Page 1

CB-434D

CB-434D XW

Vibratory Asphalt

Compactors

Cat®3054C Diesel Engine

Gross power 62 kW (83 hp)

Drum width

CB-434D

CB-434D XW 1.70 m (67")

Operating weight (w/ROPS)

CB-434D 7500 kg (16,538 lb)

CB-434D XW 7700 kg (16,979 lb)

1.50 m (59")

Page 2

Productivity and Reliability in a Durable Package

The CB-400 D-Series Asphalt Compactors offer performance, versatility and comfort that

maximizes productivity while providing exceptional product quality.

Vibratory System

Pod-style eccentric weights with more

amplitude selections provide peak

compaction performance and minimal

service. High dynamic force helps

achieve density in the fewest number of

passes. The five amplitude vibratory

system provides versatility for working

in a variety of conditions. The optional

dual amplitude, dual frequency system

provides excellent versatility for the

contractor with a flip of the switch from

the operator’s console.

Page 4

CB-434D XW

The CB-434D XW utilizes a 1.7 m

(67") drum for increased lane coverage.

This versatile machine can be equipped

with either the standard five amplitude

vibratory system or the dual amplitude,

dual frequency system.

Page 5

Performance and reliability you can depend on.

Engine

Cat 3054C diesel engine delivers

62 kW (83 hp) and is built for

performance and reliability with

excellent fuel economy. The cooling

system delivers fresh air from above the

engine for clean and efficient operation.

Page 5

Based upon the industry-proven reputation of the

Caterpillar

®

Asphalt Compactors, the CB-400 D-Series

Asphalt Compactors establish innovative standards for

productivity and reliability in the asphalt compaction

industry.

Durable Cat

®

powertrain, field-proven hydraulic

systems and vibratory systems, and the world’s

largest and most dedicated dealer support system

ensures that the CB-400 D-Series Asphalt

Compactors will provide maximum productivity.

2

Page 3

Operator’

The operator’s station features comfort

and visibility. A tilting steering column,

propel lever arm rest, and conveniently

located and grouped control switches

and gauges increase operator

productivity and reduce fatigue.

Heavy-duty isolation mounts provide a

smooth ride. Machines with the

ROPS/FOPS platform incorporate quick

release handrails that can be

individually adjusted to accommodate

multiple operator positions. For FOPS

protection to be ef

must be seated under the canopy.

Page 6

s Station

fective, the operator

ater Spray System

W

The large capacity 800 liter (211 gal)

water tank provides increased working

time and single points to fill and drain.

Caterpillar’s exclusive dual pump spray

system provides the operator with an

efficient, easy access drum watering

system. The triple water filtration

reduces contaminants, providing a

reliable water spray system. An optional

overnight freeze protection kit is also

available for cool weather protection.

Page 7

viceability

Ser

The one-piece fiberglass hood opens

upward and rearward to allow access to

the engine and daily maintenance

points. The daily check points are

accessible from ground level. Ground

level service is also provided on the

water spray system with pumps, filters,

and drain valves grouped together and

centrally located.

The rear-mounted cooling system with

fresh air intake reduces the need for

cleaning.

is 500 hours. Vibratory bearing lube

service interval of 3 years/3000 hours

keeps maintenance to a minimum and

maximizes production. The articulation

hitch area features sealed-for-life

bearings that reduce the need for

maintenance.

Page 8

The engine oil change interval

Comfort and serviceability you deserve.

The operator’s station provides a comfortable and

user friendly environment that promotes productive

operation. Simplified service access and extended

service intervals minimize maintenance time and

increase overall machine production.

