Nidek AR-600 ARK 700 Service

NIDEK

AR-600/ARK-700 SERIES

SERVICE MANUAL

FOR AR-600 ARK-700

AR-600A ARK-700A

AR-660A ARK-760A

MAR10*RTZ001C/E

Total Page: 164

2003. 12

Table of Contents

§

1 INTRODUCTION ........................................................................................................ 1-1

§

2 CAUTION ..................................................................................................................... 2-1

2.1 Check flows and items to be checked ...................................................................... 2-2

§

3 TROUBLESHOOTING .............................................................................................. 3-1

3.1 The TV monitor display nothing/the monitor display is abnormal .......................... 3-1

3.2 The message “Err” appears after turning ON the Power Switch.............................. 3-2

3.2.1 “Err 1” (Sensor carry error) appears ................................................................ 3-2

3.2.2 “Err 2” (Chart carry error) appears .................................................................. 3-3

3.2.3 “Err 3” (rotary error) appears .......................................................................... 3-4

3.2.4 “Err 4” (Chart error) appears ........................................................................... 3-5

3.2.5 “Err 5”(CL1 error) or “Err 6” (CL2 error) appears ......................................... 3-5

3.2.6 “Err 7”([line] printer error) appears ................................................................ 3-6

3.2.7 “Err 8”([serial] printer error)appears............................................................... 3-6

3.2.8 “Err 9” (MEMORY FAILURE ON E2PROM) appears .................................. 3-7

3.2.9 “Err A” (MEMORY FAILURE ON RAM) appears........................................ 3-7

3.2.10 “PD ERR” appears ........................................................................................ 3-8

3.3 The shutter does not open (only for AR-600 whose S/N is earlier than 10121) ...... 3-9

3.4 The raster does not appear (The TV monitor does not light well) ........................... 3-9

3.5 Eye image does not appear on the TV monitor ........................................................ 3-9

3.6 The characters or target are not clear or they do not appear on the TV monitor .... 3-10

3.7 The switching between the manual mode and auto-tracking mode can not be done ....

...................................................................................................................................... 3-10

3.8 The instrument can not be placed into the mode

where the objective measurement is performed. ..................................................... 3-10

3.9 The parameter settings can not be changed ............................................................ 3-11

3.10 The measuring mode can not be changed............................................................. 3-12

3.11 The movement of the measuring unit is not smooth on a plane ........................... 3-12

3.12 The vertical movement of the measuring unit is not smooth ............................... 3-12

3.13 The measuring unit is unstable ............................................................................. 3-13

3.14 The alignment light does not appear (only for AR-600 series) ............................ 3-13

3.15 The Mire Ring does not appear (only for ARK-700 series) ................................. 3-13

3.16 The model eye image is not clear ......................................................................... 3-14

3.17 AR measurement does not start ............................................................................ 3-14

3.18 The message “Err” appears during AR measurements ......................................... 3-15

3.19 Only the obtained SPH value is shifted ................................................................ 3-16

3.20 The obtained CYL value is too high ..................................................................... 3-17

3.21 A short beep can not be heard when pressing the Start button ............................. 3-18

3.22 The IOL mode can not be turned ON ................................................................... 3-18

3.23 The Cylinder mode can not be changed ............................................................... 3-18

3.24 The instrument can not recognize the left and right ............................................. 3-19

3.25 The instrument can not be placed in the PD mode ............................................... 3-19

3.26 The obtained PD value is abnormal ..................................................................... 3-20

3.27 The message “Err” appears during KM measurement ......................................... 3-20

3.28 The obtained KM value is abnormal .................................................................... 3-20

3.29 The up-and-down movement of the Chin rest is not smooth ............................... 3-21

3.30 The charts can not be seen.................................................................................... 3-21

3.31 “Err” does not appear though the patient blinked during measurement............... 3-22

3.32 The auto-tracking function does not work ........................................................... 3-23

3.33 The auto-shot function does not work .................................................................. 3-24

3.34 The instrument can not be placed in the VA TEST mode

where the subjective measurement is done .......................................................... 3-24

3.35 VA charts can not be changed............................................................................... 3-25

3.36 The presented chart is out of focus during the subjective measurement

(except when a patient has irregular astigmatism) ............................................... 3-25

3.37 The message “Err IF” (Interface error) appears.................................................... 3-26

3.38 The printer does not operate ................................................................................. 3-27

3.39 Light printed text/loss of text ............................................................................... 3-27

3.40 The Eyeprint function can not be turned On ........................................................ 3-28

3.41 The TV auto-OFF function does not work ........................................................... 3-28

3.42 The shutter does not close

(only for the instruments whose S/N earlier than 10121) ............................................ 3-28

§

4 Checking the obtained data with Model eyes ............................................................ 4-1

4.1 Cleaning the Model eyes and Steel balls .................................................................. 4-1

4.2 Cleaning the measuring window .............................................................................. 4-2

4.3 Measuring the Model eyes ....................................................................................... 4-3

4.4 Tolerance on AR measurement error ........................................................................ 4-3

4.5 Measuring the Steel balls ......................................................................................... 4-4

4.6 Tolerance on KM measurement error ....................................................................... 4-4

§

5 Removing covers ........................................................................................................... 5-1

5.1 Removing the Front, Left and Right covers ............................................................. 5-1

5.2 Removing the Rear cover of the measuring unit ...................................................... 5-3

5.3 Removing the Inner cover ........................................................................................ 5-3

5.4 Removing the Rear cover ......................................................................................... 5-4

5.5 Removing the TV panel ........................................................................................... 5-5

5.6 Removing the bottom plate of the instrument .......................................................... 5-6

§

6 Checking the mains supply condition ......................................................................... 6-1

6.1 Checking the supply voltage to AC INLET .............................................................. 6-1

6.2 Checking the secondary voltage of the transformer ................................................. 6-1

6.3 Checking output voltage on PC7 board.................................................................... 6-2

6.4 Checking output voltage from backup battery ......................................................... 6-2

6.5 Checking voltage in D1 and D2 on the PC6 board .................................................. 6-3

§

7 Checking continuity of switches .................................................................................. 7-1

7.1 START SW ............................................................................................................... 7-1

7.2 Switches on the PC2 board ...................................................................................... 7-1

7.3 Switches on the PC3 board (except AR-600)........................................................... 7-3

7.4 Switches on the PC12 board (only for AR-660A and ARK-760A).......................... 7-4

§

8 Checking electric parts ................................................................................................ 8-1

8.1 Checking origin sensor for the chart carry ............................................................... 8-1

8.2 Checking L/R origin sensor (except AR-600 & ARK-700) ..................................... 8-2

8.3 Checking the Origin sensor for the Rotator.............................................................. 8-3

8.4 AR measurement LED and LED cable ..................................................................... 8-4

8.5 Checking the ILLUMI. LED voltage........................................................................ 8-5

8.6 Checking the Chart lamp voltage ............................................................................. 8-5

8.7 Checking the alignment light LED voltage .............................................................. 8-5

8.8 Checking the PD LED voltage ................................................................................. 8-5

8.9 Checking the FOCUS LED voltage (only for AR-600A, AR-660A) ....................... 8-6

8.10 Checking the AKM LED voltage (only for AR-700 series) ................................... 8-6

8.11 Checking the AKM LED voltage (except AR-600)................................................ 8-6

§

9 Replacing circuit boards .............................................................................................. 9-1

9.1 Replacing PC1 (MAIN) board ................................................................................. 9-1

9.2 Replacing PC2 (DISPLAY) board............................................................................ 9-2

9.3 Replacing PC3 (INC.DEC SW) board (except AR-600) ......................................... 9-3

9.4 Replacing PC6 (ADJUST) board ............................................................................. 9-4

9.5 Replacing PC7 (POWER SUPPLY) board............................................................... 9-5

9.6 Replacing PC8 (PRINTER) board and printer ......................................................... 9-6

9.7 Replacing PC10 (MIRE) board ................................................................................ 9-8

9.8 Replacing PC12 (CHART SELECT SW) board .................................................... 9-10

9.9 Replacing the PC22 (TRACKING) board.............................................................. 9-11

9.10 Replacing the PC23 (PD CCD) board .................................................................. 9-12

9.11 Replacing the PC24 (PD LED) board .................................................................. 9-13

§

10

Replacing parts ........................................................................................................... 10-1

10.1 Replacing the transformer .................................................................................... 10-1

10.2 Replacing the Joystick .......................................................................................... 10-2

10.3 Cleaning and replacing the Slide plate ................................................................. 10-3

10.4 Replacing LED and cleaning IR filter .................................................................. 10-4

10.5 Replacing LED and cleaning of the G29.............................................................. 10-5

10.6 Replacing the Front cover .................................................................................... 10-6

10.7 Replacing the FOCUS LED ................................................................................. 10-7

10.8 Replacing the Shutter ........................................................................................... 10-8

10.9 Replacing the LED cable ...................................................................................... 10-9

10.10 Replacing the Chart lamp ................................................................................. 10-10

10.11 Replacing the Chart carry limit sensor ............................................................. 10-11

10.12 Replacing the Rotator unit origin sensor ......................................................... 10-12

10.13 Replacing U/D limit switches .......................................................................... 10-13

10.14 Replacing the Left and Right limit sensor unit................................................. 10-15

10.15 Replacing the U/D Motor

§

(for moving the measurement unit up and down) (Except AR-600) ................ 10-16

10.16 Replacing the R/L motor (For moving the instrument to the right or left)

(Except AR-600 and ARK-700) ....................................................................... 10-17

10.17 Replacing the TV Monitor ............................................................................... 10-18

10.18 Replacing the CCD camera .............................................................................. 10-19

10.19 Replacing the Chart unit ................................................................................... 10-20

10.20 Replacing CYL unit (Only for AR-660A and ARK-760A) .............................. 10-21

10.21 Replacing the Battery ....................................................................................... 10-22

10.22 Replacing the Measuring unit .......................................................................... 10-23

11

Adjusting each part ................................................................................................... .11-1

11.1 Adjusting the tightness of roller bearing (#67) for up-and-down shaft ................ 11-1

11.2 Adjusting the Sway stopper unit ........................................................................... 11-3

11.3 Adjusting the up-and-down movement of the Chin rest....................................... 11-4

11.4 Calibrating by adjusting the focus of CCD camera lens ...................................... 11-6

11.5 Positioning the target square ................................................................................ 11-7

11.6 Sensor calibration (adjusting VR1 and VR2 on the PC6 board) .......................... 11-8

11.7 KM auto-calibration (only for ARK-700 series) ................................................ 11-10

11.8 Setting EEPROM DATA .................................................................................... 11-12

11.8.1 Setting Sensor Offset (SO) ........................................................................ 11-13

11.8.2 Setting Print Density (PC) ......................................................................... 11-14

11.8.3 Setting Target Offset (TO) ......................................................................... 11-15

11.8.4 Setting Target Gain (TG) ........................................................................... 11-15

11.8.5 Setting PD Gain (PA) ................................................................................ 11-16

11.8.6 Setting Mask Blink Level (ML) ................................................................ 11-16

11.8.7 Setting Horizontal Position (HP) of display.............................................. 11-17

11.8.8 Setting Vertical Position (VP) of display................................................... 11-17

11.8.9 Adjusting scale for CS (Corneal Size) measurement

(only for ARK-700 series)......................................................................... 11-18

11.8.10 Setting CYL zero (C1) and CYL axis (C2)

(Only for AR-660A and ARK-760) ......................................................... 11-20

11.9 Adjusting image centering .................................................................................. 11-21

11.10 Adjusting Brightness and Sharpness of display................................................ 11-22

11.11 Tracking auto-calibration (except AR-600 and ARK-700)............................... 11-23

§

§

§

§

§

12

Program for adjustment ............................................................................................ 12-1

13

Replacing ROM (Program) ....................................................................................... 13-1

14

List of SW 1 and SW2 operations ............................................................................. 14-1

15

Principle of Measurement.......................................................................................... 15-1

16

References ................................................................................................................... 16-1

y AR-600 CONSTRUCTION DRAWING ................................................................... 16-1

y AR-600 WIRING DIAGRAM ................................................................................... 16-3

y AR-600A CONATRUCTION DRAWING ................................................................ 16-4

y AR-600A WIRING DIAGRAM ................................................................................ 16-6

y AR-660A CONSTRUCTION DRAWING ................................................................ 16-7

y AR-660A WIRING DIAGRAM ................................................................................ 16-9

y ARK-700 CONSTRUCITON DRAWING .............................................................. 16-10

y ARK-700 WIRING DIAGRAM .............................................................................. 16-12

y ARK-700A CONSTRUCTION DRAWING ........................................................... 16-13

y ARK-700A WIRNG DIAGRAM ............................................................................ 16-15

y ARK-760A CONSTRUCTION DRAWING ........................................................... 16-16

y ARK-760A WIRING DIAGRAM ........................................................................... 16-18

y AR-600, ARK-700 SERIES WIRING DIAGRAM ................................................. 16-19

y AR-600, ARK-700 SERIES CONNECTOR TABLE.............................................. 16-22

y ERROR CODE CHART ......................................................................................... 16-28

§

1

• This manual provides information on after-sales servicing procedures of NIDEK AUTO

• For correct after-sales service, it is necessary to understand this manual thoroughly before

• If the instrument cannot be repaired by following the procedures described in this manual,

INTRODUCTION

REFRACTOMETER AR-600 series and AUTO REF/KERATOMETER ARK-700 series.

service.

contact NIDEK or your authorized distributor and let us know the serial number and

details of the symptom. If it is possible to obtain measurements in the condition, also

send us the data obtained by measuring with the model eye (-10D, 0D, +10D) and steel

balls (5.95mm, 7.94mm and 9.13mm).

§

TROUBLESHOOTING

2

• For correct after-sales service, follow the procedures described in “2.1 Check flows and

items to be checked” of this manual. For operating procedure, refer to “Operator’s

Manual” for each instrument.

• If you encounter any abnormal condition, track down the failure’s source as described in

“3 TROUBLESHOOTING” and then immediately turn OFF the Power Switch of the

instrument.

