Page 1

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

No.99MBC034B3

SERIES No.542

23456789012345678901234567890121234567890123456789012345678901212345

23456789012345678901234567890121234567890123456789012345678901212345

23456789012345678901234567890121234567890123456789012345678901212345

23456789012345678901234567890121234567890123456789012345678901212345

23456789012345678901234567890121234567890123456789012345678901212345

23456789012345678901234567890121234567890123456789012345678901212345

23456789012345678901234567890121234567890123456789012345678901212345

23456789012345678901234567890121234567890123456789012345678901212345

23456789012345678901234567890121234567890123456789012345678901212345

23456789012345678901234567890121234567890123456789012345678901212345

23456789012345678901234567890121234567890123456789012345678901212345

23456789012345678901234567890121234567890123456789012345678901212345

23456789012345678901234567890121234567890123456789012345678901212345

23456789012345678901234567890121234567890123456789012345678901212345

EV Counter

23456789012345678901234567890121234567890123456789012345678901212345

23456789012345678901234567890121234567890123456789012345678901212345

Linear Gage

Counter

User’s Manual

Read this User's Manual thoroughly

before operating the instrument. After reading,

retain it close at hand for future reference.

Page 2

CONVENTIONS USED IN USER'S MANUAL

Safety Precautions

To operate the instrument correctly and safely, Mitutoyo

manuals use various safety signs (Signal Words and Safety

Alert Symbols) to identify and warn against hazards and

potential accidents.

The following signs indicate general warnings:

Indicates an imminently hazardous situation

which, if not avoided, will result in serious injury

DANGER

CAUTION

WARNING

The following signs indicate specific warnings or prohibited

actions, or indicate a mandatory action:

or death.

Indicates a potentially hazardous situation

which, if not avoided, could result in serious

injury or death.

Indicates a potentially hazardous situation

which, if not avoided, may result in minor or

moderate injury or property damage.

Alerts the user to a specific hazardous situation.

The given example means "Caution, risk of

electric shock".

Prohibits a specific action. The given example

means " Do not disassemble".

Specifies a required action. The given example

means "Ground".

i

Page 3

CONVENTIONS USED IN USER'S MANUAL

On Various Types of Notes

The following types of notes are provided to help the operator

obtain reliable measurement data through correct instrument

operation.

IMPORTANT • An important note is a type of note that

NOTE A note emphasizes or supplements important

provides information essential to the completion of a task. You cannot disregard this note

to complete the task.

• An important note is a type of precaution,

which if neglected could result in a loss of

data, decreased accuracy or instrument

malfunction/failure.

points of the main text. A note supplies

information that may only apply in special cases

(e.g.. Memory limitations, equipment configurations, or details that apply to specific versions of

a program).

TIP A tip is a type of note that helps the user apply

the techniques and procedures described in the

text to their specific needs.

It also provides reference information associated with the topic being discussed.

Mitutoyo assumes no liability to any party for any

loss or damage, direct or indirect, caused by use

of this instrument not conforming to this manual.

Information in this document is subject to change

without notice.

© Copyright Mitutoyo Corporation. All rights

reserved.

ii

Page 4

PRECAUTIONS

To obtain the optimum performance from it, obey the

following precautions

• Neither remove the cover nor disassemble

this counter.

WARNING

Doing so may expose personnel to electric

shock or result in damage or fire to this

counter due to a short circuit caused by metal

chippings or dust.

• Note the warning labels on the top surface of

this counter.

• This counter is a precision instrument. Do not

bump or apply excessive force to any part of

this counter when setting it up or operating it.

• Use this counter in an environment where the

temperature is between 0°C and 40°C. The

temperature variation should be minimized so

there is no condensation.

• Avoid operating this counter in the following

places:

where it will be exposed to cutting chips and

oil, dirt, dust, or significant vibrations,

where it will be exposed to direct sunlight, or

near high-voltage/large current power

equipment.

CONFORMANCE TO EC DIRECTIVES

This counter conforms to the following EC Directives:

• Low Voltage Directive (73/23/EEC)

EN61010-1: 1993, Demand of safety

• EMC Directive (89/336/EEC)

EN61326-1:1997 + A1:1998

Immunity test requirement: Annex A

Emission limit: Class B

iii

Page 5

WARRANTY

In the event that the Mitutoyo EV Counter should prove

defective in workmanship or material, within one year from

the date of original purchase for use, it will be repaired or

replaced, at our option, free of charge upon its prepaid return

to us.

This warranty shall not apply if the product has been subject

to fair wear and tear, abuse through misuse or improper use/

handling/storage/maintenance/service/repair or through

adaptation/modification by the original purchaser or any third

party without prior written consent of Mitutoyo or as a result

of damage by an actual disaster or circumstances beyond the

control of Mitutoyo.

To obtain service under this warranty the product must be

returned to the nearest Mitutoyo Service Center. Any postage,

insurance, or shipping charges incurred in returning the

product for service are the responsibility of the purchaser.

* This warranty is not transferable and is only valid within

the country of the original purchase.

* You may have additional rights under the laws of country

of original purchase that do not allow the exclusion of

implied warranties or the exclusion or limitation of certain

damages. If these laws apply, Mitutoyo's limitations and

exclusions may not apply to you.

iv

Page 6

CONTENTS

CONVENTIONS USED IN USER'S MANUAL...... i

PRECAUTIONS...................................................iii

CONFORMANCE TO EC DIRECTIVES..............iii

WARRANTY ....................................................... iv

1 OVERVIEW ...................................................1-1

1.1 EV Counter .................................................... 1-1

1.1.1 Features ........................................................ 1-1

1.1.2 Name and dimensions of each part .............. 1-2

1.2 D-EV External Display Unit (optional) ............ 1-5

1.2.1 Features ........................................................ 1-5

1.2.2 Name and dimensions of each part .............. 1-5

1.3 Internal Block Diagram................................... 1-7

2 SETUP...........................................................2-1

2.1 Installing the EV Counter ............................... 2-1

2.2 Connecting Cables......................................... 2-2

2.2.1 Connecting gages ......................................... 2-2

2.2.2

Connecting the D-EV (External Display Unit)...............

2.2.3

RS-232C, I/O/BCD, and RS LINK connections ............

2.2.4

2.3 Power On ....................................................... 2-4

3 SETTING PARAMETERS .............................3-1

3.1 Setting Parameters (with D-EV)..................... 3-1

3.2 Setting Parameters (with EV Counter)........... 3-6

Connecting the power supply and grounding .................

3.1.1 Parameter mode ON ..................................... 3-1

3.1.2

Specifying the gage resolution (for EV-16P and EV-16Z) .....

3.1.3 Setting the axes to be used ........................... 3-2

3.1.4 Parameter mode OFF ................................... 3-3

3.1.5 List of parameters......................................... 3-4

3.2.1 Parameter mode ON ..................................... 3-6

3.2.2 Setting the parameters .................................. 3-7

3.2.3 Parameter mode OFF ................................... 3-7

3.2.4 List of parameters......................................... 3-8

2-3

2-3

2-3

3-2

v

Page 7

CONTENTS

4 BASIC OPERATION......................................4-1

4.1 Power ON Precautions .................................. 4-1

4.2

Switching the Display/Output CH (with D-EV) ..................

4.3 Switching the Peak Mode (with D-EV) ........... 4-4

4.4 Clearing the Peak Value (with D-EV)............. 4-5

4.5

Input of Preset Value/Tolerance Value (with D-EV) .........

4.6 Clearing the Error State ................................. 4-8

4.7 Presetting (with the D-EV) ............................. 4-9

4.8 Tolerance Judgment (with the D-EV)........... 4-10

5

RS-232C COMMUNICATION FUNCTION............

5.1 RS-232C Connection ..................................... 5-1

5.2 RS-232C Output Specifications ..................... 5-1

5.2.1 Specifications of cables and connectors....... 5-1

5.2.2 Communication specifications ..................... 5-1

5.2.3 Pin assignment ............................................. 5-2

5.2.4 List of available commands ......................... 5-2

5.2.5

RS-232C command and RS-232C response output

5.2.6

HOLD input and RS-232C response output ...................

5.2.7 Time required for RS-232C data output ...... 5-6

6 RS LINK FUNCTION ..................................... 6-1

6.1 Connection Method........................................ 6-1

6.2 Start-Up Method............................................. 6-2

6.3 Troubleshooting ............................................. 6-3

7 I/O FUNCTION ..............................................7-1

7.1 Overview of the I/O function........................... 7-1

7.2 Connectors..................................................... 7-1

7.3 Input/Output Circuit ........................................ 7-1

7.3.1 Output circuit ............................................... 7-1

7.3.2 Input circuit .................................................. 7-1

7.4 NORMAL Mode............................................. 7-2

7.4.1 Overview of the NORMAL mode ............... 7-2

7.4.2 Tolerance judgment output .......................... 7-2

7.4.3 BCD output .................................................. 7-4

7.4.4 Segment output ............................................ 7-6

7.5 Calculation Mode ......................................... 7-10

7.5.1 Overview of the calculation mode ............. 7-10

7.5.2 Tolerance judgment result output .............. 7-10

7.5.3 BCD output ................................................ 7-11

7.5.4 Segment output .......................................... 7-11

4-2

4-6

5-1

..... 5-5

5-5

vi

Page 8

CONTENTS

7.6 High-speed Mode......................................... 7-12

7.6.1 Overview of the high-speed mode ............. 7-12

7.6.2 Tolerance judgment result output .............. 7-13

7.6.3 BCD output ................................................ 7-13

7.6.4 Segment output .......................................... 7-13

7.7 Timing Chart ................................................ 7-14

7.7.1 Power ON characteristics ........................... 7-14

7.7.2

Output period of tolerance judgment result .................

7.7.3 Data output ................................................. 7-15

7.7.4 External presetting ..................................... 7-16

7.7.5

Designating CELs to be output/Specifying the

calculation method .......................................................

7.7.6 Peak clear ................................................... 7-17

7.7.7 HOLD timing ............................................. 7-18

8 SPECIFICATIONS.........................................8-1

8.1 Specifications................................................. 8-1

8.2 Standard Accessories .................................... 8-1

8.3 Optional Accessories ..................................... 8-2

8.4 List of Error Outputs....................................... 8-3

SERVICE NETWORK

7-14

7-17

vii

Page 9

OVERVIEW

This chapter outlines the features of the EV

1

Counter for linear gages.

1.1 EV Counter

1.1.1 Features

• Three models of EV counter (EV-16P, EV-16D, and EV-16Z) are

available according to the linear gage connected. The applicable

gages for each model are as follows.

