustment.

– Operation mode

– AGC value

Vibra test....command

Activation Status Bar Text

Alt, E, V Initialising phone to local mode

Command used to test vibrator functionality

Dialog mode: modal

Issue 1 07/99

Page 49

Page 50

NSE 8/9

PAMS

Service Software Instructions

Software

Product Profile... command

Activation Status Bar Text

Alt, S,P Open Product Profile settings dialog box.

Function is used for making product profile settings.

When command is activated the product profile information is read from

EEPROM and Product Profile dialog is opened.

Technical Documentation

Page 50

Dialog mode: modal

Product Profile dialog has following items:

Se

ttings list box (ALT+E):

A list where user can select desired setting.

User can toggle setting with following Options drop list or by double

clicking desired setting in list box.

Issue 1 07/99

Page 51

PAMS

NSE 8/9

Technical Documentation

Options drop list (ALT+O):

List allows user to set options to each settings which are listed in Settings

list box.

Save(OK) button (ENTER)

Selections are accepted and saved to EEPROM.

Cancel button (ESC)

Selections are ignored and control is returned back to main menu.

S

tart Up Self–tests... command

Activation Status Bar Text

Alt, S,S Open MCU start Up self–tests dialog box.

Function is used for changing the state of the EEPROM selectable tests in

MCU Start Up Self–tests dialog.

Service Software Instructions

Dialog mode: modal

MCU Start Up Self–tests dialog has following items:

Tests list box (ALT+T):

When dialog is opened, the previous values will be read from the MCU

EEPROM and shown on the list box.

Status group:

When radio button On is selected, the test will be run every time when

automatic start up self–tests are activated (e.g. in power up).

Save button (ENTER)

Selections are accepted and saved to EEPROM. A power up routine is

made to phone.

Cancel button (ESC)

Selections are ignored and control is returned back to main menu.

Issue 1 07/99

Page 51

Page 52

NSE 8/9

PAMS

Service Software Instructions

Selectable Start–Up self tests:

1. PPM Validity

3. A/D Converter

Set Factory Values... command

Activation Status Bar Text

Alt, S,V Set factory values

Application does not ask confirmation. Next kind of text will be shown to

user:

“Setting UI and SCM Factory values...”

Technical Documentation

Dialog mode: modal

Default Factory Values dialog has following items:

Settings list box:

Contains the selectable factory values.

Set button:

Sets the selected factory value to phone. Before setting software asks

confirmation:

Cancel button:

Closes the Default Factory Values dialog.

Page 52

Issue 1 07/99

Page 53

PAMS

NSE 8/9

Technical Documentation

Phone Identity... command

Activation Status Bar Text

Alt, S,I Open Phone Identity dialog box for editing

Function is used to edit phone identity. With this dialog IMEI or SIM locks

may be changed in following manner:

– current phone information is read from phone

– user edits User Name (and IMEI, Product Code and Product Id, if they

were not read correctly from phone)

– dialog information is saved to file, which is sent to secure place where

actual programming information may be constructed

– programming information is got from secure place in an other file, which

is loaded to dialog

Service Software Instructions

– program checks input values and if they are correct programming

information is written to phone

Function opens Phone Identity dialog.

Dialog mode: modal

Issue 1 07/99

Page 53

Page 54

NSE 8/9

PAMS

Service Software Instructions

Phone Identity dialog has following items:

User Name edit box (ALT+U):

Field where user can enter user identification.

IMEI edit box (ALT+I):

Field where user can enter IMEI value. Field can contain up to 40 digits.

This field is automatically filled, if ME is connected to the PC when dialog

is loaded.

Product Code edit box (ALT+P):

Field where user can enter Product Code value.

This field is automatically filled, if ME is connected to the PC when dialog

is loaded.

MS Id edit box (ALT+M):

Technical Documentation

Field where user can enter MS Id corresponding programming data. This

field is automatically filled, if ME is connected to the PC when dialog is

loaded.

Pr

oduct Id edit box (ALT+R):

Field where user can enter Product Id. This field is automatically filled, if

ME is connected to the PC when dialog is loaded.

ta edit box (ALT+A):

Da

Field where user can enter Data entry. This field is automatically filled,

when file is loaded or data is saved.

IMEI radio button:

File and ME operations contains only IMEI data.

