Nissan Versa 2008 Owner's Manual

AIR CONDITIONER

Revision: May 2007 2008 Versa

A

B

SECTION MTC

MANUAL AIR CONDITIONER

CONTENTS

SERVICE INFORMATION ............................ 3

PRECAUTIONS ................................................... 3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

Precaution for Procedure without Cowl Top Cover ......3

Precaution for Working with HFC-134a (R-134a) ......3

General Refrigerant Precaution ................................4

Oil Precaution ............................................................4

Precaution for Refrigerant Connection ......................4

Precaution for Service of Compressor ......................7

Precaution for Service Equipment .............................7

Precaution for Leak Detection Dye ...........................9

PREPARATION ..................................................10

Special Service Tool ...............................................10

HFC-134a (R-134a) Service Tool and Equipment .... 10

Commercial Service Tool ........................................13

REFRIGERATION SYSTEM ..............................14

Refrigerant Cycle ....................................................14

Refrigerant System Protection ................................14

Component Part Location .......................................15

OIL ......................................................................16

Maintenance of Oil Quantity in Compressor ...........16

AIR CONDITIONER CONTROL .........................19

Control Operation ....................................................19

Discharge Air Flow ..................................................20

System Description .................................................20

CAN Communication System Description ...............21

TROUBLE DIAGNOSIS .....................................22

CONSULT-III Function (BCM) ................................. 22

How to Perform Trouble Diagnosis for Quick and

Accurate Repair ......................................................

Component Parts and Harness Connector Loca-

tion ..........................................................................

Schematic ...............................................................25

Wiring Diagram - Heater - .......................................26

22

23

Wiring Diagram - A/C,M - ........................................27

Operational Check ...................................................30

Mode Door ...............................................................31

Air Mix Door .............................................................32

Intake Door ..............................................................33

3

Front Blower Motor Circuit .......................................33

Magnet Clutch Circuit (If Equipped) .........................37

Insufficient Cooling ..................................................45

Insufficient Heating ..................................................52

Noise .......................................................................53

CONTROLLER ..................................................55

Removal and Installation .........................................55

Disassembly and Assembly .....................................56

THERMO CONTROL AMPLIFIER ....................57

Removal and Installation .........................................57

A/C UNIT ASSEMBLY ......................................58

Removal and Installation .........................................58

Disassembly and Assembly .....................................60

BLOWER MOTOR ............................................62

Removal and Installation .........................................62

INTAKE DOOR ..................................................63

Intake Door Cable Adjustment .................................63

AIR MIX DOOR .................................................64

Air Mix Door Cable Adjustment ...............................64

MODE DOOR ....................................................65

Mode Door Cable Adjustment .................................65

BLOWER FAN RESISTOR ...............................66

Removal and Installation .........................................66

HEATER CORE .................................................67

Removal and Installation .........................................67

AIR CONDITIONER FILTER .............................68

Removal and Installation .........................................68

C

D

E

F

G

H

I

MTC

K

L

M

N

O

P

MTC-1

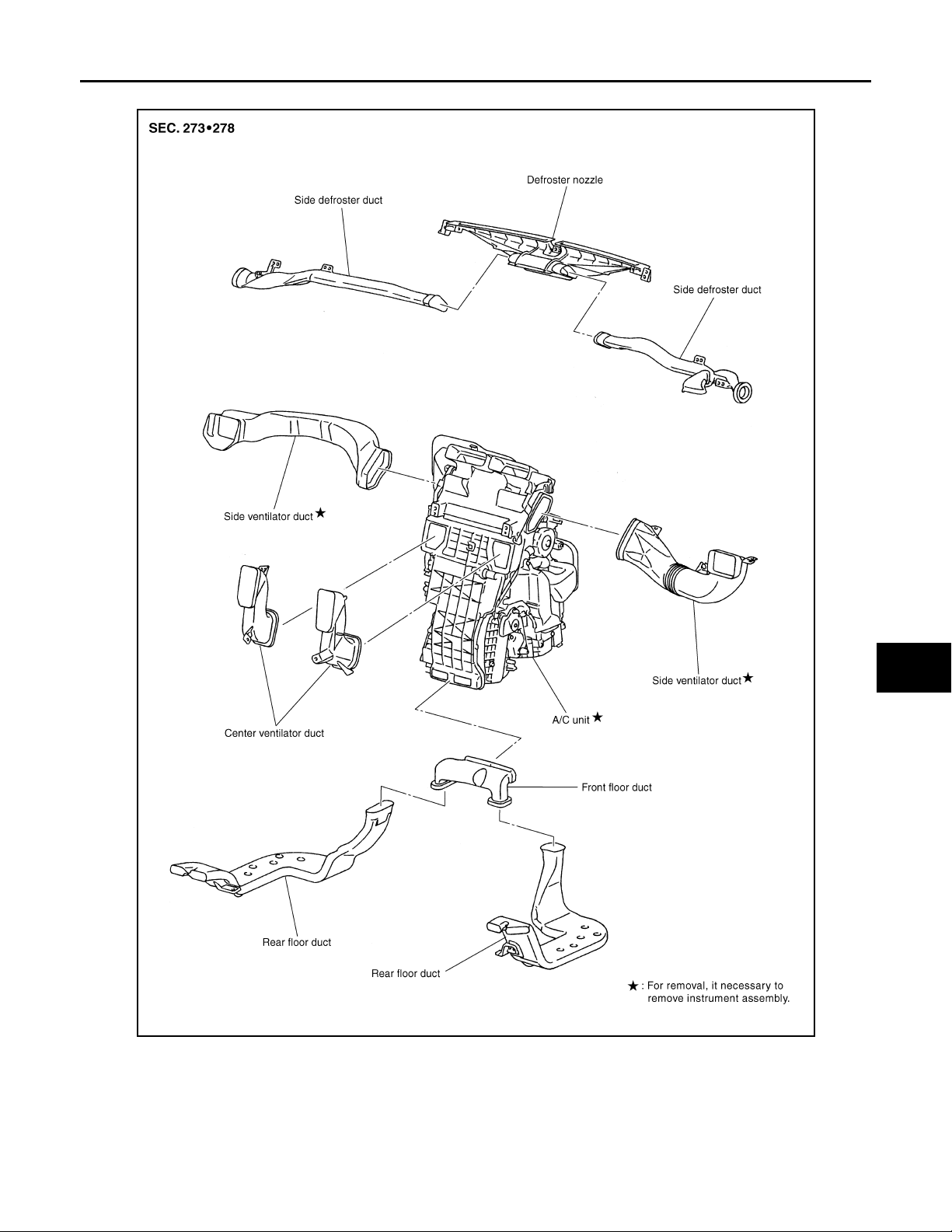

DUCTS AND GRILLES ...................................... 69

Revision: May 2007 2008 Versa

Removal and Installation ........................................ 69

REFRIGERANT LINES ...................................... 74

HFC-134a (R-134a) Service Procedure ................. 74

Component ............................................................. 76

Removal and Installation of Compressor ................ 78

Removal and Installation of Low-Pressure Flexi-

ble Hose .................................................................

Removal and Installation of High-pressure Flexi-

ble Hose .................................................................

Removal and Installation of High-pressure Pipe .... 81

Removal and Installation of Refrigerant Pressure

Sensor ....................................................................

Removal and Installation of Condenser .................. 82

Removal and Installation of Liquid Tank ................. 82

79

80

81

Removal and Installation of Evaporator .................. 83

Removal and Installation of Expansion Valve ......... 84

Checking of Refrigerant Leaks ................................ 84

Checking System for Leaks Using the Fluorescent

Leak Detector ..........................................................

Dye Injection ........................................................... 85

Electronic Refrigerant Leak Detector ...................... 85

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

Compressor ............................................................ 88

Oil ............................................................................88

Refrigerant .............................................................. 88

Engine Idling Speed ................................................ 88

Belt Tension ............................................................ 88

85

88

MTC-2

< SERVICE INFORMATION >

Revision: May 2007 2008 Versa

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Manual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or harness connectors.

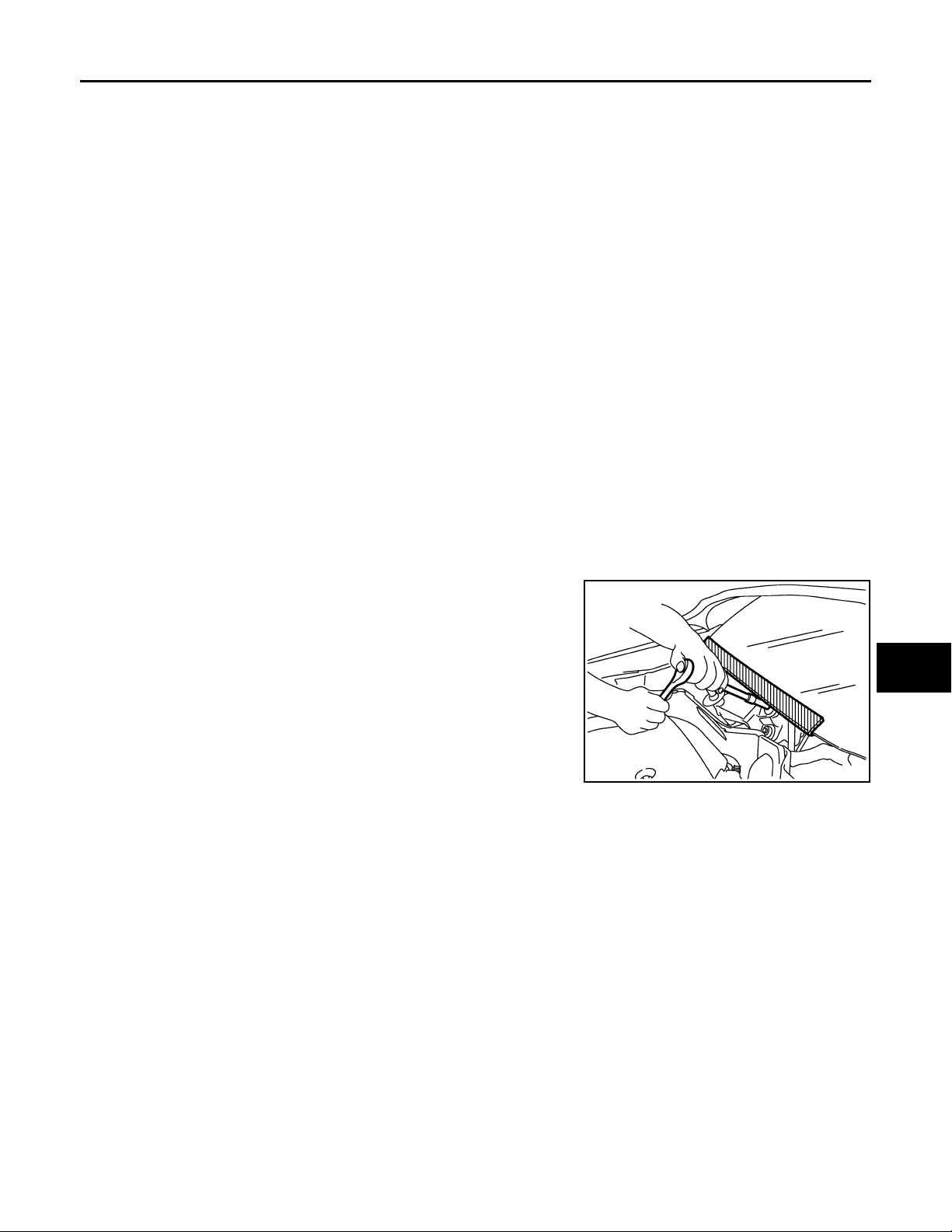

Precaution for Procedure without Cowl Top Cover

INFOID:0000000001704274

INFOID:0000000001704275

A

B

C

D

E

F

G

H

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

PIIB3706J

Precaution for Working with HFC-134a (R-134a)

WARNING:

• CFC-12 (R-12) refrigerant and HFC-134a (R-134a) refrigerant are not compatible. These refrigerants

must never be mixed, even in the smallest amounts. If the refrigerants are mixed a compressor malfunction is likely to occur.

• Use only specified oil for the HFC-134a (R-134a) A/C system and HFC-134a (R-134a) components. If

oil other than that specified is used, compressor malfunction is likely to occur.

• The specified HFC-134a (R-134a) oil rapidly absorbs moisture from the atmosphere. The following

handling precautions must be observed:

- When removing refrigerant components from a vehicle, immediately cap (seal) the component to

minimize the entry of moisture from the atmosphere.

- When installing refrigerant components to a vehicle, do not remove the caps (unseal) until just

before connecting the components. Connect all refrigerant loop components as quickly as possible

to minimize the entry of moisture into system.

- Only use the specified oil from a sealed container. Immediately reseal containers of oil. Without

proper sealing, oil will become moisture saturated and should not be used.

- Avoid breathing A/C refrigerant and oil vapor or mist. Exposure may irritate eyes, nose and throat.

Use only approved recovery/recycling equipment to discharge HFC-134a (R-134a) refrigerant. If accidental system discharge occurs, ventilate work area before resuming service. Additional health and

safety information may be obtained from refrigerant and oil manufacturers.

INFOID:0000000001704276

I

MTC

K

L

M

N

O

P

MTC-3

PRECAUTIONS

Revision: May 2007 2008 Versa

< SERVICE INFORMATION >

- Do not allow A/C oil to come in contact with styrofoam parts. Damage may result.

General Refrigerant Precaution

INFOID:0000000001704277

WARNING:

• Avoid breathing A/C refrigerant and oil vapor or mist. Exposure may irritate eyes, nose and throat.

Use only approved recovery/recycling equipment to discharge HFC-134a (R-134a) refrigerant. If accidental system discharge occurs, ventilate work area before resuming service. Additional health and

safety information may be obtained from refrigerant and oil manufacturers.

• Do not release refrigerant into the air. Use approved recovery/recycling equipment to capture the

refrigerant every time an air conditioning system is discharged.

• Always wear eye and hand protection (goggles and gloves) when working with any refrigerant or air

conditioning system.

• Do not store or heat refrigerant containers above 52°C (126° F).

• Do not heat a refrigerant container with an open flame; if container warming is required, place the

bottom of the container in a warm pail of water.

• Do not intentionally drop, puncture, or incinerate refrigerant containers.

• Keep refrigerant away from open flames: poisonous gas will be produced if refrigerant burns.

• Refrigerant will displace oxygen, therefore be certain to work in well ventilated areas to prevent suffocation.

• Do not pressure test or leak test HFC-134a (R-134a) service equipment and/or vehicle air conditioning systems with compressed air during repair. Some mixtures of air and HFC-134a (R-134a) have

been shown to be combustible at elevated pressures. These mixtures, if ignited, may cause injury or

property damage. Additional health and safety information may be obtained from refrigerant manufacturers.

