Nissan Pathfinder 2008 User Manual

VENTILATION, HEATER & AIR CONDITIONER

SECTION HAC

A

B

HEATER & AIR CONDITIONING CONTROL SYSTEM

CONTENTS

AUTOMATIC AIR CONDITIONER

BASIC INSPECTION ....................................

DIAGNOSIS AND REPAIR WORKFLOW ..........4

How to Perform Trouble Diagnosis For Quick And

Accurate Repair ........................................................

INSPECTION AND ADJUSTMENT ..................... 5

Operational Check (Front) .........................................5

Operational Check (Rear) .........................................6

FUNCTION DIAGNOSIS ...............................8

FUNCTION INFORMATION ................................8

Component Part Location ...................... ...................8

Symptom Table .......................................................11

REFRIGERATION SYSTEM ..............................13

Refrigerant Cycle ....................................................13

Refrigerant System Protection ................................13

AUTOMATIC AIR CONDITIONER SYSTEM .....14

Control System Diagram .........................................14

Control System Description .....................................14

Discharge Air Flow (Front) ......................................17

Switches And Their Control Function (Front) ..........18

Switches And Their Control Function (Rear) ...........19

CAN COMMUNICATION SYSTEM ....................20

System Description .................................................20

DIAGNOSIS SYSTEM (HVAC) ..........................21

CONSULT-III Function (HVAC) ...............................21

COMPONENT DIAGNOSIS .........................25

MODE DOOR MOTOR ......................................25

4

System Description ..................................................25

Mode Door Motor (Front) Component Function

4

Check ......................................................................

Mode Door Motor (Front) Diagnosis Procedure ......27

AIR MIX DOOR MOTOR ...................................31

System Description ..................................................31

Air Mix Door Motor Component Function Check .....32

Air Mix Door Motor (Driver) Diagnosis Procedure ....33

Air Mix Door Motor (Passenger) Diagnosis Proce-

dure .........................................................................

INTAKE DOOR MOTOR ...................................41

System Description ..................................................41

Intake Door Motor Component Function Check ......42

Intake Door Motor Diagnosis Procedure .................43

BLOWER MOTOR CONTROL SYSTEM ..........45

System Description ..................................................45

Front Blower Motor Component Function Check ....46

Front Blower Motor Diagnosis Procedure ................47

Front Blower Motor Component Inspection .............50

Rear Blower Motor Description ................................51

Rear Blower motor Component Function Check .....52

Rear Air Control (Front) Diagnosis Procedure #1 ....53

Rear Air Control (Rear) Diagnosis Procedure #2 ....54

Rear Air Control (Rear) Diagnosis Procedure #3 ....55

Rear Air Control (Rear) Diagnosis Procedure #4 ....58

Rear Blower Motor And Relay Component Inspec-

tion ................................ ................................... ........

26

37

59

C

D

E

F

G

H

HAC

J

K

L

M

N

O

DIAGNOSIS SYSTEM (BCM) ............................22

CONSULT-III Function (BCM) .................................22

SELF-DIAGNOSIS FUNCTION ..........................23

A/C Auto Amp. Self-Diagnosis ................................23

A/C and AV Switch Assembly Self-Diagnosis .........23

A/C System Self-Diagnosis Code Chart ..................24

HAC-1

REAR AIR CONTROL SYSTEM .......................61

Rear Air Control System Description .......................61

Rear Air Control Component Function Check .........61

Rear Air Control (Front) Diagnosis Procedure .........62

Rear Air Control (Rear) Diagnosis Procedure .........64

MAGNET CLUTCH ...........................................67

System Description ..................................................67

P

Magnet Clutch Component Function Check ........... 67

Magnet Clutch Diagnosis Procedure ...................... 68

MEMORY FUNCTION DOES NOT OPERAT E ..119

Memory Function Check ....................................... 119

WATER VALVE CIRCUIT ..................................72

Water Valve Description (VK56DE) ........................ 72

Water Valve Diagnosis Procedure (VK56DE) ......... 72

HEATER PUMP ................................................. 74

System Description (VQ40DE) ............................... 74

Diagnosis Procedure (VQ40DE) ............................. 74

Component Inspection (VQ40DE) .......................... 76

AMBIENT SENSOR ........................................... 77

Component Description .......................................... 77

Ambient Sensor Diagnosis Procedure .................... 77

Ambient Sensor Component Inspection ................. 78

IN-VEHICLE SENSOR ....................................... 80

Component Description .......................................... 80

In-Vehicle Sensor Diagnosis Procedure ................. 80

In-Vehicle Sensor Component Inspection .............. 82

OPTICAL SENSOR ........................................... 83

Component Description .......................................... 83

Optical Sensor Diagnosis Procedure ...................... 83

INTAKE SENSOR .............................................. 85

System Description .......................... .... ... ... ... .......... 85

Intake Sensor Diagnosis Procedure ....................... 85

Intake Sensor Component Inspection .................... 86

PRECAUTION ...........................................120

PRECAUTIONS ................................................120

Supplemental Restraint System (SRS) "AIR BAG"

and "SEAT BELT PRE-TENSIONER" ..................

Working with HFC-134a (R-134a) ......................... 120

Precaution for Service Equipment ........................ 121

120

MANUAL AIR CONDITIONER

BASIC INSPECTION .................................122

DIAGNOSIS AND REPAIR WORKFLOW ........122

How to Perform Trouble Diagnosis For Quick And

Accurate Repair ..................... .... ... ........................

122

INSPECTION AND ADJUSTMENT ..................123

Operational Check ................................................ 123

FUNCTION DIAGNOSIS ...........................125

FUNCTION INFORMATION .............................125

Component Part Location ..................................... 125

Symptom Table ..................................................... 127

REFRIGERATION SYSTEM .............................128

Refrigerant Cycle .................................................. 128

Refrigerant System Protection .............................. 128

POWER SUPPLY AND GROUND CIRCUIT

FOR CONTROLLER ..........................................

Component Description .......................................... 87

A/C Auto Amp. Component Function Check .......... 87

A/C Auto Amp Power and Ground Diagnosis Pro-

cedure ........................... .......................... ................

87

88

ECU DIAGNOSIS ........................................ 89

AIR CONDITIONER CONTROL ........................89

A/C Auto Amp. Terminals Reference Values ......... 89

Wiring Diagram ....................................................... 91

SYMPTOM DIAGNOSIS ............................106

AIR CONDITIONER CONTROL ...................... 106

Symptom Matrix Chart .........................................106

INSUFFICIENT COOLING ............................... 107

Component Function Check ..................................107

Performance Test Diagnoses ........................... .....108

Performance Chart . ... ... ... ......................................110

Test Reading .........................................................111

Trouble Diagnoses for Unusual Pressure ..............112

INSUFFICIENT HEATING ............................... 115

Component Function Check ..................................115

NOISE .............................................................. 117

Component Function Check ..................................117

MANUAL AIR CONDITIONER SYSTEM .........129

Control System Diagram ....................................... 129

Control System Description .................................. 129

Discharge Air Flow ................................................ 131

Switches And Their Control Function .................... 131

CAN COMMUNICATION SYSTEM ..................133

System Description ............................................... 133

DIAGNOSIS SYSTEM (BCM) ...........................134

CONSULT-III Function (BCM) ......................... ... .. 134

COMPONENT DIAGNOSIS ......................135

MODE DOOR MOTOR .....................................135

System Description ............................................... 135

Mode Door Motor (Front) Component Funct ion

Check ............................... .....................................

Mode Door Motor (Front) Diagnosis Procedure .... 136

AIR MIX DOOR MOTOR ..................................139

System Description ............................................... 139

Air Mix Door Motor Component Function Check .. 140

Air Mix Door Motor Diagnosis Procedure .............. 141

INTAKE DOOR MOTOR ...................................143

System Description ............................................... 143

Intake Door Motor Component Function Check .... 143

Intake Door Motor Diagnosis Procedure ............... 144

BLOWER MOTOR ............................................146

135

HAC-2

System Description ...............................................