• Before disassembling the instrument, be sure to turn OFF the Power Switch and

disconnect the power cord from the wall outlet.

• In “3 TROUBLESHOOTING”, check the following for cables, referring to the attached

WIRING DIAGRAM and CONNECTOR TABLE.

All the connectors are connected or crimped securely.

There is no contact failure of connectors.

(Check by connecting or disconnecting them.)

The cable has no break.

Take care not to strain the cable.

• Take care not to lose the removed screws or parts, or not to drop them inside the

instrument.

• Be sure to apply Locktight to the fixed screws.

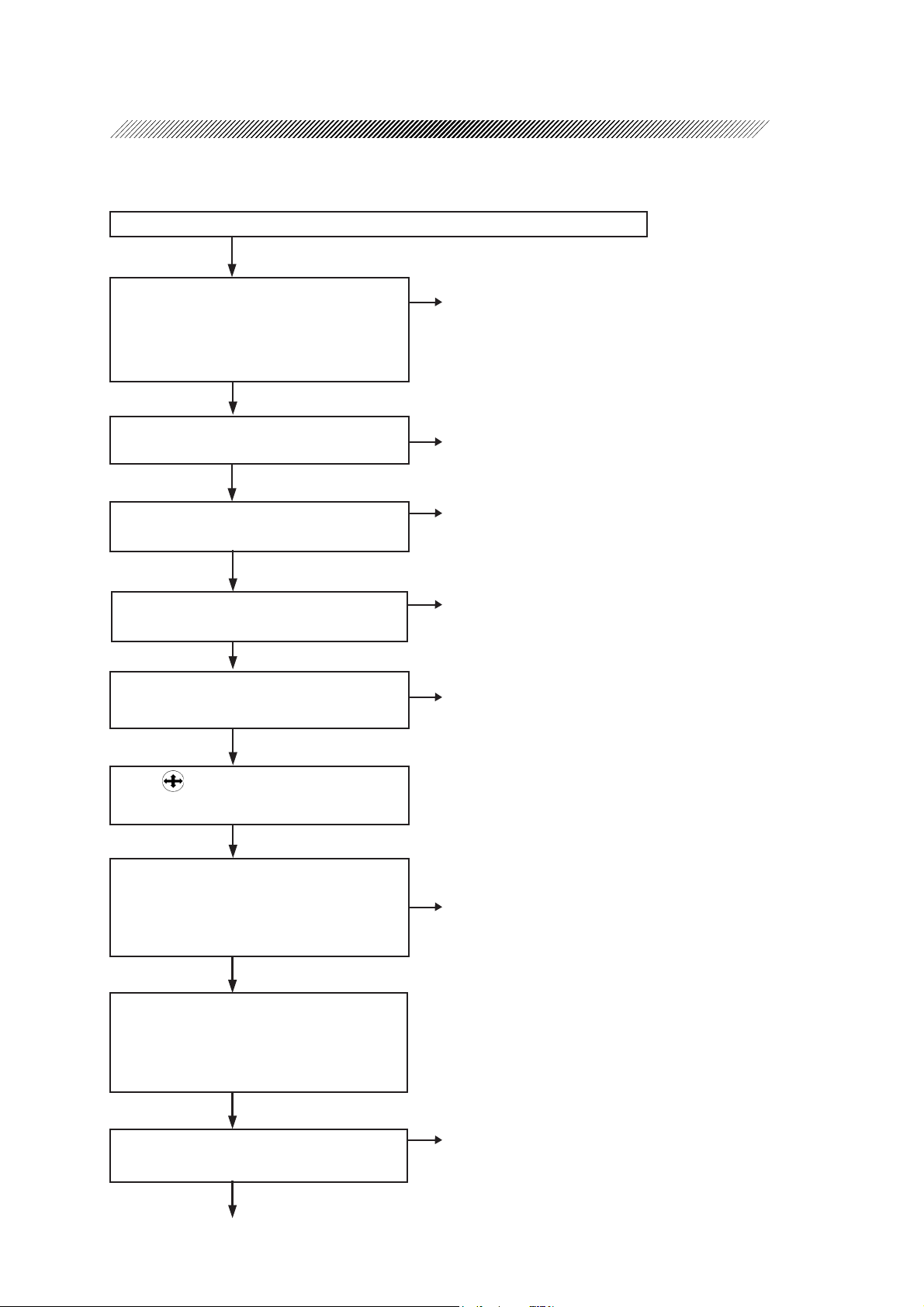

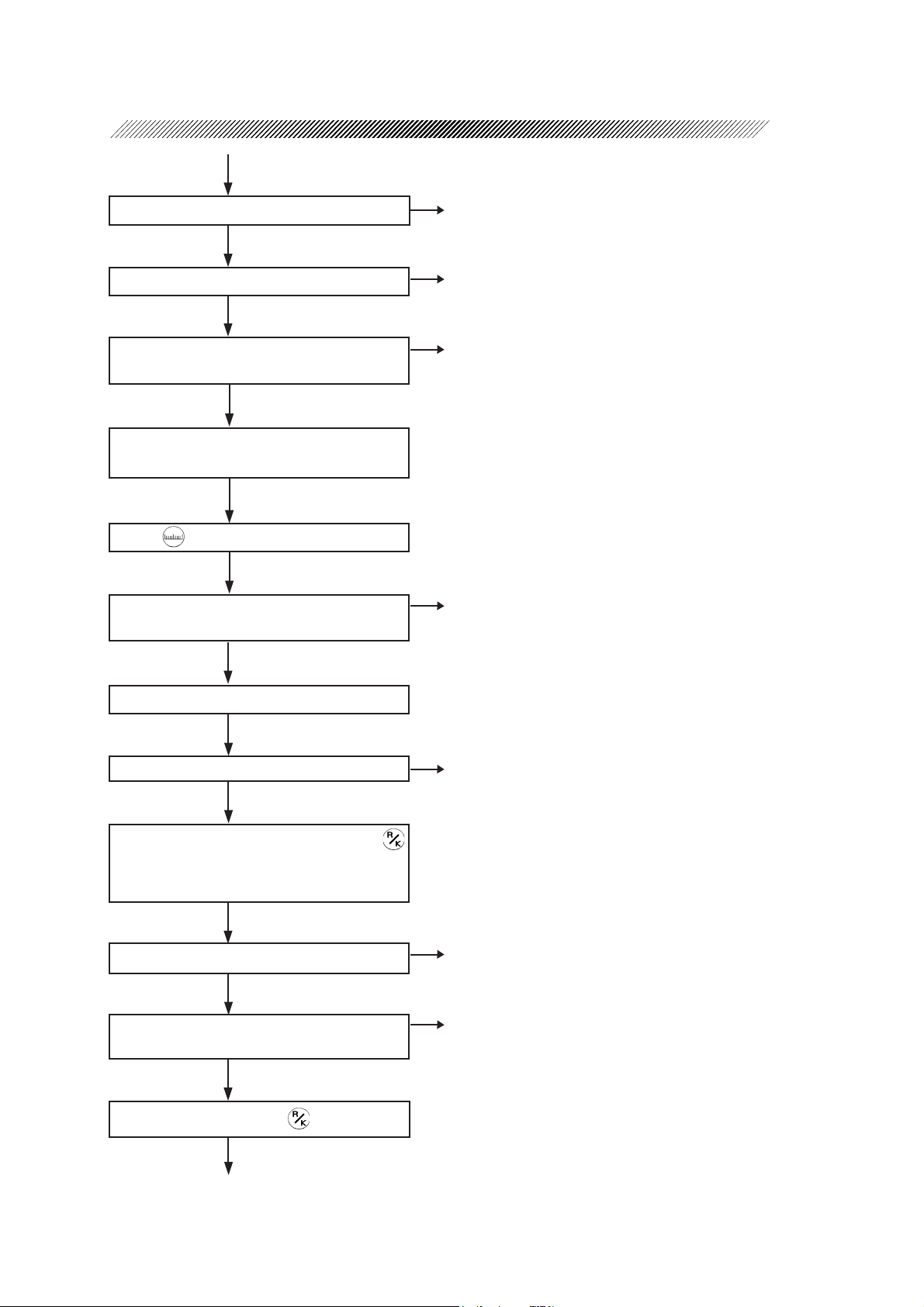

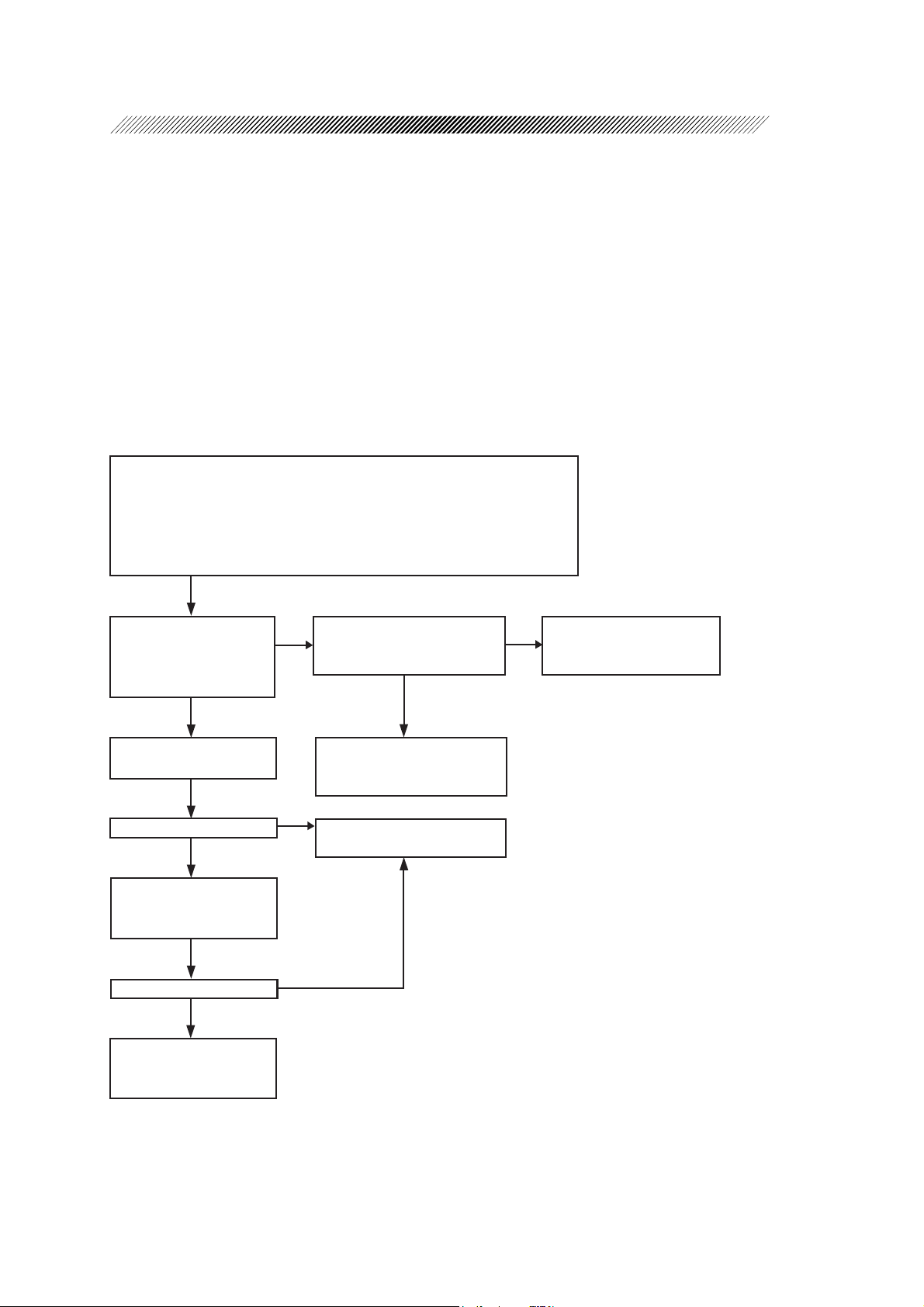

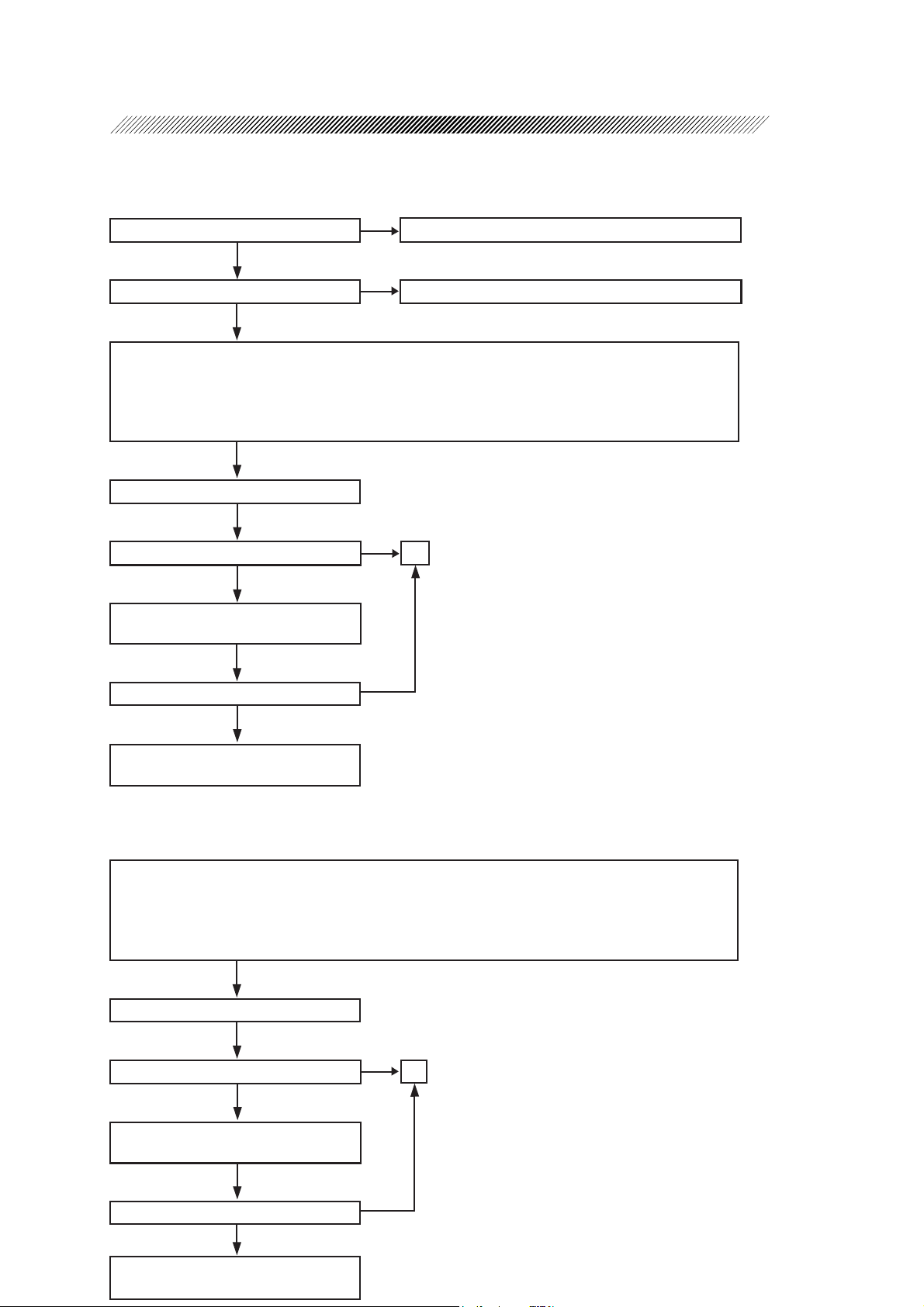

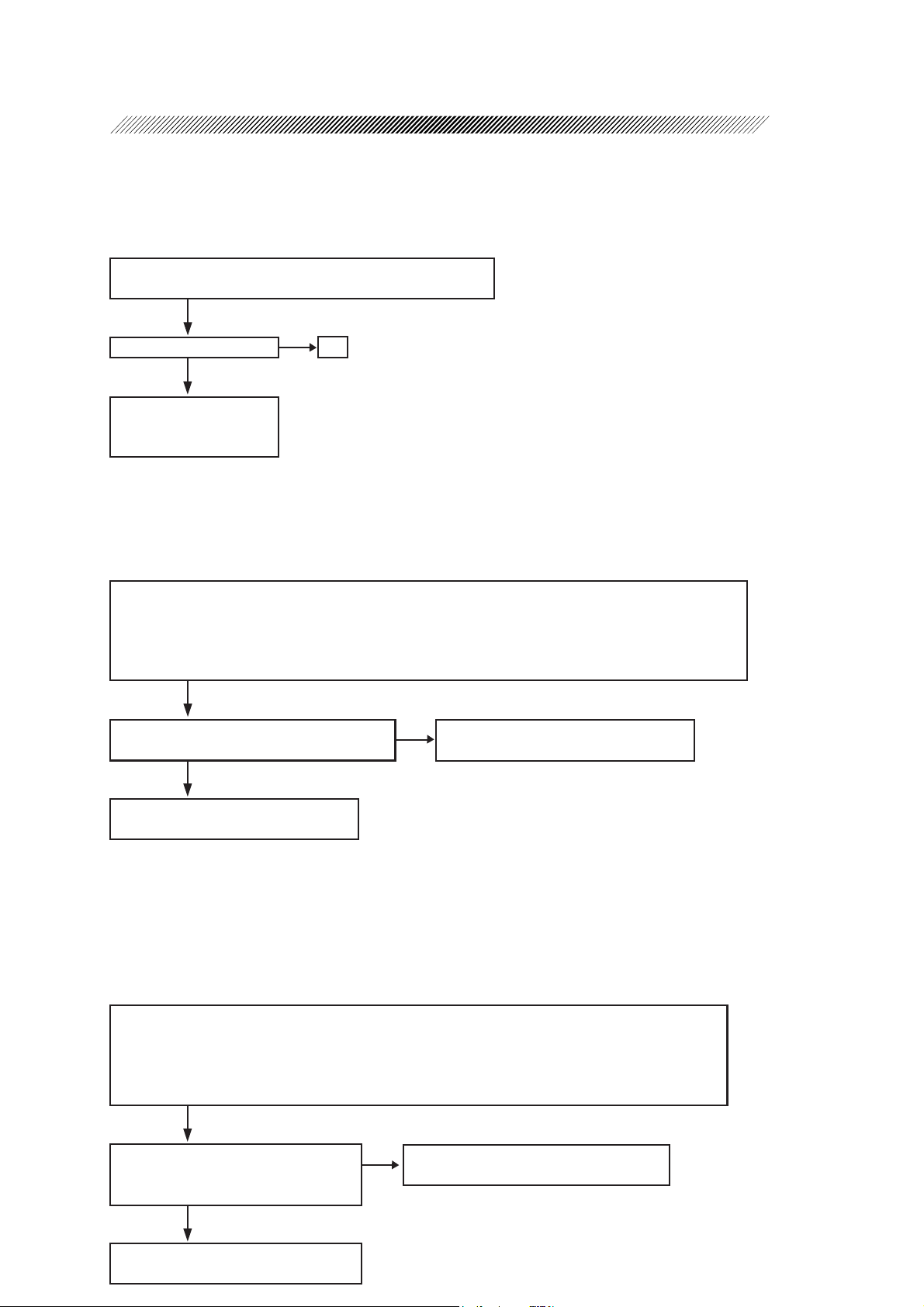

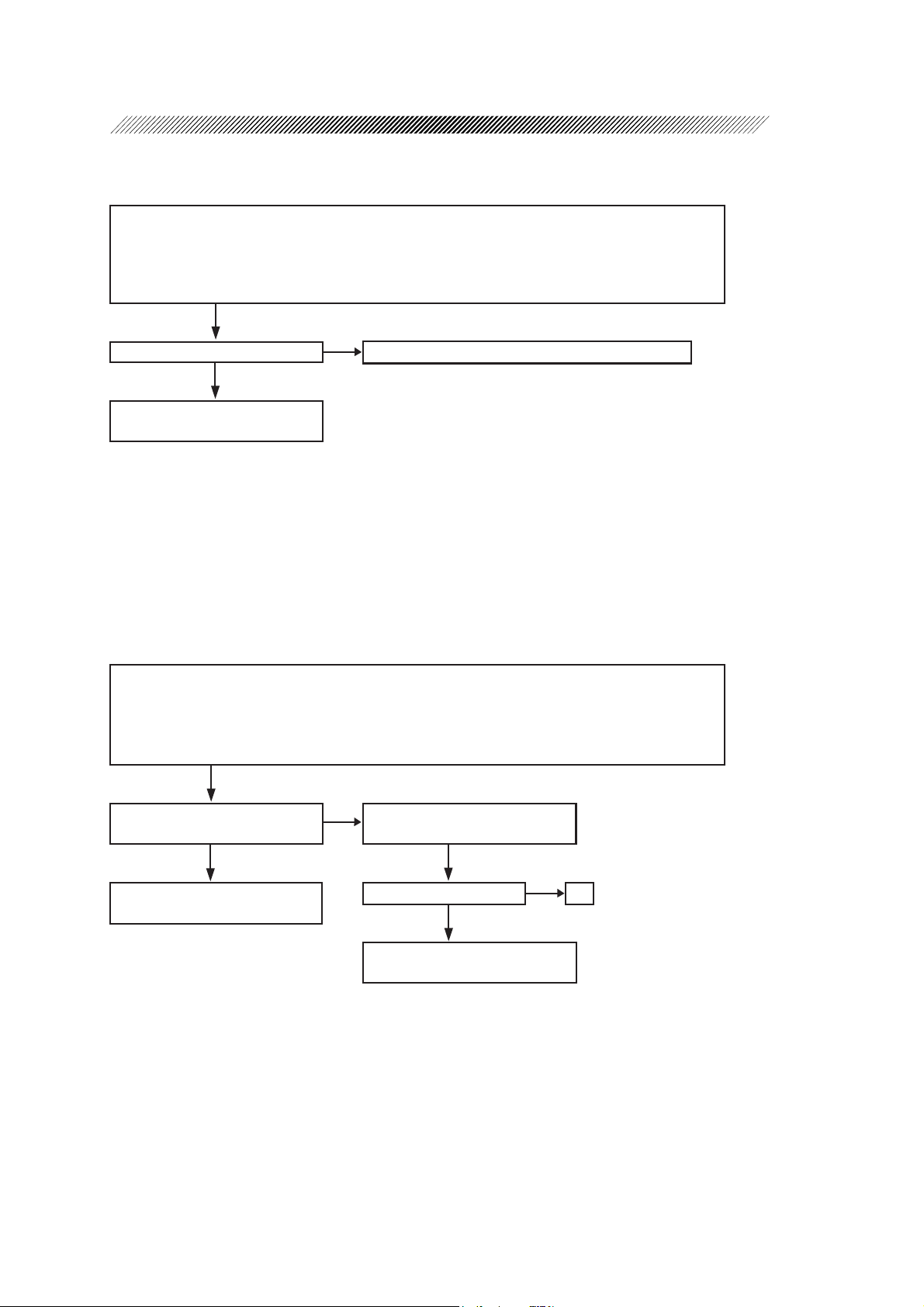

2.1 Check flow and items to be checked

