Page 1

INSTRUCTIONS FOR USE

N

uvo

Lite

(Model

92

5)

shown for reference.

Mark 5 Nuvo Lite Family

(Nuvo Lite and Nuvo Lite 3)

OXYGEN CONCENTRATOR

For models: 525, 535, 925 and 935

(and variants thereof)

EN

[Original language is English]

This unit is not a life-support device. Geriatric,

pediatric, or any other patient unable to

communicate discomfort while using this device

should receive additional monitoring.

This device supplies highly concentrated oxygen

enriched product gas that promotes rapid

burning.

DO NOT allow smoking or open flames within the

same room of this device or the administration

accessory (cannula). Failure to observe this

warning can result in severe fire, property

damage, and / or cause physical injury or death.

Contents

1 GLOSSARY OF SYMBOLS ................... 2

2 YOUR DEVICE ....................................... 2

2.1 Intended Use and Operation .............. 2

2.2 Device Features ................................. 2

2.3 Alarms and Safety Features............... 3

2.4 Device Performance and

Specifications ............................................... 3

2.5 Accessories and Spare Parts .............. 4

3 UNPACKING AND INSPECTION ......... 4

Oxygen accelerates the combustion of flammable

substances. DO NOT use oil, grease, petroleum

based or other flammable products on the

device, the administration accessory (cannula) or

the patient’s face / neck.

Only persons who have read and understood this

entire manual should be allowed to operate the

device.

CONTRAINDICATIONS - Those who continue to

smoke (because of the increased fire risk and the

probability that the poorer prognosis by smoking

will offset the treatment benefit).

4 INSTALLATION AND OPERATION .... 4

4.1 Installation ......................................... 4

4.2 Start-Up ............................................. 5

4.3 Shut Down ......................................... 5

5 CLEANING AND MAINTENANCE ...... 5

5.1 Cleaning ............................................ 5

5.2 Maintenance ...................................... 5

6 DISPOSAL ............................................... 6

6.1 Method for Waste Disposal ............... 6

6.2 Disposing of the Device .................... 6

7 TROUBLESHOOTING ........................... 6

Federal Law (US) restricts this device to sale by, or

on the order of, a licensed physician. This oxygen

℞Only

______________________________________________________________________________________________________________

2010-8401CE-E February 2018 Page 1 of 8

concentrator should be used only under the

supervision of a licensed physician.

8 EMC INFORMATION............................. 7

9 CONFORMITY WITH EN 60601-1 ........ 8

Page 2

1 GLOSSARY OF SYMBOLS

To ensure your safety, u

se

only after one or more

ON (Power switched on)

OFF (Power switched off)

Manufacturer Name and Address

Type B Device

Class II Protection

IPX1

Protection from vertically falling water drops

Do Not Expose to Open Flames

Do Not Expose to Oil or Grease

Tools Required / Technician Only

Refer to Technical Information / Service Manual

Refer to Instructions for Use / User’s Guide

Keep in Vertical Position

The Mark 5 Nuvo Lite Family begins their operation

with air being pulled into the external air intake filter.

This filtered air enters the compressor via a suction

resonator and fine filter. Pressurized air then exits the

compressor and passes through a heat exchanger, which

reduces the temperature of the compressed air. Next, an

electronic valve system directs the air into one of two

tubes that contain molecular sieve (sieve beds). The

molecular sieve adsorbs (physically attracts) the nitrogen

from the air as it is pushed through the sieve beds. This

allows the oxygen enriched product gas to pass through

before being delivered to the pressure regulator. As one

tube is generating the product gas, the other is being

purged of the adsorbed nitrogen, this process is called

pressure swing adsorption (PSA). After passing through

the regulator, the rate of product gas being delivered to

the patient is set by the flow meter adjusting valve.

Finally, it passes through a fine particle filter and then

over a sensor that detects the oxygen concentration of the

product gas before it exits the device through a fire

resistant outlet.