EV-16P: LGF, LGB, and LGE series linear gage (excluding the models that output sine waves)

EV-16D: LGD and LGS series linear gage

EV-16Z: LGF-Z series linear gage

• EV counter is a multi-axis counter to which plural gages can be con-

nected. The maximum number of gages that each model can connect

is 6.

Only EV-16Z supports the origin embedded gages.

• The origin function of EV-16Z realizes high-speed response and re-

duces the time and labor taken by referencing with a master each time

the power is turned on.

• With the RS LINK function a maximum of ten EV Counter units can

be linked. This makes it possible to construct a system consisting of a

maximum of sixty linear gages through one RS-232C port, which is

on, for example, a personal computer.

• The display unit is of a separate type (optional) which takes in-line

use into consideration.

• Depending on the external devices to be connected and uses, the fol-

lowing I/F connection and output mode can be selected:

[Connection I/F]

Tolerance judgment output

Separately outputs the judgment result from each CEL.

Segment output

Outputs the range specified by the external signal after evenly dividing it into ± ten stages.

The objective CEL to be output and its range can be specified with

the external SET signal.

BCD output

Output of sign and 6-digit data.

The objective CEL to be output can be designated with the external

SET signal.

RS-232C/RS LINK

A maximum of 10units/60 channels can be linked.

Preset and tolerance values can be remotely controlled.

Can be used simultaneously with other I/O devices.

[Output mode]

NORMAL mode (factory-set default)

Calculation mode

Calculate the sum, mean, maximum, minimum, and width between the specified CELs and outputs the results.

High-speed mode

Quickly outputs the specified CEL.

No. 99MBC034B

1 - 1

Page 10

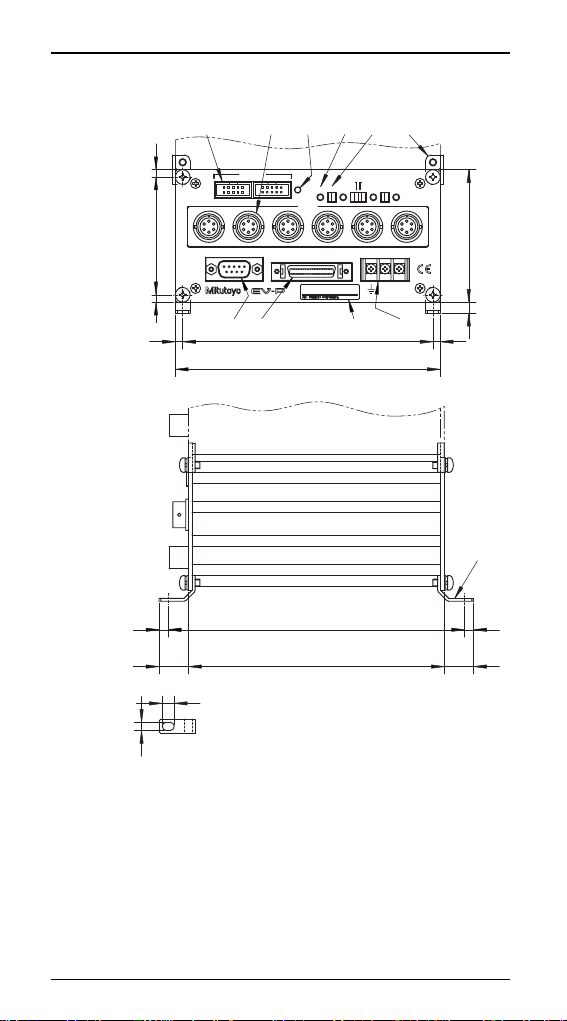

1.1.2 Name and dimensions of each part

1) EV-16P Unit: mm

54321

RS LINK

OUTIN

Err.

87

6543

LOAD

MODE

SEL.21DATA

CBA

FED

INPUT

1110

RS-232C

4 464

4 4136

IO/BCD

Code No.***-*** Model EV-16P

Code No.***-***

+V -V

DC12-24V

700mA

MADE IN JAPAN

9876

144

5

16

161

139

6.5

4.5

1. RS LINK connector 2. Error LED

3. Parameter input switch (4 pieces)

4. Parameter LED (8 pieces)

5. Gage input connector (INPUT A - F)

6. RS-232C connector 7. I/O connector

8. Power inlet terminal strip 9. Name plate

10. Junction bracket

11. M4 x 8 screw

12. Fixing leg

*

*

*

* Standard accessory

6 72

11, 12

5

16

1 - 2

No. 99MBC034B

Page 11

1 OVERVIEW

D

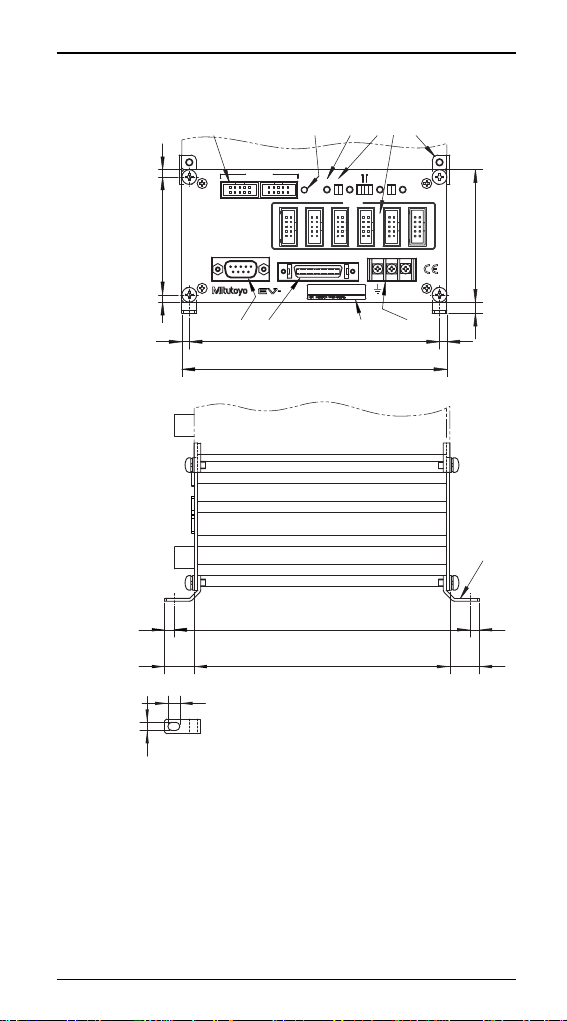

2) EV-16D Unit: mm

5

1110

4321

RS LINK

OUTIN

6543

Err.

LOAD87MODE

SEL.21DATA

INPUT

FEDCBA

RS-232C

4 464

4 4136

IO/BCD

Code No.***-*** Model EV-16D

Code No.***-***

+V -V

DC12-24V

700mA

MADE IN JAPAN

9876

144

5

16

161

139

6.5

4.5

1. RS LINK connector 2. Error LED

3. Parameter input switch (4 pieces)

4. Parameter LED (8 pieces)

5. Gage input connector (INPUT A - F)

6. RS-232C connector 7. I/O connector

8. Power inlet terminal strip 9. Name plate

10. Junction bracket

11. M4 x 8 screw

12. Fixing leg

*

*

*

* Standard accessory

6 72

11, 12

5

16

No. 99MBC034B

1 - 3

Page 12

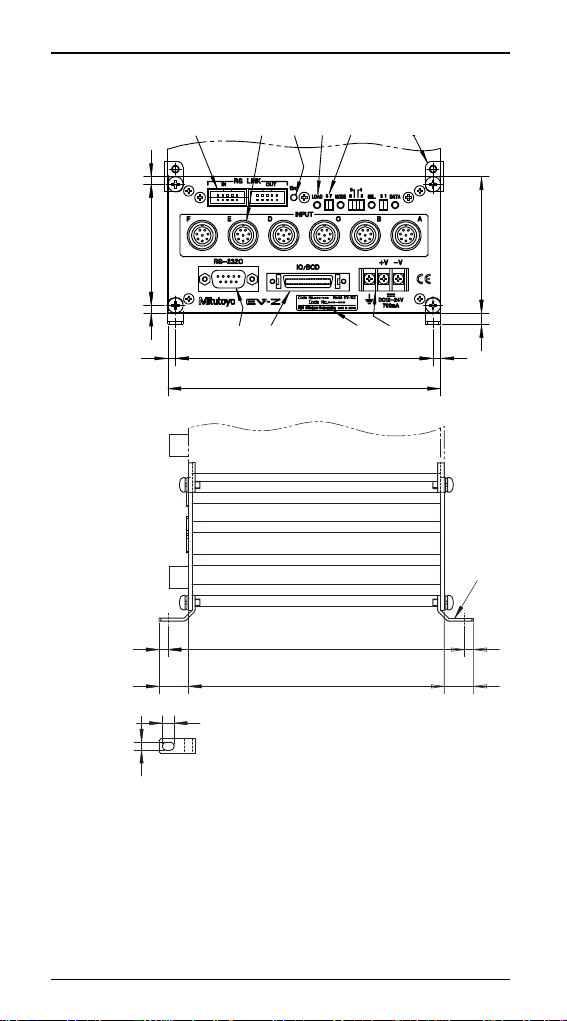

3) EV-16Z Unit: mm

54321

64

1110

1 - 4

44

4

5

16

6.5

4.5

76

136

144

98

161

139

1. RS LINK connector 2. Error LED

3. Parameter input switch (4 pieces)

4. Parameter LED (8 pieces)

5. Gage input connector (INPUT A - F)

6. RS-232C connector 7. I/O connector

8. Power inlet terminal strip 9. Name plate

10. Junction bracket

11. M4 x 8 screw

12. Fixing leg

*

*

*

* Standard accessory

672

4

11, 12

5

16

No. 99MBC034B

Page 13

1 OVERVIEW

1.2 D-EV External Display Unit (optional)

1.2.1 Features

The D-EV External Display Unit is an optional product used to

set the measurement conditions (parameters) and externally display EV Counter measurements.

A single D-EV can display/set up one EV Counter.