Plug the power cord to the wall outlet and turn ON the Power Switch.

Y

2 - 2

Does the TV monitor displays zero for

S, C, A values? However, if the

measuring mode is set to <K>, the

monitor will display nothing.

Y

Does the shutter open ?

(For early model AR-600 only)

Y

Does a raster appear on the TV

monitor?

Y

Does the TV monitor display a

human eye?

Y

Does the TV monitor display

characters clearly?

Y

N

3.1 The TV monitor displays nothing/the monitor

display is abnormal

3.2 The message “ERR” appears after turning O N

the Power Switch.

N

3.3 The shutter does not open (Only for AR-600

whose S/N is earlier than 10121)

N

3.4 A raster does not appear.

(The TV monitor does not turn ON.)

N

3.5 Eye image does not appear on the TV monitor.

N

3.6 The characters or target square are not clear or

they do not appear on the monitor.

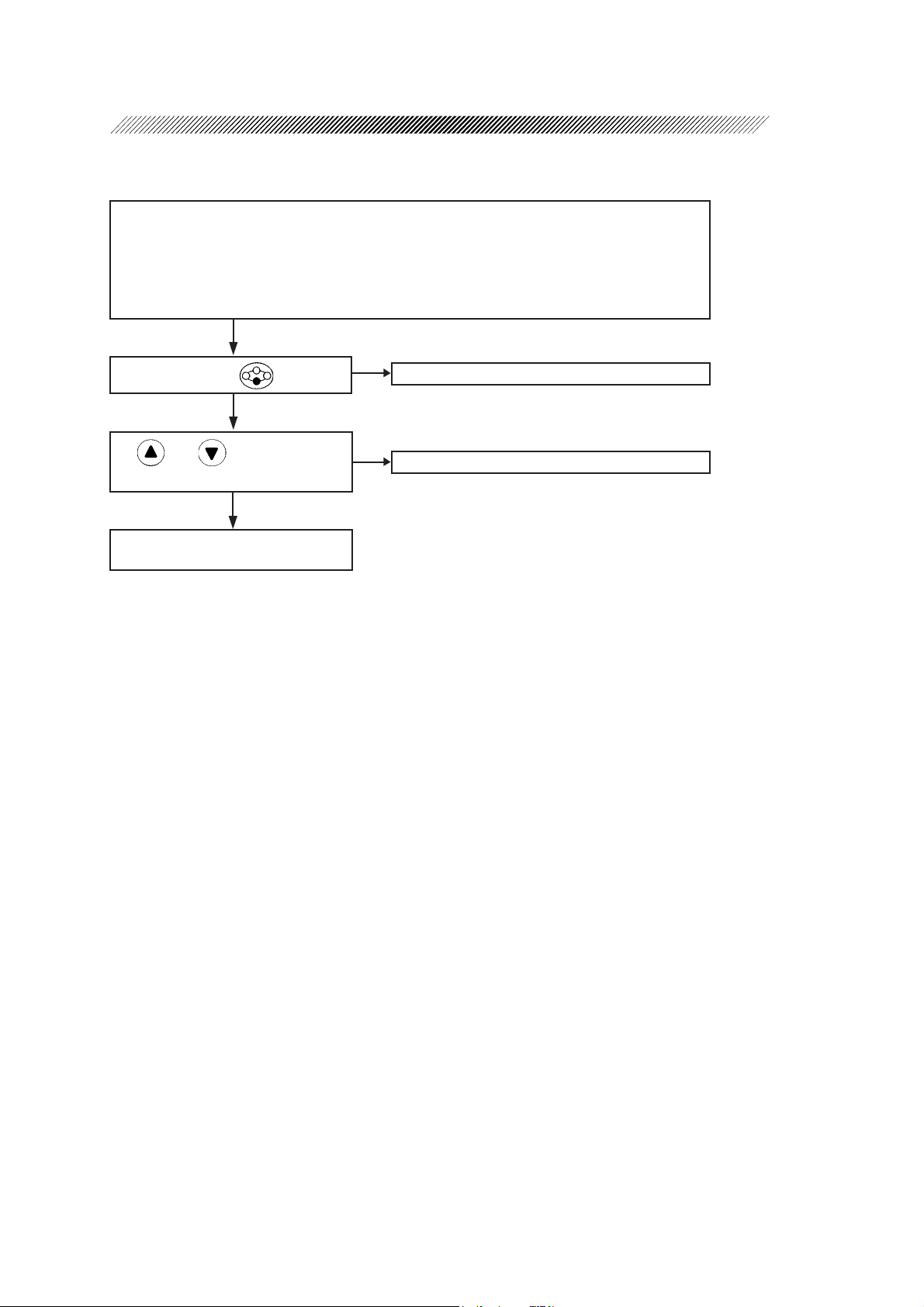

Press .

