Page 1

www.mivec.co.nz

ENGINE

4G9 SERIES

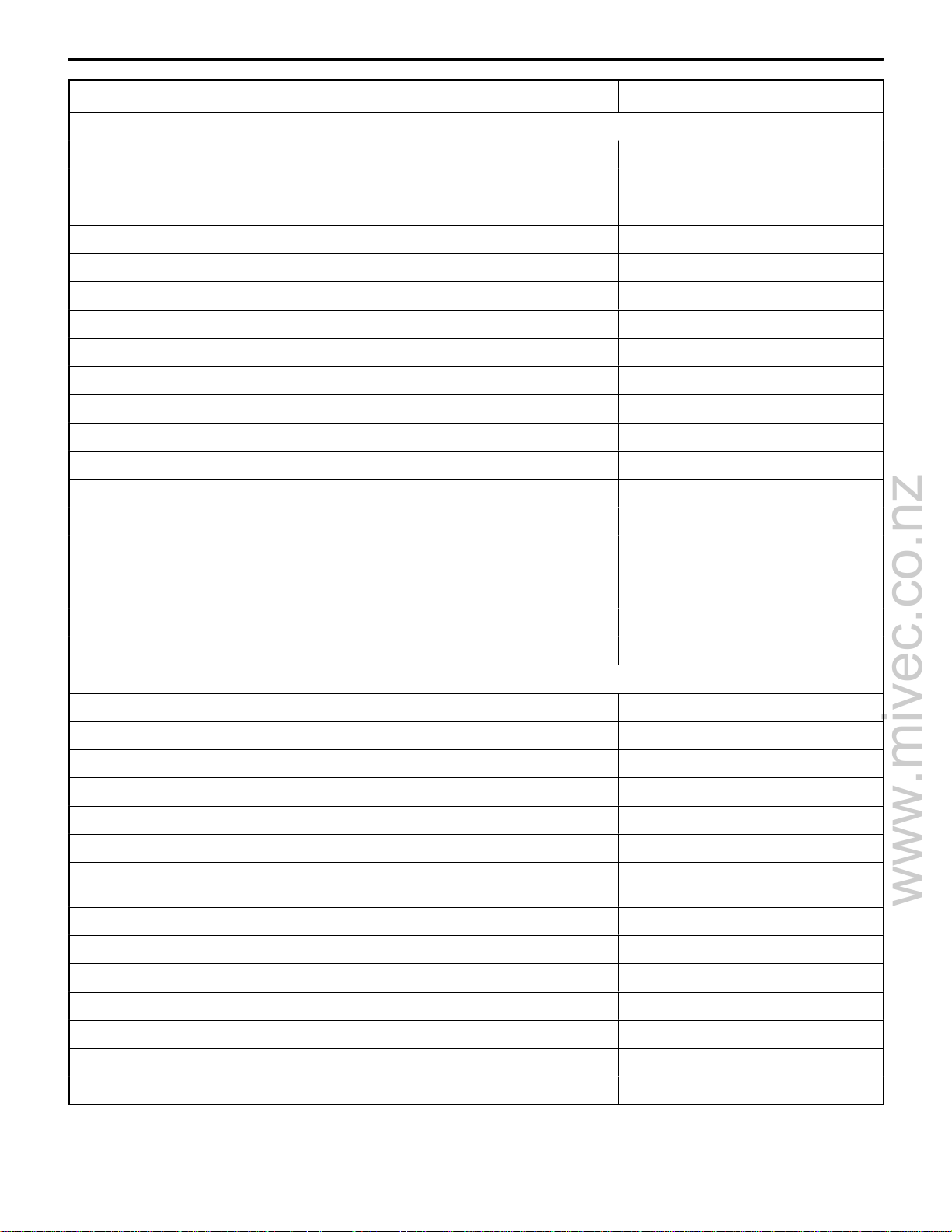

CONTENTS

GENERAL INFORMATION 11A-0-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

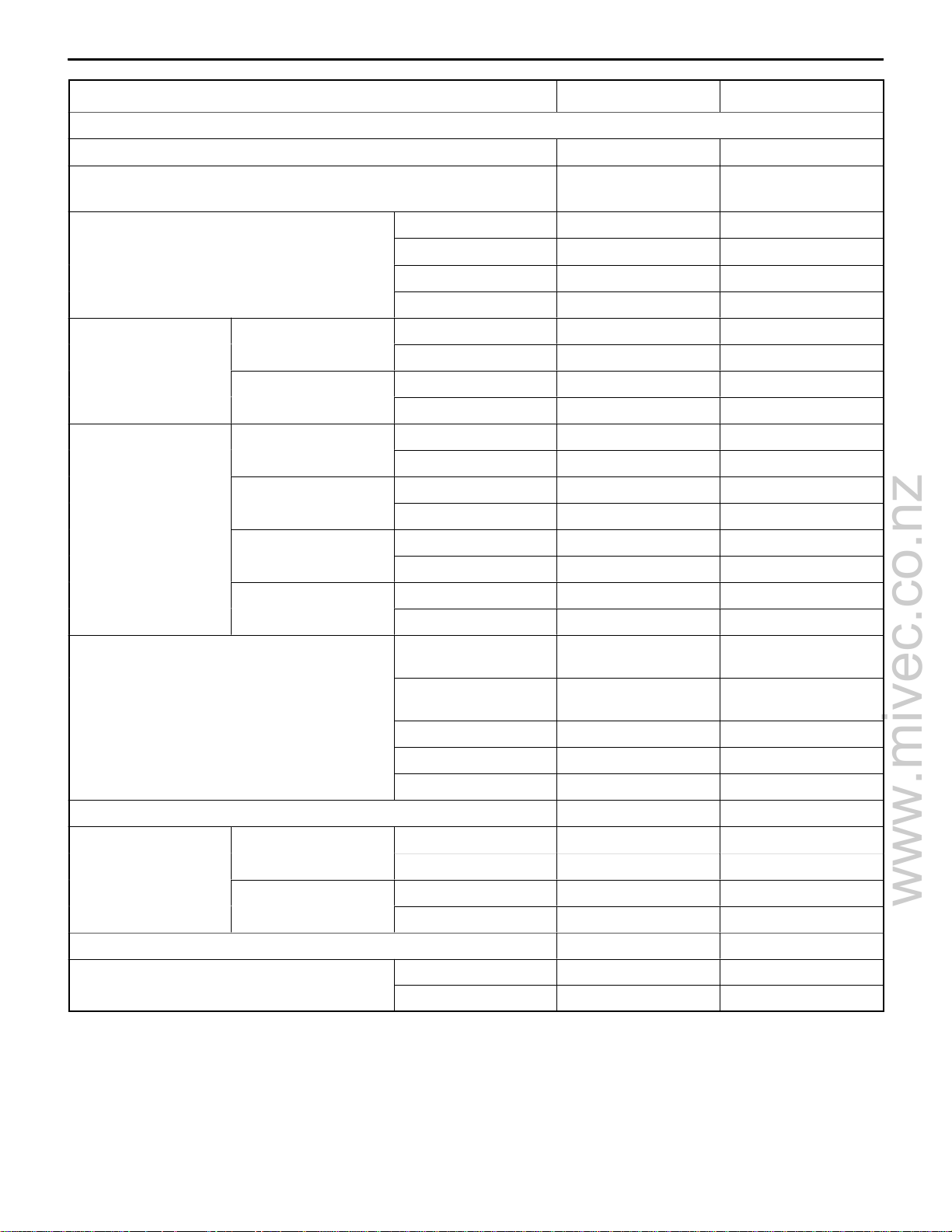

1.SPECIFICATIONS 11A-1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SERVICE SPECIFICATIONS 11A-1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

REWORK DIMENSIONS 11A-1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TORQUE SPECIFICATIONS 11A-1-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

NEW TIGHTENING METHOD–BY USE OF BOLTS TO BE

TIGHTENED IN PLASTIC AREA 11A-1-7

SEALANT 11A-1-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FORM-IN-PLACE GASKET 11A-1-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.SPECIAL TOOLS 11A-2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.ALTERNATOR AND IGNITION SYSTEM 11A-3-1. . . . . . . . . . . . . . . . . . . . . . . .

4.TIMING BELT 11A-4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.FUEL AND EMISSION CONTROL SYSTEM 11A-5-1. . . . . . . . . . . . . . . . . . . . .

5a.THROTTLE BODY AND EGR SYSTEM (GDI) 11A-5a-1. . . . . . . . . . . . . . . . .

6.INTAKE AND EXHAUST MANIFOLD 11A-6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

6a.INTAKE MANIFOLD (GDI) 11A-6a-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6b.EXHAUST MANIFOLD (GDI) 11A-6b-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6c.INJECTOR AND FUEL PUMP ASSEMBLY (GDI) 11A-6c-1. . . . . . . . . . . . .

6d.INTAKE AND EXHAUST MANIFOLD

<4G94–GDI for PAJERO io> 11A-6d-1

7.WATER PUMP AND WATER HOSE 11A-7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.ROCKER ARMS AND CAMSHAFTS 11A-8-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8a.ROCKER COVER AND CAMSHAFTS (MIVEC) 11A-8a-1. . . . . . . . . . . . . . .

8b.ROCKER ARMS AND ROCKER SHAFT CAPS (MIVEC) 11A-8b-1. . . . .

9.CYLINDER HEAD AND VALVES 11A-9-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.FRONT CASE AND OIL PUMP 11A-10-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.PISTON AND CONNECTING ROD 11A-11-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.CRANKSHAFT, CYLINDER BLOCK, FLYWHEEL AND DRIVE

PLATE 11A-12-1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11A-0-1

E

Mar . 2001Mitsubishi Motors Corporation Revised

PWEE9502-I

Page 2

www.mivec.co.nz

11A-0-2

NOTES

E

May 1995Mitsubishi Motors Corporation

PWEE9502

Page 3

www.mivec.co.nz

4G9 ENGINE (E-W) -

General Information

GENERAL INFORMATION

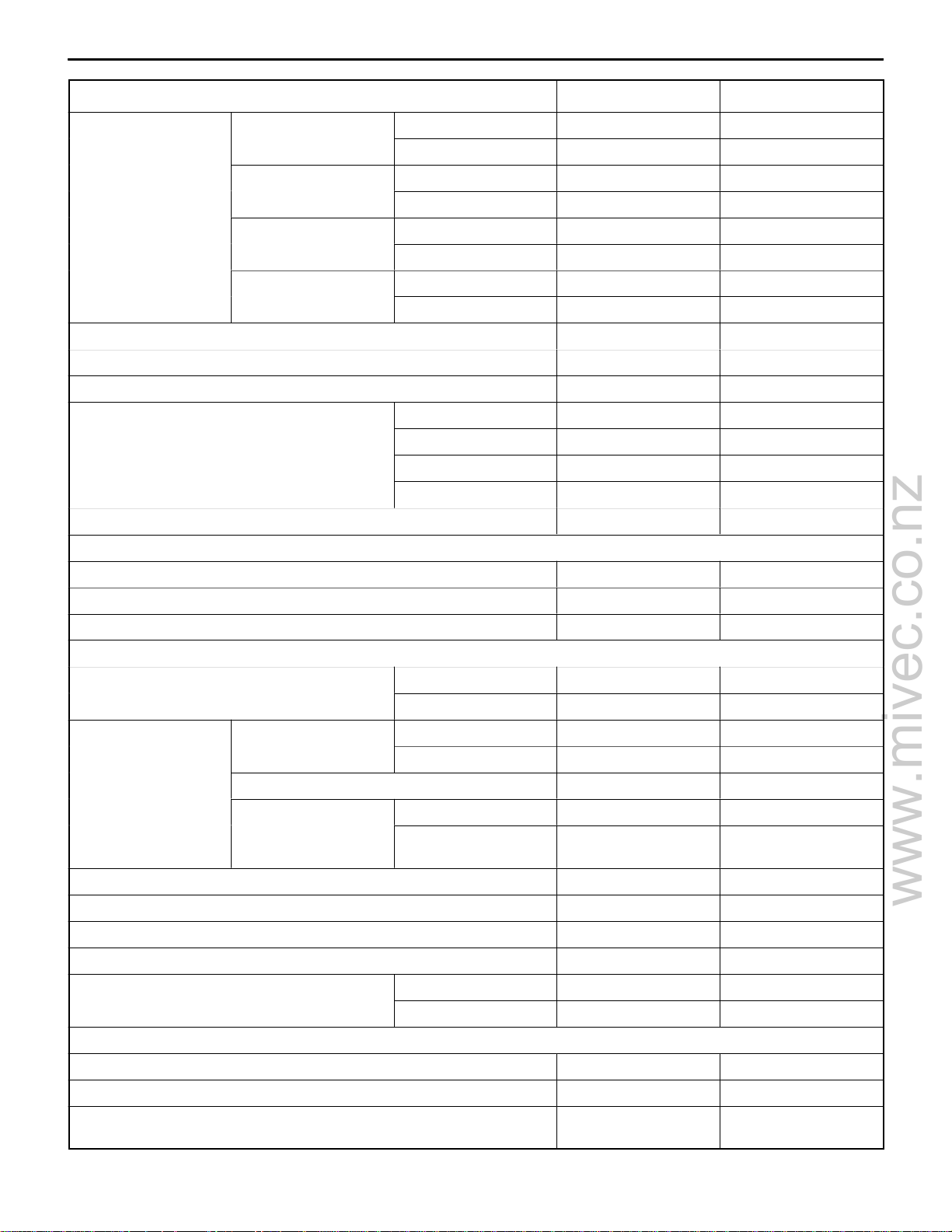

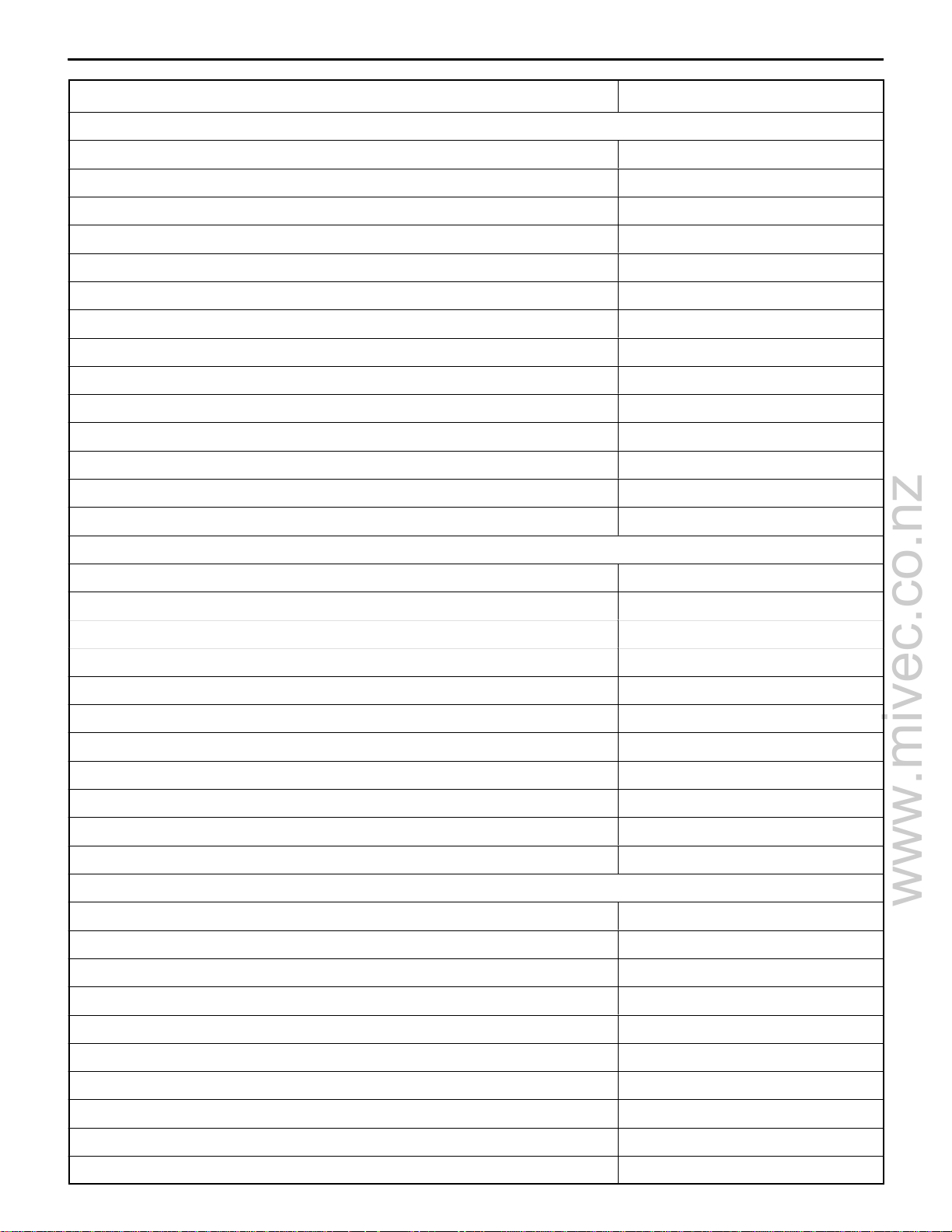

4G92

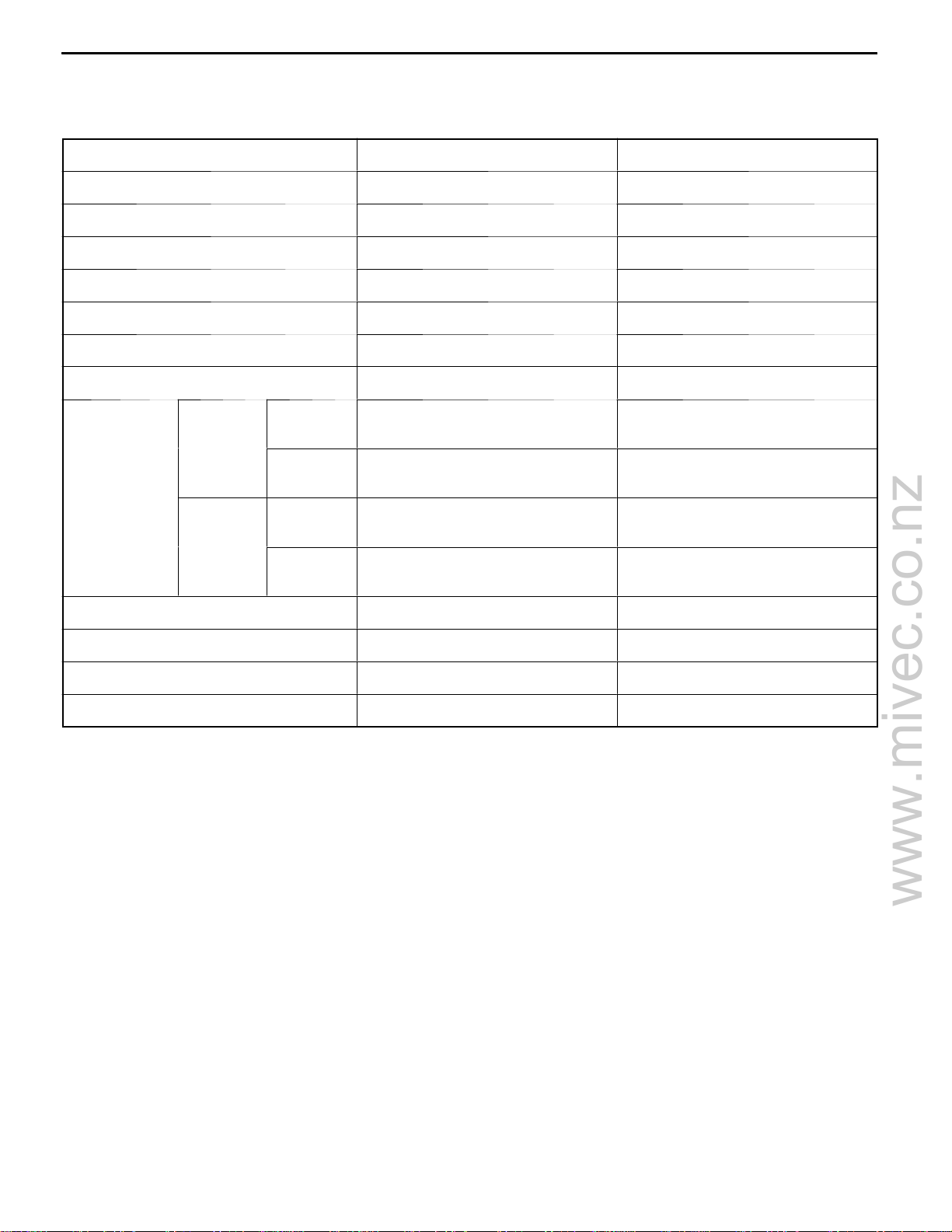

Descriptions 4G92- SOHC 4G92-DOHC- MIVEC

Type In-line OHV, SOHC In-line OHV, DOHC

Number of cylinders 4 4

Combustion chamber Pentroof type Pentroof type

11A-0-3

Total displacement dm

Cylinder bore mm 81.0 81.0

Piston stroke mm 77.5 77.5

Compression ratio 10.0 11.0

V alve timing Intake

Lubrication system Pressure feed, full-flow filtration Pressure feed, full-flow filtration

