Nissan Pathfinder 2007 User Manual

I BODY

A

B

SECTION RF

CONTENTS

PRECAUTIONS .......................................................... 2

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” ..................................................................2

Precautions .............................................................. 2

PREPARATION ........................................................... 3

Special service tool ..................................................3

Commercial Service Tool .........................................3

SQUEAK AND RATTLE TROUBLE DIAGNOSES ..... 4

Work Flow ................................................................ 4

CUSTOMER INTERVIEW ....................... .............. 4

DUPLICATE THE NOISE AND TEST DRIVE ....... 5

CHECK RELATED SERVICE BULLETINS ........... 5

LOCATE THE NOISE AN D IDENTIFY THE

ROOT CAUSE ...................................................... 5

REPAIR THE CAUSE ........................................... 5

CONFIRM THE REPAIR ........ ............................... 6

Generic Squeak and Rattle Troubleshooting ........... 6

INSTRUMENT PANEL .......................................... 6

CENTER CONSOLE .......... ................ ................... 6

DOORS ................................................................. 6

TRUNK .................................................................. 7

SUNROOF/HEADLINING ..................................... 7

OVERHEAD CONSOLE (FRONT AND REAR) ..... 7

SEATS ................................................................... 7

UNDERHOOD ....................................................... 7

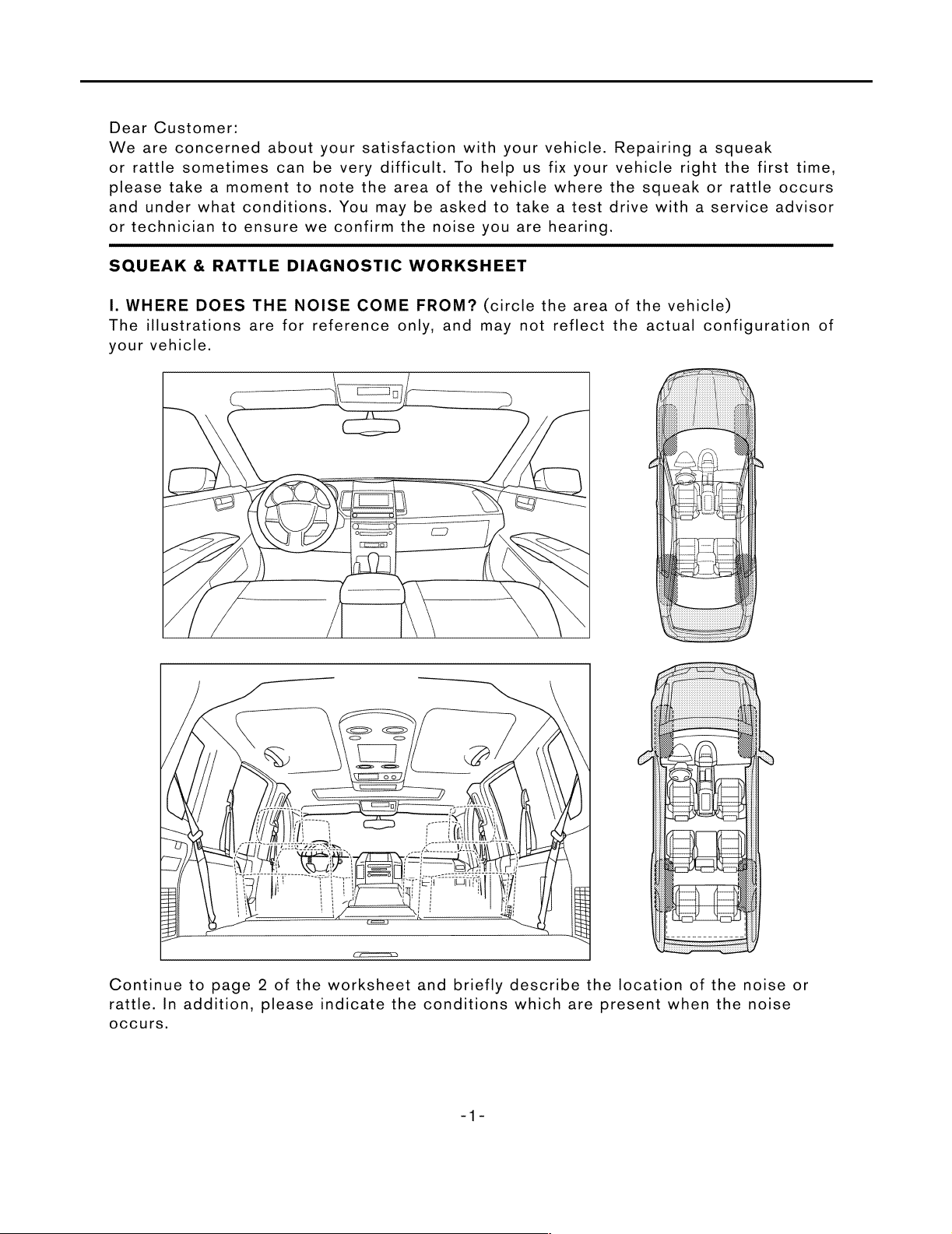

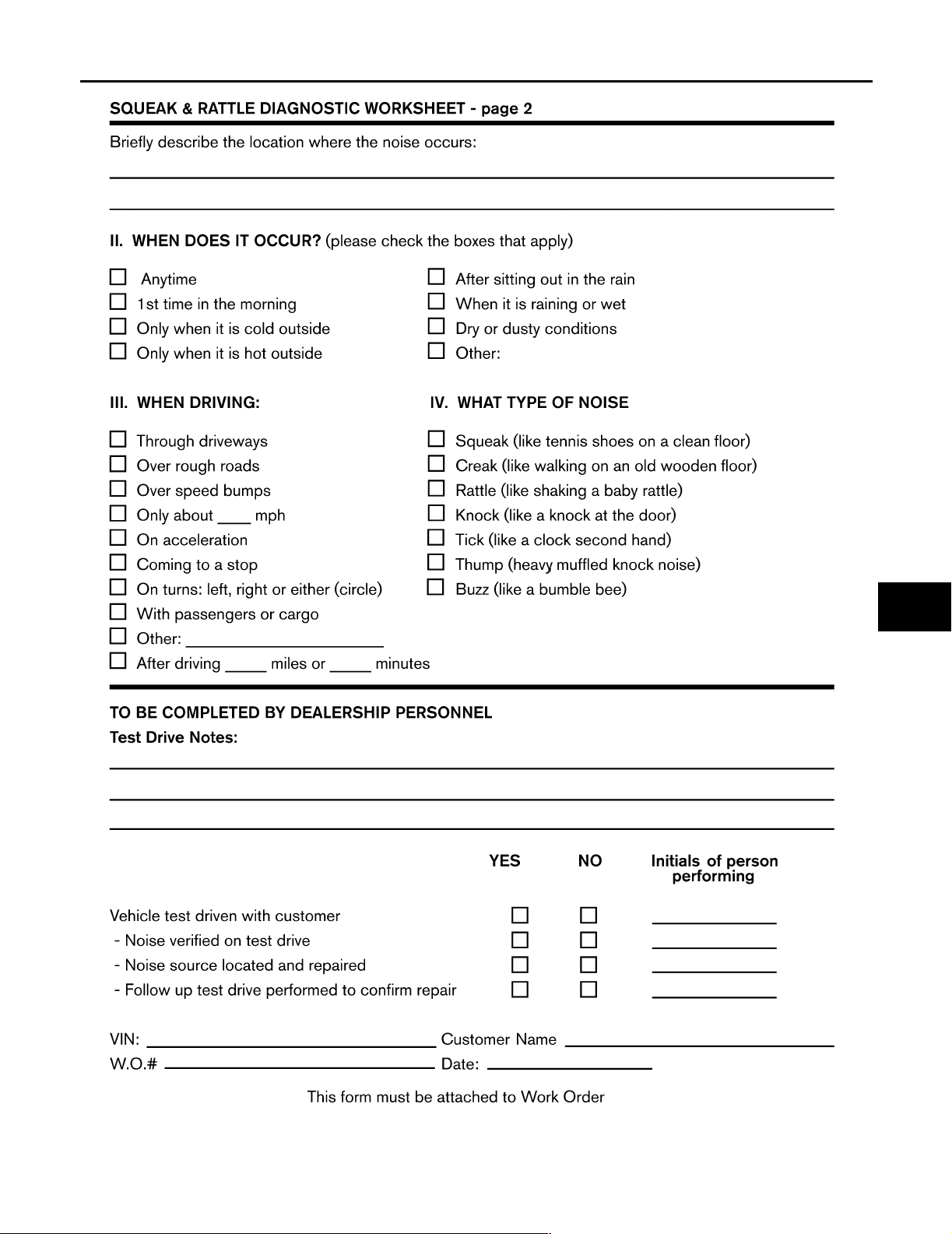

Diagnostic Worksheet .............................................. 8

SUNROOF ................................................................ 10

Component Parts and Harness Connector Location ... 10