Oil Precaution

INFOID:0000000001704278

• Use only specified oil for the HFC-134a (R-134a) A/C system and HFC-134a (R-134a) components. If oil

other than that specified is used, compressor malfunction is likely to occur.

• The specified HFC-134a (R-134a) oil rapidly absorbs moisture from the atmosphere. The following handling

precautions must be observed:

- When removing refrigerant components from a vehicle, immediately cap (seal) the component to minimize

the entry of moisture from the atmosphere.

- When installing refrigerant components to a vehicle, do not remove the caps (unseal) until just before connecting the components. Connect all refrigerant loop components as quickly as possible to minimize the

entry of moisture into system.

- Only use the specified oil from a sealed container. Immediately reseal containers of oil. Without proper sealing, oil will become moisture saturated and should not be used.

• Avoid breathing A/C refrigerant and oil vapor or mist. Exposure may irritate eyes, nose and throat.

Use only approved recovery/recycling equipment to discharge HFC-134a (R-134a) refrigerant. If accidental

system discharge occurs, ventilate work area before resuming service. Additional health and safety information may be obtained from refrigerant and oil manufacturers.

• Do not allow A/C oil to come in contact with styrofoam parts. Damage may result.

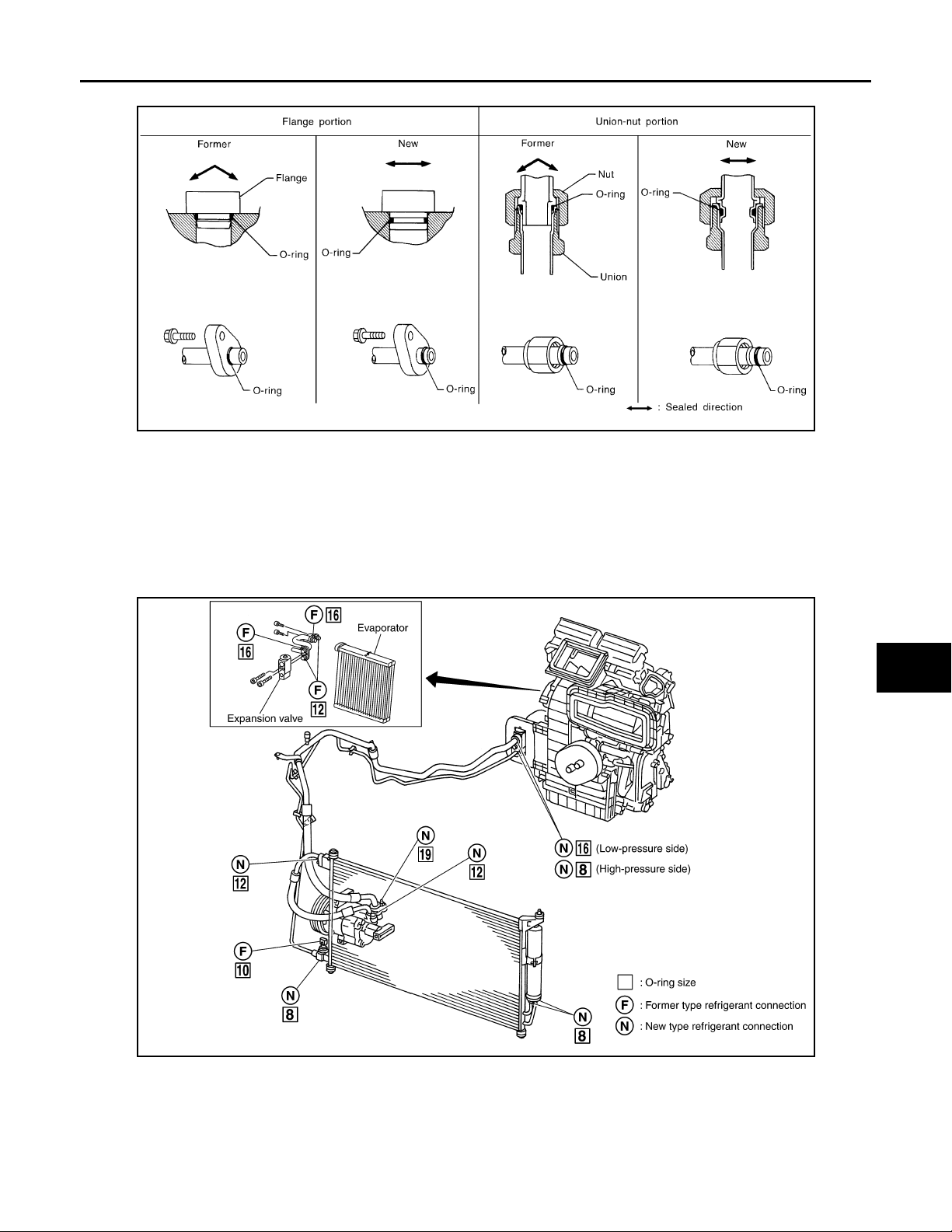

Precaution for Refrigerant Connection

INFOID:0000000001704279

A new type refrigerant connection has been introduced to all refrigerant lines except the following location.

• Expansion valve to evaporator

• Refrigerant pressure sensor to condenser

MTC-4

PRECAUTIONS

Revision: May 2007 2008 Versa

< SERVICE INFORMATION >

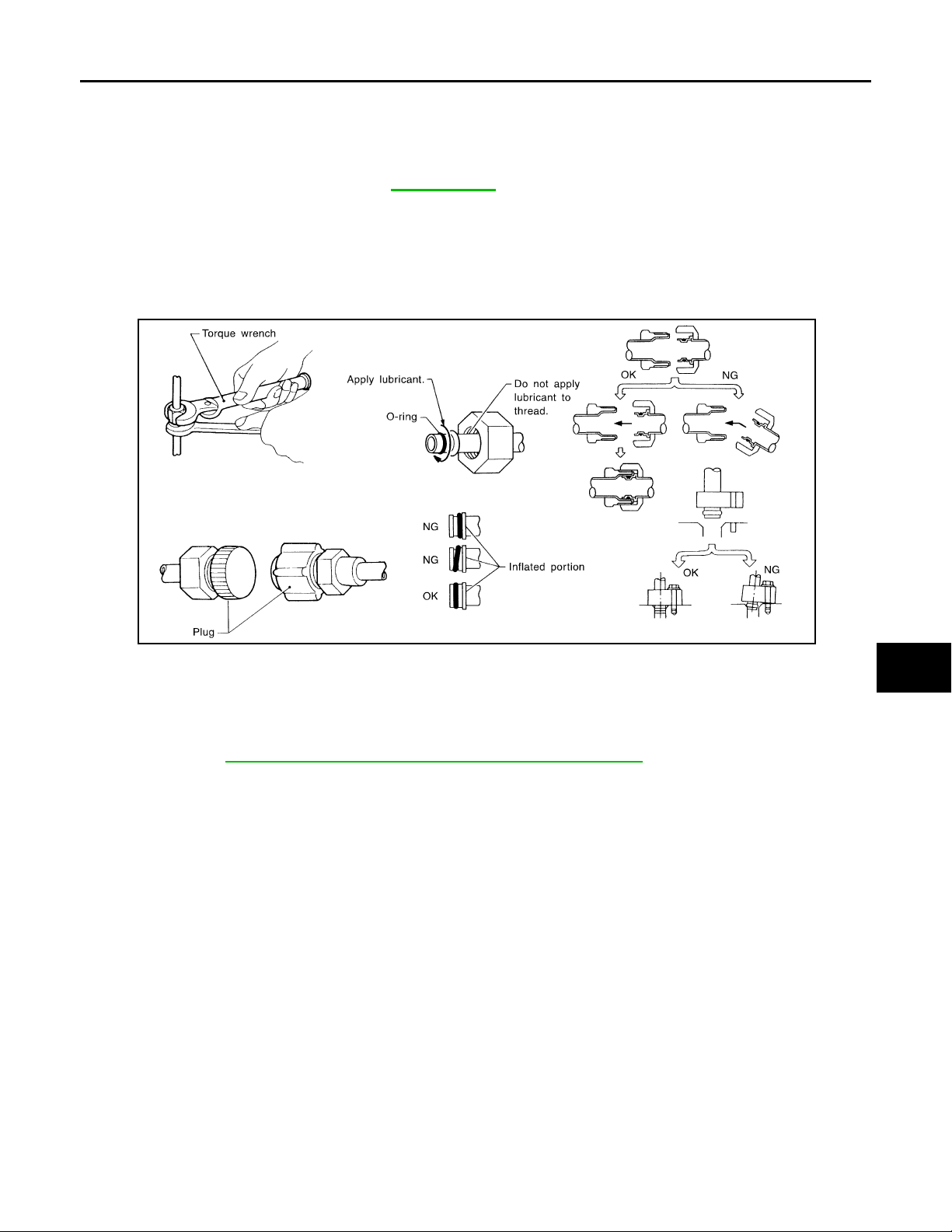

FEATURES OF NEW TYPE REFRIGERANT CONNECTION

A

B

C

D

E

SHA815E

• The O-ring has been relocated. It has also been provided with a groove for proper installation. This eliminates the chance of the O-ring being caught in, or damaged by, the mating part. The sealing direction of the

O-ring is now set vertically in relation to the contacting surface of the mating part to improve sealing characteristics.

• The reaction force of the O-ring will not occur in the direction that causes the joint to pull out, thereby facilitating piping connections.

O-RING AND REFRIGERANT CONNECTION

TYPE 1

F

G

H

I

MTC

K

L

M

SJIA0697E

MTC-5

N

O

P

< SERVICE INFORMATION >

Revision: May 2007 2008 Versa

PRECAUTIONS

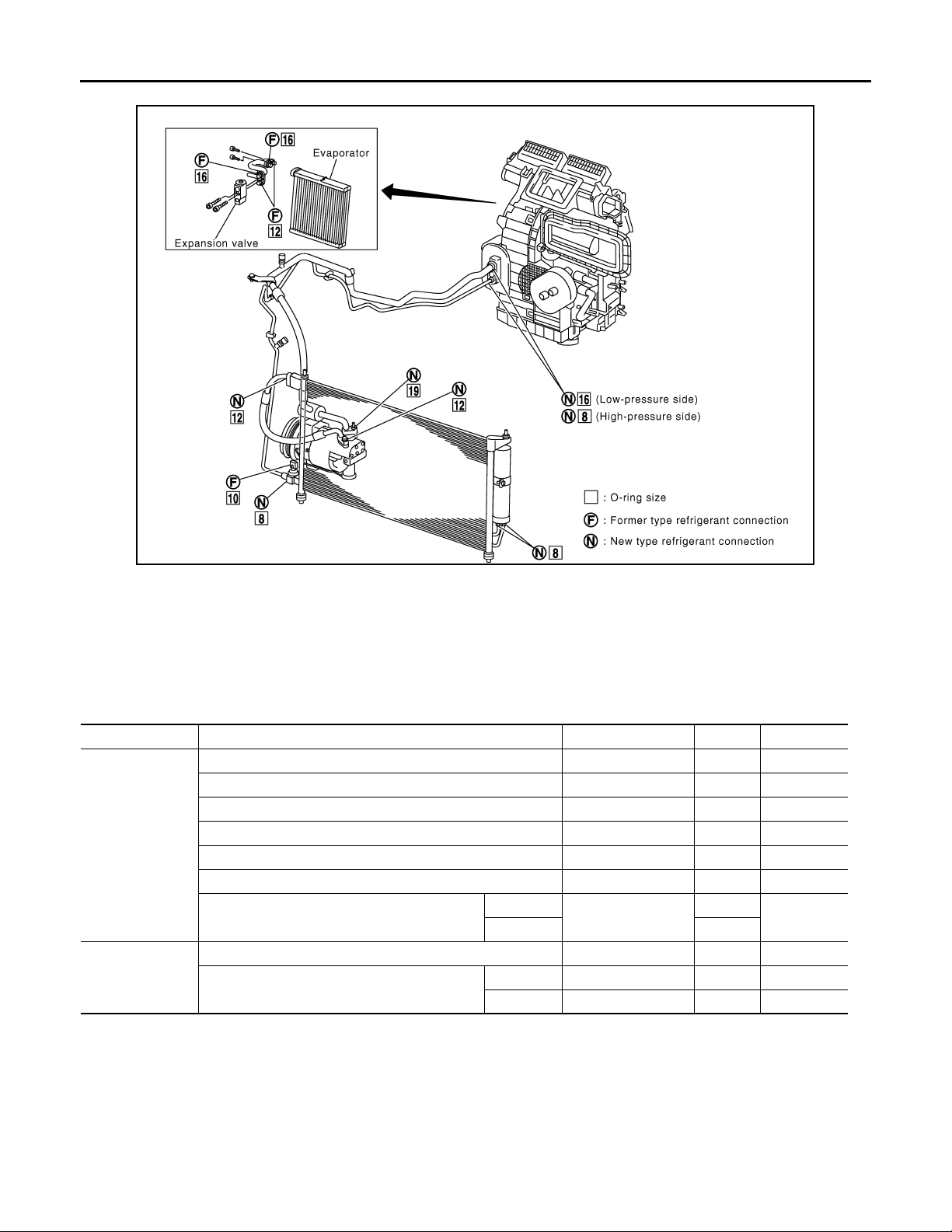

TYPE 2

SJIA1327E

WARNING:

Make sure all refrigerant is discharged into the recycling equipment and the pressure in the system is

less than atmospheric pressure. Then gradually loosen the discharge side hose fitting and remove it.

CAUTION:

The new and former refrigerant connections use different O-ring configurations. Do not confuse Orings since they are not interchangeable. If a wrong O-ring is installed, refrigerant will leak at, or

around, the connection.

O-Ring Part Numbers and Specifications

Connection type Piping connection point Part number QTY O-ring size

Condenser to high-pressure flexible hose 92472 N8210 1 12

Condenser to high-pressure pipe 92471 N8210 1 8

Low-pressure flexible hose to expansion valve 92473 N8210 1 16

New

Former

High-pressure pipe to expansion valve 92471 N8210 1 8

Compressor to low-pressure flexible hose 92474 N8210 1 19

Compressor to high-pressure flexible hose 92472 N8210 1 12

Liquid tank to condenser pipe

Refrigerant pressure sensor to condenser J2476 89956 1 10

Expansion valve to evaporator

Inlet

Outlet 1

Inlet 92471 N8200 2 12

Outlet 92473 N8200 2 16

92471 N8210

1

8

CAUTION:

When replacing or cleaning refrigerant cycle components, observe the following.