2.2 Device Features

FRAGILE – Handle with Care

Visual Alarm Indicator

WARNING – A hazard or unsafe practice that

can result in serious injury or death if

conditions are not avoided.

Caution - A hazard or unsafe practice that can

result in minor injury and / or property damage

if conditions are not avoided.

Note – Information important enough to

emphasize or repeat

2 YOUR DEVICE

2.1 Intended Use and Operation

The Mark 5 Nuvo Lite Family (Nuvo Lite and Nuvo Lite

3) Oxygen Concentrators are used as a means of

providing continuous oxygen enriched product gas for

patients, adolescent to geriatric, suffering from health

conditions that cause low levels of oxygen in the blood

(hypoxaemia).

settings have been individually determined or prescribed

for you at your specific activity levels – AND – only use

the accessories that were used when your settings were

determined.

While undergoing oxygen therapy, if you feel discomfort

or experience a medical emergency, seek medical

assistance immediately.

Front panel (Fig. 1)

1 – Flow adjustment knob 4 – Circuit Breaker

2 – Oxygen Product Outlet 5 – Indicator Lights

3 – Mains Power Switch (green and yellow)

Rear panel (Fig. 2)

6 – Humidfier (space reserved) 9 – Air Filter / Grill

7 – Technical Label

8 – Mains Cable 10 – Hour Meter

(Inlet Filter under – Fig 5)

______________________________________________________________________________________________________________

2010-8401CE-E February 2018 Page 2 of 8

Page 3

EN

Use the power cord provided.

Check that the electrical characteristics of the power

outlet used match those indicated on the manufacturer’s

technical label (Fig 2-7) on the rear panel of the device.

This unit may be equipped with a polarized plug. That is

one blade wider than the other. If it does not fit into the

outlet, reverse the plug. If it still does not fit, contact a

qualified electrician. Do not defeat this safety feature.

2.3 Alarms and Safety Features

The device has an audible alarm to warn the user of

problems. In order that the alarm may be heard, the

maximum distance that the user can move away from it

must be determined to suit the surrounding noise level.

No voltage detection: In the event of a loss of mains

power, an intermittent audible alarm is activated and the

green light is no longer illuminated.

Test alarm by actuating the Power Switch (Fig 1-3) when

Oxygen Concentration Status Indicator: The oxygen

concentration monitor is an electronic module capable of

checking the effective oxygen concentration supplied by

the concentrator. The oxygen monitor measures the

concentration and activates an audible and visual alarm if

it falls below the alarm set point percentage. When the

device is started, the indicator lights (Fig 1-5) located on

the front panel operate as described below.

Green indicator: This light indicates that power is

applied to the concentrator and that it is ready to provide

oxygen enriched air to the patient.

Yellow indicator: This light and a continuous audible

alarm will activate when the oxygen concentration level

falls below the set point.

Devices manufactured prior to 2018 included a red indicator light.

Blocked Cannula detection: If supplied, the device has a

Blockage Alarm. A continuous audible alarm and both

indicator lights will be lit immediately in the event the

flow of oxygen to patient becomes blocked.

Malfunction detection: If low pressure occurs due to a

mechanical failure, the indicator light will flash yellow

and a continuous audible alarm will actuate.

Thermal safety: The compressor motor is protected by a

thermal switch situated in the stator winding (145 ± 5° C).

One tubeaxial fan cools the compressor compartment.

the mains cable is not plugged into the power outlet.

On initial power up, this indicator light will flash green

until the device has reached normal operating conditions.

This should happen within approximately 2 minutes.

No special maintenance is required. The alarm set-point is

factory set and the setting cannot be adjusted.

All OCSI models are set at 85% ± 3%.

If any of the above alarm conditions occur, press the

Power Switch (Fig 1-3) to the “O” (OFF) position.

Call your equipment supplier to service the device.

Electrical protection:

• A 5A circuit breaker is incorporated into the front

cabinet of all 230V models

• A 10A circuit breaker is incorporated into the front

cabinet of all 115V models

• Class II devices with insulated casings (EN60601-1

standard)

Safety valve: This is fitted on the compressor outlet and

is calibrated to 3.4 bar (50 psig).

