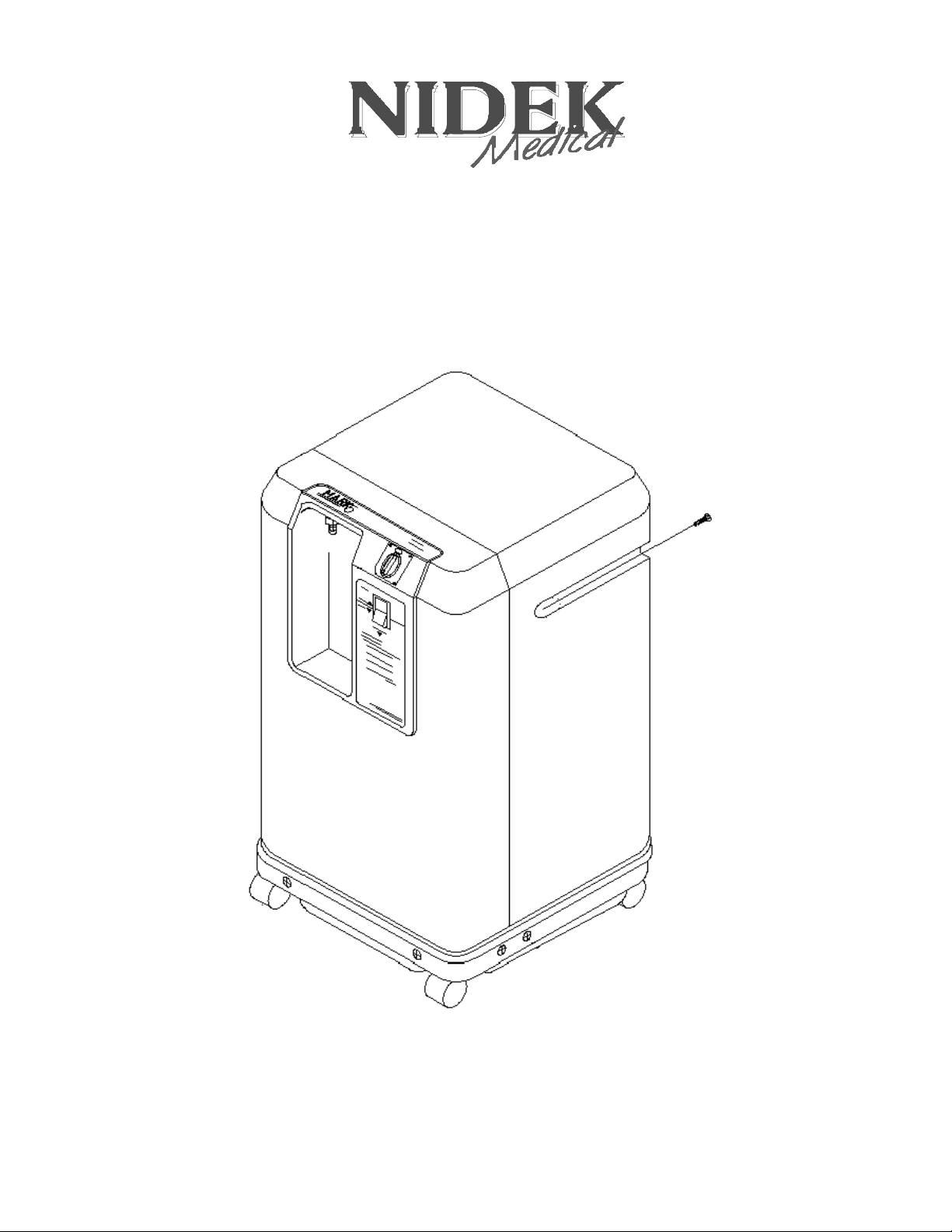

Page 1

Mark 5 Plus Oxygen Concentrator

Domestic Models –115V; 60Hz

Configurations 1373-31100 and 1373-71100 (Part 1)

Configurations 1373-31103 and 1373-71103 (Part 2)

2010-1010QD Rev A

Page 2

Mark 5 Plus Oxygen Concentrator

Domestic Models –115V; 60Hz

Configurations 1373-31100 and 1373-71100 (Part 1)

Configurations 1373-31103 and 1373-71103 (Part 2)

Introduction.................................................................................................... 1-1

Specifications................................................................................................ 1-1

Safety Information......................................................................................... 1-2

Principles of Operation.................................................................................. 1-3