• When the compressor is removed, store it in the same position as it is when mounted on the vehicle.

Doing so will cause oil to enter the low-pressure chamber.

• When connecting tubes, always use a torque wrench and a back-up wrench.

• After disconnecting tubes, immediately plug all openings to prevent entry of dirt and moisture.

• When installing an air conditioner in the vehicle, connect the pipes as the final stage of the operation. Do not remove the seal caps of pipes and other components until just before required for connection.

MTC-6

PRECAUTIONS

Revision: May 2007 2008 Versa

< SERVICE INFORMATION >

• Allow components stored in cool areas to warm to working area temperature before removing seal

caps. This prevents condensation from forming inside A/C components.

• Thoroughly remove moisture from the refrigeration system before charging the refrigerant.

• Always replace used O-rings.

• When connecting tube, apply the specified A/C oil to circle of the O-rings as shown. Be careful not to

apply oil to threaded portion. Refer to MTC-88, "

• O-ring must be closely attached to dented portion of tube.

• When replacing the O-ring, be careful not to damage O-ring and tube.

• Connect tube until you hear it click, then tighten the nut or bolt by hand until snug. Make sure that

the O-ring is installed to tube correctly.

• After connecting line, perform leak test and make sure that there is no leakage from connections.

When the refrigerant leaking point is found, disconnect that line and replace the O-ring. Then tighten

connections of seal seat to the specified torque.

Oil".

A

B

C

D

E

F

G

RHA861F

Precaution for Service of Compressor

INFOID:0000000001704280

• Plug all openings to prevent moisture and foreign matter from entering.

• When the compressor is removed, store it in the same position as it is when mounted on the car.

• When replacing or repairing compressor, follow “Maintenance of Oil Quantity in Compressor”

exactly. Refer to MTC-16, "

Maintenance of Oil Quantity in Compressor" .

• Keep friction surfaces between clutch and pulley clean. If the surface is contaminated, with oil, wipe

it off by using a clean waste cloth moistened with thinner.

• After compressor service operation, turn the compressor shaft by hand more than five turns in both

directions. This will equally distribute oil inside the compressor. After the compressor is installed,

let the engine idle and operate the compressor for one hour.

• After replacing the compressor magnet clutch, apply voltage to the new one and check for usual

operation.

Precaution for Service Equipment

INFOID:0000000001704281

RECOVERY/RECYCLING EQUIPMENT

Be certain to follow the manufacturer’s instructions for machine operation and machine maintenance. Never

introduce any refrigerant other than that specified into the machine.

H

I

MTC

K

L

M

N

O

ELECTRONIC LEAK DETECTOR

Be certain to follow the manufacturer’s instructions for tester operation and tester maintenance.

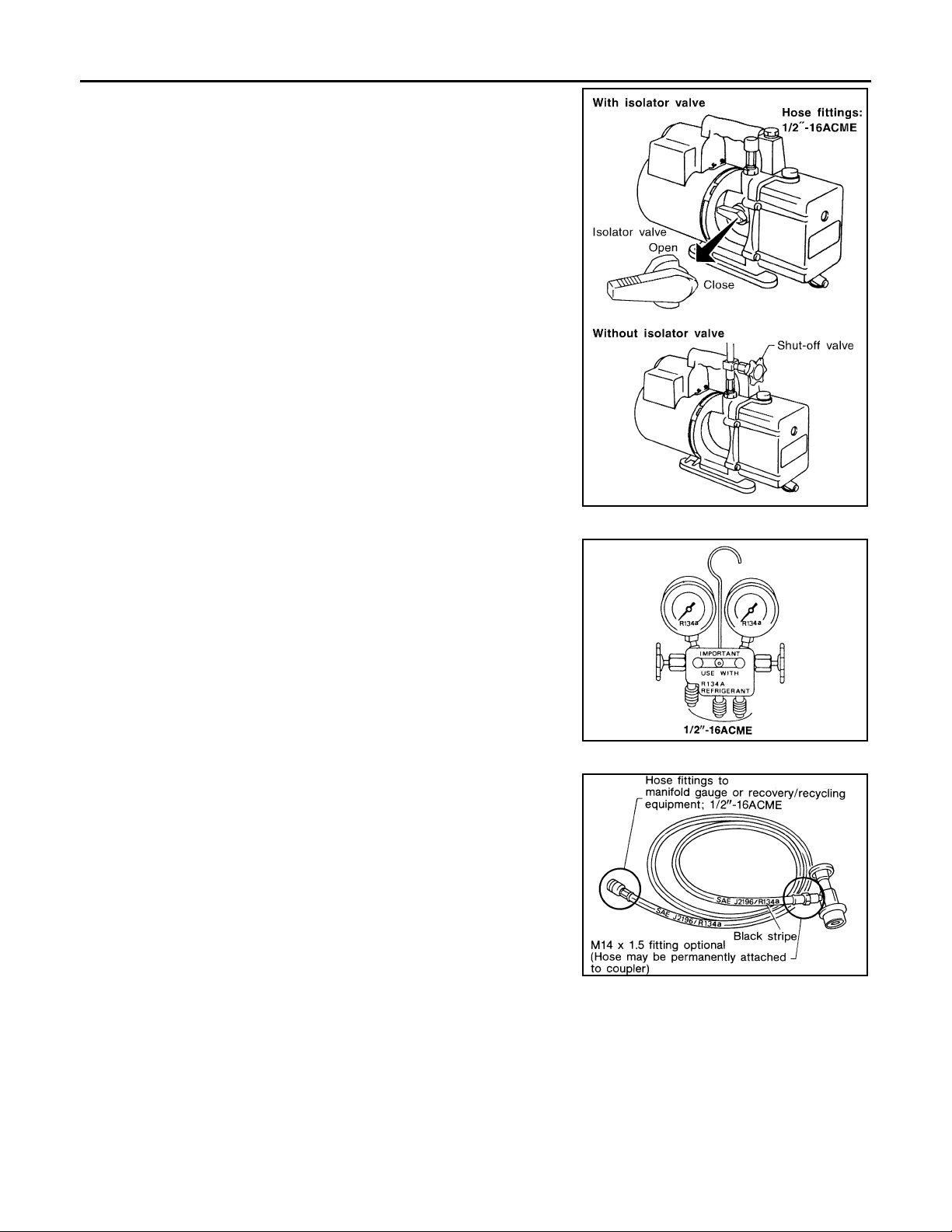

VACUUM PUMP

MTC-7

P

PRECAUTIONS

Revision: May 2007 2008 Versa

< SERVICE INFORMATION >

The oil contained inside the vacuum pump is not compatible with the

specified oil for HFC-134a (R-134a) A/C systems. The vent side of

the vacuum pump is exposed to atmospheric pressure. So the vacuum pump oil may migrate out of the pump into the service hose.

This is possible when the pump is switched off after evacuation (vacuuming) and hose is connected to it.

To prevent this migration, use a manual valve placed near the hoseto-pump connection, as follows.

• Usually vacuum pumps have a manual isolator valve as part of the

pump. Close this valve to isolate the service hose from the pump.

• For pumps without an isolator, use a hose equipped with a manual

shut-off valve near the pump end. Close the valve to isolate the

hose from the pump.

• If the hose has an automatic shut-off valve, disconnect the hose

from the pump. As long as the hose is connected, the valve is open

and lubricating oil may migrate.

Some one-way valves open when vacuum is applied and close

under a no vacuum condition. Such valves may restrict the pump’s

ability to pull a deep vacuum and are not recommended.

MANIFOLD GAUGE SET

Be certain that the gauge face indicates HFC-134a or R-134a. Be

sure the gauge set has 1/2″-16 ACME threaded connections for service hoses. Confirm the set has been used only with refrigerant

HFC-134a (R-134a) and specified oils.

SERVICE HOSES

Be certain that the service hoses display the markings described

(colored hose with black stripe). All hoses must include positive shutoff devices (either manual or automatic) near the end of the hoses

opposite the manifold gauge.

RHA270DA

SHA533D

SERVICE COUPLERS

MTC-8

RHA272D

PRECAUTIONS

Revision: May 2007 2008 Versa

< SERVICE INFORMATION >

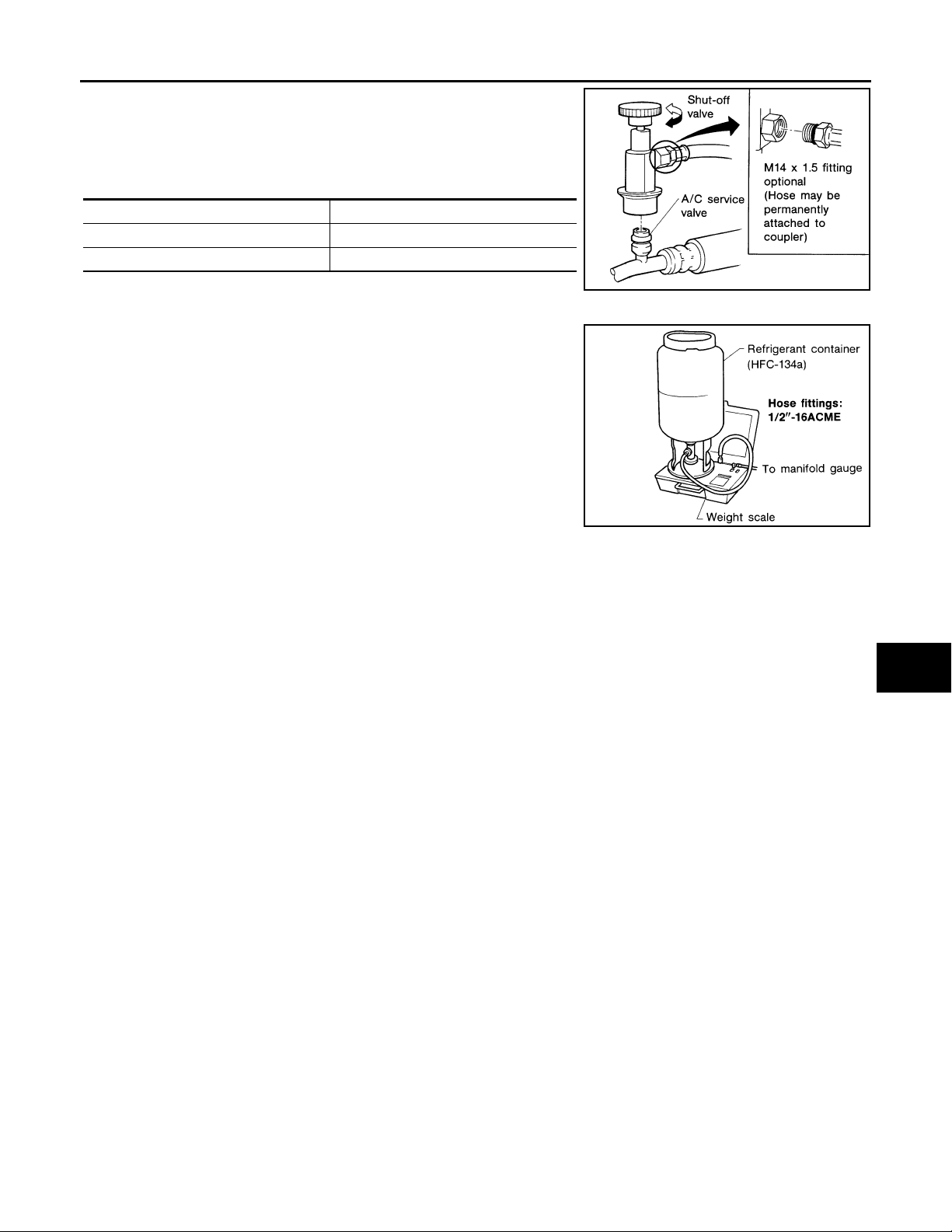

Never attempt to connect HFC-134a (R-134a) service couplers to a

CFC-12 (R-12) A/C system. The HFC-134a (R-134a) couplers will

not properly connect to the CFC-12 (R-12) system. However, if an

improper connection is attempted, discharging and contamination

may occur.

Shut-off valve rotation A/C service valve

Clockwise Open

Counterclockwise Close

REFRIGERANT WEIGHT SCALE

Verify that no refrigerant other than HFC-134a (R-134a) and specified oils have been used with the scale. If the scale controls refrigerant flow electronically, the hose fitting must be 1/2″-16 ACME.

A

B

C

RHA273D

D

E

F

G

RHA274D

CHARGING CYLINDER

Using a charging cylinder is not recommended. Refrigerant may be vented into air from cylinder’s top valve

when filling the cylinder with refrigerant. Also, the accuracy of the cylinder is generally less than that of an

electronic scale or of quality recycle/recharge equipment.

Precaution for Leak Detection Dye

• The A/C system contains a fluorescent leak detection dye used for locating refrigerant leaks. An ultraviolet

(UV) lamp is required to illuminate the dye when inspecting for leaks.

• Always wear fluorescence enhancing UV safety goggles to protect your eyes and enhance the visibility of

the fluorescent dye.

• The fluorescent dye leak detector is not a replacement for an electronic refrigerant leak detector. The fluorescent dye leak detector should be used in conjunction with an electronic refrigerant leak detector to pinpoint refrigerant leaks.

• For your safety and your customer’s satisfaction, read and follow all manufacture’s operating instructions

and precautions prior to performing the work.

• A compressor shaft seal should not be repaired because of dye seepage. The compressor shaft seal should

only be repaired after confirming the leak with an electronic refrigerant leak detector.

• Always remove any remaining dye from the leak area after repairs are complete to avoid a misdiagnosis during a future service.

• Do not allow dye to come into contact with painted body panels or interior components. If dye is spilled,

clean immediately with the approved dye cleaner. Fluorescent dye left on a surface for an extended period of

time cannot be removed.

• Do not spray the fluorescent dye cleaning agent on hot surfaces (engine exhaust manifold, etc.).

• Do not use more than one refrigerant dye bottle (1/4 ounce /7.4 cc) per A/C system.

• Leak detection dyes for HFC-134a (R-134a) and CFC-12 (R-12) A/C systems are different. Do not use HFC134a (R-134a) leak detection dye in CFC-12 (R-12) A/C system or CFC-12 (R-12) leak detector dye in HFC134a (R-134a) A/C system or A/C system damage may result.

• The fluorescent properties of the dye will remain for over three (3) years unless a compressor malfunction

occurs.

INFOID:0000000001704282

H

I

MTC

K

L

M

N

O

P

IDENTIFICATION LABEL FOR VEHICLE

Vehicles with factory installed fluorescent dye have this identification label on the front side of hood.

NOTE:

• Vehicles with factory installed fluorescent dye have a green label.

• Vehicles without factory installed fluorescent dye have a blue label.