1.2.2 Name and dimensions of each part

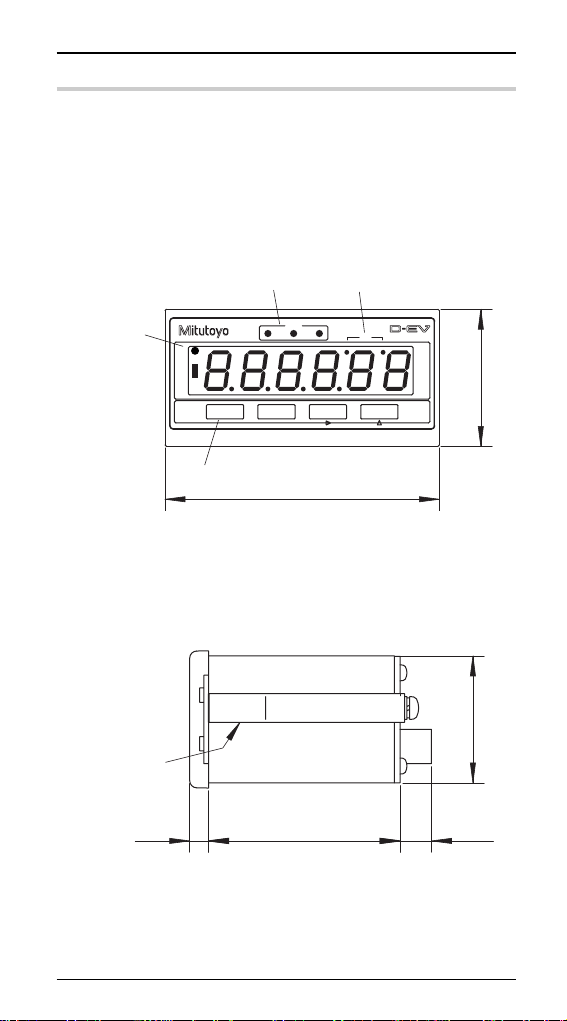

1) D-EV appearance (front view) Unit: mm

2

3

1

UNIT

4

GAGE

96

MODE P.SETFnDISP

TIR

MAX MIN

+NG

GO

48

-NG

1. UNIT LED

2. GAGE No. LED

3. Peak mode LED

4. Key switch

2) D-EV appearance (side view) Unit: mm

44.4

5

(11)676.6

5. Panel-mounting bracket

No. 99MBC034B

1 - 5

Page 14

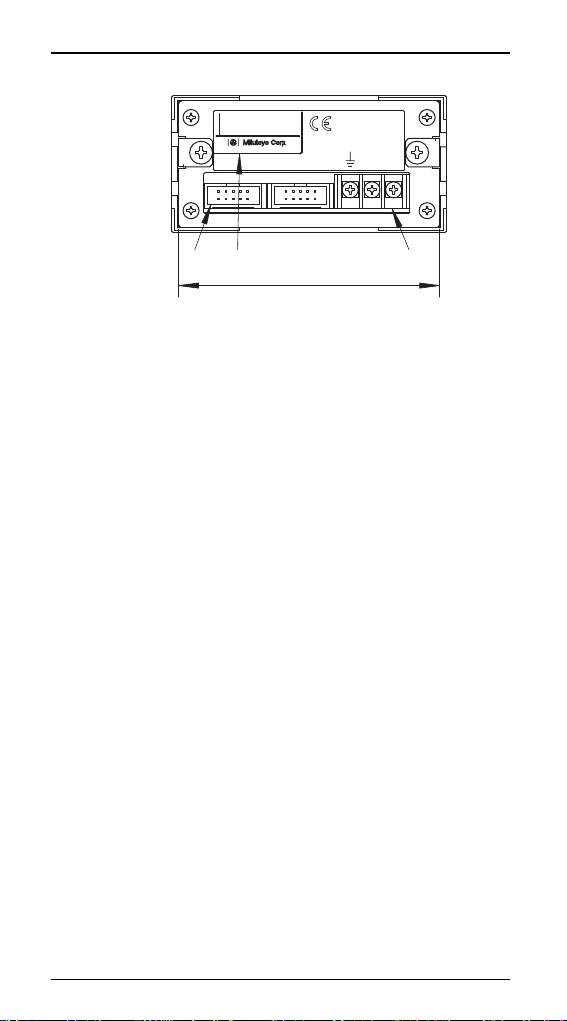

3) D-EV appearance (rear view) Unit: mm

02ADD400

Code No.

D-EV

Model

000001

Serial No.

MADE IN JAPAN

RS LINK

OUTIN

DC12-24V

200mA

+V

-V

687

91.4

6. RS LINK connector

7. Name plate

8. Power inlet terminal strip

1 - 6

No. 99MBC034B

Page 15

1.3 Internal Block Diagram

CEL designation

Peak mode switching

Zero-setting

Presetting

Peak clear

Tolerance value inputI/O output

RS-232C

Output function

mode

Calculation

Internal counter

Origin and

NORMAL mode

High-speed mode

CEL1

CELs

Sum of

tolerance setup

CELs

Mean of

Origin and

tolerance setup

Peak measurement

Peak measurement

CEL2

CELs

Maximum of

Origin and

tolerance setup

Peak measurement

CEL3

Simultaneously

Minimum of

Origin and

CEL4

1 OVERVIEW

Tolerance judgment output

Segment output

BCD outputCEL designation

BCD

Segment

judgment

Tolerance

CELs

tolerance setup

CELs

MAX - MIN of

Origin and

tolerance setup

Peak measurement

Peak measurement

CEL5

Calculation result

Tolerance judgment

Origin and

tolerance setup

Peak measurement

CEL6

function

Calculation

Internal counterGage

Gage selector:

Internal counter:

No. 99MBC034B

Gage

selector

Gage A

Gage C

Gage B

Gage D

Gage F

Gage E

By setting the appropriate parameters it is possible to connect a single gage output either to one internal counter or to

multiple internal counters. With this function, multiple origins and tolerance setups can be set for a single gage.

Origin setup, peak measurement, and tolerance setup can be

performed individually for each of the six internal counters

(CEL1 - CEL6).

1 - 7

selector

Page 16

Calculation function:

Each of the internal counters has a specific calculation function. Therefore, calculation can be performed between the

counters specified by the parameters.

Output function:

Either RS-232C, BCD, tolerance judgment, or segment output can be selected. The objective CEL to be output can be

selected using the RS-232C command or SET signal.

1 - 8

No. 99MBC034B

Page 17

SETUP

SETUP

This chapter describes the method used to in-

This chapter describes the method used to install and connect the EV Counter and make its

2

stall and connect the EV Counter and make its

initial conditions.

initial conditions.

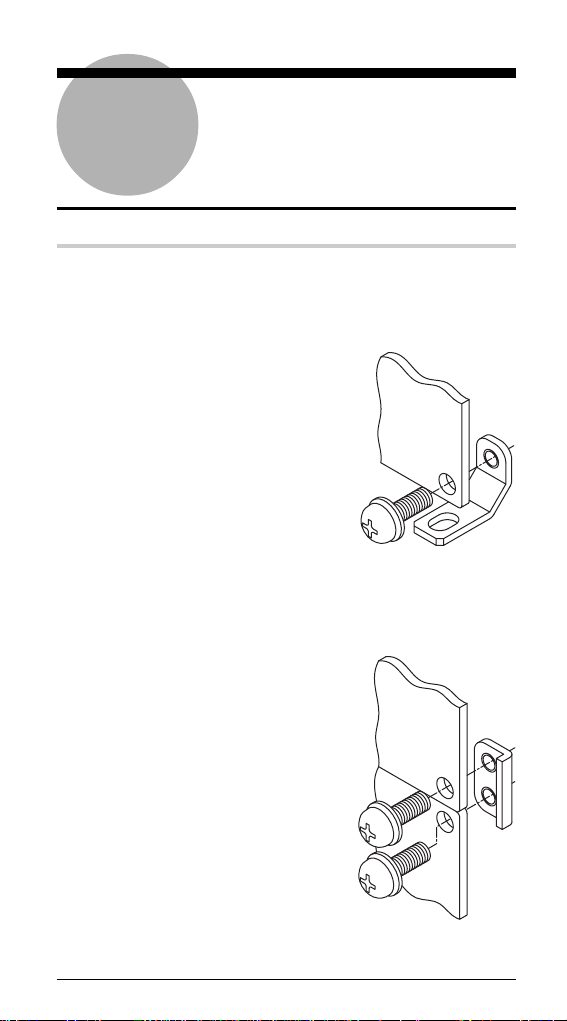

2.1 Installing the EV Counter

Both the front and rear panels of the EV Counter have four

mounting holes. Use the fixing legs and junction brackets which

come as the standard accessories to install the EV Counter.

a) The fixing legs

(1) Attach the fixing legs (4 places) on

the counter main unit using the

supplied screws.

(2) Use the oval hole provided on each

fixing leg to secure the counter to

an appropriate surface.

b) The junction brackets

Use the junction brackets and supplied screws to join the two panels

along the vertical.

No. 99MBC034B

2 - 1

Page 18

2.2 Connecting Cables

IMPORTANT • Connection should be made only after the

2.2.1 Connecting gages

(1) Sequentially connect the required number of linear gages to

(2) If the EV-16P or EV-16Z is connected to a gage that does

NOTE • The gage resolution has been factory-set to 1mm.

(3) Set the parameter for designating available axes according

power to the main unit and to the partner device

of the connection have been turned off. Otherwise, the counter main unit and the connected

device will be damaged.

• Use a 12 - 24VDC power supply with a control

output current of 1A or greater. Do not draw

power from a source which is used by highpower equipment.

• Do not route the power cable, I/O cable, RS232C cable, RS LINK cable, or gage connection cable with other power cables.

• Use a shielded I/O cable not longer than 3m.

• Always ground.

• Each cable should be secured (to, for example,

the main body of the device).

the corresponding connectors, starting with the INPUT A

connector.

not have a resolution of 1µm, refer to section 3.1 Setting

Parameters (with D-EV) and section 3.2 Setting Parameters (with EV Counter) to adjust the resolution.

• It is not necessary to modify the resolution on the EV16D.

to the number of gages to be connected.

(Refer to section 3.1 Setting Parameters (with D-EV) and

section 3.2 Setting Parameters (with EV Counter)).

2 - 2

No. 99MBC034B

Page 19

+V -V

DC12-24V

700mA

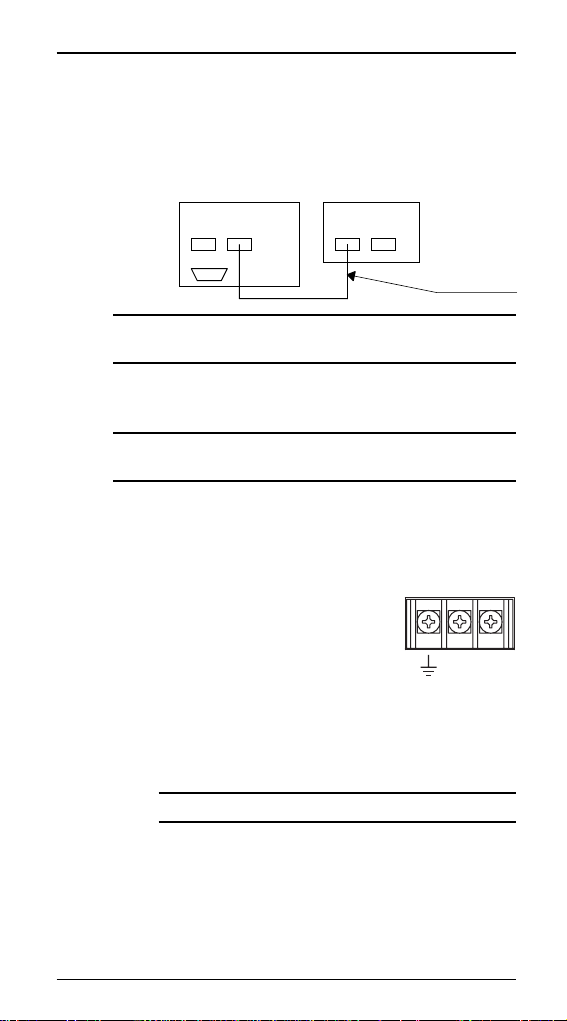

2.2.2 Connecting the D-EV (External Display Unit)

If a D-EV (External Display Unit) is used, make the necessary

connections according to the following procedure.

