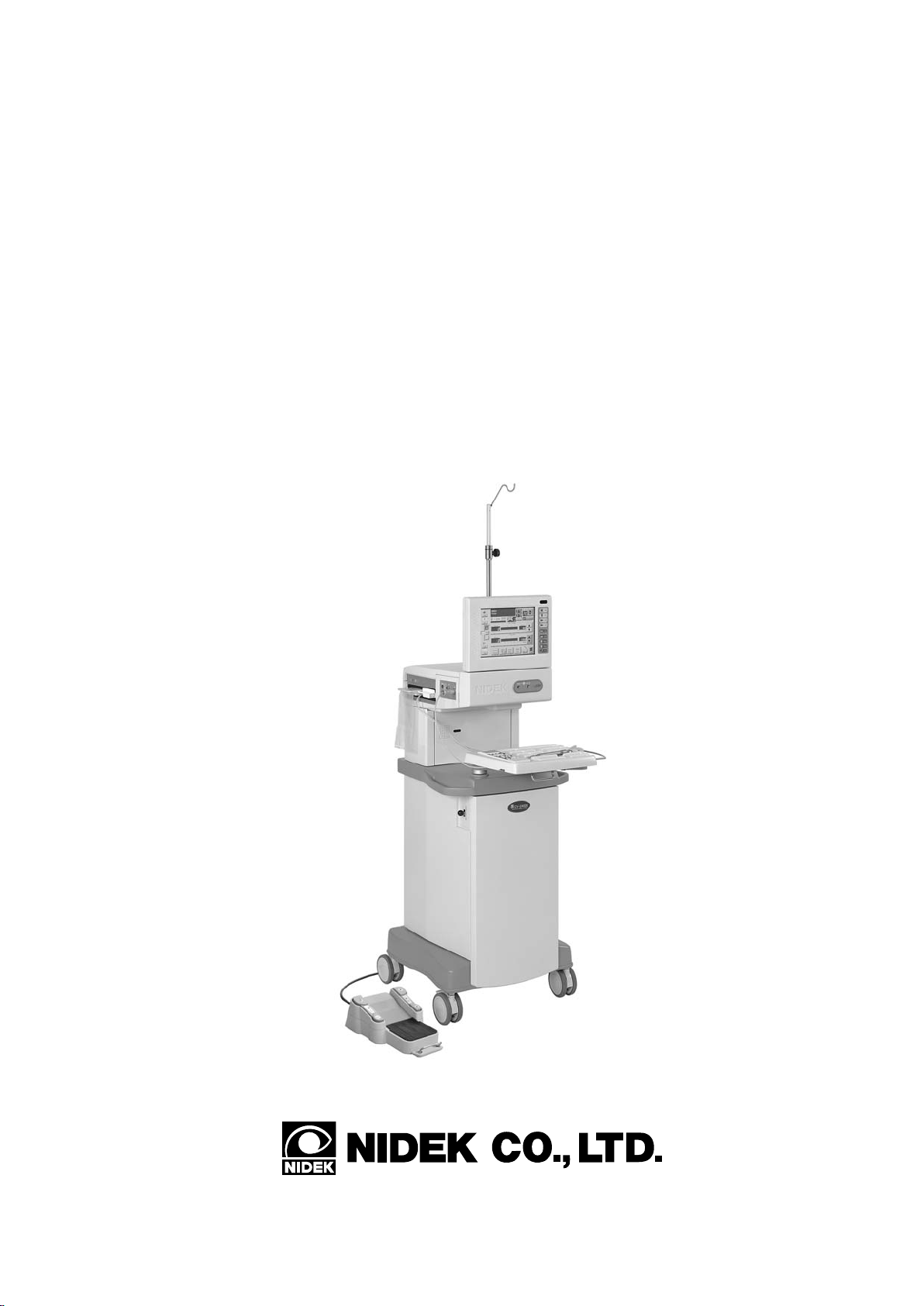

Page 1

NIDEK

OPHTHALMIC SURGICAL SYSTEM

Model CV-24000

OPERATOR’S MANUAL

Page 2

* Specifications are subject to change without notice for improvement.

NIDEK CO., LTD. : 34-14, Maehama, Hiroishi-cho, Gamagori, Aichi 443-0038, Japan

(Manufacturer) Telephone: (0533) 67-6611

Facsimile: (0533) 67-6610

NIDEK CO., LTD : 6th Floor, Takahashi Bldg., No.2, 3-chome, Kanda-jinboucho

(Tokyo Office) Chiyoda-ku, Tokyo 101-0051, Japan

Telephone: (03) 3288-0571

Facsimile: (03) 3288-0570

Telex: 2226647 NIDEK J

NIDEK INCORPORATED : 47651 Westinghouse Drive Fremont, California 94539, U. S. A.

(United States Agent) Telephone: (510) 226-5700

Facsimile: (510) 226-5750

NIDEK SOCIETE ANONYME : Europarc 13, rue Auguste Perret, 94042 CRETEIL, France

(Authorized Representative) Telephone: (01) 49 80 97 97

Facsimile: (01) 49 80 32 08

2005. 3

18214-P902I

Printed in JAPAN

Page 3

BEFORE USE OR MAINTENANCE, READ THIS MANUAL.

THIS MANUAL CONTAINS ONLY INFORMATION TO UNDERSTAND

THE OPERATING PROCEDURES AND MAINTENANCE.

The Operator’s Manual contains information necessary for the operation of the NIDEK

OPHTHALMIC SURGICAL SYSTEM Model CV-24000.

This manual includes the operating procedures, cautions for safety, specifications and

maintenance instructions.

This manual complies with IEC 60601. This manual is required to correctly use this system.

Especially , the cautions for safety and operating procedures must be thoroughly understood

before using the instrument. Keep this manual handy to verify use whenever necessary .

Use of this system is limited to the cataract and vitreous surgery by qualified physicians only .

The physicians are responsible for the application of this system to various surgical techniques.

If you encounter any problems or have questions about the instrument, contact NIDEK or

your authorized distributor.

[NOTE]

There are 3 types of the CV-24000. To make a distinction, each system is abbreviated

according to the specifications and abbreviated names such as A type (or A), AP type

(or AP), and P type (or P) are used in this manual to simplify descriptions (see below).

In addition, it is possible to select the language indicated on the screen between English

and Japanese, however, in this manual, English version is presented.

Model name Types Abbreviations

For c a taract s urgery A type (or A)

CV-24000

For c atarac t and vit reous s urgeri es AP ty pe (or AP)

For vitreous surgery P type (or P )

Page 4

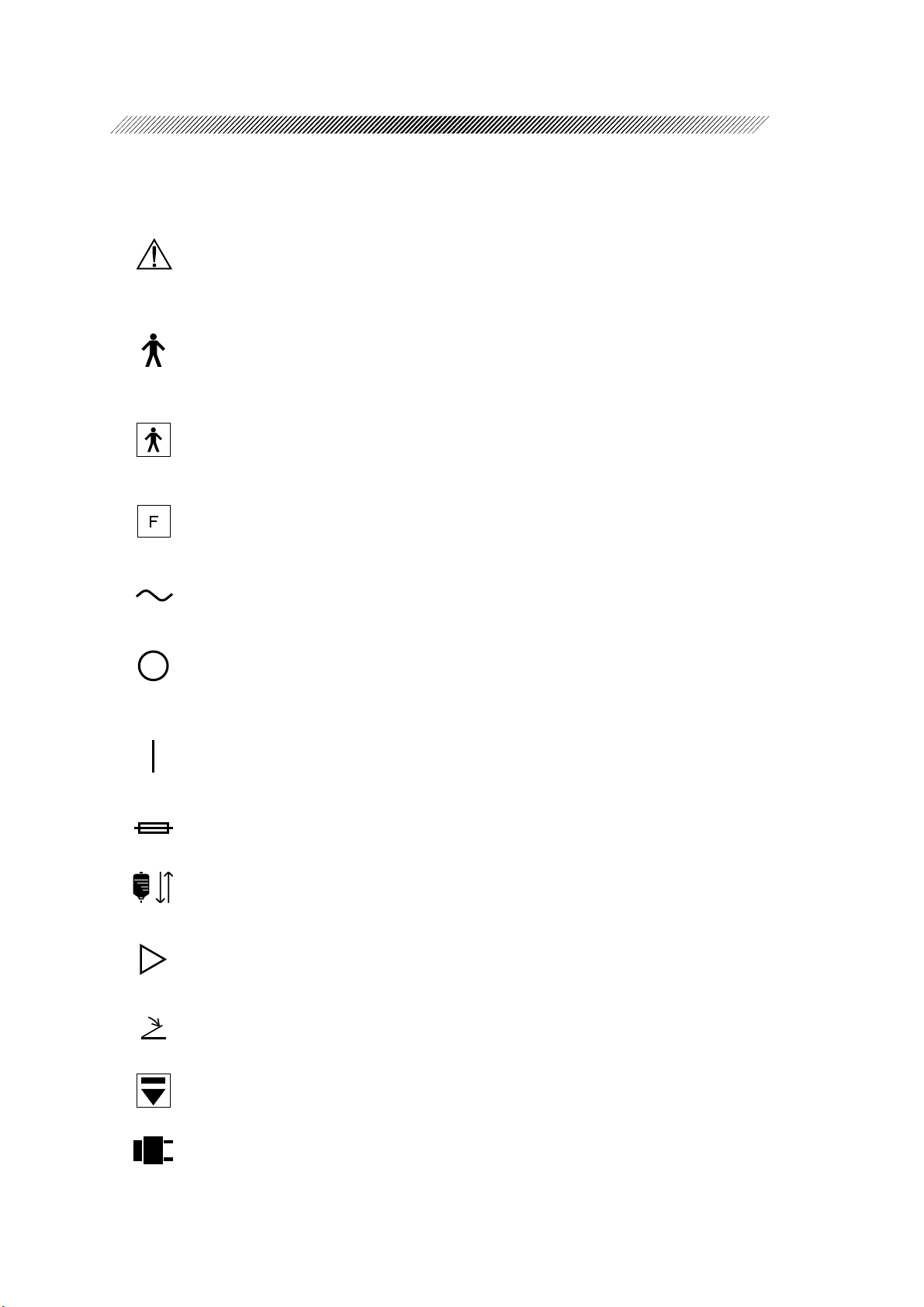

§

§

Table of Contents

1

INTRODUCTION .......................................................................................................1-1

1.1 Outline .......................................................................................................................1-1

1.2 Principles ................................................................................................................... 1-2

1.3 Classifications.............................................................................................................1-4

1.4 Symbol Information ....................................................................................................1-5

2

SAFETY ........................................................................................................................ 2-1

2.1 Storing, Transport, and Installation .......................................................................... 2-1

2.2 Wiring and Connection ............................................................................................2-3

2.3 During Use ............................................................................................................... 2-4

2.3.1 In general......................................................................................................... 2-4

2.3.2 Sterilization ..................................................................................................... 2-5