MTC-9

< SERVICE INFORMATION >

Revision: May 2007 2008 Versa

PREPARATION

PREPARATION

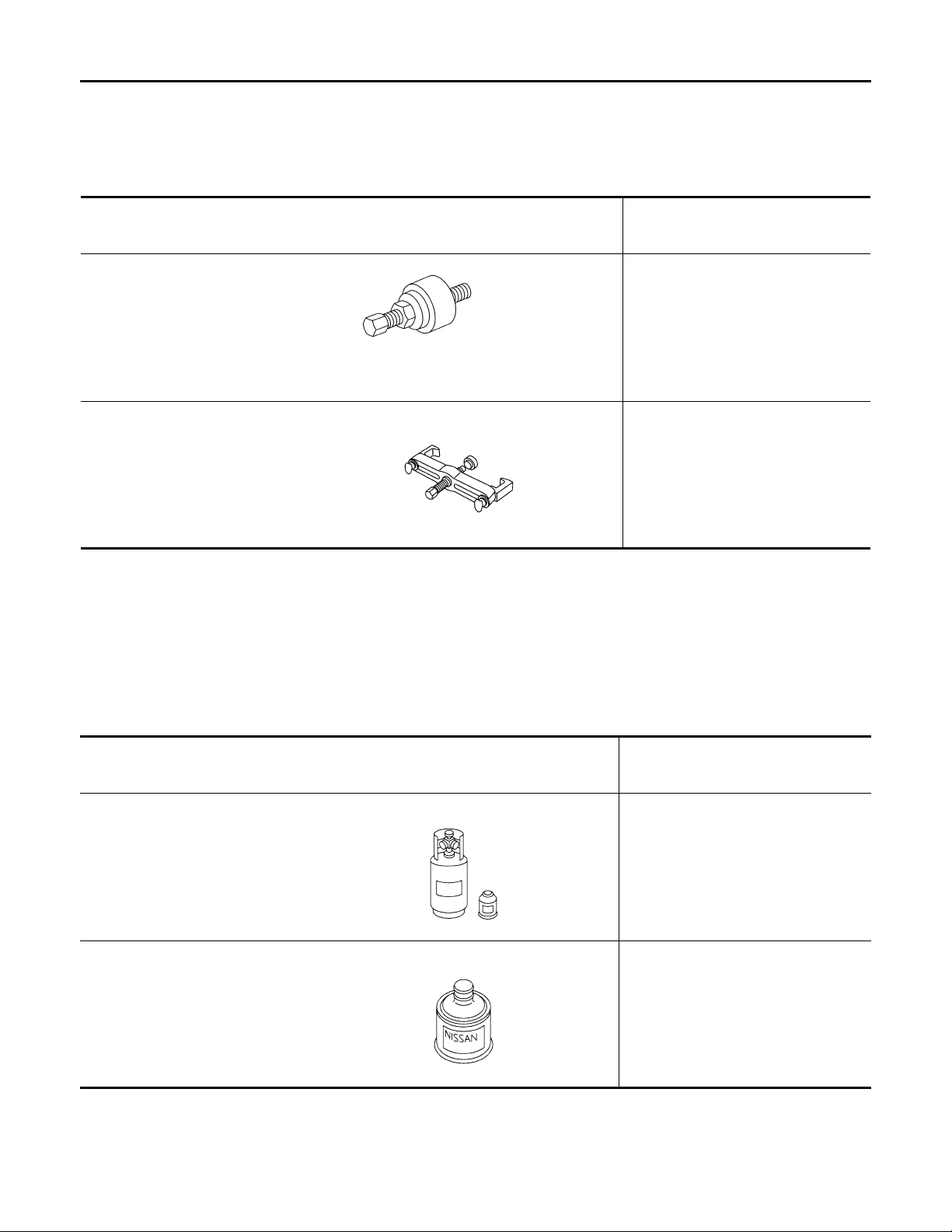

Special Service Tool

INFOID:0000000001704283

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool number

(Kent-Moore No.)

Tool name

—

(J-38873-A)

Pulley installer

LHA171

KV99233130

(J-29884)

Pulley puller

LHA172

HFC-134a (R-134a) Service Tool and Equipment

Description

Installing pulley

Removing pulley

INFOID:0000000001704284

Never mix HFC-134a refrigerant and/or its specified oil with CFC-12 (R-12) refrigerant and/or its oil.

Separate and non-interchangeable service equipment must be used for handling each type of refrigerant/oil.

Refrigerant container fittings, service hose fittings and service equipment fittings (equipment which handles

refrigerant and/or oil) are different between CFC-12 (R-12) and HFC-134a (R-134a). This is to avoid mixed

use of the refrigerants/oil.

Adapters that convert one size fitting to another must never be used refrigerant/oil contamination will occur

and compressor failure will result.

Tool number

(Kent-Moore No.)

Tool name

HFC-134a (R-134a)

(—)

Refrigerant

S-NT196

—

(—)

NISSAN A/C System Oil Type S

Description

Container color: Light blue

Container marking: HFC-134a (R134a)

Fitting size: Thread size

• large container 1/2”-16 ACME

Type: Poly Alkylene glycol oil (PAG),

type S

Application: HFC-134a (R-134a) variable displacement swash plate compressors (NISSAN only)

S-NT197

MTC-10

< SERVICE INFORMATION >

Revision: May 2007 2008 Versa

PREPARATION

Tool number

(Kent-Moore No.)

Tool name

—

(—)

NISSAN A/C System Oil Type R

KV991J0130

(ACR2005-NI)

ACR5 A/C Service Center

—

(J-41995)

Electronic refrigerant leak detector

S-NT197

WJIA0293E

Description

Type: Poly Alkylene glycol oil (PAG),

type R

Application: HFC-134a (R-134a) vane

rotary compressors (NISSAN only)

Refrigerant recovery, recycling and recharging

Checking for refrigerant leaks

Power supply: DC 12V (battery terminal)

A

B

C

D

E

F

G

H

—

(J-43926)

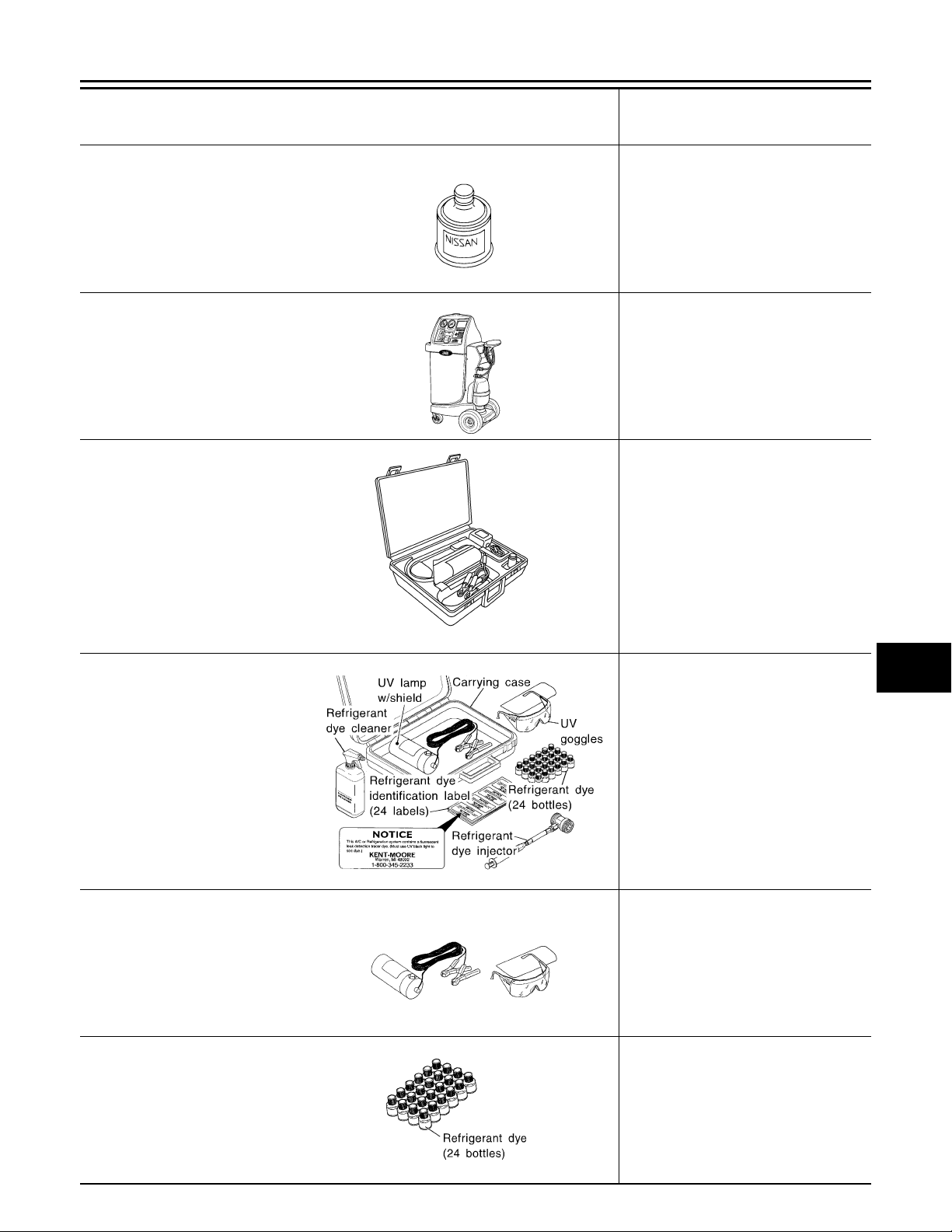

Refrigerant dye leak detection kit

Kit includes:

(J-42220)

UV lamp and UV safety goggles

(J-41459)

Refrigerant dye injector

(J-41447)

Quantity 24, 1/4 ounce bottles of

HFC-134a (R-134a) fluorescent

leak detection dye

(J-43872)

Refrigerant dye cleaner

—

(J-42220)

Fluorescent dye leak detector

—

(J-41447)

HFC-134a (R-134a) fluorescent

leak detection dye

(Box of 24, 1/4 ounce bottles)

SHA438F

AHA281A

ZHA200H

Leak detection dye

Power supply: DC 12V (battery terminal)

Checking for refrigerant leaks when fluorescent dye is installed in A/C system.

Includes: UV lamp and UV safety goggles

Power supply: DC 12V (battery terminal)

Application: For HFC-134a (R-134a)

PAG o i l

Container: 1/4 ounce (7.4cc) bottle

(Includes self-adhesive dye identification labels for affixing to vehicle after

charging system with dye.)

I

MTC

K

L

M

N

O

P

SHA439F

MTC-11

< SERVICE INFORMATION >

Revision: May 2007 2008 Versa

PREPARATION

Tool number

(Kent-Moore No.)

Tool name

—

(J-41459)

HFC-134a (R-134a) Dye injector

Use with (J-41447) 1/4 ounce bottles

—

(J-43872)

Refrigerant dye cleaner

—

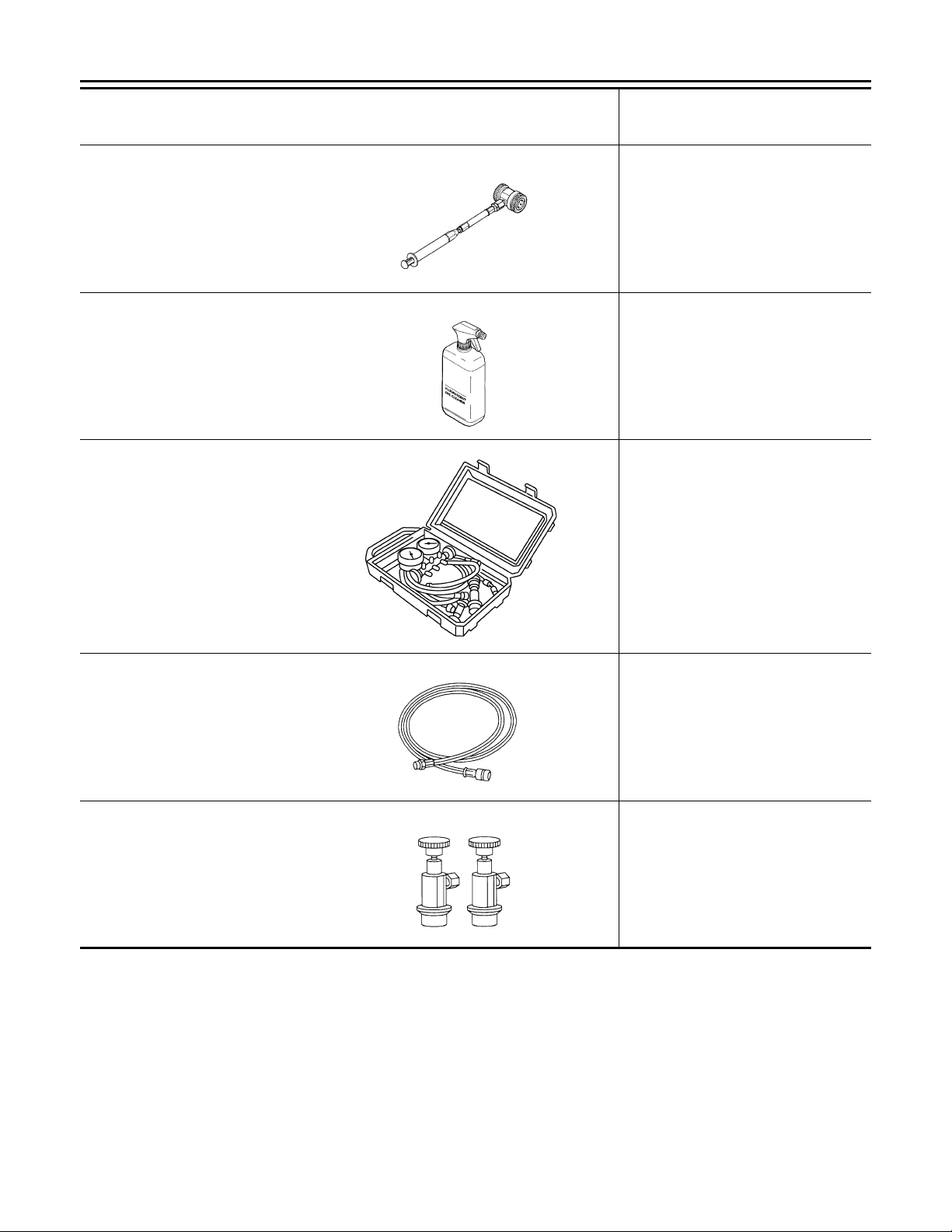

(J-39183-C)

Manifold gauge set (with hoses

and couplers)

Description

For injecting 1/4 ounce of fluorescent

leak detection dye into A/C system.