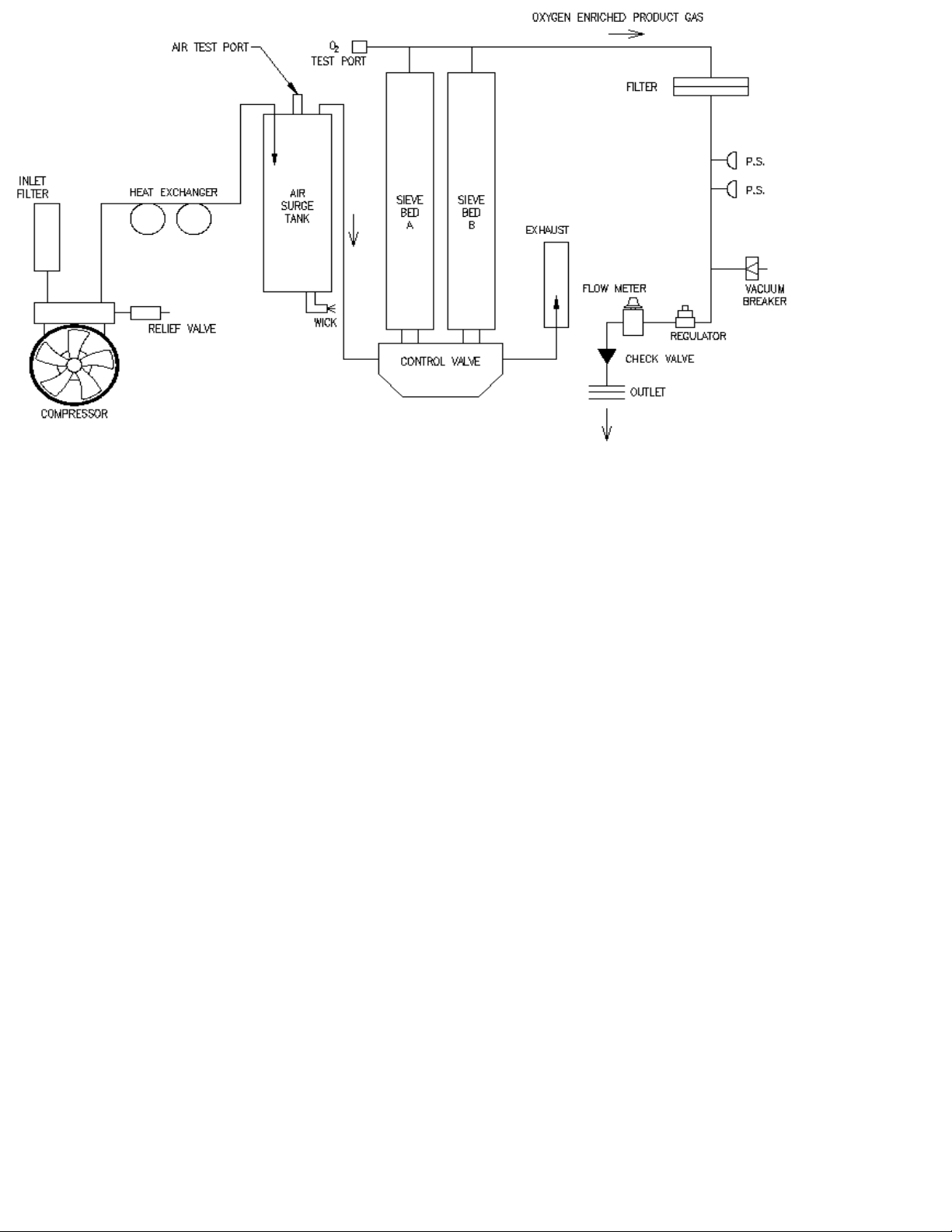

Pneumatic Diagram..................................................................................... 1-4

Component Function................................................................................... 1-4

Initial Setup Instruction.................................................................................. 1-5

Precautions and Safe Practices.................................................................... 1-6

Preventive Maintenance................................................................................ 1-7

Trouble Shooting........................................................................................... 1-8

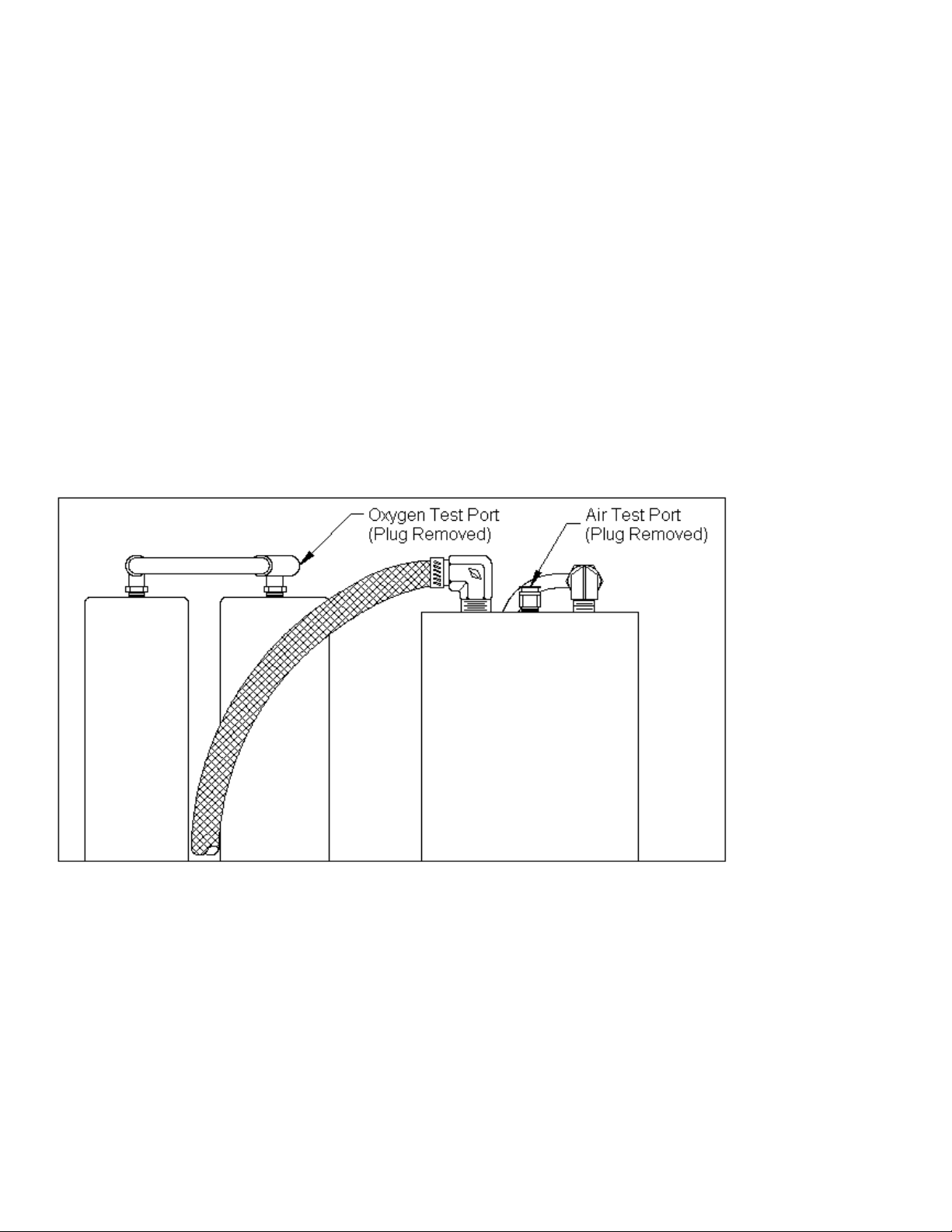

Test Port Diagram....................................................................................... 1-8

System Diagnosis Chart.............................................................................. 1-9

Trouble Shooting Guide.............................................................................. 1-10

Component Replacement.............................................................................. 1-11

Reference Material

Electrical Schematic.................................................................................... 1-13

Illustrations and Part Numbers.................................................................... 1-14

Oxygen Monitoring System Information

Price List/Sample Forms/Reference Material

Nidek Medical Products, Inc.

3949 Valley East Industrial Drive

Birmingham, AL 35217 U.S.A.

(800) 822-9255

Phone (205) 856-7200

Fax (205) 856-0533

2010-1010QD Rev. A

See Section Two

➋

➌ See Section Three

Page 3

Introduction

Thank you for purchasing the Mark 5 Plus Oxygen Concentrator.

