Page 1

GYC-1000 Training

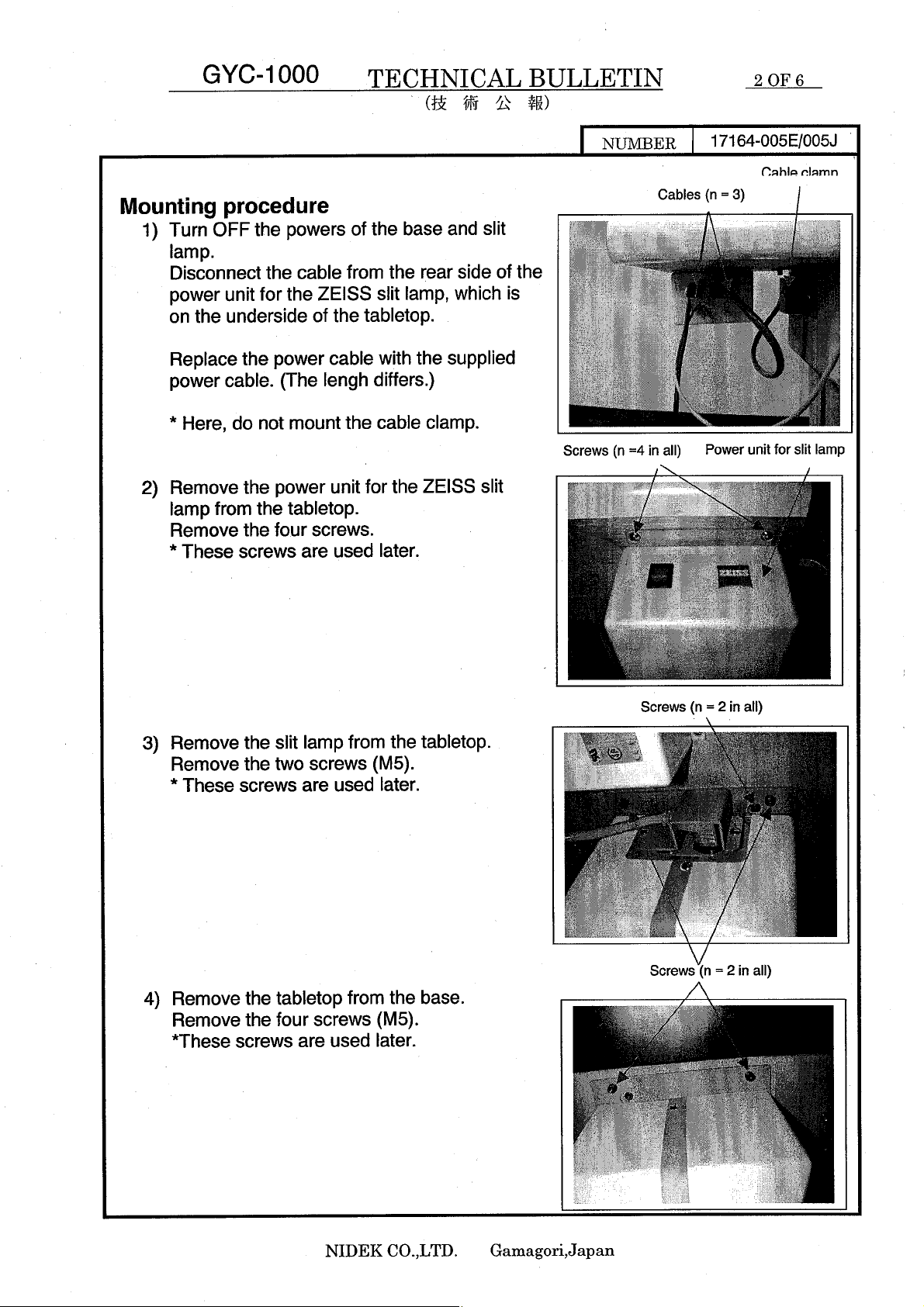

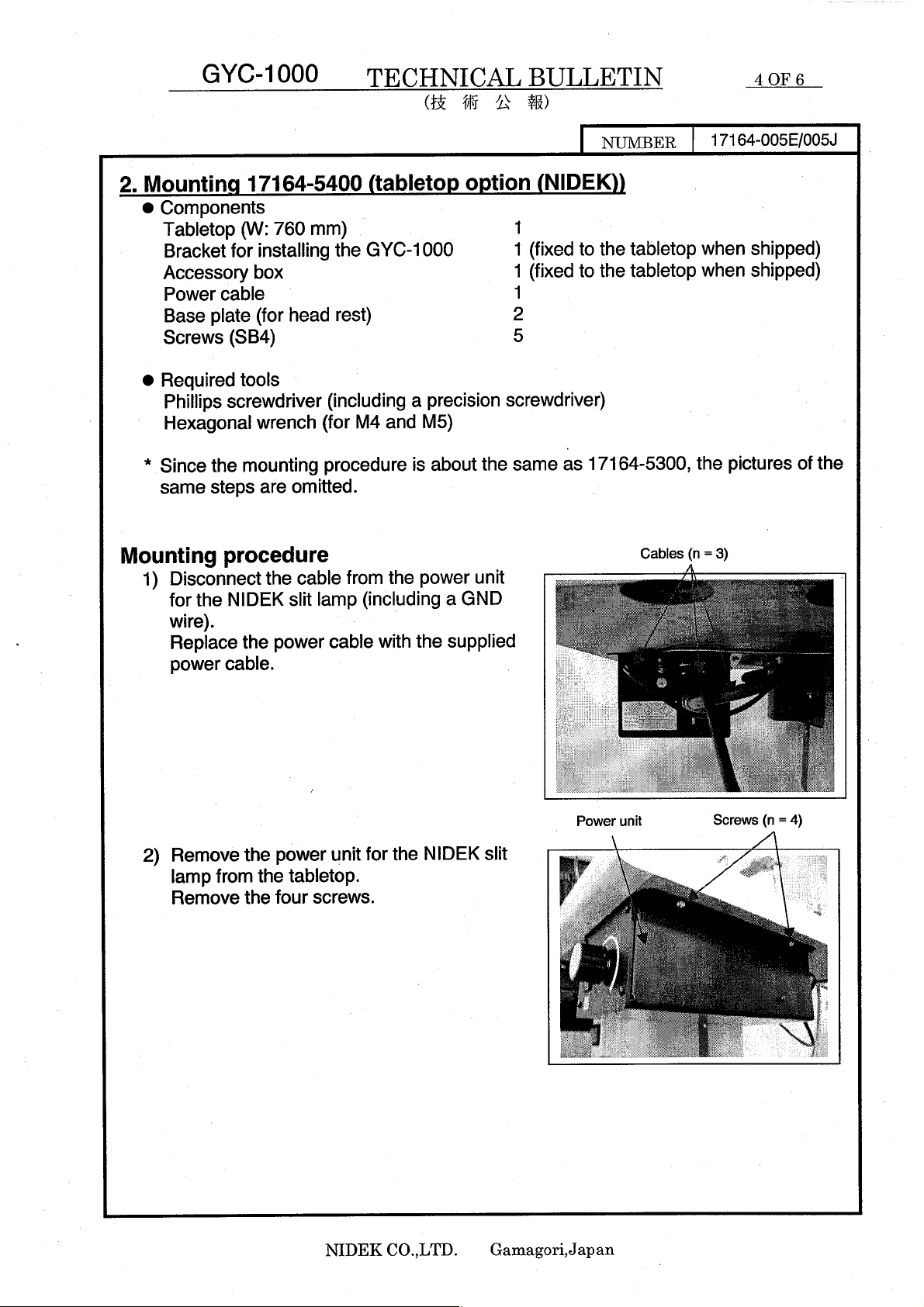

GYC-1000 Training

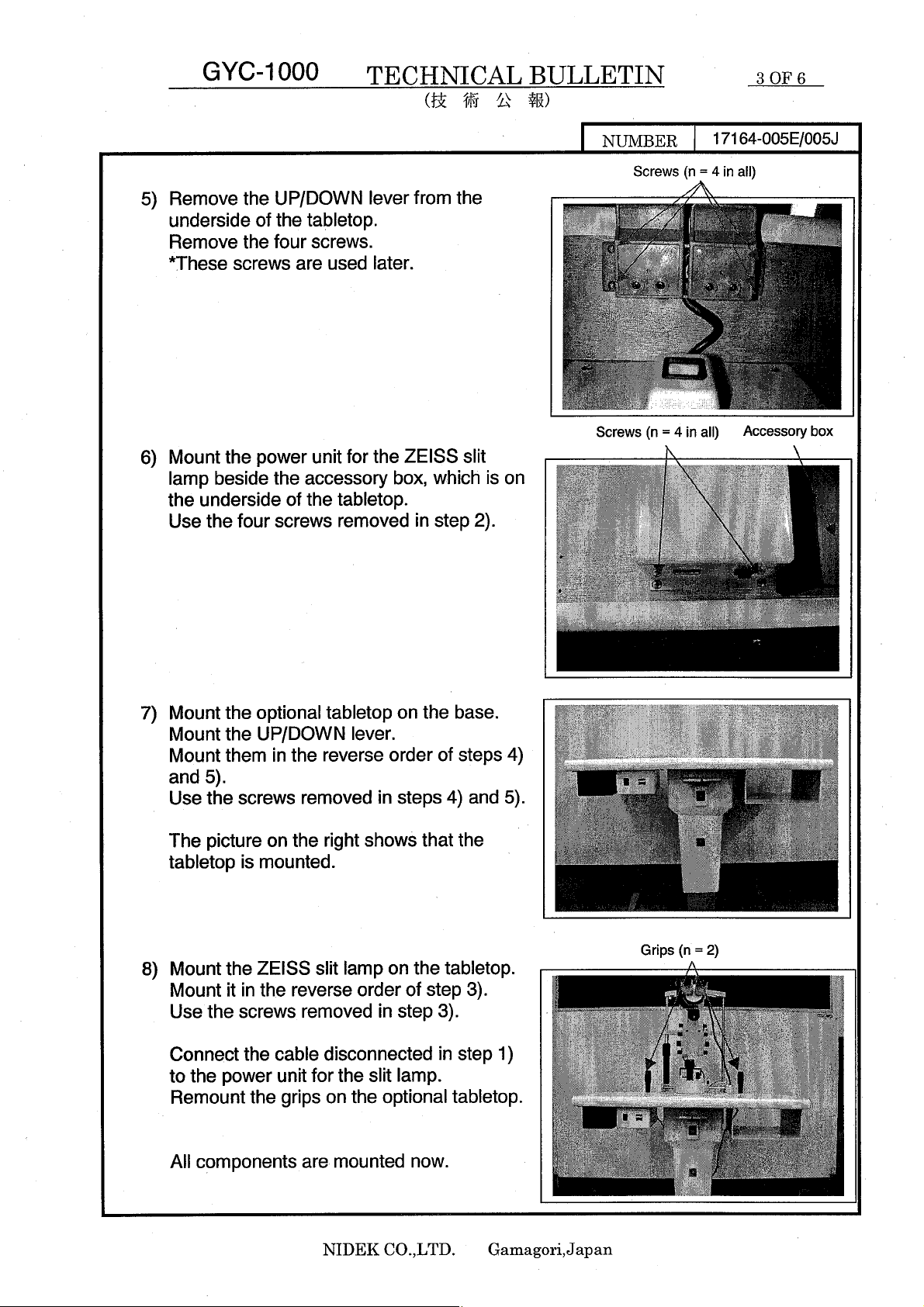

GYC-1000 TrainingGYC-1000 Training

Table of Contents

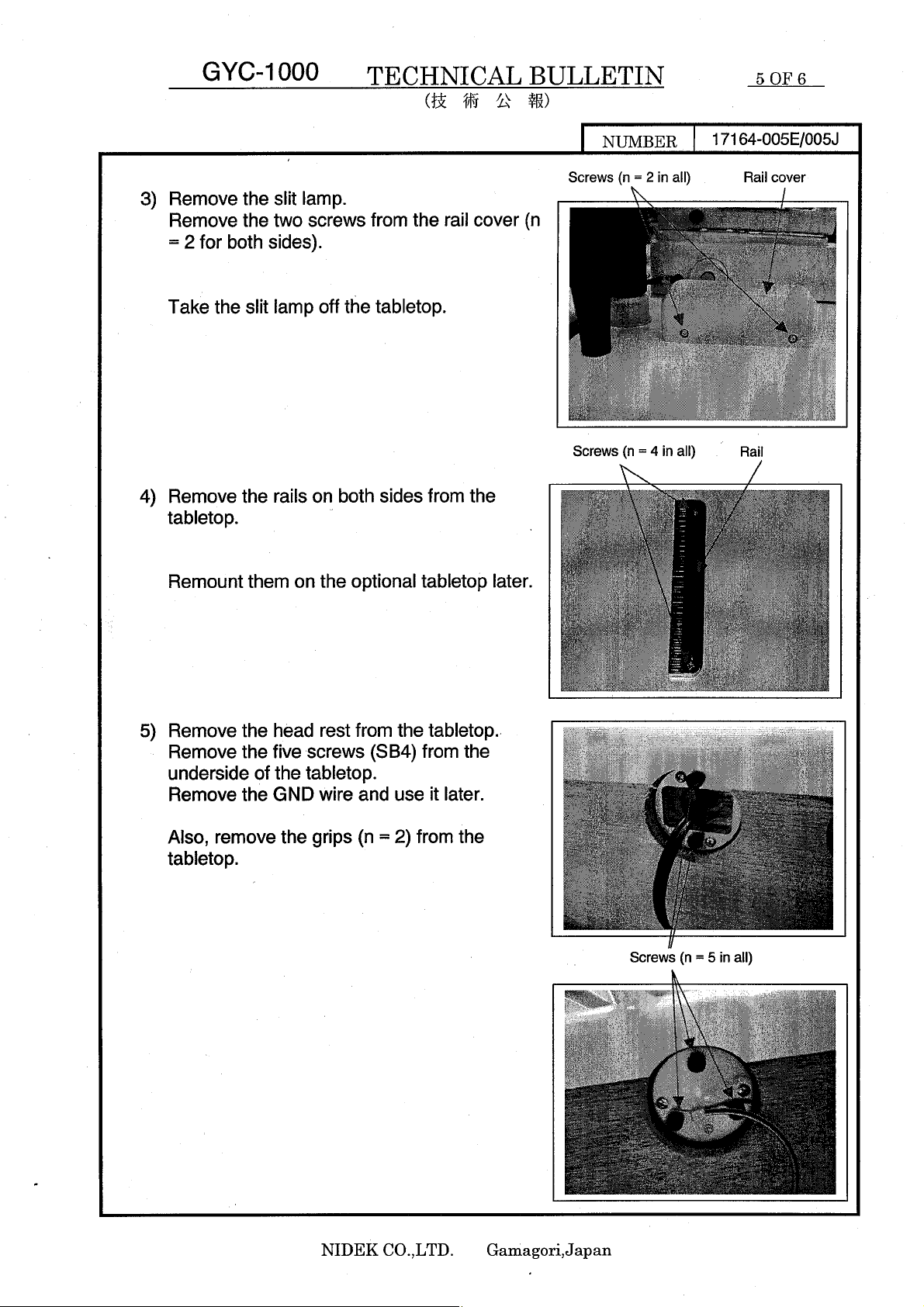

1. Safety

2. Outline, Principles

3. Specifications

4. Operation

5. Installation : Slit、Delivery、Check Power

6. Light control and Current control

7. Output power

8. Fiber alignment

9. Optical Axis

10. Adjusting Light Control

11. Over Power

12. Block Diagram

13. Replacement

14. Troubleshooting

Page 2

1. Safety

Operators Manual

Classifications

Safety

Warning

2. Outline(Operators Manual)→Power、Laser Head、Wave Length

Principles (Operators Manual )

3. Specifications

Operators Manual (9-1,9-2)

Power : 50mW-1700mW

Time : 0.01sec.-3.00sec.

