Page 1

USER'S GUIDE

Mark 5 Nuvo 8

(OCSI)

OXYGEN CONCENTRATOR

[Original language is English]

FederalLaw(US)restrictsthisdevicetosale

by, or on the order of, a licensed physician.

This oxygen concentrator should be used

only under the supervision of a licensed

physician.

CONTENTS

GLOSSARYOFSYMBOLS..........................................1

GENERALSAFETYGUIDELINES............................2

I. DESCRIPTION.......................................................2

I.1. F

ront panel (Fig. I. 1)........................................... 3

I.2. Rear panel (Fig. I. 2)..................................................3

II. STARTING-UP/ INSTALLATION .......................3

II.1. Use in direct oxygen therapy.....................................3

III. CLEANING-MAINTENANCE.............................4

III.1.Cleaning....................................................................4

III.2.

Everyday disinfection....................................................4

III.3.Maintenance..............................................................4

GLOSSARYOFSYMBOLS

0413: Complies with the 93/42/ EEC directive

certi ed by the approved organization no 0413.

Danger: Donot smokewhenusing oxygen or when

near this device

IV.USEFULINFORMATION .........................................4

IV.1. Accessories and spare parts.......................................4

IV.2. Materials in direct/indirect contact with patient........4

IV.3. Operating principles..................................................5

IV.4. Alarms - Safety devices ............................................5

IV.5. Oxygen Monitor (OCSI) function ...........................5

IV.6. Technical characteristics ...........................................5

IV.7. Standards...................................................................6

IV.8. Method for disposing of waste..................................6

IV.9. Method for disposing of device.................................6

IV.10.Troubleshooting......................................................... 7

V. EMC, Electromagnetic statements...........................8-9

.

: ON (power switched on)

: Off (power switched off)

: Type B device

: Class II protection

: Do not expose to open ames

: Do not use oil or grease

: Technical information

: Consult the accompanying documents

: Keep in the vertical position

: Fragile - handle with care

: Oxygen concentration warning light

May 20112010-2238CE Rev C 1

Page 2

GENERALSAFETY GUIDELINES

Only persons who have read and understood this entire manual

should be allowed to operate the Mark 5 Nuvo 8.

USE OFOXYGEN

Oxygen is not a ammable gas, but it accelerates

the combustion of materials. To avoid all risks of

re, the Mark 5 Nuvo 8 should be kept away from

all ames, incandescent sources and sources of heat

(cigarettes), as well as any combustible products

such as oil, grease, solvents, aerosols, etc.

Do not use in an explosive atmosphere.

Avoid letting oxygen accumulate on an upholstered

seat orotherfabrics.Iftheconcentratorisoperating

while not supplying oxygen to a patient, position it

so that the gas ow is diluted in the ambient air.

Place the device in a ventilated area free from

smoke and atmospheric pollution (rear filter

unobstructed).

The Mark 5 Nuvo 8 must only be used for oxygen

therapy and only on a medical prescription. The

indicated daily duration and ow must be followed,

otherwise it may present a risk to the health of the

patient.

Do not use in a speci cally magnetic environment

(MRI, X-ray, etc.)

CONFORMITYWITH IEC60601-1 (§ 6.8.2 B):

"The manufacturer, assembler, installer or distributor are not

consideredtobe responsiblethemselvesfor theconsequences

on the safety, reliability and characteristics of a device

unless:

• The assembly, tting, extensions, adjustments, modi cations

or repairs have been performed by persons authorized by the

party in question,

• The electrical installation of the corresponding premises

complies with local electrical codes. (e.g. IEC / NEC).

• The device is used in accordance with the instructions for

use."

If the replacement parts used for the periodic servicing by an

approved technician do not comply with the manufacturer’s

speci cations, the manufacturer is not responsible in the event

of an accident.