3

Page 4

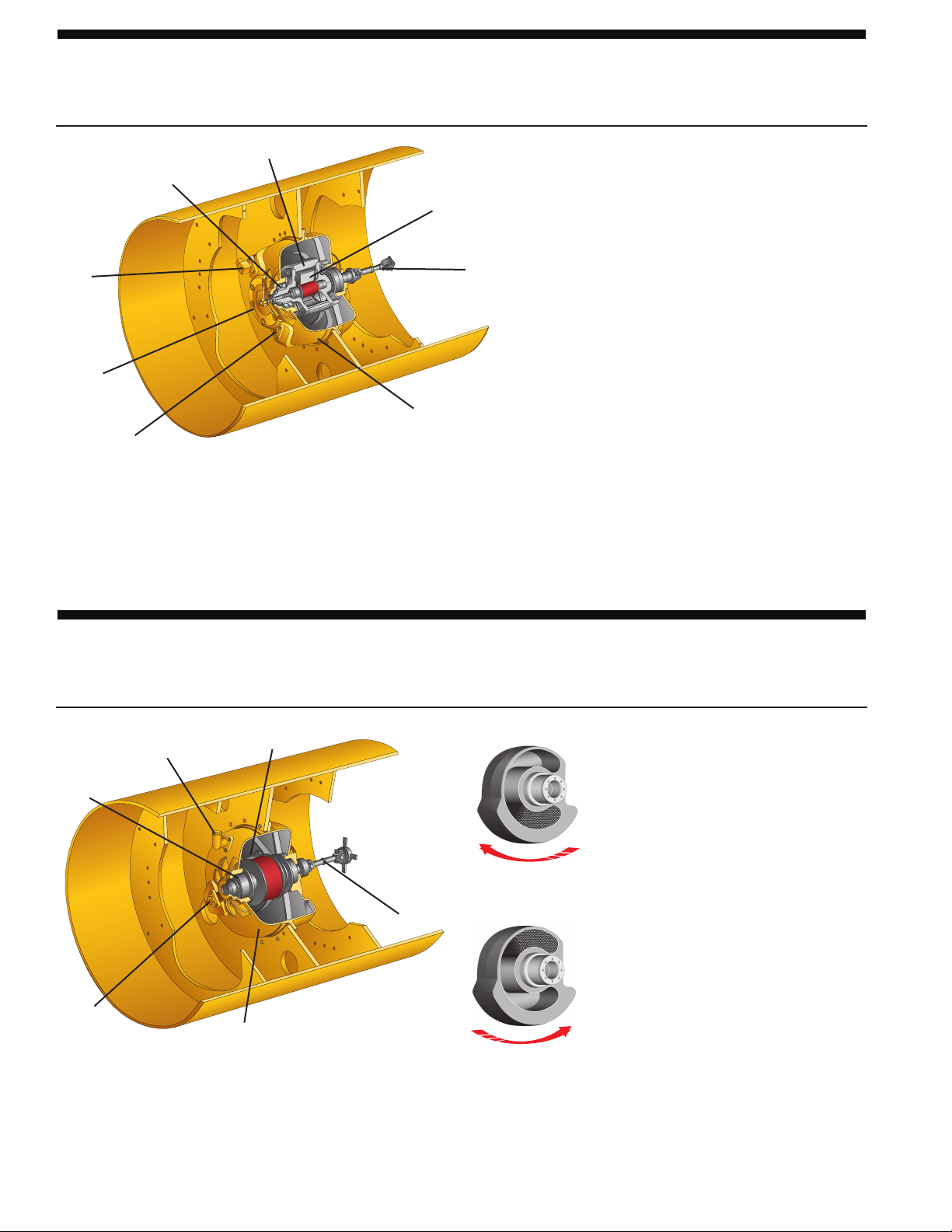

Five Amplitude Vibratory System

The pod-style vibratory system delivers optimum compactive force while offering

serviceability advantages.

t

r

e

w

q

1 Oil Level Sight Gauge

2 Amplitude Selection Wheel

3 Oil Drain

4 Eccentric Weight Shaft Bearings

y

u

i

5 Fixed Eccentric Weight

6 5-Position Counterweight

7 Weight Drive Shaft to Motor

8 Eccentric Weight Housing

Five Amplitude Selections

The five amplitudes with a single

frequency of 53 Hz (3,200 vpm)

provide efficient operation on thick or

thin lift applications.

Automatic Corresponding Rotation

Eccentric weight rotation automatically

matches drum rotation providing good

mat quality.

Automatic Vibration Control

The vibratory system automatically

starts when the propel lever is moved

from neutral and stops when positioned

in neutral. A manual vibratory control is

also provided.

