Page 1

NAD

SERVICE MANUAL

C 445

CFM / AM

C 445

FM / AM

DAB TUNER

DAB TUNER

Page 2

PRODUCT SAFETY SERVICING GUIDELINES

CAUTION : DO NOT ATTEMPT TO MODIFY THIS PRODUCT IN

ANY WAY. NEVER PERFORM CUSTOMIZED INSTALLATIONS

WITHOUT MANUFACTURER’S APPROVAL. UNAUTHORIZED

MODIFICATIONS WILL NOT ONLY VOID THE WARRANTY, BUT

MAY LEAD TO YOUR BEING LIABLE FOR ANY RESULTING

PROPERTY DAMAGE OR USER INJURY.

SERVICE WORK SHOULD BE PERFORMED ONLY AFTER YOU

ARE THOROUGHLY FAMILIAR WITH ALL OF THE FOLLOWING

SAFETY CHECKS AND SERVICING GUIDELINES. TO DO

OTHERWISE, INCREASES THE RISK OF POTENTIAL HAZARDS

AND INJURY TO THE USER.

WHILE SERVICING, USE AN ISOLATION TRANSFORMER FOR

PROTECTION FROM AC LINE SHOCK.

SAFETY CHECKS

AFTER THE ORIGINAL SERVICE PROBLEM HAS BEEN

CORRECTED. A CHECK SHOULD BE MADE OF THE

FOLLOWING.

SUBJECT : FIRE & SHOCK HAZARD

1. BE SURE THAT ALL COMPONENTS ARE POSITIONED IN

SUCH A WAY AS TO AVOID POSSIBILITY OF ADJACENT

COMPONENT SHORTS. THIS IS ESPECIALLY IMPORTANT

ON THOSE MODULES WHICH ARE TRANSPORTED TO AND

FROM THE REPAIR SHOP.

2. NEVER RELEASE A REPAIR UNLESS ALL PROTECTIVE

DEVICES SUCH AS INSULATORS, BARRIERS, COVERS,

SHIELDS, STRAIN RELIEFS, POWER SUPPLY CORDS, AND

OTHER HARDWARE HAVE BEEN REINSTALLED PER

ORIGINAL DESIGN. BE SURE THAT THE SAFETY PURPOSE

OF THE POLARIZED LINE PLUG HAS NOT BEEN DEFEATED.

3. SOLDERING MUST BE INSPECTED TO DISCOVER POSSIBLE

COLD SOLDER JOINTS, SOLDER SPLASHES OR SHARP

SOLDER POINTS. BE CERTAIN TO REMOVE ALL LOOSE

FOREIGN PARTICLES.

4. CHECK FOR PHYSICAL EVIDENCE OF DAMAGE OR

DETERIORATION TO PARTS AND COMPONENTS. FOR

FRAYED LEADS, DAMAGED INSULATION (INCLUDING AC

CORD). AND REPLACE IF NECESSARY FOLLOW ORIGINAL

LAYOUT, LEAD LENGTH AND DRESS.

5. NO LEAD OR COMPONENT SHOULD TOUCH A RECEIVING

TUBE OR A RESISTOR RATED AT 1 WATT OR MORE. LEAD

TENSION AROUND PROTRUDING METAL SURFACES MUST

BE AVOIDED.

6. ALL CRITICAL COMPONENTS SUCH AS FUSES,

FLAMEPROOF RESISTORS, CAPACITORS, ETC. MUST BE

REPLACED WITH EXACT FACTORY TYPES, DO NOT USE

REPLACEMENT COMPONENTS OTHER THAN THOSE

SPECIFIED OR MAKE UNRECOMMENDED CIRCUIT

MODIFICATIONS.

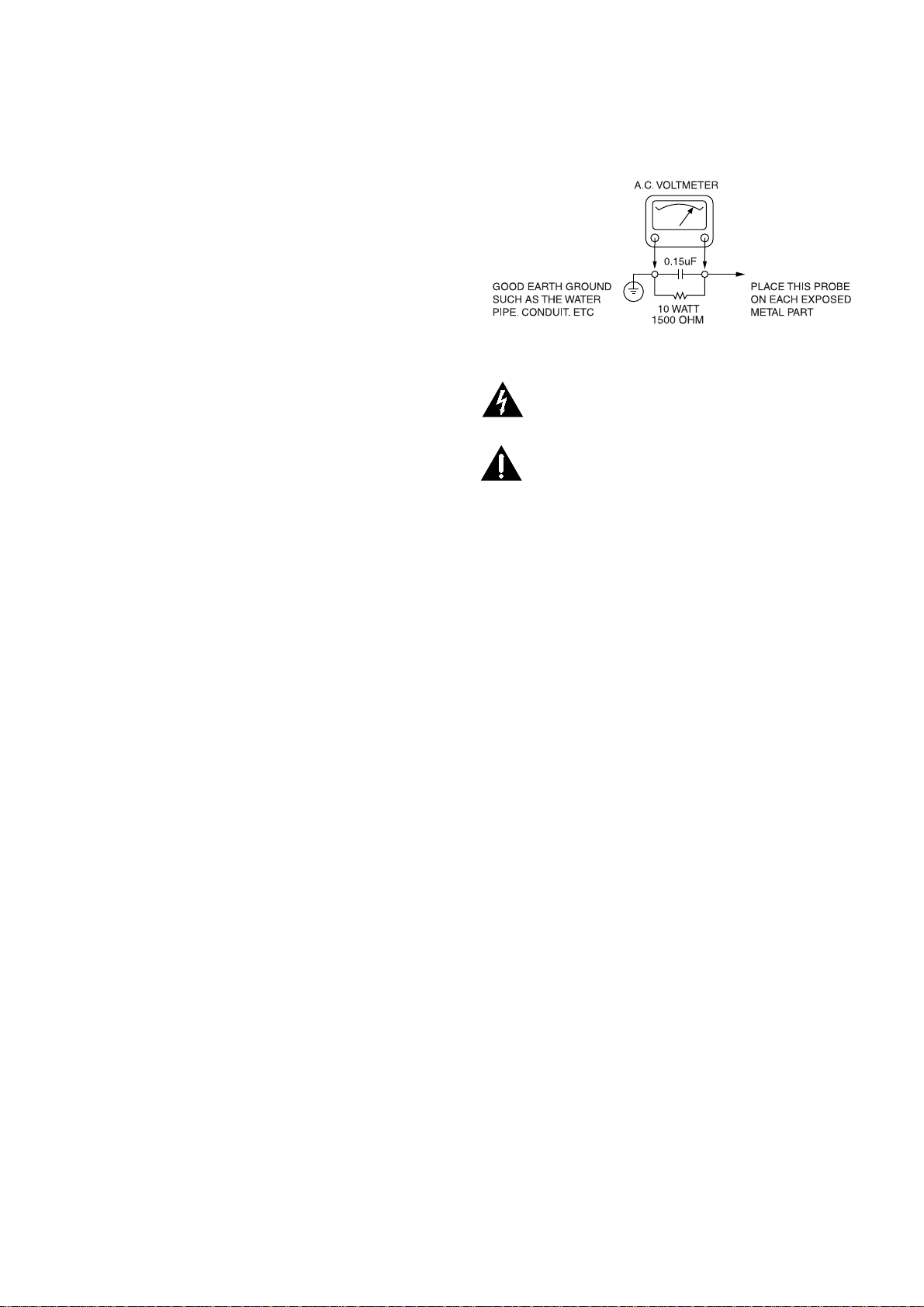

7. AFTER RE-ASSEMBLY OF THE SET ALWAYS PERFORM AN

AC LEAKAGE TEST ON ALL EXPOSED METALLIC PARTS OF

THE CABINET, (THE CHANNEL SELECTOR KNOB, ANTENNA

TERMINALS. HANDLE AND SCREWS) TO BE SURE THE SET

IS SAFET TO OPERATE WITHOUT DANGER OF ELECTRICAL

SHOCK. DO NOT USE A LINE ISOLATION TRANSFORMER

DURING THIS TEST USE AN AC VOLTMETER, HAVING 5000

OHMS PER VOLT OR MORE SENSITIVITY, IN THE

FOLLOWING MANNER; CONNECT A 1500 OHM 10 WATT

RESISTOR, PARALLELED BY A .15 MFD, 150V AC TYPE

CAPACITOR BETWEEN A KNOWN GOOD EARTH GROUND

(WATER PIPE, CONDUIT, ETC.) AND THE EXPOSED

METALLIC PARTS, ONE AT A TIME.