Oil pump type Trochoid type Trochoid type

Cooling system Water-cooled forced circulation Water-cooled forced circulation

Water pump type Centrifugal impeller type Centrifugal impeller type

3

valve

Exhaust

valve

Opens

(BTDC)

Closes

(ABDC)

Opens

(BBDC)

Closes

(ATDC)

1,597 1,597

20_,14_* 17_(Low-speed cam)

47.5_(High-speed cam)

42_,58_* 31_(Low-speed cam)

72.5_(High-speed cam)

54_,52_* 41_(Low-speed cam)

70_(High-speed cam)

2_,16_* 11_(Low-speed cam)

35_(High-speed cam)

*: LANCER for general export and CARISMA for 6B model

E

July 1997Mitsubishi Motors Corporation Revised

PWEE9502-C

Page 4

www.mivec.co.nz

11A-0-4

4G9 ENGINE (E- W) -

General Information

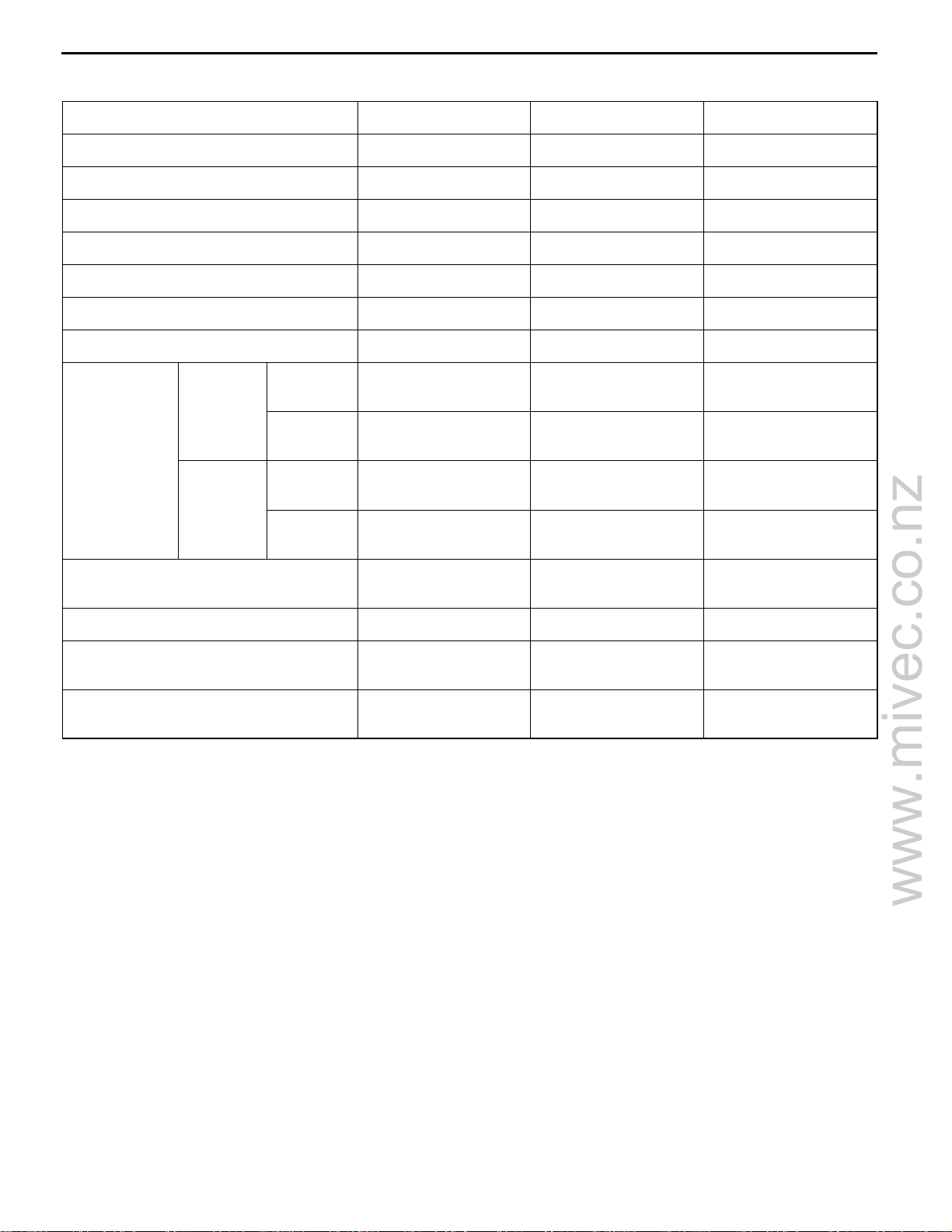

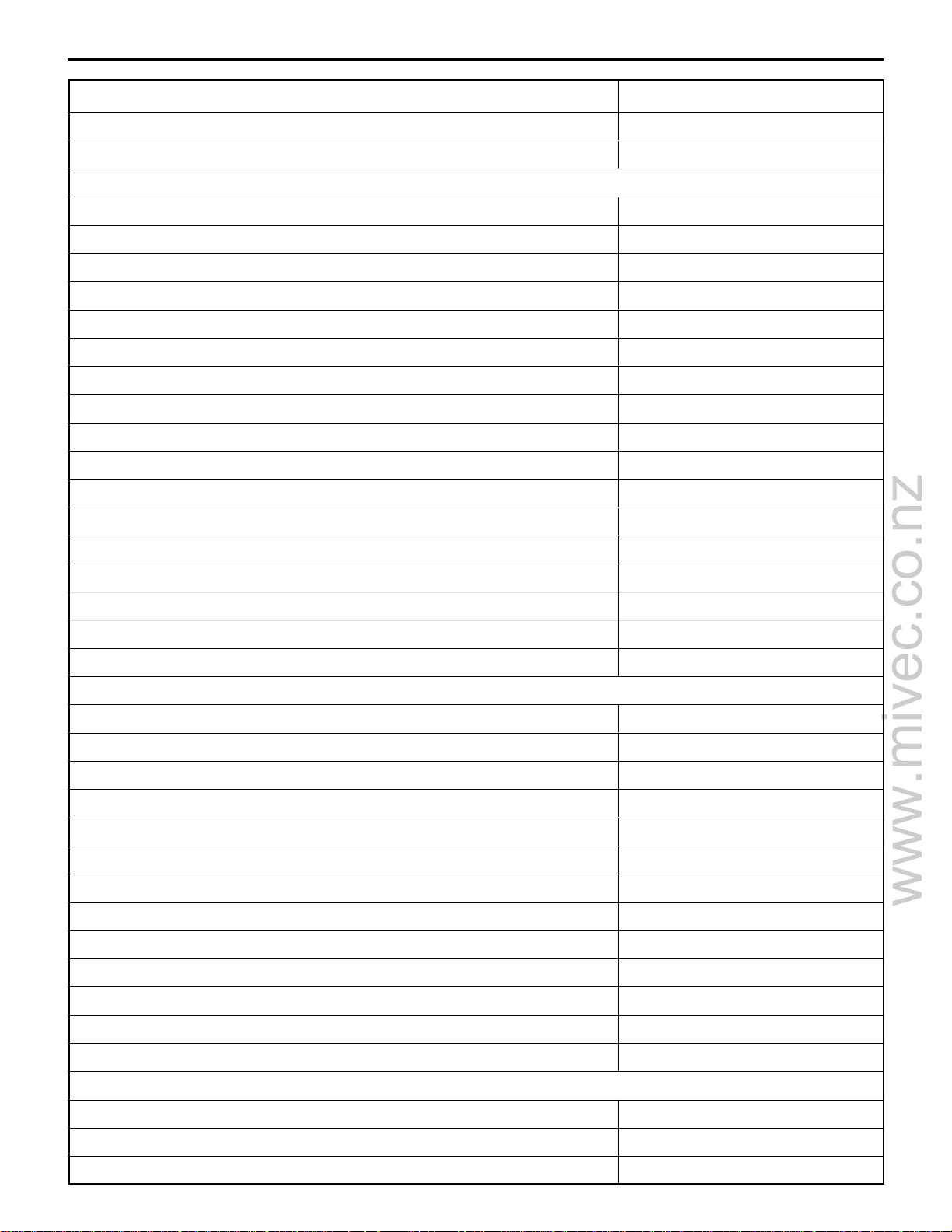

4G93

Descriptions 4G93-SOHC 4G93-DOHC 4G93- DOHC - GDI

Type In-line OHV, SOHC In-line OHV, DOHC In-line OHV, DOHC

Number of cylinders 4 4 4

Combustion chamber Pentroof type Pentroof type Pentroof type

Total displacement dm

Cylinder bore mm 81.0 81.0 81.0

Piston stroke mm 89.0 89.0 89.0

Compression ratio 10.0, 9.5 10.5 11.7*1, 12.0*

Valve timing Intake

Lubrication system Pressure feed, full-

Oil pump type Trochoid type Trochoid type Trochoid type

Cooling system Water-cooled forced

3

valve

Exhaust

valve

Opens

(BTDC)

Closes

(ABDC)

Opens

(BBDC)

Closes

(ATDC)

1,834 1,834 1,834

_

14

_

50

_

58

_

10

flow filtration

circulation

_

20

_

60

_

61

_

15

Pressure feed, fullflow filtration

Water-cooled forced

circulation

_

15

_

56

_

55

_

15

Pressure feed, fullflow filtration

Water-cooled forced

circulation

2

Water pump type Centrifugal impeller

type

*1: Up to 1999 model

2

*

: From 2000 model

Centrifugal impeller

type

Centrifugal impeller

type

E

May 2000Mitsubishi Motors Corporation Revised

PWEE9502-G

Page 5

www.mivec.co.nz

4G9 ENGINE (E–W) – General Information

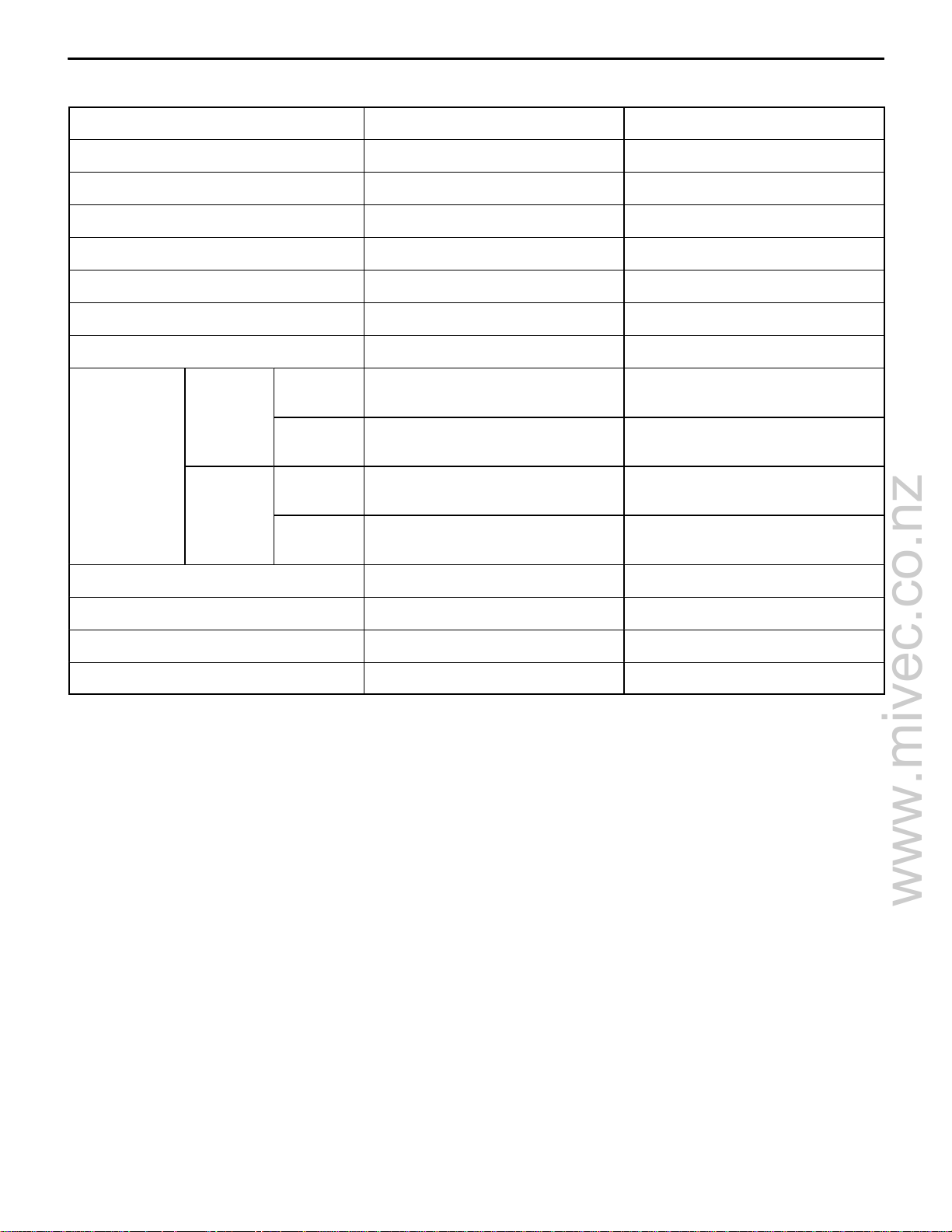

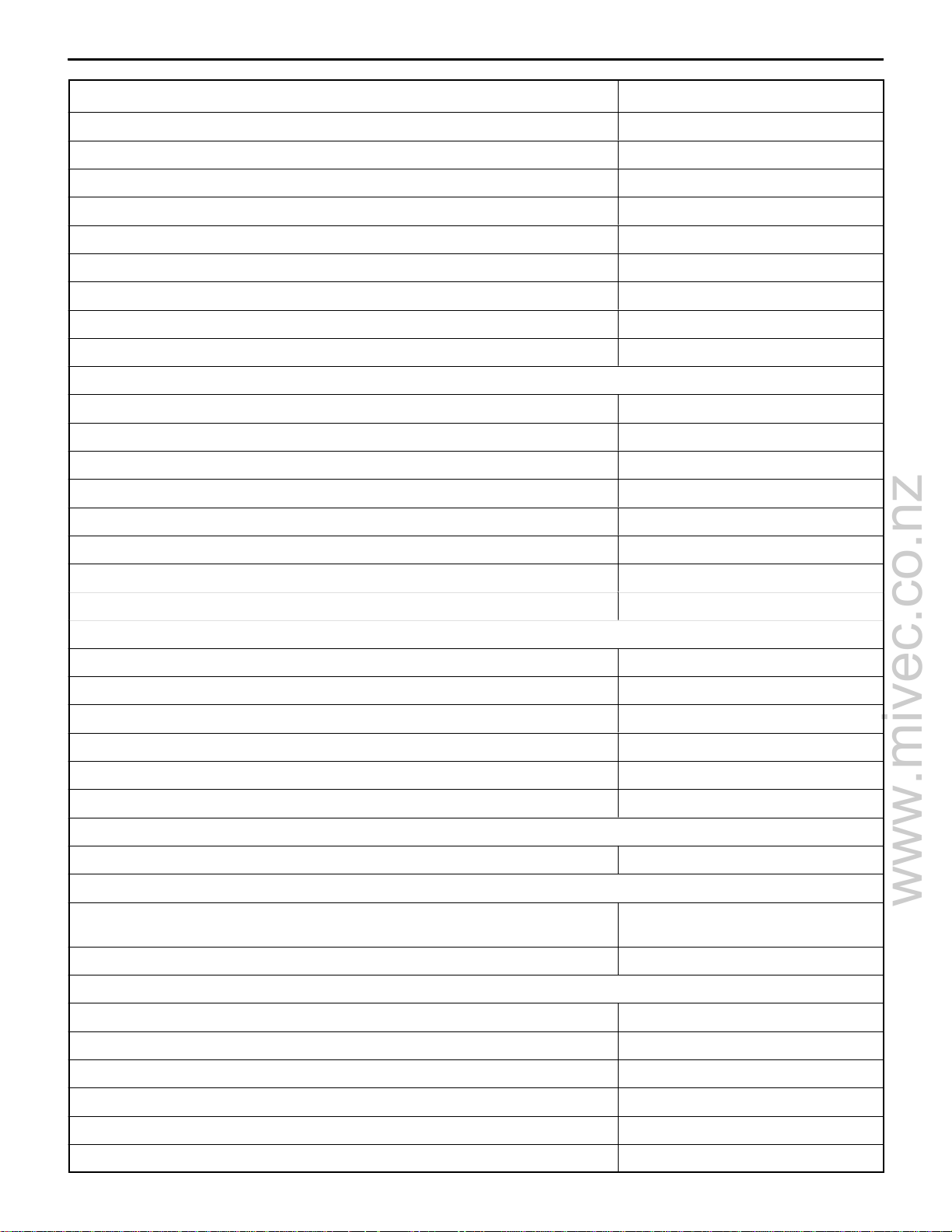

4G94

Descriptions 4G94–SOHC 4G94–DOHC–GDI

Type In-line OHV, SOHC In-line OHV, DOHC

Number of cylinders 4 4

Combustion chamber Pentroof type Pentroof type

11A-0-5

Total displacement dm

Cylinder bore mm 81.5 81.5

Piston stroke mm 95.8 95.8

Compression ratio 9.5 10.6

Valve timing Intake

Lubrication system Pressure feed, full-flow filtration Pressure feed, full-flow filtration

Oil pump type Trochoid type Trochoid type

Cooling system Water-cooled forced circulation Water-cooled forced circulation

Water pump type Centrifugal impeller type Centrifugal impeller type

3

valve

Exhaust

valve

Opens

(BTDC)

Closes

(ABDC)

Opens

(BBDC)

Closes

(ATDC)