System Descrip tion ..... ........................................... 10

OUTLINE ............................................................. 10

OPERATION ....................................................... 10

ROOF

CAN Communication System Description ..............12

Wiring Diagram — SROOF — ........... .....................13

Terminals and Reference Values for BCM .............. 15

Sunroof Motor Assembly Harness Connector Ter-

minal Layout ........................................................... 15

T erminals and Reference Values f or Sunroof Motor

Assembly ................................................................15

Work Flow .... ...........................................................15

CONSULT-II Function (BCM) .................................16

CONSULT-II START OPERATIO N ......................16

Work Support ........... ............................................... 16

Active Test .............................................. ................16

Data Monitor ...................................... .....................16

Trouble Diagnosis Chart by Symptom .................... 17

BCM Power Supply and Ground Circuit Check ......17

Sunroof Switch System Check ............................... 17

Sunroof Motor Assembly Power Supply and Ground

Circuit Check .......................................................... 19

Door Switch Check .................................................20

Adjustment ..............................................................22

GAP ADJUSTMENT ........................................ .... 2 2

HEIGHT DIFFERENCE ADJUSTMENT ..............22

Removal and Insta llation ....... .................................23

SUNROOF UNIT .................................................24

GLASS LID ..........................................................24

WIND DEFLECTOR ..................................... .......25

SUNSHADE ........................................................25