(1) Connect the RS LINK OUT connector of the EV Counter to

the RS LINK IN connector of the D-EV using an RS LINK

connection cable.

EV Counter D-EV

RS LINK

IN

RS-232C

OUT

RS LINK

IN OUT

2 SETUP

RS LINK

connecting

cable (optional)

NOTE Always use the RS LINK connection cable specified by

Mitutoyo. Refer to section 8.3 Optional Accessories.

(2) To link more than one counter with the RS LINK connec-

tion cables, refer to chapter 6 RS LINK FUNCTION.

TIP The D-EV will display the data of the EV Counter which

is connected to the RS LINK IN connector of the D-EV.

2.2.3 RS-232C, I/O/BCD, and RS LINK connections

The EV Counter has an RS-232C connector, I/O/BCD connector, and RS LINK connector. If these connectors are used, refer

to chapter 5 RS-232C COMMUNICA-

TION FUNCTION; chapter 6 RS LINK

FUNCTION; and chapter 7 I/O FUNCTION for information about cable connec-

tions.

2.2.4 Connecting the power supply and grounding

The EV Counter and D-EV do not have a power switch. Power

is supplied by connecting the power source to the +V and -V

terminals on the power inlet terminal strip.

IMPORTANT Positively ground the grounding terminal.

No. 99MBC034B

2 - 3

Page 20

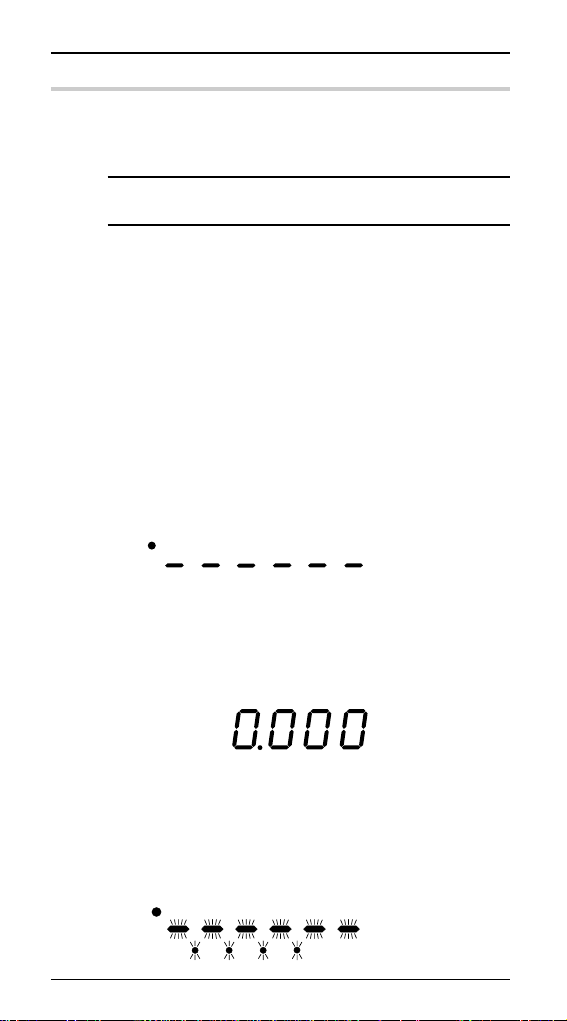

2.3 Power On

When the power source is connected to the EV Counter, it enters the counting stand-by state. To start operation and enter the

counting state, quit the stand-by state.

TIP The counting stand-by function is an alarm function that

is entered if there is a power interruption during use.

a) If a D-EV is not connected

(1) If the EV-16P or EV-16D is used,enter the RS-232C com-

mand or I/O signal (a HOLD signal to clear the error) in the

EV Counter. For information refer to chapter 5 RS-232C

COMMUNICATION FUNCTION; and chapter 7 I/O

FUNCTION.

(2) If the EV-16Z is used, push in the spindles of all connected

gages to pass through the origins after completing the procedure (1) described above.

b) If a D-EV is connected

(1) When the EV Counter and D-EV are on, the counting stand-

by state is entered.

[Display on the D-EV]

UNIT

(2)-1

If the EV-16P or EV-16D is used, press the P.SET key to

quit the counting stand-by state and enter the counting state.

[Display on the D-EV]

UNIT

+NG

GO

-NG

+NG

GO

-NG

2 - 4

(2)-2

If the EV-16Z is used, press the P.SET key to cancel the

counting stand-by mode, then the counter enters the origin

detection wait mode. All decimal points flash in the origin

detection wait mode.

[Display on the D-EV]

UNIT

+NG

GO

-NG

No. 99MBC034B

Page 21

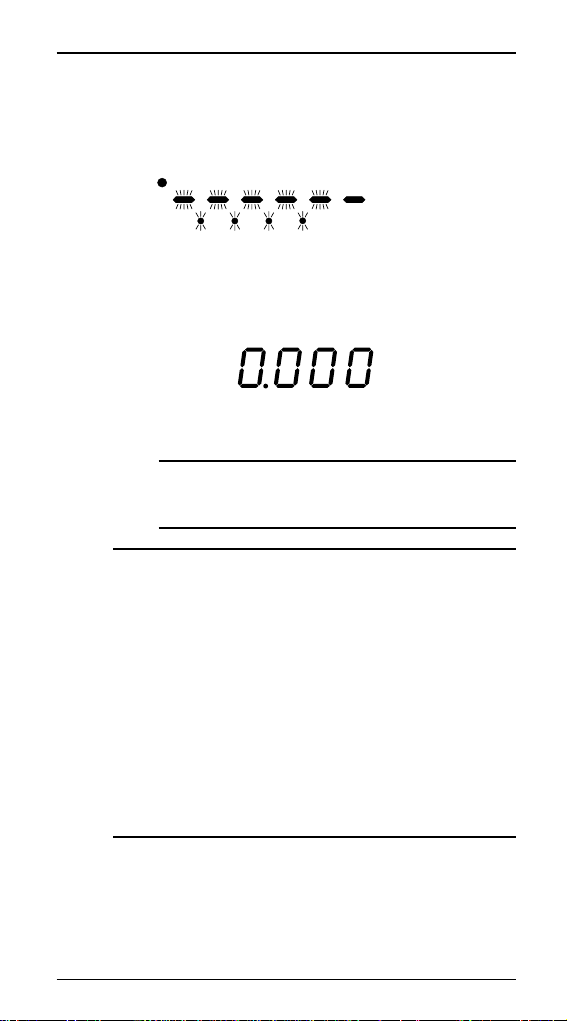

2 SETUP

(3) If the EV-16Z is used, push in the spindle of the connected

gages to pass through the origin one after another, and each

time it passes through the origin the corresponding bar display of the CH starts flashing.

[Display on the D-EV]

UNIT

+NG

-NG

GO

(4) If the EV-16Z is used, push in the spindles of all connected

gages to pass through the origins, then the counter enters the

counting mode.

[Display on the D-EV]

UNIT

+NG

GO

-NG

c) Precautions in using the EV-16Z

If the EV-16Z is used, note the following precautions.

IMPORTANT Be sure to pass the spindle through the origin for

detection properly. If the spindle vibrates near the

origin, the origin may not be detected correctly.

TIP • The origin-embedded gage has a specific origin in-

side the gage. When the spindle passes through the

origin the signal generates, then the preset position is

restored.

• Origin detection is usually performed when the power

is turned on. If the origin re-detection parameter

(P.No.42) is set to 1, the counter enters the origin detection wait mode after completing preset or tolerance

setup (for details, refer to the section, “3.1 Setting

Parameters (with D-EV)”), or when the HOLD signal

is triggered.

• If the HOLD signal is input again during origin re-detection, the counter resets origin re-detection, except

when resetting an error.

No. 99MBC034B

2 - 5

Page 22

Page 23

SETTING PARAMETERS

This chapter describes the method used to set

3

the parameters required to use the EV

Counter.

3.1 Setting Parameters (with D-EV)

Before using the EV Counter, various parameters must be set

up. This section explains the setup method using the essential

parameters, "gage resolution" (for EV-16P and EV-16Z) and

"designation of available axes", as examples.

NOTE For the resolution of 0.1µm setting, a D-EV is absolutely

3.1.1 Parameter mode ON

NOTE If a parameter setting needs to be modified, first modify

necessary.

Set the parameter mode to ON to modify the existing parameter

settings.

(1) Press the P.SET key while holding down the Fn key to set

the parameter mode to ON.

[Display on the D-EV]

UNIT

(2) Press the P.SET key one more time to modify the setup

value to 1.

[Display on the D-EV]

UNIT

the setting of Parameter 00 to 1. Parameter modification

cannot be attempted while the setting of Parameter 00 is

0 (Reference mode).

(3) Begin setting the parameters.

+NG

GO

-NG

+NG

GO

-NG

No. 99MBC034B

3 - 1

Page 24

3.1.2 Specifying the gage resolution (for EV-16P and EV-16Z)

In order to connect a gage with a resolution that is not 1µm, the

counter must modify its resolution setting to that of the connected gage.

(1) Press the Fn key repeatedly to display Parameter No. 12 and

the INPUT number of A.

[Display on the D-EV]

UNIT

+NG

GO

-NG

(2) Press the P.SET key to modify the setup value. (Refer to

section 3.1.5 List of parameters.)

(3) If more than one gage is connected, repeat steps (1) and (2)

to set the resolution of all gages while sequentially switching the INPUT number by pressing the Fn key.

(4) To complete the setting operation press the P.SET key

while holding down the Fn key.

If the EV-16Z is used, push in the spindle to pass through

the origin.

In order to continue the setup operation for other parameters

simply press the Fn key.

NOTE

In order to modify the existing resolution setting, either

press the Fn key repeatedly until the desired Parameter

No./INPUT number is displayed or exit from the parameter

mode and start the setup operation from the beginning.