1,999 1,999

2_ 15_

58_ 51_

58_ 55_

10_ 15_

E

E

July 1997Mitsubishi Motors Corporation Revised

Mar. 2001Mitsubishi Motors Corporation Revised

PWEE9502-C

PWEE9502-I

Page 6

www.mivec.co.nz

4G9 ENGINE (E–W) – Specifications

GSC

GSC

GSC

GSC

GSC

SC

GC

4G93 DOHC GDI

4G94 DOHC GDI

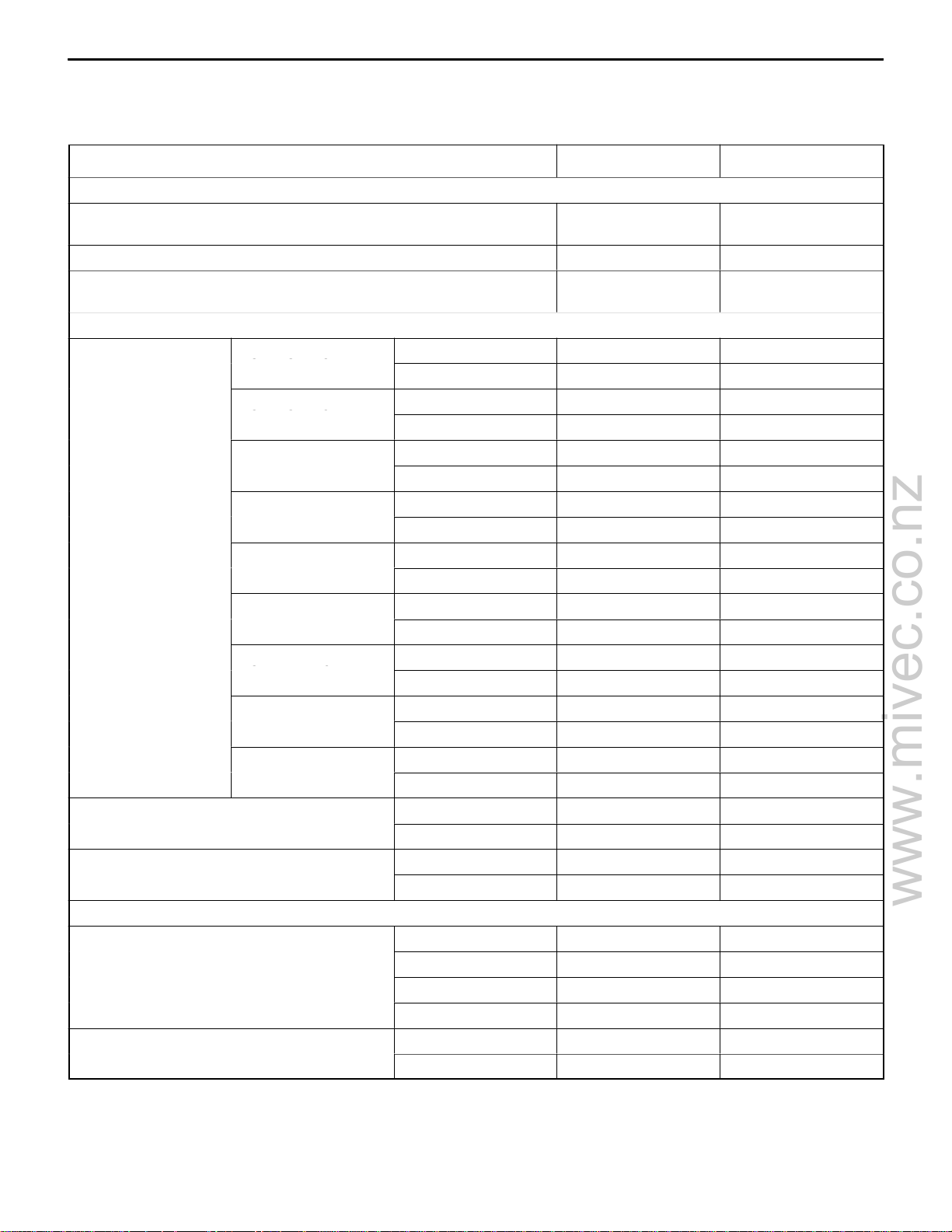

1. SPECIFICATIONS

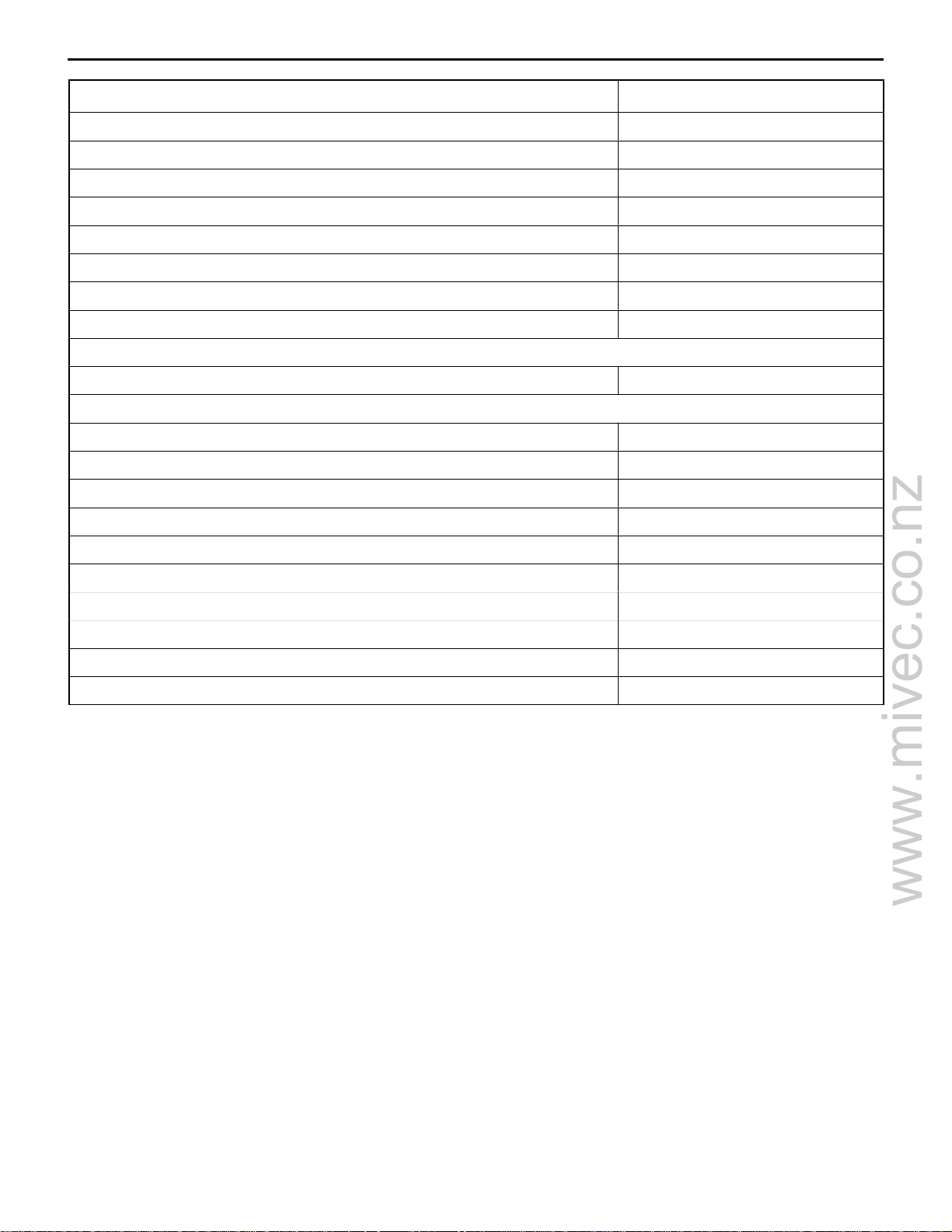

SERVICE SPECIFICATIONS

Items Standard value Limit

Timing belt

Auto-tensioner rod protrusion amount (When removed from engine)mm11 –

Auto-tensioner rod stroke mm Within 1 –

Auto-tensioner rod protrusion amount (When checking with installed

on engine) mm

Rocker arms and camshaft

Camshaft cam

height mm

Valve clearance mm Intake 0.09 –

Camshaft journal O.D. mm SOHC 26.0 –

Rocker cover and camshaft (MIVEC)

Camshaft height mm Intake A 36.41 36.91

Valve clearance (cold engine) mm Intake 0.1 –

4G92–SOHC*

4G92–SOHC*

4G92–SOHC*

4G93–SOHC*

4G93–SOHC*

4G94–SOHC

4G93–DOHC

4G93–DOHC–GDI

4G94–DOHC–GDI

1

2

3

4

5

Intake 37.34 36.84

Exhaust 36.79 36.29

Intake 37.78 37.28

Exhaust 37.83 37.33

Intake 36.92 36.42

Exhaust 36.70 36.65

Intake 37.53 37.03

Exhaust 37.64 37.14

Intake 37.11 36.61

Exhaust 37.15 36.65

Intake 37.91 37.41

Exhaust 37.70 37.20

Intake 35.31 34.81

Exhaust 35.20 34.70

Intake 35.49 34.99

Exhaust 34.73 34.23

Intake 35.49 34.99

Exhaust 34.91 34.41

Exhaust 0.20 –

DOHC 45.0 –

Intake B 33.58 33.08

Exhaust A 35.83 35.33

Exhaust B 34.24 33.74

Exhaust 0.2 –

3.8 – 4.5 –

11A-1-1

*1: LANCER for Europe and CARISMA for Europe

*2: LANCER for general export and CARISMA for 6B model

*3: LANCER for Europe (from 2001 model) and CARISMA for Europe (from 2001 model)

*4: Except for Europe

*5: For Europe

E

Jun. 2002Mitsubishi Motors Corporation Revised

PWEE9502-K

Page 7

www.mivec.co.nz

11A-1-2

Items Standard value Limit

Cylinder head and valve

Cylinder head gasket surface flatness mm Less than 0.03 0.2

4G9 ENGINE (E–W) – Specifications

Grinding limit of cylinder head gasket surface mm

*Total resurfacing depth of both cylinder head and cylinder block

Cylinder head overall height mm SOHC 119.9 – 120.1 –

DOHC 131.9 – 132.1 –

DOHC–MIVEC 119.8 – 120.0 –

DOHC–GDI 131.9 – 132.1 –

Thickness of valve

head (margin) mm

Valve overall height

mm

SOHC Intake 1.0 0.5

Exhaust 1.3 0.8

DOHC Intake 1.0 0.5

Exhaust 1.2 0.7

SOHC Intake 110.15 109.65

Exhaust 113.70 113.20

DOHC Intake 104.19 103.69

Exhaust 103.87 103.37

DOHC–MIVEC Intake 115.63 115.13

Exhaust 115.63 115.13

DOHC–GDI Intake 104.19 103.69

Exhaust 103.87 103.37

– 0.2*

Valve spring free length mm SOHC (with lash ad-

juster)

SOHC (with adjust-

ing screw)

DOHC 45.0 44.0

DOHC–MIVEC 51.5 50.5

DOHC–GDI 44.8 43.8

Valve spring out-of-squareness Max. 2_ 4_

Valve stem to valve

guide clearance mm for PAJERO io

Valve seat valve contact width mm 0.9 – 1.3 –

Valve guide projection from cylinder head

upper surface mm

Except DOHC–GDI

DOHC–GDI

for PAJERO io

Intake 0.02 – 0.05 0.10

Exhaust 0.05 – 0.09 0.15

Intake 0.02 – 0.05 0.10

Exhaust 0.04– 0.06 0.15

SOHC 14.0 –

DOHC 19.0 –

50.9 49.9

49.5 48.5

E

Jun. 2002Mitsubishi Motors Corporation Revised

PWEE9502-K

Page 8

www.mivec.co.nz

4G9 ENGINE (E–W) – Specifications

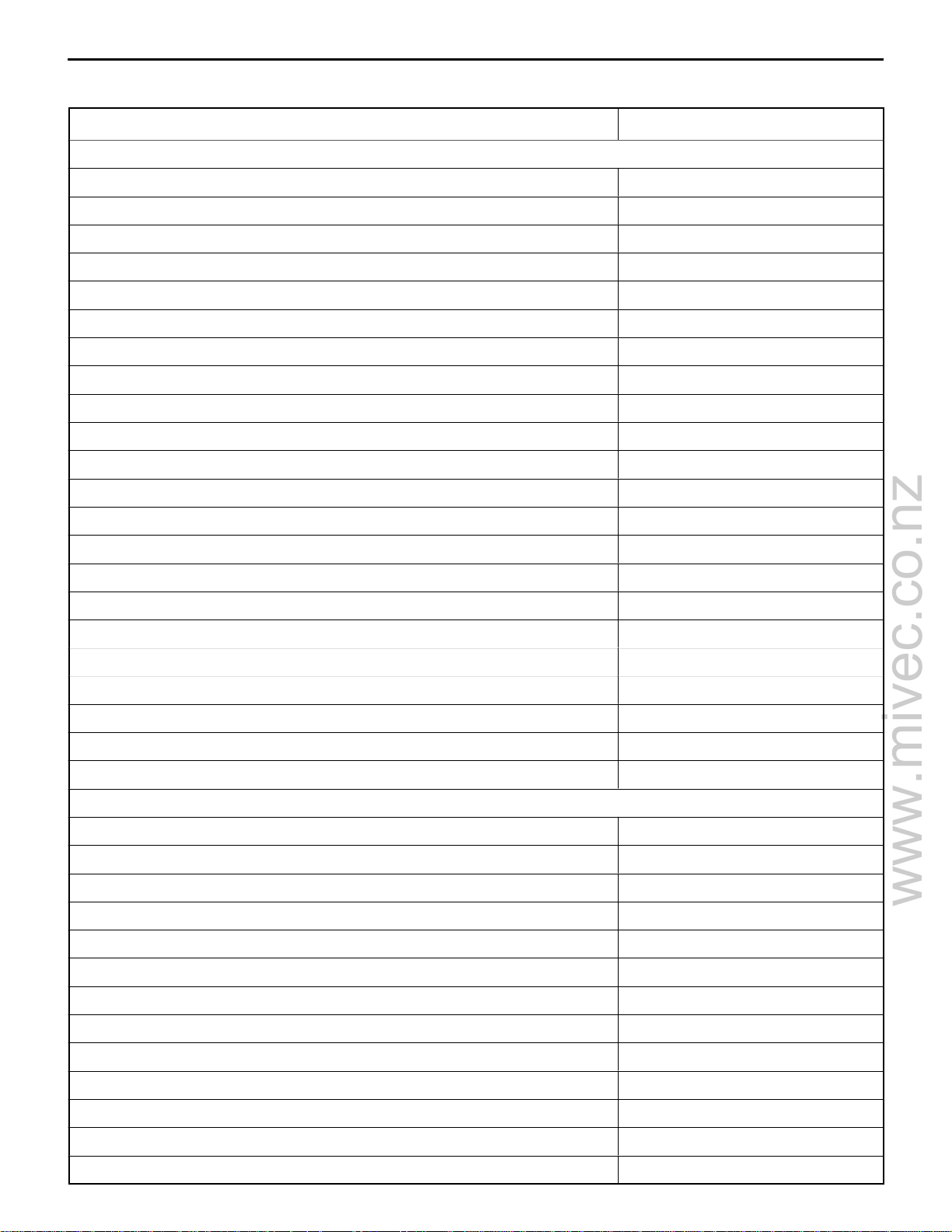

Items LimitStandard value

11A-1-3

Valve stem projection mm

Cylinder head bolt shank length mm – 96.4

Valve stem O.D. mm 6.0 –

V alve face angle 45_ – 45.5_ –

Valve spring load/installed height N/mm SOHC 216/44.2 –

Valve guide I.D. mm 6.0 –

Font case, oil pump and oil pan

Oil pump tip clearance mm 0.06 – 0.18 –

SOHC Intake 49.30 49.80

Exhaust 49.35 49.85

DOHC Intake 46.70 47.20

Exhaust 46.65 47.15

DOHC–MIVEC Intake 58.13 58.63

Exhaust 57.85 58.35

DOHC–GDI Intake 46.70 47.20

Exhaust 46.65 47.15

DOHC 255/44.5 –

DOHC–MIVEC 255/44.5 –

DOHC–GDI 196/37.5 –

Oil pump side clearance mm 0.04 – 0.10 –

Oil pump body clearance mm 0.10 – 0.18 0.35

Piston and connecting rod

Piston ring to piston ring groove clearance

mm

Piston ring end gap

mm

Crankshaft pin oil clearance mm 0.02 – 0.05 0.1

Piston pin press-in load N [Room temperature] 4,500 – 14,700 –

Connecting rod big end side clearance mm 0.10 – 0.25 0.4

Piston pin O.D. mm 19.0 –

Piston O.D. mm 4G92, 4G93 81.0 –

Crankshaft, cylinder block, flywheel and drive plate

No. 1 4G92, 4G93 0.25 – 0.40 0.8

No. 2 0.40 – 0.55 0.8

Oil ring SOHC (4G92, 4G93) 0.20 – 0.60 1.0

No. 1 0.03 – 0.07 0.1

No. 2 0.02 – 0.06 0.1

4G94 0.15 – 0.30 0.8

SOHC (4G94),

DOHC

4G94 81.5 –

0.10 – 0.35 1.0

Crankshaft journal oil clearance mm 0.02 – 0.04 0.1

Cylinder block gasket surface flatness mm 0.05 0.1

Grinding limit of cylinder block gasket surface mm

*Total resurfacing depth of both cylinder head and cylinder block

E

Mar . 2001Mitsubishi Motors Corporation Revised

PWEE9502-I

– 0.2*

Page 9

www.mivec.co.nz

11A-1-4

Items LimitStandard value

Cylinder block overall height mm 4G92 243.5 –

Cylinder block I.D. mm 4G92, 4G93 81.0 –

Piston to cylinder clearance mm 0.02 – 0.04 –

Bearing cap bolt shank length mm – 71.1

Crankshaft end play mm 0.05 – 0.25 0.4

Crankshaft journal O.D. mm 50 –

Crankshaft pin O.D. mm 45 –

4G9 ENGINE (E–W) – Specifications

4G93 263.5 –

4G94 286.7 –

4G94 81.5 –

REWORK DIMENSIONS

Items Standard value

Cylinder head and valve

Oversize rework dimensions of valve guide hole (both intake and

exhaust) mm

Oversize rework dimensions of intake valve

seat hole mm

Oversize rework dimensions of exhaust valve

seat hole mm

Crankshaft, flywheel and drive plate

Crankshaft out of roundness and taper of journal and pin mm 0.005

NOTE

O.D.: Outer diameter

I.D.: Inner diameter

O.S.: Oversize diameter

SOHC 0.30 O.S. 31.80 – 31.83

DOHC 0.30 O.S. 34.30 – 34.32

SOHC 0.30 O.S. 29.30 – 29.32

DOHC 0.30 O.S. 30.80 – 30.82

0.05 O.S. 11.05 – 11.07

0.25 O.S. 11.25 – 11.27

0.50 O.S. 11.50 – 11.52

0.60 O.S. 32.10 – 32.13

0.60 O.S. 34.60 – 34.62

0.60 O.S. 29.60 – 29.62

0.60 O.S. 31.10 – 31.13

E

Mar . 2001Mitsubishi Motors Corporation Revised

PWEE9502-I

Page 10

www.mivec.co.nz

4G9 ENGINE (E–W) – Specifications

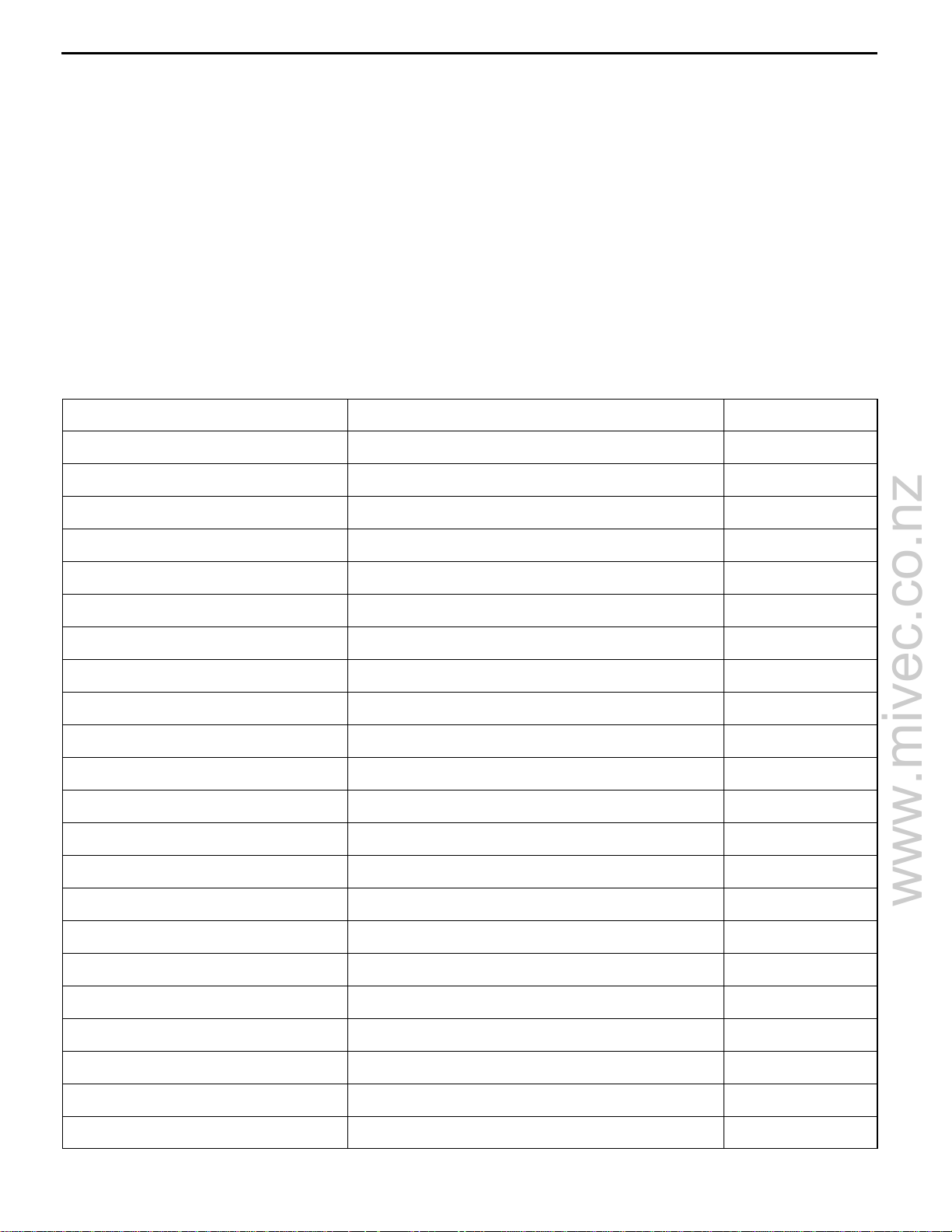

TORQUE SPECIFICATIONS

Items Nm

Alternator and ignition system

Oil level gauge 13

Distributor 12

Ignition coil 10

Spark plug 25

Crankshaft bolt 182 ± 4

Alternator brace (M8) 23

Alternator brace (M10) 49

Lock bolt 23

Adjusting bolt 5

Power steering pump pulley 25

Power steering pump bracket stay 49

Power steering pump bracket (M8) 21

11A-1-5

Power steering pump bracket (M10) 44

Alternator pivot bolt 44

Center cover 3

Ignition failure sensor (M6) 5

Ignition failure sensor (M8) 23

Ignition failure sensor bracket 10

Cam position sensor 9

Cam position sensor support 13

Cam position sensing cylinder 21

Engine cover 2.9

Timing belt

Camshaft sprocket bolt 88

Cam position sensor 9.8

Crank angle sensor 9.8

Timing belt rear cover 11

Timing belt rear upper cover 11

Timing belt tensioner 24

Engine support bracket, right 49

Accessory mount 49

Timing belt cover 11

Tensioner pulley bolt 49

Tensioner arm bolt 44

Auto-tensioner bolt 13

Idler pulley bolt 36

E

Jun. 2002Mitsubishi Motors Corporation Revised

PWEE9502-K

Page 11

www.mivec.co.nz

11A-1-6

Items Nm

Fuel system and emission system

Breather tube 21

Fuel pump 18

Carburetor 17

EGR valve 21

Cover <Without EGR valve> 12

Fuel return pipe 9

Delivery pipe 12

Fuel pressure regulator 9

Throttle body stay <MIVEC> 23

Throttle body stay <4G94> 24

Throttle body 19

Throttle cable bracket 19

Stay 24

4G9 ENGINE (E–W) – Specifications

Harness bracket 11

Vacuum hose and pipe assembly <Engine with solenoid valve> (Flange bolt) 11

Vacuum hose and pipe assembly <Engine with solenoid valve> (Bolt and

washer assembly)

