Nidek DC-3300 Service manual

NIDEK

LASER DIODE PHOTOCOAGULATOR

Model DC-3300

SERVICE MANUAL

December, 2004

XDC7**RDA001E/E

Total 50 pages

NIDEK CO., LTD. : 34-14, Maehama, Hiroishi-cho, Gamagori, Aichi 443-0038, Japan

(Manufacturer) Telephone: (0533) 67-6611

Facsimile: (0533) 67-6610

NIDEK CO., LTD : 6th Floor, Takahashi Bldg., No.2, 3-chome, Kanda-jinboucho

(Tokyo Office) Chiyoda-ku, Tokyo 101-0051, Japan

Telephone: (03) 3288-0571

Facsimile: (03) 3288-0570

Telex: 2226647 NIDEK J

NIDEK INCORPORATED : 47651 Westinghouse Drive, Fremont, California 94539, U. S. A.

(United States Agent) Telephone: (510) 226-5700

NIDEK SOCIETE ANONYME : Europarc 13, rue Auguste Perret, 94042 CRETEIL, France

(Authorized Representative) Telephone: (01) 49 80 97 97

Facsimile: (510) 226-5750

Facsimile: (01) 49 80 32 08

Table of Content s

§

1 CAUTIONS FOR MAINTENANCE .........................................................................1-1

§

2 TROUBLESHOOTING .............................................................................................. 2-1

§

3 SUB-TROUBLESHOOTING ..................................................................................... 3-1

3.1 The system does not start at all ................................................................................ 3-1

3.2 Fan does not work ....................................................................................................3-3

3.3 Indication on the front panel is not correct...............................................................3-3

3.4 Err. 20 appears..........................................................................................................3-4

3.5 Setting of coagulation power output cannot be changed correctly........................... 3-5

3.6 Setting of coagulation time cannot be changed correctly......................................... 3-5

3.7 Repeat mode cannot be set correctly ........................................................................ 3-5

3.8 Brightness of aiming beam cannot be changed correctly ......................................... 3-5

3.9 Aiming beam cannot be seen....................................................................................3-5

3.10 Err. 3 appears..........................................................................................................3-6

3.11 READY indication does not light up by pressing the STATUS switch.................. 3-7

3.12 STAND BY indication does not light up by pressing the STATUS switch ............ 3-7

3.13 Counter cannot be reset .......................................................................................... 3-7

3.14 Laser beam cannot be emitted ................................................................................ 3-7

3.15 Err. 1 appears..........................................................................................................3-8

3.16 Err. 10 appears........................................................................................................3-9

3.17 Err. 12 appears........................................................................................................3-9

3.18 Err. 13 appears........................................................................................................3-9

3.19 Err. 15 appears........................................................................................................3-9

3.20 Err. 53 appears......................................................................................................3-10

3.21 Err. 54 appears......................................................................................................3-10

3.22 INTLK2.7 appears................................................................................................ 3-11

3.23 INTLK4.7 appears................................................................................................3-12

3.24 Actual power output is low................................................................................... 3-13

3.25 Actual power output is high .................................................................................3-14

3.26 EMERGENCY OFF button does not work .......................................................... 3-14

3.27 Err. 4 appears........................................................................................................3-14

Page

§

4 REPLACEMENT......................................................................................................... 4-1

4.1 Replacement of fuses ...............................................................................................4-1

4.2 Replacement of upper cover..................................................................................... 4-1

4.3 Replacement of lower cover..................................................................................... 4-2

4.4 Replacement of front cover ...................................................................................... 4-2

4.5 Replacement of PS1 .................................................................................................4-3

4.6 Replacement of BA05 (SW BOARD)......................................................................4-3

4.7 Replacement of BA02 (LASER CONTROL BOARD) ........................................... 4-3

4.8 Replacement of BA01 (MASTER BOARD) ........................................................... 4-3

4.9 Replacement of Key control switch ......................................................................... 4-4

4.10 Replacement of EMERGENCY OFF button ......................................................... 4-4

4.11 Replacement of fan.................................................................................................4-5

4.12 Replacement of BA03 (DISPLAY BOARD) ......................................................... 4-5

4.13 Replacement of BA09 (SENSOR BOARD) of safety shutter................................4-6

4.14 Replacement of BA09 (SENSOR BOARD) of coagulation shutter ...................... 4-6

4.15 Replacement of microswitch of CONDENSOR ASSY.........................................4-7

§

5 ADJUSTMENT ............................................................................................................5-1

5.1 Optical adjustment ...................................................................................................5-1

5.1.1 Adjustment of optical axis of aiming beam .................................................... 5-1

5.1.2 Adjustment of fiber alignment ........................................................................5-2

5.1.3 Operation check of coagulation shutter sensor ............................................... 5-3

5.1.4 Operation check of safety shutter sensor.........................................................5-3

5.2 Electrical adjustment ................................................................................................ 5-4

5.2.1 Setting of LASER CONTROL BOARD (BA02)............................................ 5-4

5.2.2 Setting of DISPLAY BOARD (BA03)............................................................ 5-4

5.2.3 Input voltage check ......................................................................................... 5-4

5.2.4 Adjustment of T .E.COOLER .......................................................................... 5-5

5.2.5 COAG STANDBY check................................................................................ 5-5

5.2.6 D/A converter signal check .............................................................................5-5

5.2.7 Current limit check..........................................................................................5-5

5.3 General adjustment................................................................................................... 5-6

5.3.1Current limit adjustment .................................................................................. 5-6

5.3.2 Adjustment of 1/4 wavelength constant position ............................................ 5-6

5.3.3 Overshoot check.............................................................................................. 5-6

5.3.4 Light control adjustment ................................................................................. 5-6

5.3.5 Adjustment of each monitor............................................................................ 5-7

5.3.6 Adjustment of overpower................................................................................ 5-7

5.3.7 Adjustment of each delivery unit ....................................................................5-8

5.3.8 Adjustment of aiming beam ............................................................................ 5-9

5.3.9 Adjustment of COAG TIME .........................................................................5-10

5.3.10 Adjustment of REPEAT TIME....................................................................5-10

Page

§

6 REFERENCES.............................................................................................................6-1

6.1 Wiring diagram (CABLE ASSY) ............................................................................. 6-1

6.2 Tools ......................................................................................................................... 6-2

6.3 Error code list ........................................................................................................... 6-3

6.4 Interlock code list ..................................................................................................... 6-3

6.5 DIP SW function list ................................................................................................6-4

6.6 System parameter .....................................................................................................6-4

6.6.1 Change/Setting method of value of parameter................................................6-4

6.6.2 System parameter list ......................................................................................6-5

§

1

• Be sure to use this manual after reading and understanding the operator’s manual for the DC3300 thoroughly .