SUNROOF MOTOR ............................................ 25

DRAIN HOSES .................................................... 2 6

WEATHERSTRIP ................................................ 27

LINK AND WIRE ASSEMBLY .............................27

C

D

E

F

G

H

RF

J

K

L

M

Revision: September 2006 2007 Pathfinder

RF-1

PRECAUTIONS

PRECAUTIONS PFP:00001

Precautions fo r Su ppl em ental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSION ER”, used along

with a front sea t belt, h el ps to red uce the ris k or sever ity of injur y to the driv er and f ron t passe nger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Manual.

WARNING:

● To avoid rend ering the SRS in operative , w hich cou ld increas e t he risk o f pers onal inj ury or deat h

in the event of a collision which w ould result in air bag inflation, all maintena nce must be performed by an authorized NISSAN/INFINITI dealer.

● Improper main tenance, including in correct removal and installation of the SRS, can lead to per-

sonal injury caused by un intenti onal act iva tion of t he syste m. Fo r removal o f Spiral Ca ble and Air

Bag Modu le, see the SRS section.

● Do not use electrical t est equipme nt on any circu it related to the SR S unless ins tructed to in this

Service Manual. SR S wiring harnesses can be identified by yellow and /or orange harnesses or

harness connectors.

EIS007SU

Precautions EIS007SV

● Disconnect both battery cables in advance.

● Never tamper with or force air bag lid open, as this may adversely affect air bag performance.

● Be careful not to scratch pad and other parts.

● When removing or disassembling any part, be careful not to damage or deform it. Protect parts which may

get in the way with cloth.

● When removi ng parts with a screwdriver or other tool, protect parts by wrapping them with vinyl or tape.

● Keep removed parts protected with cloth.

● If a clip is deformed or damaged, replace it.