The Mark 5 Plus Concentrator is the latest in the high quality Mark series of

concentrators manufactured by Nidek Medical Products, Inc. It is a reliable concentrator,

requiring very little maintenance and is designed to operate efficiently for a long period of

time. We have accomplished this by combining real world experience with the latest of

control and process technology.

We believe that the Mark 5 Plus is the best machine available in today’s market and

will operate to your complete satisfaction. We invite your comments on our devices and

our service. The Mark5 Plus is manufactured under the controls of FDA-GMP’s and ISO9001 and EN46001 Quality Management Systems.

Anand Chitlangia

President & CEO

Nidek Medical Products, Inc.

This edition of the Mark5 Plus Maintenance Manual is effective for

configuration models 1373-31100 and 1373-71100 beginning with

serial number 992-18378. See Section 2 for configurations 137331103 and 1373-71103.

Specifications (Stated at 70°F (20° C) and 1 Atm.)

Height. ............................................................................ 26 in / 660 mm

Width............................................................................... 15 in / 380 mm

Depth.............................................................................. 15 in / 380 mm

Weight............................................................................. 60 lbs / 27 kg

Output............................................................................. 90% +/- 3% @ 5 lpm

Voltage............................................................................ 115 V; 60 Hz

Average Power Consumption.......................................... 420W @ 60 Hz

Cooling Air Temperature Rise.........................................

Less than 30°F / 16°C

9/99__________________________________________________________Sect 1 Pg1

Page 4

Safety

Oxygen Safety

Oxygen does not burn, but it does cause fire to burn more rapidly. Any material that

will burn in air will ignite more rapidly and burn more violently in an oxygen-enriched

atmosphere. While the oxygen concentrator does not contain a large volume of oxygen at

any one given time, oxygen hazards can occur. If the output is allowed to return to the

atmosphere no real hazard is likely; however, if the output hose is under a chair cushion

or a pile of shop rags, these materials may become saturated with oxygen and could burn

violently if ignited. The possibility of fire is the most serious hazard associated with the use

of oxygen equipment. Observe the following precautions to prevent the possibility of a fire

occurring in the vicinity of the oxygen outlet from this unit.

CAUTION

Eliminate Sources of Flame, Heat and Sparks

A fire can be started by almost anything that produces flame, heat and sparks. Do not

permit the use of matches, cigarette lighters, burning tobacco, candles, or other flame

sources in rooms where oxygen is used or stored. Electrical heaters or equipment that

gets hot or sparks during operation can be a source of ignition.

Keep Flammable Materials Away From Oxygen

It is not possible to completely eliminate the presence of combustible materials such as

clothing, bedding, and even parts of the therapy equipment itself, but the presence of

highly flammable materials can and must be avoided. Do not lubricate oxygen equipment.

Oil and grease, including petroleum jelly such as Vaseline ignite very easily and burn

vigorously in the presence of oxygen.

Prevent Accumulation of Oxygen

Since any material that will burn in air will burn more vigorously in an oxygen-enriched

atmosphere, prevent any local accumulation of oxygen that may saturate combustibles. All

connections on the apparatus should be made carefully and observed for leakage.

Sect. 1 Pg.2_________________________________________________________9/99

Page 5

Principles of Operation

The Mark 5 Plus Concentrator takes in room air that contains 21% oxygen, 78%

nitrogen and trace amounts of inert gases. The air is filtered, compressed and passed

through one of the two molecular sieve beds which allows the oxygen to pass but traps

most of the nitrogen. Before the nitrogen saturates the molecular sieve in the first bed it is

vented to the atmosphere and purged with oxygen while air is fed to the second bed. This

process of alternate feeding and venting of beds is continued thus producing oxygen

enriched gas at one end and exhaust at the other end of the sieve beds. The oxygen

produced is then filtered, regulated, and set at a given flow rate for delivery to the patient.

The operation of the Mark 5 Plus can be grouped into three distinct systems; the

compressed air system, the process system and the delivery system.

Compressed Air System

Air enters the system through filters which prevent dust and other particles from

entering and potentially damaging the air compressor. The compressor is a reciprocating

two cylinder positive displacement type that compresses the air to the necessary pressure.

The compressed air is then routed through a heat exchanger to reduce its temperature and

then to the air surge tank. The surge tank reduces air pressure swing and traps moisture.

The wick assembly, located at the bottom of the surge tank, allows the moisture to be

evaporated to atmosphere. The system also has a safety relief valve to prevent pressure

buildup should a blockage occur and a test port for measuring system pressure.

Process System

The process system consist of two sieve beds and a rotary poppet valve. The valve

controls the process by alternately feeding air into and exhausting nitrogen from the sieve

beds. The valve utilizes a gear motor to cause a cam action to alternately open and close

feed and exhaust poppets. Thus, what normally is a complex control system in other

concentrators is reduced to a simple and easily understandable mechanical control in the

Mark 5 Plus.

Delivery System

exits the beds. In order to provide a stable flow, the oxygen, after passing through a

bacterial filter to remove any contaminants, is passed through a regulator to establish a

fixed delivery pressure. A flow control valve consisting of multiple orifices then establishes

a fixed flow rate to the patient. The use of a vacuum relief breaker and check valve in this

section prevents the possibility of contaminants entering the system from the outside. Two

pressure switches monitor the oxygen pressure and cause an alarm to sound if the

pressure is high or low. An Oxygen Monitoring System for continuously monitoring oxygen

purity is available as an option. The operation of the Oxygen Monitoring System is

described separately in Section ➋ .

The cyclic process described above causes pressure variations in the oxygen as it

9/99__________________________________________________________Sect 1 Pg3

Page 6

A

A

g

r

Component Function

A brief description of the principal function of each of the major components is

provided below:

CABINET FILTER..............................................................Filters dust from cooling air

INLET FILTER................................................Filters Particles To Protect Compressor

COMPRESSOR.................................................................Pumps Air Into The System

RELIEF VALVE...............................................Safety Device To Limit System Pressur

HEAT EXCHANGER....................... ................................Cools Air After Compression

WICK ASSY............................................Removes Moisture from the Compressed Air

IR SURGE TANK..................................................Reduces air pressure fluctuations

IR TEST PORT.......................................................A Connection For System Testin

ROTARY POPPET VALVE...............................Controls The Pressure Swing Process

SIEVE BEDS...................................