3 Year/3000 Hour Service Interval

Moving parts are separated from

lubricating oil keeping oil clean to

ensure long bearing life. Bearing oil has

a 3 year/3000 hour service interval.

Dual Amplitude, Dual Frequency Vibratory System (optional)

The dual amplitude, dual frequency vibratory system provides high amplitude or high

frequency that is controlled from the operator’s station.

Dual Amplitude Selection

Amplitude selection is determined by

the position of the steel shot inside the

hollow eccentric weight. The rotational

direction of the weight shaft determines

the amplitude level.

Dual Frequencies

Two frequencies of 53 Hz (3,200 vpm)

and 70 Hz (4,200 vpm) provide

customers with high amplitude and high

frequency in one machine.

Vibratory Control Switch

The vibratory control switch located on

the console allows the operator to

change vibratory settings on-the-run.

Automatic Vibration Control

The vibratory system automatically

starts when the propel lever is moved

from neutral and stops when positioned

in neutral.

q

y

t

r

1 Oil Drain

eight

2 Exclusive Eccentric

3 Weight Drive Shaft to Motor

4

W

w

High Amplitude

e

eight Housing

4 Eccentric

5 Oil Level Sight Gauge

6 Eccentric Weight Shaft Bearings

W

Low Amplitude

Page 5

100

90

80

70

60

50

40

30

20

10

0

Time

Power Draw Comparison

%

Max

Power

With POR Valve – CB-434D

Without POR Valve – Competition

Power Saved With POR Valve

CB-434D XW

The CB-434D XW offers a wider drum for increased production and versatility.

Wider Drum Width

The CB-434D XW

width of 1.7 m (67") providing

increased lane coverage resulting in

fewer passes.

Operating Weight

The operating weight of the

CB-434D XW is 7700 kg (16,979 lb)

providing a centrifugal force of 78 kN

(17,550 lb).

Vibratory Systems

The CB-434D XW can be equipped

with the five amplitude or the

dual amplitude, dual frequency

vibratory systems. Both systems offer

effective operation on thick or thin lift

applications.

incorporates a drum

Caterpillar®3054C Diesel Engine

High-tech four-cylinder engine provides outstanding performance and reliability.

Cat®3054C Engine

The 3054C engine produces 62 kW

(83 hp) of power at 2,200 rpm providing

fuel efficiency.

Clean Operation

The 3054C meets U.S. EPA Tier 2 and

E.U. Stage II engine emissions

regulations.

Balanced Power

The Pressure Override (POR) valve

balances power demand in order to

provide responsiveness.

5

Page 6

Operator’s Station

Ergonomically designed for maximum operator productivity and unmatched comfort.

Comfortable Operating Environment

The console and instrumentation move

with the operator, staying in the same

relative position to the operator.

Multi-Position Operator’s Station

The operating station has nine rotating

and seven sliding positions, maximizing

comfort.

Multi-Function Propel Handle

The multi-function propel handle

simplifies operation with the following

controls: propel speed, vibe on/off,

water spray on/off, horn and optional

drum offset.

Steering Console

The entire console tilts for simple

entrance and exit. A lockable vandal

cover is provided for the console.

For FOPS protection to be effective, the operator must be seated under the canopy.

Automatic Speed

Control Dial

Comfortable and Durable Seat

The seat has adjustable fore/aft

positioning, suspension stiffness, and

flip-up arm rests with a 76 mm (3")

wide retractable seat belt.

Isolated Operator’s Station

The operator’s station utilizes four,

heavy-duty rubber mounts to reduce

machine vibration to the operator.

Automatic Speed Contr

speed control dial located on the

A

operator’s console simplifies operation

by allowing the operator to preset the

machine speed or impact spacing.

The speed control dial allows the

operator to push the propel lever to the

forward or reverse positions while

repeating the desired speed or impact

spacing.

ol

6

Page 7

Water Spray System

Corrosion resistant system and long life components for reliable operation.

High-Capacity Water Tank

The single, high-capacity

water tank is enclosed within the

machine frame providing extended

operation.

Two Pump System

An auto pump control setting selects

water from one pump while traveling

forward and water from the other pump

while traveling rearward. The system

provides uniform pump usage

promoting a productive life for both

pumps. A manual override control is

also provided.