Front Blower Motor Component Function Check ..146

Front Blower Motor Diagnosis Procedure . ... .... .....147

Front Blower Motor Component Inspection ...........151

146

MAGNET CLUTCH ...........................................152

System Description ...............................................152

Magnet Clutch Component Function Check .........152

Magnet Clutch Diagnosis Procedure .....................152

INTAKE SENSOR ............................................157

System Description ...............................................157

Intake Sensor Diagnosis Procedure ......................157

Intake Sensor Component Inspection ...................158

POWER SUPPLY AND GROUND CIRCUIT

FOR CONTROLLER ........................................

Component Description ................................ .... .....159

Front Air Control Component Function Check ......159

Front Air Control Power and Ground Diagnosis

Procedure ..................... ................ ................ .........

159

160

ECU DIAGNOSIS .......................................161

AIR CONDITIONER CONTROL .......................161

System Description ...............................................161

System Operation .................................................161

Front Air Control Terminals Reference Values .....162

Wiring Diagram ......................................................164

SYMPTOM DIAGNOSIS ............................171

AIR CONDITIONER CONTROL ......................171

Symptom Matrix Chart .........................................171

INSUFFICIENT COOLING ..............................172

Component Function Check ..................................172

Performance Test Diagnoses ................................173

Performance Chart ................................................175

Test Reading ......................................... ................176

Trouble Diagnoses for Unusual Pressure ..............177

INSUFFICIENT HEATING ...............................181

Component Function Check ..................................181

NOISE ..............................................................183

Component Function Check ..................................183

PRECAUTION ............................................185

PRECAUTIONS ...............................................185

Supplemental Restraint System (SRS) "AIR BAG"

and "SEAT BELT PRE-TENSIONER" ...................

Working with HFC-134a (R-134a) ................... ... ...185

Precaution for Service Equipment .........................186

185

A

B

C

D

E

F

G

H

HAC

J

K

L

M

N

O

P

HAC-3

DIAGNOSIS AND REPAIR WORKFLOW

< BASIC INSPECTION >

[AUTOMATIC AIR CONDITIONER]

BASIC INSPECTION

DIAGNOSIS AND REPAIR WORKFLOW

How to Perform Trouble Diagnosis For Quick And Accurate Repair INFOID:0000000001366682

WORK FLOW

1.LISTEN TO CUSTOMER COMPLAINT

Listen to customer complaint. Get detailed information about the conditions and environment when the symptom occurs.

>> GO TO 2

2.CHECK FOR SERVICE BULLETINS

Check for any service bulletins.

>> GO TO 3.

3.VERIFY THE SYMPTOM WITH OPERATIONAL CHECK

Verify the symptom with operational check. Refer to HAC-123, "

Can a symptom be duplicated?

YES >> GO TO 4

NO >> GO TO 5

4.GO TO APPROPRIATE TROUBLE DIAGNOSIS

Go to appropriate trouble diagnosis. Refer to HAC-171, "

Can a symptom be duplicated?

>> GO TO 5.

Symptom Matrix Chart".

5.PERFORM THE A/C AUTO AMP SELF-DIAGNOSIS

Perform A/C auto amp. self-diagnosis. Refer to HAC-23, "

>> If any diagnostic trouble codes set. Refer to HAC-24, "

>> Confirm the repair by performing operational check. Refer to HAC-123, "

A/C Auto Amp. Self-Diagnosis".

Operational Check".

A/C System Self-Diagnosis Code Chart".

Operational Check".

HAC-4

< BASIC INSPECTION >

INSPECTION AND ADJUSTMENT

[AUTOMATIC AIR CONDITIONER]

INSPECTION AND ADJUSTMENT

Operational Check (Front) INFOID:0000000001366683

The purpose of the operational check is to confirm that the system operates properly.

Conditions : Engine running and at normal operating temperature

CHECKING MEMORY FUNCTION

1. Set the temperature to 32°C (90°F).

2. Press the OFF switch.

3. Turn ignition switch OFF.

4. Turn ignition switch ON.

5. Press the AUTO switch.

6. Confirm that the set temperature remains at previous temperature.

7. Press the OFF switch.

If NG, go to trouble diagnosis procedure for HAC-119, "

If OK, continue with next check.

CHECKING BLOWER

1. Press the blower speed control switch (+) once, blower should operate on low speed. The fan display

should have one bar lit (on display).

2. Press the blower speed control switch (+) again, and continue checking blower speed and fan display until

all speeds are checked.

3. Leave blower on maximum speed.

If NG, go to trouble diagnosis procedure for HAC-147, "

If OK, continue with next check.

Memory Function Check".

Front Blower Motor Diagnosis Procedure".

A

B

C

D

E

F

G

H

HAC

CHECKING DISCHARGE AIR

1. Press MODE switch four times and the DEF switch.

2. Each position indicator should change shape (on display).

3. Confirm that discharge air comes out according to the air distribution table. Refer to HAC-17, "

Air Flow (Front)"

Mode door position is checked in the next step.

If NG, go to trouble diagnosis procedure for HAC-136, "

If OK, continue the check.

NOTE:

Confirm that the compressor clutch is engaged (sound or visual inspection) and intake door position is at

fresh when the FOOT, DEF or D/F is selected.

Mode Door Motor (Front) Diagnosis Procedure".

Discharge

CHECKING RECIRCULATION ( , ONLY)

1. Press recirculation ( ) switch one time. Recirculation indicator should illuminate.

2. Press recirculation ( ) switch one more time. Recirculation indicator should go off.

3. Listen for intake door position change (blower sound should change slightly).

If NG, go to trouble diagnosis procedure for HAC-144, "

If OK, continue the check.

NOTE:

Confirm that the compressor clutch is engaged (sound or visual inspection) and intake door position is at fresh

when the FOOT, DEF or D/F is selected. REC ( ) is not allowed in DEF ( ) D/F ( ) or FOOT ( ).

Intake Door Motor Diagnosis Procedure".

CHECKING TEMPERATURE DECREASE

1. Rotate temperature control dial (drive or passenger) counterclockwise until 18°C (60°F) is displayed.

2. Check for cold air at appropriate discharge air outlets.

J

K

L

M

N

O

P

HAC-5

INSPECTION AND ADJUSTMENT

< BASIC INSPECTION >

If NG, listen for sound of air mix door motor operation. If OK, go to trouble diagnosis procedure for HAC-172,

"Component Function Check". If air mix door motor appears to be malfunctioning, go to HAC-32, "Air Mix Door

Motor Component Function Check".

If OK, continue the check.

CHECKING TEMPERATURE INCREASE

1. Rotate temperature control dial clockwise (drive or passenger) until 32°C (90°F) is displayed.

2. Check for hot air at appropriate discharge air outlets.

If NG, listen for sound of air mix door motor operation. If OK, go to trouble diagnosis procedure for HAC-181,

"Component Function Check". If air mix door motor appears to be malfunctioning, go to HAC-32, "Air Mix Door

Motor Component Function Check".

If OK, continue with next check.

CHECK A/C SWITCH

1. Press A/C switch when AUTO switch is ON, or in manual mode.

2. A/C switch indicator will turn ON.

• Confirm that the compressor clutch engages (sound or visual inspection).

NOTE:

If current mode setting is DEF or D/F, compressor clutch will already be engaged and cannot be turned off.

If NG, go to trouble diagnosis procedure for HAC-152, "

If OK, continue with next check.

Magnet Clutch Diagnosis Procedure".

