Nikon AF-S DX NIKKOR 18-200mm Repair manual

作成承認印 配布許可印

INC

AF-S VR DX Zoom Nikkor

18-200/3.5-5.6G ED

JAA79471-R.3678.A

JAA79471

JAA79451

REPAIR MANUAL

(MADE IN JAPAN)

(MADE IN THAILAND)

Printed in Japan Dec 2005

Copyrighc2005 by Nikon Corporation.

All Rights Reserved.

無断転載を禁ず

!!

JAA79471-R.3678.A

INC

Specications

Type of lens: G-type AF-S DX VR Zoom-Nikkor lens having built-in CPU and Nikon

bayonet mount [Specially designed for use with the Nikon digital SLR cameras

(Nikon DX format)]

Focal length: 18mm–200mm

Maximum aperture: f/3.5–5.6

Lens construction: 16 elements in 12 groups (3 aspherical lens and 2 ED lens elements)

Picture angle: 76°– 8°

Focal length scale: 18, 24, 35, 50, 70, 135, 200mm

Distance information: Output to camera body

Zoom control: Manually via separate zoom ring

Focusing: Nikon Internal Focusing (IF) system (utilizing an internal Silent

Wave Motor); manually via separate focus ring

Vibration reduction: Lens-shift method using voice coil motors (VCMs)

Shooting distance scale: Graduated in meters and feet from 0.5m (3 ft.) to innity ( ‡)

Closest focus distance: 0.5m (1.6 ft.) at all zoom settings

No. of diaphragm blades: 7 pcs. (rounded)

Diaphragm: Fully automatic

Aperture range: f/3.5 to f/22 (at 18mm), f/5.6 to f/36 (at 200mm)

Exposure measurement: Via full-aperture method

Attachment size: 72mm (P = 0.75mm)

Dimensions: Approx. 77mm dia. x 96.5mm extension from the camera’s lens mount ange

Weight: Approx. 560g (19.8 oz)

- M1

AF-S VRDX 18-200/3.5-5.6G -

・

JAA79471-R.3678.A

INC

※ Before Disassembly / (Re)assembly / Adjustment

On this lens, the VR (vibration-reduction) unit is mounted to correct the picture blur.

In order to maintain the functional accuracy of the picture blur correction, if detaching the VR

(vibration-reduction) unit and gyro base plate or if removing the main PCB unit, be sure to adjust the VR by

using the VR lens adjustment equipment (J15380).

However, if disassembling the parts except the above, the VR adjustment is NOT necessary.

At service agencies where the "VR lens adjustment equipment" is not prepared, do NEITHER disassemble

NOR repair the products of the above case.

Caution:

① When disassembling, make sure to memorize the processing state of wires, screws to be xed and their types, etc.

② Because prototypes are used for "Disassembly/(Re)assembly/Adjustment", they may differ from the actual

products in forms, etc.

③ Because pictures are processed by a special method, they may differ from the actual ones in texture.

Points to notice for Lead-free solder products

・Lead-free solder is used for this product.

・For soldering work, the special solder and soldering iron are required.

・Do NOT mix up lead-free solder with traditional solder.

・Use the special soldering iron respectively for lead-free solder and lead solder.

They cannot be used in common.

