Nissan Pathfinder 2008 User Manual

TRANSMISSION & DRIVELINE

A

B

SECTION DLN

CONTENTS

TRANSFER: ATX14B

BASIC INSPECTION ....................................

DIAGNOSIS AND REPAIR WORKFLOW ..........8

Work Flow .................................................................8

Preliminary Check .....................................................9

FUNCTION DIAGNOSIS ..............................12

4WD SYSTEM ....................................................12

System Diagram ......................................................12

System Description .................................................13

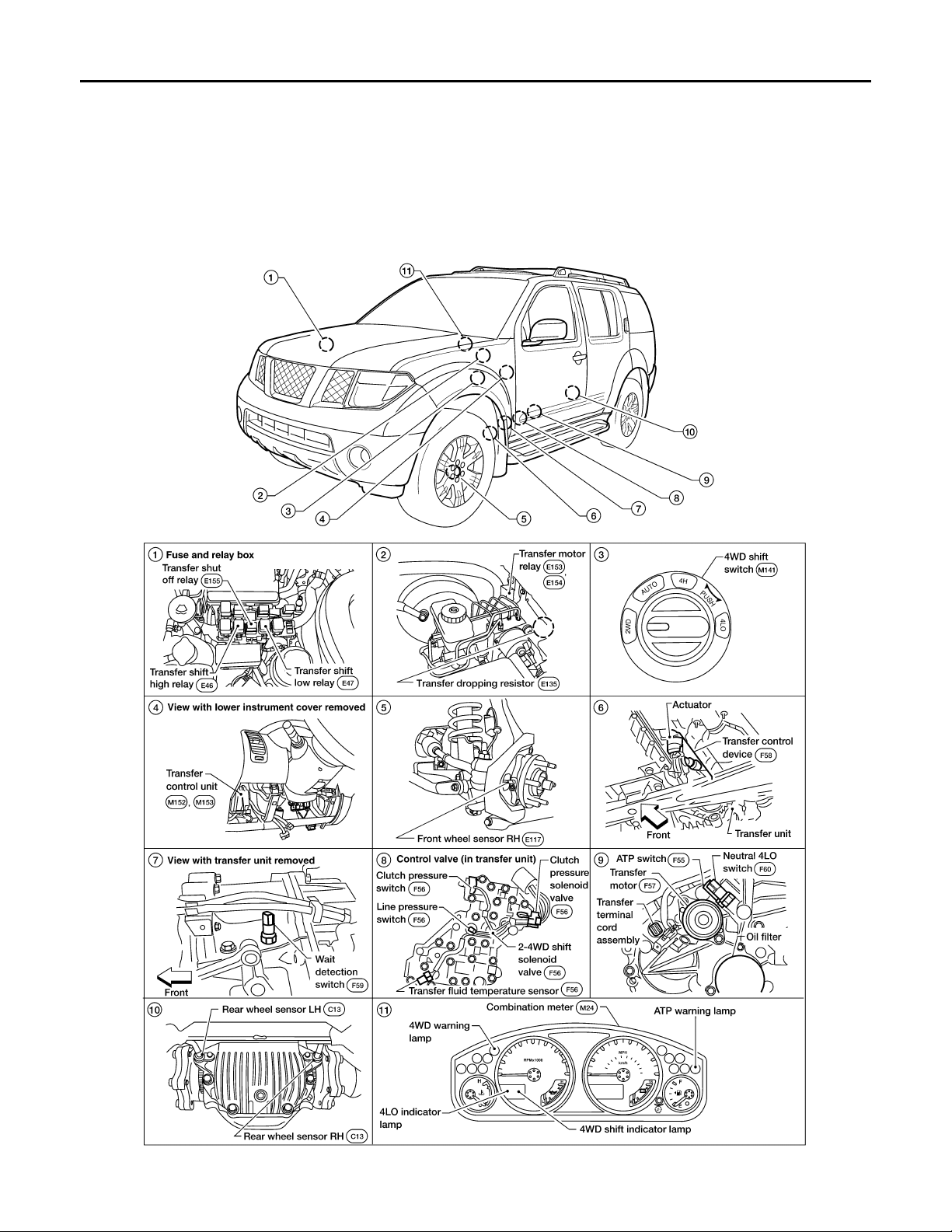

Component Parts Location . .....................................18

CAN Communication ...............................................19

DIAGNOSIS SYSTEM (TRANSFER CON-

TROL UNIT) ........................................................

CONSULT-III Function (ALL MODE AWD/4WD) ....20

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ............................

NVH Troubleshooting Chart ....................................24

COMPONENT DIAGNOSIS .........................25

P1811 POWER SUPPLY CIRCUIT FOR

TRANSFER CONTROL UNIT ............................

Description ..............................................................25

DTC Logic ...............................................................25

Diagnosis Procedure ........................... ... ... ... .... .......25

Component Inspection .... ... .... ... ..............................26

P1802 – P1804, P1809 TRANSFER CON-

TROL UNIT .........................................................

Description ..............................................................27

DTC Logic ...............................................................27

Diagnosis Procedure ........................... ... ... ... .... .......27

P1807 VEHICLE SPEED SENSOR (A/T) ..........29

Description ..............................................................29

DTC Logic ...............................................................29

20

24

25

27

DRIVELINE

Diagnosis Procedure ...............................................29

P1808 VEHICLE SPEED SENSOR (ABS) .......30

8

Description .......................... ... ....... ...... ....... ...... ........30

DTC Logic ................................................................30

Diagnosis Procedure ...............................................30

P1810 NEUTRAL-4LO SWITCH .......................31

Description .......................... ... ....... ...... ....... ...... ........31

DTC Logic ................................................................31

Diagnosis Procedure ...............................................31

Component Inspection .............................................33

P1813 4WD SHIFT SWITCH .............................34

Description .......................... ... ....... ...... ....... ...... ........34

DTC Logic ................................................................34

Diagnosis Procedure ...............................................34

Component Inspection .............................................36

P1814 WAIT DETECTION SWITCH .................38

Description .......................... ... ....... ...... ....... ...... ........38

DTC Logic ................................................................38

Diagnosis Procedure ...............................................38

Component Inspection .............................................40

P1816 PNP SWITCH .........................................41

Description .......................... ... ....... ...... ....... ...... ........41

DTC Logic ................................................................41

Diagnosis Procedure ...............................................41

P1817 ACTUATOR MOTOR .............................42

Description .......................... ... ....... ...... ....... ...... ........42

DTC Logic ................................................................42

Diagnosis Procedure ...............................................42

Component Inspection .............................................46

P1818 ACTUATOR POSITION SWITCH ..........48

Description .......................... ... ....... ...... ....... ...... ........48

DTC Logic ................................................................48

Diagnosis Procedure ...............................................48

Component Inspection .........................................

....

C

DLN

E

F

G

H

I

J

K

L

M

N

O

P

50

DLN-1

P1819 TRANSFER CONTROL DEVICE ...........51

Description ....................... .......................... ............. 51

DTC Logic ............................................................... 51

Diagnosis Procedure .............................................. 51

P1832 TCS OPERATION SIGNAL (ABS) ......... 82

Description ..............................................................82

DTC Logic .............. ... ..............................................82

Diagnosis Procedure ..... ... .......................................82

P1820 ENGINE SPEED SIGNAL ...................... 55

Description ....................... .......................... ............. 55

DTC Logic ............................................................... 55

Diagnosis Procedure .............................................. 55

P1822 CLUTCH PRESSURE SOLENOID .........56

Description ....................... .......................... ............. 56

DTC Logic ............................................................... 56

Diagnosis Procedure .............................................. 56

Component Inspection ............................................ 58

P1823 2-4 SOLENOID .......................................60

Description ....................... .......................... ............. 60

DTC Logic ............................................................... 60

Diagnosis Procedure .............................................. 60

Component Inspection ............................................ 63

P1824 TRANSFER MOTOR ..............................64

Description ....................... .......................... ............. 64

DTC Logic ............................................................... 64

Diagnosis Procedure .............................................. 64

Component Inspection ............................................ 68

P1826 TRANSFER FLUID TEMPERATURE .... 70

Description ....................... .......................... ............. 70

DTC Logic ............................................................... 70

Diagnosis Procedure .............................................. 70

Component Inspection ............................................ 71

P1827 CLUTCH PRESSURE SWITCH .............73

Description ....................... .......................... ............. 73

DTC Logic ............................................................... 73

Diagnosis Procedure .............................................. 73

Component Inspection ............................................ 74

P1828 LINE PRESSURE SWITCH .................... 76

Description ....................... .......................... ............. 76

DTC Logic ............................................................... 76

Diagnosis Procedure .............................................. 76

Component Inspection ............................................ 78

P1829 THROTTLE POSITION SIGNAL (ECM)

79

...

Description ....................... .......................... ............. 79

DTC Logic ............................................................... 79

Diagnosis Procedure .............................................. 79

P1830 ABS OPERATION SIGNAL (ABS) ........ 80

Description ....................... .......................... ............. 80

DTC Logic ............................................................... 80

Diagnosis Procedure .............................................. 80

P1831 VDC OPERATION SIGNAL (ABS) ........ 81

Description ....................... .......................... ............. 81

DTC Logic ............................................................... 81

Diagnosis Procedure .............................................. 81

ECU DIAGNOSIS ....................................... 83

TRANSFER CONTROL UNIT ........................... 83

Reference Value .....................................................83

Wiring Diagram .......................................................91

DTC Index ........................................... ... .... ... ........ 101

SYMPTOM DIAGNOSIS ...........................106

4WD SYSTEM SYMPTOMS .............................106

Symptom Table ..................................................... 106

4WD SHIFT INDICATOR LAMP AND 4LO IN-

DICATOR LAMP DO NOT TURN ON ..............

Description ............................................................ 107

Diagnosis Procedure ..... ... ..................................... 107

107

4WD WARNING LAMP DOES NOT TURN ON ..110

Description ............................................................ 110

Diagnosis Procedure ..... ... ..................................... 110

4WD SHIFT INDICATOR LAMP OR 4LO INDI-

CATOR LAMP DO NOT CHANGE ...................

Description ............................................................ 113

Diagnosis Procedure ..... ... ..................................... 113

113

ATP WARNING LAMP DOES NOT TURN ON ..115

Description ............................................................ 115

Diagnosis Procedure ..... ... ..................................... 115

4WD SHIFT INDICATOR LAMP KEEPS

FLASHING ........................................................

Description ............................................................ 117

Diagnosis Procedure ..... ... ..................................... 117

117

4WD WARNING LAMP FLASHES RAPIDLY ..118

Description ............................................................ 118

Diagnosis Procedure ..... ... ..................................... 118

4WD WARNING LAMP FLASHES SLOWLY ..119

Description ............................................................ 119

Diagnosis Procedure ..... ... ..................................... 119

HEAVY TIGHT-CORNER BRAKING SYMP-

TOM OCCURS ..................................................

Description ............................................................ 120

Diagnosis Procedure ..... ... ..................................... 120

120

ATP SWITCH ....................................................122

Description ............................................................ 122

Diagnosis Procedure ..... ... ..................................... 122

4WD SYSTEM DOES NOT OPERATE ............124

Description ............................................................ 124

Diagnosis Procedure ..... ... ..................................... 124

PRECAUTION ...........................................125

DLN-2

PRECAUTIONS ................................................125

Precaution for Supplemental Restrain t System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...............................................................

Precaution for Transfer Assembly and Transfer

Control Unit Replacement .....................................

Precaution .............................................................126

Service Notice .......................................................126

125

125

PREPARATION .........................................128

PREPARATION ................................................128

Special Service Tool ................................. ... .... .....128

Commercial Service Tool ......................................131

ON-VEHICLE MAINTENANCE ..................132

TRANSFER FLUID ...........................................132

Replacement .........................................................132

Inspection ..................... .........................................132

TRANSFER OIL FILTER ..................................133

Removal and Installation .......................................133

ON-VEHICLE REPAIR ...............................135

TRANSFER CONTROL UNIT ..........................135

Removal and Installation .......................................135

FRONT OIL SEAL ............................................136

Removal and Installation .......................................136

REAR OIL SEAL ..............................................138

Removal and Installation .......................................138

SIDE OIL SEAL ................................................140

Removal and Installation .......................................140

TRANSFER CONTROL DEVICE .....................141

Removal and Installation .......................................141

AIR BREATHER HOSE ....................................142

Removal and Installation .......................................142

TRANSFER MOTOR ........................................147

Removal and Installation .......................................147

Inspection and Adjustment ....................................186

TRANSFER: TX15B

BASIC INSPECTION .................................188

DIAGNOSIS AND REPAIR WORKFLOW ...... 188

Work Flow ..............................................................188

FUNCTION DIAGNOSIS ............................ 190

4WD SYSTEM ................................................. 190

System Diagram ....................................................190

System Description ................................................191

Component Parts Location ....................................193

CAN Communication .............................................194

Cross-Sectional View ............................................194

Power Transfer ......................................................195

DIAGNOSIS SYSTEM (TRANSFER CON-

TROL UNIT) ....................................................

CONSULT-III Function (ALL MODE AWD/4WD) ..197

197

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING .........................

NVH Troubleshooting Chart ..................................200

200

COMPONENT DIAGNOSIS .......................201

P1801, P1811 POWER SUPPLY CIRCUIT

FOR TRANSFER CONTROL UNIT ................

Description .......................... ... ....... ...... ....... ...... ......201

DTC Logic ..............................................................201

Diagnosis Procedure .............................................201

Component Inspection ...........................................203

P1802 – P1804, P1809 TRANSFER CON-

TROL UNIT ......................................................

Description .......................... ... ....... ...... ....... ...... ......204

DTC Logic ..............................................................204

Diagnosis Procedure .............................................204

P1807 VEHICLE SPEED SENSOR (A/T) .......206

Description .......................... ... ....... ...... ....... ...... ......206

DTC Logic ..............................................................206

Diagnosis Procedure .............................................206

201

204

A

B

C

DLN

E

F

G

H

I

J

K

L

M

REMOVAL AND INSTALLATION .............148

TRANSFER ASSEMBLY .................................148

Removal and Installation .......................................148

DISASSEMBLY AND ASSEMBLY ............149

TRANSFER ASSEMBLY .................................149

Disassembly and Assembly ...... ... .........................149

SERVICE DATA AND SPECIFICATIONS

(SDS) ..........................................................

SERVICE DATA AND SPECIFICATIONS

(SDS) ................................................................

General Specification ............................................186

186

186

DLN-3

P1808 VEHICLE SPEED SENSOR (ABS) .....207

Description .......................... ... ....... ...... ....... ...... ......207

DTC Logic ..............................................................207

Diagnosis Procedure .............................................207

P1810 4 LO SWITCH ......................................208

Description .......................... ... ....... ...... ....... ...... ......208

DTC Logic ..............................................................208

Diagnosis Procedure .............................................208

Component Inspection ...........................................210

P1813 4WD SHIFT SWITCH ...........................211

Description .......................... ... ....... ...... ....... ...... ......211

DTC Logic ..............................................................211

Diagnosis Procedure .............................................211

N

O

P

Component Inspection ...........................................213

Diagnosis Procedure ..... ... ..................................... 255

P1814 WAIT DETECTION SWITCH ................ 214

Description ....................... .......................... ............214

DTC Logic ..............................................................214

Diagnosis Procedure .............................................214

Component Inspection ...........................................216

P1816 PNP SWITCH ....................................... 217

Description ....................... .......................... ............217

DTC Logic ..............................................................217

Diagnosis Procedure .............................................217

P1817 ACTUATOR MOTOR ........................... 218

Description ....................... .......................... ............218

DTC Logic ..............................................................218

Diagnosis Procedure .............................................218

Component Inspection ...........................................223

P1818 ACTUATOR POSITION SWITCH ........ 225

Description ....................... .......................... ............225

DTC Logic ..............................................................225

Diagnosis Procedure .............................................225

P1819 TRANSFER CONTROL DEVICE ......... 228

Description ....................... .......................... ............228

DTC Logic ..............................................................228

Diagnosis Procedure .............................................228

4WD SHIFT INDICATOR LAMP KEEPS

FLASHING ........................................................

