Page 1

NEC S1300UG Disk Array Unit User Guide

The information disclosed in this document, including all designs and related materials, is

the valuable property of NEC Solutions (America), Inc. and/or its licensors. NEC Solutions

(America), Inc. and/or its licensors, as appropriate, reserve all patent, copyright and other

proprietary rights to this document, including all design, manufacturing, reproduction, use,

and sales rights thereto, except to the extent said rights are expressly granted to others.

instrunction manuals to help users access anytime and

anywhere, helping users make better use of products.

Page 2

()

■■■■■■■

■■■■■■■

■■■■■■■

■■■■■■■

■■■■■■■

■■■■■■■

■■■■■■■

■■■■■■■

■■■■■■■

■■■■■■■

■■■■■■■

■■■■■■■

■■■■■■■

■■■■■■■

User’s Guide

S1300 Disk Array Unit

Page 3

xxx

Page 4

Proprietary Notice and Liability Disclaimer

The information disclosed in this document, including all designs and related materials, is

the valuable property of NEC Solutions (America), Inc. and/or its licensors. NEC Solutions

(America), Inc. and/or its licensors, as appropriate, reserve all patent, copyright and other

proprietary rights to this document, including all design, manufacturing, reproduction, use,

and sales rights thereto, except to the extent said rights are expressly granted to others.

The NEC Solutions (America), Inc. product(s) discussed in this document are warranted in

accordance with the terms of the Warranty Statement accompanying each product.

However, actual performance of each product is dependent upon factors such as system

configuration, customer data, and operator control. Since implementation by customers of

each product may vary, the suitability of specific product configurations and applications

must be determined by the customer and is not warranted by NEC Solutions (America), Inc.

To allow for design and specification improvements, the information in this document is

subject to change at any time, without notice. Reproduction of this document or portions

thereof without prior written approval of NEC Solutions (America), Inc. is prohibited.

Trademarks

All product, brand, or trade names used in this publication are the trademarks or registered

trademarks of their respective trademark owners.

PN: 456-01689-000 July 2003

Copyright 2003

NEC Solutions (America), Inc

10850 Gold Center Drive, Suite 200,

Rancho Cordova, CA 95670

All Rights Reserved

Page 5

FEDERAL COMMUNICATIONS COMMISSION

RADIO FREQUENCY INTER FERENCE STATEMENT

NOTE: This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in a residential

area is likely to cause harmful interference in which case the user will be required to correct

the interference at his own expense.

Warning

This is a Class A product. In domestic environment this product may cause radio

interference in which case the user may be required to take adequate measures.

Page 6

Contents iii

Contents

Proprietary Notice

Using This Guide

Text Conventions................................................................................................................viii

Safety Notices.......................................................................................................................ix

Safety Notices for Users Outside of the U.S.A. and Canada...........................................ix

Care and Handling.................................................................................................................x

1. Overview

Overview.............................................................................................................................1-2

High Capacity Cooling Fans...............................................................................................1-4

Power Supplies...................................................................................................................1-4

Security...............................................................................................................................1-4

DAU Functionality .............................................................................................................1-5

Hot Spare Feature..........................................................................................................1-5

Write Cache Feature......................................................................................................1-6

Cross Call Feature.........................................................................................................1-6

Initial Assignment Feature ............................................................................................1-7

Auto Assignment Feature..............................................................................................1-7

Expand LUN Feature.....................................................................................................1-8

Auto Repair Mode.........................................................................................................1-8

Repair Time Feature......................................................................................................1-8

1BBU Cache Enable Mode ...........................................................................................1-9

1CNT (Controller) Cache Enable Mode........................................................................1-9

Access Control Features................................................................................................1-9

Path Fail-over Feature.................................................................................................1-12

Dynamic Capacity Expansion.....................................................................................1-12

Management Software.................................................................................................1-12

RAID Configurations..................................................................................................1-13

Arbitrary Logical Disk Capacity.................................................................................1-14

Maximum Logical Disk Capacity................................................................................1-14

Features and Indicators.....................................................................................................1-15

Front Panel ..................................................................................................................1-15

Front Chassis Features and Indicators.........................................................................1-15

Rear Chassis Features..................................................................................................1-17

Power Supply...............................................................................................................1-18

DAU Controller...........................................................................................................1-19

Battery Backup Unit....................................................................................................1-21

SVP Service Processor................................................................................................1-22

Disk Enclosure Controller..........................................................................................1-23

2. Setting Up The DAU

Overview.............................................................................................................................2-2

Selecting a Site ...................................................................................................................2-2

Unpacking the DAU and Rack Mounting Hardware..........................................................2-3

Rack-Mount Subsystem Assembly.....................................................................................2-5

Before You Begin..........................................................................................................2-5

Page 7

iv Contents

Static Precautions.......................................................................................................... 2-5

Installing the Rails........................................................................................................ 2-6

Installing the DAU into the System Rack..................................................................... 2-9

Connecting Disk Array Unit............................................................................................2-10

Host Connection ......................................................................................................... 2-10

Disk Enclosure Connection.........................................................................................2-10

Connecting the Ethernet Cable...................................................................................2-11

Connection Notes........................................................................................................ 2-12

Setting DAU and Disk Enclosure Switches................................................................ 2-12

Connecting the Power Cords............................................................................................2-13

Connecting the DAU to Uninterruptible Power Supplies................................................2-15

Cable Dressing............................................................................................................2-16

Powering On/Off.............................................................................................................. 2-16

Turning On AC Power................................................................................................ 2-16

Turning Off AC power ............................................................................................... 2-17

Scheduled Stop Procedure................................................................................................2-18

3. Adding and Removing Components

General Information........................................................................................................... 3-2

Static Precautions...............................................................................................................3-2

Preparing Your DAU for Upgrade..................................................................................... 3-3

Accessing the DAU............................................................................................................ 3-3

Hard Disk Drives ............................................................................................................... 3-4

Installing or Swapping a Hard Disk Drive Modules in a Hot-swap Bay...................... 3-4

Installing or Swapping a Hard Disk Drive.................................................................... 3-5

Replacing a Controller Module.......................................................................................... 3-7

Replacement Procedure................................................................................................ 3-7

Replacing a SVP Service Processor................................................................................. 3-11

Replacement Procedure.............................................................................................. 3-11

Replacing the Power Supply............................................................................................ 3-14

Replacement Procedure.............................................................................................. 3-14

Replacing the Battery Backup Unit..................................................................................3-20

Replacement Procedure.............................................................................................. 3-20

4. Maintenance and Troubleshooting

Introduction........................................................................................................................4-2

Static Precautions...............................................................................................................4-2

Routine Maintenance......................................................................................................... 4-2

Cleaning.............................................................................................................................4-2

Initial DAU Startup Problems............................................................................................ 4-3

Troubleshooting.................................................................................................................4-4

LED Indicators ................................................................................................................... 4-5

SERVICE LED: On / FLT LED: Off................................................................................. 4-5

Troubleshooting Flowcharts .............................................................................................. 4-6

Media Errors on a Rebuilt Disk......................................................................................... 4-8

Temporary Degrade and Rebuild (Phoenix Feature) ......................................................... 4-8

A. Controller DIP Switch Settings

Controller DIP Switch Settings......................................................................................... A-2

Page 8

Contents v

B. Specifications

Disk Array Unit Basic Specifications................................................................................B-2

Environmental Specifications............................................................................................B-2

Power Specifications .........................................................................................................B-2

Size and Weight Specifications.........................................................................................B-3

Component Life Expectancies...........................................................................................B-3

Equipment Log

Glossary

Index

Page 9

Page 10

Using This Guide vii

Using This Guide

This User’s Guide provides a quick reference to information about your S1300 Disk Array

Unit (DAU). Its goal is to familiarize you with your DAU and the tasks necessary for

setting up your DAU, using the DAU, and configuring and upgrading the DAU. This guide

assumes that the reader is already familiar with the host system, Fibre Channel technology,

and operating system environments in which the DAU will be installed.

This guide contains the following information:

! Chapter 1, “DAU Overview” provides an overview of your DAU and describes its major

system components. See this chapter to familiarize yourself with your DAU.

! Chapter 2, “Setting Up Your DAU” tells you how to select a site, unpack the DAU and

provides you with assembly information for preparing and mounting the DAU into a

system rack. Also described are DAU to host cabling configurations, connecting the

power cord(s), powering On/Off the DAU, and configuring the Fibre Channel address

switches.

! Chapter 3, “Adding and Removing Components” provides you with information for

upgrading your DAU with additional disk drives. Information on a power supply, battery

backup unit, controller module and the SVP processor module are also included.

! Chapter 4, “Maintenance and Troubleshooting” contains helpful information for

maintaining your DAU and for solving problems that might occur with your DAU.

! Appendix A, “Controller DIP Switch Settings” contains information on setting DIP

switches located in the controller modules.

! Appendix B, “Specifications” includes physical, power, and environmental information

about your system.

! “Glossary” defines the standard acronyms and technical terms associated with the DAU.

Page 11

viii Using This Guide

Text Conventions

This guide uses the following text conventions.

Warnings, cautions, and notes have the following meanings:

!

WARNING

Warnings alert you to situations that could result in serious personal injury or loss

of life.

!

CAUTION

Cautions indicate situations that can damage the system hardware or software.

Note: Notes give important information about the material being described.

! Names of keyboard keys are printed as they appear on the keyboard. For example, Ctrl,

Alt, or Enter.

! Text or keystrokes that you enter appear as boldface type. For example, type abc123 and

press ENTER.

! File names are printed in uppercase letters. For example, AUTOEXEC.BAT.

Page 12

Using This Guide ix

Safety Notices

!

! Caution: To reduce the risk of electric shock which could cause personal injury, follow

all safety notices. The symbols shown are used in your documentation and on your

equipment to indicate safety hazards.

! Warning: The detachable power supply cords are intended to serve as the disconnect

devices.

! Warning: This equipment has a 3-wire, grounded power cords. To prevent electrical

hazards, do not remove or defeat the ground prong on the power cords. Replace a power

cord if it gets damaged. Contact your dealer for an exact replacement.

In the U.S.A. and Canada, the power cord must be a UL-listed detachable power cord (in

Canada, CSA-certified), type ST or SJT, 16 AWG, 3-conductor, provided with a molded-on

NEMA type 5-15 P plug cap at one end and a molded-on cord connector body at the other

end. The cord length must not exceed 9 feet (2.7 meters).

Outside the U.S.A. and Canada, the plug must be rated for 250 VAC, 10 amp minimum,

and must display an international agency approval marking. The cord must be suitable for

use in the end-user country. Consult your dealer or the local electrical authorities if you are

unsure of the type of power cord to use in your country. The voltage change occurs via a

switch in the power supply.

! Warning: Under no circumstances should the user attempt to disassemble the power

supply. The power supply has no user-replaceable parts. Inside the power supply are

hazardous voltages that can cause serious personal injury. A defective power supply

must be returned to your dealer.

Safety Notices for Users Outside of the U.S.A. and Canada

! PELV (Protected Extra-Low Voltage) Integrity: To ensure the extra-low voltage

integrity of the equipment, connect only equipment with mains-protected electricallycompatible circuits to the external ports.

! Remote Earths: To prevent electrical shock, connect all local (individual office)

computers and computer support equipment to the same electrical circuit of the building

wiring. If you are unsure, check the building wiring to avoid remote earth conditions.

! Earth Bonding: For safe operation, only connect the equipment to a building supply

that is in accordance with current wiring regulations in your country. In the U.K., those

regulations are the IEE.