MEASURE THE AC VOLTAGE ACROSS THE COMBINATION

OF 1500 OHM RESISTOR AND .15 MFD CAPACITOR.

REVERSE THE AC PLUG AND REPEAT AC VOLTAGE

MEASUREMENTS FOR EACH EXPOSED METALLIC PART.

VOLTAGE MEASURE MUST NOT EXCEED 75 VOLTS R.M.S.

THIS CORRESPONDS TO 0.5 MILLIAMP AC ANY VALUE

EXCEEDING THIS LIMIT CONSTITUTES A POTENTIAL

SHOCK HAZARD AND MUST BE CORRECTED IMMEDIATELY.

SUBJECT : GRAPHIC SYMBOLS

SUBJECT : TIPS ON PROPER INST ALLATION

1. NEVER INSTALL ANY PRODUCT IN A CLOSED-IN RECESS,

CUBBYHOLE OR CLOSELY FITTING SHELF SPACE. OVER

OR CLOSE TO HEAT DUCT, OR IN THE PATH OF HEATED

AIR FLOW.

2. AVOID CONDITIONS OF HIGH HUMIDITY SUCH AS:

OUTDOOR PATIO INSTALLATIONS WHERE DEW IS A

FACTOR, NEAR STEAM RADIATORS WHERE STEAM

LEAKAGE IS A FACTOR, ETC.

3. AVOID PLACEMENT WHERE DRAPERIES MAY OBSTRUCT

REAR VENTING. THE CUSTOMER SHOULD ALSO AVOID THE

USE OF DECORATIVE SCARVES OR OTHER COVERINGS

WHICH MIGHT OBSTRUCT VENTILATION.

4. WALL AND SHELF MOUNTED INSTALLATIONS USING A

COMMERCAL MOUNTING KIT MUST FOLLOW THE FACTORY

APPROVED MOUNTING INSTRUCTIONS A PRODUCT

MOUNTED TO A SHELF OR PLATFORM MUST RETAIN ITS

ORIGINAL FEET (OR THE EQUIVALENT THICKNESS IN

SPACERS) TO PROVIDE ADEQUATE AIR FLOW ACROSS

THE BOTTOM, BOLTS OR SCREWS USED FOR FASTENERS

MUST NOT TOUCH ANY PARTS OR WIRING. PERFORM

LEAKAGE TEST ON CUSTOMIZED INSTALLATIONS.

5. CAUTION CUSTOMERS AGAINST THE MOUNTING OF A

PRODUCT ON SLOPING SHELF OR A TILTED POSITION,

UNLESS THE PRODUCT IS PROPERLY SECURED.

6. A PRODUCT ON A ROLL-ABOUT CART SHOULD BE STABLE

ON ITS MOUNTING TO THE CART. CAUTION THE

CUSTOMER ON THE HAZARDS OF TRYING TO ROLL A CART

WITH SMALL CASTERS ACROSS THRESHOLDS OR DEEP

PILE CARPETS.

7. CAUTION CUSTOMERS AGAINST THE USE OF A CART OR

STAND WHICH HAS NOT BEEN LISTED BY UNDERWRITERS

LABORATORIES, INC. FOR USE WITH THEIR SPECIFIC

MODEL OF TELEVISION RECEIVER OR GENERICALLY

APPROVED FOR USE WITH T.V.’S OF THE SAME OR

LARGER SCREEN SIZE.

8. CAUTION CUSTOMERS AGAINST THE USE OF EXTENSION

CORDS, EXPLAIN THAT A FOREST OF EXTENSIONS

SPROUTING FROM A SINGLE OUTLET CAN LEAD TO

DISASTROUS CONSEQUENCES TO HOME AND FAMILY.

THE LIGHTNING FLASH WITH ARROWHEAD SYMBOL, WITHIN AN

EQUILATERAL TRIANGLE, IS INTENDED TO ALERT THE USER TO THE

PRESENCE OF UNINSULATED “DANGEROUS VOLTAGE” WITHIN THE

PRODUCT’S ENCLOSURE THAT MAY BE OF SUFFICIENT MAGNITUDE TO

CONSTITUTE A RISK OF ELECTRIC SHOCK.

THE EXCLAMATION POINT WITHIN AN EQUILATERAL TRIANGLE IS

INTENDED TO ALERT THE USER TO THE PRESENCE OF IMPORTANT

OPERATING AND MAINTENANCE (SERVICING) INSTRUCTIONS IN THE

LITERATURE ACCOMPANYING THE APPLIANCE.

Page 2 of 28

Page 3

Page 3 of 28

Page 4

SPECIFICATIONS

Page 4 of 28

FM SECTION

Frequency Range: 87.50 MHz to 108.00 MHz

(50 kHz steps)

Signal-to-Noise Ratio: 65dB (Mono) 60dB (Stereo)

Presets: 30

AM SECTION

Frequency Range: 522 kHz to 1620 kHz (9 kHz steps)

Signal-to-Noise Ratio: 35dB

Presets:

DAB SECTION

Band lll: 174MHz - 240MHz

Band L : 1452MHz - 1492MHz

Max signal: ~ -3dBm

Sensitivity: -96dBm

Adjacent Channel Rejection: ~ 35dB

Presets:

30

~

99

Display: 2-line by 16-character DOT Matrix

Audio Output Stereo: 2.5V P-P

48kHz sample rate, 16 bit sample resolution

Optical S/PDIF: IEC60958 Compliant.

48kHz sample rate, 24 bit sample resolution

GENERAL

Power Requirement: 230-240V AC, 50Hz

Power Consumption: 12W 0.8W(standby)

DIMENSIONS (MAX)

Width Height Depth: 435 x 86 x 318mm

Weight:

6kg

Page 5

TROUBLESHOOTING

Page 5 of 28

This unit is designed for trouble-free operation. Most problems users encounter are due to operating errors. If you have a problem, first check this list

for a possible solution. If the problem persists, consult your authorized Service Centre.

Symptom Cause/Correction

No lights appear when System Power button is pressed Unit is plugged into a live outlet.

No sound is heard Tune to an active station.

Sound distorts, particularly in stereo mode. Use a more directional antenna.

Intermittent or continuous buzzing or hissing Place the unit further away from these appliances.

Display says 'No stations Available' Check that antenna is connected.

Display has gone blank or says 'service off air' This may occur if a broadcaster changes the label of a service or removes a label

Unit's operation or the displays seem abnormal To correct this problem, first unplug the unit from the AC wall outlet and wait at

Make sure the outlet is active.

Check for correct amplifier settings.

Check the connections and wires.

Install noise filters on the appliances.

Ensure that DAB coverage exists in your area.

whilst you are listening to it. Try to retune to this station, using the Autotune

procedure.

least three minutes. After the pause, reconnect the AC power cord and check the

unit's operation.

Reset the C445 Tuner; press and hold the Menu/FM Mute Button for 5 seconds,

until the Information Display shows FACTORY RESET. Note that when the system

is reset, all tuner presets will be lost and must be re-entered.