Description ............................................................ 257

Diagnosis Procedure ..... ... ..................................... 257

257

4WD WARNING LAMP FLASHES SLOWLY ..258

Description ............................................................ 258

Diagnosis Procedure ..... ... ..................................... 258

ATP SWITCH ....................................................259

Description ............................................................ 259

Diagnosis Procedure ..... ... ..................................... 259

Component Inspection .......................................... 260

PRECAUTION ...........................................262

PRECAUTIONS ................................................262

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................. ..................................

Precaution for Transfer Assembly and Transfer

Control Unit Replacement .....................................

Precaution ........................ ..................................... 264

Service Notice ..................................... ... .... ... ... ... .. 264

262

262

PREPARATION .........................................266

P1820 ENGINE SPEED SIGNAL .................... 231

Description ....................... .......................... ............231

DTC Logic ..............................................................231

Diagnosis Procedure .............................................231

ECU DIAGNOSIS .......................................232

TRANSFER CONTROL UNIT .......................... 232

Reference Value ..................... ... ... ... ......................232

Wiring Diagram ......................................................237

DTC Index .............................................................245

SYMPTOM DIAGNOSIS ............................248

4WD SYSTEM SYMPTOMS ............................ 248

Symptom Table .................. .... ... ............................248

4WD WARNING LAMP DOES NOT TURN ON . 249

Description ....................... .......................... ............249

Diagnosis Procedure .............................................249

4WD SHIFT INDICATOR LAMP AND 4LO IN-

DICATOR LAMP DO NOT TURN ON .............

Description ....................... .......................... ............251

Diagnosis Procedure .............................................251

4WD SHIFT INDICATOR LAMP OR 4LO INDI-

CATOR LAMP DO NOT CHANGE ..................

Description ....................... .......................... ............253

Diagnosis Procedure .............................................253

ATP WARNING LAMP DOES NOT TURN ON . 255

Description ....................... .......................... ............255

251

253

PREPARATION ................................................266

Special Service Tool ..................... ... ... ... .... ... ... ..... 266

Commercial Service Tool ........................... ... ... ..... 268

ON-VEHICLE MAINTENANCE ................. 269

TRANSFER FLUID ...........................................269

Replacement .................... ..................................... 269

Inspection ......................... ................ ................ ..... 269

ON-VEHICLE REPAIR ..............................270

TRANSFER CONTROL UNIT ..........................270

Removal and Installation ....................................... 270

FRONT OIL SEAL ............................................271

Removal and Installation ....................................... 271

REAR OIL SEAL ..............................................273

Removal and Installation ....................................... 273

TRANSFER CONTROL DEVICE .....................275

Removal and Installation ....................................... 275

AIR BREATHER HOSE ....................................277

Removal and Installation ....................................... 277

PLANETARY CARRIER ...................................279

Disassembly and Assembly .................................. 279

FRONT DRIVE SHAFT .....................................283

Disassembly and Assembly .................................. 283

SHIFT CONTROL .............................................285

DLN-4

Disassembly and Assembly ...... ... .........................

285

REMOVAL AND INSTALLATION .............287

TRANSFER ASSEMBLY .................................287

Removal and Installation .......................................287

DISASSEMBLY AND ASSEMBLY ............288

TRANSFER ASSEMBLY .................................288

Disassembly and Assembly ...... ... .........................288

SERVICE DATA AND SPECIFICATIONS

(SDS) ..........................................................304

SERVICE DATA AND SPECIFICATIONS

(SDS) ................................................................

General Specification ............................................304

Inspection and Adjustment ........................ ............304

304

PROPELLER SHAFT: 2F1310

PREPARATION .........................................305

PREPARATION ................................................305

Commercial Service Tool ......................................305

FUNCTION DIAGNOSIS ............................ 306

NOISE, VIBRATION, AND HARSHNESS

(NVH) TROUBLESHOOTING .........................

NVH Troubleshooting Chart ..................................314

314

ON-VEHICLE REPAIR ............................... 315

PROPELLER SHAFT ......................................315

On-Vehicle Service .......................................... ... ...315

REMOVAL AND INSTALLATION .............316

PROPELLER SHAFT ......................................316

Removal and Installation .......................................316

DISASSEMBLY AND ASSEMBLY ............ 318

PROPELLER SHAFT ......................................318

Disassembly and Assembly ...................................318

SERVICE DATA AND SPECIFICATIONS

(SDS) ..........................................................320

SERVICE DATA AND SPECIFICATIONS

(SDS) ...............................................................

General Specification ............................................320

Snap Ring . .... .........................................................321

320

PROPELLER SHAFT: 2S1350

A

B

C

DLN

E

F

G

H

NOISE, VIBRATION, AND HARSHNESS

(NVH) TROUBLESHOOTING ..........................

NVH Troubleshooting Chart ..................................306

306

ON-VEHICLE REPAIR ...............................307

PROPELLER SHAFT .......................................307

On-Vehicle Service ...............................................307

REMOVAL AND INSTALLATION .............308

PROPELLER SHAFT .......................................308

Removal and Installation .......................................308

DISASSEMBLY AND ASSEMBLY ............310

PROPELLER SHAFT .......................................310

Disassembly and Assembly ...... ... .........................310

SERVICE DATA AND SPECIFICATIONS

(SDS) ..........................................................

SERVICE DATA AND SPECIFICATIONS

(SDS) ................................................................

General Specification ............................................312

Snap Ring .............................................................312

312

312

PROPELLER SHAFT: 2S1330

PREPARATION .........................................313

PREPARATION ................................................313

Commercial Service Tool ......................................313

FUNCTION DIAGNOSIS ............................ 314

PREPARATION .........................................322

PREPARATION ...............................................322

Commercial Service Tool ......................................322

FUNCTION DIAGNOSIS ............................ 323

NOISE, VIBRATION, AND HARSHNESS

(NVH) TROUBLESHOOTING .........................

NVH Troubleshooting Chart ..................................323

323

ON-VEHICLE REPAIR ............................... 324

PROPELLER SHAFT ......................................324

On-Vehicle Service .......................................... ... ...324

REMOVAL AND INSTALLATION .............325

PROPELLER SHAFT ......................................325

Removal and Installation .......................................325

DISASSEMBLY AND ASSEMBLY ............ 327

PROPELLER SHAFT ......................................327

Disassembly and Assembly ...................................327

SERVICE DATA AND SPECIFICATIONS

(SDS) ..........................................................329

SERVICE DATA AND SPECIFICATIONS

(SDS) ...............................................................

General Specification ............................................329

Snap Ring . .... .........................................................330

329

FRONT FINAL DRIVE: R180A

I

J

K

L

M

N

O

P

DLN-5

PRECAUTION ............................................331

PRECAUTIONS ............................................... 331

Precaution for Servicing Front Final Drive .............331

PREPARATION ..........................................332

PREPARATION ............................................... 332

Special Service Tool ..............................................332

Commercial Service Tool ................ .... ..................334

FUNCTION DIAGNOSIS ............................336

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ..........................

NVH Troubleshooting Chart ............ .... ..................336

336

DESCRIPTION ................................................. 337

Cross-Sectional View ............................................337

ON-VEHICLE MAINTENANCE ..................338

DIFFERENTIAL GEAR OIL ............................. 338

Changing Differential Gear Oil ...............................338

Checking Differential Gear Oil ...............................338

ON-VEHICLE REPAIR ...............................339

FRONT OIL SEAL ........................................... 339

Removal and Installation .......................................339

SIDE OIL SEAL ............................................... 341

Removal and Installation .......................................341

PREPARATION ................................................367

Special Service Tool ..................... ... ... ... .... ... ... ..... 367

Commercial Service Tool ........................... ... ... ..... 369

FUNCTION DIAGNOSIS ...........................370

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ...........................

NVH Troubleshooting Chart .................................. 370

370

ON-VEHICLE MAINTENANCE ................. 371

DIFFERENTIAL GEAR OIL ..............................371

Changing Differential Gear Oil .............................. 371

Checking Differential Gear Oil ............................ .. 371

ON-VEHICLE REPAIR ..............................372

SIDE OIL SEAL ................................................372

Removal and Installation ....................................... 372

FRONT OIL SEAL ............................................373

Removal and Installation ....................................... 373

CARRIER COVER ............................................375

Removal and Installation ....................................... 375

REMOVAL AND INSTALLATION ............. 376

FRONT FINAL DRIVE ......................................376

Removal and Installation ....................................... 376

DISASSEMBLY AND ASSEMBLY ........... 378

CARRIER COVER ........................................... 342

Removal and Installation .......................................342

REMOVAL AND INSTALLATION ..............343

FRONT FINAL DRIVE ASSEMBLY ................ 343

Removal and Installation .......................................343

DISASSEMBLY AND ASSEMBLY ............345

FRONT FINAL DRIVE ..................................... 345

Disassembly and Assembly ................................... 345

SERVICE DATA AND SPECIFICATIONS

(SDS) ..........................................................364

SERVICE DATA AND SPECIFICATIONS

(SDS) ................................................................

General Specification ................ ... ... .... ..................364

Inspection and Adjustment ....................................364

364

FRONT FINAL DRIVE: M205

PRECAUTION ............................................

PRECAUTIONS ............................................... 366

Precaution for Servicing Front Final Drive .............366

366

PREPARATION ..........................................367

FRONT FINAL DRIVE ......................................378

Disassembly and Assembly .................................. 378

SERVICE DATA AND SPECIFICATIONS

(SDS) .........................................................395

SERVICE DATA AND SPECIFICATIONS

(SDS) ................................................................

General Specification ............................................395

Inspection and Adjustment .................................... 395

395

REAR FINAL DRIVE: R200

PRECAUTION ...........................................

PRECAUTIONS ................................................397

Precaution for Servicing Rear Final Drive ............. 397

397

PREPARATION .........................................398

PREPARATION ................................................398

Special Service Tool ..................... ... ... ... .... ... ... ..... 398

Commercial Service Tool ........................... ... ... ..... 401

FUNCTION DIAGNOSIS ...........................402

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ...........................

NVH Troubleshooting Chart .................................. 402

402

DLN-6

DESCRIPTION .................................................403

Cross-Sectional View ............................................403

Special Service Tool ..............................................435

Commercial Service Tool ......................................438

A

ON-VEHICLE MAINTENANCE ..................404

DIFFERENTIAL GEAR OIL ..............................404

Changing Differential Gear Oil ..............................404

Checking Differential Gear Oil ...............................404

ON-VEHICLE REPAIR ...............................405

FRONT OIL SEAL ............................................405

Removal and Installation .......................................405

SIDE OIL SEAL ................................................407

Removal and Installation .......................................407

CARRIER COVER ............................................409

Removal and Installation .......................................409

REMOVAL AND INSTALLATION .............410

REAR FINAL DRIVE ........................................410

Removal and Installation .......................................410

DISASSEMBLY AND ASSEMBLY ............413

REAR FINAL DRIVE ........................................413

Disassembly and Assembly ...... ... .........................413

SERVICE DATA AND SPECIFICATIONS

(SDS) ..........................................................432

SERVICE DATA AND SPECIFICATIONS

(SDS) ................................................................

General Specification ............................................432

Inspection and Adjustment ........................ ............432

432

REAR FINAL DRIVE: R230 (4WD)

PRECAUTION ............................................434

PRECAUTIONS ................................................434

Precaution for Servicing Rear Final Drive .............434

PREPARATION .........................................435

PREPARATION ................................................435

FUNCTION DIAGNOSIS ............................ 439

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING .........................

NVH Troubleshooting Chart ..................................439

439

DESCRIPTION ................................................ 440

Cross-Sectional View ............................................440

ON-VEHICLE MAINTENANCE .................. 441

DIFFERENTIAL GEAR OIL ............................441

Changing Differential Gear Oil ...............................441

Checking Differential Gear Oil ...............................441

ON-VEHICLE REPAIR ............................... 442

FRONT OIL SEAL ...........................................442

Removal and Installation .......................................442

SIDE OIL SEAL ...............................................444

Removal and Installation .......................................444

CARRIER COVER ........................................... 446

Removal and Installation .......................................446

REMOVAL AND INSTALLATION .............447

REAR FINAL DRIVE ....................................... 447

Removal and Installation .......................................447

DISASSEMBLY AND ASSEMBLY ............ 450

REAR FINAL DRIVE ....................................... 450

Disassembly and Assembly ...................................450

SERVICE DATA AND SPECIFICATIONS

(SDS) ..........................................................

SERVICE DATA AND SPECIFICATIONS

(SDS) ...............................................................