Page 13

x Using This Guide

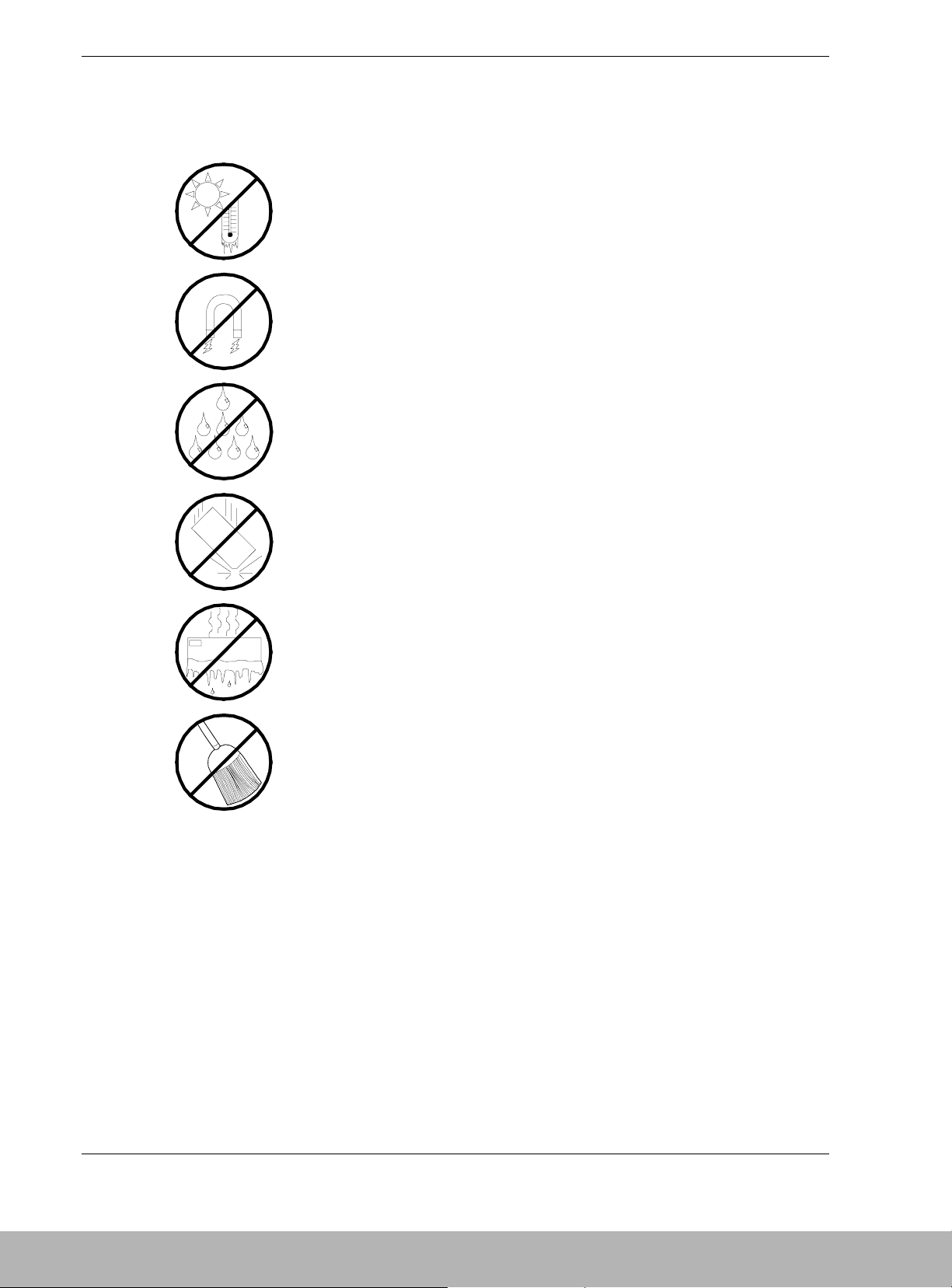

Care and Handling

Use the following guidelines to properly handle and care for your system.

Protect the system from extremely low or high temperatures. Let

the system warm (or cool) to room temperature before using it.

Keep the system away from magnetic forces.

Keep the system dry. Do not wash the system with a wet cloth or

pour fluid into it.

Protect the system from being bumped or dropped.

Check the system for condensation. If condensation exists, allow it

to evaporate before powering on the system.

Keep the system away from dust, sand, and dirt.

Page 14

1

Overview

! Overview

! High Capacity Cooling Fans

! Power Supplies

! Security

! DAU Functionality

! Features and Indicators

Page 15

1-2 Disk Array Unit Overview

Overview

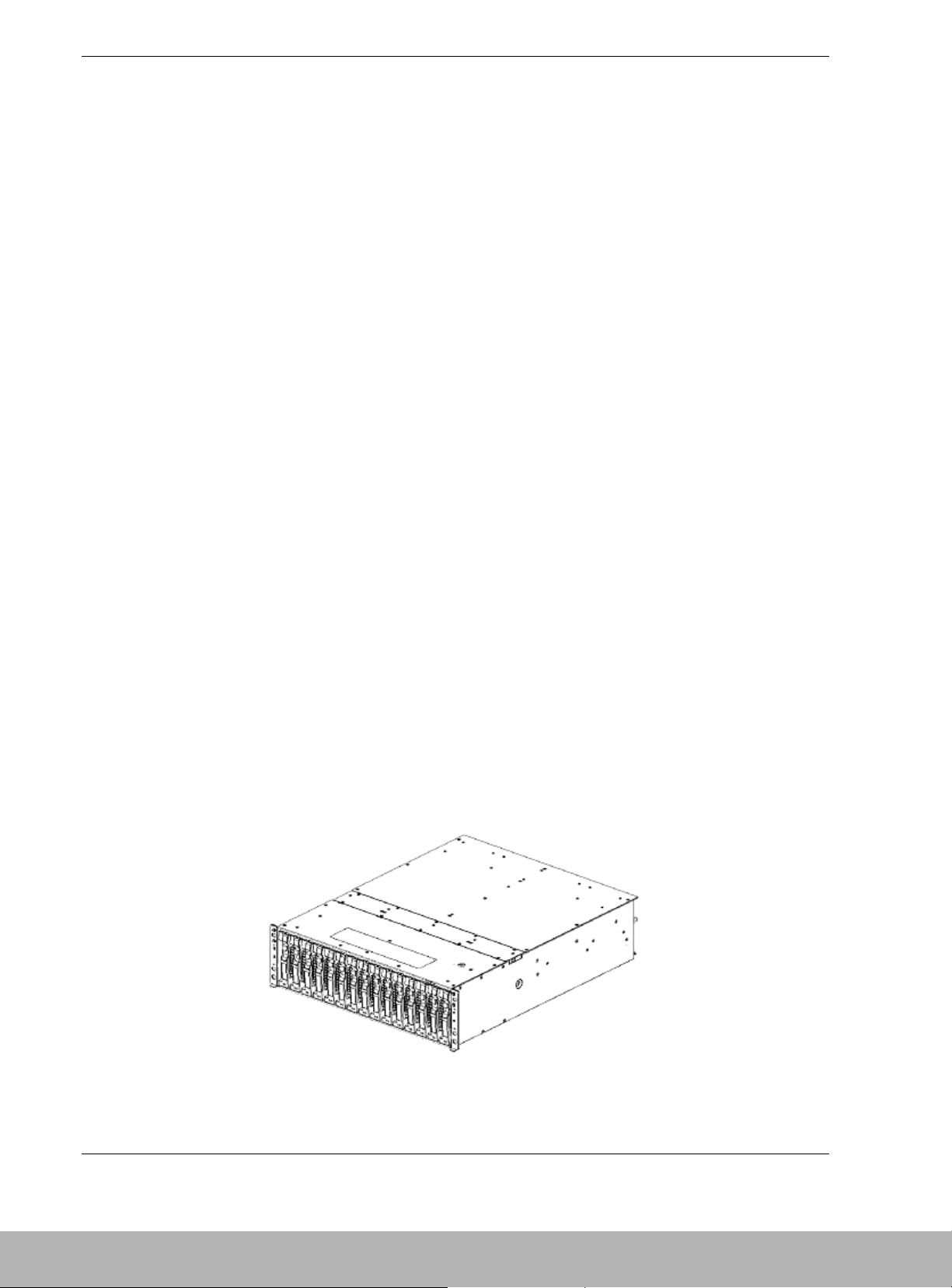

The NEC S1300 Disk Array Unit (DAU) provides highly available, fault-tolerant

storage in a rack-mount subsystem. The DAU uses high-speed Fibre Channel

technology. See Figure 1-1.

The Fibre Channel is a scalable, high-performance interconnect standard that enables

fast transfer of data between workstations, shared storage, peripherals and host systems.

At up to speeds of 2 Gigabits per second this data transfer technology combines the

attributes of a data channel with the attributes of a network. Fibre Channel is capable of

supporting multiple protocols and a variety of topologies, making it the most versatile

data transfer technology available.

The DAU supports RAID levels 0, 1, 5, and 10. Even if one disk module fails, the disk

array unit continues to function normally without interruption (Except for RAID

level 0).

A faulty disk module can be replaced without system shutdown. The DAU includes an

automatic rebuild feature by which data is automatically restored when a faulty disk

module is replaced. When one disk module is defined as a spare drive, the data in the

faulty disk module is immediately restored to the spare drive (hot spare feature). Using

the auto recovery and hot spare feature increases overall system availability and

reliability.

The DAU also includes a battery-backed cache memory data storage feature to increase

reliability and high-speed data processing. In addition to the disk modules, the cooling

fan system, the power supply system, and dual array controllers all have system

redundancy capabilities. Therefore, even if one of the redundant system components

fails, the disk array unit continues normal operation.

The DAU cabinet holds up to a maximum of fifteen hard disk drives. A disk enclosure

unit (option) is available to enable expansion of the storage capacity of the DAU by

adding up to fifteen additional hard disk drives.

The DAU has a relatively small form factor of 3U and is available as a rack-mount

system that fits into a standard EIA 19-inch rack assembly.

Figure 1-1. Rack-Mount DAU Front View (Front Bezel not Shown)

Page 16

Disk Array Unit Overview 1-3

The DAU includes the following major features:

! 2.0 Gigabit per second data transfer rate .

! High bandwidth for demanding applications.

! The ability to share storage assets among many workstations.

! Easy cabling to host bus adapters.

! Hot-swap hard disk drive bays accessible from the front of the chassis. The drives

can be swapped in or out of the DAU without powering it down. The bays support

up to fifteen hard disk drives. Disk drives are high performance 10,000RPM and

15,000RPM hard disk drives connected to a high speed Fibre Channel-Arbitrated

Loop (FC-AL) disk drive interface. Drive capacities are 36GB, 73GB or 146GB.

! Hardware monitors (temperature, fans, and voltage) and software monitors to

indicate failures.

! LEDs to provide failure notifications.

! Support of RAID levels 0, 1, 5, and 10. If a fault occurs in a single disk module, the

DAU can continue the operation without loss of data (except RAID level 0).

! Battery-backed cache memory to ensure high-speed data processing.

The DAU system is designed for minimum downtime. Thus, the DAU contains the

following:

! A more reliable and flexible storage architecture that helps ensure continuous data

availability.

! Two power supplies for power system redundancy. With two power supplies, the

DAU will continue to operate with a single power supply failure. The self-contained

power supply units can be easily and safely hot-swapped from the rear of the chassis

without shutting down the DAU.

! Dual controllers, each containing cache memory. Cache memory data is protected by

battery backup units, to retain write data in the event of a system shutdown or power

failure.

! Fibre Channel disk drive bays accessible from the front of the chassis.

! Hot-swap Fibre Channel disk drive backplane, supporting fifteen drives. A failed

drive can be removed and a new drive installed without turning off system power.

Page 17

1-4 Disk Array Unit Overview

! Disk Drive Bays

The DAU supports 36GB, 72GB and 146GB hard disk drives. The chassis includes

fifteen Fibre Channel hot-swappable hard disk drive bays for mounting up to fifteen

hard disk drives in easily removable drive carriers. Each bay accommodates 1-inch hard

disk drives.

Note: The DAU contains a hot-swap backplane that requires a

40-pin single connector attachment connector on the drives that you

install.

The design of the drive mounting uses a carrier rail system making it possible to "hot

swap" a drive without shutting down the DAU.

High Capacity Cooling Fans

The DAU contains two power supplies, each of which contains two high capacity

cooling fans. The DAU will be adequately cooled even if one of the fans fails. Also,

should any of the fans fail, they may be replaced without powering down the DAU. The

fans draw air across the hard disk drives and electronics of the system and exhaust out

through the rear panel.

Power Supplies

The DAU contains two auto-sensing 480-watt power supplies at an operating frequency

of 50/60 Hz. With two power supplies installed, in the event of a power supply failure,

the load is transferred to the remaining power supply without interruption to normal

operation.

Note: The power supplies are not hot swappable unless there

are two supplies installed.

The power supplies are designed to comply with existing emission standards and

provide sufficient power for a fully loaded system configuration.

Security

A security lock on the front bezel of the DAU prevents unauthorized entry to the

storage drives. Rack-mounted DAUs are also secured in the system cabinet by locking

mechanisms installed on the system rack front and rear doors.

Page 18

Disk Array Unit Overview 1-5

DAU Functionality

Hot Spare Feature

Spare disks can be installed in a disk array configuration that includes several disks. If a

disk fails in a configuration that includes the spare disk, the data located in the defective

disk is recovered to the spare disk. After the data recovery, the disk array configuration

operates normally. The defective disk module can be replaced without turning off the

power of the disk array unit, provided the disk array unit is configured as RAID level 1,

5, or 10.

To use the hot-spare feature, an optional spare disk must be installed.