2.3.3 About the US handpiece and US tip ............................................................... 2-6

2.3.4 About ultrasound oscillation ........................................................................... 2-7

2.3.5 About use of the diathermy function ...................................................................2-8

2.3.6 About use of the vitreous cutter..........................................................................2-9

2.4 After Use, Maintenance, and Check............................................................................2-9

2.4.1 Cleaning and sterilization....................................................................................2-9

2.4.2 Others ............................................................................................................2-10

2.5 Disposal...................................................................................................................2-11

2.6 Safety Devices .........................................................................................................2-12

2.7 Labels......................................................................................................................2-13

§

§

3

SYSTEM DESCRIPTION............................................................................................ 3-1

4

OPERATING PROCEDURES ...................................................................................4-1

4.1 Preparation Before Surgery ...................................................................................... 4-1

4.1.1 Sterilization of instruments ............................................................................. 4-1

4.1.2 Setup................................................................................................................ 4-3

4.2 Setting and Testing Each Cassette ............................................................................ 4-5

4.2.1 For anterior single cassette --For A and AP types...........................................4-5

4.2.2 For anterior dual cassette -- For A and AP types..............................................4-14

4.2.3 For anterior/posterior dual cassette --For AP type ...........................................4-18

4.2.4 For posterior dual cassette (Posterior setting) --For A P type ............................4-26

4.2.5 For posterior dual cassette (ANT/POST setting) --For AP type .......................4-32

4.2.6 For posterior dual cassette (Dual setting) --For P type .....................................4-39

4.2.7 For posterior dual cassette (Single setting) --For P type ...................................4-45

4.2.8 Selectable mode after test................................................................................4-49

4.2.9 switch .........................................................................................4-49

Page 5

4.3 Operation Screens....................................................................................................4-50

4.3.1 Anterior mode screen (main screen) --For AP and P types ...............................4-50

4.3.2 Dia mode screen (anterior mode) --For AP and P types ...................................4-53

4.3.3 Irr mode screen (anterior mode) --For A and AP types ....................................4-55

4.3.4 US mode screen (anterior mode) --For A and AP types ...................................4-56

4.3.5 US Propedal mode screen (anterior mode) --For A and AP types ....................4-59

4.3.6 I/A mode screen (anterior mode) --For A and AP types ...................................4-64

4.3.7 I/A Propedal mode screen (anterior mode) --For A and AP types.....................4-67

4.3.8 V it mode screen (anterior mode) --For A and AP types....................................4-70

4.3.9 Posterior mode screen (main screen) For A P and P types.................................4-72

4.3.10 Dia mode screen (posterior mode) --For A P and P types ...............................4-75

4.3.11 Vit mode screen (posterior mode) --For AP and P types ................................4-77

4.3.12 Asp mode screen (posterior mode) --For AP and P types ..............................4-80

4.3.13 US PPL mode screen (posterior mode) --For A P type...................................4-82

4.3.14 Scis mode screen (posterior mode) --For AP and P types ..............................4-85

4.3.15 Small screens ................................................................................................4-87

4.3.15.1 FGX small screen..............................................................................4-88

4.3.15.2 Illum1, Illum2 small screen .................................................................4-89

4.3.16 Custom setting screen.................................................................................... 4-90

4.3.17 Program contents screen ...............................................................................4-94

4.3.17.1 Changing settings on the anterior screen .............................................4-95

4.3.17.2 Changing settings on the posterior screen .........................................4-105

4.3.18 File screen .................................................................................................. 4-111

4.4 Cleaning the Instruments ......................................................................................... 4-114

§

§

5

TROUBLESHOOTING .............................................................................................. 5-1

5.1 Error During Cassette Test .......................................................................................5-1

5.2 Error During System Test.........................................................................................5-3

5.3 Error During Use ......................................................................................................5-8

6

MAINTENANCE ......................................................................................................... 6-1

6.1 List of Consumables and Maintenance Parts ........................................................... 6-1

6.2 Replacement of Printer Paper................................................................................... 6-1

6.3 Replacement of Halogen Lamp................................................................................6-2

6.4 Replacement of Fuses...............................................................................................6-3

6.5 Cleaning ................................................................................................................... 6-5

6.5.1 Cleaning the exterior .......................................................................................6-5

6.5.2 Cleaning the LCD touch panel ........................................................................6-6

Page 6

§

7

SPECIFICATIONS ...................................................................................................... 7-1

7.1 Specifications of Each Part ......................................................................................7-1

7.2 Power Requirements and Others .............................................................................. 7-5

§

8

ACCESSORIES............................................................................................................8-1

8.1 Configurations for A Type........................................................................................8-1

8.2 Configurations for AP Type .....................................................................................8-2

8.3 Configurations for P Type ........................................................................................ 8-3

8.4 Option....................................................................................................................... 8-4

8.4.1 Anterior mode ................................................................................................. 8-4

8.4.2 Posterior mode ................................................................................................ 8-4

8.4.3 Foot pedal........................................................................................................ 8-4

Words in this manual .................................................................................... end of the manual

Page 7

§

1

1.1 Outline

NIDEK OPHTHALMIC SURGICAL SYSTEM Model CV-24000 is a system for cataract and

vitreous surgeries and has 3 available types, for cataract surgery , for cataract and vitreous surgeries,

and for vitreous surgery.

The system for cataract surgery (A type) has the functions such as the irrigation control, vacuum

pressure/aspiration flow control, ultrasound power control, anterior vitrectomy, and diathermy.

The system for cataract and vitreous surgeries (AP type) has the functions such as the posterior

vitrectomy, fluid/gas exchange, intraocular scissors driving, and intraocular illumination in

addition to the functions of the system for cataract surgery.

The system for vitreous surgery (P type) has the functions such as the vacuum pressure/aspiration

flow control, posterior vitrectomy, fluid/gas exchange, intraocular scissors driving, intraocular

illumination, and diathermy.

INTRODUCTION

These 3 systems are comprised of a main body, foot pedal, and accessories. To enhance the

usability of each function of the system, the CV-24000 adopts the followings:

(1) A color LCD touch panel and infrared wireless remote control*

values and check of the system condition.

(2) An automatic loading-type tube cassette enables you to perform quick setting and cleaning

of tubes.

(3) A built-in printer makes it possible to print surgery data of US Time/US Ener gy, vacuum

pressure, etc.

The CV-24000 is the user-friendly system whose functions of cataract and vitreous surgeries

and their operabilities are successfully combined.

1

achieve easy input of setting

*1 An infrared wireless remote control is for A and AP types only , not for P type.

Page 8

1 - 2

1.2 Principles

(a) Phacoemulsification

When a voltage is applied to an oscillator inside the US handpiece, the oscillator is vibrated

according to the amplitude and frequency of the AC voltage.

The obtained vibration is transmitted to the US tip via a trumpetlike part called as a horn.

In phacoemulsification, the AC voltage is applied to the oscillator at a ultrasound range of

frequency, and the obtained ultrasound vibration is amplified by the horn and transmitted to

the US tip. Then, the end of US tip fragmentates the lens nucleus and the emulsification is

achieved.

(b) Irrigation

The irrigation solution flows into the eye via a tube and handpiece by gravitation. Because

the irrigation pressure changes according to the height between the eye to be operated and the

fluid level of the irrigation bottle, the pressure can be controlled by raising or lowering the

motorized pole, which the irrigation bottle is hung on, with the switch operation.

Furthermore, the built-in pinch valve supplies and stops the irrigation solution.

(c) Aspiration

When the peristaltic pump rotates, the fluid inside the aspiration tube is pressed out by the

roller, the vacuum pressure is generated, and substance inside the eye is aspirated. In other

words, as the volume of pressed-out fluid is equal to the flow rate, it can be controlled by the

rotation speed of pump.

In addition, the pressure sensor monitors and controls the vacuum pressure.

(d) Vitrectomy

When the air pressure generated by the built-in air compressor or external compressed air

source is intermittently supplied to the vitrectomy cutter, the inner blade at the tip of the cutter

is vibrated. The cutting speed is controlled by the intermittent period of the supplied air

pressure which is controlled by the special solenoid valve.

(e) Intraocular scissors

The scissors are opened or closed when the air pressure generated by the built-in air compressor

or external compressed air source is intermittently supplied to the intraocular scissors. The

cutting speed is controlled by the intermittent period of the supplied air pressure which is

controlled by the special solenoid valve. It is also possible to open or close the scissors by the

air pressure according to the pressing amount of foot pedal.

Page 9

(f) Fluid/gas exchange

When the compressed air adjusted by the built-in small pump is conveyed to the inside of the

eye via sclera, the air pressure presses the fluid out of the vitreous cavity and the pressed-out

fluid is drained. Then, the fluid is exchanged with gas.

(g) Intraocular illumination

The illumination adopts the halogen lamp as a light source, whose infrared ingredients are

eliminated by the filter inside the illumination unit in advance. The illumination is led to the

inside of the eye by the acrylic light guide probe.

(h) Diathermy

The Joule heat is generated when the electrical current is applied to tissue. Diathermy is to

dehydrate, coagulate the tissue with the Joule heat, stop bleeding, or prevent bleeding of the

incised area.

(i) Fragmentation

This is used for the pars plana lensectomy. From the incision made at the pars plana, the

special US tip is inserted into the vitreous cavity and the lens is fragmented and aspirated by

the ultrasound oscillation of the US tip.

1 - 3

Page 10

1 - 4

1.3 Classifications

[Protection method against electric shock] Class I

CV-24000 is classified into a Class I system.

A Class I system is a system in which the protection against electric shock does not rely on

basic insulation only, but which includes an additional safety precaution in such a way that

means are provided for the connection of accessible conductive parts to the protective (earth)

conductor in the fixed wiring of the installation in such a way that accessible conductive parts

cannot become live in the event of a failure of the basic insulation.

[Degree of protection against electric shock] Type BF applied part, Type B applied part

The diathermy of CV-24000 is classified into a Type BF applied part and others are classified

into a Type B applied part.

A Type BF applied part is isolated from other parts of the medical/electrical equipment to

such a degree that no current higher than the patient leakage current allowable in single fault

condition flows if 1.1 times of maximum rated supply voltage is applied between the applied

part and earth.

A Type B applied part contains an internal electrical power source providing an adequate

degree of protection against electric shock particularly regarding;

- allowable leakage currents

- reliability of the protective earth connection (if present)

[Degree of protection by the enclosure]

The main body of the CV -24000 is classified as IP20, and the foot switch is classified as IPX8.

An IP20 system is protected against an ingress of solid foreign objects, such as a finger having a

diameter of 12.5mm or greater, however , it is an ordinary system without protection against an

ingress of liquids. Be careful not to get water on the main body and control box.

An IPX8 system is a waterproof system provided with an enclosure preventing the effects caused

by immersion in water.

[Sterilization methods recommended by the manufacturer]

Non-sterilized instruments of CV-24000 should be autoclaved under 132ºC.

[Degree of safety in the presence of flammable anesthetics and/or flammable cleaning agents]

CV-24000 should be used in an environments where no flammable anesthetics and/or

flammable cleaning agents are present.