General Specification ............................................466

Inspection and Adjustment ....................................466

466

466

B

C

DLN

E

F

G

H

I

J

K

L

M

N

DLN-7

O

P

DIAGNOSIS AND REPAIR WORKFLOW

B

< BASIC INSPECTION >

[TRANSFER: ATX14B]

BASIC INSPECTION

DIAGNOSIS AND REPAIR WORKFLOW

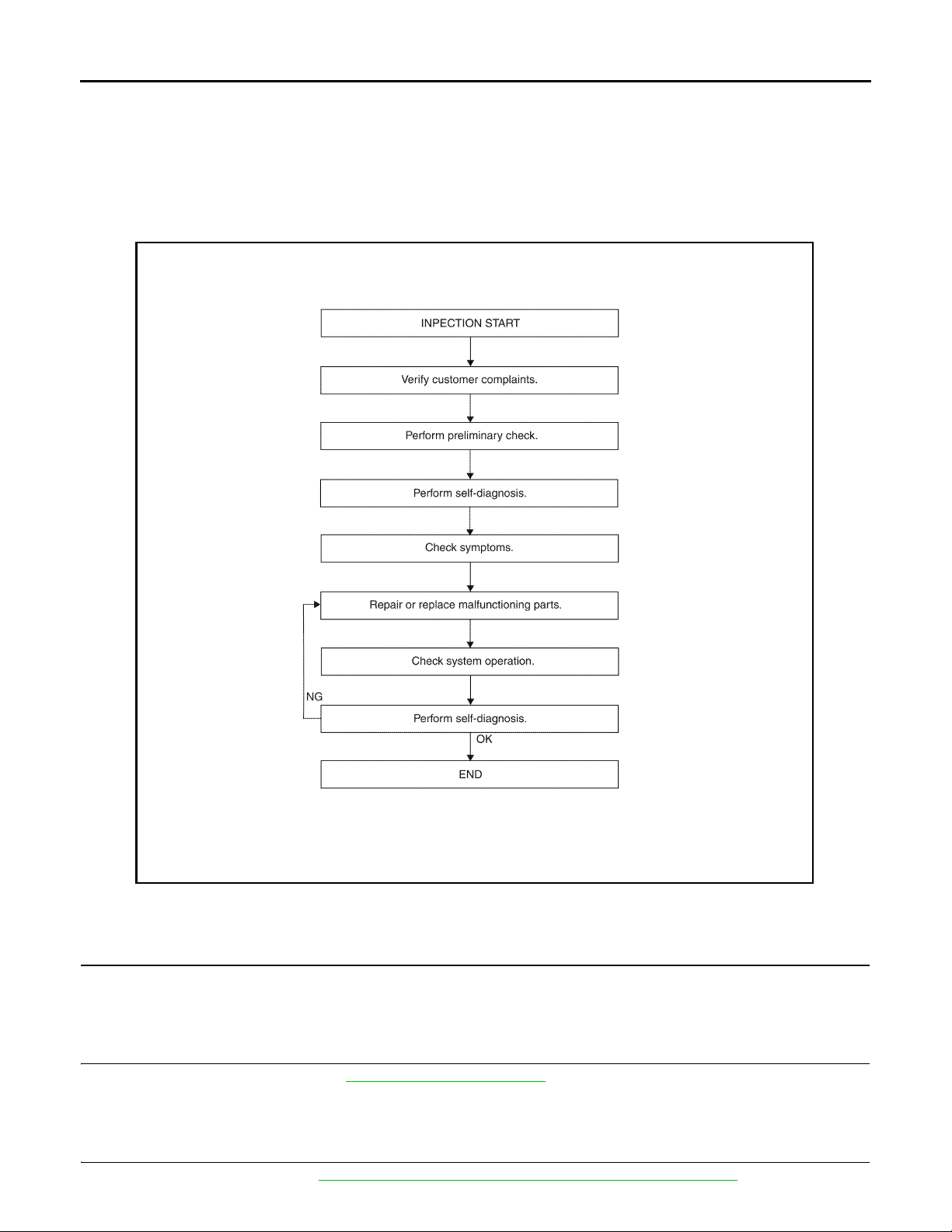

Work Flow INFOID:0000000001728331

WORK FLOW

DETAILED FLOW

1.CUSTOMER INFORMATION

Interview the customer to obtain detailed information about the symptom.

>> GO TO 2

2.PRELIMINARY CHECK

Perform preliminary check. Refer to DLN-9, "

>> GO TO 3

Preliminary Check".

3.SELF-DIAGNOSIS

Perform self-diagnosis. Refer to DLN-20, "

CONSULT-III Function (ALL MODE AWD/4WD)".

DLN-8

AWNIA0126G

< BASIC INSPECTION >

DIAGNOSIS AND REPAIR WORKFLOW

[TRANSFER: ATX14B]

>> GO TO 4

4.SYMPTOM

Check for symptoms. Refer to DLN-106, "

>> GO TO 5

Symptom Table".

5.MALFUNCTIONING PARTS

Repair or replace the applicable parts.

>> GO TO 6

6.SYSTEM OPERATION

Check system operation.

>> GO TO 7

7.SELF-DIAGNOSIS

Perform self-diagnosis.

Are any DTC's displayed?

YES >> GO TO 5

NO >> Inspection End

Preliminary Check INFOID:0000000001728332

A

B

C

DLN

E

F

G

H

TRANSFER FLUID CHECK

Check for leaks and fluid level. Refer to DLN-132, "Inspection".

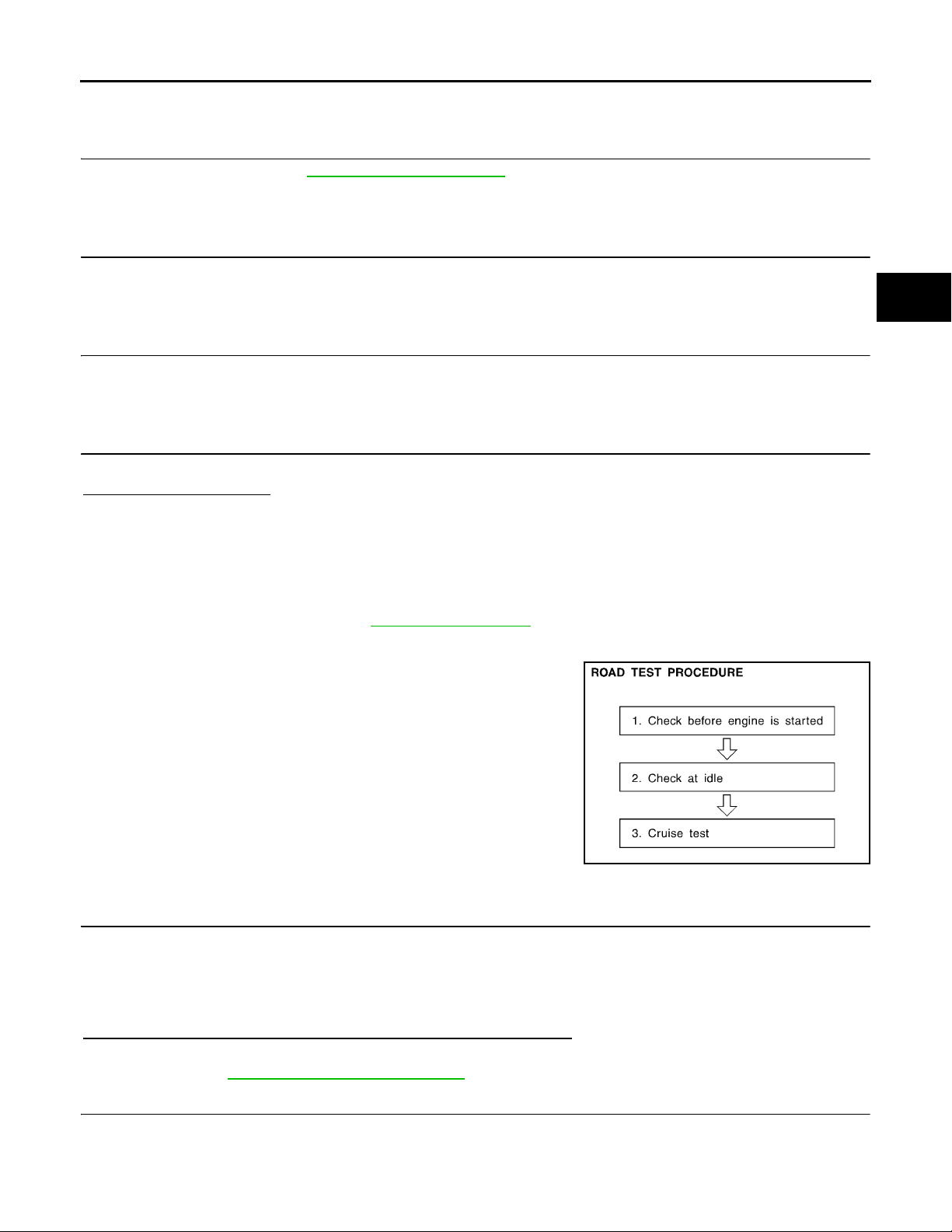

PREPARATION FOR ROAD TEST

The purpose of the test is to determine overall performance of transfer case and analyze causes of malfunctions.

When a malfunction is found in any part of transfer, perform the road

test to locate the malfunction area and repair the malfunction parts.

The road test consists of the following three parts.

1. CHECK BEFORE ENGINE IS STARTED

2. CHECK AT IDLE

3. CRUISE TEST

CHECK BEFORE ENGINE IS STARTED

1.CHECK 4WD SHIFT INDICATOR LAMP

1. Park vehicle on flat surface.

2. Turn ignition switch to OFF position.

3. Move A/T selector lever to P position.

4. Set 4WD shift switch to 2WD position.

5. Turn ignition switch to ON position. (Do not start engine.)

Does 4WD shift indicator lamp turn ON for approximately 1 second?

YES >> GO TO 2.

NO >> GO TO DLN-107, "

Diagnosis Procedure".

2.CHECK 4WD WARNING LAMP

SMT089D

I

J

K

L

M

N

O

P

1. Turn ignition switch to OFF position.

2. Move A/T selector lever to P position.

3. Set 4WD shift switch to 2WD position.

4. Turn ignition switch to ON position. (Do not start engine.)

DLN-9

DIAGNOSIS AND REPAIR WORKFLOW

< BASIC INSPECTION >

Does 4WD warning lamp turn ON?

YES >> GO TO CHECK AT IDLE.

NO >> GO TO DLN-110, "

Diagnosis Procedure".

CHECK AT IDLE

[TRANSFER: ATX14B]

1.CHECK 4WD SHIFT INDICATOR LAMP

1. Park vehicle on flat surface and engage the parking brake.

2. Turn ignition switch to OFF position.

3. Move A/T selector lever to P position.

4. Set 4WD shift switch to 2WD position.

5. Start engine.

Does 4WD shift indicator lamp turn ON?

YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK 4WD WARNING LAMP

Check 4WD warning lamp state.

Is 4WD warning lamp turned ON?

YES >> Perform the self-diagnosis. Refer to DLN-20, "CONSULT-III Function (ALL MODE AWD/4WD)".

NO >> Refer to DLN-113, "

Diagnosis Procedure".

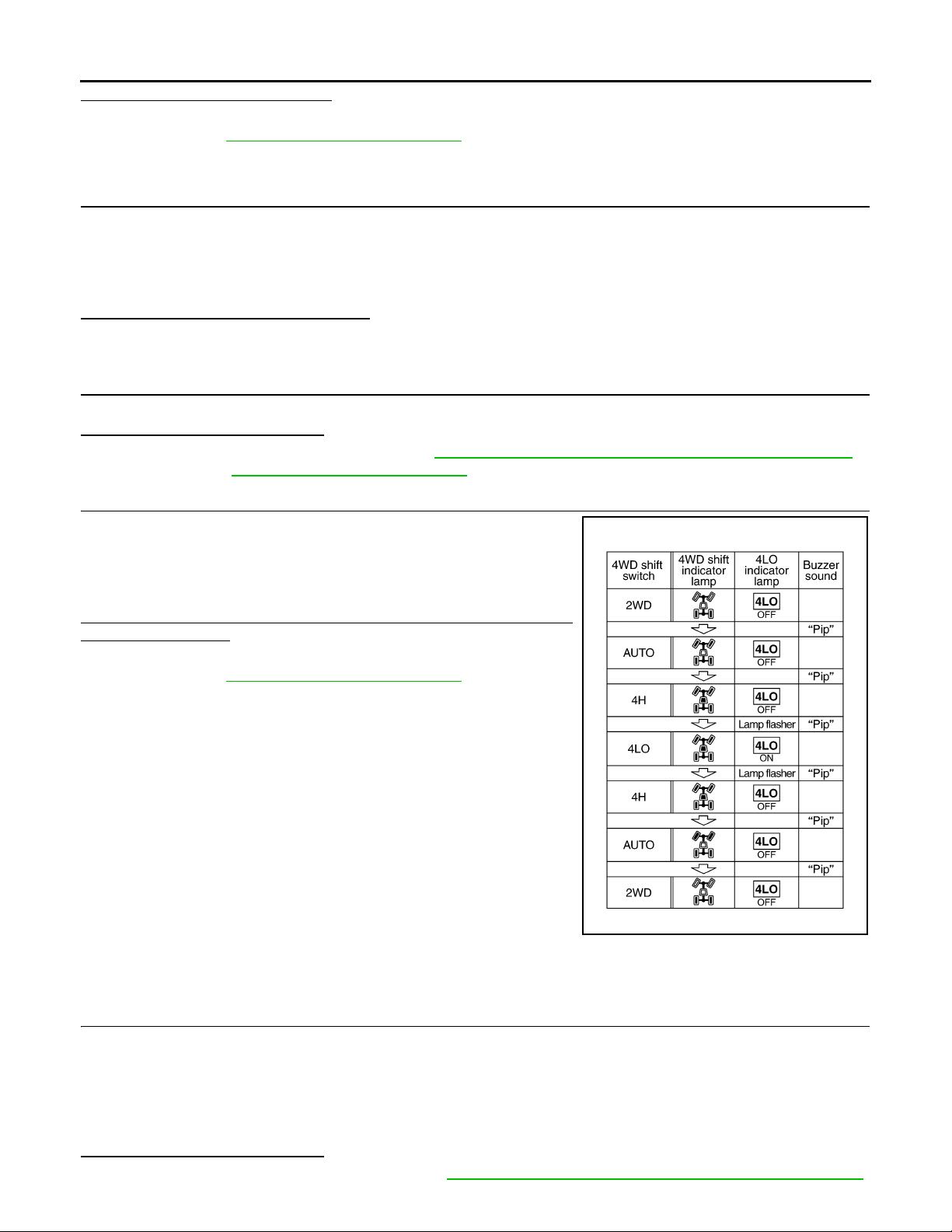

3.CHECK 4WD SHIFT INDICATOR AND 4LO INDICATOR OPERATION

1. Brake pedal depressed.

2. Move A/T selector lever to N position.

3. Set 4WD shift switch to 2WD, AUTO, 4H, 4LO, 4H, AUTO and

2WD in order. (Stay at each switch position for at least 1 second.)

Do 4WD shift indicator and 4LO indicator lamps change properly?

Does buzzer sound?

YES >> GO TO CRUISE TEST.

NO >> GO TO DLN-113, "

Diagnosis Procedure".

CRUISE TEST

WDIA0136E

1.CHECK INPUT SIGNAL

1. Warm up engine to normal operating temperature.

2. Park vehicle on flat surface.

3. Move A/T selector lever to P position.

4. Set 4WD shift switch to AUTO position.

5. Start engine.

6. Drive vehicle for at least 30 seconds at a speed higher than 20 km/h (12 MPH).

Is 4WD warning lamp turned ON?

On steady>>Perform the self-diagnosis. Refer to DLN-20, "CONSULT-III Function (ALL MODE AWD/4WD)".

DLN-10

DIAGNOSIS AND REPAIR WORKFLOW

< BASIC INSPECTION >

Flash rapidly>>Refer to DLN-118, "Diagnosis Procedure".

Flash slowly>>Refer to DLN-119, "

NO >> GO TO 2.

Diagnosis Procedure".

[TRANSFER: ATX14B]

2.CHECK TIGHT CORNER BRAKING SYMPTOM (1)

1. Set 4WD shift switch to AUTO position.

2. Drive vehicle at speed lower than 20 km/h (12 MPH) with steering wheel fully turned.

Does tight corner braking symptom occur?

YES >> GO TO DLN-120, "Diagnosis Procedure".

NO >> GO TO 3.

3.CHECK TIGHT CORNER BRAKING SYMPTOM (2)

1. Set 4WD shift switch to 4HI position.

2. Drive vehicle at speed lower than 20 km/h (12 MPH) with steering wheel fully turned.

Does tight corner braking symptom occur?

YES >> Inspection End.

NO >> GO TO DLN-124, "

Diagnosis Procedure".