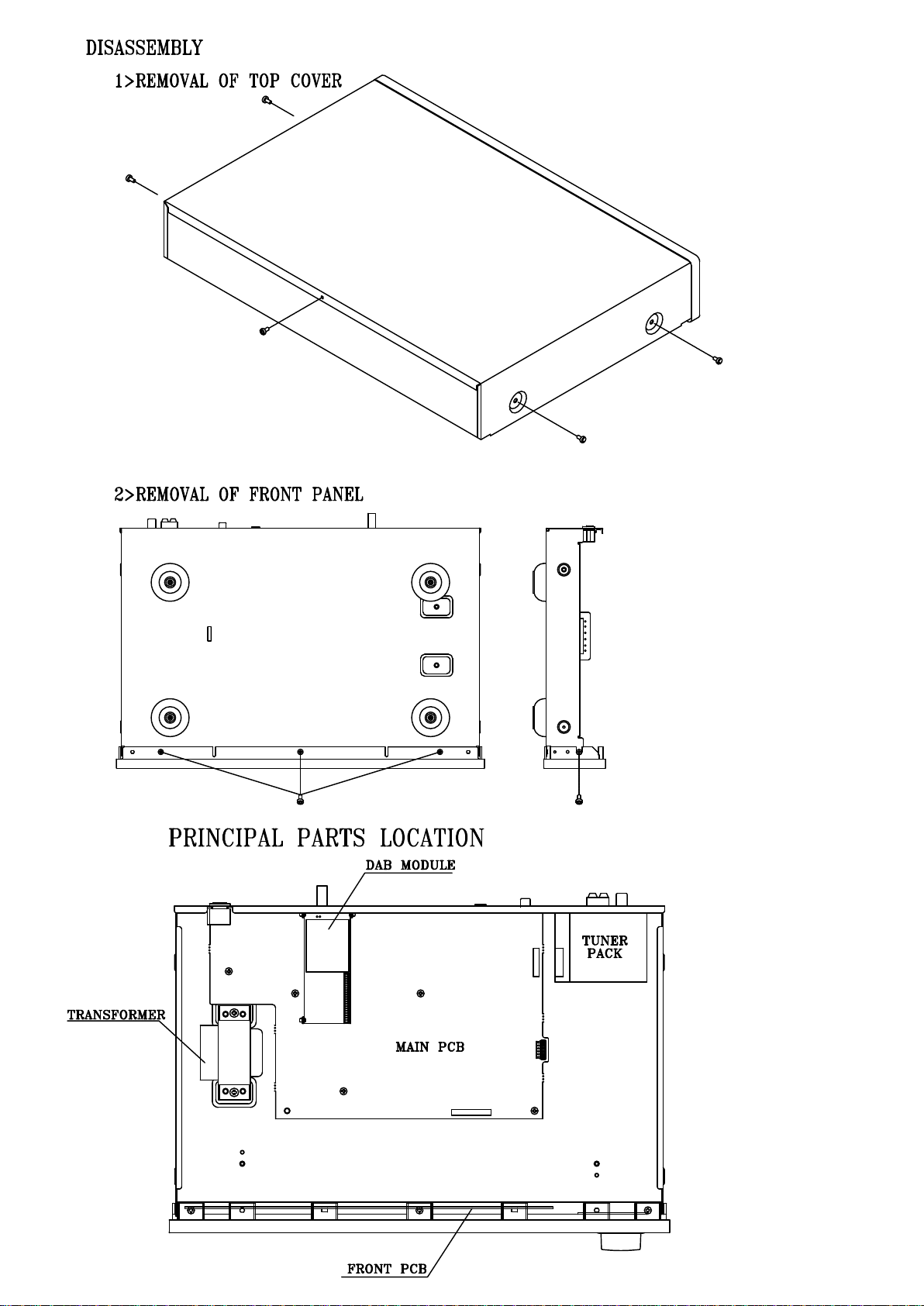

Press the RESET switch lightly once or twice with a pencil or ballpoint pen as per

example below.

If these steps do not solve the problem, consult your dealer or an authorized

service centre.

Rear Panel

Page 6

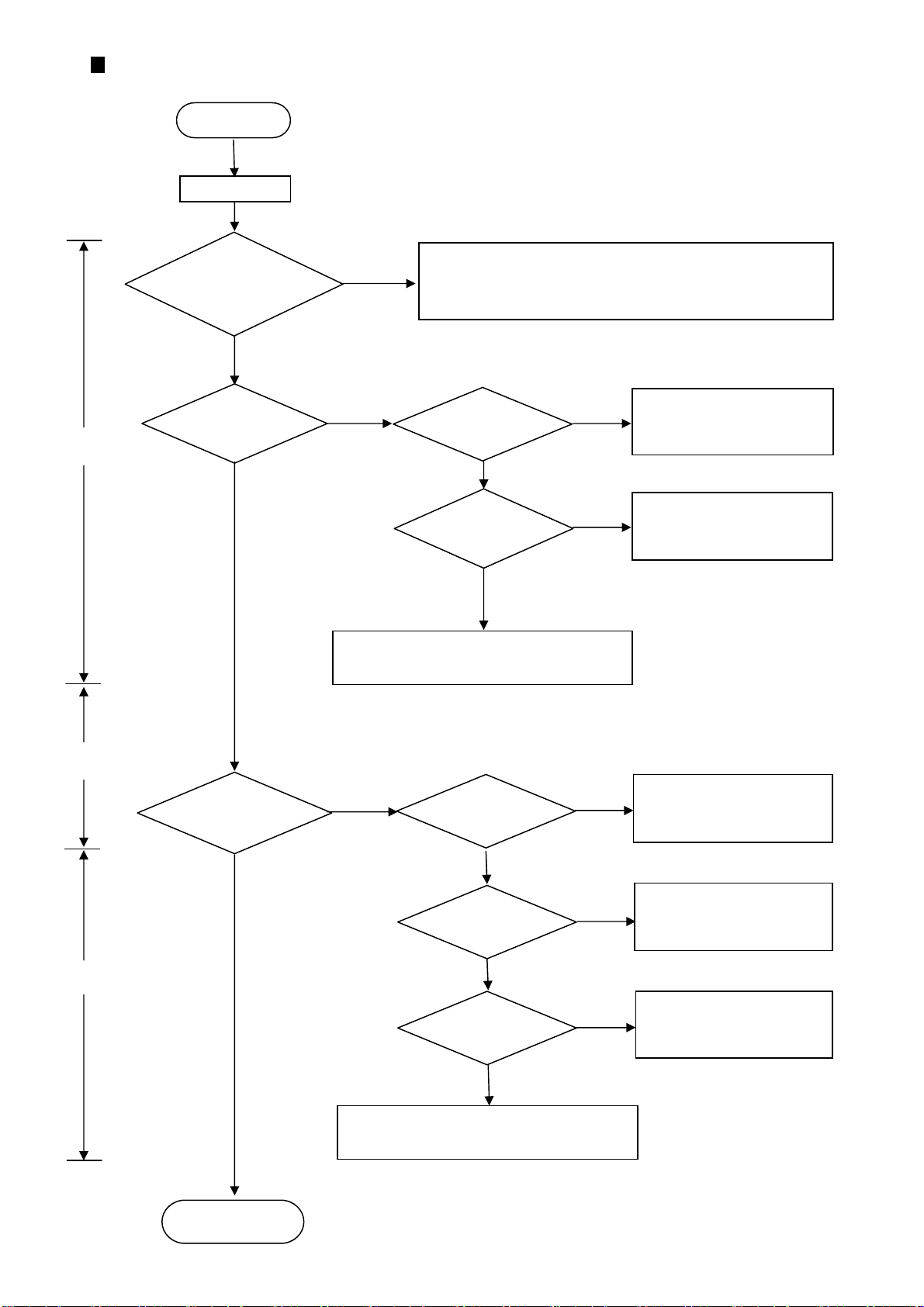

MAINTENANCE FLOW CHART

Page 6 of 28

Start

Power on

Voltages NO 1. Check Cable

at pins of connector 2. Replace Power Supply unit if Power Board is not shorted,

(CN93) are normal? otherwise find out first where the short is.

