Page 1

TRANSISTORIZED INVERTER

FR-F500J

INSTRUCTION MANUAL (Detailed)

AIR-CONDITIONING INVERTER

FR-F520J-0.4K to 15K (F)

FR-F540J-0.4K to 15K (F)

WIRING

FUNCTIONS

PROTECTIVE

FUNCTIONS

SPECIFICATIONS

Chapter 1

Chapter 2

Chapter 3

Chapter 4

Page 2

Thank you for choosing this Mitsubishi Transistorized inverter.

This instruction manual (detailed) provides instructions for advanced use of the FR-

F500J series inverters.

Incorrect handling might cause an unexpected fault. Before using the inverter, always

read this instruction manual and the instruction manual (basic) [IB-0600129E]

packed with the product carefully to use the equipment to its optimum.

This section is specifically about safety matters

Do not attempt to install, operate, maintain or inspect the inverter until you have read

through this instruction manual (basic) and appended documents carefully and can

use the equipment correctly. Do not use the inverter until you have a full knowledge

of the equipment, safety information and instructions.

In this instruction manual (detailed), the safety instruction levels are classified into

"WARNING" and "CAUTION".

WARNING

CAUTION

Assumes that incorrect handling may cause hazardous

conditions, resulting in death or severe injury.

Assumes that incorrect handling may cause hazardous

conditions, resulting in medium or slight injury, or may cause

physical damage only.

Note that even the level may lead to a serious consequence

according to conditions. Please follow the instructions of both levels because they are

important to personnel safety.

CAUTION

1. Electric Shock Prevention

WARNING

zWhile power is on or when the inverter is running, do not open the front cover. You

may get an electric shock.

zDo not run the inverter with the front cover removed. Otherwise, you may access

the exposed high-voltage terminals or the charging part of the circuitry and get an

electric shock. Also, the inverter’s ability to withstand earthquakes will deteriorate.

zEven if power is off, do not remove the front cover except for wiring or periodic

inspection. You may access the charged inverter circuits and get an electric shock.

zBefore starting wiring or inspection, check to make sure that the 3-digit LED inverter

monitor is off, wait for at least 10 minutes after the power supply has been switched off,

and check to make sure that there are no residual voltage using a tester or the like.

zThis inverter must be earthed (grounded). Earthing (grounding) must conform to

the requirements of national and local safety regulations and electrical codes.

(NEC section 250, IEC 536 class 1 and other applicable standards)

zAny person who is involved in the wiring or inspection of this equipment should be

fully competent to do the work.

zAlways install the inverter before wiring. Otherwise, you may get an electric shock

or be injured.

zPerform setting dial and key operations with dry hands to prevent an electric shock.

You may get an electric shock.

zDo not subject the cables to scratches, excessive stress, heavy loads or pinching.

Otherwise you may get an electric shock.

zDo not change the cooling fan while power is on. It is dangerous to change the

cooling fan while power is on.

A-1

Page 3

2. Fire Prevention

CAUTION

zInstall the inverter (filter pack) on an incombustible wall without holes, etc.

Mounting it to or near combustible material can cause a fire.

zIf the inverter has become faulty, switch off the inverter power. A continuous flow of

large current could cause a fire.

z

Do not connect the resistor directly to the DC terminals P and N. This coule cause a fire.

3. Injury Prevention

CAUTION

zApply only the voltage specified in the instruction manual to each terminal to

prevent damage, etc.

zAlways connect to the correct terminal to prevent damage, etc.

zAlways make sure that polarity is correct to prevent damage, etc.

zWhile power is on or for some time after power-off, do not touch the inverter (filter

pack) or break register as they are hot and you may get burnt.

4. Additional Instructions

Also note the following points to prevent an accidental failure, injury, electric shock,

etc.

(1) Transportation and installation

CAUTION

zWhen carrying products, use correct lifting gear to prevent injury.

zDo not stack the inverter boxes higher than the number recommended.

zEnsure that installation position and material can withstand the weight of the

inverter. Install according to the information in the instruction manual.

zDo not install or operate if the inverter (filter pack) is damaged or has parts missing.

zWhen carrying the inverter, do not hold it by the front cover or setting dial; it may fall

off or fail.

zDo not stand or rest heavy objects on the inverter.

zCheck the inverter mounting orientation is correct.

zPrevent other conductive bodies as screws and metal fragments or other

flammable substance as oil from entering the inverter (filter pack).

zAs the inverter (filter pack) is a precision instrument, do not drop or subject it to impact.

zUse the inverter under the following environmental conditions: This could cause the

inverter (filter pack) damage.

Surrounding Air

Temperature

Ambient

humidity

Storage

temperature

Atmosphere

Environment

Altitude/

vibration

*1 Temperatures applicable for a short time, e.g. in transit.

*2 When using with the filter pack installed on the rear panel of the FR-F520J-15K or

FR-F540J-15K, do not install this combination on moving objects or places that

have vibrations exceeding 1.96m/s

-10°C to +50°C (non-freezing)

90%RH maximum (non-condensing)

-20°C to +65°C *1

Indoors (free from corrosive gas, flammable gas, oil mist,

dust and dirt)

Max.1000m above sea level 5.9m/s

2

.

2

or less *2

A-2

Page 4

(2) Wiring

CAUTION

zDo not fit capacitive equipment such as power factor correction capacitor, radio

noise filter (option FR-BIF(-H)) or surge suppressor to the output of the inverter.

zThe connection orientation of the output cables U, V, W to the motor will affect the

direction of rotation of the motor.

(3) Trial run

CAUTION

zCheck all parameters, and ensure that the machine will not be damaged by a

sudden start-up.

zWhen the load GD

output current may vary when the output frequency is in the 20Hz to 30Hz range.

If this is a problem, set the Pr.72 "PWM frequency selection" to 6kHz or higher.

(When setting the PWM to a higher frequency, check for noise or leakage current

problem and take countermeasures against it.)

(4) Operation

2

is small (at the motor GD or smaller) for 400V from 1.5K to 3.7K, the

WARNING

zWhen you have chosen the retry function, stay away from the equipment as it will

restart suddenly after an alarm stop.

zSince the key is valid only when functions are set (refer to page 116),

provide a circuit and switch separately to make an emergency stop (power off,

mechanical brake operation for emergency stop, etc).

zMake sure that the start signal is off before resetting the inverter alarm. A failure to

do so may restart the motor suddenly.

zThe load used should be a three-phase induction motor only. Connection of any other

electrical equipment to the inverter output may damage the equipment.

zDo not modify the equipment.

zDo not perform parts removal which is not instructed in this manual. Doing so may

lead to fault or damage of the inverter.

STOP

RESET

A-3

Page 5

CAUTION

zThe electronic thermal relay function does not guarantee protection of the motor

from overheating.

zDo not use a magnetic contactor on the inverter input for frequent starting/stopping

of the inverter.

zUse a noise filter to reduce the effect of electromagnetic interference. Otherwise

nearby electronic equipment may be affected.

zTake measures to suppress harmonics. Otherwise power supply harmonics from

the inverter may heat/damage the power capacitor and generator.

zWhen a 400V class motor is inverter-driven, please use an insulation-enhanced

motor or measures taken to suppress surge voltages. Surge voltages attributable to

the wiring constants may occur at the motor terminals, deteriorating the insulation of

the motor.

zWhen parameter clear or all clear is performed, reset the required parameters

before starting operations.

zThe inverter can be easily set for high-speed operation. Before changing its setting,

fully examine the performances of the motor and machine.

zIn addition to the inverter's holding function, install a holding device to ensure safety.

zBefore running an inverter which had been stored for a long period, always perform

inspection and test operation.

(5) Emergency stop

CAUTION

zProvide a safety backup such as an emergency brake which will prevent the

machine and equipment from hazardous conditions if the inverter fails.

zWhen the breaker on the inverter primary side trips, check for the wiring fault (short

circuit), damage of the inner parts of the inverter, etc. Identify the cause of the trip,

then remove the cause and power on the breaker.

zWhen any protective function is activated, take the appropriate corrective action,

then reset the inverter, and resume operation.

(6) Maintenance, inspection and parts replacement

CAUTION

zDo not carry out a megger (insulation resistance) test on the control circuit of the

inverter.

(7) Disposing of the inverter

CAUTION

zTreat as industrial waste.

(8) General instructions

Many of the diagrams and drawings in this instruction manual show the inverter without a

cover, or partially open. Never run the inverter in this status. Always replace the cover and

follow this instruction manual when operating the inverter.

A-4

Page 6

CONTENTS

1. WIRING 1

1.1 Standard connection diagram and terminal specifications........... 2

1.1.1 Standard connection diagram ......................................................................... 2

1.1.2 Explanation of main circuit terminals............................................................... 3

1.2 Main circuit terminals.................................................................... 7

1.2.1 Terminal block layout ...................................................................................... 7

1.2.2 Cables, wiring length, and crimping terminals................................................. 8

1.2.3 Wiring instructions ........................................................................................... 9

1.2.4 Selection of peripheral devices ..................................................................... 10

1.2.5 Leakage current and installation of earth (ground) leakage circuit breaker .. 11

1.2.6 Power-off and magnetic contactor (MC)........................................................ 15

1.2.7 Regarding the installation of the reactor........................................................ 16

1.2.8 Regarding noise (EMI) and the installation of a noise filter ........................... 17

1.2.9 Earthing (Grounding) precautions ................................................................. 18

1.2.10 Power supply harmonics............................................................................... 19

1.2.11 Harmonic suppression guideline ................................................................... 20

1.2.12 Inverter-driven 400V class motor .................................................................. 24

1.3 How to use the control circuit terminals ...................................... 25

1.3.1 Terminal block layout .................................................................................... 25

1.3.2 Wiring instructions ......................................................................................... 25

1.3.3 Changing the control logic............................................................................. 26

1.4 Input terminals............................................................................ 28

1.4.1 Run (start) and stop (STF, STR, STOP) ....................................................... 28

1.4.2 Connection of frequency setting potentiometer and

output frequency meter (10, 2, 5, 4, AU) ....................................................... 31

1.4.3 External frequency selection (REX, RH, RM, RL)......................................... 32

1.4.4 Indicator connection and adjustment (FM).................................................... 34

1.4.5 Control circuit common terminals (SD, 5, SE)............................................... 36

1.4.6 Signal inputs by contactless switches ........................................................... 36

1.5 How to use the input signals

(assigned terminals AU, RM, RH, STR) ..................................... 37

1.5.1 Multi-speed setting (RL, RM, RH, REX signals):

Pr. 60 to Pr. 63 setting "0, 1, 2, 8"

Remote setting (RL, RM, RH signals):

Pr. 60 to Pr. 63 setting "0, 1, 2" ..................................................................... 37

1.5.2 Second function selection (RT signal): Pr. 60 to Pr. 63 setting "3" ............... 37

1.5.3 Current input selection "AU signal": Pr. 60 to Pr. 63 setting "4" .................... 37

1.5.4 Start self-holding selection (STOP signal): Pr. 60 to Pr. 63 setting "5" ......... 38

1.5.5 Output shut-off (MRS signal): Pr. 60 to Pr. 63 setting "6" ............................. 38

CONTENTS

I

Page 7

1.5.6 External thermal relay input: Pr. 60 to Pr. 63 setting "7"................................39

1.5.7 Jog operation (JOG signal): Pr. 60 to Pr. 63 setting "9".................................39

1.5.8 Reset signal: Pr. 60 to Pr. 63 setting "10"......................................................40

1.5.9 PID control valid terminal: Pr. 60 to Pr. 63 setting "14"..................................41

1.5.10 PU operation/external operation switchover: Pr. 60 to Pr. 63 setting "16".....41

1.6 Connection to the stand-alone option .........................................42

1.6.1 Connection of the brake unit (FR-BU2)..........................................................42

1.6.2 Connection of the brake unit (FR-BU)............................................................44

1.6.3 Connection of the brake unit (BU type)..........................................................45

1.6.4 Connection of the high power factor converter (FR-HC)................................46

1.6.5 Connection of the power regeneration common converter (FR-CV)..............47

1.7 Handling of the RS-485 connector..............................................48

1.7.1 Connection of the parameter unit (FR-PU04) ................................................48

1.7.2 Wiring of RS-485 communication ..................................................................48

1.8 Design information ...................................................................... 52

1.9 Failsafe of the system which uses the inverter ...........................53

2. FUNCTIONS 57

2.1 Function (Parameter) list.............................................................58

2.2 List of parameters classified by purpose of use..........................71

2.3 Explanation of functions (parameters) ........................................73

2.3.1 Torque boost (Pr. 0 , Pr. 46 ) .........................................................................73

2.3.2 Maximum and minimum frequency (Pr. 1 , Pr. 2 ) .........................................74

2.3.3 Base frequency, base frequency voltage (Pr.3 , Pr.19 , Pr.47 ).....................75

2.3.4 Multi-speed operation (Pr. 4, Pr. 5, Pr. 6, Pr. 24 to Pr. 27, Pr. 80 to Pr. 87)..77

2.3.5 Acceleration/deceleration time (Pr. 7 , Pr. 8 , Pr. 20 , Pr. 44 , Pr. 45 ) ..........78

2.3.6 Selection and protection of a motor (Pr. 9 , Pr. 71 ).......................................80

2.3.7 DC injection brake (Pr. 10 , Pr. 11 , Pr. 12 ) ..................................................81

2.3.8 Starting frequency (Pr. 13 )............................................................................82

2.3.9 Load pattern selection (Pr. 14 )......................................................................83

2.3.10 Jog operation (Pr.15 , Pr.16 ).........................................................................84

2.3.11 RUN key rotation direction selection (Pr.17 ).................................................84

2.3.12 Stall prevention function and current limit function (Pr. 21 ) ..........................85

2.3.13 Stall prevention (Pr. 22 , Pr. 23 , Pr. 28 ) .......................................................87

2.3.14 Acceleration/deceleration pattern (Pr. 29 ) ....................................................89

2.3.15 Extended function display selection (Pr. 30 ).................................................90

2.3.16 Frequency jump (Pr. 31 to Pr. 36 )................................................................90

2.3.17 Speed display (Pr. 37 ) ..................................................................................91

2.3.18 Biases and gains of the frequency setting voltage (current)

(Pr. 38 , Pr. 39 , C2 to C7 ) ...........................................................................92