MUFFLER...............................................................................Reduces Exhaust Noise

OXYGEN TEST PORT............................................A Connection For System Testing

PRESSURE SWITCHES...........................Activates Alarm For High Or Low Pressure

BACTERIAL FILTER....................... .....................Removes contaminant from oxygen

VACUUM BREAKER...........................................................Prevents System Vacuum

REGULATOR................................................................Sets A Fixed Output Pressure

FLOW CONTROL VALV..E.............

CHECK VALVE......................................Prevents Any Reverse Flow Into The System

OUTLET..........................................

.....Separates Gases As Air Is Moved In And Out

................Sets The Flow Rate To ASpecific Flow

...Provides A Connection For Hose Or Humidifie

Sect. 1 Pg.4_________________________________________________________9/99

Page 7

Operating Instructions

The operating instructions for the Mark 5 Plus Concentrator are provided in a

separate booklet written for the patient's use. Maintenance personnel must make

themselves familiar with the contents of this book and use it for all questions that relate to

the operation of the unit.

Initial Setup

Preparing a new Mark 5 Plus Concentrator for patient use consists of little

more than taking it out of its shipping carton. After completing the Carton Unpacking

Instructions found in the shipping carton follow these important checks to insure that

shipping damage has not occurred and unit is performing properly.

Step One: Flow Control Limit Adjustment

The flow control setting on the Mark 5 Plus Concentrator may be locked to

limit the maximum output available to the user. This limit is preset at the factory to 5 liters

per minute but may be changed to any flow setting. From the front of the unit remove the

flow control knob by pulling the knob straight off its shaft. The back of the knob assembly

has a flow locking disc. To reset the flow, remove the screw from the locking disc, lift and

rotate the disc in the desired flow setting, reinstall the screw and replace the flow control

knob.

Step Two: Alarm Test

Before connecting power to the unit, press the ON button to test the battery and power

failure alarm. It should sound when the switch is on and the power disconnected. If there

is no alarm, check the 9-volt battery inside the front cabinet on switch plate and replace if

necessary.

With the unit is plugged-in, push the ON button. The audible alarm should sound and the

Service Required light should be lit and the compressor should run. After approximately

15 seconds both the alarm and the Serviced Required light should turn off.

Step Three: Purity Test

With unit running connect an oxygen Analyzer (Example: OxyChek) to oxygen outlet and

verify results of 90% +/- 3% @ 5 LPM.

Mark 5 Plus Oxygen Concentrator is ready to be placed in service.

9/99__________________________________________________________Sect 1 Pg5

Page 8

Precautions and Safe Practices

The following precautions and safe practices are specifically directed to personnel

who are experienced in the service of medical oxygen equipment. The device covered

by these instructions is an electro-mechanical device that deserves all the respect inherent

in servicing such equipment. Operation of this equipment also requires an awareness of

all the potential hazards associated with handling and using oxygen.

Maintenance Safety

Maintenance personnel must be properly trained in the service of

oxygen concentrators. Electrical shock hazards exist inside the cabinet of this equipment.

Good shop practices must be observed at all times.

Use only approved replacement parts. Medical oxygen equipment

should be repaired with parts supplied by the manufacturer. Substitution of unauthorized

parts can effect the performance of the unit. All parts that will come in contact with oxygen

must be thoroughly cleaned. Remember, human health is affected by the end product of

this device and a foreign substance left by maintenance could be inhaled by a patient.

Thread sealant and lubricants used on oxygen equipment must be of approved quality for

such use.

Always follow printed instructions when maintaining or repairing this equipment.

Repair procedures may involve special techniques that must be followed when performing

such work.

WARNING

The sieve beds of the concentrator covered by these instructions contain a highly

compressed spring. DO NOT ATTEMPT TO DISASSEMBLE a sieve bed or the

spring may eject parts with dangerous velocity sufficient to cause personal injury.

Sect. 1 Pg.6_________________________________________________________9/99

Page 9

Preventive Maintenance

To ensure proper performance of the Mark 5 Plus Oxygen Concentrator purity

checks are recommended every three (3) months.

When operating under normal conditions the following maintenance schedule is

recommended and should be followed for proper operation of the unit. In severe conditions

such as high temperature, dusty and/or dirty atmosphere, it may be necessary to perform

the maintenance functions at more frequent intervals. Where procedures are involved, they

are shown elsewhere in this publication.

Preventive Maintenance Schedule

Mark 5 Plus Oxygen Concentrator

12 Months 24 Months 36 Months

Inlet Filter X X X

Bacterial Filter X X X

Battery X X X

Muffler X

Wick Assy x

Compressor

Rebuild or perform maintenance when oxygen

purity and/or operating pressure falls below

minimum specifications.

Note: In the Reference Material Section

Maintenance Record Check List sample for your convenience.

9/99__________________________________________________________Sect 1 Pg7

➌ of this manual we have provided a

Page 10

Trouble Shooting

System Problem Diagnosis

With system problem isolation in mind, the Mark 5 Plus was designed

with two test ports that allow the monitoring of the system pressures at two

key points. The pressure swings / ranges at these test ports will provide

important diagnostic clues when used with the SYSTEM DIAGNOSIS chart.

Each port has a plug that is held into place by a quick disconnect fitting.

The plug may be removed by depressing the ring around the plug. A

suitable pressure gauge with ¼ diameter tube lead can then be connected

to the quick disconnect fitting to measure the pressure swings.

Normal Pressure Swings Are:

*20 – 30 psig (140-205 kPa) at Air Test Port; 5 – 6 psig (35-42 kPa)

difference between high pressure and low pressure

*10 – 15 psig (70-105 kPa) at Oxygen Test Port; 1 – 2 psig (7-15 kPa)

difference between high pressure and low pressure

Note: To obtain accurate readings please observe the following check list.

1. Make sure that the filters are clean.

2. Leak test all fittings and repair all leaks (a leak will distort all

measurements).

3. Make sure that the oxygen flow is set correctly at 5 lpm and that actual flow is 5

lpm with an accurate flowmeter..

4. Always be sure of the accuracy of your test instruments.

Sect. 1 Pg.8_________________________________________________________9/99

Page 11

A

A

A

System Diagnosis Chart

Symptom Possible Cause Corrective Action

Power Failure Alarm 1) No Electrical Power

Service Req'd Light 1) Low Oxygen Pressure

2) High Oxygen Pressure

Low Product Flow 1) System Leak A) Test Product Pressure

1) Clogged Bacterial

Filter

High Product Flow 1) Product Regulator A) Test Product Pressure

Noisy Compressor 1) Worn Piston Seals

2) Rods or Bearings

Compressor Turns Off

and Comes On

Fluctuating Flow 1) Dirty or Defective

The trouble shooting guide which follows has been prepared to provide a logical sequence

of measurements and evaluations that will lead to a probable conclusion as to the cause of

a problem. As with all diagnostic efforts, the more highly trained and experienced

individual is more likely to determine the root cause of any problem.