ThisdevicecomplieswiththerequirementsoftheFDAQuality

System Regulation and the 93/42/EEC European directive

but its operation may be affected by other devices being used

near by, such as diathermy and high frequency electro-surgi-

cal equipment, de brillators, short wave therapy equipment,

mobiletelephones,CBand otherportabledevices,microwave

ovens, induction plates or even remote control toys or any

other electromagnetic interferences which exceed the levels

speci ed by the EN 60601-1-2 standard.

USEAND MAINTENANCE OF DEVICE

Do not open the device while in operation: risk of

electrical shock.

Use the power cord provided, and check that the

electrical characteristics of the power socket used

match those indicated on the manufacturer’s plate

on the rear panel of the machine.

We recommend against the use of extension cords

or adapters, as they are potential sources of sparks

and re.

The Mark 5 Nuvo 8 has an audible alarm to warn

the user of problems. In order that the alarm may

be heard, the maximum distance that the user can

move away from it must be determined to suit the

surrounding noise level.

2

I. DESCRIPTION

TheMark5Nuvo8isintendedtosupplysupplementaloxygen

to persons requiring low ow oxygen therapy. It is not intended

to be life supporting or life sustaining. Itproducesan oxygen

enriched product by concentrating the oxygen contained in

roomair. It can beusedeitherto administer oxygenwithnasal

cannulas or another probe or mask type of device.

The Mark 5 Nuvo 8 is easy to use.

The single ow adjustment knob allows:

• the device to be easily adjusted to the prescribed ow rate,

• the equipment supplier or medical staff to limit ows to a

speci c ow rate with a built-in locking device.

It has a power failure alarm and an operating fault alarm.

Note: the performances described pertain to the use of

the Mark 5 Nuvo 8 with the accessories recommended by

Nidek Medical Products, Inc.