II

Page 8

2.3.19 Start-time earth (ground) fault detection selection (Pr. 40 ) .......................... 96

2.4 Output terminal function ............................................................. 96

2.4.1 Up-to-frequency sensitivity (Pr. 41 ) .............................................................. 96

2.4.2 Output frequency detection (Pr. 42 , Pr. 43 )................................................. 97

2.5 Current detection function .......................................................... 98

2.5.1 Output current detection functions (Pr. 48 , Pr. 49 )...................................... 98

2.5.2 Zero current detection (Pr. 50 , Pr. 51 )......................................................... 99

2.6 Display function ........................................................................ 100

2.6.1 Monitor display (Pr. 52 , Pr. 54 ).................................................................. 100

2.6.2 Setting dial function selection (Pr. 53 )........................................................ 101

2.6.3 Monitoring reference (Pr. 55 , Pr. 56 )......................................................... 102

2.7 Restart operation...................................................................... 102

2.7.1 Restart setting (Pr. 57 , Pr. 58 )................................................................... 102

2.8 Additional function .................................................................... 105

2.8.1 Remote setting function selection (Pr. 59 ) ................................................. 105

2.9 Terminal function selection....................................................... 109

2.9.1 Input terminal function selection (Pr. 60 , Pr. 61 , Pr. 62 , Pr. 63 ) .............. 109

2.9.2 Output terminal function selection (Pr. 64 , Pr. 65 ) .................................... 111

2.10 Operation selection function ..................................................... 112

2.10.1 Retry function (Pr. 66 , Pr. 67 , Pr. 68 , Pr. 69 ) .......................................... 112

2.10.2 PWM carrier frequency (Pr. 70 , Pr. 72 ) ..................................................... 114

2.10.3 Voltage input selection (Pr. 73 ) .................................................................. 115

2.10.4 Input filter time constant (Pr. 74 ) ................................................................ 116

2.10.5 Reset selection/PU stop selection (Pr. 75 )................................................. 116

2.10.6 Cooling fan operation selection (Pr. 76 )..................................................... 118

2.10.7 Parameter write disable selection (Pr. 77 ) ................................................. 119

2.10.8 Reverse rotation prevention selection (Pr. 78 )........................................... 120

2.10.9 Operation mode selection (Pr. 79 ) ............................................................. 120

2.10.10PID control (Pr. 88 to Pr. 94 )..................................................................... 124

2.11 Auxiliary function ...................................................................... 132

2.11.1 Slip compensation (Pr. 95 , Pr. 96 , Pr. 97 )................................................ 132

2.11.2 Automatic torque boost selection (Pr. 98 ) .................................................. 133

2.11.3 Motor primary resistance (Pr. 99 )............................................................... 134

2.12 Maintenance function ............................................................... 134

2.12.1 Maintenance output function (H1, H2 )........................................................ 134

2.12.2 Output phase failure protection selection (H8 )........................................... 135

2.13 Calibration parameters ............................................................. 137

2.13.1 Meter (frequency meter) calibration (C1 ) ................................................... 137

2.14 Clear parameters...................................................................... 140

2.14.1 Parameter clear (CLr )................................................................................. 140

III

CONTENTS

Page 9

2.14.2 Alarm history clear (ECL ) ............................................................................140

2.15 Communication parameters ...................................................... 141

2.15.1 Communication settings (n1 to n7 , n11 ) ...................................................143

2.15.2 Operation and speed command source (n8 , n9 ) .......................................158

2.15.3 Link startup mode selection (n10 )...............................................................159

2.15.4 EEPROM write selection (n12 ) ...................................................................161

2.16 Parameter unit (FR-PU04) setting.............................................162

2.16.1 PU display language selection (n13 ) ..........................................................162

2.16.2 PU buzzer control (n14 )..............................................................................162

2.16.3 PU contrast adjustment (n15 ) .....................................................................163

2.16.4 PU main display screen data selection (n16 )..............................................163

2.16.5 Disconnected PU detection/PU setting lock selection (n17 ) .......................164

3. PROTECTIVE FUNCTIONS 167

3.1 Errors (Alarms)..........................................................................168

3.1.1 Error (alarm) definitions ...............................................................................169

3.1.2 To know the operating status at the occurrence of alarm

(only when FR-PU04 is used)......................................................................177

3.1.3 Correspondence between digital and actual characters..............................177

3.1.4 Resetting the inverter ...................................................................................177

3.2 Troubleshooting ........................................................................178

3.2.1 Motor remains stopped ................................................................................178

3.2.2 Motor rotates in opposite direction...............................................................179

3.2.3 Speed greatly differs from the setting ..........................................................179

3.2.4 Acceleration/deceleration is not smooth ......................................................179

3.2.5 Motor current is large...................................................................................179

3.2.6 Speed does not increase .............................................................................179

3.2.7 Speed varies during operation .....................................................................179

3.2.8 Operation mode is not changed properly.....................................................180

3.2.9 Operation panel display is not operating......................................................180

3.2.10 Parameter write cannot be performed .........................................................180

3.2.11 Motor produces annoying sound..................................................................180

3.3 Precautions for maintenance and inspection ............................181

3.3.1 Precautions for maintenance and inspection...............................................181

3.3.2 Inspection item.............................................................................................181

3.3.3 Periodic inspection.......................................................................................181

3.3.4 Insulation resistance test using megger.......................................................182

3.3.5 Pressure test................................................................................................182

3.3.6 Daily and periodic inspection .......................................................................183

3.3.7 Replacement of parts...................................................................................186

3.3.8 Measurement of main circuit voltages, currents and powers .......................191

IV

Page 10

4. SPECIFICATIONS 195

4.1 Specification list........................................................................ 196

4.1.1 Ratings ........................................................................................................ 196

4.1.2 Common specifications............................................................................... 198

4.2 Outline dimension drawings ..................................................... 200

APPENDIX 205

APPENDIX 1 Parameter instruction code list..................................... 206

APPENDIX 2 SERIAL number check................................................. 211

CONTENTS

V

Page 11

1. WIRING

This chapter explains the basic "wiring" for use of this product. Always

read the instructions before use.

For description of "installation", refer to the instruction manual (basic).

1.1 Standard connection diagram and terminal

specifications .....................................................

1.2 Main circuit terminals ........................................ 7

1.3 How to use the control circuit terminals.......... 25

1.4 Input terminals.................................................... 28

1.5 How to use the input signals (assigned

terminals AU, RM, RH, STR) ..............................

1.6 Connection to the stand-alone option.............. 36

1.7 Handling of the RS-485 connector.................... 48

1.8 Design information............................................. 52

1.9 Failsafe of the system which uses the inverter 53

<Abbreviations>

•PU

Operation panel and parameter unit (FR-PU04)

•Inverter

Mitsubishi transistorized inverter FR-F500J series

•FR-F500J

Mitsubishi transistorized inverter FR-F500J series

•Pr.