● If an unreusable part is removed, replace it with a new one.

● Tighten bolts and nuts firmly to the specifie d torque.

● After re-assembly has been c ompleted, make sure each part functions correctly.

● Remove stains in the following way.

Water-soluble stains:

Dip a soft cloth in warm wa ter, and then squeeze it tightly. After wipi ng the stain, wipe with a soft dry cloth.

Oil stain:

Dissolve a sy nthetic detergent in warm water (density of 2 to 3% or less), dip the cloth, then clean off the stain

with the cloth. Next, dip the cloth in fresh water and squeeze it tightly. Then clean off the detergent completely.

Then wipe the area with a soft dry cloth.

● Do not use any organic solvent, such as thinner or benzine.

Revision: September 2006 2007 Pathfinder

RF-2

PREPARATION

PREPARATION PFP:00002

Special service tool EIS007SW

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool numbe r

(Kent-Moore No.)

Tool name

—

(J-39570)

Chassis ear

Description

Locating the noise

A

B

C

D

SIIA0993E

—

(J-43980)

NISSAN Squeak and

Rattle Kit

SIIA0994E

Repairing the cause of nois e

Commercial Service Tool EIS007SX

(Kent-Moore No.)

Tool name

(J-39565)

Engi ne ear

SIIA0995E

Description

Locating the noise

E

F

G

H

RF

J

K

L

Revision: September 2006 2007 Pathfinder

RF-3

M

SQUEAK AND RATTLE TROUBLE DIA GNOSES

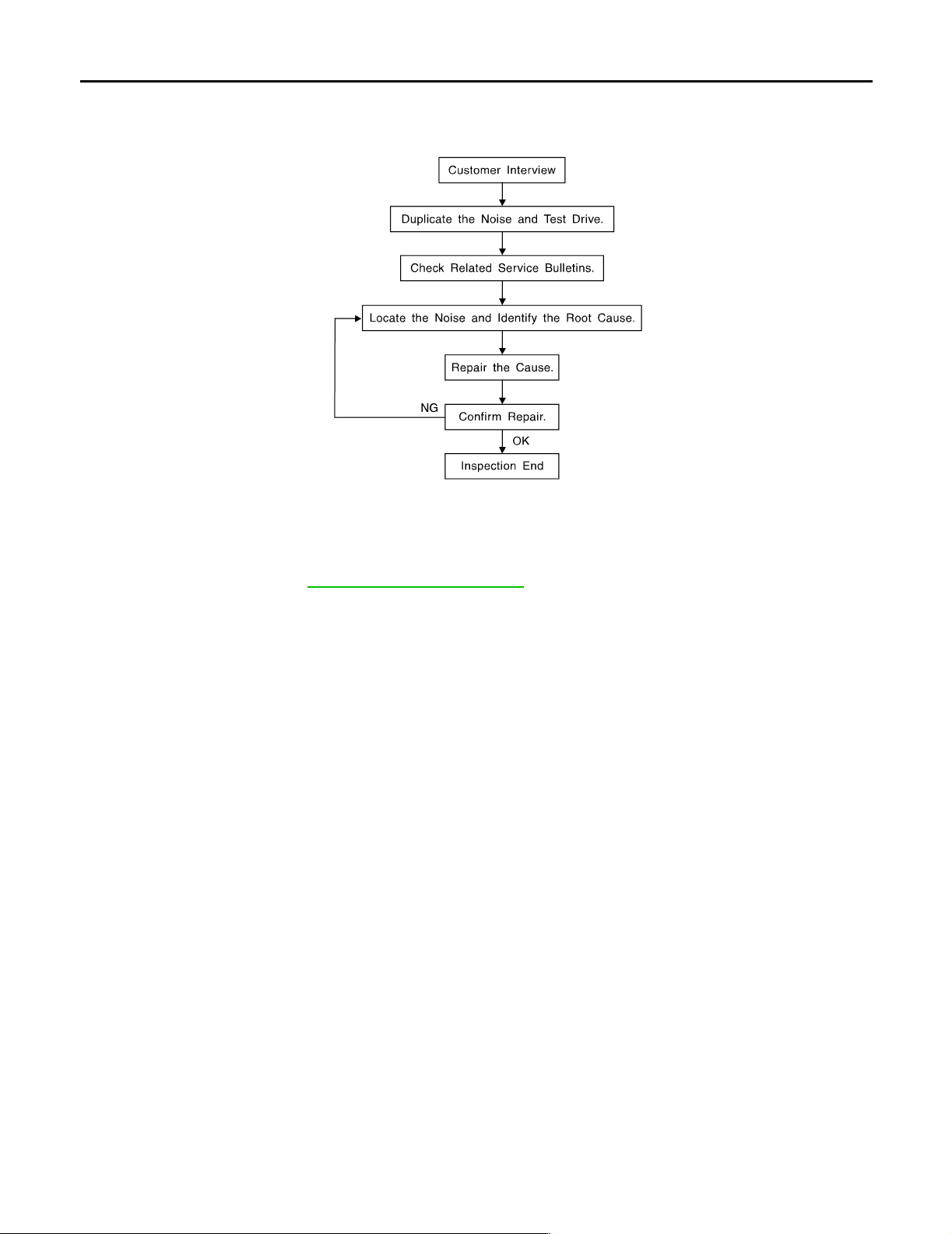

SQUEAK AND RATTLE TRO UBLE DIAGNOSES PFP:00000 Work Flow EIS007SY

SBT842

CUSTOMER INTERVIEW

Interview the customer if possible, to determine the conditions that exist when the noise occurs. Use the Diagnostic Workshe et during the interview to doc ument the facts and conditio ns when the noise occurs and any

customer's comments; refer to RF-8, "

conditions that exist when the noise occurs.

● The customer may not be able to provide a detailed descriptio n or the location of the noise. Attem pt to

obtain all the facts and conditions that exist when the noise occurs (or does not occur).

● If there is more t han o ne no ise in th e vehic le, be s ure to diagno se and repair the no ise th at th e cus tome r

is concerned about. This can be accomplis hed by test driving the vehicle with the customer.