May 2011

2010-2238CE Rev C

Page 3

II. STARTING UP / INSTALLATION

6

6

4

4

5

5

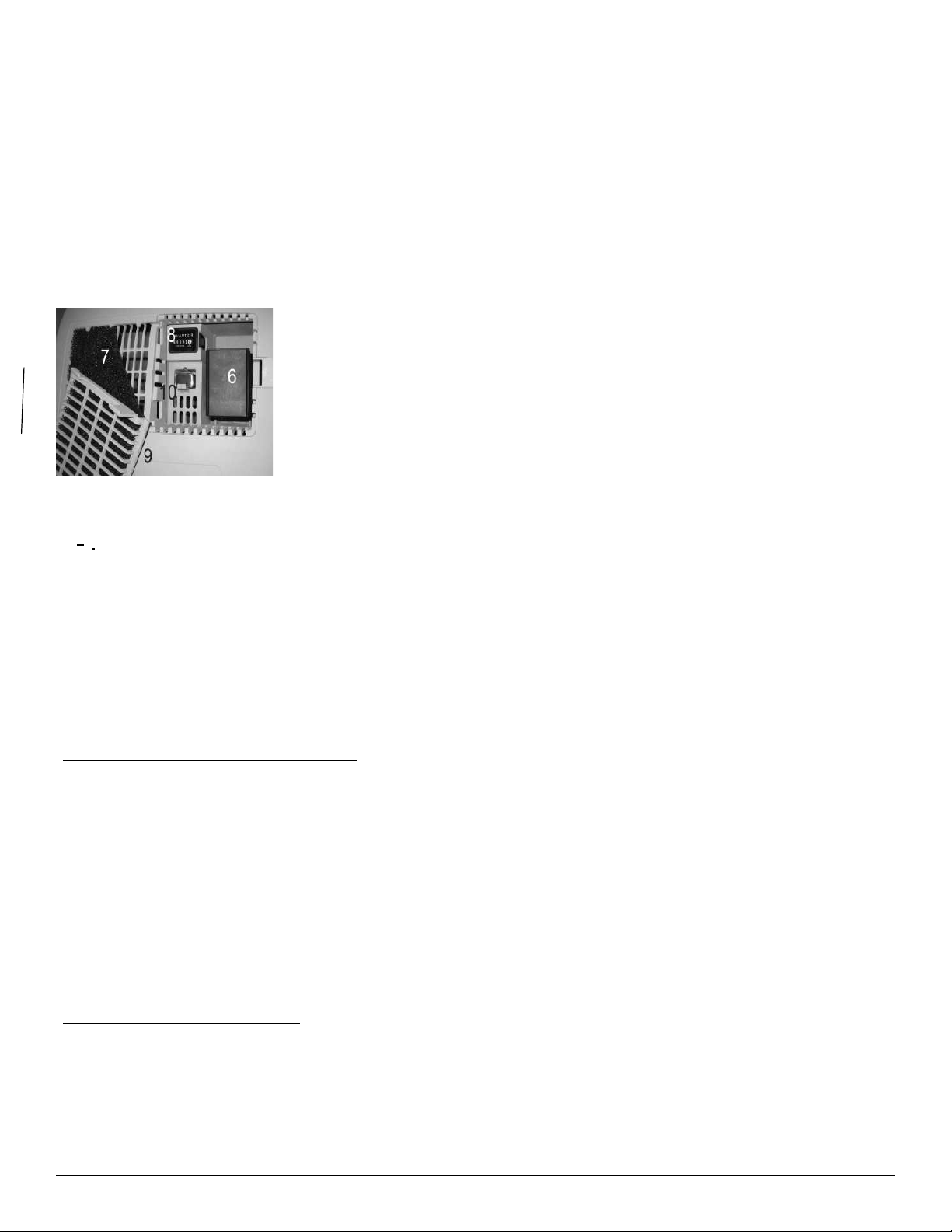

I.1. Front panel (Fig. I.1)

1 - (I/0) On/Off Power Switch

2 - Humidi er (space reserved)

3 - Oxygen product outlet

4 - Flow adjustment knob (l/min)

5 - Circuit Breaker

6 - OCSI (Oxygen Concentration

Status Indicator) Indicator Lights

5

1

1

32

3

3

3

3

4

2

5

II.1. Use in direct oxygen therapy

a. Ensure that the switch (1) is in the 0 (OFF) position.

b. If used with a humidi er:

Unscrew the ask and ll it with water up

to the line (see humidi er instructions). Then

screw the lid on the humidi er ask until there

are no leaks.

c. Connect the oxygen tube to the humidi er outlet nozzle or to

the concentrator outlet if a humidi er has not been prescribed.

Thetubebetweenthecannula and the Mark 5Nuvo8should

belimitedto20meters (60 feet)long,inordertoensurethat

the oxygen ow rate remains within speci cation values.

d. Ensure that all of the parts are connected correctly so as

to avoid leaks.

e. Plug the power cable into a power outlet of the correct

voltage and frequency as de ned on the

manufacturer's technical label (8).

f. Press the power switch ( I / 0 ) to the ON position ( I ).

Thegreenindicatorwill light when theoxygenconcentration

exceeds the set point. Note: After turning the unit off,

the user must wait 3-5 minutes before turning it back

on. System pressure must dissipate before the unit will

properly restart.

9

I.2. Rear panel (Fig. I.2)

7 - Cabinet Air Filter

8 - Manufacturer's Technical Label

9 - Power Cord

g. Turn the ow adjustment knob (4) to the prescribed value.

This knob may have already been locked in the medically

7

8

prescribed position. In this case, do not force it. Only the

technician or medical personnel are authorized to release

it. Note: View the owmeter in the horizontal plane for

accurate settings.

h. Check that the oxygen ows out of the administration

device (nasal cannulas or other) by placing the ori ce(s) on

the surface of a glass of water. The ow should disturb the

surface of the water.

i. Adjust the nasal cannula to suit your face.

Note:therequiredoxygenconcentrationisnormallyobtained

within ve minutes after the unit is started.