(for A-type model only)

Is the auto-tracking mode switched to

the manual mode (the mode where

the auto-tracking function is off ) ?

(for A-type model only)

Y

Press the Recall Switch.

(For the instruments provided with

subjective measurement function

only)

Can the instrument be placed in

the objective measurement mode?

Y

N

3.7 The switching between the manual mode and

auto-tracking mode can not be done.

N

3.8 The instrument can not be placed in the mode

where the objective measurement is performed.

Y

Can the parameter setting of “1: Step”

be changed to “0.01D”?

Y

Can the mode be switched to <R>

mode ?

(For model ARK-700 series only)

Y

Attach the Model eyes to the

Forehead rest..

Y

Is the movement of the measuring

unit smooth on a plane?

Y

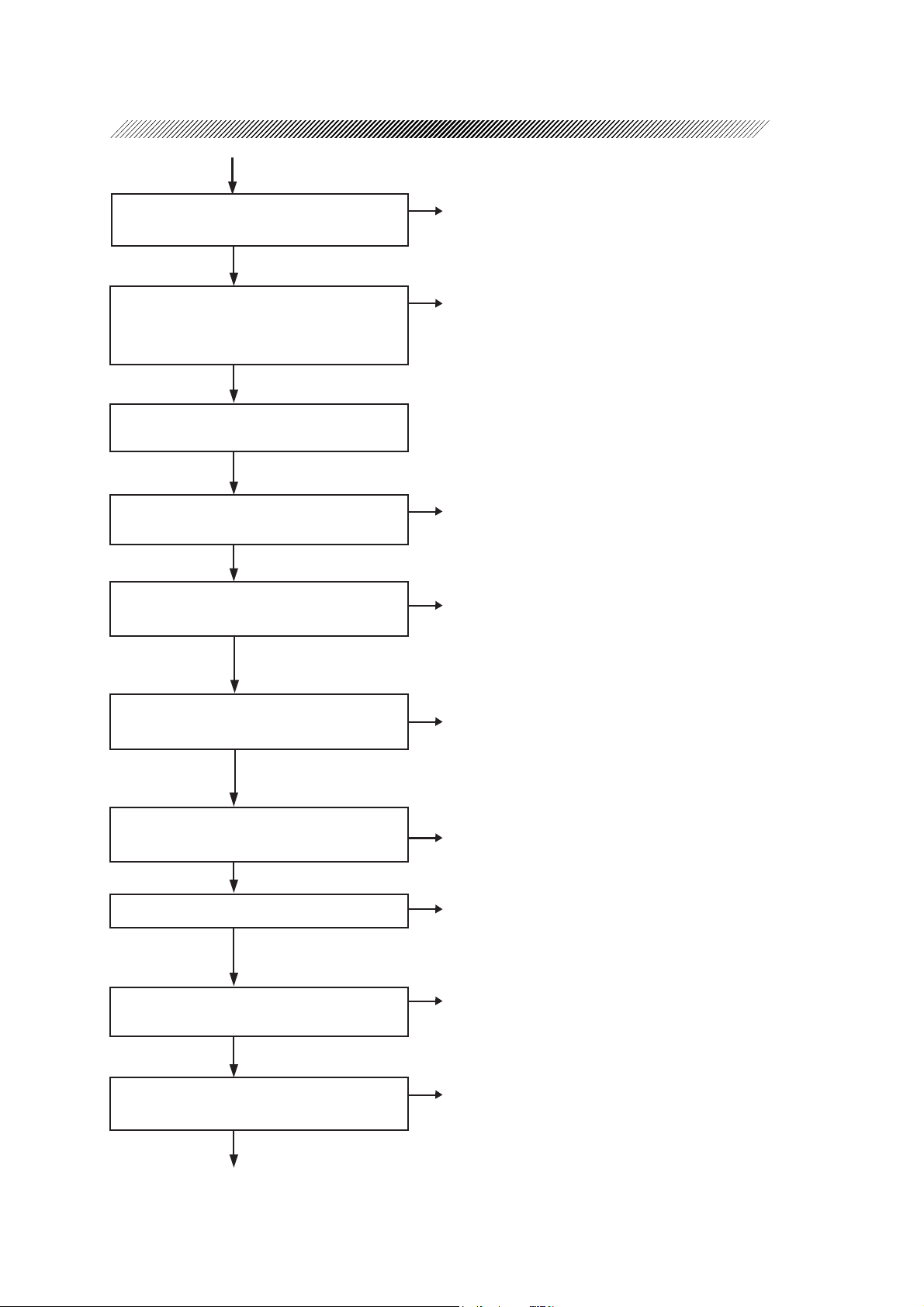

2 - 3

N

3.9 The parameter settings can not be changed.

N

3.10 The measuring mode can not be changed.

N

3.11 The movement of the measuring unit is

not smooth on a plane..

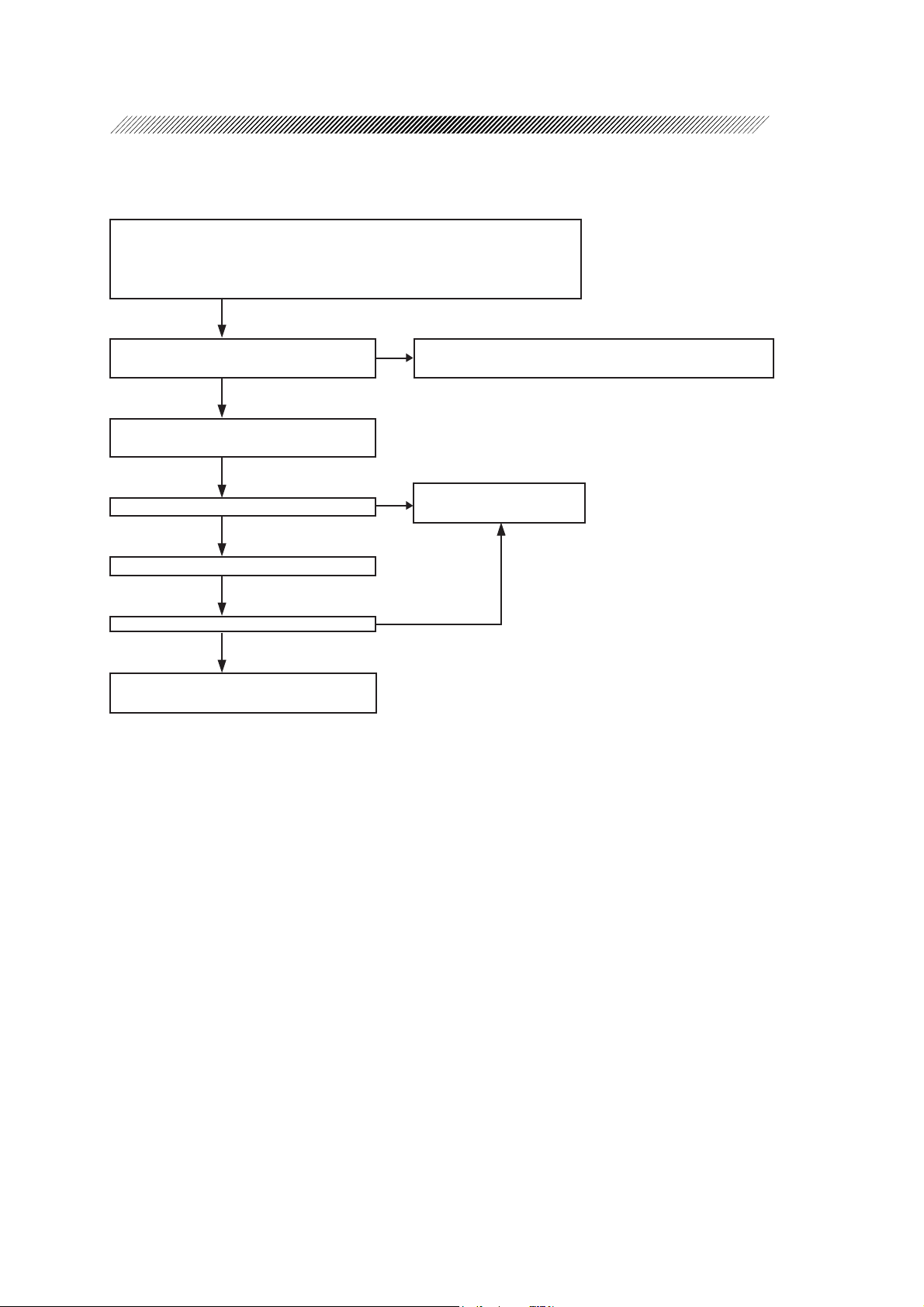

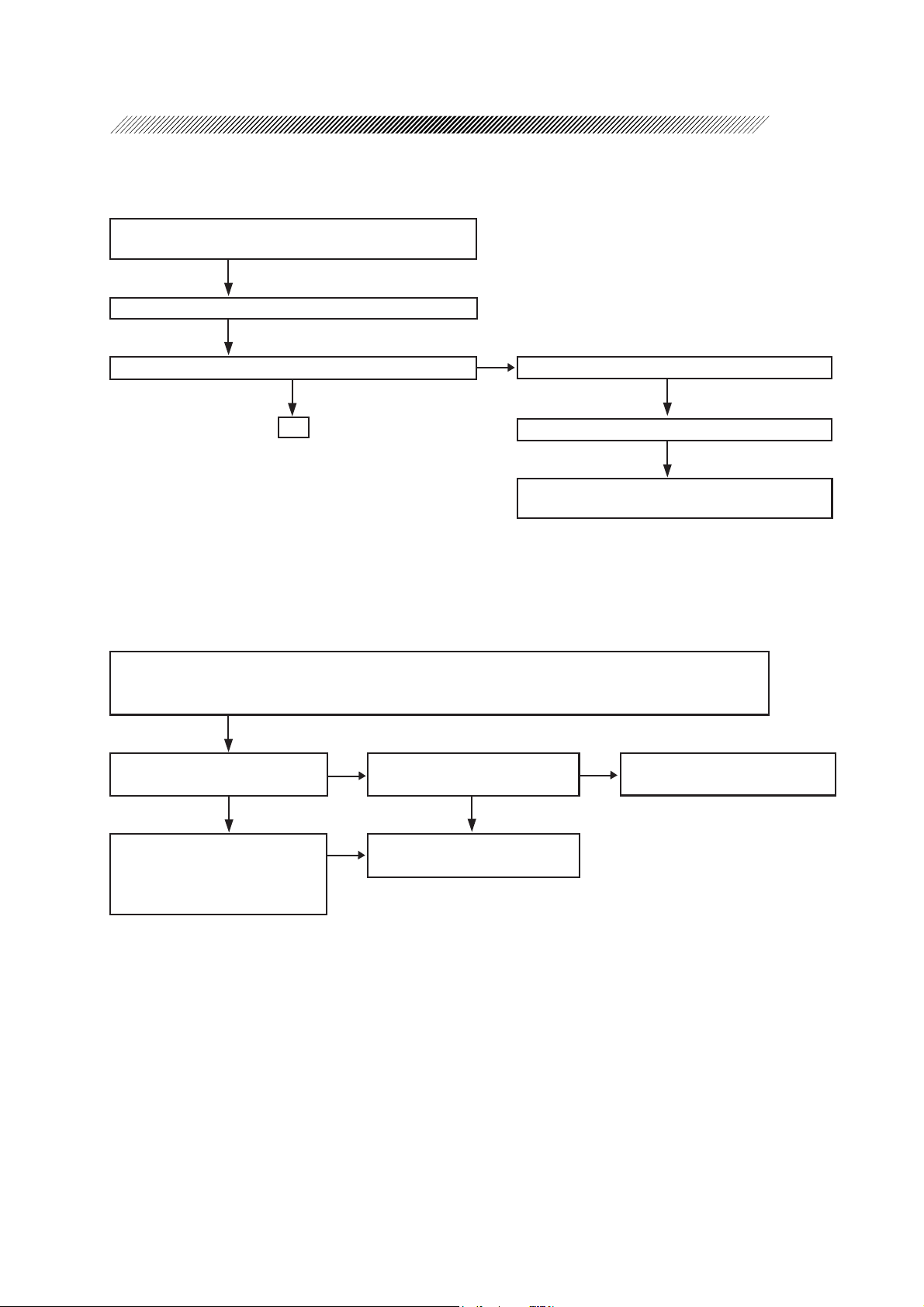

Is the up and down movement of the

measuring unit smooth ?

Y

Do the Alignment Light and Mire

Ring appear on the TV monitor?

Y

Does the Model eye image appear

clearly on the TV monitor ?.

Y

Can you measure the Model eye ?

Y

Is the measured data of the model

eye correct?

Y

N

3.12 The vertical movement of the measuring unit is

not smooth.

3.13 The measuring unit is unstable

N

3.14 The Alignment Light does not appear on the

TV monitor. (only for AR-600 series)

3.15 The Mire Ring does not appear on the TV

monitor. (only for ARK-700 series)

N

3.16 The Model eye image on the TV monitor

is not clear.

N

3.17 AR measurement does not start.

3.18 The message “ERR” appears during AR

measurement.