• Only properly trained service technicians can repair the system.

• During the repair, any indications are necessary to prohibit the unauthorized persons from

entering the working area and to prevent the accidents such as emitting laser to personnel.

• Wear protective goggles when the laser is emitted.

• Never look directory into the laser diode beam even if wearing goggles.

• Never point the probe tip or the laser aperture to personnel.

• Apply the lock-tight to the screws when they are loosened and tightened again.

• For maintenance, turn OFF the power and disconnect the socket from the wall-outlet unless

this manual specifies “Turn ON the power”.

CAUTIONS FOR MAINTENANCE

• In case that the abnormal smell and/or noise is produced from DC-3300, turn the key switch to

the OFF position immediately or press the EMERGENCY OFF button.

• When performing a maintenance with the covers (upper, lower or front cover) removed, take

the following measures in order to protect the laser diodes from static electricity.

• Spread a conductive mat on the workbench, then connect the earth wire from the mat to a

ground.

• Field service representative should put a wrist strap on his/her wrist, and connect the earth

wire from it.

• Earth the measuring instruments such as oscilloscope and laser power meter as well.

• Use a soldering iron provided with an earth wire.

• Before using a tool, always touch the metal part to the conductive mat.

• Connect an earth wire to the terminal on the rear panel as well.

• Specifications and design are subject to change without notice for improvement. Since the

T echnical Bulletin will be released every time significant changes are made to the system, refer

to the Technical Bulletin together with this manual.