At the end of the treatment, press the I/0 Switch to place it

in the 0 (OFF) position to stop the device. The oxygen enri-

ched air ow continues for approximately one minute after

the device is stopped.

For the equipment supplier or medical staff:

The ow adjustment knob may be locked to limit it to a

speci c predetermined value.

May 20112010-2238CE Rev C 3

7

Page 4

III. CLEANING - MAINTENANCE

III.3. Maintenance

III.1. Cleaning

Only the outside of the Mark 5 Nuvo 8 is to be cleaned,

with a soft, dry cloth or, if necessary, a damp sponge, then

thoroughly dried with wipes and an alcohol based solution.

Acetone, solvents or any other in ammable products must

not be used. Do not use abrasive powders.

The removable cabinet air lter (7) must be cleaned in warm

waterandhousehold detergentweekly orafterapproximately

100 hours of use. More frequent cleaning is recommended in

dusty enviroments. Dry before reinstalling.

7

8

8

7

9

9

.

II.2. Daily disinfection

Because there is a nal product lter inside the device, daily

disinfection concerns only the external oxygen therapy

accessories: humidi er, probes, nasal cannulas (refer to the

respective instructions for use).

The device must be switched off when alcohol based solutions are used.

a. The following minimum guidelines must be

observed:

10

66

6

6

6 Filter / Silencer

7 Cabinet Air Filter

8 Hour Meter

9 Ventilation Grille

10 Battery, if equipped

• Humidi er : (If prescribed by a physician)

Clean according to the manufacturer's instructions. If no

instructions are provided, do the following:

Daily:

• Empty the water from the humidi er.

• Rinse the humidi er ask under running water.

• Fill humidi er up to the mark with distilled water.

Regularly:

• Disinfect the humidi er parts by immersing them in a

disinfectant solution (In general, we recommend using a

solution of 1 part vinegar diluted with 10 parts water).

• Rinse and dry.

• Check that the humidi er lid seal is in good condition.

• Oxygen tubing and nasal cannula:

Follow the manufacturer’s instructions.

b. For each new patient:

Follow the instructions from the humidi er manufacturer.

TheMark5Nuvo8mustbecleanedanddisinfectedasper the

above instructions. The cabinet air lter should be washed or

replaced. The entire oxygen administration circuit (oxygen

therapy nasal cannulas, etc.) must be changed.

4

No special maintenance needs to be carried out by the

patient. Your equipment supplier performs periodic main-

tenance operations to assure continued reliable service from

the Mark 5 Nuvo 8.

Note: If the concentrator unit is to be stored (not used) for

a period of time exceeding 6 months, the 9 volt battery, if

equipped, should be disconnected and removed.

IV. USEFUL INFORMATION

IV.1.Accessories and spare parts

The accessories used with the Mark 5 Nuvo 8 must:

• be oxygen compatible,

• be biocompatible,

• comply with the general requirements of the FDA

Quality System Regulation or the 93/42/EEC European

Directive as appropriate.

The connectors, tubes, nasal cannulas, probes or masks

must be designed for oxygen therapy usage.

TheaccessorieswithaNidekMedicalpartnumber reference,

or included in the set of accessories supplied with the device,

comply with these requirements.

Contact your dealer to obtain these accessories.

Note: The use of certain administration accessories which

are not speci ed for use with this concentrator may reduce

its performance and void the manufacturer’s responsibility

(ISO 8359).

AVAILABLEACCESSORIES

IF PRESCRIBED BYAPHYSICIAN

Humidi er: P/N 9012-8774

Cannula with 2 m (7 ft) tubing: P/N 9012-8780

Extension Tubing 7.7 m (25ft): P/N 9012-8781

TubingAdapter: P/N 9012-8783

The items listed above are available from

Nidek Medical Products, Inc.