N

3.19 Only the obtained SPH value is shifted

3.20 The obtained CYL value is too large

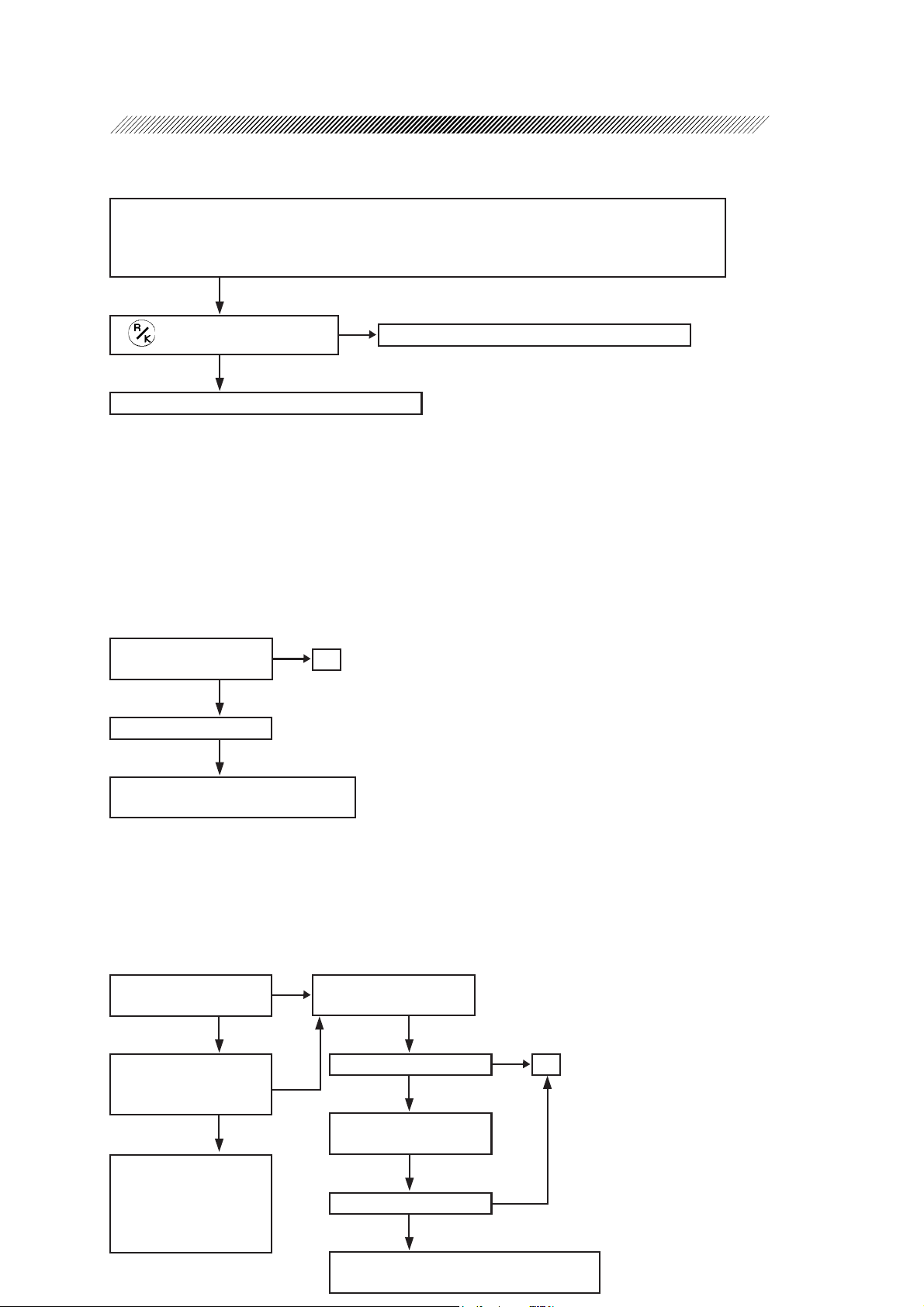

Does a beeper sound a short beep

when pressing the Start Button?

N

3.21 A short beep can not be heard when pressing

the Start Button.

Y

Is the IOL mode turned ON?

Y

Is the Cylinder mode changed?

Y

Does the instrument recognize the left

and right?

Y

Set “1: Step” of the parameter back

to “0.25”.

Y

Press .

Y

Is the instrument placed in the PD

mode?

Y

2 - 4

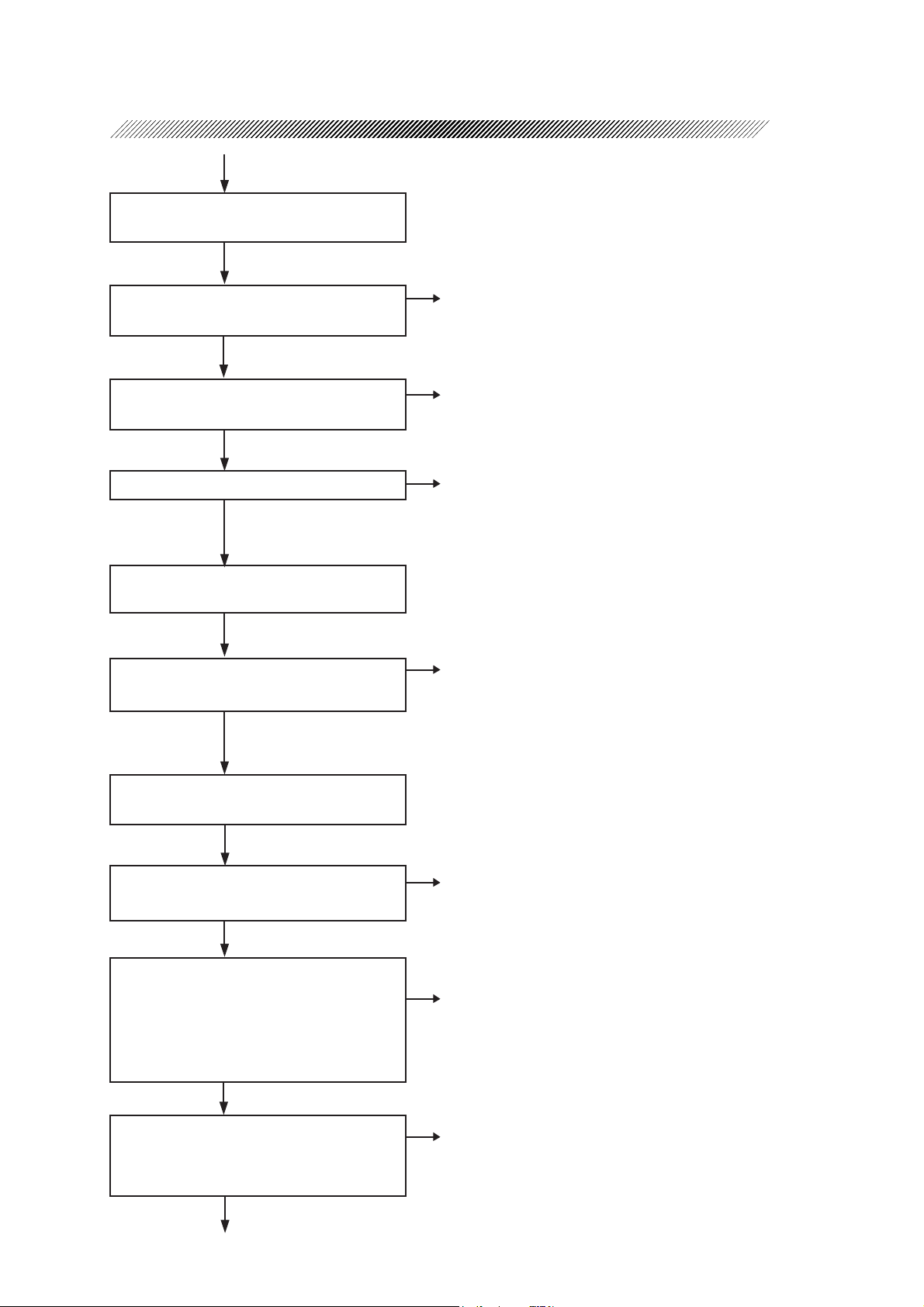

N

3.22 The IOL mode can not be turned ON.

N

3.23 The Cylinder mode can not be changed.

N

3.24 The instrument can not recognize the left and

right..

N

3.25 The instrument can not be placed in the PD

mode where the PD measurement will be

performed.

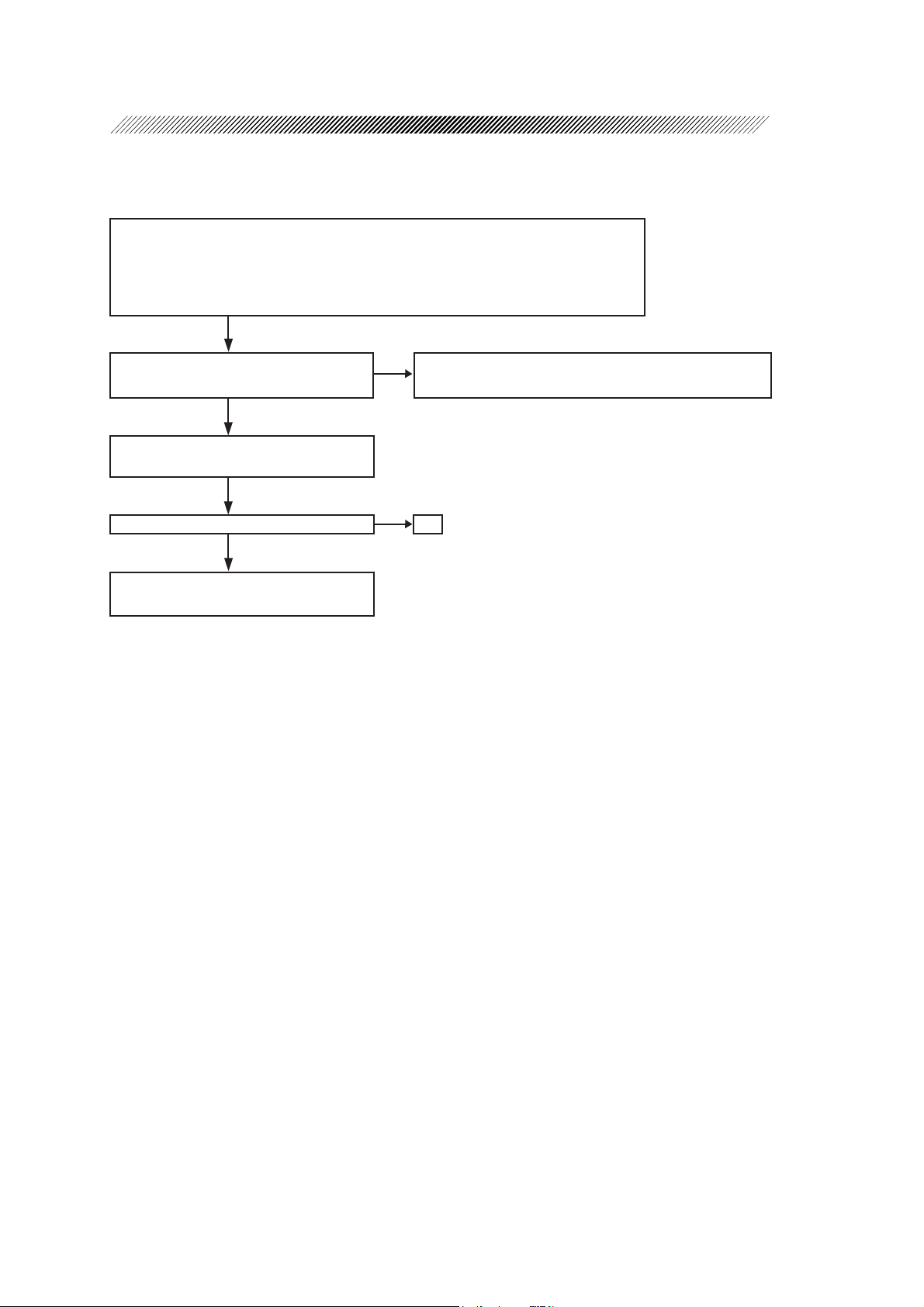

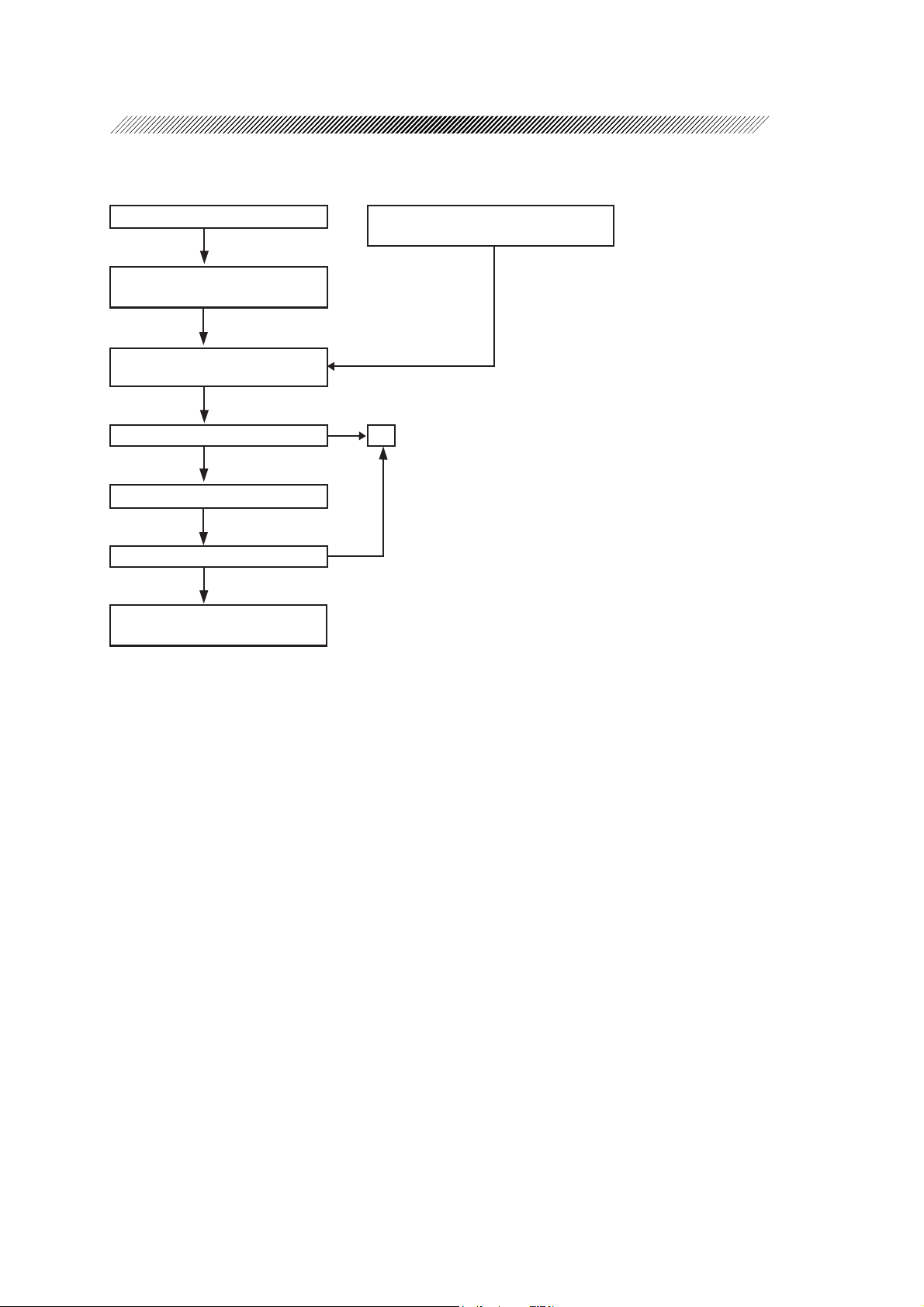

Set the steel balls to the chin rest.