- D1・ AF-S VRDX18-200/3.5-5.6G -

1. Disassembly

INC

JAA79471-R.3678.A

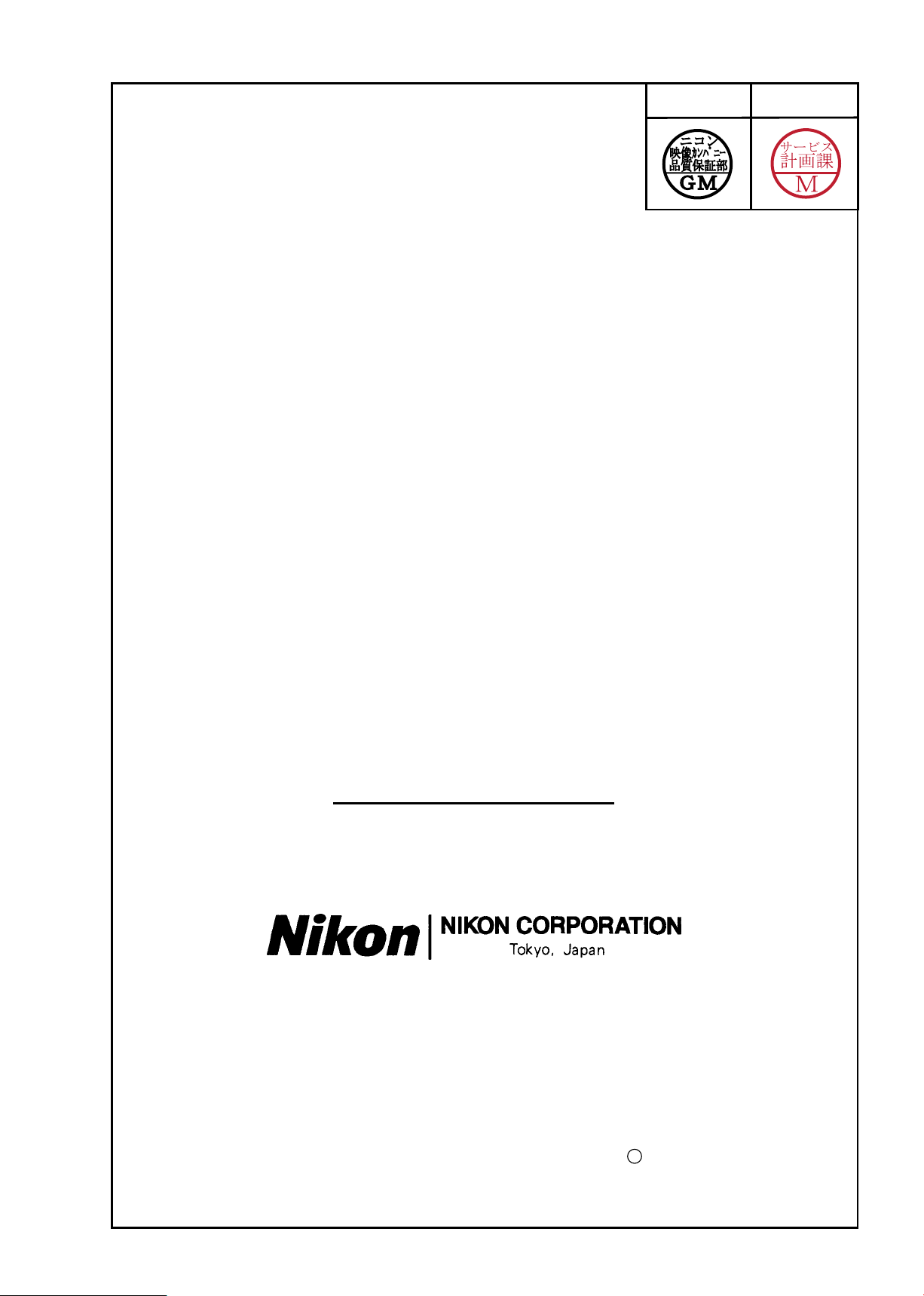

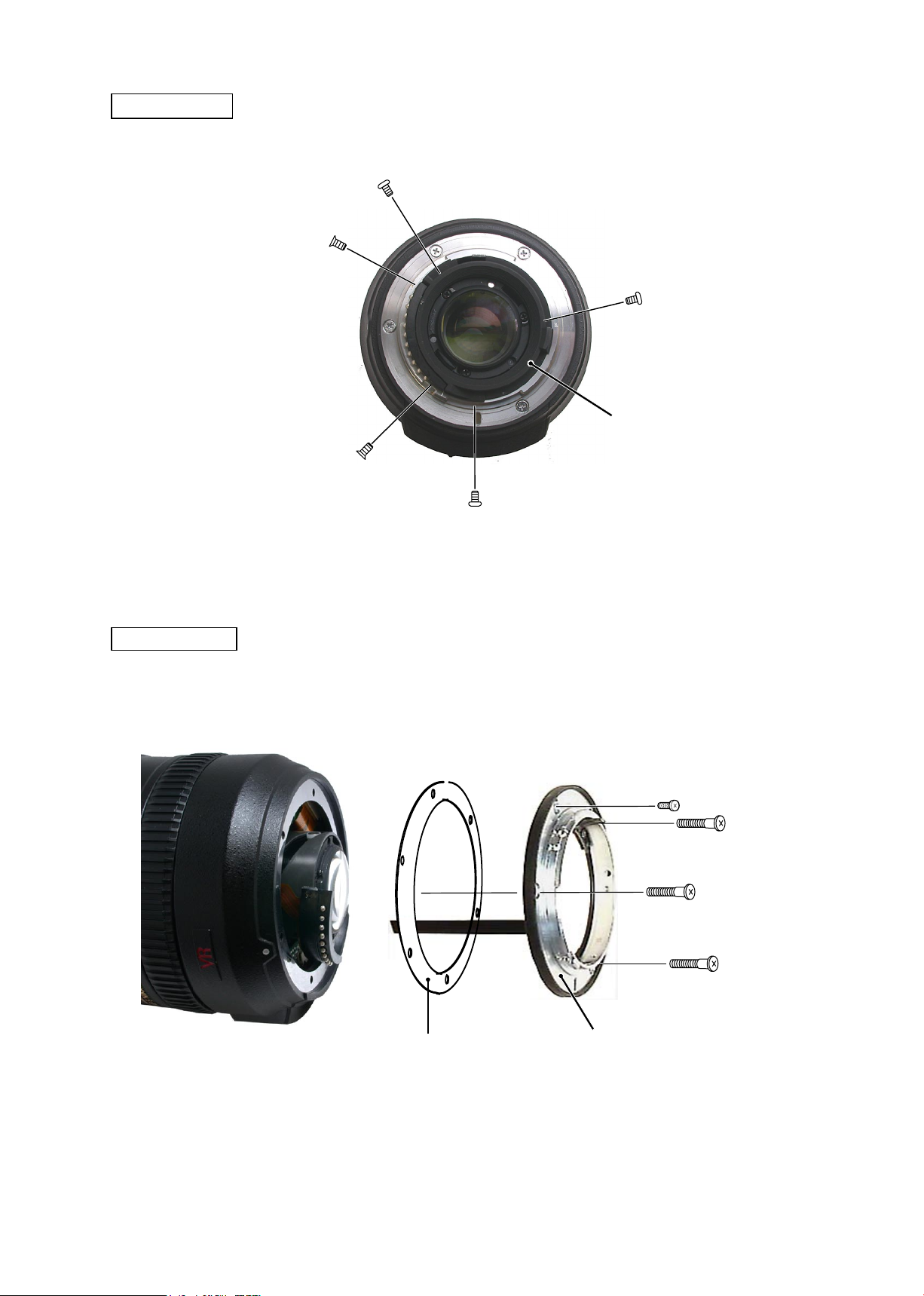

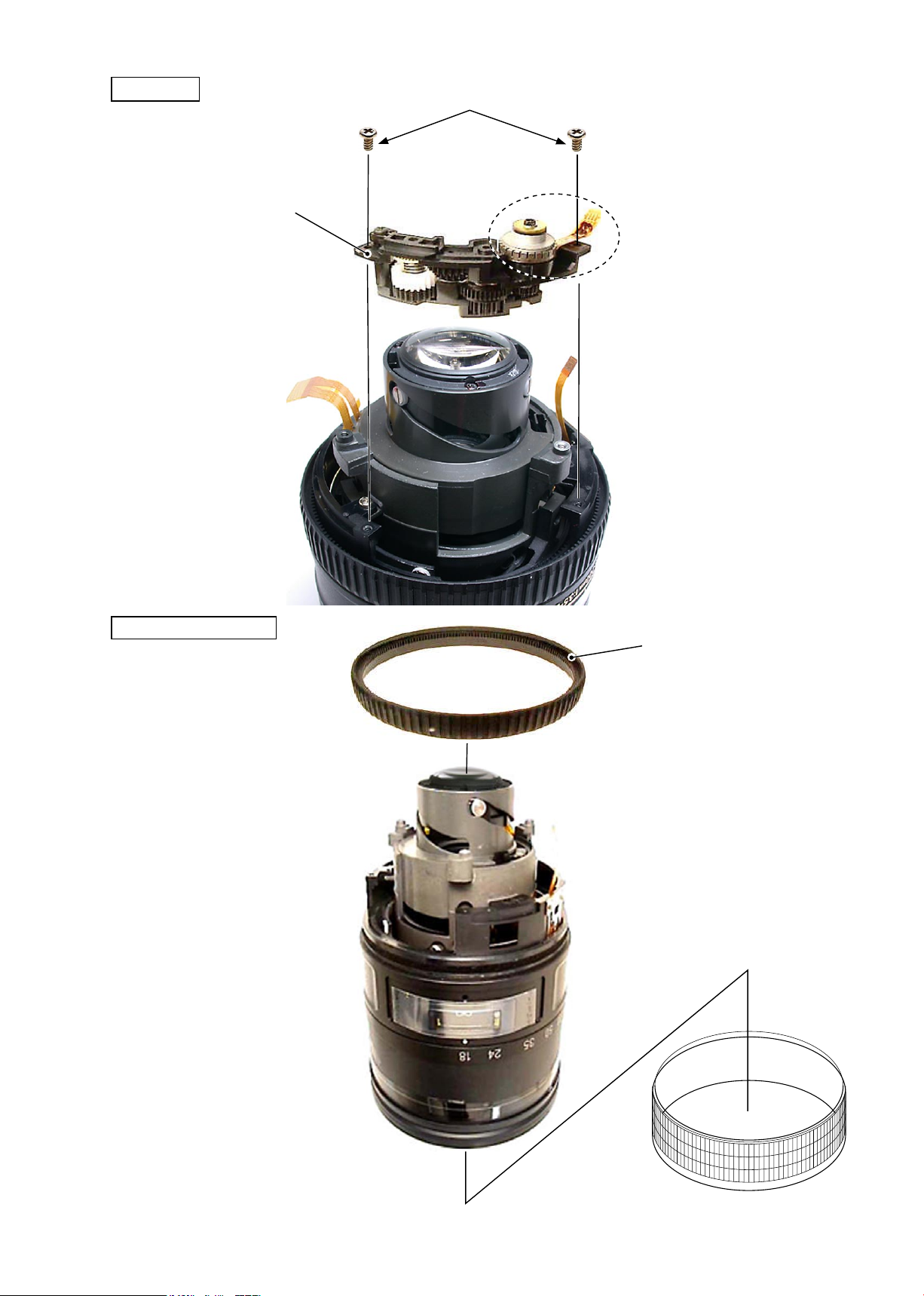

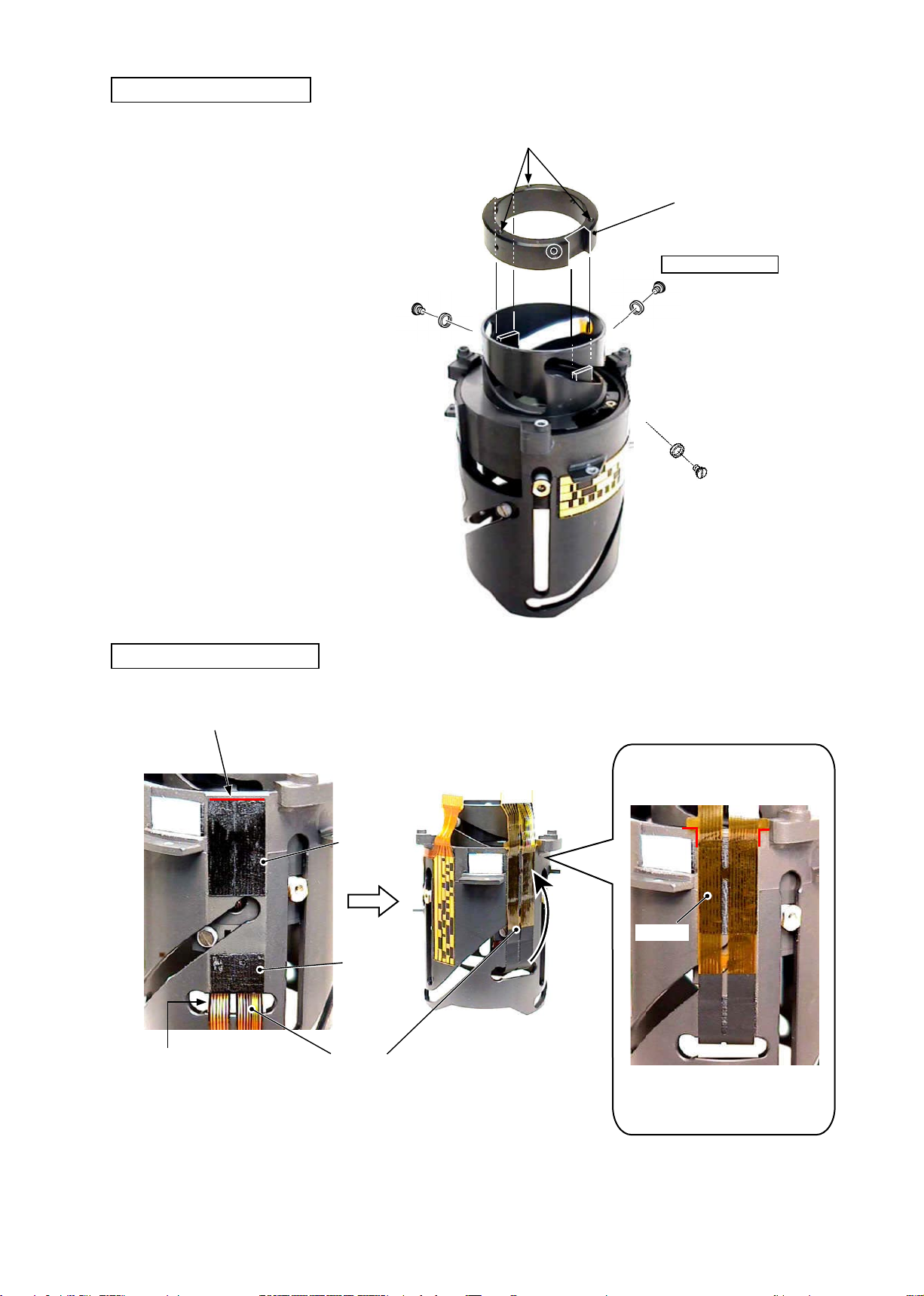

1st lens group

Retaining ring (#42)

#133

G1-2 cemented lens

1st lens group (B0006)

Filter ring

#60

Cover ring (#62)

1st lens-group cover ring

(#60)