Wavelength :532nm

Laser Power :2.5W @ 11.0-15.0A

Beam Diameter:30um-40um

Transmittance of fiber:90%

4. Operation

Control box

Page 3

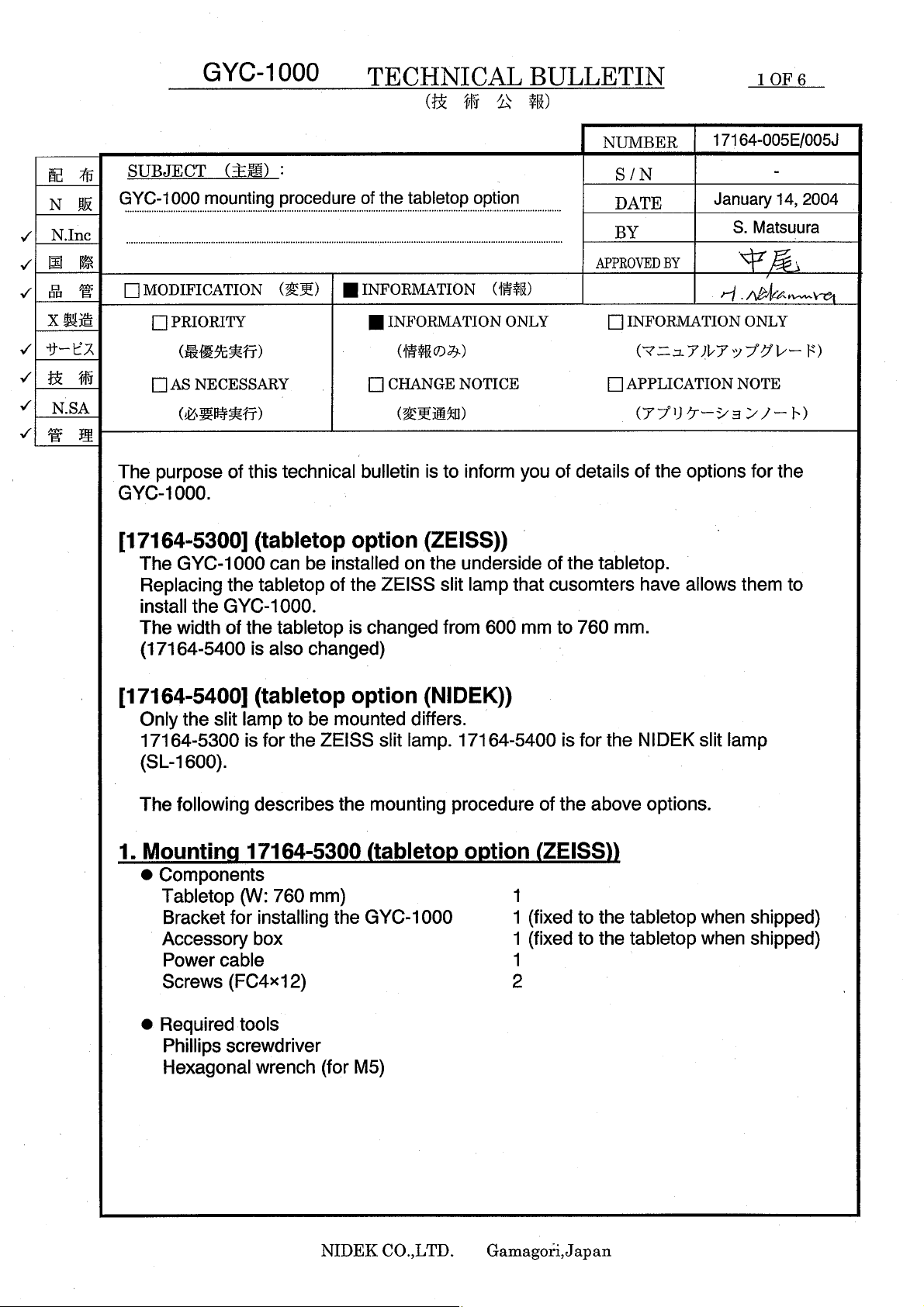

5. Installation : Slit、Delivery、Check Power

a. 100V / single phase

b. Check Slit Lamp

confirm the adjust bar position

Confirm the aiming focus on 500um and 50um

Coaxial between 50um and 500um

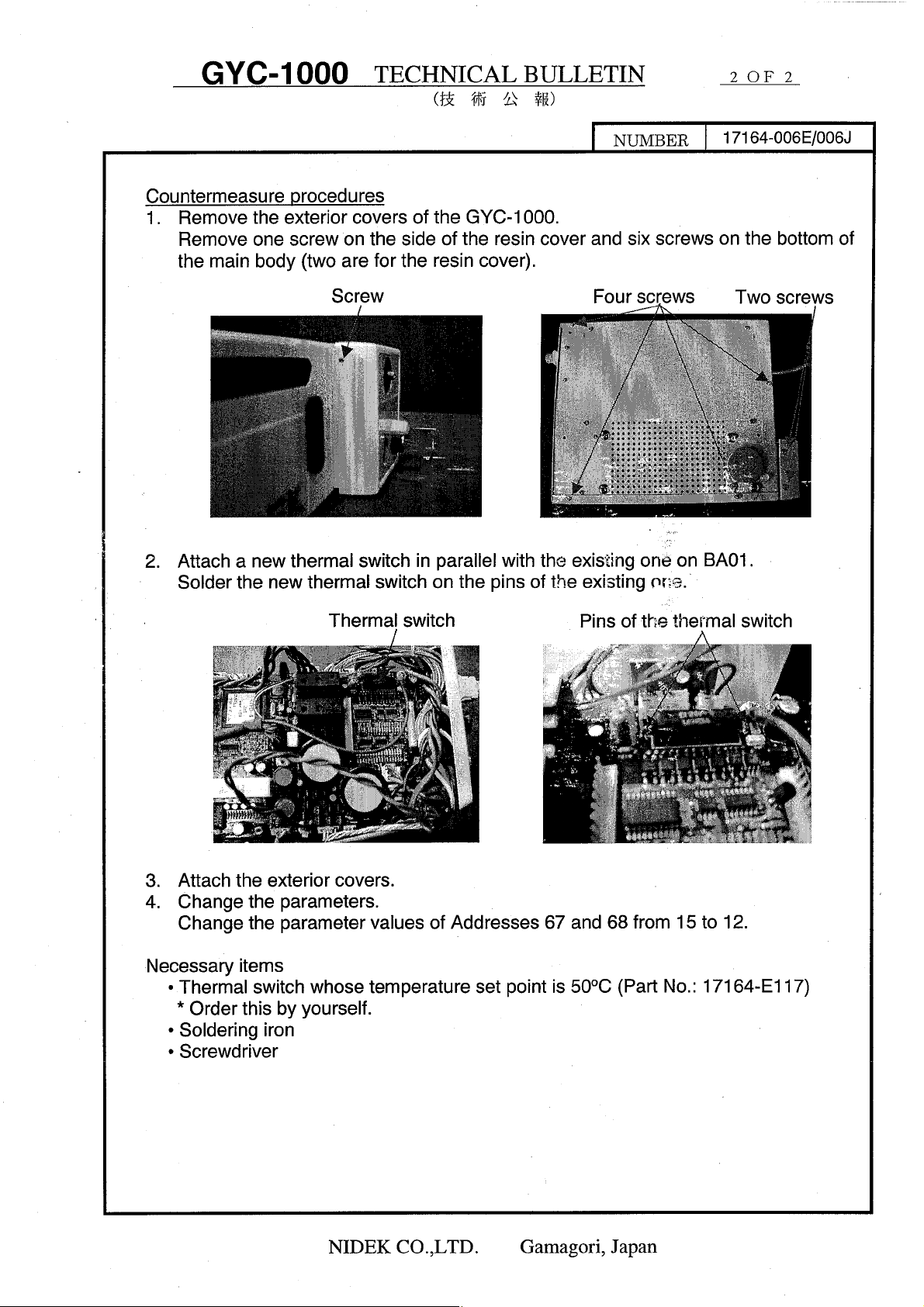

c. Dip switch function

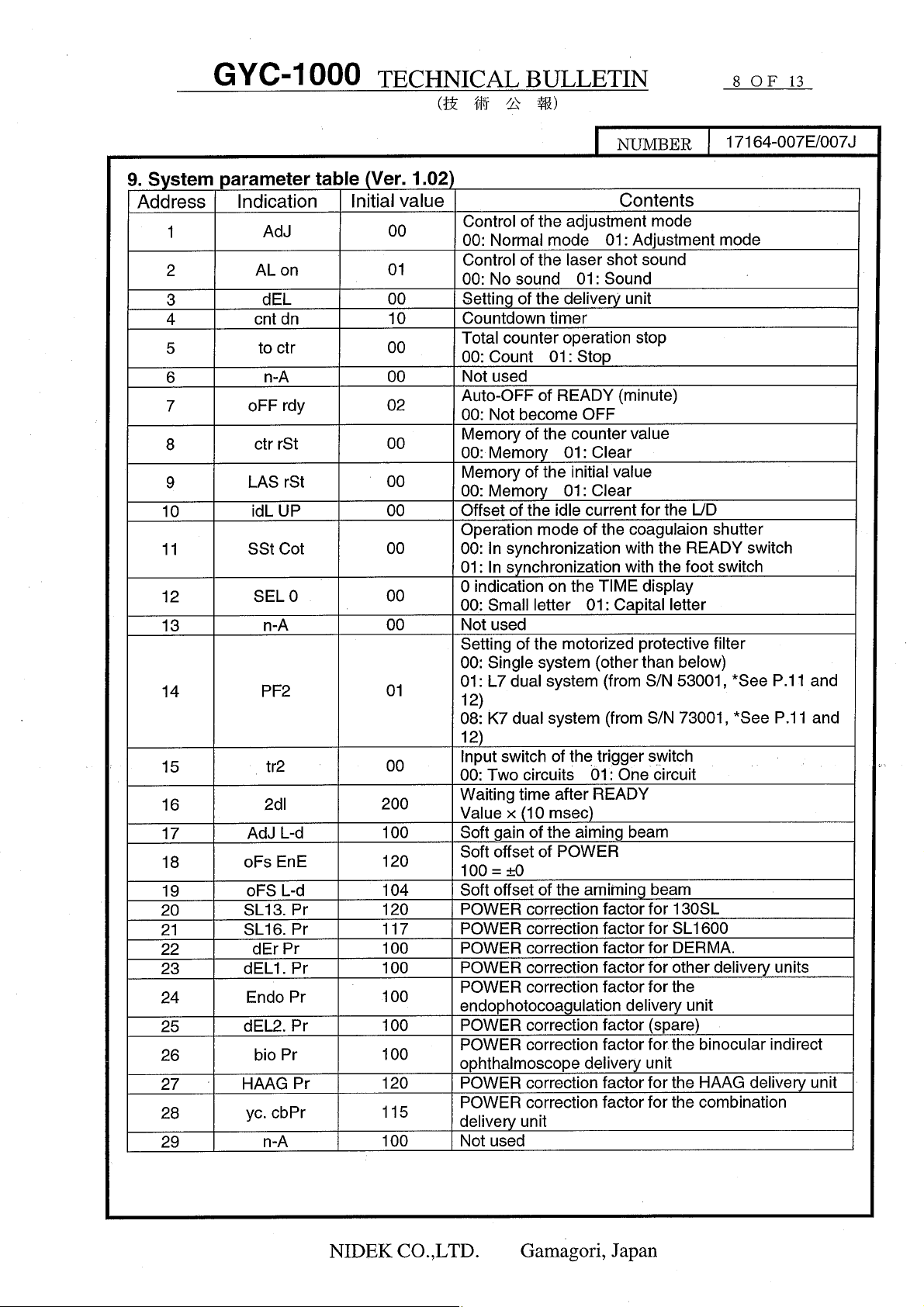

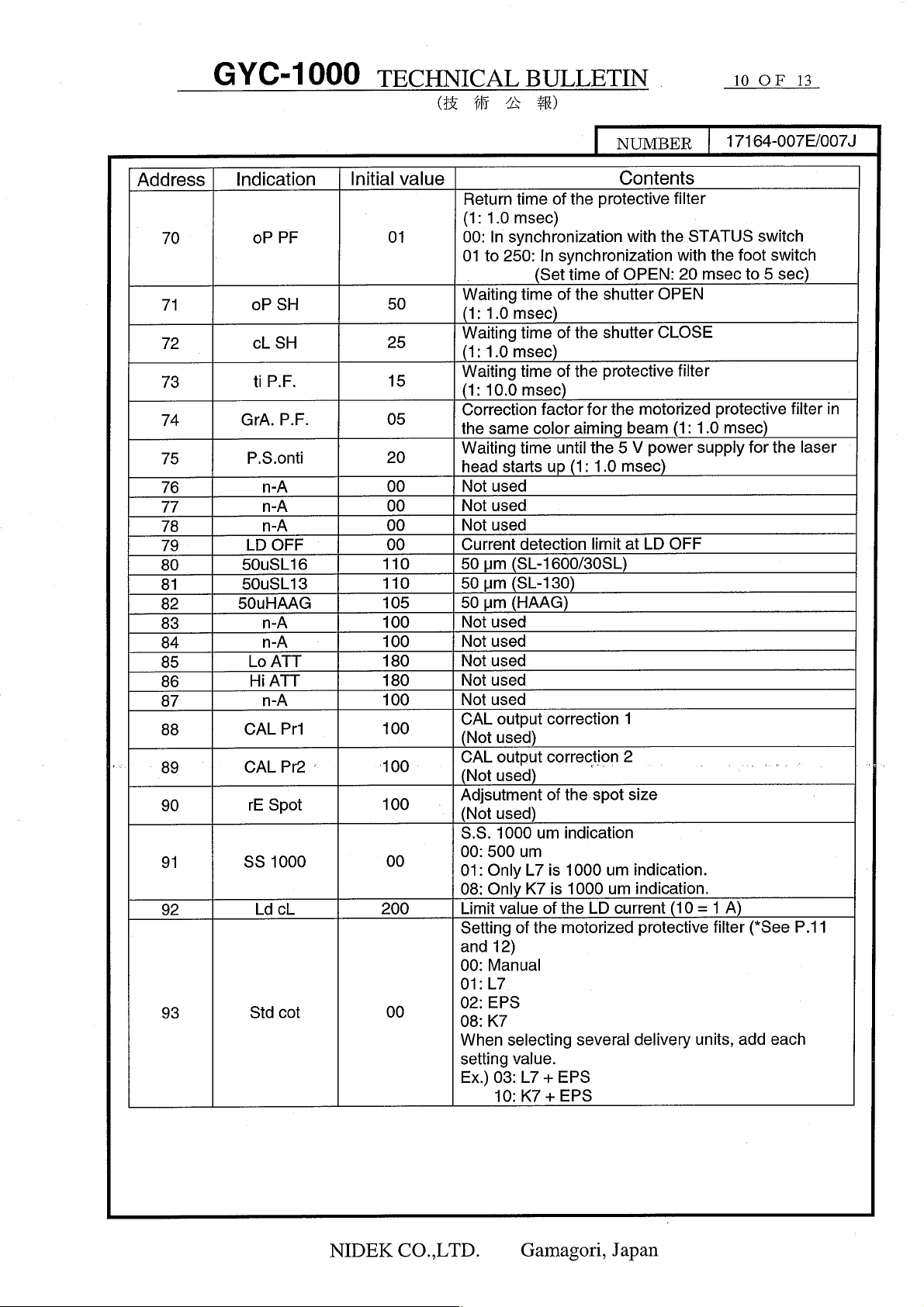

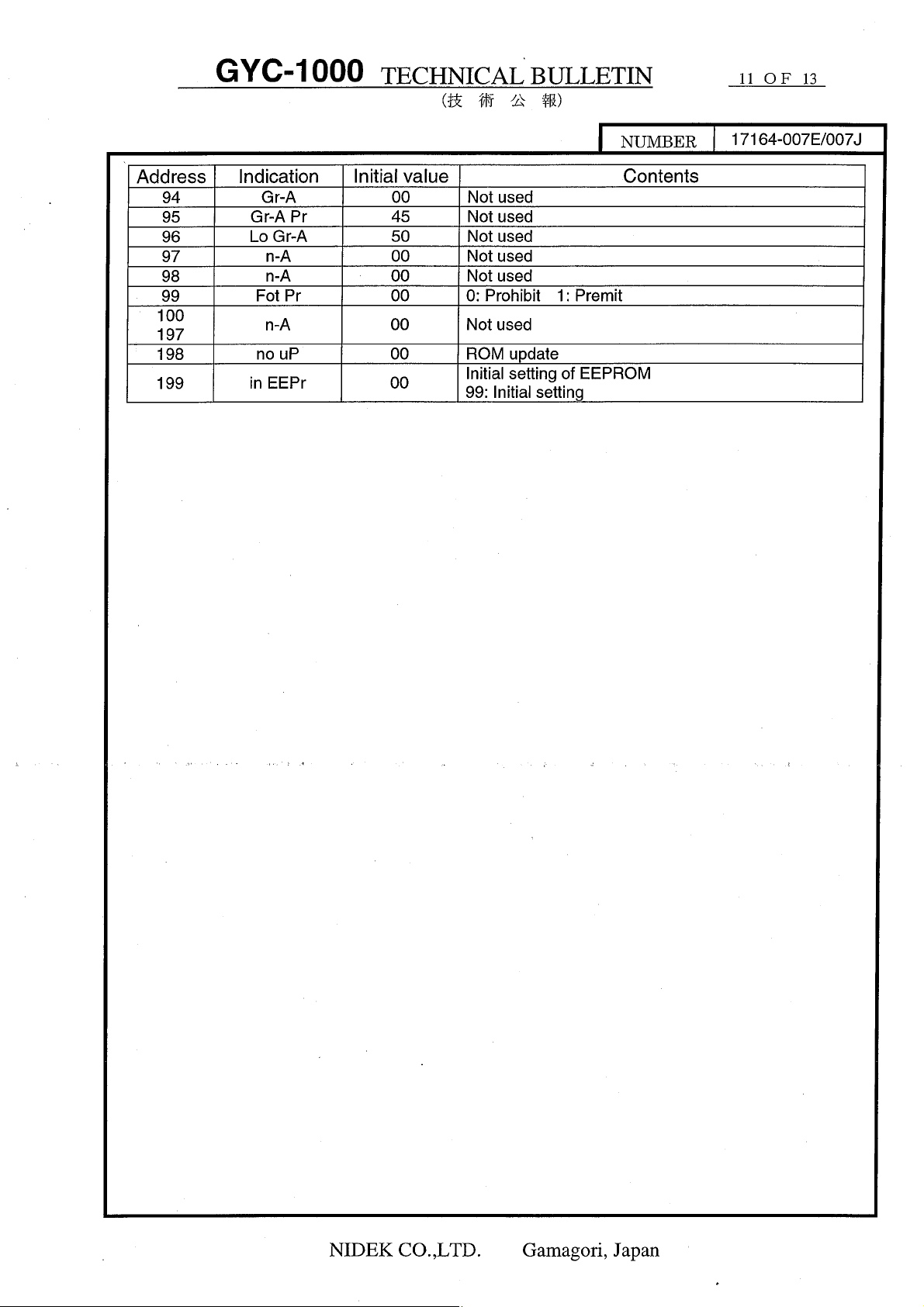

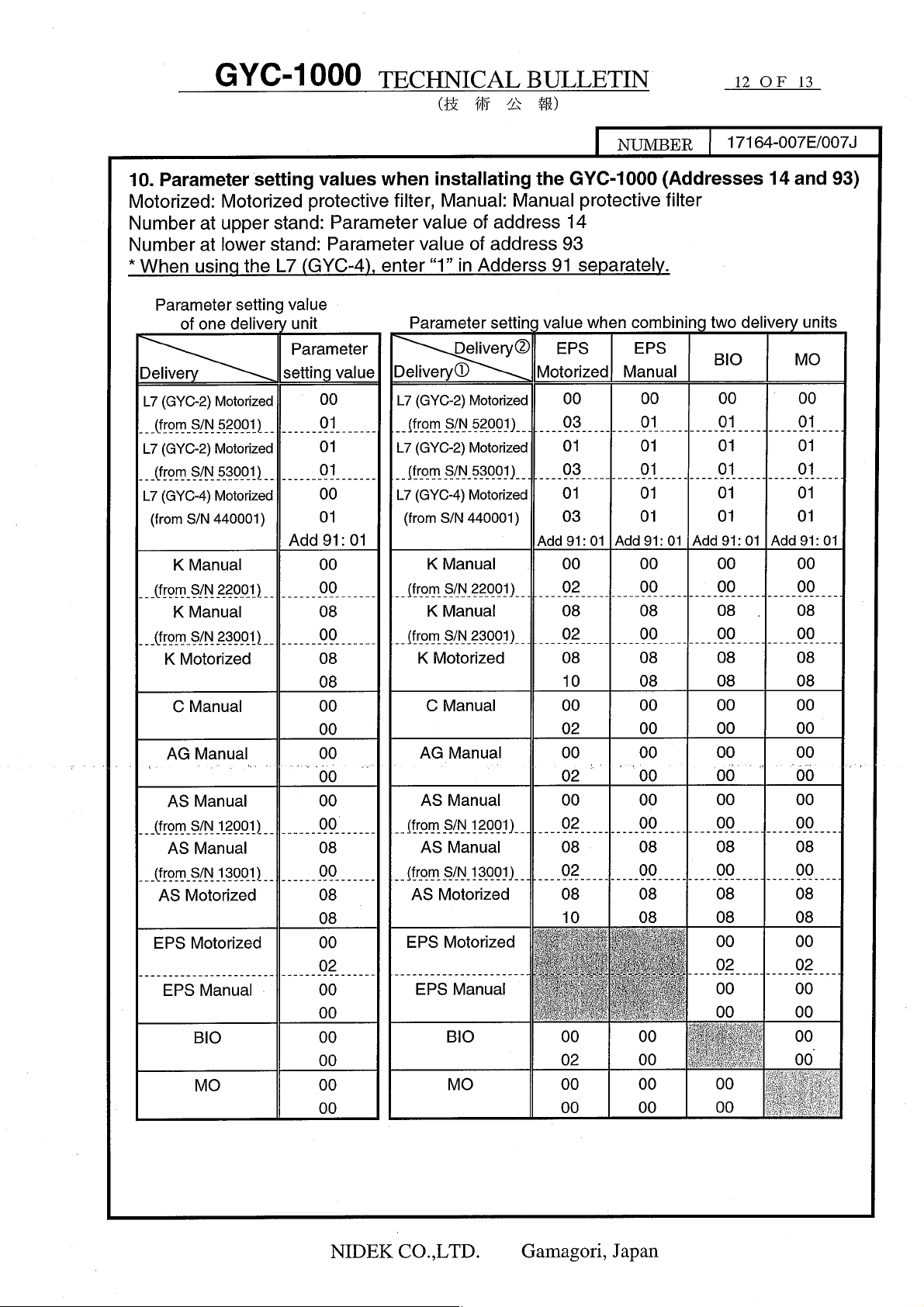

e. Parameter settings(Technical Bulletin/ Rom Version)

f. Check Focus of Aiming Beam

g. Check power by burn paper

Spot Size Power Time Result

Spot Size Power Time Result

Spot Size Power Time Result Spot Size Power Time Result

200um 200mW 0.2sec Check burn spot over 80%

50um 1000mW 0.02sec Laser pass through on second shoot

h. Check actual power at delivery end by power meter.

*Need to perform the fiber alignment, over power and power

check.

*You must use electrical static protect service kit

*Before you install the fiber optics, you must clean the fiber

surface.

Fiber alignment

Service Manual 7.5.5

Over Power

Service Manual 7.6.3

Power check