Vacuum hose and pipe assembly <Engine without solenoid valve> 10

Solenoid valve assembly 9

Throttle body and EGR system (GDI)

Air intake resonator 9

Intake manifold stay (M8) 20

Intake manifold stay (M10) 30

Water hose clamp 13

Water pipe 11

Throttle body 18

Throttle body stay

<CARISMA from 2001 model, SPACE STAR from 2001 model, GALANT>

Throttle body stay <For PAJERO io – 4G94> 18

EGR valve (Bolt and washer assembly) 18

9

24

EGR valve (Flange bolt) 24

Engine hanger 18

EGR valve support bolt 18

EGR valve support nut 23

Air by-pass valve 9

Mar . 2001Mitsubishi Motors Corporation RevisedPWEE9502-K

E

E

Jun. 2002Mitsubishi Motors Corporation Revised

PWEE9502-I

Page 12

www.mivec.co.nz

4G9 ENGINE (E–W) – Specifications

Items Nm

Intake manifold and exhaust manifold

Exhaust manifold (M8) 18

Exhaust manifold (M10) 29

Exhaust manifold bracket (M8) 19

Exhaust manifold bracket (M10 Bolt and washer assembly) 35

Exhaust manifold bracket (M10 Flange bolt) 98

Engine hanger (Bolt with head mark “4”) 12

Engine hanger (Bolt with head mark “7”) 19

Oil level gauge guide 14

Boost sensor 5

Intake air temperature sensor 13

Heat protector 13

Intake manifold 20

Intake manifold stay 31

11A-1-6a

Oxygen sensor 44

Intake manifold (GDI)

Vacuum pipe and hose <Except for PAJERO io> 11

Vacuum pipe and hose <For PAJERO io> 9

Solenoid valve 9

Fuel pump protector 23

Connector bracket 11

Branch tube (M6 x 14) 11

Branch tube (M6 x 18) 9

Intake manifold stay 30

Accelerator cable bracket 9

V acuum pipe 11

Intake manifold 19

Exhaust manifold (GDI)

Oil level gauge guide 13

Exhaust manifold cover 13

Engine hanger bolt 24

Engine hanger nut (M8) 18

Engine hanger nut (M10) 29

Exhaust manifold bracket (M8 × 20) 18

Exhaust manifold bracket (M8 × 22) 35

Exhaust manifold bracket (M8 × 25) 19

Exhaust manifold bracket (M10) 35

Exhaust manifold bracket <For PAJERO io> 98

E

Jun. 2002Mitsubishi Motors Corporation Revised

PWEE9502-K

Page 13

www.mivec.co.nz

11A-1-6b

Items Nm

Exhaust manifold (M8) 17

Exhaust manifold (M10) 29

Injector and fuel pump assembly (GDI)

Fuel low pressure pipe (M6) 18

Fuel low pressure pipe (M8) 9

Fuel nipple 9

Clamp 9

Fuel feed pipe 11

Fuel pump 17

Harness bracket 11

Fuel pipe 11

Fuel return pipe 11

Fuel return pipe clamp 9

Fuel high pressure regulator 18

4G9 ENGINE (E–W) – Specifications

Fuel pressure sensor <Except for PAJERO io> 23

Fuel pressure sensor <For PAJERO io> 18

Spacer 18

Pump camshaft case 23

Injector holder 22

Delivery pipe and injector 11

Intake and exhaust manifold <4G94–GDI for PAJERO io>

V acuum pipe and hose 9

Solenoid valve 9

Fuel pump protector 23

Connector bracket 11

Intake manifold stay nut 29

Intake manifold stay bolt 31

Low pressure fuel pipe 9

Intake manifold 20

Exhaust manifold cover 13

Engine hanger 18

Exhaust manifold bracket 98

Exhaust manifold (M8) 17

Exhaust manifold (M10) 29

Water pump and water hose

Water pump 24

Water inlet pipe 14

Thermostat case 24

E

Jun. 2002Mitsubishi Motors Corporation Revised

PWEE9502-K

Page 14

www.mivec.co.nz

4G9 ENGINE (E–W) – Specifications

Items Nm

Water inlet fitting <Except PAJERO io> 19

Water inlet fitting <PAJERO io> 24

Water by-pass fitting 24

Water pipe 14

Water outlet fitting <Except PAJERO io> 19

Water outlet fitting <PAJERO io> 24

Engine coolant temperature gauge unit 10

Engine coolant temperature sensor 29

Water fitting 24

Rocker arms and camshaft

Lock nut 9

Rocker arm shaft 31

Harness bracket 10

Rocker cover 3.5

11A-1-6c

Bearing cap bolt (M6) 11

Bearing cap bolt (M8) 24

Beam camshaft cap (M6) 11

Beam camshaft cap (M8) 21

Rocker cover and camshafts (MIVEC)

Rocker cover 4

Oil pump 11

Arm spring holder 11

Camshaft bearing cap (M6) 11

Camshaft bearing cap (M8) 23

Oil control valve 9

Rocker arms and rocker shaft caps (MIVEC)

Rocker shaft cap 11

Cylinder head and valves

CylInder head bolt 74 Nm and then completely loosen,

finally tighten 20 Nm + 90_ + 90_

Oil pressure switch 10

Front case and oil pump

Oil pump cover 10

Oil pump case 14

Relief plug 44

Oil screen 19

Oil pan 9

Upper oil pan (M6) 9

E

Jun. 2002Mitsubishi Motors Corporation Revised

PWEE9502-K

Page 15

www.mivec.co.nz

11A-1-6d

Items Nm

Upper oil pan (M8) 24

Lower oil pan 11

Cover 7

Baffle plate <DOHC–MPI> 7

Baffle plate <Except DOHC–MPI> 11

Drain plug 39

Oil pressure switch 10

Transmission stay 23

Piston and connecting rod

Connecting rod cap nut 20 + 90_ to 100_

Crankshaft, cylinder block, flywheel and drive plate

Bearing cap bolt 25 + 90_ to 100_

Oil seal case 11

Bell housing cover (Flange bolt) 10

4G9 ENGINE (E–W) – Specifications

Bell housing cover (Bolt and washer assembly) 9

Rear plate <SPACE STAR> 10

Rear plate <Except SPACE STAR> 11

Drive plate bolt 98

Flywheel bolt 98

Baffle plate 9

Knock sensor 23

E

Jun. 2002Mitsubishi Motors Corporation Revised

PWEE9502-K

Page 16

www.mivec.co.nz

4G9 ENGINE (E- W) -

Specifications

11A-1-7

NEW TIGHTENING METHOD - BY USE OF BOLTS TO BE TIGHTENED IN PLASTIC AREA

A new type of bolts, to be tightened in plastic area, is currently used for some parts of the engine.

The tightening method for bolts of this type is different from the conventional one. Be sure to observe

the method described in the text when tightening the bolts.

Service limits are provided for the bolts. Make sure that the service limits described in the text are strictly

observed.

D

Areas where the bolts are in use:

(1) Cylinder head bolts

(2) Main bearing cap bolts

(3) Connecting rod cap bolts

D

Tightening method

After tightening the bolts to the specified torque, tighten them another 90_or 180_(twice 90_). The

tightening method varies on different areas. Observe the tightening method described in the text.

SEALANT

Items Specified sealant Quantity

Water pump Mitsubishi Genuine Part No.MD970389 or equivalent As required

Thermostat case Mitsubishi Genuine Part No.MD970389 or equivalent As required

Water by-pass fitting Mitsubishi Genuine Part No.MD970389 or equivalent As required

Water fitting Mitsubishi Genuine Part No.MD970389 or equivalent As required

Engine coolant temperature sensor 3M Nut Locking Part No.4171 or equivalent As required

Engine coolant temperature gauge unit 3M ATD Part No.8660 or equivalent As required

Camshaft bearing cap 3M ATD Part No.8660 or equivalent As required

Semi-circular packing 3M ATD Part No.8660 or equivalent As required

Rocker cover 3M ATD Part No.8660 or equivalent As required

Beam camshaft cap Mitsubishi Genuine Part No.MD970389 or equivalent As required

Cover 3M ATD Part No.8660 or equivalent As required

Cylinder head Mitsubishi Genuine Part No.MD970389 or equivalent As required

Oil pressure switch 3M ATD Part No.8660 or equivalent As required

Water outlet fitting Mitsubishi Genuine Part No.MD970389 or equivalent As required

Oil pump case Mitsubishi Genuine Part No.MD970389 or equivalent As required

Oil pan/Upper oil pan/Lower oil pan Mitsubishi Genuine Part No.MD970389 or equivalent As required

Oil seal case Mitsubishi Genuine Part No.MD970389 or equivalent As required

Drive plate bolt 3M Nut Locking Part No.4171 or equivalent As required

Flywheel bolt 3M Nut Locking Part No.4171 or equivalent As required

Cam position sensor support Mitsubishi Genuine Part No.MD970389 or equivalent As required

Oil control valve 3M ATD Part No.8660 or equivalent As required

Camshaft holder 3M ATD Part No.8660 or equivalent As required

E

July 2000Mitsubishi Motors Corporation Revised

PWEE9502-H

Page 17

www.mivec.co.nz

11A-1-8

4G9 ENGINE (E-W) -

Specifications

FORM-IN-PLACE GASKET

The engine has several areas where the form-in-place gasket (FIPG) is in use. To ensure that the gasket

fully serves its purpose, it is necessary to observe some precautions when applying the gasket. Bead

size, continuity and location are of paramount importance. Too thin a bead could cause leaks. Too thick

a bead, on the other hand, could be squeezed out of location, causing blocking or narrowing of the

fluid feed line. To eliminate the possibility of leaks from a joint, therefore, it is absolutely necessary to

apply the gasket evenly without a break, while observing the correct bead size.

The FIPG used in the engine is a room temperature vulcanization (RTV) type and is supplied in a 100-gram

tube (Part No. MD970389 or MD997110). Since the RTV hardens as it reacts with the moisture in the

atomospheric air, it is normally used in the metallic flange areas. The FIPG, Part No. MD970389, can

be used for sealing both engine oil and coolant, while Part No. 997110 can only be used for engine

oil sealing.

Disassembly

The parts assembled with the FIPG can be easily disassembled without use of a special method. In

some cases, however, the sealant between the joined surfaces may have to be broken by lightly striking

with a mallet or similar tool. A flat and thin gasket scraper may be lightly hammered in between the

joined surfaces. In this case, however, care must be taken to prevent damage to the joined surfaces.

For removal of the oil pan, the special tool “Oil Pan Remover” (MD998727) is available. Be sure to use

the special tool to remove the oil pan. <Except aluminium die-cast oil pans>

Surface Preparation

Thoroughly remove all substances deposited on the gasket application surfaces, using a gasket scraper

or wire brush. Check to ensure that the surfaces to which the FIPG is to be applied is flat. Make sure

that there are no oils, greases and foreign substances deposited on the application surfaces. Do not

forget to remove the old sealant remained in the bolt holes.

Form-In-Place Gasket Application

When assembling parts with the FIPG, you must observe some precautions, but the procedures is very

simple as in the case of a conventional precut gasket.

Applied FIPG bead should be of the specified size and without breaks. Also be sure to encircle the

bolt hole circumference with a completely continuous bead. The FIPG can be wiped away unless it is

hardened. While the FIPG is still moist (in less than 15 minutes), mount the parts in position. When

the parts are mounted, make sure that the gasket is applied to the required area only. In addition, do

not apply any oil or water to the sealing locations or start the engine until a sufficient amount of time

(about one hour) has passed after installation is completed.

The FIPG application procedure may vary on different areas. Observe the procedure described in the

text when applying the FIPG.

E

May 1995Mitsubishi Motors Corporation

PWEE9502

Page 18

www.mivec.co.nz

4G9 ENGINE (E-W) -

Special Tools

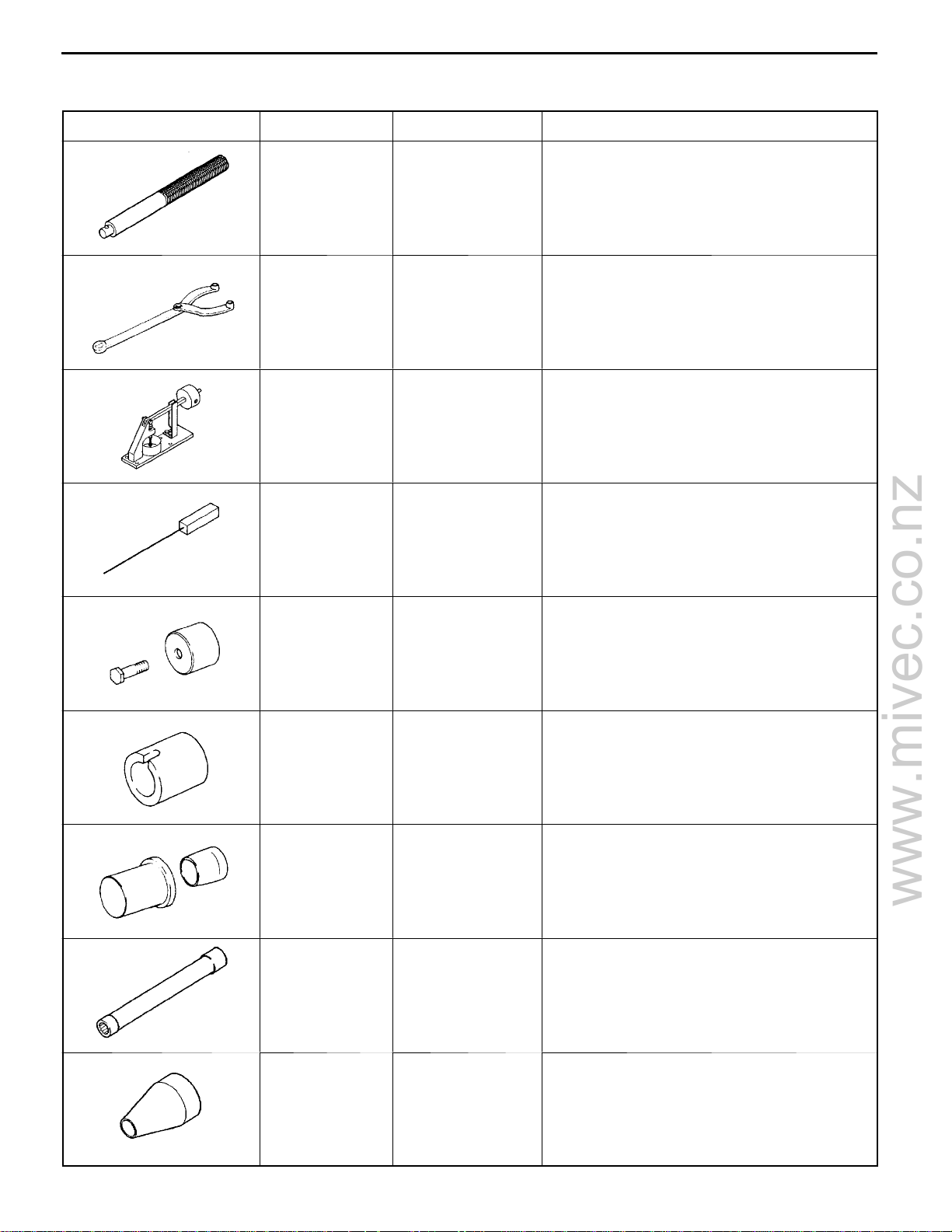

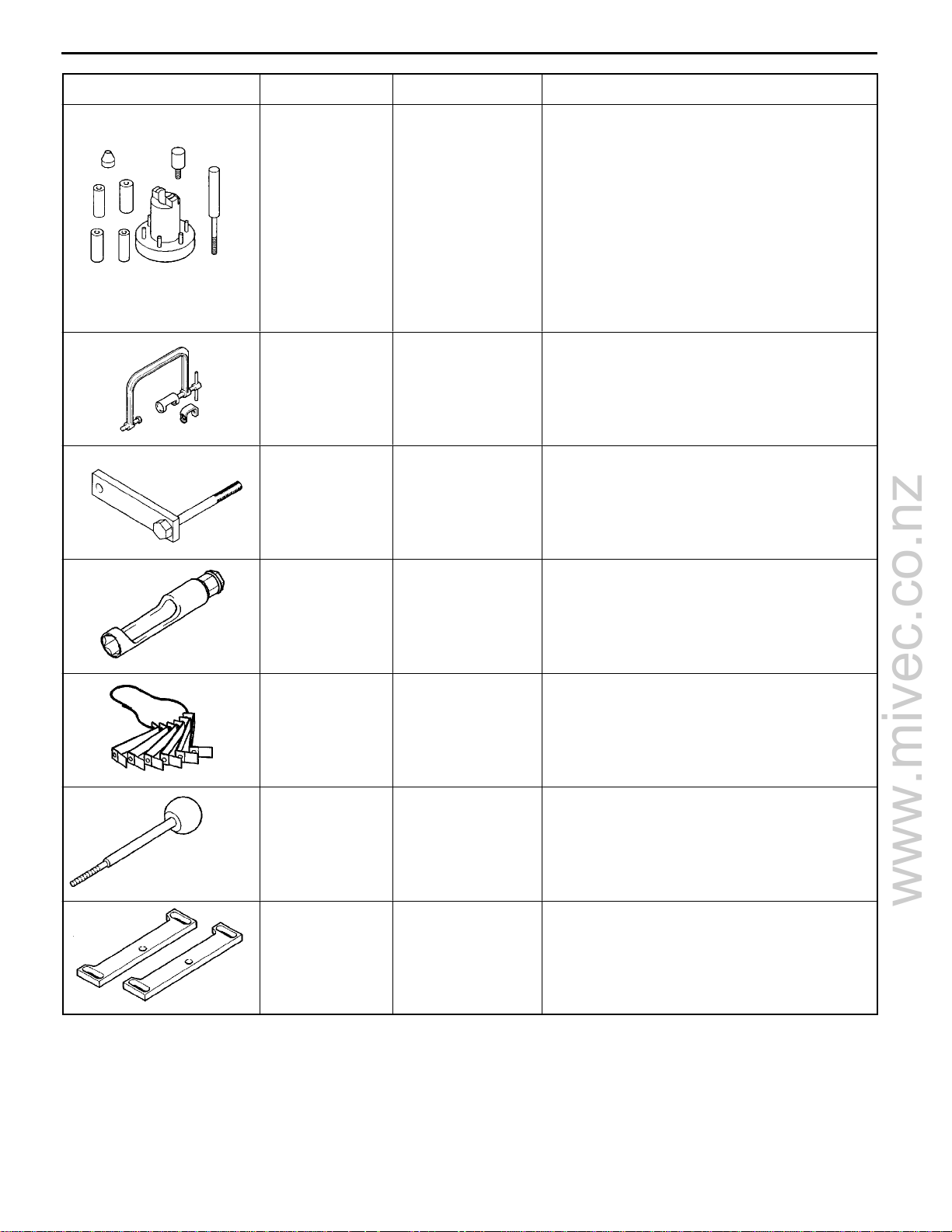

2. SPECIAL TOOLS

Tool Number Name Use

MB990938 Handle Use with MD998776

11A-2-1

MB990767 Crankshaft pulley

holder

MD998440 Leak-down tester Leak-down test of lash adjuster

MD998442 Air bleed wire Air bleeding of lash adjuster

MD998713 Camshaft oil seal

installer

Holding camshaft sprocket when loosening

and tightening of bolt.

Use with MD998719

Installation of camshaft oil seal

MD998716 Crankshaft wrench Rotation of crankshaft when installing piston

and timing belt.