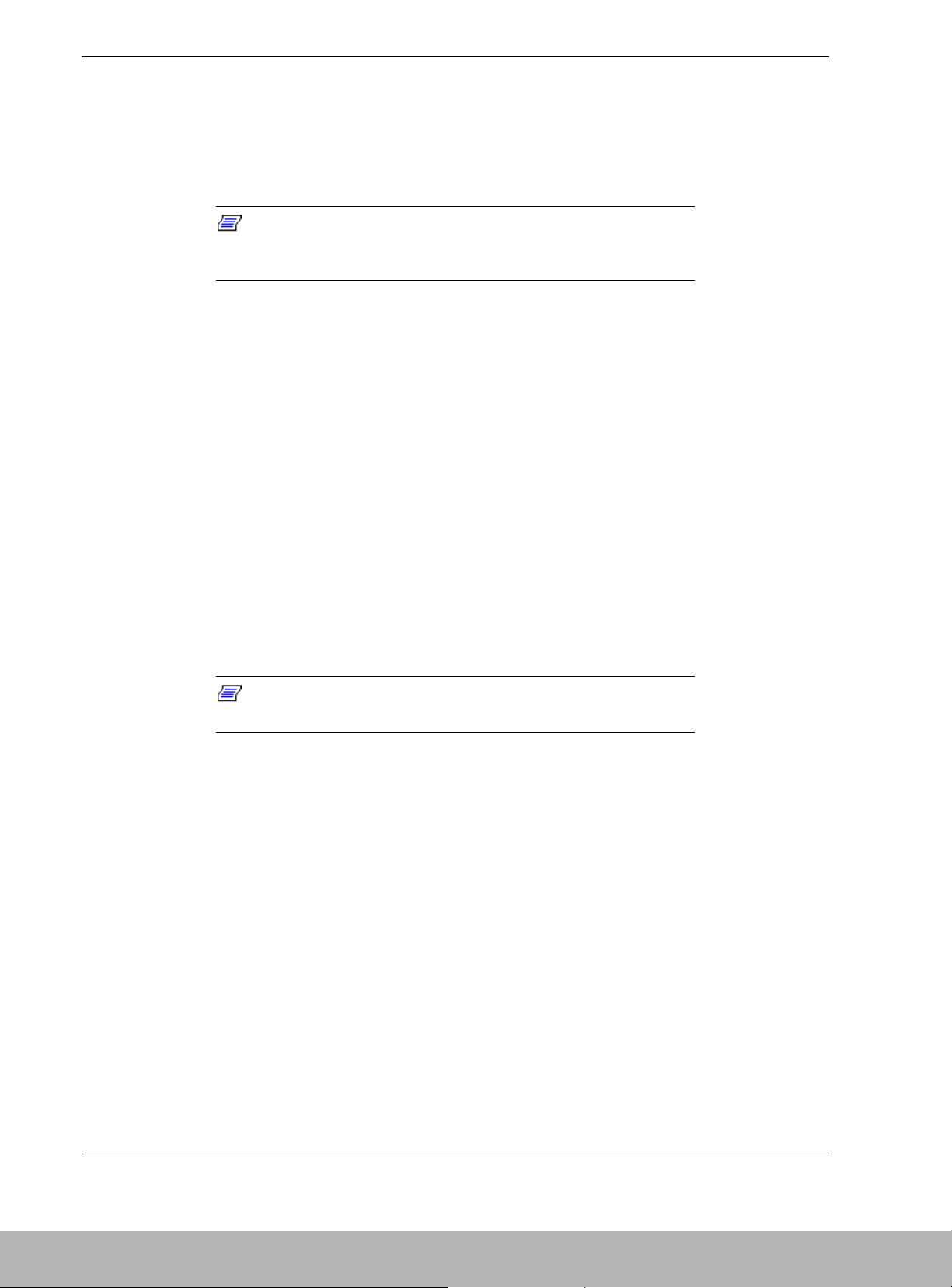

An example of the hot spare feature is shown in Table 1-1. In this example, hard disk

drives DRV0, 1, 2, 3, 4, and 14 are configured as a disk array. DRV14 is designated as

the spare disk. Disk DRV1 fails and its data is recovered in spare disk DRV14. When

recovery is complete, disk DRV1 is replaced without powering down the unit. Once

disk DRV1 is replaced, data is restored from spare disk DRV14 to the new disk DRV1.

Table 1-1. Hot Spare Feature Example

DRV14

Spare disk

DRV14 DRV14

Spare disk

DRV13 DRV13 DRV13

DRV12 DRV12 DRV12

DRV11 DRV11 DRV11

DRV10 DRV10 DRV10

DRV9 DRV9 DRV9

DRV8 → DRV8 → DRV8

DRV7 DRV7 DRV7

DRV6 DRV6 DRV6

DRV5 DRV5 DRV5

DRV4 DRV4 DRV4

DRV3 DRV3 DRV3

DRV2

LDN0 RAID5

DRV2

LDN0 RAID5

DRV2

LDN0 RAID5

DRV1 DRV1 DRV1

DRV0 DRV0 DRV0

Failure in DRV1 Recovery of data

in spare disk

Replacement of DRV 1

Restore the data from spare

disk to DRV 1

* DRV: Disk module

LDN: Logical Disk Number

Notes: The hot spare feature cannot be used with RAID

level 0. Use the hot spare feature with RAID levels 1, 5, or 10.

Do not move any factory-installed disk modules into another

slot.

The hot spare feature works only when a spare disk has the

same capacity and speed as the defective disk.

Page 19

1-6 Disk Array Unit Overview

Write Cache Feature

With RAID level 5, the performance of the DAU may be decreased somewhat when

writing small amounts of data to a disk. To increase performance, the DAU is equipped

with cache memory. When write data is stored in cache memory, the DAU may

terminate command processing and then write data to disks for improved performance.

However, if the power is disrupted before the data in cache memory is written to disk,

the data in the cache memory could be lost. To prevent this, the DAU power supplies

each include a battery backup unit to supply power to the cache memory, thereby

retaining data in the cache memory should the power fail. The battery backup unit is

fully charged after eight hours of operation.

Cross Call Feature

By using the cross call feature, logical disk drives can be accessed from alternative

paths within the DAU, even if a controller fails. The cross call feature minimizes server

downtime thereby enhancing system performance. The cross call feature of the DAU

can be set with management software. The cross call feature has two states:

! Off state In this state, the DAU is accessible only from the host adapter (HBA) of

the bound host.

! On state (shipping default) In this state, all logical drive numbers (LDNs) in the

DAU are accessible from both controllers or one controller should one of the

controllers fail.

Note: Since one LDN is recognized from each controller, this

cross call must be used on the system where the logical disks can be

controlled exclusively. When you want to use the alternative path

switching feature of the host, the cross call feature must be turned

on.

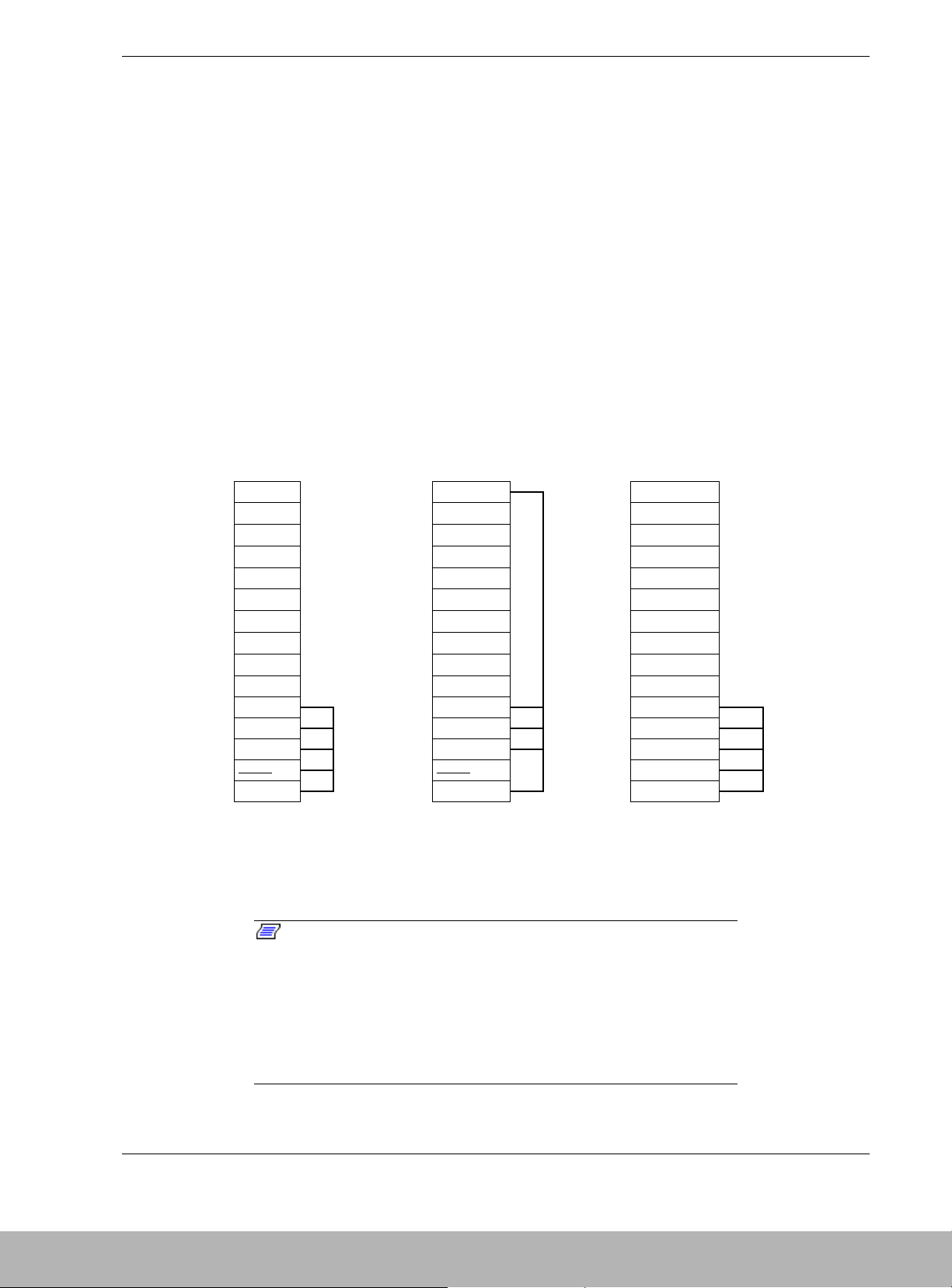

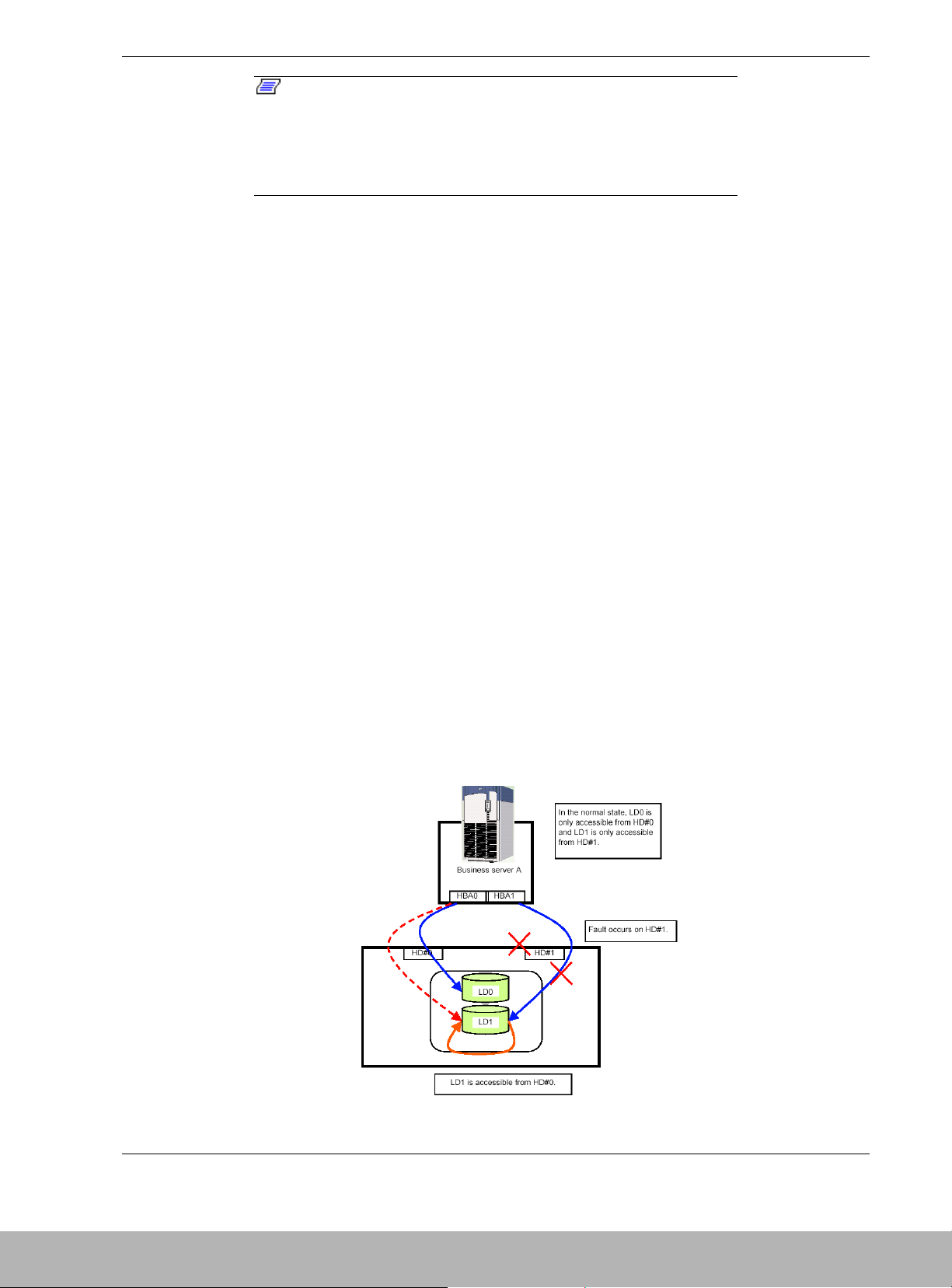

Figure 1-2 illustrates a system connected to the DAU with the cross call feature turned

on and a failure with DAU controller HD#1.

