Page 1

Operating instructions

Commercial dishwasher

G 7860

To avoid the risk of accidents or

damage to the machine it is

essential to read these operating instructions

before it is installed, commissioned or used

for the first time.

G

M.-Nr. 06 134 790

Page 2

Contents

Description of the machine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Guide to the machine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Warning and Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Caring for the environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Before using for the first time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Opening and closing the door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Water softener . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Setting the water softener . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Filling the salt reservoir . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Salt indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Adding rinsing agent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Setting the dosage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Adding cleaning agent. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Loading the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Loading the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Adjusting the top basket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Items not suitable for dishwashers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Selecting a programme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Programme chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Switching on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Starting a programme. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Changing a programme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Selecting an additional function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Programme sequence display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Switching off. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

To cancel a programme. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Programming special functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Cleaning and care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Correcting minor faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

After sales service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Electrical connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Plumbing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

2

Page 3

Description of the machine

This Miele machine is a professional

washer disinfector with a freshwater

system, very short batch times and

high cleaning performance.

This equipment may only be

installed in mobile installations such

as ships, oil rigs etc. if a risk

assessment of the installation has

been carried out by a suitably

qualified engineer.

This machine is equipped with a water

softener (WE), a steam condenser

(DHK) and an electro-thermal door lock

(ET) as standard.

3

Page 4

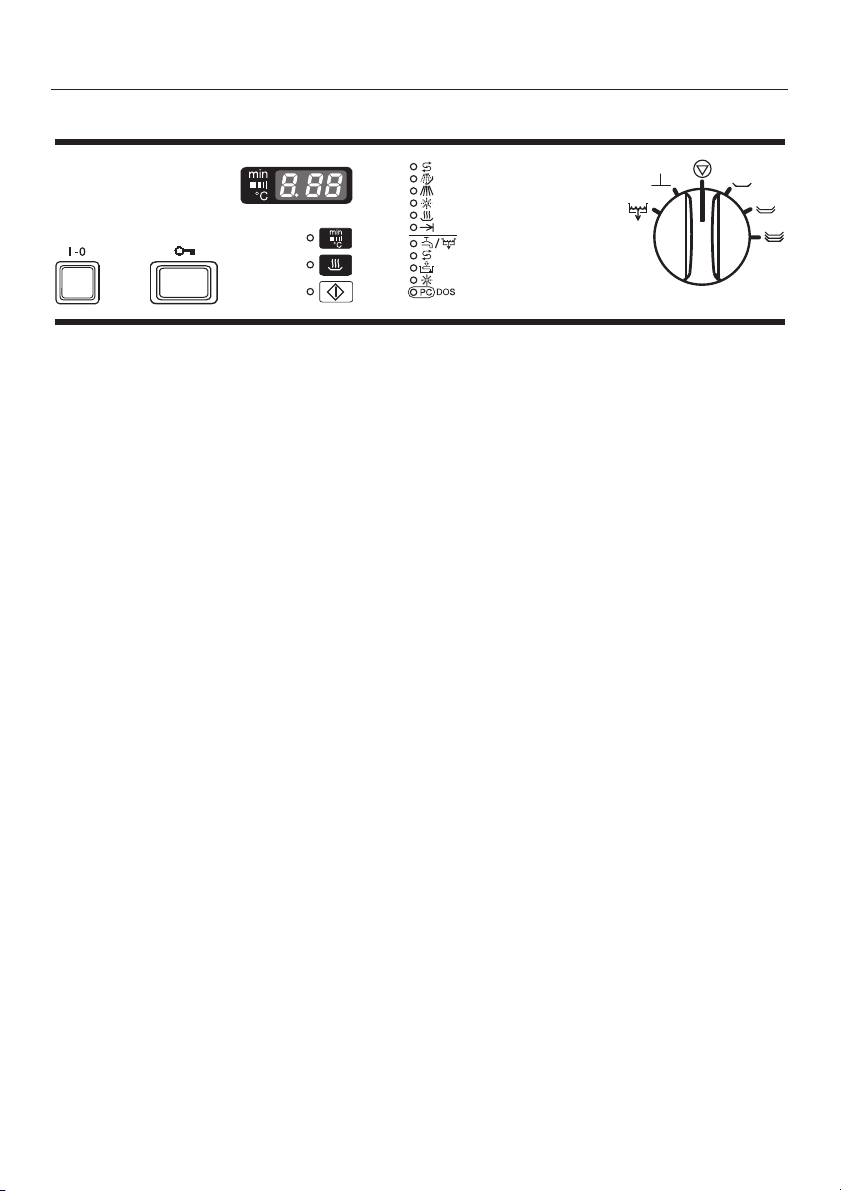

Guide to the machine

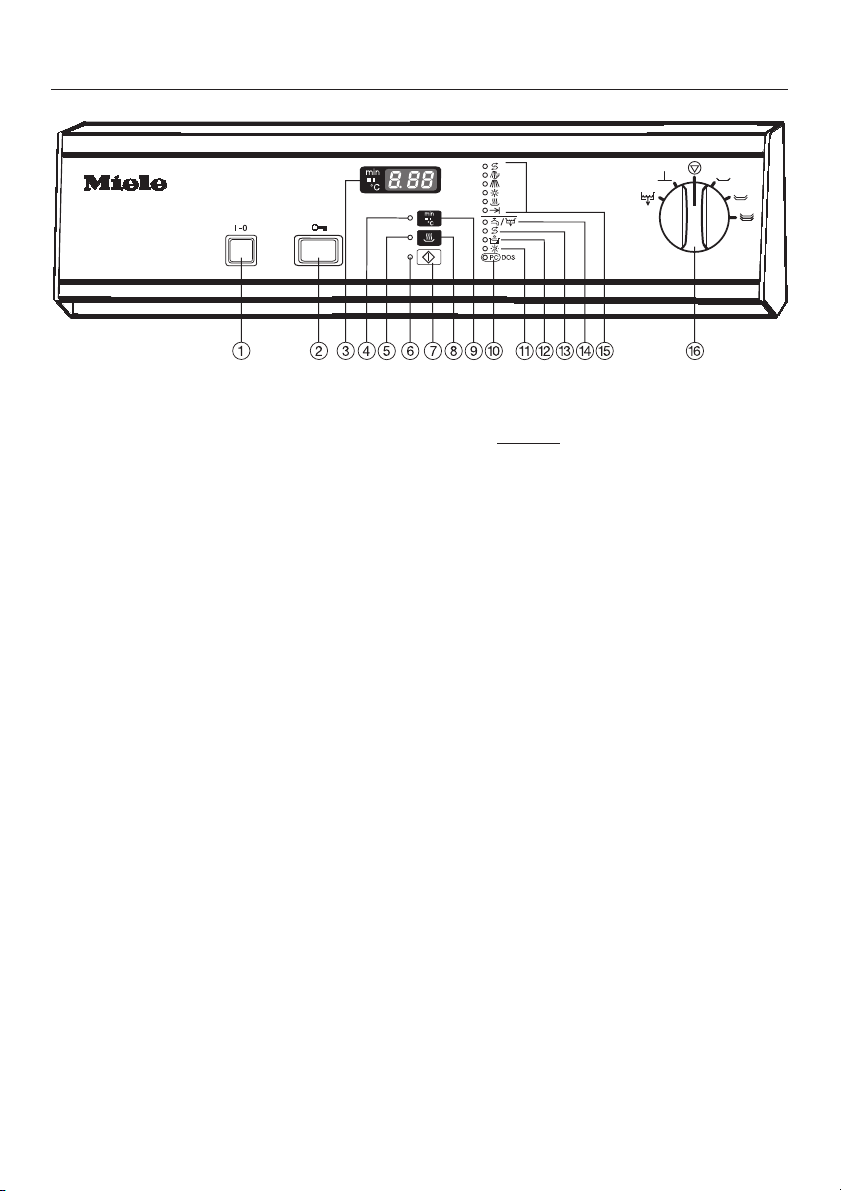

a On/Off button (I-0)

b Door release

c Display

d Delay start indicator light

e Drying indicator light

f Programme start indicator light

g Start button

h Drying button

i Button to toggle between the actual

temperature, elapsed time and active

washing block displays

j Add (liquid)