SIM Lock radio button:

File and ME operations contains only SIM Lock data.

IM

EI Programming Data edit box (ALT+I):

IMEI programming data is read from file or entered by user to this field.

Page 54

SIM Lock Programming D

SIM Lock programming data is read from file or entered by user to this

field.

Close button (ESC):

Cancels all edits and does not save values to phone.

ata edit box (ALT+D):

Issue 1 07/99

Page 55

PAMS

NSE 8/9

Technical Documentation

Help button

Opens a help text.

Write button (ALT+W):

Writes programming data to phone. Actions are selected with Action

Selection radio button.

Read button (ALT+R):

Reads identification data from phone and shows it in dialog controls.

Needed data is selected by Action Selection radio button.

Save File... button (ALT+S):

Writes a file containing data needed by security place application to create

needed programming data. File is selected with File Save As dialog.

Load File... button (ALT+L):

Service Software Instructions

Reads a file containing data needed to program selected data. File is

selected with File Open dialog.

arranty State... command

W

Activation Status Bar Text

Alt, S,W Warranty state: Reading from ME.....

Command used to read warranty information from MS

Dialog Mode: Modal

Issue 1 07/99

Page 55

Page 56

NSE 8/9

PAMS

Service Software Instructions

Production Data Edit... command

Activation Status Bar Text

Alt, S,P Open Production Data Edit dialog box

This command is used for programming HW version to phone. Function

opens the following Production Data Edit dialog box.

Technical Documentation

Dialog mode: modal

Production Data dialog has the following items:

Production Code edit box (read only):

Displays production code.

Order Number edit box (read only):

Displays order number.

Production Ser. No edit box (read only):

Displays production serial number.

Manufacture Month edit box (read only):

Displays manufacturing month.

HW Version edit box:

User can edit HW version.

Basic Product Code edit box (read only) displays the product code

OK button (ENTER):

Page 56

Closes the dialog box and

Cancel button (ESC):

Closes the dialog box and

writes HW version to ME.

does not

write HW version to ME.

Issue 1 07/99

Page 57

PAMS

NSE 8/9

Technical Documentation

Dealer

The dealer sub menu offers functions for ME settings for dealers.

U

ser Settings... command

Activation Status Bar Text

Alt, D,U Open User Setting dialog box

This command is used to edit user settings.

Service Software Instructions

Dialog mode: modal

User Settings dialog box has following items:

Save File... button (ALT+S):

User can save user settings to file.

Load File button (ALT+L):

User can load user settings from file.

Ed

it... button (ALT+D):

Start Windows Paintbrush to edit loaded or saved graphical Wake up

message.

Preview picture:

Shows graphical Wake up message.

Ok button (ENTER):

Writes user settings to phone.

Issue 1 07/99

Page 57

Page 58

NSE 8/9

PAMS

Service Software Instructions

Cancel button (ESC):

Closes the dialog box

Short C

ode Memory... command

Activation Status Bar Text

The NSE–8 phone does not contain a ME short code memory and the MS

selection is disabled. Only the SIM SCM can be used and if no SIM card is

present in the phone the SCM dialog will not open.

Technical Documentation

Page 58

Dialog mode: modal

Edit SCM dialog has the following items:

Loc static text:

Display current location.

Na

me edit box (ALT+A):

Edit the Name.

Number edit box (ALT+N):

Edit the Number.

Group edit box:

Edit the Group number.

SCM list box (ALT+C):

Issue 1 07/99

Page 59

PAMS

NSE 8/9

Technical Documentation

List for available names and numbers.

Write button (ALT+W):

Write SCM values to phone and checks the validity of names

and numbers.

Read button (ALT+R):

Read SCM values from phone.

Save File... button (ALT+S):

Opens a default Windows File Save As dialog and asks

filename where to save SCM values.

Load File... button (ALT+L):

Opens a default Windows File Open dialog and asks filename

where from load SCM values. Checks the validity of names and

numbers.

Service Software Instructions

Memory group box selection:

SCM memory can be defined to ME or SIM.

When all values are sent and responses received, waiting window is

removed and Edit SCM is back in control. The waiting state can be

broken with Cancel (ESC) button. If writing to the ME is broken, only part

of the SCM entries in the ME may be changed.

& User Settings... command

SCM

Activation Status Bar Text

Alt, D,M Open SCM & User settings dialog box.