Triple Water Filtration

Water filtration reduces machine

downtime caused by system clogs. A

mesh strainer is located in the water fill

port. The water pump and spray nozzles,

include screen filters that provide simple

access and cleaning.

1 Single Fill Port

q

w

e

4 Water Filter

, polyethylene

2 Spray Nozzle with Filter

3 Water Distribution Mat

t

5 Water Pumps

r

Constant or Intermittent Spray

Capability

The water spray system provides

constant or intermittent spray settings.

The intermittent spray setting provides

longer operation between refills. The

intermittent spray is infinitely variable

allowing fine-tuning for any condition.

On/Off Spray Contr

The spray control is located on the

propel lever providing simple operation.

Quick-Release Spray Bars Covers

Quick-release spray bar covers shield

the spray bars and nozzles from wind

and sun, allowing the spray nozzles to

provide consistent coverage across the

drum surface.

Freeze Protection Kit (Optional)

The freeze protection kit includes an

in-line antifreeze bottle that allows the

operator to pump antifreeze into the

system.

ol

7

Page 8

Reliability and Serviceability

The CB-400 D-Series Asphalt Compactors provide exceptional reliability and serviceability

that you’ve come to expect from Caterpillar.

Vertical-Lift Hood Arrangement

The vertical-lift hood allows routine

service when parked close to other

machines and structures, providing easy

ground level access to routine

maintenance points.

Easy Access and Removal

The water filters and spray nozzles are

easily removed by hand without the

need for special tools.

8

Sealed Hitch Design

The sealed hitch design simplifies

overall machine maintenance.

Product Link Ready

The Product Link System ensures

maximum uptime and minimum repair

costs by simplifying tracking of

equipment fleets. The system provides

automatic machine location and hour

updates.

Quick-Connect Hydraulic Test Ports

Quick-connect sampling ports simplify

system diagnosis.

Oil-bath Lubrication

Oil-bath lubrication reduces routine

maintenance of eccentric weights to

3 year/3000 hour intervals.

Page 9

Engine

The Caterpillar®3054C engine is a four

cylinder diesel engine. The engine

meets U.S. EPA Tier 2 and E.U. Stage

II engine emission regulations.

Engine Cat®3054C

Gross Power kW hp

SAE J1995 62 83

Net Power kW hp

ISO 9249 59 78

EEC 80/1269 59 78

SAE J1349 58 78

Specifications

Bore 105 mm 4.12"

Stroke 127 mm 5.0"

• The power ratings apply at a rated

speed of 2200 RPM when tested

under the reference conditions for the

specific standard.

• The net power advertised is the power

available at the flywheel when the

engine is equipped with alternator, air

cleaner, muffler and fan at minimum

speed.

• 12-volt electrical starting system with

80-amp alternator and one 12-volt,

950 cold cranking amp,

maintenance-free battery.

Transmission

Variable displacement piston pump

supplies pressure flow to low-speed

high torque hydraulic motors driving

the front and rear drums. A single

propel lever located on the control

console provides smooth hydrostatic

control of the machine’s infinitely

variable speeds in both forward and

reverse.

positioned in reverse, a backup alarm

emits an audible alarm.

Speeds (forward and reverse):

W

When the propel lever is

ork/T

ravel

0-11.6 km/hr 0-7 mph

Brakes

Service Brake Features

• Closed-loop hydrostatic drive system

provides dynamic braking during

machine operation.

Secondary Brake Features

• Spring-applied/hydraulically released

brake on front and rear drums. Actuated

by switch on console or automatically

when pressure is lost in brake circuit or

when the engine is shut off. A manual

release tool is included.

Steering

Priority-demand hydraulic power-assist

steering system provides smooth, firm

machine handling. The automotive-type

steering wheel and column are integral

with the operator’s swivel platform and

allow steering from multiple positions.

Minimum turning radius:

Inside drum edge

CB-434D 3.5 m 11' 6"

CB-434D XW 3.4 m 11' 2"

Outside drum edge

CB-434D 5.0 m 16' 5"

CB-434D XW 5.1 m 16' 9"

Steering angles 40°

Frame

Fabricated from heavy gauge steel plate

and rolled sections. The frame is joined

at the articulation pivot, 50% of the

machine is rear of the articulation pivot

A

steering

°

The

and 50% is in front of the pivot.

two sections are joined by two

hardened steel pins that are supported

by heavy-duty roller bearings.