1 - 2

§

2

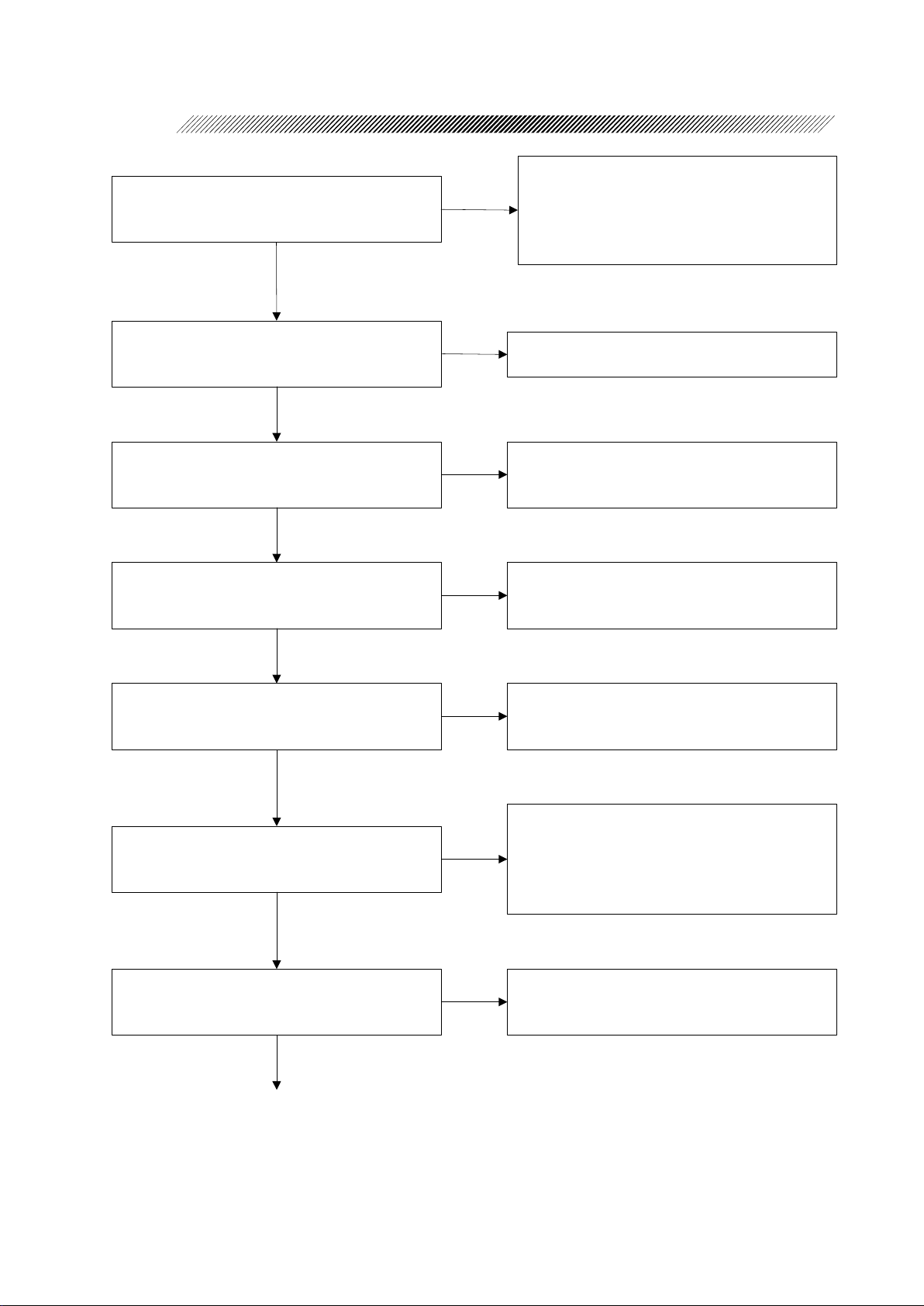

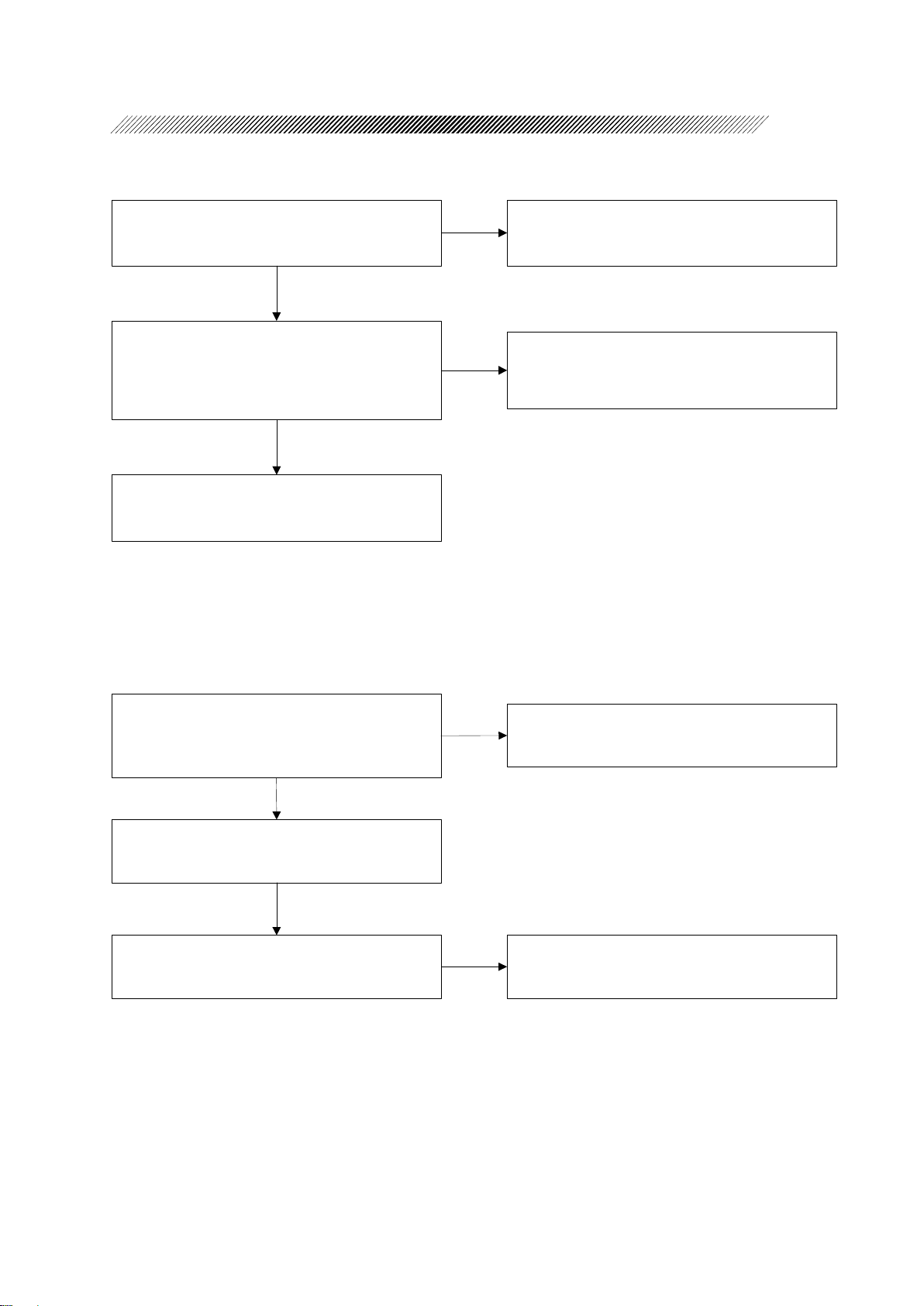