#128×6

#62

#100

Filter ring

- D2・ AF-S VRDX18-200/3.5-5.6G -

JAA79471-R.3678.A

INC

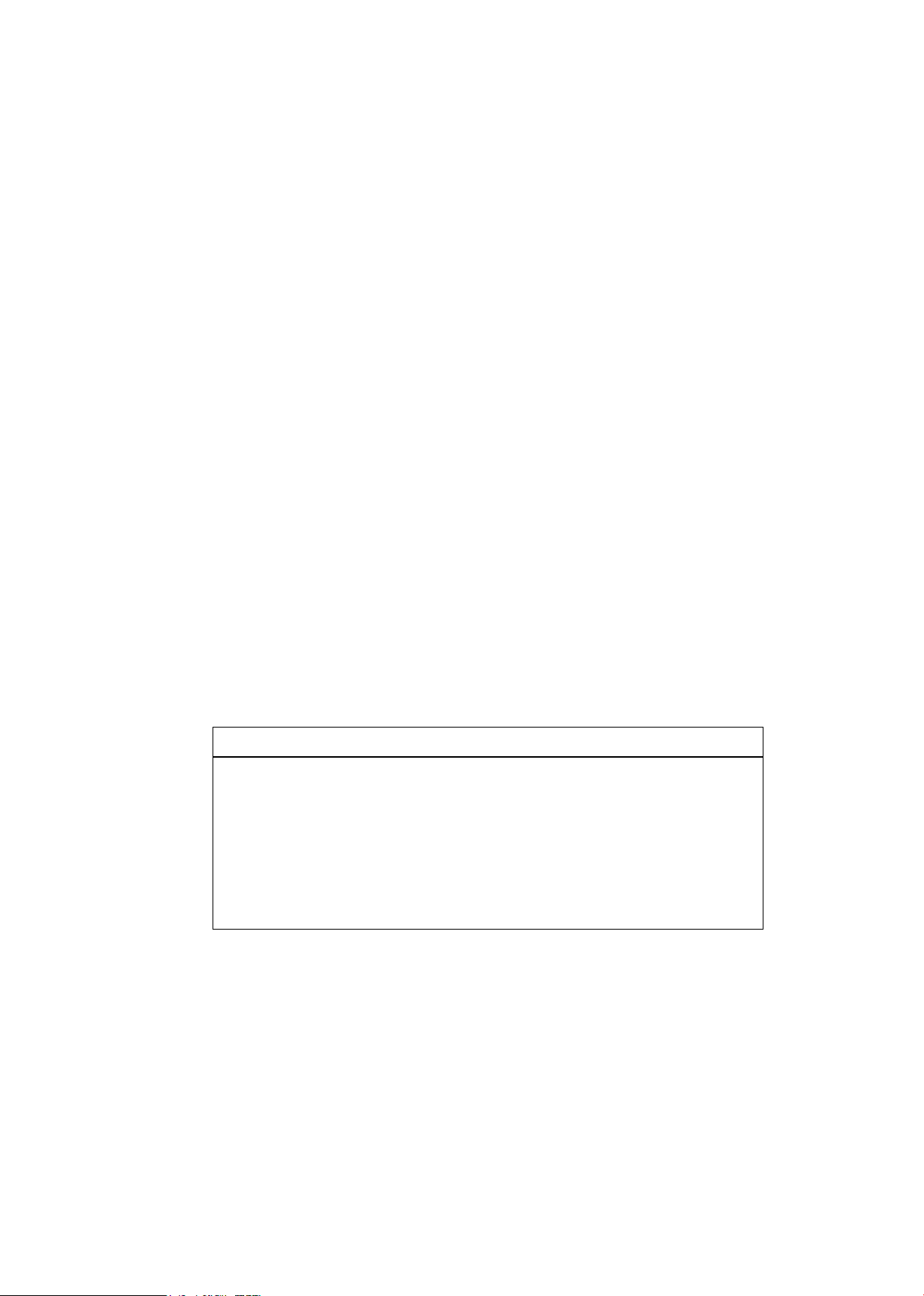

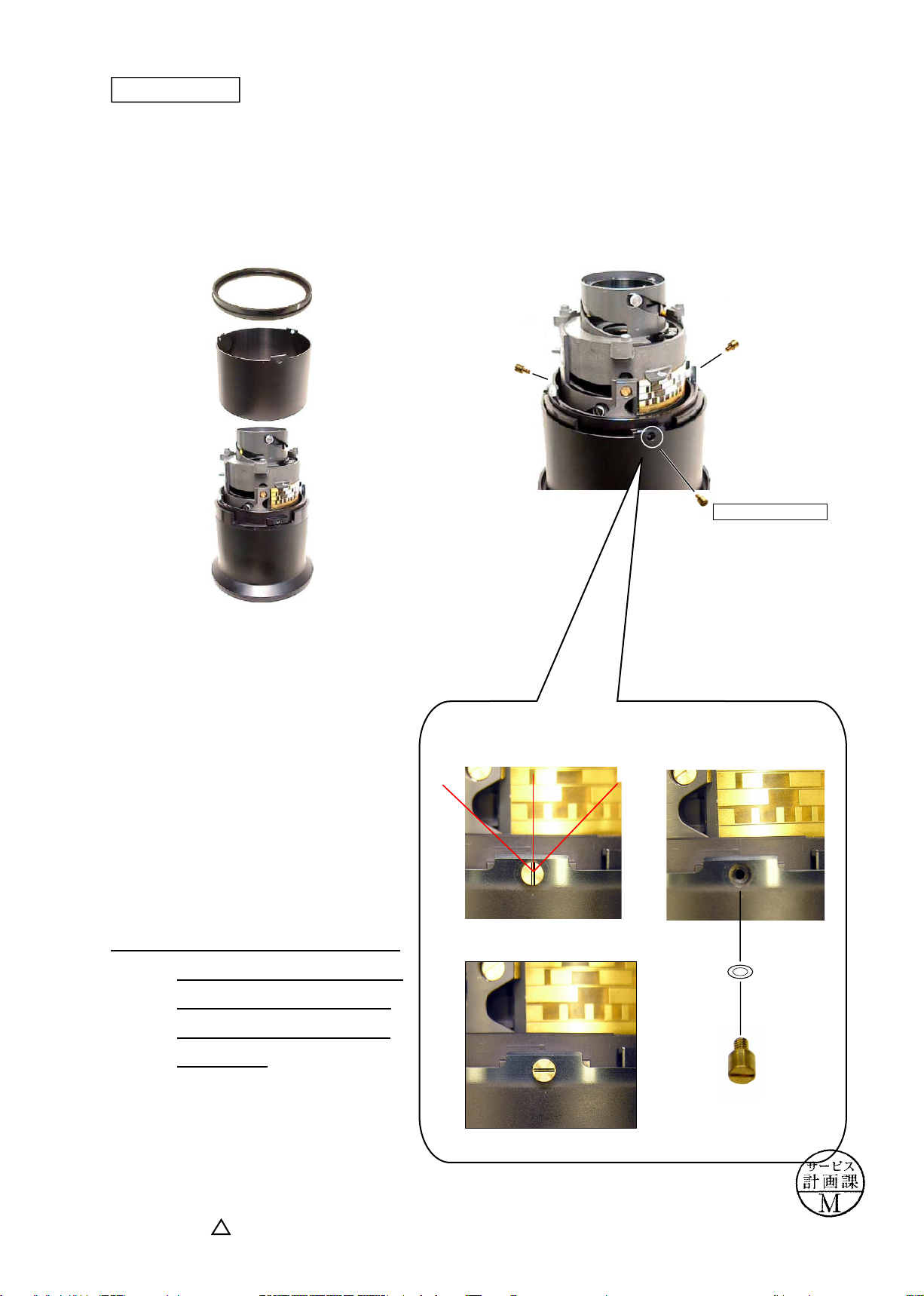

2nd lens group

★

New Tool

① Set the lens zoom position to 18, while the focus ring to "∞" position.

② Mount the 2nd lens-group retaining tool ( J11318) on the lens by aligning the indexes with each other.

Index

Index

★

Convex portion×3

2nd lens-G retaining

tool (J11318)

★

J11318

Pin×2

Hole×2

Groove×3

Enter the three convex portions of (J11318) into the three

grooves of (J11318), while two pins into the two holes of the

lens.

Caution)

focus ring little by little, then align the pins with the holes.

Remove the 2nd lens-group and the washer (#80) by using the wrench ( J11317).

③

★

If the positions of pins do not match, turn the

J11317

★

2nd lens group

Washer (#80A~K)

- D3・ AF-S VRDX18-200/3.5-5.6G -

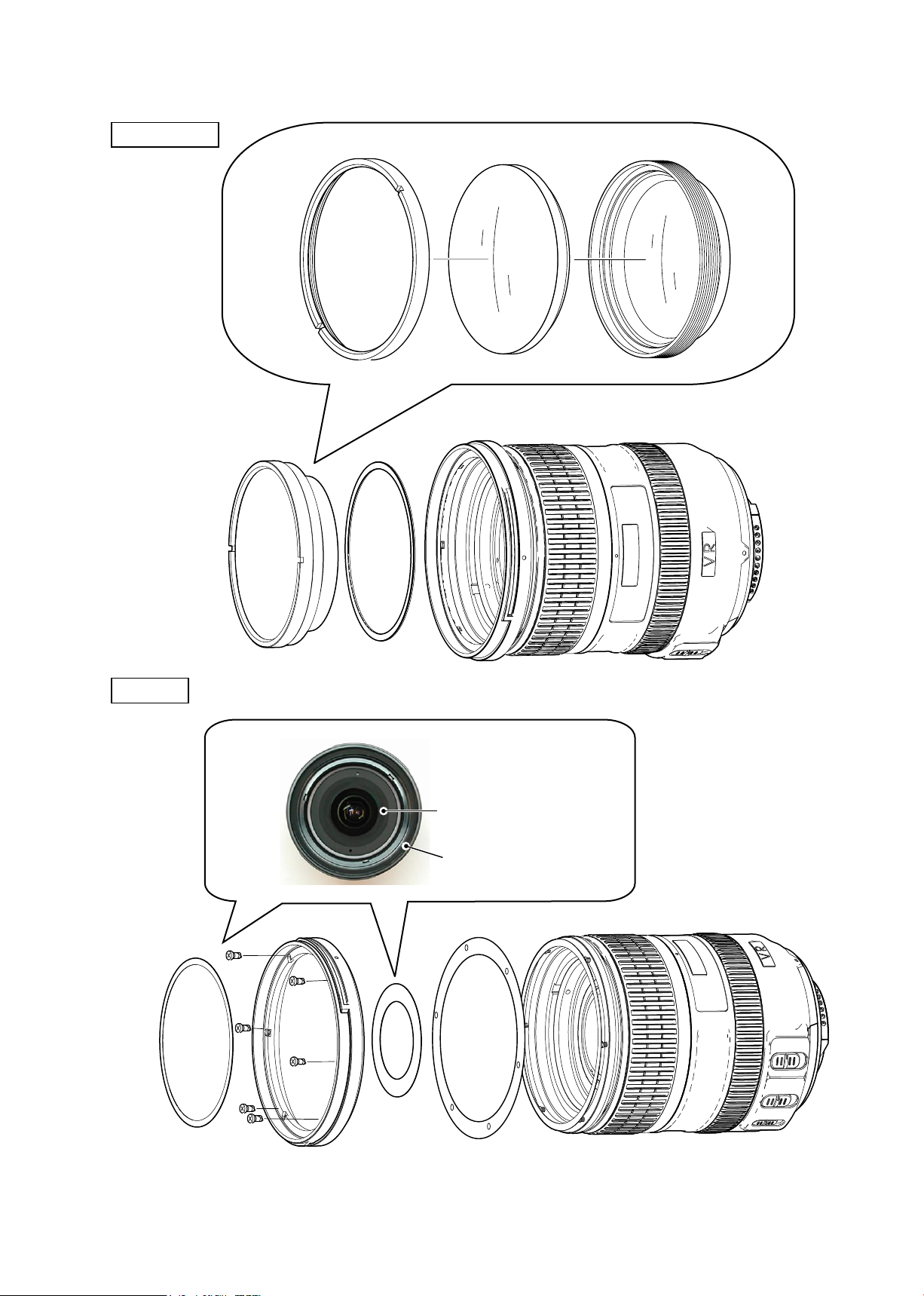

Rear cover ring

INC

JAA79471-R.3678.A

#118×3

#117×2

Rear cover ring

Bayonet mount

#79

#114

#115×3

Bayonet mount

- D4・ AF-S VRDX18-200/3.5-5.6G -

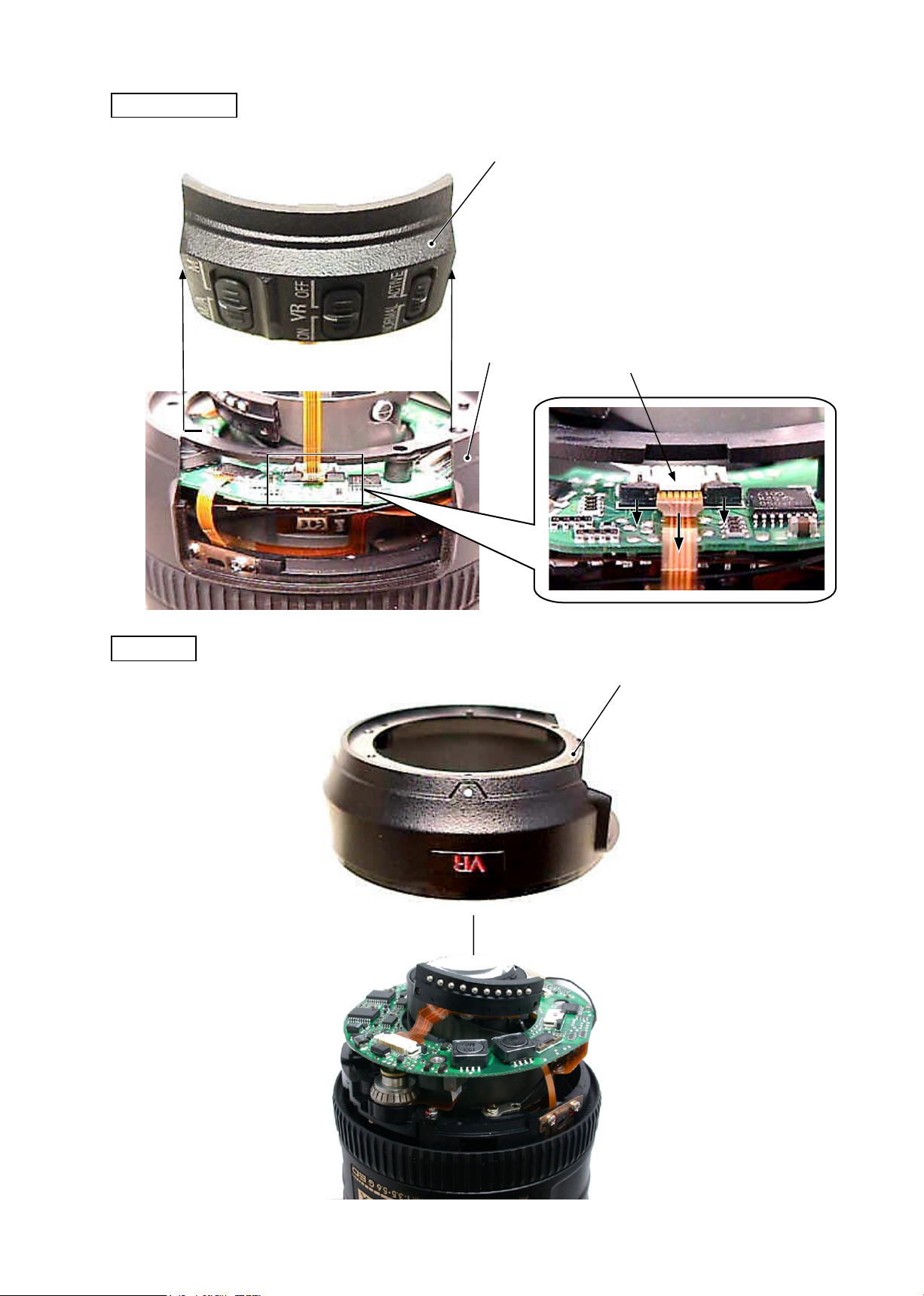

Change-SW unit

INC

While holding the rear cover by hand, remove the change-SW unit.