[AUTOMATIC AIR CONDITIONER]

CHECKING AUTO MODE

1. Press AUTO switch.

2. Display should indicate AUTO.

• If ambient temperature is warm, and selected temperature is cool, confirm that the compressor clutch

engages (sound or visual inspection). (Discharge air and blower speed will depend on ambient, in-vehicle, and set temperatures.)

If NG, go to trouble diagnosis procedure for HAC-160, "

dure", then if necessary, trouble diagnosis procedure for HAC-152, "Magnet Clutch Diagnosis Procedure".

If all operational checks are OK (symptom cannot be duplicated), go to malfunction Simulation Tests in HAC-

122, "How to Perform Trouble Diagnosis For Quick And Accurate Repair" and perform test s as outlined to sim-

ulate driving conditions environment. If symptom appears. Refer to HAC-171, "

perform applicable trouble diagnosis procedures.

Front Air Control Power and Ground Diagnosis Proce-

Symptom Matrix Chart", and

Operational Check (Rear) INFOID:0000000001366684

The purpose of the operational check is to confirm that the system operates properly.

Conditions : Engine running and at normal operating temperature

CHECKING REAR BLOWER MOTOR

1. Turn the ignition switch ON.

2. Rotate rear air control (front) blower control dial to low speed.

3. Rotate the blower control dial clockwise and continue checking blower speed until all speeds are checked.

4. Leave blower on maximum speed.

5. Press the REAR CTRL switch from the rear air control (front).

6. Rotate rear air control (rear) blower control dial to low speed.

7. Rotate the blower control dial clockwise and continue checking blower speed until all speeds are checked.

8. Leave blower on maximum speed.

If NG, go to trouble diagnosis procedure for HAC-52, "

If OK, continue with next check.

Rear Blower motor Component Function Check".

CHECKING REAR TEMPERATURE DECREASE

1. Press the REAR CTRL switch (indicator off).

2. Rotate the rear air control (front) temperature control dial counterclockwise to maximum cold.

3. Check for cold air at appropriate discharge air outlets.

HAC-6

INSPECTION AND ADJUSTMENT

< BASIC INSPECTION >

4. Press the REAR CTRL switch (indicator on) from the rear air control (front).

5. Rotate the rear air control (rear) temperature control dial counterclockwise to maximum cold.

6. Check for cold air at appropriate discharge air outlets.

If NG, listen for sound of air mix door motor operation. If OK, go to trouble diagnosis procedure for HAC-140,

"Air Mix Door Motor Component Function Check". If air mix door motor appears to be malfunctioning, go to

HAC-64, "

If OK, continue with next check.

Rear Air Control (Rear) Diagnosis Procedure".

CHECKING REAR TEMPERATURE INCREASE

1. Press the REAR CTRL switch (indicator off).

2. Rotate the rear air control (front) temperature control dial clockwise to maximum heat.

3. Check for hot air at appropriate discharge air outlets.

4. Press the REAR CTRL switch (indictor on) from the rear air control (front).

5. Rotate the rear air control (rear) temperature control dial clockwise to maximum heat.

6. Check for hot air at appropriate discharge air outlets.

If NG, listen for sound of air mix door motor operation. If OK, go to trouble diagnosis procedure for HAC-115,

"Component Function Check". If air mix door motor appears to be malfunctioning, go to HAC-64, "Rear Air

Control (Rear) Diagnosis Procedure".

If NG, go to trouble diagnosis procedure for HAC-181, "

If all operational checks are OK (symptom cannot be duplicated), go to HAC-122, "

Diagnosis For Quick And Accurate Repair" and perform tests as outlined. If symptom appears, refer to HAC171, "Symptom Matrix Chart" and perform applicable trouble diagnosis procedures.

Component Function Check".

[AUTOMATIC AIR CONDITIONER]

How to Perform Trouble

A

B

C

D

E

F

G

H

HAC

J

K

L

M

N

O

P

HAC-7

FUNCTION INFORMATION

< FUNCTION DIAGNOSIS >

[AUTOMATIC AIR CONDITIONER]

FUNCTION DIAGNOSIS

FUNCTION INFORMATION

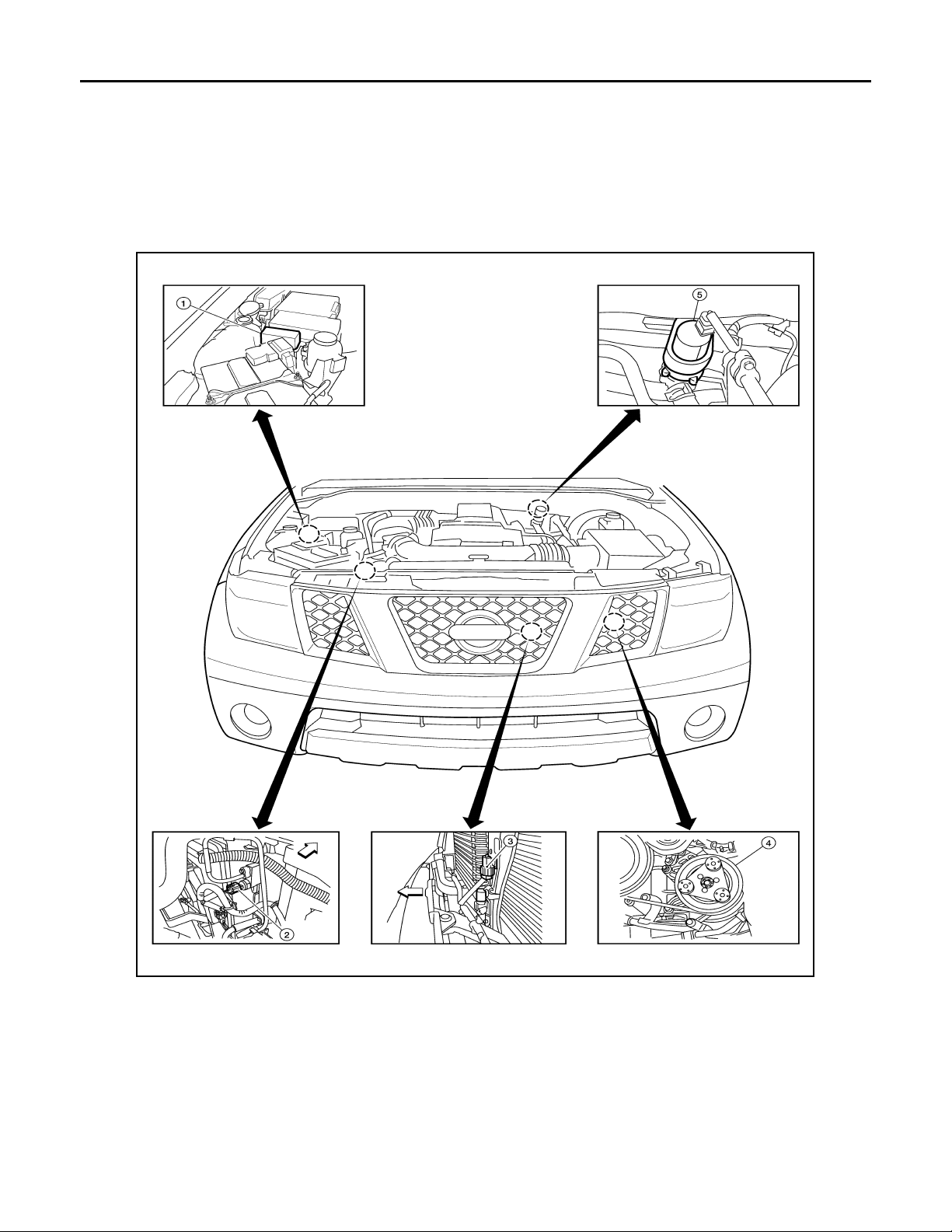

Component Part Location INFOID:0000000001366685

ENGINE COMPARTMENT

VQ40DE

1. Heater pump relay E144 2. Refrigerant pressure sensor E48

(View with battery removed)