MD998717 Crankshaft front oil

seal installer

MB991653 Cylinder head bolt

wrench

MB991659 Guide D Removal of piston pin (Use with MD998780)

Installation of crankshaft front oil seal

Tightening and loosening of cylinder head bolt

E

Nov. 1995Mitsubishi Motors Corporation Revised

PWEE9502-A

Page 19

www.mivec.co.nz

11A-2-2

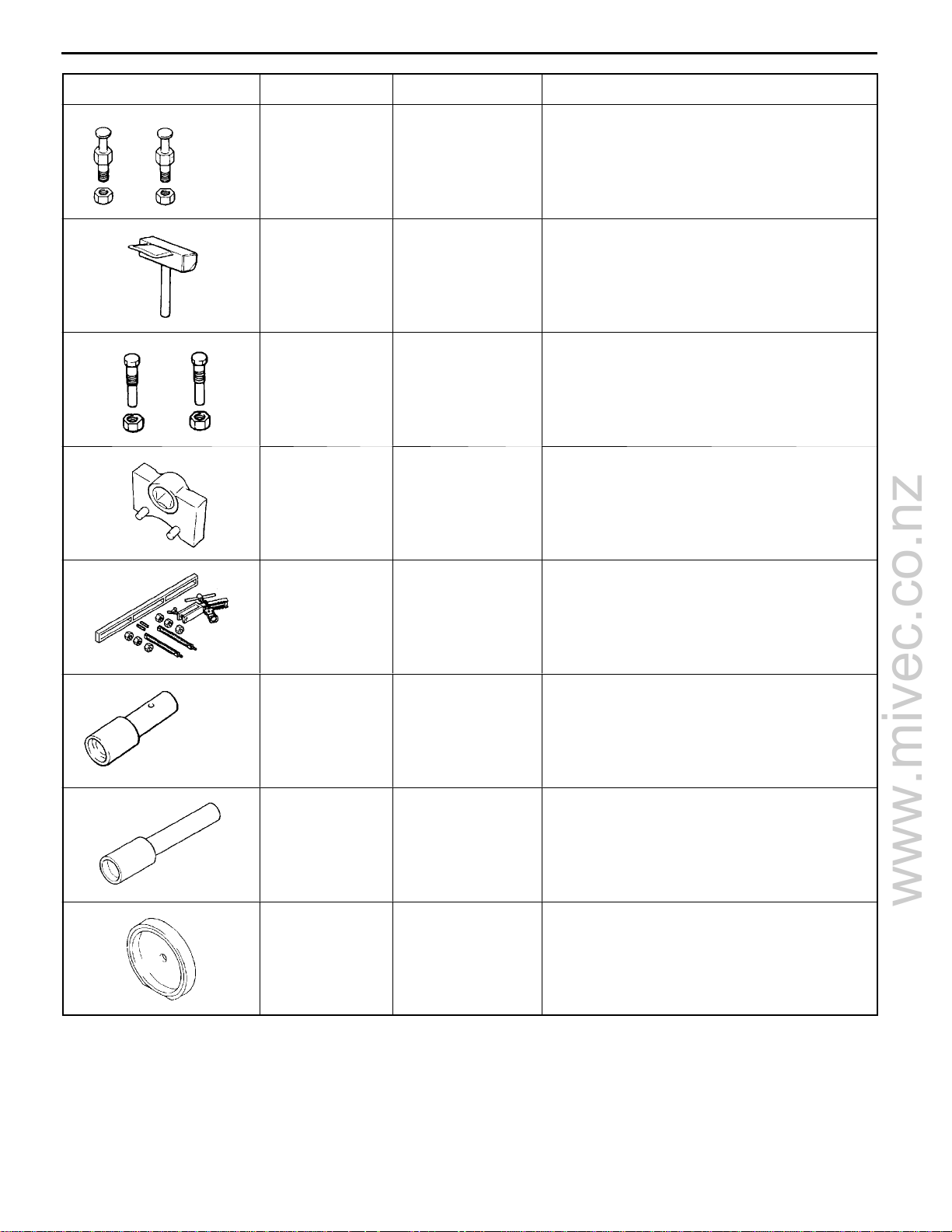

Tool UseNameNumber

4G9 ENGINE (E-W) -

Special Tools

MD998719 Pulley holder pin

(2)

MD998727 Oil pan remover Removal of the oil pan

MD998754 Pin Use with MB990767

MD998767 Tensioner pulley

socket wrench

Use with MB990767

Adjustment of timing belt tension

MD998772 Valve spring

compressor

MD998774 Valve stem seal

installer

MD998775 Valve stem seal

installer

MD998776 Crankshaft rear oil

seal installer

Removal and installation of valve and related

parts

Installation of valve stem seal

Installation of valve stem seal

Installation of crankshaft rear oil seal

Use with MB990938

E

Nov. 1995Mitsubishi Motors Corporation

PWEE9502-A

Revised

Page 20

www.mivec.co.nz

4G9 ENGINE (E-W) -

Tool UseNameNumber

Special Tools

11A-2-3

MD998780 SETTING TOOL

Piston pin

MD998735 Valve spring

compressor

MD998781 Flywheel stopper Holding flywheel and drive plate

Removal and installation of piston pin

Compression of valve spring

MB991477 Valve adjusting

wrench

MB991478 Valve adjusting

wrench feeler

gauge set

MB991479 Rocker arm

piston checker

MD998784 Valve spring

compressor

adapter

Adjustment of valve clearance (MIVEC)

Adjustment of valve clearance (MIVEC)

Adjustment of valve clearance (MIVEC)

Compression of valve spring (MIVEC)

(Use with MD998772)

E

Nov. 1995Mitsubishi Motors Corporation Revised

PWEE9502-A

Page 21

www.mivec.co.nz

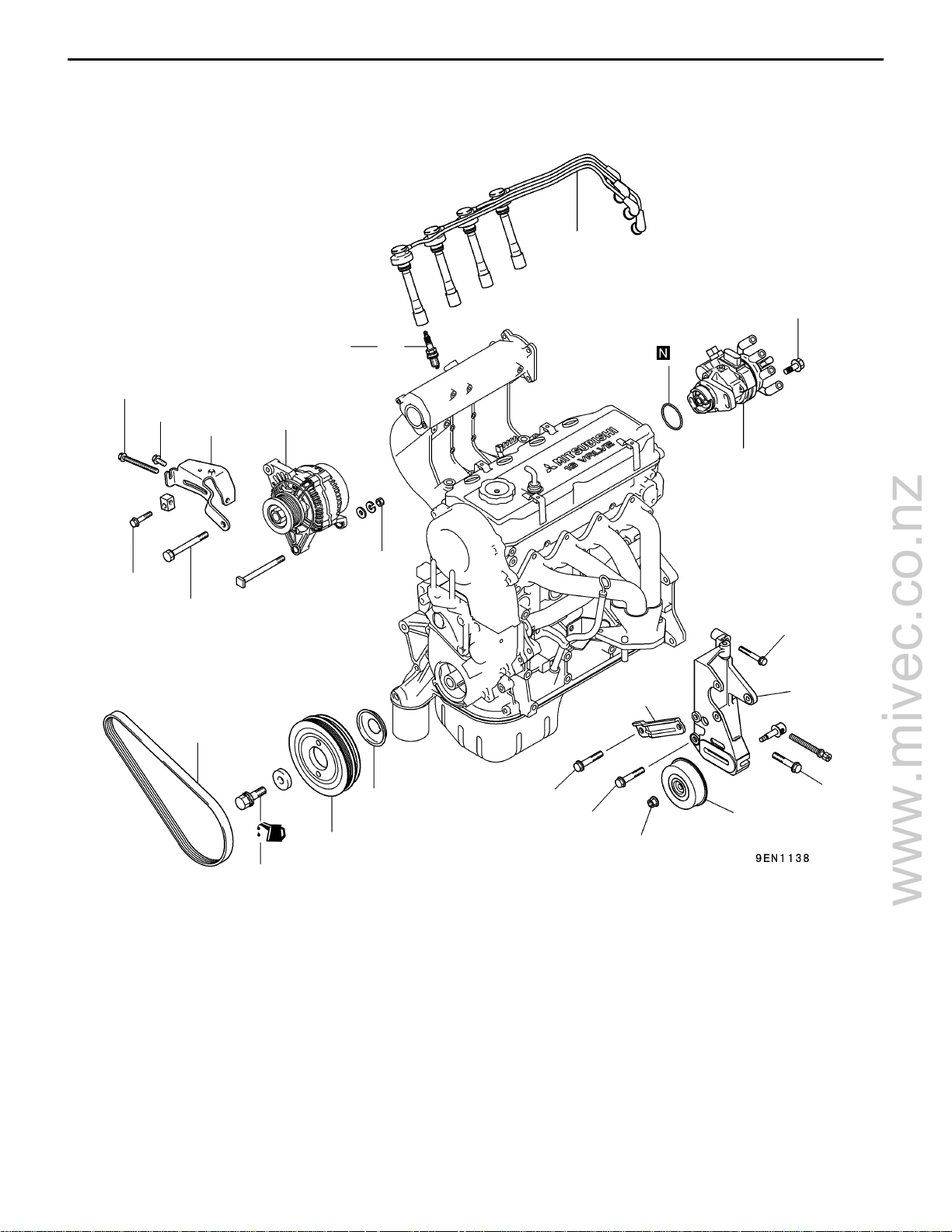

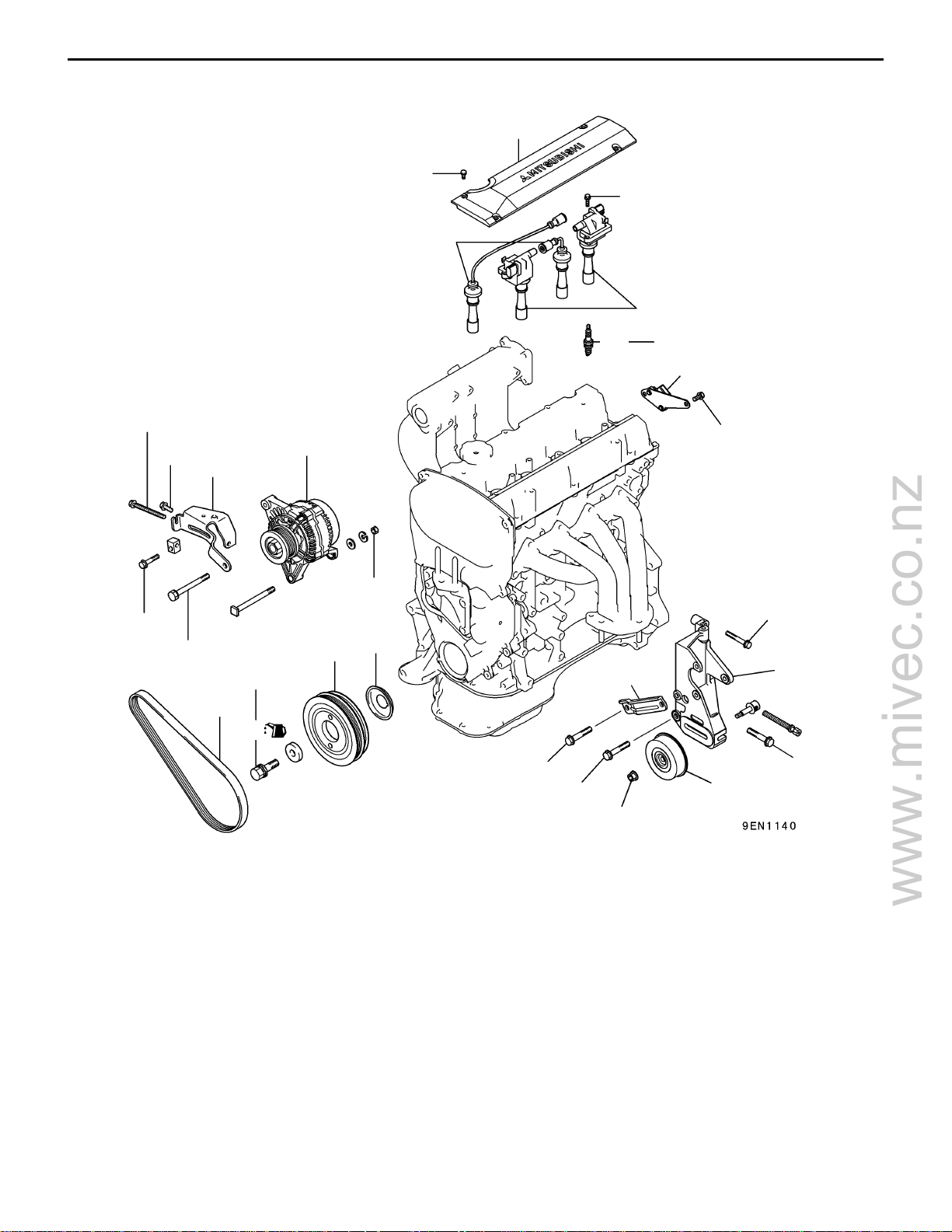

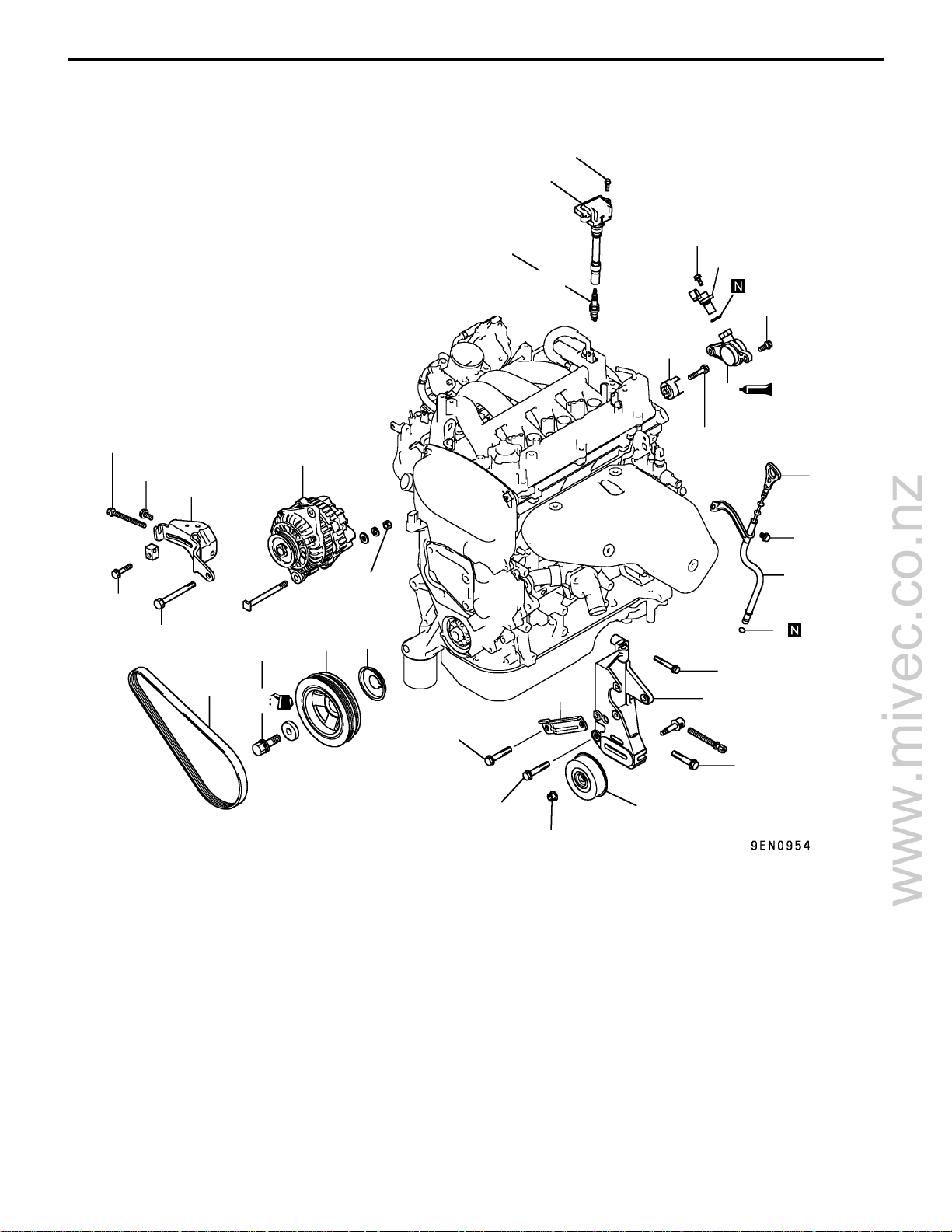

4G9 ENGINE (E–W) – Alternator and Ignition System

3. ALTERNATOR AND IGNITION SYSTEM

REMOVAL AND INSTALLATION <SOHC> (Engines with distributor)

7

11A-3-1

12 Nm

5 Nm

23 Nm

23 Nm

49 Nm

25 Nm

3

2

8

9

10

44 Nm

21 Nm

12

13

1

6

4

5

49 Nm

44 Nm

11

25 Nm

44 Nm

182 ± 4 Nm

Removal steps

1. Drive belt*

2. Alternator

3. Alternator brace

AA""BA 4. Crankshaft bolt

"BA 5. Crankshaft pulley

"BA 6. Front flange

7. Spark plug cable

E

Apr. 2002Mitsubishi Motors Corporation Revised

PWEE9502-J

8. Spark plug

9. O-ring

10. Distributor

11. Power steering pump pulley

12. Power steering pump bracket stay

13. Power steering pump bracket

NOTE:

*: For details of adjustment, refer to the relevant model’s

chassis workshop manual.

Page 22

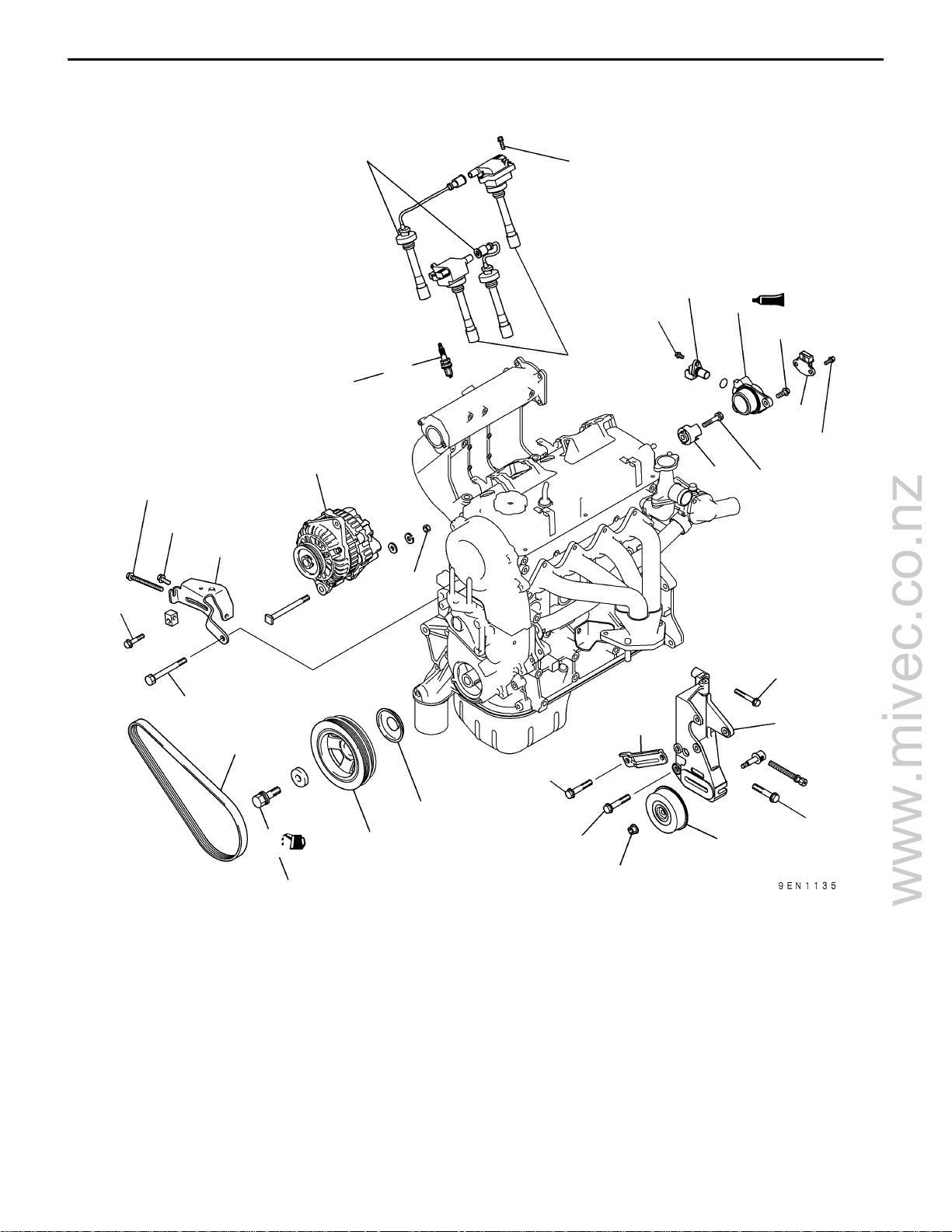

www.mivec.co.nz

11A-3-2

4G9 ENGINE (E–W) – Alternator and Ignition System

REMOVAL AND INSTALLATION <SOHC for other than PAJERO io>

(Engines without distributor)

23 Nm

5 Nm

23 Nm

7

9

25 Nm

10 Nm

8

9 Nm

11

12

13 Nm

10

5 Nm

2

13

21 Nm

3

44 Nm

49 Nm

1

4

182 ± 4 Nm

Removal steps

1. Drive belt*

2. Alternator

3. Alternator brace

AA""BA 4. Crankshaft bolt

"BA 5. Crankshaft pulley

"BA 6. Front flange

7. Spark plug cable

8. Ignition coil

9. Spark plug

10. Ignition failure sensor (From 2001

model vehicles for Europe)

21 Nm

15

49 Nm

16

6

44 Nm

5

NOTE:

*: For details of adjustment, refer to the relevant model’s

chassis workshop manual.