1) Compressor Thermal

Overload Switch

Activated Due to

Overheating

Regulator

2) Leak on Oxygen Side

3) Low Oxygen Pressure

) Check Power Source

) See Trouble Shooting

Guide

B) Adjust Regulator

C) Change Inlet Filter

B) Adjust Regulator

A) Replace Piston Seals

or Replace Compressor

A) Check Fan and

Cooling Airway Path

B) Replace Fan

C) Replace Compressor

) Check Operation

B) Clean or Replace

Regulator

C) See Trouble Shooting

Guide

9/99__________________________________________________________Sect 1 Pg9

Page 12

Troubleshooting Guide

Low Purity

Check and Adjust Flow

Measure Air Pressure

(Air Test Port)

Low High

Check Inlet Filter Check Sieve Beds

Check For Leaks Check Control Valve

Check Compressor Check Muffler

Air Pressure Normal

Low High

Check for Leaks Check Muffler

Check Control Valve Check Sieve Beds

Leak Test

--Regulator

Measure Oxygen Pressure

(Oxygen Test Port)

--Check Valves

--Oxygen Outlet

Sect. 1 Pg.10_________________________________________________________9/99

Page 13

Repair Procedures

Compressor Replacement (Part # 7355-3535 – New)

(Compressor Model 2650CE37) (Part # 7355-3537 – Rebuilt)

Carefully follow the step-by-step procedure described below:

1. Disconnect concentrator from electrical source and remove front cabinet enclosure

(2 Phillips head screws in the handle recesses; 4 screws around the base).

2. Remove front of the compressor enclosure (6 Phillips head screws).

3. Disconnect hose from the exhaust muffler located on the compressor front enclosure.

4. Disconnect the capacitor wires from the capacitor located on the compressor front enclosure.

5. Remove the inlet hose from the right side of the compressor

6. Loosen top hose clamp on left side of the compressor and remove the hose from compressor

outlet fitting.

7. Remove the two Phillips head screws securing the compressor plate.

8. Clip the tie wrap above the compressor box enclosure that bundles the compressor electrical

wires.

9. Disconnect the compressor electrical wires from the terminal block located on the top of the

compressor box enclosure.

10. Slide compressor forward approximately 6 mm, lift up and pull out.

11. Remove all fittings including the relief valve.

12. Remove the compressor plate from the compressor by removing the four bolts holding the

compressor and compressor plate together.

13. Reinstall replacement compressor in reverse order using thread sealant on metal fittings.

14. Check for leaks.

9/99__________________________________________________________Sect 1 Pg11

Page 14

Sieve Module Assembly Replacement (P/N 9012-8G06)

The Sieve Module Assembly in the Mark 5 Plus Concentrator consist of:

2 Sieve Beds, Gearmotor and Control Valve and is replaced by removing the entire

assembly. Carefully follow the instructions below.

1. Disconnect the gearmotor wires from the terminal strip.

2. Disconnect product line tubing.

3. Disconnect exhaust hose from fitting.

4. Pull open Velcro straps from sieve beds.

5. Remove the air hose from the back of the control valve by loosening the

clamp.

6. Install in reverse

7. Check for leaks.

WARNING

The sieve beds of the concentrator covered by these instructions contain a highly

compressed spring. DO NOT ATTEMPT TO DISASSEMBLE a sieve bed or the

spring may eject parts with dangerous velocity sufficient to cause personal injury.

Sect. 1 Pg.12_________________________________________________________9/99

Page 15

Electrical Schematic

Mark 5 Plus Oxygen Concentrator

9/99__________________________________________________________Sect 1 Pg13

Page 16

Parts Call-Out Illustration (Side View)

Mark 5 Plus Oxygen Concentrator

Sect. 1 Pg.14_________________________________________________________9/99

Page 17

)

)

A

)

(

)

(

)

)

A

A

PARTS CALL OUT – SIDE VIEW

MODEL ILL# ITEM PART NUMBER DESCRIPTION

1373-31110T 1 5161-1027 CAPACITOR 15 MFD

1373-71100 * 5161-1029 CAPACITOR RUBBER CAP

1373-71100C 2 5190-2233 TIE WRAP HOLDER

1373-71110 * 5190-2234 TIE WRAP 12 INCH LONG

1373-71110CA 3 6491-1005 CONNECTOR, 4-WAY, 3/16 BARB

1373-71100JM 4 6814-9228 ELBOW NYLON DOUBLE BARB ½ INCH

1373-71110T 5 6816-4162 TEE MALE BRANCH 1/8 NPT x ¼ ODT

1373-71110TB 6 6814-4183 ELBOW BRASS ¼ NPT x 3/8 HOSE BARB

1373-81110 7 6956-9673 CHECK VALVE / VACUUM BREAKER

8 6998-9005 FLOW CONTROL VALVE (1/8 to 5 LPM

6998-9001 FLOW CONTROL VALVE (1/2 to 6 LPM

9 7206-0027 BATTERY 9 VOLT

10 7355-3535 COMPRESSOR 115 V (NEW)

* 7355-3537 COMPRESSOR 115 V (REBUILT)

* 7355-3556 COMPRESSOR REBUILD KIT

* 6953-9073 RELIEF VALVE 44 PSIG

11 7500-0004 GEARMOTOR/VALVE ASSEMBLY

* 7500-0003 GEARMOTOR ASSEMBLY

12 7603-0005

13 7631-1053 BACTERIAL FILTER

14 7631-1058 EXHAUST MUFFLER

15 7631-1059 INLET FILTER

16 7631-1063 CAP INLET FILTER

17 7764-5587 BUSHING ¾ INCH

18 7854-6110 HOSE BLUE PVC ¾ IN OD

19 7854-6051 HOSE SILICONE 5/32 ID x 3 LONG

20 7854-6049 HOSE SILICONE 5/32 ID x 8 LONG

21 8300-8068 CASTER

22 8316-5018 HOURMETER ASSEMBLY

23 8354-3071 VIBRATION ISOLATOR BLUE

24 8816-1056 REGULATOR

25 8986-0016 SWITCH ON/OFF

8986-0023 SWITCH ON/OFF W/10A BREAKER(SCHURTER

26 9010-0G14 SIEVE BED STRAP VELCRO

27 9010-8G03 SHOCK MOUNT KIT (COMPLETE)