indicator light *

Optical interface for

service technician

k Add rinsing agent indicator

light

l Add neutralising agent

indicator light

(not used on this machine)

m Add salt indicator light

n Water inlet / Drain

indicator light

o Programme sequence indicators

p Programme selector

* only applies to machine fitted with

optional external DOS Module

cleaning agent

4

Page 5

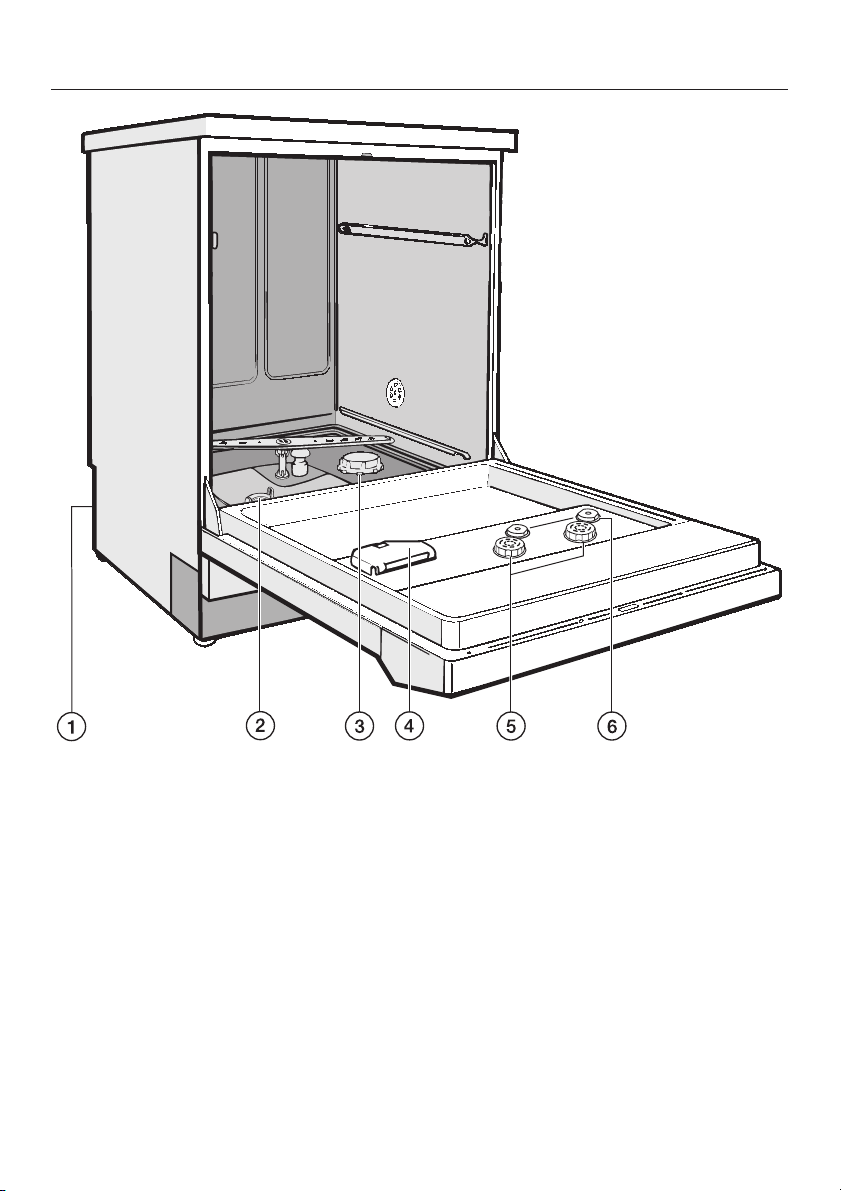

Guide to the machine

a Connections for optional DOS

module dispenser pump for

liquid cleaning agent

- at the back of the machine -

b Filter combination

c Salt reservoir

(for the water softener)

d Dispenser for powder cleaning agent

e Dual rinsing agent reservoir

(with dosage selector)

f Level indicators

5

Page 6

Warning and Safety instructions

Please pay attention to the following

This machine complies with all

relevant local and national safety

requirements. Incorrect use can lead

to personal injury and damage to

property.

Read the operating instructions

carefully before starting to use this

machine. This way you will avoid the

risk of accidents and damage to the

machine.

Keep these instructions in a safe

place for reference, and pass them

on to any future user.

Correct use

This machine is designed for

commercial use only, as described

in these Operating Instructions.

Alterations to the machine, or using it

for purposes other than those for which

it was designed, are unauthorised and

could cause harm. The manufacturer

cannot be held liable for damage

caused by improper or incorrect use of

the machine.

notes to avoid injury and damage.

by a Miele authorised and trained ser

vice technician or other suitably qualified

and competent approved person.

Repairs and other work by unqualified

persons could be dangerous.

explosion or of freezing conditions.

connected to a correctly installed

earthing system on site. It is imperative

that this basic safety requirement is

tested regularly and, where there is any

doubt, the electrical wiring system on

site should be inspected by a qualified

electrician.

The manufacturer cannot be held liable

for damage or injury caused by the lack

of or inadequacy of an effective

earthing system (e.g. electric shock).

This machine should be

commissioned and then maintained

-

Do not install the machine in an

area where there is any danger of

The electrical safety of this

machine can only be guaranteed if

This equipment may only be

installed in mobile installations

such as ships, oil rigs etc. if a risk

assessment of the installation has been

carried out by a suitably qualified

engineer.

6

A damaged machine is dangerous.

Switch off at the mains immediately

and call the Miele Service Department

or an authorised and trained Miele Ser

vice Dealer or other suitably qualified

and competent approved person.

-

Page 7

Warning and Safety instructions

Personnel operating the machine

should be trained regularly.

Untrained personnel should not be

allowed access to the machine or its

controls.

This machine is not a toy! Do not

allow children to play in or around

it, or to operate it. There is a danger

they could injure themselves, or get into

the machine and lock themselves in.

Take great care when handling

liquid agents and additives. These

may contain irritant or corrosive

ingredients. Do not use organic

solvents as these could cause an

explosion.

Follow all relevant safety procedures

carefully. Wear protective gloves and

goggles. With all chemical agents, the

manufacturer’s safety conditions must

be observed.

Avoid inhalation of powder

cleaners. They can cause burning

in the mouth and throat if swallowed,

and can inhibit breathing.

The water in the machine must not

be used as drinking water.

Do not sit or lean on an open door.

The machine could tip up and be

damaged, or cause an injury.

Be careful when sorting items with

sharp pointed ends and

positioning them in the machine that

you do not hurt yourself or create a

danger for others. Sharp knives etc.

should be placed in the baskets with

the pointed end facing downwards.

When using this machine in the

higher temperature ranges be

especially careful not to scald or burn

yourself when opening the door.

Baskets and inserts must be allowed to

cool down before they are unloaded.

Any water remaining in containers

could still be very hot. Empty them into

the wash cabinet before taking them

out.

Do not touch the heating elements

if you open the door during or

directly after the end of a programme:

you could burn yourself. They remain

hot for some time after the end of the

programme.

Never clean the machine or near

vicinity with a water hose or a high

pressure hose.

Before any maintenance or repair

work is carried out, the machine

must be disconnected from the mains

supply by switching off at the mains

isolator or withdrawing the mains fuse.

The following points should be

observed to assist in maintaining

quality standards, to protect users,

and to avoid damage to the machine

and items being cleaned.

Only use Miele approved cleaning

agents in this machine. Use of

unsuitable cleaning agents could

adversely affect the components of the

machine as well as items being

cleaned.

Foam can have an adverse effect

on the cleaning process. Only use

low-foaming cleaning agents which

have been approved by Miele. Some

types of soiling can also cause foaming

to occur.

7

Page 8

Warning and Safety instructions

Where a chemical additive is

recommended on technical

application grounds (e.g. a cleaning

agent), this does not imply that the

manufacturer of the machine accepts

liability for the effect of the chemical on

the items being cleaned.

Please be aware that changes in

formulation, storage conditions etc.

which may not be publicised by the

chemical manufacturer, can have a

negative effect on the cleaning result.