A

B

C

DLN

E

F

G

H

K

M

N

O

I

J

L

DLN-11

P

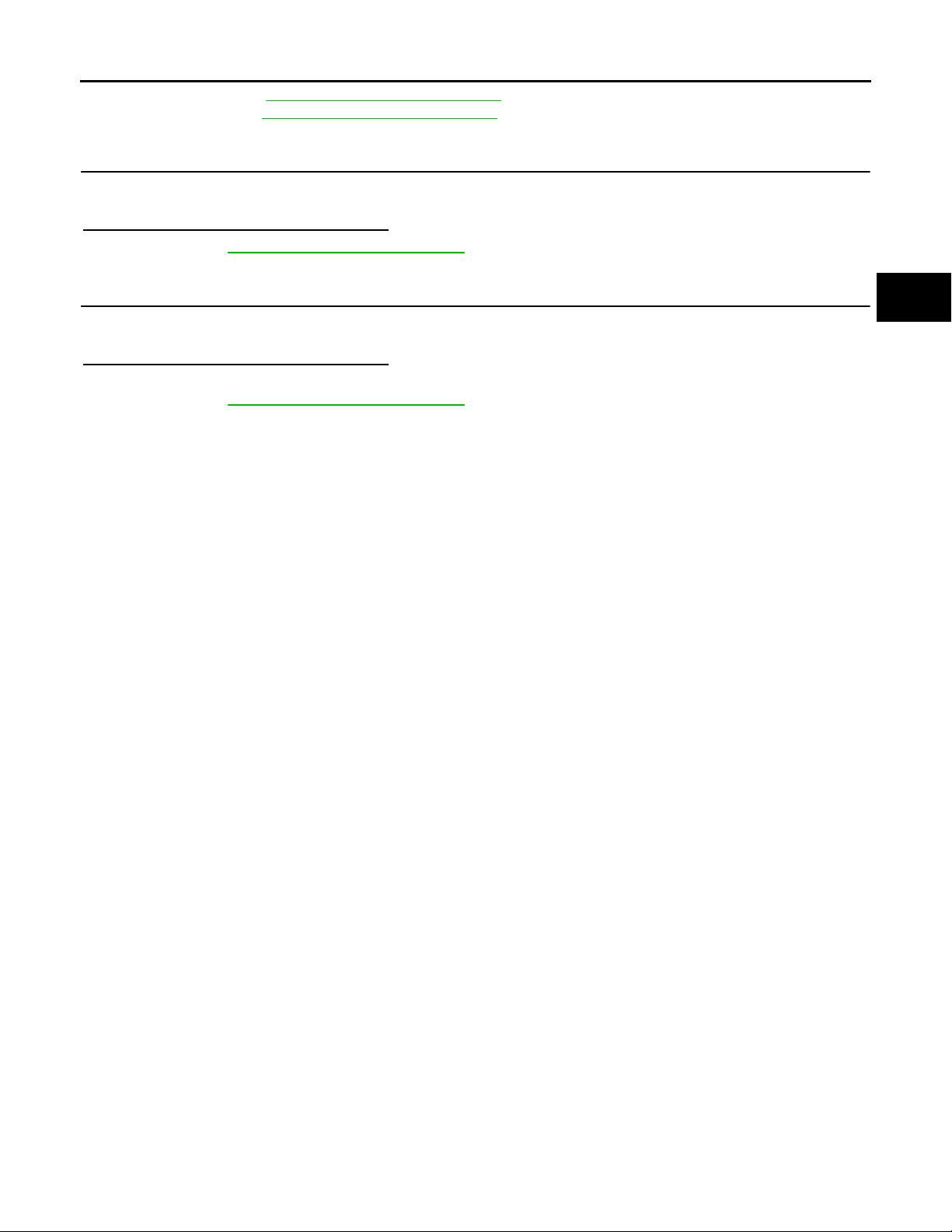

4WD SYSTEM

< FUNCTION DIAGNOSIS >

[TRANSFER: ATX14B]

FUNCTION DIAGNOSIS

4WD SYSTEM

System Diagram INFOID:0000000001728333

WDIA0164E

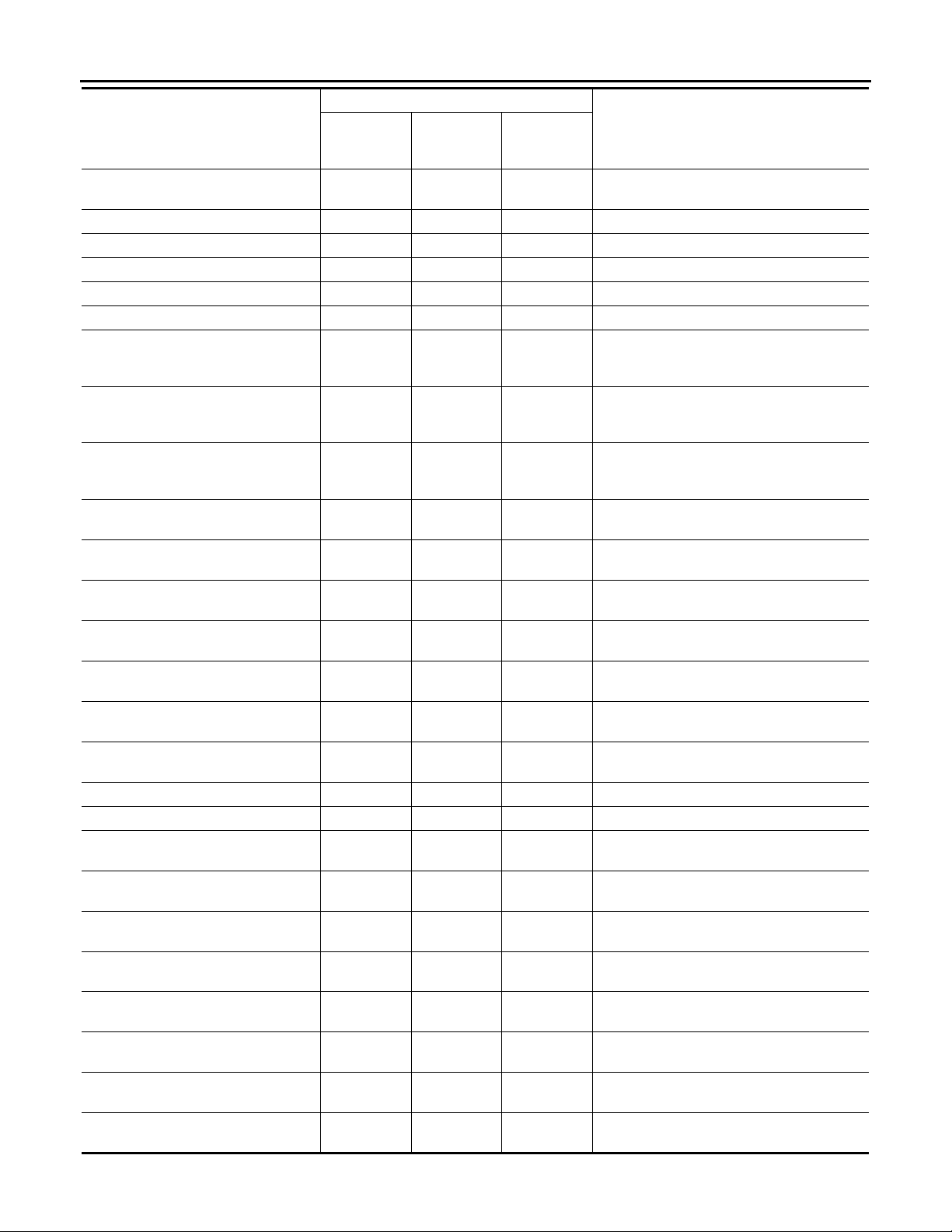

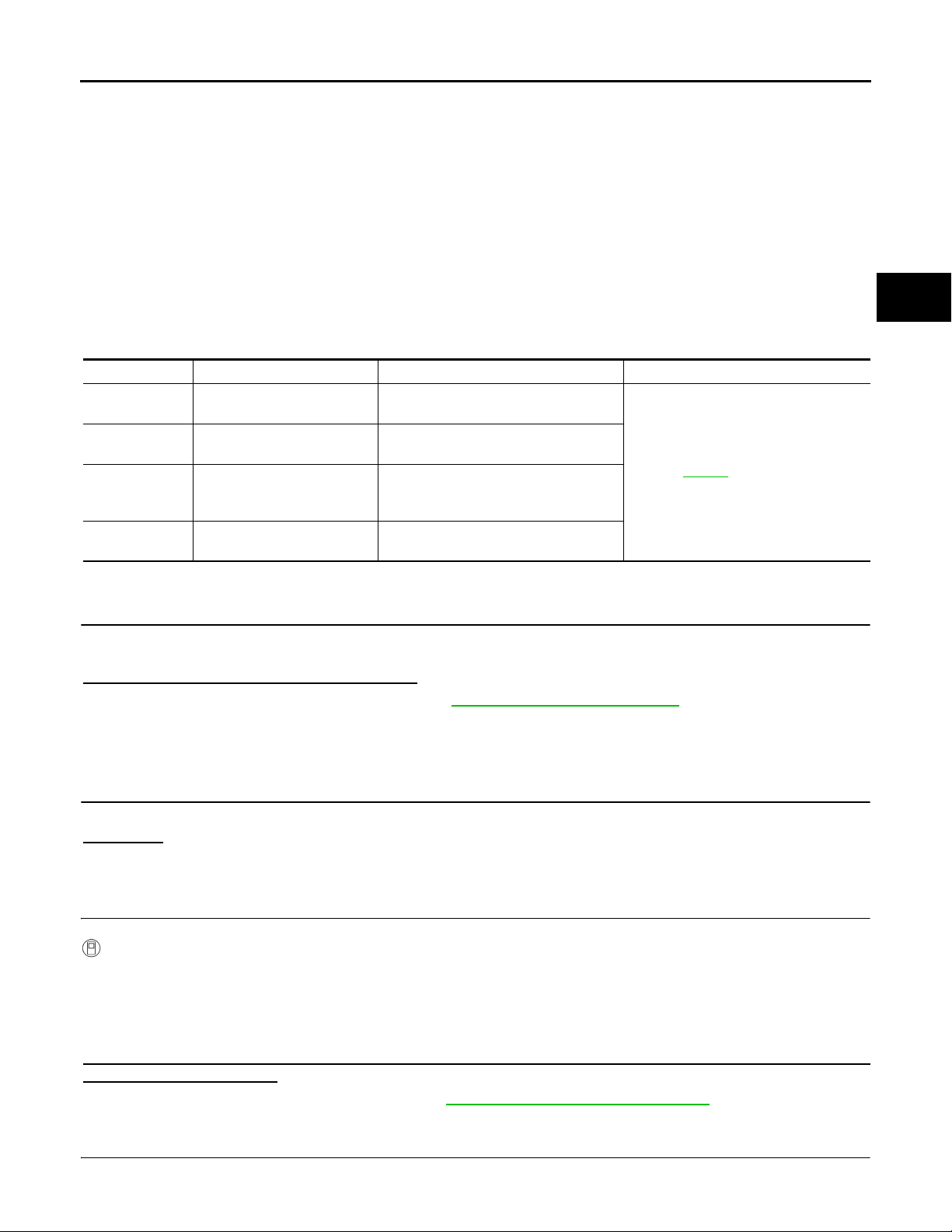

COMPONENT DESCRIPTION

Components Function

Transfer control unit Controls transfer control device, control valves and shifts between 2WD/4WD and 4H/4LO.

Transfer control device Integrates actuator motor and actuator position switch.

2-4WD shift solenoid valve Controls oil pressure and allows shifting between 2WD and 4WD.

Clutch pressure solenoid valve Controls oil pressure and distributes torque between front and rear tires.

Line pressure switch Detects line pressure.

Clutch pressure switch Detects clutch pressure.

Transfer fluid temperature sensor Detects transfer fluid temperature.

Actuator motor Moves shift rods when signaled by transfer control unit.

Actuator position switch Detects actuator motor position.

Wait detection switch Detects whether or not 4WD lock gear is locked.

4LO switch Detects if transfer case is in 4LO.

ATP switch Detects if transfer case is in neutral.

4WD shift switch Allows driver to select from 2WD/4WD, 4H/4LO and AUTO.

• Illuminates if malfunction is detected in 4WD system.

4WD warning lamp

ATP warning lamp

4WD shift indicator lamp Displays driving range selected by 4WD shift switch.

4LO indicator lamp Displays 4LO range.

• Flashes (1 flash / 2 seconds) if large difference in diameter of front and rear tires.

• Flashes (2 flashes / 1 second) if high transfer fluid temperature is detected.

Indicates that A/T parking mechanism does not operate when A/T selector lever is in P position

because transfer case is in neut ral.

DLN-12

< FUNCTION DIAGNOSIS >

4WD SYSTEM

[TRANSFER: ATX14B]

Components Function

ABS actuator and electric unit

(control unit)

TCM

ECM

Transmit s vehicle speed signal via CAN communication to transfer control unit.

Transmits the following signal via CAN communication to transfer control unit.

• Output shaft revolution signal

• A/T position indicator signal (PNP switch signal)

Transmits the following signals via CAN communication to transfer control unit.

• Engine speed signal

• Accelerator pedal position signal

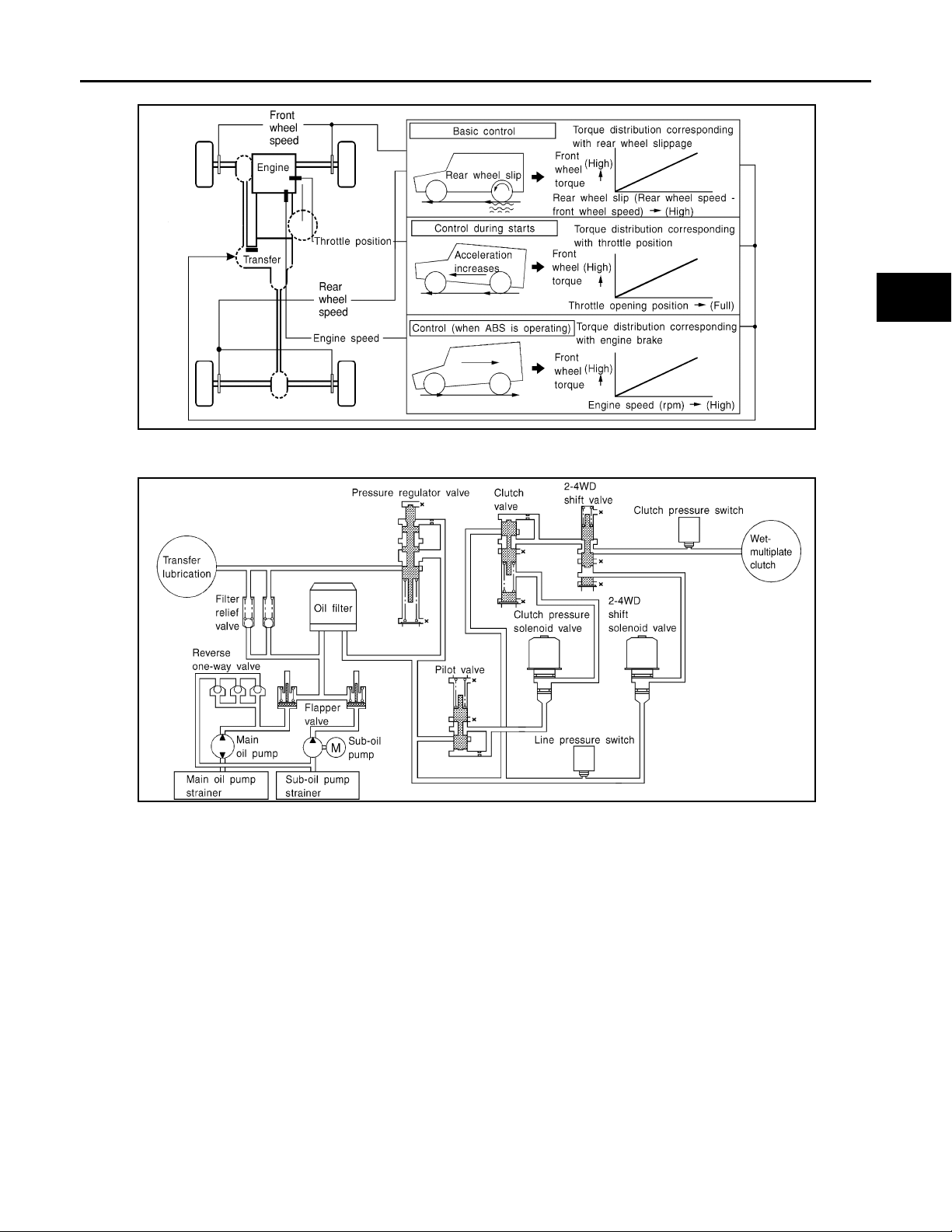

System Description INFOID:0000000001728334

CONTROL SYSTEM

A

B

C

DLN

E

F

G

H

K

M

N

O

P

I

J

L

DLN-13

< FUNCTION DIAGNOSIS >

4WD SYSTEM

[TRANSFER: ATX14B]

ALL-MODE 4WD Transfer Basic Cont rol

SDIA3396E

DLN-14

< FUNCTION DIAGNOSIS >

4WD SYSTEM

[TRANSFER: ATX14B]

A

B

C

DLN

E

LDIA0055E

Hydraulic Control Circuits

WDIA0163E

TRANSFER CONTROL UNIT

• Transfer control unit controls transfer control device and it directs shifts from 4H-4LO and 2WD-4WD.