Parameter number

•Filter pack

FR-BFP

2

37

Chapter 1

Chapter 2

Chapter 3

Chapter 4

1

Page 12

Standard connection diagram and terminal specifications

1.1 Standard connection diagram and terminal specifications

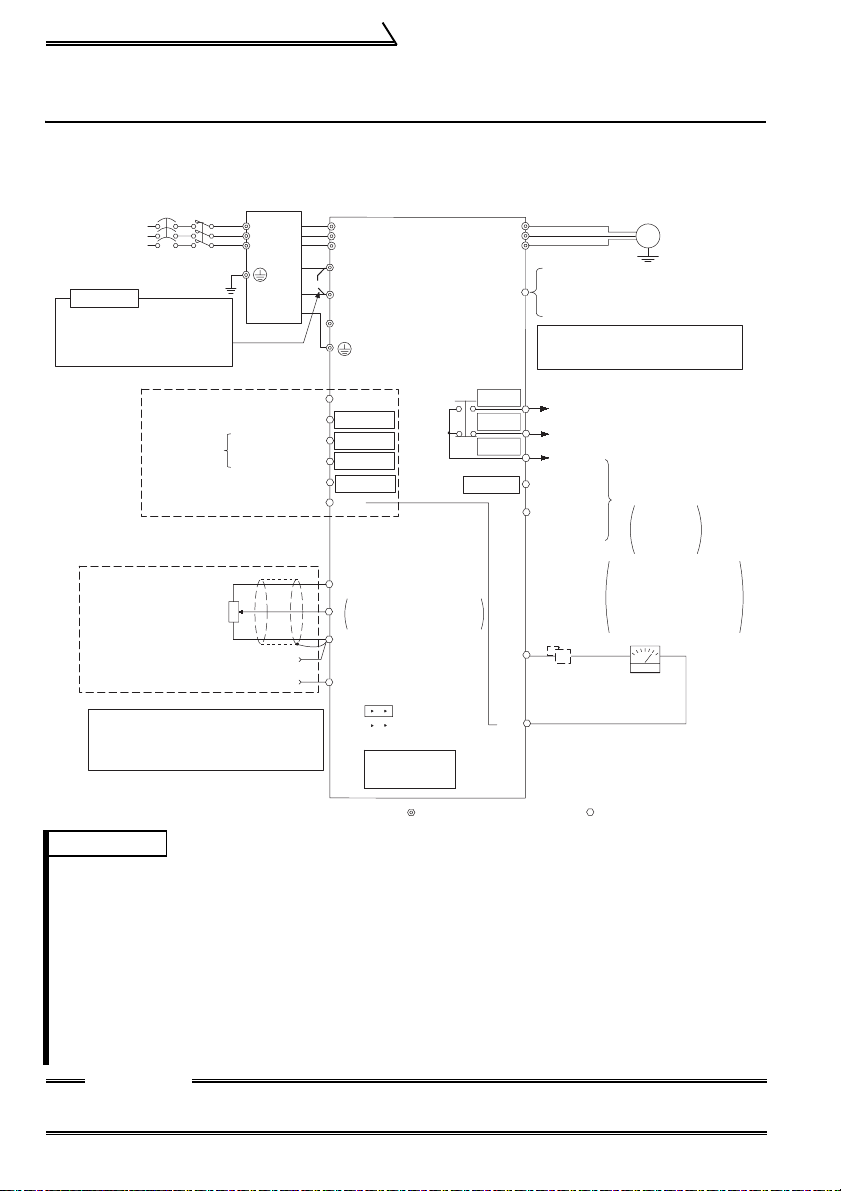

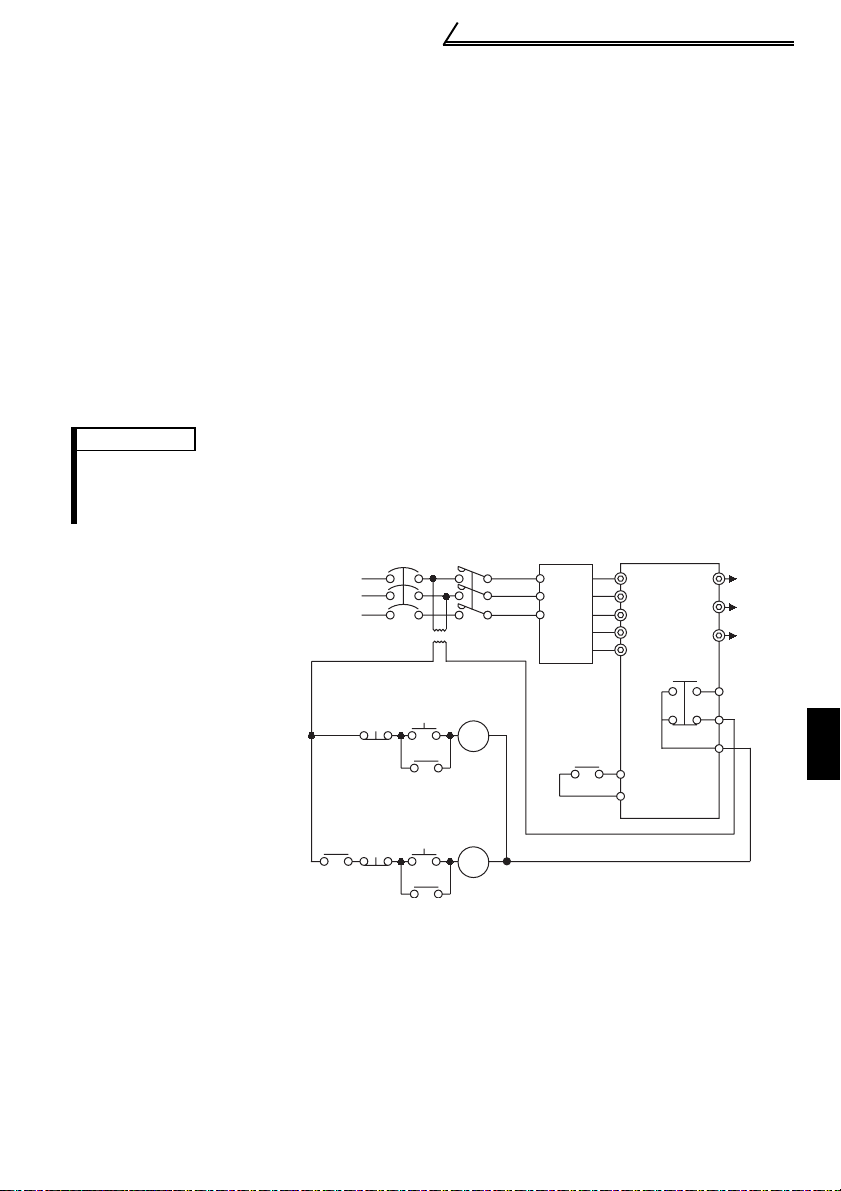

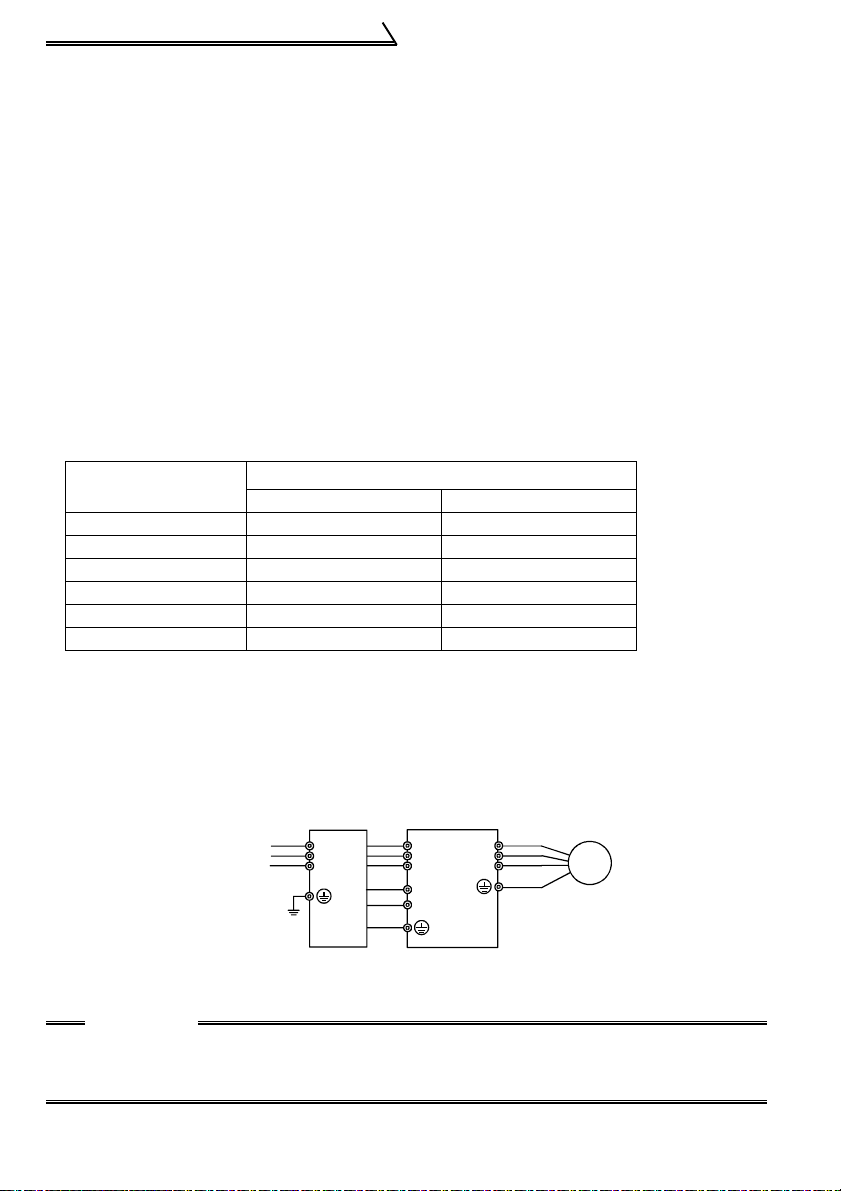

1.1.1 Standard connection diagram

zWith filter pack

*4

*4

*4

*4

Selected

SINK

*2

SOURCE

RS-485

connector

Inverter

*5

RUN

U

V

W

External transistor common

24VDC power supply

PC

Contact input common (source)

Take care not to short

terminals PC-SD.

*5

A

B

*5

*5

C

SE

Alarm output

Running

Open

collector

output

common

FM

Calibration

resistor

SD

Motor

IM

Earth (Ground)

Operation status

output

Open

collector

outputs

Indicator

1mA full-scale

Analog meter

(Digital indicator)

1mA

(+)

*1

3-phase AC

power supply

POINT

MCCB MC

Earth

*6

(Ground)

Jumper: Remove this

jumper to connect

the filter pack.

Control input

signals

(No voltage

input allowed)

Frequency setting signals (Analog)

Frequency setting

potentiometer

1/2W1kΩ

When using current input as the

frequency setting signal, turn the

AU signal on.

Forward rotation start

Reverse rotation start

Multi-speed

selection

Current input selection

Contact input common

*3

Current input(-)

4 to 20mADC(+)

Filter pack

R0

S0

T0

P1

GND

High speed

Middle speed

3

2

1

R

R/L1

S/L2

S

T/L3

T

P/+

P

P1

N/-

STF

STR

RH

RM

AU

SD

10

(+5V)

0 to 5VDC

2

0 to 10VDC

5

(Common)

4

(4 to 20mADC)

(-)

Control circuit terminalMain circuit terminal

REMARKS

*1. Not needed when the setting dial is used for calibration.

Used when calibration must be made near the frequency meter for such a reason as a remote frequency meter.

However, the frequency meter needle may not deflect to full-scale if the calibration resistor is connected.

In this case, use this resistor and setting dial together.

*2. You can switch the position of sink and source logic. Refer to page 26.

*3. When the setting potentiometer is used frequently, use a 2W1kΩ potentiometer.

*4. The terminal functions change with input terminal function selection (Pr. 60 to Pr. 63). (Refer to page 109.)

(RES, RL, RM, RH, RT, AU, STOP, MRS, OH, REX, JOG, X14, X16, (STR) signal selection)

*5. The terminal function changes with the setting of output terminal function selection (Pr. 64, Pr. 65). (Refer to

page 111.) (RUN, SU, OL, FU, RY, Y12, Y13, FDN, FUP, RL, Y95, LF, ABC signal selection)

*6. Connect the GND cable of the filter pack to the earth (ground) terminal of the inverter. Use the earth (ground)

terminal of the filter pack to earth (ground). For inverter earthing (grounding), earth (ground) the inverter

through the filter pack.

CAUTION

To prevent a malfunction due to noise, keep the signal cables more than 10cm away

from the power cables.

2

Page 13

Standard connection diagram and terminal specifications

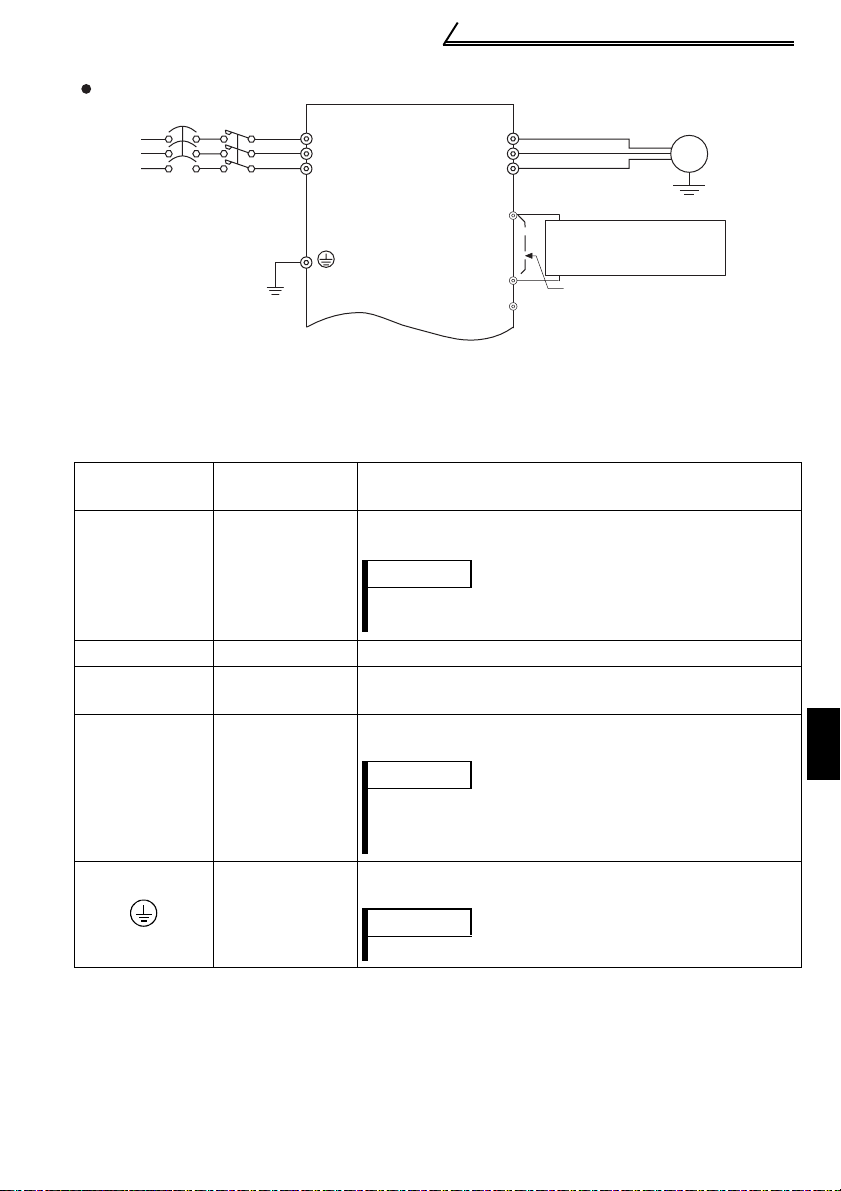

Without filter pack

MCCB

Earth (Ground)

MC

R/L1

S/L2

T/L3

U

V

W

P1

DC reactor

(FR-HEL/BEL: option)

P/+

N/-

1.1.2 Explanation of main circuit terminals

(1) Main circuit

zInverter

Motor

IM

Earth

(Ground)

Jumper: Remove

this jumper when

DC reactor is connected.

Termina l

Symbol

Terminal Name Description

R/L1, S/L2, T/L3 AC power input

U, V, W Inverter output

N/-

P/+, P1

DC voltage

common

Filter pack

connection

Earth (Ground)

Connect the R, S, T cables of the filter pack to these

terminals.

REMARKS

For the inverter without filter pack, connect these to the

commercial power supply.

Connect to a three-phase squirrel-cage motor.

DC voltage common terminal. This is not insulated from

the power and inverter output.

Remove the jumper across terminals P-P1 and connect

the P and P1 cables of the filter pack.

REMARKS

For the inverter without filter pack, remove the jumper

across terminals P-P1 and connect the optional DC

reactor (FR-HEL/BEL).

For earthing (grounding) the inverter chassis.

Connect the GND cable of the filter pack.

REMARKS

Earth (Ground) the inverter without filter pack.

1

WIRING

3

Page 14

Standard connection diagram and terminal specifications

zFilter pack

Termin al

Symbol

R0, S0, T0

Terminal Name Description

Commercial power

supply input

Earth (Ground)

Crimping

Termin al

Terminal Name

Symbol

R, S, T

Inverter power

supply

P, P1 DC reactor terminal

Inverter earth

GND

(ground)

connection

Connect to the commercial power supply.

For earthing (grounding) the filter pack. Must be earthed

(grounded).

Cable

Color

Black Connect to the R, S, T of the inverter.

Red

Green and

yellow

stripes

Remove the jumper across terminals PP1 and connect to the P and P1 terminals

of the inverter.

Connect to the earth (ground) terminal of

the inverter. (Refer to page 2.)

Description

4

Page 15

Standard connection diagram and terminal specifications

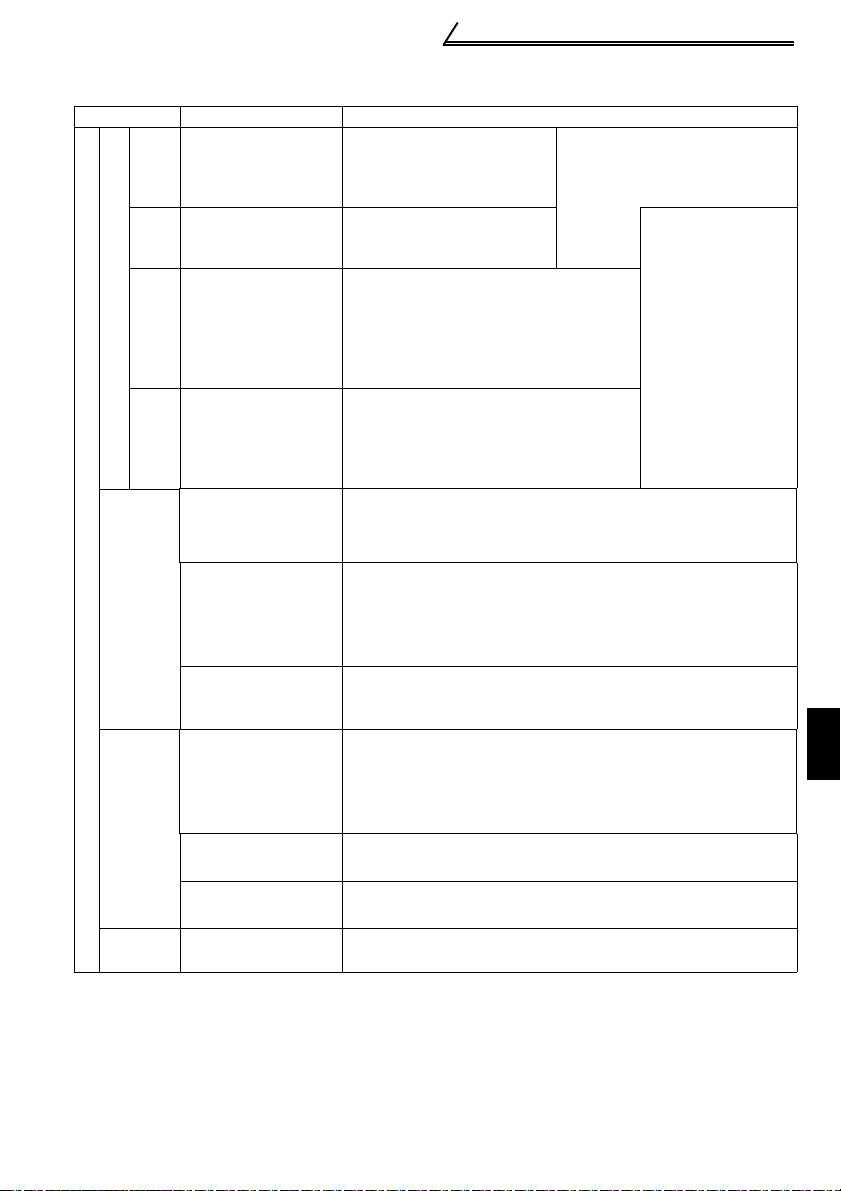

(2) Control circuit

Symbol Terminal Name Definition

Turn on the STF signal to

start forward rotation and

turn it off to stop.

Turn on the STR signal to

start reverse rotation and

turn it off to stop.

Turn on the RH, RM signals in

appropriate combinations to select

multiple speeds.

The priorities of the speed commands

are in order of jog, multi-speed setting

(RH, RM, RL, REX) and AU.

Only when the AU signal is turned on,

the inverter can be operated with the 4

to 20mADC frequency setting signal.

Turning the AU signal on makes voltage

input (across terminals 2-5) invalid.

Common terminal for contact input terminal (sink logic) and

terminal FM.

When connecting the transistor output (open collector

output), such as a programmable controller, when source

logic is selected, connect the external power supply

common for transistor output to this terminal to prevent a

malfunction caused by undesirable currents.

Common output terminal for 24VDC 0.1A power supply (PC

terminal).

Isolated from terminals 5 and SE.

When connecting the transistor output (open collector

output), such as a programmable controller, when sink logic

is selected, connect the external power supply common for

transistor output to this terminal to prevent a malfunction

caused by undesirable currents.

Common terminal for contact input terminal (source logic).

Can be used as 24VDC 0.1A power supply.

5VDC, Permissible load current 10mA.