28 9012-8G06 SIEVE MODULE

* 9012-5G00 SIEVE BED

* 9012-5G01 SIEVE BED

29 9012-7G00 CONTROL VALVE ASSEMBLY

30 0450-0001 SWITCH PLATE ASSEMBLY (STANDARD SWITCH

0450-0011 SWITCH PLATE ASSEMBLY (SCHURTER

* 9114-9G14 SWITCH PLATE

* 8230-9037

31 9010-4G05

32 9114-6G37 CABINET BASE ASSEMBLY

33 9114-6G20 DUAL COIL HEAT EXCHANGER

34 9114-9G12 RESONATOR

35 9077-7008 TUBING BLUE POLYURETHANE ¼ OD

36 6491-1004 ELBOW 3/16 HOSE X 1/8 NPT NYLON

BLOWER ASSEMBLY

NEW

REBUILT

LARM LIGHT

IR SURGE TANK

9/99__________________________________________________________Sect 1 Pg15

Page 18

Parts Call-Out Illustration (Top View)

Sect. 1 Pg.16_________________________________________________________9/99

Page 19

PARTS CALL OUT – TOP VIEW

MODEL ILL# ITEM PART NUMBER DESCRIPTION

1373-31110T

1373-71100

1373-71100C

1373-71110

1373-71110CA

1373-71100JM

1373-71110T

1373-71110TB

1373-81110

1 7603-0005A BLOWER ASSEMBLY (115 V)

2 5120-3181 WIRE SADDLE WIDE

3 6120-9855 SCREW PHILLIPS HEAD BLACK

4 5161-1016 TERMINAL STRIP

5 9010-4G01 ELBOW/TUBE ASSEMBLY

6 9010-4G05 AIR SURGE TANK

7 7355-4775 CONNECTOR 1/8 NPT x ¼ ODT

8 6814-9223 ELBOW 3/8 NPT x ½ HOSE BARB

9 7854-6026 HOSE 1/2 INCH BLACK x 20 LG

10 7342-1977 CLAMP HOSE

11 9007-4G25 WICK ASSEMBLY

12 7631-1063 CAP INLET FILTER

13 7631-1059 INLET FILTER

14 8830-6140 O-RING FOR FILTER HOLDER

15 9077-7008 TUBING ¼ OD BLUE POLYURETHANE

16 6814-9228 ELBOW ½ DOUBLE BARB NYLON

17 7854-6004 EXHAUST HOSE ¾ BLUE

18 6816-4162 TEE ¼ MALE BRANCH

19 8986-0012 PRESSURE SWITCH LOW SILVER

20 8986-0015 PRESSURE SWITCH HIGH GOLD

21 7854-6051 HOSE 5/32 ID X 3 LONG

22 7854-6049 HOSE 5/32 ID X 8 LONG

23 7854-6047 HOSE 5/32 ID X 1.5 LONG

9/99__________________________________________________________Sect 1 Pg17

Page 20

Parts Call-Out Illustration (Front Outside View)

Mark 5 Plus Oxygen Concentrator

Sect. 1 Pg.18_________________________________________________________9/99

Page 21

PARTS CALL OUT – FRONT VIEW

MODEL ILL# ITEM PART NUMBER DESCRIPTION

1373-31110T

1373-71100

1373-71100C

1373-71110

1373-71110CA

1373-71100JM

1373-71110T

1373-71110TB

1373-81110

1 6120-9855 SCREW PHILLIPS HEAD BLACK

2 6132-4902 SCREW PHILLIPS HEAD SILVER

3 8300-8068 CASTER

4 9007-6G32 FITTING HUMIDIFIER DISS 1240

5 9014-6G10 CABINET FRONT

6 9014-6G11 CABINET BACK

7 9114-6G37 CABINET BASE ASSEMBLY

8 9114-6G45 LABEL CABINET TOP

9 9114-6G46 LABEL ON / OFF

10 9014-6G50 FLOW CONTROL KNOB ASSY (1/8 – 5 LPM)

9010-6G50 FLOW CONTROL KNOB ASSY (1/2 – 6 LPM)

9/99__________________________________________________________Sect 1 Pg19

Page 22

Parts Call-Out Illustration (Back Outside View)

Mark 5 Plus Oxygen Concentrator

Sect. 1 Pg.20_________________________________________________________9/99

Page 23

PARTS CALL OUT – BACK VIEW

MODEL ILL# ITEM PART NUMBER DESCRIPTION

1373-31110T

1373-71100

1373-71100C

1373-71110

1373-71110CA

1373-71100JM

1373-71110T

1373-71110TB

1373-81110

1 6120-9855 SCREW PHILLIPS HEAD BLACK

2 6132-4902 SCREW PHILLIPS HEAD SILVER

3 7355-5019 POWER CORD ASSEMBLY

* 7281-5010 STRAIN RELIEF

4 8300-8068 CASTER

5 9007-6G37 CABINET FILTER

6 9010-0G13 CORD RETAINER

7 9014-6G08 ACCESS DOOR

* 0580-0001 LATCH ACCESS DOOR

* 9114-6G52 LABEL FILTER ACCESS DOOR

8 9014-6G10 CABINET FRONT

9 9014-6G11 CABINET BACK

10 9114-6G37 CABINET BASE ASSEMBLY

11 9114-6G47 BACK LABEL 115V 60 HZ

* 9114-6G47C BACK LABEL (CSA)

9/99__________________________________________________________Sect 1 Pg21

Page 24

Page 25

Operational Description for Oxygen Monitoring System

This portion of the manual is effective for configuration models 1373-31103 and 137371103 which are equipped with an Ultrasonic Oxygen Monitoring System. This is effective

with for Oxygen Monitor equipped units beginning with serial number 98219700.

The Oxygen Monitor is an electronic module that continuously monitors the actual

concentration of O2 supplied by the MARK 5 PLUS concentrator. The Oxygen Monitor

detects concentrations of 85% or below and triggers a visible and audible alarm. The

Oxygen Monitor is available as an option. The Oxygen Monitor module reinforces and

relays the standard operating alarms on the concentrator.

When powering on the MARK 5 PLUS the Oxygen Monitor module operates as below.

- In addition to the normal test of the MARK 5 PLUS, the Oxygen Monitor red indicator

light comes on.