⇐: Front

4. A/C Compressor F3 5. Heater pump E141

HAC-8

WJIA2270E

3. Ambient sensor E1 (View with grille

removed)

< FUNCTION DIAGNOSIS >

FUNCTION INFORMATION

[AUTOMATIC AIR CONDITIONER]

VK56DE

A

B

C

D

E

F

G

1. Refrigerant pressure sensor E48

(View with battery removed)

⇐: Front

4. Water valve F68

2. Ambient sensorE1 (View with grille

removed)

3. A/C Compressor F3

H

HAC

J

K

L

AWIIA0220ZZ

M

N

O

PASSENGER COMPARTMENT

P

HAC-9

< FUNCTION DIAGNOSIS >

FUNCTION INFORMATION

[AUTOMATIC AIR CONDITIONER]

1. A/C Auto amp. M49, M50 2. In-vehicle sensor M32 3. Intake sensor M146

4. Intake door motor M58 5. Variable blower control (front)

M122

7. Mode door motor (front) M142 8. Air mix door motor (passenger)

M143

⇐ :Front ⇐

6. Air mix door motor (driver) M147

9. Optical sensor M145

HAC-10

AWIIA0221ZZ

FUNCTION INFORMATION

< FUNCTION DIAGNOSIS >

REAR PASSENGER COMPARTMENT

[AUTOMATIC AIR CONDITIONER]

A

B

C

D

E

F

G

AWIIA0222ZZ

1. Rear air control (front) R2 2. Air mix door motor (rear) B155 3. Rear blower motor B501

4. Variable blower control (rear) B133 5. Rear air control (rear) M208

Symptom Table INFOID:0000000001366686

Symptom Reference Page

A/C system does not come on. Go to Trouble Diag nosis Procedure for A/C System. HAC-87

A/C system display is malfunctioning (with

NAVI).

A/C system display is malfunctioning (without

NAVI).

A/C system cannot be controlled. Go to Self-diagnosis Function. HAC-23

Air outlet does not change.

Mode door motor is malfunctioning.

Discharge air temperature does not change.

Air mix door motor is malfunctioning.

Go to Navigation System. AV-337

Go to Mid-level Audio System. AV-179

Go to Trouble Diagnosis Procedure for Mode Door Motor. HAC-27

Go to Trouble Diagnosis Procedure for Air Mix Door Motor. HAC-32

H

HAC

J

K

L

M

N

O

P

HAC-11

FUNCTION INFORMATION

< FUNCTION DIAGNOSIS >

Symptom Reference Page

Intake door does not change.

Intake door motor is malfunctioning.

Front blower motor operation is malfunction-

ing.

Rear blower motor operation is malfunction-

ing.

Rear discharge air temperature and/or air

outlet does not change.

Magnet clutch does not engage. Go to Trouble Diagnosis Procedure for Magnet Clutch. HAC-68

Insufficient cooling Go to Trouble Diagnosis Procedure for Insufficient Cooling. HAC-107

Insufficient heating Go to Trouble Diagnosis Procedure for Insufficient Heating. HAC-115

Noise Go to Trouble Diagnosis Procedure for Noise. HAC-117

Self-diagnosis cannot be performed. Go to Trouble Diagnosis Procedure for Self-diagnosis. HAC-87

Memory function does not operate. Go to Trouble Diagnosis Procedure for Memory Function. HAC-119

Go to Trouble Diagnosis Procedure for Intake Door Motor. HAC-43

Go to Trouble Diagnosis Procedure for Front Blower Motor. HAC-47

Go to Trouble Diagnosis Procedure for Rear Blower Motor. HAC-52

Go to Trouble Diagnosis Procedure for Rear Air Control circuit. HAC-61

[AUTOMATIC AIR CONDITIONER]

HAC-12

< FUNCTION DIAGNOSIS >

REFRIGERATION SYSTEM

[AUTOMATIC AIR CONDITIONER]

REFRIGERATION SYSTEM

Refrigerant Cycle INFOID:0000000001366687

Refer to HAC-13, "Refrigerant Cycle".

Refrigerant System Protection INFOID:0000000001366688

Refer to HAC-13, "Refrigerant System Protection".

A

B

C

D

E

F

G

H

HAC

J

K

L

M

N

O

P

HAC-13

AUTOMATIC AIR CONDITIONER SYSTEM

< FUNCTION DIAGNOSIS >

[AUTOMATIC AIR CONDITIONER]

AUTOMATIC AIR CONDITIONER SYSTEM

Control System Diagram INFOID:0000000001366689

CONTROL SYSTEM

The control system consists of input sensors, switches, the A/C auto amp. (microcomputer) and outputs.

The relationship of these components is shown in the figure below:

AWIIA0223GB

Control System Description INFOID:0000000001366690

CONTROL OPERATION

HAC-14

AUTOMATIC AIR CONDITIONER SYSTEM

< FUNCTION DIAGNOSIS >

[AUTOMATIC AIR CONDITIONER]

A/C Auto Amp.

A

B

C

D

E

AWIIA0081ZZ

DISPLAY SCREEN

Displays the operational status of the system.

AUTO SWITCH

• Pressing the AUTO switch will illuminate the LED and "Auto" will be visible on the display. The A/C indicator

will illuminate.

• The A/C compressor, intake door, air mix doors, outlet doors and blower speed are automatically controlled

so that the in-vehicle temperature will reach, and be maintained at the set temperature selected by the operator.

• When pressing AUTO switch, air inlet, air outlet, blower speed, and discharge air temperature are automatically controlled.

• A partial AUTO mode can be achieved by only changing the blower speed or by changing the mode position.

If both the blower speed and the mode positions are changed, the AUTO mode will be cancelled.

TEMPERATURE CONTROL DIAL (DRIVER)

Increases or decreases the set temperature.

TEMPERATURE CONTROL DIAL (PASSENGER)

Increases or decreases the set temperature.

RECIRCULATION ( ) SWITCH

• When REC switch is ON, REC switch indicator turns ON, and air inlet is set to REC.

• When REC switch is turned OFF, or when compressor is turned from ON to OFF, REC switch is automatically turned OFF. REC mode can be re-entered by pressing REC switch again.

• REC switch is not operated when DEF switch is turned ON, at the D/F position, or in floor position.

F

G

H

HAC

J

K

L

M

DEFROSTER ( ) SWITCH

Positions the air outlet doors to the defrost position. Also positions the intake doors to the outside air position,

and turns A/C compressor ON.

REAR WINDOW DEFOGGER SWITCH

When switch is ON, rear window and door mirrors are defogged.

OFF SWITCH

The A/C compressor and blower are OFF, the intake doors are set to the out side ai r position, and the ai r outl et

doors are set to the foot (75% foot and 25% defrost) position.

A/C SWITCH

The compressor is ON or OFF.

(Pressing the A/C switch when the AUTO switch is ON will turn off the A/C switch and compressor.)

MODE SWITCH

Controls the air discharge outlets.

HAC-15

N

O

P

AUTOMATIC AIR CONDITIONER SYSTEM

< FUNCTION DIAGNOSIS >

FRONT BLOWER CONTROL SWITCHES

Manually control the blower speed.

Rear Air Controls

1. Rear air control (front) 2. Rear air control (rear)

[AUTOMATIC AIR CONDITIONER]

AWIIA0224ZZ

TEMPERATURE CONTROL DIAL (TEMPERATURE AND MODE CONTROL)

The temperature increases or decreases the set temperature. The mode also changes from foot at full hot setting, to foot/vent at mid-range (warm) setting, and then to vent at full cold setting.