[Mode of operation]

CV-24000 is an intermittent operation system.

[Classification by transference]

CV-24000 is classified into a transportable system.

Page 11

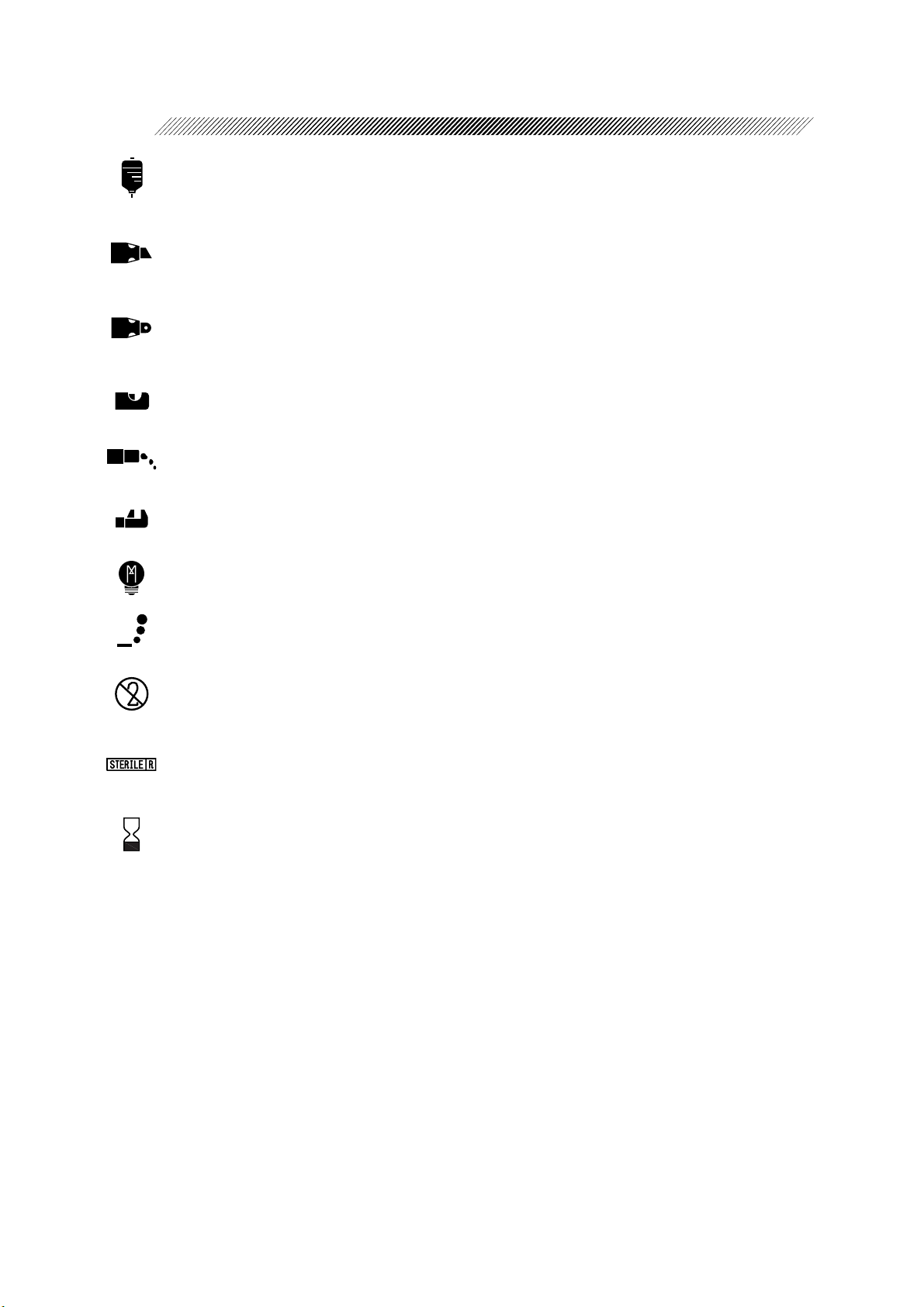

1.4 Symbol Information

This symbol indicates that important descriptions related to operation or maintenance

are contained in the operator’s manual and that an operator must refer to the operator’s

manual prior to operation and maintenance.

This symbol indicates that the degree of protection against electric shock is a type B

applied part.

This symbol indicates that the degree of protection against electric shock is a type BF

applied part.

This symbol indicates that the applied part is non-grounding type according to the high

frequency.

1 - 5

This symbol indicates that the system should be operated only with alternating current.

This symbol indicates the master switch setting. When the switch is flipped to the

symbol side, the power is not supplied to the system.

This symbol indicates the master switch setting. When the switch is flipped to the

symbol side, the power is supplied to the system.

This symbol indicates the fuse rating.

This symbol indicates the function to raise or lower the irrigation pole.

This symbol indicates the slot where the memory card is inserted. When inserting the

memory card, align the symbol on the memory card with the one on the main body.

This symbol indicates the connector to which the foot pedal shall be connected.

This symbol indicates the switch to eject a cassette.

This symbol indicates the switch to display the Dia mode screen.

Page 12

1 - 6

This symbol indicates the switch to display the Irr mode screen. The symbol on the

cassette indicates the connection line with the irrigation bottle.

This symbol indicates the switch to display the US mode screen. The symbol on the

cassette indicates the connection line with the US handpiece.

This symbol indicates the switch to display the I/A mode screen. The symbol on the

cassette indicates the connection line with the I/A handpiece.

This symbol indicates the switch to display the Vit mode screen.

This symbol indicates the switch to display the Asp mode screen.

This symbol indicates the switch to display the Scis mode screen.

This symbol indicates the switch to indicate the setting of the intraocular illumination.

This symbol indicates the switch to indicate the setting of the gas exchange.

This symbol indicates the effective number of use and means the prohibition of reuse.

This symbol indicates the method of sterilization and means that the radiation sterilization

has been performed.

This symbol indicates the time period over which the part can be used safely.

Page 13

§

2

In this manual, Signal Words are used to designate a degree or level of safety alerting,

whose definitions are as follows.

WARNING: Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury or property damage accident.

Some items described in WARNING and CAUTION may cause a serious

accident according to the circumstances. Follow all the instructions mentioned below

since they are very important.

2.1 Storing, Transport, and Installation

SAFETY

CAUTION

• Prior to storage, verify that the storage area meets the following conditions:

- Not exposed to ultraviolet rays and direct sunlight.

- Not splashed with rain or water .

- No chemical agents and organic solvent are present.

- No salt, sulfur content, toxic gas or large amounts of dust is contained in the air .

- Level and stable without vibration and shock.

- The following environmental conditions in storage and transport ( packed condition) specified

in the specification are met.

Temperature: -10 to 60ºC / Humidity: 30 to 90% (non-condensing)

Atmospheric pressure: 700 to 1060 hPa

• Lower the irrigation pole to the lowest position before transporting the system.

In addition, fold the irrigation hook and store it inside the pole.

Failure to do so may bump the pole or catch the hook.

• Transport the system after hanging the foot pedal and cords on their special hooks on the

stand.

If the system is transported without the foot pedal and cords properly stored, the cords

may be caught causing a fall of system and break of cords.

Page 14

2 - 2

CAUTION

• Hold the handle on the stand when transporting the system. Avoid sudden operation at

the start/stop of transportation.

Otherwise, the system may fall down and an injure or system malfunction may result.

• Never drag the system by holding the power cord or cable of the foot pedal when

transporting the system.

Otherwise, the system may fall down and an injure or system malfunction may result.

• If the temperature differs substantially before and after the transport, condensation may

occur in the system. After transport, confirm that the system is at room temperature

before turning on the power of the system.

If the power is turned on while the condensation is happening, malfunction or electric

shock may result from short-circuit.

• Prior to installation, verify that the installation area meets the following conditions:

- Level and stable without vibration and shock.

- Not exposed to liquids such as water.

- No flammable gases (including anesthetic gas) or solvents is present.

- No large amount of dust is contained in the air .

- Not exposed to direct air-conditioning flow .

- Not exposed to direct sunlight or ultraviolet rays.

- The following environmental conditions in installation (unpacked condition) are met.

T emperature: 10 to 30ºC / Humidity: 30 to 75% (non-condensing)

Atmospheric pressure: 860 to 1060 hPa

• Install the system where it is not exposed to strong electromagnetic waves during operation.

Strong electromagnetic waves may cause the system to malfunction.

• Install the system so as not to block the ventilation hole on the cover of the main body.

The cooling fan cannot radiate heat properly and the system may be adversely affected.

Page 15

2.2 W iring and Connection

CAUTION

• Use a grounded power outlet which meets the power requirements labeled on the system.

Otherwise, the system may not perform sufficiently or may be damaged. If the power outlet is

not a grounded type and a leakage of current occurs because of a system malfunction, an

electric shock may result.

Moreover, it may cause electromagnetic interference for other devices or hum noise.

• Do not overload the electrical outlet.

Abnormal heat generation may occur and result in fire.

• Always pull the plug, not the cord, when unplugging the power cord.

The cable core may break, and an ignition or electric shock due to a short-circuit may

result.

• Be sure not to get the power cord pinched under a heavy object such as the system.

The cable sheath may break, and a short-circuit or electric shock may result.

2 - 3

• If the inside wires of the power cord are exposed, do not continue using the system but

unplug the power cord and contact NIDEK or your authorized distributor.

An electric shock or fire may occur.

• Never remove the cover that holds the power cord except in order to replace the fuse.

If the power cord is disconnected during the operation, the result of the surgery may be

seriously affected.

• After inserting the cable plug of the foot pedal, lock the plug with the ring to hold it.

If the cable plug becomes loose during the operation, the result of the surgery may be

seriously affected.

• Securely connect the plug of connecting cables for the handpiece, etc. and the luer connector

for the tube, etc. following the instructions on this operator’s manual.

Otherwise, the system may not work normally and an accident or malfunction may occur.

• Hold the plug, not the cable or cord, to when connecting or disconnecting the US handpiece or

diathermy cord.

If the inside wires of the cable or cord break, ultrasound oscillation and diathermy become

impossible.

Page 16

2 - 4

2.3 During Use

2.3.1 In general

CAUTION

• Never use this system for purposes other than cataract surgery.

If any accident occurs because of use for other purposes, NIDEK assumes no

responsibility.

• Prior to the first use of the system each day, perform the system test and function checks referring

to the Pre-operation check manual (18214-P912A). NIDEK assumes no responsibility if failure

occurs during the operation of each mode without performing the test and checks.

• If any abnormality occurs to the system, do not touch the inside of the system. Unplug the power

cord from the power outlet and contact NIDEK or your authorized distributor .

• In case of failure of the system, take backup measures for the surgery to be performed.

• Do not modify or touch the inside of the system.

T o do so may cause an electric shock or system malfunction.

• This system is provided with a T ype B applied part. A void the combined use of this system and

other systems which contact the patient during use.