• Self-diagnosis can be done.

F

G

H

I

J

K

L

M

TRANSFER SHIFT HIGH AND LOW RELAYS

Transfer shift high and low relays apply power supply to transfer control device (actuator motor).

TRANSFER SHUT OFF RELAY

Transfer shut off relay applies power supply to transfer motor relay.

4WD SHIFT SWITCH AND INDICATOR LAMPS

4WD Shift Switch

Able to select from 2WD, AUTO, 4H or 4LO.

4WD Shift Indicator Lamp

• Displays driving conditions selected by 4WD shift switch with 2WD, AUTO and 4H indicators while engine is

running. (When 4WD warning lamp is turned on, all 4WD shift indicator lamps are turned off.)

• Turns ON for approximately 1 second when ignition switch is turned ON, for purpose of lamp check.

4LO Indicator Lamp

DLN-15

N

O

P

4WD SYSTEM

< FUNCTION DIAGNOSIS >

• Displays 4LO condition while engine is running. 4LO indicator lamp flashes if transfer gear does not shift

completely under 2WD, AUTO, 4H⇔4LO. (When 4WD warning lamp is turned on, 4LO indicator lamp is

turned off.)

• Turns ON for approximately 1 second when ignition switch is turned ON, for purpose of lamp check.

4WD WARNING LAMP

Turns on or flashes when there is a malfunction in 4WD system.

Also turns on when ignition switch is turned ON, for purpose of lamp check. Turns OFF approximately 1 second after the engine starts if system is normal.

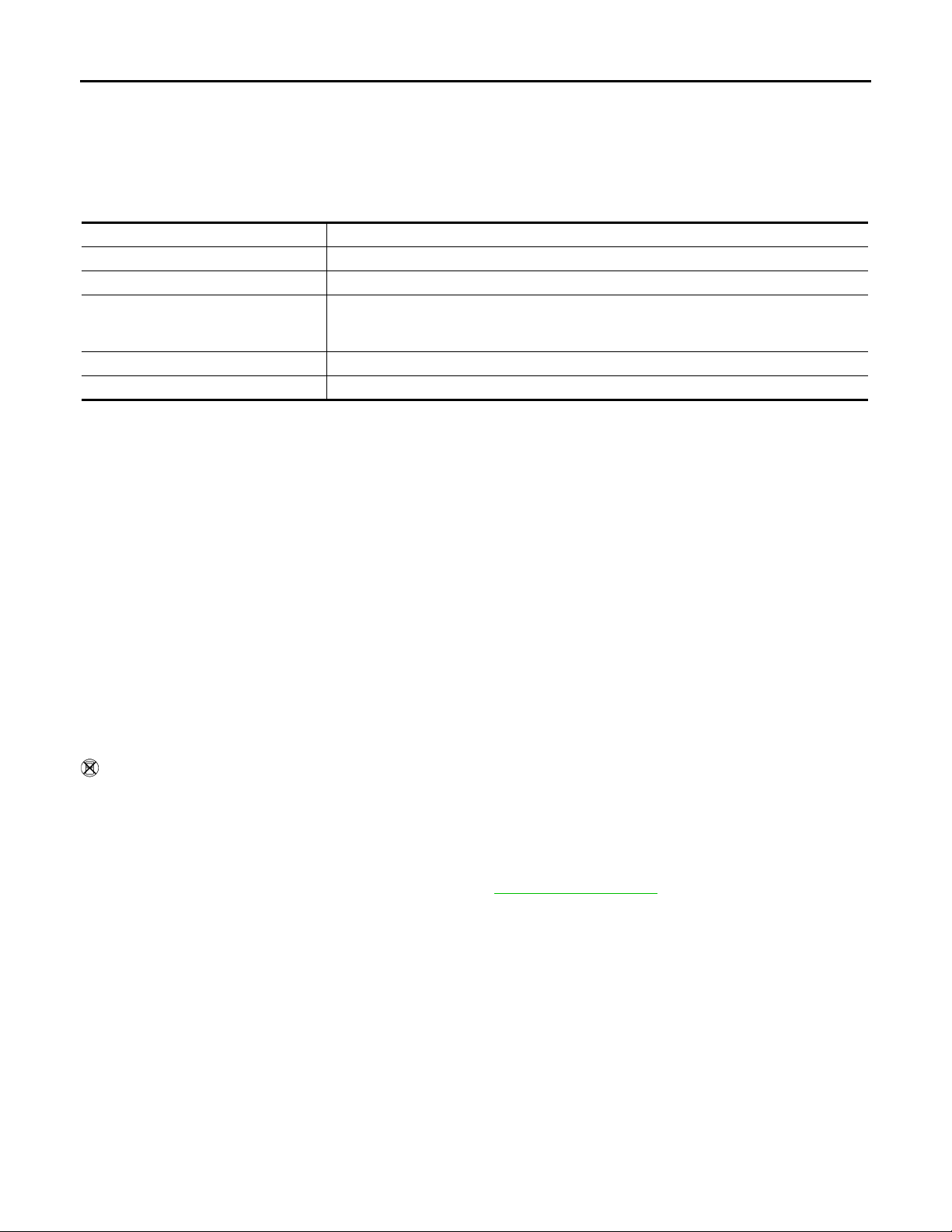

4WD Warning Lamp Indication

Condition 4WD warning lamp

System normal OFF

Lamp check

4WD system malfunction ON

During self-diagnosis Flashes malfunction mode.

Large difference in diameter of front/

rear tires

High fluid temperature in transfer case

Turns ON when ignition switch is turned ON.

Turns OFF after engine start.

Flashes slow (1 flash / 2 seconds)

(Continues to flash until the ignition switch is turned OFF)

Flashes rapidly (2 flashes / 1 second)

(Continues to flash until fluid temperature returns to normal)

[TRANSFER: ATX14B]

ATP WARNING LAMP

When the A/T selector lever is in P position, the vehicle may move if the transfer case is in neutral. ATP warning lamp is turned on to indicate this condition to the driver.

LINE PRESSURE SWITCH

• With the transfer system design, control of the oil pressure provides the transmission of drive torque to the

front wheels. The main pressure to control the oil pressure is referred to as the line pressure.

• The line pressure switch determines whether or not adequate line pressure has built up under different operating conditions.

• The line pressure switch closes when line pressure is produced.

• The line pressure switch senses line pressure abnormalities and turns the 4WD warning lamp ON.

CLUTCH PRESSURE SWITCH

• The clutch pressure switch determines whether or not adequate clutch pressure has built up under different

operating conditions.

• The clutch pressure switch closes when clutch pressure is produced.

• The clutch pressure switch senses clutch pressure abnormalities and turns the 4WD warning lamp ON.

WAIT DETECTION SWITCH

• The wait detection switch operates when there is circulating torque produced in the propeller shaft (L→H) or

when there is a phase difference between 2-4 sleeve and clutch drum (H→L). After the release of the circulating torque, the wait detection switch helps provide the 4WD lock gear (clutch drum) shifts. A difference

may occur between the operation of the 4WD shift switch and actual drive mode. At this point, the wait

detection switch senses an actual drive mode.

• The wait detection switch operates as follows.

- 4WD lock gear (clutch drum) locked: ON

- 4WD lock gear (clutch drum) released: OFF

• The wait detection switch senses an actual drive mode and the 4WD shift indicator lamp indicates the vehicle drive mode.

ATP SWITCH

ATP switch detects if transfer case is in neutral by the position of the L-H shift fork.

NOTE:

Transfer case may be in neutral when shifting between 4H-4LO.

NEUTRAL-4LO SWITCH

The neutral-4LO switch detects that transfer gear is in neutral or 4LO (or shifting from neutral to 4LO) condition by L-H shift fork position.

DLN-16

4WD SYSTEM

< FUNCTION DIAGNOSIS >

TRANSFER FLUID TEMPERATURE SENSOR

The transfer fluid temperature sensor detects the transfer fluid temperature and sends a signal to the transfer

control unit.

[TRANSFER: ATX14B]

A

TRANSFER MOTOR

• The transfer motor drives the sub-oil pump to provide proper lubrication and oil pressure control when the

vehicle is at standstill, during low-speed operations or is being driven in reverse.

• The main oil pump is operated by the driving force of the mainshaft. In other words, sufficient oil pressure

buildup does not occur when the vehicle is at standstill or during low-speed operations. While the vehicle is

being driven in reverse, the main oil pump rotates in the reverse direction. Therefore the main oil pump does

not discharge oil pressure. During any of the above vehicle operations, the transfer motor drives the sub-oil

pump to compensate for insufficient oil pressure.

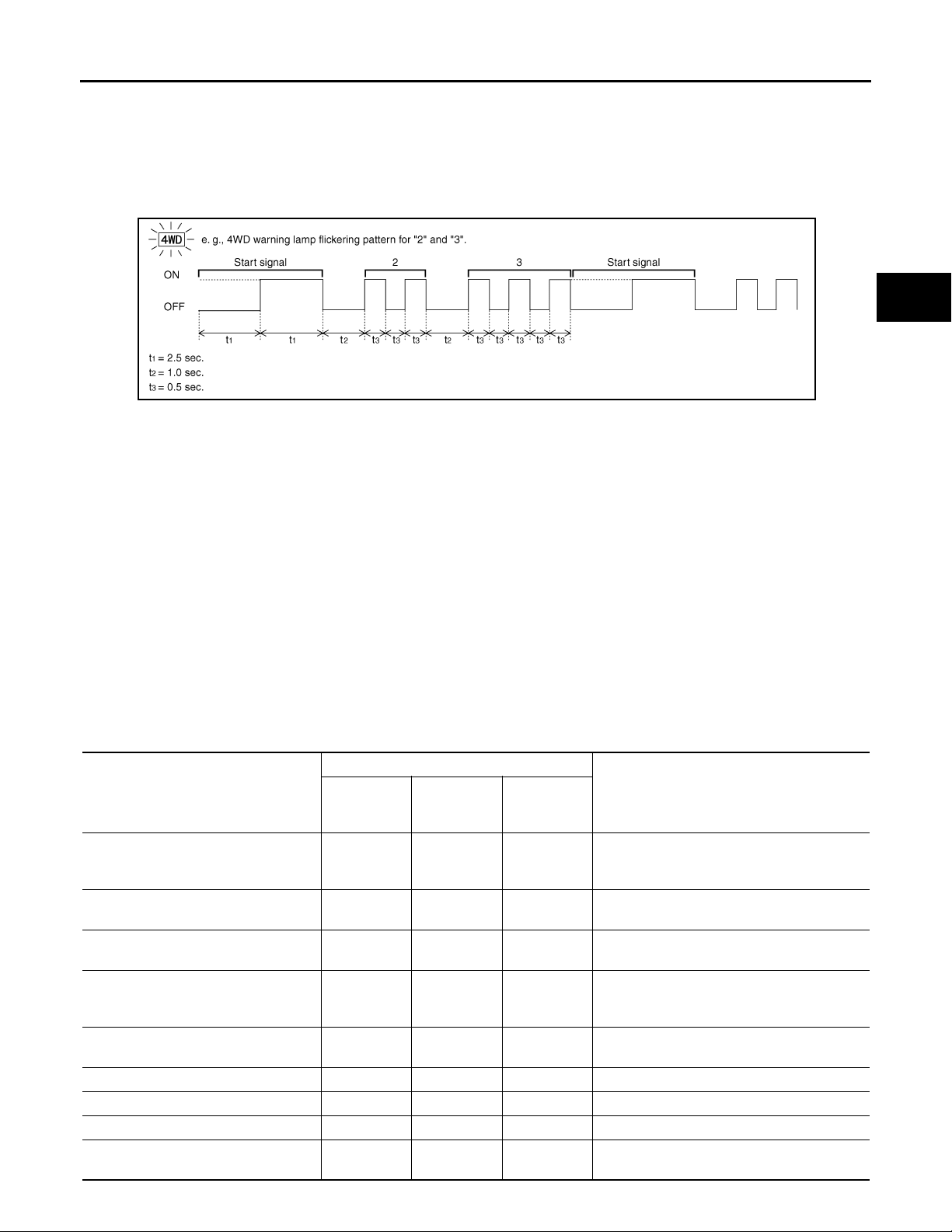

• The transfer motor operates as follows:

- The motor relay turns OFF in the 2WD mode.

- The motor relay operates as described in the table below in modes other than the 2WD mode.

• 4WD shift switch, PNP switch, Neutral-4LO switch, vehicle speed sensor and throttle position sensor are

used in conjunction with the transfer motor.