・

Change-SW unit

JAA79471-R.3678.A

Rear cover

Rear cover

(B1001) connector unit

Rear cover

- D5・ AF-S VRDX18-200/3.5-5.6G -

Contacts unit

INC

Remove the FPC of the contacts unit from the connector.

・

Contacts unit

Connector

Main PCB unit

Remove the VR FPC, encoder FPC, GMR sensor, and SWM-FPC from each connector.

①

JAA79471-R.3678.A

VR FPC

SWM FPC

Connector

Encoder FPC

GMR sensor FPC

Remove the gyro-FPC from the body.

②

Gyro-FPC

Remove the two wires from the

③

SWM unit.

Orange

White

Remove the main PCB unit by taking

④

#123

- D6・ AF-S VRDX18-200/3.5-5.6G -

out the screw (#123) of lug plate.

Lug plate

Distance-brush

INC

JAA79471-R.3678.A

Revision

(

Rotate the focusing ring to "close"-end.

①

Take out the screw (#112) to remove the distance-brush.

②

Revision

(

MF ring

Rotate the MF ring, and set the distance scale to "1 m".

)

)

#112

Distance-brush

Focus key

Position where the distance-brush must be

removed

1

Distance scale

(Reference line)

#122

#157

Focus key

Changed page

× 2

- D7・ AF-S VRDX18-200/3.5-5.6G -

March. 17. 2006

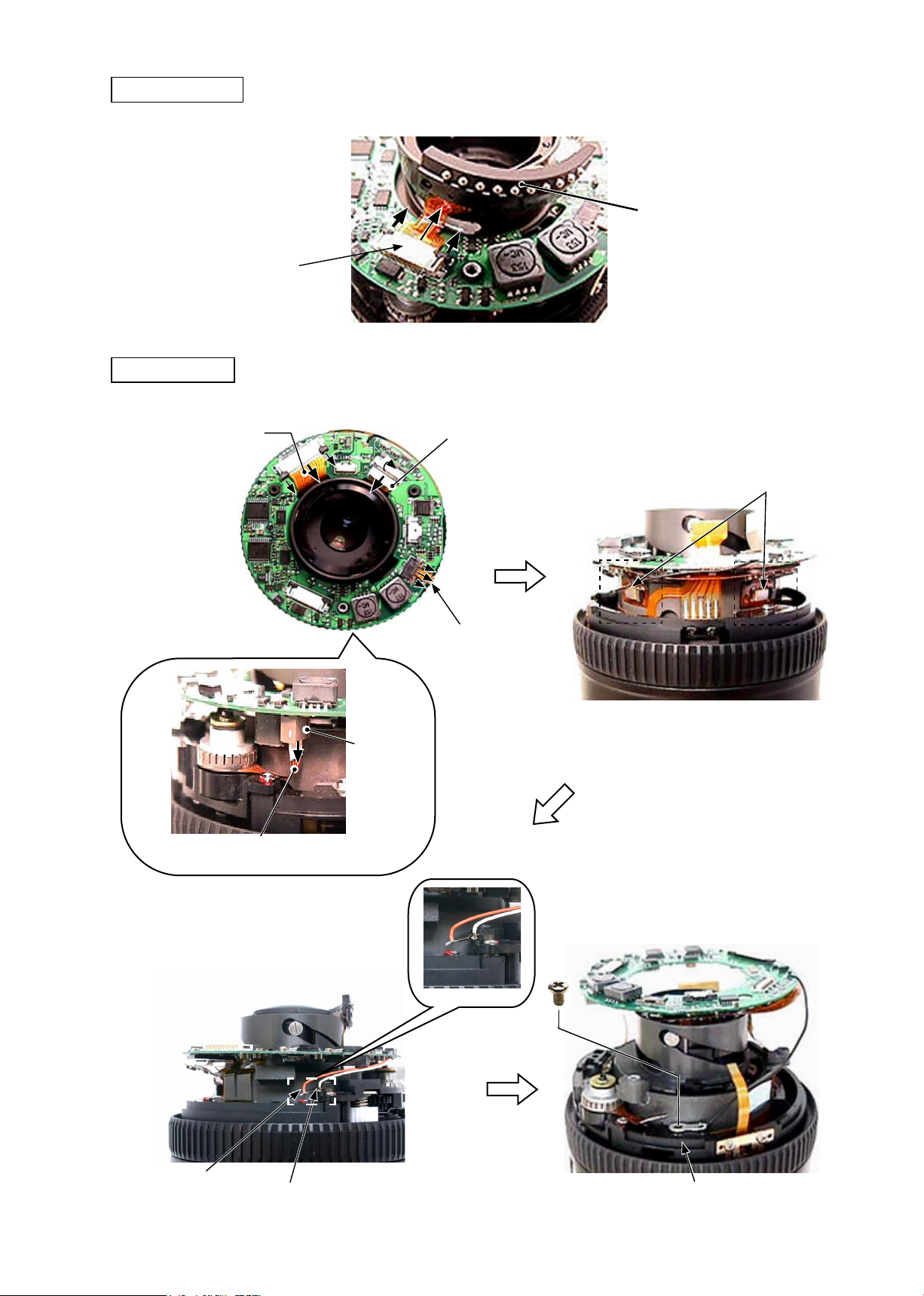

SWM unit

INC

JAA79471-R.3678.A

#154×2

Be careful NOT to touch A-part directly

SWM unit

by hand.

A-part

MF-ring, Rubber ring

MF-ring

Rubber ring

- D8・ AF-S VRDX18-200/3.5-5.6G -

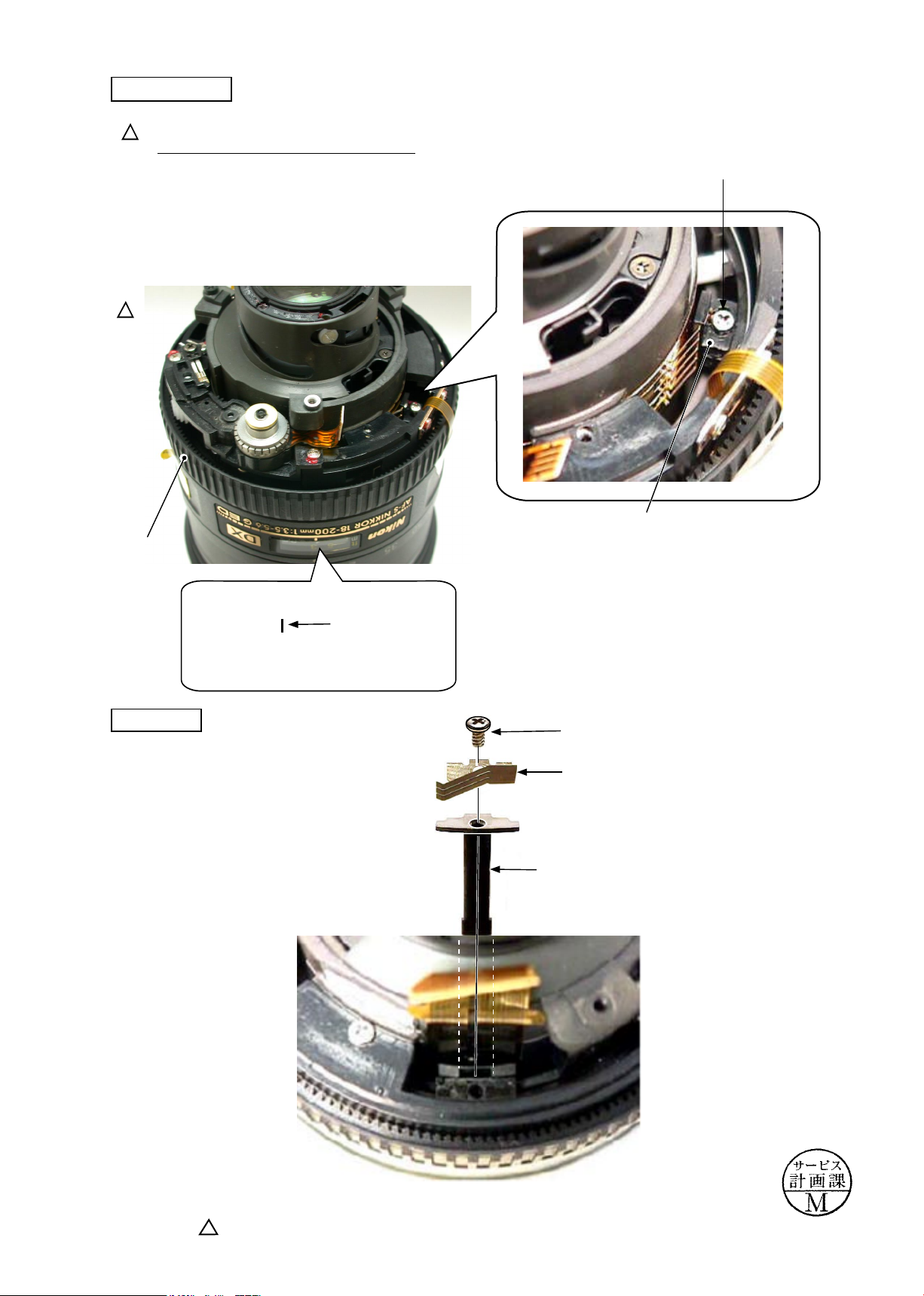

Removal of Zoom index ring unit from Lens body

INC

JAA79471-R.3678.A

① Remove the polyester tape.

Polyester tape

② Take out two screws (#123).

#123×2

Rotate the gear unit and set to "close"-side.

③

Remove the zoom index unit from the lens body.

④

Gear unit

Zoom index ring unit

Lens body

- D9・ AF-S VRDX18-200/3.5-5.6G -

GMR sensor FPC unit

INC

JAA79471-R.3678.A

#97

#122×2

#130

Caution:

When the GMR sensor FPC unit is removed, do

NOT bend the area of doted lines.

GMR sensor

FPC unit

Zoom index ring

Take out the screw (#144) and remove the lens zoom control key.

①

Rotate the zoom ring by slightly exceeding its index "18-200", and remove the zoom ring from the zoom

②

index ring.

#144

Zoom ring

Distance scale sticker

Gear unit

Zoom index ring

#155

Name plate

#76

Zoom control key

Rotate so that the edge of "∞" side of the distance

③

scale sticker is aligned with the index of the

zoom index ring, and remove the gear unit.

Take out two screws (#112), and remove the block

④

(#155).