Figure 1-2. Cross Call Feature Connections

Page 20

Disk Array Unit Overview 1-7

Notes: A controller is called as HD (Host Director) in the

management software.

A logical disk configuring the RAID is called as LD (Logical Disk), and

the internal number of LD is called LDN (Logical Disk Number) in the

management software.

Initial Assignment Feature

You can assign a logical disk to the controller on the path to which you bound the

logical disk (built the RAID).

When an attempt is made to access the logical disk from the unassigned controller, the

error "illegal request - not assigned" is returned. When an attempt is made to unbind

this logical disk from the unassigned controller, the same error is returned. However, if

the ownership has been changed, the initial assignment feature is transferred to the

unassigned controller.

Auto Assignment Feature

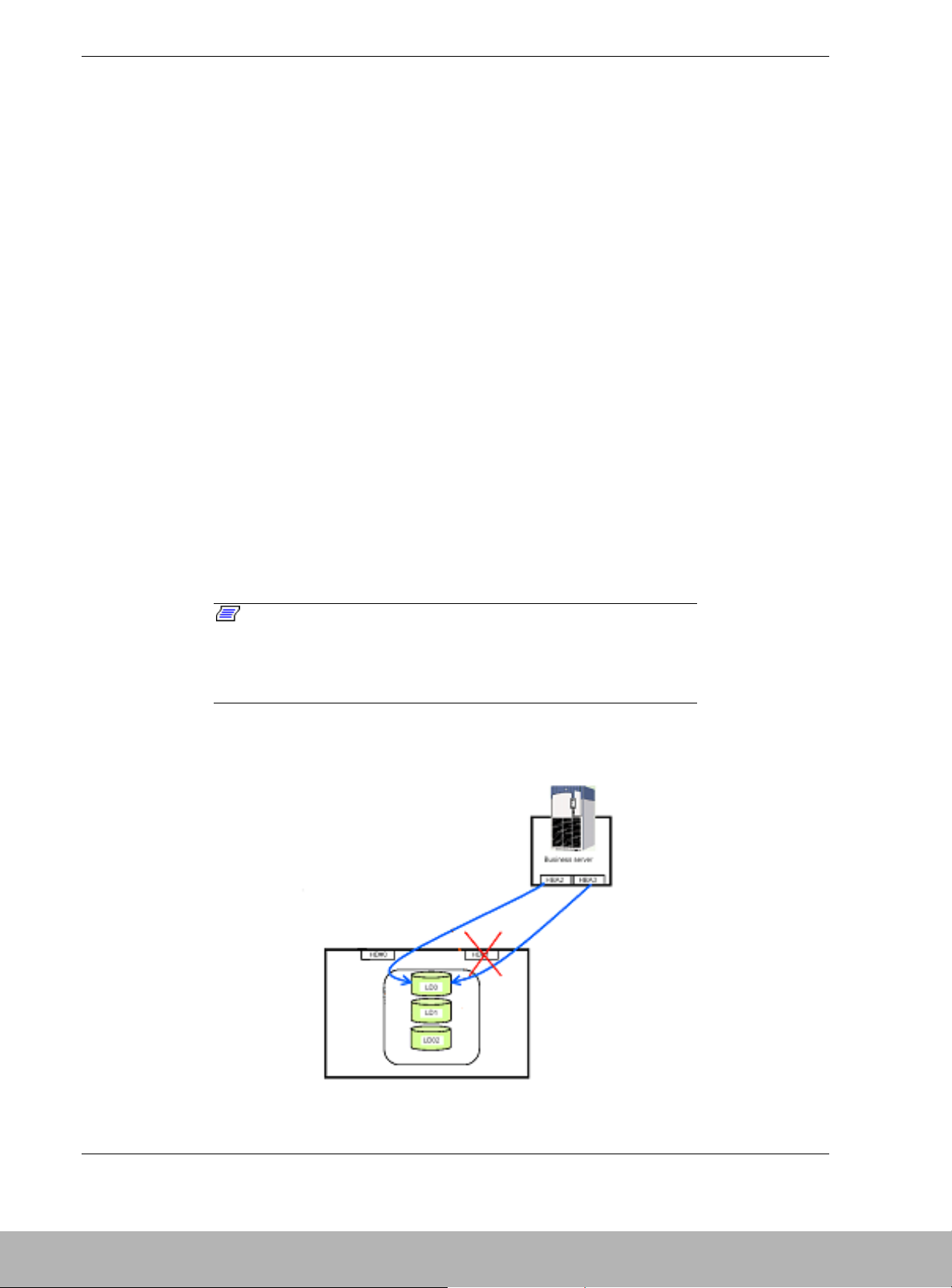

The auto assignment feature allows you to access any logical disk in the subsystem

from the unassigned controller if the assigned controller is down. This feature is active

while the cross call is disabled.

When an I/O request to a logical disk not assigned to a DAU controller is received, the

system examines whether the adjacent controller is down. If the adjacent controller is

down, the system cancels assigning the logical disk to that controller and reestablishes

the assignment to the controller receiving the request. This reassignment is maintained

until the downed controller is operable, or a status change is received from management

software.

Even when the system in not equipped with the alternative auto assignment feature,

making the system recognize the logical disk again permits the access, allowing to

minimize the influence to the system operation. Figure 1-3 illustrates the Auto

assignment feature.

Figure 1-3. Auto Assignment Feature

Page 21

1-8 Disk Array Unit Overview

Expand LUN Feature

The Expand LUN feature increases the number of logical disks available from the host.

When running Windows NT or Windows 2000, the expand LUN feature is disabled

(shipping default). This setting can be changed with the NEC Storage Manager

(management software).

Note: When the DAU is connected to a host server that does not

support the Expand LUN feature, and this feature is turned on, the

host server may not recognize the DAU. If this occurs, the default

setting (Expand LUN feature off) may not be restored with the NEC

Storage Manager management software, resulting in system fault.

Auto Repair Mode

When the disk array includes an unused spare disk, you can select whether the repair

operation is started automatically or manually by using the NEC Storage Manager

management software. Auto repair mode is set to enable (shipping default).

Notes: If auto repair mode is disabled during a repair, the

current repair continues and is not terminated. The new setting will

take affect for the next repair.

When auto repair mode is enabled in the standby state, the repair is

not immediately initiated. The new setting will take affect for the next

repair.

When auto-repair mode is turned on and the physical disk status is

examined from the management software, "rebuilding" status is

displayed indicating the repair is in process. When auto-repair is

turned off and a disk fails, the status “reduce” is displayed until the

rebuild process is started manually.

Repair Time Feature

The default repair time is 10 hours. This time can be set from 0 (fastest) to 24 hours.

However, the repair might not be completed within the predetermined time depending

on the required repair. If a repair time is not specified, the fastest possible repair is

automatically executed.

With the repair time set to the shortest value (0), the RAID redundancy is rebuilt as fast

as possible to minimize exposure to a second failure. Setting the repair time to 24 hours

minimizes loss of performance during the repair.

Page 22

Disk Array Unit Overview 1-9

1BBU Cache Enable Mode

Normally your DAU includes two battery backup units to retain write data in the cache

memory of each controller in the event of a system shutdown or power failure. When

only one battery backup unit is in service, the DAU is not redundant and data loss may

occur if this battery unit fails. For this reason, it is recommended that 1BBU cache

enable mode be turned off when only one battery backup unit is in use.

OFF state: The write cache is disabled in the single-BBU condition.

ON state: The write cache is enabled even in the single-BBU condition. (Shipping default)

1CNT (Controller) Cache Enable Mode

Normally your DAU includes two controllers, each containing cache memory to retain

write data in the event of a system shutdown or power failure. When only one controller

is in service, the DAU is not redundant and lost data may occur if the cache in this

controller is enabled and this controller fails. For this reason, it is recommended that

1CNT cache enable mode be turned off when only one controller is in use.

OFF state: The write cache is disabled in the single-controller condition. (Shipping default)

ON state: The write cache is enabled even in the single-controller condition.

Access Control Features

Objective of Access Control

Access control allows logical disks in a DAU the ability to establish port and host

access permissions. Access control also provides a logical disk masking feature on a

port-by-port or host-by-host basis to protect the data and ensure the security.

About Access Control

To achieve the above objectives, the access control determines those logical disks

accessible from the controller or host and masks these disks. When you want to use the

access control, the cross call feature must be turned on.

Modes Supported by Access Control

The access control feature supports the following two modes.

! Port mode

! WWN mode

Page 23

1-10 Disk Array Unit Overview

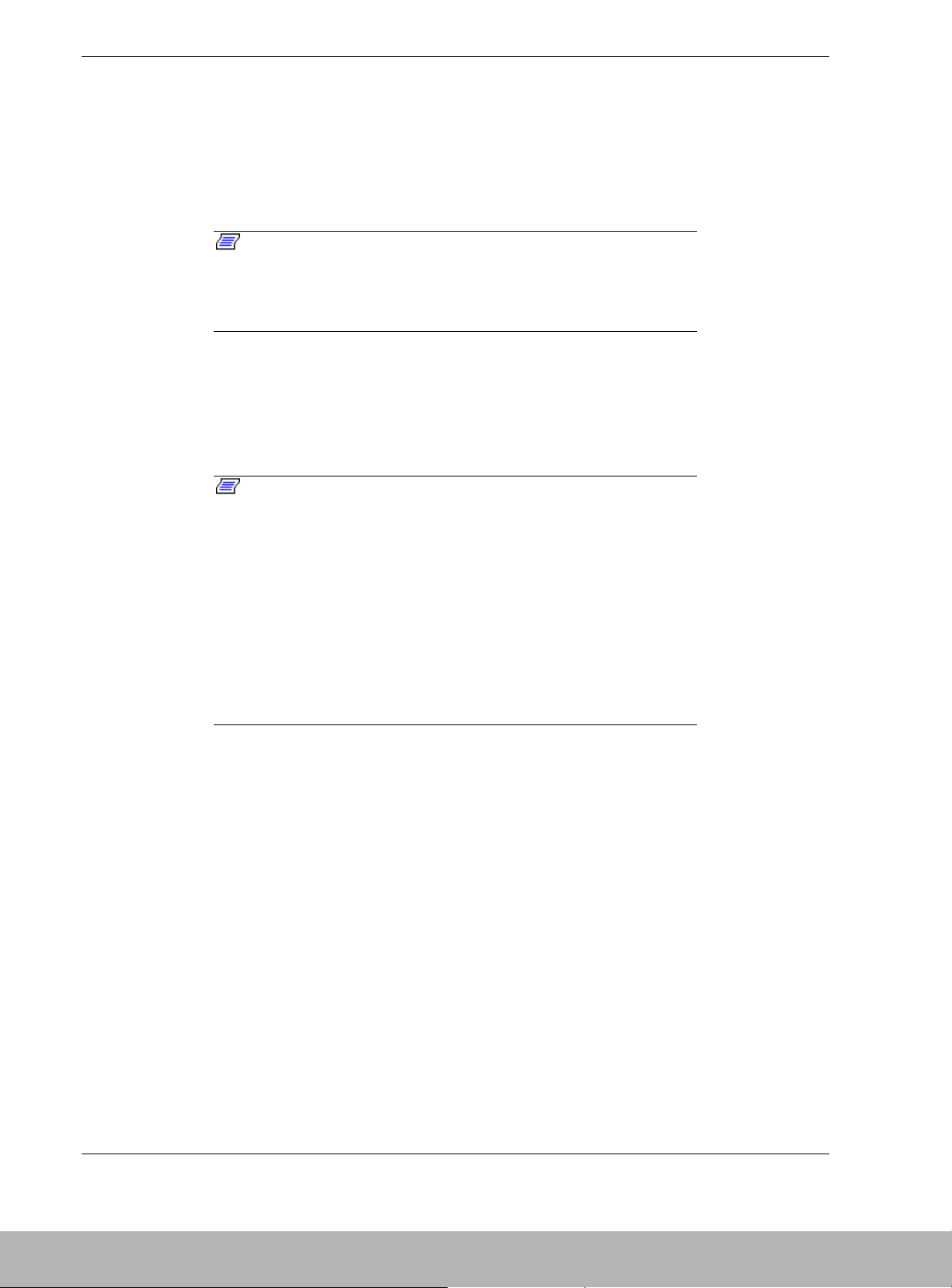

Port Mode

Port Mode establishes and maintains the logical disks accessible from each port

(controller) in the DAU. Table 1-2 shows logical disks assigned to each port in a DAU.

Figure 1-4 shows two business servers and the logical disks (LDs) assigned to each

using port mode. Business server A can access logical disks LD0, LD01, LD04, and

LD06 while business server B can access logical disks LD02, LD03, LD05, and LD07.

LD08 and LD09 are inaccessible from either business server.