44 Nm

25 Nm

11. Cam position sensor

"AA 12. Cam position sensor support

13. Cam position sensing cylinder

14. Power steering pump pulley

15. Power steering pump bracket stay

16. Power steering pump bracket

14

E

Apr. 2002Mitsubishi Motors Corporation Revised

PWEE9502-J

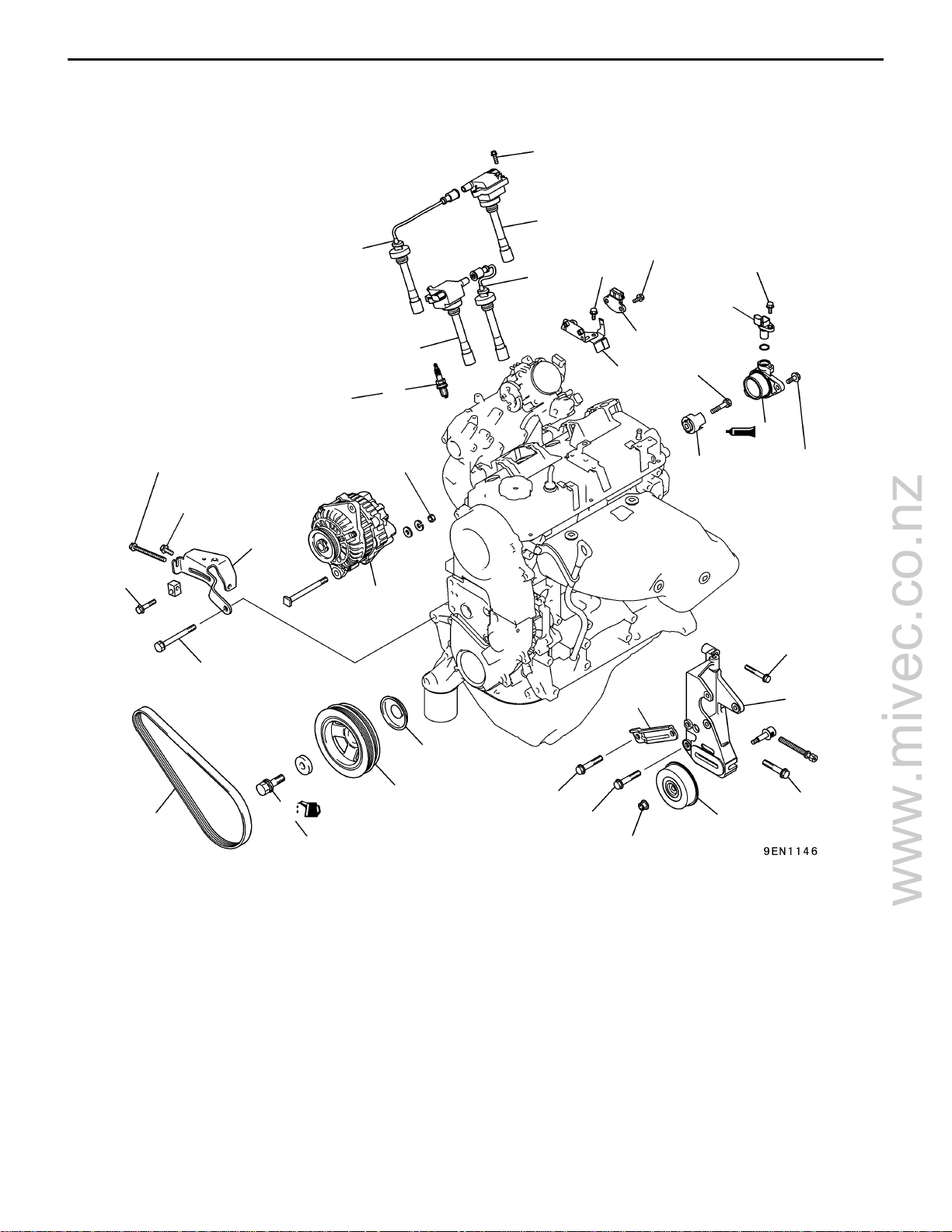

Page 23

www.mivec.co.nz

4G9 ENGINE (E–W) – Alternator and Ignition System

REMOVAL AND INSTALLATION <SOHC for PAJERO io>

(Engines without distributor)

10 Nm

8

11A-3-2a

23 Nm

5 Nm

23 Nm

49 Nm

7

7

10 Nm

5 Nm

9 Nm

12

11

10

21 Nm

25 Nm

8

9

13

44 Nm

14

13 Nm

3

2

21 Nm

16 17

1

Removal steps

1. Drive belt*

2. Alternator

3. Alternator brace

AA""BA 4. Crankshaft bolt

"BA 5. Crankshaft pulley

"BA 6. Front flange

7. Spark plug cable

8. Ignition coil

9. Spark plug

E

4

182 ± 4 Nm

Jun. 2002Mitsubishi Motors Corporation Revised

5

6

PWEE9502-K

49 Nm

44 Nm

25 Nm

10. Ignition failure sensor (For Europe)

11. Ignition failure sensor bracket

(For Europe)

12. Cam position sensor

"AA 13. Cam position sensor support

14. Cam position sensing cylinder

15. Power steering pump pulley

16. Power steering pump bracket stay

17. Power steering pump bracket

NOTE

*: For details of adjustment, refer to the relevant model’s

chassis workshop manual.

15

44 Nm

Page 24

www.mivec.co.nz

11A-3-2b

4G9 ENGINE (E-W) -

Alternator and Ignition System

Intentionally blank

E

Dec. 1998Mitsubishi Motors Corporation Added

PWEE9502-E

Page 25

www.mivec.co.nz

4G9 ENGINE (E–W) – Alternator and Ignition System

REMOVAL AND INSTALLATION <DOHC>

3 Nm

9

11A-3-3

7

10 Nm

8

5 Nm

23 Nm

23 Nm

29 Nm

3

182 ± 4 Nm

1

4

10

25 Nm

11

2

23 Nm

44 Nm

21 Nm

6

5

14

44 Nm

49 Nm

44 Nm

13

12

25 Nm

Removal steps

1. Drive belt*

2. Alternator

3. Alternator brace

AA""BA 4. Crankshaft bolt

"BA 5. Crankshaft pulley

"BA 6. Front flange

7. Center cover

8. Ignition coil

E

E

Nov. 1995Mitsubishi Motors Corporation

Apr. 2002Mitsubishi Motors Corporation Revised

PWEE9502-A

PWEE9502-J

9. Spark plug cable

10. Spark plug

11. Ignition failure sensor

12. Power steering pump pulley

13. Power steering pump bracket stay

14. Power steering pump bracket

NOTE:

*: For details of adjustment, refer to the relevant model’s

chassis workshop manual.

Page 26

www.mivec.co.nz

11A-3-4

4G9 ENGINE (E–W) – Alternator and Ignition System

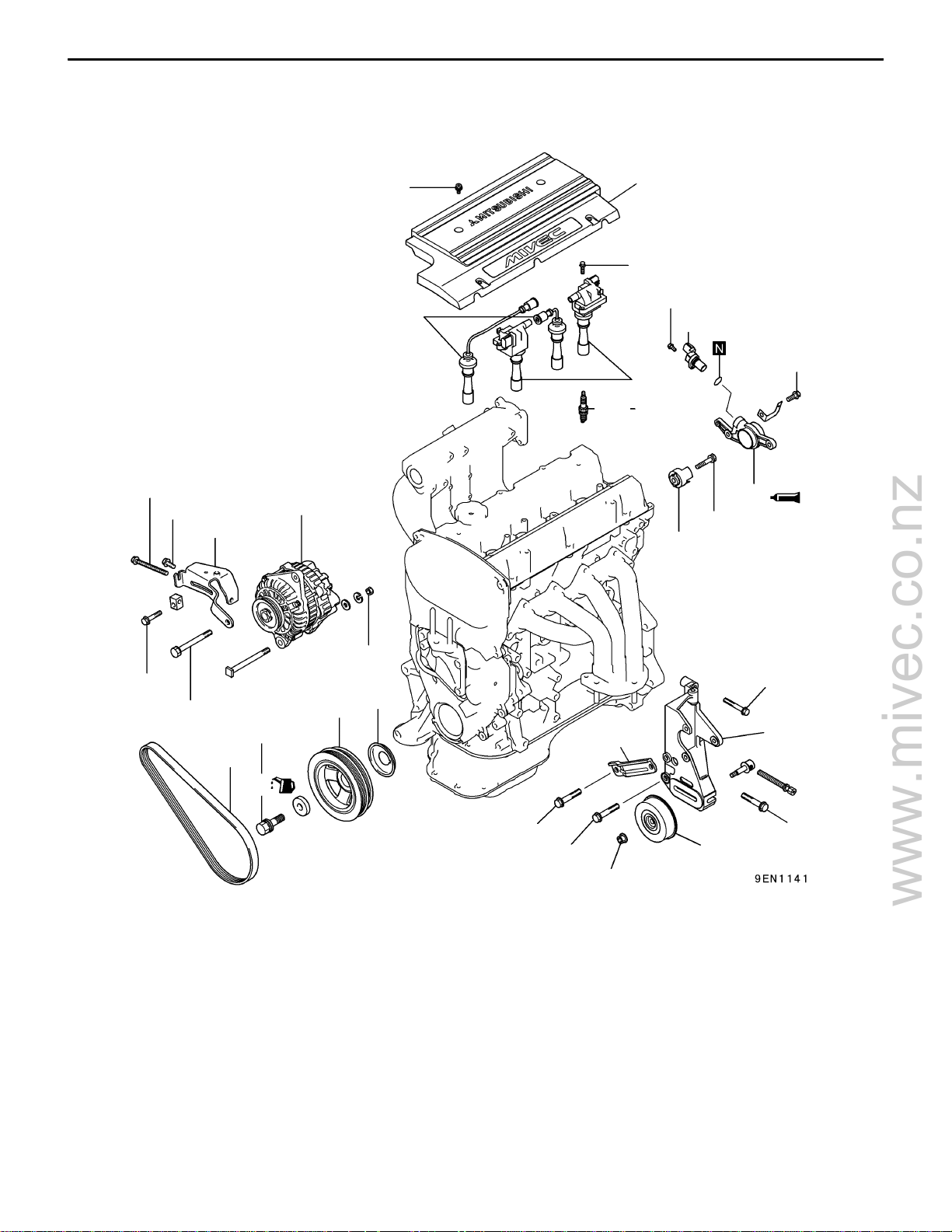

REMOVAL AND INSTALLATION <DOHC–MIVEC>

5 Nm

23 Nm

3 Nm

8

7

10 Nm

9 Nm

11

13 Nm

9

25 Nm

10

2

3

21 Nm

12

13

23 Nm

49 Nm

182 ± 4 Nm

1

4

Removal steps

1. Drive belt*

2. Alternator

3. Alternator brace

AA""BA 4. Crankshaft bolt

"BA 5. Crankshaft pulley

"BA 6. Front flange

7. Center cover

8. Spark plug cable

9. Ignition coil

44 Nm

5

21 Nm

6

15

49 Nm

44 Nm

25 Nm

10. Spark plug

11. Cam position sensor

"AA 12. Cam position sensor support

13. Cam position sensing cylinder

14. Power steering pump pulley

15. Power steering pump bracket stay

16. Power steering pump bracket

NOTE:

*: For details of adjustment, refer to the relevant model’s

chassis workshop manual.

14

16

44 Nm

E

E

Nov. 1995Mitsubishi Motors Corporation Added

Apr. 2002Mitsubishi Motors Corporation Revised

PWEE9502-A

PWEE9502-J

Page 27

www.mivec.co.nz

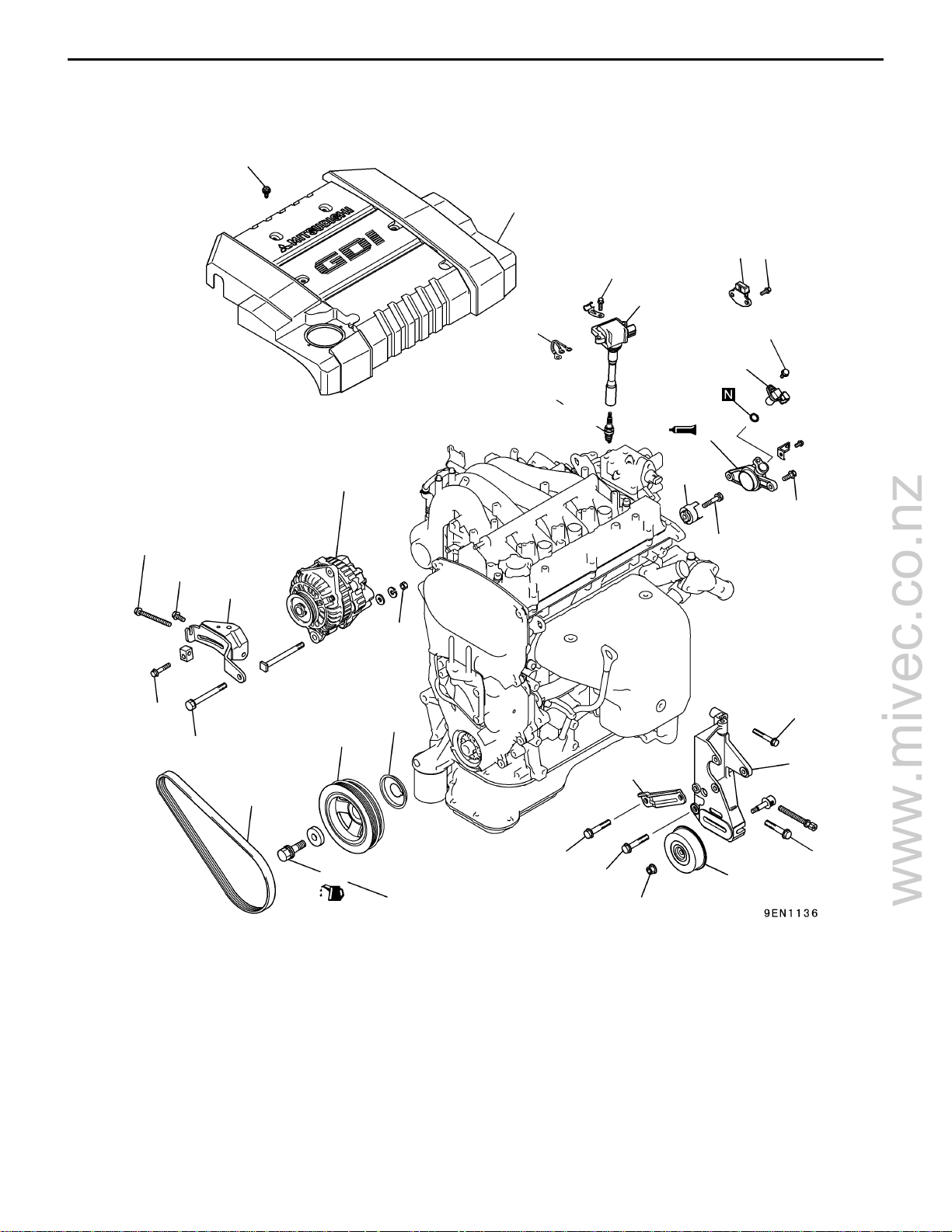

4G9 ENGINE (E–W) – Alternator and Ignition System

REMOVAL AND INSTALLATION

<DOHC–GDI for CARISMA, SPACE STAR, SPACE RUNNER, GALANT>

2.9 Nm

7

14

10 Nm

9

11A-3-5

5 Nm

5 Nm

23 Nm

23 Nm

49 Nm

8

9 Nm

11

25 Nm

10

12

2

13

13 Nm

21 Nm

3

44 Nm

6

21 Nm

5

16

17

1

4

182 ± 4 Nm

Removal steps

1. Drive belt*

2. Alternator

3. Alternator brace

AA""BA 4. Crankshaft bolt

"BA 5. Crankshaft pulley

"BA 6. Front flange

7. Engine cover

8. Earth strap (From 2001 model for

CARISMA, From 2001 model for

SPACE STAR)

9. Ignition coil

10. Spark plug

E

E

Nov. 1995Mitsubishi Motors Corporation

Apr. 2002Mitsubishi Motors Corporation Revised

PWEE9502-A

PWEE9502-J

49 Nm

44 Nm

25 Nm

11. Cam position sensor

"AA 12. Cam position sensor support

13. Cam position sensing cylinder

14. Ignition failure sensor (From 2001

model for CARISMA, From 2001

model for SPACE STAR)

15. Power steering pump pulley

16. Power steering pump bracket stay

17. Power steering pump bracket

NOTE:

*: For details of adjustment, refer to the relevant model’s

chassis workshop manual.

15

44 Nm

Page 28

www.mivec.co.nz

11A-3-6

4G9 ENGINE (E–W) – Alternator and Ignition System

REMOVAL AND INSTALLATION <DOHC–GDI for PAJERO io>

10 Nm

13

5 Nm

23 Nm

23 Nm

44 Nm

6

3

4

182 ± 4 Nm

7

25 Nm

9 Nm

15

14

13 Nm

17

16

21 Nm

5

1

13 Nm

2

3

8

44 Nm

9

11

21 Nm

12

Removal steps

1. Oil level gauge

2. Oil level gauge guide

3. O-ring

4. Drive belt*

5. Alternator

6. Alternator brace

AA""BA 7. Crankshaft bolt

"BA 8. Crankshaft pulley

"BA 9. Front flange

49 Nm

44 Nm

44 Nm

25 Nm

"AA 16. Cam position sensor support

NOTE:

*: For details of adjustment, refer to the relevant model’s

chassis workshop manual.

10

10. Power steering pump pulley

11. Power steering pump bracket stay

12. Power steering pump bracket

13. Ignition coil

14. Spark plug

15. Cam position sensor

17. Cam position sensing cylinder

E

E

Nov. 1995Mitsubishi Motors Corporation Added

Mar . 2001Mitsubishi Motors Corporation Revised

PWEE9502-A

PWEE9502-I

Page 29

www.mivec.co.nz

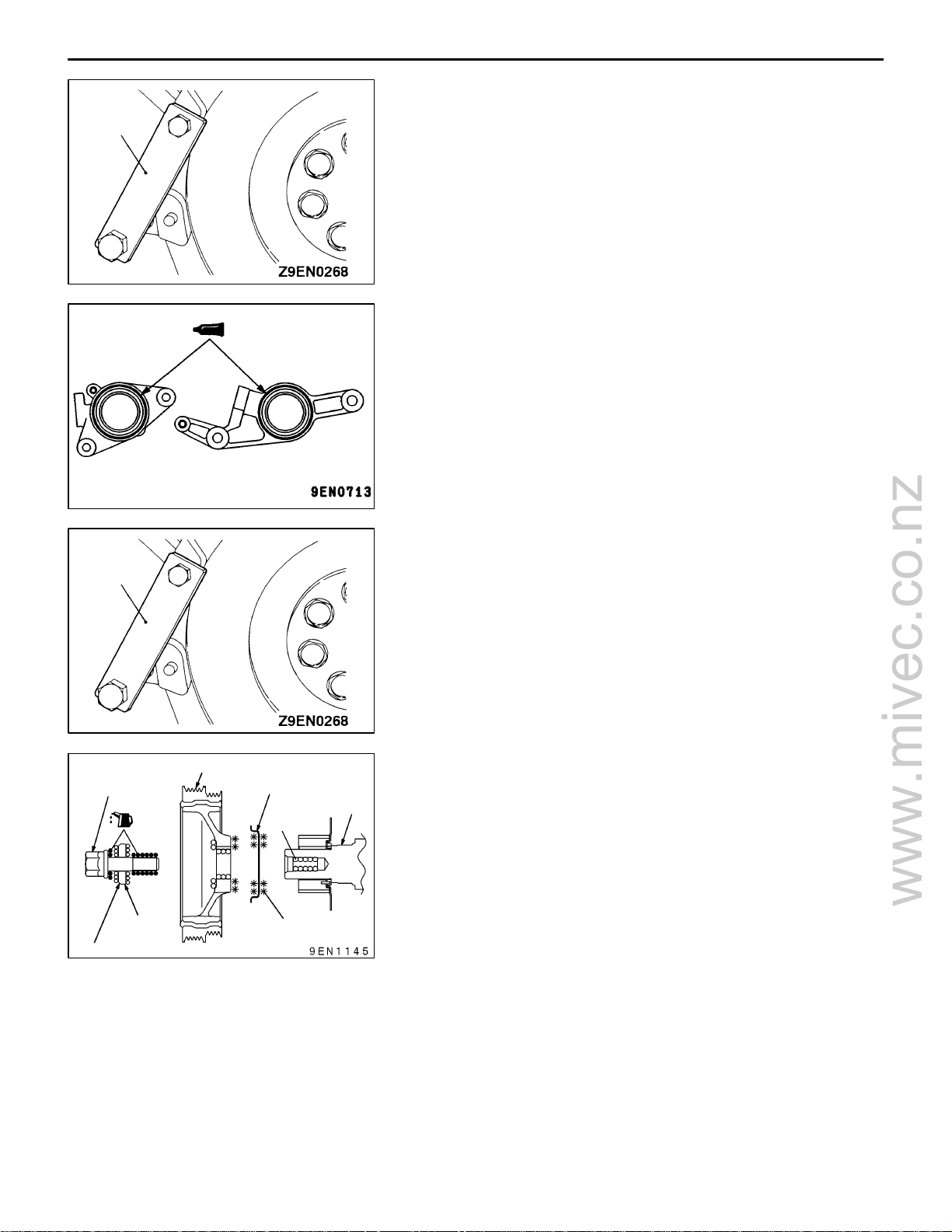

MD998781

4G9 ENGINE (E–W) – Alternator and Ignition System

REMOVAL SERVICE POINT

AA" CRANKSHAFT BOLT REMOVAL

(1) Use the special tool to hold the flywheel or the drive

plate, and then loosen the crankshaft mounting bolts.