YES

NO NO Check CNVMB114MA18L

Are FM/AM Is Power Supply (Tuner Module)

MAIN Board normal? normal? and peripheral circuit.

(CUP11866Y)

YES

NO

Is PLL Check S3F84BB

Clock normal? and peripheral circuit.

YES YES

Chcek TUNER module connection Antenna.

Power Board

(CUP11866Y)

NO NO Check DAB Module

Is DAB Is Power Supply and peripheral

normal? normal? circuit.

YES

NO Check 74ACT04(IC73) or

Is Voltage level 74LVC04(IC74) and

normal? peripheral circuit.

MAIN Board YES

(CUP11866Y)

YES NO Check S3F84BB or DAB

Are Clock and Module and peripheral

Data normal? Circuit.

YES

Check DAB Module connection Antenna.

Normal Operation

Page 7

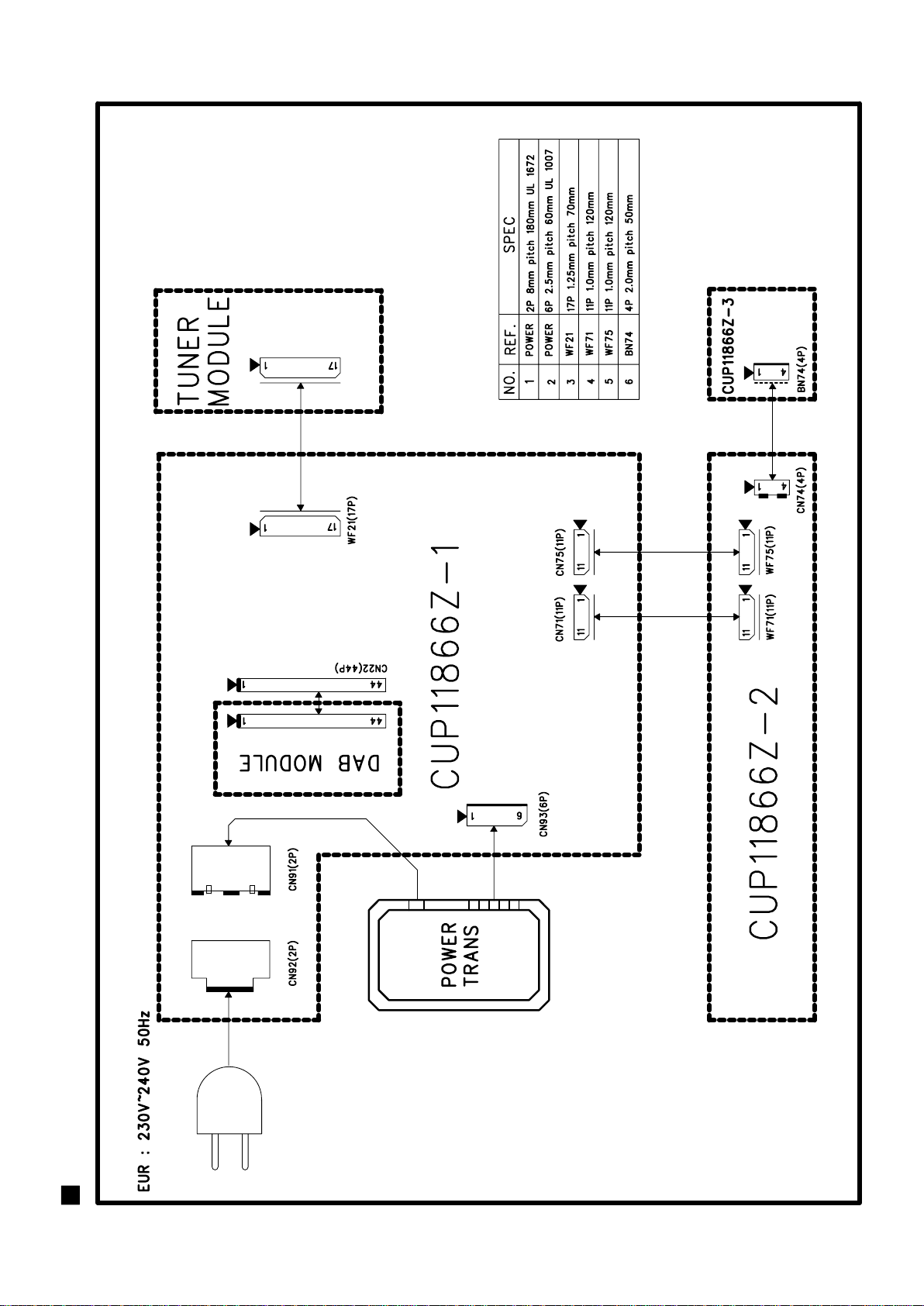

WIRING DIAGRAM

Page 7 of 28

Page 8

Page 8 of 28

Page 9

Page 9 of 28

Page 10

Page 10 of 28

Page 11

Page 11 of 28

Page 12

Page 12 of 28

Page 13

Terminal assignment

Relay - top view

Non-latching type,

not energized condition

latching, 2 coils

reset condition

Latching type,

reset condition

FP2 Relay (RT21)