When using cleaning agents and

special application products, it is

essential that the manufacturer’s

instructions are followed. Only use such

products for the purpose and in the

situation specifed to avoid such

dangers as chemical reactions and

material damage.

The machine is designed for

operation with water and additive

cleaning agents only. Organic solvents

must not be used in this machine, as

there is the danger under certain

circumstances of fire or explosion.

(Although this is not the case with all

organic solvents, other problems could

arise with their use, for example

damage to rubber and synthetic

materials).

In critical applications where very

stringent requirements have to be

met, it is strongly recommended that all

the relevant factors for the process,

such as cleaning agents, water quality

etc., are discussed with the Miele

Application Technology specialists.

If cleaning and rinsing results are

subject to particularly stringent

requirements (e.g. chemical analysis,

specialised industrial processes etc.), a

regular quality control test must be

carried out by the user to ensure that

required standards of cleanliness are

being achieved.

The special inserts should only be

used for their specific application.

Empty any containers or utensils

before arranging them in the

machine.

Do not allow any remains of acids

or solvents, and in particular

hydrochloric acid or chloride solutions,

to get into the wash cabinet. Similarly

avoid any materials with a corrosive

effect.

The presence of solvents exceeding

trace levels should not be present in

soiling (especially those in hazard class

A1).

To avoid any corrosion damage,

ensure that solutions or steam

containing hydrochloric acid do not

come into contact with the steel outer

casing of the machine.

Please follow the advice on

installation in these instructions

and the separate Installation

Instructions.

8

Page 9

Warning and Safety instructions

Using accessories

Only use genuine Miele

accessories with this machine.

Consult Miele on the type and

application of such equipment.

Disposal of your old machine

Before disposing of your old

machine first make it unusable.

Disconnect from the mains, cut off the

cable near the machine and any plug

from the cable.

For environmental and safety reasons

ensure the machine is completely

drained of any residual water and

cleaning agent. (Observe safety

regulations and wear safety goggles

and gloves).

Make the door lock inoperative, so that

children cannot accidentally shut

themselves in. Then make appropriate

arrangements for the safe disposal of

the machine.

The manufacturer cannot be held

liable for damage caused by

non-compliance with these Warning

and Safety instructions.

9

Page 10

Caring for the environment

Disposal of the packing

material

The transport and protective packing

has been selected from materials which

are environmentally friendly for disposal

and can normally be recycled.

Ensure that any plastic wrappings,

bags etc. are disposed of safely and

kept out of the reach of babies and

young children. Danger of suffocation!

Rather than just throwing these

materials away, please ensure that they

are recycled.

Disposal of your old machine

Old machines contain materials which

can be reclaimed or recycled. Please

contact your dealer, your waste

collection centre or scrap merchant

about potential recycling schemes.

Ensure that the machine presents no

danger to children while being stored

for disposal.

See the appropriate section in the

Warning and Safety instructions.

10

Page 11

Before using for the first time please

pay special attention to the following

points.

Detailed information on these points

can be found in the relevant sections of

these Operating Instructions.

Before using for the first time

Load the machine carefully

Arrange the load so that water will

come into contact with all surfaces.

Concealed surfaces will not be

cleaned.

The spray arms must not be blocked by

any items.

Set the water softener unit

The water softener unit must be set for

the water hardness level in your area.

The salt reservoir also has to be filled,

first with water

reactivation salt.

Filling the salt reservoir with

,

cleaning agent by mistake will cause

serious damage to the water

softener. Please check every time

before refilling that the package

contains reactivation salt.

Add rinsing agent

,

Inadvertently filling the reservoir

for rinsing agent with cleaning agent

(including liquid cleaning agents

and washing up liquid) will cause

serious damage to the reservoir.

Only use designated cleaning agents

for special applications.

and then with

Add cleaning agent

Follow the cleaning agent

manufacturer’s recommendations on

dosage.

The amount required will depend on the

type of cleaning agent and the

programme chosen.

Make sure you read the notes on

dosing given in the programme chart.

Cleaning results may vary from brand

to brand. If you are not satisfied with

the results from one brand, try another

quality brand before contacting Miele

for advice.

The filter combination at the base of

the wash cabinet and the spray arms

must be kept clean.

Regular checking and cleaning is

essential.

Do not use cleaning agents formulated

for use in domestic dishwashers.

11

Page 12

Opening and closing the door

Electro-thermal door lock

The machine is equipped with an

electro-thermal door lock.

The door can only be opened when:

the electricity supply to the machine

^

is switched on and:

the On/Off button I-0 is pressed in.

^

To open the door a

Press the door button in as far as it

^

will go, and at the same time, grip the

handle and open the door.

Do not touch the heating

,

elements if you open the door during

or directly after the end of a

programme, you could burn

yourself. The elements remain hot for

some time after the end of the

programme.

To close the door

To cancel a programme

If a programme has to be cancelled in

an emergency, e.g. when articles in the

machine jostle against each other or

the programme has been interrupted

because of a fault, the door will have to

be opened manually:

Turn the programme selector to the

^

f position (the programme is

cancelled after approx. 2 secs.).

Important!

See "To cancel a programme" in the

"Operation" section of this booklet for

details of how to continue from here.

^

Lift the door upwards and push until

it clicks shut. Do not press the

release catch whilst shutting the

door!

After the first intake of water, it is no

longer possible to open the door,

except in the D (PRE-RINSE) and 6

(DRAIN) programmes. The machine

can be opened during drying if this

option has been selected.

The door remains locked until the end

of the programme. It can then be

opened.

12

Page 13

To open the door with the

emergency release

The emergency release should only

be used when the door cannot be

opened normally, e.g. in the event of

a power failure.

Turn the programme selector to f.

^

Press the On/Off button I-0 to switch

^

the machine off.

Opening and closing the door

^

The emergency release cable is

located at the bottom of the machine

behind the service panel. Pull it

downwards to open the door.

13

Page 14

Water softener

The water needs to be softened to

avoid calcium deposits building up on

instruments and utensils and in the

machine itself.

To ensure a steady supply of soft water

the water softener unit must always be:

1. correctly set (programmed) and

2. the salt reservoir must be filled.

(If the water hardness level is below

0.7 mmol/l (4 °d - German scale) the

reservoir does not need to be filled

with reactivation salt.)

The machine is set at the factory for a

water hardness level of 3.4 mmol/l

(19 °d).

If the water supply is harder or softer

than this (including below 0.7 mmol/l

or 4 °d) the factory setting will need

to be changed following the

instructions in "Setting the water

softener". See chart on the next

page for settings.

Your local water authority will advise

you on the water hardness in your area.

For fluctuating levels (e.g. 1.4 - 3.1

mmol/l or 8 - 17 °d) set the water

softener to the highest setting (in this

example to 3.1 mmol/l or 17 °d).

Important

The built-in water softener has settings

from 0.2 - 10.8 mmol/l or 1 °d - 60 °d.