REAR BLOWER CONTROL DIAL (FRONT)

When the REAR CTRL switch is in the off (indicator off) the rear air control (front) controls the rear blower

motor speed regardless of the rear air control (rear) blower control dial (rear) position. The rear air control

(front) controls the blower motor speed.

REAR BLOWER CONTROL DIAL (REAR)

When the REAR CTRL switch is on (indicator on) the rear air control (rear) controls the rear blower motor

speed regardless of the rear air control (front) blower control dial (front) position. The rear air control (rear)

controls the blower motor speed.

MAGNET CLUTCH CONTROL

AWIIA0089GB

When A/C switch or DEF switch is pressed, A/C auto amp. inputs compressor ON signal to BCM.

BCM sends compressor ON signal to ECM and A/C auto amp., via CAN communication line.

HAC-16

AUTOMATIC AIR CONDITIONER SYSTEM

< FUNCTION DIAGNOSIS >

ECM judges whether compressor can be turned ON, based on each sensor status (refrigerant pressure sensor signal, throttle angle sensor, etc.). If it judges compressor can be turned ON, it sends compressor ON signal to IPDM E/R, via CAN communication line.

Upon receipt of compressor ON signal from ECM, IPDM E/R turns air conditioner relay ON to operate compressor.

[AUTOMATIC AIR CONDITIONER]

Discharge Air Flow (Front) INFOID:0000000001366691

LJIA0172E

Mode door position

Vent Foot Defroster

100% 0% —

Air outlet/distribution

A

B

C

D

E

F

G

H

60% 40% —

18% 64% 18%

14% 53% 33%

—13% 87%

HAC

J

K

L

M

N

O

HAC-17

P

AUTOMATIC AIR CONDITIONER SYSTEM

< FUNCTION DIAGNOSIS >

[AUTOMATIC AIR CONDITIONER]

Switches And Their Control Function (Front)

INFOID:0000000001366693

WJIA1680E

HAC-18

AWIIA0236GB

AUTOMATIC AIR CONDITIONER SYSTEM

< FUNCTION DIAGNOSIS >

[AUTOMATIC AIR CONDITIONER]

Switches And Their Control Function (Rear) INFOID:0000000001366694

A

B

C

D

E

F

G

AWIIA0239GB

H

HAC

J

K

L

M

N

O

HAC-19

P

AWIIA0240GB

CAN COMMUNICATION SYSTEM

< FUNCTION DIAGNOSIS >

[AUTOMATIC AIR CONDITIONER]

CAN COMMUNICATION SYSTEM

System Description INFOID:0000000001366695

Refer to LAN-4, "System Description".

HAC-20

< FUNCTION DIAGNOSIS >

DIAGNOSIS SYSTEM (HVAC)

[AUTOMATIC AIR CONDITIONER]

DIAGNOSIS SYSTEM (HVAC)

CONSULT-III Function (HVAC) INFOID:0000000001366696

CONSULT-III can display each diagnostic item using the diagnostic test modes shown following.

Diagnostic mode Description

SELF-DIAG RESULTS Displays A/C auto amp. self-diagnosis results.

DATA MONITOR Displays A/C auto amp. input/output data in real time.

CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication can be read.

ECU PART NUMBER A/C auto amp. part number can be read.

SELF-DIAGNOSIS

Display Item List

DTC Description

B2573 Battery voltage out of range CHG-4, "

B2578 In-vehicle sensor circuit out of range (low)

B2579 In-vehicle sensor circuit out of range (high)

B257B Ambient sensor circuit short

B257C Ambient sensor circuit open

B257F Optical sensor (Driver) circuit open or short

B2580 Optical sensor (Passenger) circuit open or short

B2581 Intake sensor circuit short

B2582 Intake sensor circuit open

U1000 CAN bus fau lt LAN-4, "

HAC-80, "

HAC-77, "

HAC-83, "

HAC-85, "

Work Flow"

In-Vehicle Sensor Diagnosis Procedure"

Ambient Sensor Diagnosis Procedure"

Optical Sensor Diagnosis Procedure".

Intake Sensor Diagnosis Procedure"

System Description"

Reference page

A

B

C

D

E

F

G

H

HAC

J

DATA MONITOR

Display Item List

Monitor item Value Contents

BATT VIA CAN "V" Displays battery voltage signal.

IGN VIA CAN "ON/OFF" Displays ignition switch signal.

DVR SUNLD SEN "w/m2" Displays optical sensor (driver) signal.

PAS SUNLD SEN "w/m2" Displays optical sensor (passenger) signal.

AMB TEMP SEN "°C/°F" Displays ambient sensor signal.

EVAP TEMP SEN "°C/°F" Displays intake sensor signal.

INCAR TMP SEN "°C/°F" Displays in-vehicle sensor signal.

RR TEMPSET FR "V" Displays air mix door (front) set point signal.

RR TEMPSET RR "V" Displays air mix door (rear) set point signal.

MODE FDBCK "V" Displays mode door motor feedback signal.

DVR MIX FDBCK "V" Displays air mix door motor (driver) feedback signal.

PAS MIX FDBCK "V" Displays air mix door motor (passenger) feedback signal.

RR FDBCK "V" Displays air mix door motor (rear) feedback signal.

K

L

M

N

O

P

HAC-21

DIAGNOSIS SYSTEM (BCM)

< FUNCTION DIAGNOSIS >

[AUTOMATIC AIR CONDITIONER]

DIAGNOSIS SYSTEM (BCM)

CONSULT-III Function (BCM) INFOID:0000000001366697

CONSULT-II can display each diagnostic item using the diagnostic test modes shown following.

BCM diagnostic

test item

Inspection by part

Diagnostic mode Description

Supports inspections and adjustments. Co mmands are transmit ted to the BCM for

WORK SUPPORT

DATA MONITOR Displays BCM input/output data in real time.

ACTIVE TEST Operation of electrical loads can be checked by sending drive signal to them.

SELF-DIAG RESULTS Displays BCM self-diagnosis results.

CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication can be read.

ECU PART NUMBER BCM part number can be read.

CONFIGURATION Performs BCM configuration read/write functions.

setting the status suit able for req uired operatio n, input/ou tput signals a re received

from the BCM and received data is displayed.

DATA MONITOR

Display Item List

Monitor item name “operation or

unit”

IGN ON SW “ON/OFF” Displays “IGN Position (ON)/OFF, ACC Position (OFF)” status as judged from ignition switch signal.

COMP ON SIG “ON/OFF” Displays “COMP (ON)/COMP (OFF)” status as judged from air conditioner switch signal.

FAN ON SIG “ON/OFF” Displays “FAN (ON)/FAN (OFF)” status as judged from blower motor switch signal.

Contents

HAC-22

< FUNCTION DIAGNOSIS >

Z

SELF-DIAGNOSIS FUNCTION

[AUTOMATIC AIR CONDITIONER]

SELF-DIAGNOSIS FUNCTION

A/C Auto Amp. Self-Diagnosis INFOID:0000000001366698

A/C SYSTEM SELF-DIAGNOSIS FUNCTION

The self-diagnosis function is built into the A/C auto amp. to quickly locate the cause of malfunctions.

DESCRIPTION

The self-diagnostic system diagnoses sensors, CAN system, and battery voltage on A/C auto amp. Refer to

applicable sections (items) for details. Fault codes (if any are present) will be displayed in the ambient temperature display area. Refer to HAC-24, "

SELF-DIAGNOSTIC MODE

NOTE:

Radio must be OFF.

1. Turn the ignition switch ON.

2. On the A/C and AV switch assembly, press the "SETTING" button and twist the volume knob clockwise and counterclockwise

until the Self-Diagnosis screen shows on the display.

3. Scroll down to "Confirmation/Adjustment" and press the

"ENTER" button.