Page 13 of 28

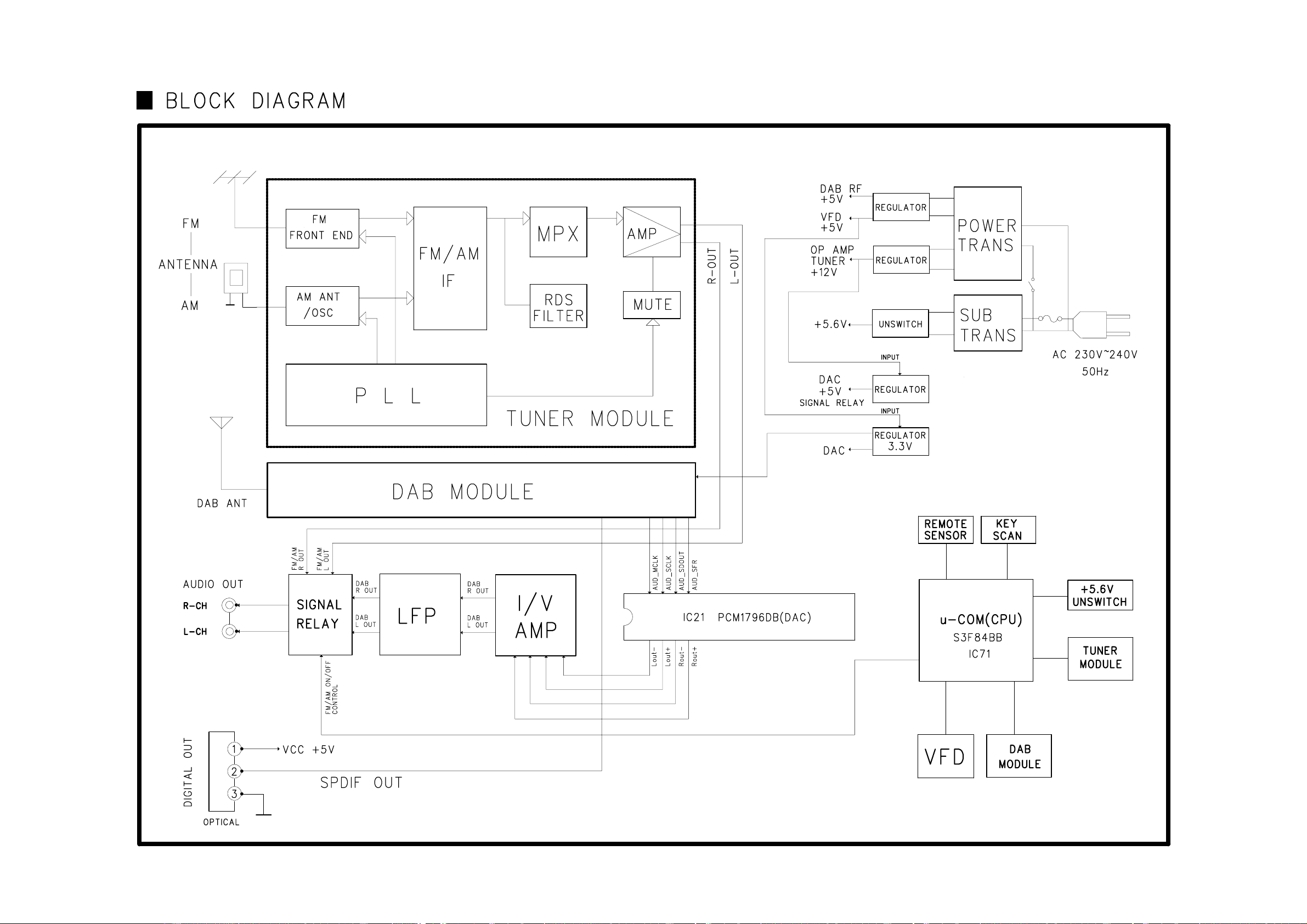

BLOCK DIAGRAM (IC22, IC23, IC24: OP AMP)

Out A

–In A

+In A

V–

OPA2134

1

A

2

3

4

8-Pin DIP, SO-8

V+

8

Out B

7

B

–In B

6

+In B

5

Page 14

HEX INVERTER (IC73: 74ACT04)

Page 14 of 28

INPUT AND OUTPUT EQUIVALENT CIRCUIT PIN DESCRIPTION

PIN No SYMBOL NAME AND FUNCTION

1, 3, 5, 9, 1 1,

13

2, 4, 6, 8, 10,

12

7 GND Ground (0V)

14

H TABLE

TRUT

1A to 6A Data Inputs

1Y to 6Y Data Outputs

AY

LH

HL

V

CC

Positive Supply Voltage

PIN CONNECTION AND IEC LOGIC SYMBOLS

Page 15

Terminal Functions (IC21: PCM1796)

I/O

DESCRIPTIONS

Page 15 of 28

TERMINAL

NAME PIN

AGND1 19 − Analog ground (internal bias)

AGND2 24 − Analog ground (internal bias)

AGND3L 27 − Analog ground (L-channel DACFF)

AGND3R 16 − Analog ground (R-channel DACFF)

BCK 6 I Bit clock input

DATA 5 I Serial audio data input

DGND 8 − Digital ground

I

L+ 25 O L-channel analog current output+

OUT

I

L– 26 O L-channel analog current output–

OUT

I

R+ 17 O R-channel analog current output+

OUT

I

R– 18 O R-channel analog current output–

OUT

I

REF

LRCK 4 I Left and right clock (fS) input

MC 12 I Mode control clock input

MDI 11 I Mode control data input

MDO 13 I/O Mode control readback data output

MS 10 I/O Mode control chip-select input

MSEL 3 I I2C/SPI select

RST 14 I Reset

SCK 7 I System clock input

VCC1 23 − Analog power supply, 5 V

VCC2L 28 − Analog power supply (L-channel DACFF), 5 V

VCC2R 15 − Analog power supply (R-channel DACFF), 5 V

V

L 22 − L-channel internal bias decoupling pin

COM

V

R 21 − R-channel internal bias decoupling pin

COM

V

DD

ZEROL 1 I/O Zero flag for L-channel

ZEROR 2 I/O Zero flag for R-channel

(1)

Schmitt-trigger input, 5-V tolerant

(2)

Schmitt-trigger input and output. 5-V tolerant input and CMOS output

(3)

Schmitt-trigger input and output. 5-V tolerant input. In I2C mode, this pin becomes an open-drain 3-state output; otherwise, this pin is a CMOS

output.

20 − Output current reference bias pin

9 − Digital power supply, 3.3 V

(1)

(1)

(1)

(1)

(1)

(3)

(2)

(1)

(1)

(1)

(2)

(2)

Page 16

FUNCTIONAL BLOCK DIAGRAM (IC21: PCM1796)

L

R

Page 16 of 28

LRCK

BCK

DATA

RST

MDO

MDI

MC

MS

MSEL

Audio

Data Input

I/F

Function

Control

I/F

8

Oversampling

Digital

Filter

and

Function

Control

Advanced

Segment

DAC

Modulator

Current

Segment

DAC

Bias

and

Vref

Current

Segment

DAC

I

OUT

I

OUT

V

COM

I

REF

V

COM

I

OUT

I

OUT

L−

L+

R−

R+

V

OUT

L

R

I/V and Filter

V

OUT

ZEROL

ZEROR

Zero

Detect

System

Clock

Manager

SCK

DGND

Power Supply

DD

V

AGND1

AGND2

AGND3L

1

CC

V

AGND3R

2L

V

CC

2R

CC

V

I/V and Filter

Page 17

PIN ASSIGNMENTS(IC21: PCM1796)

Page 17 of 28

PCM1796

(TOP VIEW)

ZEROL

ZEROR

MSEL

LRCK

DATA

BCK

SCK

DGND

V

DD

MS

MDI

MC

MDO

RST

1

2

3

4

5

6

7

8

9

10

11

12

13

14

28

27

26

25

24

23

22

21

20

19

18

17

16

15

VCC2L

AGND3L

I

L−

OUT

I

L+

OUT

AGND2

V

1

CC

L

V

COM

V

R

COM

I

REF

AGND1

I

R−

OUT

I

R+

OUT

AGND3R

VCC2R

Page 18

RESET IC (RE5VL28CATZ) : IC72

Page 18 of 28

Page 19

IC71 FUNCTION (MI-COM S3F84BB)

Page 19 of 28

Pin No. PIN NAME I/O DESCRIPTION

1~8 FIP-DA O FIP Data output port

9 N.C - Non connection

10 SINO I UART Data input port

11 SOTO O UART Data output port

12 VDD1 I Power supply port(+5V)

13 VSS1 I GND

14 XTOUT O

15 XIN I

16 TEST I Back-up Input

17,18 N.C - Non connection

19 RESET I Reset input port("L")

20 N.C - Non connection

21 DAB_DIN I DAB Data input port

22 DAB_DOUT O DAB Data output port

23 DAB_CLK O DAB Clock control port("L")

24 FM/AM_MUTE O FM/AM MUTE control port("L")

25 PLL_DATA O PLL Data output port

26 PLL_CE O PLL Enable control port

27 PLL_CLK O PLL Clock control port

28 STEREO I Tuner module stereo control port

29 TUNED I Tuner module tuned control port

30 PLL_DIN I PLL Data input port

31 RDS_CLK O RDS Clock control port

32 RDS_DATA I RDS Data input port

33 BACK_UP I BACK-UP mode control port("L")

34 REMOTE_IN I Remote unit data input port

35~38 N.C - Non connection

39,40 GND I GND

41 SCROLL_UP I Scroll up control port

42 SCROLL_DN I Scroll down control port

43 VREF I A/D converter reference voltage

44 AVSS I

45 GND

46 KEY3 I

47 KEY2 I

48 KEY1 I KEY 1 control port

49~51 N.C - Non connection

52 VSS2 I GND

53 VDD2 I Power supply port(+5V)

54 SYSTEM_MUTE O System MUTE control port("L")

55 STAND_BY O Standby on control port("L")

56 FM/AM_ON O FM/AM on control port("L")

57 N.C - Non connection

58 POWER_ON O Unit turn on control port("L")

59~64 N.C - Non connection

65~68 OPTION I GND or OPEN

69~70 N.C - Non connection

71 OPTION I GND or OPEN

72~74 N.C - Non connection

75 OPTION I GND or OPEN

76~77 N.C - Non connection

78 RS_P O Register selection port

79 WRITE O Write enable port

80 READ O Read enable port

I

10MHz crystal connection port

GND

Page 20

BLOCK DIAGRAM (IC71: S3F84BB)