40

vertical pin provides a

angle and the frame/yoke provides ±4°

oscillation for a smooth ride, uniform

drum loading and no maintenance

interval.

±

Instrumentation

The instrument panel is located in front

of the operator and contains the

speedometer, vibe tachometer, vibration

mode selector, light switches, hour

meter, alternator indicator light, fuel

gauge, water tank gauge and warning

lights. An audible alarm sounds and a

warning light illuminates if abnormal

conditions occur in engine oil pressure,

engine coolant temperature or charge

pressure. Operational lights are also

positioned on the instrument panel.

They illuminate if the vibratory system,

drum spray system, neutral or parking

brake are engaged.

Machine controls are also located to the

operator’s right on the control console.

These controls include the start switch

with cold-start aid, electric throttle,

propel lever, speed selector switch,

automatic speed control (ASC) dial,

drum spray switch, vibration switch,

horn and secondary brake switch.

Electrical system fuses and relays are

located on the side of the control

console.

Drum Spray System

The entire drum spray system is

corrosion resistant and includes a large

water tank with a single fill port and

drain valve.

The system consists of two diaphragm

pumps driven by electric motors. Only

one pump operates at a time, supplying

pressurized water to both sets of drum

spray bars. The pump operation is

s station.

controlled from operator

system provides complete back-up

capability controlled from the

s station.

operator

Spray can be set on continuous for

maximum wetting action or intermittent

for maximum duration between refills.

The “Auto” selection pulls water from

one pump traveling forward, from the

other pump while traveling backward

and automatically shuts off when the

propel lever is in the neutral position.

The spray nozzles on the drum can be

easily removed for replacement or

cleaning without the need for tools.

’

’

The

CB-434D and CB-434D XW specifications

9

Page 10

Optional Equipment

Service Refill Capacities

• ROPS Cab

• Open Platform

• Dual Amplitude, Dual Frequency Vibratory System

• Offset Hitch

• Water Distribution Mats

• Cocoa Mats

• Water Spray Freeze Protection Kit

• Drum Covers

• Roading Lights

• High Intensity Discharge Lights

• Warning Beacon

• External Mirrors

• Stainless Steel Water Spray Nozzles

Fuel Tank 132 35

Cooling System 18 4.75

Engine Oil (w/filter)

Vibratory Bearing Lubrication 20 5.3

Hydraulic Tank* 50 13.2

Water (Spray) Tank 800 211

Figures describe tank at “full” level. Actual tank capacity is higher. Hydraulic/Charge

*

ed by a 10 micron charge oil filter.

oil is filter

Five Amplitude Vibratory System

Frequency: 53 Hz (3,200 vpm)

Nominal Amplitude CB-434D CB-434D XW

High 0.68 mm 0.027" 0.60 mm 0.024"

Medium-high 0.58 mm 0.023" 0.51 mm 0.020"

Medium 0.47 mm 0.019" 0.42 mm 0.017"

Medium-low 0.36 mm 0.014" 0.32 mm 0.013"

Low 0.25 mm 0.010" 0.22 mm 0.009"

Liters Gallons

9 2.4

Centrifugal Force Per Drum

High 78 kN 17,550 lb 78 kN 17,550 lb

Medium-high 66 kN 14,850 lb 66 kN 14,850 lb

Medium 54 kN 12,150 lb 54 kN 12,150 lb

Medium-low 42 kN 9,450 lb 42 kN 9,450 lb

Low 29 kN 6,525 lb 29 kN 6,525 lb

Dual Amplitude, Dual Frequency Vibratory System

Frequency: 53 Hz (3,200 vpm)

CB-434D

Nominal Amplitude 0.69 mm 0.027" 0.61 mm 0.024"

Centrifugal Force

77 kN

17,310 lb

Frequency: 70 Hz (4,200 vpm)

CB-434D

Nominal

Centrifugal Force

Amplitude

0.25 mm

48 kN

0.010"