- D10 ・ AF-S VRDX18-200/3.5-5.6G -

#112×2

Edge

Gear unit

Index

Zoom index ring

Cover ring unit

INC

Take out three screws (#110), and remove the reinforcing ring unit and cover ring unit.

・

#110×3

JAA79471-R.3678.A

Reinforcing ring

unit

Cover ring unit

In some cases, the

adjustment washer (#107)

is put in.

Zoom brush

Take out two screws (#109) and remove the

・

zoom brush.

#107

#110

#109×2

#106

Zoom brush

- D11 ・ AF-S VRDX18-200/3.5-5.6G -

JAA79471-R.3678.A

- D12 ・ AF-S VRDX18-200/3.5-5.6G -

Caution:

The 2nd lens-G straight ring unit must not be disassembled any further at service facilities, because if it is,

special tools and several selected rollers become necessary for assembly.

Caution:

When the 4th lens group is removed, it becomes necessary to perform lens alignment work after assembly.

・

Remove the 4th lens-G cover ring (#70).

・

Take out three screws (#124), and remove the 4th lens group and

washer (#13).

#70

4th lens group

#139A~H

#124×3

・

Take out three screws (#67), and remove the 2nd lens-group straight

ring unit.

4th lens group

2nd lens-group straight ring unit

2nd lens-G straight ring unit

#67×3

#68×3

#99

At service facilities where the alignment work is impossible, do

not remove the 4th lens group.

Changed page

× 1

March. 17. 2006

#139

△ (Revision)

INC

Removal VR FPC unit

INC

Remove the VR FPC.

・

JAA79471-R.3678.A

VR FPC unit

4th lens group sliding ring

Take out three screws (#81), and remove the 4th lens-G sliding ring.