Page 20 of 28

XIN

XOUT

RESETB

P2.7/TAOUT

P2.6/TACAP

P2.5/TACK

P2.4/TBOUT

P3.7/TCOUT0

P3.6/TCOUT1

P3.4/T1OUT0

P3.2/T1CAP0

P3.0/T1CK0

P3.5/T1OUT1

P3.3/T1CAP1

P3.1/T1CK1

P2.2/SCK

P2.1/SI

P2.0/SO

P5.3/RXD0

P5.2/TXD0

P5.1/RXD1

P5.0/TXD1

P0.0~P0.7/

PG0~PG7

OSC/RESETB

8-Bit

Basic Timer

8-Bit

Timer

/CounterA,B

8-Bit

Timer/

CounterC0,C1

16-Bit

Timer

/Counter10,11

SIO/

UART0,1

PG

AV

REF AVSS

Port 0 Port 1A/D

I/O Port and Interrupt Control

SAM88RC CPU

64K-Byte

ROM

P1.0-P1.7P0.0-P0.7

2064-Byte

RAM

Port 2 P2.0-P2.7

Port 3 P3.0-P3.7

Port 4

Port 5 P5.0-P5.7

Port 6 P6.0-P6.7

P4.0-P4.7/

INT0~INT7

Port 8 Port 7D/A

P8.0-P8.5/

INT8,INT9

P2.3/

DAOUT

P7.0-P7.7/

ADC0~ADC7

Figure 1-1. S3C84BB/F84BB Block Diagram

Page 21

PIN ASSIGNMENT (IC71: S3F84BB)

Page 21 of 28

P0.2/PG2

P0.1/PG1

P0.0/PG0

78

79

80

P0.5/PG5

P0.4/PG4

P0.3/PG3

75

76

77

P0.7/PG7

P0.6/PG6

P1.0

72

73

74

P1.1

71

P1.2

70

P1.3

69

P1.4

68

P1.5

67

P1.6

66

P1.7

65

P2.7/TAOUT

P2.6/TACAP

P2.5/TACK

P2.4/TBPWM

P2.3/DAOUT

P2.2/SCK

P2.1/SI

P2.0/SO

P5.7

P5.6/SDAT

P5.5/SCLK

VDD1

VSS1

XOUT

XIN

TEST

P5.4

P5.3/RxD0

RESETB

P5.2/TxD0

P5.1/RxD1

P5.0/TxD1

P3.7/TCOUT1

P3.6/TCOUT0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

S3C84BB/F84BB

(80-QFP-1420C)

252627282930313233343536373839

40

64

63

62

61

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

P8.0

P8.1

P8.2

P8.3

P8.4/INT8

P8.5/INT9

P6.0

P6.1

P6.2

P6.3

P6.4

VDD2

VSS2

P6.5

P6.6

P6.7

P7.0/ADC0

P7.1/ADC1

P7.2/ADC2

P7.3/ADC3

AVSS

AVREF

P7.4/ADC4

P7.5/ADC5

P4.7/INT7

P4.6/INT6

P4.5/INT5

P4.4/INT4

P4.3/INT3

P4.2/INT2

P4.1/INT1

P4.0/INT0

P7.7/ADC7

P3.3/T1CAP1

P3.5/T1OUT1

P3.4/T1OUT0

P3.2/T1CAP0

P3.1/T1CK1

P3.0/T1CK0

P7.6/ADC6

Figure 1-2. S3C84BB/F84BB Pin Assignment (80-QFP)

Page 22

HEX INVERTER (IC74: 74LVC04A)

Page 22 of 28

PIN CONFIGURATION

1

1A

2

1Y

3

2A

4

2Y

5

3A

6

3Y

GND

7

LOGIC SYMBOL

1

1A 1Y

2A

3

5

3A 3Y

9

4A 4Y

11

5A 5Y

6A

13

14

13

12

11

10

9

8

SV00396

2Y

6Y

PIN DESCRIPTION

V

CC

6A

6Y

5A

5Y

4A

4Y

PIN NUMBER SYMBOL NAME AND FUNCTION

1, 3, 5, 9, 11, 13 1A to 6A Data inputs

2, 4, 6, 8, 10, 12 1Y to 6Y Data outputs

7 GND Ground (0 V)

14 V

Positive supply voltage

CC

LOGIC DIAGRAM (ONE GATE)

2

4

6

8

10

12

FUNCTION TABLE

NOTES:

H = HIGH voltage level

L = LOW voltage level

AY

SV00399

INPUTS OUTPUTS

nA nY

L H

H L

LOGIC SYMBOL (IEEE/IEC)

12

34

56

98

11 10

13 12

1

1

1

1

1

1

SV00397

SV00398

Page 23

TRANSISTOR, REGULATOR IC BLOCK DIAGRAM

Page 23 of 28

TO-92

123

KTC2874

TO-220FP

123

NJM7805FA

L7812CP

1. Emitter

2. Collector

3. Base

1. INPUT

2. GND

3. OUTPUT

TO-220FP

123

L7912CP

TO-92M

123

KRA107M

KRC107M

1. GND

2. INPUT

3. OUTPUT

1. Emitter

2. Collector

3. Base

TO-92L

1. Emitter

2. Collector

3. Base

123

KTC2316

Page 24

ELECTRICAL PARTS LIST

Page 24 of 28

RESISTORS AND CAPACITORS

Notes : Parts numbers are indicated for most mechanical parts.

Please use this part number for parts order.

IMPORTANT SAFETY NOTICE.

Components identified by ! Mark have special characteristics important for safety.

When replacing any of these components, use only manufacture's specified parts.

The unit of resistance is OHM (Ω)

k=1000 (Ω) , M=1000 (kΩ)

The nuit of capacitance is MICROFARAD (uF)

P=10-6 uF

Numbering System of Resistor

Example

CRD 25 F J 101

Type Wattage Shape Tolerance Value

Resistor Type Wattage Tolerance

K[C]RD : Carbon 20 : 1/5W F : ±1%

K[C]RD : Metal Oxide 25 : 1/4W J : ±5%

50 : 1/2W K : ±10%

1 : 1W

2 : 2W

3 : 3W

K[C]RJ : Carbon,Chip 10 : 1/10W

14 : 1/4W

Numbering System of Capacitor

Example

HCKR 1H 101 K B

Type Wattage Value Tolerance Peculiarity

Capacitor Type

HCB : Ceramic 0J : 6.3V 1H : 50V DC C : ±0.25pF

CCC : Ceramic 1A : 10V 1 : 125V DC G : ±2%

CCK : Ceramic 1C : 16V KC : 400V AC J : ±5%

HCQI : Polyester 1E : 25V K : ±10%

HCQP : Polypropylene 1V : 35V Z : +80% , -20%

HCQS : Polystyrol 1H : 50V

HCUS : Ceramic 1J : 63V

HCEA : ELECT

HCEA Type Other

Voltage

Tolerance

LOAD NO. PART NO. DESCRIPTION SPECIFICATION

CUP11866Y PCB MAIN (DUAL DAB)

