Page 1

NIDEK

OPHTHALMIC SURGICAL SYSTEM

[PHACOEMULSIFICATION • VITREOUS SURGERY]

Model CV-24000

SERVICE MANUAL

December 21, 2001

XCV4**RDA001B/E Total 142 pages

Page 2

Page 3

Table of Contents

§

1 CAUTIONS .................................................................................................................. 1-1

1.1 Cautions in using the manual ................................................................................... 1-1

1.2 Cautions in repairing ................................................................................................ 1-1

§

2 TROUBLESHOOTING .............................................................................................. 2-1

§

3 SUB-TROUBLESHOOTING ..................................................................................... 3-1

3.1 Pilot lamp does not illuminate.................................................................................. 3-1

3.1.1 Check of P.S. board ......................................................................................... 3-2

3.2 Nothing appears on screen ....................................................................................... 3-3

3.2.1 Communication error of screen ....................................................................... 3-4

3.3 Back light can not be adjusted.................................................................................. 3-4

3.4 Touch panel does not work ....................................................................................... 3-5

3.5 Seat switch does not work ........................................................................................ 3-6

3.6 Remote control does not work ................................................................................. 3-7

3.7 Sounds do not come out ........................................................................................... 3-8

3.8 Volume can not be adjusted ...................................................................................... 3-8

3.9 Irrigation pole does not move by irrigation UP/DOWN switch ............................... 3-9

3.10 Printer does not work normally ............................................................................ 3-11

3.11 Memory inside of main body does not work correctly ......................................... 3-12

3.12 Memory card does not work correctly .................................................................. 3-12

3.13 Cassette test is not passed .................................................................................... 3-13

3.14 Cassette can not be removed ................................................................................ 3-14

3.15 SYSTEM (cataract) test is not passed .................................................................. 3-16

3.15.1 SINGLE CASSETTE .................................................................................. 3-16

3.15.2 ANT DUAL CASSETTE ............................................................................ 3-20

3.16 US test is not passed ............................................................................................. 3-24

3.17 DIA test is not passed ........................................................................................... 3-24

3.18 SYSTEM (vitrectomy) test is not passed ............................................................. 3-25

3.18.1 ANT/POST DUAL CASSETTE ................................................................. 3-25

3.18.2 POST DUAL CASSETTE .......................................................................... 3-29

3.19 PPL test is not passed ........................................................................................... 3-32

3.20 Foot switch does not work ................................................................................... 3-33

3.21 Irrigation does not move correctly ....................................................................... 3-35

3.22 Aspiration does not work correctly ...................................................................... 3-36

3.23 US oscillation is not performed correctly............................................................. 3-38

3.24 Diathermy output is abnormal .............................................................................. 3-39

3.25 Cutter does not work (for using built-in compressor) .......................................... 3-40

3.25.1 Check of air pressure piping for cutter (only for ANTERIOR) .................. 3-41

3.25.2 Check of air pressure piping for cutter (for both of ANT/POST) ............... 3-42

Page

Page 4

3.26 Cutter does not work (in the case of using external air pressure) ........................ 3-44

3.27 Scissors do not work correctly ............................................................................. 3-46

3.27.1 Check of air pressure piping for using built-in compressor ........................ 3-46

3.27.2 Check of air pressure piping for using external air pressure ....................... 3-48

3.28 FGX does not work correctly ............................................................................... 3-50

3.29 Illumination does not work correctly ................................................................... 3-52

3.30 Check of power (P.S. board)................................................................................. 3-54

§

4 REPLACEMENT ......................................................................................................... 4-1

4.1 Replacement of top cover ......................................................................................... 4-1

4.2 Replacement of rear cover ........................................................................................ 4-1

4.3 Replacement of lower part of left cover ................................................................... 4-2

4.4 Replacement of lower part of right cover ................................................................. 4-2

4.5 Replacement of front cover ...................................................................................... 4-3

4.6 Replacement of inverter ........................................................................................... 4-3

4.7 Replacement of display board .................................................................................. 4-4

4.8 Replacement of main board...................................................................................... 4-4

4.9 Replacement of limit switch ..................................................................................... 4-5

4.10 Replacement of driving (AC) motor ...................................................................... 4-6

4.11 Replacement of control unit ................................................................................... 4-7

4.12 Replacement of P.S. board...................................................................................... 4-8

4.13 Replacement of US unit ......................................................................................... 4-9

4.14 Replacement of compressor ................................................................................. 4-10

4.15 Replacement of printer ......................................................................................... 4-10

4.16 Replacement of noise filter .................................................................................. 4-11

4.17 Replacement of power switch .............................................................................. 4-11

4.18 Replacement of transformer ................................................................................. 4-12

4.19 Replacement of BU CONNECT board (BA06) ................................................... 4-12

4.20 Replacement of VR board (BA21) ....................................................................... 4-13

4.21 Replacement of RECEIVER board (BA02) ......................................................... 4-13

4.22 Replacement of speaker ....................................................................................... 4-14

4.23 Replacement of irrigation pole UP/DOWN switch (EA56) ................................. 4-15

4.24 Replacement of PRINT/FEED switch (BA29)..................................................... 4-15

4.25 Replacement of POLE CONTROL board (BA07) ............................................... 4-16

4.26 Replacement of microswitch (SW56, 58) ............................................................ 4-16

4.27 Replacement of EJECT switch board (BA29) ..................................................... 4-17

4.28 Replacement of TUBE SENS board (BA28) ....................................................... 4-17

4.29 Replacement of DRIVER board (BA05) .............................................................. 4-18

4.30 Replacement of CASSETTE SENS board (BA27) .............................................. 4-18

4.31 Replacement of FGX/SCIS board (BA08) ........................................................... 4-19

4.32 Replacement of ILL/SCIS SELECT board (BA09) ............................................. 4-19

4.33 Replacement of solenoid valve ............................................................................ 4-20

4.34 Replacement of pressure sensor for control (EA86) ............................................ 4-21

4.35 Replacement of pressure sensor (EA84) .............................................................. 4-22

4.36 Replacement of condenser (C1) for AC motor (driving motor) ........................... 4-22

4.37 Replacement of VACUUM SENS board (BA26) ................................................ 4-23

4.38 Replacement of CARD board (BA24) ................................................................. 4-23

4.39 Replacement of valve unit (1 set and 2 sets) ........................................................ 4-24

4.40 Replacement of pressure sensor for FGX output (EA88) .................................... 4-24

Page 5

4.41 Replacement of seat switch .................................................................................. 4-25

4.42 Replacement of load cell unit (EA31) .................................................................. 4-25

4.43 Replacement of aspiration motor (EA39) ............................................................ 4-26

4.44 Replacement of pilot lamp ................................................................................... 4-27

§

5 ADJUSTMENT ............................................................................................................ 5-1

5.1 Transformer output (check at secondary side) ......................................................... 5-1

5.2 Output voltage check of P.S. board (BA04) ............................................................. 5-1

5.3 Output voltage check of BU CONNECT board (BA06) .......................................... 5-1

5.4 Output voltage check of MAIN board (BA03)......................................................... 5-2

5.5 Output voltage check of DRIVER board (BA05) .................................................... 5-2

5.6 Output voltage check of FGX/SCIS board (BA08) .................................................. 5-2

5.7 Output voltage check of US unit (E100) .................................................................. 5-2

5.8 Voltage adjustment of FGX/SCIS board (BA08) ..................................................... 5-3

5.9 Output voltage check of DISPLAY board (BA02) ................................................... 5-3

5.10 Adjustment of irrigation height detection potentiometer ....................................... 5-4

5.11 Adjustment of control unit ..................................................................................... 5-4

5.12 Adjustment of FGX/SCIS mode ............................................................................ 5-5

5.13 Adjustment of pinch valve ..................................................................................... 5-6

5.14 Adjustment of load cell positioning ....................................................................... 5-6

5.15 Adjustment of aspiration motor (EA39) positioning.............................................. 5-7

§

6 WIRING DIAGRAM ................................................................................................... 6-1

6.1 Block diagram .......................................................................................................... 6-1

6.2 Display unit diagram ................................................................................................ 6-2

6.3 Main unit diagram .................................................................................................... 6-3

6.4 P.S. unit diagram....................................................................................................... 6-4

6.5 Driver unit diagram .................................................................................................. 6-5

6.6 BU CONNECT unit diagram ................................................................................... 6-6

6.7 POLE CONTROL unit diagram ............................................................................... 6-7

6.8 FGX/SCIS unit diagram ........................................................................................... 6-8

6.9 ILL/FGX SELECT unit diagram .............................................................................. 6-9

§

7 TOOLS AND SOLVENTS .......................................................................................... 7-1

7.1 Tools ......................................................................................................................... 7-1

7.2 Solvents .................................................................................................................... 7-1

§

8 ERROR CODE ............................................................................................................. 8-1

Page 6

§

1

CAUTIONS

1.1 Cautions in using the manual

• This manual is for the service work of the Phacoemulsification System, Model CV-24000.

• Before using this manual, thoroughly read and understand the operator’s manual for CV-24000.

• This manual does not contain the contents written in the operator’s manual.

• The specifications are subject to change without notice for improvement. For the important

change, see the technical bulletin issued for the change concurrently.

1.2 Cautions in repairing

• For repairing, make sure to wear rubber gloves to protect from the infection of bacteria.

• Never touch the things which are used for surgery and not yet sterilized.

• When checking the motion, ensure to use the sterilized handpiece.

• Repairing the system is prohibited except the personnel who received the training.

• For maintenance, turn OFF the power and disconnect the socket from the power unless this

manual specifies “Turn ON the power”.

• Prepare a case for removed screws and parts not to miss or drop them into the system.

• For loosening and tightening threadlocker-applied screws, apply the threadlocker again.