Y

Can the PD measurement be done ?.

Y

Place the system in <K> mode with

where the KM measurement is done

(only for ARK-700 series).

Y

Can you measure the steel ball ?

Y

Is the measured data of the steel ball

normal ?

Y

Select R/K mode with .

N

3.26 The obtained PD value is abnormal.

N

3.27 The message “ERR” appears when starting

KM measurement.

N

3.28 The obtained KM value is abnormal.

Check the measurements by

measuring human eyes.

Is the up-and-down movement of the

Chin Rest smooth?

Y

2 - 5

N

3.29 The up-and-down movement of the Chin Rest

is not smooth

Can you see the chart from the

Measuring Window ?

Y

Is blinking error detected?

Y

Turn ON the auto-tracking function

(for A-type model only).

Y

Does the auto-tracking function work?

(for A-type model only)

Y

Turn ON the auto-shot function

(for A-type model only)

N

3.30 The chart can not be seen

N

3.31 “Err” does not appear though a patient blinked

during measurement.

N

3.32 The auto-tracking function does not work

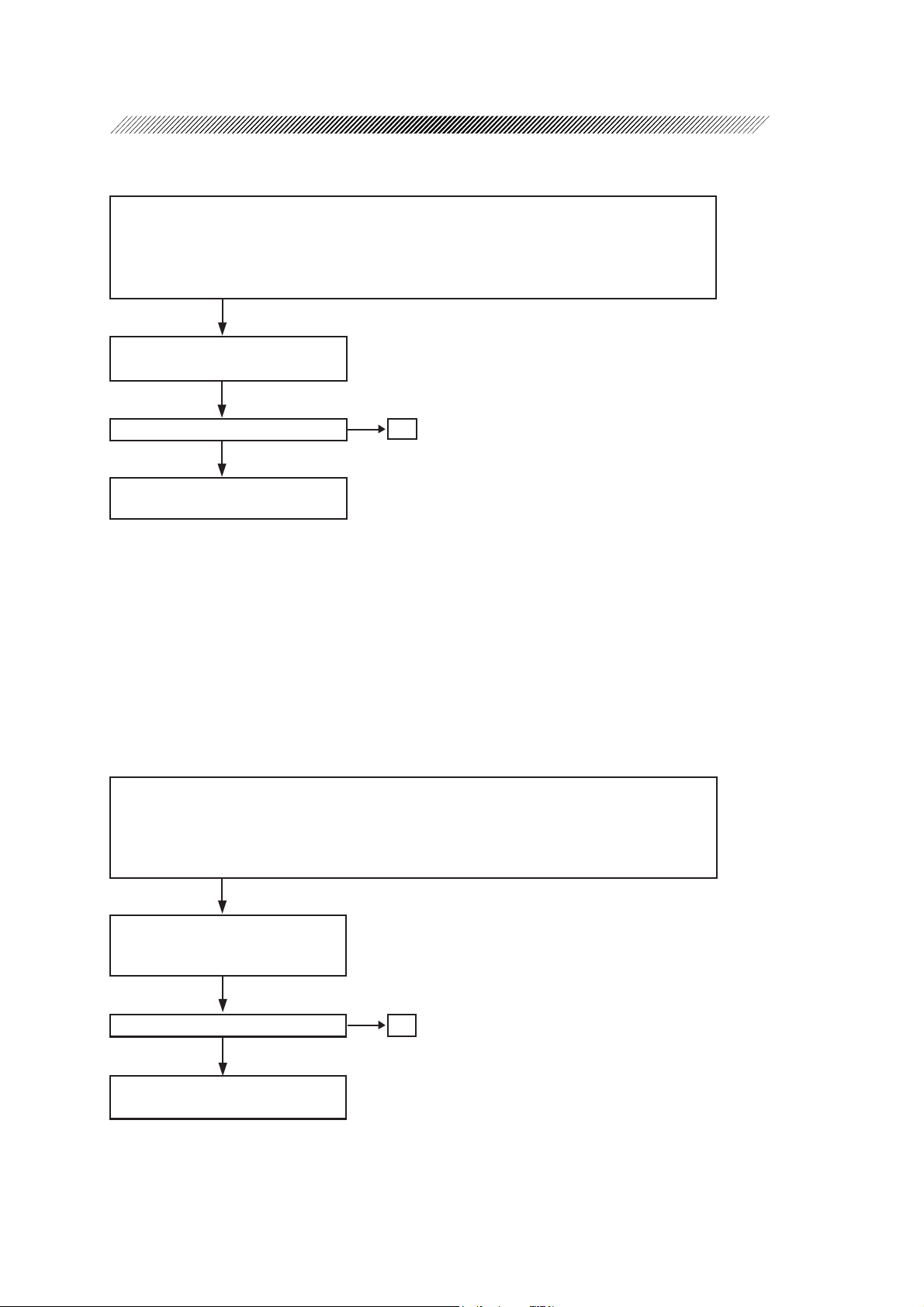

Y

Does the auto-shot function work?

(for A-type model only)

Y

Can the instrument be placed in the

VA TEST mode where the subjective

refraction is done?

(only for the models with subjective

measurement function).

Y

Can the visual acuity checked ?

(only for the models provided with

the subjective measurement function)

Y

N

3.33 The auto-shot function does not work.

N

3.34 The instrument can not be placed in the VA

TEST mode where the subjective refraction is

done.