Service Manual 7.6.1

7. Shutter Unit

8. Optical Axis for Laser Beam and coaxial between aiming beam and laser

beam.

9. Output Power

Settings

*Dip switch 1, 2 and 4 up

*Display 1700mW

*Remove the fiber optics

Check the Output Power at end of shutter unit.

Over 2.4W

Over 2.4W

Over 2.4W Over 2.4W

Page 4

10. Fiber Alignment

See Service Manual

Note: Loosen set screw

Mark the focus lens holder before remove

Rotate the fiber connector after align

Difference of X-Y stage on GYC-1500 and GYC-2000

11. Adjusting the Light Control

See service manual

Power calibration for each delivery by parameter

Check the output power by Power Meter

12.Adjusting the over power

See service manual : Page 5-9

*Note - Set the dip switches 1,2 and 5

- Dip switch Pack->See Service Manual Page 7-8

13.Block Diagram / Wiring Diagram

See service manual : 8.1 Peltie

Input

Laser Diode

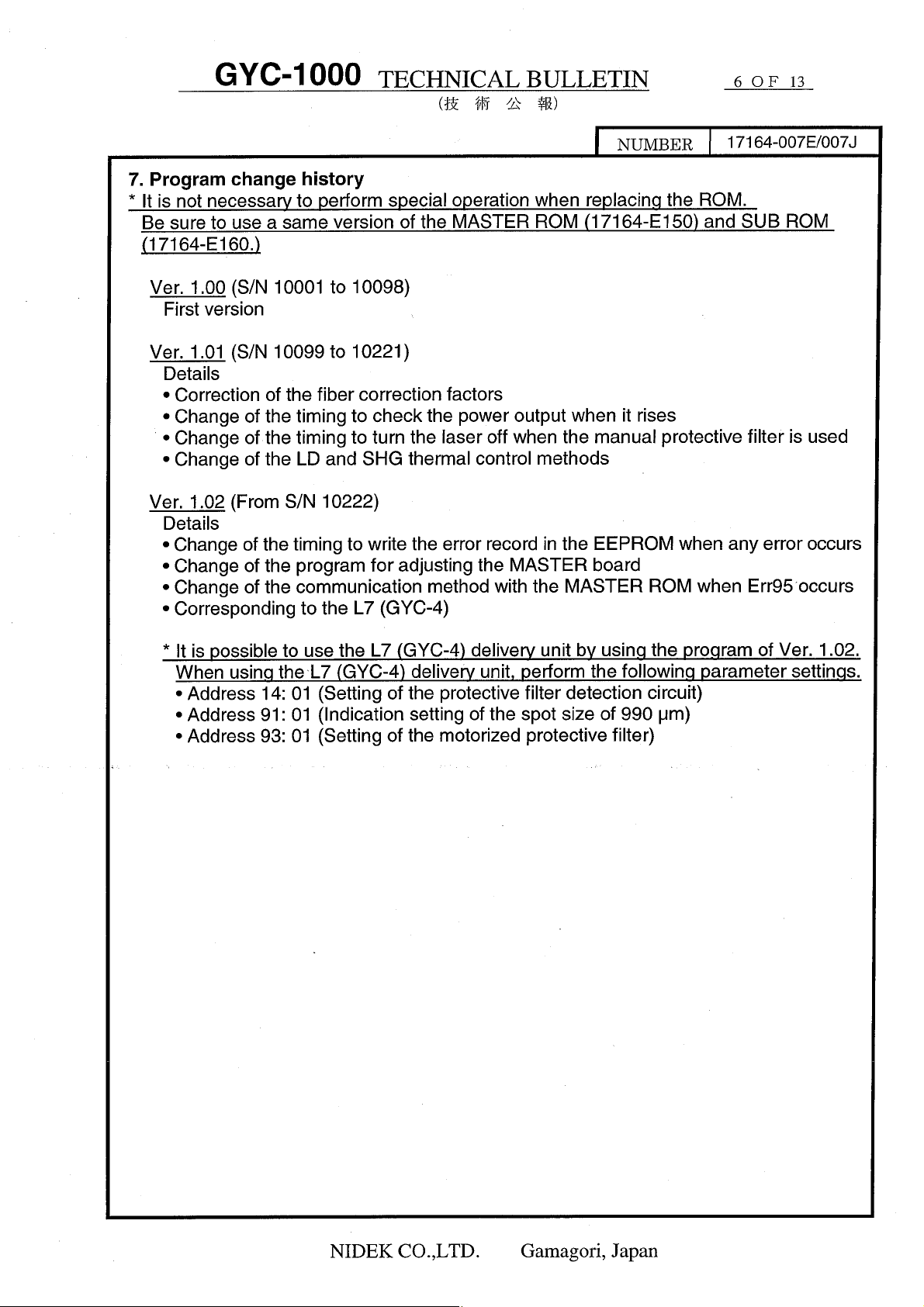

14. Replacement

Master Board

Power Supply Board

15. Trouble shooting

Parameters : See Service Manual

Error Code : See Service Manual

Inter lock : See Service Manual

Other indications : See Service Manual

Check the laser head condition by service mode

Power down

– Power Supply Board(12V,5V) Main Board(12V,15A) System(12V)

(5V,23A)

(5V)