INSTALLATION SERVICE POINTS

"AA CAM POSITION SENSOR SUPPORT

INSTALLATION

(1) Apply a 3 mm bead of form-in-place gasket (FIPG) to

the area shown.

Specified sealant:

Mitsubishi Genuine Part No. MD970389 or

equivalent.

11A-3-7

MD998781

Crankshaft pulley

Crankshaft bolt

Washer

Big chamfered side

Front flange

Crankshaft

Clean

Degrease

"BA FRONT FLANGE / CRANKSHAFT PULLEY /

CRANKSHAFT BOLT INSTALLATION

(1) Use the special tool to hold the flywheel or the drive

plate.

(2) Clean and then degrease the front flange contacting

surface of the crankshaft pulley.

NOTE

Degreasing is necessary to prevent decrease in the friction

between contacting surfaces.

(3) Clean the bolt hole in the crankshaft, the crankshaft

contacting surface and washer contacting surface of the

crankshaft pulley, and the washer.

(4) Apply an appropriately small amount of oil to the threads

and seating surface of the crankshaft bolt.

(5) Tighten the crankshaft bolt to the specified torque of 182

± 4 Nm.

E

E

Nov. 1995Mitsubishi Motors Corporation

Jun. 2002Mitsubishi Motors Corporation Revised

PWEE9502-A

PWEE9502-K

Page 30

www.mivec.co.nz

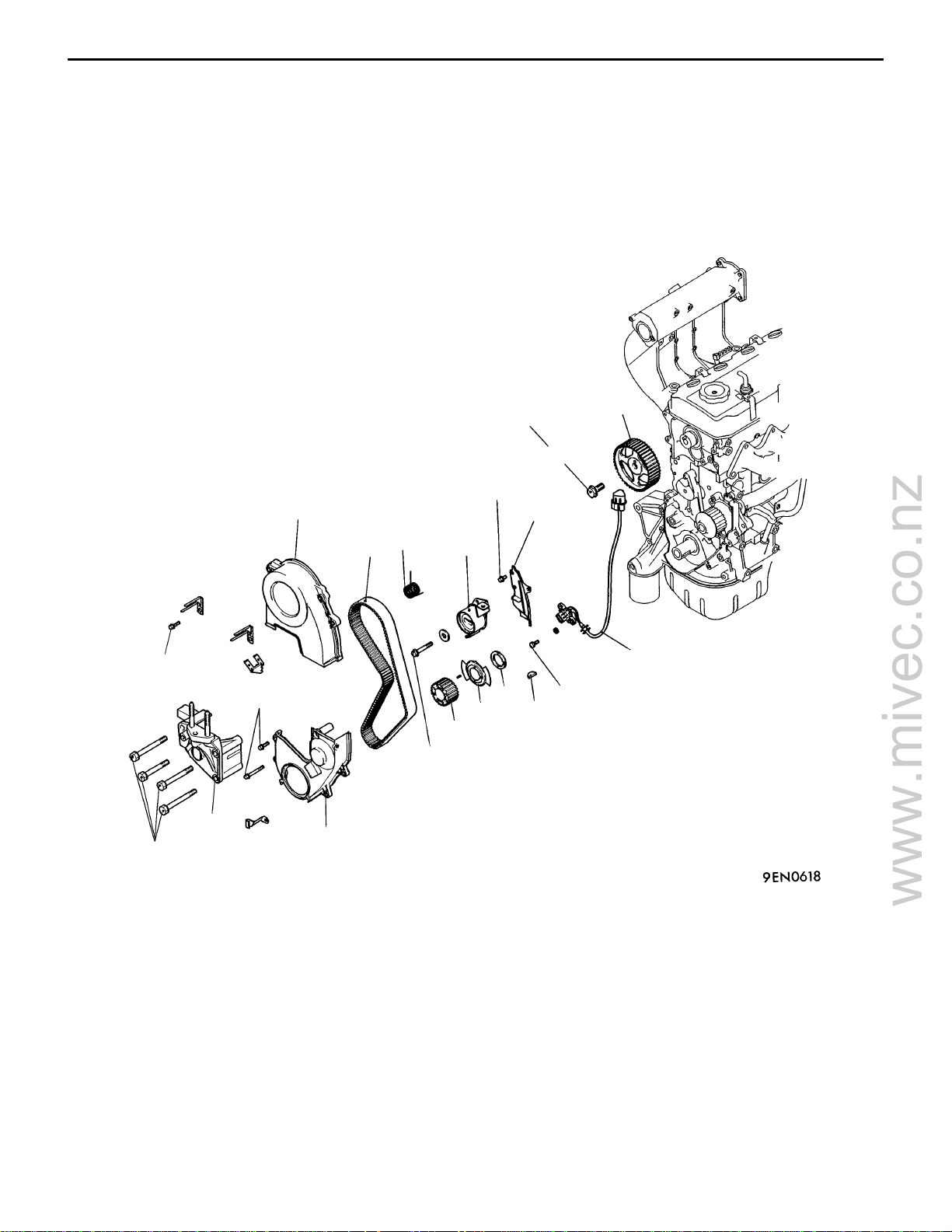

4G9 ENGINE (E–W) – Timing Belt

4. TIMING BELT

REMOVAL AND INSTALLATION <SOHC for CARISMA (Up to 1999 model),

LANCER (Except from 2001 model for Europe), GALANT>

11A-4-1

11 N m

49 Nm

88 Nm

14

13

11 N m

1

5

4

6

7

8

11 N m

10

11

9.8 Nm

12

9

23 Nm

3

2

Removal steps

1. Timing belt front upper cover

2. Timing belt front lower cover

3. Engine support bracket, right

AA""DA 4. Timing belt

"CA 5. Tensioner spring

"BA 6. Timing belt tensioner

7. Timing belt rear cover

E

Mar . 2001Mitsubishi Motors Corporation Revised

PWEE9502-I

8. Crankshaft angle sensor

(Engines without distributor)

"GA 9. Crankshaft sprocket

"GA 10. Crankshaft spacer

(Engines without distributor)

"GA 11. Crankshaft sensing blade

(Engines without distributor)

12. Crankshaft key

AB""AA 13. Camshaft sprocket bolt

14. Camshaft sprocket

Page 31

www.mivec.co.nz

11A-4-1a

4G9 ENGINE (E–W) – Timing Belt

REMOVAL AND INSTALLATION

<SOHC for CARISMA (From 2000 model), LANCER (From 2001 model for

Europe), SPACE STAR>

11 N m

11 N m

88 Nm

14

13

1

5

11 Nm

7

4

6

10

11

12

8

9.8 Nm

9

23 Nm

49 Nm

2

3

Removal steps

1. Timing belt front upper cover

2. Timing belt front lower cover

3. Engine support bracket, right

AA""DA 4. Timing belt

"CA 5. Tensioner spring

"BA 6. Timing belt tensioner

7. Timing belt rear cover

8. Crankshaft angle sensor

(Engines without distributor)

E

Apr. 2002Mitsubishi Motors Corporation Revised

PWEE9502-J

"GA 9. Crankshaft sprocket

"GA 10. Crankshaft spacer

(Engines without distributor)

"GA 11. Crankshaft sensing blade

(Engines without distributor)

12. Crankshaft key

AB""AA 13. Camshaft sprocket bolt

14. Camshaft sprocket

Page 32

www.mivec.co.nz

4G9 ENGINE (E- W) -

Timing Belt

11A-4-1b

Intentionallyblank

E

May 2000Mitsubishi Motors Corporation Added

PWEE9502-G

Page 33

www.mivec.co.nz

11A-4-2

4G9 ENGINE (E–W) – Timing Belt

REMOVAL AND INSTALLATION <SOHC for PAJERO io>

11 N m

49 Nm

88 Nm

14

13

1

23 Nm

11 N m

5

6

7

8

3

10

11

12

9.8 Nm

9

4

2

Removal steps

1. Timing belt front upper cover

2. Timing belt front lower cover

3. Accessory mount

AA""DA 4. Timing belt

"CA 5. Tensioner spring

"BA 6. Timing belt tensioner

7. Timing belt rear cover

E

Mar . 2001Mitsubishi Motors Corporation Revised

PWEE9502-I

8. Crankshaft angle sensor

"GA 9. Crankshaft sprocket

"GA 10. Crankshaft spacer

"GA 11. Crankshaft sensing blade

12. Crankshaft key

AB""AA 13. Camshaft sprocket bolt

14. Camshaft sprocket

Page 34

www.mivec.co.nz

4G9 ENGINE (E–W) – Timing Belt

REMOVAL AND INSTALLATION <DOHC>

11A-4-2a

19

11 N m

49 Nm

11 N m

3

88 Nm

4

18

17

5

24 Nm

1

6

10

36 Nm

11

11 N m

44 Nm

7

14

16

15

13

20

9

11 N m

8

13 Nm

9.8 Nm

12

2

Removal steps

1. Timing belt upper cover

2. Timing belt lower cover

3. Engine support bracket

AA""FA 4. Timing belt

5. Tensioner pulley

6. Tensioner arm

7. Shaft

"EA 8. Auto-tensioner

9. Timing belt rear cover

10. Idler pulley

E

Mar . 2001Mitsubishi Motors Corporation Revised

PWEE9502-I

11. Cam position sensor

12. Crankshaft angle sensor

"GA 13. Crankshaft sprocket

"GA 14. Crankshaft spacer

"GA 15. Crankshaft sensing blade

16. Crankshaft sprocket key

AB""AA 17. Camshaft sprocket bolt

18. Camshaft sprocket

19. Timing belt rear cover

20. Timing belt rear cover

Page 35

www.mivec.co.nz

11A-4-2b

4G9 ENGINE (E–W) – Timing Belt

REMOVAL AND INSTALLATION <DOHC–MIVEC>

18

11 N m

88 Nm

11 Nm

4

16

17

5

48 Nm

1

6

10

7

35 Nm

48 Nm

15

13

14

12

11 Nm

3

49 Nm

Removal steps

1. Timing belt front upper cover

2. Timing belt front lower cover

3. Engine support bracket, right

AA""FA 4. Timing belt

5. Tensioner pulley

6. Tensioner arm

7. Shaft

"EA 8. Auto tensioner

9. Timing belt rear cover

10. Idler pulley

2

13 Nm

8

11 Nm

19

9

9.8 Nm

11. Crankshaft angle sensor

"GA 12. Crankshaft sprocket

"GA 13. Crankshaft spacer

"GA 14. Crankshaft sensing blade

15. Crankshaft key

AB""AA 16. Camshaft sprocket bolt

17. Camshaft sprocket

18. Timing belt rear cover

19. Timing belt rear cover

11

E

Mar . 2001Mitsubishi Motors Corporation Revised

PWEE9502-I

Page 36

www.mivec.co.nz

4G9 ENGINE (E–W) – Timing Belt

REMOVAL AND INSTALLATION

<DOHC–GDI for CARISMA, SPACE STAR, SPACE RUNNER>

21

11 Nm

11 Nm

4

11A-4-2c

19

49 Nm

11 Nm

3

88 Nm

17

1

48 Nm

5

48 Nm

6

9

7

35 Nm

18

10

13

12

15

14

11 Nm

16

20

8

11 Nm

13 Nm

2

12

9.8 Nm

9.8 Nm

11

Removal steps

1. Timing belt front upper cover

2. Timing belt front lower cover

3. Engine support bracket, right

AA""FA 4. Timing belt

5. Tensioner pulley

6. Tensioner arm

7. Shaft

"EA 8. Auto tensioner

9. Timing belt rear cover

10. Idler pulley

11. Crankshaft angle sensor

(Up to 1999 model)

12. Crankshaft angle sensor

(From 2000 model)

E

Mar . 2001Mitsubishi Motors Corporation Revised

PWEE9502-I

"GA 13. Crankshaft sprocket

"GA 14. Crankshaft spacer

"GA 15. Crankshaft sensing blade

16. Crankshaft key

AB""AA 17. Camshaft sprocket bolt

18. Camshaft sprocket

19. Timing belt rear cover

(Up to 2000 model)

20. Timing belt rear cover

(Up to 2000 model)

21. Timing belt rear upper cover

(From 2001 model)

Page 37

www.mivec.co.nz

11A-4-2d

4G9 ENGINE (E–W) – Timing Belt

REMOVAL AND INSTALLATION <DOHC–GDI for GALANT>

18

11 Nm

4

49 Nm

11 Nm

3

88 Nm

17

16

1

48 Nm

5

48 Nm

6

7

35 Nm

10

14

13

15

12

9

8

13 Nm

11 Nm

9.8 Nm

11

2

Removal steps

1. Timing belt front upper cover

2. Timing belt front lower cover

3. Engine support bracket, right

AA""FA 4. Timing belt

5. Tensioner pulley

6. Tensioner arm

7. Shaft

"EA 8. Auto tensioner

9. Timing belt rear cover

E

Mar . 2001Mitsubishi Motors Corporation Revised

PWEE9502-I

10. Idler pulley

11. Crankshaft angle sensor

"GA 12. Crankshaft sprocket

"GA 13. Crankshaft spacer

"GA 14. Crankshaft sensing blade

15. Crankshaft key

AB""AA 16. Camshaft sprocket bolt

17. Camshaft sprocket

18. Timing belt rear upper cover

Page 38

www.mivec.co.nz

4G9 ENGINE (E–W) – Timing Belt

REMOVAL AND INSTALLATION <DOHC–GDI for PAJERO io>

21

11 Nm

19

11 Nm

4

88 Nm

17

18

11A-4-2e

49 Nm

11 N m

5

1

48 Nm

6

10

7

15

20

14

35 Nm

48 Nm

16

12

13

11 Nm

11 Nm

9

9.8 Nm

11

11 Nm

8

3

13 Nm

2

Removal steps

1. Timing belt front upper cover

2. Timing belt front lower cover

3. Accesory mount

AA""FA 4. Timing belt

5. Tensioner pulley

6. Tensioner arm

7. Shaft

"EA 8. Auto tensioner

9. Timing belt rear cover

10. Idler pulley

E

Mar . 2001Mitsubishi Motors Corporation Revised

PWEE9502-I

11. Bracket

12. Crankshaft angle sensor

"GA 13. Crankshaft sprocket

"GA 14. Crankshaft spacer

"GA 15. Crankshaft sensing blade

16. Crankshaft key

AB""AA 17. Camshaft sprocket bolt

18. Camshaft sprocket

19. Timing belt rear cover <4G93>

20. Timing belt rear cover <4G93>

21. Timing belt rear upper cover

<4G94>

Page 39

www.mivec.co.nz

11A-4-2f

4G9 ENGINE (E- W) -

Timing Belt

Intentionallyblank

E

May 2000Mitsubishi Motors Corporation Added

PWEE9502-G

Page 40

www.mivec.co.nz

4G9 ENGINE (E-W) -

REMOVAL SERVICE POINTS

AA"

(1) Mark belt running direction for reinstallation.

TIMING BELT REMOVAL

Timing Belt

11A-4-3

MD998719

or

MD998754

MB990767

AB"

<With rocker cover removed> (Except SOHC)

(1) Use a wrench to hold the hexagonal part of the camshaft,

CAMSHAFT SPROCKET BOLT REMOVAL

and then remove the camshaft sprocket mounting bolt.

INSTALLATION SERVICE POINTS

MD998719

or

MD998754

E

MB990767

Nov. 1995Mitsubishi Motors Corporation Revised

"AA

PWEE9502-A

CAMSHAFT SPROCKET BOLT INSTALLATION

Page 41

www.mivec.co.nz

11A-4-4

4G9 ENGINE (E-W) -

Timing belt

Exhaust

side

“A”

Pliers

Tensioner

pulley fixing

bolt

Tensioner

“B”

"BA

TIMING BELT TENSIONER INSTALLATION

(1) Let the pulley of the timing belt tensioner comr closest

to the exhaust side. Temporarily tighten the tensioner

pulley fixing bolt.

"CA

TENSIONER SPRING INSTALLATION

(1) Insert the tip A (shorter one) of the tensioner spring into

the oil pump case.

(2) Use pliers or similar tool to pinch the tip B (longer one),

and then hook it to the tensioner bracket arm.

"DA

TIMING BELT INSTALLATION

(1) Turn the crankshaft sprocket by three teeth from the timing

mark.

Caution

Aligning the timing marks positions the piston to the

topdead centre. Then, if the camshaftturns,thevalves

may hit and damage the pistons.

Timing mark

Timing marks

E

(2) Check that the timing belt tensioner and tensioner spring

are installed correctly. (Refer to the service points B and

C.)

(3) Align the timing marks on the camshaft sprocket to that

on the cylinder head.

(4) Align the timing mark on the crankshaft sprocket to that

on the oil pump case.

(5) Place the timing belt over t he sprocket according in the

following order.

1. Crankshaft sprocket

2. Water pump sprocket

3. Camshaft sprocket

4. Tension pulley

May 1995Mitsubishi Motors Corporation

PWEE9502

Page 42

www.mivec.co.nz

MD998716

4G9 ENGINE (E-W) -

(6) Slightly loosen the tensioner pulley fixing bolt which is

tightened temporarily to tighten the belt by a force of

the tensioner spring.

(7) Turn th e crankshaft clockwise by two turns.

(8) Check that the timing marks are aligned.

(9) Tighten the fixing bolt of the tensioner pulley.

Timing Belt

11A-4-5

Set hole (A)

Set hole (B)

"EA

(1) If the auto-tensioner rod is fully extended, set it in the

(2) Install the auto-tensioner

AUTO-TENSIONER INSTALLATION

retracted position with the following procedure.

1) Hold the auto-tensioner in a vice, being careful not

to tilt it.

2) Slowly close the vice to force the rod in to align hole

(A) of the rod with the set hole (B).

3) Insert a 2.0-mm-Allen key in diameter or similar into

the set holes.

4) Remove the auto-tensioner from the vice.

Leave the align key until installation of the timing belt

is completed.

E

Nov. 1995Mitsubishi Motors Corporation Revised

PWEE9502-A

Page 43

www.mivec.co.nz

11A-4-6

4G9 ENGINE (E-W) -

Timing Belt

Timing mark

Timing marks

Paper clip

"FA

(1) Make sure that the auto-tensioner is installed properly.

(2) Align the timing mark on each sprocket with the

(3) Turn the crankshaft sprocket one half the tooth width

(4) Fit t he timing belt to the intake camshaft sprocket and

TIMING BELT INSTALLATION

(Refer to service point F.)

corresponding mark on the timing belt.

counterclockwise.

secure with a paper clip at the illustrated position.

Timing mark

Timing mark

E

Nov. 1995Mitsubishi Motors Corporation Revised

(5) Use two wrenches to fit the timing belt to the exhaust

sprocket while aligning the timing marks.

PWEE9502-A

Page 44

www.mivec.co.nz

4G9 ENGINE (E-W) -

(6) Secure the timing belt with a paper clip at the illustrated

position.

(7) Fit the belt to the idler pulley water pump sprocket,

crankshaft sprocket and tensioner pulley in that order.

Idler pulley

Water

pump

sprocket

Timing Belt

11A-4-7

Tensioner

pulley

Crankshaft sprocket

(8) Raise the tensioner pulley in the direction of an arrow

and tighten the tensioner pulley bolt.

(9) Remove the two paper clips.

(10)Make sure that all timing marks are in alignment.

(11)Give a 1/4 counterclockwise turn to the crankshaft. Then

turn the crankshaft clockwise to align the timing marks

again.

E

May 1995Mitsubishi Motors Corporation

PWEE9502

Page 45

www.mivec.co.nz

11A-4-8

MD998767

4G9 ENGINE (E–W) – Timing Belt

(12)Install the special tool and a torque wrench to the tensioner

pulley.

(13)Using torque wrench, torque to 2.6 Nm.

(14)While holding the tensioner pulley to prevent it from

turning, tighten the center bolt to the specified torque.

(15)Give two clockwise turns to the crankshaft and leave

as it is for approx. 15 minutes.

(16)Check if the Allen wrench inserted during installation of

the auto-tensioner can be pulled out lightly. If it can be

pulled out lightly , the belt is properly tensioned. Therefore,

pull out the wrench. The belt is also properly tensioned

if the auto-tensioner projection is of standard value.