- The red indicator light may remain on for a few minutes (3 minutes maximum), which is

the time necessary for the gas concentration supply to reach and exceed 85% O2.

-The green indicator light comes on after this value is reached and the concentrator is then

operating satisfactorily.

Operating principle

The oxygen monitor module is an electronic module that continuously monitors the oxygen

enriched product that is actually supplied to the user.

The sensor, which utilizes the principle of sound velocity as a function of molecular weight,

measures the velocity of sound in the product gas and compares it to stored values which

correspond to the oxygen concentration. The preset threshold value is 85% for 115 volt

devices.

A red light indicates a concentration below the preset threshold level. When the light is red

for 15 minutes (±2 minutes) a continuously audible alarm is activated.

The oxygen monitor module incorporates a 9V transformer, a pressure sensor, the oxygen

sensor, a 9V battery, red and green LEDs, the alarm buzzer and associated electronic

circuits.

Other alarms

Detection of absence of line voltage. In the event of a powerline cut, a continuous audible

alarm is triggered (and the green LED goes out). The power supply for the alarm is a 9V

battery.

Operating fault:In the case of a distribution malfunction (pressure of oxygen enriched air <

4 psig or > 20 psig) an audible alarm and visual alarm is triggered (red LED and

continuous audible alarm).

9/99_________________________________________________________Sect. 2 Pg 1

Page 26

Interfacing

The oxygen monitoring system is fully contained on the printed circuit board on which the

ON/OFF switch is located. Electrical power is supplied to the board from the switch

terminals to terminals E1 and E2 on the board. The transformer and rectifier located on

the board converts the line supplied power to the 5 V dc and 12 V dc power that is required

to operate the electronic parts. Battery supplied power is received from the battery

mounted on the board. This is the extent of the power requirement.

The product gas interface to the board is achieved by routing the product gas, which is to

be delivered to the user via the outlet fitting, from the flow control valve to the oxygen

monitoring unit. All of the gas produced by the concentrator is routed through the

analyzer. From the analyzer sensor tube, the gas is routed to the concentrator outlet fitting

and then to the user. The analyzer is designed to operate at low pressures only. The gas

supplied must always pass through the regulator and the flow control valve before being

routed to the analyzer tube. Use caution to be sure that no gas with pressure greater than

5 psig is fed to the analyzer sensor tube assembly.

Additional to the regulated product gas being connected to the sensor tube, a signal of

unregulated product gas is connected to the pressure sensor located on the printed circuit

board. This provides the signal to sound the low or high pressure alarm.

Operation

The oxygen monitor is a single level oxygen monitoring system. The monitor is

calibrated at both air and concentrator levels of oxygen concentration. The internal alarm

switch is pre-set to a setting of 85 percent oxygen purity. When the concentration of the

input gas drops below pre-set level, the red LED is lighted. If the concentration stays

below the pre-set level for approximately 15 minutes, an audible alarm signal is generated.

When the average purity is maintained above 85 percent for several concentrator cycles,

the alarms are reset.

The process high and low pressure alarms are also included in the printed circuit

board. It is no longer necessary to supply the high and low pressure switches in the

product circuit.

Trouble Shooting

1 Connect mains power to terminals E1 and E2.

2. Connect concentrator product gas to the left barb on the sensor tube. Check the

purity of the product gas at the outlet fitting.

3 Turn power on. The alarm should sound until product pressure exceeds 4 psig.

4 Allow unit to reach operating temperature before starting the test. (1-3 minutes).

5. When gas purity reaches 85 percent, the green LED should light.

6 Bleed off some product gas at the sieve bed to reduce purity. When the input gas

concentration is below the pre-set level, the red LED should be lighted. After about 15

minutes, the audible alarm should sound.

Sect. 2 Pg 2 ____________________________________________9/99

Page 27

Electrical Schematic

Mark 5 Plus Oxygen Concentrator with Oxygen Monitoring System

9/99_________________________________________________________Sect. 2 Pg 3

Page 28

Pneumatic outline diagram with Oxygen Monitor System

A

.

…

Component Function

A brief description of the principal function of each of the major components is

provided below:

CABINET FILTER..........................................................Filters dust from cooling air

INLET FILTER.............................................Filters Particles To Protect Compressor

COMPRESSOR.............................................................Pumps Air Into The System

RELIEF VALVE............................. ...........Safety Device To Limit System Pressure

HEAT EXCHANGER...................................................Cools Air After Compression

WICK ASSY........................................Removes Moisture from the Compressed Air

IR SURGE TANK..............................................Reduces air pressure fluctuations

AIR TEST PORT.................................................A Connection For System Testing

ROTARY POPPET VALVE...........

SIEVE BEDS.................................

MUFFLER...........................................................................Reduces Exhaust Noise

OXYGEN TEST PORT........................................A Connection For System Testing

PRESSURE SENSOR….......................Activates Alarm For High Or Low Pressure

BACTERIAL FILTER........................................Removes contaminant from oxygen

VACUUM BREAKER.......................................................Prevents System Vacuum

REGULATOR............................................................Sets A Fixed Output Pressure

OXYGEN SENSOR..…………….

FLOW CONTROL VALVE..........................Sets The Flow Rate To A Specific Flow

CHECK VALVE.................................Prevents Any Reverse Flow Into The System

OUTLET........................................ ....Provides Connection For Hose Or Humidifier

...............Controls The Pressure Swing Process

...Separates Gases As Air Is Moved In And Out

.............................Activates alarm for low purity

Sect. 2 Pg 4 ____________________________________________9/99

Page 29

Preventive Maintenance

To ensure proper performance of the Mark 5 Plus Oxygen Concentrator purity

checks are recommended every twelve (12) months or each time a unit is returned from a

patient.

When operating under normal conditions the following maintenance schedule is

recommended and should be followed for proper operation of the unit. In severe

conditions such as high temperature, dusty and/or dirty atmosphere, it may be necessary

to perform the maintenance functions at more frequent intervals. Where procedures are

involved, they are shown elsewhere in this publication.

Preventive Maintenance Schedule

Mark 5 Plus Oxygen Concentrator with Oxygen Monitoring System

Inlet Filter

Bacterial Filter

Battery

Muffler

Wick

Compressor Rebuild or perform maintenance when

The most frequent cause of low purity is that the air supply has been restricted. It is

particularly important to be sure that the cabinet air filter is cleaned on a regular basis. If it

is permitted to get dirty, it will reduce the amount of cooling air available to the machine

which may result in premature loss of performance of the compressor and the sieve

module.