• Do not touch the LCD touch panel with anything other than fingers during operation. Do not

touch 2 or more places at the same time.

T ouching with a hard or sharp object (such as ball-point pen) may scratch the panel. If 2 or

more places are touched at the same time, a system malfunction may occur .

• Make sure that the LCD touch panel is not exposed to the direct sunlight or ultraviolet

rays during operation.

The LCD touch panel may be damaged.

• Contents of cassette pack and connection set are disposable items. Never open the package

until just before use. Be sure to dispose of them after use and never reuse them.

• Use the specified infusion tube (another package including the cassette pack) only.

Using unspecified infusion tube may cause an insufficient irrigation flow and the anterior

chamber or eyeball to collapse.

• When using the optional I/A tip (φ 0.5mm), pay special attention to the aspiration pressure

so that it does not become so high.

If the I/A tip (φ 0.5mm) is used at the setting of the aspiration pressure over 300 mmHg,

the anterior chamber may become shallow at the time of aspiration.

Page 17

2 - 5

CAUTION

• Never let a hard substance contact the ends of tips (especially US tip), diathermy forceps,

vitrectomy cutter and intraocular scissors.

They may be deformed or cannot be used any longer.

• The height of IV pole indicated on the screen is intended for use of a 500 mL glass bottle.

Using other bottles may cause a gap between the indication and actual heights.

• Never splash water onto the main body . Besides, be sure not to splash water onto the foot

pedal as much as possible.

Otherwise, a system malfunction or electric shock may result.

• Tray is to place the surgical instruments such as handpiece, etc. during surgery.

Do not place heavy objects or rest your weight on the tray.

Otherwise, it may be deformed or the system may fall down.

2.3.2 Sterilization

WARNING

• Be sure to sterilize all accessories that need to be sterilized before the surgery.

Otherwise, the physician, patient or assistant may be infected.

CAUTION

• Sterilize the accessories according to the specified method. (For details, refer to “4.1.1

Sterilization of instruments” (p.4-1).)

If not, they may be deformed or damaged.

• Confirm that no dirt or foreign object is on the instruments before sterilization. If dirt or

foreign object is found, remove it be cleaning.

(For the details of cleaning, see “4.4 Cleaning the Instruments” (p.4-109).)

• Autoclave the parts observing their useful lifetime and the number of times they can be

used that are written on the package.

If the useful lifetime or the number of uses is exceeded, the parts may have problems

and may interfere with the surgery.

Page 18

2 - 6

2.3.3 About the US handpiece and US tip

CAUTION

• Never modify the US handpiece or the US tip by bending, cutting, or engraving them.

The US handpiece or the US tip may break or malfunction.

• When autoclaving the US handpiece, always use a vacuum drying type sterilizer.

Using a sterilizer other than that of a vacuum drying type may damage or accelerate the

deterioration of the US handpiece.

• Use only the NIDEK US tip for the US handpiece. Never use the I/A tip or other manufacturers’

US tips.

Normal ultrasound oscillation may not be achieved. NIDEK assumes no responsibility

for accidents caused by use of unspecified tips.

• Confirm that the plug of the US handpiece is completely dry before connecting it to the

US connector.

Failure to do so may cause an electric shock and damage to the US handpiece.

• Connect the US tip to the US handpiece, and the cable plug of the US handpiece to the US

connector of the main body securely.

Insecure connections may cause ultrasound oscillation failure and poor electrical contact.

• Never immerse the US handpiece and plug in a liquid.

Ultrasound oscillation failure or poor electrical contact may result.

• Use the US handpiece at ordinary temperatures. After autoclaving, leave it for approximately

15 minutes or more and check that it has cooled down before use.

Otherwise, burns may occur .

• If abnormal heat is generated from the US handpiece or US tip, do not touch the internal

structure of the system. Disconnect the US handpiece from the system and contact NIDEK or

your authorized distributor.

The untrasound may not be oscillated and burns may occur to the patient or the user .

Page 19

2.3.4 About ultrasound oscillation

CAUTION

• Never touch the US tip during ultrasound oscillation.

Injuries may occur.

• Never let the end of the US tip contact other medical devices (instrument for nuclear

segmentation, etc.) during ultrasound oscillation.

The US tip or other medical devices may break and generate pieces of metal.

• Before ultrasound oscillation, check the setting values (ultrasound output power, aspiration

pressure, aspiration flow rate, US control mode, etc.). During ultrasound oscillation,

observe the motion of the US tip.

Otherwise, the US tip may be damaged beyond repair.

• When oscillating the ultrasound, make sure that the US tip operates with sufficient irrigation

and aspiration (the US tip must be in the test chamber filled with the irrigation solution or

in the eye).

Ultrasound oscillation without irrigation and aspiration may damage the US tip beyond

repair.

2 - 7

• During ultrasound oscillation, do not move the US tip close to a side of the incision or

perpendicular to the dome of the cornea.

The area around the incision may be burned.

• If the ultrasound is oscillated while the US tip is in the viscoelastic, the viscoelastic

blocks the irrigation flow. It causes insufficient cooling of the US tip and, as a result, a

burn.

Create a space filled with the irrigation solution between the lens and the viscoelastic in

advance. Perform ultrasound oscillation with the irrigation and aspiration ports in the

space.

• In phacoemulsification, a phenomenon, known as cavitation, may occur in which the ultrasonic

vibration forms bubbles from the gas in the irrigation solution that flows through the US handpiece.

If this bubbles enter the patient’s eye, they may obstruct the physician’ s view and interfere with

surgery . To control the formation of bubbles, use the pulse mode or other methods not to use

ultrasound more than necessary . If the bubbles enter the patient’ s eye, aspirate them using the

devices such as the US tip to secure the physician’s view .

Page 20

2 - 8

2.3.5 About use of the diathermy function

WARNING

• When using the diathermy function for patients with a cardiac pacemaker or its electrode

implanted, consult the cardiac surgeon or manufacturer of the pacemaker.

The function of the pacemaker may be affected or the pacemaker may be damaged.

CAUTION

• The diathermy forceps and pencil, and the cord that are standard accessories can be used

exclusively for the CV-24000. Do not connect them to unspecified terminals or other

manufacturer’s bipolar/monopolar device.

Especially , if the diathermy cord is connected to the monopolar output terminal, unexpected

output voltage may be generated and serious adverse events may occur .

• Never modify the diathermy forceps, pencil, or cord by bending, cutting, or engraving them.

The diathermy forceps, pencil, or cord may break or malfunction.

• Connect the diathermy forceps or pencil and the cord securely.

Insecure connections may cause coagulation failure and poor electrical contact.

• When using the diathermy function, observe the following conditions to avoid a burn or

electric shock:

- Use the diathermy forceps and pencils, and the cords that are in the standard accessories.

- Make sure that the diathermy cord is not deformed (change in shape or cracks).

- Flammable gas should not be in the air.

- The diathermy power selected should be as low as possible for the intended purpose.

- The patient should not come into contact with metal parts which are earthed or which

have an appreciable capacitance to earth (for example operating table supports, etc.).

- The diathermy cord should be positioned in such a way that contact with the patient

or other cords is avoided.

- When physiological monitoring equipment is used simultaneously on the same patient,

any monitoring electrodes should be placed as far as possible from the patient’s eye.

- Use monitoring systems incorporating high frequency current-limiting devices.

Page 21

2.3.6 About use of the vitreous cutter

CAUTION

• Observe the following points when using the vitreous cutter to avoid trouble during the surgery:

- Confirm the connections of the drive/aspiration tube and the leur adapter beforehand.

- Before using the vitreous cutter, put the needle part in the water and check the operation. If

it malfunctions, replace it.

• Even after the check described above, performance of the vitreous cutter may decrease due to

failure of the system infrequently . Before moving the tip of the cutter away from the incision,

check that the incision has been made completely .

If the tip of the cutter is moved away from the incision when the incision is incomplete, retinal

tear may result.

2 - 9

2.4 After Use, Maintenance, and Check

2.4.1 Cleaning and sterilization

CAUTION

• Observe the following points in the first cleaning after use:

- Use distilled water for the first cleaning instead of tap water to avoid rust or stain.

- T o avoid rust, use only enzyme detergent for cleaning. (Refer to the user’s guide attached to

the detergent before use.)

- T o avoid rust, wash the cleaned parts sufficiently and dry them as quickly as possible.

• Observe the following points in the first sterilization after use:

- T o avoid rust, use only glutaral preparation for cleaning. Do not use other preparations such

as phtharal preparation. (Refer to the user’s guide attached to the preparation before use.)

- T o avoid inflammation by touching the sterilized parts, wash them sufficiently and dry them

as quickly as possible. (Refer to the user’s guide attached to the preparation before use.)

• Observe the following points in the ultrasonic cleaning:

- Do not subject the US handpiece and diathermy cord to the ultrasonic cleaning to avoid

break of terminal or deterioration of the electrical characteristics that may occur depending

on the conditions.

- To protect the ends of the US tip, I/A tip, and diathermy forceps, put the rubber cap on

them before using the ultrasonic cleaning for them.

Page 22

2 - 10

CAUTION

• Observe the following points in the cleaning and sterilization of the US handpiece and diathermy

cord:

- T o avoid contact failure from short circuit or rust, do not immerse the parts in the detergent

or sterilizing solution.

- Wipe the exterior of the US handpiece and the diathermy cord with gauze or absorbent

cotton soaked in the detergent or sterilizing solution and wrung sufficiently . Do not wipe

them with excessive force.

- T o avoid break of wire, wipe the areas where the cable and cord are attached with special

care.

- To avoid break of wire, do not press or pull the cables and cords forcefully when wiping

them.

2.4.2 Others

CAUTION

• If the system will not be used for a long period of time, unplug the power cord from the power

outlet.

If dust settles on the plug of the power cord, the dust absorbs moisture and may cause a

short-circuit and fire.

• If the system is not being used, turn OFF the power and put the dust cover on the system.

Dust settles on the system and makes it dirty.

• Use the specified fuses only.

Otherwise, the system may not perform sufficiently and a system malfunction or fire may

result.

• Use the specified lamp for intraocular illumination.

Otherwise, the system may not perform sufficiently and a system malfunction or fire may

result.

• Use the specified printer paper.

Otherwise, data cannot be printed out or the printer paper may be jammed.

Page 23

2 - 11

CAUTION

• When sending the system back to NIDEK for repair or maintenance, wipe the surface of

the system (except the LCD touch panel) with a gauze dampened with glutaral preparation.

Wipe the LCD touch panel with a gauze dampened with alcohol.

Then, wipe the part which has been cleaned with glutaral preparation with a gauze dampened

with sodium hypochlorite.

Failure to do so may cause personnel who repair or preform maintenance to become infected.

• Ask NIDEK for inspection of the system once a year.

According to the frequency of use, the part which drives the irrigation pole may need to be

greased.

• Only service technicians properly trained by NIDEK can modify and repair the system.

NIDEK assumes no responsibility for accidents caused by improper repair.