STF

STR

RHRMMulti-speed

Contact input

AU

SD

(*1, *6)

Input signals

PC

(*1)

10

Forward rotation

start

Reverse rotation

start

selection

Current input

selection

Contact input

common (sink)

(initial setting)

External

transistor

common (source)

24VDC power

supply common

External

transistor

common (sink)

(initial setting)

Contact input

common (source)

24VDC power

supply

Frequency setting

power supply

When the STF and STR

signals are turned on

simultaneously, the stop

command is given.

The terminal

functions change

with input terminal

function selection

(Pr. 60 to Pr.63).

(*3)

1

WIRING

5

Page 16

Standard connection diagram and terminal specifications

Symbol Terminal Name Definition

Inputting 0 to 5VDC (or 0 to 10V) provides the maximum output

Frequency setting

2

(voltage signal)

Frequency setting

4

(current signal)

Input signals

Frequency setting

Frequency setting

5

input common

A

BCAlarm output

Inverter

RUN

running

Open collector

Open collector

SE

common

Output signals

FM For meter

Indicator

frequency at 5V (10V) and makes input and output proportional.

Switch between 5V and 10V using Pr. 73 "0-5V, 0-10V selection".

Input resistance 10kΩ. Maximum permissible input voltage 20V

Input 4 to 20mADC. It is factory set at 0Hz for 4mA and at

60Hz for 20mA.

Maximum permissible input current 30mA. Input resistance

approximately 250Ω.

Turn ON signal AU for current input.

Turning the AU signal on makes voltage input invalid. Use any of

Pr. 60 to Pr. 63 (input terminal function selection) to set the AU

signal.

Frequency setting signal (terminal 2, 4) common terminal.

Do not earth (ground).

1 changeover contact output indicates

that the inverter protective function has

activated and the output stopped.

230VAC 0.3A, 30VDC 0.3A. Alarm:

discontinuity across B-C (continuity

across A-C), Normal: continuity across

B-C (discontinuity across A-C).(*5)

Switched low when the inverter output

frequency is equal to or higher than the

starting frequency (factory set to 0.5Hz

variable). Switched high during stop or

DC injection brake operation. (*2)

Permissible load 24VDC 0.1A (a

voltage drop is 3.4V maximum when

the signal is on)

Common terminal for inverter running terminal RUN.

The output signal across terminals FM-SD is factory set to about

1mA at 60Hz and is proportional to the corresponding output

frequency. Since output voltage is pulse waveform, a digital

meter can be connected.

Frequency permissible load current 1mA

Pulse specification 1440 pulses/s at 60Hz

The function of the

terminals changes

according to the

output terminal

function selection

(Pr. 64, Pr.65).

(*4)

(*6)

Using the parameter unit connection cable (FR-CB201 to

——

RS-485

connector

205), the parameter unit (FR-PU04) can be connected.

Communication operation can be performed using RS-485.

For details of RS-485 communication, refer to page 48.

Communication

*1. Do not connect terminals SD and PC each other or to the earth (ground).

For sink logic (factory setting), terminal SD acts as the common terminal of contact input.

For source logic, terminal PC acts as the common terminal of contact input. (Refer to

page 26 for switching method.)

*2. Low indicates that the open collector output transistor is on (conducts). High indicates

that the transistor is off (does not conduct).

*3. RL, RM, RH, RT, AU, STOP, MRS, OH, REX, JOG, RES, X14, X16, (STR) signal

selection (Refer to page 109.)

*4. RUN, SU, OL, FU, RY, Y12, Y13, FDN, FUP, RL, Y95, LF, ABC signal selection (Refer to

page 111.)

*5. To be compliant with the European Directive (Low Voltage Directive), the operating

capacity of relay outputs (A, B, C) should be 30VDC 0.3A.

*6. Terminals SD, SE and 5 are isolated from each other. Do not earth (ground).

Avoid connecting the terminal SD and 5 and the terminal SE and 5.

6

Page 17

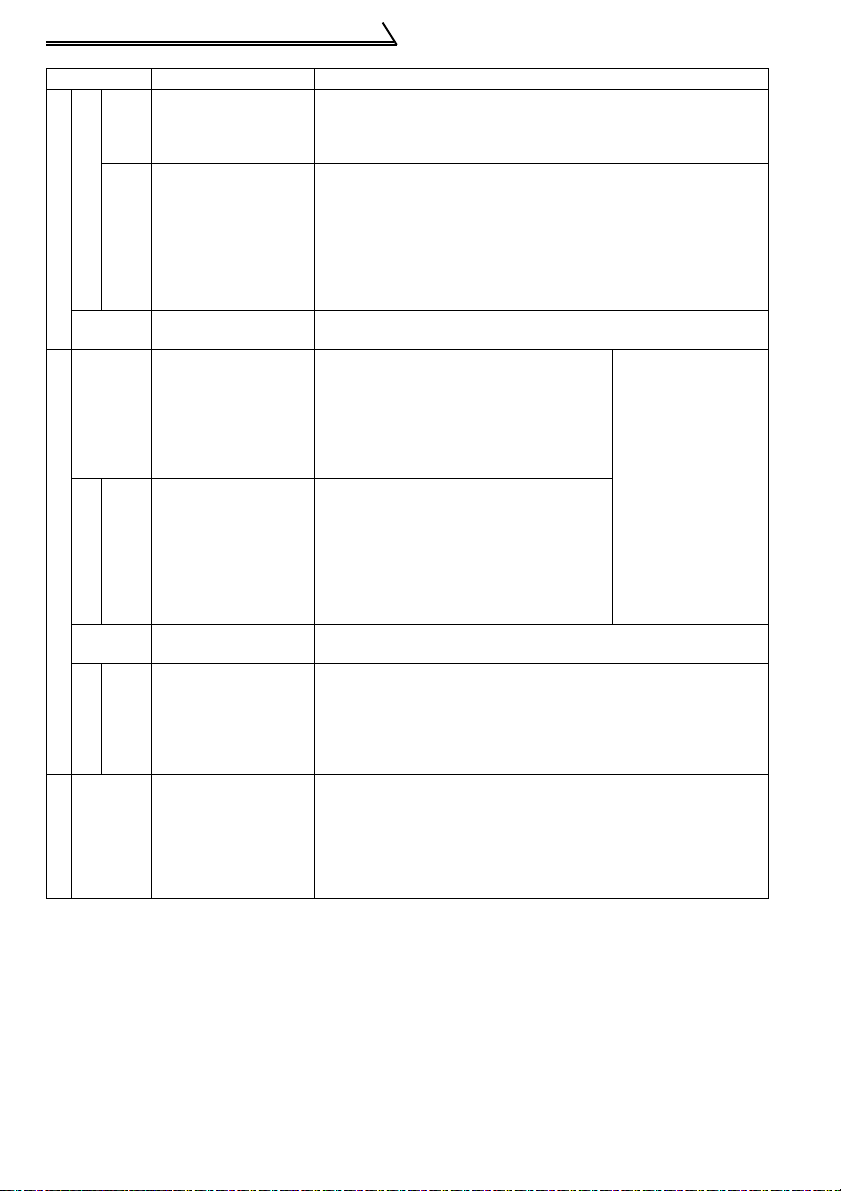

1.2 Main circuit terminals

r

y

1.2.1 Terminal block layout

zFR-F520J-0.4K, 0.75K

N/- P/+

P1

Jumpe

Main circuit terminals

zFR-F520J-1.5K, 2.2K, 3.7K

z

FR-F540J-0.4K, 0.75K, 1.5K, 2.2K, 3.7K

N/-

Jumper

P/+

R/L1 S/L2 T/L3

Power supply

U V W

IM

Motor

zFilter pack

zFR-F520J-5.5K, 7.5K, 11K, 15K

FR-BFP-(H)0.4K to (H)15K

zFR-F540J-5.5K, 7.5K, 11K, 15K

Jumper

P1

P/+

R/L1 S/L2

N/-

Power supply

T/L3

U V W

IM

Motor

zConnection of the inverter and filter pack

(For details, refer to the instruction manual (basic).)

Filter pack

(FR-BFP)

R0 S0 T0

Earth

(Ground)

Power supply

GND

P1

Power suppl

RST P1PGND

To the inverter

terminal block

Jumper

N/-

P/+

P1

P1 P R S T

R/L1 S/L2 T/L3

Inverter

(FR-F500J)

R/L1 S/L2

T/L3

U V W

IM

Motor

R0 S0 T0

Power

supply

U V W

IM

Motor

1

WIRING

CAUTION

•Make sure the power cables are connected to the R0, S0, T0 of the filter pack (FR-

BFP) (If using the inverter without filter pack, connect to the R, S, T of the

inverter). Never connect the power cable to the U, V, W of the inverter. (Phase

need not be matched)

•Connect the motor to U, V, W. At this time, turning on the forward rotation switch

(signal) rotates the motor in the counterclockwise direction when viewed from the

motor shaft.

•When connecting the filter pack, make sure the jumper across the terminals P1-P

of the inverter is removed.

7

Page 18

Main circuit terminals

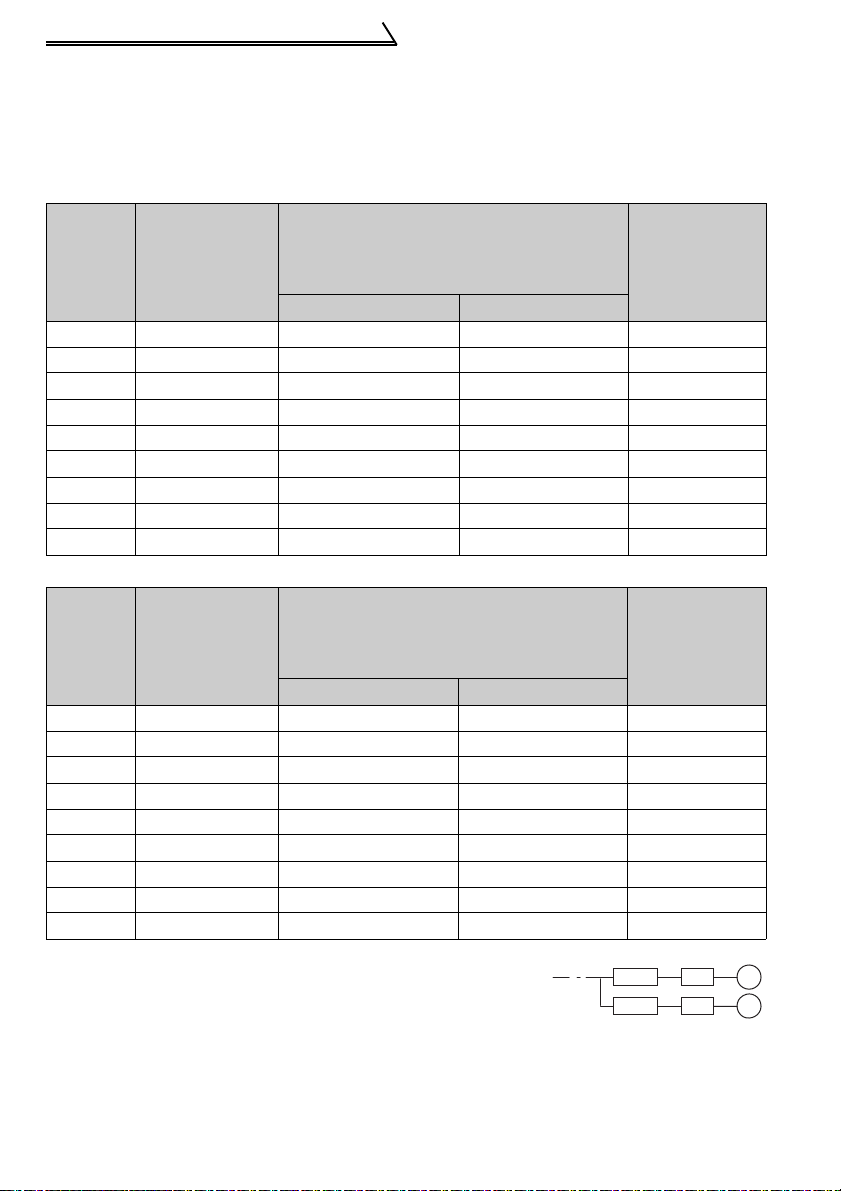

1.2.2 Cables, wiring length, and crimping terminals

The following table indicates a selection example for the wiring length of 20m.

<200V class>

2

)

Cable Sizes

AWG

R, S, T

U, V, W

Cable Sizes

AWG

PVC Cable

(mm2)

R, S, T U, V, W

PVC Cable

(mm2)

U, V, W

Ter-

Applicable

Inverter

FR-F520J-0.4K to

0.75K

FR-F520J-1.5K,

2.2K

FR-F520J-3.7K

FR-F520J-5.5K

FR-F520J-7.5K

FR-F520J-11K

FR-F520J-15K

Tight-

minal

ening

Screw

Torque

size

N

M3.5 1.2 2-3.5 2-3.5 2 2 14 14 2.5 2.5

M4 1.5 2-4 2-4 2 2 14 14 2.5 2.5

M4 1.5 5.5-4 5.5-4 3.5 3.5 12 12 4 2.5

M5 2.5 5.5-5 5.5-5 5.5 5.5 10 10 6 6

M5 2.5 14-5 8-5 14 8 6 8 16 10

M5 2.5 14-5 14-5 14 14 6 6 16 16

M6 4.4 22-6 22-6 22 22 4 4 25 25

Crimping

⋅

m

R, S, T U, V, W

Termin al

HIV Cable

(mm

R, S, T

U, V, W

<400V class>

Ter-

Applicable

Inverter

FR-F540J-0.4K to

3.7K

FR-F540J-5.5K

FR-F540J-7.5K

FR-F540J-11K

FR-F540J-15K

Tight-

minal

ening

Screw

Torque

size

N

M4 1.5 2-4 2-4 2 2 14 14 2.5 2.5

M4 1.5 5.5-4 2-4 3.5 2 12 14 4 2.5

M4 1.5 5.5-4 5.5-4 3.5 3.5 12 12 4 4

M4 1.5 5.5-4 5.5-4 5.5 5.5 10 10 6 6

M6 4.4 14-6 8-6 14 8 6 8 16 10

Crimping

Termin al

⋅

m

R, S, T U, V, W R, S, T U, V, W R, S, T U, V, W R, S, T

HIV Cable

(mm2)

*The terminal screw size of the filter pack (FR-BFP) is the same as that of the inverter.