10,800 lb

CB-434D XW

77 kN 17,310 lb

CB-434D XW

0.22 mm

48 kN

0.009"

10,800 lb

10

CB-434D and CB-434D XW specifications

Page 11

Dimensions and Weights

CB-434D

H

F

A

I

E

D

G

C

B

Dimensions CB-434D CB-434D XW

Length (A) 4.20 m 13' 9" 4.20 m 13' 9"

Body width (B) 1.67 m 5' 6" 1.87 m 6' 1"

Drum width (C) 1.50 m 59" 1.7 m 67"

Drum shell thickness 18 mm 0.71" 18 mm 0.71"

Drum diameter 1.3 m 4' 3" 1.3 m 4' 3"

Height at steering wheel (D) 2.26 m 7' 5" 2.26 m 7' 5"

Height at ROPS/FOPS (E) 3.01 m 9' 11" 3.01 m 9' 11"

Wheelbase (F) 3.10 m 10' 2" 3.10 m 10' 2"

Curb clearance (G) 720 mm 28" 720 mm 28"

Ground clearance (H) 255 mm 10" 255 mm 10"

Width ROPS/FOPS and Canopy (I) 1.94 m 6' 4" 1.94 m 6' 4"

Weights

Operating Weight

with ROPS 7500 kg 16,535 lb 7700 kg 16,975 lb

without ROPS

with Cab 7380 kg 16,270 lb 7580 kg 16,710 lb

Shipping Weight

with ROPS 6620 kg 14,595 lb 6820 kg 15,035 lb

without ROPS

with Cab 6500 kg 14,330 lb 6700 kg 14,770 lb

Static Linear Load (at drum) 25 kg/cm 138 lb/in 23 kg/cm 127 lb/in

* Standard operating weights include lubricants, coolant, 75 kg (165 lb) operator, 1/2 full fuel tank, full hydraulic system and

1/2 full water tank.

7150 kg

6270 kg

15,765 lb 7350 kg 16,204 lb

13,823 lb

6470 kg

14,265 lb

CB-434D and CB-434D XW specifications

11

Page 12

Caterpillar offers a comprehensive line of vibratory asphalt compactors.

Contact your local Caterpillar dealer to learn more about the complete line of Caterpillar Paving Products.

CB-634D

Operating Weight (with ROPS) 12 800 kg 28,160 lb

Drum Width 2.13 m 84"

Frequency 44 Hz 2,640 vpm

Centrifugal Force

Maximum 159 kN 35,745 lb

Minimum 58 kN 13,039 lb

Gross Power 108 kW 145 hp

CB-564D

Operating Weight (with ROPS) 12 600 kg 27,783 lb

Drum Width 2.13 m 84"

Frequency 42/63 Hz 2,520/3,800 vpm

Centrifugal Force

Maximum 112.6 kN 25,208 lb

Minimum 76.7 kN 17,22 lb

Gross Power 97 kW 130 hp

CB-534D XW

11 Ton 11 Ton 12 Ton 12 Ton

QEHQ1232 (7/06)

Replaces QEHQ1025

Operating Weight (with ROPS) 11 300 kg 24,860 lb

Drum Width 2.0 m 79"

Frequency 42/63 Hz 2,520/3,800 vpm

Centrifugal Force

Maximum 112.6 kN 25,208 lb

Minimum 35 kN 7,922 lb

Gross Power 97 kW 130 hp

CB-534D

Operating Weight (with ROPS) 10 380 kg 22,836 lb

idth

W

Drum

Frequency 42/63 Hz 2,520/3,800 vpm

Centrifugal Force

Maximum 112.6 kN 25,208 lb

Minimum 35 kN 7922 lb

Gross Power 97 kW 130 hp

TERPILLAR, their r

, CA

T

CA

identity used her

1.7 m 67"

ed machines in photography may include optional equipment.

Featur

Materials and specifications are subject to change without notice.

espective logos and “Caterpillar Y

e trademarks of Caterpillar and may not be used without permission.

ein, ar

ellow”, as well as corporate and product

© 2006 Caterpillar

All Rights Reserved.

www.cat.com

Loading...

Loading...