2.5 Disposal

CAUTION

• Follow local governing ordinances and recycling plans regarding disposal or recycling of

device components when disposing of the system.

Especially , the disposing method of lithium batteries varies according to the government.

This system has electric circuit boards with lithium batteries in the main body. When

disposing of the board, follow the instruction of the government.

• When disposing of packing materials, sort them by the materials and follow local governing

ordinances and recycling plans.

• When disposing of the main body and foot pedal, wipe the surface of them with a gauze

dampened with rubbing solution such as glutaric aldehyde.

Failure to do so may cause personnel who are involved in the disposal to become infected.

• When disposing of accessories such as tips, tubes, handpiece, forceps and scissors, follow

the recommended disposal procedure for medical wastes such as needles from an injection

or blood infusion tubes as specified by your local medical institution and ordinances

against environmental pollution.

Page 24

2 - 12

2.6 Safety Devices

[TEST mode]

This mode is to check the conditions of each part of the system before surgery , and performing

this test prevents troubles from occurring during surgery.

CV-24000 automatically checks the following items according to the inserted cassette by

pressing each switch in the “Test” box indicated on the LCD touch panel.

• Cataract surgery...............................Motion check of irrigation and aspiration

* When the US handpiece is connected to the

system, ultrasound output is also checked.

• Vitreous surgery ..............................Motion check of aspiration

* When the US handpiece is connected to the

system, ultrasound output is also checked.

• Cataract & Vitreous surgeries

.................Anterior screen: Motion check of irrigation and

aspiration

* When the US handpiece is connected to the

system, ultrasound output is also checked.

Posterior screen: Motion check of aspiration

* When the US handpiece is connected to the

system, ultrasound output is also checked.

If an abnormality is found by checking these items, error and contents are indicated on the

display.

[Self-diagnostic function]

The system automatically checks the connecting condition of each part and own functions

even during surgery. If an abnormality occurs, error and contents are indicated on the display

and the beep sound is produced. (The beep sound stops by pressing the part indicated as an

error.)

[Aspiration pump]

A peristaltic pump system which controls the aspiration flow rate by pressing the aspiration

tube is adopted in order to achieve the ease of operation and stable aspiration.

Page 25

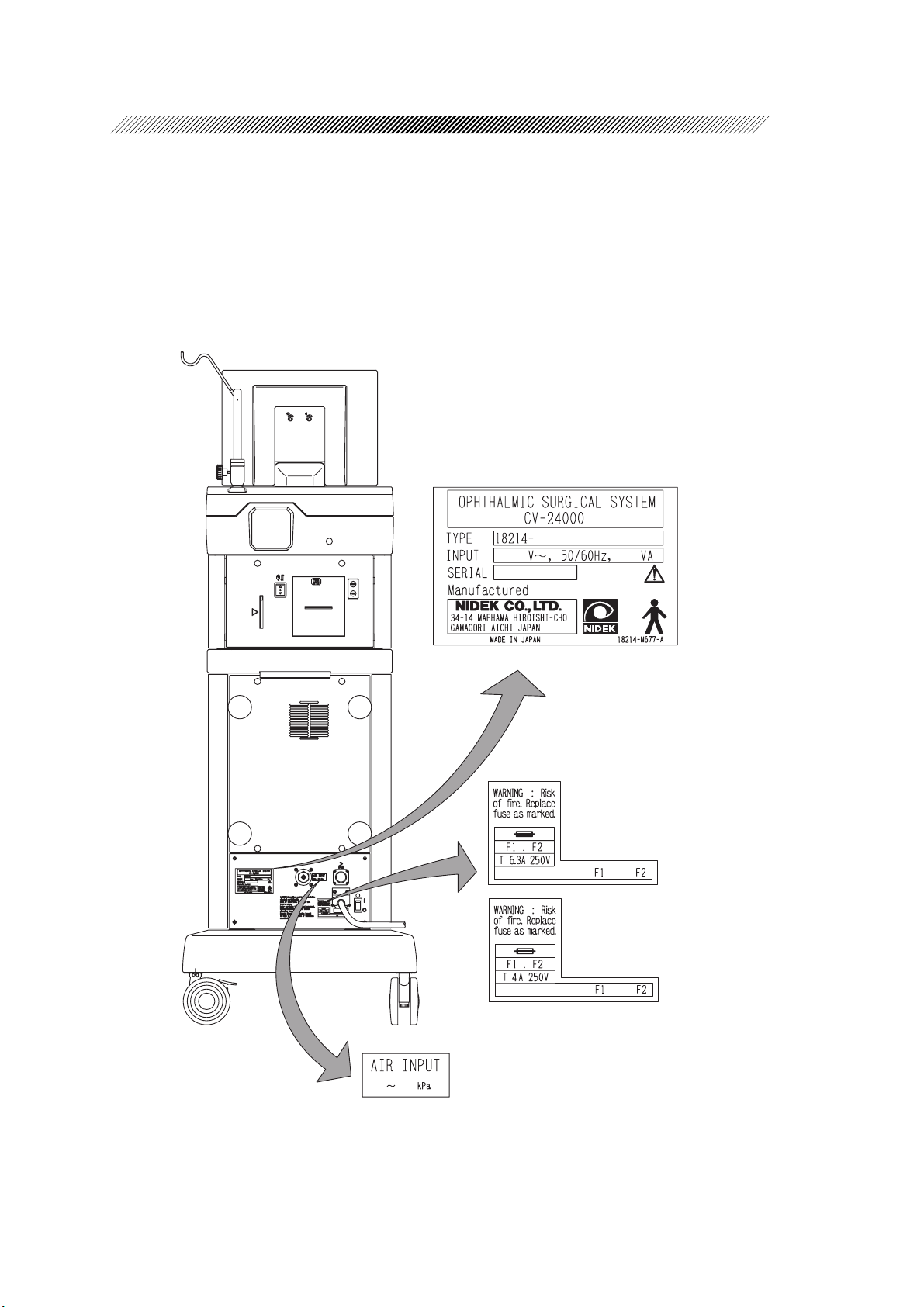

2.7 Labels

In order to call the operator’s attention, the appropriate warning labels are affixed to the designated

locations on the system.

[Rear side of the main body (AP type)]

2 - 13

450

For AC 100V/AC 115V

For AC 230V

550

Page 26

2 - 14

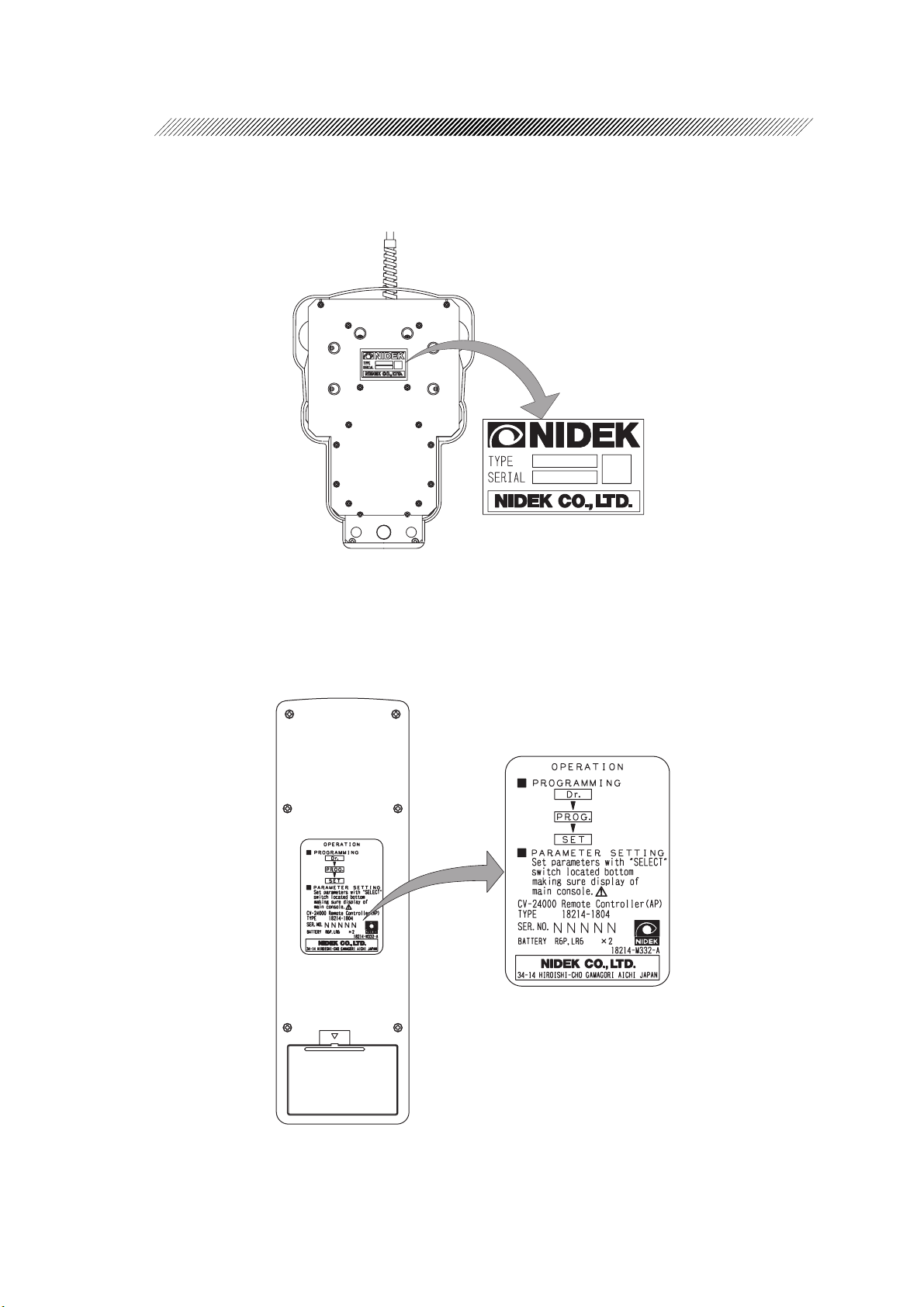

[Bottom side of the foot pedal]

[Rear side of the remote control (AP type)]

Page 27

2 - 15

This page is intentionally left blank.