・

4th lens-G sliding ring

#81×3

#84×3

- D13 ・ AF-S VRDX18-200/3.5-5.6G -

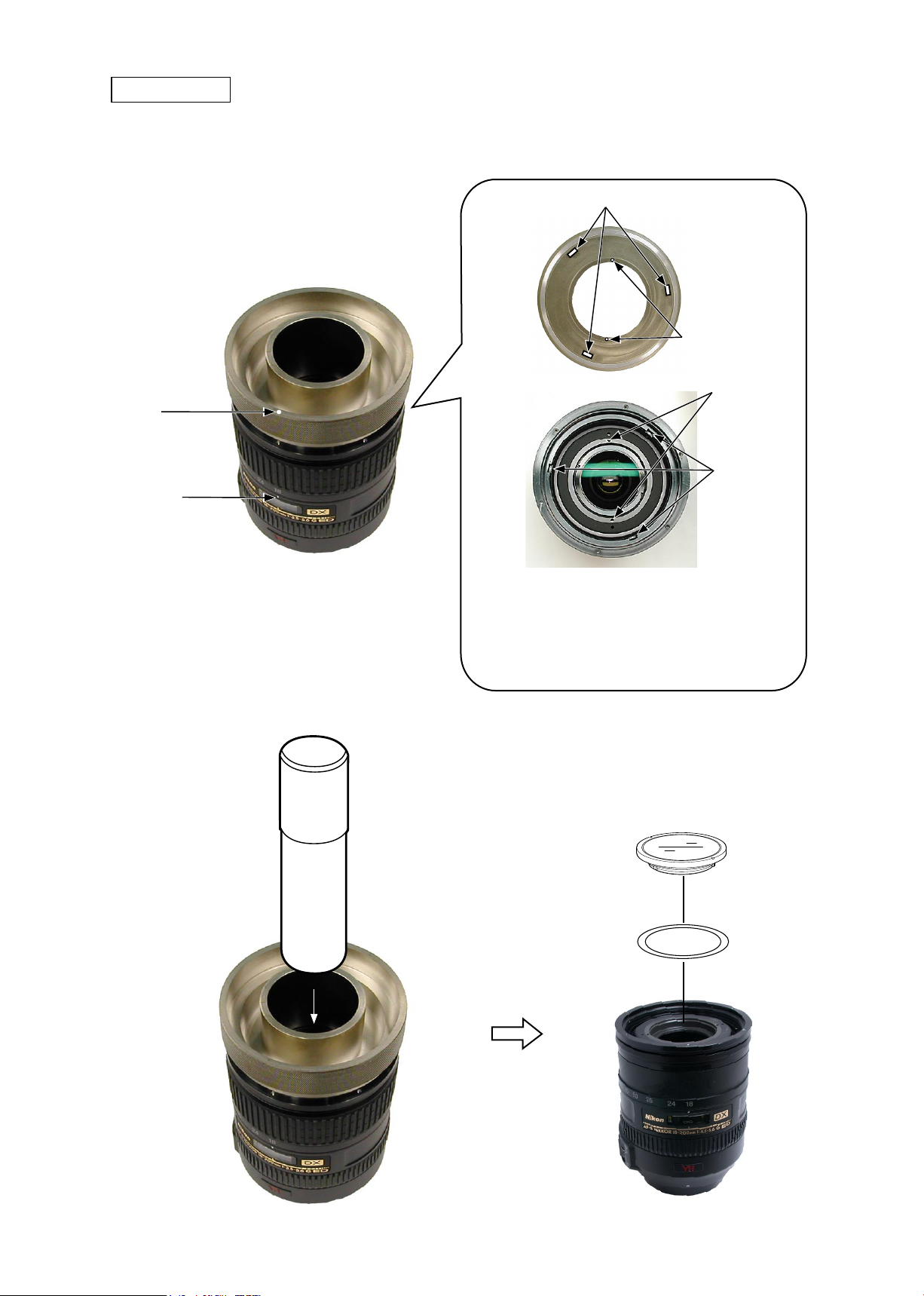

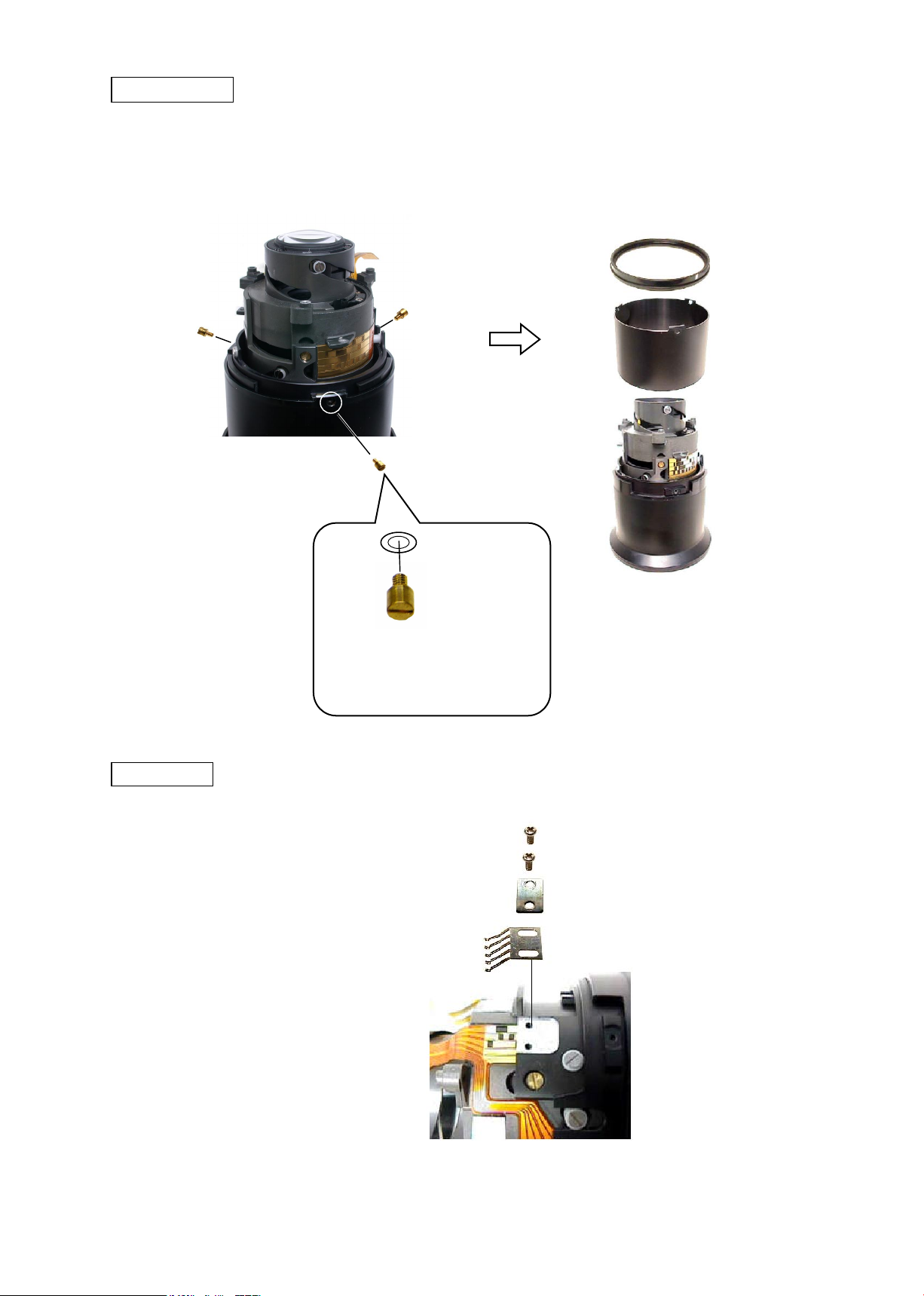

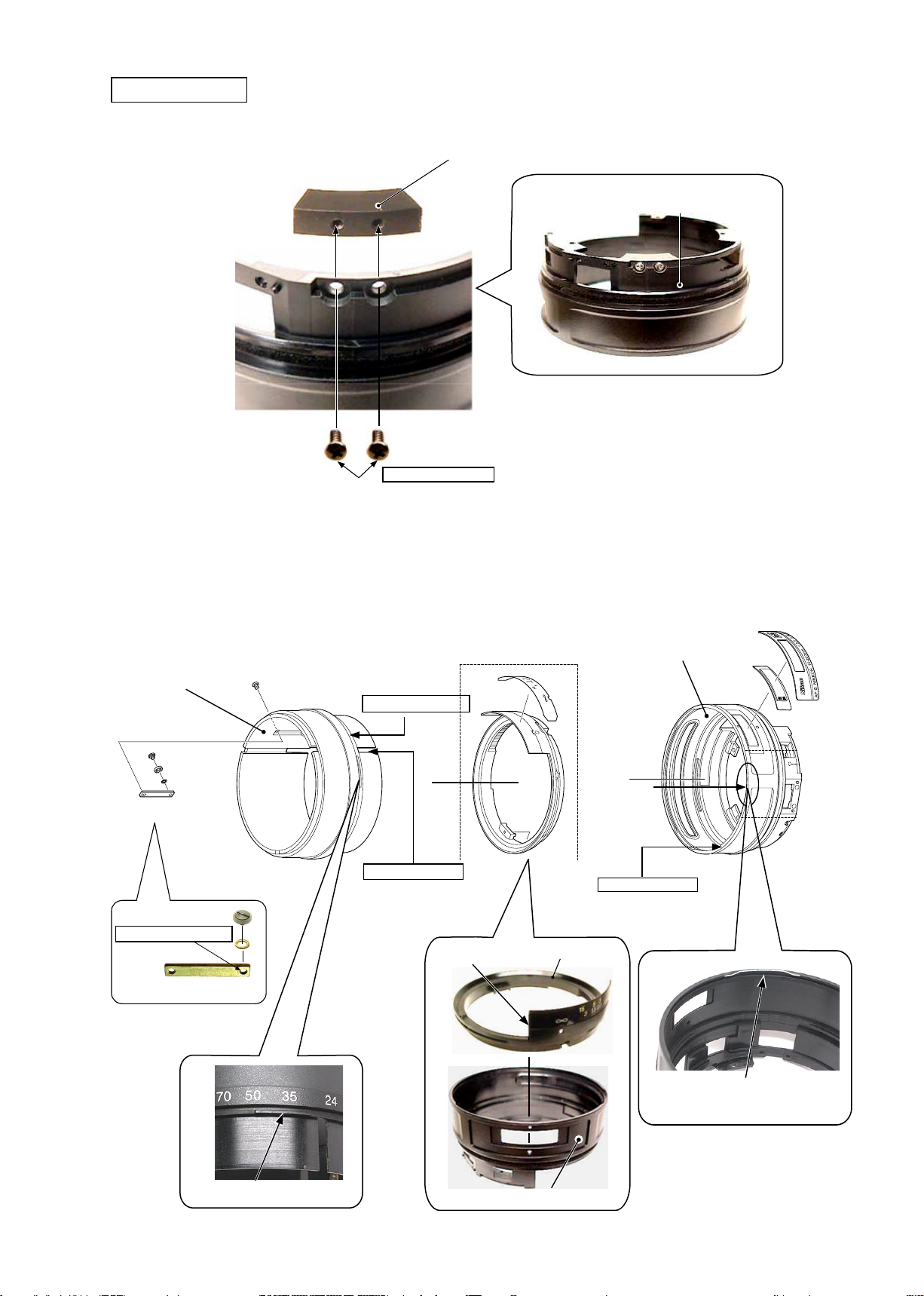

Removal of VR unit

INC

Take out three screws (#68).

①

(Addition)

Caution) The smaller diameter side of the stepped

rollers (#148 X 3) comes to VR unit.

#68×3

#147×3

#148×3

VR unit

②

JAA79471-R.3678.A

Remove the VR unit.

Aperture blade unit

Retaining plate

Blade actuating plate

Fixed tube

VR unit

Blade mounting plate

Blade×7

Changed page

#63

× 1

#56×3

- D14 ・ AF-S VRDX18-200/3.5-5.6G -

VR FPC unit

March. 17. 2006

3rd-4th lens group cam ring

INC

Remove each roller.

Remove 3rd-4th lens-G cam ring.

#102

#103 AF

#82

JAA79471-R.3678.A

#102

#103AH

#82

#99

#94AD

#82

#82

#84AD

#83

#149

#102×3

#146

#150

Revision

3rd-4th lens-G cam ring

#111

Encoder FPC

Changed page

1 October. 20. 2006

- D15 ・ AF-S VRDX18-200/3.5-5.6G -

2. Assembly / Adjustment

INC

JAA79471-R.3678.A

Encoder FPC

Distance encoder

Reference position for attachment

Fixed tube

3rd-4th lens group cam ring

Apply to the overall surface of the inside.

Grease: MZ-800S

Zoom encoder

Reference position for attachment

To cam groove

Grease: I-40

Align the concave portion of the 3rd-4th lens-group cam ring with the cutout of the xed tube, and assemble

①

them.

Attach each roller that ts the grooves.

②

Attach each tape.

③

Revision

△(

Adhesive: Lockend BR

#102

)

#103

A-F

#82

#103 A-H

#82

#99

#94 A-D

#82

#82

#84 A-D

#83

Adhesive: Lockend R

Addition

△(

#102

Fixed tube

#111

)

Apply to the sliding surface with Fixed tube

Grease: MZ-800S

#146×3

Cutout

Concave portion

3rd-4th lens-G cam ring

Addition

△(

Cam groove× 6 places

Grease: GP-1RS

Addition

△(

)

)

Changed page

#149

#146×3

△(

5 October.20.2006

△×

#150

Addition

)

#149

- A1 ・ AF-S VRDX18-200/3.5-5.6G -

#111

#150

JAA79471-R.3678.A

INC

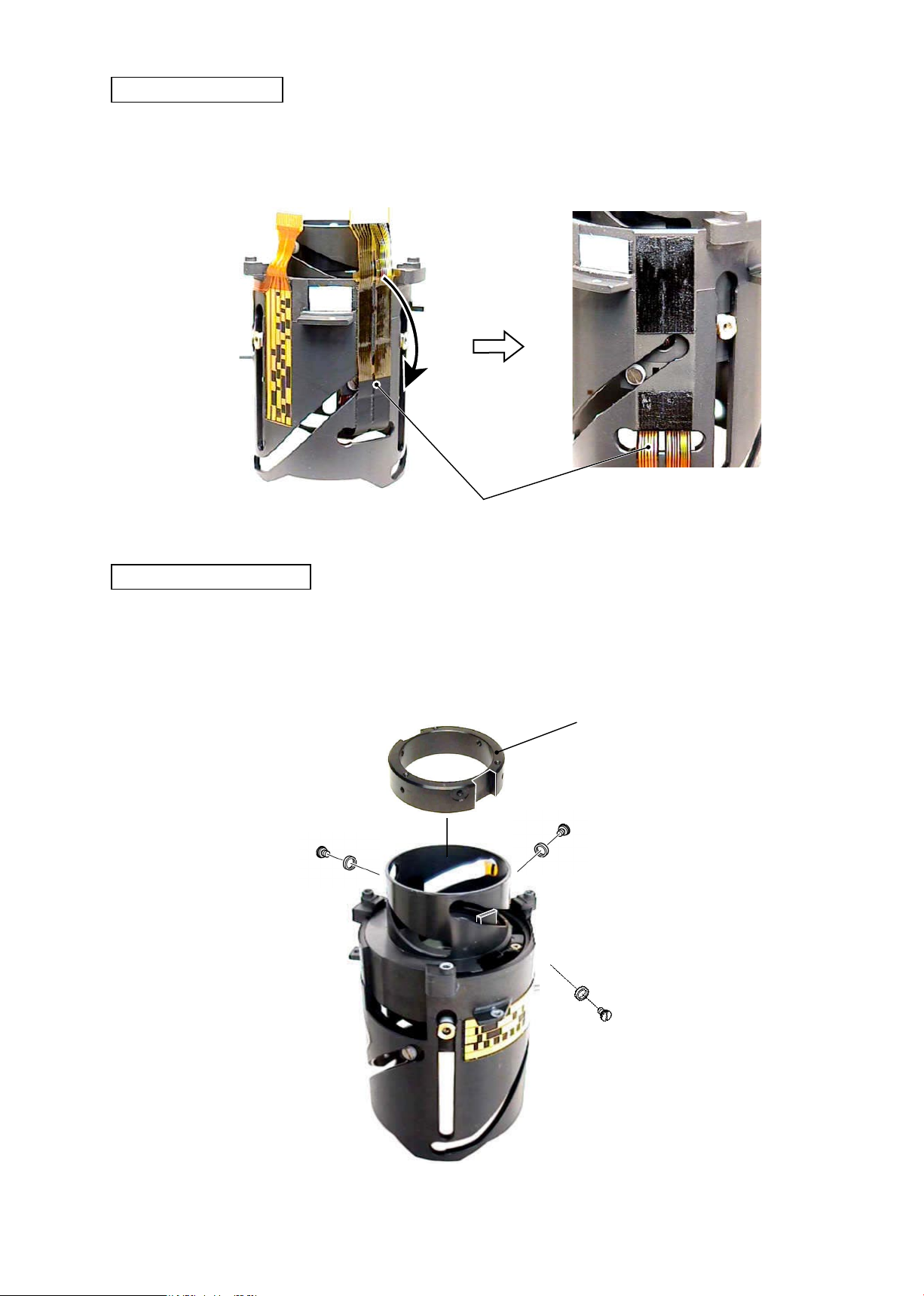

Aperture blade unit

Fit the three convex portions of the retaining plate into the three holes of the blade mounting plate in the order

・

of ① and ②.

VR unit

Retaining plate

①

②

①

Adhesive: Screwlock

Blade actuating plate

Blade×7

Installation of VR unit into Fixed tube

① Assemble the VR unit into the xed tube.

(Addition)

Caution) The smaller diameter side of the stepped

rollers (#148 X 3) comes to VR unit.

Blade mounting plate

Insert the three nuts (#68) at the position

②

shown in Fig.1.

VR FPC unit

#68×3

#147×3

#148×3

Grease: MZ-800S

VR unit

Fixed tube

Fig.1

Changed page

× 1

- A2・ AF-S VRDX18-200/3.5-5.6G -

March.17.2006

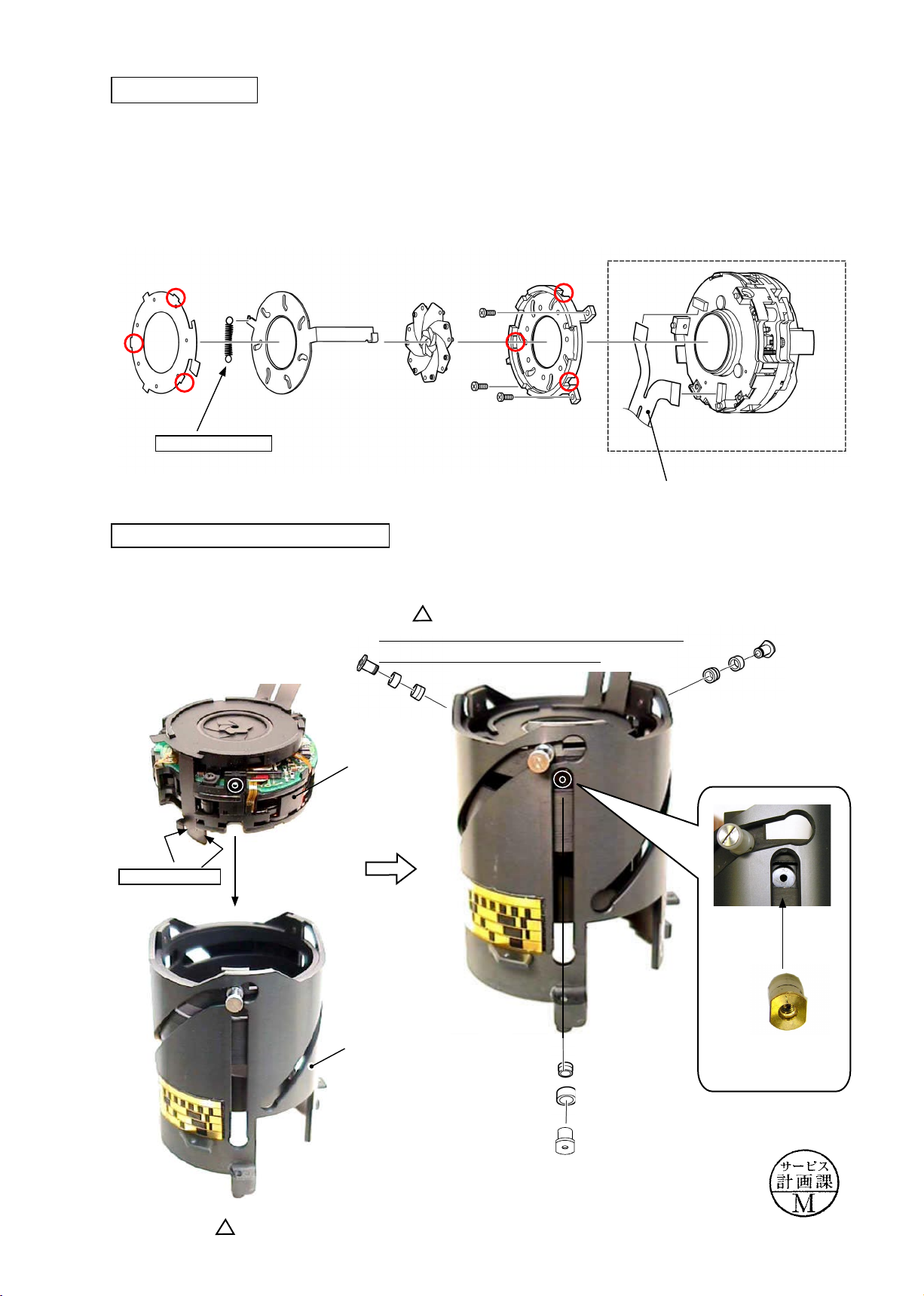

4th lens group sliding ring

INC

Assemble the 4th lens-group sliding ring into

・

the xed tube.