CUP11866Y-1 MAIN PCB

C201 CCEA1AH471T CAP , ELECT 470UF 10V

C202 CCFT1H223ZF CAP, CERAMIC 0.022UF 50V

C203 CCEA1AH471T CAP , ELECT 470UF 10V

C204 CCFT1H223ZF CAP, CERAMIC 0.022UF 50V

C205 CCFT1H104ZF CAP , SEMICONDUCTOR 0.1UF 50V

C206 CCEA1CH100T CAP , ELECT 10UF 16V

C207 CCEA1CH470T CAP , ELECT 47UF 16V

C208 CCEA1CH100T CAP , ELECT 10UF 16V

C209 CCEA1CH101T CAP , ELECT 100UF 16V

C210 , C211 CCFT1H104ZF CAP , SEMICONDUCTOR 0.1UF 50V

C212 CCEA1CH101T CAP , ELECT 100UF 16V

C213 , C214 HCQI1H222JZT CAP , MYLAR 0.0022UF 50V

C215 CCFT1H104ZF CAP , SEMICONDUCTOR 0.1UF 50V

C216 CCEA1CH221T CAP , ELECT 220UF 16V

C217 CCFT1H104ZF CAP , SEMICONDUCTOR 0.1UF 50V

C218 CCEA1CH221T CAP , ELECT 220UF 16V

C219 , C220 HCQI1H222JZT

C221 CCFT1H104ZF CAP , SEMICONDUCTOR 0.1UF 50V

C222 CCEA1CH221T CAP , ELECT 220UF 16V

C223 CCFT1H104ZF CAP , SEMICONDUCTOR 0.1UF 50V

C224 CCEA1CH221T CAP , ELECT 220UF 16V

C225 HCQI1H273JZT CAP , MYLAR 0.027UF 50V

CAP , MYLAR 0.0022UF 50V

Page 25

Q

C226 , C227 HCQI1H822JZT CAP , MYLAR 0.0082UF 50V

,

Page 25 of 28

C228 HCQI1H273JZT CAP , MYLAR 0.027UF 50V

C229 , C230 HCQI1H822JZT CAP , MYLAR 0.0082UF 50V

C231 CCFT1H104ZF CAP , SEMICONDUCTOR 0.1UF 50V

C232 , C233 CCEA1CH221T CAP , ELECT 220UF 16V

C234 CCFT1H104ZF CAP , SEMICONDUCTOR 0.1UF 50V

C235 , C236 CCEA1HH470T CAP , ELECT 47UF 50V

C237 CCEA1CH100T CAP , ELECT 10UF 16V

C238 CCEA1HH4R7T CAP , ELECT 4.7UF 50V

C239 , C240 CCEA1HH470T CAP , ELECT 47UF 50V

C241 , C242 HCQI1H152JZT CAP , MYLAR 0.0015UF 50V

C243 , C244 CCEA1HH470T CAP , ELECT 47UF 50V

C245 CCFT1H103ZF CAP, CERAMIC 0.01UF 50V

C246 CCEA1AH101T CAP , ELECT 100UF 10V

C247 CCEA1CH471T CAP , ELECT 470UF 16V

C248 CCFT1H223ZF CAP, CERAMIC 0.1UF 50V

C249 ~ C254 HCQI1H104JZT CAP , MYLAR 0.1UF 50V

C706 CCFT1H223ZF CAP, CERAMIC 0.022UF 50V

C710 CCFT1H223ZF CAP, CERAMIC 0.022UF 50V

C711 , C712 HCBS1H330JT CAP , CERAMIC 33PF 50V

C713 CCFT1H223ZF CAP, CERAMIC 0.022UF 50V

C714 CCEA1CH470T CAP , ELECT 47UF 16V

C715 CCKT1H101KB CAP , CERAMIC 100PF 50V

C716 CCEA1AH101T CAP , ELECT 100UF 10V

C717 , C718 CCKT1H221KB CAP , CERAMIC 220PF 50V

C719 CCEA1AH471T CAP , ELECT 470UF 10V

C720 CCFT1H223ZF CAP, CERAMIC 0.022UF 50V

C722 ~ C724 CCKT1H101KB CAP , CERAMIC 100PF 50V

C725 CCFT1H223ZF CAP, CERAMIC 0.022UF 50V

C726 CCEA1AH101T CAP , ELECT 100UF 10V

C727 CCFT1H223ZF CAP, CERAMIC 0.022UF 50V

C728 CCEA1AH471T CAP , ELECT 470UF 10V

C729 , C902 CCFT1H223ZF CAP, CERAMIC 0.022UF 50V

C903 CCEA1EH471T

C904 CCEA1CH101T CAP , ELECT 100UF 16V

C905 CCEA1EH331T CAP , ELECT 33OUF 25V

C906,C907 CCFT1H223ZF CAP, CERAMIC 0.022UF 50V

C908 CCEA1HH220T CAP , ELECT 22UF 50V

C910 CCEA1CH470T CAP , ELECT 47UF 16V

C911 ~ C916 CCFT1H223ZF CAP, CERAMIC 0.022UF 50V

C919 , C920 CCEA1CH471T CAP , ELECT 470UF 16V

C921 , C922 CCFT1H223ZF CAP, CERAMIC 0.022UF 50V

C924 CCEA1AH101T CAP , ELECT 100UF 10V

C925 CCFT1H223ZF CAP, CERAMIC 0.022UF 50V

C926 CCEA1AH101T CAP , ELECT 100UF 10V

C927 CCFT1H223ZF CAP, CERAMIC 0.022UF 50V

C928 CCEA1AH101T CAP , ELECT 100UF 10V

C929 CCFT1H223ZF CAP, CERAMIC 0.022UF 50V

C930 CCEA1AH101T CAP , ELECT 100UF 10V

C931 CCFT1H223ZF CAP, CERAMIC 0.022UF 50V

C932 CCFT1H104ZF CAP , SEMICONDUCTOR 0.1UF 50V

D201 , D702 ~ D706 CVD1SS133MT DIODE 1SS133

D901 ~ D904 CVD1N4003ST RECT , DIODE 1N4003

D905 CVD1SS133MT DIODE 1SS133

D906 CVDZJ6.8BT DIODE , ZENER ZJ6.8B 1/2W

D907 CVD1SS133MT DIODE 1SS133

D908 CVD1N4003ST RECT , DIODE 1N4003

D909 CVDZJ4.7BT DIODE , ZENER ZJ4.7B 1/2W

D910 CVD1SS133MT DIODE 1SS133

D911 ~ D916 CVD1N4003ST RECT , DIODE 1N4003

F901 KJCFC5S HOLDER , FUSE

IC72 HVIRE5VL28CATZ IC , RESET

L201 , L202 HLQ02C2R7KT COIL, AXIAL 2.7UH, K

Q201 , Q202 HVTKTC2874BT T.R , MUTE KTC2874B

Q203 HVTKRC107MT T.R KRC107M

Q701

Q702 , Q704 , HVTKRA107MT T.R KRA107M

CAP , ELECT 470UF 25V

Page 26

Q901 HVTKSC2316YT T.R KSC2316Y

Page 26 of 28

Q902 HVTKRC107MT T.R KRC107M

R201 CRD20TJ220T RES , CARBON 22 OHM 1/5W J

R203 CRD20TJ103T RES , CARBON 10K OHM 1/5W J

R204 , R205 CRD20TJ3R3T RES , CARBON 3.3 OHM 1/5W J

R206 ~ R210 CRD20TJ103T RES , CARBON 10K OHM 1/5W J

R211 , R212 CRD20TJ911T RES , CARBON 910 OHM 1/5W J

R215 , R216 CRD20TJ100T RES , CARBON 10 OHM 1/5W J

R217 , R218 CRD20TJ911T RES , CARBON 910 OHM 1/5W J

R219 , R220 CRD20TJ100T RES , CARBON 10 OHM 1/5W J

R221 , R222 CRD20TJ221T RES , CARBON 220 OHM 1/5W J

R223 CRD20TJ201T RES , CARBON 200 OHM 1/5 W

R224 , R225 CRD20TJ181T RES , CARBON 180 OHM 1/5W J

R226 CRD20TJ201T RES , CARBON 200 OHM 1/5 W

R227 , R228 CRD20TJ221T RES , CARBON 220 OHM 1/5W J