SHA440F

For cleaning dye spills.

SHA441F

Identification:

• The gauge face indicates R-134a.

Fitting size: Thread size

• 1/2”-16 ACME

Service hoses:

• (J-39500-72B)

High side hose

• (J-39500-72R)

Low side hose

• (J-39500-72Y)

Utility hose

Service couplers:

• (J-39500-20A)

High side coupler

• (J-39500-24A)

Low side coupler

RJIA0196E

Hose colors:

• Low side hose: Blue with black stripe

• High side hose: Red with black stripe

• Utility hose: Yellow with black stripe

or green with black stripe

Hose fitting to gauge:

• 1/2”-16 ACME

S-NT201

Hose fitting to service hose:

• M14 x 1.5 fitting is optional or permanently attached.

S-NT202

MTC-12

< SERVICE INFORMATION >

Revision: May 2007 2008 Versa

PREPARATION

Tool number

(Kent-Moore No.)

Tool name

—

(J-39699)

Refrigerant weight scale

—

(J-39649)

Vac u u m pump

(Including the isolator valve)

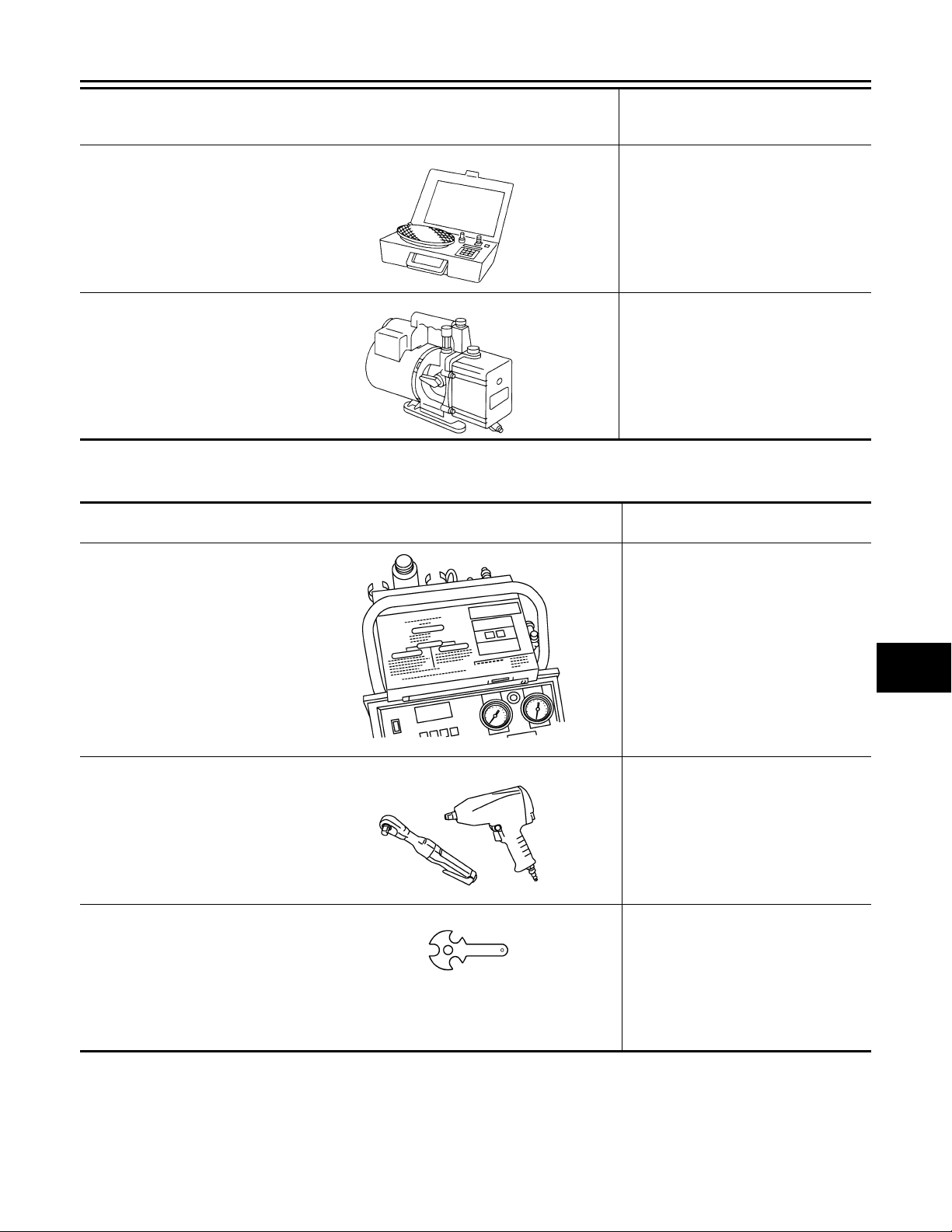

Commercial Service Tool

(Kent-Moore No.)

Tool name

(J-41810-NI)

Refrigerant identifier equipment (R134a)

S-NT200

S-NT203

Description

For measuring of refrigerant

Fitting size - thread size:

• 1/2” - 16 ACME

Capacity:

• Air displacement: 4 CFM

• Micron rating: 20 microns

• Oil capacity: 482 g (17 oz)

Fitting size: Thread size

• 1/2”-16 ACME

INFOID:0000000001704285

Description

For checking refrigerant purity and

system contamination

A

B

C

D

E

F

G

H

I

RJIA0197E

Power tool Loosening bolts and nuts

PBIC0190E

(J-44614)

Clutch disc holding tool

WHA230

Clutch disc holding tool

MTC

K

L

M

N

O

P

MTC-13

REFRIGERATION SYSTEM

Revision: May 2007 2008 Versa

< SERVICE INFORMATION >

REFRIGERATION SYSTEM

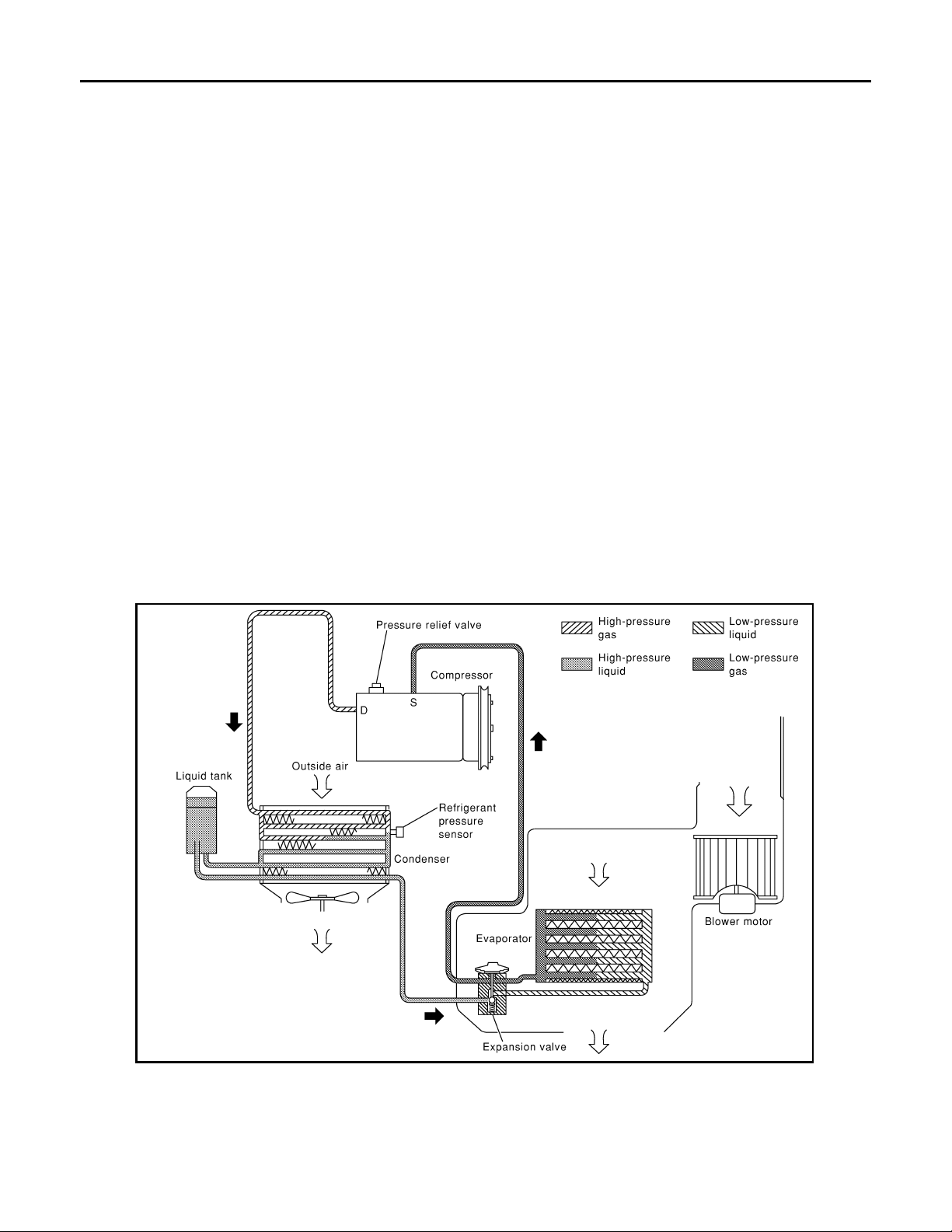

Refrigerant Cycle

INFOID:0000000001704286

REFRIGERANT FLOW

The refrigerant flows in the standard pattern, that is, through the compressor, the condenser with liquid tank,

through the evaporator, and back to the compressor. The refrigerant evaporation through the evaporator is

controlled by an externally equalized expansion valve, located inside the evaporator case.

FREEZE PROTECTION

Under usual operating conditions, when the A/C is switched ON, the compressor runs continuously, and the

evaporator pressure, and temperature is controlled by the compressor to prevent freeze up.

Refrigerant System Protection

INFOID:0000000001704287

REFRIGERANT PRESSURE SENSOR

The refrigerant system is protected against excessively high or low pressures by the refrigerant pressure sensor, located on the condenser. If the system pressure rises above, or falls below the specifications, the refrigerant pressure sensor detects the pressure inside the refrigerant line and sends the voltage signal to the ECM.

ECM makes the A/C relay go OFF and stops the compressor when pressure on the high-pressure side

2

detected by refrigerant pressure sensor is over about 2,746 kPa (27.46 bar, 28.0 kg/cm

2

about 134 kPa (1.34 bar, 1.4 kg/cm

, 20 psi).

, 398 psi), or below

PRESSURE RELIEF VALVE

The refrigerant system is also protected by a pressure relief valve, located in the rear head of the compressor.

When the pressure of refrigerant in the system increases to an unusual level [more than 3.8 MPa (38 bar,

38.76 kg/cm

erant into the atmosphere.

2

, 551 psi)], the release port on the pressure relief valve automatically opens and releases refrig-

RJIA0849E

MTC-14

< SERVICE INFORMATION >

Revision: May 2007 2008 Versa

REFRIGERATION SYSTEM

Component Part Location

INFOID:0000000001704288

A

B

C

D

E

F

G

H

SJIA0698E

I

MTC

K

L

M

N

O

P

MTC-15

< SERVICE INFORMATION >

Revision: May 2007 2008 Versa

OIL

OIL

Maintenance of Oil Quantity in Compressor

The oil in the compressor circulates through the system with the refrigerant. Add oil to compressor when

replacing any component or after a large refrigerant leakage occurred. It is important to maintain the specified

amount.

If oil quantity is not maintained properly, the following malfunctions may result:

• Lack of oil: May lead to a seized compressor.

• Excessive oil: Inadequate cooling (thermal exchange interference)

INFOID:0000000001704289

OIL

TYPE 1 Compressor (CR-10) : NISSAN A/C System Oil Type R

TYPE 2 Compressor (CSV511) : NISSAN A/C System Oil Type S

OIL RETURN OPERATION

Adjust the oil quantity according to the test group shown below.

1.CHECK OIL RETURN OPERATION

Can oil return operation be performed?

• A/C system works properly.

• There is no evidence of a large amount of oil leakage.

CAUTION:

If excessive oil leakage is noted, do not perform the oil return operation.

OK or NG

OK >> GO TO 2.

NG >> GO TO 3.

2.PERFORM OIL RETURN OPERATION, PROCEEDING AS FOLLOWS

1. Start engine, and set the following conditions:

- Engine speed: Idling to 1,200 rpm

- A/C blower switch: ON

- Blower speed: Max. position

- Temp. control: Optional [Set so that intake air temperature is 25° to 30°C (77° to 86° F)].

- Intake position: Recirculation (REC)

2. Perform oil return operation for about 10 minutes.

3. Stop engine.

>> GO TO 3.

3.CHECK REPLACEMENT PART

Should the compressor be replaced?

YES >> GO TO "OIL ADJUSTING PROCEDURE FOR COMPRESSOR REPLACEMENT".

NO >> GO TO "OIL ADJUSTING PROCEDURE FOR COMPONENTS REPLACEMENT EXCEPT COM-

PRESSOR".

OIL ADJUSTING PROCEDURE FOR COMPONENTS REPLACEMENT EXCEPT COMPRESSOR

After replacing any of the following major components, add the correct amount of oil to the system.

Amount Of Oil To Be Added

Oil to be added to system

Part replaced

Evaporator 35 (1.2, 1.2) -

Condenser 15 (0.5, 0.5) -

Liquid tank 5 (0.2, 0.2) -

Amount of oil

m (US fl oz, Imp fl oz)

Remarks

MTC-16

< SERVICE INFORMATION >

Revision: May 2007 2008 Versa

OIL

Oil to be added to system

Part replaced

In case of refrigerant leak

*1: If refrigerant leak is small, no addition of oil is needed.