Page 5

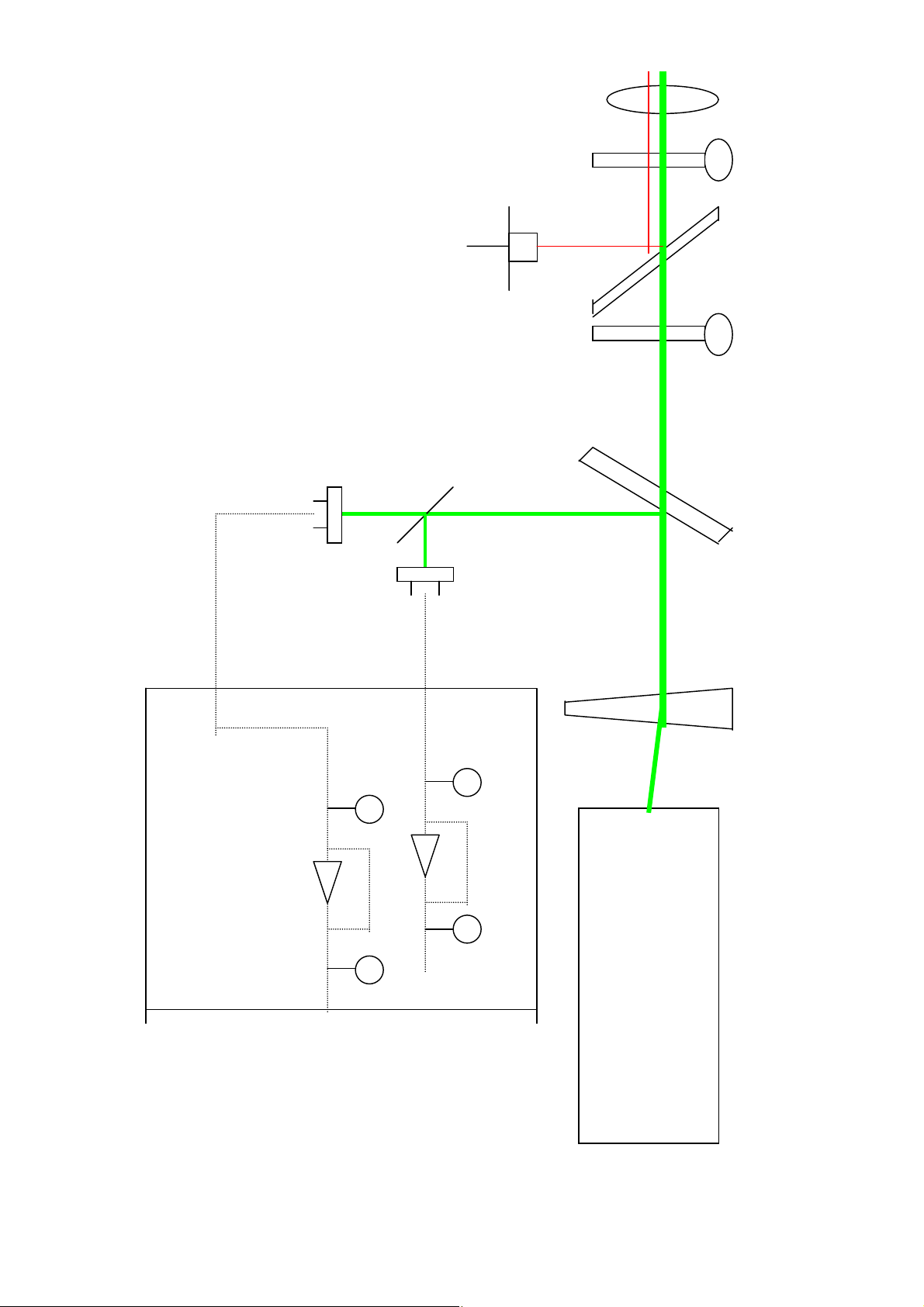

Objective lens

Aiming shutter

Dichroic mirror

Aiming diode

Coag shutter

Beam spritter

Beam spritter

1

st

Photo detector

TP9(TP5)

2

nd

Photo detector

TP8(TP4)

Prism

TP8

TP9

Main Board

Laser Head

TP4

TP5

Memo

At Current Control

Display 1000mW=5A

Display 2000mW=10A

Display 3000mW=15A

Display 4000mW=20A

Page 6

Page 7

Page 8

Page 9

Page 10

Page 11

Page 12

Page 13

Page 14

Page 15

Page 16

Page 17

Page 18

Page 19

Page 20

Page 21

Page 22

Page 23

Page 24

Page 25

Page 26

Page 27

Page 28

Page 29

Page 30

Page 31

Page 32

Page 33

Page 34

Page 35

Page 36

Page 37

Page 38

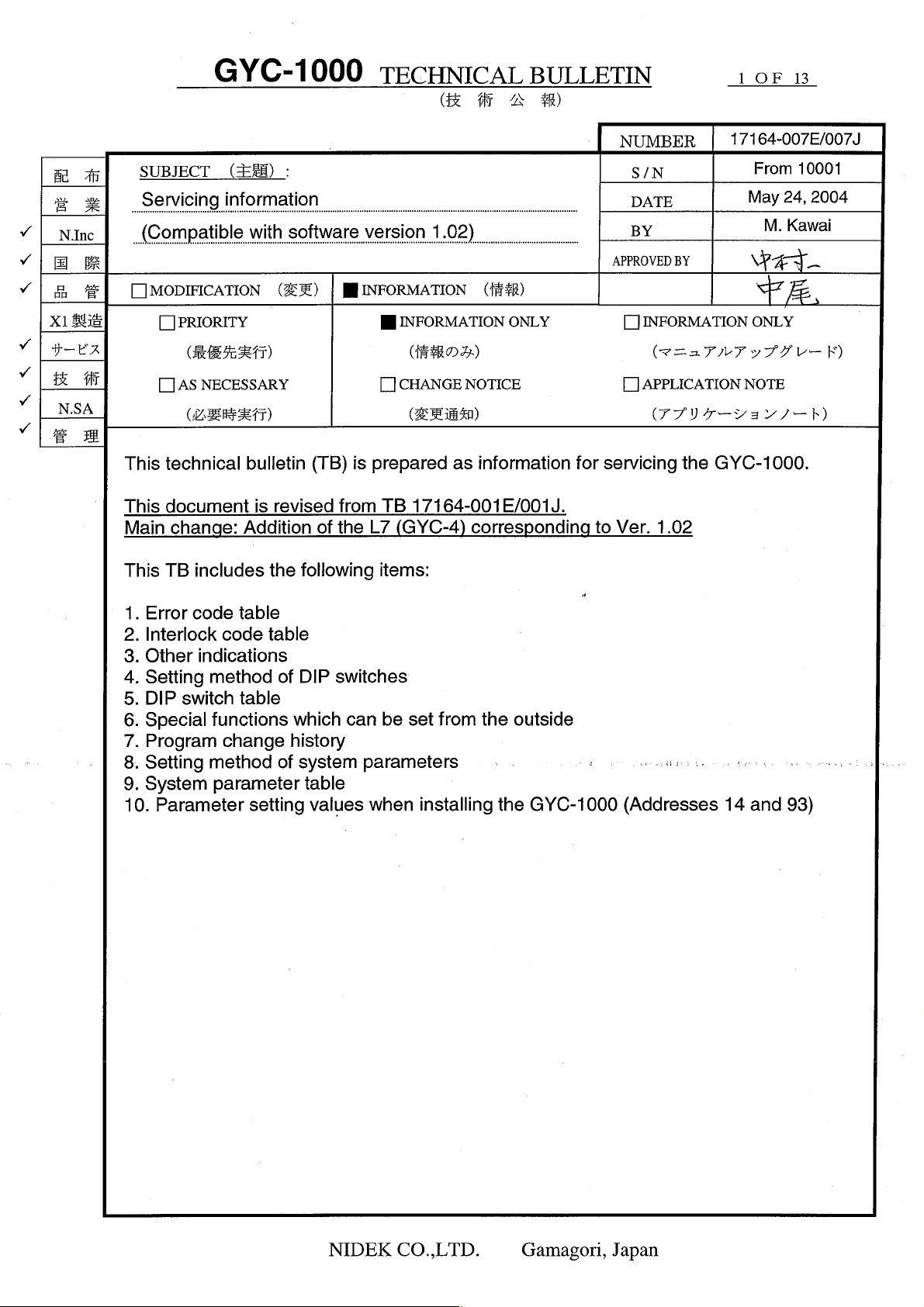

NIDEK

GREEN LASER PHOTOCOAGULATOR

Model GYC-1000

SERVICE MANUAL

January 22, 2004

Pages in total: 68

XGYC4*RDA001A/E

Page 39

This page is intentionally vacant.

Page 40

Table of Contents

§

1 INTRODUCTION ......................................................................................................... 1-1

§

2 SAFETY ......................................................................................................................... 2-1

2.1General precautions ..................................................................................................... 2-1

2.2 Cautions in maintenance ..............................................................................................2-1

2.3 Cautions in adjustment ................................................................................................ 2-2

§

3 TROUBLESHOOTING ............................................................................................... 3-1

§

4 SUB-TROUBLESHOOTING ...................................................................................... 4-1

4.1The LINE indicator does not light up. ...........................................................................4-1

4.2 The fan does not work. ............................................................................................... 4-1

4.3 INTERLOCK 6.3 appears......................................................................................... 4-2

4.4 Error 1 appears. .........................................................................................................4-2

4.5 Error 3 appears. .........................................................................................................4-3

4.6 Error 13 appears. .......................................................................................................4-3

4.7 Error 20 appears. .......................................................................................................4-4

4.8 Error 21 appears. .......................................................................................................4-4

4.9 Error 54 appears. .......................................................................................................4-5

4.10 Any error in the 90s appears. .................................................................................... 4-5

4.11 INTERLOCK 4.7 appears. ......................................................................................4-6

4.12 The coagulation power cannot be changed. ............................................................... 4-6

4.13 The coagulation time cannot be changed. ...................................................................4-7

4.14 The brightness of the aiming beam cannot be changed. ...............................................4-7

4.15 The aiming beam is invisible. ..................................................................................... 4-7

4.16 The interval time cannot be changed. ......................................................................... 4-7

4.17 The READY indicator does not light up. ....................................................................4-7

4.18 The counter cannot be reset. .....................................................................................4-7

4.19 Error 2 appears. .......................................................................................................4-8

4.20 Error 53 appears. ..................................................................................................... 4-9

4.21 Error 55 appears. ..................................................................................................... 4-9

4.22 INTERLOCK 2.7 appears....................................................................................... 4-9

4.23 Error 10 appears. ................................................................................................... 4-10

4.24 Error 15 appears. ................................................................................................... 4-10

4.25 The power output is out of the specified range. ........................................................ 4-11

4.26 When the spot size is set to 50µm, the power output is out of the specified range. ..... 4-11

4.27 The emergency stop switch cannot be activated. ...................................................... 4-12

Page

Page 41

§

5 REMOVING COVERS................................................................................................ 5-1

5.1 Removing covers ........................................................................................................ 5-1

§

6 REPLACEMENT ......................................................................................................... 6-1

6.1 Replacing the switching power supply ......................................................................... 6-1

6.2 Replacing the fan ........................................................................................................ 6-1

6.3 Replacing the COAG shutter ...................................................................................... 6-2

6.4 Replacing the COAG SHUTTER ASSY..................................................................... 6-3

6.5 Replacing the AIMING shutter ................................................................................... 6-3

6.6 Replacing the AIMING SHUTTER ASSY.................................................................. 6-4

6.7 Replacing the TRANSISTOR .....................................................................................6-4

6.8 Replacing the FIBER SW ........................................................................................... 6-4

6.9 Replacing the CPU ..................................................................................................... 6-5

6.10 Repairing and replacing the CB ASSY ...................................................................... 6-5

6.11 Replacing the LD ASSY ........................................................................................... 6-6

6.12 Replacing the DELIVERY BOARD .......................................................................... 6-6

6.13 Replacing the monitor ASSY .................................................................................... 6-7

6.14 Replacing the EMERGENCY switch ........................................................................ 6-7

6.15 Replacing the MASTER BOARD .............................................................................6-8

6.16 Replacing the LASER HEAD ................................................................................... 6-9

§

7 ADJUSTMENT ............................................................................................................ 7-1

7.1 Setting parameters ...................................................................................................... 7-1

7.2 Adjustment of the MASTER BOARD ........................................................................ 7-1

7.2.1 Initial setting of the MASTER BOARD ..............................................................7-1

7.2.2 Adjustment for Peltier device ............................................................................. 7-2

7.2.3 Current adjustment of the limiter ........................................................................ 7-4

7.3 Connection check of the laser head ............................................................................. 7-5

7.4 Operation check of the shutter .................................................................................... 7-6

7.4.1 Operation check of the COAG SHUTTER ASSY .............................................7-6

7.4.2 Operation check of the AIMING SHUTTER ASSY .......................................... 7-6

7.5 Optical adjustment ......................................................................................................7-7

7.5.1 Optical axis adjustment of green laser ................................................................ 7-7

7.5.2 Optical axis adjustment of aiming beam .............................................................. 7-8

7.5.2.1 Near point confocal adjustment ............................................................. 7-8

7.5.2.2 Far point confocal adjustment ................................................................ 7-8

7.5.3 1W and 1V adjustment ..................................................................................... 7-9

7.5.4 Condenser adjustment ....................................................................................... 7-9

7.5.5 Laser alignment for the fiber optic cable ........................................................... 7-10

7.6 Total adjustment ....................................................................................................... 7-11

7.6.1 Adjustment of the light control.......................................................................... 7-11

7.6.2 Power adjustment of the aiming beam .............................................................. 7-12

7.6.3 Adjustment for overpower ...............................................................................7-13

7.6.3.1 Adjustment at 1000mW ...................................................................... 7-13

7.6.3.2 Adjustment at 50mW .......................................................................... 7-14

7.6.4 Check of overpower ....................................................................................... 7-15

7.6.5 Adjustment of the COAG TIME and REPEAT TIME ...................................... 7-16

Page 42

§

8 REFERENCES ............................................................................................................. 8-1

8.1 Wiring diagram ...........................................................................................................8-1

8.2 Connectors and cables ............................................................................................... 8-2

8.3 Configuration ............................................................................................................ 8-10

8.4 Labels ...................................................................................................................... 8-11

8.5 List of replacement parts ........................................................................................... 8-14

8.6 Tools ........................................................................................................................8-14

8.7 DIP switches ............................................................................................................ 8-15

8.8 Error code table ....................................................................................................... 8-15

8.9 INTERLOCK code table .........................................................................................8-16

8.10 Other messages ......................................................................................................8-16

8.11 Special key operations ............................................................................................8-16

Page 43

This page is intentionally vacant.

Page 44

§

INTRODUCTION

1

This service manual contains service instructions for the NIDEK GREEN LASER

PHOTOCOAGULATOR, GYC-1000.

For correct service, thorough understanding of the contents of this manual is required prior to

the service.