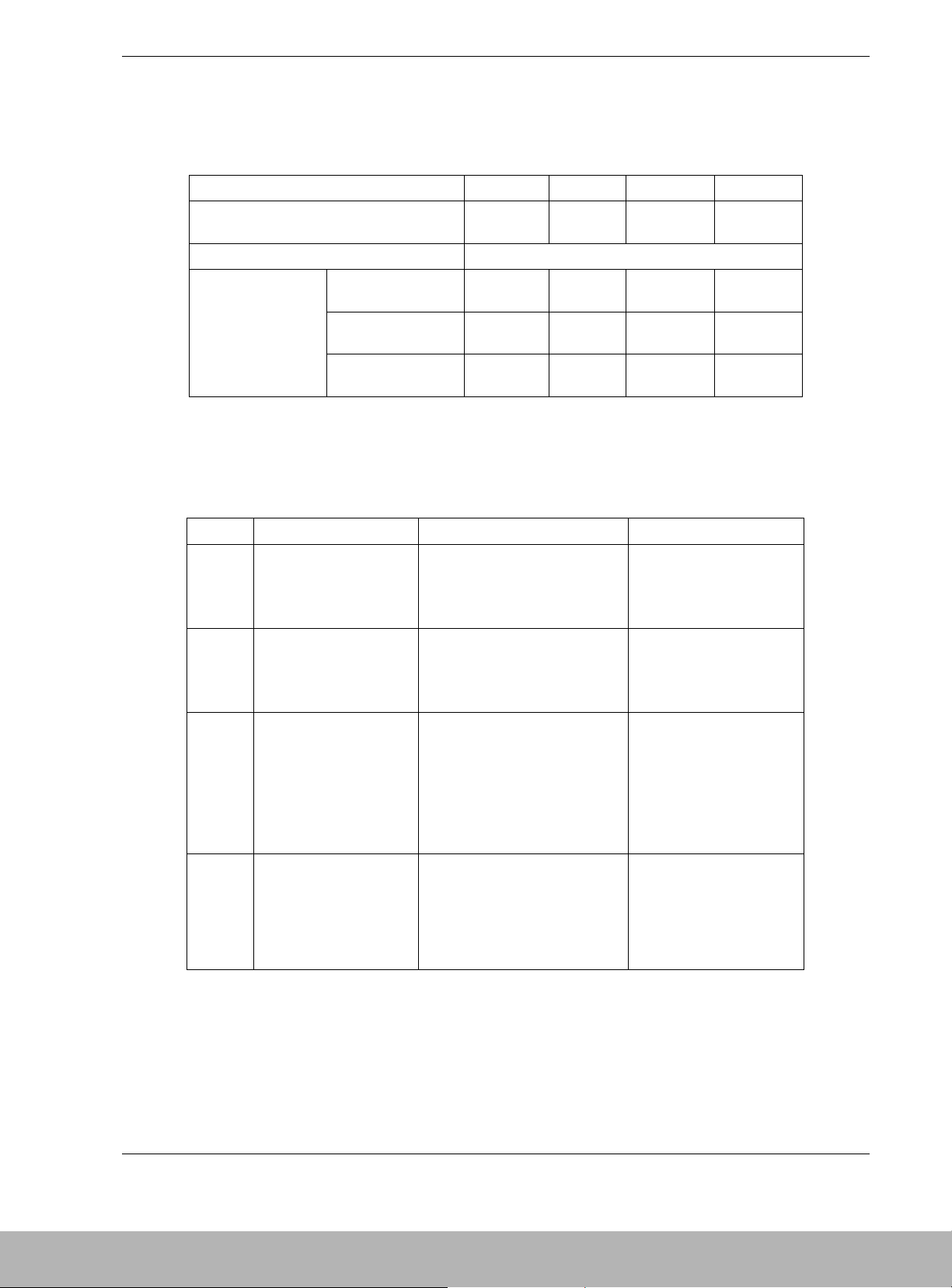

Table 1-2. Setup of HD and LD Numbers

Logical Disk Number (LD)

Hard Disk (HD) Port

Number

00 01 02 03 04 05 06 07 08 09

0

√√

––

√

–

√

–––

1––

√√

–

√

–

√

––

Legends

√: Registers the HD number in the access limitation list as accessible number.

–: Registers the HD number in the access limitation list as inaccessible number.

Figure 1-4. Port Mode Logical Drives Assignments to Business Servers

Page 24

Disk Array Unit Overview 1-11

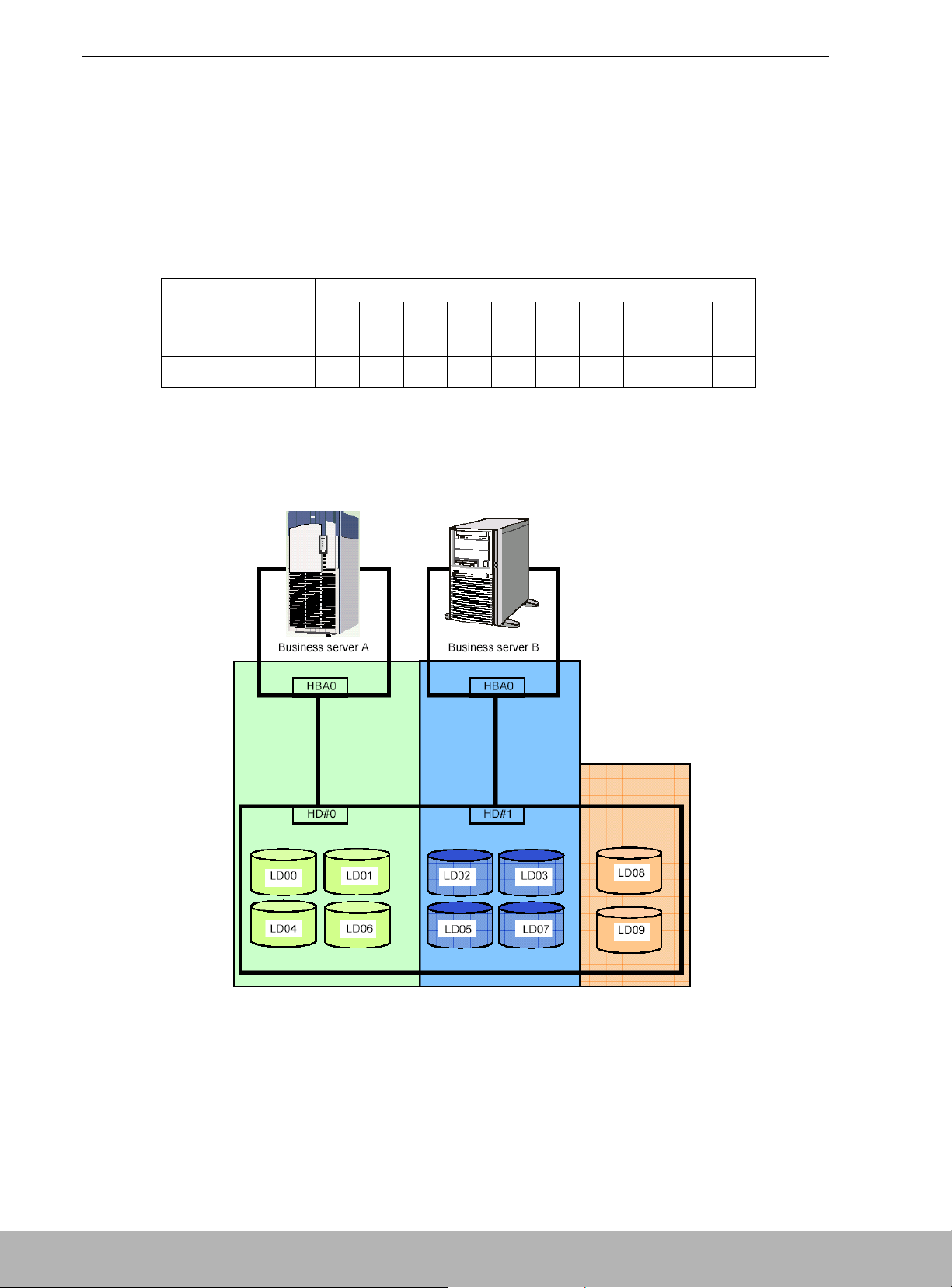

WWN (World Wide Node) Mode

WWN mode establishes and maintains the logical disks accessible from each WWN of

the host HBA in the DAU to control the access to the logical disks on a host-by-host

basis. Table 1-3 shows logical disks assigned to each HBA. Figure 1-5 shows two

business servers and the logical disks (LDs) assigned to each using WWN mode.

Business server A can access logical disks LD00, LD01, LD04, and LD06 while

business server B can access logical disks LD02, LD03, LD05, and LD07. LD08 and

LD09 are inaccessible from either business server. If business server A supports the

path switching feature, the logical disks of HD#0 are accessible through switch 1 even

when switch 0 is unavailable and access is rejected.

Table 1-3. Setup of WWN and LD Numbers

Logical Disk Number (LD)

Host Bus Adapter

(HBA) Number

00 01 02 03 04 05 06 07 08 09

0

√√

––

√

–

√

–––

1

∆∆

––

∆

–

∆

–––

2––

√√

–

√

–

√

––

Legends

√: Registers the HBA WWN and HD number in the access limitation list as accessible items.

–: Registers the HBA WWN and HD number in the access limitation list as inaccessible items.

∆: Registers the WWN of HBA0/HBA1 and the HD number in the access limitation list as accessible

items. If the business server A supports the path switching feature, the logical disks are accessible

through switch 1 even in case that switch 0 is faulty and the access is rejected.

Figure 1-5. WWN Mode Logical Drives Assignments to Business Servers

Page 25

1-12 Disk Array Unit Overview

Path Fail-over Feature

The DAU is equipped with two disk array controllers to enable dynamic cross call

control. The two disk array controllers can access to all logical disks. If either of the

disk array controllers fails, the DAU can continue the operation by using the remaining

disk array controller. In order to use this function, optional software may be required, as

well as the operating system.

Dynamic Capacity Expansion

The Dynamic Capacity Expansion feature can be used to add capacity to the RAID 5.

RAID 5 configurations of 3 to 14 drives can be expanded. Physical disks may be added

one at a time, and the expansion can be started only after the previous expansion has

completed. NEC Storage Management or MSMGR are used to initiate the expansion.

Management Software

NEC Storage Management software provided with your DAU, allows you to perform

the following functions from the host computer:

! Setting and resetting RAID configurations (RAID0, 1, 5, 10, and hot spare disk)

! Setting of various features

! Downloading firmware updates

! Collecting error logs.

Page 26

Disk Array Unit Overview 1-13

RAID Configurations

Available DAU RAID configurations are shown in Table 1-4.

Table 1-4. RAID Configurations

RAID Level RAID0 RAID1 RAID5 RAID10

Number of physical drives in configuration 1, 3, 5, 10,151+1 2+1 to 14+1 2+2 to 7+7

Number of logical drives per subsystem 1,024 max.

With 36-GB disks 35.7 to

536.1GB

35.7GB 71.4 to

500.3GB

71.4 to

250.1GB

With 73-GB disks 71.6 to

1074GB

71.6GB 143.2 to

1002GB

143.2 to

501.2GB

Storage capacity per

logical drive

With 146 GB disks 142.9 to

2144GB

142.9GB 285.8 to

2001GB

285.8 to

1000GB

* A combination of disk modules of the same capacity and same rotational speed are required for

configuring logical drives.

Characteristics of the RAID levels are shown in Table 1-5.

Table 1-5. RAID Level Characteristics

Level Function Advantage Disadvantage

RAID0 Striping Highest data read/write rate

Maximum storage capacity

Data recovery disabled

(Fault in a single disk

module causes data to be

lost.)

RAID1 Mirroring Data recovery enabled Low-speed data writing

All data is written to two

disk modules.

Minimum data recovery time The required disk capacity

is twice the used storage

capacity.

RAID5 Striping of data and

redundant data

Data recovery enabled Three or more disk

modules are required.

Larger capacity is available for

users because the capacity of

redundant data is smaller than

that of RAID1.

The required storage

capacity is one extra

physical disk per rank.

High-speed data write

RAID10 Use of both mirroring

and striping

Data recovery enabled Four or more disk modules

are required.

High-speed data read/write The required storage

capacity of disk module is

twice the used storage

capacity.

Page 27

1-14 Disk Array Unit Overview

Arbitrary Logical Disk Capacity

An arbitrary logical disk capacity can be bound by using the management software. To

bind logical disks, enter the capacity in MBs (M=1024^2).

For management software, the logical disk capacity can be specified with an integer

multiple of the basic capacity, or the least common multiple of (stripe size) × (number

of data disks) and 1024 (400h).

Ex: Capacity secured in RAID-5 (6+P)

Stripe size (100h) × number of data disks (6h) = 600h (768 KB)

The basic capacity is the least common multiple of 400h and 600h.

The capacity must be an integer multiple of C00h (1536 KB).

Maximum Logical Disk Capacity

The maximum capacity per logical disk is shown in the table below (including the

system capacity of 2 MB).

Enter the value resulting from subtracting the system capacity (2 MB) from the capacity

in Table 1-6 as the LD capacity.