● After identifying the type of noise, isolate the noise in terms of its characteristics. The noise characteristics

are provided so the c ustomer, service adviser and technic ian are all speaking the same language wh en

defining the n o ise.

● Squeak —(Like tennis shoes on a clean floor)

Squeak characte ristics include the light contact/fast movem ent/brought on by road conditions/ha rd surfaces = higher pitch noise/softer surfaces = lower pitch noises/edge to surface = chirping.

● Creak—(Like walking on an old wooden floor)

Creak characteristics include firm contact/slow movement/twisting with a rotational movement/pitch

dependent on materials/often brought on by activity.

● Rattle—(Like shaking a baby rattle)

Rattle characte ristics include the fas t repeated con tact/vibration or similar movement /loose parts/missi ng

clip or fastener /incorrect clearance.

● Knock —(Like a knock on a door)

Knock characteristics include hollow sounding/sometimes repeating/often brought on by driver action.

● Tick—(Like a clock second hand)

Tick characteristics include gentle contacting of light materials/loose components/can be caused by driver

action or road conditions.

● Thump—(Heavy, muffled knock noise)

Thump characteristics include softer knock/dead sound oft en brought on by activity.

● Buzz—(Like a bumble bee)

Buzz characteristics include hi gh frequency rattle/firm contact.

● Often the degr ee of acceptable noise level will vary depend ing upon the pers on. A noise that you may

judge as acceptable may be very irritating to the customer.

● Weather conditions, especially humidity and temperature, may have a great effect on noise level.

Diagnostic Worksheet" . This infor mation is n ecessary to duplicate the

Revision: September 2006 2007 Pathfinder

RF-4

SQUEAK AND RATTLE TROUBLE DIAGNOSES

DUPLICATE THE NOISE AND TEST DRIVE

If possible, drive the vehicle with the customer until the noise is duplicated. Note any additional information on

the Diagno stic Worksheet regarding th e conditions or location of the noise. This informati on can be used to

duplicate the same conditions when you confirm the repair.