Page 7

§

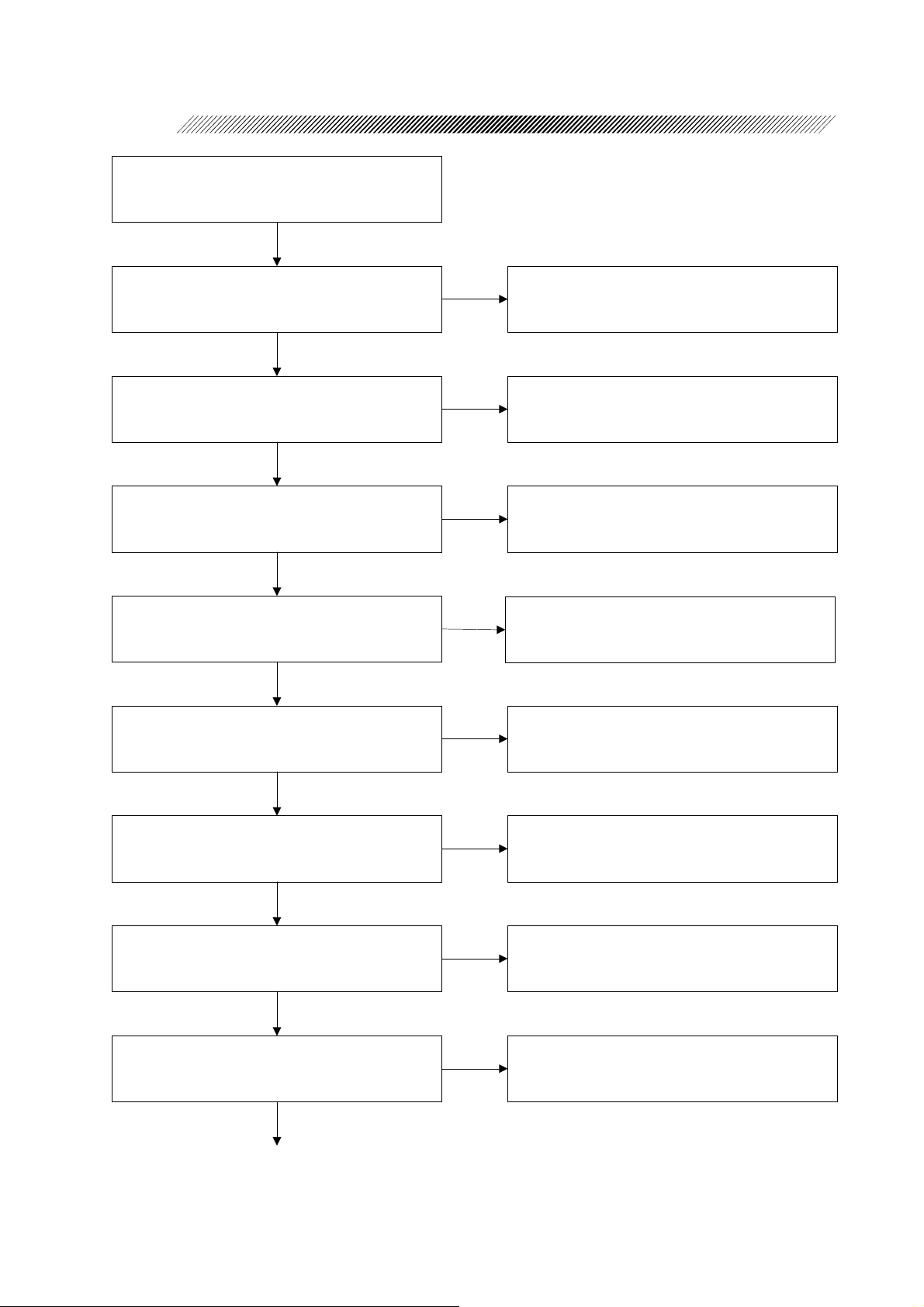

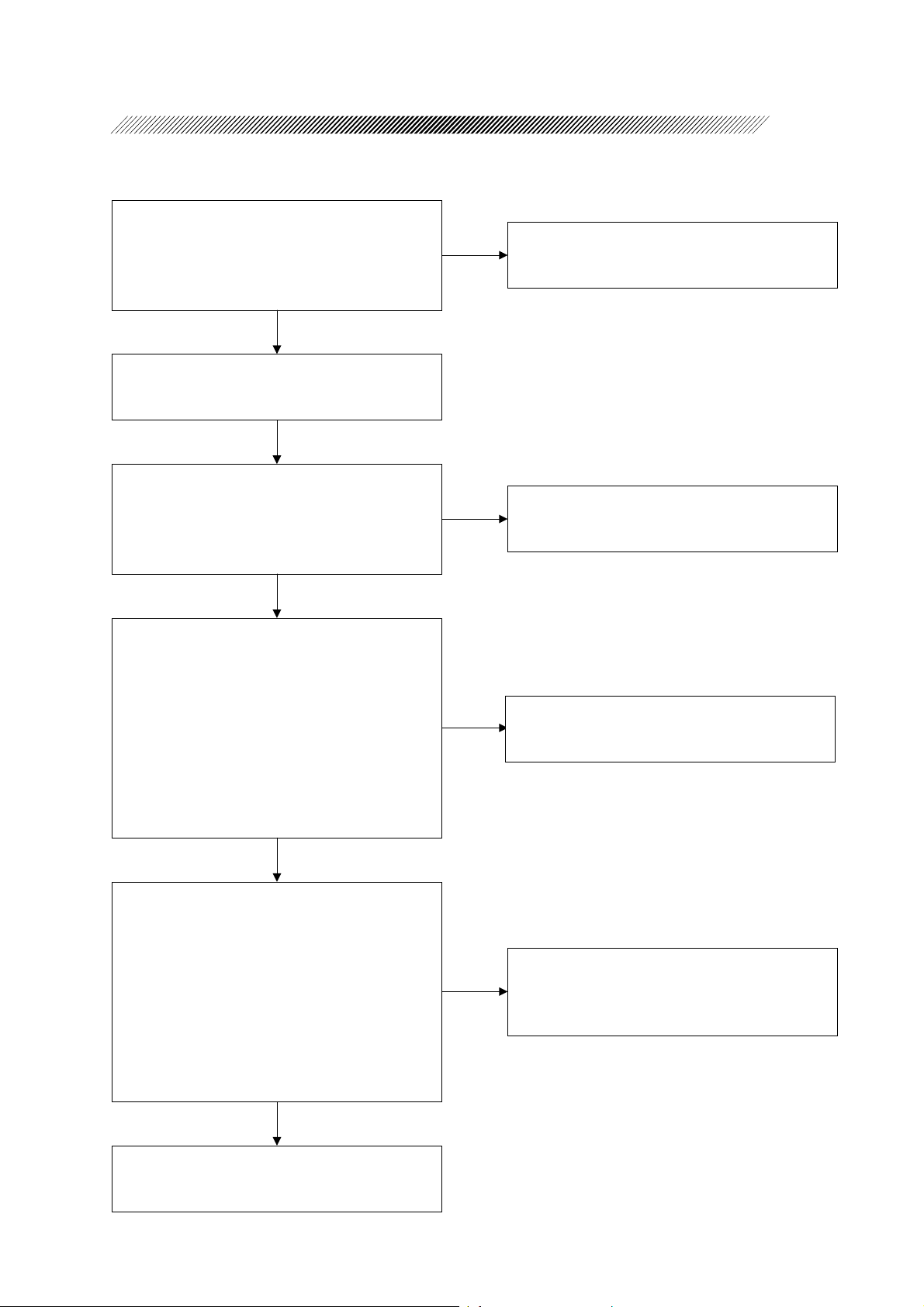

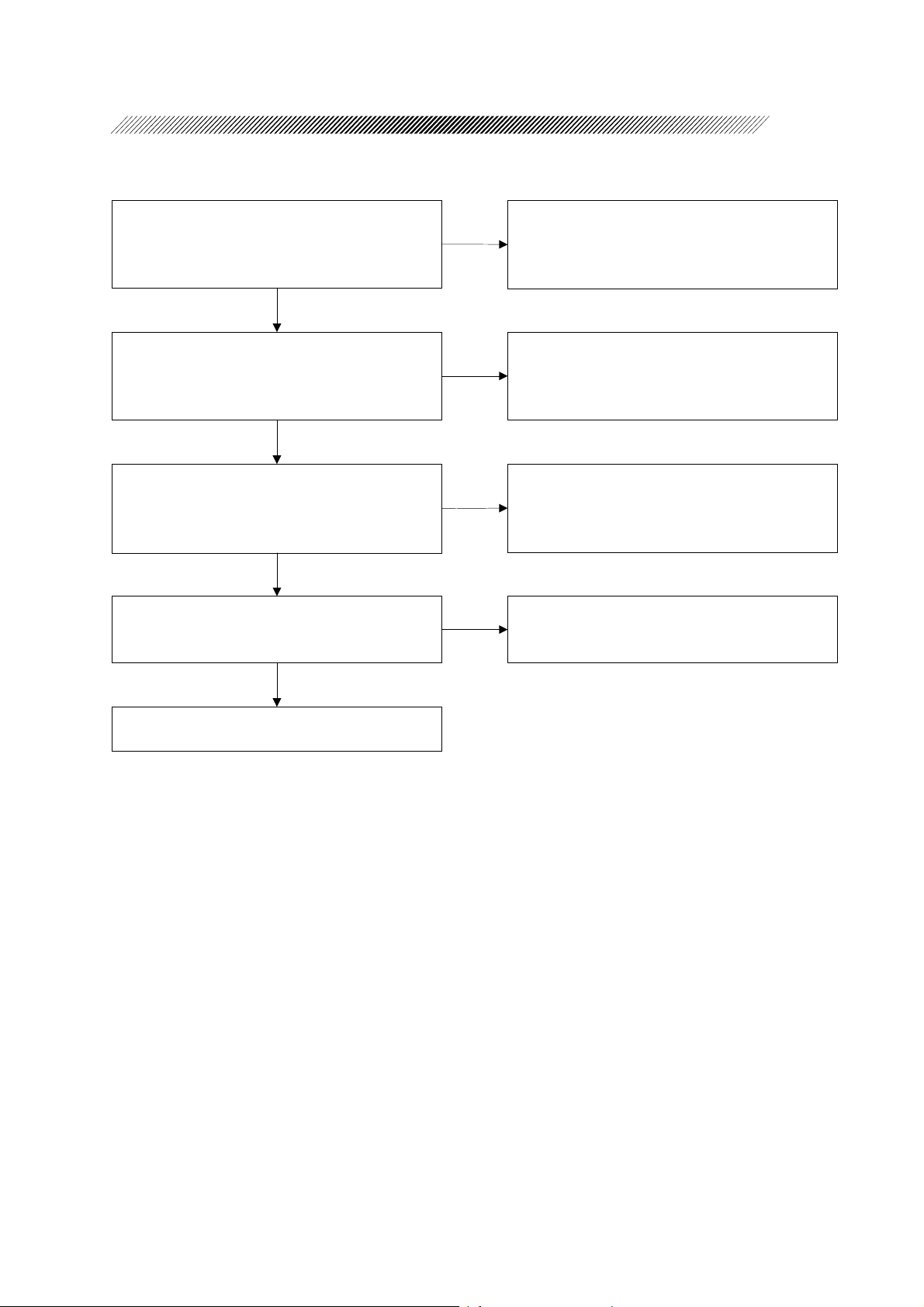

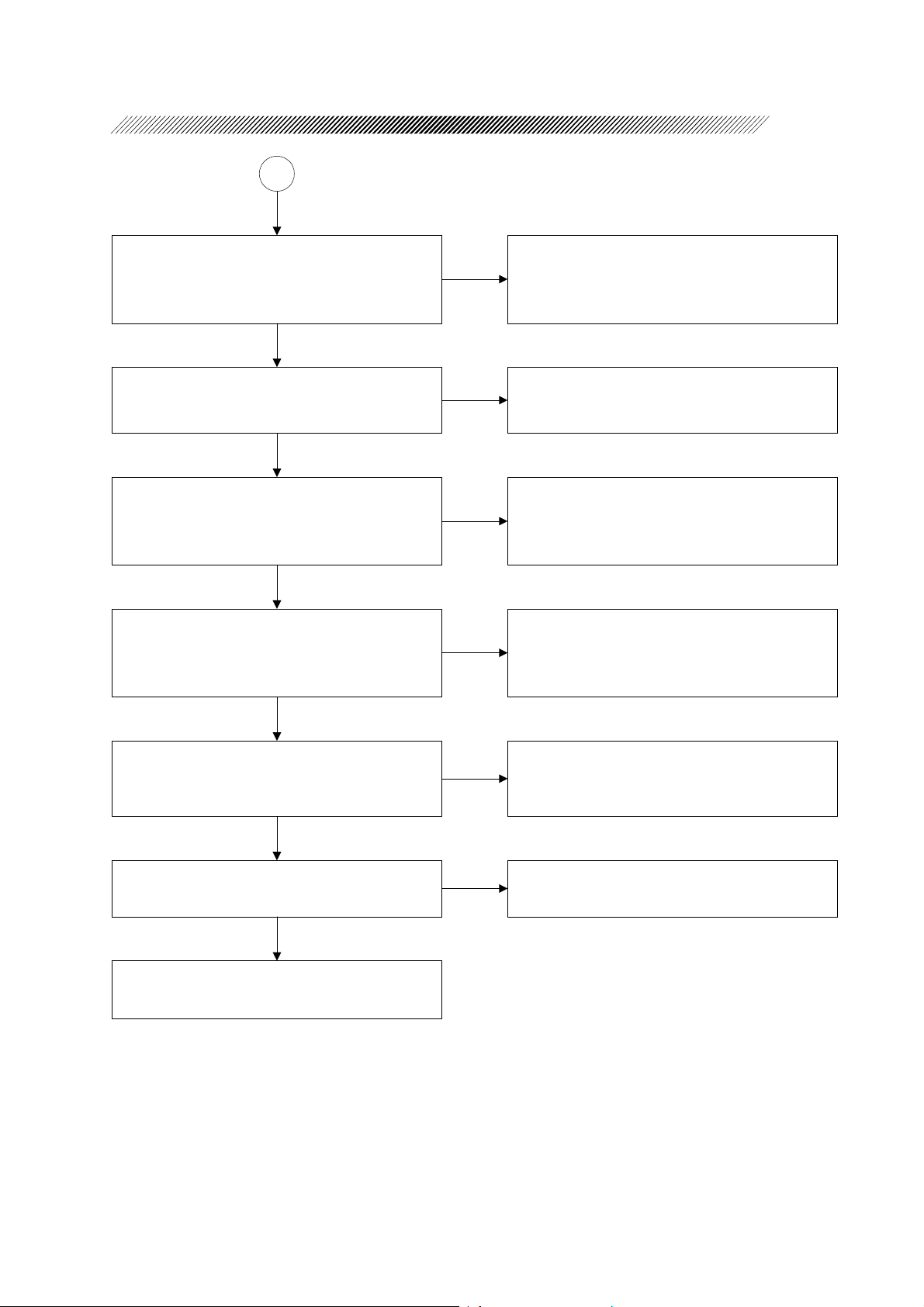

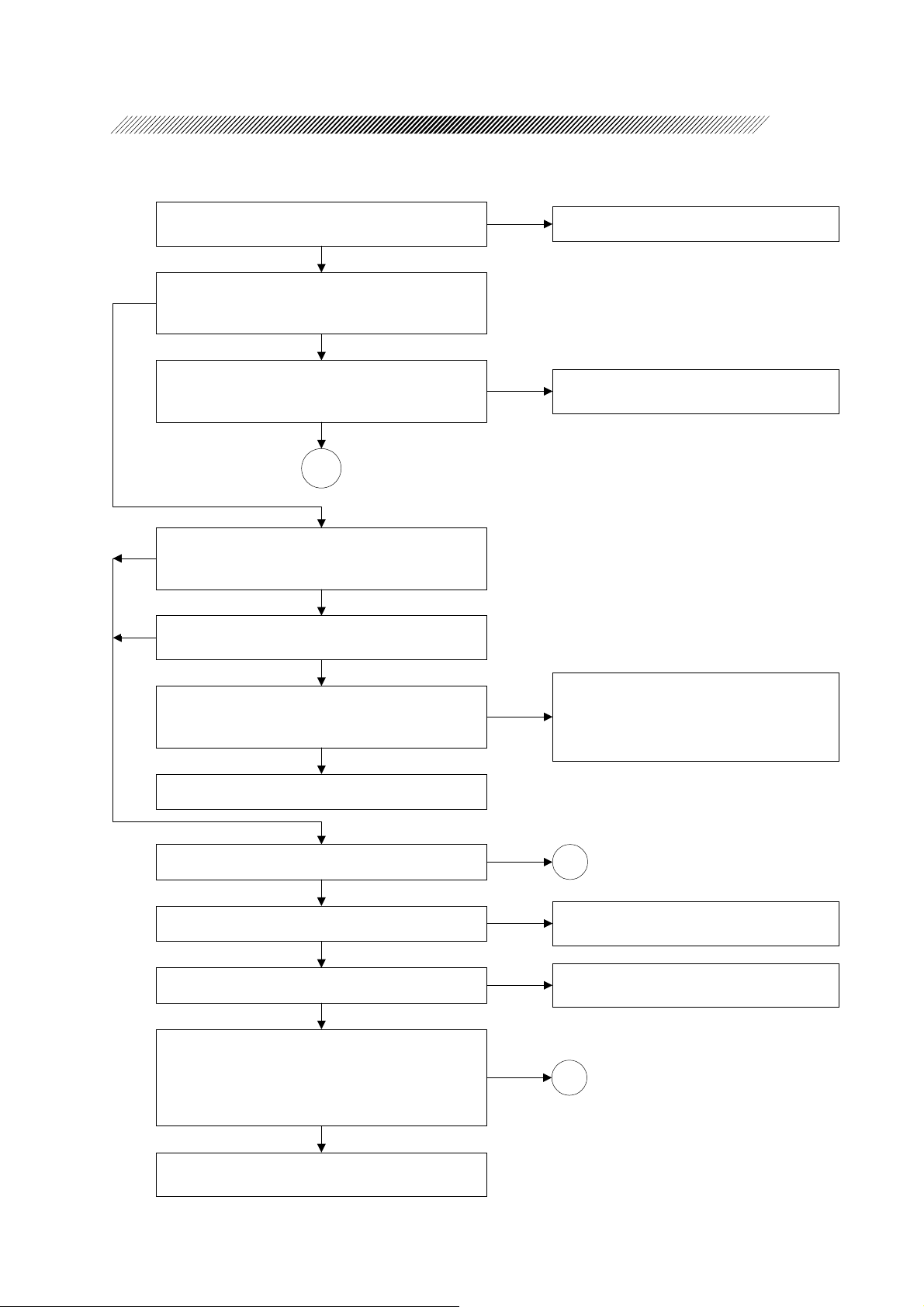

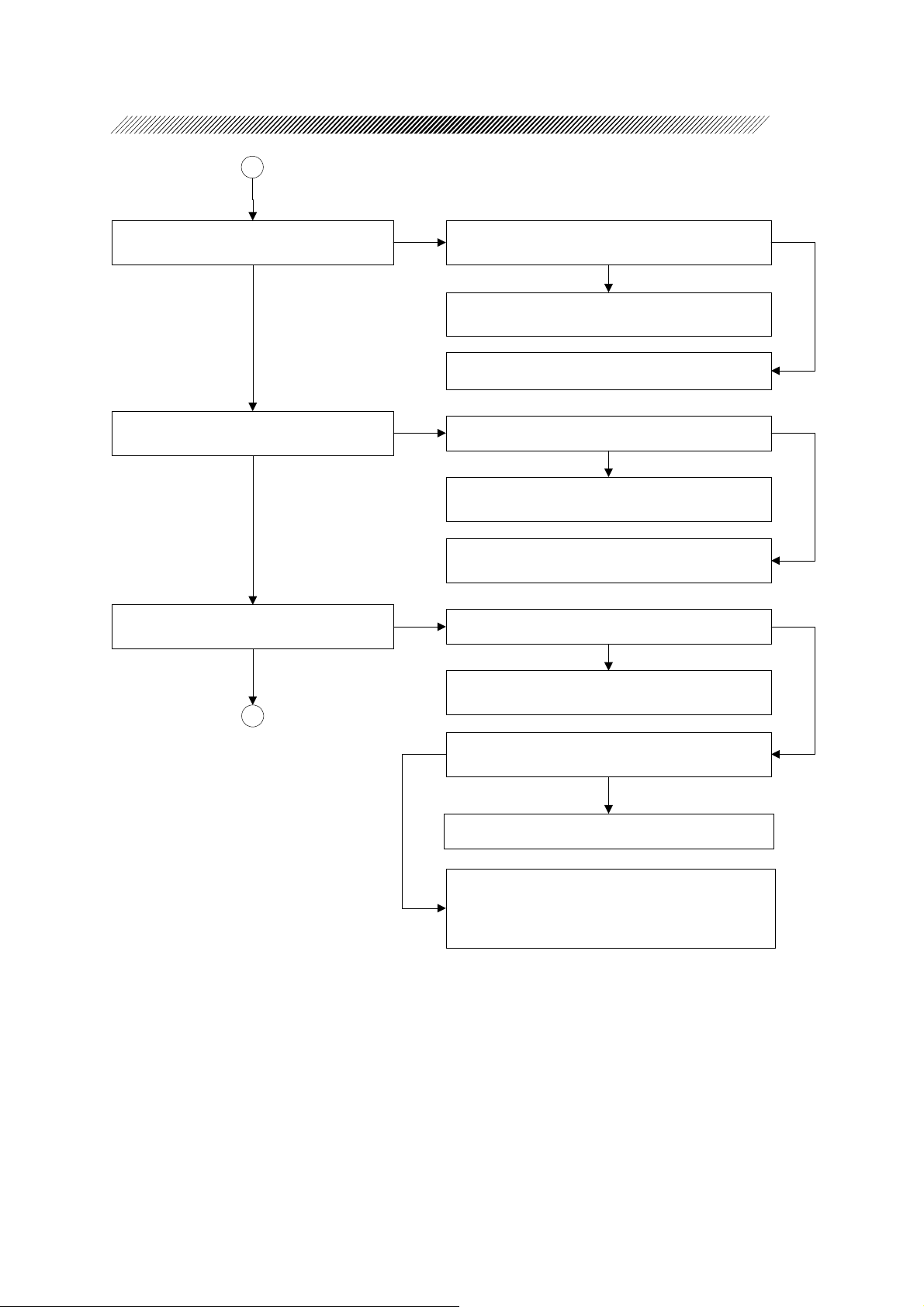

2

Turn ON the power.

TROUBLESHOOTING

Is an error indicated?

YES

Does the pilot lamp illuminate?

YES

Does an operation screen appear?

YES

Can the back light be adjusted by the knob on the

rear panel?

YES

Does the touch panel work?

NO

Check the indicated error.

NO

3.1 Pilot lamp does not illuminate

NO

3.2 Nothing appears on screen

NO

3.3 Back light can not be adjusted

NO

3.4 Touch panel does not work

YES

Does the set switch work?

YES

Does the remote control work?

YES

Do sounds come out of speaker?