Fire Break: This device is fitted with a metal fire break

at the Oxygen Product Outlet (Fig 1-2). This break will

keep fire from entering the device.

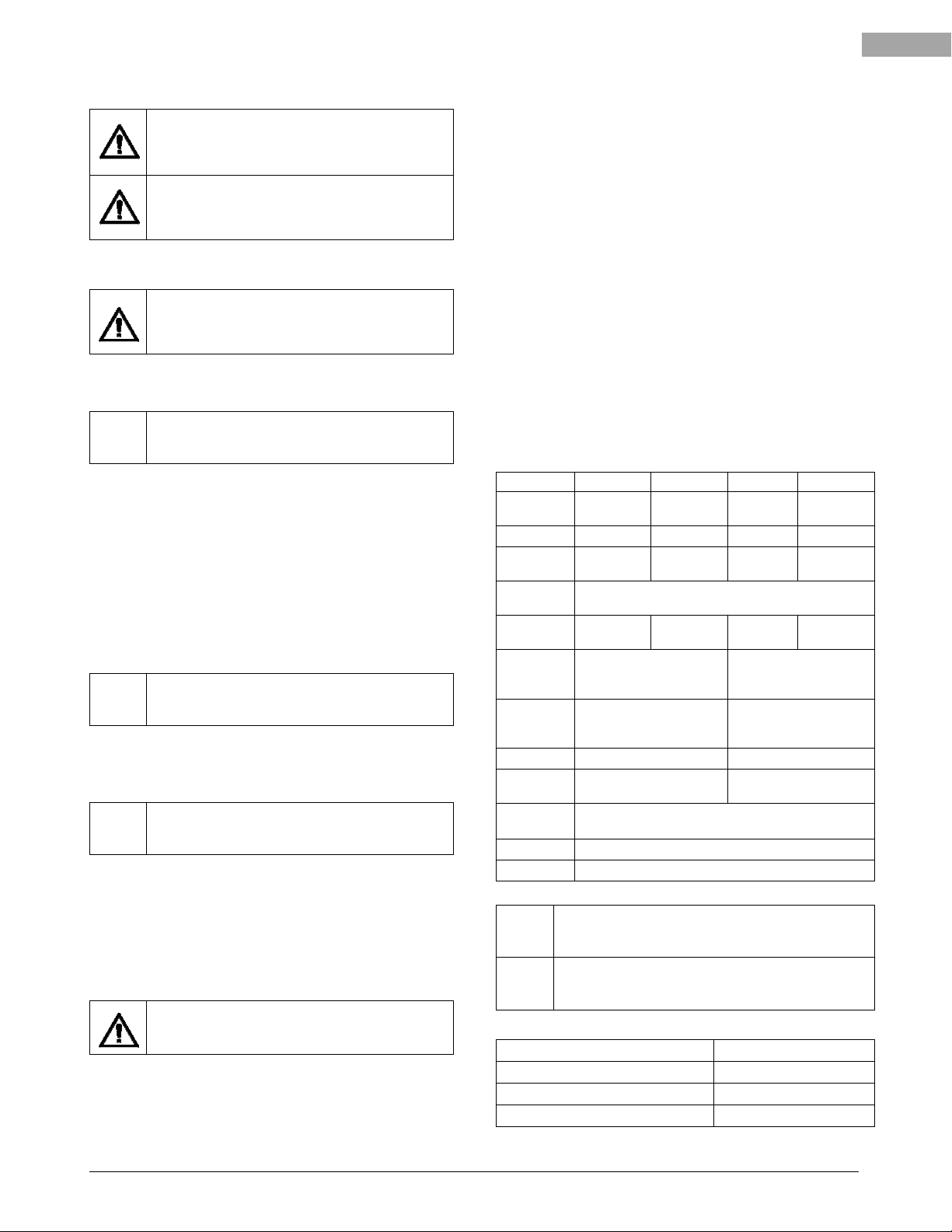

2.4 Device Performance and Specifications

The performance of the device (especially the oxygen

concentration) is quoted at 21°C (70°F) and one

atmosphere. The specifications may change with

temperature and altitude.