Amount of oil

m (US fl oz, Imp fl oz)

30 (1.0, 1.1) Large leak

None *1

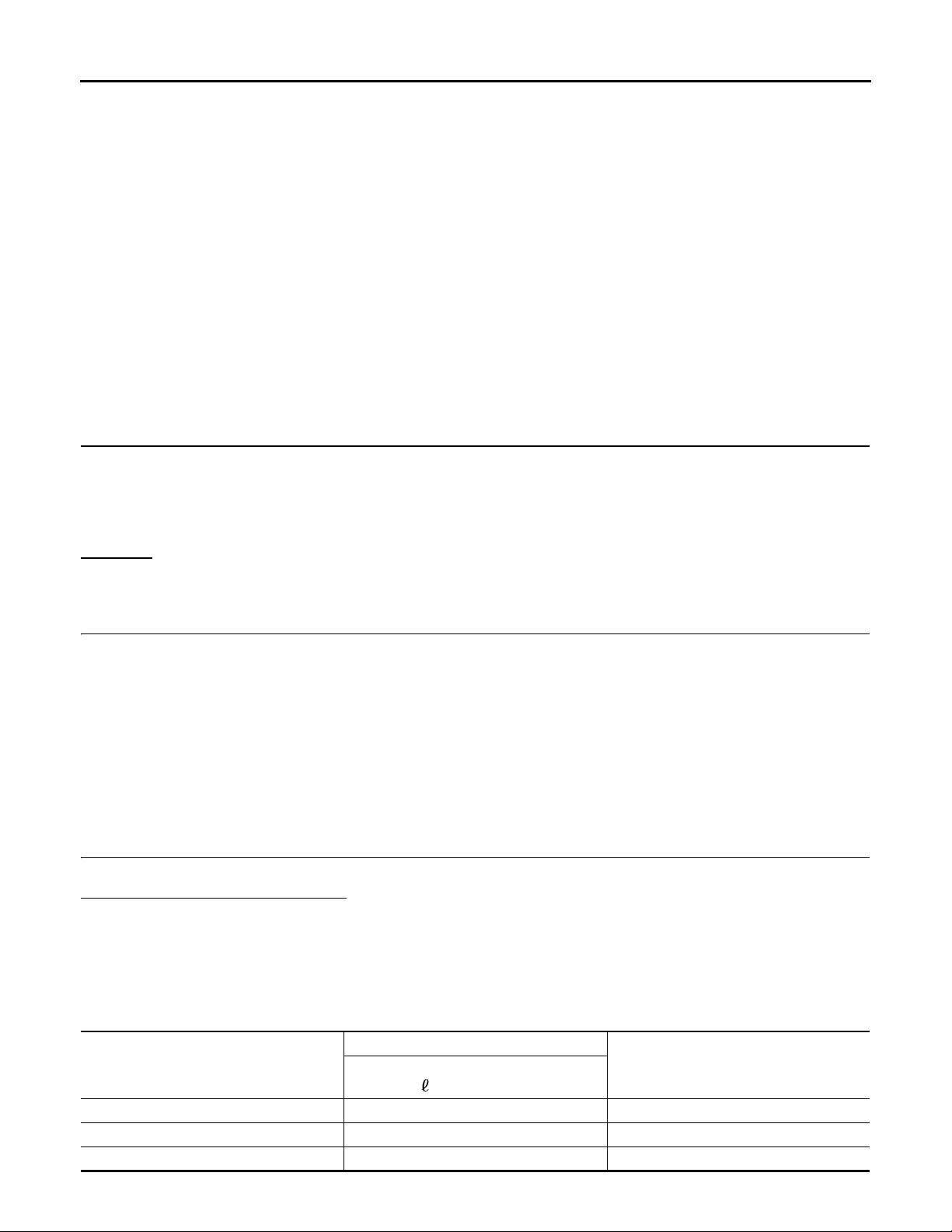

OIL ADJUSTING PROCEDURE FOR COMPRESSOR REPLACEMENT

Remarks

Small leak

A

B

*1

C

D

E

F

G

H

WJIA1716E

1. New compressor 2. Old compressor 3. Recovery/recycling equipment

4. Measuring cup X 5. Measuring cup Y 6. New oil

A. Drain oil from the new compressor

into clean container

D. Install new oil equal to recorded

amounts in measuring cups X plus Y

B. Record amount of oil recovered C.

Add an additional 5 m (0.2 US fl oz,

0.2 Imp fl oz) of new oil when replacing

liquid tank

1. Before connecting recovery/recycling equipment to vehicle, check recovery/recycling equipment gauges.

No refrigerant pressure should be displayed. If NG, recover refrigerant from equipment lines.

2. Discharge refrigerant into the refrigerant recovery/recycling equipment. Measure oil discharged into the

recovery/recycling equipment.

3. Drain the oil from the old (removed) compressor into a graduated container and recover the amount of oil

drained.

4. Drain the oil from the new compressor into a separate, clean container.

5. Measure an amount of new oil installed equal to amount drained from old compressor. Add this oil to new

compressor through the suction port opening.

6. Measure an amount of new oil equal to the amount recovered during discharging. Add this oil to new compressor through the suction port opening.

I

MTC

K

L

M

N

O

P

MTC-17

OIL

Revision: May 2007 2008 Versa

< SERVICE INFORMATION >

7. If the liquid tank also needs to be replaced, add another 5 m (0.2 US fl oz, 0.2 Imp fl oz.) of oil at this

time.

Add this 5 m (0.2 US fl oz, 0.2 Imp fl oz.) of oil only when replacing the compressor.

MTC-18

< SERVICE INFORMATION >

Revision: May 2007 2008 Versa

AIR CONDITIONER CONTROL

AIR CONDITIONER CONTROL

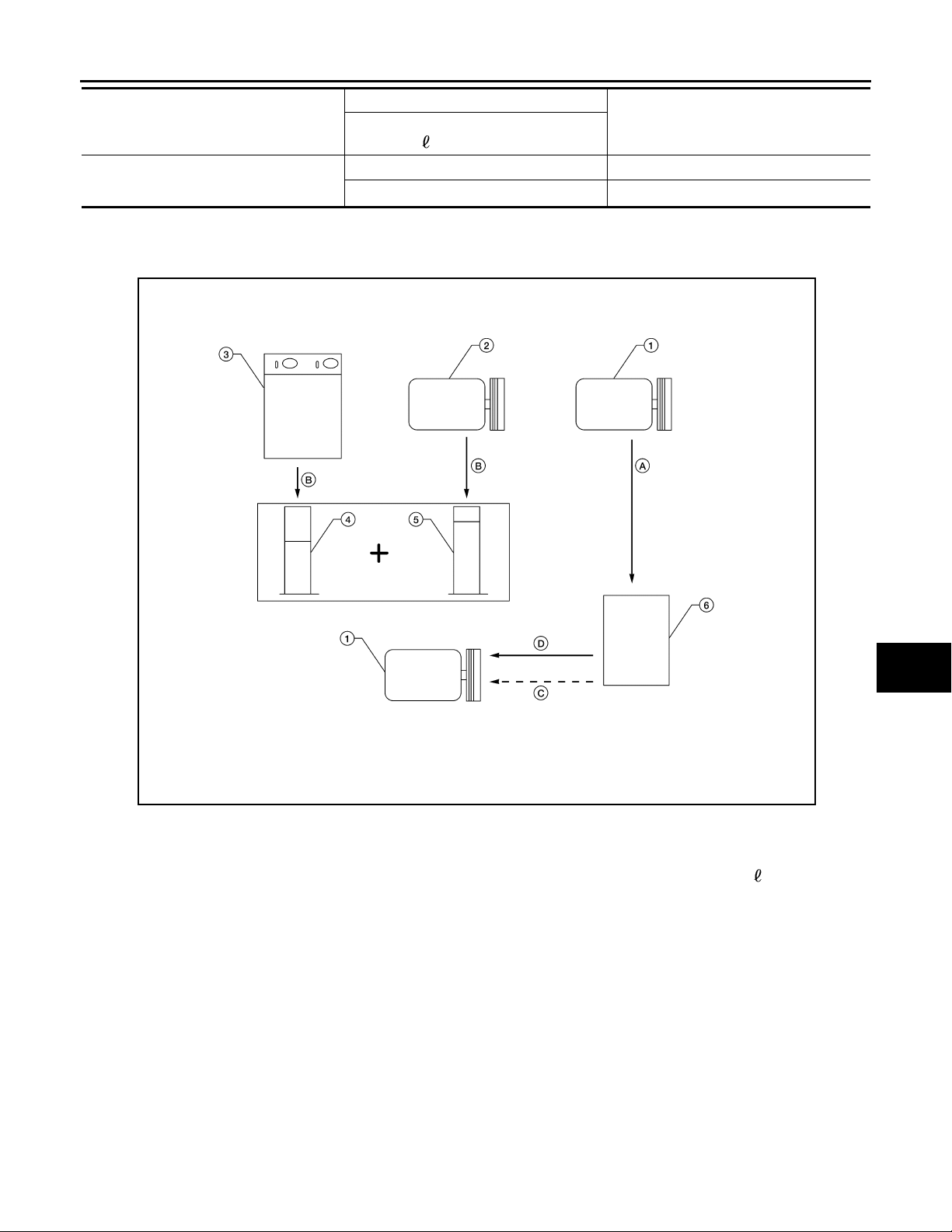

Control Operation

1. Intake door lever 2. Mode door control dial 3. Rear window defogger switch

4. Blower control dial 5. A/C switch (if equipped) 6. Temperature control dial

INFOID:0000000001704290

WJIA2189E

A

B

C

D

E

F

G

H

BLOWER CONTROL DIAL

This dial turns the fan ON and OFF, and controls fan speed.

TEMPERATURE CONTROL DIAL

This dial allows you to adjust the temperature of the discharge air.

MODE DOOR CONTROL DIAL

This dial controls the outlet air flow.

INTAKE DOOR LEVER

• Recirculation (REC) position: Interior air is recirculated inside the vehicle.

• Fresh (FRE) position: Outside air is drawn into the passenger compartment.

REAR WINDOW DEFOGGER SWITCH

When illumination is ON, rear window is defogged.

A/C SWITCH (IF EQUIPPED)

The A/C switch controls the air conditioner system. When the switch is depressed with the fan ON, the compressor will turn ON. The indicator lamp also illuminates.