Fix them with three screws (#81).

・

JAA79471-R.3678.A

Screw holes for 4th lens-G×3

4th lens-G sliding ring

Adhesive: Lockend R

#81×3

#84×3

Installation of VR FPC unit

Reference plane for attaching VR FPC

Pull out the VR FPC from the

hole.

#150

#149

VR FPC

Position for attaching VR

FPC unit.

VR FPC

Caution: Attach the FPC

without any slacks.

- A3・ AF-S VRDX18-200/3.5-5.6G -

JAA79471-R.3678.A

- A4・ AF-S VRDX18-200/3.5-5.6G -

・

Attach the brush by turning the convex portion all the way to the direction of the arrow so that the brush is

positioned as shown in "Fig.1".

#67×3

Adhesive: Lockend B

Aligned position of Zoom brush

Fig.1

#109×2

#106

Zoom brush

Convex portion

・

Assemble the xed tube into the 2nd lens-group straight ring unit, and x them with three screws (#67).

Fixed tube

Adhesive: Screwlock

2nd lens-group straight ring unit

2nd lens-G straight ring unit

Zoom brush

INC

JAA79471-R.3678.A

INC

Cover ring unit

Assemble the reinforcing ring unit and the cover ring unit, and x them with three screws (#110).

・

Reinforcing ring

unit

Cover ring unit

#110×3

Adhesive: Lockend B

When the three screws (#110) are attached,

・

the vertical position of the screw slot is

considered as 90°-direction. Then, if the

screw stops where the slot is at an angle

exceeding 45°, or in a horizontal position

(See "NG"), put the washer (#107) and

tighten the screw again.

(Addition)

△

Caution: In case of "NG", the screw slot

touches and scrapes against the

inner groove of the cover ring

unit. The may cause a dirt or

malfunction. (ref. Fig.1)

45°

GOOD

90°

45°

NG

#107

#110

Fig.1

Changed page

× 1

- A5・ AF-S VRDX18-200/3.5-5.6G -

March.17.2006

Zoom index ring

INC

Put the two screws (#112) into the block (#155).

①

JAA79471-R.3678.A

Block

Zoom index ring

#112×2

Adhesive: Screwlock

② Align the edge of "∞" of the distance scale sticker with the index of the zoom index ring, and assemble the

gear unit. Then, turn the gear unit clockwise and align the "∞" mark with the index. (Fig1)

③ Align the cutout of the zoom index ring with the convex portion of the zoom ring, and assemble them.

(Fig2)

④ Fix the zoom control key with the screw (#144).

⑤ Attach the name plate and window (#76).

Name plate

Zoom ring

#83

#84A-D

#82

Zoom control key

Adhesive: Lockend R

Apply to

the hole.

#144

Apply to the overall contacting

surface with Zoom index ring.

Grease: MZ-800S

Grease: MZ-800S

Apply to the sliding surface at 3

locations with the shoulder screw

(#110) of the previous page.

Edge of "∞"

Gear unit

Apply to the entire circumferential

jointing surface.

Gear unit

Zoom index ring

Cutout

Grease: MZ-800S

#76

Convex portion

Fig

2

Fig1

- A6・ AF-S VRDX18-200/3.5-5.6G -

Zoom index ring

Cutout

Fig

2

GMR sensor FPC unit

INC

① Pass the FPC of the GMR sensor FPC unit

through the hole to assemble.

GMR sensor

FPC unit

Attach the retaining plate (#97) and the plate spring

②

(#130), then x them with two screws (#112).

Zoom index ring

JAA79471-R.3678.A

#97

#130

Caution:

When the GMR sensor FPC unit is mounted, do NOT bend the

area of doted lines.

#112×2

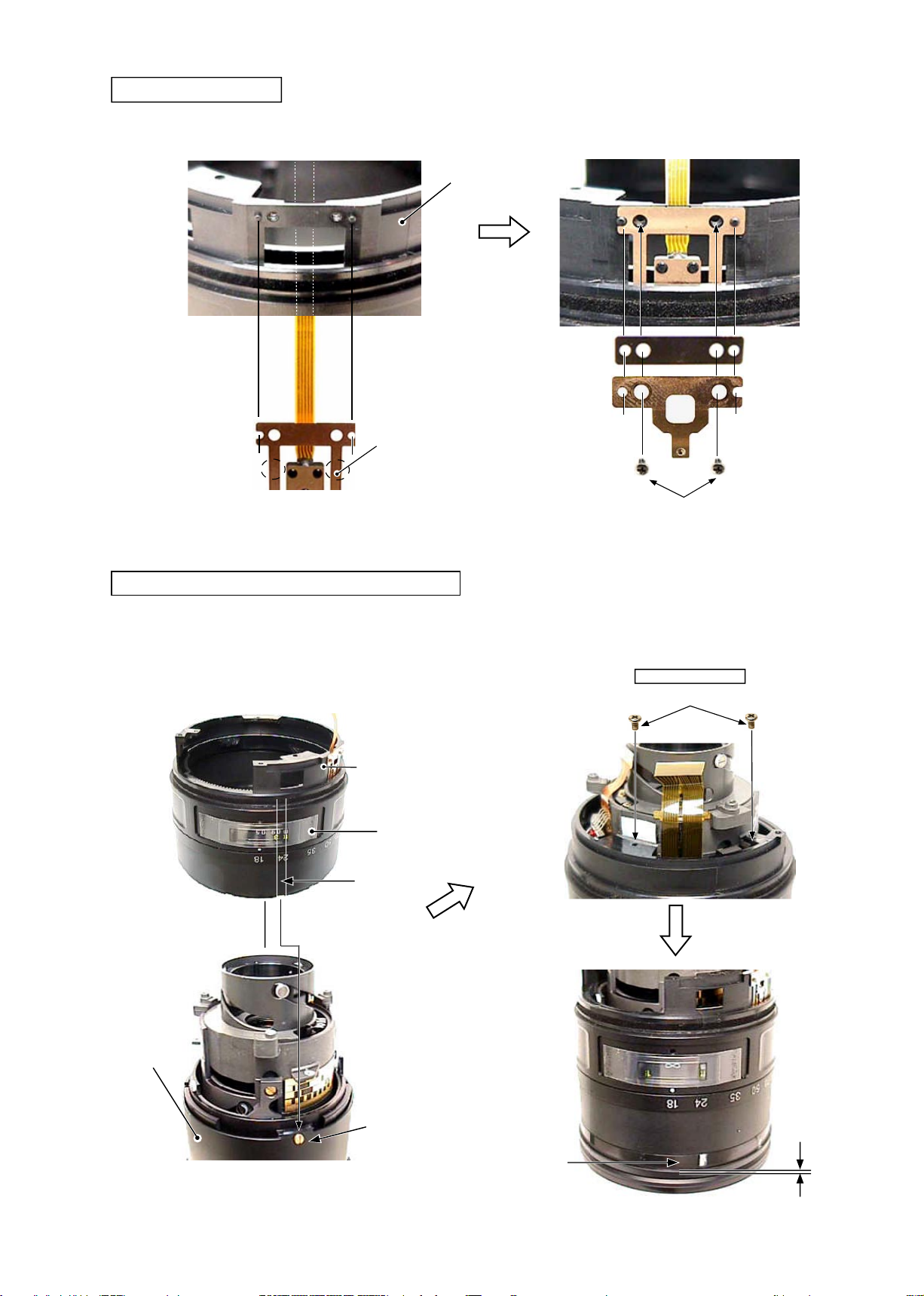

Installation of Zoom index ring unit in Lens body

① Align the vertical groove of the zoom index ring unit with the pin "A" of the lens body, and assemble them.

Set the zoom ring to the wide-position, while the distance index to "close"-side.

②

Tighten the two screws

③

#123).

(

Adhesive: Screwlock

#123×2

Zoom index ring unit

Distance index

Vertical groove

Lens body

Attach the polyester tape.

④

Pin A

Polyester tape

- A7・ AF-S VRDX18-200/3.5-5.6G -

Position for at

taching tape

Clearance:

approx.1

-

JAA79471-R.3678.A

INC

4th lens group

Moved to page A16-1

△(

)

・ Fit the two cutouts and three screw holes of the washer (#139) in the 4th lens-group sliding frame.

Fit the two cutouts and three screw holes of the 4th lens group in the 4th lens-group sliding frame, then x

・

them with three screws (#124).

#124×3

4th lens group

#139A~H

MF ring

・ Assemble the MF-ring into the

zoom ring.

Apply to the overall sliding surface.

Grease: MZ-800S

MF ring

Changed page

△×

1

- A8 ・ AF-S VRDX18-200/3.5-5.6G -

October.20.2006

SWM unit

INC

SWM unit

JAA79471-R.3678.A

Adhesive: Screwlock

#145×2

Caution:

Do NOT touch the A-part directly by

hand.

A-part

Focus key

① Set the MF ring to "close"-side, while the zoom ring to "wide"-side.

② Rotate #25 (See "Pic.1") by hand so that the groove of #25 is set at the position of "Pic. 2".

③ Put the focus key and the plate spring (#157) in the groove of #25, and x them with the screw (#122).

Attach the screw (#122) by

*

MF ring

Zoom ring

#25

Pic. 1

Groove

positioning #157 outwards.

#122

Adhesive:Screwlock

#157

Edge

Focus key

#25

Focus key screw hole

- A9・ AF-S VRDX18-200/3.5-5.6G -

Pic. 2

JAA79471-R.3678.A

INC

Inspection and adjustment of output waveform of MR encoder

● When the MR head is disassembled and replaced, be sure to make an adjustment.

1. Device:

・

・

・

Caution:

Single-output rated voltage power-supply

Oscilloscope

Self-made tool 1 unit

1 unit

1 unit: 5V 100mA

If there is a problem with continuity between the contacts of the self-made tool and the relay FPC,

the contacting surface of the relay FPC may be dirty, eroded, or oxidized. So polish the contacts and

connect them.

2. Preparation of the lens for measurement

・

Assemble the MR-head-attached zoom index ring unit, the SWM, and the MF ring into the lens body.

Then connect the assembled lens to each measuring machines as follows:

Attachment diagram

・

【

】

PCB (Front)

Rated voltage power-supply

PCB (Back)

To back

side

Oscilloscope

Oscilloscope

Rated voltage power-supply

Rated voltage power-supply

Caution:

The connector of the back of

the PCB is not used.