3.1.3 Setting the axes to be used

If there are less than six gages connected, the setting of the number of available axes must be modified.

(1) Press the Fn key to display Parameter No.13.

[Display on the D-EV]

UNIT

+NG

GO

-NG

(2) Press the P.SET key to modify the setup value. (Refer to

section 3.1.5 List of parameters.)

NOTE If the setup is made as (Number of available axes) >

(Number of gages), an error display/output (Error40) will

result.

If the setup is made as (Number of available axes) <

(Number of gages), gages that have not been designated will be ignored.

For information refer to section 8.4 List of Error Outputs.

3 - 2

No. 99MBC034B

Page 25

3 SETTING PARAMETERS

(3) To complete the setting operation press the P.SET key

while holding down the Fn key. If the EV-16Z is used, push

in the spindle to pass through the origin.

In order to continue the setup operation for other parameters

simply press the Fn key.

TIP Relationship between the parameter setup values and

available axes

An EV Counter has six internal counters (CEL 1 - 6).

Data of gages connected to the gage input connectors,

INPUT A - F, will be displayed/output as the data of CEL

1 - 6, respectively.

Available axes are designated by determining the relationship between INPUT A - F and CEL 1 - 6. The following table lists the possible combinations.

Setup value

1

2

3

4

5

6

CEL1 CEL2 CEL3 CEL4 CEL5 CEL6

INPUT A INPUT A INPUT A INPUT A INPUT A INPUT A

*1

INPUT A INPUT B INPUT A INPUT B INPUT A INPUT B

INPUT A INPUT B INPUT C INPUT A INPUT B INPUT C

INPUT A INPUT B INPUT C INPUT D INPUT A INPUT B

INPUT A INPUT B INPUT C INPUT D INPUT E INPUT A

*2

INPUT A INPUT B INPUT C INPUT D INPUT E INPUT F

*1

: If the setup value is "2", internal counters CEL1, 3, and 5 will

display/output the data of INPUT A. Internal counters CEL2, 4,

and 6 will display/output the data of INPUT B. By setting a different tolerance value for each of CEL1, 3, and 5, three different

types of tolerance judgments can be made from the data of INPUT A.

*2 : The factory-set default is "6".

3.1.4 Parameter mode OFF

(1) Press the P.SET key while holding down the Fn key to set

the parameter mode to OFF. If the EV-16Z is used, push in

the spindle to pass through the origin. The parameter setup

is modified and the Display Unit returns to the count value

display.

NOTE • If the P.SET key is pressed during the setup operation

and while the Fn key is being held down, the setup

operation is interrupted and the count value display is

restored. (If the EV-16Z is used, push in the spindle to

pass through the origin.) If this occurs, the modifications made up to the interruption are reflected in actual operation.

• During parameter setup operation, the parameter in-

put switch, RS-232C output, and external signal input

are all disabled.

No. 99MBC034B

3 - 3

Page 26

3.1.5 List of parameters

* Factory-set default

No.

Parameter name Setup value: function

00 Reference/Modification 0*: For reference only

1: Can be modified

3: Not available

10 Parameter clear

11

Selection of counting direction

(to be set for each INPUT number)

1: Resets to factory-set default

If the spindle is pushed-in

0*: + counting

1: - counting

12 Case of EV-16P or EV-16Z 0: 10µm gage

Specification of gage resolution*11: 5µm gage

(to be set for each INPUT number)

2*: 1µm gage

3: 0.5µm gage

4: 0.1µm gage

12 Case of EV-16D 0: INC (LGS series)

Specification of gage type 1*: ABS (LGD series)

2*: ABS ORG

13 Designation of available 6*: 6 gages are used

*2

axes

5: 5 gages are used

4: 4 gages are used

3: 3 gages are used

2: 2 gages are used

1: 1 gage is used

14 Start-up mode 0*: Counting stand-by

15 Display unit

*1

1: Counting execution

0*: mm

1: E (=1/25.4 mm)

17 Designation of calculation 0*: CEL1, 2

*4

axis

1: CEL1, 2, 3

2: CEL1, 2, 3, 4

3: All CELs designated as

20 I/O output mode

21

I/O output logic

*6

*7

available axis

0: Command

1*: Interval

Tolerance judgment and segment

0*: Output terminal is L

1: Output terminal is H

BCD

0*: H at output 1

1: L at output 1

22 Selection of I/O function

*60*

1: Calculation mode

23 Selection of I/O type

*6

2: High-speed mode

0*: Tolerance judgment

1: Segment output

2: BCD output

3 - 4

2: Not available

*3

*5

: NORMAL mode

No. 99MBC034B

Page 27

3 SETTING PARAMETERS

No.

Parameter name Setup value: function

25 Baud rate

*8, *9

0: 4800 bps

1*: 9600 bps

26 Parity

*8, *9

2: 19200 bps

0: None

1: Odd number

27 Data bits

*8, *9

28 HOLD selection

*9

2: Even number

0*: 7 bits

1: 8 bits

0*: HOLD

1: RS-232C output

41

Origin detect direction (EV-16Z only)

42

Origin re-detection

*11

(EV-16Z only)

0*: origin detection at + count

1: origin detection at - count

0*: not detect

1: detect

43

Origin initialize (EV-16Z only) Starts with 0 from the origin.

1: initialize (one-shot)

*1 : If this parameter is modified, each zero point, preset value,

and tolerance value for CEL1 to CEL6 will be cleared.

*2 :

For information about this function refer to TIP on page 3-3.

*3 : This is not modified even if an attempt is made to clear the

parameters. If the display unit is set to E, the UNIT LED

lights in green.

*4 : Sets the CEL to be used for the calculation function. (This

function is valid only if Selection of I/O function is set to

Calculation mode.)

*5 : If all CELs designated as the available axis are se-

lected, CELs to be used for calculation will be as shown in

the table below.

Setup value for designating CEL to be used for calculation

the available axes

6 1, 2, 3, 4, 5, 6

5 1, 2, 3, 4, 5

4 1, 2, 3, 4

3 1, 2, 3

2 or 1 1, 2

*6 : For information about this function refer to chapter 7 I/O

FUNCTION.

*7 : The output logic of the data section will vary depending on

the I/O type selection result. However, the logic of the input signal, NORMAL, READY, START, and EXTEND

output remains fixed.

*8 : For information about this function refer to chapter 5 RS-

232C COMMUNICATION FUNCTION.

No. 99MBC034B

* Factory-set default

*10

3 - 5

Page 28

*9 : The parameter modification will be made valid after reset-

ting the power.

*10: This function will output data from the RS-232C connector

if a HOLD signal is input through the I/O connector. In this

case, all RS-232C commands will be ineffective.

*11: For details, refer to the section, "2.3 Power On".

3.2 Setting Parameters (with EV Counter)

Before using the EV Counter, various parameters must be set

up. The parameter setup operation is easily performed if a DEV is used.

IMPORTANT The EV-16Z can not modify the origin-related set-

tings by itself. For making this modification in EV16Z, prepare a D-EV.

NOTE • Use a D-EV for the resolution of 0.1µm setting.

Set up of EV Counter alone, is not possible.

• Only a D-EV allows setting when the modification is

made for the parameter no.41, 42, and 43.

• In order to connect a gage with a resolution that is not

1µm, the counter must modify its resolution setting to

that of the connected gage if the EV-16P or EV-16Z is

used.

• The gage type (INC, ABS, etc.) must be set for the

EV-16D.

• If the setup is made as (Number of available axes) >

(Number of gages), an error display/output (Error40)

will result.

If the setup is made as (Number of available axes) <

(Number of gages), gages that are not designated will

be ignored. For information refer to section 8.4 List of

Error Outputs.

3.2.1 Parameter mode ON

Set the parameter mode to ON to modify the existing parameter

settings.

(1) Press the LOAD button while holding down the DATA but-

ton to set the parameter mode to ON.

[Parameter LED Indicator]

54

87 6

LOAD MODE SEL. DATA

321

(2) Begin setting the parameters.

3 - 6

No. 99MBC034B

Page 29

3 SETTING PARAMETERS

3.2.2 Setting the parameters

(1) Select the parameter name using the SEL. button and

MODE button. Each time the SEL. button is pressed, the

on/off pattern of LEDs No.3, 4, 5, and 6 will change. Each

time the MODE button is pressed, the on/off pattern of

LEDs No.7 and 8 will change.

[Parameter LED Indicator]

54

6

3

SEL.

54

6

3

SEL.

54

6

3

SEL.

54

6

3

SEL.

87

MODE

87

MODE

87

MODE

(2) Select the parameter value using the DATA button. Each

time the DATA button is pressed, the on/off pattern of LEDs

No.1 and 2 will change.

[Parameter LED Indicator]

21

DATA

21

DATA

21

DATA

21

DATA

(3) Accept the parameter value selected by pressing the LOAD

button. The next parameter for setup is automatically moved

to.

NOTE The modifications will not be reflected in the actual op-

eration unless they have been accepted.

(4) Repeat steps (1) to (3) to set the other required parameters.

(Refer to section 3.2.4 List of parameters.)

3.2.3 Parameter mode OFF

(1) Press the LOAD button while holding down the DATA but-

ton to set the parameter mode to OFF.

[Parameter LED Indicator]

54

87 6

LOAD MODE SEL. DATA

321

(2) The count value display will be restored. (after passing

through the origin, only EV-16Z restores the count value

display)

No. 99MBC034B

3 - 7

Page 30

NOTE • If the LOAD button is held down for more than 1 sec-

ond while the MODE button is held down, all parameters will be reset to the factory-set defaults.

• During the parameter setup operation, the D-EV keys,

RS-232C output, and external signal input are disabled.