IV.2. Materials in direct or indirect contact with the

patient

Concentrator casing ......................................Polycarbonate

Mains cable ...................................................................PVC

Cabinet air lter ..................................................... Polyester

I/0 (On/Off) switch......................................................Nylon

Casters.........................................................................Nylon

Flow adjustment knob...................................................ABS

Oxygen product outlet .................................................Brass

Printed labels..................................................Polycarbonate

Pipe/Tubing........Aluminium,PVC, polyurethane or silicone

Humidi er .....................................................Polypropylene

Filter ..............................................................Polypropylene

May 2011

2010-2238CE Rev C

Page 5

IV.3. Operating principle

The compressor sends ltered ambient air to an electronic

valving system, which allows compressed air to pass to the

column in production. The columns contain a molecular

sieve,whosefunctionis to adsorbthenitrogenandthus allow

oxygen to pass.

The oxygen enriched product is then directed to a pressure

reducing valve through the adjustable ow meter to the

oxygen outlet tting.

During this time, the column which is being "regenerated"

is connected to the ambient air and ow of oxygen enriched

productispassedthroughit(fromthecolumn"inproduction").

In this way,whenone column is in production, the other is in

a nitrogen desorption or "regeneration" phase. The oxygen

enriched product nally passes through a bacterial lter located

prior to the oxygen outlet tting.

IV.5. OCSI (oxygen concentration status indicator) function

IV.5.1. Operating principle

The oxygen monitor (6) is an electronic module capable of

checking the effective oxygen concentration supplied by the

Mark 5 Nuvo 8 concentrator.

The oxygen monitor measures the concentration and activates an audible and visual alarm if it falls below the alarm set

point percentage.

When the Mark 5 Nuvo 8 is started, the indicator lights

operates as follows:

IV.5.2. Green indicator (OCSI ONLY)

IV.4.Alarms - Safety devices

IV.4.1.Alarms

• No voltage detection:

In the event of a loss of mains power, a continuous audible

alarm is activated and the green light turns off. Test alarm by

actuating the I/0 (On/Off) switch when the power cord is not

plugged into the wall receptacle.

• Process fault:

In the case of a process fault, a visible and audible alarm is

activated (continuous red light or lighted alarm and audible

alarm, see p. 7)

.

• No Oxygen Flow Alarm (Optional):

If supplied the Nuvo 8 Oxygen Concentrator has a No Flow

Alarm. This device provides an continuous audible alarm in

the event the Oxygen Flow to patient becomes blocked.

IV.4.2. Safety devices

• Compressor motor:

Thermal safety is ensured by a thermal switch situated in the

stator winding (145 ± 5oC).

• Ambient air valve:

In the case of a negative pressure in the molecular sieve columns, this valve allows ambient air to enter.

• Electrical protection of the Mark 5 Nuvo 8:

A 5A circuit breaker is incorporated into the front cabinet of

all 230V models.A 10Acircuit breaker is included with 115V

models.

The green indicator light indicates that power is applied

to the concentrator and that it is ready to provide oxygen

enriched air to the patient. To be lighted, it is necessary that

the concentrator power plug be inserted into the wall outlet,

that the I/O (On/Off) switch be actuated and that the oxygen

concentration has reached the alarm set-point

IV.5.3. Red indicator (OCSI ONLY)

The red indicator light is used to warn the patient of a system

fault. The two events that can cause the red indicator to be

lightedarelowoxygenconcentrationandlossofmainspower.

The low oxygen concentration warning will light when the

oxygen concentration set point level is not reached. When

the red indicatorlightislightedfor15minutes(±2minutes),

a continuous audible alarm is activated. Call the equipment

supplier to service the device.

IV.5.4. Maintenance of the device alarms

• No special maintenance is required. The alarm set-point is

factorysetandthesettingcannotbeadjusted.Modelsoperating

at 50 Hz are set at 83% and 60 Hz models are set at 85%.

• The equipment supplier checks that the device is still

operating correctly when the routine checks are performed

on the Mark 5 Nuvo 8.

IV.6. Technical characteristics

Dimensions: L x W x H: 394 x 396 x 706 mm (15.5 x 15.6

x 27.8 in.)