N

3.35 VA charts can not be changed

2 - 6

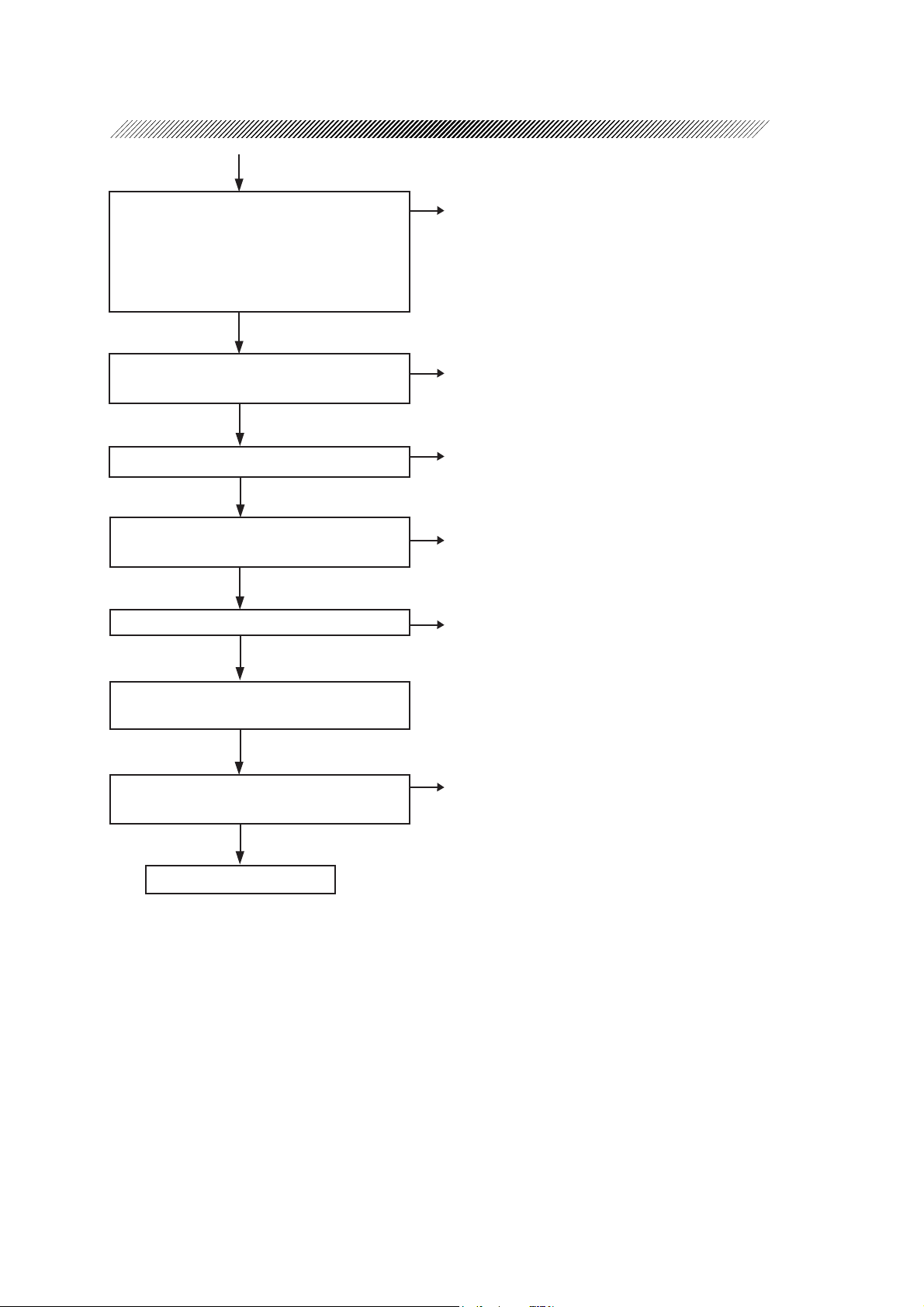

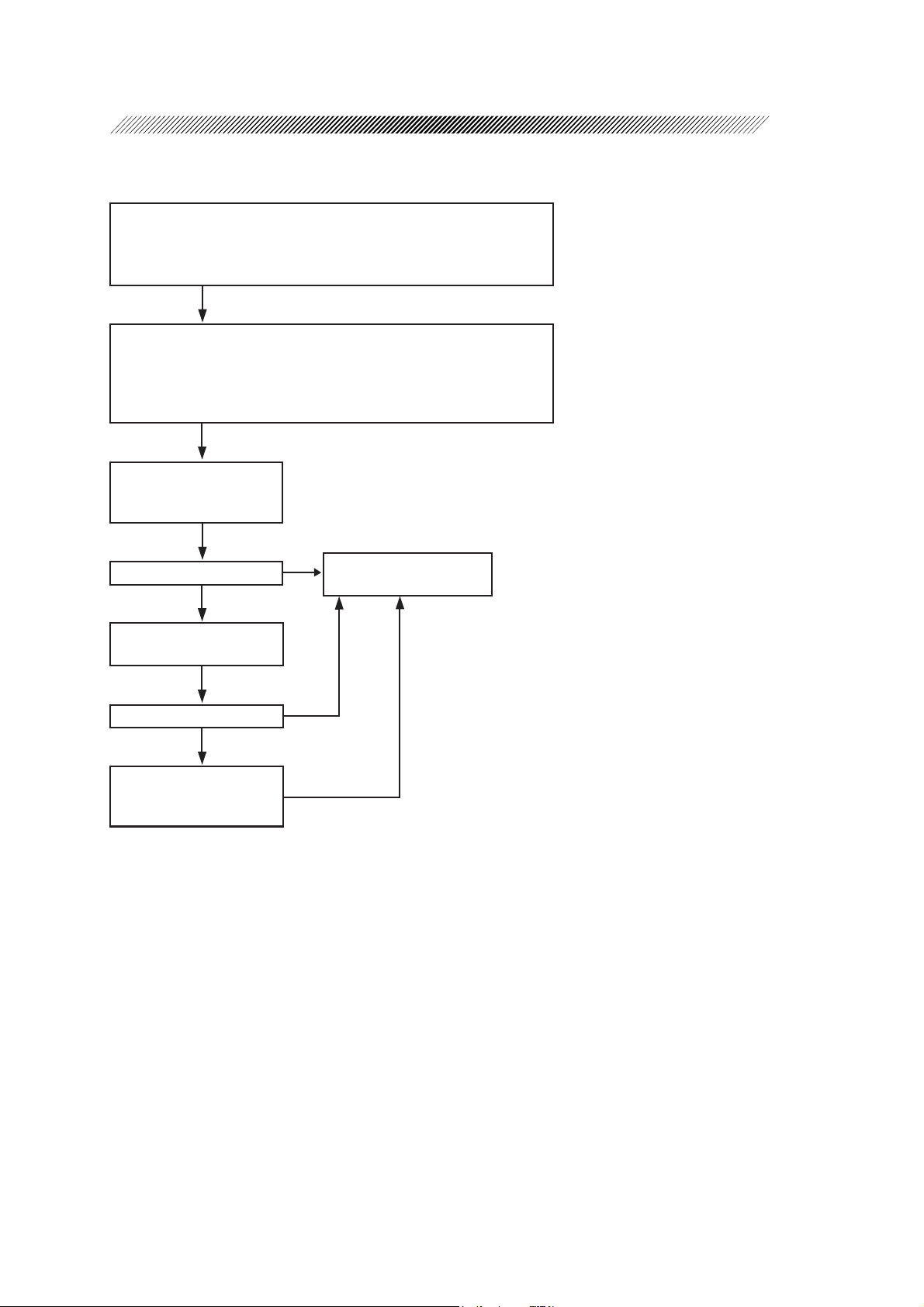

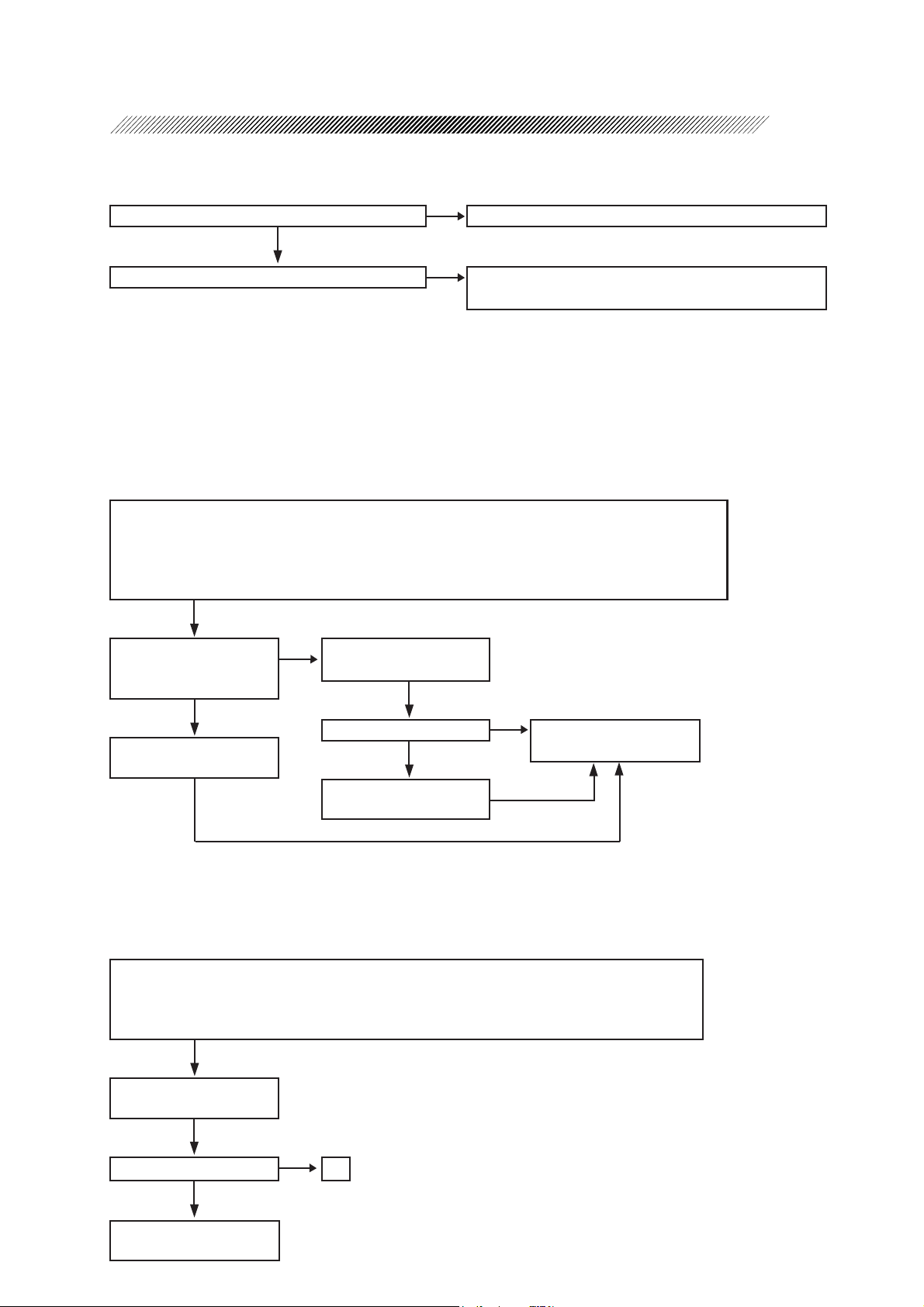

Can the presented chart be in focus

during the subjective measurement or

while checking visual acuity?

(only for the models with subjective

measurement function)

Y

Can the instrument transmit or receive

data with external devices ?

Y

Can the instrument produce printout ?

Y

Can the Eyeprint be output on the

printout?

Y

Does the TV Auto-off function work ?

Y

N

3.36 The presented chart is out of focus during the

subjective measurement (except when a patient

has irregular astigmatism)

N

3.37 The message “ERR IF” appears

N

3.38 The printer does not operate

3.39 Light printed text/loss of text

N

3.40 The Eyeprint function can not be turned ON.

N

3.41 The TV Auto-off function does not work

Turn OFF the Power Switch of the

instrument.

Does the shutter close?

(For early model AR-600 only)

Y

End of the check flow

N

3.42 The shutter does not close

(only for AR-600 whose S/N is earlier than

10121)

§

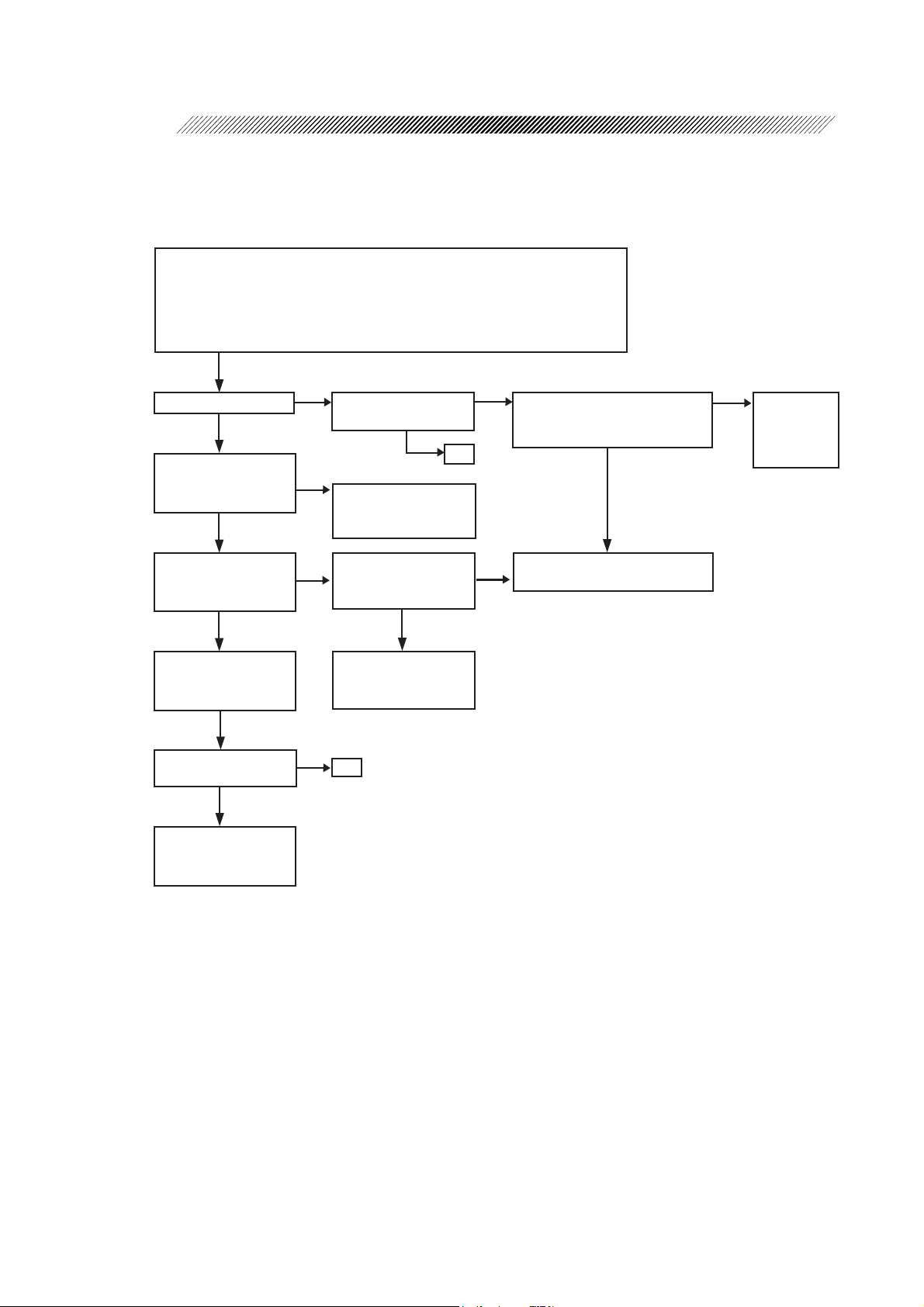

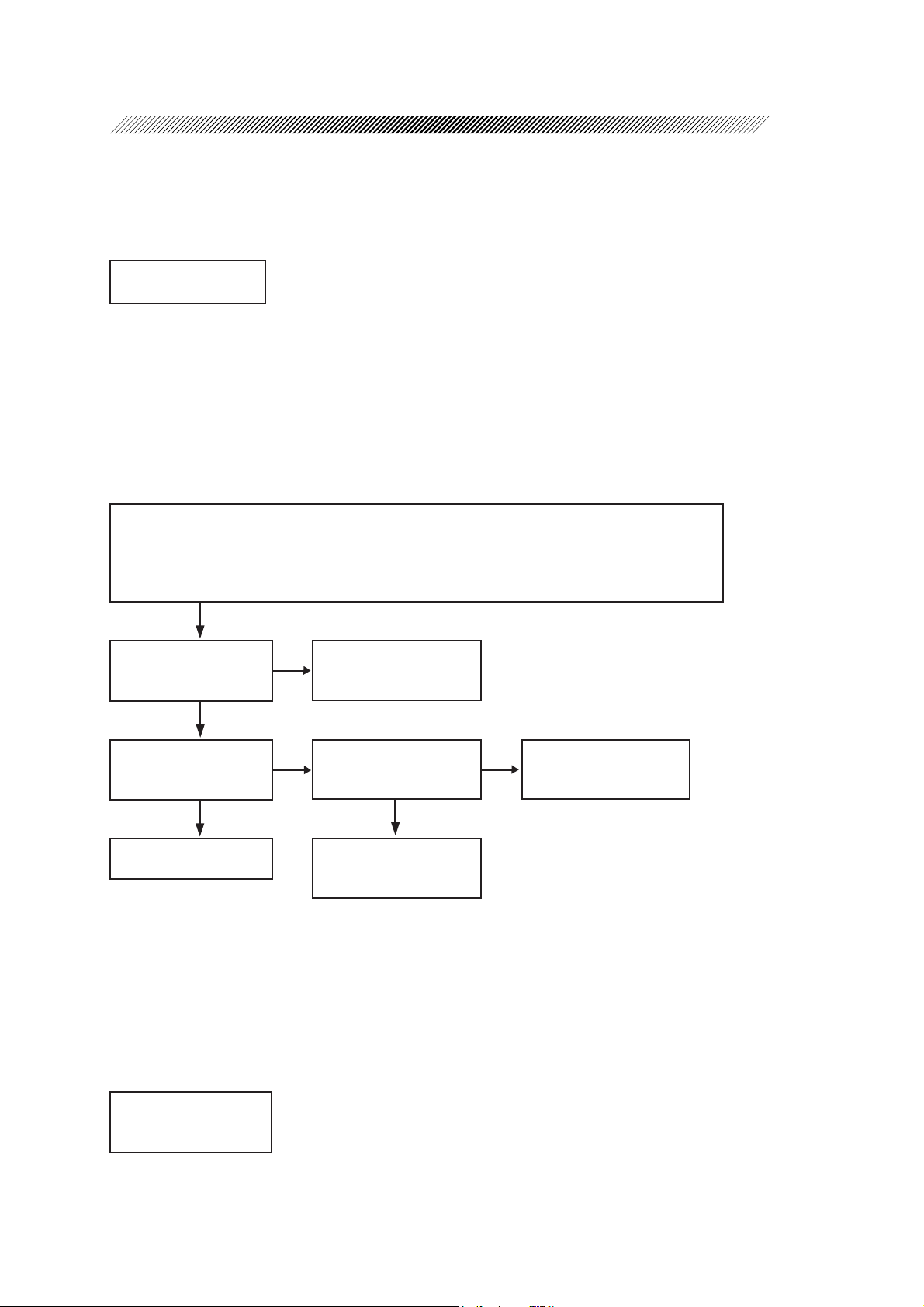

3

3.1 The T V monitor displays nothing/the monitor

display is abnormal

Check the following connectors.

PJ103, 104 (PC1)

PJ201 (PC2)

PJ701, 702 (PC7)

* For details of each connector, see the Wiring Diagram and connector table.

TROUBLESHOOTING

Are the fuse nomal?

Y

Is the voltage supplied

to AC INLET normal?

(See 6.1.)

Y

Is the votage between

3-pin and GND +5V?

(See 6.3.)

Y

Replace the PC1

board with a new one.

(See 9.1.)

Does the symptom

clear?

N

N

Are the fuses frequently blown?

N

It is recommendable to

install a voltage stabilizer.

Is the voltage between

N

9-pin and 10-pin 10V?

(See 6.2.)

Replace the PC7 board

with a new one.

(See 9.5.)

Y

OK

Y

Are the fuses all right even

though P701 is disconnected and

N

OK

Y

the Power Switch is turned OFF.

N

Replace the transformer with a

N

new one. (See 10.1.)

Y

Replace the

PC7 board

with a new

one.

Replace the PC2

board with a new one.

(See 9.2.)

3.2 The message “Err” appears after turning ON the

Power Switch

* If the message “Err” appears after turning ON the Power Switch, set the following

parameter to “YES”, following the instructions in Operator’s Manual.

For AR-600 series (PARAMETERS 33: Err Code YES)

For ARK-700 series (PARAMETERS 37: Err Code YES)

3.2.1 “Err 1” (Sensor carry error) appears.