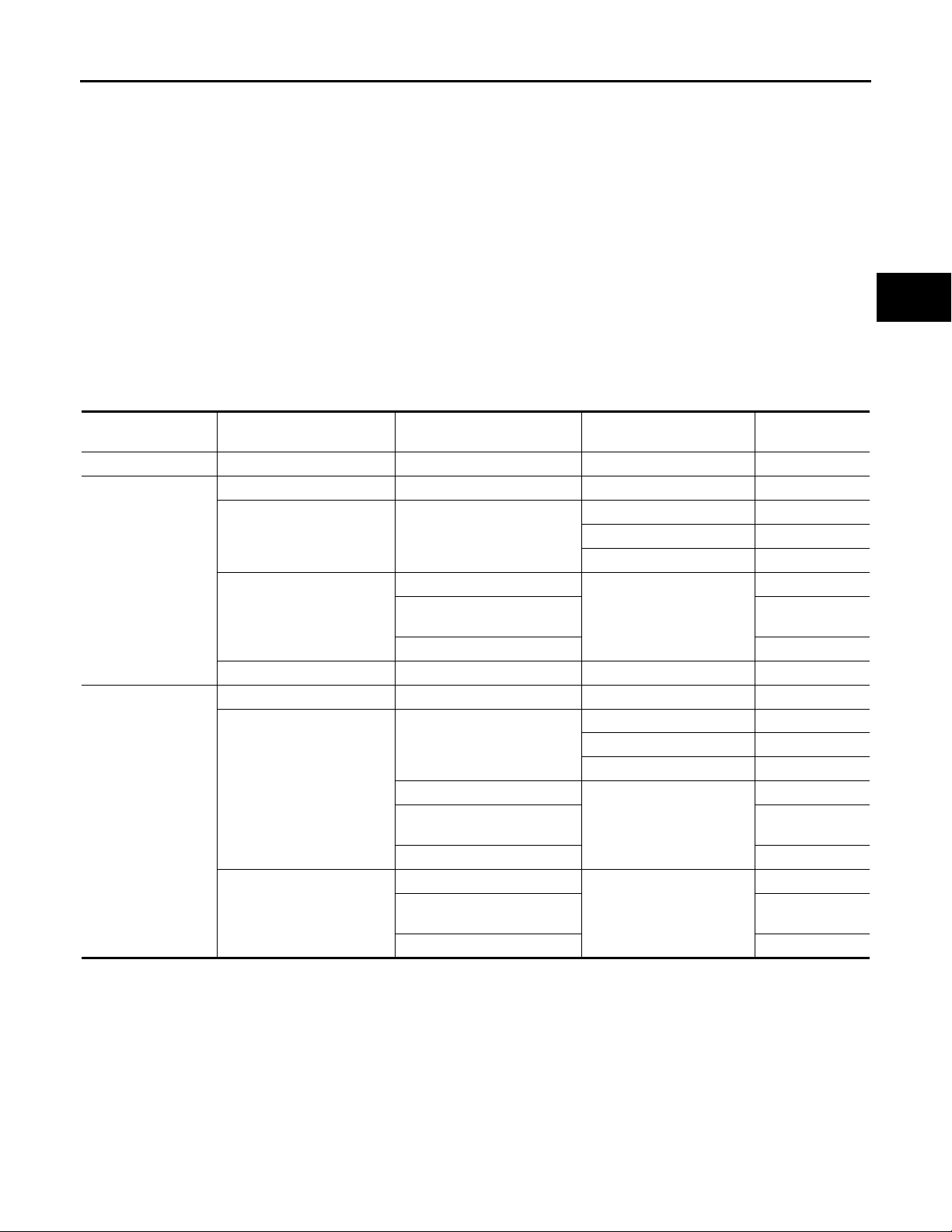

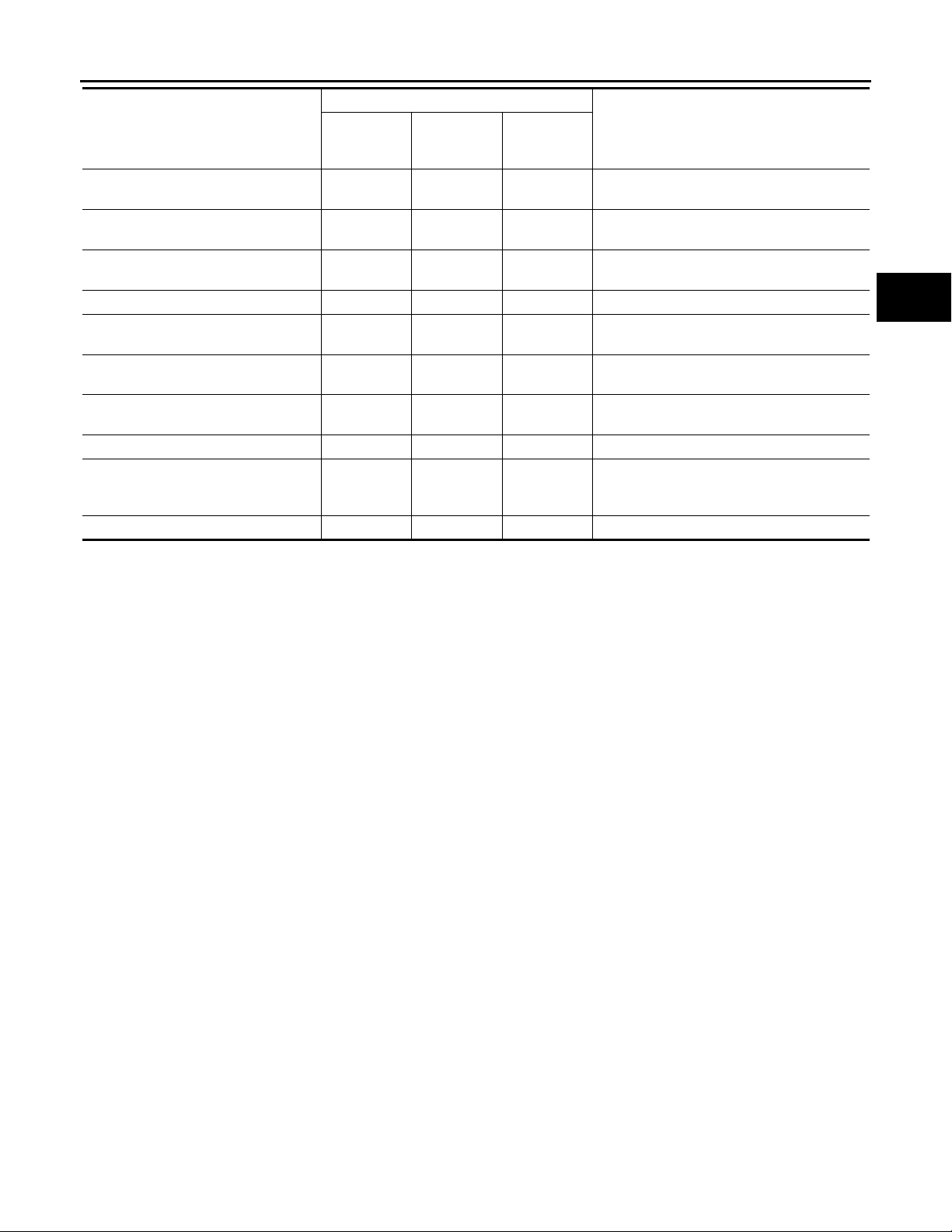

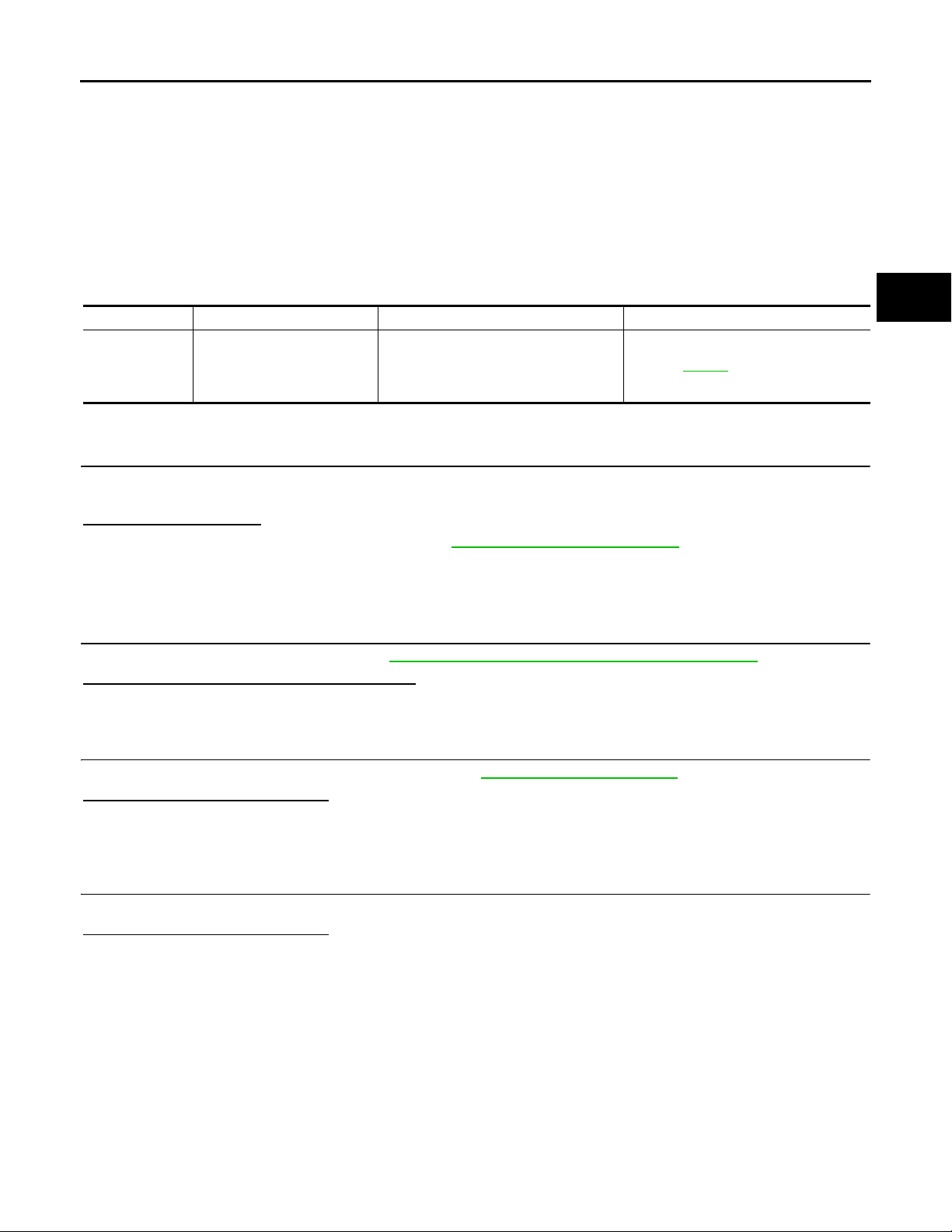

Transfer Motor Relay Operation

4WD shift switch A/T selector lever position

2WD — — — OFF

N position 0 — ON

P position 0

4H (LOCK) and 4LO

Other than R position

R position — — ON

R position — — ON

P or N position

AUTO

Other than R, P and N position

*: After 2.5 seconds have elapsed.

Vehicle speed

(VSS)

0 < VSS ≤ 50 km/h (31 MPH)

50 km/h (31 MPH) < VSS < 55

km/h (34 MPH)

55 km/h (34 MPH) ≤ VSS OFF

0

0 < VSS ≤ 50 km/h (31 MPH)

50 km/h (31 MPH) < VSS < 55

km/h (34 MPH)

55 km/h (34 MPH) ≤ VSS OFF

0 < VSS ≤ 50 km/h (31 MPH)

50 km/h (31 MPH) < VSS < 55

km/h (34 MPH)

55 km/h (34 MPH) ≤ VSS OFF

Accelerator pedal position

0 - 0.07/8 OFF*

0.07/8 - 1/8 HOLD

1/8 - MAX ON

—

0 - 0.07/8 OFF*

0.07/8 - 1/8 HOLD

1/8 - MAX ON

—

—

Motor relay drive

command

ON

HOLD

ON

HOLD

ON

HOLD

CLUTCH PRESSURE SOLENOID VALVE

The clutch pressure solenoid valve distributes front and rear torque in AUTO mode.

2-4WD SHIFT SOLENOID VALVE

The 2-4WD shift solenoid valve operates to apply oil pressure to the wet-multiplate clutch, depending on the

drive mode. The driving force is transmitted to the front wheels through the clutch so the vehicle is set in the

4WD mode. Setting the vehicle in the 2WD mode requires no pressure buildup. In other words, pressure force

applied to the wet-multiplate clutch becomes zero.

B

C

DLN

E

F

G

H

I

J

K

L

M

N

O

P

TRANSFER CONTROL DEVICE

Integrates actuator motor and actuator position switch.

DLN-17

4WD SYSTEM

< FUNCTION DIAGNOSIS >

Actuator Motor

Moves shift rods when signaled by transfer control unit.

Actuator Position Switch

Detects actuator motor position and then sends signal to transfer control unit.

[TRANSFER: ATX14B]

Component Parts Location INFOID:0000000001728335

DLN-18

WDIA0124E

4WD SYSTEM

< FUNCTION DIAGNOSIS >

[TRANSFER: ATX14B]

CAN Communication INFOID:0000000001728336

Refer to LAN-10, "Self-Diagnosis".

A

B

C

DLN

E

F

G

H

K

M

N

O

I

J

L

DLN-19

P

DIAGNOSIS SYSTEM (TRANSFER CONTROL UNIT)

< FUNCTION DIAGNOSIS >

[TRANSFER: ATX14B]

DIAGNOSIS SYSTEM (TRANSFER CONTROL UNIT)

CONSULT-III Function (ALL MODE AWD/4WD) INFOID:0000000001728337

FUNCTION

CONSULT-III can display each diagnostic item using the diagnostic test modes shown following.

ALL MODE AWD/4WD diag no sti c mod e Description

SELF-DIAG RESULTS Displays transfer control unit self-diagnosis results.

DATA MONITOR Displays transfer control unit input/output data in real time.

Supports inspections and adjustments. Commands are transmitted to the transfer control

WORK SUPPORT

CAN DIAG SUPPORT MNTR The results of transmit/receive diagnosis of CAN communication can be read.

ECU PAR T NUMBER Transfer control unit part number can be read.

SELF-DIAG RESULT MODE

Operation Procedure

1. Connect CONSULT-III.

2. With engine at idle, touch SELF-DIAG RESULTS.

Display shows malfunction experienced since the last erasing operation.

NOTE:

The details for TIME are as follows:

• 0: Error currently detected with transfer control unit.

• Except for 0: Error detected in the past and memorized with transfer control unit.

Detects frequency of driving after DTC occurs (frequency of turning ignition switch ON/OFF).

unit for setting the status suitable for required operation, input/output signals are received

from the transfer control unit and received data is displayed.

How to Erase Self-diagnostic Results

1. Perform applicable inspection of malfunctioning item and then repair or replace.

2. Start engine and select SELF-DIAG RESULTS mode for ALL MODE AWD/4WD with CONSULT-III.

3. Touch ERASE on CONSULT-III screen to erase DTC memory.

CAUTION:

If memory cannot be erased, perform applicable diagnosis.

SELF-DIAGNOSTIC PROCEDURE (WITHOUT CONSULT-III)

Description

If the engine starts when there is a malfunction in the 4WD system, the 4WD warning lamp turns ON or flickers

in the combination meter. When the system functions properly, the warning lamp turns ON when the ignition

switch is turned to ON, and it turns OFF after engine starts. To locate the cause of a malfunction, start the selfdiagnosis function. The 4WD warning lamp in the combination meter will indicate the malfunction area by

flashing according to the self-diagnostic results. Refer to DLN-101, "

Diagnostic Procedure

1. Warn up engine.

2. Move A/T selector lever to P position.

3. Turn 4WD shift switch to 2WD position.

4. Turn ignition switch ON and OFF at least twice, and then turn ignition switch OFF.

5. Turn 4WD shift switch to AUTO position.

6. Turn ignition switch ON. (Do not start engine.)

7. 4WD warning lamp ON.