3.2.4 List of parameters

* Factory-set default

Parameter name LED Setup content LED

8 7 6 5 4 3 2 1

Case of EV-16P or EV-16Z

*1

Resolution of INPUT A

Resolution of INPUT B

Resolution of INPUT C

Resolution of INPUT D

Resolution of INPUT E

Resolution of INPUT F

*1

*1

*1

*1

*1

10µm

5µm

1µm

0.5µm

*

Case of EV-16D

*2

INC (LGS series)

ABS (LGD series)

ABS ORG

+ Counting

- Counting

If the spindle is pushed-in

Axis designation 2 is valid

Gage type of INPUT A

Gage type of INPUT B

Gage type of INPUT C

Gage type of INPUT D

Gage type of INPUT E

Gage type of INPUT F

Counting direction of INPUT A

Counting direction of INPUT B

Counting direction of INPUT C

Counting direction of INPUT D

Counting direction of INPUT E

Counting direction of INPUT F

Designation of available axis 1

1 gage is connected

2 gages are connected

3 gages are connected

*2

Designation of available axis 2

Axis designation 1 is valid

4 gages are connected

5 gages are connected

6 gages are connected

3 - 8

*

*

*

*

*

No. 99MBC034B

Page 31

3 SETTING PARAMETERS

* Factory-set default

Parameter name LED Setup content LED

8 7 6 5 4 3 2 1

Start-up mode

Display unit

*1*3

Designation of calculation axis

I/O output mode

I/O output logic

*6

*7

Selection of I/O function

Selection of I/O type

*8, *9

Baud rate

*8, *9

Parity

*8, *9

Data bits

HOLD selection

*9

*4

*6

*6

Counting stand-by

Counting execution

*

mm

E (=1/25.4 mm)

*

CEL1, 2

CEL1, 2, 3

CEL1, 2, 3, 4

*5

All CELs

Command

*

Interval

Output terminal is H

Output terminal is L

NORMAL mode

Calculation mode

High-speed mode

Tolerance judgment output

Segment output

BCD output

4800 bps

*

9600 bps

19200 bps

None

Odd number

Even number

7 bits

*

*

8 bits

*

HOLD

RS-232C output

*10

*

*

*

No. 99MBC034B

3 - 9

Page 32

*1: If this parameter is modified, each zero point, preset value,

and tolerance value for CEL1 to CEL6 will all be cleared.

*2: For information about this function refer to TIP below.

*3: This is not modified even if an attempt is made to clear the

parameters. If the display unit is set to E, the UNIT LED

lights in green.

*4: Sets the CEL to be used for the calculation function. (This

function is valid only if Selection of I/O function is set to

Calculation mode.)

*5: If all CELs designated as the available axis are se-

lected, CELs to be used for calculation will be as shown in

the table below.

Setup value for designating CEL to be used for calculation

the available axes

6 1, 2, 3, 4, 5, 6

5 1, 2, 3, 4, 5

4 1, 2, 3, 4

3 1, 2, 3

2 or 1 1, 2

*6: For information about this function refer to chapter 7 I/O

FUNCTION.

*7: The output logic of the data section will vary depending on

the I/O type selection result. However, each logic of the

input signal, NORMAL, READY, START, and EXTEND

output remains fixed.

Tolerance judgment and segment output BCD output

The corresponding output terminal is 1=H, 0=L

L, and others are H.

The corresponding output terminal is 1=L, 0=H

H, and others are L.

*8: For information about this function refer to chapter 5 RS-

232C COMMUNICATION FUNCTION.

*9: The parameter modification will be made valid after reset-

ting the power.

*10: This function will output data from the RS-232C connector

if a HOLD signal is input through the I/O connector.

In the case of " ", all RS-232C commands will be ineffective.

3 - 10

No. 99MBC034B

Page 33

BASIC OPERATION

This chapter describes the basic operation of

4

the EV Counter with a D-EV.

4.1 Power ON Precautions

Turn on the power to the EV Counter by referring to section

2.3 Power On.

Neither move the gage stylus nor operate any key until the EV

Counter enters the counting stand-by state.

[Counting stand-by state (on D-EV)]

UNIT

+NG

GO

-NG

No. 99MBC034B

4 - 1

Page 34

4.2 Switching the Display/Output CH (with D-EV)

Use the DISP key to switch the display/output CH (channel).

This section explains the procedure, using the top EV Counter

connected via the RS LINK function as an example.

(1) When the counter enters the counting mode after the power

is turned on, the count value of CH01 (CEL1) is displayed

on the D-EV, and the corresponding GAGE No. LED is

turned on.

[GAGE No. LED Indicator]

TIP • CH numbers (01 - 99) will be automatically assigned

to the EV counters sequentially from the top as they

are connected via the RS LINK function. If only one

counter is connected, it is assigned CH numbers 01

through 06, which corresponds to CEL1 through

CEL6. For more information refer to chapter 5, "RS

LINK FUNCTION".

• GAGE No. LEDs show the currently displayed CEL

number with the corresponding on/off pattern.

CEL1

CEL3

CEL5

GAGE

GAGE

GAGE

(2) If the DISP key is pressed, the display/output CH is

switched to the next display/output CH, displaying the

count value of CH02 (CEL2). While the DISP key is held

down, the CH number (CH02) and gage input connector

number (= b) is displayed on the D-EV.

[GAGE No. LED Indication]

CEL2

CEL4

CEL6

GAGE

GAGE

GAGE

GAGE

GAGE

[Display on D-EV (while the DISP key is held down)]

UNIT

+NG

GO

-NG

(3) Each time the DISP key is pressed, the current CH number

is switched, sequentially displaying the count values of

CH03 (CEL3) to CH06 (CEL6) in order.

4 - 2

No. 99MBC034B

Page 35

4 BASIC OPERATION

(4) If the DISP key is pressed again, a 6-axis tolerance judg-

ment bar is displayed on the D-EV, showing all the judgment results from CEL1 to CEL6 at the same time.

[Indication of GAGE No. LED]

GAGE

[Display on D-EV]

UNIT

CEL1CEL2CEL3CEL4CEL5CEL6

+NG

GO

-NG

NOTE • While the bar is being displayed, only the DISP key

can be operated.

• The +NG and -NG bars are turned on for a CEL that

causes an error.

(5) If the DISP key is pressed again, the display of CH01

(CEL1) restores.

No. 99MBC034B

4 - 3

Page 36

4.3 Switching the Peak Mode (with D-EV)

The internal counters, CEL1 - CEL6, will hold (lock) the peak

values (Max., Min., and TIR) of the count values. Therefore, by

switching the peak mode with the MODE key, it is possible to

switch the value to be displayed (on the D-EV) or output.

(1) Press the DISP key to select a CEL number. The count

value of the selected CEL will be displayed (on the D-EV)

or output.

(2) Press the MODE key to switch the peak mode.

The on/off pattern of the LEDs (on the D-EV) shows the

selected peak mode.

TIR

MAX MIN

MAX MIN

MAX MIN

MAX MIN

Current value: Current stylus position

TIR

Max.: Maximum value since the peak value

was last cleared.

TIR

Min.: Minimum value since the peak value

was last cleared.

TIR

TIR: Max. - Min.

NOTE • Peak values are retained in memory even when the

power is off.

• The peak mode can be switched by RS-232C communication.

4 - 4

No. 99MBC034B

Page 37

4 BASIC OPERATION

4.4 Clearing the Peak Value (with D-EV)

Held (retained) peak values can be cleared as necessary.

(1) Press the DISP key to select a CEL number. The count

value of the selected CEL will be displayed (on D-EV) or

output.

(2) Press the MODE key to select one of the Max., Min., and

TIR modes. The corresponding LED on the D-EV is turned

on to indicate the selected mode. (Refer to section 4.3

Switching the Peak Mode (with D-EV).)

(3) Press the P.SET key to clear the peak value.

This results in Max. = Min. = Current value, and TIR = 0.

NOTE • If the P.SET key is pressed in the current-value mode,

both peak-value clear and presetting are executed.

(Refer to section 4.7 Presetting (with D-EV).

• Press the P.SET key to clear the peak values of all

CELs assigned the same INPUT number.

(Example: With available axes = 2 if the peak value of

CEL1 is cleared with the P.SET key, the peak values

of CEL3 and CEL5 will also be cleared. Refer to section 3.2.4 List of parameters.)

No. 99MBC034B

4 - 5

Page 38

4.5

Input of Preset Value/Tolerance Value (with D-EV)

With the D-EV it is possible to input a setting value consisting

of a maximum of six digits.

(1) Press the DISP key to select a CEL number. The count

value of the selected CEL will be displayed (on the D-EV)

or output.

(2) Press the Fn key to select the type of setting value (preset

value, lower limit, and upper limit). The on pattern of the

GAGE No. LED, indicating the selected CEL number, will

flash in a different color according to the type of setting

value selected, and the current setting value will be displayed on the D-EV.

Preset value

Lower tolerance limit

Upper tolerance limit

GAGE

GAGE

GAGE

green

amber

red

[Display on the D-EV (current value display)]

UNIT

+NG

GO

-NG

NOTE The D-EV Counter uses a 6-digit display, however a

value consisting of a maximum of eight digits can be

set using the RS-232C communication function. If a

number consisting of more than seven digits has already been set, the most significant one or two digits

will be represented by an "F", as in F34.567, on the

display.

(3) Enter the setting value.

MODE key: Shifts the digit place (flash) for input.

P.SET key: Inputs the setting value (places a digit).

Fn key: Aborts the input operation (modification of

the setting value is canceled).

[Display on the D-EV]

UNIT

UNIT

Either ± sign must be set with the most signifi-

+NG

GO

-NG

cant digit. The displayed number will change in

the following order: 0, 1, ...9, -0, -1, ...-9, 0.

4 - 6

No. 99MBC034B

Page 39

4 BASIC OPERATION

(4) Repeat step 3 as required to place all digits, including the

least significant digit.

[Display on the D-EV]

UNIT

+NG

GO

-NG

NOTE • If the gage resolution has been set to 5µm/0.5µm, set

the least significant digit to 0 or 5.

• Only one set of tolerance values can be set for each

CEL.

(5) While the least significant digit is flashing, press the MODE

key. The entered value is accepted and the flashing stops.

[Display on the D-EV]

UNIT

+NG

GO

-NG

(6) Press the Fn key to move to the next setup item.

The selected item will change as follows: preset value,

lower limit value, upper limit value, count value.

NOTE • Preset values and tolerance values are retained in

memory even when the power is off.

• Set a lower tolerance limit that is equal to or smaller

than the upper tolerance limit. An incorrect setting

may cause a tolerance setting error (Err90). If this occurs, press the P.SET key and perform the input operation again, starting with the lower tolerance limit.

• In the case of using the EV-16D, perform presetting/

tolerance limit setting with the linear gage connected,

as the connected linear gage sets the resolution automatically

TIP • If the RS-232C communication function is used, a pre-

set value/tolerance value of a maximum of eight digits

can be set.

• The factory-set default preset value, lower limit value,

and upper limit value are as follows:

If a 1µm gage is used:00000.000 / -99999.999 /

99999.999

Display on D-EV: 000.000/ -F99.999/ F99.999

No. 99MBC034B

4 - 7

Page 40

4.6 Clearing the Error State

The error state can be cleared with the following procedures.

If the EV-16Z is used, push in the spindle to pass through the

origin after completing the following procedures.

(1) Press the DISP key to select a CEL number in the error

state. Then press P.SET key.

(2) The HOLD input signal rises to "H". (I/O)

(3) Input the CS command. (RS-232C)

NOTE • While the error state is being canceled, Error40 is dis-

played (on D-EV) or output.

• While the error state is being canceled, the GAGE No.

LED flashes.