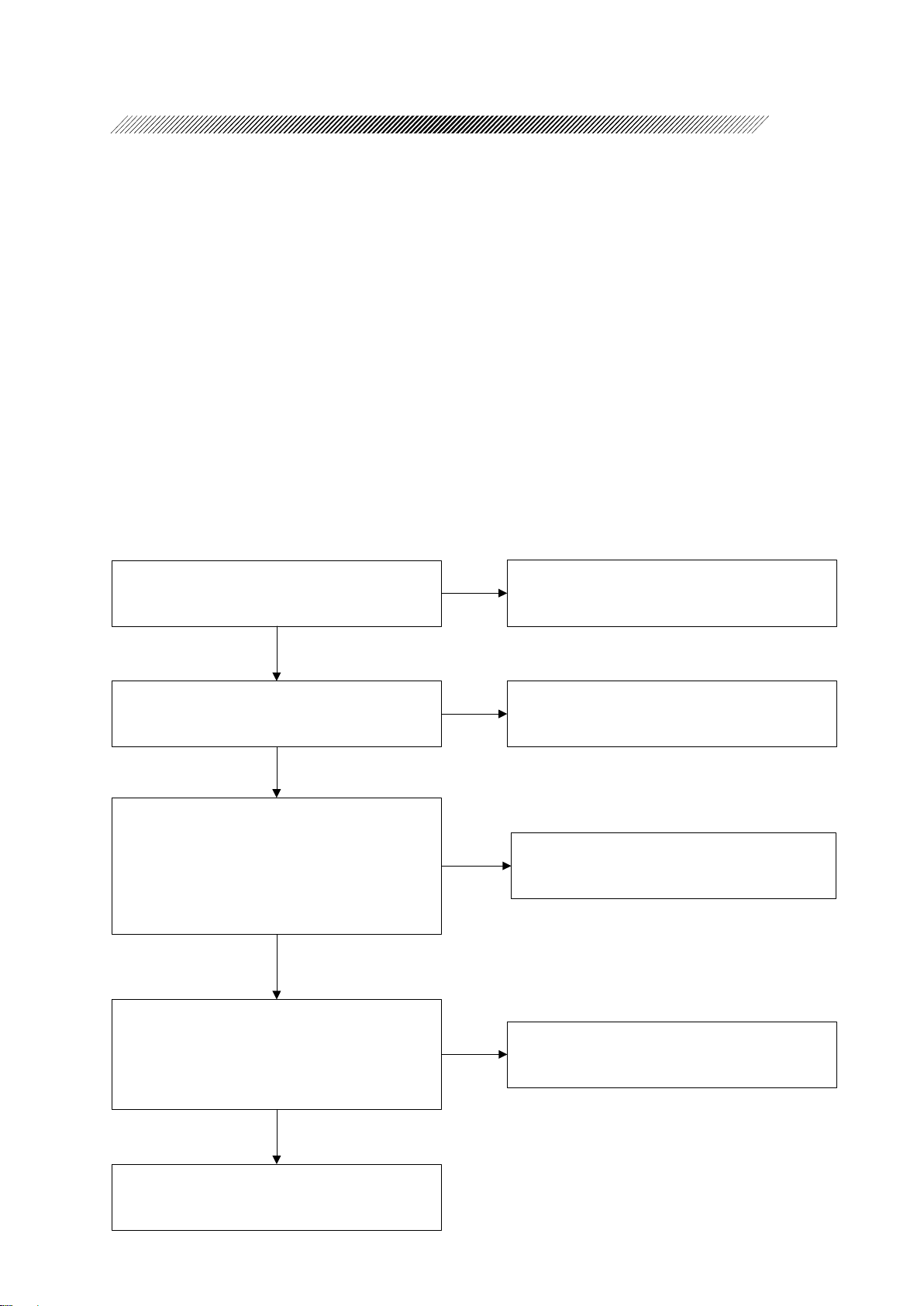

Turn ON the key control switch. Does the

system start correctly?