Caster diameter: 50 mm (2.0 in.).

Tilt angle (transport with humidi er tted): 70

o

.

Weight: 24 kg /54 lbs

Noise level < 53 dBA

• Class II devices with insulated castings (EN60601-1

standard)

• Safety valve:

This is tted on the compressor outlet and is calibrated to 3.4

bar (50 psig).

May 20112010-2238CE Rev C 5

Flow values:

ContinuouslyAdjustable Flowmeter: 2 to 8 liters/minute.

(Some models may have other values.)

Page 6

Accuracy of ow supplied:

IV.8. Method for disposing of waste

In compliance with the ISO 8359 standard, the ow supplied

is equal to the ow set on the owmeter, accurate to within ±

10% or 200 ml/min, whichever is the larger of the two.

Average oxygen content:

8 l/min: 90%. +5.5% / -3.0%

(Values at 21oC and at one atmosphere pressure).

Minimum recommended ow, 2 lpm.

Maximum recommended ow, 8 lpm.

The variation of the maximum recommended ow does not

exceed ± 10 % of the indicated value when a back pressure

of 6.9 kPa (1 psig) is applied to the output of the device. The

maximum outlet pressure is 117 kPa (17 psig).

Electrical power supply:

115V Units 230 V Units

Frequency: 60Hz 50/60Hz

Average Power: 490 watts 490/585 watts

Protection Class: Class II Class II

Mains Protection: 10A 5A

Filters:

At the rear of the device: a cabinet air lter.

At the compressor input: an inlet air lter, behind cabinet

air lter.

Before the oxygen outlet: a nal product lter < 0.3 µm.

(technician only)

Air circulation:

One tubeaxial fan cools the compressor compartment and a

second fan cools the heat exchanger coil.

.

Environmental limit conditions:

Theperformanceofthedevice(especiallytheoxygenconcentration) are quoted at 21oC (70oF) and one atmosphere. They

may change with temperature and altitude. For further information, please consult the maintenance manual.

• The device must be stored, transported and used in the

vertical position only.

• Ambient temperature of between 10oC and 40oC (50oF

to 105oF) operation.

• Storage temperature from -20oC to 60oC (0oF to 140oF).

• Relative humidity of between 15 % and 95 % operation

and storage, both non-condensing.

• Altitude(21oC): Up to 1500m (5000ft) without degradation; Consult your equipment provider for further infor

mation regarding 1500 m to 4000m (5000 to 13000ft).

• Complies with EN60601-1 standard; spilling of a glass

of water.

IV. 7. Standards

ISO 8359:1996 Oxygen concentrators for medical use.

EN60601-1[UL60601-1:2003],CAN/CSA-C22.2No.601.1M90 w/A1&A2: Electrical Safety- Medical Devices.

EN60601-1-2:2000 Electromagnetic Compatibility

6

May 2011

AllwastefromtheMark5 Nuvo 8 (patient circuit, lter, etc.)

mustbedisposed ofusingthe methodsappropriateto thecivil

authority of the location where disposed.

IV.9. Method for disposing of the device

In order to preserve the environment, the concentrator must

only be disposed of using the appropriate methods. All materials of construction are recycleable.

Furthermore, as part of the marking (directive 93/42/EEC),

the serial number of the device disposed of must be sent to

the Nidek Medical technical service department if the unit

has the marking.

Nuvo Serial No. ___________________________

Date rst used: ___________________________

_________________________________________

Maintained by: ___________________________

_________________________________________

Your distributor: _________________________

Address : ________________________________

_________________________________________

_________________________________________

Telephone : ______________________________

PREVENTIVE MAINTENANCE:

a. Wash cabinet lter weekly.

b. Inspect inlet air lter at each patient visit.

Replace lter annually, or more often depending on

environment.

c. Check oxygen concentration every 15,000 hours or

3 years to verify the continuing OCSI function.