I

MTC

K

L

M

N

O

MTC-19

P

< SERVICE INFORMATION >

Revision: May 2007 2008 Versa

AIR CONDITIONER CONTROL

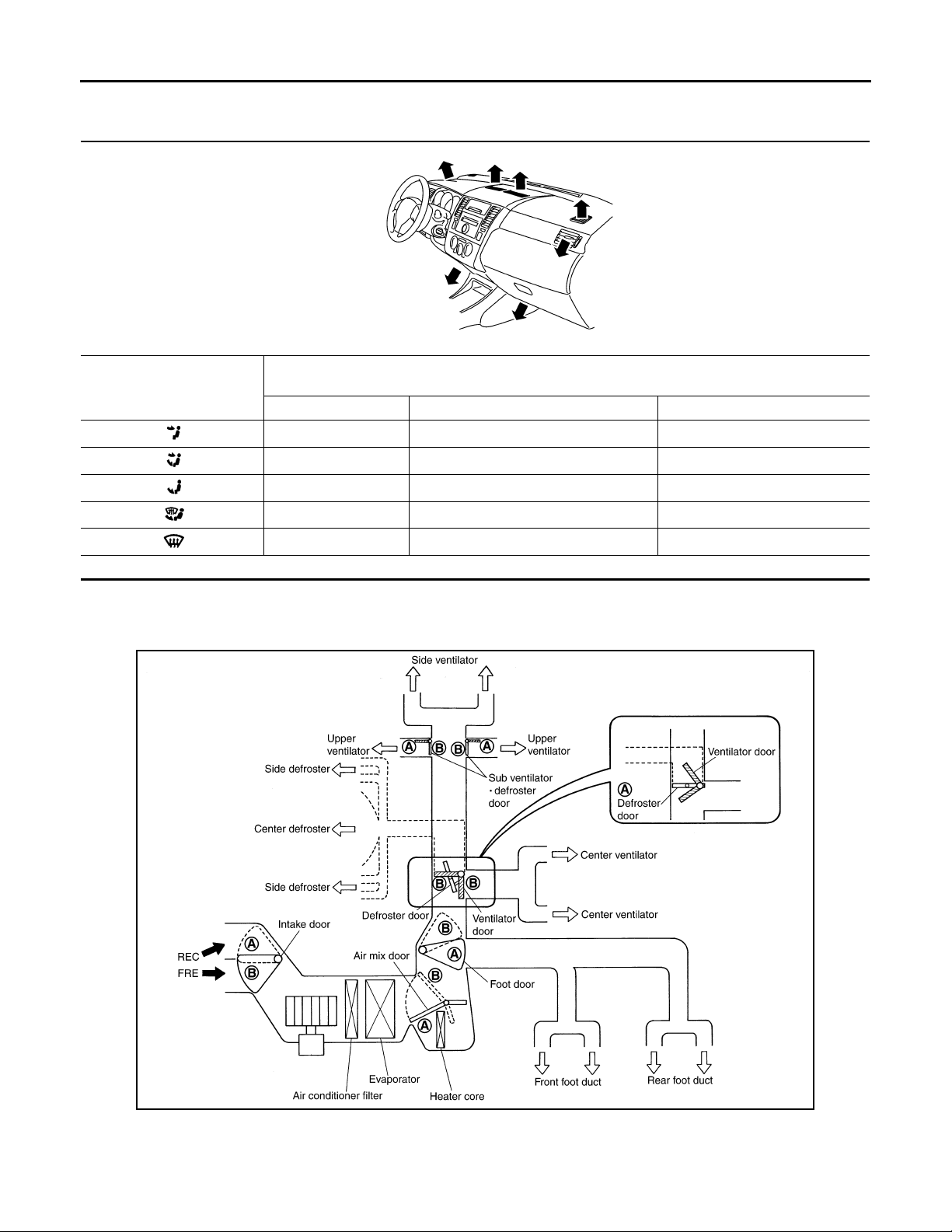

Discharge Air Flow

Mode door position

INFOID:0000000001704291

WJIA2190E

Air outlet/distribution

Vent Foot Defroster

100% — —

56% 44% —

16% 64% 20%

16% 53% 31%

17% — 83%

Airflow always present at driver and passenger side demisters

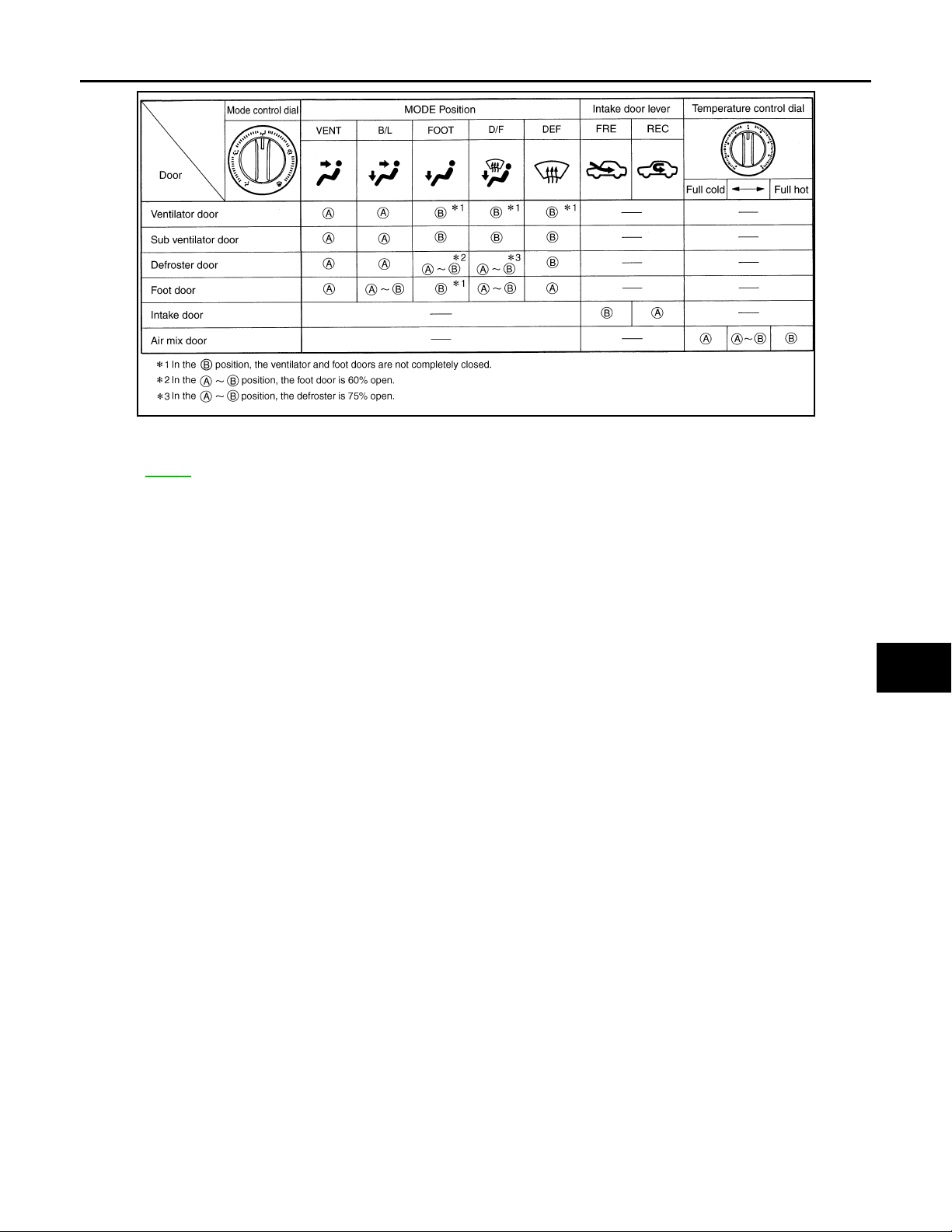

System Description

SWITCHES AND THEIR CONTROL FUNCTION

INFOID:0000000001704292

WJIA2249E

MTC-20

AIR CONDITIONER CONTROL

Revision: May 2007 2008 Versa

< SERVICE INFORMATION >

CAN Communication System Description

WJIA2234E

INFOID:0000000001704293

A

B

C

D

E

F

Refer to LAN-6.

G

H

I

MTC

K

L

M

N

MTC-21

O

P

< SERVICE INFORMATION >

Revision: May 2007 2008 Versa

TROUBLE DIAGNOSIS

TROUBLE DIAGNOSIS

CONSULT-III Function (BCM)

CONSULT-III can display each diagnostic item using the diagnostic test modes shown following.

BCM diagnostic

test item

Inspection by part

DATA MONITOR

Display Item List

Monitor item name

“operation or unit”

IGN ON SW “ON/OFF”

FAN ON SIG “ON/OFF”

AIR COND SW “ON/OFF”

Diagnostic mode Description

Supports inspections and adjustments. Commands are transmitted to the BCM for

WORK SUPPORT

DATA MONITOR Displays BCM input/output data in real time.

ACTIVE TEST Operation of electrical loads can be checked by sending drive signal to them.

SELF-DIAG RESULTS Displays BCM self-diagnosis results.

CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication can be read.

ECU PART NUMBER BCM part number can be read.

CONFIGURATION Performs BCM configuration read/write functions.

Displays “IGN Position (ON)/OFF, ACC Position (OFF)” status as judged from ignition switch signal

through the CAN communication.

Displays “FAN (ON)/FAN (OFF)” status as judged from blower fan motor switch signal through CAN

communication.

Displays “COMP (ON)/COMP (OFF)” status as judged from air conditioner switch signal through the

CAN communication.

setting the status suitable for required operation, input/output signals are received

from the BCM and received data is displayed.

Contents

INFOID:0000000001704294

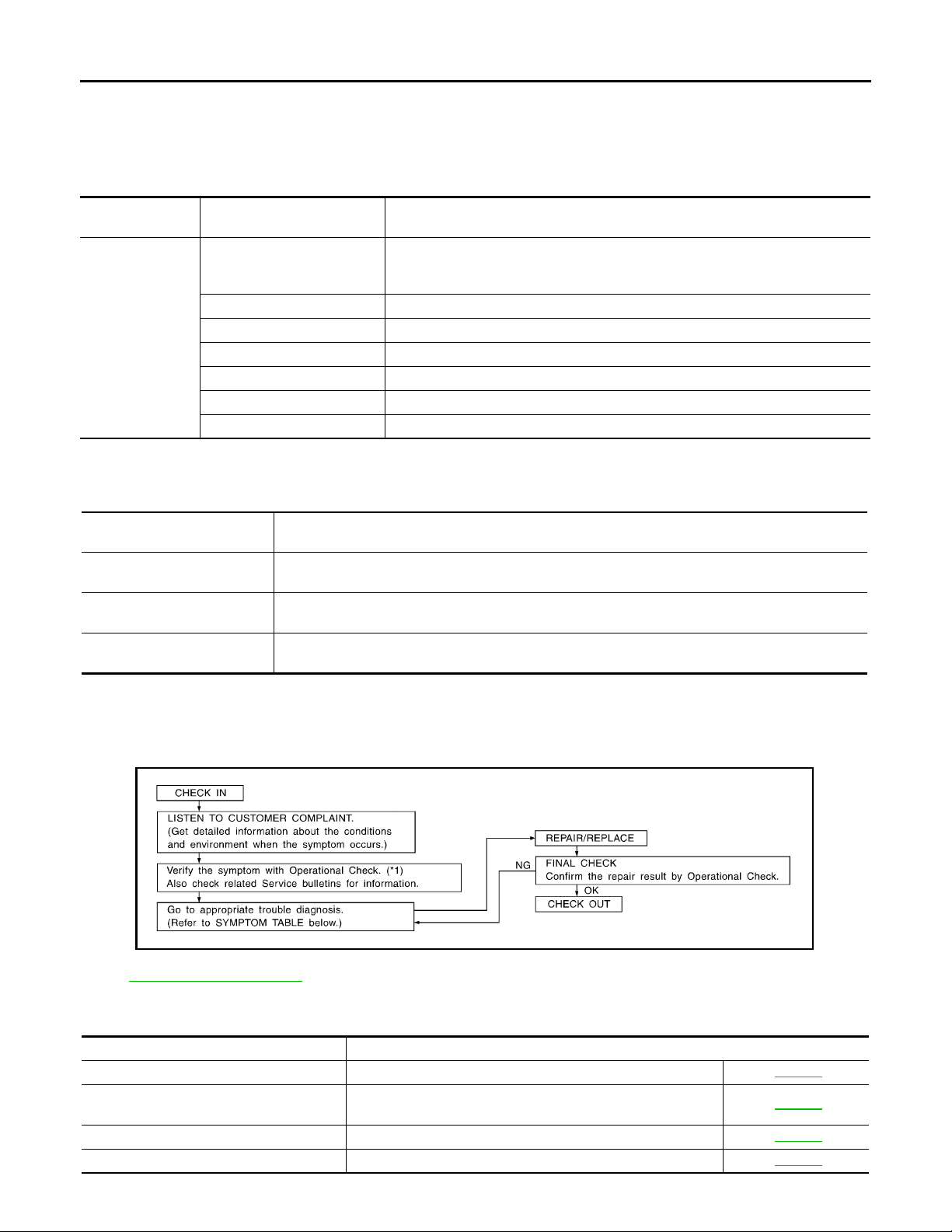

How to Perform Trouble Diagnosis for Quick and Accurate Repair

INFOID:0000000001704295

WORK FLOW

SHA900E

*1 MTC-30, "Operational Check"

SYMPTOM TABLE

Symptom Reference Page

Air outlet does not change. Go to Trouble Diagnosis Procedure for Mode Door. MTC-31

Discharge air temperature does not

change.

Intake door does not change. Go to Trouble Diagnosis Procedure for Intake Door. MTC-33

Blower motor operation is malfunctioning. Go to Trouble Diagnosis Procedure for Blower Motor. MTC-33

Go to Trouble Diagnosis Procedure for Air Mix Door. MTC-32

MTC-22

< SERVICE INFORMATION >

Revision: May 2007 2008 Versa

TROUBLE DIAGNOSIS

Symptom Reference Page

Magnet clutch does not engage in A/C, defrost/foot, or defrost mode.

Insufficient cooling Go to Trouble Diagnosis Procedure for Insufficient Cooling. MTC-45

Insufficient heating Go to Trouble Diagnosis Procedure for Insufficient Heating. MTC-52