TROUBLESHOOTING

YES

NO

3.1 The system does not start at all

3.2 Fan does not work

3.3 Indication on the front panel is not

correct

3.27 Err. 4 appears

Is the system put in the initial condition

correctly after count down?

YES

Can the setting of coagulation power

output be changed correctly?

YES

Can the setting of coagulation time be

changed correctly?

YES

Can the repeat mode be set correctly? 3.7 Repeat mode cannot be reset correctly

YES

NO

NO

NO

NO

3.4 Err. 20 appears

3.5 Setting of coagulation power output

cannot be changed correctly

3.6 Setting of coagulation time cannot be

changed correctly

Can the brightness of aiming beam be

changed correctly?

YES

Does READY light up by pressing the

STATUS switch?

YES

NO

NO

3.8 Brightness of aiming beam cannot be

changed correctly

3.9 Aiming beam cannot be seen

3.10 Err. 3 appears

3.11 READY indication does not light up

by pressing the STATUS switch

2 - 2

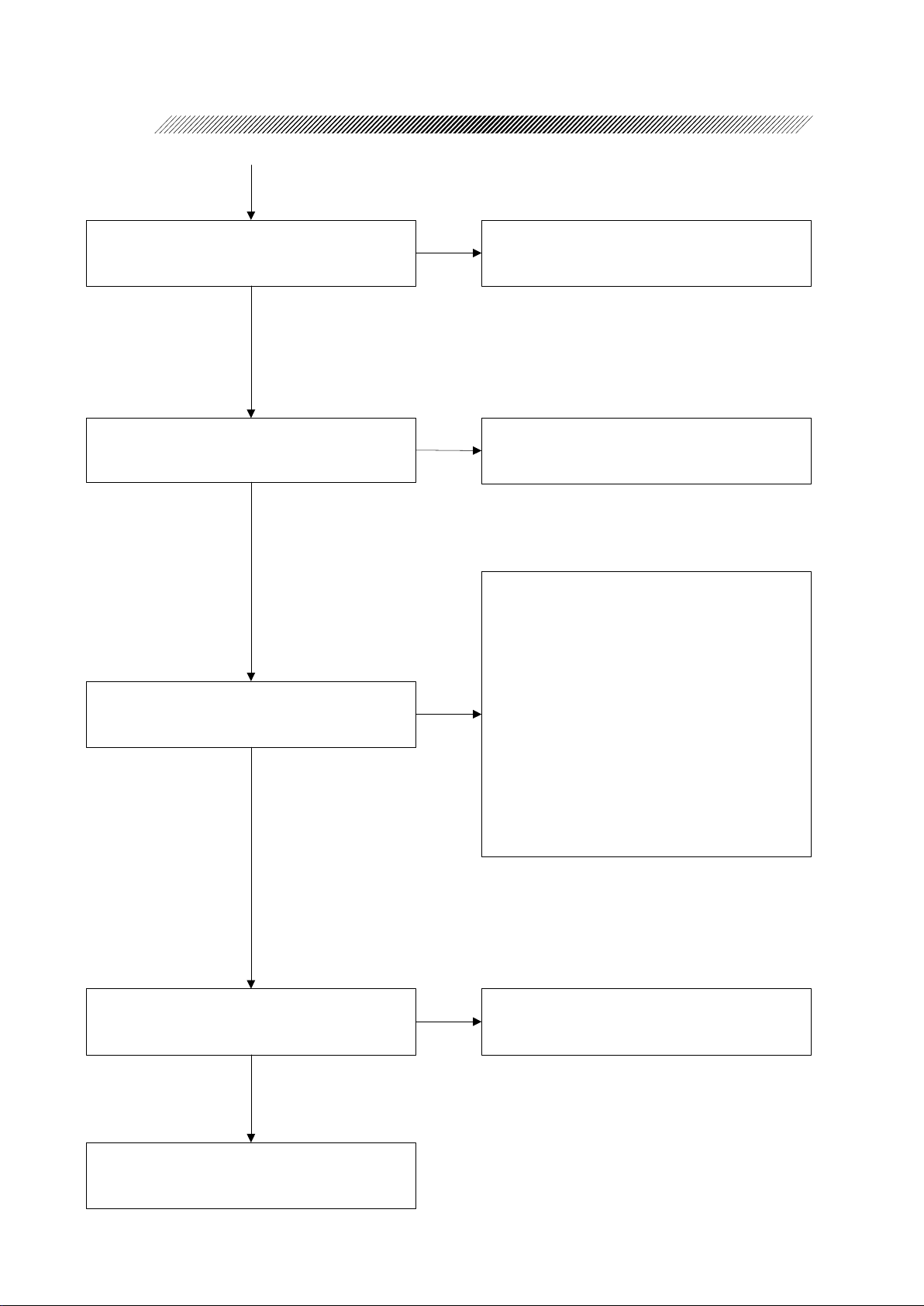

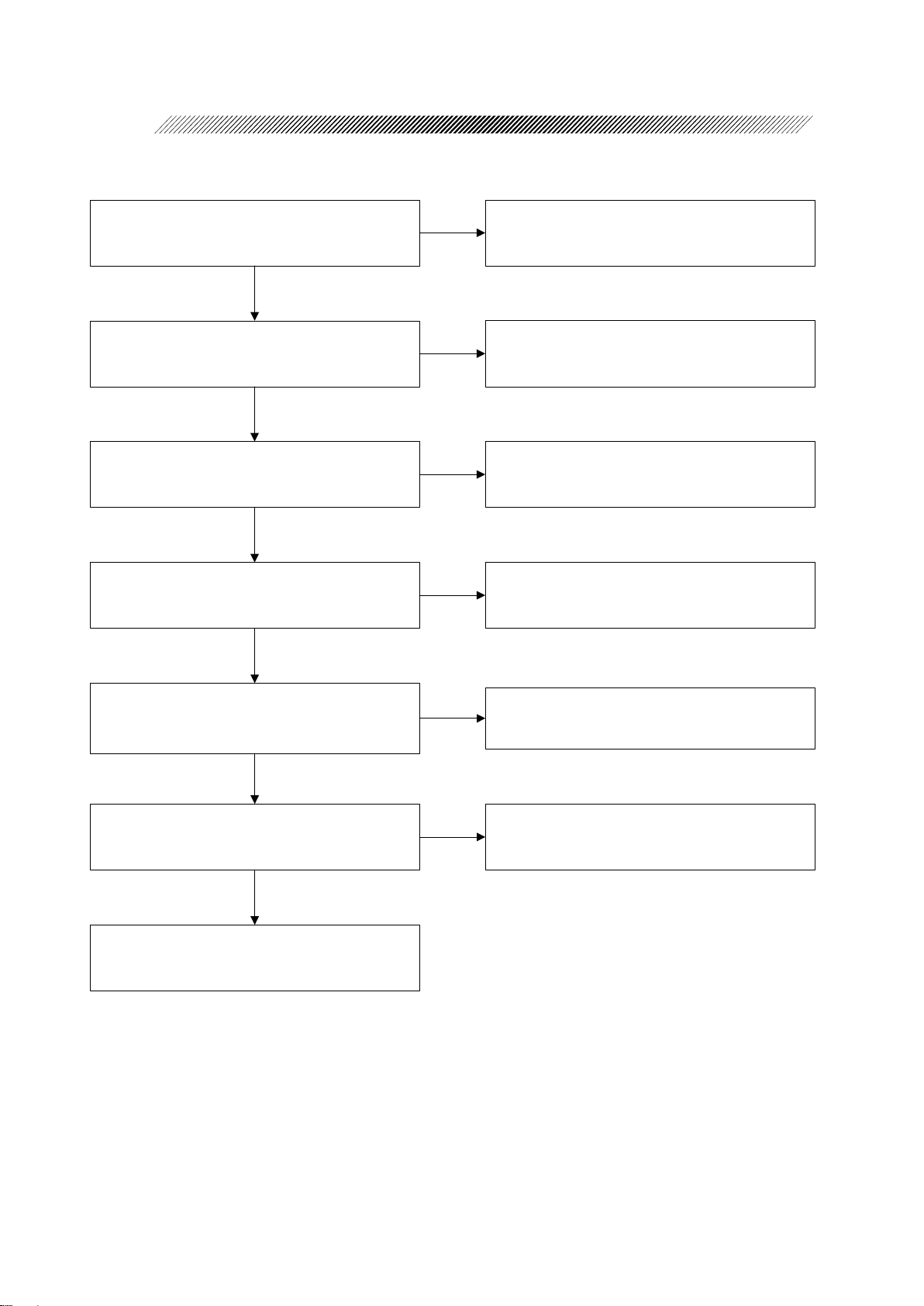

Does STAND BY light up by pressing the

STATUS switch?

YES

Is the Application COUNTER reset by

pressing the Counter Reset switch?

YES

Is the laser diode beam emitted correctly

by pressing the foot switch?

NO

NO

NO

3.12 STAND BY does not light up by

pressing the STATUS switch

3.13 Counter cannot be reset

3.14 Laser beam cannot be emitted

3.15 Err. 1 appears

3.16 Err. 10 appears

3.17 Err. 12 appears

3.18 Err. 13 appears

3.19 Err. 15 appears

3.20 Err. 53 appears

3.21 Err. 54 appears

3.22 INTLK2.7 appears

3.23 INTLK4.7 appears

3.24 Actual power output is low

3.25 Actual power output is high

YES

Does the system stop by pressing the

EMERGENCY OFF button?