Use this manual together with the GYC-1000 Operator’s Manual and Parts List.

The specifications and design of this instrument are subject to change without notice for

improvement. In the case of major changes, refer to the corresponding TECHNICAL BULLETIN

issued in each occasion.

If the instrument cannot be repaired by repair operations in accordance with this Service Manual,

please inform NIDEK of the Serial Number of the instrument, and details of the symptom.

Page 45

This page is intentionally vacant.

Page 46

§

2

2.1 General precautions

SAFETY

• Only NIDEK service persons and persons trained by NIDEK for the GYC-1000 service work

are allowed to repair the instrument.

• Observe the procedures to perform the repair work. If not, accidents or failure of the instrument

may result.

• When performing the maintenance work, turn OFF the power switch, and disconnect the

power cord from the wall outlet unless the power needs to be ON.

2.2 Cautions in maintenance

• Take action against static electricity before service work.

• In case of instrument malfunction, turn OFF the power switch after checking the symptom.

• Never drop parts or screws inside the instrument, nor bump it against surrounding objects.

• Prepare storage cases so as not to lose the removed screws or parts.

• Screw or unscrew the screws with proper tools.

• After loosening the screws fixed by a thread-locking adhesive, be sure to reapply the thread-

locking adhesive to the screws when you retighten them.

• After replacing parts, make sure that they are fixed securely before turning ON the power.

• If you observe strange odors or smoke being issued from the instrument, immediately turn

OFF the instrument, disconnect the power cord from the outlet, and diagnose the cause. If the

instrument is powered in abnormal conditions, fire, electric shock or total loss of the instrument

may result.

• Refer to “8.1 Wiring diagram” and “8.2 Connectors and cables,” for checking cable breaks as

described in “§4 SUB-TROUBLESHOOTING”. In addition, check cables for the following:

Connectors are connected and crimped securely.

No contact failure occurs after re-connection of connectors.

Cables are soldered properly.

• Do not pull the cables strongly. Cable breaks etc. may result.

Page 47

2 - 2

• Never perform continuous emission for more than 10 seconds because this puts an enormous

load on the power supply.

• Never emit the laser beam onto reflective objects such as a metal surface.

• Wear the safety goggles for the GYC-1000.

• Never emit the laser beam (direct light) to a human body or any object.

2.3 Cautions in adjustment

• Perform adjustment on a vibration-free, stable and level surface.

A slanted floor or place subject to vibration will obstruct accurate adjustment.

• Do not use a calibration jig for usage other than described in this manual.

Page 48

§

TROUBLESHOOTING

3

Turn ON the master switch.

Does the LINE indicator light up?

Yes

Does the LASER EMISSION indicator light

up by turning ON the key switch and does the

system start a countdown for 10 seconds?

Yes

Does the fan work?

Yes

After the countdown, do the POWER and

TIME displays indicate the setting values?

Yes

Can the coagulation power output be set

properly?

Yes

No

No

No

No

No

4.1 The LINE indicator lights up.

4.3 INTERLOCK 6.3 appears.

4.2 The fan does not work.

4.4 Error 1 appears.

4.5 Error 3 appears.

4.6 Error 13 appears.

4.7 Error 20 appears.

4.8 Error 21 appears.

4.9 Error 54 appears.

4.10 Any error in the 90s appears.

4.11 INTERLOCK 4.7 appears.

4.12 The coagulation power cannot be changed.

Can the coagulation time be set properly?

Yes

Can the brightness of the aiming beam

changed by pressing the AIMING switch?

Yes

Does the indication on the INTERVAL

display light up by pressing the INTERVAL

switch?

Yes

No

No

No

4.13 The coagulation time cannot be changed.

4.14 The brightness of the aiming beam cannot

be changed.

4.15 The aiming beam is invisible.

4.16 The interval time cannot be set.

Page 49

3 - 2

This page is intentionally vacant.

Does the READY indicator light up by

pressing the STATUS switch?

Yes

Is the indication on the COUNTER display

reset to “0” by pressing the RESET switch?

Yes

Is the laser emitted by depressing the foot

switch?

Yes

Is the measured power output within the

specifications for the set values?

Yes

Do the laser emission stop, the indications of

the control box light off, and the fan stop by

pressing the emergency stop switch?

Yes

No

No

No

No

No

4.17 The READY indicator does not light up.

4.18 Counter cannot be reset.

4.19 Error 2 appears.

4.20 Error 53 appears.

4.21 Error 55 appears.

4.22 INTERLOCK 2.7 appears.

4.23 Error 10 appears.

4.24 Error 15 appears.

4.25 The power output is out of the specified

range.

4.26 When the spot size is set to 50μm, the

power output is out of the specified range.

4.27 The emergency stop switch cannot be

activated.

Turn ON the key switch. After the

countdown for 10 seconds, turn OFF the key

switch.

Turn OFF the master switch.

Completion of operation

Page 50

§

4

4.1 The LINE indicator does not light up.

SUB-TROUBLESHOOTING

Is the fuse in the fuse carrier blown?

No

Is the voltage between the 1st and 3rd pins of

P125 on the MASTER BOARD + 12 VDC?

Yes

Is the voltage between the 24th and 20th pins

of J108 on the MASTER BOARD

approximately + 4.0 VDC?

Yes

Does the cable between the 20th and 24th

pins of the CB CABLE ASSY have a break?

No

Replace the DISPLAY BOARD.

(See “6.15”.)

Yes

No

No

Yes

4.2 The fan does not work.

Replace the fuse with a new one.

(Refer to the Operator’s Manual.)

Replace the switching power supply.

(See “6.1”.)

Replace the MASTER board. (See “6.15”.)

Repair the faulty point.

* The fan does not work when the temperature is lower than the specified one (25 degrees C).

Does the LINE indicator of the control box

light up?

Yes

Is the voltage between the 1st and 2nd pins of

J112 on the MASTER BOARD + 12 VDC?

Yes

Replace the FAN ASSY. (See “6.2”.)

No

No

Check the articles described in “4.1 The LINE

indicator does not light up.” (See “4.1”.)

Replace the MASTER BOARD. (See “6.15”.)

Page 51

4 - 2

4.3 INTERLOCK 6.3 appears.

Is the REMOTE connector connected?

Yes

Is electricity applied between the 3rd and 4th

pins of the REMOTE connector?

Yes

Replace the MASTER BOARD.

(See “6.15”.)

4.4 Error 1 appears.

Does the COAG SHUTTER ASSY (EA04)

have a break?

No

Is the COAG SHUTTER ASSY positioned at

the detectable area of the sensor?

Yes

Is the voltage between the 3rd and 7th, 4th

and 7th pins of P106 (J106) on the MASTER

BOARD approximately + 1.3 DVC?

Yes

No

No

Yes

No

No

Connect the REMOTE connector.

Repair the faulty point between the 3rd and 4th

pins of the REMOTE connector, or replace the

REMOTE connector.

Repair or replace the COAG SHUTTER ASSY

(EA04). (See “6.4”.)

Perform the position adjustment of the COAG

SHUTTER ASSY.

Replace the COAG SHUTTER ASSY (EA04).

(See “6.4”.)

Is the voltage of P106 (J106) on the

MASTER BOARD as follows when the

COAG shutter is closed?

TP17: 5 V

TP18: 0 V

Yes

Is the voltage of P106 (J106) on the

MASTER BOARD as follows when the

COAG shutter is open?

TP17: 0 V

TP18: 5 V

Yes

Replace the MASTER BOARD.

No

No

Repair or replace the COAG SHUTTER ASSY

(EA04). (See “6.4”.)

Repair or replace the COAG SHUTTER ASSY

(EA04). (See “6.4”.)

Page 52

4.5 Error 3 appears.

4 - 3

Does the AIMING SHUTTER ASSY (EA03)

have a break?

No

Is the AIMING SHUTTER ASSY positioned

at the detectable area of the sensor?

Yes

Is the voltage between the 3rd and 5th, 6th

and 5th pins of P107 (J107) on the MASTER

BOARD approximately + 1.3 DVC?

Yes

Is the voltage of P107 (J107) on the

MASTER BOARD as follows when the

aiming beam is OFF?

4th - 5th pins: 5 V

7th - 5th pins: 0 V

Yes

Is the voltage of P107 (J107) on the

MASTER BOARD as follows when the

aiming beam is ON?

4th - 5th pins: 0 V

7th - 5th pins: 5 V

Yes

No

No

No

No

Repair or replace the AIMING SHUTTER

ASSY (EA03). (See 6.6.)

Perform the position adjustment of the AIMING

SHUTTER ASSY.

Replace the AIMING SHUTTER ASSY (EA03).

(See 6.4.)

Repair or replace the AIMING SHUTTER

ASSY (EA03). (See 6.6.)

Repair or replace the AIMING SHUTTER

ASSY (EA03). (See 6.6.)

Yes

Replace the MASTER BOARD.

4.6 Error 13 appears.

Disconnect P113 (J113) on the MASTER

BOARD. Is the circuit between the 1st and

3rd pins of P113 on the TRANSISTOR

ASSY short-circuited?

No

Disconnect P114 (J114) on the MASTER

BOARD. Is the circuit between the 1st and

3rd pins of P114 on the TRANSISTOR

ASSY short-circuited?

No

Replace the MASTER BOARD. (See 6.15.)

Yes

Yes

Replace the TRANSISTOR ASSY. (See 6.7.)

Replace the TRANSISTOR ASSY. (See 6.7.)

Page 53

4 - 4

4.7 Error 20 appears.

Does the LH CABLE ASSY have a break?

No

Disconnect P123 (J123) on the MASTER

BOARD. Is the resistance between the 1st

and 2nd pins of P123 of the LH CABLE

ASSY 6 - 12 KΩ?

Yes

Replace the MASTER BOARD. (See 6.15.)

Is the symptom improved?

Yes

Completion of operation

4.8 Error 21 appears.

Yes

No

No

Repair or replace the LH CABLE ASSY.

Replace the laser head. (See 6.16.)

Replace the laser head. (See 6.16.)

Does the LH CABLE ASSY have a break?

No

Disconnect P123 (J123) on the MASTER

BOARD. Is the resistance between the 3rd

and 2nd pins of P123 of the LH CABLE

ASSY 8 - 12.5 KΩ?

Yes

Replace the MASTER BOARD. (See 6.15.)

Is the symptom improved?

Yes

Completion of operation

Yes

No

No

Repair or replace the LH CABLE ASSY.

Replace the laser head. (See 6.16.)

Replace the laser head. (See 6.16.)

Page 54

4.9 Error 54 appears.

4 - 5

Can the FIBER SW be turned ON when the

fiber optic cable plug is connected?

Yes

Is electricity applied between the 2nd and 3rd,

5th and 6th pins of P105 when the micro

switch of the FIBER SW ASSY (EA01) is

turned ON?

Yes

Disconnect P105 (J105) on the MASTER

BOARD. Is the voltage of J105 as follows?

2nd - 3rd pins: 5 V

5th - 6th pins: 5 V

Yes

Completion of operation

No

No

No

Perform the position adjustment of the FIBER

SW.

Replace the MASTER BOARD. (See 6.15.)

4.10 Any error in the 90s appears.

Replace the FIBER SW ASSY (EA01).

(See 6.8.)

Replace the MAIN CPU (17164-E150) and SUB CPU (17164-E160). (See 6.9.)

Page 55

4 - 6

4.11 INTERLOCK 4.7 appears.

Does the fan work?

Yes

Does any object block the air vent of the

instrument?

Yes

Is the temperature of the room within the

specified range (10 - 30℃) for usage?

Yes

Leave the instrument for 30 minutes or longer

for natural cooling.

Can the instrument be used without

INTERLOCK 4.7 when restarting the

instrument?

Yes

The instrument is normal.

Although INT4.7 appeared because the

temperature of the instrument temporarily

rose. The temperature of the instrument has

lowered now and the instrument can be used.

No

No

No

No

Check the articles described in “4.2 The fan does

not work.” (See “4.2”.)

Move the object which blocks the air vent, or

move the instrument.

Make the temperature of the room the same as

the specified.

Replace the MASTER BOARD. (See 6.15.)

4.12 The coagulation power cannot be changed.

Turn OFF the key switch. After the

indications of the control box go off, turn ON

the key switch again.

Is the voltage between the 16th and 18th, 17th

and 19th pins of P108 (J108) of the

MASTER BOARD 5 V?

Yes

Does the CB CABLE ASSY (EA13) have a

faulty soldering or break?

No

Replace the MASTER BOARD. (See 6.15.)

No

Yes

Replace the MASTER BOARD. (See 6.15.)

Repair or replace the CB CABLE ASSY.

(See 6.10.)

Page 56

4 - 7

4.13 The coagulation time cannot be changed.

Check and perform the articles described in 4.12.

4.14 The brightness of the aiming beam cannot be changed.

Check and perform the articles described in 4.12.

4.15 The aiming beam is invisible.

Does the aiming shutter block the optical

path?

No

Is the voltage between the TP12 and GND on

the MASTER BOARD 1.2 V, and is the

aiming beam emitted from the AIMING LD

ASSY (EA02)?

Yes

Can the aiming beam be seen by turning VR1

on the MASTER BOARD clockwise?

Yes

Adjust the power output of the aiming beam.

(See 7.6.2.)

Yes

No

No

Adjust the operation of the AIMING SHUTTER

ASSY.

Replace the AIMING LD ASSY. (See 6.11.)

Replace the MASTER BOARD. (See 6.15.)

4.16 The interval time cannot be changed.

Check and perform the articles described in 4.12.

4.17 The READY indicator does not light up.

Check and perform the articles described in 4.12.

4.18 The counter cannot be reset.

Check and perform the articles described in 4.12.

Page 57

4 - 8

4.19 Error 2 appears.

Is the connector of the delivery unit

connected to P702 (J702) on the DELIVERY

BOARD (17621-E4965)?

Yes

Does the delivery setting of the main body

coincide with the connected delivery unit?

Yes

Does the DELIVERY BOARD ASSY

(EA08) have a break?

No

Is the voltage of P104 (J104) on the

MASTER BOARD as follows?

11th - 12th pins: About + 15 V

Yes

Is the voltage of TP on the MASTER

BOARD as follows?

TP14: 0 V

TP15: 5 V

Yes

No

No

Yes

No

No

Connect the connector of the delivery unit to

P702 (J702) on the DELIVERY BOARD.

Select the proper delivery setting of the main

body.

Repair or replace the DELIVERY BOARD

ASSY (EA08). (See 6.12.)

Replace the MASTER BOARD. (See 6.15.)

The delivery unit malfunctions. (Refer to the

Service Manual of the delivery unit.)

Is the voltage of TP on the MASTER

BOARD as follows when the filter is open?

TP14: 5 V

TP15: 0 V

Yes

Replace the MASTER BOARD. (See 6.15.)

No

The delivery unit malfunctions. (Refer to the

Service Manual of the delivery unit.)

Page 58

4.20 Error 53 appears.

4 - 9

Does the FOOT SW ASSY (EA11) have a

break?