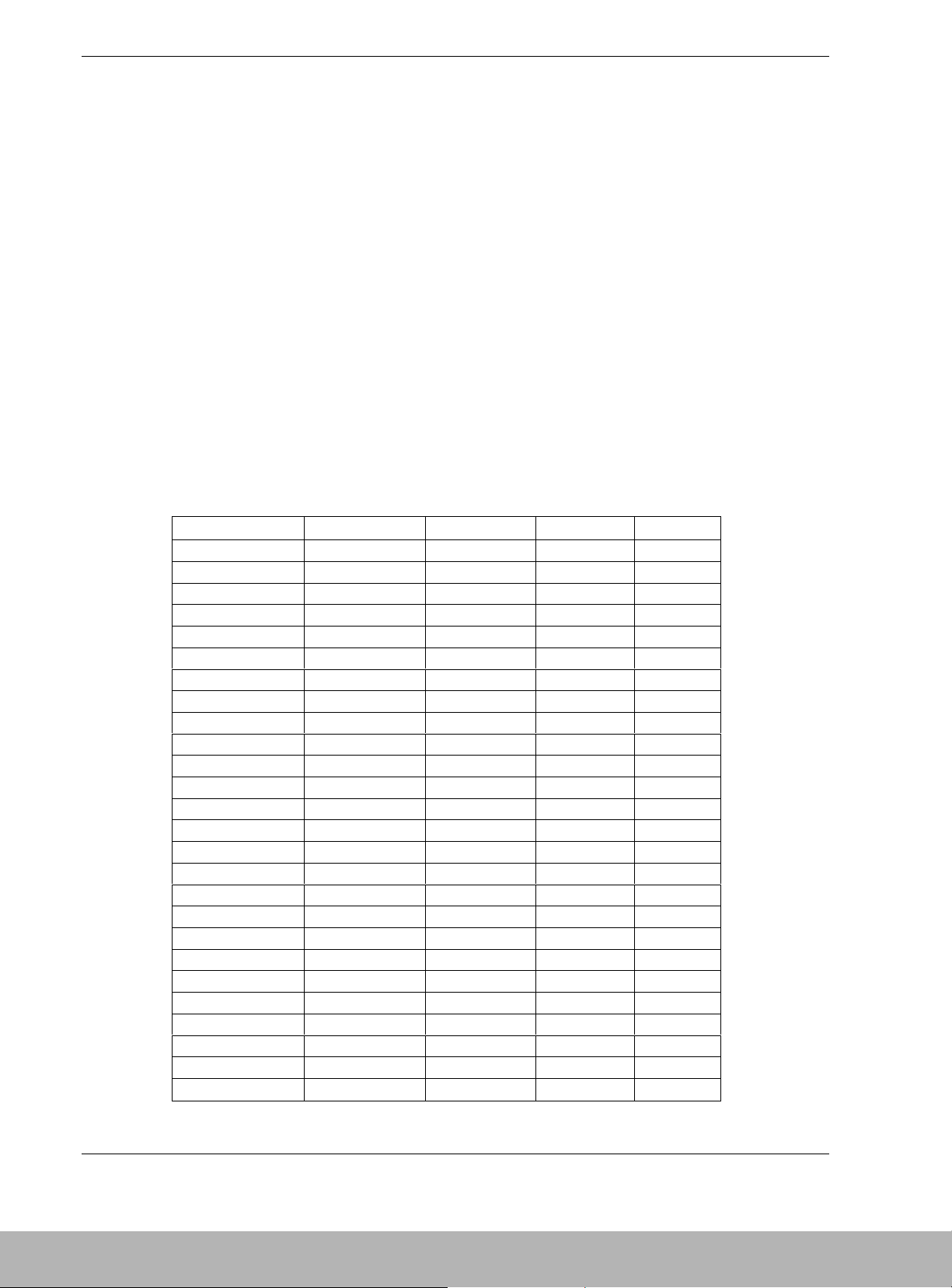

Table 1-6. Maximum Logical Disk Capacity (MB) M=1024^2

RAID Type Number of PDs 36GB 73GB 1476GB

Single unit 34087 68284 136325

RAID0 (1) 1 34087 68284 136325

RAID0 (3) 3 102261 204852 408975

RAID0 (5) 5 170435 341420 681625

RAID0 (10) 10 340870 682840 1363251

RAID0 (15) 15 511305 1024260 2044876

RAID1 (1+1) 2 34087 68284 136325

RAID5 (2+P) 3 68174 136568 272650

RAID5 (3+P) 4 102261 204852 408975

RAID5 (4+P) 5 136348 273137 545300

RAID5 (5+P) 6 170435 341420 681625

RAID5 (6+P) 7 204522 409704 817950

RAID5 (7+P) 8 238609 477988 954275

RAID5 (8+P) 9 272697 546274 1090600

RAID5 (9+P) 10 306783 614556 1226926

RAID5 (10+P) 11 340870 682840 1363251

RAID5 (11+P) 12 374957 751124 1499576

RAID5 (12+P) 13 409044 819411 1635901

RAID5 (13+P) 14 443131 887692 1772226

RAID5 (14+P) 15 477218 955976 1908551

RAID10 (2+2) 4 68174 136568 272650

RAID10 (3+3) 6 102261 204852 408975

RAID10 (4+4) 8 136348 273137 545300

RAID10 (5+5) 10 170435 341420 681625

RAID10 (6+6) 12 204522 409704 817950

RAID10 (7+7) 14 238609 477988 954275

Note:The capacities in the table above include the system capacity (in T&D area) of 2 MB.

Page 28

Disk Array Unit Overview 1-15

Features and Indicators

The DAU contains several features and indicators located on the front and rear of its

chassis. The LED indicators assist in determining the current state of the DAU

subsystem. The following subsections describe the front and rear chassis features and

indicators of the DAU.

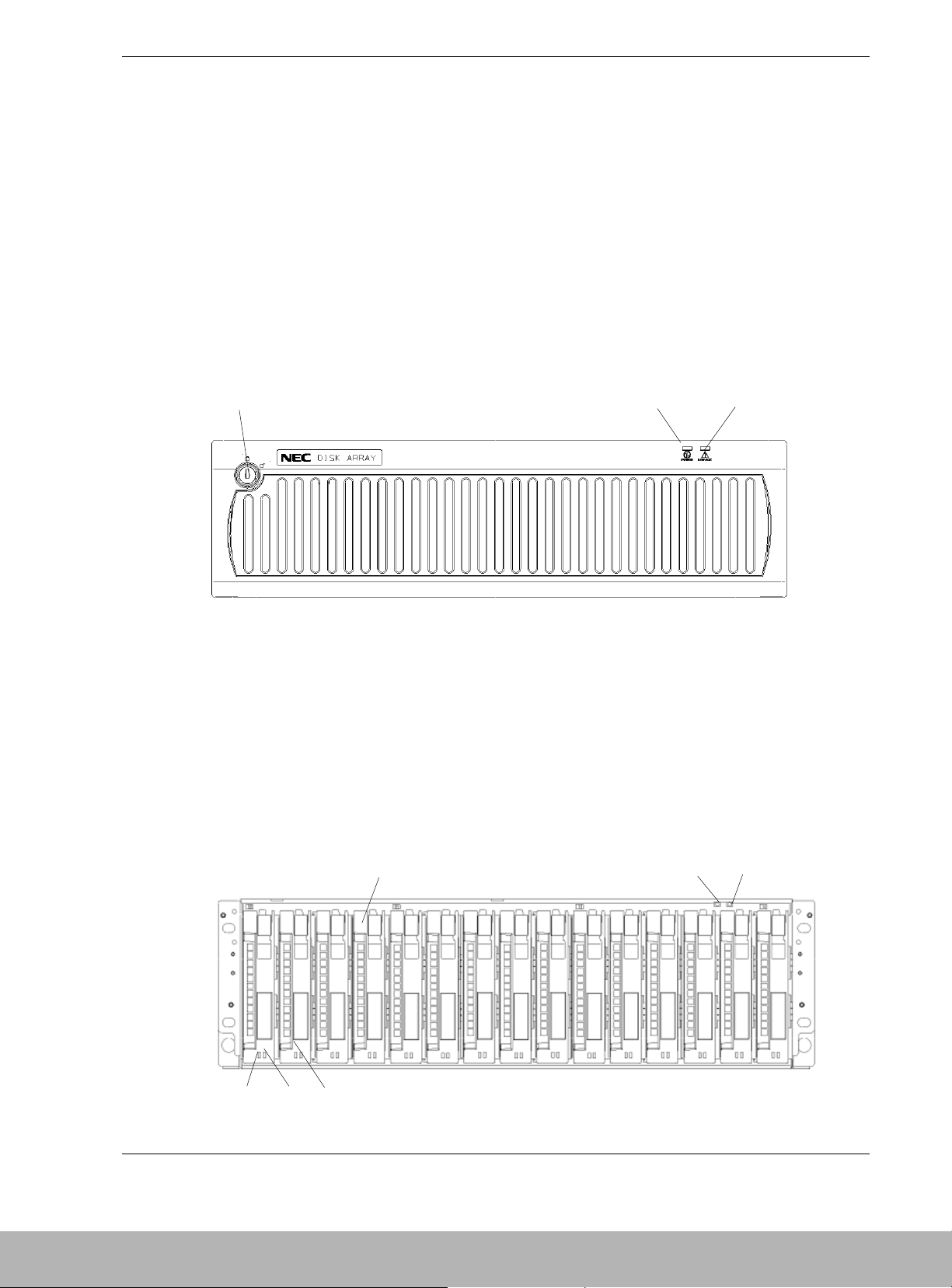

Front Panel

Figure 1-6 shows the front bezel and the indicators visible when the front bezel is

installed. The front bezel can be removed by releasing the lock with the accessory key.

Grasp the sides of the bezel and pull the bezel toward you. The power and service LEDs

are described in Figure 1-7.

A Security Lock

B Power LED (green)

C Service LED (Orange)

Figure 1-6. Front Chassis Features and Indicators (Bezel Installed)

Front Chassis Features and Indicators

Figure 1-7 shows the features and indicators located on the front of the DAU with the

front bezel removed. Disk modules are labeled 00 – 14 and are installed left to right.

00 01 02 03 04 05 06 07 08 09 10 11

12 13 14

A

B

C

C

A

B

D

E

F

Page 29

1-16 Disk Array Unit Overview

A Tray Ejector The ejector is used to secure and remove the disk module

or dummy tray to the chassis.

B POWER LED (green) The POWER LED lights green if the AC power is supplied

and the power switch is set to ON. The LED is off if the

power switch is set to OFF.

C SERVICE LED (orange) The SERVICE LED lights orange when the disk array unit

encounters an error. The LED flashes during the self-test

and initialization immediately after the power is turned on.

The LED goes off when the disk array unit has started, and

it is off while the disk array unit is operating normally.

D Disk module The dedicated tray containing the HDD (hard disk drive).

The disk modules are installed in three slots from the left

and bound as RAID level 5 (shipping default). The remaining

twelve slots contain dummy trays.

E HDD READY LED (green) The HDD READY LED lights green while the disk module

operates normally. The LED blinks when the disk module

transfers data.

The HDD READY LED blinks during the self-test or

initialization just after power-on.

F HDD FAUL T LED

(orange)

The HDD FAULT LED lights at the occurrence of an error in

the disk drive. The LED is off while the disk drive operates

normally.

Figure 1-7. Front Chassis Features and Indicators (Bezel Removed)

Page 30

Disk Array Unit Overview 1-17

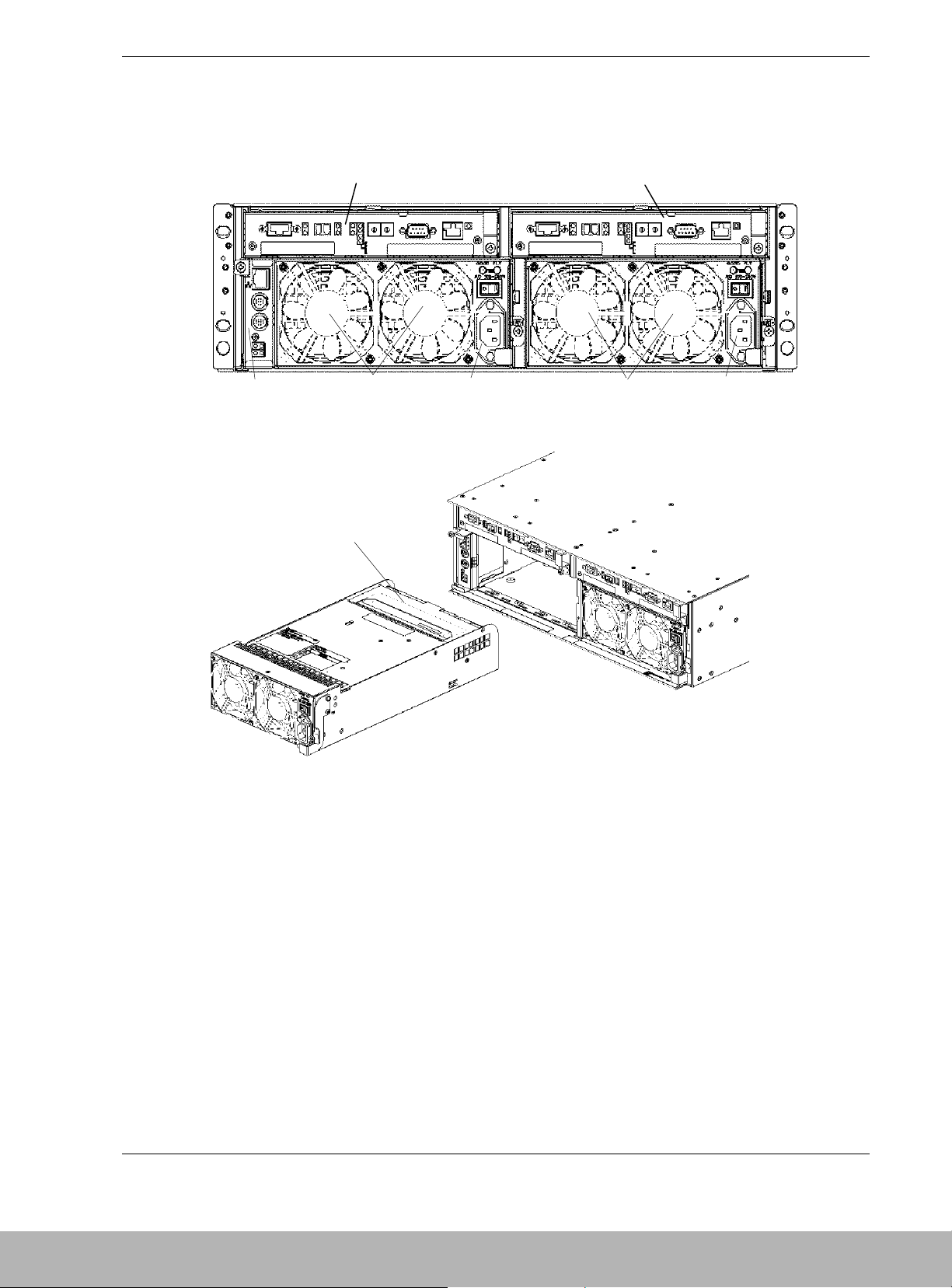

Rear Chassis Features

Figure 1-8 shows the features and indicators located on the rear of the DAU.