Wiring length

• FR-F540J-0.4K ............................. 50m or less

• FR-F520J-0.4K to 3.7K

FR-F540J-0.75K to 3.7K ............... 100m or less

• FR-F520J-5.5K to 15K

FR-F540J-5.5K to 15K .................. 500m or less

CAUTION

•If the wiring length of the FR-F540J-0.4K or 0.75K is 30m or more, use the

carrier frequency of 1kHz.

•When automatic torque boost is selected in Pr. 98 "automatic torque boost

selection (motor capacity)", the wiring length must be 30m maximum. (Refer

to page 133.)

•If the wiring distance between the inverter and motor is long, the motor torque

will decrease due to the voltage drop of the main circuit cable (especially at

low-frequency output).

Use thick cables so that a voltage drop is 2% or less.

8

Page 19

Main circuit terminals

1.2.3 Wiring instructions

1) Use crimping terminals with insulation sleeve to wire the power supply and motor.

2) Application of power to the output terminals (U, V, W) of the inverter will damage the

inverter. Never perform such wiring.

3) After wiring, wire offcuts must not be left in the inverter (filter pack).

Wire offcuts can cause an alarm, failure or malfunction. Always keep the inverter

clean.

When drilling mounting holes in an enclosure etc., take care not to allow chips and

other foreign matter to enter the inverter.

4) Use cables of the recommended size to make a voltage drop 2% maximum.

If the wiring distance is long between the inverter and motor, a main circuit cable

voltage drop will cause the motor torque to decrease especially at the output of a

low frequency.

5) For long distance wiring, the high response current limit function may be reduced or

the devices connected to the secondary side may malfunction or become faulty

under the influence of a charging current due to the stray capacity of wiring.

Therefore, note the maximum overall wiring length.

6) Electromagnetic wave interference

The input/output (main circuit) of the inverter includes high frequency components,

which may interfere with the communication devices (such as AM radios) used near

the inverter. When using the inverter without the filter pack, install a FR-BIF(-H)

optional radio noise filter (for use on the input side only) or FR-BSF01 or FR-BLF

line noise filter to minimize interference.

7) Do not install a power capacitor, surge suppressor or radio noise filter (FR-BIF(-H)

option) on the output side of the inverter.

This will cause the inverter to trip or the capacitor and surge suppressor to be

damaged. If any of the above devices are connected, remove them.

8) Before starting wiring or other work after the inverter is operated, wait for at least 10

minutes after the power supply has been switched off, and check that there are no

residual voltage using a tester or the like. The capacitor is charged with high

voltage for some time after power off and it is dangerous.

9

1

WIRING

Page 20

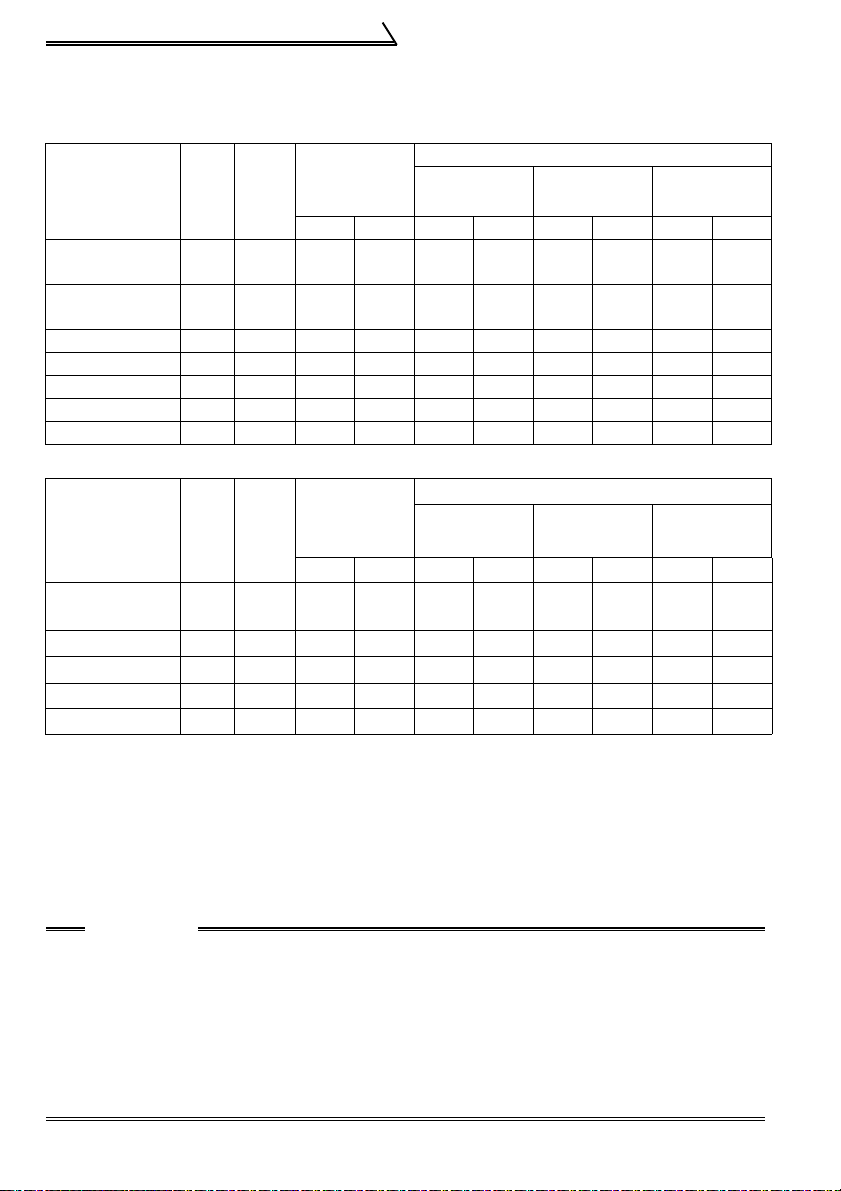

Main circuit terminals

1.2.4 Selection of peripheral devices

Check the inverter type of the inverter you purchased. Appropriate peripheral devices

must be selected according to the capacity.

Refer to the following list and prepare appropriate peripheral devices:

<200V class>

Moulded Case Circuit Breaker

Motor

Output

Inverter Type

Earth Leakage Circuit Breaker (ELB)

(kW)

With filter pack Without filter pack

0.4 FR-F520J-0.4K

0.75 FR-F520J-0.75K

1.5 FR-F520J-1.5K 30AF/15A 30AF/15A S-N10

2.2 FR-F520J-2.2K

3.7 FR-F520J-3.7K

5.5 FR-F520J-5.5K 50AF/40A 50AF/50A S-N25

7.5 FR-F520J-7.5K

11 FR-F520J-11K

15 FR-F520J-15K 100AF/100A 225AF/125A S-N65

<400V class>

Motor

Output

Inverter Type

Earth Leakage Circuit Breaker (ELB)(*2,

(kW)

With filter pack Without filter pack

0.4 FR-F540J-0.4K

0.75 FR-F540J-0.75K

1.5 FR-F540J-1.5K 30AF/10A 30AF/10A S-N10

2.2 FR-F540J-2.2K

3.7 FR-F540J-3.7K

5.5 FR-F540J-5.5K 30AF/20A 30AF/30A S-N20, S-N21

7.5 FR-F540J-7.5K

11 FR-F540J-11K

15 FR-F540J-15K 50AF/50A 100AF/60A S-N35

(MCCB)(*1, *3) or

Magnetic

Contactor

(*2, *3)

30AF/5A 30AF/5A S-N10

30AF/10A 30AF/10A S-N10

30AF/15A 30AF/20A S-N10

30AF/30A 30AF/30A S-N20,S-N21

50AF/50A 100AF/60A S-N35

100AF/75A 100AF/75A S-N50

(MC)

Moulded Case Circuit Breaker

(MCCB)(*1, *3) or

Magnetic

Contactor

*3)

30AF/5A 30AF/5A S-N10

30AF/5A 30AF/5A S-N10

30AF/10A 30AF/15A S-N10

30AF/15A 30AF/20A S-N20, S-N21

30AF/30A 30AF/30A S-N20, S-N21

50AF/40A 50AF/50A S-N25

(MC)

• Select the MCCB according to the power supply

*1.

capacity.

• Install one MCCB per inverter.

MCCB

MCCB

INV

INV

IM

IM

*2. For installations in the United States or Canada, the

circuit breaker must be inverse time or instantaneous trip type.

*3. When the breaker on the inverter primary side trips, check for the wiring fault (short

circuit), damage to internal parts of the inverter, etc.

Identify the cause of the trip, then remove the cause and power on the breaker.

10

Page 21

Main circuit terminals

1.2.5 Leakage current and installation of earth (ground) leakage circuit breaker

Due to static capacitances existing in the inverter I/O wiring and motor, leakage

currents flow through them. Since their values depend on the static capacitances,

carrier frequency, etc., take the following countermeasures.

(1) To-earth (ground) leakage currents

Leakage currents may flow not only into the inverter's own line but also into the

other line through the earth (ground) cable, etc.

These leakage currents may operate earth (ground) leakage circuit breakers and

earth (ground) leakage relays unnecessarily.

Countermeasures

• If the carrier frequency setting is high, decrease the carrier frequency (Pr. 72) of the

inverter.

Note that motor noise increases. Selection of Soft-PWM control (Pr. 70) will make it

unoffending. (Factory setting)

• By using earth leakage circuit breakers designed for harmonic and surge

suppression in the inverter's own line and other line, operation can be performed

with the carrier frequency kept high (with low noise).

REMARKS

When the filter pack is provided, leakage current can be reduced by removing the earth (ground)

cable for the capacitive filter and securing it with the supplied screw for leakage current

countermeasure (plastic) and spacer (plastic). However, the noise reduction effect of the

capacitive filter is lost.

(Pull out the earth (ground) cable for the capacitive filter a little to wire.)

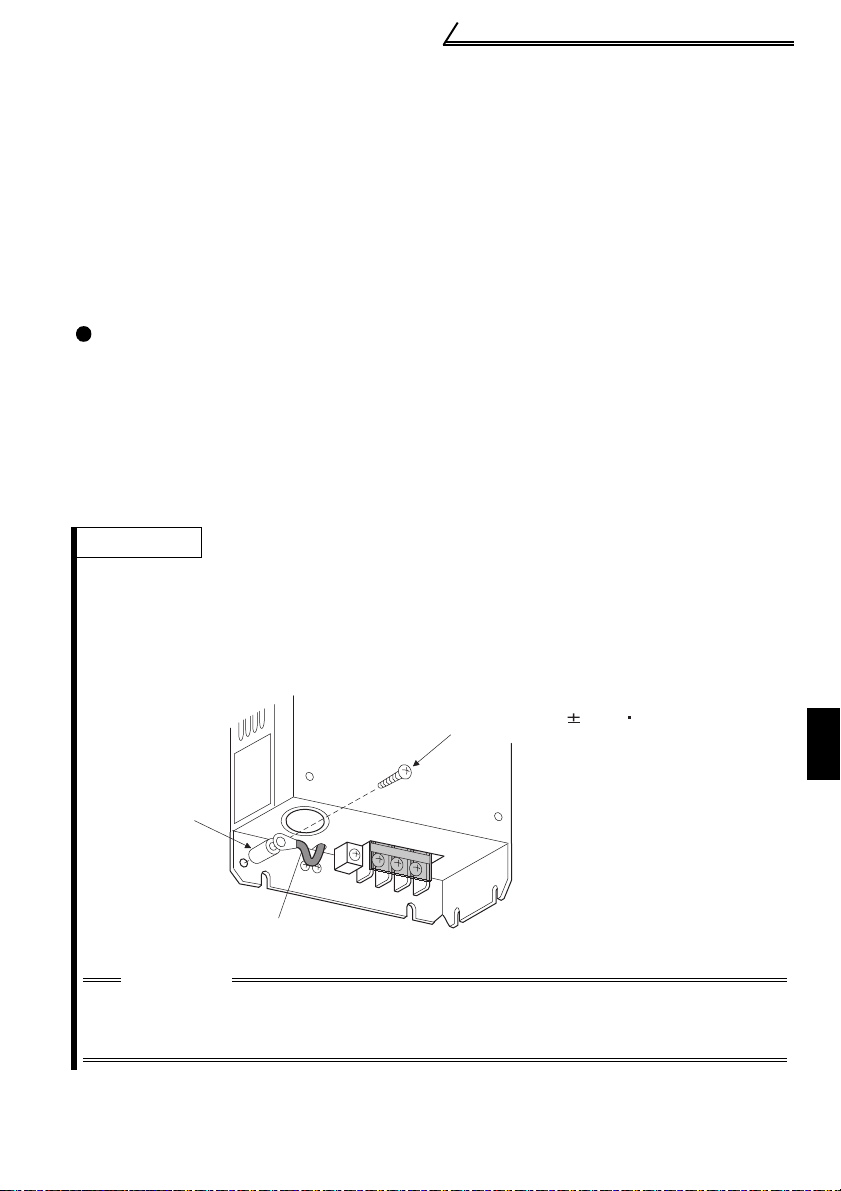

<Mounting method>

Filter pack

Screw for leakage current countermeasure (plastic)

(Tightening torque is 0.35 0.05N m)

1

Spacer

(plastic)

Earth (Ground) cable for capacitive filter

CAUTION

If the earth (ground) cable for the capacitive filter is removed, it is charged

while power is on or shortly after power off. Do not touch the earth (ground)

cable as you may get an electric shock.