The manufacturer’s instructions for the preventive

maintenance of the devices are de ned in the

maintenance manual. Check with your service

provider for any updates to recommended schedules.

The work must be carried out by suitably trained tech-

nicians certi ed by the manufacturer.

Use original spare parts only (see Pg. 7).

Uponrequest,the supplier canprovidecircuitdiagrams,

sparepartslists,technicaldetailsoranyotherinformation

of use to quali ed technical personnel for parts of the

devicewhicharedesignatedasbeingthe manufacturer’s

responsibility or by the manufacturer as repairable.

Medical Device Regulations require users and

service providers to report to the manufacturerany

incident that could, if repeated, result in injury to

any person.

2010-2238CE Rev C

Page 7

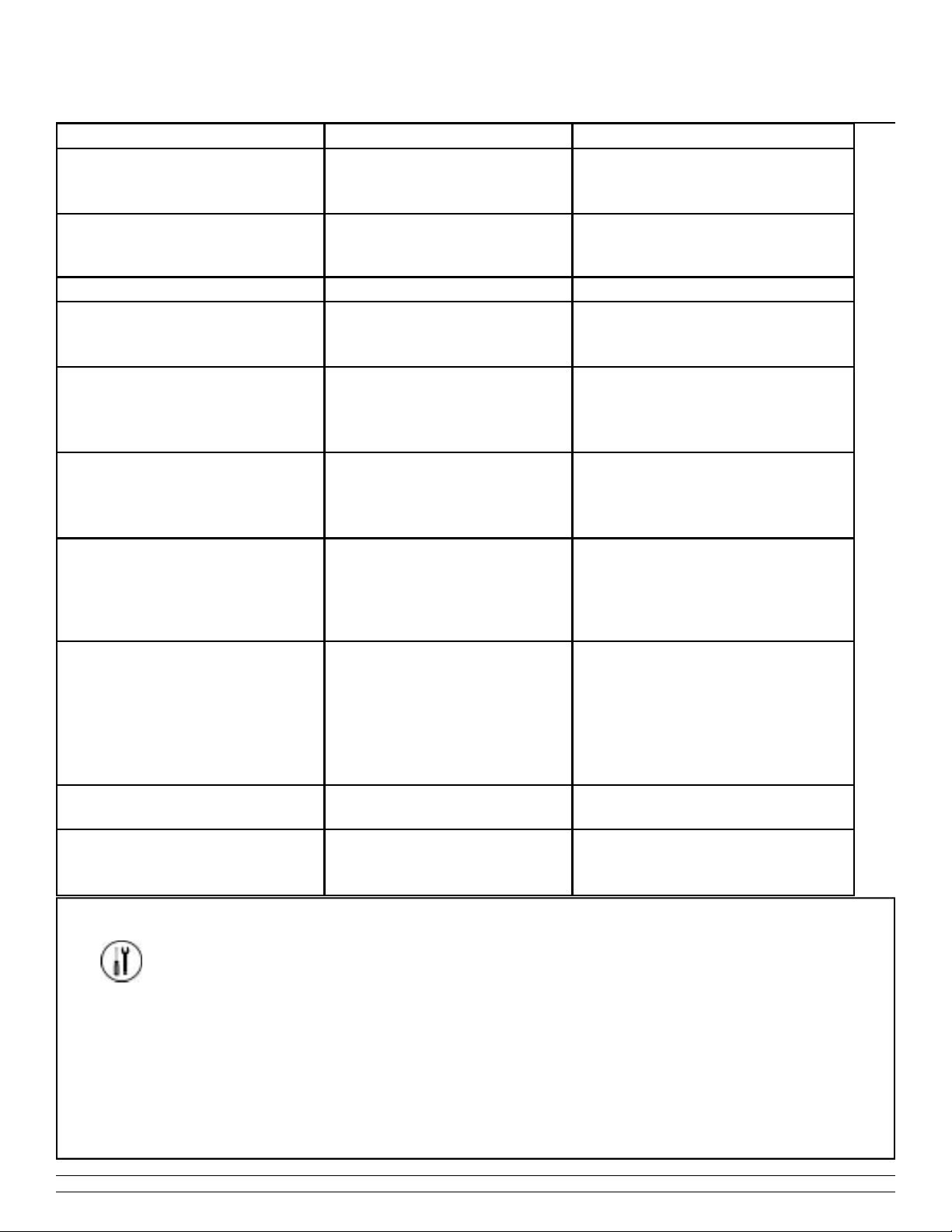

IV. 10. Troubleshooting.

Observations Possible Causes Solutions

The I-0 (ON/OFF) button is in the

“I” (ON) position but the device

does not operate.

The audible alarm sounds continu-

ously.

Red light remains lighted. Oxygen concentration is too low. Contact your equipment supplier.

The alarm test does not work. See

IV 4.1.

The compressor operates and the I-0

(ON/OFF) button is in the “I” (ON)

position but the green indicator is

not lighted.

The I-0 (ON/OFF) button is in the

“I” (ON) position but there is no

ow. The audible alarm sounds con-

tinuously.

The I-0 (ON/OFF) button is in the

“I” (ON) position, the compressor is

operating and there is a ow but the

audible alarm sounds continuously.

Power cable (9) is not correctly

plugged into the wall outlet.

Power failure. Check the circuit breaker (5) on the

Faulty 9 Volt battery.

Internal electrical fault.

Faulty indicator. Contact your equipment supplier.

Pneumatic connection broken or

other pressure problem.

Internal electrical fault.

Pneumatic circuit fault.

Check the cable connection.

front of the unit; Reset if necessary.

Replace battery.

Contact your equipment supplier.

Stop the device by pressing the I-0