Model 525 925 535 935

Description

Frequency 60 Hz 50 Hz 60Hz 50 Hz

Average

Power

Protection

Class

Mains

Protection

Average

Oxygen

Content

Average

Oxygen

Content

Liter Flow 0.125 to 5 LPM 0.125 to 3 LPM

Outlet

Pressure

Dimensions

(L x W x H)

Weight 14.5 kg (32 lbs.)*

Noise Level < 58 dBA

* Weight dependent on model and features

5 LPM

115V

330 Watts 300 Watts 210 Watts 180 Watts

10A 5A 5A 5A

87% to 95.5%

In compliance with EN ISO 80601-2-69, the flow supplied is

equal to the flow set on the flowmeter, accurate to within

± 10% or 200 ml/min, whichever is greater.

The variation of the maximum recommended flow does not

exceed ± 10 % of the indicated value when a back pressure

of 6.9 kPa (1 psig) is applied to the output of the device.

Materials in direct or indirect contact with the patient

Concentrator enclosure ABS/Polycarbonate

Printed labels Polycarbonate

Power switch (Fig 1-3) Nylon

Oxygen product outlet (Fig 1-2) SS, brass or aluminum

5 LPM

230V

At 2 LPM

> 90%

At 5 LPM

7 Psig 7 Psig

36 x 23 x 58.5 cm (14 x 9 x 23 in.)

3 LPM

115V

Class II

At 2 LPM

> 90%

At 3 LPM

87% to 95.5%

3 LPM

230V

______________________________________________________________________________________________________________

2010-8401CE-E February 2018 Page 3 of 8

Page 4

Flow adjustment knob (Fig 1-1) ABS

Improper patient connection to and use of the cannula

Cabinet air filter (Fig 2-9) Polyester

Mains cable (Fig 2-8) PVC

Inlet Filter (Fig 5) Polypropylene

Humidifier Polypropylene

Casters Nylon

Pipe/Tubing Aluminum, PVC,

polyurethane and/or

silicone

2.5 Accessories and Spare Parts

The accessories used with the device must be oxygen

compatible, designed for oxygen therapy use,

biocompatible and comply with the general requirements

of the FDA Quality System Regulation or the 93/42/EEC

European Directive, or any other applicable regulatory

requirements.

The accessories below, available from Nidek Medical

Products, Inc. and our distributors, comply with these

requirements. Contact your equipment supplier to obtain

these accessories.

Accessories Part Ref

Humidifier (1 to 5 LPM) 9012-8774

Cannula with 2m (7ft) tubing (1 to 5 LPM) 9012-8780

Extension Tubing 7.7m (25 ft) 9012-8781

Tubing Adapter 9012-8783

The use of certain administration accessories and/or spare

parts which are not recommended by the manufacturer

may reduce its performance and void the manufacturer’s

responsibility.

Spare Parts Part Ref

Cabinet air filter (Fig 2-9) 8400-1025

Inlet Filter (Under Fig 2-9) 8400-1180

Ventilation Grill (Fig 2-9) 8400-0108

Casters 8300-8068

Mains Cable Wrap 8400-0022

Please consult the Nuvo Lite Maintenance Manual (PN

2010-8405) for instructions on replacing any above spare

parts.

3 UNPACKING AND INSPECTION

The Oxygen Concentrator is packaged to protect the

device from damage while being transported and stored.

After the device is removed from the package, inspect

for damage. If damage is detected, please contact your

equipment provider.

If you do not plan to use your device immediately, please

consult the Environmental Storage Conditions below.

Environmental Storage Conditions:

The device should be stored in a dry area, with an

ambient temperature between -20°C to 60°C (0°F to

140°F) at 15-95% relative humidity. It must be stored,

transported and used in the vertical position only.