14

Page 15

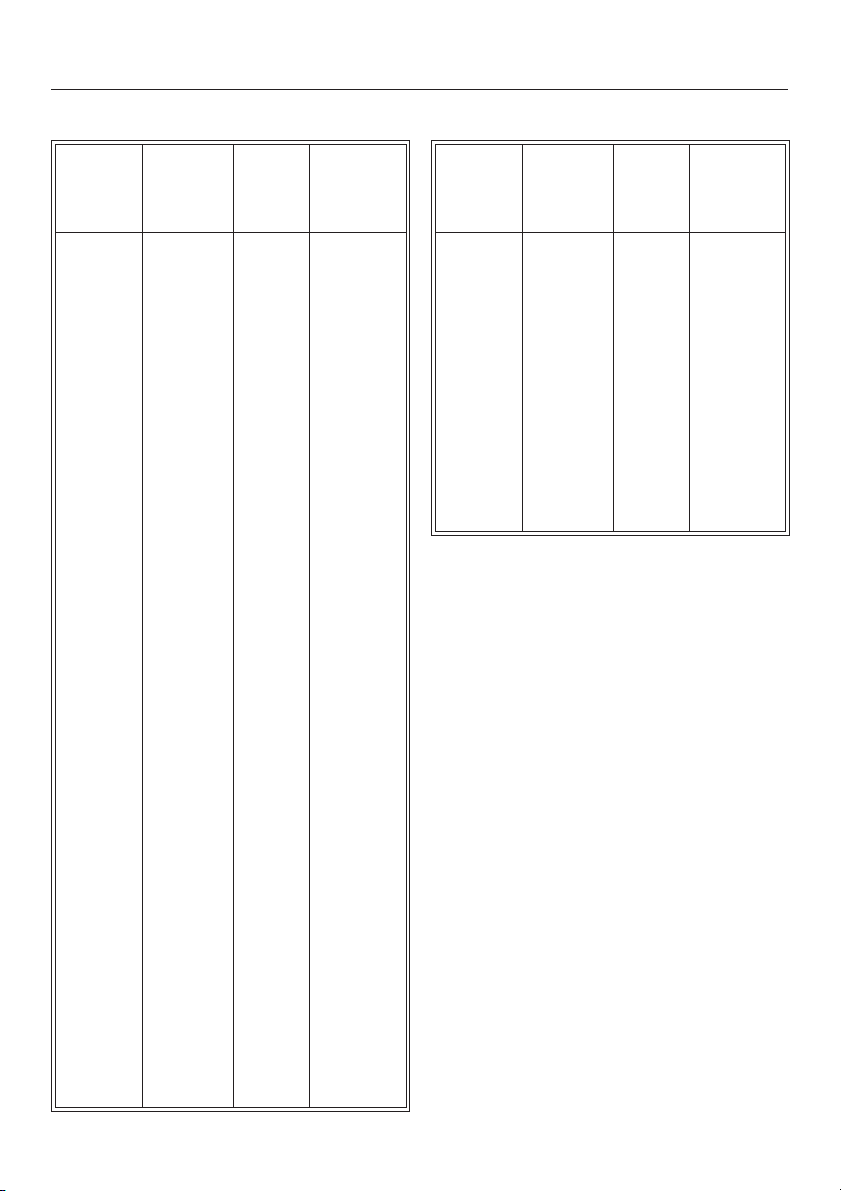

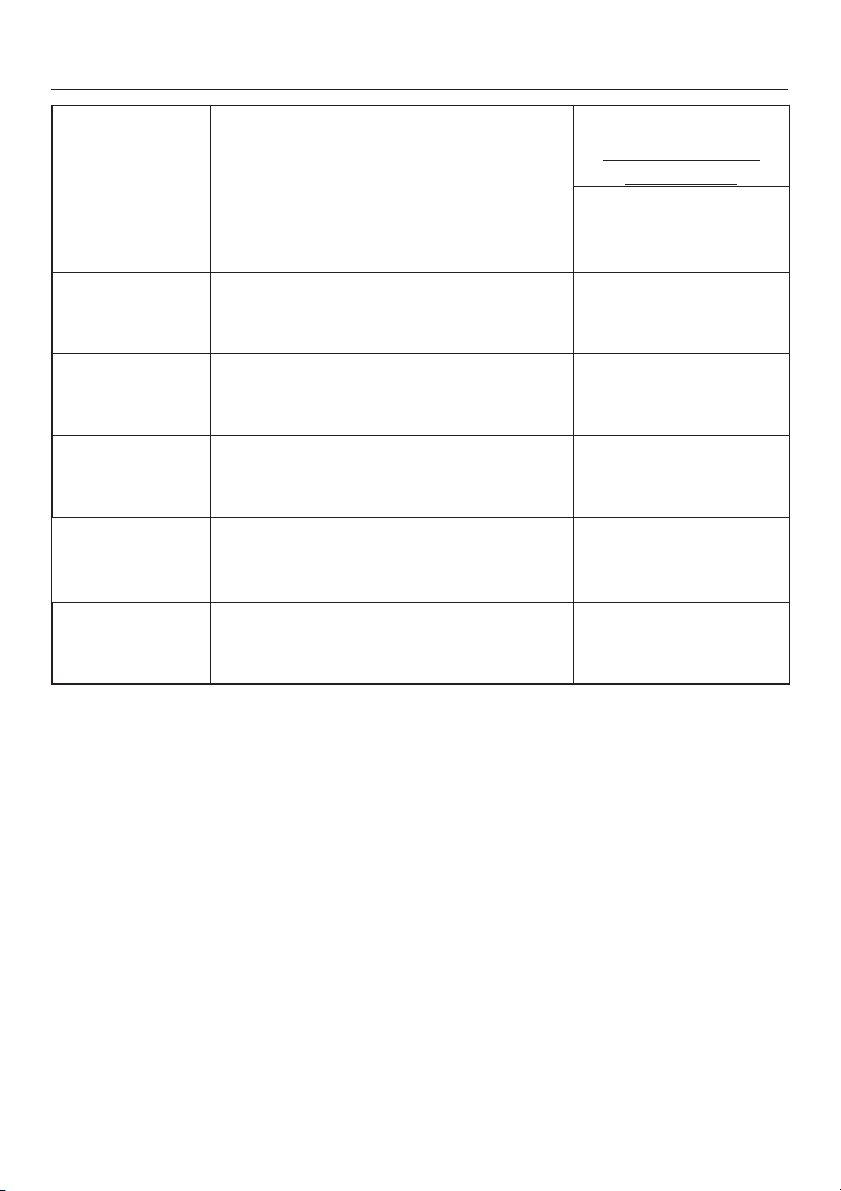

Settings

Water softener

°d

(German

scale)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19 *)

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

mmol/l °f Setting

0.2

0.4

0.5

0.7

0.9

1.1

1.3

1.4

1.6

1.8

2.0

2.2

2.3

2.5

2.7

2.9

3.1

3.2

3.4

3.6

3.8

4.0

4.1

4.3

4.5

4.7

4.9

5.0

5.2

5.4

5.6

5.8

5.9

6.1

6.3

6.5

6.7

6.8

7.0

7.2

7.4

7.6

7.7

7.9

8.1

2

4

5

7

9

11

13

14

16

18

20

22

23

25

27

29

31

32

34

36

38

40

41

43

45

47

49

50

52

54

56

58

59

61

63

65

67

68

70

72

74

76

77

79

81

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

°d

(German

scale)

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

*) factory setting

mmol/l °f Setting

8.3

8.5

8.6

8.8

9.0

9.2

9.4

9.5

9.7

9.9

10.1

10.3

10.4

10.6

10.8

83

85

86

88

90

92

94

95

97

99

101

103

104

106

108

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

15

Page 16

Water softener

Setting the water softener

Switch off the machine.

^

Turn the programme selector to the

^

STOP position f.

Press ß and 6 at the same time,

^

hold them in and, whilst doing so,

switch the machine on with the I-0

button.

The current programme status "P..."

will show in the display.

The indicator light p / 6 will come

on.

Press 0 once, E01 for programming

^

level 1 will appear in the display.

^ Turn the programme selector one

switch position clockwise (1 o’clock

position).

The number 19 appears in the

display (the factory water hardness

setting in °d), (equivalent to 3.4

mmol/l).

^ Press ß as many times as is

necessary, or hold it in until the

required value (hardness level in °d)

appears in the display.

Once the number 60 has been

reached, the counter will begin again

at 0.

For future servicing it is useful to make

a note of your water hardness level.

Enter your water hardness level here:

^

°d (German scale) or

mmol/l

^

Press the 6 button. SP will appear in

the display.

^

Press 6 again. The setting will now

be stored in memory. The display will

go out.

^

The machine is now ready for use.

16

Page 17

Water softener

Filling the salt reservoir

Please only use special coarse grained

reactivation salt

approx. 1-4 mm. Do not use other types

of salt, e.g. table salt, agricultural or

gritting salt. These could contain

components which are insoluble in wa

ter which could result in damage to the

water softener. If in doubt consult your

Miele Professional Department.

The salt reservoir holds approx. 2.5 kg

of salt.

Inadvertently filling the salt

,

reservoir with cleaning agent

damage the water softener.