This command is used to get SCM and user settings from phone to file

and vice versa. The following information is loaded/saved with this dialog:

– All user settings

– Speed dial keys

– Operator Logo

– Over The Air / Composed Ringing tones

– Graphical / Text wake up message

– Alarms

– Graphical Messages pictures

– T9 User dictionary

– CLI Ringing tones

Issue 1 07/99

Page 59

Page 60

NSE 8/9

PAMS

Service Software Instructions

When data is written or read phone waiting dialog is showed to user.

Dialog mode: modal

SCM & User Settings dialog box has following items:

File Name edit field (ALT+F):

Technical Documentation

User can edit file name or select file with Open File dialog. When dialog is

opened, it contains name of the previously saved or loaded file.

Write Phone button (ALT+W):

Loads settings from file and writes them to phone.

Read Phone button (ALT+R):

Reads settings from phone and writes them to file.

Select File button (ALT+S):

Opens Open File dialog, with which user can select the file, that contains

the data to be loaded to ME or file to which data is saved from ME. If user

selects OK button, the name of selected file is copied to File Name edit

field.

Close button (ESC):

Closes the dialog box.

Page 60

Issue 1 07/99

Page 61

PAMS

NSE 8/9

Technical Documentation

Restore User Defaults... command

Activation Status Bar Text

Alt, D,R Restore user default settings: Reading from ME....

Command is used to restore the user settings of the MS

Service Software Instructions

All settings specified in the selected market area and with setting files

present are enabled and can be selected.

The files to be used are defined for each market area in the ini–file

wintesla\nse–8\nse–8.ini. This ini–file is maintained by phone software

installation packages and all setting files are contained in the package.

Example:

[EURO_A]

WugFile=NSE8EURO.WUG

//CliFile=

PpFile=NSE8EURO.PP

//PpFileBody=EURO

//OlgFile=

//DwnFile=

//MbxFile=

Issue 1 07/99

Page 61

Page 62

NSE 8/9

PAMS

Service Software Instructions

//VasFile=

GMSFile=NSE8EURO.GMS

CLI Logos and VAS Settings are not supported by the NSE–8 and NSE–9

phones and must not be specified.

Set UI/DEV Default V

Activation Status Bar Text

Alt, D,V Reset phone to UI and SCM factory settings

After selection application asks confirmation: “Are you sure you want to

set UI to factory settings?”. If Yes is answered, default settings are

resetted to phone.

alues... command

Technical Documentation

Page 62

Issue 1 07/99

Page 63

PAMS

NSE 8/9

Technical Documentation

Flash PPM... command

Activation Status Bar Text

Alt, D,P Open Post–programmable Memory dialog box.

This command is used to load PPM from file to phone. Application checks

version numbers of PPM package and ME, when file is loaded.

Service Software Instructions

Dialog mode: modal

Issue 1 07/99

Page 63

Page 64

NSE 8/9

PAMS

Service Software Instructions

Operator Settings.......command

Activation Status Bar Text

Alt, DO Operator settings: Reading from ME.....

Command is used to set the operator settings to the MS

Technical Documentation

IWR Swap data ......command

Activation Status Bar Text

Alt, D, I

Command is used to swap IWR data.

Page 64

Issue 1 07/99

Page 65

PAMS

NSE 8/9

Technical Documentation

Flash Phone... command

Activation Status Bar Text

Alt, S,F

This command is used for flashing new software into the phone. Function

opens the following Flash Phone dialog box. When flashing is started, a

window will show status and progress.

Service Software Instructions

Flashing the phone supports both the FPS4 flash prommer setup and the

FLS–X device. The device used is selected in the menu Configure |

FLS–1. If Use FLS–X is checked then the FLS–X device is activated or

else is the FPS4 prommer activated.

Both the image file and the PPM file are flashed to the phone. The files to

be used are defined for each market area in the ini–file

wintesla\nse–8\nse–8.ini. This ini–file is maintained by phone software

installation packages.

Issue 1 07/99

Page 65

Page 66

NSE 8/9

PAMS

Service Software Instructions

Example:

[EURO_A]

// flash files 1.priority

Rom4ImageFile=nse8nx03.000

Rom4PpmFile=nse8nx03.00a

If the image file entry is missing in the market area section then the

common reference is searched for:

[NSE–8_RESTOREFILES]