11

WIRING

Page 22

Main circuit terminals

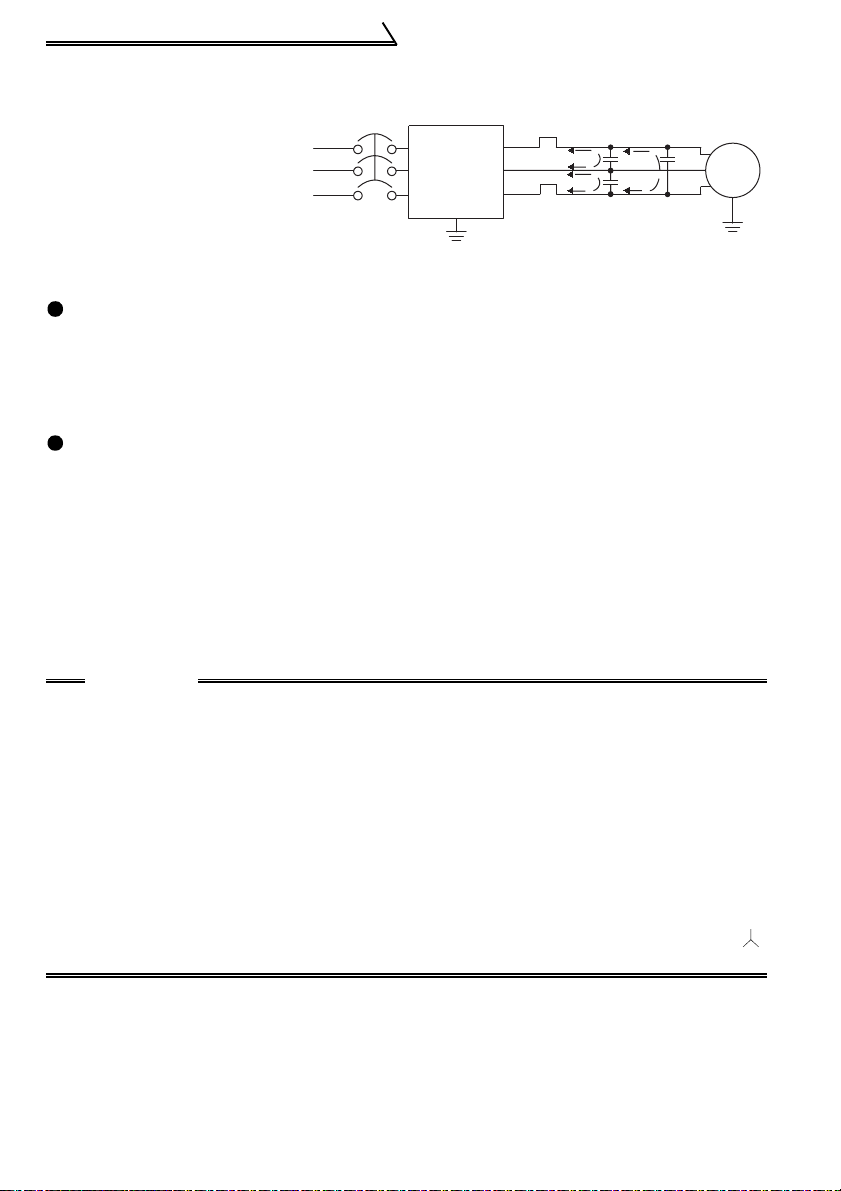

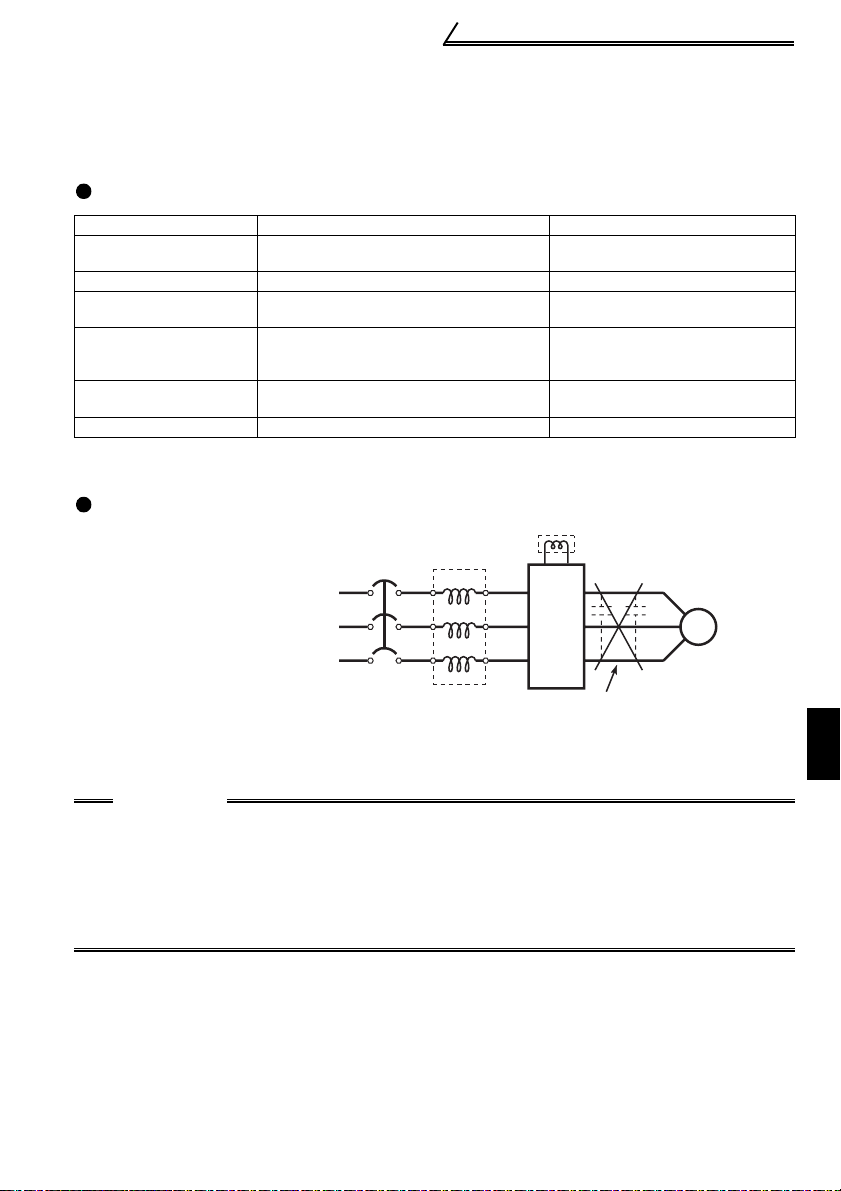

(2) Line-to-line leakage currents

Harmonics of

leakage currents

flowing in static

capacities between

Power

supply

MCCB

Inverter

the inverter output

cables may operate

the external thermal

Line-to-Line Leakage Current Path

relay unnecessarily.

Countermeasures

• Use the electronic thermal relay function of the inverter.

• Decrease the carrier frequency. Note that motor noise increases. Selection of

Soft-PWM (Pr. 70) makes it unoffending.

To ensure that the motor is protected against line-to-line leakage currents, it is

recommended to use a temperature sensor to directly detect motor temperature.

Installation and selection of moulded case circuit breaker

Install a moulded case circuit breaker (MCCB) on the power receiving side to

protect the wiring of the inverter primary side. Select the MCCB according to the

power supply side power factor (which depends on the power supply voltage, output

frequency and load). Especially for a completely electromagnetic MCCB, one of a

slightly large capacity must be selected since its operation characteristic varies with

harmonic currents. (Check it in the data of the corresponding breaker.) As an earth

(ground) leakage breaker, use the Mitsubishi earth (ground) leakage breaker

designed for harmonics and surge suppression. (Refer to page 10 for the

recommended models.)

Thermal relay

Line static

capacitances

Motor

IM

CAUTION

•Select the MCCB according to the inverter power supply capacity.

•Install one MCCB per inverter.

•The inverter has a protective function based on electronic overcurrent protection

(electronic thermal relay function) to protect the motor from overheating.

However, when running multiple motors with one inverter or operating a multipole motor, provide a thermal relay (OCR) between the inverter and motor. In this

case, set the electronic thermal relay function (electronic overcurrent protection)

of the inverter to 0A. And set the electronic overcurrent relay, add the line-to-line

leakage current to 1.0 times the current value at 50 Hz on the motor rating plate or

to 1.1 times the current value at 60 Hz.

•When the FR-BFP (filter pack) is used, leakage current is 4mA.(8mA for 400V

class.) (equivalent to one-phase of cable for the three-phase three wire

connection)

12

Page 23

Main circuit terminals

)

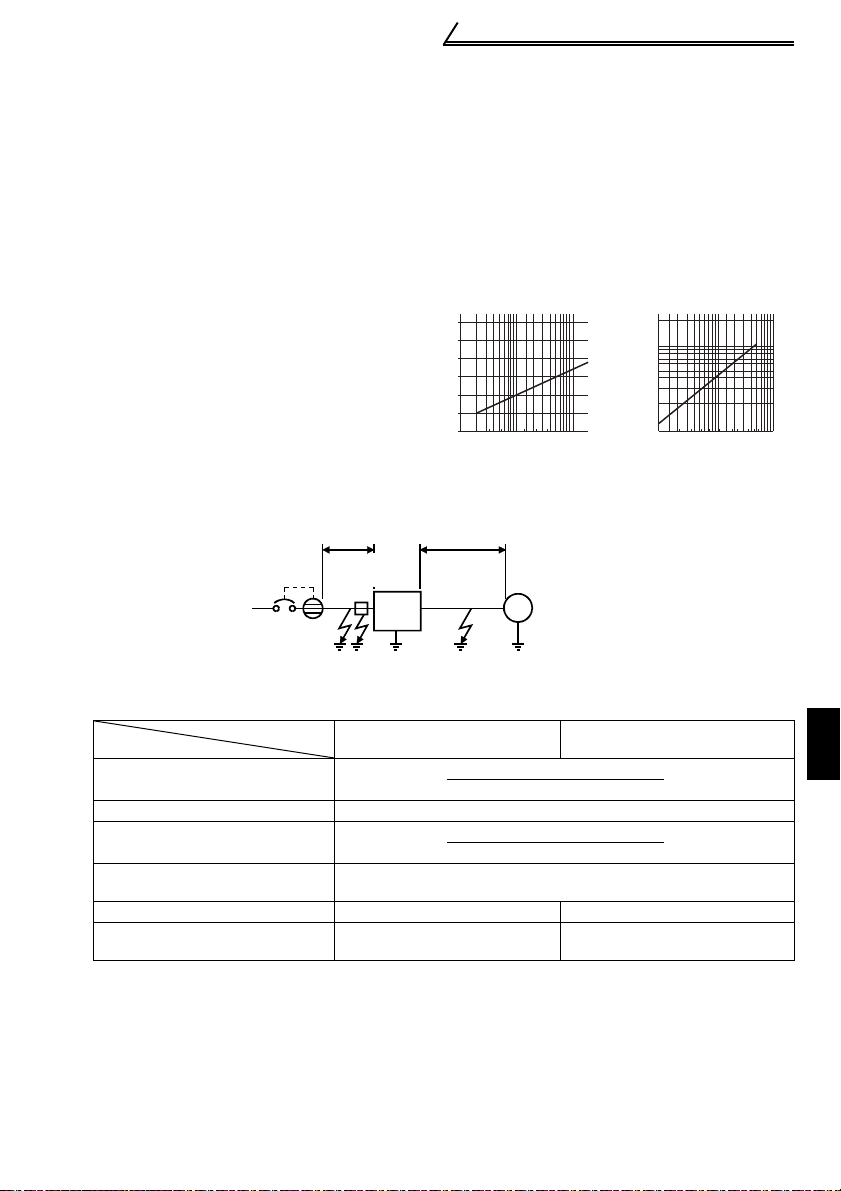

(3) Selecting the rated sensitivity current for the earth leakage circuit

breaker

When using the earth leakage circuit breaker with the inverter circuit, select its rated

sensitivity current as follows, independently of the PWM carrier frequency:

• Breaker for harmonic and surge

Rated sensitivity current:

I

∆n ≥ 10 × (lg1+Ign+lg2+lgm)

• Standard breaker

Rated sensitivity current:

I

∆n ≥ 10 × {lg1+lgn+3 × (lg2+lgm)}

lg1, lg2 : Leakage currents of cable

path during commercial

power supply operation

lgn : Leakage current of noise

filter on inverter input side

lgm : Leakage current of motor

during commercial power

supply operation

<Example>

22

2mm ×5m

NV

Filter

pack

Example of leakage

current per 1km in cable

path during commercial

power supply operation

when the CV cable is

routed in metal conduit

(200V 60Hz)

120

100

80

60

40

20

0

2 3.5 8 142238 80

Leakage current (mA)

Cable size (mm)

2mm ×70m

Inverter

5.5 3060100

φ

3 200V

IM

1.5kW

Leakage current

example of three-phase

induction motor

during commercial

power supply

operation

(200V 60Hz)

2.0

1.0

0.7

0.5

0.3

0.2

150

2

0.1

Leakage current (mA)

Motor capacity (kW

1.5 3 .7

2.2

7.5 152 21137

5.5 18.5

55

45

30

Ig1 Ign Ig2 Igm

Leakage current (Ig1) (mA)

Breaker for Harmonic and

Surge

20 ×

1000m

5m

Standard Breaker

= 0.10

Leakage current (Ign) (mA) 0 (without filter pack)

Leakage current (Ig2) (mA)

Motor leakage

current (Igm) (mA)

20 ×

70m

1000m

0.16

= 1.40

Total leakage current (mA) 1.66 4.78

Rated sensitivity current

(mA) (≥ Ig

× 10)

30 100

13

1

WIRING

Page 24

Main circuit terminals

CAUTION

•The earth (ground) leakage circuit breaker should be installed to the primary

(power supply) side of the inverter.

•In the connection neutral point earth (grounded) system, the sensitivity

current becomes worse for earth (ground) faults on the inverter secondary

side. Earthing (Grounding) must conform to the requirements of national and

local safety regulations and electrical codes. (NEC section 250, IEC 536 class

1 and other applicable standards)

•When the breaker is installed on the secondary side of the inverter, it may be

unnecessarily operated by harmonics if the effective value is less than the

rating. In this case, do not install the breaker since the eddy current and

hysteresis loss increase and the temperature rises.