Page 28

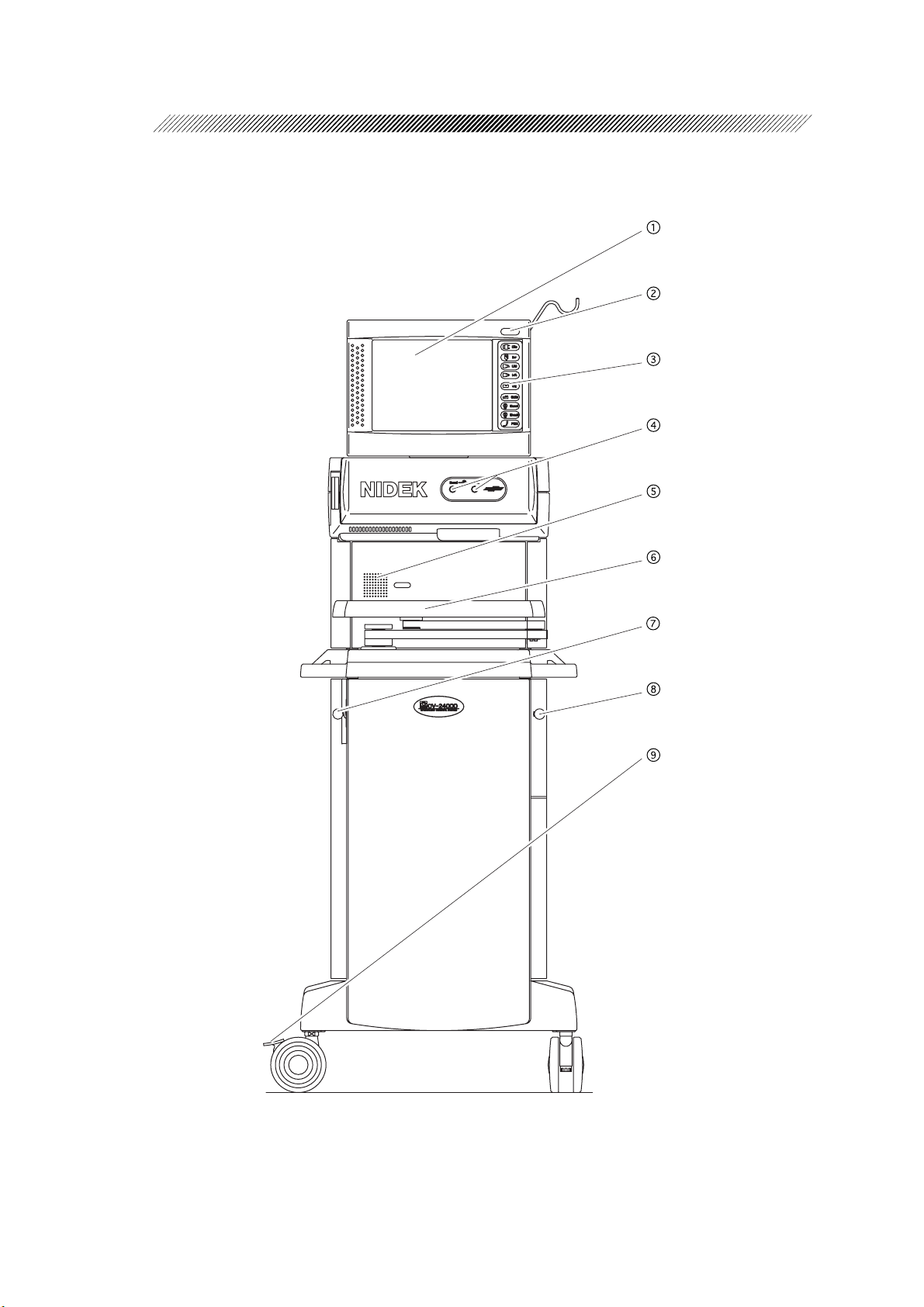

§

SYSTEM DESCRIPTION

3

[Front side of the main body (AP type)]

LCD touch panel

Photodetector of

remote control

Switch panel

Plugs for light guide

Speaker

Tray

Tray UP/DOWN knob

Storage box

Caster lock

Page 29

3 - 2

LCD touch panel

Displays various operation screens, setting

values of each mode, and present system conditions.

By pressing the indicated operation switch, it

is possible to change the mode and input/

change the setting value.

Photodetector of remote control

Receives the infrared signal from the remote

control.

Do not block the anterior part of this photodetector . (P type does not have this function.)

Switch panel

Indicates available modes for each system

type. By pressing these switches on this panel,

the corresponded mode is selected.

Available modes for each system are as follows.

Tray UP/DOWN knob

Used to adjust the height of tray . While raising this knob with one hand, adjust the height

of tray by holding the tray arm with the other

hand.

Releasing this knob fixes the adjusted height.

Storage box

The door of this storage box can be opened

and closed with the knob.

Caster lock

Used to transport the system and fix the position of the system. The caster is locked by

lowering the lever, and it is released by raising the lever .

Type Available m ode s

A type Dia, Irr, US, I/A, Vit

AP type

P type

Dia, Irr, US, I/A, Vit, Scis,

Illum1, Illum2, ON/OFF of FGX

Dia, Asp, Vit, Scis, Illum1,

Illum2, ON/OFF of FGX

Plugs for light guide

For AP and P types, the connector of the light

guide for intraocular illumination is inserted

here.

Speaker

This is for a voice guidance, operation sound,

and beep sound.

T ray

The remote control, each handpiece for US,

I/A, and irrigation, vitrectomy cutter, intraocular scissors, and light guide probe are placed

here.

Be sure not to place heavy object or rest your

weight on this tray.

Page 30

3 - 3

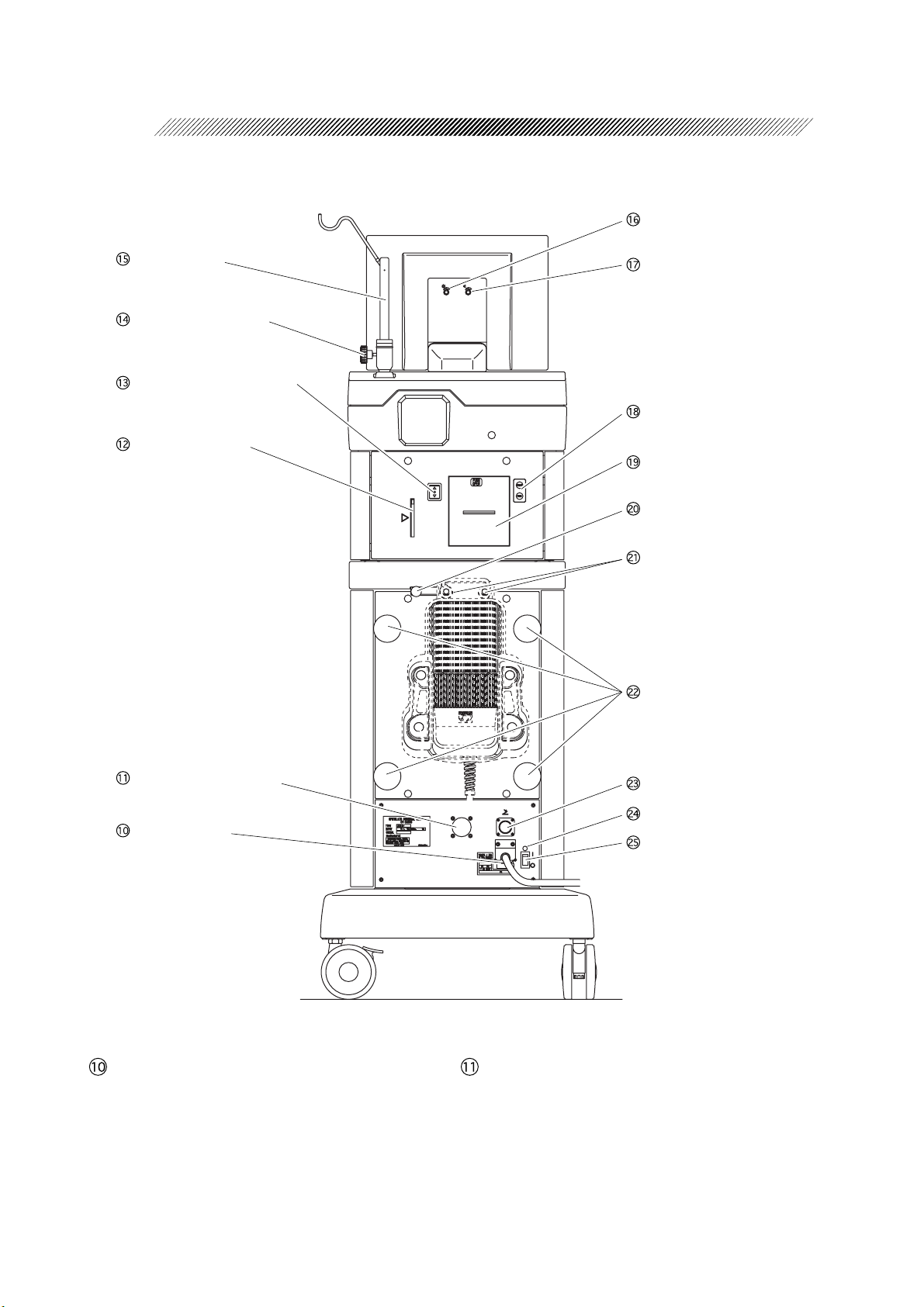

[Rear side of the main body (AP type)]

Back light control

Irrigation pole

Irrigation pole height

fixing knob

Irrigation pole UP/DOWN

switch

Memory card slot

Volume control

PRINT/FEED switch

Printer cover

Hook for foot pedal cable

Hook for foot pedal

Hook for power cord

Connector for external

pressure source

Inlet with fuse

Inlet with fuse

Inlet with the built-in fuse carrier.

The power cord is connected here.

When the power is not supplied to the system, there is a fear that fuses inside the carrier may be burnt.

Foot pedal connector

Pilot lamp

Power switch

Connector for external pressure source

When using a compressed air or nitrogen gas

cylinder as a driving source for the vitrectomy

cutter and intraocular scissors with AP or P

type, the external pressure source is connected

here.

Page 31

3 - 4

Memory card slot

A memory card for storing data of surgery

conditions is inserted here.

Irrigation pole UP/DOWN switch

Used to adjust the height of irrigation pole.

By pressing the side, the irrigation pole is

raised, and it is lowered by pressing the

side.

Irrigation pole height fixing knob

When the adjustable range of the height is not

enough with the irrigation pole UP/DOWN

switch, loosen this knob and adjust the height

of irrigation pole.

Irrigation pole

This is for hanging an irrigation bottle.

The height of bottle can be adjusted with the

electric switch.

The irrigation bottle is hung on the hook at

the top of this pole.

Printer cover

A printer is built in this cover. When “PUSH

OPEN” at the top of this cover is pressed, the

cover opens and it becomes possible to re-

place the printer paper.

Hook for foot pedal cable

A foot pedal cable is hung on here when the

system is transported and stored.

Hook for foot pedal

A foot pedal is hung on here when the system

is transported and stored.

Hook for power cord

A power cord is hung on here when transporting and storing the system.

Foot pedal connector

A connector of the foot pedal is connected

here.

Back light control

Used to adjust the light quantity of the back

light for LCD touch panel. Turning this control clockwise brightens the back light, and

turning this control counterclockwise darkens the back light.

Volume control

Used to adjust the volume of speaker. Turning this control clockwise turns up the volume, and turning this control counterclockwise turns down the volume.

PRINT/FEED switch

When the PRINT switch is pressed, the surgery data displayed on the LCD touch panel

is printed out.

When the FEED switch is pressed, the printer

paper is fed. This switch is also used when

the printer paper is replaced.