If the noise ca n be dup licate d ea sily during t he te s t drive , to help i de ntify the s ource of the nois e, try to dup licate the noi se with the vehicle stopped by doing one or all of the following:

1) Close a door.

2) Tap or push/pull ar ound the area where the noise appears to be coming from.

3) Rev the engine.

4) Use a floor jack to recreate vehicle “twist”.

5) At idle, apply engine load (electrical load, half-clutch on M/T model, drive position on A/T model).

6) Raise the vehicle on a hoist and hit a tire with a rubber hammer.

● Drive the vehicle and attempt to duplicate the conditions the cust omer states exist when the noise occurs.

● If it is difficult to du plic ate the no ise, dr ive the vehic le slo wly on an und ul ating or rough roa d to str ess the

vehicle body.

CHECK RELATED SERVICE BULLETINS

After verifyin g the cus tom er co ncern or sympt om, che ck AS IST for Technical Service Bulletins (TS Bs) rel ated

to that conc ern or symptom.

If a TSB relates to the symptom, follow the procedure to repair the noise.

A

B

C

D

E

F

LOCATE THE NOISE AND IDENTIFY THE ROOT CAUSE

1. Narrow down the noise to a gen eral area.To help pinpoi nt the source of the noise, use a listening to ol

(Chassis Ear: J-39570, Engine Ear: J-39565 and mechanic's stethoscope).

2. Narrow dow n the noise to a more specific area and identify the cause of the noise by:

● removing the components in the area that you suspect the noise is coming from.

Do not use too m uc h forc e when re movi ng cl ips and fas tene rs, oth erwise clips and fas ten ers can be br oken or lost d u ring the repair, resulting in the creation of new noise.

● tapping or pushing/p ulling the component that you suspect is causing the noise.

Do not tap or pus h/pull the component with excessive force, othe rwise the noise will be elimina ted only

temporarily.

● feeling for a vibration with y our hand by tou ching the comp onent(s) that you suspect is ( are) causing the

noise.

● placing a piece of paper between components that yo u suspect are causing the nois e.

● looking for loose components and c ontact marks.

Refer to RF-6, "

Generic Squeak and Ra ttle Troubleshooting" .

REPAIR THE CAUSE

● If the cause is a loose component, tighten the component securely.

● If the cause is insufficient clearance between components:

– separate components by repositioning or loosening and retightening the component, if possible.

– insulate components with a suitable insulator such as urethane pads, foam blocks, felt cloth tape or ure-

thane tape. A NISSAN Squeak and R attle Kit (J-43980) is available through your authorized NISSAN

Parts Department.

CAUTION:

Do not use excessive force as many components are constructed of plas tic and may be damaged.

Always check with the Parts Department for the latest parts information .

The following materials are contained in the NISSAN Squeak and Rattle Kit (J-43980). Each item can be

ordered separately as needed.

URETHANE PADS [1.5 mm (0.059 in) thick]

Insulates connectors, harness, etc.

76268-9E 005: 100×135 m m (3.94×5.31 in)/76884-71L01: 60×85 mm (2.36 ×3.35 in)/76884-71L02: 15×25

mm (0.59×0.98 in)

INSULATOR (Foam blocks)

Insulates components from contact. Can be used to fill space behind a panel.

73982-9E000: 45 mm (1.77 in) thick, 50×50 mm (1.97×1.97 in)/73982-50Y00: 10 mm (0.39 in) thick,

50×50 mm (1.97×1.97 in)

INSULATOR (Light foam block)

G

H

RF

J

K

L

M

Revision: September 2006 2007 Pathfinder

RF-5

SQUEAK AND RATTLE TROUBLE DIA GNOSES

80845-71L00: 30 mm (1.18 in) thick, 30×50 mm (1.18×1.97 in)

FELT CLOTH TAPE

Used to insulate where movement does not occur. Ideal for instrument panel applications.

68370-4B000: 15×25 mm (0.59 ×0.98 in) pad/68239-13E0 0: 5 mm (0.20 in) wide tape roll. The following

materials not found in the kit can also be used to repair squeaks and rattles.