YES

END

NO

3.26 EMERGENCY OFF button does not

work

§

3

SUB-TROUBLESHOOTING

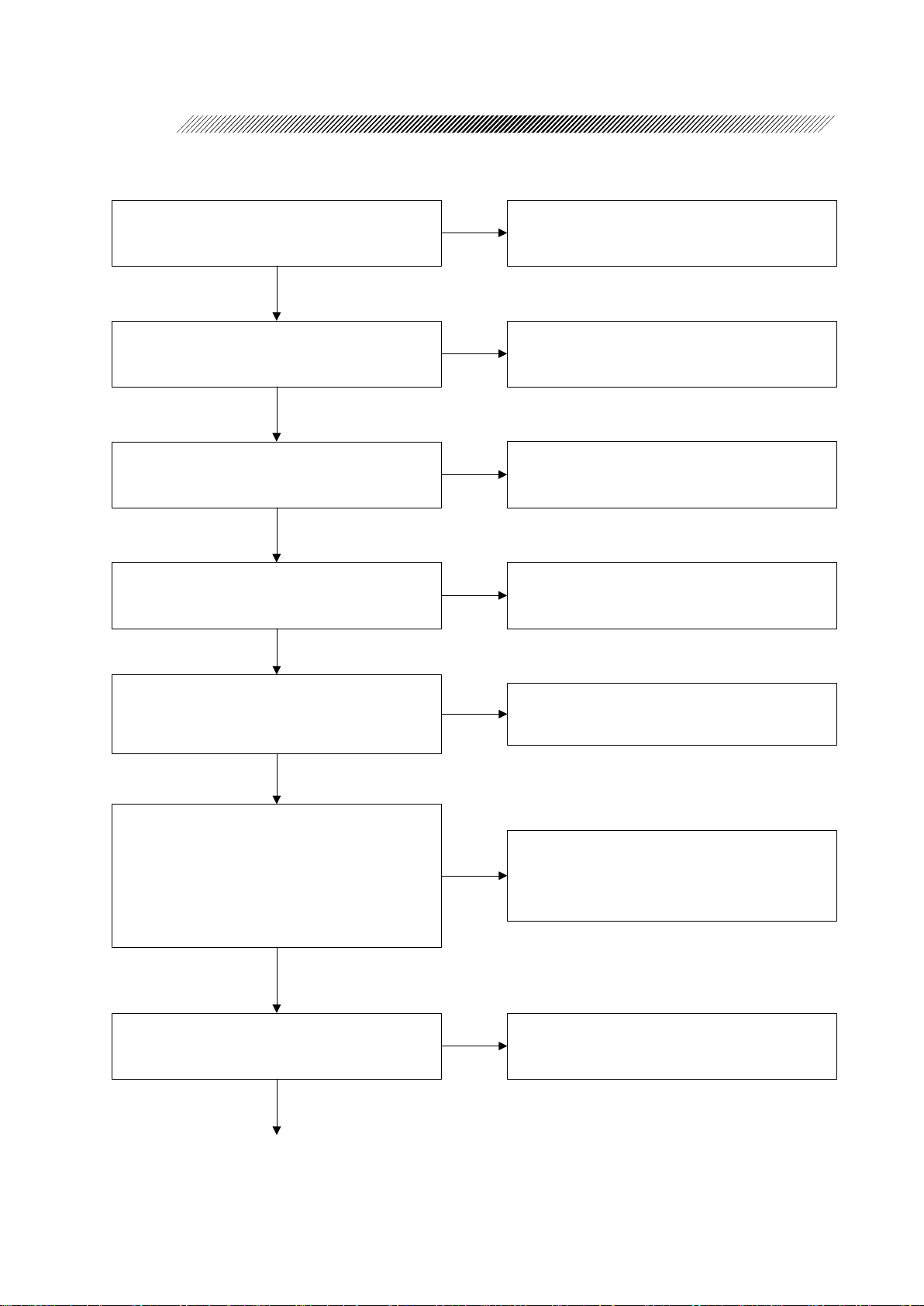

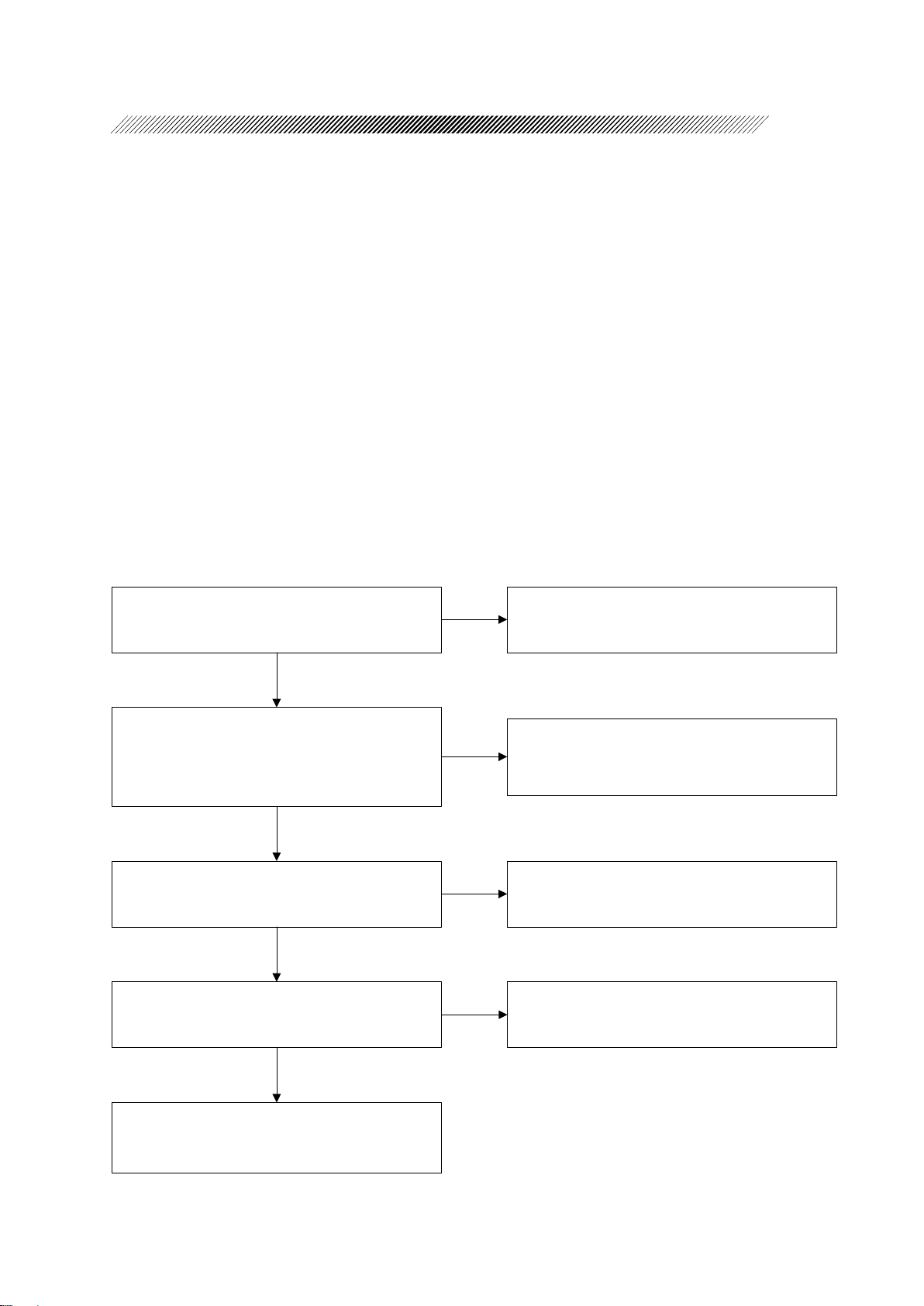

3.1 The system does not start at all

Is the voltage of the outlet proper?

YES

Are the fuses normal?

YES

Are connectors P901, P902 and P903 on

PS1 (switching power supply) connected

correctly?

YES

Are connectors P501, P502, P503, P504

and P505 on BA05 connected correctly?

YES

NO

NO

NO

NO

Obtain the proper line voltage.

Replace the fuses with the new ones (see

4.1).

Correct the connection.

Correct the connection.

Is the voltage between 2nd and 3rd pins of

the connector J901 on PS1 (switching

power supply) proper?

YES

Is the voltage between 1st pin of the

connector J902 and 1st pin of J903 on PS1

(switching power supply) +12V?

Is the voltage between 2nd pin of J902 and

2nd pin of J903 on PS1 (switching power

supply) +12V?

YES

Is the voltage between 1st and 2nd pins of

the connector P505, and, P501 and P503 on

BA05, +12V?

YES

NO

NO

NO

Failure of EA20.

Repair or replace it with the new one.

Failure of PS1 (switching power supply).

Replace it with the new one (see 4.5).

Failure of EA21.

Repair or replace it with the new one.