Check the following connectors.

PJ103, 106 (PC1)

PJ601, 603, 604 (PC6)

PJ701, 702 (PC7)

* Also check the state of the soldered connection.

For details of each connector, see the Wiring Diagram and connector table.

3 - 2

Is the voltage between 1-2

pin +15V and the voltage

between 6-7 pin -15V?

(See 6.3.)

Y

Replace the PC6 board

with a new one. (See 9.4.)

Does the symptom clear?

N

Replace the PC1 board

with a new one.

(See 9.1.)

Does the symptom clear?

N

Replace the measuring

unit.

(See 10.2.)

Is the voltage of P701 AC 18V

N

(the voltage between 5-6 pin

and 7-8 pin)? (See 6.2.)

Y

Replace the PC7 board with a

new one.

(See 9.5.)

Y

Perform sensor calibration.

(See 11.6.)

Y

Replace the trasnformer with

N

a new one.

(See 10.1.)

3.2.2 “Err2” (Chart carry error) appears.

Check the following connectotrs.

PJ107 (PC1)

PJ601, 607, 608 (PC6)

* For details of each connector, see the Wiring Diagram and connector table.

N

Is the origin sensor for chart carry normal?

(See 8.1.)

Y

Replace the PC6 board with a new one.

(See 9.4.)

Does the symptom clear?

N

Replace the PC1 board with a new one.

Replace the origin sensor for the chrtcarry with a new one.

(See 10.1)

Y

Perform sensor calibration.

(See 11.6.)

3 - 3

Does the symptom clear?

N

Replace the measuring unit with a new one.

(See 10.22.)

Y

3.2.3 “Errr 3” (Rotator error) appears.

Check the following connectors.

PJ107 (PC1)

PJ601, 606 (PC6)

* For details of each connector, see the Wring Diagram and connector table attached to

this manual.

3 - 4

Is the origin sensor for the rotator normal?

(See 8.3.)

Y

Replace the PC1 board with a new one.

(See 9.1.)

Does the symptom clear?

N

Replace the measuring unit with a new one.

(See 10.22.)

N

Replace the origin sensor for the rotator with the new one.

(See 10.12.)

Y

OK

3.2.4 “Err 4” (Chart error) appears.

Check the following connector.

PJ1 11 (PC1)

* Also check the state of the soldered connection.

For details of the connector, see the Wiring Diagram and connector tabel attached to this manual.

Replace the Chart unit (32908-3150).

(See 10.19.)

Y

Does the symptom clear?

N

Replace the PC1 board with a new one.

(See 9.1.)

OK

3 - 5

3.2.5 “Err 5” (CL1 error) or “Err 6” (CL2 err or) appears.

Check the following connector.

PJ1 13 (PC1)

* Also check the state of the soldered connectoin.

For details of the connector, see the Wiring Diagram and connector t able attached to this manual.

Replace the Cylinder unit (32908-

3160).

(See 10.20.)

Y

Does the symptom clear?

N

Replace the PC1 board with a new one.

(See 9.1.)

OK

3.2.6 “Err 7” ([line] printer error) appears.

3 - 6

Is the printer paper set?

Y

Is the head lever flipped down?

Y

Check the following connectors.

PJ105 (PC1)

PJ703, 704 (PC7)

PJ801, 802 (PC8)

* For details of each connector, see the Wiring Diagram and connector table attached to this manual.

Replace the printer unit. (See 9.6.)

Does the symptom clear?

N

Replace the PC8 board with a new one.

(See 9.6.)

N

Set in a new paper roll. (Refer to Operator’s Manual.)

N

Flip down the head lever. (Refer to Operator’s Manual.)

Y

OK

Does the symptom clear?

N

Replace the PC1 board with a new one.

(see 9.1.)

Y

3.2.7 “Err 8” ([serial] printer error) appears.

Check the following connectors.

PJ105 (PC1)

PJ703, 704 (PC7)

PJ801, 802 (PC8)

* For details of each connector, see the Wiring Diagram and connector table attached to this manual.

Replace the Printer unit. (See 9.6.)

Y

Does the symptom clear?

N

OK

Replace the PC8 board with a new one.

(See 9.6.)

Does the symptom clear?

N

Replace the PC1 board with a new one.

(See 9.1.)

Y

3 - 7

3.2.8 “Err 9” (MEMORY FAILURE ON EEPROM) appears.

Print out the EEPROM DATA (Refer to Operator’s Manual.)

Confirm that all items of EEPROM DATA are zero.

Set all items of EEPROM DATA. (See 11.8.)

N

Was EEPROM DATA memorized properly?

Y

Replace the PC6 board with a new one. (See 9.4.)

OK

Perform sensor calibration. (See 11.6.)

Perform auto-calibration of the tracking function.

(See 11.11.)

3.2.9 “Err A” (MEMORY FAILURE ON RAM) appears.

Change the parameter setting or data, time and comments acording to the instructions in Operator’s Manual.

Turn OFF the power of the instrument and leave it for a while. Then check the set contents above.

Was EEPROM DATA memorized

properly?

Y

Use the instrument for some time.

If the message appears again, replace the battery or the PC1 board.

(See 9.1.)

N

Is the output voltage of the battery

+3V? (See 6.4.)

Y

Replace the PC1 board with a new

one. (See 9.1.)

N

Turn ON the Power Switch to recharge the batery.

3.2.10 “PD ERR” appears.

Avoid using the instrument in the environment where it is exposed to the

direct sunlight or an incandescent light.

If dust settles on the LED filter for PD (located at the foot of the Chin

Rest), remove it with a blower brush.

Check the following connectors.

PJ105, 113 (PC1)

PJ703, 706 (PC7) PJ2301 (PC23)

* For details of each connector, refer to the Wiring Diagram or connec-

tor tabel attached to this manual.

Replace the PC23 board

with a new one.

(See 9.10.)

Y

Does the symptom clear?

N

Reform PD calibration.

(See11.8.5.)

3 - 8

Replace the PC24 board

with a new one. (See 9.10.)

Does the symptom clear?

N

Replace the PC1 board

with a new one.

(See 9.1.)

Y

3 - 9

3.3 The shutter does not open (only for AR-600 whose S/N

is earlier than 10121)

Remove the shutter unit.

(See 10.8.)

3.4 A raster does not appear (The TV monitor does not

light well.)

Check the following connectors.

PJ005 (MONITOR) PJ103,106,112 (PC1)

PJ601 (PC6)

PJ701, 702 (PC7)

* For details of each connector, see the Wiring Diagram and connector table attached to this manual.

Is the brightness of the TV

monitor adjusted properly?

Y

Is the voltage between 8pin and 9-pin +12V?

(See 6.3.)

Y

Replace the TV monitor .

(See 10.17.)

Adjust the brightness by

N

turning the brightness control.

Is the voltage between 1-pin

N

and 2-pin AC 14V.

(See 6.2.)

Replace the PC7 board

with a new one.

(See 9.5.)

Replace the transformer

N

with a new one.

(See 10.1.)

Y

3.5 Eye image does not appear on the T V monitor

Replace the CCD camera

unit with a new one.

(See 10.18.)

3 - 10

3.6 The characters or target are not clear or they do not

appear on the TV monitor

Adjust VR2 or VR3 achieve the best brightness of the monitor.

(See 11.10.)

Y

Does the symptom clear?

N

Replace the PC1 board

with a new one.

(See 9.1.)

OK

3.7 The switching between the manual mode and autotracking mode can not be done

Check the following connectors.

PJ104 (PC1)

PJ201, 203 (PC2)

* For details of each connector, refer to the Wiring Diagram and connector table attached to this manual.

Is there continuity in the Auto-tracking button?

(See 7.3.)

Y

Replace the PC1 board with a new one.

(See 9.1.)

N

Replace the PC3 board with the new one.

(See 9.3.)

3.8 The instrument can not be placed into the mode wher e

the objective measurement is performed.

Check the following connector.

PJ108 (PC1)

* Also check the state of the soldered connection.

For details os each connector, see the Wiring Diagram and connector table attached to this manual.

N

Is there continuity in the recall switch on

the PC12 board?

(See 7.4.)

Y

Replace the PC1 board with a new one.

(See 9.1.)

Replace the PC12 board with the new one.

(See 9.8.)

3.9 The parameter settings can not be changed

Check the following connectors.

PJ104 (PC1)

PJ201, 203 (PC6)

* For details of each connector , see the Wiring Diagram and connector table attached to this manual.

Check the state of the soldered connection.

N

Is there continuity in

? (See 7.2.)

Y

Replace the PC2 board with a new one. (See 9.2.)

3 - 11

Do

(See 7.3.)

Replace the PC1 board with a new one.

(See 9.1.)

and function normally?

Y

N

Replace the PC3 board with a new one. (See 9.3.)

3 - 12

3.10 The measuring mode can not be changed

Check the following connectors.

PJ104 (PC1)

PJ201 (PC2)

* For details of each connector, see the Wiring Diagram and connector table attached to this manual.

N

function normally? (See 7.2.)

Is

Y

Replace the PC1 board with a new one. (See 9.1.)

Replace the PC2 board with a new one. (See 9.2.)

3.11 The movement of the measuring unit is not smooth

on a plane.

Clean the Slide plate.

(See 10.3.)

Does the symptom clear?

N

Replace the Slide plate with a new one.

(See 10.3.)

Y

OK

3.12 The vertical movement of the measuring unit is not

smooth

Does the measuring unit

move up and down?

Y

Is a strange sound heard

when it is near to the top

and bottom position?

Y

Replace the upper or

lower limit switch with a

new one or adjust the

switches’ fixed position.

(See 9.1.)

N

Replace the joy stick with

a new one. (See 10.2.)

N

Does the symptom clear? OK

Replace the PC22 board

with a new one. (See 9.9.)

Does the symptom clear?

Replace the up-and-down motor with a one.

(See 10.15.)

Y

N

Y

N

3.13 The measuring unit is unstable

N

Do rollers of the bearing turn normally? (See 11.1.)

Y

Is the sawy stopper unit fixed properly? (See 11.2.)

Adjust 3-fixed position of rollers of the bearing. (See 11.1.)

N

Adjust tightness of the screws fixing the sway stopper unit.

(See 11.2.)

3.14 The alignment light does not appear

(only for AR-600 series)

Check the following connector.

PJ613 (PC6)

* Also check the state of the soldered condition.

For details of each connector, see the Wiring Diagram and connector table attached to this manual.

Y

3 - 13

Is the volatge applied to

LED for the alignment light

proper? (See 8.7.)

Y

Replace LED for the Alignment light.

N

Replace the PC1 board

with a new one. (See 9.1.)

Does the symptom clear?

Replace the PC6 board

with a new one. (See 9.4.)

Y

Perform sensor calibratoin.

N

(See 11.6.)

3.15 The Mire Ring does not appear

(only for ARK-700 series)

Check the following connectors.

PJ604, 616 (PC6)

* For details of the connector, see the Wiring Diagram and connector tabel att ached to this manual.

Replace the Mire with a

new one. (See 9.7.)

Does the symptom clear?

N

Replace the measuring unit

with a new one. (See 9.1.)

Y

OK

3.16 The model eye image is not clear

Check the following connector.

PJ614 (PC6)

* Also check the state of the soldered connection.

For details of each connector, see the Wiring Diagram and connector table attached to this manual.

N

Is the ILLUMI.LED lit? (See 10.6.)

Y

Replace the CCD camera with a

new one. (See 10.18.)

Replace the ILLUMI.LED with a new one. (See 10.6.)

3 - 14

3.17 AR measur ement does not start

Check the following connectors.

PJ104 (PC1)

PJ201, 202 (PC2)

* For details of each connector, see the Wiring Diagram and connector table attached to this manual.

Does the Start button function normally? (See 7.1.)

Y

Replace the PC1 board with a new

one. (See 9.1.)

N

Replace the Joystick with a new

one. (See 10.2.)

Does the symptom clear?

N

Replace the PC2 board with a new

one. (See 9.2.)

Y

OK

3 - 15

3.18 The message “Err” appears during AR measurements

Check the following connectors.

PJ101, 106 (PC1)

PJ601, 602 (PC6)

* For details of each connector, see the Wring Diagram and connector table attached to this manual.

Are the measuring light

source LEDs normal? (See

8.4.)

Y

Is the Target square in the

correct position?

(See 11.5.)

Y

Replace the PC1 board with

a new one. (See 9.1.)

Does the symptom clear?

N

N

Is the LED cable right? (See

8.4.)

Replace the PC1 board with

a new one. (See 9.1.)

Does the symptom clear?

Replace the PC6 board with

a new one. (See 9.4.)

N

Adjust the Target square position. (See 11.5.)

Y

N

Replace the LED cable

with a new one. (See 10.9.)

Y

Y

Perform sensor

N

calibratoin. (See 11.6.)

Set the parameter “No. 18 ERROR

CODE” to “YES” as instructed on

Operator’s Manual so that error code

is displayed on the TV monitor.

Replace the measuring unit

with a new one. (See 10.22.)

Err 81 - Blinking error detected by MASK signal

Err 82 - Blinking error due to the amount of S-DIV change

Err 83 - Error due to gradient coefficient

Err 91 - SPH + over error caused when SPH value is +

23D or more (VD12mm)

Err 92 - SPH - over error caused when SPH is-18D or less

(VD12mm)

Err 93 - CYL - over error caused when CYL is 8D or more

(VD12mm)

Err 94 - CONF error caused by the desparity between the

measuring value and the rough approximation of a sine

wave.

3.19 Only the obtained SPH value is shifted

3 - 16

Adjust Sensor offset. (See 11.8.1.)

Is the volatge applied to two diodes

proper? (See 6.5.)

Y

Perform the sensor calibration.

(See 11.6.)

Does the Symptom clear?

N

Replace the PC1 board. (See 9.1.)

Does the symptom clear?

N

Replace the measuring unit with a

new one. (See 10.22.)

Replace the PC6 board with a new one.

(See 9.4.)

Y

OK

Y

Loading...

Loading...