•General products indicate the following models: BV-C1, BC-V, NVB, NV-L, NVG2N, NV-G3NA, NV-2F, earth (ground) leakage relay (except NV-ZHA), NV with

AA neutral wire open-phase protection

The other models are designed for harmonic and surge suppression: NV-C/

NV-S/MN series, NV30-FA, NV50-FA, BV-C2, earth (ground) leakage alarm

breaker (NF-Z), NV-ZHA, NV-H

14

Page 25

Main circuit terminals

r

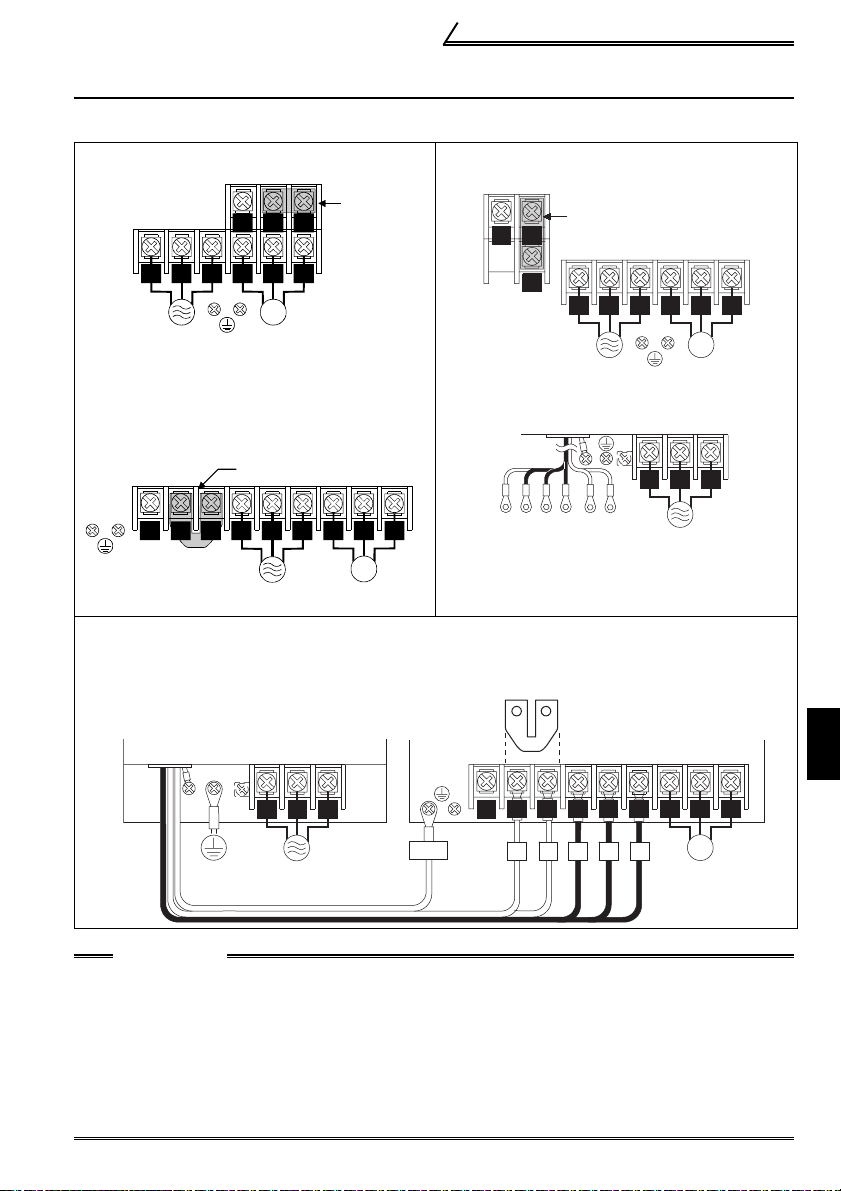

1.2.6 Power-off and magnetic contactor (MC)

(1) Inverter input side magnetic contactor (MC)

On the inverter's input side, it is recommended to provide an MC for the following

purposes. (Refer to page 10 for selection)

1) To release the inverter from the power supply when the inverter protective function

is activated or the drive becomes faulty (e.g. emergency stop operation)

2) To prevent any accident due to an automatic restart at restoration of power after an

inverter stop made by a power failure

3) To rest the inverter for an extended period of time

The control power supply for inverter is always running and consumes a little power.

When stopping the inverter for an extended period of time, powering off the inverter

will save power slightly.

4) To separate the inverter from the power supply to ensure safe maintenance and

inspection work

The inverter's input side MC is used for the above purpose, select class JEM1038AC3 for the inverter input side current when making an emergency stop during

normal operation.

REMARKS

The MC may be switched on/off to start/stop the inverter. However, since repeated inrush

currents at power on will shorten the life of the converter circuit (switching life is about 100,000

times), frequent starts and stops must be avoided. Turn on/off the inverter start controlling

terminals (STF, STR) to run/stop the inverter.

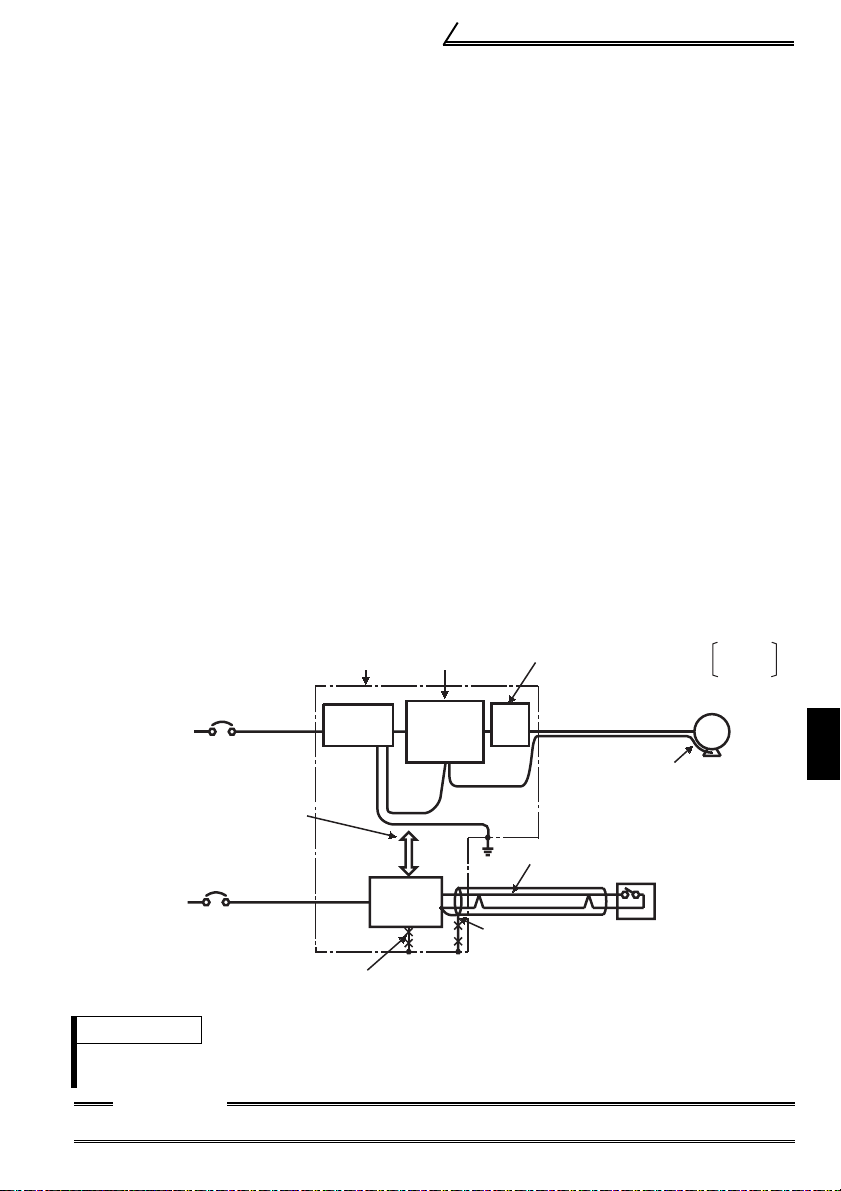

As shown on the right,

always use the start signal

(ON or OFF across

terminals STF or STR-SD)

Power

supply

to make a start or stop.

(Refer to page 28)

*1. When the power supply

is 400V class, install a

step-down transformer.

(2) Handling of output side magnetic contactor

In principle, do not provide a magnetic contactor between the inverter and motor and

switch it from off to on during operation. If it is switched on during inverter operation, a

large inrush current may flow, stopping the inverter due to overcurrent shut-off. When

an MC is provided for switching to the commercial power supply, for example, switch it

on/off after the inverter and motor have stopped.

MCCB

Operation ready

ON

OFF

MC

Start/Stop

OFF

Operation

RA

MC

Inverter Start/Stop Circuit Example

MC

R0

S0

T0

T (*1)

MC

RA

(with filter pack)

R

S

T

P1

P

RA

R

S

T

P1

P

Inverter

STF(STR)

SD

W

U

To

V

moto

A

B

C

1

WIRING

15

Page 26

Main circuit terminals

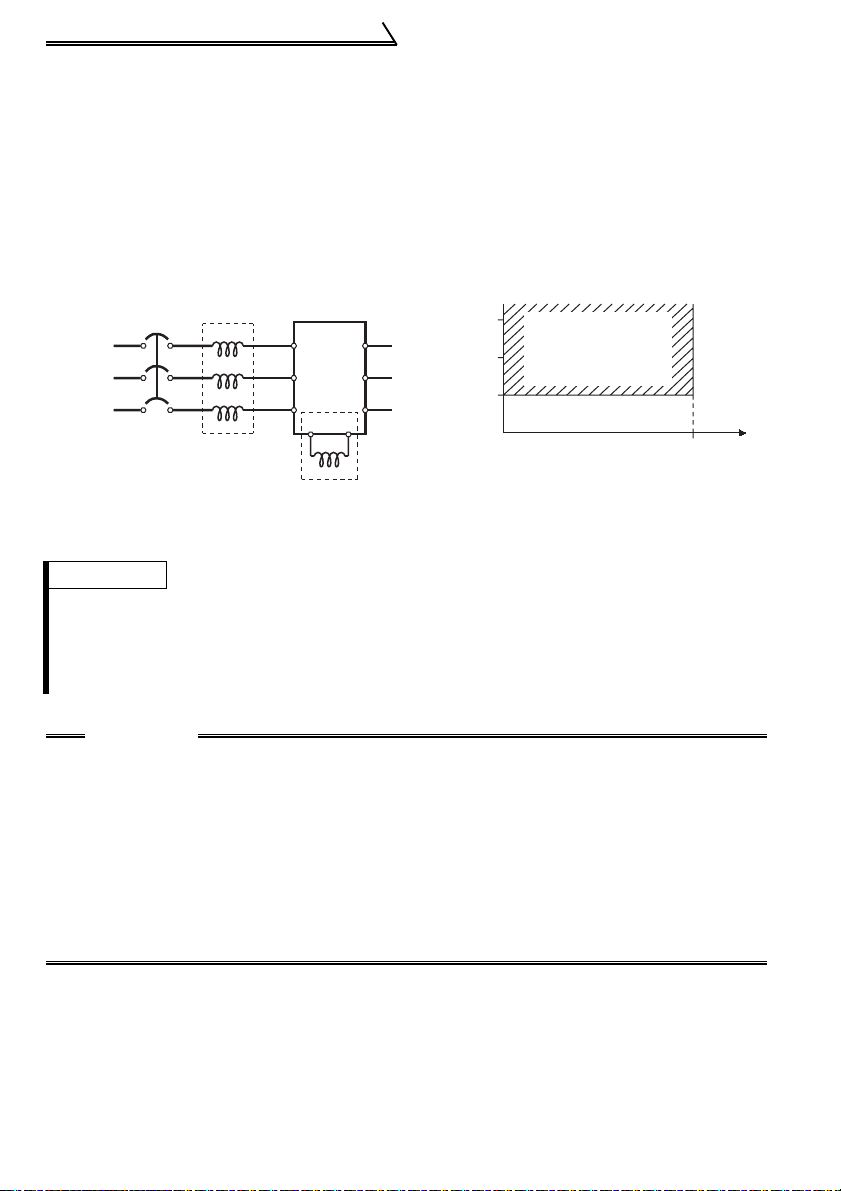

1.2.7 Regarding the installation of the reactor

When the inverter is installed near a large-capacity power transformer (500kVA or

more with the wiring length of 10m (32.81feet) or less) or the power capacitor is to be

switched, an excessive peak current will flow in the power supply input circuit,

damaging the converter circuit. In such a case, always install the reactor (FR-HEL(-H)

/FR-BEL(-H) or FR-HAL(-H)/FR-BAL(-H)). Since the filter pack includes a power factor

improving DC reactor, a reactor need not be installed separately.

Power

supply

MCCB

FR-HAL(-H)/

FR-BAL(-H)

R

S

TZ

Inverter

X

R

Y

S

T

P

FR-HEL(-H)/

FR-BEL(-H)(*)

P1

W

1500

U

V

1000

Power supply equipment

capacity (kVA)

Reactor installation

range

500

010

Wiring length (m)

REMARKS

*When connecting the FR-HEL(-H)/FR-BEL(-H) (filter pack), remove the jumper across

terminals P-P1.

The wiring length between the FR-HEL(-H)/FR-BEL(-H) and the inverter should be 5m

maximum and as short as possible.

Use the cables which are equal in size to those of the main circuit. (Refer to page 8)

CAUTION

•The power factor improving capacitor and surge suppressor on the inverter

output side may be overheated or damaged by the high frequency

components of the inverter output. Also, since an excessive current flows in

the inverter to activate overcurrent protection, do not install a capacitor or

surge suppressor. Use a power factor improving reactor for power factor

improvement.

•If a surge voltage occurs in the power supply system, this surge energy may

flow into the inverter, causing the inverter to display OV1, OV2 or OV3 and

come to an alarm stop. In such a case, also install the optional FR-HEL(-H)/FRBEL(-H) or FR-HAL(-H)/FR-BAL(-H) power factor improving reactor.

16

Page 27

Main circuit terminals

1.2.8

Regarding noise (EMI) and the installation of a noise filter

Some noise enters the inverter causing it to malfunction and others are generated by

the inverter causing the malfunction of peripheral devices. Though the inverter is

designed to have high immunity performance, it handles low-level signals, so it

requires the following general countermeasures to be taken.

(1) General countermeasures

• Do not run the power cables (I/O cables) and signal cables of the inverter in parallel

with each other and do not bundle them.

• Use twisted shield cables for the detector connecting and control signal cables and

connect the sheathes of the shield cables to terminal SD.

• Earth (Ground) the inverter, motor, etc. at one point.

• Capacitances exist between the inverter's I/O wiring, other cables, earth (ground)

and motor, through which leakage currents flow to cause the earth leakage circuit

breaker, earth (ground) leakage relay and external thermal relay to operate

unnecessarily. To prevent this, take appropriate measures, e.g. set the carrier

frequency in Pr. 72 to a low value, use an earth (ground) leakage circuit breaker

designed for suppression of harmonics and surges, and use the electronic thermal

relay function built in the inverter.

• The input and output of the inverter main circuit include high-degree harmonics,

which may disturb communication devices (AM radios) and sensors used near the

inverter.

<Noise (EMI) reduction examples>

Inverter

power supply

Separate inverter and power

line by more than 30cm

and at least 10cm

from sensor circuit.

Control

power supply

Do not earth (ground)

enclosure directly.

Do not earth (ground)

control cable.

Enclosure

Filter

pack

Power

supply

for sensor

Reduce carrier

frequency.

Inverter

FRBLF

Do not earth (ground) shield but connect

it to signal common cable.

Install a line noise filter

on inverter's output side.

Use 4-core cable for motor

power cable and use one

cable as earth (ground) cable.

Use twisted pair shielded cable.