Noise Go to Trouble Diagnosis Procedure for Noise. MTC-53

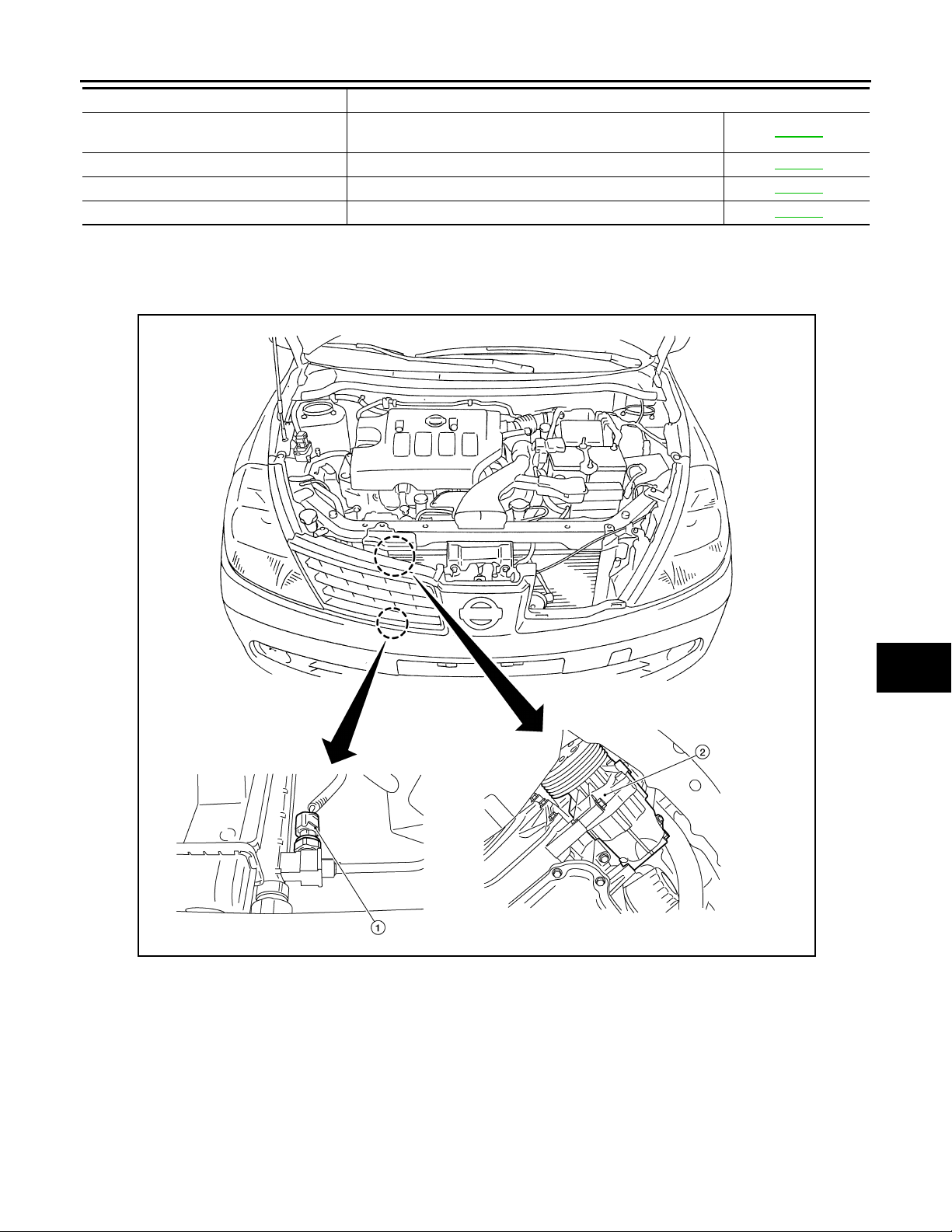

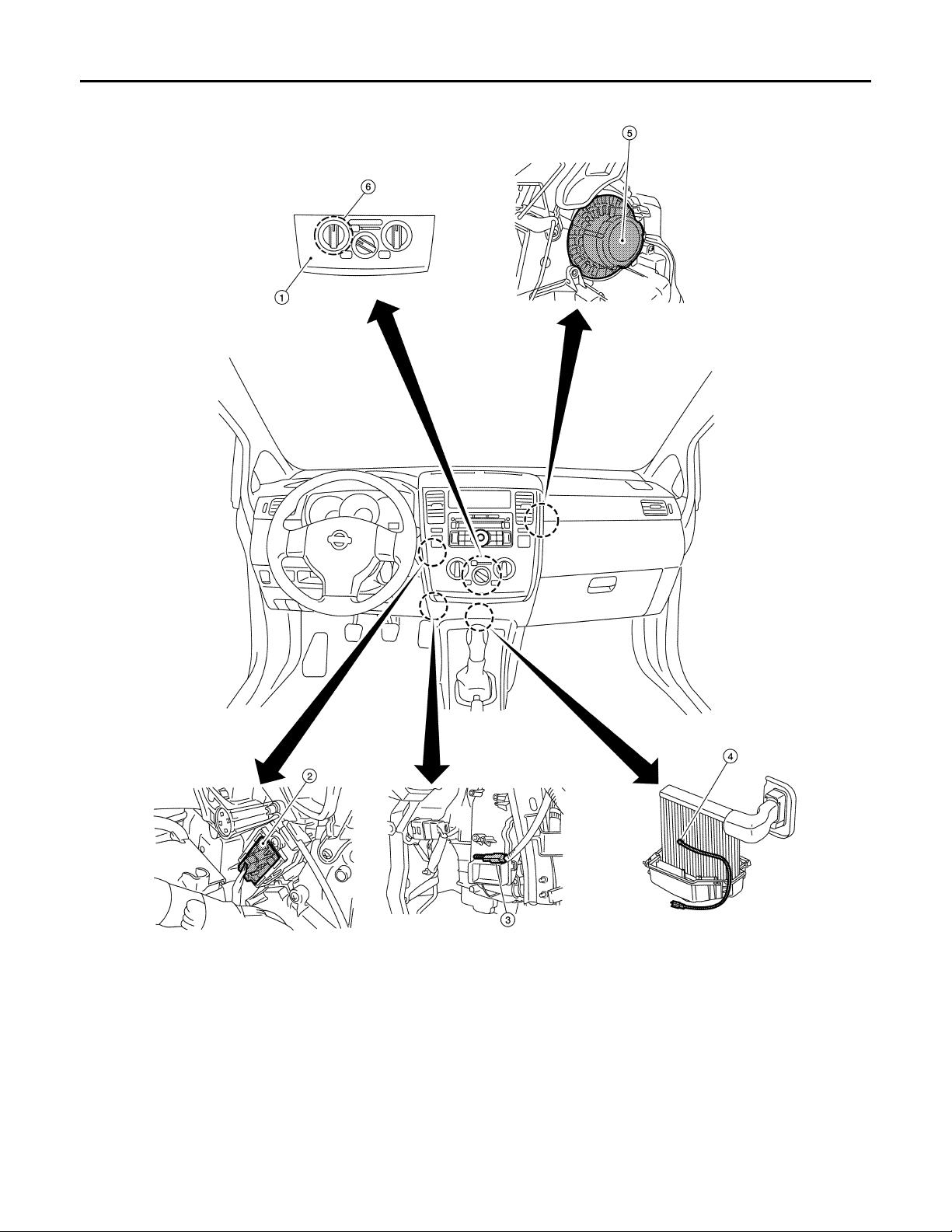

Component Parts and Harness Connector Location

Go to Trouble Diagnosis Procedure for Magnet Clutch. MTC-37

INFOID:0000000001704296

ENGINE COMPARTMENT

A

B

C

D

E

F

G

H

1. Refrigerant pressure sensor E17 2. A/C compressor F3

PASSENGER COMPARTMENT

I

MTC

K

L

M

N

WJIA2235E

O

P

MTC-23

< SERVICE INFORMATION >

Revision: May 2007 2008 Versa

TROUBLE DIAGNOSIS

WJIA2302E

1. Front air control M33 2. Front blower motor resistor M151 3. Thermo control amp. jumper connector (with CVT)

4. Thermo control amp. M42 (without CVT) 5. Front blower motor M62 6. Defrost A/C switch M41 (located on

back side of front air control)

MTC-24

< SERVICE INFORMATION >

Revision: May 2007 2008 Versa

TROUBLE DIAGNOSIS

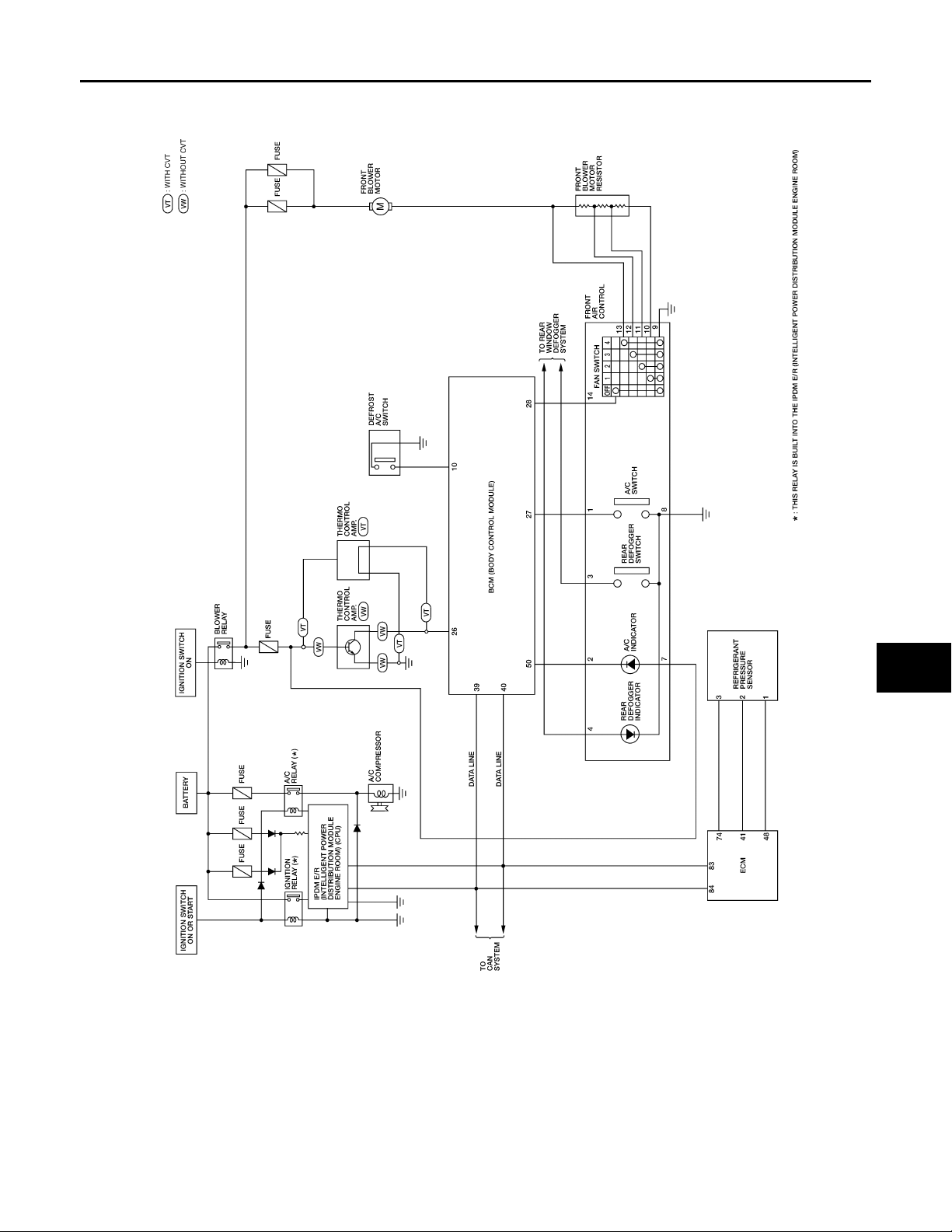

Schematic

INFOID:0000000001704297

A

B

C

D

E

F

G

H

WJWA0487E

I

MTC

K

L

M

N

O

P

MTC-25

< SERVICE INFORMATION >

Revision: May 2007 2008 Versa

TROUBLE DIAGNOSIS

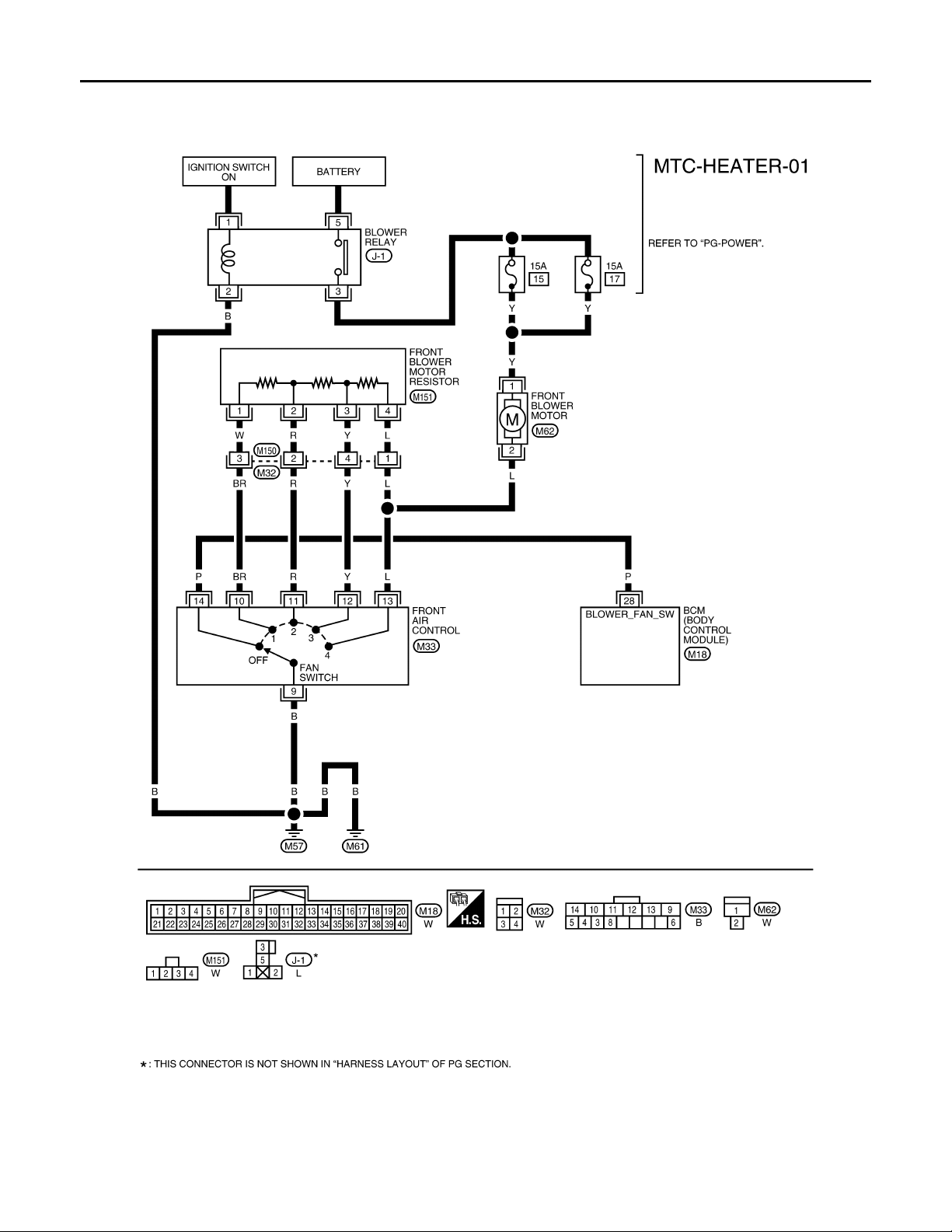

Wiring Diagram - Heater -

WITHOUT A/C

INFOID:0000000001704298

WJWA0485E

MTC-26

< SERVICE INFORMATION >

Revision: May 2007 2008 Versa

TROUBLE DIAGNOSIS

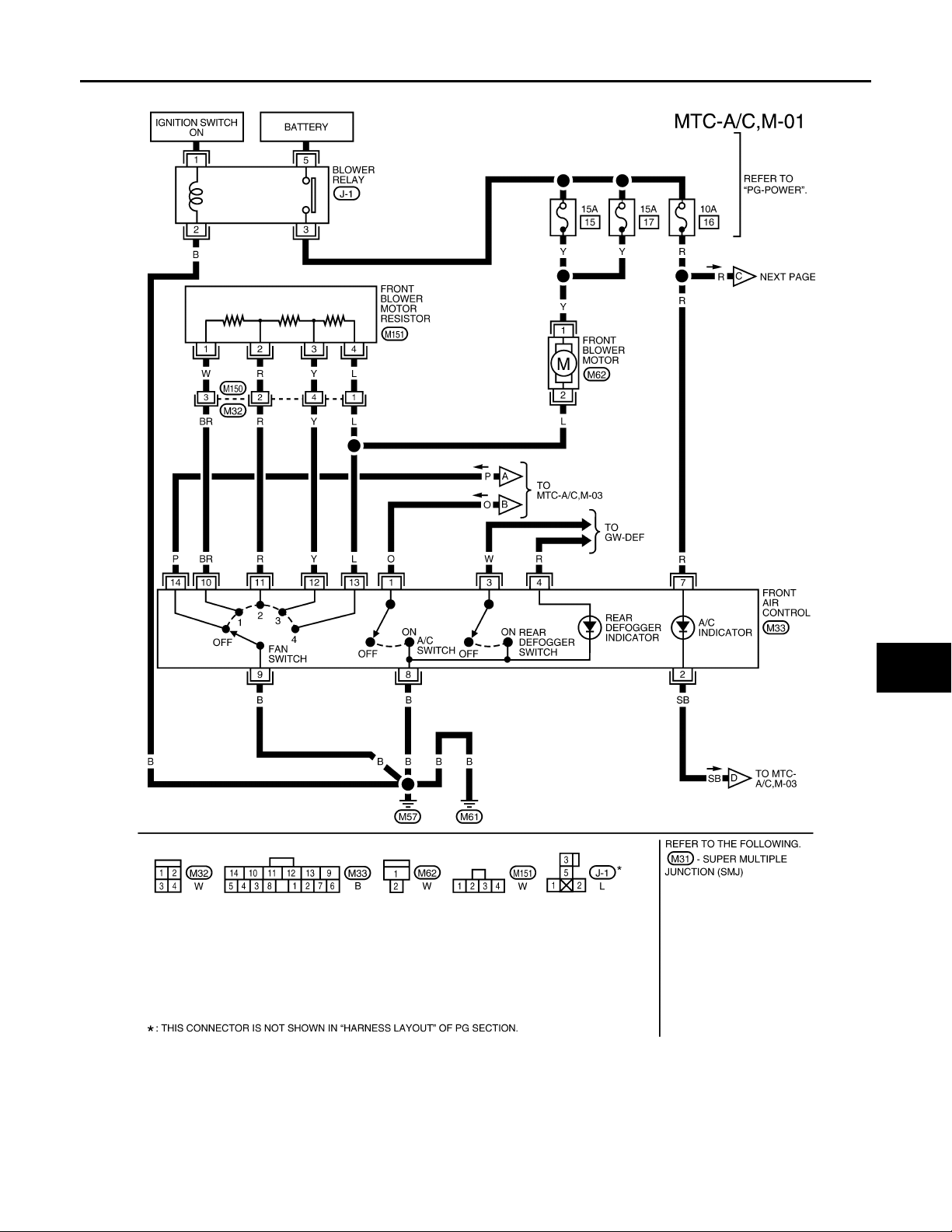

Wiring Diagram - A/C,M -

INFOID:0000000001704299

A

B

C

D

E

F

G

H

WJWA0484E

I

MTC

K

L

M

N

O

P

MTC-27

Loading...

Loading...