YES

NO

3.5 Seat switch does not work

NO

3.6 Remote control does not work

NO

3.7 Sounds do not come out

Page 8

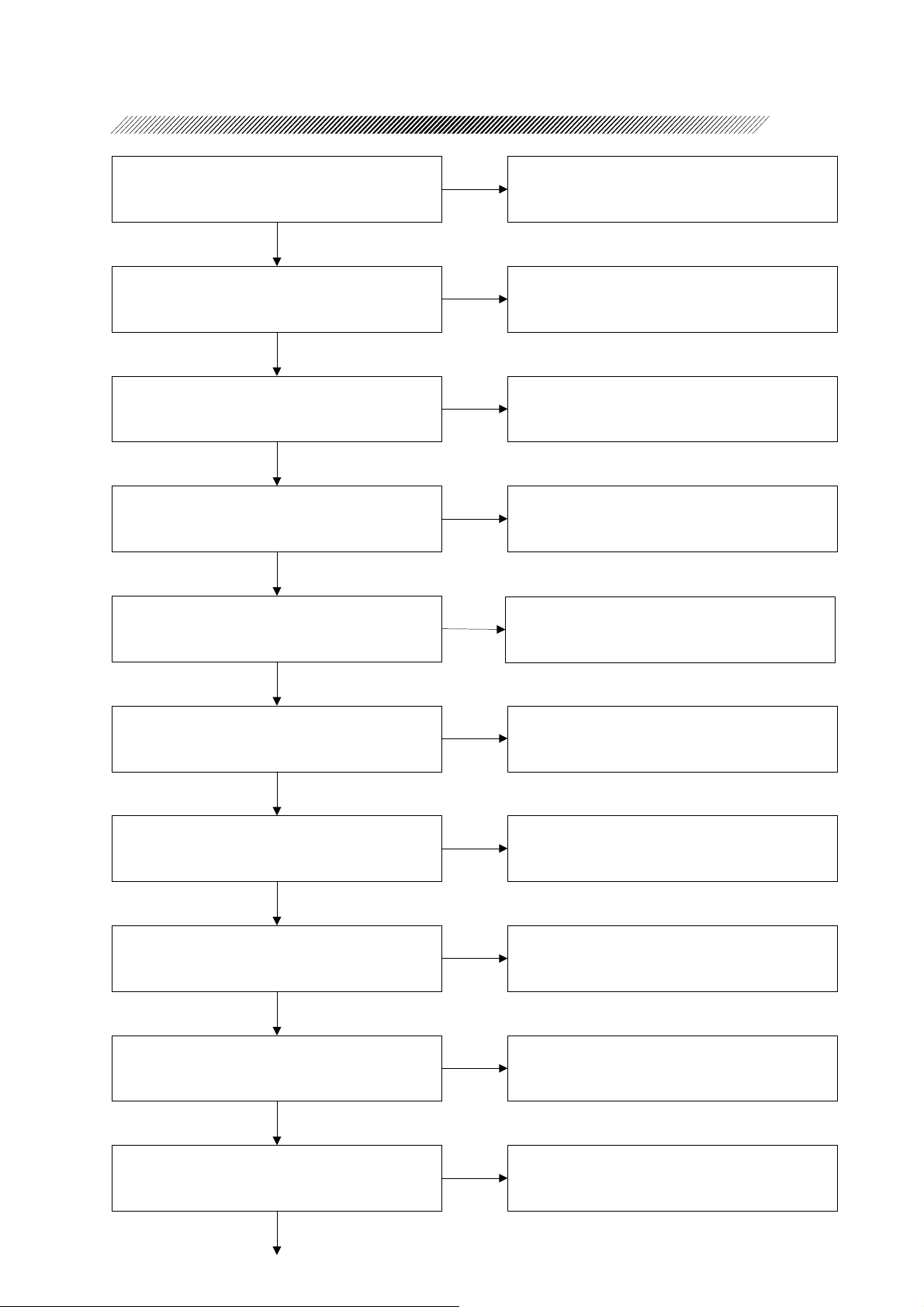

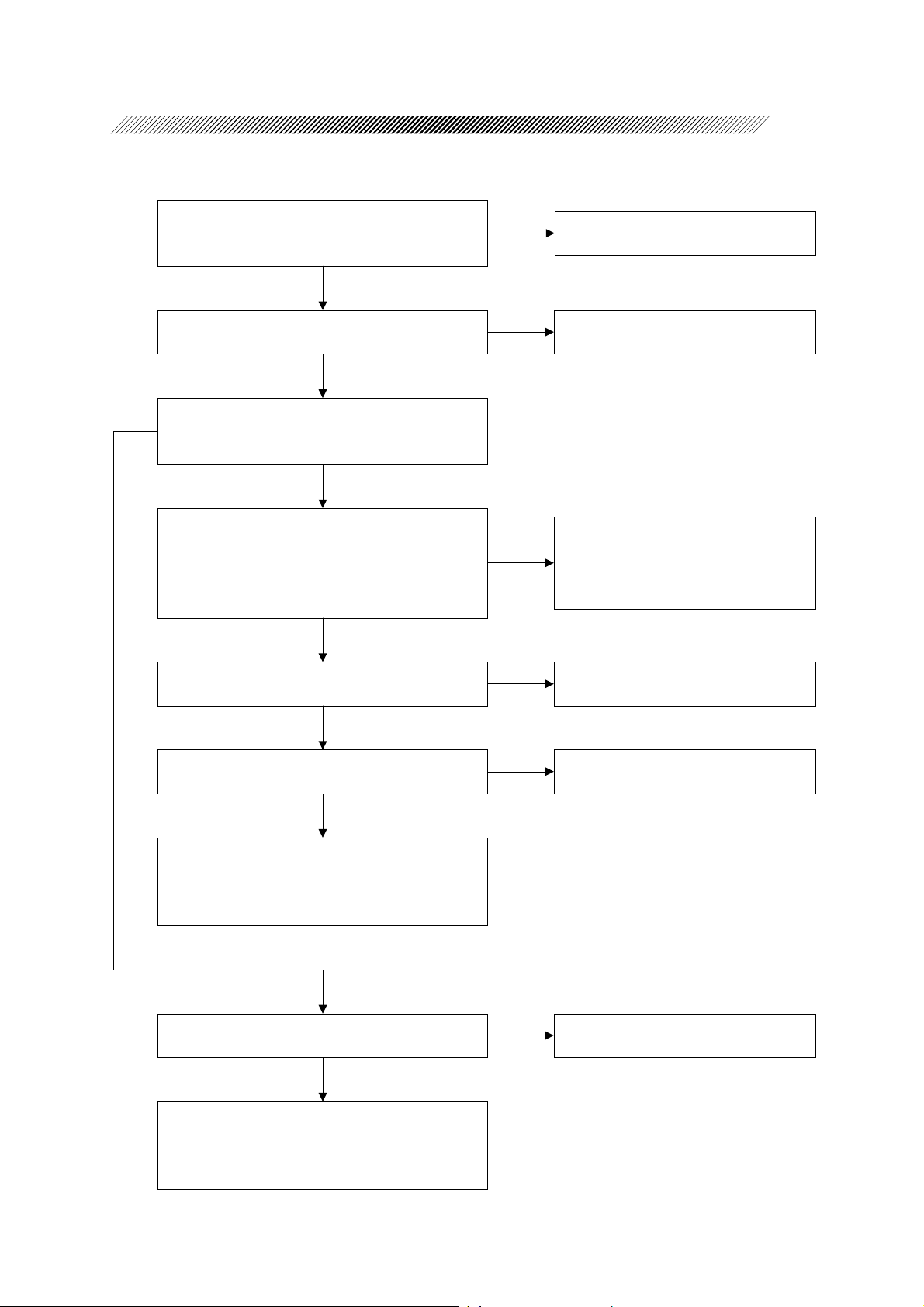

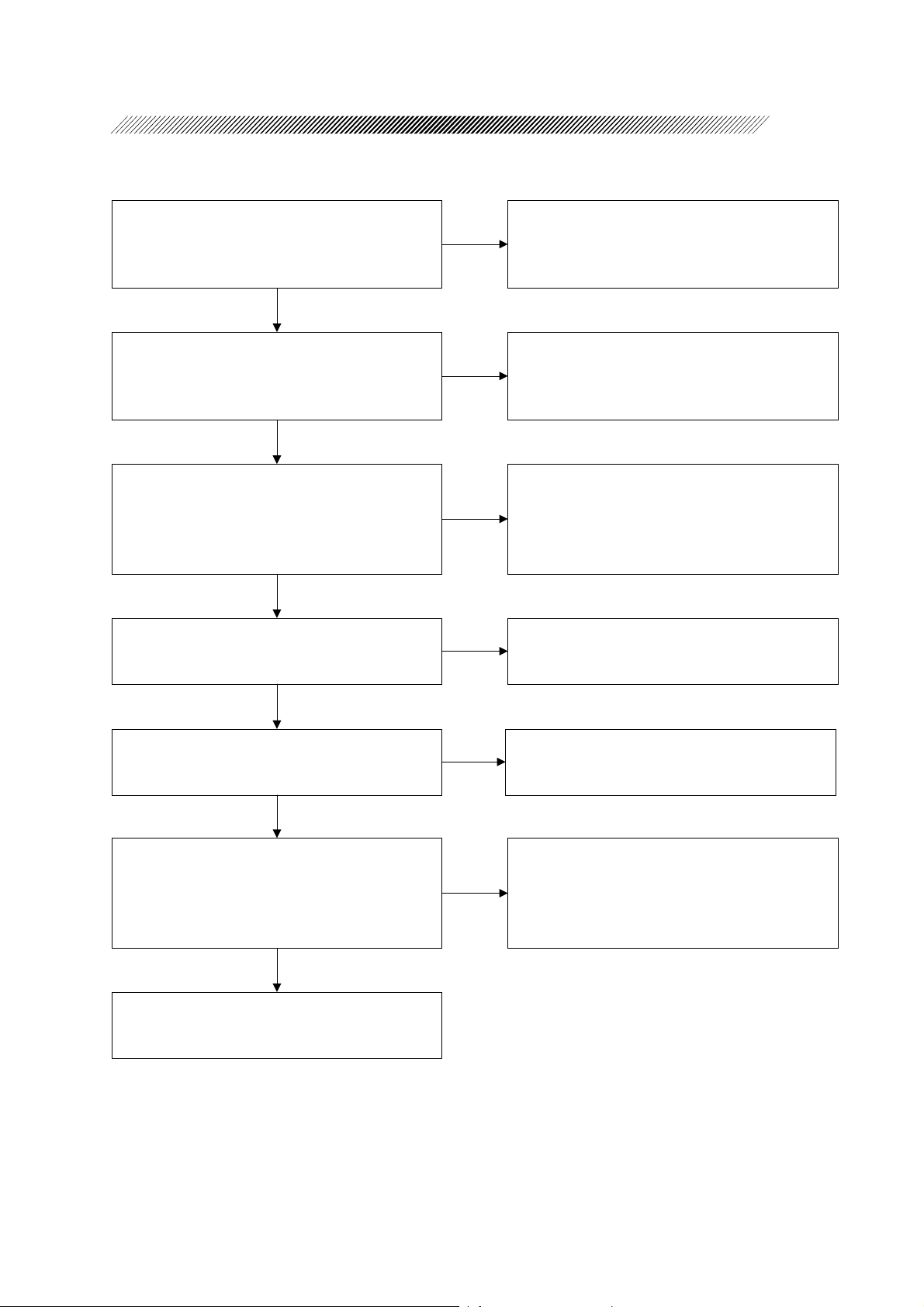

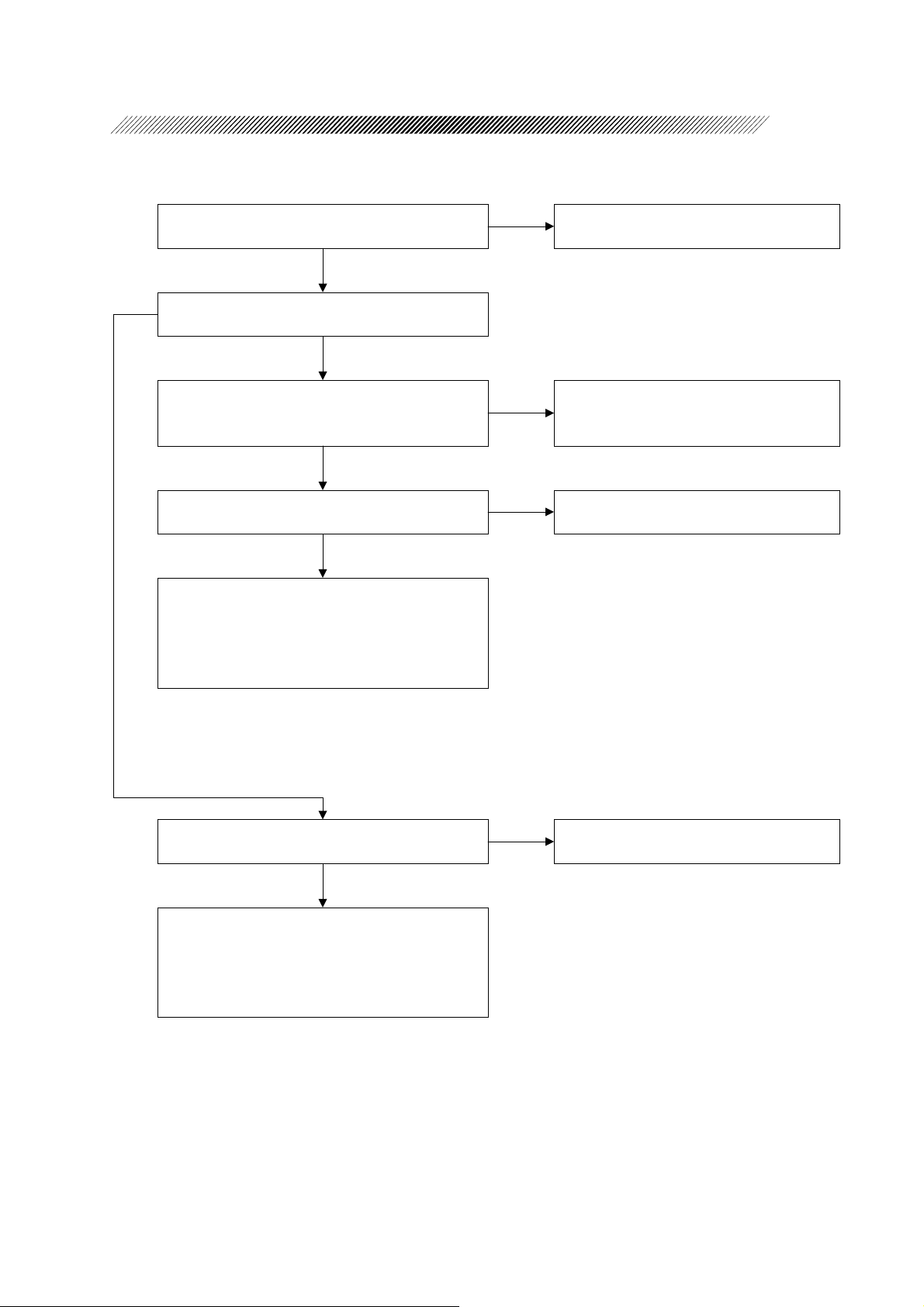

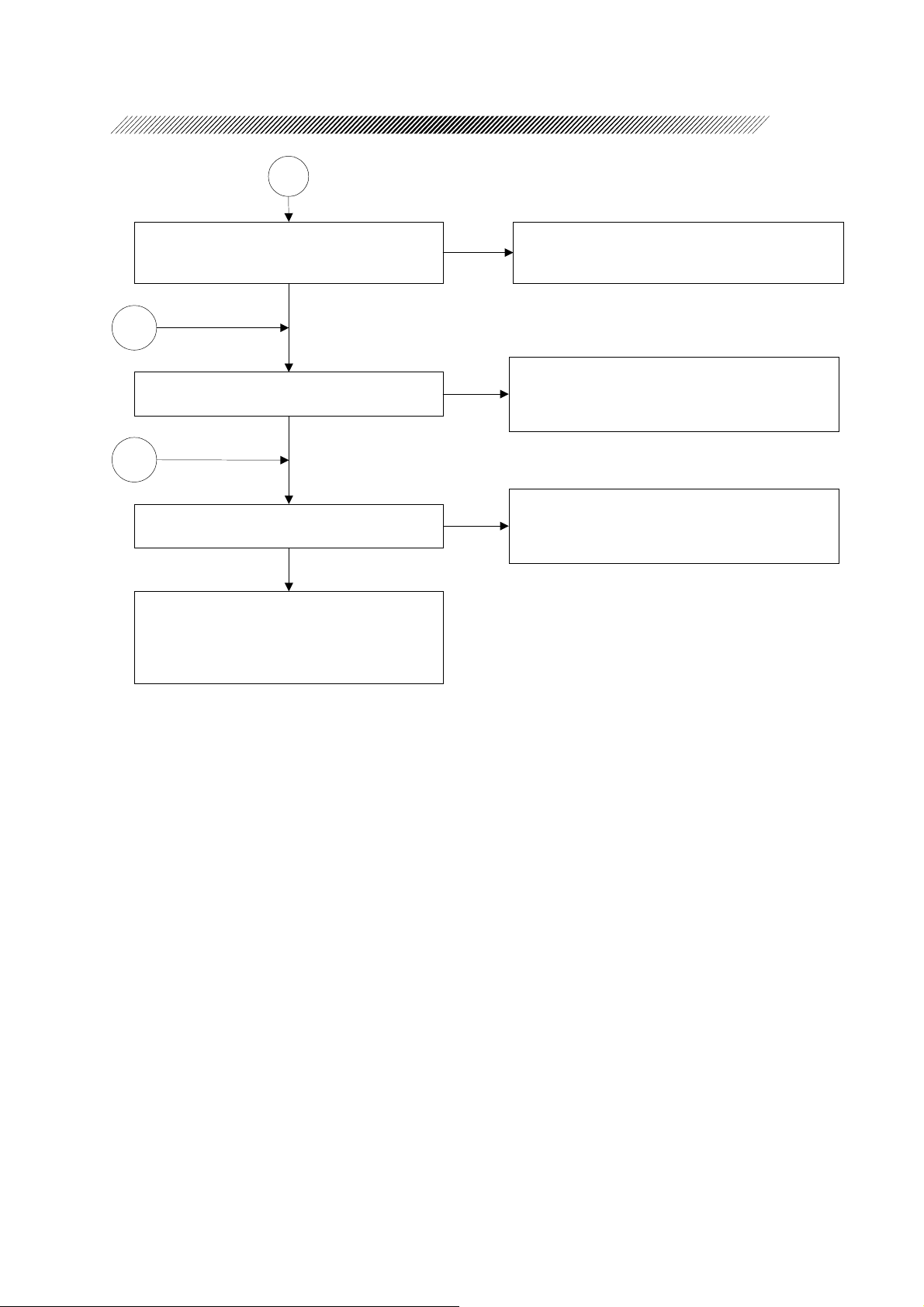

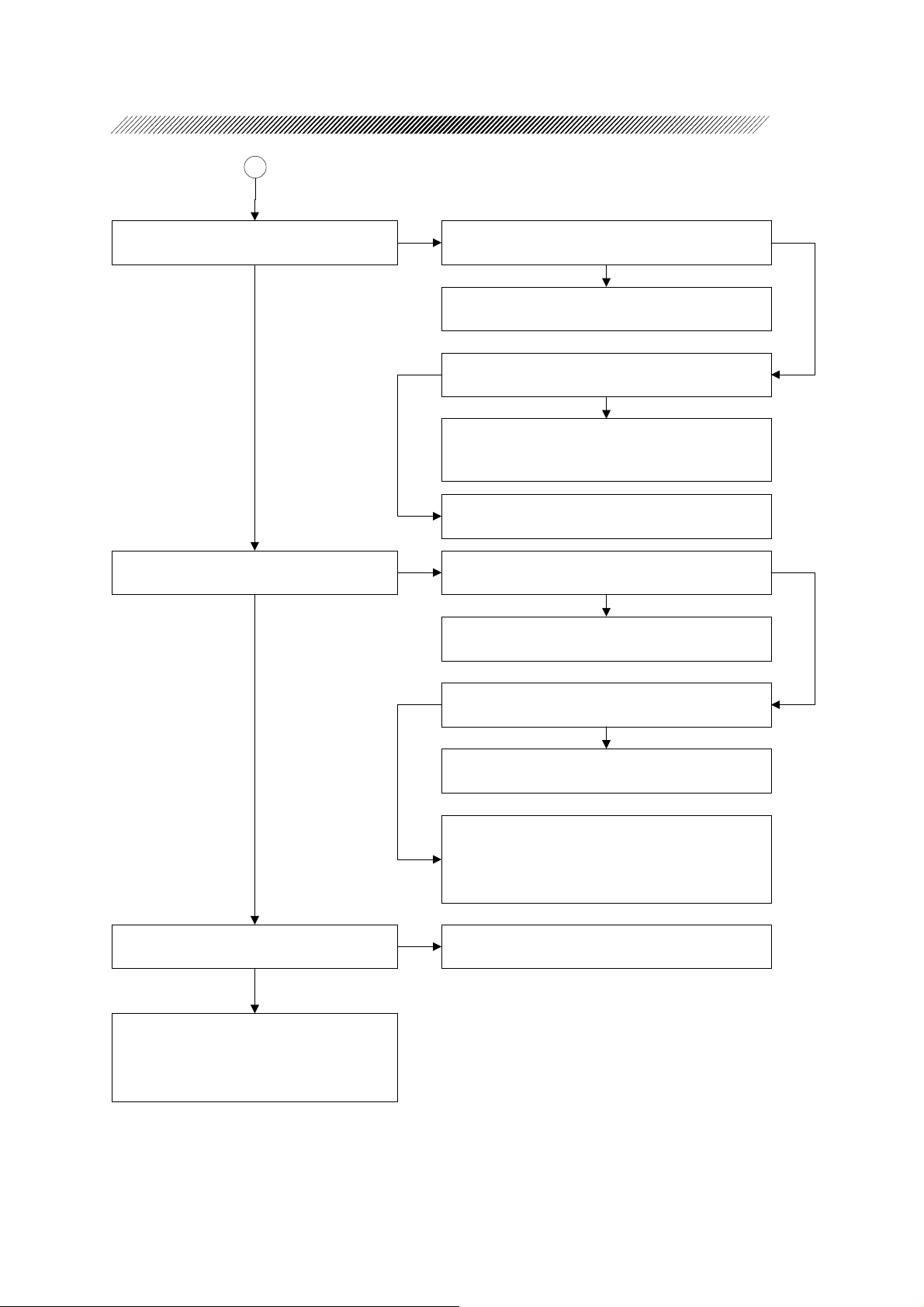

2 - 2

Can the volume of speaker be adjusted by the

volume control on the rear panel?

YES

Does the irrigation pole move by irrigation pole

UP/DOWN switch on the rear panel?

YES

Does the printer work normally?

YES

Is data stored or read to the main body correctly?

YES

Is data stored or read to memory card correctly?

NO

3.8 Volume can not be adjusted

NO

3.9 Irrigation pole does not move by irrigation

pole UP/DOWN switch

NO

3.10 Printer does not work normally

NO

3.11 Memory inside of main body does not work

correctly

NO

3.12 Memory card does not work correctly

YES

Does the system start a cassette test and pass it

by inserting cassette?

YES

Can the cassette be removed by EJECT switch

while the cassette is inserted?