4. Scroll down to "Climate Control" and press the "ENTER" button.

5. The fan bars will flash on the display during the self-test, and

then the fault codes will display in the ambient temperature area.

They will continue scrolling until diagnostic mode is exited.

6. Exit by pressing the "BACK" button on A/C and AV switch

assembly until display returns to its normal operation screen.

HVAC system will be OFF or by turning the ignition switch OFF.

A/C System Self-Diagnosis Code Chart".

AWNIA0098Z

A

B

C

D

E

F

G

H

HAC

The self-diagnostic system diagnoses sensors, CAN system, and battery voltage on A/C auto amp. Refer to

applicable sections (items) for details. Fault codes (if any are present) will be displayed in the ambient temperature display area. Refer to HAC-24, "

A/C System Self-Diagnosis Code Chart".

AWIIA0081ZZ

A/C and AV Switch Assembly Self-Diagnosis INFOID:0000000001366699

J

K

L

M

N

O

P

A/C and AV switch assembly self-diagnosis function

The ON/OFF operation (continuity) of each switch in the A/C and AV switch assembly can be checked.

Self-diagnosis mode

HAC-23

SELF-DIAGNOSIS FUNCTION

< FUNCTION DIAGNOSIS >

• Press the “BACK” switch and the “UP” switch within 10 seconds

after turning the ignition switch from OFF to ACC and hold them for

3 seconds or more. Then the buzzer sounds, all indicators of the

preset switch illuminate, and the self-diagnosis mode starts.

• The continuity of each switch and control dials (A/C and AV switch

assembly only) at the ON position can be checked by pressing

each switch and turning each control dial. The buzzer sounds and

LED's will illuminate if the switch is normal.

Finishing self-diagnosis mode

Self-diagnosis mode is canceled when turning the ignition switch OFF.

[AUTOMATIC AIR CONDITIONER]

AWIIA0171GB

A/C System Self-Diagnosis Code Chart INFOID:0000000001366700

SELF-DIAGNOSTIC CODE CHART

Code No. Reference page

02 EE changed by calibration VTL-8, "

03 Battery voltage out of range CHG-10, "Inspection Procedure"

12 Passenger air mix door open/short/out of limits

22 Driver air mix door open/short HAC-33, "Air Mix Door Motor (Driver) Diagnosis Procedure"

30 In-vehicle sensor circuit out of range (low)

31 In-vehicle sensor c ircuit out of range (high)

38 Air mix door motor (rear) circuit failure HAC-61, "

40 Ambient sensor circuit short

41 Ambient sensor circuit open

44 Intake door motor open

46 Intake door motor short

50 Optical sensor (Driver) circuit open or short

52 Optical sensor (Passenger) circuit open or short

56 Intake sensor circuit short

57 Intake sensor circuit open

80 CAN bus fault

81 BCM message missing

82 Intake door motor circuit malfunction HAC-43, "Intake Door Motor Diagnosis Procedure"

90 Stuck button VTL-8, "Removal and Installation "

92 Mode door motor circuit malfunction

HAC-37, "

dure"

HAC-80, "

HAC-77, "

HAC-43, "

HAC-83, "

HAC-157, "

LAN-14, "

HAC-26, "

Check"

Removal and Installation"

Air Mix Door Motor (Passenger) Diagnosis Proce-

In-Vehicle Sensor Diagnosis Procedure"

Rear Air Control Component Function Check "

Ambient Sensor Diagnosis Procedure"

Intake Door Motor Diagnosis Procedure"

Optical Sensor Diagnosis Procedure"

Intake Sensor Diagnosis Procedure"

Trouble Diagnosis Flow Chart"

Mode Door Motor (Front) Component Function

HAC-24

< COMPONENT DIAGNOSIS >

MODE DOOR MOTOR

[AUTOMATIC AIR CONDITIONER]

COMPONENT DIAGNOSIS

MODE DOOR MOTOR

System Description INFOID:0000000001366701

SYSTEM DESCRIPTION

Component Parts

Mode door control system components are:

• A/C auto amp.

• A/C and AV switch assembly

• Mode door motor (front)

• PBR (built into mode door motor)

• In-vehicle sensor

• Ambient sensor

• Optical sensor

• Intake sensor

System Operation

The mode door position (vent, B/L, foot, D/F, and defrost) is set by the A/C auto amp. by means of the mode

door motor (front). When a mode door position is selected on the A/C auto amp., voltage is applied to one circuit of the mode door motor (front) while ground is applied to the other circuit, causing the mode door motor

(front) to rotate. The direction of rotation is determined by which circuit has voltage applied to it, and which one

has ground applied to it. The A/C auto amp. monitors the mode door position by measuring the voltage signal

on the PBR circuit.

In AUTO mode the mode door position is set by the A/C auto amp. which determines the proper position

based on inputs from the in-vehicle sensor, ambient sensor, optical sensor , intake sensor, and the temperature

selected by the driver or passenger.

A

B

C

D

E

F

G

H

HAC

Mode Door Control Specification

COMPONENT DESCRIPTION

Mode Door Motor (Front)

J

K

L

M

N

AWIIA0092GB

O

P

HAC-25

AWIIA0093GB

MODE DOOR MOTOR

< COMPONENT DIAGNOSIS >

The mode door motor (front) is attached to the heater & cooling unit

assembly. It rotates so that air is discharged from the outlet as indicated by the A/C auto amp. Motor rotation is conveyed to a link

which activates the mode door.

[AUTOMATIC AIR CONDITIONER]

WJIA1084E

Mode Door Motor (Front) Component Function Check INFOID:0000000001366702

INSPECTION FLOW

1.CONFIRM SYMPTOM BY PERFORMING OPERATIONAL CHECK - DISCHARGE AIR

1. Press mode switch four times and then press the (DEF) switch. Each position indicator should change

shape (on display).

2. Confirm that discharge air comes out according to the air distribution table. Refer to HAC-131, "

Air Flow".

NOTE:

Confirm that the compressor clutch is engaged (visual inspection) and intake door position is at FRESH

when FOOT ( ), DEF ( ) or D/F ( ) is selected.

Can a symptom be duplicated?

YES >> GO TO 3.

NO >> GO TO 2.

Discharge

2.PERFORM COMPLETE OPERATIONAL CHECK

Perform a complete operational check and check for any symptoms. Refer to HAC-123, "

Can a symptom be duplicated?

YES >> Refer to HAC-122, "How to Perform Trouble Diagnosis For Quick And Accurate Repair".

NO >> System OK.

Operational Check".

3.CHECK FOR SERVICE BULLETINS

Check for any service bulletins.

>> GO TO 4.

4.CHECK MODE DOOR OPERATION

Check and verify mode door mechanism for smooth operation in each mode.

Is the inspection result normal?

YES >> GO TO 5.

NO >> Repair as necessary.

5.PERFORM A/C AUTO AMP. SELF-DIAGNOSIS

Perform self-diagnosis to check for any codes. Refer to HAC-23, "

Are any self-diagnosis codes present?

YES >> Refer to HAC-24, "A/C System Self-Diagnosis Code Chart".

NO >> GO TO 6.

A/C Auto Amp. Self-Diagnosis".

6.PERFORM A/C AND AV SWITCH ASSEMBLY SELF-DIAGNOSIS

Perform self-diagnosis to check the A/C and AV switch assembly. Refer to HAC-23, "

Assembly Self-Diagnosis".

Is the inspection result normal?

YES >> Replace A/C and AV switch assembly. Refer to VTL-8, "Removal and Installation".

NO >> GO TO 6.

A/C and AV Switch

HAC-26

< COMPONENT DIAGNOSIS >

MODE DOOR MOTOR

[AUTOMATIC AIR CONDITIONER]

7.CHECK THE MODE DOOR MOTOR (FRONT) PBR CIRCUIT

Perform diagnostic procedure for the mode door motor (front). Refer to HAC-135, "

Component Function Check".