No

Does Err.53 occur when depressing the foot

switch slowly?

No

Is electricity applied between the 1st and 4th,

3rd and 4th pins of P101 (J101) on the

MASTER BOARD when the foot switch is

depressed?

Yes

Replace the MASTER BOARD. (See 6.15.)

Yes

Yes

No

4.21 Error 55 appears.

Check and perform the articles described in 4.19.

Repair or replace the FOOT SW ASSY (EA11).

Adjust the switch in the foot switch.

Replace the foot switch (10149-0000).

4.22 INTERLOCK 2.7 appears.

Does the 1st MONITOR of the POWER

MONITOR ASSY (EA05) have a break?

No

Measure the actual power output at the

aperture of the delivery unit. Is the measured

power output within the specified range?

[Specified power]

90 mW or less: ±20%

100 mW or more: ±15%

No

Perform the adjustment for the overpower.

(See 7.6.3.)

Is the symptom improved? Completion of operation

No

Replace the MASTER BOARD. (See 6.15.)

Yes

Yes

Yes

Repair or replace the POWER MONITOR

ASSY (EA05).

Adjust the power output at the aperture of the

delivery unit until it becomes within the

specified range. (See 7.6.1.)

Page 59

4 - 10

4.23 Error 10 appears.

Does the LD CABLE ASSY (EA19) have a

break?

No

Does the POWER MONITOR ASSY (EA05)

have a break?

No

Replace the laser head. (See 6.16.)

4.24 Error 15 appears.

Does the 2nd MONITOR of the POWER

MONITOR ASSY (EA05) have a break?

No

Measure the power output at the aperture of

the delivery unit. Is the actual power output

within the specified range?

[Specified power]

90 mW or less: ±20%

100 mW or more: ±15%

Yes

Yes

Yes

Yes

Repair or replace the LD CABLE ASSY

(EA19). (See 6.13.)

Repair or replace the POWER MONITOR

ASSY (EA05). (See 6.13.)

Replace the POWER MONITOR ASSY.

(See 6.13.)

Perform the adjustment for overpower.

(See 7.6.3.)

No

Adjust the power output at the aperture of the

delivery unit until it becomes within the

specified range. (See 7.6.1.)

Measure the power output at the aperture of

the delivery unit. Is the power output

adjusted so that it becomes within the

specified range?

Yes

Perform the adjustment for overpower.

(See 7.6.3.)

Is the symptom improved?

No

Replace the MASTER BOARD. (See 6.15.)

No

Yes

Replace the laser head. (See 6.16.)

Completion of operation

Page 60

4.25 The power output is out of the specified range.

4 - 11

Is the laser alignment for the fiber optic cable

proper?

No

Does the burn pattern have any unburnt area?

No

Is the transparency of the fiber optic cable

90% or more?

Yes

Adjust the coagulation power output.

(See 7.6.1.)

Is the power output too high?

No

Is the power output too low?

No

Yes

Yes

No

Yes

Yes

Perform the laser alignment for the fiber optic

cable properly.

(See 7.5.5.)

Replace the fiber optic cable or laser head.

(See 6.16.)

Replace the fiber optic cable.

Replace the MASTER BOARD. (See 6.15.)

Replace the laser head. (See 6.16.)

Completion of operation

4.26 When the spot size is set to 50µm, the power output is

out of the specified range.

Adjust the power output when the spot size is set to 50µm. (See 7.6.1.)

Page 61

4 - 12

4.27 The emergency stop switch cannot be activated.

Is electricity between the 3rd and 4th, 5th and

6th pins of P301 of the EMERGENCY SW

ASSY (EA21) as follows?

EMERGENCY SW is ON: Not applied

EMERGENCY SW is OFF: Applied

Yes

No

Repair or replace the EMERGENCY SW ASSY

(EA21). (See 6.14.)

Does the CB CABLE ASSY (EA13) have

faulty soldering?

No

Replace the MASTER BOARD. (See 6.15.)

Yes

Repair or replace the CB CABLE ASSY.

(See 6.10.)

Page 62

7.5 Optical adjustment

7 - 7

7.5.1 Optical axis adjustment of green laser

1. Remove the following parts of the

CONDENSER ASSY (17164-1700)

according to the right figure.

(a) Mount (17164-M110)

(b) Receptacle (17164-M107)

(c) Plate (17164-M111)

(d) Pin (17164-M115)

(e) Base (17164-M105)

(f) Spring (17164-M109)

2. Connect the clamp tester to the 2 BRN cables

of J117 (+5V PS ASSY: 17164-EA16) on the

MASTER BOARD (17164-BA01). Set DIP

SW No. 6 on the CB (17164-BA03) to the

OFF position, and turn ON the master and

key switches.

3. Set the power meter (COHERENT, Model

201) to the laser beam window (receptacle

of the main body).

5$

%-

%-

4. Adjust the current by pressing the POWER

switch on the CB so that the clamp tester

reads the same current as the one (2.5W) in

the Shipping Record when emitting the laser.

At the same time, verify that the power meter

reads 2.3W or more.

5. Attach the near point optical axis calibration

jig (19344-M910) to the attached position of

the receptacle (17164-M107).

6. Loosen SB3×12 (n=6) (illustrated on the right

figure), and adjust the vertical and

horizontal positions so that the optical axis

of the green laser coincides with the center

of the near point optical axis calibration jig.

5$

Vertical position adjustment

Horizontal position adjustment

5$

Page 63

7 - 8

7.5.2 Optical axis adjustment of aiming beam

1. Loosen HH3×6 and turn the LD (17164EA02) to adjust the optical axis of the aiming

beam so that the shape of the aiming beam

becomes lateral as illustrated on the right

when matching the aiming beam position to

the near point optical axis calibration jig

(19433-M910).

* The optical axis adjustment of the aiming

**

beam described above is a rough adjustment.

7.5.2.1 Near point confocal adjustment

1. Follow the instructions below to adjust the LD ASSY (17164-1600) so that the optical axis

of the aiming beam coincides with the center of the near point optical axis calibration jig

(19433-M910) and so it coincides with the green laser coaxially.

(1) Loosen SB3×8 (n=2) and adjust the

horizontal position of the LD ASSY (17164-

1600) at the position of the base (17164M088).

(2) Loosen SB3×12 (n=2) and adjust the vertical

position of the LD ASSY (17164-1600).

(3) Fasten and unfasten SB3×15 (n=4), and

finely adjust the vertical and horizontal

position of the LD ASSY (17164-1600).

Turn the LD.

5$

.

The shape of the AIMING beam is lateral.

5$

5$

7.5.2.2 Far point confocal adjustment

1. Emit the laser to a wall that is 1m or more away from the instrument. Follow the instructions

below to adjust the DICHROIC ASSY (17164-1400) so that the aiming beam coincides

with the green laser coaxially.

**

(1) Loosen SB3×10 (n=2) and move the

DICHORIC ASSY horizontally, forward and

backward to adjust the position of the

DICHORIC ASSY (17164-1400) with the

play of the screw.

(2) Loosen SB2×5 (n=2), and fasten and

unfasten HH3×6 (n=2) to adjust the

horizontal position of the DICHORIC ASSY

(17164-1400).

(3) Fasten and unfasten HH3×6 and SB3×12 to

adjust the vertical position of the

&+%*14+%#55;

DICHORIC ASSY (17164-1400).

2. Perform the near point (see 7.5.2.1) and far point confocal adjustment repeatedly so that

the aiming beam coincides with the green laser coaxially at the near point and far point.

**

5$

5$

5$

Page 64

7 - 9

7.5.3 1W and 1V adjustment

1. Remove the parts of the CONDENSER ASSY (17164-1700) that are the same as the parts

removed in 7.5.1. (See 7.5.1.)

* Before removing the parts, verify that the optical axis of the green laser coincides with the

center of the near point optical axis calibration jig (19433-M910). (See 7.5.1.)

2. Turn OFF the master and key switches. Connect the oscilloscope between TP8 and TP9,

and turn ON the master and key switches.

3. Press the POWER switch on the CB to set the laser power so that the power at the end of

the laser becomes 1000mW when emitting the laser.

4. Follow the instructions below to adjust the voltage so that the voltage of TP8 and TP9

becomes 1V when emitting the laser.

(a) Voltage of TP8: Adjust it with VR6 on the MASTER BOARD (17164-B01).

(b) Voltage of TP9: Adjust it with VR3 on the MASTER BOARD (17164-BA01).

* If the voltage cannot be adjusted to 1V, remove the MONITOR ASSY (17164-1200) from the

bench (17164-M001), insert 3PW3 (n=2) between the MONITOR ASSY (17164-1200) and

bench (17164-M001), and adjust the position of the MONITOR ASSY (17164-1200). Then,

check the voltage again.

5. Set DIP SW No. 1 and 2 on the CB (17164-BA03) to the OFF position.

6. Connect the oscilloscope to TP8 on the MASTER BOARD (17164-BA01).

7. Verify that the waveform of TP8 by the oscilloscope does not have any overshooting, noise

etc. when emitting the laser at the POWER of 500mW and 50mW.

8. Set DIP SW No. 1 and 2 on the CB (17164-BA03) to the ON position.

7.5.4 Condenser adjustment

1. Attach the receptacle (17164-M107) that was

removed in the green laser optical axis

adjustment. (See 7.5.1.)

2. Set the power meter (COHERENT Model

201) in front of the laser beam window of

the main body. Press the POWER switch

on the CB to adjust the laser power so that

the power meter reads 500mW. Take notes

of the measured power and the power on the

POWER display of the CB.

3. Connect the condensed laser magnification

jig (19344-9100) to the FIBER connector

(receptacle: 17164-M107) of the main body.

4. Loosen SB3×12 and lock rings (17162-M070, n=2) of the adjustment screws (17164-M112,

n=2).

5. First, lower the laser power by pressing the POWER switch, then gradually increase it

until the laser slightly lights up.

6. Emit the laser and turn the adjustment screws (17164-M112, n=2) so that the position of

the green laser coincides with the center of the condensed laser magnification jig (19433-

9100).

7. Connect the fiber optic cable to the base (17164-M105) and FIBER connector of the main

body (receptacle: 17164-M107) together with the condenser. Set the power meter to the

end of the fiber optic cable.

8. Set the POWER of the CB to the same power as in step 2.

5$

%-

5$

Page 65

7 - 10

9. Emit the laser and follow the instructions

;CZKU

below to adjust the adjustment screw of each

axis and holder so that the power meter reads

the maximum power.

(1) Turn the adjustment screw for the X axis

(17164-M112) to adjust its position so that

the power meter reads the maximum power.

(2) Turn the adjustment screw for the Y axis

(17164-M112) to adjust its position so that

the power meter reads the maximum power.

(3) Push and draw out the holder to adjust its

position so that the power meter reads the

maximum power.

(4) Repeat steps (1) to (4).

10.

Emit the laser and verify that the power measured by the power meter is 90% or more of

the power obtained in step 2.

* If it is not, perform step 9 again.

11.

Make the fiber optic cable turn one rotation at 90 degree intervals. Verify that the measured

power at every 90 degrees is 90% or more of the power obtained in step 10.

* If it is not, perform step 9 again.

12.

Screw SB3×12 and lock rings (17162-M070) of the adjustment screws (17164-M112). Then,

perform steps 10 and 11 again.

13.

After the condenser adjustment is completed, reassemble the plate (17164-M111), pin

(17164-M115), mount (17164-M110) and spring (17164-M109).

:CZKU

7.5.5 Laser alignment for the fiber optic cable

* Follow the instructions below to perform the laser alignment for the fiber optic cable only

when the laser alignment for the fiber optic cable has shifted.

1. Loosen SB3×12 and lock rings (17164-M070). (See 7.5.4.)

2. Attach the fiber optic cable to the CONDENSER ASSY (17164-1700), set the laser power

output to 500mW and emit the laser onto a wall etc.

3. Turn the adjustment screws for the X and Y

axes (17164-M112) so that the periphery of

Center of the laser beam

the burn pattern on the wall etc. fades out

(lightly burnt).

4. Set the power meter to the end of the fiber

optic cable.

5. Turn the adjustment screws for the X and Y

axes (17164-M112) to adjust the position so

that the power meter reads the maximum.

6. Perform step 5 repeatedly to adjust the

position finely so that the power meter reads

the maximum laser power.

7. Make the fiber optic cable turn one rotation at 90 degree intervals. Verify that the measured

power at every 90 degrees is 90% or more of the power obtained in step 6.

8. Tighten SB3×12 and the lock rings (17164-M112) of the adjustment screws. Then, perform

step 7 and verify that the measured power is 90% or more.

* If it is not, repeat steps 5 to 8.

Periphery of the

burn pattern

Page 66

7 - 11

7.6 Total adjustment

7.6.1 Adjustment of the light control

1. Set DIP SW No. 1 and 2 on the CB to the OFF position, and No. 3 to 8 to the ON position.

2. Detach the fiber optic cable and set the value of parameter address 24 to “100”. (See 7.1.)

3. Attach the fiber optic cable and set the power meter (COHERENT Model 201) to the end

of the fiber optic cable.

4. Follow the instructions below to adjust the POWER display of the CB and the power

measured by the power meter when the POWER display of the CB is 50mW and 500mW.

At the power of 500mW: Adjust the value with VR3 on the MASTER BOARD (17164-BA01).

At the power of 50mW: Adjust the value with parameter address 18.

* Firstly, perform the adjustment at the power of 500mW. Then, perform the adjustment both

at the power of 500mW and 50mW so that the POWER display of the CB and the measured

power do not shift.

5.

Turn OFF the key switch and attach the fiber optic cable of each delivery unit to the main body.

6. Set the power meter (COHERENT Model 201) to each delivery unit.

7. Measure the power output of each delivery unit when the POWER display of the CB is

500mW. Follow the instructions below to adjust the power so that the measured power

becomes 500mW ± 15%.

(1) Set DIP SW No. 6 of the CB to the OFF position.

(2) Change the parameters below. (See 7.1.)

SL-130 delivery unit : Parameter address 20

SL-1600/30SL delivery unit : Parameter address 21

Other delivery units : Parameter address 23

ENDO delivery unit : Parameter address 24

BIO delivery unit : Parameter address 26

HAAG delivery unit : Parameter address 27

COMBO delivery unit : Parameter address 28

(3) Set DIP SW No. 6 of the CB to the ON position.

(4) Measure the power output again, repeat steps

(1) to (4) until the power output becomes

500mW ± 15%.

* Set the spot size of each delivery unit to

the maximum.

* If the power output is 500mW ± 15%, it

is not necessary to change the parameters.

8. Measure the power output when the POWER

display of the CB is 100 to 1700mW.

9. Adjust the power output with the parameter

addresses 30 to 46 as in the right table so

that the power output becomes 100 1700mW ± 15%. (See 7.1.)

* Set the spot size of each delivery unit to the

maximum.