• Time required for error cancelation: 30ms (EV-16P

and EV-16Z), max. 8s ( EV-16D)

4 - 8

No. 99MBC034B

Page 41

4 BASIC OPERATION

4.7 Presetting (with the D-EV)

Replace the current value with a preset value.

(1) Press the DISP key to select a CEL number. The count

value of the selected CEL will be displayed (on the D-EV)

or output.

(2) Press the MODE key to select the current-value mode.

The on/off pattern of the LEDs show the selected mode.

[MODE LED Indicators]

(3) Press the P.SET key to replace the current value (displayed

value) with a preset value. At this time the peak values will

be cleared and Max. = Min. = Current value, and TIR = 0.

TIR

MAX MIN

NOTE • The EV Counter can count a maximum of eight digits,

however the D-EV Counter can display a maximum of

six digits. If a number has more than six digits, the

most significant one or two digits will be represented

by an "F". If the count value returns to a number of six

digits or less, the D-EV also returns to normal display.

Example)

Count value of EV Counter main unit: 1000.001

Display on the D-EV: F00.001

• If the EV-16D is connected to an ABS_ORG type

gage, approximately four seconds is required for the

preset value to be recalled on the EV-16D. During this

time do not move the spindle. Doing so may displace

the zero point.

• An ABS or ABS_ORG type gage can be preset one

million times (nominal).

No. 99MBC034B

4 - 9

Page 42

4.8 Tolerance Judgment (with the D-EV)

Three tolerance judgment result stages can be displayed on the

GAGE No. LEDs and output through the I/O connector. (For

more information about the I/O output function refer to chapter

7 I/O FUNCTION.)

(1) Press the DISP key to select a CEL number. The count

value of the selected CEL will be displayed (on the D-EV)

or output.

(2) Press the MODE key to select one of the peak modes: Max.,

Min., and TIR. The GAGE No. LED's on pattern, indicating

the selected CEL number will light in a different color according to the tolerance judgment result.

(Display example of tolerance judgment result from CEL1)

+NG:

GO:

-NG:

GAGE

Red

(upper tolerance limit < design value)

GAGE

Green

(lower tolerance limit ≤ design value ≤ upper

tolerance limit)

GAGE

Amber

(design value < lower tolerance limit)

NOTE • There will always be six I/O output channels.

• The tolerance judgment result can be also verified

with the 6-axis tolerance judgment bar display. (Refer

to section 4.2 Switching the Display/Output CH (with

the D-EV).

4 - 10

No. 99MBC034B

Page 43

RS-232C COMMUNICATION

FUNCTION

5

This chapter describes the RS-232C communication function.

5.1 RS-232C Connection

Connect the specified cable (D-sub, 9-pin cross-type cable) to

the RS-232C connector. The user must separately purchase this

cable.

NOTE If multiple EV Counters are connected via the RS LINK

function, connect the above-mentioned cable to the RS232C connector of the first EV Counter.

5.2 RS-232C Output Specifications

5.2.1 Specifications of cables and connectors

Receptacle specification:

D-sub, 9-pin (male) inch-screw specification

Applicable plug specification:

D-sub, 9-pin (female) inch-screw specification

Examples of commercially available cables:

DOS/V: KRS-403XF 1K (1.5m, Manufacturer: Sanwa Supply)

PC-98: KRS-423XF 1K (1.5m, Manufacturer: Sanwa Supply)

5.2.2 Communication specifications (Conforms to EIA: RS232C standard)

Home position

Communication method

Data transfer rate 4800, 9600, 19200bps

Bit configuration Start bit: 1 bit

Communication

condition settings

DTE (terminal), with cross-type cable

Half-duplex, teletype protocol

Data bits: 7 or 8-bit ASCII

uppercase characters

Parity bit: None, Even number,

Odd number

Stop bit: 2 bits

To be set with parameters

Refer to chapter 3 SETTING

PARAMETERS.

No. 99MBC034B

5 - 1

Page 44

5.2.3 Pin assignment

Pin No. Signal name I/O Description

1NC

----

2 RXD I Received Data

3 TXD O Transmission Data

4 DTR O Data Terminal Ready

5 GND

----

6 DSR I Data Set Ready

7 RTS O Request to Send

8 CTS I Clear to Send

9NC

1

----

RS-232C

Not connected

Ground

Not connected

5

6

5.2.4 List of available commands

Command format Corresponding Operation

output

GA**CRLF G#

**

Outputs the displayed value.

+01234.567CRLF

CN**CRLF CH**CRLF

CX**CRLF CH**CRLF

CM**CRLF CH**CRLF

CW**CRLF CH**CRLF

Switches to the current value display

Switches to the max. value display

Switches to the min. value display

Switches to the TIR display

CR**CRLF CH**CRLF Zero-sets.

CL**CRLF CH**CRLF Clears peak values

CP**,CH

+01234.567CRLF

CD**,CH

+01234.567CRLF

**

CG

**

CRLF Presets.

**

CRLF

CH**CRLF

Inputs lower tolerance limit

Inputs upper tolerance limit

+01234.567CRLF

CS** CRLF CH**CRLF Clears the error.

CK** CRLF

CT\\CRLF CH\\,

CH**, %CRLF Returns the HOLD status

Outputs the calculation data

+01234,567CRLF

*1:A "#" denotes the data type (N: Current value, X: Maxi-

mum, M: Minimum, W: TIR).

*2:For a preset value or tolerance value input a number that

consists of a maximum of eight digits (not including a decimal point) and its sign.

9

*1

*2

*2,*3

*2,*3

*4,*6

*5,*6,*7

5 - 2

No. 99MBC034B

Page 45

5 RS-232C COMMUNICATION FUNCTION

*3:For the tolerance setting, first enter the lower limit value,

then the upper limit value.

An error will result if the entries are not made in this order.

If this is the case, make the setting again, starting with the

CD command entry.

*4:The response output value (%) for the entered CK command

represents the HOLD status.

% = 1: The counter is in the HOLD state.

% = 0: The counter is not in the HOLD state.

*5:Precautions to be observed when calculation data is output

by the CT command:

This command is valid only if the I/O function selection parameter is set to "Calculation mode".

A double backslash (\\) is used to specify the calculation

method between the axes which have been specified by the

calculation axis designation parameter.

Value of double

backslash

01, 07*, 12

02, 08*, 13

03, 09*, 14

04, 10*, 15

05, 11*, 16

Operation

**

Obtains each total of specified axes.

**

Obtains each mean of specified axes.

**

Obtains the max. value of specified axes.

**

Obtains the min. value of specified axes.

**

Obtains Max. - Min. of specified axes.

If more than one EV Counter unit is connected via the RSLINK function:

*: Value of double backslash on the second counter.

**: Value of double backslash on the third counter.

*6:An all-channels specification is not permitted with the CK

or CT command. If all channels are specified, a command

error results.

*7:The CT command cannot be used with the EF Counter.

NOTE • A double asterisk (**) denotes a channel number be-

tween 01 and 99 (00 means all channels).

• CRLF means a CR (carriage return) and an LF (line

feed).

• The output when an error occurs will be "CH**,

Error$$CRLF".

("$$" denotes the error code number. Refer to section

8.4 List of Error Outputs.)

• Send the next command only after the response output to the current command has been received. If no

response to the current command has been received,

clear the buffer and wait for more than one second,

then send the same command again.

No. 99MBC034B

5 - 3

Page 46

• The RS-232C communication function is suspended

during a parameter, preset value, or tolerance value

setup operation. If the counting state is restored, output of the command or data will be resumed.

• To quit the counting stand-by state use "CS00CRLF"

(all-channels specification).

• Note that the GA command and CT command look

similar, however, their functions differ.

GA command: Outputs the count data of a CH

specified by "##".

CT command: Outputs the calculation result

specified by a double backslash.

• If the peak mode is switched using an RS-232C command, peak values cannot be backed up in memory.

5 - 4

No. 99MBC034B

Page 47

5 RS-232C COMMUNICATION FUNCTION

5.2.5 RS-232C command and RS-232C response output

Max. 10ms

LF

LF

)

LF

Min. 10ms

Command

Response

output

If the GA command is issued

(

NOTE During key operation RS-232C output will be sus-

pended, and it will be resumed after the key operation

has been completed.

5.2.6 HOLD input and RS-232C response output

* A value in brackets denotes a numeric value

HOLD

EXTEND

Response

output

Data latch for

10 µs [10 ms]*

at a MAX, MIN, or TIR measurement.

Max. 70ms

Min. 10ms

LF

Min. 10ms

NOTE • During key operation RS-232C output will be sus-

pended, and it will be resumed after the key operation

has been completed.

• If the RS LINK connection has been established, the

EXTEND command is valid for the counter placed at

the end of the chain.

• EXTEND output will be in effect only if the I/O mode

parameter is set to "Interval mode".

• While the HOLD signal is being input, the D-EV UNIT

LED flashes.

• In order to trigger data output from the RS-232C connector with the HOLD input signal set the HOLD selection parameter to "RS-232C". (In this state an RS232C command cannot be input.)

• If the High-speed mode is specified, set the output cell

to "All CELs".

No. 99MBC034B

5 - 5

Page 48

5.2.7 Time required for RS-232C data output

The maximum output time (ms) as a result of executing the alldata output command (GA00CRLF) is calculated as follows:

= (number of connected counters x 10) + (number of available

channels x 17) + 6

[= (number of connected counters x 10) + (number of available

channels x 8.5) + 3]

Transmission speed: 9600bps [19200bps]

(Example)

One EV-16P unit (total 6 gage channels): Max. 118ms [64ms]

Ten EV-16P units (total 60 gage channels): Max. 1126ms [610ms]

NOTE • "Number of connected counters x 20" is used for EF

Counters.

• The above figures do not include personal computer

processing time.

• The data size required if total 60 gage channels are

used, is 900 bytes (15 bytes per gage channel). For

more information refer to the specifications of the reception-side personal computer.

5 - 6

No. 99MBC034B

Page 49

RS LINK FUNCTION

This chapter describes the RS LINK function

6

that controls multiple counters connected via

dedicated cables.

6.1 Connection Method

A maximum of ten EV Counter units can be chain-connected,

and all the counters can be controlled through the RS-232C interface of the top counter. (Refer to chapter 5 RS-232C COM-

MUNICATION FUNCTION.)

Link the IN side of the RS LINK connector of one EV Counter

with the OUT side of the RS LINK connector of another EV

Counter, as shown below.

Personal computer

RS-232C

If one D-EV is inserted in the middle, as shown below, it will

display the data of EV Counter: A.