Is the inspection result normal?

YES >> GO TO 8.

NO >> Repair PBR circuit or replace motor. Refer to HAC-136, "

cedure".

Mode Door Motor (Front) Diagnosis Pro-

Mode Door Motor (Front)

8.RECHECK FOR CODES

Perform A/C auto amp. self-diagnosis. Refer to HAC-23, "

Are any self-diagnostic codes present?

YES >> Refer to HAC-24, "A/C System Self-Diagnosis Code Chart".

NO >> GO TO 9.

A/C Auto Amp. Self-Diagnosis".

9.RECHECK FOR SYMPTOMS

Perform a complete operational check and check for any symptoms. Refer to HAC-123, "

Does another symptom exist?

YES >> Repair as necessary.

NO >> Replace A/C auto amp. Refer to VTL-8, "

Removal and Installation".

Mode Door Motor (Front) Diagnosis Procedure INFOID:0000000001366703

SYMPTOM:

• Air outlet does not change.

• Mode door motor does not operate normally.

Operational Check".

A

B

C

D

E

F

G

H

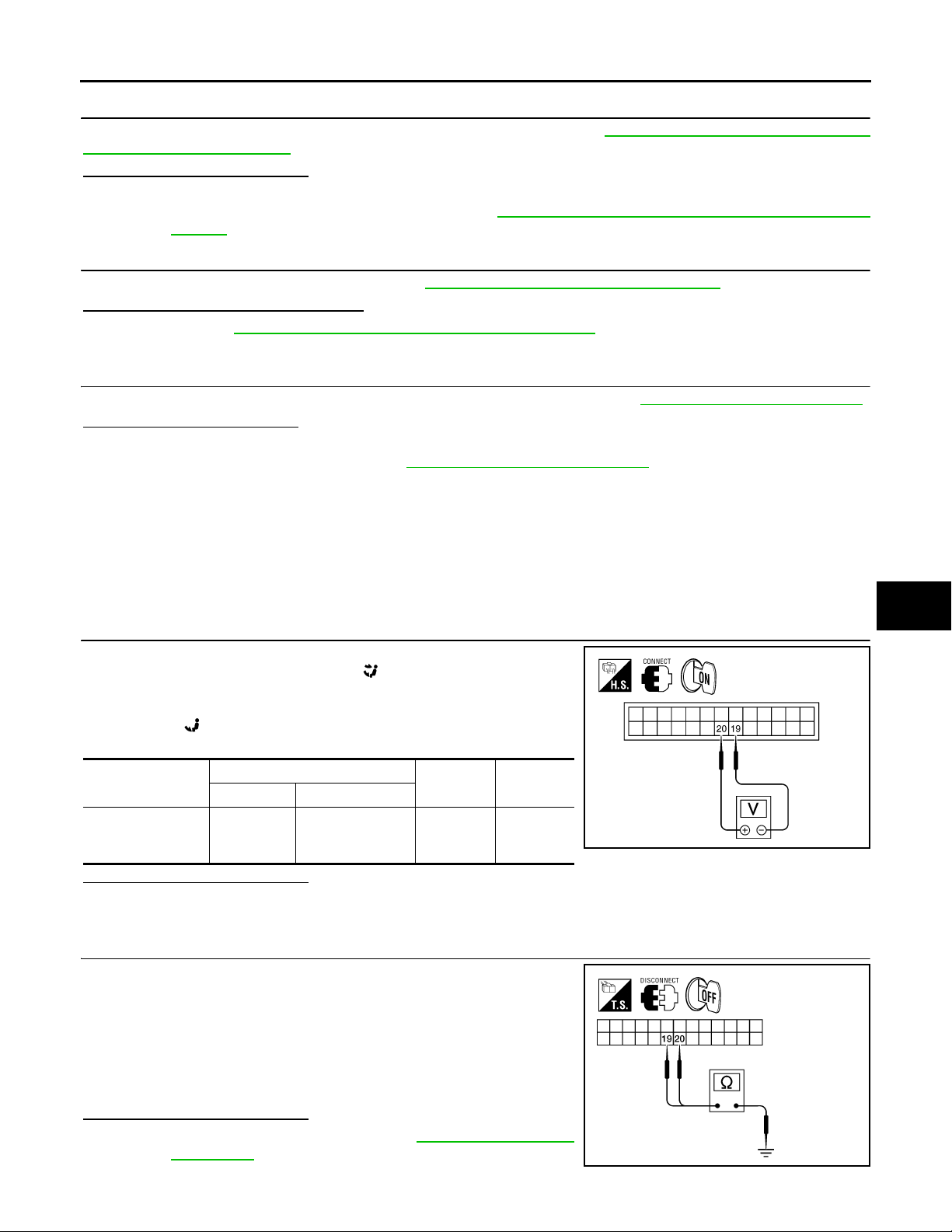

1.CHECK A/C AUTO AMP. FOR POWER AND GROUND

1. Turn ignition switch ON.

2. Press the mode switch to the B/L ( ) mode.

3. Check voltage between A/C auto amp. harness connector M49

terminal 19 and terminal 20 while pressing the mode switch to

the floor ( ) mode.

Connector

A/C auto amp.:

M49

Is the inspection result normal?

YES >> GO TO 4.

NO >> GO TO 3.

Terminals

(+) (-)

20 19

Condition

Press

mode

switch

Voltage

(Approx.)

Battery

voltage

2.CHECK MODE DOOR MOTOR CIRCUITS FOR SHORT TO GROUND

1. Turn ignition switch OFF.

2. Disconnect the A/C auto amp. harness connector.

3. Check continuity between A/C auto amp. harness connector

M49 terminal 19, 20 and ground.

19 - Ground : Continuity should not exist.

20 - Ground : Continuity should not exist.

HAC

J

K

L

AWIIA0095ZZ

M

N

O

P

Is the inspection result normal?

YES >> Replace A/C auto amp. Refer to VTL-8, "Removal and

Installation".

NO >> Repair or replace harness as necessary.

HAC-27

AWIIA0096ZZ

MODE DOOR MOTOR

< COMPONENT DIAGNOSIS >

3.CHECK A/C AUTO AMP. FOR GROUND AND POWER

1. Press the mode switch to the D/F ( ) mode.

2. Check voltage between A/C auto amp. harness connector M49

terminal 19 and terminal 20 while pressing the mode switch to

the vent ( ) mode.

[AUTOMATIC AIR CONDITIONER]

Connector

A/C auto amp.:

M49

Terminals

(+) (-)

19 20

Condition

Press

mode

switch

Voltage

(Approx.)

Battery

voltage

Is the inspection result normal?

YES >> GO TO 5.

NO >> Replace A/C auto amp. Refer to VTL-8, "

Removal and Installation".

4.CHECK MODE DOOR MOTOR AND CIRCUITS FOR OPEN

1. Turn ignition switch OFF.

2. Disconnect the A/C auto amp. harness connector.

3. Check continuity between A/C auto amp. harness connector

M49 terminal 19 and terminal 20.

Continuity should exist.

Is the inspection result normal?

YES >> GO TO 7.

NO >> GO TO 6.

5.CHECK MODE DOOR MOTOR CIRCUITS FOR OPEN

1. Disconnect the mode door motor harness connector.

2. Check continuity between A/C auto amp. harness connector

M49 (A) terminal 19, 20 and the mode door motor harness connector M142 (B) terminal 1, 6.

AWIIA0097ZZ

AWIIA0098ZZ

6 - 19 : Continuity should exist.

1 - 20 : Continuity should exist.

Is the inspection result normal?

YES >> Replace mode door motor. Refer to VTL-28, "Removal

and Installation".