Power of the fiber

optic cable

At 100mW 30

At 200mW 31

At 300mW 32

At 400mW 33

At 500mW 34

At 600mW 35

At 700mW 36

At 800mW 37

At 900mW 38

At 1000mW 39

At 1100mW 40

At 1200mW 41

At 1300mW 42

At 1400mW 43

At 1500mW 44

At 1600mW 45

At 1700mW 46

Address

Page 67

7 - 12

10.

Measure the power output when the POWER display of the CB is 50mW, and adjust it

with parameter address 18 so that it becomes 50mW ± 20%. (See 7.1.)

11.

Set the spot size of each delivery unit to the minimum, and measure the power output

when the POWER display of the CB is 50mW.

12.

Adjust the power output with the parameter addresses below so that the measured power

becomes 500mW ± 15%. (See 7.1.)

SL-1600/30SL delivery unit : Parameter address 80

SL130 delivery unit : Parameter address 81

HAAG delivery unit : Parameter address 82

13.

Verify that the power output is within the specified range for all conditions (spot size,

POWER display of the CB).

14.

Compensate for a shift in the power output according to the spot size by changing the

parameter values finely until the power output becomes within the specified range.

15.

Set the POWER display of the CB to 1700mW. Verify that the rising voltage of TP8 is

within the range of the stable voltage ± 20% when depressing the foot switch.

16.

After the adjustment is completed, set all the DIP switches of the CB (17164-BA03) to the

ON position.

7.6.2 Power adjustment of the aiming beam

1. Set the power meter (LASER MATE Q 0217-050-00) to the delivery unit, and multimeter

between TP12 on the MASTER BOARD (17164-BA01) and GND. Set the AIMING display

of the CB and the spot size of each delivery unit to the maximum.

2. Adjust the optical axis of the aiming beam again while checking the power meter so that

the power of the aiming beam becomes the maximum. (See 7.6.2.)

3. Adjust the power with VR1 on the MASTER BOARD (17164-BA01) so that the power

output of the aiming beam becomes 0.3mW.

4. Verify that the voltage (obtained by the multimeter) between TP12 on the MASTER

BOARD (17164-BA01) and GND is 1V or less.

* The voltage is normally about 0.5V or so.

5. Set the AIMING display of the CB to the minimum. Change the value of parameter

address 19 so that the power output of the aiming beam becomes 0.01mW or less. (See

7.1.)

6. Set the AIMING display of the CB to the minimum again. Verify that the power output of

the aiming beam is 0.3mW. If not, perform steps 3 to 5.

7. Turn the fiber optic cable 360 degree and verify that the power varies within the range of

± 10%.

8. A shift in the POWER according to the spot size can be compensated for with the parameter.

9. Measure the power output of the aiming beam when the spot size is set to the maximum

and minimum. Verify that the power output of the aiming beam is within the specified

range for all conditions.

Page 68

7 - 13

7.6.3 Adjustment for overpower

7.6.3.1 Adjustment at 1000mW

1. Set DIP SW No. 1, 2 of the CB to the OFF and No. 3 to 8 to the ON position.

2. Turn OFF the master and key switches. Set the oscilloscope by following the instructions

below and turn ON the master and key switches.

CH1: TP4 on the MASTER BOARD (17164-BA01)

CH2: IC1 77th pin on the MASTER BOARD (17164-BA01)

3. Set the value of parameter address 57 to “9”.

(See 7.1.)

4. Emit the laser at the POWER of 50mW and

observe the waveform with the oscilloscope.

Verify that the time-lag between CH1 and

CH2 (when the signal becomes high) is 7

msec. or less.

* Perform steps 3 and 4 only for the program Ver. 1.00.

5. Turn OFF the master and key switches. Set the oscilloscope by following the instructions

below, and turn ON the master and key switches.

CH1: TP9 on the MASTER BOARD (17164-BA01)

CH2: TP8 on the MASTER BOARD (17164-BA01)

6. Set the POWER display of the CB to “1000mW” and turn VR6 on the MASTER BOARD

(17164-BA01) to match the TP8 voltage with the TP9 voltage when emitting the laser.

* The TP9 voltage is fixed.

7. Set the POWER display of the CB to

“1000mW”. While emitting the laser, turn

VR6 on the MASTER BOARD (17164BA01) so that the TP8 voltage becomes the

TP9 voltage + 20%. Adjust the value of

parameter address 55 so that INTLK 2.7

(only a beep) occurs at that time. (See 7.1.)

8. Set the POWER display of the CB to

“1000mW”. While emitting the laser, turn

VR6 on the MASTER BOARD (17164BA01) so that the TP8 voltage becomes the

TP9 voltage -20%. Adjust the value of

parameter address 58 so that Err. 15 (only a

beep) occurs at that time. (See 7.1.)

9. Turn VR6 on the MASTER BOARD (17164-

BA01) to match the TP8 voltage with the TP9

voltage when emitting the laser.

10.

Set all DIP switches of the CB (17164-BA03)

to the ON position.

%*

%*

OUGEQTNGUU

+06.-QEEWTU

62XQNVCIG

62XQNVCIG

62XQNVCIG

62XQNVCIG

62XQNVCIG

62XQNVCIG

'TTQEEWTU

Page 69

7 - 14

7.6.3.2 Adjustment at 50mW

1. Set DIP SW No. 1, 2 of the CB (17164-BA03) to the OFF and No. 3 - 8 to the ON position.

2. Turn OFF the master and key switches. Set the oscilloscope to the terminals below and

turn ON the master and key switches.

CH1: TP5 on the MASTER BOARD (17164-BA01)

CH2: TP4 on the MASTER BOARD (17164-BA01)

3. Turn VR6 on the MASTER BOARD (17164-BA01) to match the TP4 voltage with the TP5

voltage when emitting the laser.

* The TP5 voltage on the MASTER BOARD (17164-BA01) is fixed.

4. Set the POWER display of the CB to

“50mW”. While emitting the laser, turn VR6

on the MASTER BOARD (17164-BA01) so

that the TP4 voltage becomes the TP5 voltage

+ 20%. Adjust the value of parameter

address 56 so that INTLK 2.7 (only a beep)

occurs at that time. (See 7.1.)

62XQNVCIG

62XQNVCIG

62XQNVCIG

+06.-QEEWTU

5. Set the POWER display of the CB to

“50mW”. While emitting the laser, turn VR6

on the MASTER BOARD (17164-BA01) so

that the TP4 voltage becomes the TP5 voltage

-20%. Adjust the value of parameter address

59 so that Err. 15 (only a beep) occurs at that

time. (See 7.1.)

6. Turn VR6 on the MASTER BOARD (17164BA01) to match the TP4 voltage with the TP5

voltage when emitting the laser.

7. Set all DIP switches of the CB (17164-BA03)

to the ON position.

62XQNVCIG

62XQNVCIG

62XQNVCIG

'TTQEEWTU

Page 70

7 - 15

7.6.4 Check of overpower

1. Set all DIP switches of the CB to the ON position.

2. Turn OFF the master and key switches. Set the oscilloscope by following the instructions

below and turn ON the master and key switches.

CH1: TP9 on the MASTER BOARD (17164-BA01)

CH2: TP8 on the MASTER BOARD (17164-BA01)

62XQNVCIG

3. Set the POWER display of the CB to

“1000mW”. While emitting the laser, turn

VR6 on the MASTER BOARD (17164BA01) so that the TP8 voltage becomes the

TP9 voltage -20%. Verify that Err. 15 occurs

(laser emission is OFF, as well) at that time.

4. Set the POWER display of the CB to

“1000mW”. While emitting the laser, turn

VR6 on the MASTER BOARD (17164BA01) so that the TP4 voltage becomes the

TP5 voltage + 20%. Verify that INTLK 2.7

occurs (laser emission is OFF, as well) at that

time.

5. Turn OFF the master and key switches. Set

the oscilloscope to the terminals below and

turn ON the master and key switches.

CH1: TP5 on the MASTER BOARD (17164-BA01)

CH2: TP4 on the MASTER BOARD (17164-BA01)

62XQNVCIG

62XQNVCIG

'TTQEEWTU

+06.-QEEWTU

62XQNVCIG

62XQNVCIG

62XQNVCIG

6. Set the POWER display of the CB to

“50mW”. While emitting the laser, turn VR6

on the MASTER BOARD (17164-BA01) so

that the TP4 voltage becomes the TP5 voltage

+ 20%. Verify that INTLK 2.7 occurs (laser

emission is OFF, as well) at that time.

7. Set the POWER display of the CB to

“50mW”. While emitting the laser, turn VR6

on the MASTER BOARD (17164-BA01) so

that the TP4 voltage becomes the TP5 voltage

-20%. Verify that Err. 15 occurs (laser

emission is OFF, as well) at that time.

8. Turn VR6 on the MASTER BOARD (17164-

BA01) to match the TP4 voltage when

emitting the laser with the TP5 voltage.

9. After the adjustment is completed, verify with

the oscilloscope that the waveforms at the

powers of 50 - 1700mW match.

+06.-QEEWTU

62XQNVCIG

62XQNVCIG

62XQNVCIG

62XQNVCIG

62XQNVCIG

62XQNVCIG

'TTQEEWTU

Page 71

7 - 16

7.6.5 Adjustment of the COAG TIME and REPEAT TIME

1. Set the analyzing recorder (Model 3565) to the instrument.

2. Set the POWER display of the CB to “250mW” and TIME display to “0.01 sec”.

3. Emit the laser and adjust the value of parameter address 52 so that the measured value

(COAG TIME) by the analyzing recorder becomes 0.01 sec. (See 7.1.)

4. Verify that the COAG TIME is within the specified range when the TIME display of the

CB is set to 0.02 - 3.00 sec.

[Specification of COAG TIME]

0.01 - 0.09 sec: TIME display of the CB ± 20%

0.10 - 3.00 sec: TIM display of the CB ± 10%

5. Set the REPEAT TIME display of the CB to “0.1 sec”.

6. Emit the laser and adjust the value of parameter address 53 so that the measured value

(REPEAT TIME) by the analyzing recorder becomes 0.1 sec. (See 7.1.)

7. Verify that the REPEAT TIME is within the specified range when the REPEAT TIME

display of the CB is set to 0.2 - 1.0 sec.

Specification of REPEAT TIME: REPEAT TIME display of the CB ± 10%

Page 72

§

8

8.1 Wiring diagram

REFERENCES

Page 73

8 - 2

8.2 Connectors and cables

17164-EA01

17164-EA02

17164-EA03

Page 74

17164-EA04

8 - 3

17164-EA05

17164-EA06

Page 75

8 - 4

17164-EA07

17164-EA08

Page 76

17164-EA09

17164-EA10

8 - 5

17164-EA11

Page 77

8 - 6

17164-EA12

17164-EA13

Page 78

17164-EA14

17164-EA15

8 - 7

17164-EA16

17164-EA17

Page 79

8 - 8

17164-EA18

17164-EA19

17164-EA20

17164-EA21

Page 80

17164-EA22

8 - 9

Page 81

8 - 14

8.5 List of the replacement parts

Name of part Part No.

Switching power supply 17164-E010

MASTER BOARD 17164-BA01

FAN 17164-EA06

COAG SHUTTER ASSY 17164-1310

SENSOR BOARD 17162-BA10

AIMING SHUTTER ASSY 17164-1320

Laser ASSY 17164-1000

LASER HEAD 17164-G001

FIBER SW 17164-EA01

MAIN CPU 17164-E150

SUB CPU 17164-E160

CB CABLE 17164-EA13

AIMING LD 17164-EA02

DELIVERY board 17164-BA08

MONITOR ASSY 17164-1200

EMERGENCY SW 17164-EA21

8.6 Tools

• Set of Phillips screwdrivers

• Set of flat-head screwdrivers

• Blower

• Thin stick (chopstick)

• Hex wrench

• Needle nose pliers

• Nipper

• Wire stripper

• Soldering iron

• Tweezers

•Set of precision screwdrivers

• Industrial screwdriver

• Multimeter

• Oscilloscope

• Lens cleaning paper

• Alcohol solution

• Thread-locking adhesive

• Heat shrinkage tube

• Japanese special paper (Gampi-shi)

• Solder

Page 82

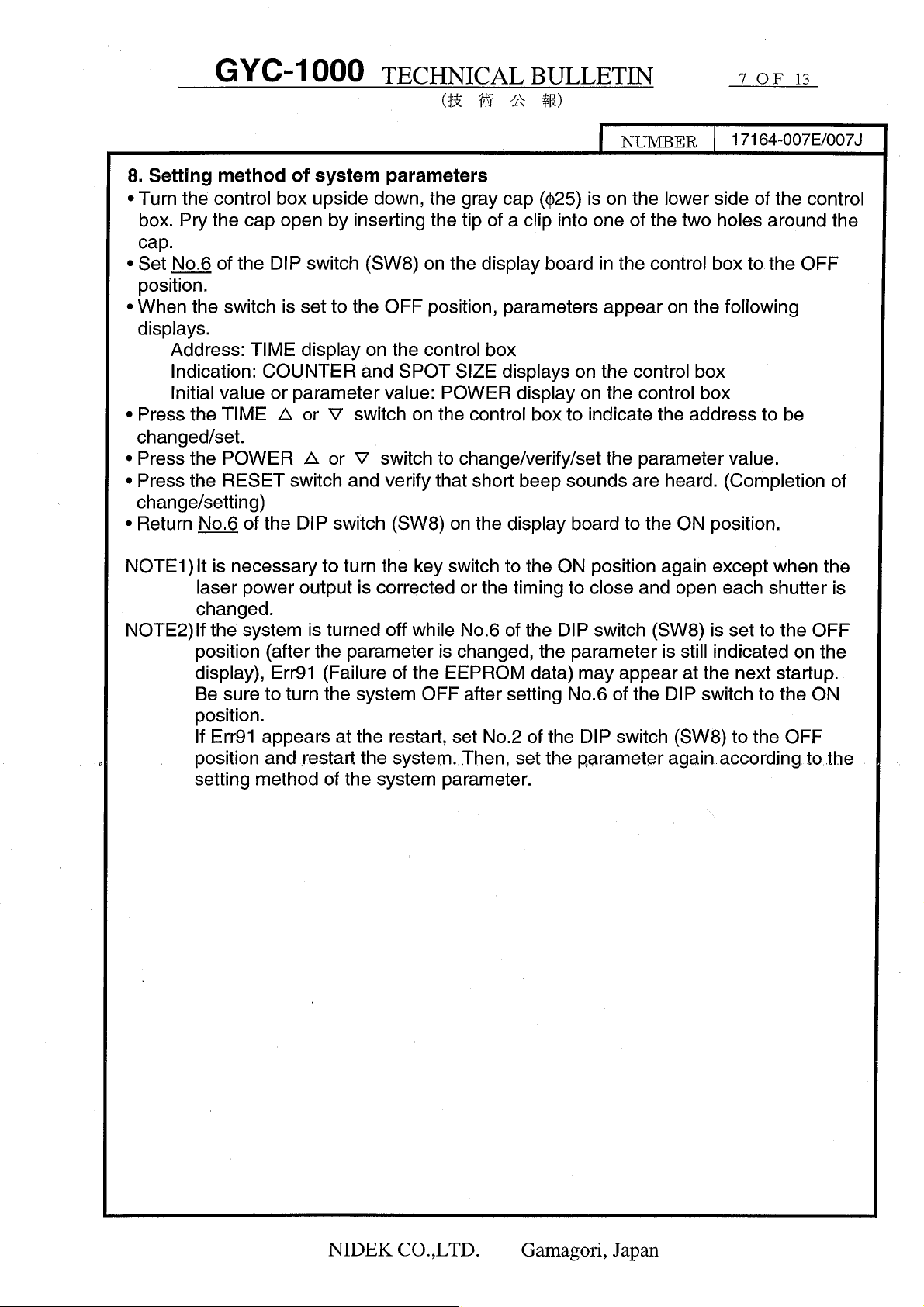

8.7 DIP switches

No. Operation Contents

1 Interlock cancellation Interlock detection is canceled. (However, laser emission is

stopped by hardware when INTLK occurs.)