3 - 2

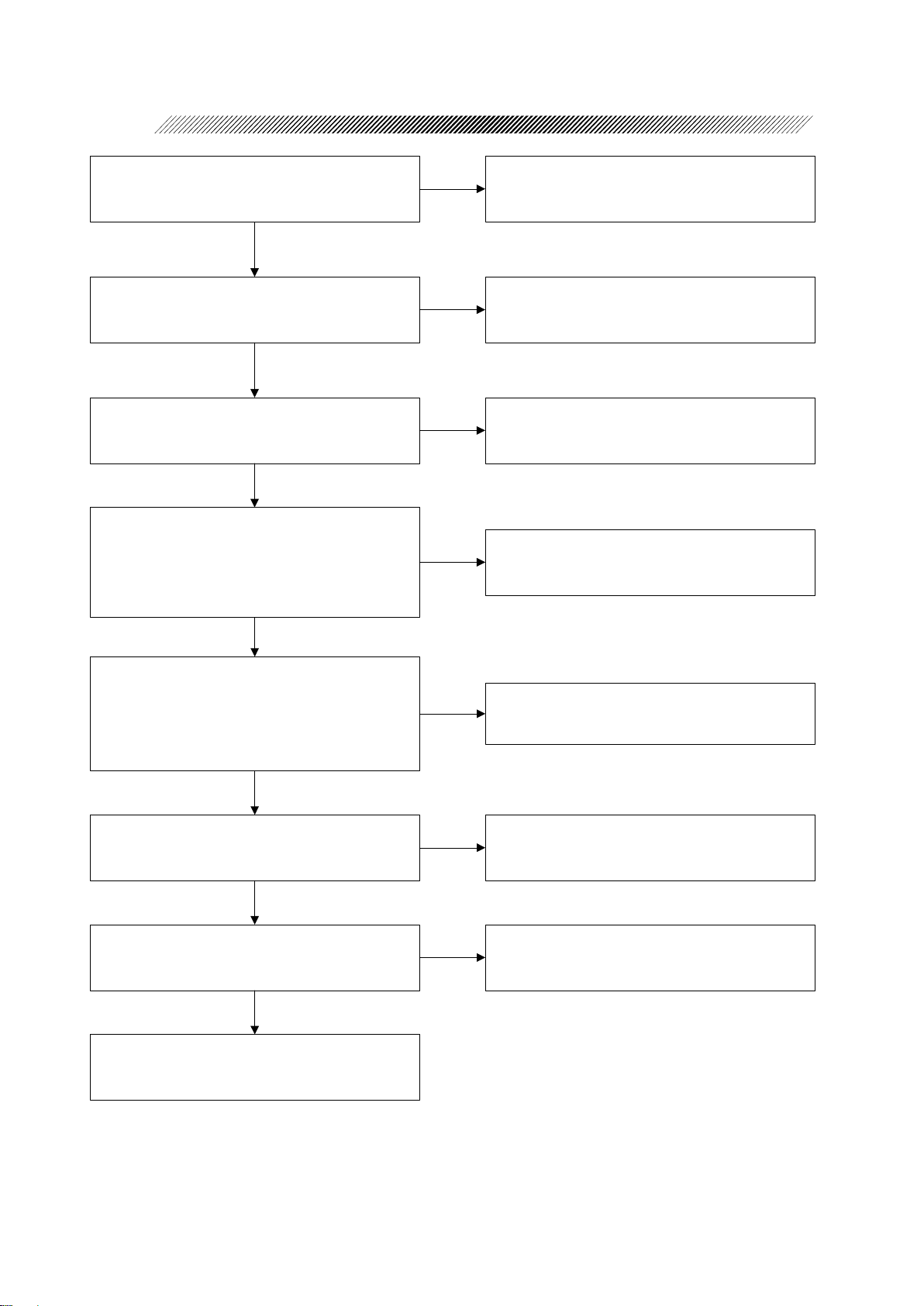

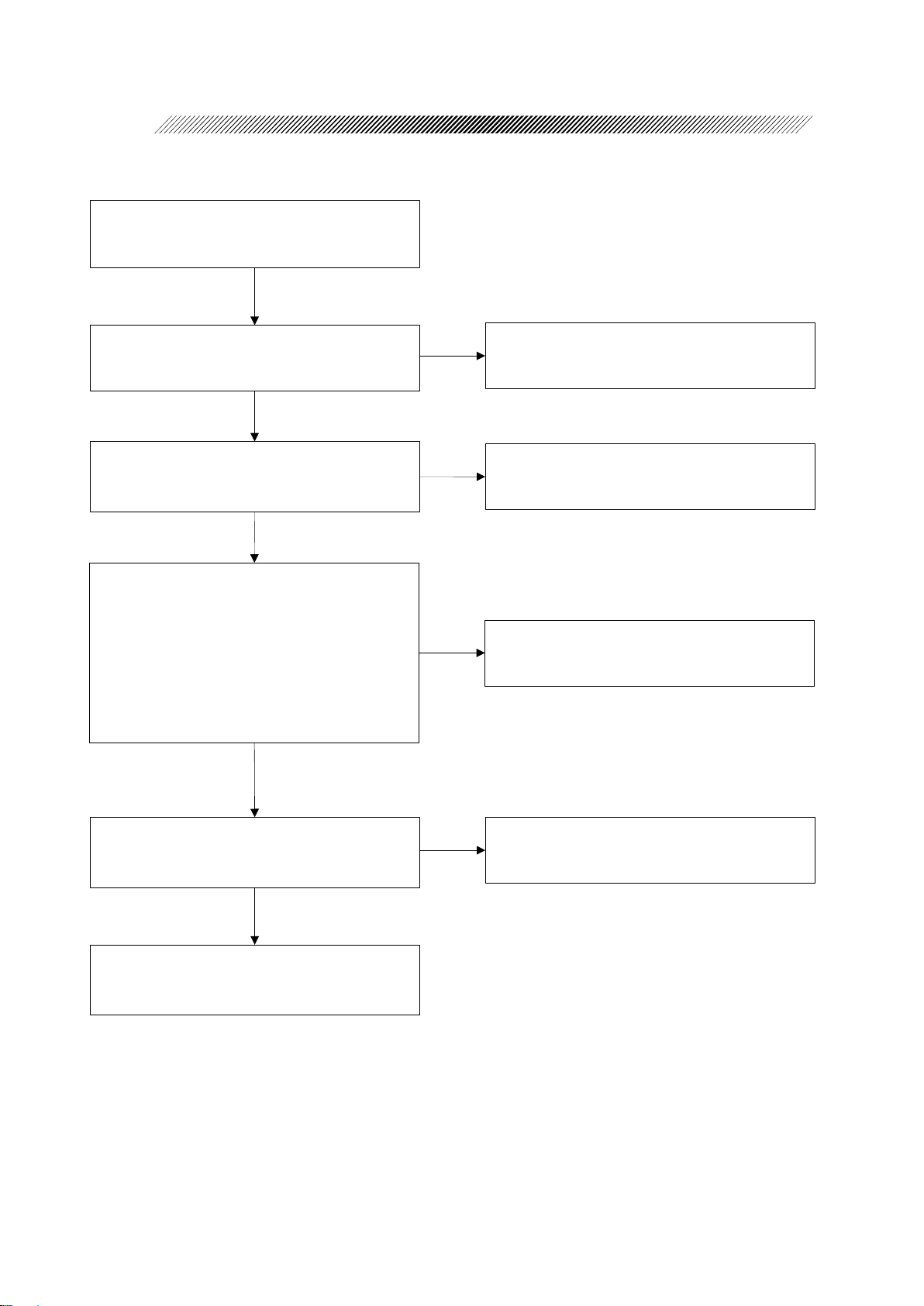

Is the voltage between connectors P502

and P504 on BA05 +12V?