NO >> Repair or replace harness as necessary.

6.CHECK A/C AUTO AMP. FOR PBR POWER AND GROUND

1. Reconnect A/C auto amp. harness connector.

2. Turn ignition switch ON.

3. Check voltage between A/C auto amp. harness connector M50

(A) terminal 28 and M49 (B) terminal 3.

Connector

A/C auto amp.: M49, M50 28 3 5V

Terminals

(+) (-)

Voltage (Ap-

prox.)

Is the inspection result normal?

YES >> GO TO 9.

NO >> GO TO 8.

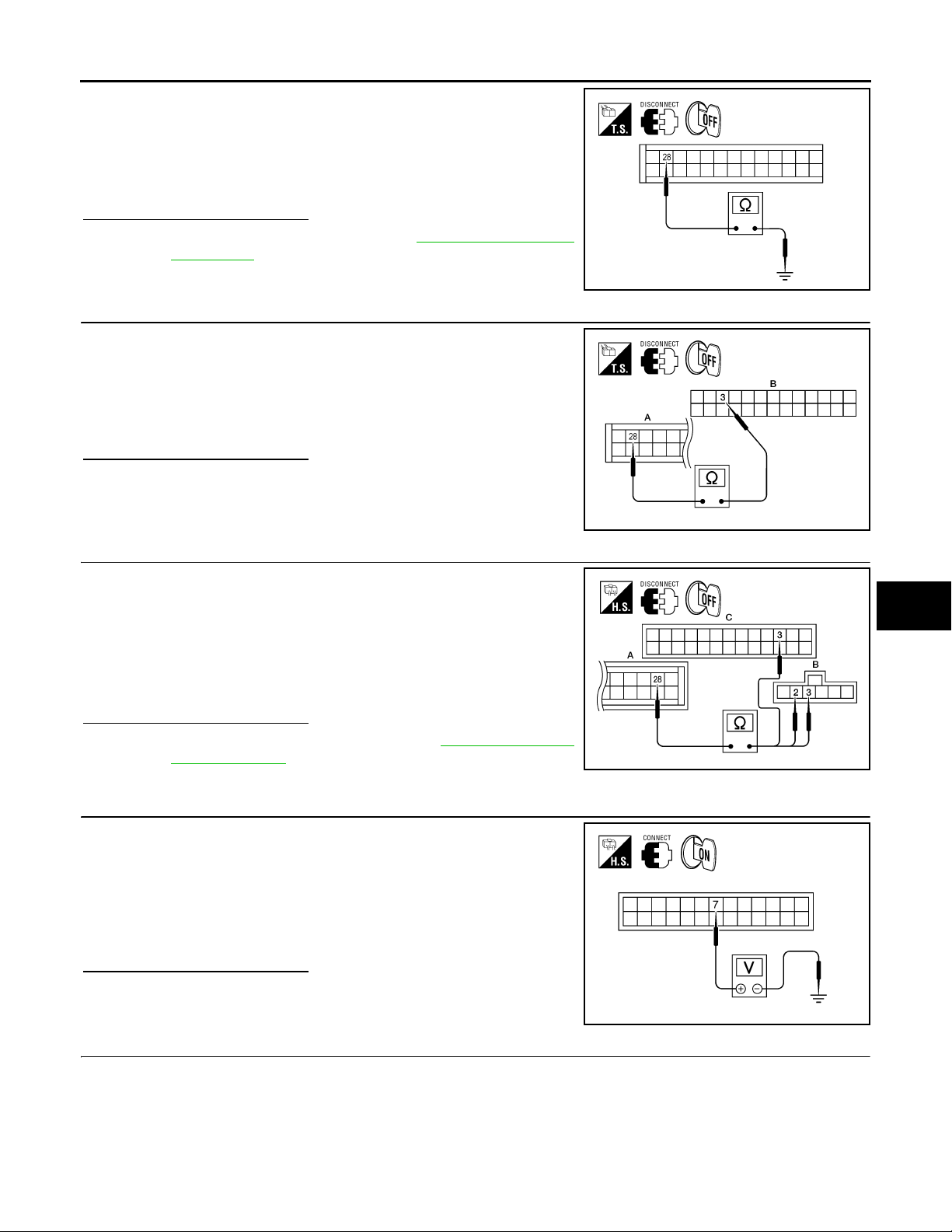

7.CHECK PBR REFERENCE VOLTAGE CIRCUIT FOR SHORT TO GROUND

HAC-28

AWIIA0225ZZ

AWIIA0099ZZ

MODE DOOR MOTOR

< COMPONENT DIAGNOSIS >

1. Turn ignition switch OFF.

2. Disconnect the A/C auto amp. harness connector.

3. Check continuity between A/C auto amp. harness connector

M50 terminal 28 and ground.

[AUTOMATIC AIR CONDITIONER]

A

Continuity should not exist.

Is the inspection result normal?

YES >> Replace A/C auto amp. Refer to VTL-8, "Removal and

Installation".

NO >> Repair or replace harness as necessary.

8.CHECK PBR REFERENCE VOLTAGE AND GROUND CIRCUITS

1. Turn ignition switch OFF.

2. Disconnect the A/C auto amp. harness connector.

3. Check continuity between A/C auto amp. harness connector

M50 (A) terminal 28 and M49 (B) terminal 3.

Continuity should exist.

Is the inspection result normal?

YES >> GO TO 11.

NO >> GO TO 10

9.CHECK PBR REFERENCE VOLTAGE CIRCUIT FOR OPEN

1. Disconnect the mode door motor harness connector.

2. Check continuity between mode door motor harness connector

M142 (B) terminal 3, 1 and A/C auto amp. harness connector

M49 (C) terminal 3, M50 (A) terminal 28.

B

C

AWIIA0100ZZ

D

E

F

G

AWIIA0101ZZ

H

HAC

28 - 3 : Continuity should exist.

3 - 2 : Continuity should exist.

Is the inspection result normal?

YES >> Replace mode door motor. Refer to VTL-28, "Removal

and Installation".

NO >> Repair or replace harness as necessary.

10.CHECK PBR FEEDBACK VOLTAGE

1. Reconnect the A/C auto amp. harness connector.

2. Turn ignition switch ON.

3. Check voltage between A/C auto amp. harness connector M49

terminal 7 and ground while cycling mode switch through all

modes.

Voltage : Approx. 1V - 4.5V

Is the inspection result normal?

YES >> GO TO 13.

NO >> GO TO 12.

11.CHECK PBR FEEDBACK SIGNAL CIRCUIT FOR SHORT TO GROUND

J

K

AWIIA0226ZZ

L

M

N

O

AWIIA0103ZZ

P

HAC-29

MODE DOOR MOTOR

< COMPONENT DIAGNOSIS >

1. Turn ignition switch OFF.

2. Disconnect A/C auto amp. harness connector.

3. Check continuity between A/C auto amp. harness connector

M49 terminal 7 and ground.

Continuity should not exist.

Is the inspection result normal?

YES >> Replace A/C auto amp. Refer to VTL-8, "Removal and

Installation".

NO >> Repair or replace harness as necessary.

12.CHECK PBR FEEDBACK CIRCUIT FOR OPEN

1. Turn ignition switch OFF.

2. Disconnect the mode door motor harness connector and A/C

auto amp. harness connector.

3. Check continuity between mode door motor harness connector

M142 terminal 4 and A/C auto amp. harness connector M49 terminal 7.

Continuity should exist.

Is the inspection result normal?

YES >> Replace mode door motor. Refer to VTL-28, "Removal

and Installation".

NO >> Repair or replace harness as necessary.

[AUTOMATIC AIR CONDITIONER]

AWIIA0104ZZ

AWIIA0227ZZ

HAC-30

Loading...

Loading...