2 Error cancellation Error detection is canceled

.*1)

3 Not used

4 Switching between Current

and Light modes

Current control mode (OFF) or Light control mode (ON) of laser

emission can be selected.

5 Continuous emission mode Laser emission time can be set to the Continuous mode.

6 Parameter setting mode Each parameter can be set.

7 Not used

8 Service mode Supplied current, etc. to the laser head can be indicated.

*1) To avoid unintended laser emission and deterioration of the laser, Err 13, Err 20 and Err 21

occur even when the error detection is canceled.

8.8 Error code table

Err Symptom Causes Countermeasures

1 The COAG shutter

does not work

properly.

2 The motorized

protective filter does

not work properly.

3 The safety shutter

does not work

properly.

10 The laser goes out. Deterioration of the green laser Replace the laser.

13 L/D driving circuit is

abnormal.

15 Power output is

unstable.

20 L/D temperature is

abnormal.

21 Temperature of the

green laser head is

abnormal.

53 Trigger signal circuit

is abnormal.

54 Fiber optics signal

circuit is abnormal.

55 Motorized protective

filter signal circuit is

abnormal.

90 Program data is

abnormal.

91 EEPROM data is

abnormal.

93 Data error Data in the memory is abnormal. Cancel the error, and input the data

94 KEYLOCK error Improper motion of the program Replace the CPU.

95 SUB CPU error Malfunction of the SUB CPU Replace the SUB CPU.

Malfunction or improper position of

the COAG shutter

Malfunction or improper position of

the motorized protective filter

Malfunction or improper position of

the safety shutter

Failure of the L/D current driving

circuit (Tr1, 2)

Unstable power output of the

green laser

Malfunction of the L/D temperature

controlling unit

Malfunction of the green laser

head temperature controlling unit

Failure of the trigger switch

Broken cable

Failure of the fiber switch

Broken cable

Failed sensor of the motorized

protective filter

Broken cable

Improper setting

Contents of the ROM are

rewritten.

Contents of the EEPROM are

rewritten.

Check the motion of the shutter.

Check the position of the sensor.

Check the motion of the motorized

protective filter.

Check the position of the sensor.

Check the DELIVERY connector.

Check the parameter setting for the

delivery unit.

Check the motion of the shutter.

Check the position of the sensor.

Check the laser control signal cables

P116 to P119.

Check or replace Tr1 and Tr2.

Readjust the detection of underpower.

Repair the broken cable between the

LD sensor and P123.

Repair the failed controlling circuit on

the BA01 board.

Repair the broken cable between the

LH sensor and P123.

Repair the failed controlling circuit on

the BA01 board.

Check for breakage of the foot switch.

Readjust the position of the micro

switch.

Reconnect the fiber optic cable plug.

Check and adjust the position of the

micro switch.

Reconnect the delivery unit to the

DELIVERY connector.

Check and adjust the sensor position of

the motorized protective filter.

Replace the CPU.

Cancel the error, and input the data

again.

again.

8 - 15

Page 83

8 - 16

8.9 INTERLOCK code table

No. Symptom Causes Countermeasures

2.7 Overpower Overpower of the laser Readjust the detection of overpower.

Repair broken cable P118.

Repair the failed BA01 board.

4.7 The system

is heated.

6.3 Remote

interlock is

OFF.

The inside of the system is overheated. Turn OFF the master switch for about 1

hour for cooling.

The remote interlock connector is not

connected, or remote interlock switch is

open.

Connect the remote interlock connector.

8.10 Other messages

Following abbreviated messages appear on the TIME display when the key operation is improper.

Message for

improper operation

A.P. The STATUS switch is pressed when the

aiming beam is OFF.

F.S. The AIMING switch is pressed when the

fiber-optic cable is not connected.

S.U. The AIMING switch, etc. is pressed when

the delivery or delivery mirror is not

positioned where the laser can be

emitted.

S.S. The foot pedal is depressed when the

“STANDBY” indication is lit up.

The foot pedal is depressed when the

motorized protective filter is not set.

The AIMING switch is pressed when a

delivery unit without the motorized

protective filter is connected.

Causes Countermeasures

Turn the aiming beam ON.

Connect the fiber optic cable.

Check the position of the delivery or

delivery mirror.

Press the STATUS switch to change the

indication to “READY”.

Set the protective filter. P. F.

Connect a delivery unit with the

protective filter.

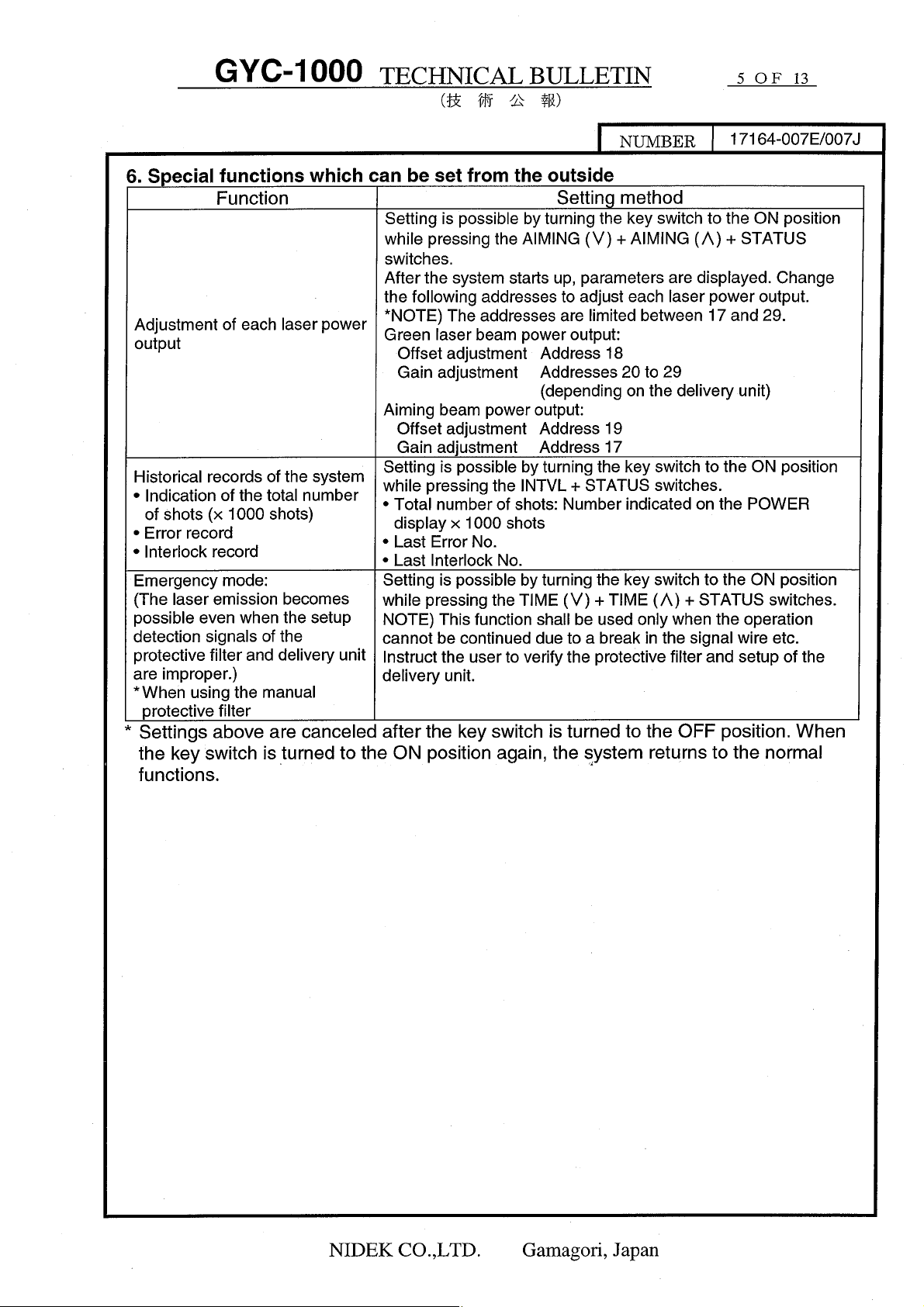

8.11 Special key operations

Function Key operation

Adjusting the laser power

output

Displaying the archival

record of the instrument

Displaying the total shot

numbers

Recording the Error

Recording the Interlock

Emergency mode

(Laser can be emitted

even when the detective

signal for the motorized

protective filter and

delivery unit is improper.)

Turn ON the key switch while holding down the AIMING switches (△, ▽) and

STATUS switch simultaneously. Setting of the laser power output becomes

possible.

Green laser power output

Offset: Address 18

Gain: Address 20 – 29 (It varies according to the delivery unit.)

AIMING laser power output

Offset: Address 19

Gain: Address 17

[NOTE]

Only values of the parameter addresses 17 – 29 can be changed.

Turn ON the key switch while holding down the INTVL and STATUS switches

simultaneously. Every pressing of the RESET switch changes the following

indications.

Total shot numbers: Number on the POWER display × 1000 shots

Latest occurred Error No.

Latest occurred Interlock No.

Turn ON the key switch while holding down the POWER switches (△, ▽) and

STATUS switch simultaneously.

[NOTE]

Use this mode only when operation cannot be continued due to a broken signal

cable, etc.

Give the operator instructions to check the protective filter and proper

installation of the delivery unit adequately.

Page 84

This page is intentionally vacant.

Page 85

* Specifications and design are subject to change without notice for improvement.

HEAD OFFICE : 34-14, Maehama, Hiroishi-cho, Gamagori, Aichi 443-0038, Japan

Telephone: (0533) 67-6611

Facsimile: (0533) 67-6610

TOKYO OFFICE : 6th Floor, Takahashi Bldg., No.2, 3-chome, Kanda-jinboucho

(International Div.) Chiyoda-ku, Tokyo 101-0051, Japan

NIDEK INCORPORATED : 47651 Westinghouse Drive Fremont, California 94539, U. S. A.

NIDEK SOCIÉTÉ ANONYME : Europarc 13, rue Auguste Perret, 94042 CRETEIL, France

(Représentant Autorisé) Telephone: (01) 49 80 97 97

Telephone: (03) 3288-0571

Facsimile: (03) 3288-0570

Telex: 2226647 NIDEK J

Telephone: (510) 226-5700

Facsimile: (510) 226-5750

Facsimile: (01) 49 80 32 08

Loading...

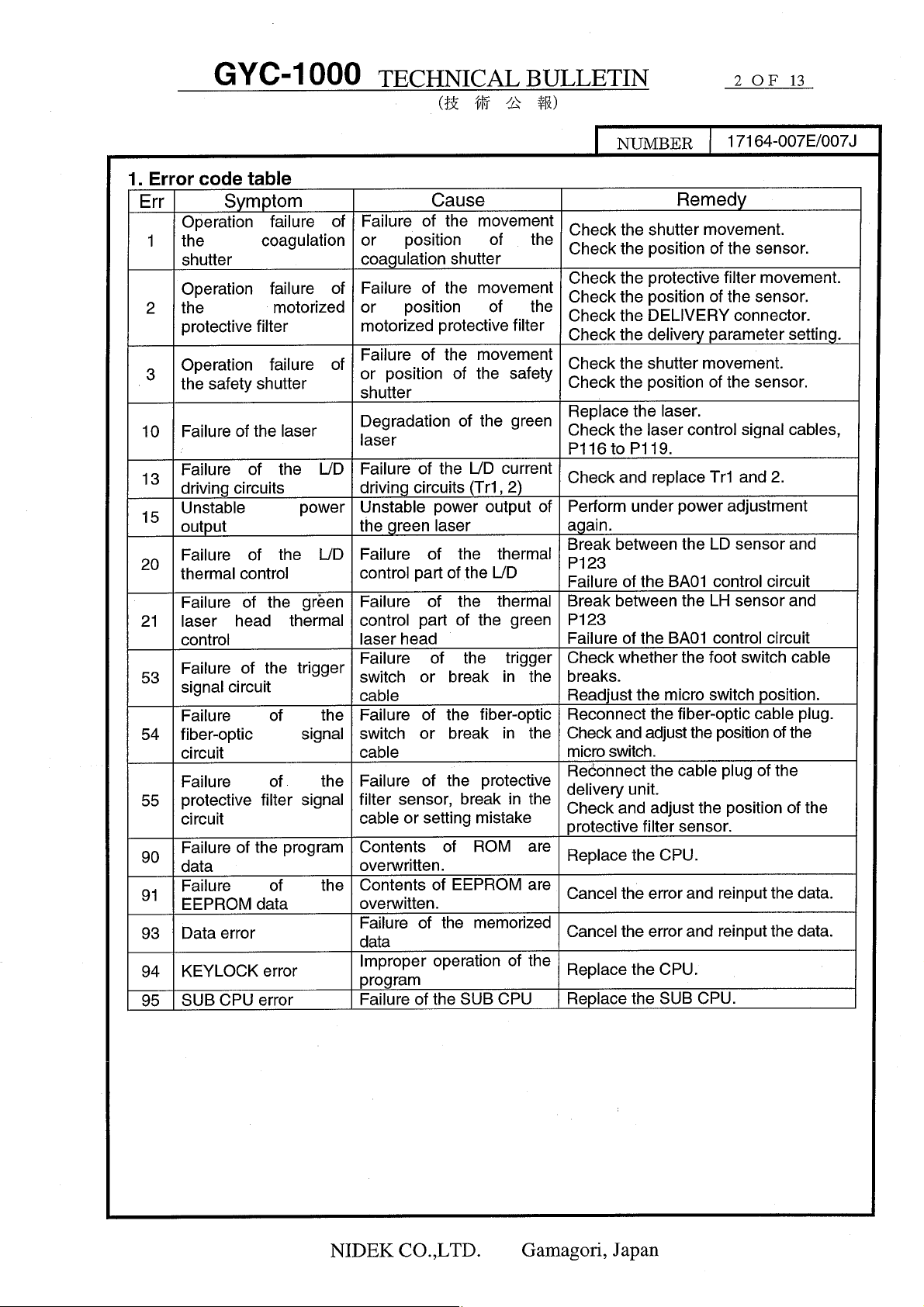

Loading...