YES

Start the SYSTEM (cataract) test.

Is it passed?

YES

Start the US test.

Is it passed?

YES

NO

3.13 Cassette test is not passed

NO

3.14 Cassette can not be removed

NO

3.15 SYSTEM (cataract) test is not passed

NO

3.16 US test is not passed

Start the DIA test.

Is it passed?

YES

NO

3.17 DIA test is not passed

Page 9

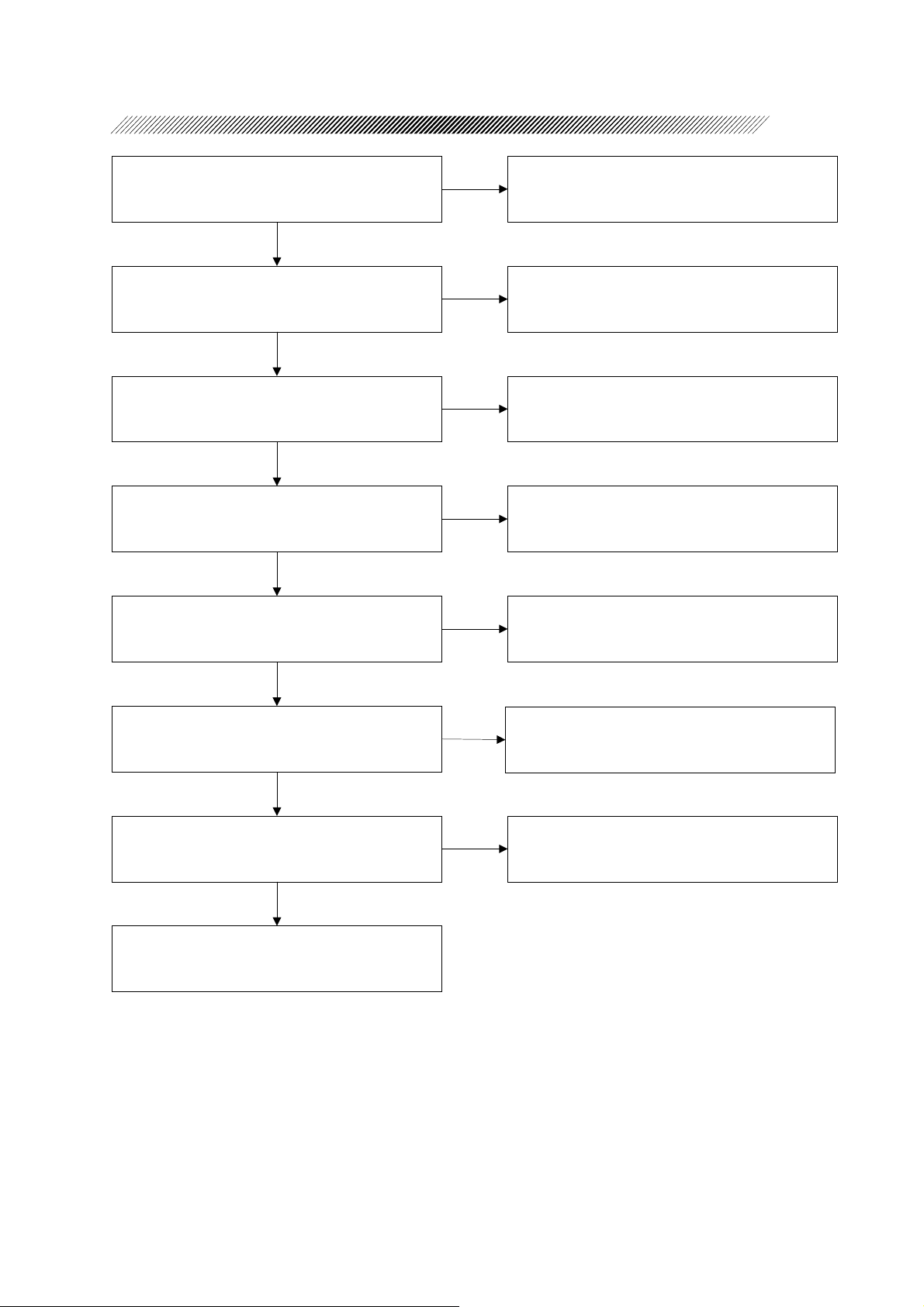

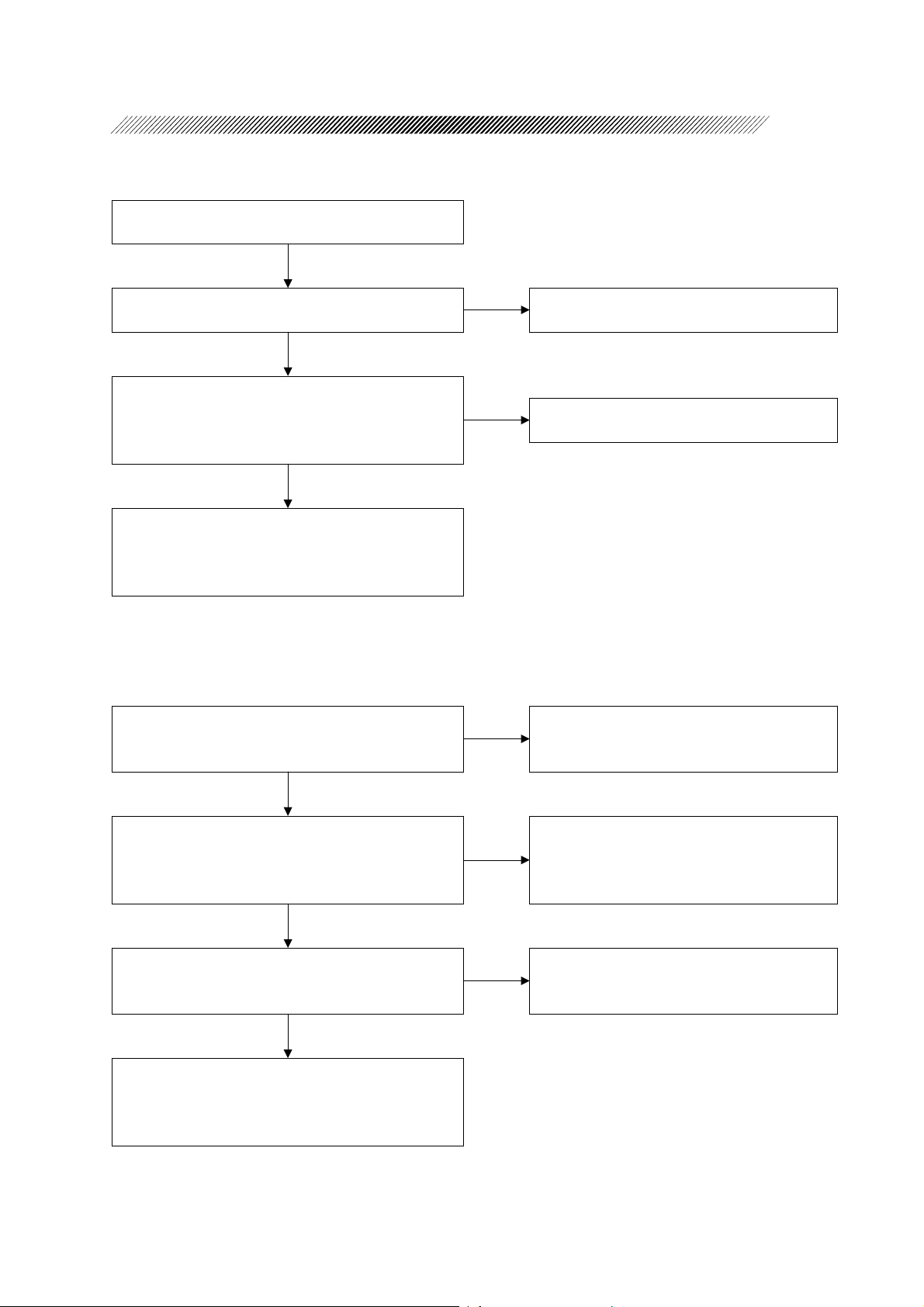

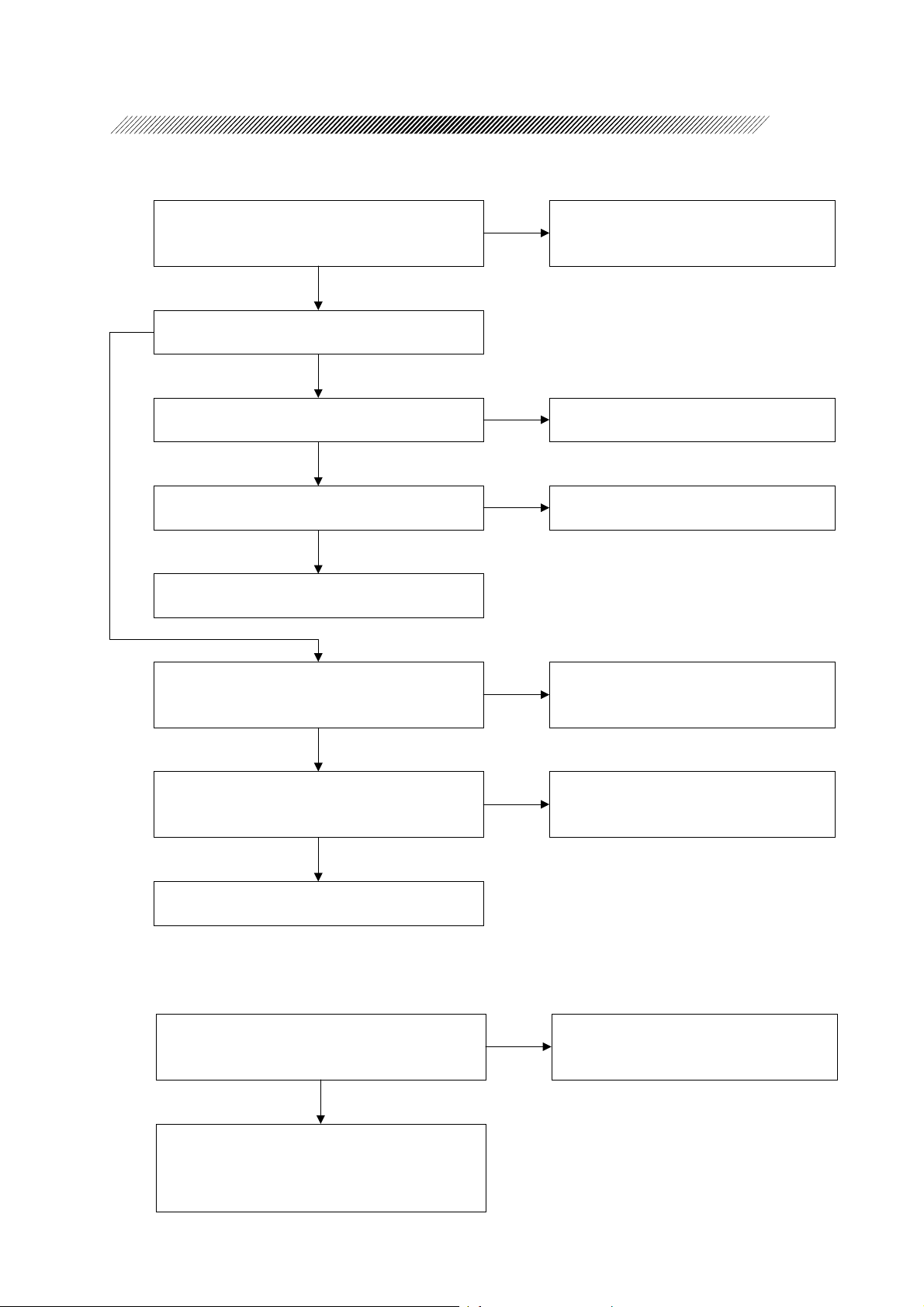

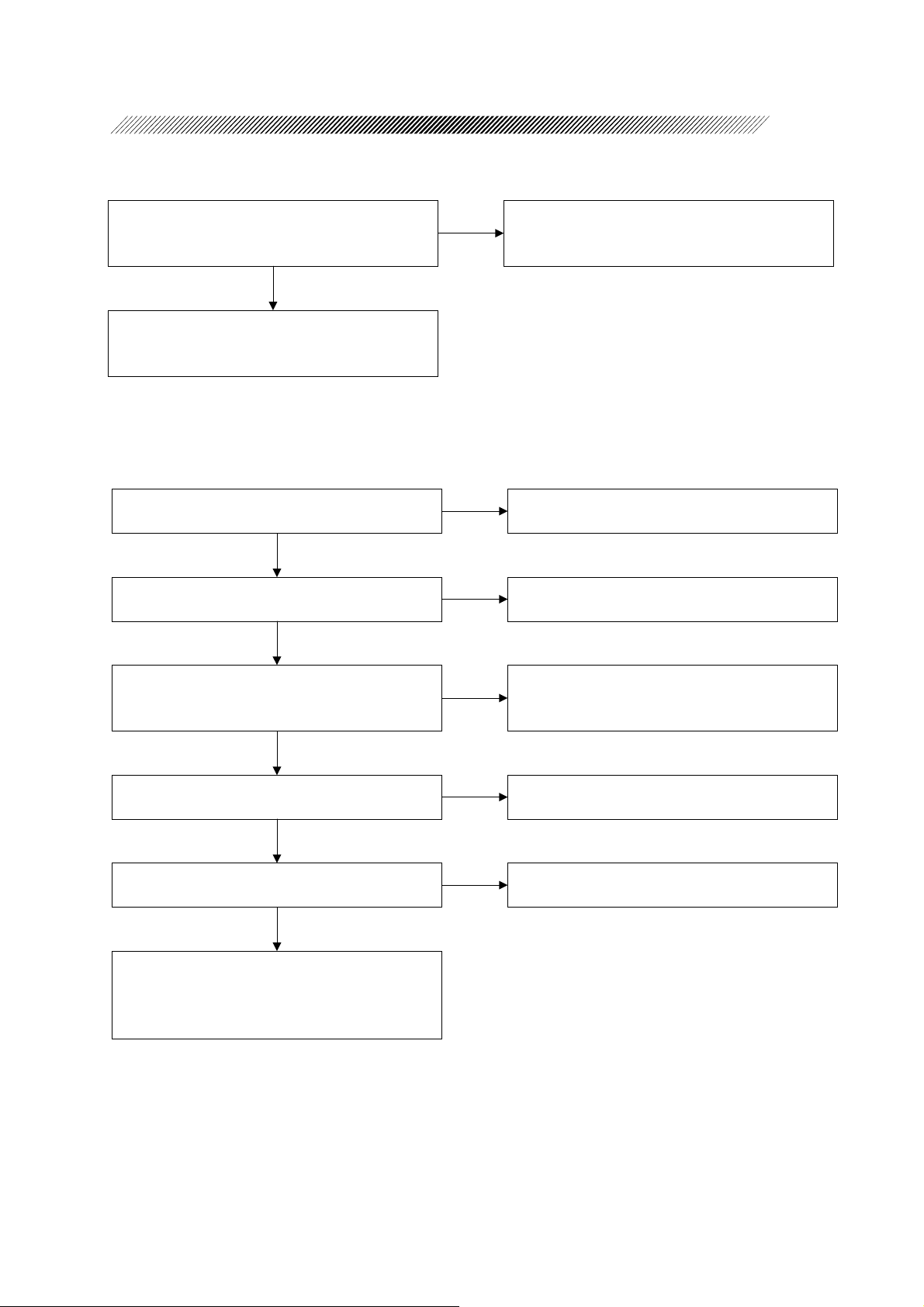

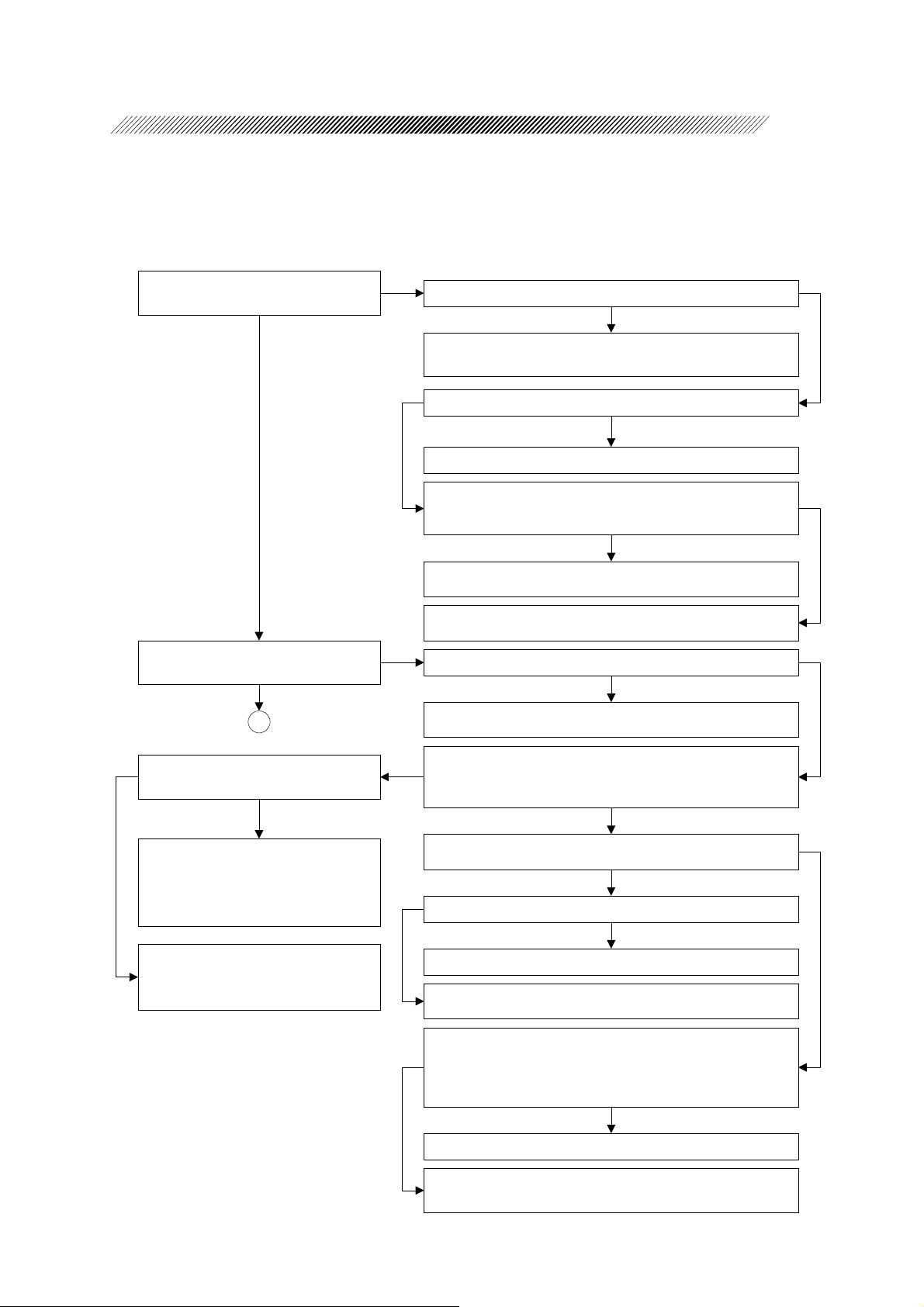

2 - 3

Does the foot switch work?