Oxygen concentration can be affected after prolonged

periods of storage – check device before use.

4 INSTALLATION AND OPERATION

4.1 Installation

Environmental Operating Conditions:

The device should be operated in a dry area, with an

Humidifier - Figure 3

Petroleum and oil based lubricants, lotions and cosmetics

are flammable and the use of them while operating the

device is hazardous.

may result in injury, including strangulation. To reduce the

risk of this occurring, avoid situations that might cause the

cannula or hose to become entangled about the patient’s

neck and do not attach more than 15.5m (50 ft) in length

of tubing.

Ears, nose and neck may become irritated after prolonged

exposure to the cannula. For relief, only a water based

lubricant is recommended.

Nasal passages may become irritated after prolonged

exposure to the product gas. If this occurs, consult your

physician about using a humidifier during treatment.

______________________________________________________________________________________________________________

Cannula - Figure 4

2010-8401CE-E February 2018 Page 4 of 8

ambient temperature between 10°C to 40°C (50°F to

105°F) at 15-95% relative humidity. The device can be

operated at an altitude of up to 2200m (7500ft) at a

temperature of 21°C (70°F) without causing product

degradation.

DO NOT use in explosive atmosphere.

To avoid risk of fire and explosion the concentrator should

be kept away from heat sources, incandescent sources,

solvents, Aerosols, etc.

Unit should be placed and operated in a well-ventilated

space that is free of pollutants or fumes and protected

from the elements with adequate lighting.

Unit should be placed and operated in a space where the

position and storage of the mains cable (Fig 2-8) and

oxygen tubing do not present a tripping hazard. The

mains cable should be easily accessible for disconnection.

For patient safety and benefit, no modification to the

equipment is allowed. It is also not recommended to

interconnect the device with any equipment or

accessories not specified in this guide.

Page 5

EN

(under air filter and grill)

Complies with

EN 60529:2001 + A2:2014 rating of

IPX1

;

Make sure during

operation and after shut down

that

Device must have power to operate. In the event of power

loss and for continued operation a backup source is

recommended.

Do not use in a specifically magnetic environment (MRI, Xray, etc.). May cause device malfunction.

We recommend against the use of extension cords and

adapters, as they are potential sources of sparks and fire.

Consult your equipment provider for further information

regarding altitudes of 2200 m to 4000m (7500 to 13000ft).

enclosure protects internal electrical components against

vertically falling water drops.

Complies with EN 60601-1:2006 [11.6.3]; enclosure

protects internal electrical components against spilling of a

glass of water (i.e. contents of humidifier).

4.2 Start-Up

1) Ensure that the Power Switch (Fig 1-1) is in the “O”

(OFF) position.

If used with a humidifier (Fig 3): Unscrew the flask

and fill it with distilled water up to the line (see

manufacturer’s instructions). Then screw the lid on

the humidifier flask until there are no leaks. Connect

the oxygen tube to the humidifier outlet nozzle.

Screw the humidifier directly to the provided Patient

Hose Kit (tubing and elbow) attached to the Oxygen

Product Outlet (Fig 1-2). Ensure that all of the parts

are connected correctly so as to avoid leaks.

Replace water in humidifier bottle before each

If not using a humidifier: Remove the Patient Hose

Kit attached to the Oxygen Product Outlet (Fig 1-3)

and connect the oxygen tube directly to the outlet.

2) Plug the power cable into a power outlet of the

correct voltage and frequency as defined on the

manufacturer’s technical label (Fig 2-7).

3) Press the Power Switch (Fig 1-3) to the ON “I”

position.

4) Turn the flow adjustment knob (Fig 1-1) to the

prescribed value.

5) Check that the oxygen flows out of the administration

device (nasal cannulas or other) by placing the

orifice(s) on the surface of a glass of water. The flow

should disturb the surface of the water.

6) Adjust the nasal cannula to suit your face.

treatment.

See the Alarms and Safety Features on page 3 for

indicator lights and meanings.