Pilot lamp

Lights up when the power is supplied to the

system by turning ON ( | ) the power switch.

Power switch

Used to turn ON/OFF the power of the system. Pressing the “ | ” side turns ON the

power, and pressing the “ ” side turns OFF

the power.

Page 32

3 - 5

[Left side of the main body (AP type)]

FGX connector

Cassette slot

CASSETTE EJECT

switch

TESTING CASSETTE

indicator

DIA connector

VIT connector

US connector

SCIS connector

Page 33

TESTING CASSETTE indicator

Blinks during a test.

CASSETTE EJECT switch

To eject the cassette, press this switch. After

the lock of cassette is unloaded, the cassette

can be pulled out.

Cassette slot

A cassette is inserted here.

FGX connector

When fluid/gas used with AP or P type is exchanged, a tube connector for fluid/gas exchange is connected here via a microfilter.

DIA connector

A banana plug of the diathermy connecting

cord is connected here.

3 - 6

VIT connector

A connector of the tube for driving the

vitrectomy cutter is connected here.

US connector

A connector plug of the connecting cable for

US handpiece is connected here when the US

handpiece is used with A or AP type.

SCIS connector

When the intraocular scissors is used with AP

or P type, a connector for driving the intraocular scissors is connected here.

Page 34

3 - 7

[Foot pedal]

Upper left switch

Left kick switch

Lower left switch

Main pedal

Upper right switch

Right kick switch

Lower right switch

Functions of each switch on the foot pedal can be changed with program setting. Here, the

factory settings are described. (As for the change of foot switch patterns and the operation of

each foot pedal position, see pages 3-10 and 3-11.)

* The factory setting is indicated with “Preset” on the LCD touch panel.

Lower left switch

Used to switch the mode.

In the anterior mode, every time this switch

is pressed, the mode during surgery is changed

Upper left switch

When this switch is pressed while the diathermy

output is possible, the diathermy is output with

the set output power.

in the following order; Dia → Irr → US → I/

A → Dia → .

In the posterior mode, the mode during surgery is changed in the following order; V it →

Upper right switch

While this switch is pressed, the irrigation pole

is raised.

ASP → Vit → .

Left kick switch

Used to reflux.

Page 35

3 - 8

Right kick switch

In the anterior mode, the modulation is changed in the following order; US1 → US2 → (US3 →)

US1 → , when the US mode is selected. When the I/A mode is selected, the modulation is

changed in the following order; I/A1 → I/A2 → (I/A3 →) I/A1 → .

In the Vit mode, the state of vitrectomy cutter is changed between READY and OFF with this

switch.

In the posterior mode, this switch changes the state of vitrectomy cutter between READY and

OFF when the V it mode is selected. When the SCIS mode is selected, the insert mode is changed

between ON and OFF with this switch.

If the US mode is selected, the ultrasound oscillation is changed between ON and OFF with this

switch.

*Whether US3 or I/A3 mode can be used or not depends on the program setting.

Lower right switch

While this switch is pressed, the irrigation pole is lowered.

Main pedal

Controls the operation such as start/stop of irrigation, aspiration, ultrasound oscillation, vitrectomy

cutter, and diathermy in the anterior mode.

In the posterior mode, it controls the operation of aspiration, vitrectomy cutter, intraocular scissors, and diathermy.

Followings are the operation of each foot pedal position.

[In anterior mode]

Mode

Position

0

1

2

3

Mode

Position

0

1

2

3

Dia Irr US US (Propedal)

-- - -

- Irrigation Irrigation Irrigation + Aspiration

Diathermy Irrigation + Aspiration Irrigation + Aspiration + US

I/A I/A (Propedal) Vit

Irrigation Irrigation + Aspiration Irrigation

Irrigation + Aspiration Irrigation + Aspiration Irrigation + Aspiration + Cutter

↑

↑

↑↑

-- -

Irrigation + Aspiration + US Irrigation + Aspiration + US

Irrigation + Aspiration

* ON/OFF of “FreeFlow” has higher priority in the irrigation setting.

* Cutter operation in V it mode depends on the setting of Ready/Off.

↑

Page 36

3 - 9

[In posterior mode]

Mode

Position

OFF

ON

Mode

Position

OFF

ON

Dia Vit Asp

---

Diathermy Aspiration + Cutter Aspiration

US Scis Auto Scis Proportional

-- -

Aspiration + US Scissors cutting operation Scissors linear operation

* Cutter operation in V it mode depends on the setting of Ready/Off.

* Ultrasound oscillation in US mode is performed only when the right kick switch is ON during

ultrasound oscillation.

Page 37

3 - 10

[Foot switch patterns]

To change the function of each foot switch, press the switch or

to switch on the screen indicating each foot switch

function, then select the desired pattern. (As for the changing method, see pages 4-97

and 4-103.)

The table below shows the function of switches in each pattern.

Upper left switch

Left kick switch

Lower left switch

Main pedal

Upper right switch

Right kick switch

Lower right switch

Switch

Upper left switch Diathermy output Diathermy output Diathermy output Diathermy output Reflux

Left kick switch Reflux

Lower left switch M ode s wi t ching Mode switc hi ng

Upper right swi t ch

Right kick switch

Lower right swi t ch

Pattern

Preset Pattern 1 Pattern 2 Pattern 3 Pattern 4 Pattern 5

FreeFlow

ON/OFF

Anterior: Switching the Modulation, Cutter READY/OFF

Posterior: Cutter READY/OFF, Scissors insert mode ON/OFF, US oscillation ON/OFF

Reflux

FreeFlow

ON/OFF

POLE UP

POLE DOWN

FreeFlow

ON/OFF

Reflux Mode switc hi ng M ode switc hi ng

FreeFlow

ON/OFF

FreeFlow

ON/OFF

Reflux

Switch

Upper left switch Diat hermy output Diathermy output Diatherm y output

Left kick switch Reflux Vit1 ⇔ Vit2 Vit1 ⇔ Vit2

Lower left switch Vit1 ⇔ Vit2 Mode switching

Upper right s wit ch

Right kick switch

Lower right s wit ch

Pattern

Anterior: Switching the Modulation, Cutter READY/OFF

Pos t eri or: Cut t er RE A DY / OF F , Scis sors ins ert mode ON/OFF, US oscillat i on ON/ OF F

*Pattern 6 *Pattern 7 *Pattern 8

FGX

ON/OFF

POLE UP

POLE DOWN

* Pattern 6 to 8 are for vitreous surgery.

Page 38

3 - 11

[Switch of main pedal position]

The position of main pedal is switched between Position 0 and Position 3 according to

the pressing amount. (The illustration below shows each switching position.)

You feel a click just before the position is switched by holding the main pedal down.

The reason why there is an overlap between positions is to surely perform the switching

operation with the main pedal by setting different switching positions between the

pressing and releasing of the pedal.

%

Page 39

[Remote control]

Type of remote control varies between A and AP types. Switches whose name and positions

are the same have the same functions. (P type does not have a remote control.)

Each switch is positioned on the color-coded sheet according to its function.

Here, the descriptions are mainly for AP type.

3 - 12

[AP type] [A type]

Page 40

3 - 13

LCD monitor

Displays the name of pressed switch. Normally, the shift code (“RC 1”, “RC 2”, “RC 3”, “RC

4”) of the remote control is indicated.

Owing to the auto-power-off function, the power is turned OFF when no operation is executed

for 30 minutes. The “OFF” indication starts blinking 1 minute before the power is automatically

turned OFF.

The “BATT” indication appears when the amount of remaining battery time becomes small.

DR./PROG./SET switch

Used to change Doctor/Program.

When the DR. switch is pressed, the selected DR. being highlighted appears in the small screen

for the change of Doctor . Keep pressing the DR. switch until the desired Doctor is highlighted,

and press the SET switch to determine.

To change the Program, use the PROG. switch in the same manner.

* “Preset” means the factory setting.

* DR. cannot be changed on the screens during surgery.

POWER switch

Turns ON/OFF the power of the remote control.

ANT/POST switch (only for AP type)

Displays the main screen for Anterior/Posterior mode.

The main screen for Anterior mode appears by pressing the ANT switch, and the one for Posterior mode appears by pressing the POST switch.

When these switches are pressed on the screen during surgery , both switches works as the “Exit”

switch.

TEST switch*

2

Used to start the system test.

Mode selection switch*

2

Used to display each mode screen. The function is the same as switches on the switch panel

which is on the right side of LCD touch panel.

* ASP switch and SCIS switch are only for AP type.

PRINT/CLEAR switch

By pressing the PRINT switch, the surgery data can be printed out.

By pressing the CLEAR switch, the surgery data is cleared.

*2 By pressing the TEST switch, the message “US, V it, Dia?” is displayed on the screen in the anterior

mode, and the message “PPL, V it, Dia?” is displayed in the posterior mode. T o start the system test,

wait 3 seconds, or press the TEST switch again. To start a test of a specific mode, press the switch

of the mode to test while the message is displayed (within 3 seconds).

Page 41

3 - 14

IV POLE/FREE FLOW switch

Pressing the up switch of IV POLE raises the irrigation pole, and it is lowered when the down

switch is pressed.

Every time the FREE FLOW switch is pressed, FreeFlow is switched between ON and OFF.

PARAMETER SELECT switch

Used to change the setting of items which are not indicated on the small screens on the LCD

touch panel. Changeable items are as follows;

• Dia Power • US Power • Vacuum • Cut Rate • Scis Pressure

(When the propedal is set, US Power and Vacuum can be set for each position.)

Keep pressing the SELECT switch until the blue triangle cursor showing the changeable item

moves to the desired item, and press the up or down switch to change the setting. To clear the

blue triangle cursor, wait for 5 seconds without any operation or press the SET switch.

FGX / ILLUM 1 / ILLUM 2 switch (only for AP type)

Every time the FGX switch is pressed, FGX is switched between ON and OFF.

Every time the ILLUM 1 or ILLUM 2 switch is pressed, the illumination is switched between

ON and OFF.

(Functions of FGX, ILLUM 1, and ILLUM 2 switches are the same as switches on the switch

panel which is on the right side of LCD touch panel.)

Small frame SELECT/SET switch

Used to indicate the small screen and change the setting of items.

Keep pressing the SELECT switch until the highlighted area moves to the desired item, and

press the up or down switch to change the setting.

To clear the small screen, wait for 5 seconds without any operation or press the SET switch.

Page 42

§

4

4.1 Preparation Befor e Surgery

CAUTION

• The words [SCRUB] or [CIRCULATOR] in the instructions indicate the personnel

responsible to perform the task.

[SCRUB]: The operator or assistant who is in the sterile area.

[CIRCULATOR]: The personnel who operate the system in the nonsterile area.

Be sure to follow the instruction, [SCRUB] or [CIRCULATOR].

4.1.1 Sterilization of instruments

(Perform sterilization considering the time required to sterilize and dry instruments before surgery .)

1. [CIRCULATOR] places all the accessories to be sterilized on the tray after washing them.