Standard value: 3.8 – 4.5 mm

(17)If the wrench cannot be pulled out lightly, repeat the steps

(12) through (15) to obtain appropriate belt tension.

NOTE

Check the tightening torque of the crankshaft bolt always

after rotating the crankshaft counterclockwise using the

crankshaft bolt. Retighten the bolt if the tightening torque

is not up to specification.

Crankshaft

sprocket

Clean

Crankshaft sensing blade

Crankshaft

Crankshaft spacer

Degrease

Oil pump case

"GA CRANKSHAFT SENSING BLADE / CRANKSHAFT

SPACER / CRANKSHAFT SPROCKET

INSTALLATION

(1) Clean and then degrease the following surfaces and parts:

front surface of oil pump case, sprocket mounting surface

of crankshaft, crankshaft spacer, crankshaft sensing

blade, and crankshaft sprocket.

NOTE

Degreasing is necessary to prevent decrease in the friction

between contacting surfaces.

(2) Clean the crankshaft contacting surface of the crankshaft

sprocket.

INSPECTION 11300200077

TIMING BELT

Replace belt if any of the following conditions exist.

(1) Hardening of back rubber.

Back side is glossy without resilience and leaves no indent

when pressed with fingernail.

(2) Cracks on rubber back.

Cracks

(3) Cracks or peeling of canvas.

(4) Cracks on tooth bottom.

(5) Cracks on belt sides.

Peeling

Cracks

Cracks

E

E

May 1995Mitsubishi Motors Corporation

Mar . 2001Mitsubishi Motors Corporation Revised

PWEE9502

PWEE9502-I

Page 46

www.mivec.co.nz

Rounded edge

Abnormal wear

(Fluffy strand)

Rubber exposed

Tooth missing

and canvas

fiber exposed

4G9 ENGINE (E-W) -

(6) Abnormal wear of belt sides. The sides are normal if

they are sharp as if cut by a knife.

(7) Abnormal wear on teeth.

(8) Missing tooth.

Timing Belt

11A-4-9

98 to 196 N

11 mm

Stroke

TENSIONER PULLER, IDLER PULLEY

(1) Check the pulley for smooth rotation, excessive play,

abnormal noise. Replace it if necessary.

AUTO-TENSIONER

(1) Check the tensioner for oil leaks. Replace it if necessary.

(2) Check the rod end for wear or damage. Replace the

tensioner if necessary.

(3) Measure the rod projection length. If not within the

standard value, replace the tensioner.

Standard value: 11 mm

(4) Press the rod by a force of 98 to 196 N and measure

the rod stroke. If not within the standard value, replace

the tensioner.

Standard value: 1 mm or less

E

May 1995Mitsubishi Motors Corporation

PWEE9502

Page 47

www.mivec.co.nz

4G9 ENGINE (E-W) -

Fuel and Emission Control System

5. FUEL AND EMISSION CONTROL SYSTEM

REMOVAL AND INSTALLATION <SOHC-CARBURETOR>

11A-5-1

3

2

21 Nm

18 Nm

17 Nm

8

4

9

5

6

7

1

21 Nm

10

11

Removal steps

1. Breather tube

2. Fuel hose

3. Fuel hose

4. Fuel pump

5. Gasket

6. Insulator

7. Gasket

8. Carburetor

9. Gasket

10. EGR valve

11. Gasket

E

Nov. 1996Mitsubishi Motors Corporation

PWEE9502-B

Revised

Page 48

www.mivec.co.nz

11A-5-2

4G9 ENGINE (E–W) – Fuel and Emission Control System

REMOVAL AND INSTALLATION <SOHC–MPI for other than PAJERO io>

12 Nm

9 Nm

10

16

17

19 Nm

2

15

13

14

12

Engine with solenoid valve Flange

Engine with solenoid valve Washer

Engine without solenoid valve

1

11 N m

9 Nm

10Nm

3

19

21

21 Nm

11

7

24 Nm

4

20

6

12 Nm

9

8

9 Nm

Removal steps

1. Vacuum hose and pipe assembly

2. Throttle body

"CA 3. Gasket

4. Engine hanger (4G94)

5. Throttle body stay (4G94)

6. Vacuum hose

7. Fuel hose

"BA 8. Fuel pressure regulator

9. O-ring

10. Delivery pipe and injector

11. Insulator

12. Insulator

5

18

9 Nm

"AA 13. Injector

14. O-ring

15. Grommet

16. Delivery pipe

17. Fuel return pipe

18. Solenoid valve assembly

(Engine with solenoid valve)

19. EGR valve

(Engine with EGR valve)

20. Cover

(Engine without EGR valve)

21. Gasket

Mar . 2001Mitsubishi Motors Corporation Revised

E

E

Nov. 1996Mitsubishi Motors Corporation Revised

PWEE9502-I

PWEE9502-B

Page 49

www.mivec.co.nz

4G9 ENGINE (E–W) – Fuel and Emission Control System

REMOVAL AND INSTALLATION <SOHC–MPI for PAJERO io>

9 Nm

12 Nm

8

18

24 Nm

11A-5-3

17

1

19 Nm

11

3

15

16

14

5

11 N m

6

13

2

12

22 Nm

20

9 Nm

4

21

7

9

19

9 Nm

10

9 Nm

Removal steps

1. Stay (From 2002 model)

2. Harness bracket

3. Throttle cable bracket

4. Vacuum hose and pipe assembly

5. Throttle body

"CA 6. Gasket

7. Vacuum hose

8. Fuel hose

"BA 9. Fuel pressure regulator

10. O-ring

11. Delivery pipe and injector

E

E

Nov. 1996Mitsubishi Motors Corporation

Jun. 2002Mitsubishi Motors Corporation Revised

PWEE9502-B

PWEE9502-K

12. Insulator

13. Insulator

"AA 14. Injector

15. O-ring

16. Grommet

17. Delivery pipe

18. Fuel return pipe

19. Solenoid valve assembly

20. EGR valve

21. Gasket

Revised

Page 50

www.mivec.co.nz

11A-5-4

4G9 ENGINE (E–W) – Fuel and Emission Control System

REMOVAL AND INSTALLATION <DOHC>

11 N m

15

14

12

13

11

1

10

9 Nm

6

9

10 Nm

17

3

9 Nm

2

23 Nm

16

4

23 Nm

18 Nm

8

7

9 Nm

Removal steps

1. Vacuum pipe assembly

2. Throttle body assembly

"CA 3. Gasket

4. Throttle body stay (MIVEC)

5. Vacuum hose

6. Fuel hose

"BA 7. Fuel pressure regulator

8. O-ring

9. Delivery pipe and injector

5

10. Insulator

11. Insulator

"AA 12. Injector

13. O-ring

14. Grommet

15. Delivery pipe

16. Fuel return pipe

17. Solenoid valve

E

E

Nov. 1996Mitsubishi Motors Corporation

Jun. 2002Mitsubishi Motors Corporation Revised

PWEE9502-B

PWEE9502-K

Revised

Page 51

www.mivec.co.nz

4G9 ENGINE (E-W) -

Fuel and Emission Control System

INSTALLATION SERVICE POINTS

"AA

(1) Apply a small amount of new engine oil to the O-ring.

(2) While turning the injector to the left and right, install it

(3) Check that the injector turns smoothly. If it does not turn

Injector connector

AB

Delivery pipe

(4) Check that the clearance between the injector connector

11A-5-5

INJECTORS INSTALLATION

Caution

Be sure not to let engine oil get into the delivery

pipe.

to t he delivery pipe.

smoothly, the O-ring may be trapped. Remove the injector

and check the O-ring for damage, and then re-insert it

into the delivery pipe and check once again.

and the delivery pipe is uniform (A = B).

<SOHC-MPI for other

than PAJERO io>

Projection

"BA

(1) Apply a small amount of new engine oil to the O-ring.

(2) Check that the fuel pressure regulator turns smoothly.

"CA

(1) Position the projection as shown in the illustration.

FUEL PRESSURE REGULATOR INSTALLATION

Insert the fuel pressure regulator into the delivery pipe

being careful not to damage the O-ring.

Caution

Be sure not to let engine oil get into the delivery

pipe.

If it does not turn smoothly, the O-ring may be trapped.

Remove the fuel pressure regulator and check the O-ring

for damage, and then re-insert it into the delivery pipe

and check once again.

GASKET INSTALLATION

E

Dec. 1998Mitsubishi Motors Corporation Added

PWEE9502-E

Page 52

www.mivec.co.nz

11A-5-6

<SOHC-MPI

forPAJEROio>

Projection

4G9 ENGINE (E-W) -

Fuel and Emission Control System

E

Dec. 1998Mitsubishi Motors Corporation Added

PWEE9502-E

Page 53

www.mivec.co.nz

4G9 ENGINE (E- W) -

Throttle Body and EGR System (GDI)

11A-5a-1

5a. THROTTLE BODY AND EGR SYSTEM (GDI)

REMOVAL AND INSTALLATION <Up to 2000 model for CARISMA, 1999 model for

SPACE STAR, SPACE RUNNER>

18 Nm

6

7

18 Nm

32

9Nm

18 Nm

14

13

18 Nm

12

24 Nm

17

11

4

15

16

9Nm

14

8

30 Nm

1

10

18 Nm

5

9

Removal steps

1. Air intake plenum resonator

2. O-ring

"BA

"AA

E

3. Intake manifold stay

4. Water hose

5. Water hose (Up to 1998 model for

CARISMA, SPACE RUNNER)

6. Throttle body

7. Throttle body gasket

8. Ignition harness

9. Water hose

10. EGR valve

11. EGR valve gasket

May 2000Mitsubishi Motors Corporation Revised

PWEE9502-G

12. Engine hanger

13. EGR valve support

14. Gasket

15. Water hose (Up to 1998 model for

CARISMA, SPACE RUNNER)

16. Air by-pass valve

(Up to 1998 model for CARISMA,

SPACE RUNNER)

17. Air by-pass valve gasket

(Up to 1998 model for CARISMA,

SPACE RUNNER)

Page 54

www.mivec.co.nz

11A-5a-2

4G9 ENGINE (E–W) – Throttle Body and EGR System (GDI)

REMOVAL AND INSTALLATION

<From 2001 model for CARISMA, SPACE STAR and GALANT>

20 Nm

24 Nm

10

18 Nm

2

6

7

3

24 Nm

5

8

12

4

11

12

30 Nm

9

24 Nm

18 Nm

1

Removal steps

"BA 1. Intake manifold stay (For GALANT)

2. Water hose

3. Water hose

4. Water hose

5. Throttle body stay

6. Throttle body

E

Apr. 2003Mitsubishi Motors Corporation Revised

PWEE9502-L

"AA 7. Throttle body gasket

8. Ignition harness

9. Water hose

10. EGR valve

11. EGR valve support

12. Gasket

Page 55

www.mivec.co.nz

4G9 ENGINE (E- W) -

Throttle Body and EGR System (GDI)

REMOVAL AND INSTALLATION <For PAJERO io - 4G93>

1

18 Nm

9

14

11A-5a-3

18 Nm

2

8

11 Nm

10

18 Nm

15

13

23 Nm

7

11 Nm

14

12

3

16

11

5

13 Nm

6

18 Nm

4

Removal steps

1. Water hose

2. Water hose

3. Water hose

4. Water hose

5. Water hose

6. Water hose clamp

7. Water pipe

8. Water pipe

E

July 2000Mitsubishi Motors Corporation Revised

PWEE9502-H

"AA

9. Throttle body

10. Throttle body gasket

11. EGR valve

12. EGR valve gasket

13. EGR valve support

14. Gasket

15. Engine hanger

Page 56

www.mivec.co.nz

11A-5a-4

4G9 ENGINE (E- W) -

Throttle Body and EGR System (GDI)

REMOVAL AND INSTALLATION <For PAJERO io - 4G94>

1

18 Nm

15

18 Nm

2

18 Nm

11

8

18 Nm

16

10

14

23 Nm

11 Nm

14

7

9

3

13

12

13 Nm

6

5

18 Nm

11 Nm

Removal steps

1. Water hose

2. Water hose

3. Water hose

4. Water hose

5. Water hose

6. Water hose clamp

7. Water pipe

8. Water pipe

4

9. Throttle body stay

10. Throttle body

"AA

11. Throttle body gasket

12. EGR valve

13. EGR valve gasket

14. EGR valve support

15. Gasket

16. Engine hanger

E

July 2000Mitsubishi Motors Corporation Revised

PWEE9502-H

Page 57

www.mivec.co.nz

4G9 ENGINE (E- W) -

Throttle Body and EGR System (GDI)

11A-5a-5

<Up to 2000 model for

CARISMA,1999model

for SPACE STAR,

SPACE RUNNER>

<From 2001 model for CARISMA,

From 2001 model for SPACE STAR,

GALANT>

Tab

INSTALLATION SERVICE POINTS

"AA

THROTTLE BODY GASKET

<PAJERO io>

<Up to 2000 model>

Bolt

Intake

manifold

stay

Cylinder block

<From 2001 model>

Bolt

Intake manifold

Intake manifold

"BA

INTAKE MANIFOLD STAY INSTALLATION

(1) Tighten the four bolts at the top and bottom of the stay

handtight.

(2) Check that the stay seating surface is in close contact

with the bosses on the intake manifold and the cylinder

block.

(3) Tighten the four bolts to the specified torque.

Cylinder

block

Bolt

Intake manifold

stay

Bolt

E

July 2000Mitsubishi Motors Corporation Added

PWEE9502-H

Page 58

www.mivec.co.nz

4G9 ENGINE (E–W) – Intake and Exhaust Manifold

6. INTAKE AND EXHAUST MANIFOLD

REMOVAL AND INSTALLATION <SOHC–CARBURETOR>

20 Nm

11A-6-1

20 Nm

2

3

5

4

9

7

Bolt with head mark “4”

Bolt with head mark “7”

13

14 Nm

29 Nm

6

12 Nm

19 Nm

12

18 Nm

13 Nm

8

31 Nm

1

11

Bolt with head mark “4”

Bolt with head mark “7”

Removal steps

1. Engine hanger

"BA 2. Intake manifold stay

3. Intake manifold

4. Intake manifold gasket

5. Oil level gauge

6. Oil level gauge guide

12 Nm

19 Nm

10

13 Nm

19 Nm

7. O-ring

8. Exhaust manifold cover

9. Engine hanger

"AA 10. Exhaust manifold bracket A

"AA 11. Exhaust manifold bracket B

12. Exhaust manifold

13. Exhaust manifold gasket

E

E

Nov. 1996Mitsubishi Motors Corporation

Mar . 2001Mitsubishi Motors Corporation Revised

PWEE9502-B

PWEE9502-I

Revised

Page 59

www.mivec.co.nz

11A-6-2

4G9 ENGINE (E–W) – Intake and Exhaust Manifold

REMOVAL AND INSTALLATION <SOHC–MPI–FRONT WHEEL DRIVE (4G92 and

4G93–Except from 2001 model for Europe)>

20 Nm

20 Nm

31 Nm

Bolt with head mark “4”

Bolt with head mark “7”

3

1

4

2

12 Nm

19 Nm

7

13

5

6

14 Nm

29 Nm

18 Nm

12

Bolt with head mark “4”

Bolt with head mark “7”

Removal steps

1. Engine hanger

2. Intake manifold stay

3. Intake manifold

4. Intake manifold gasket

5. Oil level gauge

6. Oil level gauge guide

11

10

9

19 Nm

12 Nm

19 Nm

7. O-ring

8. Exhaust manifold cover

9. Engine hanger

"AA 10. Exhaust manifold bracket A

"AA 11. Exhaust manifold bracket B

12. Exhaust manifold

13. Exhaust manifold gasket

8

13 Nm

Nov. 1996Mitsubishi Motors Corporation Revised

E

E

Mar . 2001Mitsubishi Motors Corporation Revised

PWEE9502-B

PWEE9502-I

Page 60

www.mivec.co.nz

4G9 ENGINE (E–W) – Intake and Exhaust Manifold

11A-6-2a

REMOVAL AND INSTALLATION <SOHC–MPI–FRONT WHEEL DRIVE (4G92 and

4G93–From 2001 model for Europe)>

20 Nm

20 Nm

31 Nm

3

19 Nm

1

4

7

14 Nm

13

2

30 Nm

12

5

6

8

44 Nm

18 Nm

13 Nm

10

Removal steps

1. Engine hanger

2. Intake manifold stay

3. Intake manifold

4. Intake manifold gasket

5. Oil level gauge

6. Oil level gauge guide

7. O-ring

14

9

19 Nm

11

19 Nm

13 Nm

35 Nm

8. Oxygen sensor

9. Engine hanger

10. Exhaust manifold cover

11. Exhaust manifold bracket B

12. Exhaust manifold

13. Exhaust manifold gasket

14. Exhaust manifold bracket A

E

E

Nov. 1996Mitsubishi Motors Corporation

Mar . 2001Mitsubishi Motors Corporation Revised

PWEE9502-B

PWEE9502-I

Revised

Page 61

www.mivec.co.nz

11A-6-2b

4G9 ENGINE (E–W) – Intake and Exhaust Manifold

REMOVAL AND INSTALLATION <SOHC–MPI–FRONT WHEEL DRIVE (4G94)>

20 Nm

2

20 Nm

31 Nm

3

4

5

6

14 Nm

12

1

11

29 Nm

18 Nm

10

9

7

8

19 Nm

13 Nm

19 Nm

Removal steps

1. Intake manifold stay

2. Intake manifold

3. Intake manifold gasket

4. Oil level gauge

5. Oil level gauge guide

6. O-ring

Nov. 1996Mitsubishi Motors Corporation Revised

E

E

Mar . 2001Mitsubishi Motors Corporation Revised

PWEE9502-B

PWEE9502-I

"AA 9. Exhaust manifold bracket A

"AA 10. Exhaust manifold bracket B

7. Exhaust manifold cover

8. Engine hanger

11. Exhaust manifold

12. Exhaust manifold gasket

Page 62

www.mivec.co.nz

4G9 ENGINE (E–W) – Intake and Exhaust Manifold

11A-6-2c

REMOVAL AND INSTALLATION

<SOHC–MPI – REAR WHEEL DRIVE (4G93 – Except from 2002 model for

Europe)>

6

4

19 Nm

31 Nm

20 Nm

8

13 Nm

7

12

13 Nm

5

11

9

18 Nm

1

10

35 Nm

29 Nm

2

14 Nm

3

Removal steps

1. Oil level gauge

2. Oil level gauge guide

3. O-ring

4. Engine hanger

5. Intake manifold stay

6. Intake manifold

E

E

Nov. 1996Mitsubishi Motors Corporation

Jun. 2002Mitsubishi Motors Corporation Revised

PWEE9502-B

PWEE9502-K

"AA 10. Exhaust manifold bracket

7. Intake manifold gasket

8. Exhaust manifold cover

9. Engine hanger

11. Exhaust manifold

12. Exhaust manifold gasket

Revised

Page 63

www.mivec.co.nz

11A-6-2d

4G9 ENGINE (E–W) – Intake and Exhaust Manifold

REMOVAL AND INSTALLATION

<SOHC–MPI – REAR WHEEL DRIVE (4G93 – from 2002 model for Europe)>

20 Nm

8

13 Nm

7

6

4

5

12

11

13 Nm

9

19 Nm

18 Nm

35 Nm

1

31 Nm

Removal steps

1. Oil level gauge

2. Oil level gauge guide

3. O-ring

4. Engine hanger

5. Intake manifold stay

6. Intake manifold

1

29 Nm

10

2

14 Nm

3

7. Intake manifold gasket

8. Exhaust manifold cover

9. Engine hanger

"AA 10. Exhaust manifold bracket

11. Exhaust manifold

12. Exhaust manifold gasket

E

E

Nov. 1996Mitsubishi Motors Corporation

Jun. 2002Mitsubishi Motors Corporation Revised

PWEE9502-B

PWEE9502-K

Revised

Page 64

www.mivec.co.nz

4G9 ENGINE (E–W) – Intake and Exhaust Manifold

11A-6-2e

REMOVAL AND INSTALLATION <SOHC–MPI – REAR WHEEL DRIVE (4G94)>

6

4

19 Nm

31 Nm

8

20 Nm

13 Nm

7

13 Nm

12

5

11

9

18 Nm

1

29 Nm

10

Removal steps

1. Oil level gauge

2. Oil level gauge guide

3. O-ring

4. Engine hanger

5. Intake manifold stay

6. Intake manifold

98 Nm

2

14 Nm

3

7. Intake manifold gasket

8. Exhaust manifold cover

9. Engine hanger

"AA 10. Exhaust manifold bracket

11. Exhaust manifold

12. Exhaust manifold gasket

E

E

Nov. 1996Mitsubishi Motors Corporation

Jun. 2002Mitsubishi Motors Corporation Added

PWEE9502-B

PWEE9502-K

Revised

Page 65

www.mivec.co.nz

11A-6-2f

4G9 ENGINE (E–W) – Intake and Exhaust Manifold

Intentionally blank

E

E

Nov. 1996Mitsubishi Motors Corporation