UHMW (TEFLON) TAPE

Insulates where slight movement is present. Ideal for instrument panel applications.

SILICONE GREASE

Used instead of UHMW tape that will be visible or not fit.

Note: Will o nly last a few months.

SILICONE SPRAY

Use when grease cannot be applied.

DUCT TAPE

Use to eliminate movement.

CONFIRM THE REPAIR

Confirm that t he cause of a no ise is repaired by test driv ing the vehi cle. Opera te the vehicle u nder the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Generic Sque ak and Rattle Troubleshooting EIS007SZ

Refer to Table of Contents for specific component re moval and installation information.

INSTR UME NT PANEL

Most incidents are caused by contact and movement between:

1. The cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel mounting pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incide nts can u sually be located by tappi ng or moving the comp onents to duplicate th e noise or by

pressing on the components while driving to stop the noise. Most of these incidents can be repaired by applying felt cloth tape or silicone spray (in hard to reach areas). Urethane pads can be used to insulate wiring harness.

CAUTION:

Do not use silicone spra y to isolate a squeak or rattle. If you sat urate the area with silicone, yo u will

not be able to recheck the repair.

CENTER CONSOLE

Components to pay attention to include:

1. Shifter assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses beh ind audio and A/C control unit

The instrument panel repair and is olation procedures also apply to the center console.

DOORS

Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapp ing or moving the components or pressi ng on them while driv ing to duplicate the conditions can is olate

many of these incidents. You can usually insulate the areas with felt cloth tape or insulator foam blocks from

the NISSAN Squeak and Rattle Kit (J-43980) to repair the noise.

Revision: September 2006 2007 Pathfinder

RF-6

SQUEAK AND RATTLE TROUBLE DIAGNOSES

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the owner.

In addition look for:

1. Trunk lid bumpers out of adjustment

2. Trunk lid striker out of adjustment

3. The trunk lid torsion bars knocking together

4. A loose license plate or bracket

Most of these incidents can be repaired by adjusting, s ecuring or insulating the item(s) or component(s) causing the noise.

A

B

C

SUNROOF/HEADLINING

Noises in the sunroof/headlining area can often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a r attle or light knocking noise

2. Sun visor shaft shaking in the holder

3. Front or rear windshield to uching headliner and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

OVERHE AD CONSOLE (FRONT AND REAR)

Overhead co nsole noises are often caused by the c onsole panel clips not being engaged correc tly. Mo st of

these incidents are repaired by pushing up on the console at the clip locations until the clips engage.

In addition look for:

1. Loose harness or harness connectors.

2. Front console map/reading lamp lens loose.

3. Loose screws at console attachment points.

SEATS

When isolating seat noise it's important to note the position the seat is in and the load placed on the seat when

the noise is present. These conditions should be duplicated when verifying and isolating the cause of the

noise.

Cause of seat noise inclu de:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. The rear seatback lock and bracket

These noise s can be i solated by movi ng or pr essing on the sus pe cted comp onen ts while dup lic ating th e conditions under wh ich the noise occu rs. Mos t of these incidents can be re paired by repositi oning the compo nent

or applying urethane tape to the contact area.

D

E

F

G

H

RF

J

K

L

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. Th e noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component mounted to the engine wa ll

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator mounting pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noise s can be difficult to isolate s ince they cannot be rea ched fro m the inter ior of the vehi cle. The be st

method is to secure, mov e or insulate one comp onent at a time and test drive the ve hicle. Also, engine RPM

or load can be c hanged to isol ate the noise. Repai rs can usu ally be made by mo ving, adjus ting, securin g, or

insulating the component causing the noise.

Revision: September 2006 2007 Pathfinder

RF-7

M

SQUEAK AND RATTLE TROUBLE DIA GNOSES

Diagnostic Worksheet EIS007T0

LAIA0072E

Revision: September 2006 2007 Pathfinder

RF-8

SQUEAK AND RATTLE TROUBLE DIAGNOSES

A

B

C

D

E

F

G

RF

M

H

J

K

L

LAIA0071E

Revision: September 2006 2007 Pathfinder

RF-9

Loading...

Loading...