How to inspect and adjust:

・

Conrm that the electric current and voltage of the connected rated voltage power-supply are set values, then

①

turn it ON.

Set the oscilloscope, and turn the MR ring.

②

(2ch)

(1ch)

(+)

(-)

Self-made tool

(GND)

(+)

Set value

5.0 V

100 mA

Oscilloscope

(2ch type)

Note: The waveform varies according to the rotational speed of the focus ring. So change "Time/Div” setting

accordingly.

- A10 ・ AF-S VRDX18-200/3.5-5.6G -

CH1

INC

JAA79471-R.3678.A

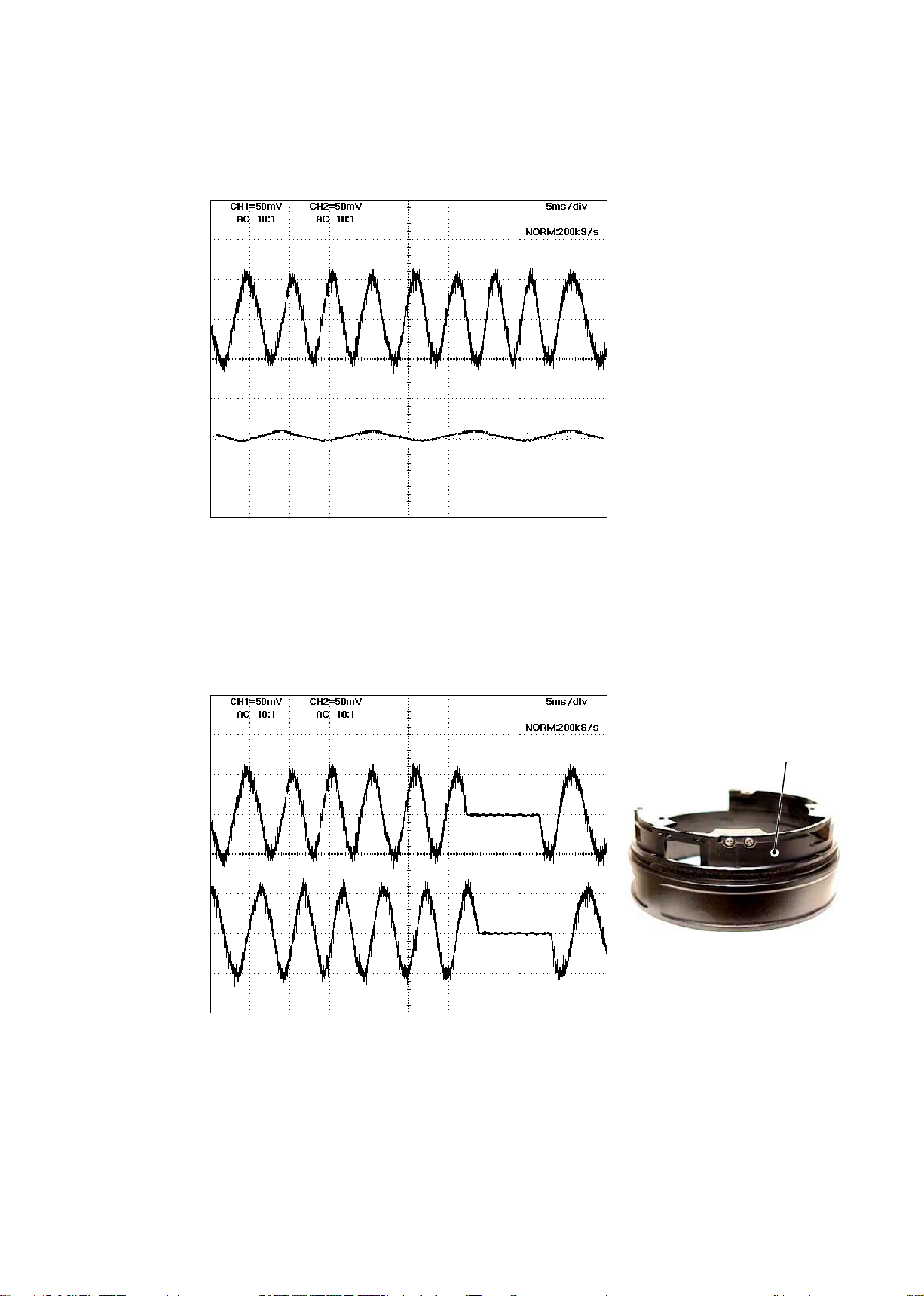

● Oscilloscope setting

V/Div (ch1) : 50 mV

V/Div (ch2) : 50 mV

Coupling : AC

Time/Div : 5 m Sec

Trigger Mode : NORMAL

Trigger Coupling : AC

CH2

Fig.1

In case large waveform-noise (as shown in Fig. 1) is detected, use the FILTER function.

③

How to set FILTER function (e.g. DL1540 manufactured by YOKOGAWA

1. Press the FILTER button.

2. Select “Smooth” of the menu on screen and turn it ON.

Amplitude

Standard:

Note:

Amplitude of all pulses/

waveforms is 80mV or more.

Check the waveform by moving the

focus ring back and forth from the

innity-end to the close-end positions

entirely.

)

④

In case the amplitude is small, disassemble up to

the stage of the GMR sensor FPC unit. Then if the

deformation is detected in the MR head, correct the

deform of the MR head. On the other hand, if such

correction is impossible or no deformation is detected,

replace the GMR sensor FPC unit. (Fig.2)

Note: When adjustments are made, prevent the

magnetic surface and MR head from touching the

magnetized driver bit. Otherwise, the magnetic

data may be damaged.

GMR sensor FPC unit

#123×2

MF ring

MR head

Fig.2

- A11 ・ AF-S VRDX18-200/3.5-5.6G -

Ref.

INC

<

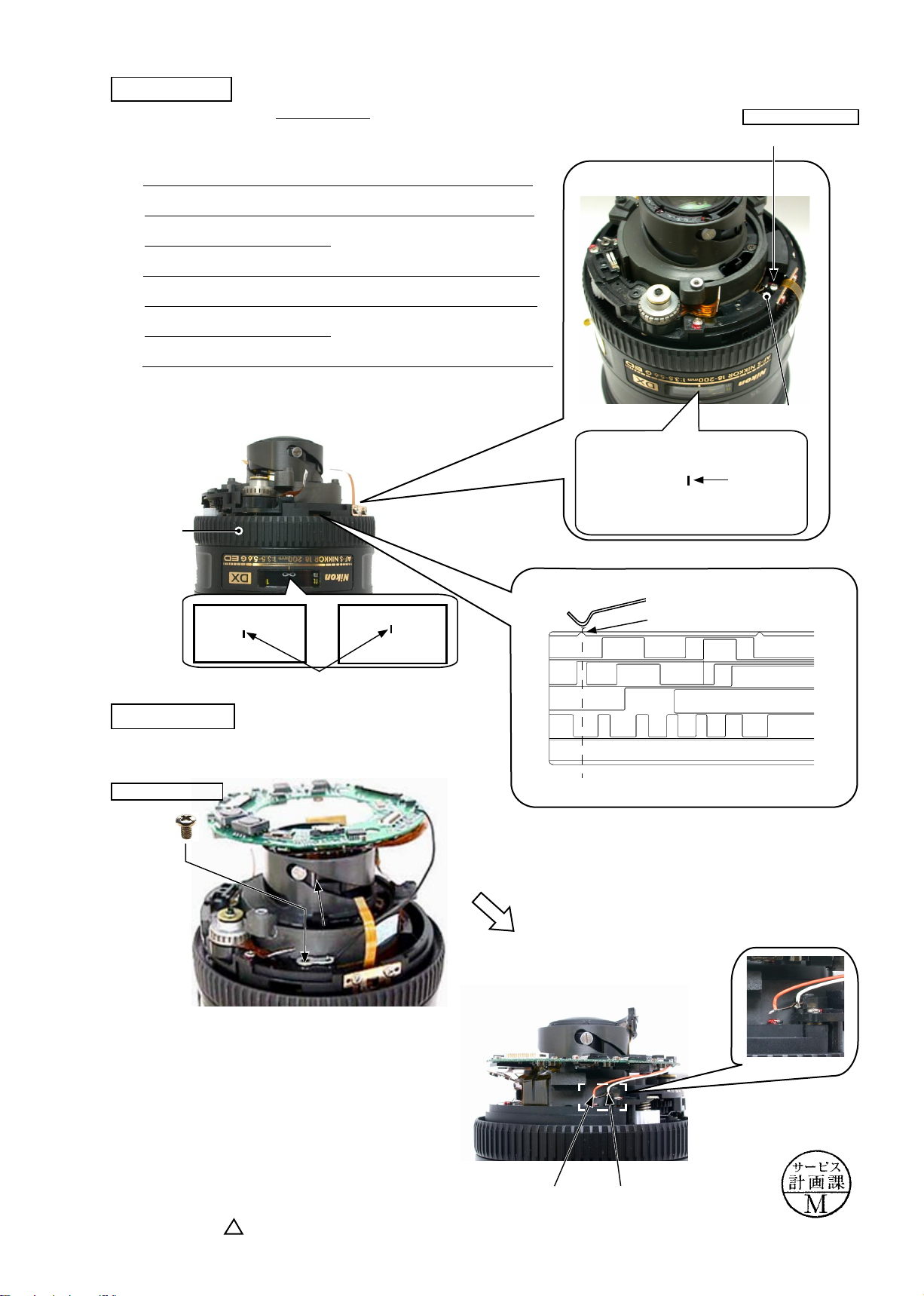

● As shown in Fig. 1,

>

JAA79471-R.3678.A

if the amplitude of only either CH1 or CH2 is small, one of the 2 screws (#218) may be

loosened, so check for it. If this is not the case, the MR head may malfunction, so replace the

FPC

unit and make a readjustment.

CH1

CH2

Fig.1

GMR sensor

As shown in Fig. 2,

●

magnetic data of the tape may be damaged. So replace the main xed tube unit and make a readjustment.

Replacing only the magnetic surface is impossible.

CH1

CH2

if the amplitude partially drops between the innity and the close-distance, the

Zoom index ring

⑤

Turn off the rated voltage power-supply.

Fig.2

- A12 ・ AF-S VRDX18-200/3.5-5.6G -

Distance-brush

INC

(Revision)

△

and set the distance scale to "1 m".

① Rotate the MF-ring to "close"-end.

② Attach the distance-brush with the screw (#112) temporarily.

(Revision)

△

③ Rotate the MF-ring and set the distance scale to the center

of "∞". Check if the ditance-brush comes to the reference

position or not. (ref. Fig.1)

④ If not, loose the screw (#112) and adjust the position. (The

screw (#112) cannot be seen, so rotate the MF-ring and set

the distance scale to "3 m".)

⑤ After the adjustment, x the screw (#112) with the screwlock.

(Revision)

△

JAA79471-R.3678.A

Adhesive: Screwlock

#112

Distance-brush

(Revision)

△

MF ring

Position for

③

∞

Distance scale

(Reference line)

Main PCB unit

Fix the lug plate with the screw (#123).

①

Adhesive: Screwlock

#123

Position

3

④

Position for

1

(Revision)

△

Position for Distance-brush

Reference position

Fig.1

①

Distance

scale

(Reference

line)

Changed page

× 5

Lug plate

Solder the two wires on the SWM unit.

②

Orange

White

- A13 ・ AF-S VRDX18-200/3.5-5.6G -

March.17.2006

Loading...

Loading...