Personal computer

RS-232C

Top counter

RS LINK

IN OUT

EV Counter: A

RS LINK

IN

IN OUT

RS LINK connection cable with

a maximum length of 10 m

IN OUT

OUT

RS LINK

D-EV

RS LINK

End counter

RS LINK

IN OUT

10 units

maximum

EV Counter: B

RS LINK

IN OUT

RS LINK connection cable (optional)

NOTE • Do not connect anything to the IN side of the RS LINK

connector of the top counter. Also, do not connect

anything except a D-EV to the OUT side of the RS

LINK connector of the end counter.

• The CH numbers of the gages connected to each EV

Counter will be automatically assigned as CH01,

CH02, CH03..., from INPUT A of the top counter

when the power is turned on (during the initial setup).

On the second EV Counter, CH07, CH08,....CH12 will

be assigned.

No. 99MBC034B

6 - 1

Page 50

• One or more EF Counters can be combined with the

EV Counters. However, if this is done, a maximum of

six EF Counters can be combined. A D-EV, if inserted, will not be included in the number of connected units.

• The maximum total length of the RS LINK cables

used in the entire system is 10m.

• Consult Mitutoyo to construct a system with more

than 10 counters and/or a total cable length greater

than 10m.

6.2 Start-Up Method

Start up the entire system with the following procedure.

(1) Either turn on the power to all the EV Counters/D-EVs si-

multaneously or turn on the power sequentially, starting

from the top EV Counter/D-EV. The initial setup will commence.

During initial setup, the D-EV displays a flashing "-----".

(2) If the initial setup has been completed, the flashing "-----"

on the D-EV will fix (indicating the counting stand-by

state).

(3) Quit the counting stand-by state by either pressing the

P.SET key or by inputting an external HOLD or RS command. (Refer to section 8.4 List of Error Outputs.)

NOTE • RS-232C-related parameters can only be modified on

6 - 2

the top counter.

• If the existing parameters are modified, reset the

power to all the connected counters.

• Always set the start-up mode to the counting stand-by

mode (factory-set default).

No. 99MBC034B

Page 51

6 RS LINK FUNCTION

6.3 Troubleshooting

If communication with the personal computer is not functioning

well, refer to the following examples:

• If no response to the entered command is received from the

EV Counter.

1) Is the RS LINK cable connected properly?

2) Is a straight-type RS-232C cable used?

3) Are the personal computer and EV Counter communication conditions consistent?

4) With some computers it is necessary to specify the communication port and whether it is to be used. Is a cable

properly connected to the specified port?

5) Is key operation or parameter setup operation being performed?

(During the above-mentioned operations, RS-232C communication function is paused/suspended.)

• The initial setup operation cannot be terminated ("-----"

flashes on the D-EV).

• Some counter enter the counting stand-by state ("-----" is

displayed on the D-EV) while the power is being turned on.

1) Is the RS LINK cable connected properly?

2) If EF Counters are being used with EV Counters, make

sure that the Digimatic selection parameter of the EF

Counter is set to "RS LINK".

After removing the cause of the error, reset the power

to all counters.

• A command (such as a zero-set or preset command) from

the personal computer can be executed, but no data can be

acquired. Or, data processing is stopped during data acquisition.

1) Is the response output from the counter read with such as

the zero-set command, etc?

2) Is the next command issued before the response output

from the counter is received?

3) Is the number of channels connected via the RS LINK

function consistent with the number of data pieces to be

acquired?

• A command abnomaly occurs if a command is issued.

1) Was a command consisting of 2-byte characters or lowercase characters issued?

2) Don't you specify a number greater than the number of

channels connected?

No. 99MBC034B

6 - 3

Page 52

6 - 4

No. 99MBC034B

Page 53

I/O FUNCTION

This chapter describes the I/O function re-

7

lated to data input and output.

7.1 Overview of the I/O function

According to the I/O-type selection parameter, the I/O connector will

perform tolerance judgment output, BCD output, and segment output.

Each output can be performed in the NORMAL mode, calculation

mode, or high-speed mode as set by the I/O function selection parameter. (Refer to chapter 3 SETTING PARAMETERS.)

NOTE

The user must separately purchase the connection cable.

7.2 Connectors

Receptacle:

Plug: 10136-3000VE (Manufacturer: 3M) or equivalent

Cover: 10336-52A0-008 (Manufacturer: 3M) or equivalent

10236-52A2 (Manufacturer: 3M, half-pitch 36-pin, female)

7.3 Input/Output Circuit

7.3.1 Output circuit

Application:

Operation:

Counter

Maximum output voltage: 24 V

Maximum output current: 10 mA

Maximum saturation voltage: 0.7 V

7.3.2 Input circuit

Application: P.SET, HOLD, SET

Operation: Input enabled at "L"

No. 99MBC034B

Tolerance judgment output, NORMAL, and segment output

Transistor turned ON at "L" (open-collector output)

TD62853 or

the equivalent

0.01uF

Counter Reference

5kΩ

Maximum input current: 1 mA

Input voltage (H): 4 - 24 V

Input voltage (L): 1 V max.

0.01uF

+5V

Output

COM

5kΩ

74HC14 or

the equivalent

Input

COM

+5V

Reference

circuit of

external

equipment

circuit of

external

equipment

Use open-collector

output or relay

output, etc.

7 - 1

Page 54

7.4 NORMAL Mode

7.4.1 Overview of the NORMAL mode

• The NORMAL mode is the factory-set default. Use it without modification for general purposes.

• Origin setting, tolerance setting, and presetting can be performed individually for each CEL.

• Tolerance judgment (for each CEL), BCD data, and segment (on selected CELs) output can be performed.

7.4.2 Tolerance judgment output

1) Function

Outputs the tolerance judgment result of each internal

counter (CEL1 to CEL6).

Measured value < Lower tolerance limit -NG output

Lower tolerance limit ≤ Measured value ≤ Upper tolerance limit

Upper tolerance limit < Measured value +NG output

2) Parameter setup

I/O function selection parameter: Set to NORMAL

I/O-type selection parameter: Set to tolerance judgment

3) Pin assignment

18

GO output

1

No. Name I/O

1

2

3

4

5

6 CEL1_NOM OUT

7 CEL2_-NG OUT

8 CEL2_GO OUT

9

10 CEL2_NOM OUT

11 CEL3_-NG OUT

12 CEL3_GO OUT

13 CEL3_+NG OUT

14 CEL3_NOM OUT

15 CEL4_-NG OUT

16 CEL4_GO OUT

17 CEL4_+NG OUT

18 CEL4_NOM OUT

7 - 2

36

19

Functional description

COM Common terminal of I/O circuit

COM (connected to internal GND)

CEL1_-NG OUT

CEL1_GO OUT

CEL1_+NG OUT

Tolerance judgment result of CEL1

Tolerance judgment result of CEL1

Tolerance judgment result of CEL1

Error signal of CEL1

*1

Tolerance judgment result of CEL2

Tolerance judgment result of CEL2

CEL2_+NG OUT

Tolerance judgment result of CEL2

Error signal of CEL2

*1

Tolerance judgment result of CEL3

Tolerance judgment result of CEL3

Tolerance judgment result of CEL3

Error signal of CEL3

*1

Tolerance judgment result of CEL4

Tolerance judgment result of CEL4

Tolerance judgment result of CEL4

Error signal of CEL4

*1

No. 99MBC034B

-NG

GO

+NG

-NG

GO

+NG

-NG

GO

+NG

-NG

GO

+NG

Page 55

7 I/O FUNCTION

No. Name I/O

Functional description

19 CEL5_-NG OUT Tolerance judgment result of CEL5 -NG

20 CEL5_GO OUT Tolerance judgment result of CEL5 GO

21 CEL5_+NG OUT Tolerance judgment result of CEL5 +NG

22 CEL5_NOM OUT Error signal of CEL5*1

23 CEL6_-NG OUT Tolerance judgment result of CEL6 -NG

24 CEL6_GO OUT Tolerance judgment result of CEL6 GO

25 CEL6_+NG OUT Tolerance judgment result of CEL6 +NG

26 CEL6_NOM OUT Error signal of CEL6*1

27 EXTENDED OUT L: Execution of an RS-232C command, which

is activated by a HOLD input, is being

performed.

H: Execution of an RS-232C command, which

was activated by a HOLD input, has been completed.

Purpose: Monitoring the RS data communica-

tion condition at the I/O port.

28 READY OUT "L" if the output data has been accepted.

29 START OUT "L" only when CEL1 data has been output.

30 NORMAL OUT "H" at an anomaly.

(Result of ORing NOMs of all CELs.)

31 P.SET IN Presets the specified CELs.

32 OUTCEL IN Sets the output CEL/calculation method

33 SET1 IN specified by SET1 through SET3 if the ON

34 SET2 IN signal of OUTCEL was input.

35 SET3 IN

36 HOLD IN The display value is held during input. The

error is cleared at the rise of this signal.

Only EV-16Z re-detects the origin if the

parameter No.42 is set to 1.

*1: "L" if counting is permitted.

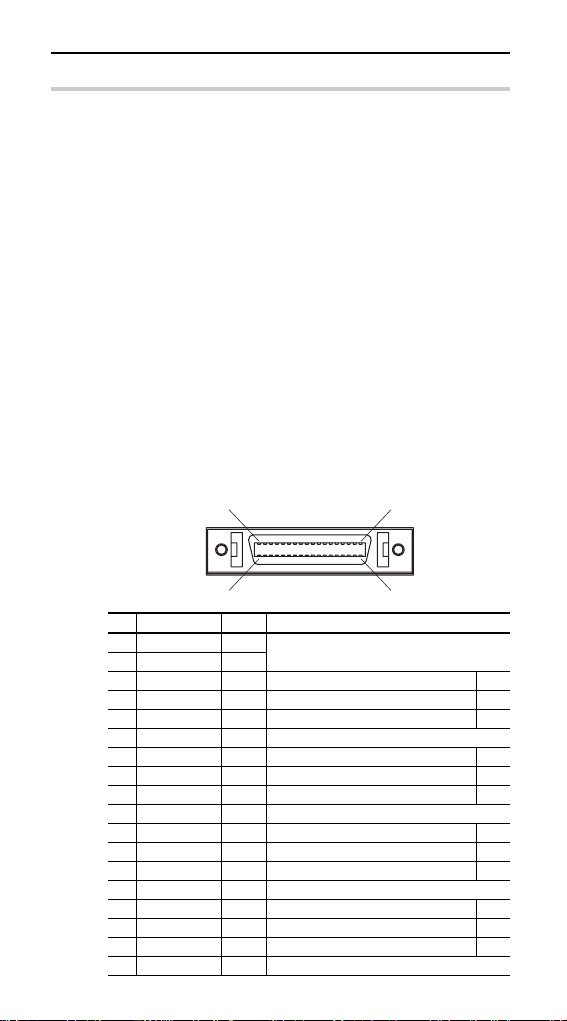

*: Outputs of No.3 through No.26 can be logically inverted by the I/O