8. Move A/T selector lever to R position.

9. Turn 4WD shift switch to 2WD, AUTO and 2WD in order.

10. Move A/T selector lever to D position.

11. Turn 4WD shift switch to 4H, AUTO and 4H in order.

DTC Index".

DLN-20

DIAGNOSIS SYSTEM (TRANSFER CONTROL UNIT)

< FUNCTION DIAGNOSIS >

12. Move A/T selector lever to N position.

13. Turn 4WD shift switch to AUTO position.

14. Move A/T selector lever to P position.

15. Read the flickering of 4WD warning lamp.

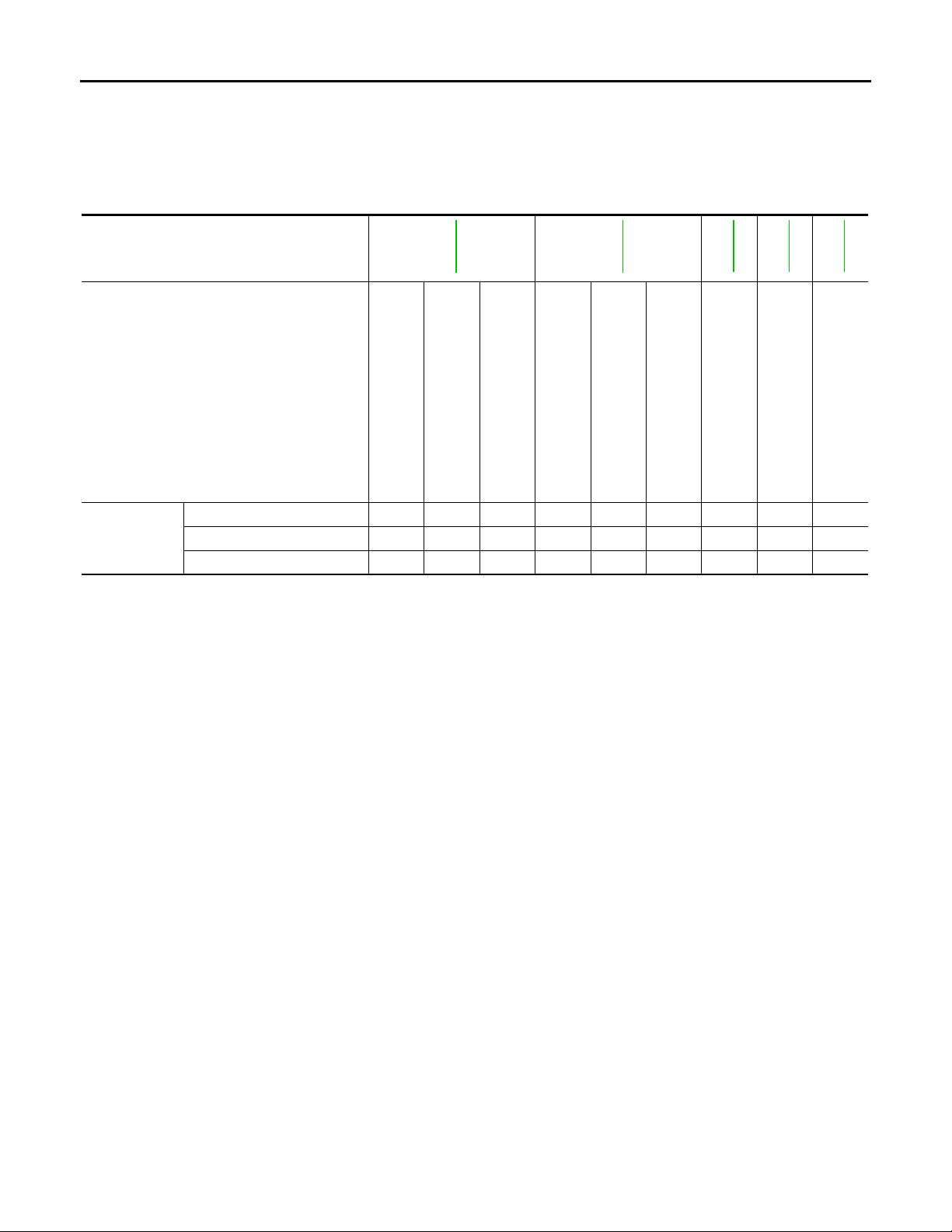

Self-diagnosis example

[TRANSFER: ATX14B]

A

B

C

DLN

E

PDIA0227E

ERASE SELF-DIAGNOSIS

• In order to make it easier to find the cause of hard-to-duplicate malfunctions, malfunction information is

stored into the control unit as necessary during use by the user. This memory is not erased no matter how

many times the ignition switch is turned ON and OFF.

• However, this information is erased by turning ignition switch OFF after performing self-diagnostics or by

erasing the memory using the CONSULT-III.

DATA MONITOR MODE

Operation Procedure

1. Connect CONSULT -III.

2. Touch DATA MONITOR.

3. Select from SELECT MONITOR ITEM, screen of data monitor mode is displayed.

NOTE:

When malfunction is detected, CONSULT-III performs REAL-TIME DIAGNOSIS.

Also, any malfunction detected while in this mode will be displayed at real time.

Display Item List

×: Standard –: Not applicable

Monitor item selection

Monitored item (Unit)

VHCL/S SEN·FR [km/h] or [mph] × – ×

VHCL/S SEN·RR [km/h] or [mph] × – ×

ENGINE SPEED [rpm] × – ×

THRTL POS SEN [V] × – ×

FLUID TEMP SE [V] × – ×

BATTERY VOLT [V] × – × Power supply voltage for transfer control unit.

2WD SWITCH [ON/OFF] × – × 4WD shift switch status is displayed.

AUTO SWITCH [ON/OFF] × – × 4WD shift switch status is displayed.

LOCK SWITCH [ON/OFF] × – ×

ECU INPUT

SIGNALS

MAIN

SIGNALS

SELEC-

TION FROM

MENU

Remarks

Wheel speed calculated by ABS actuator and

electric unit (control unit).

Signal input with CAN communication line.

Wheel speed calculated by TCM.

Signal input with CAN communication line.

Engine speed calculated by ECM.

Signal input with CAN communication line.

Accelerator pedal position (APP) sensor signal voltage is displayed.

Signal input with CAN communication line.

Transfer fluid temperature sensor signal voltage is displayed.

4WD shift switch status is displayed.

(LOCK means 4H of 4WD shift switch.)

F

G

H

I

J

K

L

M

N

O

P

DLN-21

DIAGNOSIS SYSTEM (TRANSFER CONTROL UNIT)

< FUNCTION DIAGNOSIS >

Monitor item selection

Monitored item (Unit)

4L SW [ON/OFF] × – ×

N POSI SW TF [ON/OFF] × – × Neutral-4LO switch signal status is displayed.

ATP SWITCH [ON/OFF] × – × ATP switch signal status is displayed.

WAIT DETCT SW [ON/OFF] × – × Wait detection switch status is displayed.

LINE PRES SW [ON/OFF] × – × Line pressure switch status is displayed.

CL PRES SW [ON / OFF] × – × Clutch pressure switch status is displayed.

N POSI SW AT [ON/OFF] × – ×

R POSI SW AT [ON/OFF] × – ×

P POSI SW AT [ON/OFF] × – ×

ABS OPER SW [ON/OFF] × – ×

VDC OPER SW [ON/OFF] × – ×

TCS OPER SW [ON/OFF] × – ×

THROTTLE POSI [0.0/8] – ××

4WD MODE [AUTO/LOCK/2WD/4L] – ××

VHCL/S COMP [km/h] or [mph] – ××

COMP CL TORQ [kgm] – ××

DUTY SOLENOID [%] – ××Control value of clutch pressure solenoid.

2-4WD SOL [ON/OFF] – ××Output condition to 2-4WD solenoid.

2-4WD SOL MON [ON/OFF] – – ×

MOTOR RELAY [ON/OFF] – ××

MOTOR RELAY MON [ON/OFF] – – ×

4WD FAIL LAMP [ON/OFF] – ××

2WD IND [ON/OFF] – – ×

AUTO IND [ON/OFF] – – ×

LOCK IND [ON/OFF] – – ×

4L IND [ON/OFF] – – ×

ECU INPUT

SIGNALS

MAIN

SIGNALS

SELEC-

TION FROM

MENU

4WD shift switch status is displayed.

(4L means 4LO of 4WD shift switch.)

N position signal of A/T PNP switch status is

displayed.

Signal input with CAN communication line.

R position signal of A/T PNP switch status is

displayed.

Signal input with CAN communication line.

P position signal of A/T PNP switch status is

displayed.

Signal input with CAN communication line.

ABS operation signal status is displayed.

Signal input with CAN communication line.

VDC operation signal status is displayed.

Signal input with CAN communication line.

TCS operation signal status is displayed.

Signal input with CAN communication line.

Thottle position status is displayed.

Signal input with CAN communication line.

Control status of 4WD recognized by transfer

control unit. (AUTO, 4H, 2WD or 4LO)

Vehicle speed recognized by transfer control

unit.

Calculated torque recognized by transfer control unit.

Check signal for transfer control u nit signal

output.

Transfer motor relay signal status is displayed.

Check signal for transfer control u nit signal

output.

Control status of 4WD warning lamp is displayed.

Control status of 4WD shift indicator lamp

(2WD indicator lamp) is displayed.

Control status of 4WD shift indicator lamp

(2WD and AUTO indicator lamp) is displayed.

Control status of 4WD shift indicator lamp

(2WD, AUTO and Lock indicator) is displayed.

Control status of 4LO indicator lamp is displayed.

[TRANSFER: ATX14B]

Remarks

DLN-22

DIAGNOSIS SYSTEM (TRANSFER CONTROL UNIT)

< FUNCTION DIAGNOSIS >

[TRANSFER: ATX14B]

Monitor item selection

Monitored item (Unit)

A TP IND [O N/OFF] – – ×

SHIFT POS SW1 [ON/OFF] × – ×

SHIFT POS SW2 [ON/OFF] × – ×

SHIFT ACT1 [ON/OFF] – ××Output condition to actuator motor (clockwise)

SHIFT AC MON1 [ON/OFF] × – ×

SHIFT ACT2 [ON/OFF] – ××

SHIFT AC MON2 [ON/OFF] × – ×

T/F F SPEED [km/h] or [mph] × – × Displayed, but do not use.

A/T R SPEED [km/h] or [mph] × – ×

AT GEAR POSI [1/2/3/4/5] × – × A/T actual gear position is displayed.

ECU INPUT

SIGNALS

MAIN

SIGNALS

SELEC-

TION FROM

MENU

Remarks

Control status of ATP warning lamp is displayed.

Actuator position switch 1 (Low) signal status

is displayed.

Actuator position switch 2 (high) signal status

is displayed.

Check signal for transfer control unit signal

output

Output condition to actuator motor (counterclockwise)

Check signal for transfer control unit signal

output

Output shaft revolution signal (Revolution

sensor) calculated by TCM.

Signal input with CAN communication line.

WORK SUPPORT

When there is no malfunction with transfer and 4WD system, the following symptoms in AUTO mode may be

claimed by a customer: vibration when accelerating on a low µ road (snow-covered or icy road) or a slight

shock is felt at a few hertz as if it were being pushed lightly from behind.

It is possible to deal with these symptoms by changing the CLUTCH FORCE RELEASE LIMIT VALUE. However, be careful when changing the value because it may adversely affect driving performance.

Operation Procedure

1. Connect CONSULT -III.

2. Touch WORK SUPPORT.

3. Select from CLUTCH/F RLS LIM ADJ, screen of data monitor mode is displayed.

A

B

C

DLN

E

F

G

H

I

J

K

Clutch Force Release Limit Adjustment

1. Initial CLUTCH FORCE RELEASE LIMIT value 0.3 kgm appears under CONDITION SETTING on CON-

SULT-III display.

1.2 kg-m : Tight corner braking symptom is alleviated.

However, vibration may occur when accelerating on a low µ road (icy road, etc.).

0.3 kg-m : Initial set value.

0.2 kg-m : Do not set to this value because the tight

corner braking symptom will get worse.

2. Touch 1.2 on the display.

3. Display changes to NOW ADJUSTING in a short time.

4. When clutch force release limit value is set to 1.2 kgm, current value 0.3 kgm shown on display will be

replaced by 1.2 kgm and ADJUSTMENT COMPLETE will appear at the same time. Clutch force release

limit value setting is now complete.

DLN-23

L

M

N

O

P

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

< FUNCTION DIAGNOSIS >

[TRANSFER: ATX14B]

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

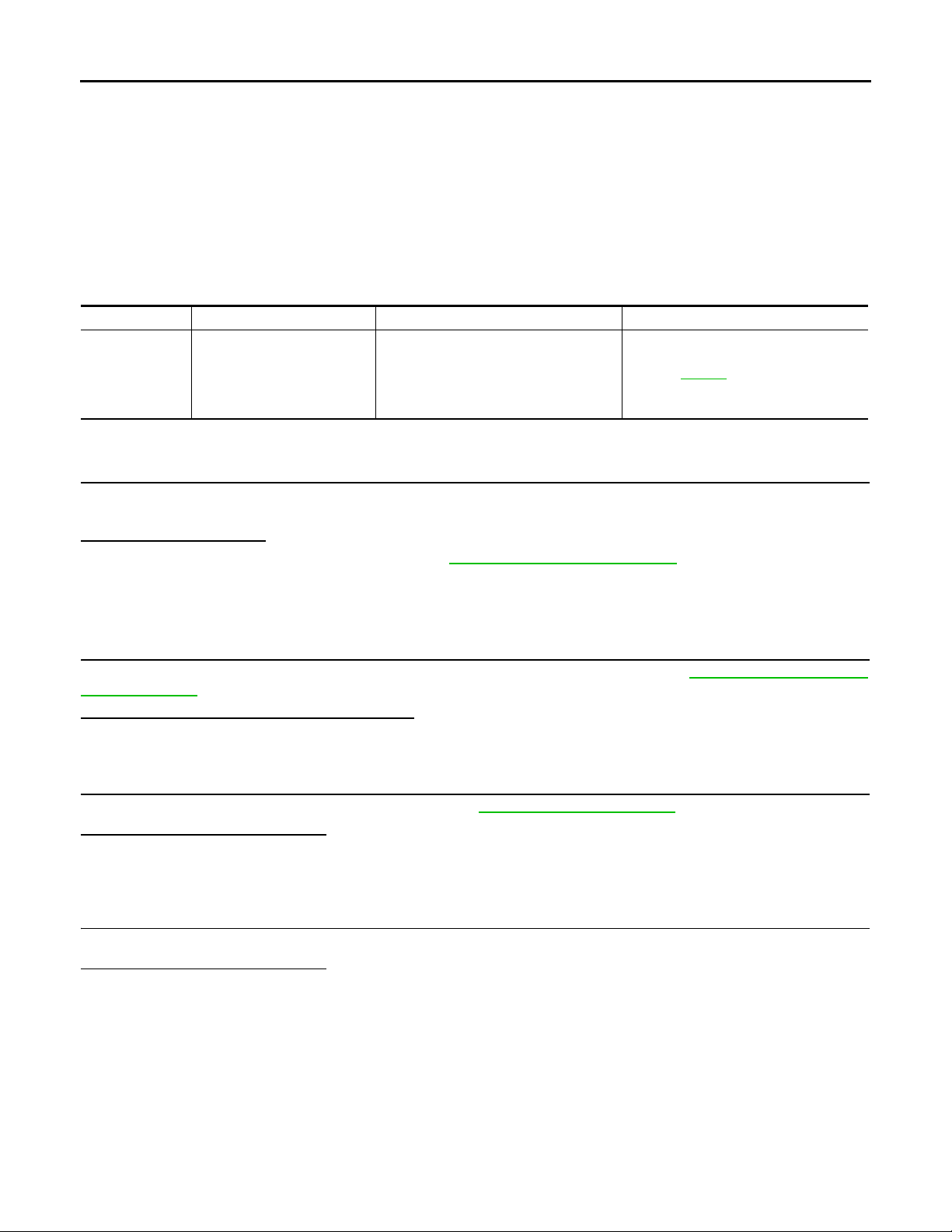

NVH Troubleshooting Chart INFOID:0000000001282210

Use the chart below to help you find the cause of the symptom. The numbers indicate the order of the inspection. If necessary, repair or replace these parts.