12 Months 24 Months 36 Months

X x X

X x X

X x X

X

X

oxygen purity and/or operating pressure

falls below minimum specifications.

Note: In the Reference Material Section ➌ of this manual we have provided a

Maintenance Record Check List sample for your convenience.

9/99_________________________________________________________Sect. 2 Pg 5

Page 30

Parts Call-Out Illustration (Side View)

Mark 5 Plus Oxygen Concentrator with Oxygen Monitoring System

Sect. 2 Pg 6 ____________________________________________9/99

Page 31

PARTS CALL OUT – SIDE VIEW

MODEL ILL# ITEM PART NUMBER DESCRIPTION

1373-31110T 1 5161-1027 CAPACITOR 15 MFD

1373-71100 * 5161-1029 CAPACITOR RUBBER CAP

1373-71100C 2 5190-2233 TIE WRAP HOLDER

1373-71110 * 5190-2234 TIE WRAP 12 INCH LONG

1373-71110CA 3 6491-1005 ADAPTER BARBED NYLON 4 WAY

1373-71100JM 4 6814-9228 ELBOW NYLON DOUBLE BARB ½ INCH

1373-71110T 5 6816-4162 TEE MALE BRANCH 1/8 NPT x ¼ ODT

1373-71110TB 6 6814-4183 ELBOW BRASS ¼ NPT x 3/8 HOSE BARB

1373-81110 7 6956-9673 CHECK VALVE / VACUUM BREAKER

8 6998-9005 FLOW CONTROL VALVE

9 7206-0027 BATTERY 9 VOLT

10 7355-3535 COMPRESSOR 115 V (NEW)

* 7335-3537 COMPRESSOR 115 V (REBUILT)

* 7355-3556 COMPRESSOR REBUILD KIT )

* 6953-9073 RELIEF VALVE 44 PSIG

11 7500-0004 GEARMOTOR/VALVE ASSEMBLY

* 7500-0003 GEARMOTOR ASSEMBLY

12 7603-0005A BLOWER ASSEMBLY

13 7631-1053 BACTERIAL FILTER

14 7631-1058 EXHAUST MUFFLER

15 7631-1059 INLET FILTER

16 7631-1063 CAP INLET FILTER

17 7764-5587 BUSHING ¾ INCH

18 7854-6110 HOSE BLUE PVC ¾ IN OD

19 7854-6049 HOSE MILKY SILICONE 5/32 ID x 8 LONG

20 7854-6047 HOSE SILICONE 5/32 ID x 1.5 LONG

21 8300-8068 CASTER

22 8316-5018 HOURMETER ASSEMBLY

23 8354-3071 VIBRATION ISOLATOR BLUE

24 8816-1066 REGULATOR

25 8986-0022 SWITCH ON/OFF W/5A BREAKER(SCHURTER)

26 9010-0G14 SIEVE BED STRAP VELCRO

27 9010-8G03 SHOCK MOUNT KIT (COMPLETE)

28 9012-8G06 SIEVE MODULE ASSEMBLY

* 9012-5G00 SIEVE BED (NEW)

* 9012-5G01 SIEVE BED (REBUILT)

29 9012-7G00 CONTROL VALVE ASSEMBLY

30 6500-4400 OXYGEN MONITOR BOARD

31 9010-4G05 AIR SURGE TANK

32 9114-6G37 CABINET BASE ASSEMBLY

33 9114-6G20 DUAL COIL HEAT EXCHANGER

34 9114-9G12 RESONATOR

35 9077-7008 TUBING BLUE POLYURETHANE ¼ OD

9/99_________________________________________________________Sect. 2 Pg 7

Page 32

Parts Call-Out Illustration (Top View)

Mark 5 Plus Oxygen Concentrator with Oxygen Monitoring System

Sect. 2 Pg 8 ____________________________________________9/99

Page 33

PARTS CALL OUT – TOP VIEW

MODEL ILL# ITEM PART NUMBER DESCRIPTION

1373-31110T

1373-71100

1373-71100C

1373-71110

1373-71110CA

1373-71100JM

1373-71110T

1373-71110TB

1373-81110

1 7603-0005A BLOWER ASSEMBLY

2 5120-3181 WIRE SADDLE WIDE

3 6120-9855 SCREW PHILLIPS HEAD BLACK

4 5161-1016 TERMINAL STRIP

5 9010-4G01 ELBOW/TUBE ASSEMBLY

6 9010-4G05 AIR SURGE TANK

7 7355-4775 CONNECTOR 1/8 NPT x ¼ ODT

8 6814-9223 ELBOW 3/8 NPT x ½ HOSE BARB

9 7854-6026 HOSE 1/2 INCH BLACK x 20 LG

10 7342-1977 CLAMP HOSE

11 9007-4G25 WICK ASSEMBLY

12 7631-1063 CAP INLET FILTER

13 7631-1059 INLET FILTER

14 8830-6140 O-RING FOR FILTER HOLDER

15 9077-7008 TUBING ¼ OD BLUE POLYURETHANE

16 6814-9228 ELBOW ½ DOUBLE BARB NYLON

17 7854-6004 EXHAUST HOSE ¾ BLUE

18 6816-4162 TEE ¼ MALE BRANCH

19 7854-6051 HOSE 5/32 ID x 11/32 OD x 3 LG SILICONE

9/99_________________________________________________________Sect. 2 Pg 9

Page 34

Parts Call-Out Illustration (Front Outside View)

Mark 5 Plus Oxygen Concentrator with Oxygen Monitoring System

Sect. 2 Pg 10 ____________________________________________9/99

Page 35

PARTS CALL OUT – FRONT VIEW

MODEL ILL# ITEM PART NUMBER DESCRIPTION

1373-31110T

1373-71100

1373-71100C

1373-71110

1373-71110CA

1373-71100JM

1373-71110T

1373-71110TB

1373-81110

1 6120-9855 SCREW PHILLIPS HEAD BLACK

2 6132-4902 SCREW PHILLIPS HEAD SILVER

3 8300-8068 CASTER

4 9007-6G32 FITTING HUMIDIFIER DISS 1240

5 9014-6G10 CABINET FRONT

6 9014-6G11 CABINET BACK

7 9114-6G37 CABINET BASE ASSEMBLY

8 9114-6G44 LABEL ON / OFF (OXYGEN MONITOR)

9 9114-6G45 LABEL CABINET TOP

10 9014-6G50 FLOW CONTROL KNOB ASSEMBLY

9/99_________________________________________________________Sect. 2 Pg 11

Loading...

Loading...