YES

Does the irrigation work correctly?

YES

Does the aspiration work correctly?

YES

Is US oscillation performed correctly?

YES

Is the diathermy output correctly?

NO

3.20 Foot switch does not work

NO

3.21 Irrigation does not move correctly

NO

3.22 Aspiration does not work correctly

NO

3.23 US oscillation is not performed correctly

NO

3.24 Diathermy output is abnormal

YES

Does the cutter (ANT) work correctly?

YES

Is it a surgical instrument for cataract and

vitrectomy?

Surgical instrument for

cataract and vitrectomy

YES

Select vitrectomy surgery screen.

Start the SYSTEM (vitrectmy) test.

Is it passed?

YES

NO

3.25 Cutter (ANT) does not work

NO

Is the power correct?

YES NO

End

NO

3.18 SYSTEM (vitrectomy) test is not passed

3.30 Check of power (P.S.board)

Page 10

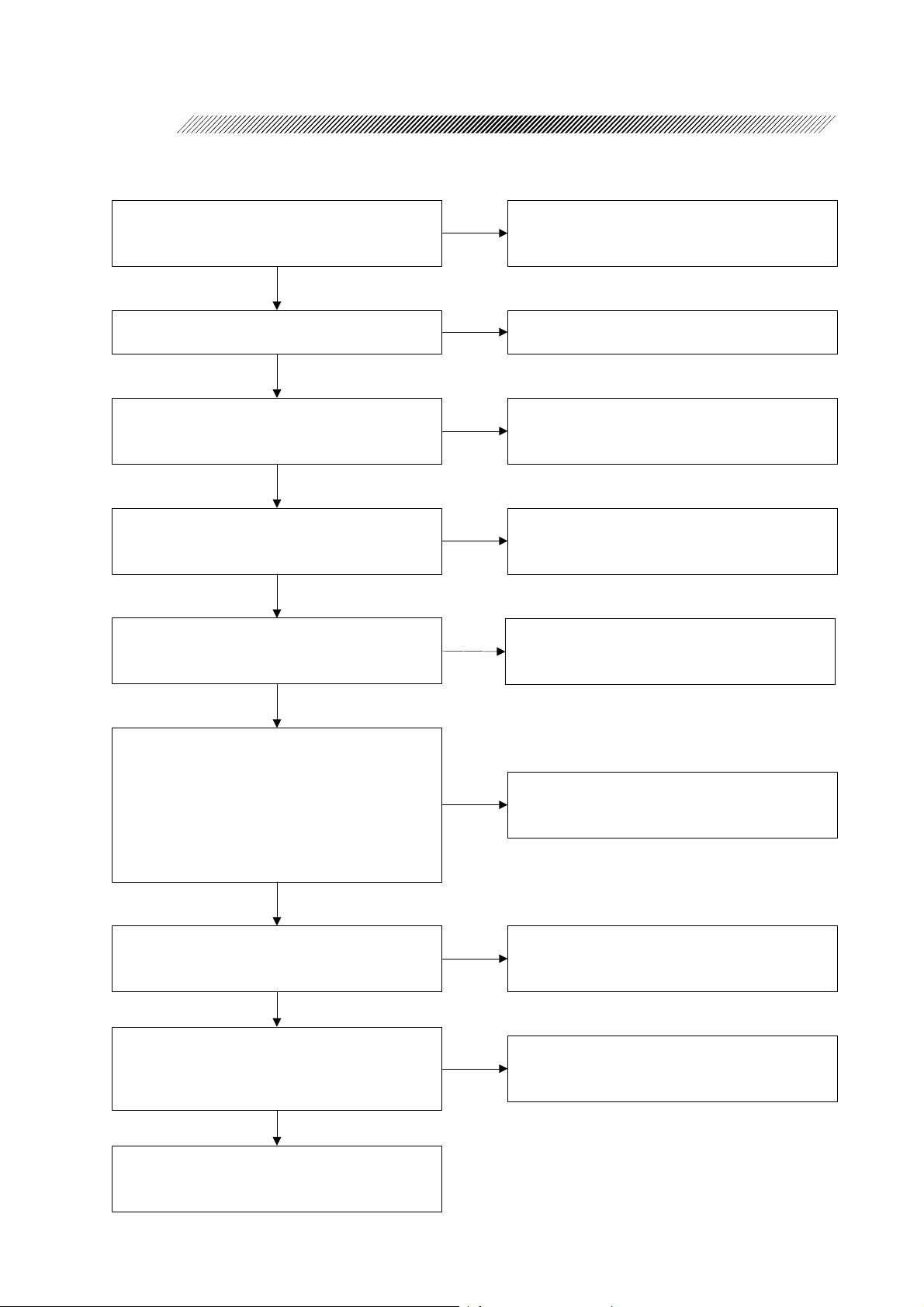

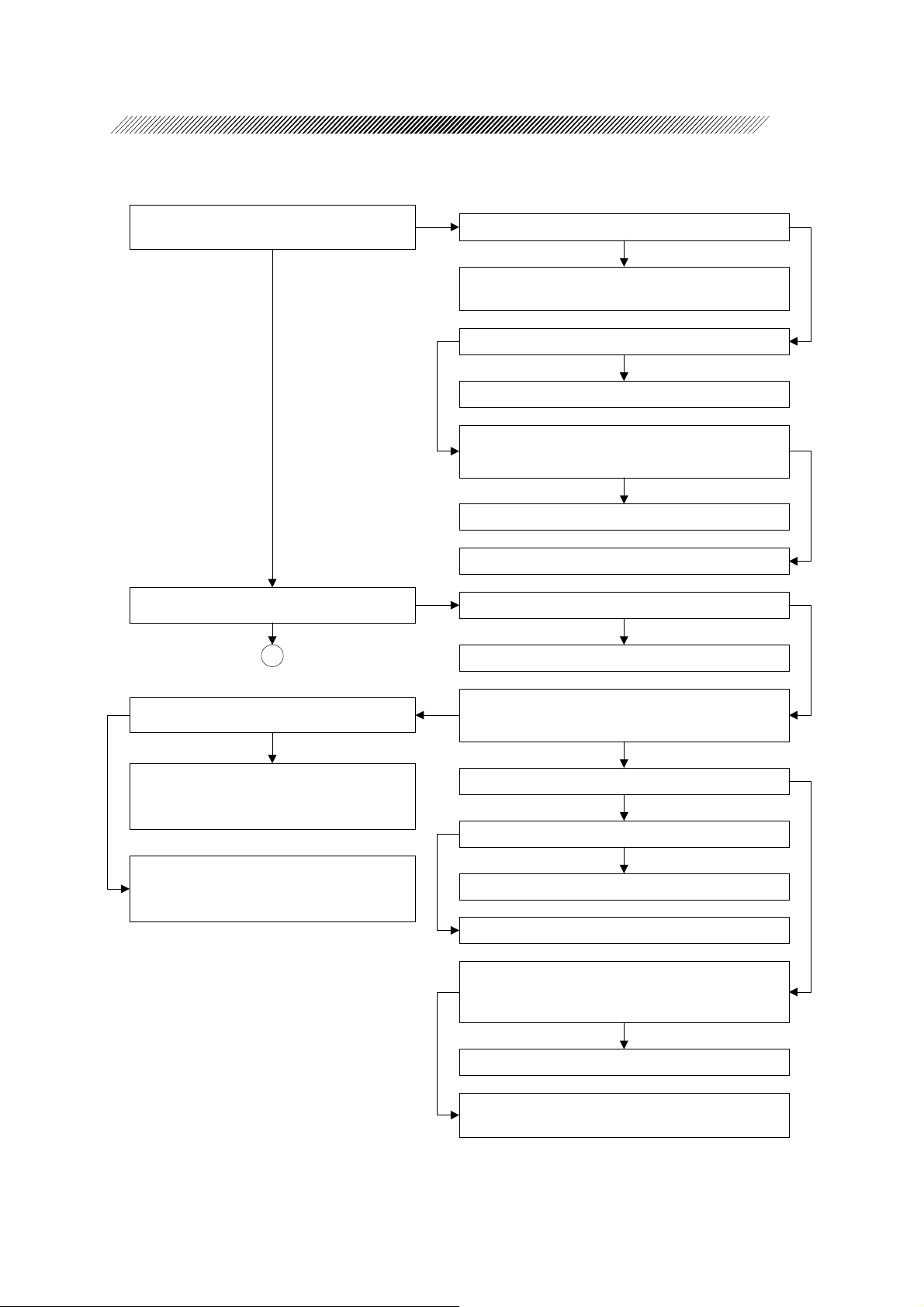

2 - 4

Start the PPL test.

Is it passed?

YES

Start the DIA test.

Is it passed?

YES

Does the cutter work correctly?

YES

Do scissors work correctly?

YES

Does FGX work correctly?

NO

3.19 PPL test is passed

NO

3.17 DIA test is passed

NO

3.26 Cutter (POST) does not work

NO

3.27 Scissors do not work correctly

NO

3.28 FGX does not work correctly

YES

Does the illumination work correctly?

YES

Is the power correct?