The required oxygen concentration is normally

obtained within two minutes after the device is

started.

4.3 Shut Down

At the end of the treatment, press the Power Switch (Fig

1-3) to the “O” (OFF) position to stop the device. The

oxygen enriched air flow continues for approximately

one minute after the device is stopped.

the cannula is facing away from soft surfaces and

clothing. Excess oxygen can accumulate and cause

ignition if exposed to a spark or open flame.

After turning the unit off, the user must wait 3-5

minutes before turning it back on. System pressure must

dissipate before the unit will properly restart.

5 CLEANING AND MAINTENANCE

5.1 Cleaning

Cleaning and disinfecting your device: Only the outside

of the device is to be cleaned. After making sure the

Power Switch (Fig 1-3) is in the "O" (OFF) position, use

a soft, dry cloth or, if necessary, a damp sponge, to wipe

the cabinet enclosure. Then thoroughly dry with wipes

and an alcohol based solution. To prevent the spread of

bacteria and viruses, this should be done daily and for

each new patient.

Acetone, solvents or any other flammable products must

Cleaning and replacing filters: The removable cabinet

air filter (Fig 2-9) must be cleaned in warm water and

household detergent. Dry

before reinstalling. The inlet /

silencer filter (see Fig 5)

should be inspected at each

patient visit and replaced if

required. The final product

filter (not pictured) should only

be replaced by a technician if

required (not common).

Cleaning and replacing accessories: Clean the

humidifier according to manufacturer’s instructions. If

no instructions are provided, do the following: empty the

water from the humidifier, rinse the flask and lid under

running water. Regularly disinfect the humidifier by

immersing the flask and lid in a disinfectant solution (we

recommend using a solution of 1 part vinegar to 10 parts

water). Rinse under running water and dry. Tubing and

cannula should be used according to the manufacturer’s

instructions and replaced for each new patient to prevent

the spreading of bacteria and viruses.

5.2 Maintenance

No special maintenance needs to be carried out by the

patient. Your equipment supplier performs periodic

maintenance operations to assure continued reliable

service from the device.

not be used. Do not use abrasive powders.

Inlet Filter - Figure 5

______________________________________________________________________________________________________________

2010-8401CE-E February 2018 Page 5 of 8

Page 6

DO NOT disassemble due to danger of electrical shock.

Refer servicing to qualified service personnel.

which are designated as being the manufacturer’s

responsibility or by the manufacturer as repairable.

The expected service life of this device is 10 years with

routine preventive and required maintenance.

Preventive Maintenance: Wash cabinet filter (see

“Cleaning and replacing filters”) weekly or after

approximately 100 hours of use and for each new patient.

More frequent cleaning is recommended in dusty

environments. Inspect inlet air filter (Fig 5) at each

patient visit. Replace filter annually, or more often

depending on environment. Check oxygen concentration

every 15,000 hours or 3 years to verify the continuing

OCSI function.

The manufacturer’s instructions for the preventive

maintenance of the devices are defined in the service

manual, (Ref. 2010-8405). Check with your service

provider for any updates to recommended schedules. The

work must be carried out by suitably trained technicians

certified by the manufacturer. Use original spare parts

only (see “Accessories and Spare Parts”). Upon request,

the supplier can provide circuit diagrams, spare parts

6 DISPOSAL

6.1 Method for Waste Disposal

All waste from the device (Patient Circuit, Filters, Etc.)

must be disposed of using methods appropriate to the

civil authority of the location where disposed.

6.2 Disposing of the Device

This device has been supplied by an environmentally

aware manufacturer. A majority of the parts in the device

are recyclable.

Follow local governing ordinances and recycling plans

regarding disposal of the device or components normally

used in operation. Any accessories not original to the

device must be disposed of in accordance with the

individual product markings for disposal. Furthermore,

as part of the marking directive 93/42/EEC, the serial

number of the device disposed of must be sent to Nidek

Medical if the unit has the marking.

lists, technical details or any other information of use to

qualified technical personnel for parts of the device

7 TROUBLESHOOTING

Observations Possible Causes Solutions

The I-O (ON/OFF) button is in the “I” (ON) position but

the device does not operate.