OPERATING PROCEDURES

[Accessories to be sterilized]

• Irrigation handpiece • I/A handpiece

• I/A tip • US handpiece

• US tip • Wrench for tip

• Diathermy forceps or pencil • Other necessary instruments

• Diathermy cable

CAUTION

• It is recommended to place the handpiece and tips in the sterilization case for

sterilization.

Since they are the precision parts, there is a fear of loss or damage.

2. [CIRCULA T OR] sterilizes the instruments together with the tray .

(1) Method

Perform the autoclave sterilization.

[CIRCULA T OR]

Page 43

(2) Sterilizer

Use a vacuum drying type sterilizer .

CAUTION

• Never fail to use a vacuum drying type sterilizer for autoclaving of the US handpiece.

Any sterilizers other than the vacuum drying type degrades the performance of the US

handpiece.

(3) Sterilizing temperatur e and time

Because the relationship between temperature and time in autoclave sterilization depends on the

characteristics of the autoclaving system and items to be sterilized, and the number of them, we

cannot provide you with reliable conditions for the sterilization. V erify the autoclave sterilizer and

the temperature and time of sterilization in your medical facility .

For reference, the following is standard number for the sterilization industry:

Sterilizing temperature at 132ºC................ 12 minutes.

CAUTION

4 - 2

• Autoclave instruments at a temperature of 132ºC or lower.

Otherwise, the instruments may be damaged because of overheating.

• Items in the sterilization case and parts of them covered with gauze, etc. are kept from the

steam to some extent. Therefore, they need sterilizing longer than under normal conditions.

(4) Drying

After the sterilization, dry the instruments for at least 10 minutes (20 minutes is recommended).

CAUTION

• Drying is the final and an important process of autoclaving. If the drying is not enough, an

adequate sterilization result cannot be expected. Therefore infection will be possible.

3. After cooling the sterilized instruments enough, store them in a clean, dry place without load

on them.

Page 44

4 - 3

4.1.2 Setup

CAUTION

• Prior to the first use of the system each day, perform the system test and function checks

referring to the Pre-operation check manual (18214-P912A).

NIDEK assumes no responsibility if failure occurs during the operation of each mode

without performing the test and checks.

1. [CIRCULATOR] sets the system on a convenient position for surgery.

When the system is set, lock the caster.

2. [CIRCULATOR] sets the foot pedal on the convenient position.

If the cable plug of the foot pedal is not connected, connect it to the foot pedal connector on the rear

side of the system.

3. As for AP or P type, [CIRCULATOR] pr epares the external pr essur e sour ce if necessary.

If the system requires the external pressure source, connect the external pressure source to the external

pressure source connector on the rear side of the system.

* Adjust the air pressure of external pressure source to 450 - 550 kPa.

4. [CIRCULA TOR] plugs the power cord in the power outlet.

5. [CIRCULATOR] turns ON ( | ) the power switch on the r ear side of the system.

The pilot lamp lights up.

6. [CIRCULATOR] verifies that the sterilization package has no wetness and break. Then,

[CIRCULA T OR] opens the package and hand the cassette to [SCRUB].

CAUTION

• If wetness or break is found, replace the sterilization package with another one.

• When opening the sterilization package and handing the contents to [SCRUB], pay

attention not to let them get nonsterilized.

Page 45

4 - 4

7. [SCRUB] receives the cassette from [CIRCULATOR]. [SCRUB] connects the cassette to

the connection set that is appropriate for the surgery to be performed. Then [SCRUB]

hands the cassette to [CIRCULA T OR].

1) [SCRUB] places the cassette on a sterile and stable place.

2) When using a cassette other than the anterior single cassette, [SCRUB] replaces the connection

set.

i ) [SCRUB] removes the protective cover from the anterior single cassette.

i i) [SCRUB] connects the appropriate connection set to the position where the protection cover

was removed while paying attention to the port from the cassette so that it is not contaminated.

* After the connection set is replaced, a lug is locked so that it cannot be removed. NIDEK

does not assure the operation of system if the connection set is forcefully removed.

* Do not connect the connection set while the cassette is inserted into the system.

3) [SCRUB] hands only the cassette to [CIRCULATOR].

NOTE

• Procedure from here varies according to the cassette to be used in connection of tubes and

test types. Verify the cassette type and refer to the description about the setting and test.

- Setting and test for the anterior single cassette <A, AP> ......................... p. 4- 5

- Setting and test for the anterior dual cassette <A, AP>....................... p. 4-9

- Setting and test for the anterior/posterior dual cassette <AP> ............ p. 4-13

-

Setting and test for the posterior dual cassette

(Posterior setting) <AP> ...........................................................................

-

Setting and test for the posterior dual cassette

(ANT/POST setting) <AP> .......................................................................

- Setting and test for the posterior dual cassette (Dual) <P> ................. p. 4-34

- Setting and test for the posterior dual cassette (Single) <P> .................... p. 4-40

• Record the result of each test in the checklist of the Pre-operation check manual (18214P912A).

p. 4-21

p. 4-27

Page 46

4 - 5

*

4.2 Setting and Testing Each Cassette

4.2.1 For anterior single cassette -- For A and AP types

Connected to VIT connector of the system.

Not connected.

*1: Protective cover

(supplied with cassette)

*1: Infusion tube

*1: Drainage bag

(attached to cassette)

*2: Wrehch for tip

*2: Irrigation handpiece (short)

*2: Irrigation handpiece (long)

*2: I/A handpiece

*1: I/A tube (bonded to cassette)

*2: US handpiece 40kHz

*2: US tip (various types)

*2: Vitrectomy cutter

*1: Accessories supplied with cassette

*2: Irrigation sleeve

*2: Other accessories and instruments

*1: Silicone sleeve

*2: I/A tip 0.3 dia.

1: Test chamber

Page 47

NOTE

• If aspiration is not performed properly during surgery, confirm the connection of the

tube first. If that does not solve the problem, replace the cassette and perform the cassette

and system tests again.

In addition, inform one of NIDEK’s sales representative of the occurrence of the problem

and the lot number of the I/A tube.

• If the drain bag becomes full during surgery, replace the cassette immediately and

perform the cassette and system tests again.

The drained water may run through the system and cause malfunction.

1. Securely insert the anterior single cassette

into the cassette slot.

1) [CIRCULATOR] opens the disposable

cassette pack. [SCRUB] takes out a cassette

and hands it to [CIRCULA T OR].

4 - 6

2) Insert the anterior single casssette into the

cassette slot on the left side of the system as far

as it goes. [CIRCULA T OR]

* After the cassette is inserted, it is

automatically tested. W ait until the cassette

test is completed.

Luer of the mark

(Connect the infusion tube)

2. After the cassette test, [CIRCULAT OR] connects the infusion tube.

1) Open the package of infusion tube and take

out the infusion tube.

2) Close the clamp of infusion tube and remove

the cap from the tip of spike. Then, securely fit

the spike onto the rubber stopper of the irrigation

bottle.

3) Connect the luer of infusion tube to the luer of

the mark on the cassette. (See step 1.)

Page 48

4 - 7

3) Remove the protector from the needle and stick

the needle straight to the rubber plug on the

irrigation bottle.

4) Pinch the dropper slowly with fingers and

release it so that the irrigation solution fills half

of the dropper.

Rubber plug

Needle

Air shut-off cap

Dropper

Infusion tube

Clamp

* Leave it open.

Connect to the luer of the

3. [SCRUB] receives a set of autoclaved instruments from [CIRCULAT OR].

4. [SCRUB] sets the I/A handpiece.

1) Screw the I/A tip with the silicone rubber tube

on into the I/A handpiece.

mark

2) When the I/A tip is screwed as far as it goes,

remove the silicone rubber tube.

3) Hold the wrench for the tip as illustrated on the

right. Tighten the root of the I/A tip firmly with

the wrench for the tip.

CAUTION

• If the tip wrench is held incorrectly, the user’s

hand may get injured with the US tip.

I/A handpiece

Silicone rubber

tube

Wrench for tip

I/A tip

Page 49

4) Put the silicone sleeve on the I/A tip. Then

hold the thick part of the sleeve and screw it.

5) Adjust the position relationship of the silicone

sleeve and I/A tip.

* The following is the standard:

The distance (= ) between the end of the

4 - 8

silicone sleeve and the port of the I/A tip is

approximately the same as the diameter of

the port.

The angle that the irrigation port of the sleeve

and the port of the I/A tip make is 90º.

6) As necessary, put the test chamber on the tip

of the I/A handpiece.

CAUTION

• Put the test chamber on the end of the I/A

handpiece when it is not used to protect the

I/A tip.

7) Connect the I/A tubes to the I/A handpiece as

illustrated on the right as necessary .

Silicone sleeve

Test chamber

Irrigation tube

Aspiration tube

Page 50

4 - 9

5. Set the US handpiece.

1) [SCRUB] screws the US tip with the silicone

rubber tube on into the US handpiece.

2) When the US tip is inserted as far as it goes,

[SCRUB] removes the silicone rubber tube.

3) [SCRUB] tightens the root of the US tip firmly

with the wrench for the tip.

US handpiece

Silicone rubber

tube

CAUTION

• If the root of the US tip is not tightened

enough, failure of ultrasound oscillation may

happen.

• If the tip wrench is held incorrectly, the user’s

hand may get injured with the US tip.

4) [SCRUB] puts the silicone sleeve on the US

tip. Then hold the thick part of the sleeve and

screw it.

Wrench for tip

US tip

Silicone sleeve

Page 51

5) [SCRUB] adjusts the position relationship of

the silicone sleeve and US tip.

* The following is the standard:

The distance (= ) between the end of the

silicone sleeve and the aspiration port of the

US tip is approximately the same as the

diameter of the port.

The angle that the irrigation port of the sleeve

and the aspiration port of the US tip make

is 90º.

4 - 10

6) As necessary, [SCRUB] puts the test chamber

Test chamber

on the tip of the US handpiece as necessary .

CAUTION

• Put the test chamber on the tip of the US handpiece when it is not used to protect the US tip.

•

Be careful not to make the end of the US tip contact the test chamber and pierce a hole in it.

7)

[SCRUB] hands the plug of the US handpiece

to the [CIRCULATOR].

8) [CIRCULAT OR] aligns the red mark on the

cable plug and the connector. Then insert the

plug straight to the connector.

Red mark

9) [SCRUB] connects the I/A tubes to the US

handpiece as illustrated on the right as

necessary .

Cable plug

Irrigation tube

Aspiration tube

Page 52

4 - 11

6. [CIRCULATOR] performs the system test.

Press the switch in the “T est” box on the main screen to perform the test of irrigation/

aspiration. (If the plug of US handpiece is connected, ultrasound oscillation is also checked.)

* T o operate with the remote control, press the TEST swich.

CAUTION

• Disconnect the plug of US handpiece when the test of ultrasound oscillation is not

performed.

If the ultrasound oscillation is performed in the air while the plug is connected, the

US handpiece may be damaged.

• Slightly hold the tip of test chamber during the system test so that the tip of the test

chamber does not get sucked into its inside.