YES

Is the connector P201 on BA02 connected

correctly?

YES

Is the voltage between 1st and 2nd pins of

the connector J201 on BA02 +12V?

YES

Is the voltage between 1st and 2nd pins of

the connector J209 on BA02 +12V?

Is the voltage between 3rd and 4th pins of

the connector J209 on BA02 +5V?

NO

NO

NO

NO

Failure of BA05.

Replace it with the new one (see 4.6).

Correct the connection.

Failure of EA22.

Repair or replace it with the new one.

Failure of BA02.

Replace it with the new one (see 4.7).

YES

Is the voltage between 1st and 3rd pins of

the connector J113 on BA01 +12V?

Is the voltage between 1st and 2nd pins of

the connector J110 on BA01 +5V?

YES

Is the key control switch correct?

YES

Is the EMERGENCY OFF button is

correct?

YES

Failure of BA01.

Replace it with the new one (see 4.8).

NO

NO

NO

Failure of EA13.

Repair or replace it with the new one.

Failure of the key control switch.

Replace it with the new one (see 4.9).

Failure of the EMERGENCY OFF button.

Replace it with the new one (see 4.10).

3.2 Fan does not work

3 - 3

Is the connector P207 on BA02 connected

correctly?

YES

NO

Correct the connection.

Is the voltage of connector P207 on BA02

correct?

Connector P207

NO

Failure of BA02.

Replace it with the new one (see 4.7).

1-2: DC12V

YES

Failure of the fan.

Replace it with the new one (see 4.11).

3.3 Indication on the front panel is not correct

Is the flexible flat cable between the

connector J301 on BA03 and the connector

J106 on BA01 connected correctly?

Y

E

S

Failure of BA03.

Replace it with the new one (see 4.12).

Y

E

S

Is the indication on the front panel correct?

NO

NO

Correct the connection.

Failure of BA01.

Replace it with the new one (see 4.8).

3 - 4

3.4 Err. 20 appears

Is the connector P901 on PS1 connected

correctly?

YES

Is the connector P201 on BA02 connected

correctly?

YES

Is the voltage output to TP9 on BA02 other

than 0V?

YES

Is the voltage output to TP9 on BA02 other

than 0V?

YES

NO

NO

NO

NO

Correct the connection.

Correct the connection.

Failure of the cable EA08.

Replace it with the new one.

Failure of the laser head.

Send the system back to NIDEK.

Is the trouble resolved?

Is the trouble resolved?

Adjust T.E.COOLER.

YES

YES

NO

NO

Failure of BA02.

Replace it with the new one (see 4.7).

Failure of BA01.

Replace it with the new one (see 4.8).

3 - 5

3.5 Setting of coagulation power output cannot be changed

correctly

Perform as described in 3.3.

3.6 Setting of coagulation time cannot be changed correctly

Perform as described in 3.3.

3.7 Repeat mode cannot be set correctly

Perform as described in 3.3.

3.8 Brightness of aiming beam cannot be changed correctly

Perform as described in 3.3.

3.9 Aiming beam cannot be seen

Is the connector P114 on BA01 connected

correctly?

YES

Is the voltage between TP12 and A. GND

on BA01 +1.2V or less?

Is the aiming beam emitted from the

AIMING ASSY?

YES

Does the safety shutter ASSY block the

aiming laser optical path?

YES

Can the aiming beam be seen by turning

VR1 on BA01 clockwise?

NO

NO

NO

NO

Correct the connection.

Failure of aiming laser.

Replace EA04 with the new one.

Adjust the safety shutter.

Failure of BA01.

Replace it with the new one (see 4.8).

YES

Misalignment of the optical axis of the

aiming beam. Send the system back to

NIDEK.

3 - 6

3.10 Err. 3 appears

Release the interlock and error.

Is the connector P103 on BA01 connected

correctly?

YES

Is the voltage between 1st-2nd, 3rd-5th and

6th-5th pins of the connector J103 on

BA01 +12V?

YES

Is the voltage between 4th and 5th pins of

the connector J103 on BA01 +5V, when

the shutter plate blocks the laser optical

path?

Is the voltage between these points 0V,

when the shutter plate does not block the

laser optical path?

S

E

Y

NO

NO

NO

Correct the connection.

Failure of BA01.

Replace it with the new one (see 4.8).

Failure of BA09 of EA02.

Replace it with the new one (see 4.13).

Is the safety shutter placed on the sensor

detection unit?

YES

Failure of BA01.

Replace it with the new one (see 4.8).

NO

Adjust the operation of the safety shutter.

3 - 7

3.11 READY indication does not light up by pressing the

STATUS switch

Perform as described in 3.5.

3.12STAND BY indication does not light up by pressing

the STATUS switch

Perform as described in 3.5.

3.13Counter cannot be reset

Perform as described in 3.5.

3.14Laser beam cannot be emitted

Is the connector P905 on the foot switch

connected correctly?

YES

Is the voltage between 7th and 10th pins of

the connector J113 on BA01 +12V?

YES

Is there continuity between these points on

EA13?

7th pin of P113 - 1st pin of J905

8th pin of P113 - 2nd pin of J905

9th pin of P113 - 3rd pin of J905

10th pin of P113 - 4th pin of J905

YES

NO

NO

NO

Correct the connection.

Failure of BA01.

Replace it with the new one (see 4.8).

Repair the broken part of EA13 or replace

it with the new one.

Is the voltage between 8th-10th and 9th10th pins of the connector J113 on BA01

+5V when the foot switch is pressed?

YES

Failure of BA01.

Repair it with the new one (see 4.8).

NO

Failure of the foot switch.

Replace it with the new one.

Loading...

Loading...