The no voltage detection alarm test does not work.

(See Alarms and Safety Features)

The Power Switch (Fig 1-3) is in the “I” (ON) position,

the compressor is operating and there is a flow but

the green light is not lighted.

The Power Switch (Fig 1-3) is in the “I” (ON) position

but there is no flow.

The audible alarm sounds continuously.

The Power Switch (Fig 1-3) is in the “I” (ON) position,

the compressor is operating and there is a flow but

the audible alarm sounds continuously.

The compressor stops in mid-cycle, then starts again

after a few minutes.

The oxygen enriched air flow is interrupted at the

nasal cannula outlet.

The flow at the nasal cannula outlet is irregular.

Mains cable (Fig 2-8) is not correctly

plugged into the wall outlet.

Capacitor is not charged Internal

electrical fault.

Faulty indicator. Contact your equipment supplier.

Pneumatic connection broken or

other pressure problem.

Internal electrical fault.

Pneumatic circuit fault or low purity.

Compressor thermal safety device

has been activated.

Dirty Filters.

Cooling fan(s) not operating.

Tube disconnected or humidifier cap

is not tight.

Cannula tubing is kinked or

restricted.

Check the cable connection.

Check the circuit breaker (Fig 1-4) on the front

of the unit; Reset if necessary.

Plug unit in for 10 minutes and retest.

Contact your equipment supplier.

Stop the device by pressing the Power Switch

(Fig 1-3) button.

Contact your equipment supplier.

Stop the device by pressing the Power Switch

(Fig 1-3) button.

Contact your equipment supplier.

Stop the device and wait for it to cool down.

Clean cabinet filter. Restart. If the device does

not start, contact your equipment supplier.

Stop the device by pressing the Power Switch

(Fig 1-3) button.

Contact your equipment supplier.

Check that tubing connections are secure and

that the humidifier is sealed.

Straighten the tubing.

Contact your equipment supplier if damaged.

______________________________________________________________________________________________________________

2010-8401CE-E February 2018 Page 6 of 8

Page 7

8 EMC INFORMATION

EN

______________________________________________________________________________________________________________

2010-8401CE-E February 2018 Page 7 of 8

Page 8

9 CONFORMITY WITH EN 60601-1

CONFORMITY WITH EN 60601-1 (§ 6.8.2 b):

The manufacturer, assembler, installer or distributor are not considered to be responsible themselves for the

consequences on the safety, reliability and characteristics of a device unless the:

• Assembly, fitting, extensions, adjustments, modifications or repairs have been performed by persons authorized by

the party in question.

• Electrical installation of the corresponding premises complies with local electrical codes. (e.g. IEC/NEC)

• Device is used in accordance with the instructions for use.

If the replacement parts used for the periodic servicing by an approved technician do not comply with the

manufacturer’s specifications, the manufacturer is not responsible in the event of an accident or non-performance.

This device complies with the requirements of the FDA Quality System Regulation and 93/42/EEC European directive

but its operation may be affected by other devices being used nearby, such as diathermy and high frequency

electrosurgical equipment, mobile telephones, CB and other portable devices, microwave ovens, induction plates or

even remote control toys or any other electromagnetic interferences which exceed the levels specified by the EN

60601-1-2 standard.

EU Representative

mdi Europa GmbH

Langenhagener Str. 71

30855 Hannover-Langenhagen

Germany

Nidek Medical Products, Inc.

3949 Valley East Industrial Drive

Birmingham, Alabama 35217 U.S.A.

Tel: 205-856-7200 Fax: 205-856-0533

______________________________________________________________________________________________________________

2010-8401CE-E February 2018 Page 8 of 8

Tel: +49-511-39-08 95 30

Fax: +49-511-39-08 95 39

info@mdi-europa.com

www.mdi-europa.com

Loading...

Loading...