YES

End

NO

3.29 Illumination does not work correctly

NO

3.30 Check of the power (P.S. board)

Page 11

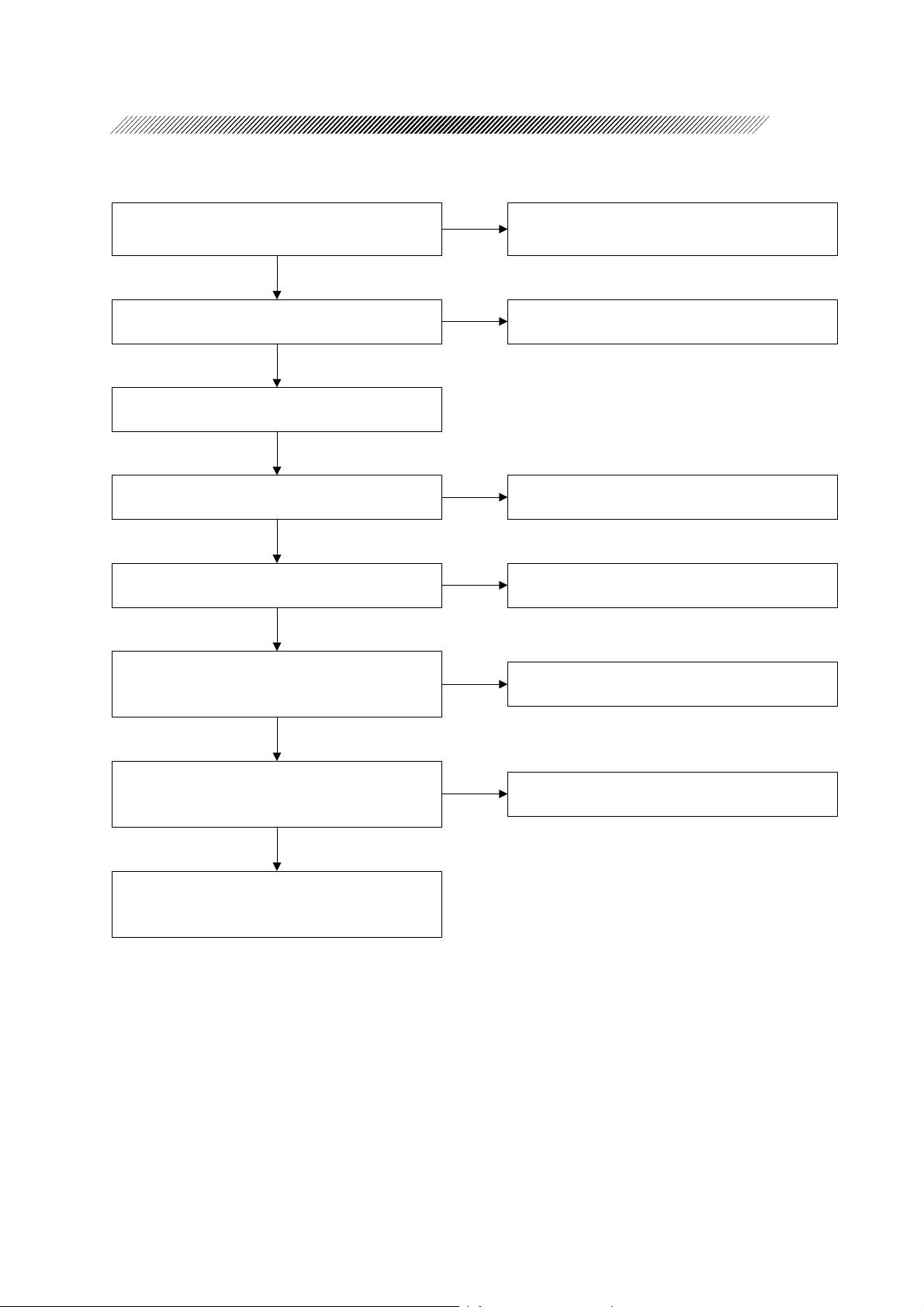

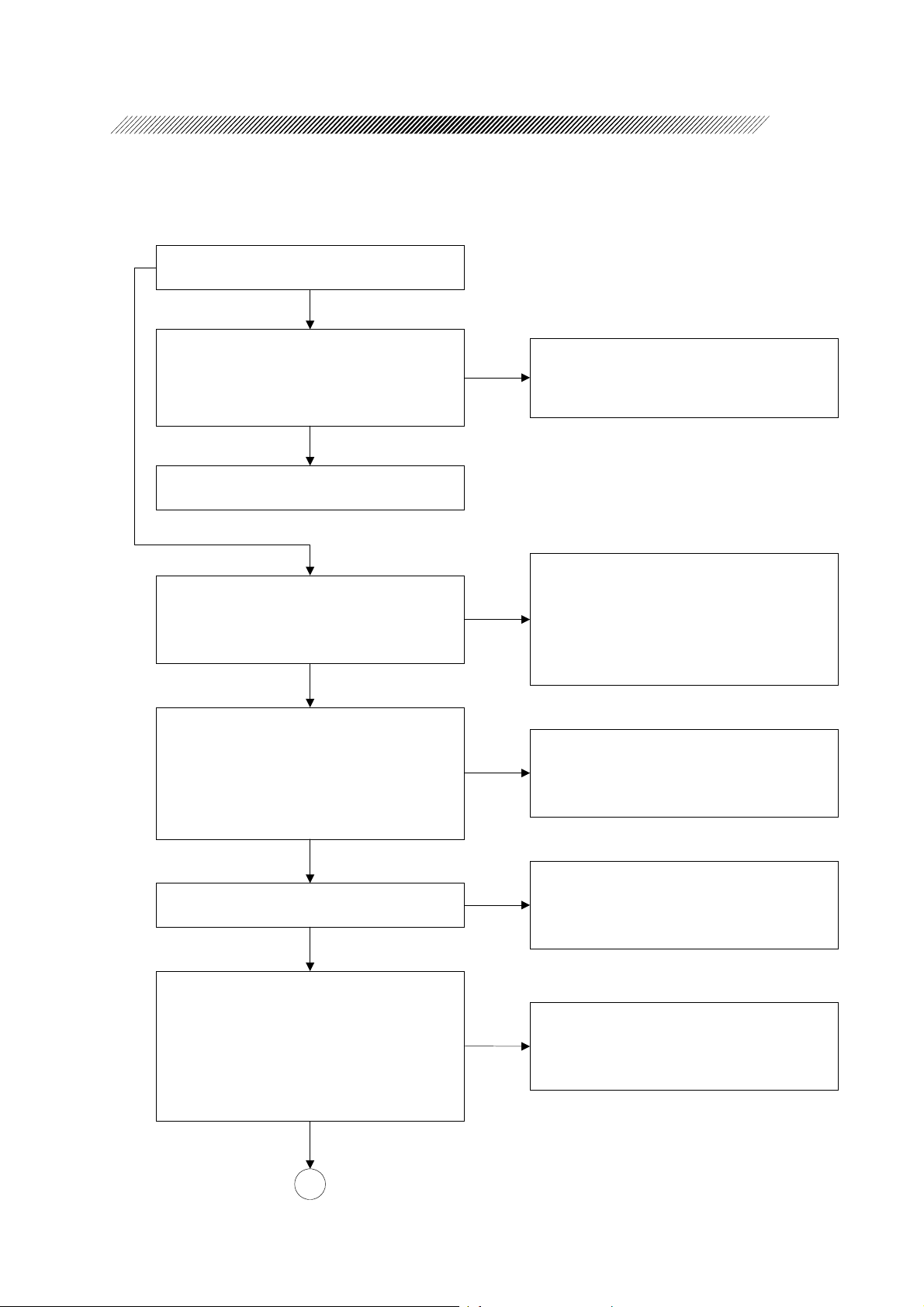

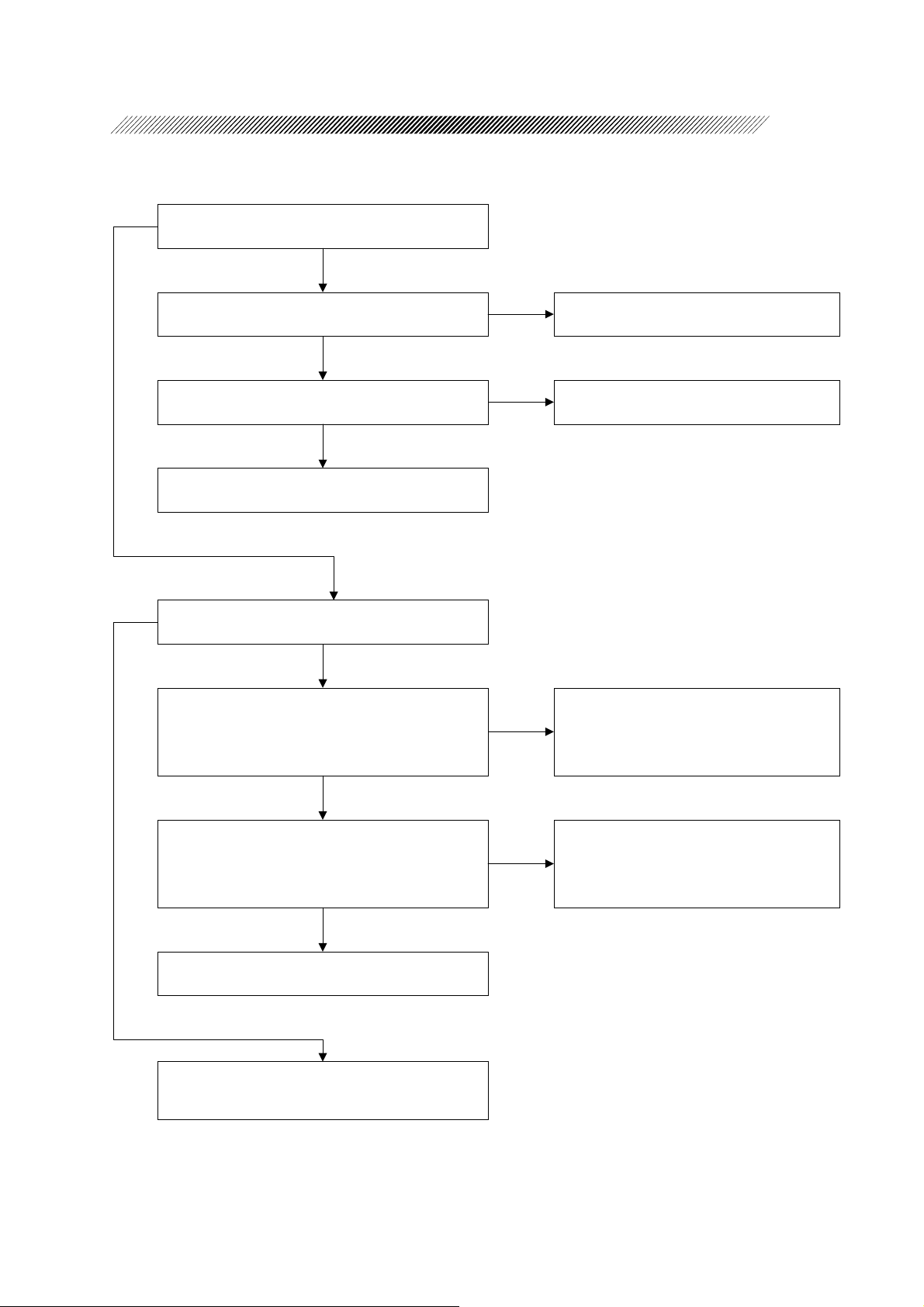

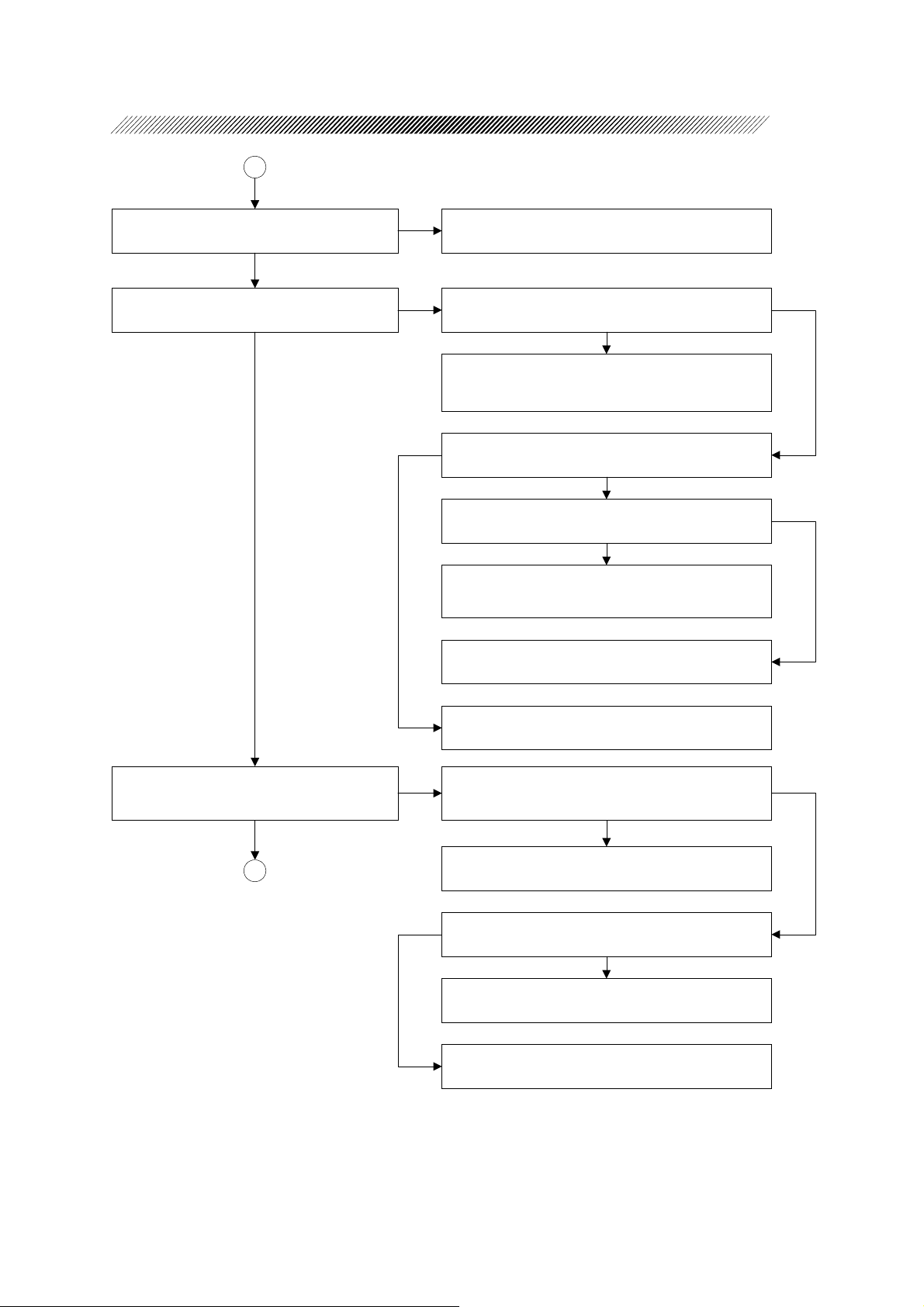

§

3

SUB-TROUBLESHOOTING

3.1 Pilot lamp does not illuminate

Is power voltage proper?

Voltage 100V/115V/230V

YES

Is the power code connected correctly?

YES

Is the fuse blown?

Disconnect the power cord from a wall outlet for

checking the fuse.

NO

Are voltages between the power input terminals

of the noise filter and the power switch (turned

OFF) same as the power voltage?

YES

Turn ON the power switch.

Is the power voltage supplied to the transformer?

(Check by TB1, a terminal block.)

NO

NO

YES

NO

NO

Use a proper power voltage.

Usable input voltage is written on the rating plate.

Connect the power cord.

Repalce the fuse with the new one.

Disconnect the power cord from a wall outlet for

checking the fuse.

Failure of the noise filter is a probable cause.

Replace it with the new one. (See 4.16.)

Replace the power switch with the new one.

(See 4.17.)

YES

Is the secondary side voltage of transformer

normal?

Check the secondary side voltage with no load.

Between YEL and YEL : AC33V±10%

Between ORN and ORN : AC33V±10%

Between BLK and BLU : AC100V±10%

Between GRY and BLU : AC66V±10%

Between VIO and BLU : AC33V±10%

YES

Is the voltage on the P.S. board (BA04) normal?

See 3.1.1 Check of P.S. board.

YES

Disconnect the P618 from the BU CONNECT

board (BA06).

Is the voltage between 1st and 2nd pins of J618

+5V?

YES

NO

Replace the transformer with the new one.

(See 4.18.)

NO

Replace the P.S. board (BA04) with the new one.

(See 4.12.)

NO

Failure of the BU CONNECT board (BA06).

Replace it with the new one. (See 4.19.)

Failure of the pilot lamp.

Replace it with the new one. (See 4.44.)

Page 12

3.1.1 Check of P.S. board

Is the input voltage to the board normal?

Disconnect terminals from the terminal block

(TB401) on the board and check voltages.

Between YEL and YEL : AC35V±10%

Between ORN and ORN : AC35V±10%

YES

Connect terminals disconnected from the terminal

block (TB401).

Disconnect all connectors.

Is the input voltage to the board normal?

Check voltages of terminal block (TB401) on the

board.

Between 1 and 2 : AC35V±10%

Between 3 and 4 : AC35V±10%

Check the input voltage of transformer. If it is

NO

normal, replace the transformer with the new one.

(See 4.17.)

Failure of the P.S. board (BA04) is a probable

NO

cause. Replace the board with the new one.

(See 4.12.)

3 - 2

YES

Check voltages between GND and each TP while

connecting only TB401.

Is voltages on the P.S. board (BA04) normal?

TP2 : +12V (+11.5 ~ +12.5V)

TP3 : +28V (+27.5 ~ +29.0V)

TP4 : -28V (-27.5 ~ -29.0V)

TP6 : +12V (+11.9 ~ +12.1V)

TP7 : -12V (-11.9 ~ -12.1V)

TP8 : +6V (+5.0 ~ +6.0V)

TP9 : +5V (+4.8 ~ +5.2V)

TP10 : +24V (+22.0 ~ +26.0V)

YES

Connect all removed connectors and check

voltages between GND and each TP.

Is voltages on the P.S. board (BA04) normal?

TP2 : +12V (+11.5 ~ +12.5V)

TP3 : +28V (+27.5 ~ +29.0V)

TP4 : -28V (-27.5 ~ -29.0V)

TP6 : +12V (+11.9 ~ +12.1V)

TP7 : -12V (-11.9 ~ -12.1V)

TP8 : +6V (+5.0 ~ +6.0V)

TP9 : +5V (+4.8 ~ +5.2V)

TP10 : +24V (+22.0 ~ +26.0V)

NO

Failure of the P.S. board (BA04) is a probable

cause. Replace it with the new one. (See 4.12.)

Not only the failure of P.S. board (BA04) but

NO

other failures of board or unit are probable

causes.

Check other symptoms.

YES

The P.S. board (BA04) is normal.

Page 13

3.2 Nothing appears on screen

3 - 3

Does the irrigation pole move up and down by the

irrigation pole UP/DOWN switch on the rear

NO

3.2.1 Communication error of screen

panel?

YES

YES

Can the error beep be heard? 3.2.1 Communication error of screen

NO

Does the back light illuminate?

YES

The screen becomes black if the back light does

not illuminate.

NO

Disconnect the connector (P201) from the

DISPLAY board and check the voltage.

Is the voltage normal?

Between 1 and 2 (0V) of P201 : +5V

Between 3 and 4 (0V) of P201 : +12V

YES

NO

Failure of the power is a probable

cause.

Check the cable and the P.S. board.

(See 3.1.1 Check of P.S. board.)

Are J205 (DISPLAY board) and CN1 (inverter)

connected by a cable?

YES

Are CN2 and 3 of inverter connected to the LCD

back light?

YES

Failure of the LCD back light or the inverter.

Replace either of them with the new one.

(See 4.6.)

Is the cable between the LCD and the display

board connected?

YES

Failure of the LCD or the display board are

probable causes.

Replace either of them with the new one.

(See 4.7.)

NO

Connect them.

NO

Connect them.

NO

Connect them.

Page 14

3.2.1 Communication error of the screen

Turn OFF the dip switch (SW1) on the MAIN board

and turn ON the power again.

3 - 4

Is an error indicated? Check the indicated error.

NO

Is the flat cable connected to the main body

correctly?

MAIN board (P304) - DRIVER board (P502)

DRIVER board (P503) - DRIVER board (P202)

YES

Failure of the MAIN board or the DISPLAY board are

probable causes.

Replace either of them with the new one.

(See 4.7 and 4.8.)

YES

NO

Connect the flat cable correctly.

3.3 Back light can not be adjusted

Does the brightness of back light change by turning

the back light control knob on the rear panel?

YES

Normal

NO

Does the voltage of TP7 (BACKLIGHT) change by

turning the back light control knob?

YES

Does the voltage of TP9 change by turning the back

light control knob?

YES

Failure of the inverter or the LCD back light are

probable causes.

Replace either of them with the new one. (See 4.6.)

Failure of cables among back light control

NO

volume, the VR board and the DISPLAY board.

Replace the VR board or the cable with the

new one.

NO

Failure of the DISPLAY board.

Replace it with the new one. (See 4.7.)

Page 15

3.4 Touch panel does not work

3 - 5

Does the touch panel work normally?

Is there no torn, worn or dented part on the

NO

Replace the LCD unit with the new one.

surface?

YES

NO

Is PJ204 connected correctly? Connect it correctly.

YES

Turn OFF the power to check.

NO

Is the resistance between TP2 and 3 several kΩ?

YES

Is the resistance between TP5 and 6 several kΩ?

YES

Failure of the touch panel is a probable cause.

Replace the LCD unit with the new one.

NO

Failure of the touch panel is a probable cause.

Replace the LCD unit with the new one.

Is the resistance between TP1 and 6 more than

10 kΩ? Does it change to several kΩ by pressing

the touch panel?

YES

Is the resistance between TP3 and 4 more than

10 kΩ? Does it change to several kΩ by pressing

the touch panel?

YES

The touch panel is probably normal.

Replace the DISPLAY board with the new one.

(See 4.7.)

NO

Failure of the touch panel is a probable cause.

Replace the LCD unit with the new one.

NO

Failure of the touch panel is a probable cause.

Replace the LCD unit with the new one.

Page 16

3.5 Seat switch does not work

NO

Does the touch panel work?

YES

3 - 6

Failure of the DISPLAY board or other units.

Replace the DISPLAY board or check other items.

(See 4.7.)

Does a mode change or the beep sound by

operating the switch on the seat switch?

If a volume is at low level, the beep can not be

heard.

NO

Is the connection terminal of seat switch

connected to the connector (J206) on the

DISPLAY board?

YES

Replace the seat switch with the new one.

Is it possible to operate by the seat switch?

YES

The cause was failure of the seat switch.

YES

NO

NO

Normal.

Refer to the operator's manual and check the

operating procedures.

Connect the terminal of seat switch to the

connector.

Failure of the DISPLAY board.

Replace it with the new one. (See 4.7.)

Page 17

3.6 Remote control does not work

Failure of DISPLAY board or the other units.

NO

Does the touch panel work?

YES

Is the power of remote control turned ON by

pressing the power switch of remote control?

YES

Are codes of remote control and RC of the main

body same?

Replace the DISPLAY board or check the other

items. (See 4.7.)

Replace batteries of remote control with the new

NO

one.

If the power is not turned ON even replacing

batteries, it shows failure of remote control itself.

Use a same cord for remote control and RC of the

main body.

NO

The cord for remote control is set by the dip

switch in batteries of remote control. The cord

for the main body is set on the CUSTOM screen.

3 - 7

YES

Are there any other infrared light on the

photoreceptor of the display unit?

NO

Is the cable of RECEIVER board connected to

J210 on the DISPLAY board?

YES

Connect the photoreceptive signal between R5

and R6 on the DISPLAY board to the oscilloscope.

Does the photoreceptor receive remote control

signal and input the signal to the oscilloscope?

YES

Failure of the DISPLAY board.

Replace it with the new one. (See 4.7.)

YES

NO

NO

Eliminate the infrared light.

Connect the cable.

Failure of the remote control or the RECEIVER

board on the display unit are probable causes.

Replace either of them with the new one.

(See 4.21.)

Page 18

3.7 Sounds do not come out

3 - 8

Is the volume control knob at proper position?

No sounds can be heard if the knob is turned to

the lowest level.

YES

YES

Can the beep sound be heard by pressing

switches?

NO

Is the cable from speaker connected to J308 on

the MAIN board?

YES

Is the resistance between 1st and 2nd pins of

P308 connector of speaker 7 to 8Ω?

YES

Failure of the MAIN board.

Replace it with the new one. (See 4.8.)

NO

Turn the volume control knob to proper

position.

NO

Connect the cable.

NO

Failure of speaker.

Replace it with the new one. (See 4.22.)

Is sound output set ON?

Check the sound output setting by VOICE on the

CUSTOM screen.

YES

Input sound data from the sound card on the

service screen. Do sounds become normal?

YES

End

3.8 Volume can not be adjusted

Does the voltage of TP8 (VOLUME) on the

DISPLAY board change by turning the volume

control knob?

YES

NO

Set the sound setting to ON.

NO

Failure of the MAIN board. (See 4.8.)

NO

Failure of the VR board.

Replace it with the new one. (See 4.20.)

Failure of the volume control circuit on the MAIN

board is a probable cause.

Replace the MAIN board with the new one.

(See 4.8.)

Page 19

3 - 9

3.9 Irrigation pole does not move by irrigation UP/DOWN

switch

NO

Does the irrigation pole move up and down by

the LCD touch panel?

YES

Disconnect P310 from the MAIN board and

check switch operation.

Is switch contact turned ON or OFF correctly

by operating the irrigation pole UP/DOWN

switch?

YES

Failure of the MAIN board.

Replace it with the new one.

Is the limit switch (micro switch) on the upper

side or the lower side of the irrigation pole

turned ON?

NO

NO

YES

Failure of the irrigation pole UP/DOWN switch.

Replace it with the new one. (See 4.23.)

The irrigation pole does not move since it

comes to the limit position.

Check the limit switch or adjust the pole

position. (See 4.9.) Moreover, the pole can

not move since the upper side or lower side of

the irrigation pole is bitten in some cases.

Is the signal of limit switch of the irrigation

pole turned ON?

MAIN board

UP LIMIT SW:IC20-2 pin 0V=ON, 5V=OFF

DOWN LIMIT SW :IC20-3 pin 0V=ON, 5V=OFF

NO

Is the indication of irrigation height within the

working range?

YES

Is the control signal output by pressing the

irrigation pole UP/DOWN switch?

MAIN board

UP SW :IC21-19 pin 0V=ON、5V=OFF

DOWN SW :IC20-18 pin 0V=ON、5V=OFF

BU CONNECT board

UP SW :IC2-12 pin 0V=ON、12V=OFF

DOWN SW :IC2-11 pin 0V=ON、12V=OFF

YES

A

YES

NO

NO

Failure of the limit switch is a probable cause.

Check the limit switch or the signal line.

The irrigation pole moves up and down only

within the working range.

Ajdust the potentiometer if the height position

is not correct. (See 5.10.)

Failure of the MAIN board or the BU

CONNECT board are probable causes.

Replace the board with the new one.

(See 4.8. and 4.19.)

Page 20

3 - 10

A

Is AC100V supplied to the POLE CONTROL

board?

Check the voltage between 1st and 3rd pins of

P712 is AC100V.

YES

Is the connector on the POLE CONTROL board

connected correctly?

YES

Press the irrigation pole UP switch.

Is the relay (RY1) on the POLE CONTROL board

turned ON? Is the AC100V supplied between 1st

and 4th pins of J706 connector?

YES

Press the irrigation pole DOWN switch.