Before filling the salt reservoir make

sure that you have picked up the

right packet of reactivation salt

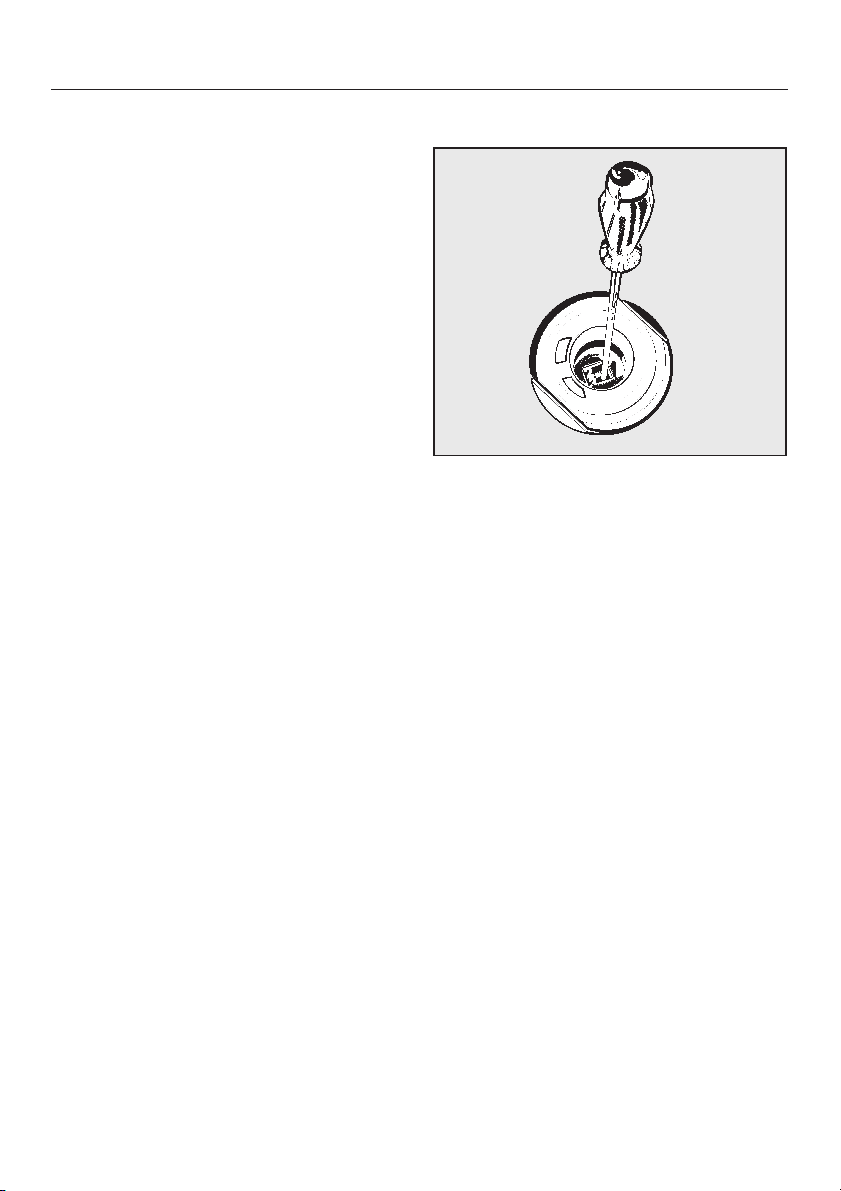

^ Remove the bottom basket from the

machine.

^ Unscrew the salt reservoir cap.

with granules of

will

.

Before filling the salt reservoir with

reactivation salt for the first time, fill it

with approx. 2.5 litres of water.

-

^ Place the funnel provided in place.

^ Fill carefully with salt. As it is filled,

displaced water will run out).

^ Wipe any residual salt off the screw

threads on the socket.

^

Screw the cap on firmly.

^

Immediately after this:

PRE-RINSE programme D to remove

any traces of salt from the cabinet.

Important:

PRE-RINSE programme D the machine

does not start for a few minutes this is

not a fault. The water softener is being

reactivated.

If after starting the

Run the

17

Page 18

Water softener

Salt indicator

When the salt reservoir is empty the k

indicator light b comes on to remind

you to fill the reservoir.

Reactivation takes place automatically

during a programme.

The programme sequence indicator

light k a lights up whilst this is

happening.

18

Page 19

Adding rinsing agent

The duo dispenser incorporated in the

door has a capacity of approximately

2 x 180 ml. for liquid agents.

Rinsing agent is necessary to ensure

water does not cling and leave marks

on items during the drying phase, and

to help items dry faster after they have

been washed.

Rinsing agent is poured into the

storage reservoirs and the amount set

is dispensed automatically.

Inadvertently filling the reservoirs

,

with powder or liquid detergent

always causes serious damage to

the reservoirs.

Open the door fully

^

^ Undo the screw caps.

.

The reservoirs must be filled with

rinsing agent

comes on.

There is also a level indicator for the

reservoirs on the inside of the door (see

illustration on the next page).

when the H indicator light

^

Pour rinsing agent into the reservoirs

until the level indicator is dark (see

arrow in the illustration). Use a funnel

if necessary.

^

Screw the cap back on and mop up

any spilt rinsing agent. This prevents

a build-up of foam occuring during

the next programme.

^

Wait until the H indicator light on the

control panel lights up again before

adding any more rinsing agent.

19

Page 20

Adding rinsing agent

Important:

Both reservoirs must always be filled

with the same liquid agent.

Setting the dosage

The dosage adjuster in both openings

has settings from 1-6 (1-6 ml). It is set

to "2" (4 ml) at the factory.

^ Use a higher setting if there are marks

on the surface of utensils after drying.

^ Use a lower setting if the surface

becomes cloudy and smeary.

20

Page 21

Only use cleaning agents

,

suitable for washer disinfectors. Do

not use detergents formulated for

domestic dishwashers.

Liquid cleaning agents (mildly

alkaline) should be dispensed via a

DOS module (available as an optional

extra - see the Note on the next

page).

If liquid cleaning agent is not being

used, powder cleaning agent

placed in the detergent dispenser

before every programme except with

PRE-RINSE D and DRAIN 6.

must be

Adding cleaning agent

Add powder cleaning agent to the

^

compartment.

Dosage:

batch.

Approx. 10.5 litres of water are used in

the wash programme sequence.

Follow detergent manufacturer’s

instructions if they differ.

Approx. 3 g/l, or 30 g per

^

Press the opening catch on the

dispenser (see arrow) forwards. The

lid will spring open. (The lid is always

open at the end of a programme).

^ Close the dispenser lid.

21

Page 22

Adding cleaning agent

Taking the effect on the environment

into consideration, please bear the

following points in mind when selecting

a cleaning agent:

What level of alkalinity is required to

^

achieve the correct level of cleaning?

Is active chlorine required for

^

disinfection or oxydation (pigment

removal)?

Are tensides required, in particular

^

for dispersal and emulsification?

Some types of soiling may require

different combinations of cleaning

agents and other additives. The Miele

Professional Department will be

pleased to advise you.

Note

As a chargeable optional extra this

machine can also be fitted with a

DOS-Module G 60 dispenser pump for

liquid cleaning agent. This is connected

externally.

See "Programming special functions"

for venting the dispensing system and

setting the dosage.

Maintenance of the dispensing

system

To ensure trouble-free operation the

following regular maintenance should

be carried out by a Miele approved ser

vice technician.

Every 12-18 months:

Replace the dispensing hoses in the

DOS modules.

Take care when handling liquid

,

agents and additives. These may

contain irritant or corrosive

ingredients.

Follow the manufacturer’s safety

instructions and relevant Health and

Safety procedures carefully.

Wear protective gloves and goggles.

-

The optional DOS Module is supplied

with its own installation and connection

instructions.

22

Page 23

Loading the machine

Loading the machine

Preparing the load

Empty all containers before loading

^

into the machine.

Ensure that no acid or solvent

,

residues, especially hydrochloric

acid or chlorides, get into the wash

cabinet.

Please note

Load items so that water will come

^

into contact with all surfaces. This

ensures that they will be properly

cleaned.

^ Do not place items to be cleaned

inside other pieces where they may

be concealed.

^ Hollow vessels such as cups,

glasses, pots etc. should be inverted

and placed in the correct inserts. The

water must be able to access them

unhindered.

^

Deep-sided items should be placed

at an angle so that water can run off

them unhindered.

^

Tall, narrow, hollow items should be

placed in the centre of the baskets to

ensure better water coverage.

^

Small pieces should be placed on

the cup racks in the upper basket.