A Controller (CONT1)

B Controller (CONT0)

C Power Supply (PS0)

D Fans (FAN0)

E Power Supply (PS1)

F Fans (FAN1)

G Service Processor (SVP)

H Battery Backup Unit (PS1)

Figure 1-8. Rear Chassis Features

A

B

C

DE

F

G

H

Page 31

1-18 Disk Array Unit Overview

Power Supply

Figure 1-9 shows the features and indicators located on the rear of the power supply.

A Power Good LED (Green) The POWER GOOD LED lights green when the AC power is

supplied to the disk array unit and the power switch is set to

ON. The LED is off if the power switch is set to OFF or a

fault occurs in the power supply.

B Power Fault LED

(Orange)

The POWER FAULT LED lights if a fault occurs in the power

supply.

C Power Switch The power switch is used to turn the disk array unit power

on or off.

D Ejector The ejector is used to eject the power supply from the DAU

chassis.

E Power Plug The power plug supplies power to the disk array unit. Plug

in one end of the attached power cord to this plug and plug

the other end of the cord to the AC outlet of a voltage of

120VAC 50Hz or 60Hz. This disk array unit uses auto-sense

power supplies for 100V - 240VAC (50/60Hz) operation.

The power cord shipped with the DAU is for 100-120VAC. If

the disk array unit is used at a voltage other than 100120VAC, prepare the proper cord for the voltage and current

capacity for the unit.

F Stopper (power cord

retainer)

The stopper prevents the power cord from being removed

unexpectedly from the power supply.

Figure 1-9. Power Supply Features and Indicators

A

C

D

E

F

B

Page 32

Disk Array Unit Overview 1-19

DAU Controller

Figure 1-10 shows the features and indicators located on the rear of the DAU controller.

M

A L INKUP LED

(DE-LINK)

This LED lights green if the Disk Enclosure Fibre Channel (DE-FC)

connector (FC port) becomes operable (linked). This LED is off during

self-test or initialization, just after power-on.

B FC Connector Connection between fiber channel controller and the host (HOST-FC).

This connector is used to connect the disk array unit to the basic

processing unit (host).

C LINKUP LED

(HOST LINK)

This LED lights green while the FC interface with the host is operable.

D LINKUP LED

(DISK-LINK)

This LED lights green if the respective disk module becomes operable

(links up). This LED is off during the self-test or initialization, just after

power-on.

E AL-PA switch This switch sets the address of the disk array unit as a fiber channel

device in the fiber channel loop.

At shipment, the addresses of CONT0 and CONT1 are set to "00" and

"01," respectively. Set AL-PA so that the address may not be the same

as that of another fiber channel device in the same host FC loop.

F RS-232C

connector

The RS-232C connector is provided for maintenance of the disk array

unit.

G Ejector This device is used to install and remove the controller.

H DE-DIAG LED

(green)

The DE-DIAG LED lights green when the controller is ready for

diagnosis.

I DE-DIAG

connector

The DE-DIAG connector is provided to connect a cable to the Disk

Enclosure (DE) for diagnosing (monitoring) functions in the DE..

J1 FAULT LED

(orange)

The FAULT LED lights orange if a fault occurs in the controller.

A

C

D

EF

B

HG

I

J

K

4

2

1

3

M

N

L

Page 33

1-20 Disk Array Unit Overview

J2 BACKUP LED

(orange)

This LED, when lit, shows that the battery backup unit is charged and on

line to supply power to cache memory in the event of a power failure.

Replacing the controller, power supply, and/or battery backup unit while

the BACKUP LED is lit, loses the data in cache memory.

The battery backup unit supplies power to the cache memory for a

maximum of three days (72 hours in the full-charged condition). After

this time period, cache data may be lost.

J3 ACCESS LED

(green)

The ACCESS LED blinks while the controller is in operation.

J4 READY LED

(green)

The READY LED lights green while the controller operates normally.

The LED blinks during the self-test or initialization, just after power-on.

K L INKUP LED

(MATE-LINK)

This LED lights green if the other controller in the DAU becomes

operable (links up). This LED is off during the self-test or initialization,

just after power-on.

L HOST-2G LED The HOST-2G LED lights green while the FC interface with host is

operating at 2Gbps.

M DE 2G LED The DE 2G LED lights green while the FC interface with Disk Enclosure

is operating at 2Gbps.

N FC connector (for

connection with

disk enclosure)

(DE-FC)

This connector is used to connect the Disk Array unit to the Disk

Enclosure (DE).

Figure 1-10. Controller Features and Indicators

Page 34

Disk Array Unit Overview 1-21

Battery Backup Unit

Figure 1-11 shows the battery backup unit.

A Connector This connector is used to connect the battery backup unit with the power

supply.

Figure 1-11. Battery Backup Unit

A

Page 35

1-22 Disk Array Unit Overview

SVP Service Processor

Figure 1-12 shows the features and indicators located on the rear of the SVp service

processor.

A Ether

(10/100BASE-T)

connector

(Ethernet connector)

B UPS connector

(UPS0/UPS1

connector)

For the configuration in which the device receives AC power from UPS

(uninterruptible power supply), the signal cable connector is used to

connect the DAU with the UPS.

C CACHE FLUSH

switch

(pushbutton

switch)

This switch, when pushed, saves the cache data to the disk.

D FLT LED (FAULT

LED)

This LED, when lit, shows a fault occurred in the SVR.

When this LED flashes during the scheduled stop, the Write Back error

has occurred.

E CFL LED This LED, when lit, indicates that data is being saved from the cache to

the disk.

F RDY LED

(READY LED)

This LED, when lit, shows the service processor (SVR) is

operating in a normal state.

GLINK LED (TX/RX

LED)

This LED lights green when transmission/reception of data is being

transferred to and from a network.

Figure 1-12. SVP Service Processor

A

C

E

F

D

G

B

Page 36

Disk Array Unit Overview 1-23

Disk Enclosure Controller

Figure 1-13 shows the features and indicators located on the rear of the Disk Enclosure

controller.

ABC D E FGHI J K

RDY FLT

FC - OUT FC - IN

DIAG RDY

DIAG ID

PORT1

ENC ID

DE - DIAG

PORT0

A READY LED

(green)

The READY LED lights green while the controller operates normally.

The LED blinks during the self-test or initialization, just after power-on.

B FAULT LED

(orange)

The FAULT LED lights orange if a fault occurs in the controller.

CFC-OUT

LINKUP LED

(2

nd

DE LINK)

This LED lights green indicating the FC interface with a second DE is

operable. A second DE is not currently available with the S1300 DAU.

D FC connector (for

connection with a

2nd DE)

This connector is used to connect the Disk Enclosure (DE) with a

second DE. A second DE is not currently available with the S1300 DAU.

E FC connector (for

connection with

Disk Array Unit)

This connector is used to connect the Disk Enclosure (DE) with the Disk

Array Unit.

FFC-IN

LINKUP LED

(DAU LINK)

This LED lights green indicating the FC interface with the DAU is

operable.

G ENC ID Switch This switch sets the ID address of the DE Controller. This switch must

be set to 1 in the DE.

H DE-DIAG LED

(green)

The DE-DIAG LED lights green when the controller has a valid

diagnostic connection to the DAU.

I DIAG ID Switches The four DIP switches are set to OFF (down) for the first DE.

J DE-DIAG

connector

The DE-DIAG connector is provided to connect a cable to a second DE

for diagnosing (monitoring) functions in the second DE. A second DE is

not currently available with the S1300 DAU.

KDAU-DIAG

connector

The DAU-DIAG connector is provided to connect a cable to the DAU for

diagnosing (monitoring) functions in the DE.

Figure 1-13. Disk Enclosure Controller Features and Indicators

Page 37

Page 38

2

Setting Up The DAU

! Overview

! Selecting a Site

! Unpacking the DAU and Rack Mounting Hardware

! Rack-Mount Subsystem Assembly

! Connecting Disk Array Unit

! Connecting the Power Cords

! Connecting the DAU to Uninterruptible Power

Supplies

! Powering On/Off

! Scheduled Stop Procedure

Page 39

2-2 Setting Up The DAU

Overview

This chapter describes how to select a site, unpack the DAU and provides you

with assembly information for preparing and mounting the DAU into a system

rack. Also described are DAU to host cabling configurations, connecting the

power cord(s), powering On/Off the DAU, and configuring the Fibre Channel

address switches.

Selecting a Site

The DAU operates reliably in a typical office environment.

Choose a site that is:

! Near grounded, three-pronged power outlets.

Note: For the United States and Canada, this means a

NEMA 5-15R outlets for 100-120 VAC or NEMA 6-15R

outlets for 200-240 VAC. For other international sites, this

means three-pronged power outlets applicable for the

electrical code of the region.

!

WARNING

Be sure the power service connection is through a properly

grounded outlet.

!

CAUTION

Be sure that the power plug from each of the power supplies

is plugged into the same common ground power outlets.

! Clean, dust-free, and well ventilated. Front and rear ventilating openings

kept free of obstructions. Away from sources of heat, vibration or

physical shock.

! Isolated from strong electromagnetic fields and electrical noise produced

by electrical devices (such as air conditioners, large fans, large electric

motors, radio and TV transmitters, and high-frequency security devices)

! Spacious enough to provide at least five inches (13 centimeters) behind

the DAU and three inches (eight centimeters) on each side of the DAU

for proper cooling, airflow, and cable clearance.

Note: Provide an additional five inches (13 centimeters)

behind the DAU to facilitate changing the self-contained hotswap power supply unit.

Page 40

Setting Up The DAU 2-3

! Easily accessible for DAU maintenance and installation of DAU

upgrades.

Unpacking the DAU and Rack Mounting

Hardware

!

WARNING

The DAU weighs approximately 80 lbs (36 kg). If the DAU

contains numerous optional devices and rack mount parts, it

will weigh more. To avoid personal injury, make sure you

have someone help you lift or move the DAU.

Although the DAU and rack mount kit are inspected and carefully packaged at

the factory, damage may occur during shipping. Follow these steps for

unpacking.

1. Visually inspect the shipping containers; notify your carrier immediately of

any damage.

2. Place the DAU shipping container on a flat, clean, stable surface. Carefully

remove the DAU and set it aside. If the DAU is damaged, notify your server

representative. See Figure 2-1, A.

3. Carefully remove the parts in the Accessories Kit and verify the contents.

See Figure 2-1, B through I and Table 2-1. If parts are missing or the

hardware is damaged, notify your server representative.

4. Save the containers and packing materials for any future reshipment.

Page 41

2-4 Setting Up The DAU

Figure 2-1. DAU and Rack Mount Kit Parts

B

D

C

A

F

G

H

I

E

Page 42

Setting Up The DAU 2-5

Table 2-1. DAU and Rack Mount Parts

Reference Description Reference Description

A Disk Array Unit (DAU) F User's Guide (located on CDROM)

B Left Rail Support Hook G Power Cords (2)

C Left Rail H Countersunk Head Screws (4)

D Right Rail Support Hook I M5 Screws (4)

E Right Rail

Rack-Mount Subsystem Assembly

Before You Begin

Before you begin, please review the following cautions, warnings, and general

guidelines.

! Avoid excessive vibration and shock. Dropping an electronic component

can cause serious damage.

! Do not disconnect or remove parts other than those specified in the

procedure.

! Do not touch I/O connector pins.

! All screws are Phillips-head, unless otherwise specified.

Static Precautions

An electrostatic discharge (ESD) can damage disk drives, option boards, and

other components. You can provide some ESD protection by wearing an

antistatic wrist strap attached to chassis ground when handling DAU

components.