(ON/OFF) button and contact your

equipment supplier.

Stop the device and contact your equipment supplier.

The compressor stops in mid-cycle,

then starts again after a few minutes.

The oxygen enriched air ow is in-

terrupted at the nasal cannula outlet.

The ow at the nasal cannula outlet

is irregular.

Compressor thermal safety device

has been activated.

Dirty Filters.

Fan is not working.

Tube disconnected or humidi er

cap is not tight.

Cannula tubing is kinked or res-

tricted.

Stop the device and wait for it to cool

down.

Clean cabinet lter. Restart.

If the device does not start, contact

your equipment supplier.

Check that tubing connections are se-

cure and that the humidi er is sealed.

Straighten the tubing; contact your

equipment supplier if damaged.

Maintenance Items

Cabinet Air Filter: Part Ref: 9250-1025; Wash weekly; Replace as needed.

Inlet Air Filter: Part Ref: 9250-1180; Inspect at each patient visit; Replace annually.

Battery, 9 Volt: Part Ref: 7206-0027; Replace annually or sooner if needed.

Please record all maintenance activity in the Maintenance Log found in the service manual and online at www.

nidekmedical.com under the 'Maintenance Log' tab.

May 20112010-2238CE Rev C 7

Page 8

V. EMC, Electromagnetic Statements

8

May 2011

2010-2238CE Rev C

Page 9

May 20112010-2238CE Rev C 9

Page 10

NOTES

-------------------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------------------

10

May 2011

2010-2238CE Rev C

Page 11

NOTES

-------------------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------------------

May 20112010-2238CE Rev C 11

Page 12

Nidek Medical Products, Inc.

3949 Valley East Industrial Drive

Birmingham,Alabama 35217 U.S.A.

Tel: 205-856-7200 Fax: 205-856-0533

EU Representative

mdi Europa GmbH

Langenhagener Str. 71

30855 Hannover-Langenhagen

Germany

Tel: +49-511-39-08 95 30

Fax: +49-511-39-08 95 39

info@mdi-europa.com

www.mdi-europa.com

12

May 2011

2010-2238CE Rev C

Loading...

Loading...