R229 CRD20TJ201T RES , CARBON 200 OHM 1/5 W

R230 , R231 CRD20TJ181T RES , CARBON 180 OHM 1/5W J

R232 CRD20TJ201T RES , CARBON 200 OHM 1/5 W

R233 CRD20TJ4R7T RES , CARBON 4.7 OHM 1/5W J

R234 CRD20TJ180T RES , CARBON 18 OHM 1/5W J

R235 , R236 CRD20TJ101T RES , CARBON 100 OHM 1/5W J

R237 CRD20TJ151T RES , CARBON 150 OHM 1/5W J

R238 CRD20TJ102T RES , CARBON 1K OHM 1/5W J

R239 CRD20TJ104T RES , CARBON 100K OHM 1/5W J

R240 , R241 CRD20TJ151T RES , CARBON 150 OHM 1/5W J

R242 , R243 CRD20TJ104T RES , CARBON 100K OHM 1/5W J

R244 , R245 CRD20TJ102T RES , CARBON 1K OHM 1/5W J

R246 , R247 CRD20TJ104T RES , CARBON 100K OHM 1/5W J

R248 , R249 CRD20TJ151T RES , CARBON 150 OHM 1/5W J

R250 , R251 CRD20TJ102T RES , CARBON 1K OHM 1/5W J

R252 CRD25TJ4R7T RES , CARBON 4.7 OHM 1/4W J

R709 CRD20TJ102T RES , CARBON 1K OHM 1/5W J

R710 CRD20TJ105T RES , CARBON 1M OHM 1/5W J

R711 CRD20TJ470T

R712 CRD20TJ332T RES , CARBON 3.3K OHM 1/5W J

R714 , R715 CRD20TJ102T RES , CARBON 1K OHM 1/5W J

R716 ~ R718 CRD20TJ103T RES , CARBON 10K OHM 1/5W J

R719 , R720 CRD20TJ102T RES , CARBON 1K OHM 1/5W J

R721 CRD20TJ470T RES , CARBON 47 OHM 1/5W J

R722 , R723 CRD20TJ102T RES , CARBON 1K OHM 1/5W J

R724 , R725 CRD20TJ151T RES , CARBON 150 OHM 1/5W J

R726 , R727 CRD20TJ102T RES , CARBON 1K OHM 1/5W J

R901 , R902 CRD20TJ102T RES , CARBON 1K OHM 1/5W J

R903 CRD20TJ472T RES , CARBON 4.7K OHM 1/5W J

R904 CRD20TJ104T RES , CARBON 100K OHM 1/5W J

K4FH300 TAPE , PROTECTIVE

BAT1 HABGP40BVH3A3H BATTERY , RECHARGEABLE GP40BBVH3A3H

BK91 CMD1A387 BRACKET , PCB

CN22 CJP44TT153ZY PIN , HEADER (2.00MM) DAB2025

CN71 CJP11GA117ZY WAFER

CN73 CJP06HA37ZM WAFER

CN75 CJP11GA117ZY WAFER

CN91 CJP02GA89ZM WAFER

CN92 CJP02KA060ZY WAFER

CN93 CJP06GA01ZY WAFER, 6PIN

C900 HCQE2E104KDE CAP , LINE ACROSS

C901 KCKDKS471ME CAP , CERAMIC(KH TYPE) DKS471ME

C917 , C918 CCEA1EH222E CAP , ELECT 2200UF 25V

C923 CCEA1CH472E CAP , ELECT

ET91 CNE75 PLATE , EARTH

IC21 CVIPCM1796DB IC , DAC

IC22 ~ IC24 HVIOPA2134UA OP AMP

IC71 HVIS3F84BB I.C , FLASH U-COM S3F84BB

IC73 HVI74ACT04MTR I.C , HEX

IC74 HVI74LVC04ADT IC, HEX INVERTER 74LVC04AD-T

IC91 CVINJM7805FAXA I.C ASS'Y

RES , CARBON 47 OHM 1/5W J

Page 27

CMY1A025 HEAT SINK

Page 27 of 28

CTB3+8JR SCREW

HVINJM7805FA I.C NJM7805FA

K8AYG6260 COMPOUND , SILICONE

IC92 CVINJM7805FAXA I.C ASS'Y

CMY1A025 HEAT SINK

CTB3+8JR SCREW

HVINJM7805FA I.C NJM7805FA

K8AYG6260 COMPOUND , SILICONE

IC93 HVIL7912CP I.C , REGULATOR L7912(ST)

IC94 HVIL7812CP I.C , REGULATOR L7812(ST)

IC95 HVINJM7805FA I.C NJM7805FA

IC96 HVIRC1117S33 REGULATOR, 3.3V (FAIRDCHILD) FAN1117AS-33X

JK21 CJJ4N067Z 2P, JACK RCA-201DAG-01

JK22 HJSTOTX177L MODULE , OPTICAL(TX) TOTX177L

RY21 HSL4C008ZE RELAY CVR700

RY91 HSL1D016ZE RELAY SDT-S-109DMR

S708 KST1A010Z SW , TACT CN

T901 CLT5I002ZE TRANS , SUB SR5400(6400)/N1

WF21 CJP17GA115ZY WAFER , CARDCABLE

X701 HOX10000E220C CRYSTAL

CUP11866Y-2 FRONT PCB

C701 ~ C703 CCKT1H221KB CAP , CERAMIC 220PF 50V

C704 CCEA1AH101T CAP , ELECT 100UF 10V

Q706 , Q707 HVTKRC107MT T.R KRC107M

Q708 HVTKRA107MT T.R KRA107M

R701 , R702 CRD20TJ102T RES , CARBON 1K OHM 1/5W J

R703 CRD20TJ152T RES , CARBON 1.5K OHM 1/5W J

R704 CRD20TJ182T RES , CARBON 1.8K OHM 1/5W J

R705 CRD20TJ272T RES , CARBON 2.7K OHM 1/5W J

R706 CRD20TJ332T RES , CARBON 3.3K OHM 1/5W J

R707 CRD20TJ562T RES , CARBON 5.6K OHM 1/5W J

R708 CRD20TJ752T RES , CARBON 7.5K OHM 1/5W J

R728 CRD20TJ471T RES , CARBON 470 OHM 1/5W J

R729 CRD20TJ122T RES , CARBON 1.2K OHM 1/5W J

R790 CRD20TJ821T RES , CARBON 820 OHM 1/5W J

S701 ~ S707 CST1A022ZT SW , TACT(H=7MM)

CN72 HFL16T202DA1E VFD , MODULE 16T202DA1E

CN74 CJP04GB46ZY

D701 CVD50BOGDWGA L.E.D , 2 COLOR

RS71 HRVNJL34H380A SENSOR , REMOTE

WF71 , WF75 CJP11GB113ZY WAFER , CARDCABLE

CUP11866Y-3 ENCODER PCB

C707 , C708 CCKT1H101KB CAP , CERAMIC 100PF 50V

C709 CCEA1AH471T CAP , ELECT 470UF 10V

BN74 CWB2B004050EN WIRE ASS'Y

VE71 HSR2A025Z ENCODER , SWITCH EC12B24S2034ZZZ

CQXC445C INSTRUCTION MANUAL ASS'Y

CABR03P BATTERY (SIZE 'AAA') 2PCS IN 1PACK

CJS4N014Z CORD , PIN

CARTC445 REMOCON TRANSMITER ASS'Y

CQX1A1079Z MANUAL , INSTRUCTION

CSA1A018Z FM 1 POLE ANT

CSA1A020Z AM LOOP ANT

CSA272 ANT , DAB T T17020N

OTHERS

KBA2C1000TLEZ FUSE

CJA2B043ZA CORD , POWER(EUR)

CLT5M029ZET TRANS , POWER

CWC1C4A17B070B CABLE , CARD

CWC4F2A11A120B CABLE , CARD

CNVFS2022V131 MODULE , DUAL BAND DAB FS2022-0101-000

CNVMB114MA18L TUNER MODULE(EUR)

CJP14TT198ZY PIN HEADER(DUAL TYPE 2.54MM)

WAFER

Loading...

Loading...