Do not obscure them by larger items

below. Cups should be on the lower

rack and bowls on the top rack so

that water reaches all items.

The water duct for the spray arm in

^

the middle of the upper basket must

not be obstructed.

The spray arms must not be blocked

^

by items which are too tall or which

hang down in their path. If necessary,

manually rotate the arms to test.

Use the upper basket for:

Small lightweight, delicate items such

^

as cups, saucers, glasses, dessert

bowls etc., as well as for lightweight

thermally stable plastic items.

Use the bottom basket for:

^ Larger and heavier items such as

plates, serving platters, saucepans,

bowls etc. Glasses may only be

cleaned in the bottom basket if it is

fitted with a special glassware insert

or if there is a special bottom basket.

Cutlery

^

Unsorted cutlery should be placed in

the cutlery holders with the handles

facing downwards.

However, to avoid the risk of injury,

sharp kinves etc. should be placed

with the pointed end facing

downwards.

Select baskets and inserts which are

appropriate for the application.

See examples on the following

pages.

23

Page 24

Loading the machine

Loading examples:

O 181 Top basket

for 20 cups, 24 saucers or 12 dessert

plates.

Separate lower baskets

U 880 Bottom basket

with E 884 insert 1/1 for 20 large plates

or 10 trays.

U 880 Bottom basket

with 2 x E 216 half inserts each for

15 plates Ø 240 mm and 2 x E 165

cutlery baskets for mixed cutlery.

24

U 880 Bottom basket

with 2 x E 205 half inserts each for 14

glasses Ø 65 mm.

Page 25

Loading the machine

Adjusting the top basket

The top basket can be adjusted above

and below the middle position by 2.5

cm. It is set in the middle position at the

factory.

Depending on the position of the top

basket, plates of the following diameter

can be accommodated in the baskets:

Example: Top basket O 181

Top basket

position

Top max. 16.5 24 *)

Middle max. 19 24 *)

Bottom max. 21.5 24 *)

*) in insert E 216. For plates up to

Ø 30 cm, use insert E 888.

Top basket

plate Ø in

cm

Bottom

basket

plate Ø in

cm

Items not suitable for

dishwashers

Cutlery with wooden or horn handles.

^

Wooden or plastic chopping boards.

^

Glued items, e.g. old knives with

^

handles which have been glued on.

Hand-made craft items.

^

Copper or tin items.

^

Plastic items which are not heat

^

resistant.

Please note

^ Silver and aluminium items can suffer

some discolouration.

^ Colours painted over a glaze may

fade after a number of washes.

^ Clouding may occur on glasses after

frequent washing.

Our recommendations

To adjust the top basket:

^

Pull out the top basket until a

resistance is felt; lift from the runners

and remove.

^

Unscrew the knurled nuts (roller

bearings) on both sides of the basket

with a suitable spanner and

reposition as required.

^ Wash delicate glassware by hand.

^

When purchasing new glasses,

dishes and cutlery make sure they

are dishwasher safe.

25

Page 26

Selecting a programme

Choose your programme according to

the type of instruments or utensils being

cleaned, and the degree of soiling.

The different programmes and their

uses are described overleaf in the

Programme chart.

26

Page 27

27

Page 28

Programme chart

Programme When to use Powder cleaning agent

(when not using liquid

cleaning agent)

Follow manufacturer’s

instructions

p

SHORT

q

UNIVERSAL

r

INTENSIVE

D

PRE-RINSE

6

DRAIN

Quick programme for lightly soiled crockery. 30 g in the powder

For normally soiled loads. 30 g in the powder

For heavily soiled crockery. Most of the soiling is

removed in an intensive cold-water pre-rinse.

To rinse heavily soiled items, (e.g. for removing

soiling or to prevent soiling drying on to dishes

when a complete programme does not yet need

to be run).

For draining water out of the machine, e.g. when

a programme has been interrupted. Turn the

programme selector to the STOP position f first.

dispenser

dispenser

30 g in the powder

dispenser

28

Page 29

Programme sequence

Pre-wash

1

KW KW WW

Pre-wash2Main wash

1)

KW WW

65°C/1’

DOS 1

KW WW

65°C/1’

DOS 1

65°C/3’

DOS 1

Rinse Rinse Final

rinse

WW

85°C/1’

DOS 2

WW WW

85°C/1’

DOS 2

WW WW

85°C/1’

DOS 2

1)

KW

1)

To change a temperature or temperature holding time see "Programming special functions".

KW = Cold water

WW = Hot water (with temperature/temperature holding time)

DOS 1 = For dispensing cleaning agent

DOS 2 = For dispensing rinsing agent

Drying

(Additional

function)

(X)

(X)

(X)

29

Page 30

Operation

Switching on

Close the door.

^

Open the stopcocks (if turned off).

^

^ Press the I-0 button.

When the programme selector is at the

STOP position f a point lights up in the

display field.

Starting a programme

^ Turn the programme selector

clockwise or anti-clockwise to the

required programme.

The temperature of the first wash of

the programme selected is shown in

the display, except with D

(PRE-RINSE) and 6 (DRAIN).

The indicator light next to the Start

button 6 flashes.

^

Select additional function DRYING

0 if required (see "Selecting an

additional function").

^

Press the Start button 6. The actual

temperature will appear in the

display.

The indicator light next to the Start

button lights up constantly.

Once the programme has started all

other programmes are blocked. If the

programme selector is then turned to

another programme, the values shown

in the display go out. The values can be

seen again if the programme selector is

turned back to the position of the

programme currently in operation.

^ During a programme, the ß button

can be used to toggle between

displaying the actual time, the

elapsed time and the active wash

block*).

*) depending on model:

1 = Pre-wash 1

2 = Pre-wash 2

3 = Main wash 1

4 = Main wash 2

5 = Chemical disinfection

6 = Rinse 1

7 = Rinse 2

8 = Rinse 3

9 = Rinse 4

10 = Final rinse 1

11 = Final rinse 2

12 = Drying TA

13 = Drying

30

Page 31

Operation

Changing a programme

Provided the Start button has not yet

been pressed, a wrongly selected

programme may be changed as

described below (if it has been

pressed, see "Cancelling a

programme"):

Turn the programme selector to the

^

required programme.

Select additional function DRYING

^

0 again if required (see "Selecting

an additional function").

Press the Start button 6.

^

Selecting an additional function

The following additional function can be

selected:

^ 0 DRYING

may be selected as an additional

function as soon as the programme

has been selected (except with D

PRE-RINSE and 6 DRAIN). Drying is

phased over 10 minutes. The total

running time of the programme

lengthens accordingly.

Programme sequence display

The indicator light for the active

programme stage lights up during the

programme.

k Reactivation

I Pre-wash

l Main wash

H Interim rinse / Final rinse

c Drying (additional function)

r End of programme

(Programme parameters have

been reached)

Programme end

The programme has ended when r

lights up constantly in the programme

sequence display and the Start

indicator light 6 has gone out. A "0"

appears in the middle of the display. All

the other indicator lights come on and

go out in sequence. At the same time a

buzzer sounds for a maximum of 30

seconds (standard setting). The buzzer

can be changed (see "Programming

special functions").

Use the ß button to call up the total

running time of a programme or the

actual temperature.

Switching off

^

Press and release the I-0 button.

Note:

As the machine is fitted with an

electro-thermal door lock, the door can

only be opened if the I-0 button is

pressed in (see "Opening and closing

the door").

31

Page 32

Operation

To cancel a programme

Once a programme is running it should

only be cancelled in extreme cases,

e.g. when articles in the machine rattle

or jostle against each other and have to

be rearranged.

Turn the programme selector to the

^

f position (the programme is

cancelled after approx. 2 secs.).

Open the door a

^

Caution. Water and items in the

,

machine may be hot. Danger of

burning or scalding.

^ Arrange the load securely,

(wear protective gloves where

necessary, and observe appropriate

health and safety regulations relating

to infectious diseases).

^ Replenish powder detergent if

necessary.

^ Close the door.

^

Select the DRAIN programme 6,

(wash liquor is pumped away).

^

Select and start the programme

again.

32

Page 33

Programming special functions

For future servicing work, please

document any alterations to the stan

dard factory settings.