Is the relay (RY2) on the POLE CONTROL board

turned ON? Is the AC100V supplied between 2nd

and 4th pins of J706 connector?

NO

NO

NO

NO

The transformer or the input power is abnormal.

Check the input power or replace the transformer

with the new one. (See 4.18.)

Connect it correctly.

Failure of the POLE CONTROL board is a

probable cause.

Replace the board with the new one. (See 4.25.)

Failure of the POLE CONTROL board is a

probable cause.

Replace the board with the new one. (See 4.25.)

YES

Does the AC motor rotate by pressing the

irrigation pole UP/DOWN switch?

YES

Does the irrigation pole move up and down if the

AC motor for the irrigation pole rotate?

YES

Normal.

Failure of the AC motor.

NO

Replace the AC motor or the condenser for motor

(C1) with the new one. (See 4.10 and 4.36.)

The gear or the belt of the motor may be

NO

abnormal.

Check them.

Page 21

3.10 Printer does not work normally

3 - 11

Is paper loaded to the printer? Load paper to the printer.

NO

YES

YES

Is it possible to print by the PRINT switch on the

rear panel?

NO

Is it possible to print by the PRINT switch on the

touch panel?

NO

Is the connector on the MAIN board (J312)

connected correctly?

YES

YES

NO

Replace the PRINT/FEED switch (BA29) or

the cable (EA41) with the new one.

(See 4.24.)

Connect it.

Failure of the printer, the board (BA08) or the

MAIN board are probable causes.

Replace the printer or the board with the new

one. If the symptom is not solved, replace the

MAIN board with the new one. (See 4.8. and 4.14.)

Are date and time printed correctly?

YES

Failure of the printer, the board (BA08) or the

MAIN board are probable causes.

Replace the printer or the board with the new

one. If the symptom is not solved, replace the

MAIN board with the new one. (See 4.8 and 4.14.)

NO

Set time on the CUSTOM screen.

Page 22

3 - 12

3.11 Memory inside of main body does not work correctly

Is the Store switch pressed to store the contents

of program?

YES

Failure of the MAIN board or the flash memory are

probable causes. Replace the board with the new

one. (See 4.8.)

NO

Press the Store switch to store the program to

the flash memory.

3.12 Memory card does not work correctly

Is the memory card for programming inserted? Insert the memory card for programming.

YES

Does the memory card operation screen appear

by pressing the memory card switch?

YES

NO

NO

The memory card is not recognised for use in

programming. Check the memory card.

Is it possible to write to the memory card?

YES

Replace the memory card with the new one.

Does it work normally?

NO

Is the cable between the MAIN board and the

CARD board connected correctly?

YES

Failure of the MAIN board (BA03) or the CARD

board (BA24) are probable causes. Replace the

board with the new one. (See 4.8 and 4.38.)

NO

YES

NO

The memory card may be protected.

Unprotect the card.

Breakage of the memory card is a probable cause.

Connect it correctly.

Page 23

3.13 Cassette test is not passed

NO

Insert the cassette. Does the cassette loading

start?

YES

3 - 13

Replace the cassette with the new one. Is the

cassette test passed?

NO

Does an error occur when the cassette test is

finished?

NO

Normal

YES

Does the screen change to the cassette test by

inserting the cassette?

NO

Is the continuity between 1st and 2nd pins of

P515 connected to the DRIVER board turned ON

from OFF by inserting the cassette?

YES

YES

NO

Failure of the cassette is a probable cause.

Check the cause of error from the error

code.

Failure of the microswitch (SW56) is a

probable cause.

Replace it or check soldering. (See 4.26.)

YES

Is the continuity between 1st and 2nd pins of

P516 connected to the DRIVER board turned ON

from OFF by inserting the cassette?

YES

Failure of the DRIVER board is a probable cause.

Replace it with the new one. (See 4.29.)

Failure of the DRIVER board is a probable cause.

Replace the board with the new one. (See 4.29.)

NO

Failure of the microswitch (SW58) is a

probable cause.

Replace it or check soldering. (See 4.26.)

Page 24

3.14 Cassette can not be removed

3 - 14

YES

Is the continuity of the cable between the

DRIVER board and the EJECT switch normal?

YES

Does the 3rd pin of IC3 on the DRIVER board

change from 5V to 0V by pressing the EJECT

switch?

NO

Disconnect the P524. Does the continuity

between 5th and 7th pins of P524 change by

pressing the EJECT switch?

YES

B

Does the CASSETTE EJECT LED change from

YES

lighting up to blinking by pressing the EJECT

siwtch?

NO

YES

Is the state of the poistion O indicated while the

foot switch is not pressed on the screen?

NO

NO

Replace or repair the cable.

NO

Replace the board of the EJECT switch

with the new one. (See 4.27.)

Disconnect the connector of the foot switch and

press the EJECT switch. Is it possible to remove

the cassette?

YES

Failure of the foot switch.

Does the DC motor of EA38 rotate?

YES

Does the cassette move down?

YES

Are all pinch valves turned up?

NO

Do pinch valves move by replacing the unmoving

valves?

If there is no pinch valve to replace, connect to

the connector of other pinch valve and check the

operation.

YES

NO

NO

NO

YES

NO

Failure of the cable and the board (BU

CONNECT board) between the foot switch

connector and the MAIN board. (See 4.19.)

A

Replace the control unit (18214-1130) with

the new one. (See 4.11.)

Replace the control unit (18214-1130) with

the new one. (See 4.11.)

C

Replace the pinch valve with the new one.

(See 4.39.)

Page 25

3 - 15

A

Does the 24V of voltage occur between 1st

and 2nd pins of J513 while ejecting the

cassette by the EJECT switch?

C

NO

Is DC 24V supplied to the 7th pin of P501?

B

YES

Is DC 5V supplied to the 1st pin of P501?

YES

Failure of the DRIVER board, the MAIN board

or the cable between boards.

Replace either of them with the new one.

(See 4.8 and 4.29.)

YES

Failure of the DC motor (EA38) or the loading

mechanism. Replace the control unit (18214-

1130) with the new one. (See 4.11.)

Failure of the power cable (EA34) to the DRIVER

NO

board, or the power. Replace the cable with the

new one or check the power following the item of

power. (See 3.30.)

Failure of the power cable (EA34) to the DRIVER

NO

board, or the power. Replace the cable with the

new one or check the power following the item of

power. (See 3.30.)

Page 26

3.15 SYSTEM (cataract) test is not passed

3.15.1 SINGLE CASSETTE

3 - 16

Does the ERROR CODE E200 No.17

appear on the screen?

NO

Does the ERROR CODE E200 No.31

appear on the screen?

NO

A

YES

Is the connection set removed during a test?

YES

Eject the cassette once. Start SYSTEM TEST again

after connecting the connection set.

YES

Are each conductors of EA44 continuous?

NO

Replace the EA44 with the new one.

Shade the each photointerrupters of BA28. Do the 2nd,

3rd and 4th pins of IC4 on the DRIVER board (BA05)

change ON or OFF?

NO

Replace the TUBE SENS board (BA28) with the new one.

(See 4.28.)

Replace the DRIVER board (BA05) with the new one.

(See 4.29.)

YES

Does the ERROR CODE E307 appear simultaneously?

YES

Failure of EA39 or the DRIVER board (BA05).

(See 4.29.)

NO

YES

NO

YES

Does the aspiration motor rotate

while all pinch valves are closed?

NO

Failure of the pinch valve. Check

the pinch valve following the item of

irrigation and aspiration.

(See 3.21 and 3.22.)

An air leakage of the cassette is a

probable cause. Replace the

cassette with the new one.

Select a mode on the service mode. Does the aspiration

YES

pressure change by pressing the aspiration sensor with a

hand?

NO

Is DC5V supplied to the 1st pin of J262 on the VACUUM

SENS board (BA26)? (See 4.37.)

NO

YES

Are each conductors of EA46 continuous?

NO

Failure of EA46.

Failure of the VACUUM SENS board (BA26).

(See 4.37.)

Select a mode in the service mode while the cassette is

YES

not inserted and press the load cell with a hand. Does

the voltage of TP1 on the VACUUM SENS board (BA26)

change?

NO

Failure of the EA31. Replace it with the new one.

Failure of the VACUUM SENS board (BA26) or EA31.

Replace or readjust either of them. (See 4.37 and 5.11.)

YES

Page 27

3 - 17

A

Does the ERROR CODE E200 No.32 appear

on the screen?

NO

Does the ERROR CODE E200 No.33 appear

on the screen?

NO

YES

An air leakage of the cassette is a probable

cause. Replace the cassette with the new one.

YES

Does the VENT VALVE work?

NO

Failure of the pinch valve. Check the pinch valve

following the item of irrigation and aspiration.

(See 3.21 and 3.22.)

YES

Is the flow rate control of transfusion tube

closed?

NO

Is the opening for air intake of spike of transfusion

tube closed?

YES

Open the opening for air intake or insert the

needle. And then, perform SYSTEM TEST again.

The cassette is probably clogged. Replace the

cassette with the new one.

YES

NO

Does the ERROR CODE E200 No.34 appear

on the screen?

NO

B

Open the flow rate control and perform SYSTEM

TEST again.

Are the aspiration line, the irrigation line,

YES

handpiece and the test chamber connected

securely?

NO

Connect the aspiration line, the irrigation line,

handpiece and the test chamber securely.

YES

Does the IRR1 valve work normally?

NO

Check the pinch valve following the item of

irrigation. (See 3.21.)

The cassette is probably clogged. Replace the

cassette with the new one.

YES

Page 28

3 - 18

B

YES

Does ERROR CODE E200 No.35 appear? Does the ASP1 valve work normally?

NO

NO

Check the pinch valve following the item of

aspiration. (See 3.22.)

The cassette or handpiece is probably clogged.

YES

Does ERROR CODE E200 No.36 appear?

NO

Is the connection set inserted securely?

NO

Insert the connection set securely and perform

SYSTEM TEST again.

An air leakage of cassette is a probable cause.

Replace the cassette with the new one.

YES

Does ERROR CODE E200 No.42 appear?

NO

Does the cassette loader work?

NO

Check the control unit following the item that

cassette can not be removed. (See 3.14.)

C

YES

Are each conductors of EA44 continuous

securely?

YES

YES

YES

NO

Replace the EA44 with the new one.

Failure of the CASSETTE SENS board (BA27) or

the adjustment failure of the control unit.

Replace the control unit or BA27, and readjust

the replaced one. (See 4.11, 4.30 and 5.11.)

Page 29

3 - 19

C

Does the ERROR CODE E200 No.43

appear?

NO

Does the ERROR CODE E200 No.44

appear?

NO

YES

Does the drainage bag come to the limit?

YES

Replace the cassette with the new one.

NO

Is the problem solved by replacing the cassette?

YES

Failure of the cassette. Readjust the control unit

if the error frequently occurs. (See 4.11.)

Readjust the control unit. (See 5.11.)

YES

Does the cassette loader work?

NO

Check the control unit following the item that

cassette can not be removed. (See 3.14.)

NO

YES

Does the ERROR CODE E210 appear?

NO

If the switch of SYSTEM TEST can not be

pressed, it means occurrence of an error.

Follow the indicated error code to solve it.

YES

Are each conductors of EA44 continuous

securely?

NO

Replace the EA44 with the new one.

Failure of the CASSETTE SENS board (BA27) or

adjustment failure of the control unit. Replace

the control unit or BA27, and readjust the

replaced one. (See 4.11, 4.30 and 5.11.)

YES

Check the ultrasound oscillation part following the

item of TEST US.

Page 30

3.15.2 ANT DUAL CASSETTE

3 - 20

Does the ERROR CODE E200 No.17

appear?

NO

Does the ERROR CODE E200 No.31

appear?

NO

A

YES

Is the connection set removed during TEST?

YES

Eject the cassette once. Perform SYSTEM TEST

again while connecting the connecting set.

YES

Are the each conductors of EA44 continuous?

NO

Replace EA44 with the new one.

Shade the each photointerrupters of BA28. Does

the 2nd, 3rd and 4th pins of IC4 of BA05 change

to ON or OFF?

NO

Replace BA28 with the new one. (See 4.28.)

Replace BA05 with the new one. (See 4.29.)

YES

Does ERROR CODE E307 appear simultaneously?

YES

Failure of EA39 or BA05. (See 4.29.)

NO

YES

NO

YES

Does the aspiration motor rotate while the

pinch valve is fully opened?

NO

Failure of the pinch valve. Check the pinch

valve following the item of irrigation and

aspiration. (See 3.21 or 3.22.)

An air leakage of the cassette is a probable

cause. Replace the cassette with the new

one.

Select a mode in the service mode and press the

YES

aspiration sensor with a hand. Does the

aspiration pressure change?

NO

Is DC5V supplied to the 1st of J262 of BA26?

NO

YES

Are each conductors of EA46 continuous?

NO

Failure of EA46.

Failure of BA26. (See 4.37.)

Select a mode without inserting a cassette and

YES

press the load cell with a hand. Does the voltage

of TP1 of BA26 change?

NO

Failure of EA31. Replace it with the new one.

Failure of BA26 or EA31. Replace or readjust

either of them (See 4.37 and 5.11.)

YES

Page 31

A

YES

Does ERROR CODE E200 No.32 appear?

NO

An air leakage of the cassette is a probable

cause. Replace the cassette with the new one.

YES

Does ERROR CODE E200 No.33 appear? Does the VENT VALVE work?

3 - 21

YES

NO

Does ERROR CODE E200 No.34 appear?

NO

B

NO

Failure of the pinch valve. Check the pinch valve

following the item of irrigation and aspiration.

(See 3.21 and 3.22.)

YES

Is the flow rate control of transfusion tube

closed?

NO

Is the opening for air intake of spike of transfusion

tube closed?

YES

Open the opening for air intake or insert the

needle. And then, perform SYSTEM TEST again.

The cassette is probably clogged. Replace the

cassette with the new one.

Open the flow rate control and perform SYSTEM

TEST again.

Are the aspiration line, the irrigation line,

YES

handpiece and the test chamber connected

securely?

NO

Connect the aspiration line, the irrigation line,

handpiece and the test chamber securely.

NO

YES

YES

Does the IRR1 valve work normally?

NO

Check the pinch valve following the item of

irrigation. (See 3.21.)

The cassette is probably clogged. Replace the

cassette with the new one.

Page 32

3 - 22

B

Does ERROR CODE E200 No.35 appear? Does the ASP1 valve work normally?

YES

NO

NO

Check the pinch valve following the item of

aspiration. (See 3.22.)

The cassette or the handpiece is probably

clogged.

Are the aspiration line, the irrigation line,

YES

Does ERROR CODE E200 No.37 appear?

handpiece and the test chamber connected

securely?

NO

NO

Connect the aspiration line, the irrigation line,

handpiece and the test chamber securely.

YES

Does the IRR2 valve work normally?

NO

Check the pinch valve following the item of

irrigation. (See 3.21.)

The cassette is probably clogged. Replace the

cassette with the new one.

YES

YES

Does ERROR CODE E200 No.38 appear? Does the ASP2 valve work normally?

YES

NO

NO

Check the pinch valve following the item of

irrigation. (See 3.22.)

The cassette or the handpiece is probably

clogged.

Does ERROR CODE E200 No.42 appear? Does the cassette loader move?

YES

NO

NO

Check the aspiration unit following the item that

cassette can not be removed. (See 3.14.)

YES

Are each conductors of EA44 continuous

securely?

C

NO

Replace EA44 with the new one.

Failure of BA27 or adjustment failure of the

control unit. Replace the control unit or BA27

and readjust the replaced one.

(See 4.11, 4.30 and 5.11.)

YES

YES

Page 33

3 - 23

C

YES

Does ERROR CODE E200 No.43 appear? Does the drainage bag come to the limit?

NO

YES

Replace the cassette with the new one.

NO

Is the symptom solved by replacing the cassette

with the new one?

YES

Failure of the cassette. Readjust the control unit

if the error frequently occurs. (See 4.11.)

Readjust the control unit. (See 4.11.)

YES

Does ERROR CODE E200 No.44 appear? Does the cassette loader work?

NO

NO

Check the aspiration unit following the item that

cassette can not be removed. (See 3.14.)

NO

YES

Does ERROR CODE E210 appear?

NO

If the switch of SYSTEM TEST can not be

pressed, it means occurrence of an error.

Follow the indicated error code to solve it.

YES

Are each conductors of EA44 continuous

securely?

NO

Replace the EA44 with the new one.

Failure of BA27 or adjustment failure of the

control unit. Replace the control unit or BA27,

and readjust the replaced one. (See 4.11, 4.30

and 5.11.)

YES

Check the ultrasound oscillation part following the

item of TEST US.

Page 34

3.16 US test is not passed

Does the error code E210 appear?

YES

NO

This is not an error of US. Check SYSTEM TEST

or the indicated error code.

3 - 24

Is the US tip fixed correctly?

YES

Replace the US handpiece with the new one and

perform the US test. Is it passed?

NO

Are +5V, ±12V and ±28V on the PS board

correct?

YES

Failure of the US unit is a probable cause.

Replace it with the new one. (See 4.13.)

3.17 DIA test is not passed

NO

YES

NO

Fix the US tip correctly.

Failure of the US handpiece.

Failure of the power. Check the power.

(See 3.30.)

Are +5V, ±12V and ±28V on the PS board

correct?

YES

Is TP18 on the MAIN board +3.7V (

outputting diathermy in the Dia test?

YES

Is TP21 on the MAIN board +1.0V (±0.3V) during

outputting diathermy in the Dia test?

YES

Failure of the US unit. Replace it with the new

one. (See 4.13.)

±0.2V) during

NO

Failure of the power. Check it.

(See 3.30.)

Failure of the D/A converter on the MAIN board.

NO

Replace the MAIN board with the new one.

(See 4.8.)

NO

Failure of the MAIN board. Replace it with the

new one. (See 4.8.)

Page 35

3 - 25

3.18 SYSTEM (vitrectomy) test is not passed

3.18.1 ANT/POST DUAL CASSETTE (same as POST DUAL

CASSETTE using A/P setting)

Does ERROR CODE E200 No.17 appear ?

NO

YES

Is the connection set disconnected from the

cassette during TEST?

YES

EJECT the cassette once. Perform SYSTEM

TEST again while connecting the connection set.

YES

Are the each conductor of EA44 continuous?

NO

Replace the EA44 with the new one.

NO

Shade each photointerrupters of BA28. Does the

2nd, 3rd or 4th pins of IC4 of BA05 change to ON

or OFF?

NO

Replace BA28 with the new one. (See 4.28.)

Replace BA05 with the new one. (See 4.29.)

Does ERROR CODE E200 No.31 appear ? Does ERROR CODE E307 appear simultaneously?

NO

A

YES

Does the aspiration motor rotate while the

pinch valve is fully closed?

NO

Failure of the pinch valve. Check the pinch

valve following the item of irrigation and

aspiration. (See 3.21 and 3.22.)