Electronic devices can be easily damaged by static electricity. To prevent

damage, keep them in their protective packaging when they are not installed in

the DAU.

Page 43

2-6 Setting Up The DAU

Installing the Rails

Note: In the following procedure the left rail is shown as

viewed from the front of the rack. Right rail installation

procedures also apply to installing the right rail.

1. Rail support hooks are marked (L) for the left hook and (R) for right hook.

With the left rail support hook (L) facing towards the inside of the cabinet,

hang the top tab of the rail support hook on the square hole of the rack front

rail to which the DAU will be mounted. Be sure the counter-sunk holes in

the rail support hook are centered within the square holes of the rack front

vertical rail. Also, the hook projections on the rail support hooks should be

facing upwards. See Figure 2-2.

Figure 2-2. Positioning the Left Rail Support Hook

Rail support hook (L)

Hook

projections are

facing upwards

Top tab

Page 44

Setting Up The DAU 2-7

2. While holding the left rail hook in position with your left hand, engage the

cutout at the front of the left rail into the rail support hooks protruding

through the cabinet vertical rail. The front of the left rail should be

positioned behind the cabinet front vertical rail and resting on the two left

rail hooks. See Figure 2-3.

Figure 2-3. Positioning the Left Rail

3. Secure the left rail to the rail support hook with two countersunk head

screws. See Figure 2-4.

Figure 2-4. Securing the Left Rail

Countersunk

head screws

Cutout of rail

Page 45

2-8 Setting Up The DAU

4. At the rear of the rack, slightly loosen the four countersunk head screws in

the side of the left rail. These screws must not be removed. See Figure 2-5.

Figure 2-5. Tightening the Countersunk Head Screws

5. Pull the inner rail toward you and engage the upper and lower rail tabs into

the rectangle holes. While holding the inner rail, screw the mounting bolts

(M5 bolts) into the threads of the inner rail. See Figure 2-6.

Figure 2-6. Securing the Inner Rail

Mounting bolt

Rail inner

Countersunk

head screws (4)

Page 46

Setting Up The DAU 2-9

6. Firmly tighten the four countersunk head screws loosened in Step 4.

See Figure 2-7.

Figure 2-7. Tightening the Countersunk Head Screws

7. Repeat steps 1 through 6 and install the right rail.

Installing the DAU into the System Rack

!

WARNING

To reduce the risk of personal injury or damage to the

equipment, a minimum of two people MUST lift the DAU into

the rack. The DAU weighs 80 lbs (36 kilograms). If the unit is

to be loaded above chest level, a third person must assist in

aligning the rails while the other two support the unit.

1. With one person grasping each side of the DAU, carefully align the DAU to

the rack’s slide rails and slide the DAU into the rack.

2. Secure the DAU to the system rack with two M5 screws. See Figure 2-8.

Countersunk

head screw

Page 47

2-10 Setting Up The DAU

Figure 2-8. Securing the DAU to the System rack

Connecting Disk Array Unit

The following sections provide information for connecting the DAU to the Host

server and the optional disk enclosure. Figure 2-9 show a typical DAU

installation and includes cabling for the optional disk enclosure.

Host Connection

1. Connect the disk array unit with the host using the two supplied

FibreChannel cables. Push the connector at either end of the cable into the

FC connector (HOST-FC) of the disk array controller (CONT0) until a click

is heard. The FC cable has the same connectors at both ends. Either

connector may be connected to the controller. See Figure 2-9.

2. Connect the other end of the FibreChannel cable to the connector of

FibreChannel controller installed in the host system. Connect the second

FibreChannel cable between the second disk array controller (CONT1) and

the host system.

Disk Enclosure Connection

1. Connect either end of the HSSDC-HSSDC cable into the DE-FC connector

(CONT0) on the disk array unit until a click is heard. The HSSDC-HSSDC

cable has the same connectors at both ends. Either connector may be

connected to the controller. Connect the other end of the HSSDC-HSSDC

cable into the FC-IN connector on adapter 0 (ADP0) of the disk enclosure

until a click is heard. See Figure 2-9.

2. Similarly, connect the second HSSDC-HSSDC cable into DE-FC connector

(CONT1) on the disk array unit until a click is heard. Connect the other end

of this HSSDC-HSSDC cable into the FC-IN connector on adapter 1

(ADP1) of the disk enclosure until a click is heard.

Page 48

Setting Up The DAU 2-11

3. Connect either end of the DE diagnosis cable into the DE-DIAG connector

of the controller (CONT0) until a click is heard. The DE diagnosis cable

also has the same connectors at both ends. Either connector may be

connected to the controller. Connect the other end of the DE diagnosis cable

into the PORT0 connector on adapter 0 (ADP0) of the disk enclosure until a

click is heard. See Figure 2-9.

4. Similarly connect either end of the second DE diagnosis cable into the DE-

DIAG connector of the controller (CONT1) until a click is heard. Connect

the other end of the DE diagnosis cable into the PORT1 connector on

adapter 1 (ADP1) of the disk enclosure until a click is heard.

Figure 2-9. Connecting the Disk Array Unit

Connecting the Ethernet Cable

To enable configuration changes and fault monitoring for the disk array unit by

the management software "NEC Storage Manager" through Ethernet, the LAN

cable must be connected.

Connect an Ethernet cable to the Ethernet connector (modular jack) on the LAN

card.

Connect the host system on which the management software "NEC Storage

Manager" is installed.

Contact your service provider to configure the LAN address.

HSSDC-HSSDC cables

DE diagnosis cables

FibreChannel cables

DAU

Disk

Enclosure

Host

Page 49

2-12 Setting Up The DAU

Connection Notes

Connection Cable

To connect the host bus adapter of the host system or the FC-AL switch with the

disk array unit, be sure to use the NEC-specified FC cable.

To connect the disk array unit with the additional disk enclosure, be sure to use

the DE cable provided with the additional disk enclosure, or the NEC-specified

DE cable.

Cable Length Limitations

FC optical cable for operating the host interface at 1Gbps: Up to [500 m]

FC optical cable for operating the host interface at 2Gbps: Up to [300 m]

Settings Topology and Data Transfer Rate

A topology and data transfer rate must be set correctly in accordance with the

host bus adapter to be connected or the connection mode of the FC-AL switch.

Factory-set topology and data transfer rate:

Topology: FC-AL Data transfer rate: 2Gbps

You can change the topology and data transfer rate of the FC connector for the

host bus adapter by changing the DIP switch settings on the controller. Refer to

Appendix A in this guide.

Setting DAU and Disk Enclosure Switches

Note: The controller IDs of disk array unit (CONT0 or

CONT1) must correspond to that of and that of disk

enclosure (CONT0 or CONT1).

The AL-PA switch sets the address of the disk array unit as a fiber channel

device in the fiber channel loop. At shipment, the addresses of DAU controllers

CONT0 and CONT1 are set to "00" and "01," respectively. Set the AL-PA so

that the address is not the same as that of another fiber channel device in the

same host FC loop. See Figure 1-10, E for the location of the controller AL-PA

switch. Refer to Appendix A for additional AL-PA switch settings.

The Enclosure ID (ENC ID) switch on each adapter of the additional disk

enclosure are factory-set to "1". See Figure 1-13, H. Make sure both ENC ID

switches are set to "1".

The DIAG ID switches on both adapters of the additional disk enclosure are

factory-set to "0". Make sure that both DE-DIAG ID switches are set to "0". See

Figure 1-13, J.

DE-DIAG ID = "0"

4 3 2 1ON

Page 50

Setting Up The DAU 2-13

Connecting the Power Cords

The DAU contains two 450-watt power supplies. The power supplies are

designed for automatic sensing of 115 or 230 VAC power, eliminating the need

for a line voltage selector switch. The power supplies operate at a frequency of

50/60 Hz. With two power supplies installed, if one fails, the second power

supply will ensure the DAU continues to operate without interruption.

Connect each power cord as follows.

1. Check that the power switch on the disk array unit and those on the host

system, host bus adapter, and FC-AL switch are all set to OFF.

See Figure 2-10.

OFF ON

Figure 2-10. Power Supply Switch

2. Insert the power cord into the power plug on the power supply, and secure

the power cord with stopper. See Figure 2-11. Repeat this step on the second

power supply.

Figure 2-11. Connecting the Power Cord to the Power Supply

3. Plug the male end of the power cords into NEMA 5-15R outlet for 100-120

VAC or NEMA 6-15R outlet for 200-240 VAC.

Page 51

2-14 Setting Up The DAU

If the power cords supplied with the DAU are not compatible with the AC

outlet in the region, obtain a suitable power cord that meets the following

criteria.

! The power cord must be rated for the available AC voltage and have a

current rating that is at least 125% of the current rating of the DAU.

! The power cord connector that plugs into the wall outlet must be

terminated in a grounding-type male plug designed for use in the region.

It must have certification marks showing certification by an agency

acceptable in the region.

! The power cord connector that plugs into the DAU must be an IEC- type

CEE-22 female connector.

! The power cord must be less than 1.8 meters (6.0 feet) long.

!

WARNING

The DAU shipped with a power cord for each power supply.

Do not attempt to modify or use the supplied AC power cord

if it is not the exact type required.

Page 52

Setting Up The DAU 2-15

Connecting the DAU to Uninterruptible Power

Supplies

Figure 2-12 shows the connection of a DAU to uninterruptible power supplies

(UPS). When the DAU is connected to a UPS, the system continues to operate

in the event of an unexpected power failure or momentary AC power

fluctuation.

Disk Array Unit

OUTPUT 1

OUTPUT 2

AC POWER

Straight cable

AC POWER

OUTPUT 1

OUTPUT 2

Figure 2-12. Connection the DAU to a UPS

To power

board

To power

board

Page 53

2-16 Setting Up The DAU

Cable Dressing

All the interface and power cables connected to the rear of the DAU should be

dressed and tie wrapped. Use special care not to kink or sharply bend the Fibre

Channel cables as they are easily damaged.

Route the cables so that they do not contact the door and guide rails on both

sides of the system rack. Also, ensure that there is some slack on all the cables

and especially the power cord to prevent it from being disconnected from the

DAU when the unit is pulled forward in the rack.

Powering On/Off

This section describes the sequence of steps for powering the disk array unit on

or off.

!

CAUTION

Carelessly turning power on or off may cause some data to

be lost, some software to operate incorrectly, or cause

damage to the unit.

Turning On AC Power

Note: Before turning on the AC power, check for loose

disk modules by ensuring each module is fully seated into

the disk bay.

1. Turn on the disk enclosure connected with the disk array controller (if

applicable), before turning on the disk array unit.

2. Turn on the power switches located on the rear panel of each power supply.

3. Confirm that the POWER LED (green) on the front panel of the DAU is on.

See Figure 1-7. Also check that the POWER LED located on each power

supply on. See Figure 1-9.

4. The disk array unit performs a self-test and initialization immediately after

the power is turned on. When the self-test and initialization complete and

the disk array unit become ready, the READY LEDs (green) on the

controllers in the disk array unit stop flashing and enter the on-state.

Confirm that the controller READY LEDs are on. See Figure 1-10, J4 for

the location of the controller LEDs.

Note: The disk array unit may take as long as four

minutes (at maximum) to start.

• Power on the host system.

Page 54

Setting Up The DAU 2-17

Turning Off AC power

1. Power off the host system.

The host writes cache data to the disk array unit.

2. Confirm that the cache data from the host is successfully written into the

disk array unit. To do this, check the DISK ACCESS LEDs located on the

rear panel of each controller. If the DISK ACCESS LEDs are flashing, data

remains in cache memory of disk array unit. Writing cache data onto disk

could take as long as 5 minutes. See Figure 1-10, J3 for the location of the

DISK ACCESS LED.

3. Turn off the AC power to the DAU. A power switch is located on the rear

panel of each power supply. See Figure 1-9.

!

CAUTION

When the DAU power is turned off before the cache data is

written to disk, the BACKUP LED on the controller is lit and

the disk array unit enters the backup mode. If the backup

mode lasts for more than three days (in the full-charged

condition), the cache data may be lost. Therefore, if the

BACKUP LED is lit, immediately turn on the disk array unit.

Since the data write is an automatic process, check the data

is completely written to the disk and then turn off the power.

4. Turn off AC power to the disk enclosure (if installed).

!

CAUTION

Turn off the power of host system, disk array unit, and disk

enclosure in that order. Turning off the power of disk

enclosure first may lose the data.

Page 55

2-18 Setting Up The DAU

Scheduled Stop Procedure

Perform the following procedure to be absolutely sure that cache data has been

completely written to disk before you power off the DAU.

1. Power off the host system.

The host writes cache data to the disk array unit.

2. Press and hold the CACHE FLUSH pushbutton (scheduled stop switch)

located on the SVP Service Processor until the CFL LED flashes or is

continuously lit (for at least two seconds). See Figure 1-12 for the location

of the CACHE FLUSH pushbutton and the CFL LED.

3. Release the CACHE FLUSH pushbutton when the CFL LED starts to flash

or is continuously lit. The CFL LED continually flashes as data is being

transferred from the cache to the disk.

4. Before turning off the disk array unit, make sure that the CFL LED is