Enter any alterations in the field

Value set:_________.

General notes:

Switch positions that have not been

–

allocated a function are indicated in

the middle part of the display by a

bar (

- ).

The programming level is called up

–

via the STOP position f .

– A number of global parameters and

programme specific parameters

can be altered.

Settings and alterations to global

parameters (setting concentration

levels for DOS 1) apply to all

programmes in which the parameter

is found.

Setting and altering programme

specific parameters (Wash/Rinse

temperatures and temperature

holding times: Main wash and Final

rinse) only applies to the

programme in which this parameter

is found.

1. Setting the dosage

concentration and venting the

-

dispensing system

Turn the programme selector to STOP

^

f.

Switch off the machine.

^

Press and hold ß and 6 at the

^

same time, and whilst doing so,

switch the machine on with the I-0

button.

The current programme status "P..."

will appear in the display and the p /

6 indicator light will come on.

^ Press 0 twice, E02 for programming

level 2 will appear in the display.

33

Page 34

Programming special functions

1.1 DOS 1 (liquid cleaning agent) via

the optional DOS-Module G 60 or

C 60.

1.1.1 Setting the dosage

concentration (global parameter):

Set the dosage selector on the DOS

^

module to position 10 (applies to

DOS Module C 60 only).

Set the concentration level according to

the cleaning agent manufacturer’s

recommendations.

Example: If the manufacturer

recommends a concentration level of

0.5% A value of 0.50 should be set.

^ Turn the programme selector to q.

The display will show either the

dosage time in seconds for cleaning

agent dispensed via the dispenser

for powder detergent in the door, or

the dosage concentration for liquid

cleaning agent as a %:

10 = Dosage via the door dispenser

(10 sec) or 0.10 - 1.00 = 0.1% -1%

dosage concentration.

^

Press ß as many times as

necessary or hold it pressed in until

the required value appears.

The dosage time / dosage

concentration is now set.

Value set:

1.1.2 Venting the dispensing system:

a) After setting the dosage

concentration:

Turn the programme selector to the

^

p position. do1 appears in the

display.

Press ß.

^

The dispensing system will be vented

automatically. do1 will appear in the

display when venting is finished.

Having changed a value or all values:

Press 6. SP appears.

^

^ Press 6 again. The change has

been recorded.

b) If venting only

because the dispensing system has

been allowed to empty by mistake)

^ Select programming level 2

(see 1.).

Then proceed as follows:

^

Turn the programme selector to the

p position. do1 appears in the

display.

^

Press ß.

The dispensing system will be vented

automatically. do1 will appear in the

display when venting is finished.

^

Switch the machine off with the I-0

button.

is required (e.g.

34

Every time the dispensing system has

been vented

^

Run the PRE-RINSE programme D

so that after venting any agents in the

wash cabinet are diluted before

being drained away.

:

Page 35

Programming special functions

2. Altering the wash/rinse

temperature and/or the

temperature holding time in

the "Main wash" and "Final

rinse" programme stages

Please make a note of any changes

to the temperature and / or the

temperature holding time in the

appropriate section of the

programme chart

The programme chart shows the factory

settings for the Main wash temperature

together with temperature holding time

and the Final rinse temperature

temperature holding time.

The special functions can be used to

alter the temperatures of the main wash

and of the final rinse from 30 °C - 93 °C

and the temperature holding time from

1-15 minutes.

^ Turn the programme selector to STOP

f.

^

Switch off the machine.

^

Press and hold ß and 6 at the

same time, and whilst doing so,

switch the machine on with the I-0

button.

The current programme status "P..."

will appear in the display and the p /

6 indicator light will come on.

.

with its

“Main wash” temperature

(programme specific parameter):

Press 0 as often as necessary or

^

hold it pressed in until E09

(programming level 9) appears in the

display.

Turn the programme selector to the

^

programme which needs to be

changed. The current value appears

in the display after °C.

Press ß or hold pressed in until the

^

required value appears in the display.

Main wash temperature holding time

(programme specific parameter):

^ Turn the programme selector to STOP

f.

^ Press 0 as often as necessary or

hold it pressed in until E10

(programming level 10) appears in

the display.

^ Turn the programme selector back to

the programme which needs to be

changed. The current value appears

in the display after min.

^

Press ß or hold pressed in until the

required value appears in the display.

35

Page 36

Programming special functions

Final rinse temperature (programme

specific parameter):

Turn the programme selector to STOP

^

f.

Press 0 as often as necessary or

^

hold it pressed in until E25

(programming level 25) appears in

the display. Then:

Turn the programme selector to the

^

programme which needs to be

changed. The current value appears

in the display after °C.

Press ß or hold pressed in until the

^

required value appears in the display.

Final rinse temperature holding time

(programme specific parameter):

Turn the programme selector to STOP

^

f.

Press 0 as often as necessary or

^

hold it pressed in until E26

(programming level 26) appears in

the display. Then:

Turn the programme selector back to

^

the programme which needs to be

changed. The current value appears

in the display after min.

Press ß or hold pressed in until the

^

required value appears in the display.

Having changed a value or all values:

^ Press 6. SP appears.

^ Press 6 again. The change has

been recorded.

36

Page 37

Programming special functions

3. Audible tone (Buzzer)

This special function allows you to

programme a buzzer (lasting up to a

maximum of 30 seconds) for the

following functions:

Programme end = Constant buzzer

–

Fault warning = Buzzer at one

–

second intervals

Removing a test item from the final

–

rinse water (this function has to be

programmed by a Miele service

engineer)

= 3 x short beeps followed by 2

second pause, then 3 short beeps

etc.

^ Turn the programme selector to STOP

f.

^ Switch off the machine.

^ Press and hold ß and 6 at the

same time, and whilst doing so,

switch the machine on with the I-0

button.

The current programme status "P..."

will appear in the display and the p /

6 indicator light will come on.

25 = Buzzer at end of programme

and for removing a test item

26 = Fault indication and buzzer for

removing a test item

27 = Buzzer for all functions

(Programme end, Fault indication,

Removing a test item).

Press ß or hold pressed in until the

^

required value appears in the display.

Press 6. SP appears.

^

Press 6 again. The change has

^

been recorded.

Value set:

Note:

The buzzer can be switched off early

by

– turning the programme selector to

the STOP position f,

– pressing the ß button, or

– interrupting the power supply (e.g.

by opening and closing the door).

^

Press 0 four times. E04

(programming level 4) appears in the

display.

^

Turn the programme selector to q. A

number from 20 to 27 will appear in

the display.

20 = Buzzer switched off

21 = Buzzer at end of programme

(standard setting)

22 = Fault indication

23 = Fault indication and buzzer at

end of programme

24 = Reminder to remove a test item

37

Page 38

Programming special functions

4. Re-setting all parameter

changes back to the factory

settings.

Turn the programme selector to STOP

^

f.

Switch off the machine.

^

Press and hold ß and 6 at the

^

same time, and whilst doing so,

switch the machine on with the I-0

button.

The current programme status "P..."

will appear in the display and the p /

6 indicator light will come on.

^ Press 0 as often as necessary or

hold it pressed in until E33

(programming level 33) appears in

the display.

^ Turn the programme selector to any

switch position (except STOP).

00 or PP will appear in the display.

00 = factory setting

(Electronics have not been

re-programmed).

PP = Electronics have been

re-programmed.

When restoring all changed

values, please note

that any new setting for the water

hardness level also reverts to the

factory setting of 19 °d (3.4 mmol/l).

The final rinse temperature of

85°C/1’ is now 93°C/3’.

Re-setting is required in both cases.

^

If PP is displayed, press ß to

change from PP to 00.

^

Press 6. SP appears.

^

Press 6 again. All values which had

been changed have now been now

reset to the factory settings.