An air leakage of cassette is a probable

cause. Replace it with the new one.

YES

Failure of EA39 or BA05.

Select a mode in the service mode and press the

YES

aspiration sensor with a hand. Does the

aspiration pressure change?

Is the DC5V supplied to the 1st pin of BA26

J262?

YES

Are each condensers of EA46 continuous?

YES

NO

NO

NO

Failure of EA46.

YES

NO

YES

Failure of BA26. (See 4.37.)

Select a mode in the service mode without

YES

inserting the cassette and press the load cell with

a hand. Does the voltage of BA26 TP1 change?

NO

Failure of the EA31. Replace it with the new one.

Failure of BA26 or EA31. Replace or readjust

either of them. (See 4.37.)

Page 36

A

YES

Does ERROR CODE E200 No32 appear ?

NO

An air leakage of the cassette is a probable

cause. Replace the cassette with the new one.

YES

Does ERROR CODE E200 No.33 appear ? Does the VENT VALVE work?

3 - 26

YES

NO

Does ERROR CODE E200 No.34 appear ?

NO

NO

Failure of the pinch valve. Check the pinch valve

following the item of irrigation and aspiration.

(See 3.21 and 3.22.)

YES

Is the flow rate control of transfusion tube

closed?

NO

Is the opening for air intake of spike of transfusion

tube closed?

YES

Open the opening for air intake or insert the

needle. And then, perform SYSTEM TEST again.

The cassette is probably clogged. Replace the

cassette with a new one.

Open the flow rate control and perform SYSTEM

TEST again.

Are the aspiration line, the irrigation line, the

YES

handpiece and the test chamber connected

securely?

NO

Connect the aspiration line, the irrigation line, the

handpiece and the test chamber securely.

NO

YES

YES

Does the IRR1 valve work normally?

NO

Check the pinch valve following the item of

irrigation. (See 3.21.)

The cassette is probably clogged. Replace the

cassette with a new one.

Does ERROR CODE E200 No.35 appear ? Does the ASP1 valve work normally?

YES

NO

B

Check the pinch valve following the item of

aspiration. (See 3.22.)

NO

The cassette or the handpiece is probably

clogged.

YES

Page 37

3 - 27

B

Does ERROR CODE E200 No.39 appear? Does the ASP2 valve work normally?

YES

NO

NO

Check the pinch valve following the item of

aspiration. (See 3.22.)

The cassette or the handpiece is probably

clogged.

Does ERROR CODE E200 No.42 appear? Does the cassette loader work normally?

YES

NO

C

Check the aspiration unit following the item that

cassette can not be removed. (See 3.14.)

YES

NO

Are each conductors of EA44 continuous?

NO

Replace the EA44 with the new one.

YES

YES

Failure of BA27 or adjustment failure of the

control unit. Replace the control unit or BA27,

and readjust the replaced one.

(See 4.11, 4.30 and 5.11.)

Page 38

3 - 28

C

YES

Does ERROR CODE E200 No.43 appear? Does the drainage bag come to the limit?

NO

YES

Replace the cassette with the new one.

NO

Is the symptom solved by replacing the cassette?

YES

Failure of the cassette. Replace the control unit

if the error frequently appears. (See 4.11.)

Replace the control unit with the new one.

(See 4.11.)

YES

Does ERROR CODE E200 No.44 appear?

NO

Does the cassette loader work?

NO

Check the aspiration unit following the item that

cassette can not be removed. (See 3.14.)

NO

YES

Does ERROR CODE E210 appear?

NO

If the switch of SYSTEM TEST can not be

pressed, it means occurrence of an error.

Follow the indicated error code to solve it.

YES

Are each conductors of EA44 continuous?

NO

Replace EA44 with the new one.

Failure of BA27 or adjustment failure of the

control unit. Replace the control unit or BA27

and readjust it. (See 4.11, 4.30 and 5.11.)

YES

Check the ultrasound oscillation part following the

item of US TEST.

Page 39

3 - 29

3.18.2 POAT DUAL CASSETTE (only for POST DUAL

CASSETTE using PD setting)

Does ERROR CODE E200 No.17 appear ? Is the connection set disconnected during TEST?

YES

NO

NO

Does ERROR CODE E200 No.31 appear ?

NO

A

YES

Eject the cassette once. Perform SYSTEM TEST

again while connecting the connection set.

YES

Are each conductors of EA44 continuous?

NO

Replace EA44 with the new one.

Shade each photointerrupters of BA28. Does the

2nd, 3rd or 4th pin of BA05 IC4 change to ON or

OFF?

NO

Replace BA28 with the new one. (See 4.28.)

Replace BA05 with the new one. (See 4.29.)

YES

Does ERROR CODE E307 appear simultaneously?

YES

Failure of EA39 or BA05.

YES

NO

YES

Does the aspiration motor rotate while the

pinch valve is fully closed?

NO

Failure of the pinch valve. Check the pinch

valve following the item of irrigation and

aspiration. (See 3.21 and 3.22.)

An air leakage of cassette is a probable

cause. Replace it with the new one.

Select a mode in the service mode and press the

YES

aspiration sensor with a hand. Does the

aspiration pressure change?

NO

Is DC5V supplied to the 1st pin of BA26 J262?

NO

YES

Are each conductors of EA46 continuous?

NO

Failure of EA46.

Failure of BA26. (See 4.37.)

Select a mode in the service mode without

YES

inserting the cassette and press the load cell with

a hand. Does the voltage of BA26 TP1 change?

NO

Failure of the EA31. Replace it with the new one.

Failure of BA26 or EA31. Replace or readjust

either of them. (See 4.37 and 5.11.)

YES

Page 40

A

YES

Does ERROR CODE E200 No32 appear ?

NO

An air leakage of the cassette is a probable

cause. Replace the cassette with the new one.

YES

Does ERROR CODE E200 No.33 appear ? Does the VENT VALVE work?

3 - 30

YES

NO

Does ERROR CODE E200 No.40 appear ?

NO

Failure of the pinch valve. Check the pinch valve

following the item of irrigation and aspiration.

(See 3.21 and 3.22.)

YES

Is the flow rate control of transfusion tube

closed?

NO

Is the opening for air intake of spike of transfusion

tube closed?

YES

Open the opening for air intake or insert the

needle. And then, perform SYSTEM TEST again.

The cassette is probably clogged. Replace the

cassette with the new one.

Open the flow rate control and perform the

SYSTEM TEST again.

YES

Does ASP1 valve work normally?

NO

YES

NO

Does ERROR CODE E200 No.41 appear ?

NO

B

NO

Check the pinch valve following the item of

irrigation. (See 3.22.)

The cassette is probably clogged. Replace the

cassette with the new one.

YES

Does ASP2 valve work normally?

NO

Check the pinch valve following the item of

aspiration. (See 3.22.)

The cassette or the handpiece is probably

clogged.

YES

Page 41

Does the aspiration pressure rise?

YES

Is the symptom loud pulsation?

NO

Does the pinch valve work correctly?

NO

NO

A

YES

Perform SYSTEM TES again. Does the ERROR

CODE E307 appear?

YES

Does the 6th pin signal of BA05 IC3 change by

YES

changing the shading condition of EA45

photointerruper?

NO

Replace EA45 with the new one.

Readjust the position of the shading plate and the

aspiration rotor, or replace the control unit with

the the new one. (See 4.11.)

The handpiece or the cassette are probably

YES

clogged. Replace either of them with the new

one.

3 - 31

NO

Can the operating sound of the relevant

aspiration pinch valve be heard by selecting a

mode of the touch panel?

YES

Readjust the pinch valve EA30. (See 5.13.)

NO

Does the operating voltage occur between 1st and

2nd pins of unmoving pinch valve?

YES

Replace the pinch valve EA30 with the new one.

(See 4.39.)

Are voltages supplied as follows?

NO

DC5V to the 1st pin of J501 of BA05

DC6V to the 5th pin of J501 of BA05

DC24V to the 7th pin of J501 of BA05

YES

Does the voltage between 9th pin-GND, and 6th

pin-GND of IC2 change by turning ON/OFF FREE

IRR in case of IRR1?

Does the voltage between 2nd pin-GND, and 5th

pin-GND of IC2 change by turning ON/OFF FREE

IRR in case of IRR2?

YES

Replace BA05 with the new one. (See 4.29.)

NO

NO

Failure of BA05, E335 or BA03.

(See 4.8 and 4.29.)

Failure of the power unit. Refer to the item of the

power unit. (See 3.30.)

Page 42

3.19 PPL test is not passed

Does the error code E210 appear?

YES

NO

This is not the error of US. Check SYSTEM

TEST or the indicated error code.

3 - 32

Is the US tip fixed correctly?

YES

Replace the US handpiece with the new one and

perform the US test. Is it passed?

NO

Are +5V, +12V and +28V on the PS board

correct?

YES

Failure of the US unit is a probable cause.

Replace it with the new one. (See 4.13.)

NO

Fix the US tip correctly.

YES

Failure of the US handpiece.

NO

Failure of the power. Check it. (See 3.30.)

Page 43

3.20 Foot switch does not work

3 - 33

Are connectors connected to the main body

securely?

YES

YES

Does the switch of the foot pedal on the LCD

screen change by operating the switch?

NO

Does RIGHT KICK SW work?

YES

Does LEFT KICK SW work?

YES

Does RIGHT UPPER SW work?

YES

Does RIGHT LOWER SW work?

NO

Reconnect it.

NO

Does the continuity between 1st and 6th pins

of connector change by SW operation?

YES

B

NO

Does the continuity between 1st and 7th pins

of connector change by SW operation?

YES

B

NO

Does the continuity between 1st and 8th pins

of connector change by SW operation?

YES

B

NO

Does the continuity between 1st and 9th pins

of connector change by SW operation?

NO

A

NO

A

NO

A

NO

A

YES

Does LEFT UPPER SW work?

YES

LEFT LOWER SW does not work.

Does the % indication of the foot pedal on the

YES

LCD screen change by operating the main

pedal?

Does the continuity between 1st and 5th

pins, 1st and 12th pins of the connector

change by operating the pedal?

YES

Are the change point of FOOT SW

POSITION and the indication of

depressing rate (%) same?

NO

A

YES

YES

B

Does the continuity between 1st and 10th,

NO

1st and 4th pins of connector change by SW

operation?

YES

B

Does the continuity between 1st and 11th

pins of connector change by SW operation?

YES

B

NO

Is 5V output between 1st and 3rd pins at the

main body side?

YES

Does the resistance value of potentiometer

between 1st and 2nd pins change by

operating the main pedal?

YES

Is the resistance value of potentiometer

between 1st and 3rd pins some 2kΩ?

YES

Failure of EA67, BA06, EA53 or BA03.

(See 4.8 and 4.19.)

NO

A

NO

A

NO

C

NO

A

NO

A

NO

B

NO

The potentiometer adjustment of EA10

FOOT PEDAL is deviated. Readjust it.

Failure of BA06 or the power supply unit.

Check voltages supplied to each boards are

C

correct following the item of power. (See

3.30.)

Page 44

3 - 34

A

Is the symptom caused by the mechanical

failure of the FOOT SW?

YES YES

NO

Is it possible to repair by adjustment?

YES

Readjust it.

Replace the relevant mechanical parts or

EA10 FOOT PEDAL with the new one.

NO

Is it possible to repair by checking connection

of terminal block or repairing wire breakage?

Repair the wiring.

Replace EA10 FOOT PEDAL with the new one.

NO

Page 45

3.21 Irrigation does not move correctly

NO

Does the irrigation solution flow?

YES

Does the irrigation solution remain in the irrigation

bottle?

YES

Is the transfusion tube connected correctly?

YES

Is the opening for air intake of spike of transfusion

tube opened?

YES

Is the flow rate control of transfusion tube

opened?

YES

Is the three-way cock in the irrigation line opened

for vitrectomy surgery?

YES

Turn ON or OFF FREE IRR on the touch panel.

Can the operation sound of the pinch valve be

heard?

YES

NO

Replace the irrigation bottle with the new one.

NO

Connect the lure connector securely.

NO

Open the opening of air intake or insert the

needle.

NO

Open the flow rate control.

NO

Open the three-way cock.

NO

Does the operating voltage between 1st and

2nd pins of unmoving pinch valve occur?

Replace the pinch valve EA30 with the new

one. (See 4.39.)

YES

3 - 35

NO

Is it possible to check visually that the pinch

valve open/close the irrigation line correctly?

YES

Does the FOOT SW position or ON/OFF of RREE

IRR by FOOT SW work normally?

YES

Failure of cassette is a probable cause.

Are voltages supplied as follows?

NO

DC5V to the 1st pin of J501 of BA05

DC6V to the 5th pin of J501 of BA05

DC24V to the 7th pin of J501 of BA05

YES

Does the voltage between 9th pin of BA05 IC2

and GND, 6th pin of BA05 IC2 and GND

change by turning ON/OFF FREE IRR in case

of IRR1?

Does the voltage between 2nd pin of BA05 IC2

and GND, 5th pin of BA05 IC2 and GND

change by turning ON/OFF FREE IRR in case

of IRR2?

YES

Replace the BA05 with the new one. (See

4.29.)

Failure of BA05, E335 or BA03.

(See 4.8 and 4.29.)

Failure of the power unit. Refer to the item of

power supply unit. (See 3.30.)

NO

Readjust the pinch valve EA30. (See 5.13.)

NO

Failure of the FOOT SW. Refer to the item of

FOOT SW. (See 3.20.)

NO

Page 46

3.22 Aspiration does not work correctly

NO

Does the aspiration pressure rise?

YES

Is the symptom loud pulsation?

NO

Does the pinch valve work correctly?

NO

A

YES

Perform SYSTEM TES again. Does the ERROR

CODE E307 appear?

Does the 6th pin signal of BA05 IC3 change by

YES

changing the shading condition of EA45

photointerruper?

Replace EA45 with the new one.

Readjust the position of the shading plate and the

aspiration rotor, or replace the control unit with

the the new one. (See 4.11.)

The handpiece or the cassette are probably

YES

clogged. Replace either of them with the new

one.

YES

NO

3 - 36

NO

Can the operating sound of the relevant

aspiration pinch valve be heard by selecting a

mode of the touch panel?

YES

Readjust the pinch valve EA30. (See 5.13.)

NO

Does the operating voltage occur between 1st and

2nd pins of unmoving pinch valve?

YES

Replace the pinch valve EA30 with the new one.

(See 4.39.)

Are voltages supplied as follows?

NO

DC5V to the 1st pin of J501 of BA05

DC6V to the 5th pin of J501 of BA05

DC24V to the 7th pin of J501 of BA05

YES

Does the voltage between 9th pin of BA05 IC2

and GND, 6th pin of BA05 IC2 and GND change by

turning ON/OFF FREE IRR in case of IRR1?

Does the voltage between 2nd pin of BA05 IC2

and GND, 5th pin of BA05 IC2 and GND change by

turning ON/OFF FREE IRR in case of IRR2?

YES

Replace BA05 with the new one. (See 4.29.)

NO

NO

Failure of BA05, E335 or BA03.

(See 4.8 and 4.29.)

Failure of the power unit. Refer to the item of the

power unit. (See 3.30.)

Page 47

3 - 37

A

Does ERROR CODE W308 appear? Is the cassette inserted securely?

YES

NO

Reinsert the cassette securely. If the problem is

not solved, perform EJECT SYSTEM TEST.

NO

Is there abnormality in the identification fin of

connection set?

Failure of BA28, EA44 or BA05 are probable

causes.

Replace the cassette with the new one.

NO

Does the FOOT SW position work normally?

YES

Does the stepping motor rotate during

aspiration?

YES

Failure of FOOT SW. Refer to the item of FOOT

SW. (See 3.20.)

Are voltages supplied as follows?

NO

DC5V to the 1st pin of J501 of BA05

DC24V to 7th pin of J501 of BA05

Failure of the stepping motor EA39 or BA05.

(See 4.29.)

NO

Is the symptom slow rising time of aspiration?

Failure of the power unit. Refer to the item of

power supply unit. (See 3.30.)

YES

YES

Does an air income to the cassette?

NO

Exhaust an air from the cassette by performing

SYSTEM TEST again.

Select a mode in the service mode without

inserting the cassette, and press the load cell

with a hand. Does the aspiration pressure

NO

Is DC5V supplied to the 1st pin of J262 of BA26?

change?

YES

YES

Are each conductors of EA46 continuous?

YES

NO

YES

NO

YES

YES

NO

Adjust the peristaltic pump.

NO

Failure of EA46.

Failure of BA26. (See 4.37.)

Select a mode in the service mode without

YES

inserting the cassette and press the load cell with

a hand. Does the voltage of BA26 TP1 change?

NO

Failure of EA31. Replace it with the new one.

Failure of BA26 or EA31. Replace or readjust

either of them. (See 4.37 and 5.11.)

Page 48

3.23 US oscillation is not performed correctly

NO

Does the US error appear during oscillating US?

YES

Is the US tip connected correctly? Connect the US its correctly.

YES

Replace the US handpiece with the new one. Is the US

error cleared?

NO

Are +5V, ±12V and ±28V on the P.S. board correct?

NO

NO

YES

Failure of the US handpiece. Replace it with the new

one.

Failure of the US unit or cable failure between the US

YES

board and the output connector.

Replace the unit or the cable with the new one.

3 - 38

Disconnect the P102 connector from the US board.

Are +5V, ±12V and ±28V on the P.S. board correct?

NO

Failure of the power. Check it. (See 3.30)

Does an error appear by performing the US test?

NO

Can the foot pedal be depressed fully (100%)?

YES

If the US tip is not soaked in irrigation water for

performing the US test, the US power is not controlled

correctly. Soak the US tip in irrigation water and

perform the test again.

Does the US oscillation become normal?

NO

YES

Failure of the US unit. Replace it with the new one.

(See 4.13.)

YES

A poor connection of the US tip is a probable cause.

Check the connection of the US tip.

NO

Check the foot pedal.

YES

Failure of load detection during the US test. The

system itself is considered as normal.

Replace the US handpiece with the new one. Does the

US oscillation become normal?

YES

Replace the US unit with the new one. (See 4.13.)

NO

Failure of the US handpiece.

Page 49

3.24 Diathermy output is abnormal

3 - 39

Perform the Dia test. Is it passed? 3.17 Dia test is not passed

YES

Replace cables, forceps or pencils with the new

one. Does it solve the symptom?

NO

NO

YES

Replace forceps or pencils with the new one.

Is the diathermy output of the main body normal?

Connect load resistance (90Ω50W) between

diathermy output connectors. Connect probes of

oscilloscope across a resistance and measure the

output voltage.

Setting 10 (W) : output voltage 30 (V)

YES

Failure of cables, forceps or pencils in use are

probable causes. Replace them with the new one.

The voltage is an execution value.

If there is no load resistance, check the voltage at

open state. (About 60V by setting 10W)

NO