Sensor

FR-BLF

FR-BSF01

IM

Motor

1

WIRING

REMARKS

For the inverter without filter pack, install a line noise filter (FR-BLF, FR-BSF01) or radio noise

filter (FR-BIF) on the inverter input side as a noise reduction measure.

CAUTION

For compliance with the EU, EMC directive, please refer the instruction manual (basic).

17

Page 28

Main circuit terminals

1.2.9 Earthing (Grounding) precautions

z Leakage currents flow in the inverter (filter pack). To prevent an electric shock, the

inverter (filter pack) and motor must be earthed (grounded). Earthing (Grounding)

must conform to the requirements of national and local safety regulations and

electrical codes.

(NEC section 250, IEC 536 class 1 and other applicable standards)

z Use the dedicated earth (ground) terminal to earth (ground) the inverter (filter pack).

(Do not use the screw in the casing, chassis, etc.)

Use a tinned* crimping terminal to connect the earth (ground) cable. When

tightening the screw, be careful not to damage the threads.

*Plating should not include zinc.

z Use the thickest possible earth (ground) cable. Use the cable whose size is equal to

or greater than that indicated in the following table, and minimize the cable length.

The earthing (grounding) point should be as near as possible to the inverter.

2

Motor Capacity

2.2kW or less 2 (2.5) 2 (2.5)

3.7kW 3.5 (4) 2 (4)

5.5kW 5.5 (6) 3.5 (4)

7.5kW 14 (16) 3.5 (4)

11kW 14 (16) 5.5 (6)

15kW 22 (25) 14 (16)

Earth (Ground) Cable Size (Unit: mm

200V class 400V class

For use as a product compliant with the Low Voltage Directive, use PVC cable

whose size is indicated within parentheses.

)

z As a noise reduction technique, use one wire of the four-core cable with the earth

(ground) terminal of the motor, and earth (ground) at one point from the filter pack

side via the inverter. (Refer to page 2.)

Inverter

R

S

T

P1

P

W

U

V

Motor

IM

Power

supply

Earthing

(Grounding)

Filter pack

R

R0

S

S0

T

T0

P1

P

GND

(For the type without filter pack, earth (ground) the motor with the inverter at one point

on the inverter side.)

CAUTION

When the inverter is run in the low acoustic noise mode, more leakage currents

occur than in the non-low acoustic noise mode due to high-speed switching

operation. Always earth (ground) the inverter, motor and filter pack before use.

18

Page 29

Main circuit terminals

1.2.10 Power supply harmonics

The inverter may generate power supply harmonics from its converter circuit to affect

the power generator, power capacitor etc. Power supply harmonics are different from

noise and leakage currents in source, frequency band and transmission path. Take the

following countermeasure suppression techniques.

The following table indicates differences between harmonics and noise:

Item Harmonics Noise

Frequency

Environment To-electric channel, power impedance To-space, distance, wiring path

Quantitative

understanding

Generated amount Nearly proportional to load capacity

Affected equipment

immunity

Suppression example Provide reactor.* Increase distance.

*The filter pack (FR-BFP) produces the same effect as when the DC reactor (FR-

HEL(-H)/FR-BEL(-H)) is connected.

Suppression technique

Harmonic currents produced

on the power supply side by

the inverter change with such

conditions as whether there

are wiring impedances and a

DC reactor (FR-HEL(-H)/FRBEL(-H) or FR-HAL(-H)/FRBAL(-H)) and the magnitudes

of output frequency and

output current on the load

side.

For the output frequency and output current, we understand that they should be

calculated in the conditions under the rated load at the maximum operating frequency.

CAUTION

The power factor improving capacitor and surge suppressor on the inverter

output side may be overheated or damaged by the high frequency components

of the inverter output. Also, since an excessive current flows in the inverter to

activate overcurrent protection, do not provide a capacitor and surge

suppressor on the inverter output side when the motor is driven by the inverter.

To improve the power factor, insert a reactor on the inverter's primary side or

DC circuit. For full information, refer to page 16.

Normally 40th to 50th degrees or less

(up to 3kHz or less)

Theoretical calculation possible

Specified in standard per equipment

FR-HEL(-H)

/FR-BEL(-H)

MCCB

FR-HAL(-H)

/FR-BAL(-H)

High frequency (several 10kHz

to 1GHz order)

Random occurrence,

quantitative grasping difficult

Change with current variation

ratio (larger as switching speed

increases)

Different depending on maker's

equipment specifications

Motor

IM

Inverter

Do not provide power factor

improving capacitor.

1

WIRING

19

Page 30

Main circuit terminals

1.2.11 Harmonic suppression guideline

Harmonic currents flow from the inverter to a power receiving point via a power

transformer. The harmonic suppression guideline was established to protect other

consumers from these outgoing harmonic current.

The three-phase 200V input specifications 3.7kW or less are previously covered by

"Harmonic suppression guideline for household appliances and general-purpose

products" and other models are covered by "Harmonic suppression guideline for

consumers who receive high voltage or special high voltage". However, the generalpurpose inverter has been excluded from the target products covered by "Harmonic

suppression guideline for household appliances and general-purpose products" in

January 2004. Later, this guideline was repealed on September 6, 2004. All capacities

of all models are now target products of "Harmonic suppression guideline for

consumers who receive high voltage or special high voltage" (hereinafter referred to

as "Guideline for specific consumers").

"Guideline for specific consumers"

This guideline sets forth the maximum values of harmonic currents outgoing from a

high-voltage or especially high-voltage consumer who will install, add or renew

harmonic generating equipment. If any of the maximum values is exceeded, this

guideline requires that consumer to take certain suppression measures.

Table 1 Maximum Values of Outgoing Harmonic Currents per 1kW Contract Power

Received Power Voltage 5th 7th 11th 13th 17th 19th 23rd

6.6 kV 3.5 2.5 1.6 1.3 1.0 0.9 0.76 0.70

22 kV 1.8 1.3 0.82 0.69 0.53 0.47 0.39 0.36

33 kV 1.2 0.86 0.55 0.46 0.35 0.32 0.26 0.24

Over

23rd

20

Page 31

(1)

Application of the guideline for specific consumers

New installation/addition/

renewal of equipment

Calculation of equivalent

capacity sum

Not more than

reference capacity

Sum of equivalent

capacities

Over reference

capacity

Calculation of outgoing

harmonic current

Main circuit terminals

Is outgoing harmonic

current equal to or lower

than maximum value?

Not more than

maximum value

Harmonic suppression

technique is not required.

Over maximum value

Harmonic suppression

technique is required.

Table 2 Conversion Factors for FR-F500J Series

Class Circuit Type Conversion Factor (Ki)

Without reactor K31 = 3.4

Three-phase bridge

3

(Capacitorsmoothed)

With reactor (AC side) K32 = 1.8

With reactor (DC side) or filter pack K33 = 1.8

With reactors (AC, DC sides) K34 = 1.4

Table 3 Equivalent Capacity Limits

Received Power Voltage Reference Capacity

6.6kV 50 kVA

22/33 kV 300 kVA

66kV or more 2000 kVA

1

WIRING

21

Page 32

Main circuit terminals

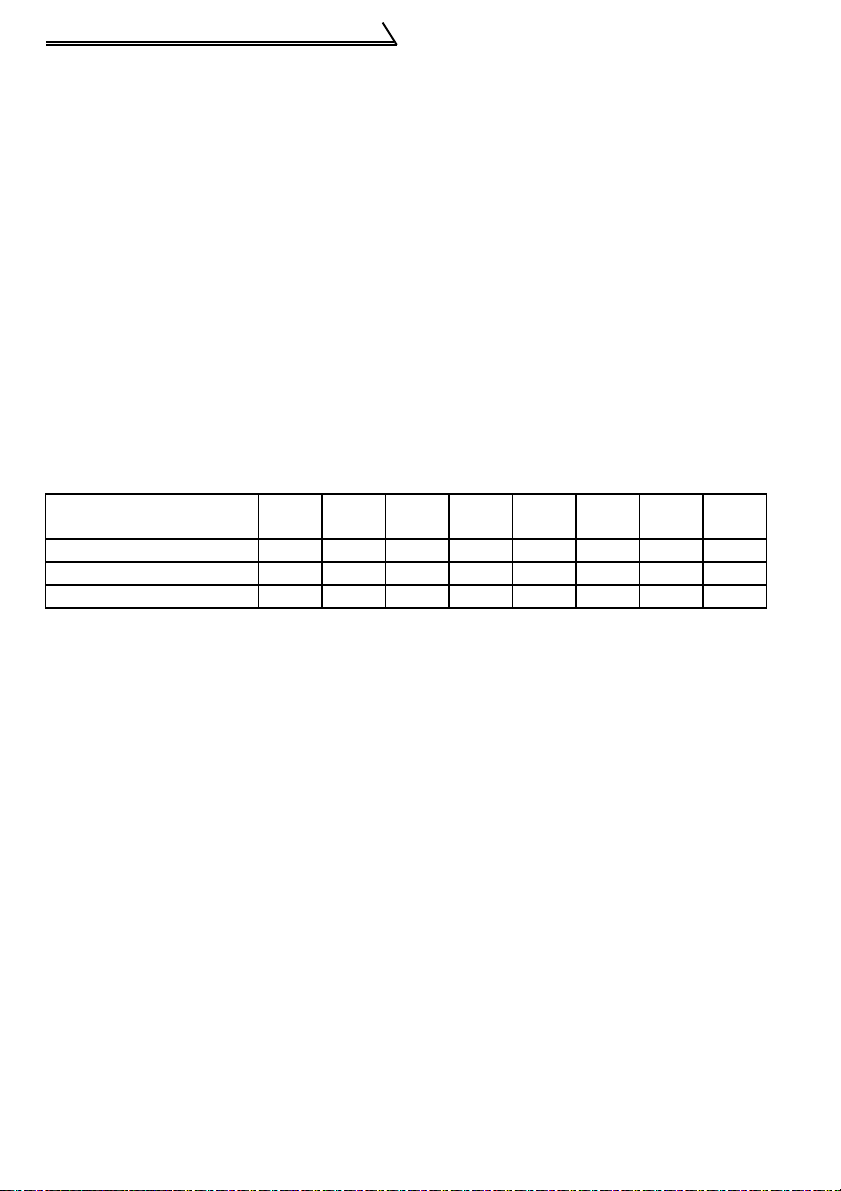

Table 4 Harmonic Contents (Values of the fundamental current of 100%)

Reactor 5th 7th 11th 13th 17th 19th 23rd 25th

Not used 65 41 8.5 7.7 4.3 3.1 2.6 1.8

Used (AC side) 38 14.5 7.4 3.4 3.2 1.9 1.7 1.3

Used (DC side)

or with filter

pack

Used (AC, DC

sides)

30 13 8.4 5.0 4.7 3.2 3.0 2.2

28 9.1 7.2 4.1 3.2 2.4 1.6 1.4

1) Calculation of equivalent capacity (P0) of harmonic generating equipment

The "equivalent capacity" is the capacity of a 6-pulse converter converted from the

capacity of consumer's harmonic generating equipment and is calculated with the

following equation. If the sum of equivalent capacities is higher than the limit in

Table 3, harmonics must be calculated with the following procedure:

P0=Σ (Ki × Pi) [kVA]

Ki: Conversion factor (refer to Table 2)

Pi: Rated capacity of harmonic

generating equipment* [kVA]

i: Number indicating the conversion

circuit type

* Rated capacity: Determined by the

capacity of the applied motor and

found in Table 5. It should be noted

that the rated capacity used here is

used to calculate a generated

harmonic amount and is different

from the power supply capacity

required for actual inverter drive.

2) Calculation of outgoing harmonic current

Outgoing harmonic current = fundamental wave current (value converted from

received power voltage) × operation ratio × harmonic

content

• Operation ratio: Operation ratio = actual load factor × operation time ratio during

30 minutes

• Harmonic content: Found in Table 4.

22

Page 33

Main circuit terminals

Table 5 Rated Capacities and Outgoing Harmonic Currents for Inverter Drive

(with filter pack)

Rated

Applied

Motor

(kW)

0.75 1.37 83 0.97 24.9 10.76 6.97 4.15 3.90 2.66 2.49 1.83

Current

[A]

400V 5th 7th 11th 13th 17th 19th 23rd 25th

0.4 0.81 49 0.57 14.7 6.37 4.12 2.45 2.30 1.57 1.47 1.08

1.5 2.75 167 1.95 50.10 21.71 14.03 8.35 7.85 5.34 5.01 3.67

2.2 3.96 240 2.81 72.00 31.20 20.16 12.00 11.28 7.68 7.20 5.28

3.7 6.50 394 4.61 118.2 51.2 33.10 19.70 18.52 12.61 11.82 8.67

5.5 9.55 579 6.77 173.7 75.27 48.64 28.95 27.21 18.53 17.37 12.74

7.5 12.8 776 9.07 232.8 100.9 65.18 38.80 36.47 24.83 23.28 17.07

11 18.5 1121 13.1 336.3 145.7 94.16 56.05 52.69 35.87 33.63 24.66

15 24.9 1509 17.6 452.7 196.2 126.8 75.45 70.92 48.29 45.27 33.20

6.6kV

Equivalent of

Fundamental

Wave

Current (mA)

Rated

Capacity

(kVA)

Outgoing Harmonic Current Converted from 6.6kV

(with filter pack, 100% operation ratio)

3) Harmonic suppression technique requirement

If the outgoing harmonic current is higher than; maximum value per 1kW (contract

power) × contract power, a harmonic suppression technique is required.

4) Harmonic suppression techniques

No. Item Description

Reactor installation

(ACL, DCL)

1

Installation of power

2

factor improving

capacitor

Transformer multiphase operation

3

Passive

4

(AC filter)

Active filter This filter detects the current of a circuit generating a harmonic

5

Install a reactor (ACL) in the AC side of the inverter or a reactor

(DCL) in its DC side or both to suppress outgoing harmonic

currents. (The DC reactor has already been installed in the type

with filter pack.)

When used with a series reactor, the power factor improving

capacitor has an effect of absorbing harmonic currents.

Use two transformers with a phase angle difference of 30

° as in -

∆, ∆-∆ combination to provide an effect corresponding to 12 pulses,

reducing low-degree harmonic currents.

A capacitor and a reactor are used together to reduce impedances

at specific frequencies, producing a great effect of absorbing

harmonic currents.

current and generates a harmonic current equivalent to a difference

between that current and a fundamental wave current to suppress

a harmonic current at a detection point, providing a great effect of

absorbing harmonic currents.

1

WIRING

23

Page 34

Main circuit terminals