Reference page

SUSPECTED PARTS

(Possible cause)

DLN-132

DLN-149

DLN-149

DLN-149

DLN-149

Symptom

TRANSFER FLUID (Level low)

Noise 1 2 3 3

Transfer fluid leakage 31222

Hard to shift or will not shift 1 1 2

TRANSFER FLUID (Wrong)

TRANSFER FLUID (Level too high)

LIQUID GASKET (Damaged)

O-RING (Worn or damaged)

OIL SEAL (Worn or damaged)

SHIFT FORK (Worn or damaged)

GEAR (Worn or damaged)

BEARING (Worn or damaged)

DLN-24

P1811 POWER SUPPLY CIRCUIT FOR TRANSFER CONTROL UNIT

< COMPONENT DIAGNOSIS >

[TRANSFER: ATX14B]

COMPONENT DIAGNOSIS

P1811 POWER SUPPLY CIRCUIT FOR TRANSFER CONTROL UNIT

Description INFOID:0000000001728338

Power supply to transfer control unit is abnormally low while driving.

DTC Logic INFOID:0000000001728339

DTC DETECTION LOGIC

DTC CONSULT-III Diagnostic item is detected when... Reference

[P1811] BATTERY VOLTAGE

DTC CONFIRMATION PROCEDURE

1.DTC CONFIRMATION PROCEDURE

1. Turn ignition switch ON.

2. Perform self-diagnosis.

Is DTC P1811 detected?

YES >> Perform diagnosis procedure. Refer to DLN-25, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis Procedure INFOID:0000000001728340

Power supply voltage fo r transfer control

unit is abnormally low while driving.

Refer to DLN-25

.

A

B

C

DLN

E

F

G

H

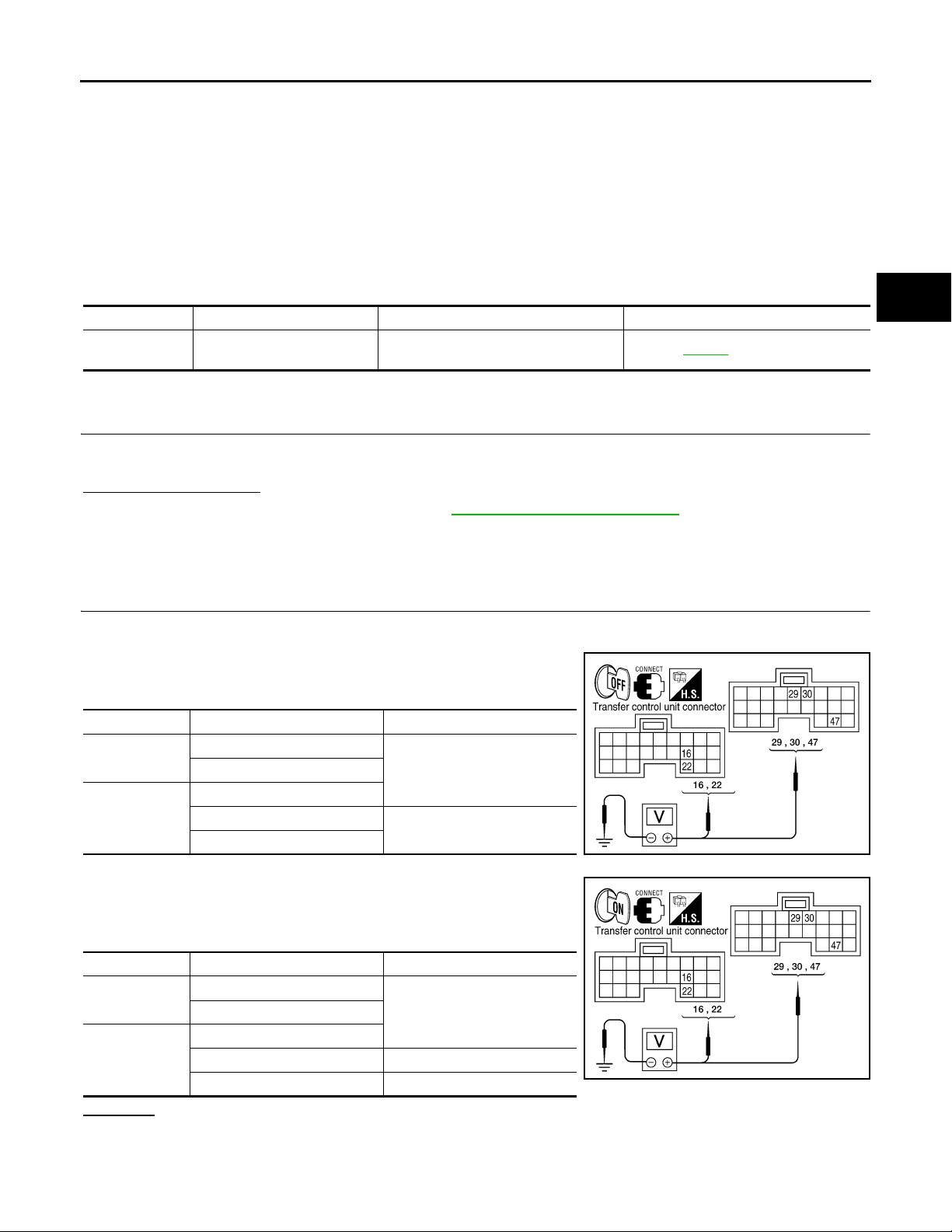

1.CHECK POWER SUPPLY

1. Turn ignition switch “OFF”. (Stay for at least 5 seconds.)

2. Connect transfer control unit harness connector.

3. Check voltage between transfer control unit harness connector

terminals and ground.

Connector Terminal Voltage (Approx.)

M152

M153

4. Turn ignition switch “ON”. (Do not start engine.)

5. Check voltage between transfer control unit harness connector

terminals and ground.

Connector Terminal Voltage (Approx.)

M152

M153

OK or NG

OK >> GO TO 2.

NG >> Check the following. If any items are damaged, repair or replace damaged parts.

• 10A fuses [No. 21 located in fuse block (J/B)] and No. 59 (located in the fuse and relay box).

16 - Ground

0V22 - Ground

29 - Ground

30 - Ground

47 - Ground

16 - Ground

29 - Ground

30 - Ground 0V

47 - Ground Battery voltage

Battery voltage

Battery voltage22 - Ground

WDIA0165E

WDIA0166E

I

J

K

L

M

N

O

P

DLN-25

P1811 POWER SUPPLY CIRCUIT FOR TRANSFER CONTROL UNIT

< COMPONENT DIAGNOSIS >

• Harness for short or open between battery and transfer control unit harness connector M153

terminals 47.

• Harness for short or open between ignition switch and transfer control unit harness connector

M153 terminal 29.

• Harness for short or open between battery and transfer shut off relay harness connector E155

terminal 1 and 3.

• Harness for short or open between transfer shut off relay harness connector E155 terminal 2

and transfer control unit harness connector M153 terminal 30.

• Harness for short or open between transfer shut off relay harness connector E155 terminal 5

and transfer control unit harness connector M152 terminals 16 and 22.

• Battery and ignition switch.

• Transfer shut off relay. Refer to DLN-26, "

Component Inspection".

2.CHECK GROUND CIRCUIT

1. Turn ignition switch “OFF”. (Stay for at least 5 seconds.)

2. Disconnect transfer control unit harness connector.

3. Check continuity between transfer control unit harness connector M152 terminals 3, 6, M153 terminal 45 and ground.

Continuity should exist.

Also check harness for short to power.

OK or NG

OK >> GO TO 3.

NG >> Repair open circuit or short to power in harness or con-

nectors.

3.CHECK TRANSFER CONTROL UNIT

[TRANSFER: ATX14B]

SDIA2691E

Check transfer control unit input/output signal. Refer to DLN-83, "

OK or NG

OK >> GO TO 4.

NG >> Check transfer control unit pin terminals for damage or loose connection with harness connector.

If any items are damaged, repair or replace damaged parts.

Reference Value".

4.CHECK DTC

Perform the self-diagnosis, after driving a vehicle for a while.

OK or NG

OK >> Inspection End.

NG >> Replace transfer control unit. Refer to DLN-135, "

Component Inspection INFOID:0000000001728341

1. Turn ignition switch OFF. (Stay for at least 5 seconds.)

2. Remove transfer shut off relay. Refer to DLN-18, "

3. Apply 12V direct current between transfer shut off relay terminals 1 and 2.

4. Check continuity between relay terminals 3 and 5.

Condition Continuity

12V direct current supply between terminals 1 and 2 Yes

OFF No

5. If inspection results are abnormal replace the transfer shut off

relay.

Component Parts Location".

Removal and Installation".

SCIA1245E

DLN-26

P1802 – P1804, P1809 TRANSFER CONTROL UNIT

< COMPONENT DIAGNOSIS >

[TRANSFER: ATX14B]

P1802 – P1804, P1809 TRANSFER CONTROL UNIT

Description INFOID:0000000001728342

The transfer control unit controls the transfer control device which controls shifts between AUTO, 4H and 4LO

and between 2WD and 4WD. A DTC may set when any of the following occur:

• Malfunction is detected in the memory (RAM) system of transfer control unit.

• Malfunction is detected in the memory (ROM) system of transfer control unit.

• Malfunction is detected in the memory (EEPROM) system of transfer control unit.

• AD converter system of transfer control unit is malfunctioning.

DTC Logic INFOID:0000000001728343

DTC DETECTION LOGIC

DTC CONSULT-III Diagnostic item is detected when... Reference

[P1802] CONTROL UNIT 1

[P1803] CONTROL UNIT 2

[P1804] CONTROL UNIT 3

[P1809] CONTROL UNIT 4

Malfunction is detected in the memory

(RAM) system of transfer control unit.

Malfunction is detected in the memory

(ROM) system of transfer control unit.

Malfunction is detected in the memory

(EEPROM) system of transfer control

unit.

AD converter system of transfer control

unit is malfunctioning.

Refer to DLN-27

.

A

B

C

DLN

E

F

G

H

DTC CONFIRMATION PROCEDURE

1.DTC CONFIRMATION PROCEDURE

1. Turn ignition switch ON.

2. Perform self-diagnosis.

Are DTC's P1802 - P1804 or P1809 detected?

YES >> Perform diagnosis procedure. Refer to DLN-27, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis Procedure INFOID:0000000001728344

1.INSPECTION START

Do you have CONSULT-III?

YES or NO

YES >> GO TO 2.

NO >> GO TO 3.

2.PERFORM SELF-DIAGNOSIS (WITH CONSULT-III)

With CONSULT-III

1. Turn ignition switch ON. (Do not start engine.)

2. Select SELF-DIAG RESULTS mode for ALL MODE AWD/4WD with CONSULT-III.

3. Touch ERASE.

4. Turn ignition switch OFF and wait at least 10 seconds.

5. Perform the self-diagnosis again.

Is the CONTROL UNIT 1 [P1802], CONTROL UNIT 2 [P1803], CONTROL UNIT 3 [P1804] or CONTROL

UNIT 4 [P1809] displayed?

YES >> Replace transfer control unit. Refer to DLN-135, "Removal and Installation".

NO >> Inspection End.

3.PERFORM SELF-DIAGNOSIS (WITHOUT CONSULT-III)

I

J

K

L

M

N

O

P

DLN-27

P1802 – P1804, P1809 TRANSFER CONTROL UNIT

< COMPONENT DIAGNOSIS >

Without CONSULT-III

1. Perform the self-diagnosis and then erase self-diagnostic results. Refer to DLN-20, "CONSULT-III Func-

tion (ALL MODE AWD/4WD)".

2. Perform the self-diagnosis again.

Do the self-diagnostic results indicate AD converter?

YES >> Replace transfer control unit.

NO >> Inspection End.

[TRANSFER: ATX14B]

DLN-28

P1807 VEHICLE SPEED SENSOR (A/T)

< COMPONENT DIAGNOSIS >

[TRANSFER: ATX14B]

P1807 VEHICLE SPEED SENSOR (A/T)

Description INFOID:0000000001728345

The transmission control module (TCM) transmits the output shaft revolution signal via CAN communication to

Transfer control unit. DTC P1807 will set when a malfunction is detected in the output shaft revolution signal

or an improper signal is input while driving.

DTC Logic INFOID:0000000001728346

DTC DETECTION LOGIC

DTC CONSULT-III Diagnostic item is detected when... Reference

• Malfunction is detected in output shaft

[P1807] VHCL SPEED SEN·AT

DTC CONFIRMATION PROCEDURE

revolution signal that is output from

TCM through CAN communication.

• Improper signal is input while driving.

Refer to DLN-29

.

1.DTC CONFIRMATION PROCEDURE

1. Turn ignition switch ON.

2. Perform self-diagnosis.

Is DTC P1807 detected?

YES >> Perform diagnosis procedure. Refer to DLN-29, "Diagnosis Procedure".

NO >> Inspection End.

A

B

C

DLN

E

F

G

H

Diagnosis Procedure INFOID:0000000001728347

1.CHECK DTC WITH TCM

Perform self-diagnosis with TCM. Refer to TM-35, "

Is any malfunction detected by self-diagnosis?

YES >> Check the malfunctioning system.

NO >> GO TO 2.

CONSULT-III Function (TRANSMISSION)".

2.CHECK TRANSFER CONTROL UNIT

Check transfer control unit input/output signal. Refer to DLN-83, "

Are the inspection results normal?

YES >> GO TO 3.

NO >> Check transfer control unit pin terminals for damage or loose connection with harness connector.

If any items are damaged, repair or replace damaged parts.

Reference Value".

3.CHECK DTC

Drive the vehicle and then perform self-diagnosis.

Are the inspection results normal?

YES >> Inspection End.

NO >> Perform self-diagnosis with TCM again.

I

J

K

L

M

N

O

DLN-29

P

P1808 VEHICLE SPEED SENSOR (ABS)

< COMPONENT DIAGNOSIS >

[TRANSFER: ATX14B]