38

Page 39

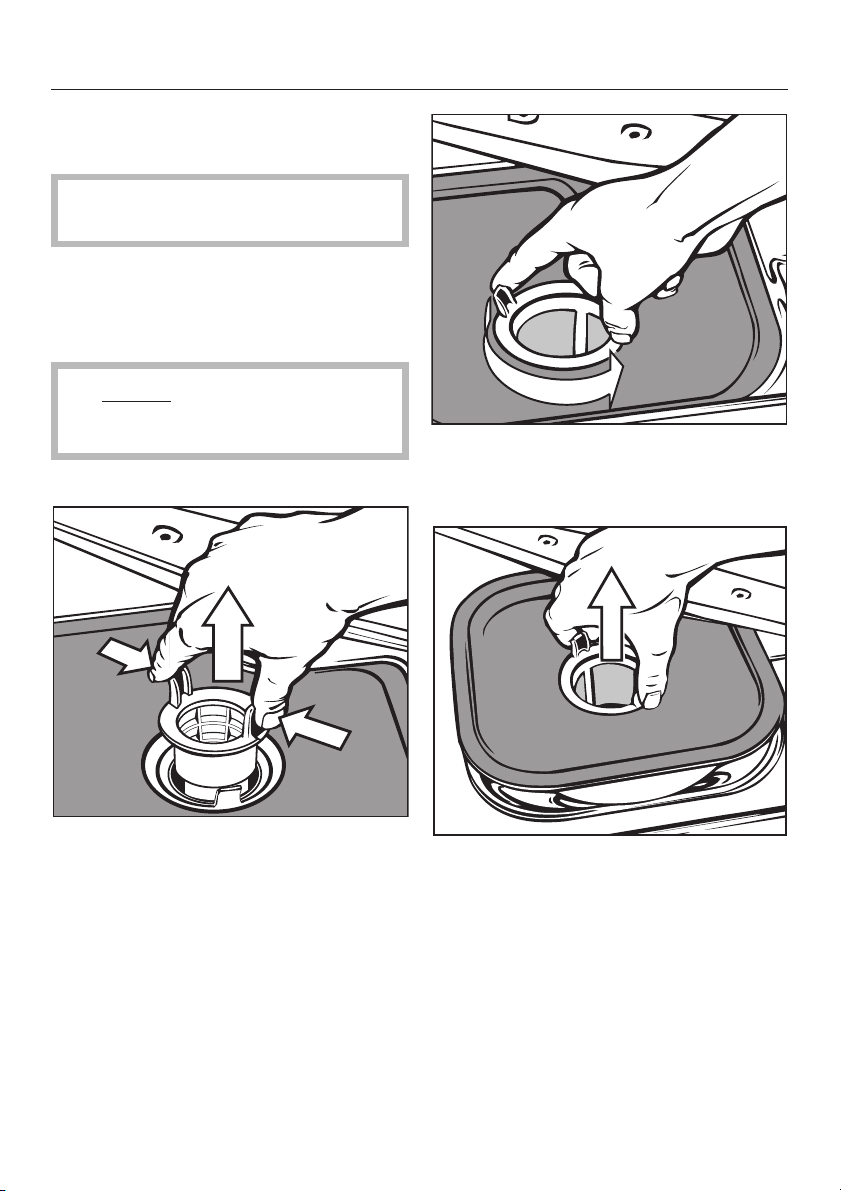

Cleaning the filters in the wash

cabinet

This machine must not be used

,

without all the filters in place.

The filter combination in the base of

the wash cabinet should be

inspected regularly and cleaned if

necessary.

Caution

,

Watch out for glass splinters which

could cause injury.

Cleaning the coarse filter

Cleaning and care

To unscrew the micro-fine filter, take

^

hold of the two lugs and turn twice in

an anti-clockwise direction.

^

Press the two lugs together, remove

and clean the coarse filter.

^

Put the clean filter back in position

and press until it clicks in place.

Cleaning the fine, flat and micro-fine

filters

^

Remove the coarse filter.

^

Remove the fine filter (if fitted) from

between the flat and the micro-fine

filters.

^

Then remove together with the flat

filter.

^

Clean the filters.

^

Replace the filter combination by

carrying out the above steps in the

reverse order. Ensure that the flat

filter sits flat in the base of the wash

cabinet.

39

Page 40

Cleaning and care

Cleaning the spray arms

Waste particles can lodge in the spray

arm jets.

It is therefore important to inspect the

spray arms regularly.

Use a sharp pointed object to push

^

particles into the spray arm jets and

rinse well under running water.

Remove the spray arms as follows:

Unscrew the upper spray arm.

^

Remove the middle spray arm by

^

unscrewing the nut

to the upper basket.

which secures it

Important:

thread and has to be turned

clockwise to unscrew it.

^ Loosen the knurled thumb nut to

unscrew the lower spray arm.

You will first need to take the bottom

basket out of the machine.

Important:

After replacing the spray arms, check

that they rotate freely.

The nut has a left hand

40

Page 41

Cleaning and care

Cleaning the drain pump and

non-return valve

If water has not been pumped away at

the end of a programme the drain

pump or the non-return valve might be

blocked. They are however, easy to

clean.

Take the filter combination out of the

^

wash cabinet.

^ Release the locking clamp.

The drain pump is situated under the

non-return valve (see arrow).

^ Before replacing the non-return valve

check that the drain pump is free of

obstructions.

^ Carefully replace the ron-return valve

and secure with the locking clamp.

For safety reasons you should clean

the load again.

^

Lift up the non-return valve and rinse

under running water.

41

Page 42

Cleaning and care

Cleaning the filters in the water

inlet

Filters are incorporated in the screw

connection of the water inlet hose to

protect the water inlet valve. If these

filters get dirty they need to be cleaned,

otherwise insufficient water flows into

the wash cabinet.

The plastic housing of the water

,

connection contains an electrical

component. It must not be dipped in

water.

To clean the filters

^ Disconnect the machine from the

mains supply (switch off at the mains

and pull out the plug, switch off the

appropriate circuit in the fuse box or

withdraw the mains fuse).

^ Turn off the stopcock and unscrew

the water inlet hose.

Replace filters and the seal. Make

^

sure they are sitting correctly.

Reconnect the hose to the water inlet,

^

making sure that it goes back on

straight.

Open the stopcock carefully.

^

If there is a leak, screw the

connections on more tightly.

Cleaning the control panel

This should only be cleaned with a

^

damp cloth or a suitable cleaner for

use on plastic materials, or with a

disinfectant tested and recognised

as suitable for this use.

Do not use abrasive cleaners,

,

glass cleaners or all-purpose

cleaners!

Because of their chemical

composition they could cause

serious damage to plastic

components.

^

Clean the large area filter (1) and fine

filter (2), and replace with new filters

if necessary.

42

Cleaning the front of the

machine

^

Clean using a proprietary cleaning

agent designed for the type of front

the machine is fitted with.

,

Do not use cleaning agents

containing ammonia or thinners.

Page 43

Correcting minor faults

With the aid of the following explanatory

notes, minor faults can be corrected

without contacting the Miele Service

Dept.

Any work on the electrical components

of the machine should only be carried

out by a suitably qualified and

competent person in accordance with

local and national safety regulations.

Unauthorised repairs could be

dangerous.

Faults / possible causes

The machine does not start

– The door is not properly closed.

– The plug is not properly inserted in

the socket.

– The fuse is defective / has blown.

A few minutes after switching on, the

p / 6 indicator light flashes (fault

code F..E appears in the display)

–

The stopcocks are closed.

–

The filters in the water inlet hose are

dirty.

–

The water pressure is too low.

^

Turn the programme selector to the

STOP position f (the fault code

goes out).

^

Switch the machine off (press I-0).

^

Open the stopcocks or clean the

filters (see "Cleaning and Care").

The wash cycle finishes too early and

the p / 6 indicator light flashes

(fault code F A appears in the

display)

The drain hose is kinked.

–

The drain pump is blocked

–

Turn the programme selector to the

^

STOP position f (the fault code goes

out).

Switch the machine off (press I-0).

^

Straighten the hose and check/clean

^

the drain pump.

^ Switch the machine on again, drain

the water away and start the

programme again (see DRAIN and

"Switching on").

Water in the wash cabinet does not

heat up; the programme takes too

long (fault code: F01 - F03, F18, F19

appears in the display).

This machine has a resettable heater

limiter which will switch off the heaters if

they over-heat. This could be caused

for example, by large articles covering

the heating elements or if the filters in

the wash cabinet are blocked.

^

Remove the cause of the fault.

^

Take off the service panel (see

"Electrical connection").

^

Press the reset button on the heater

limiter (reddish brown) located on the

left- hand side of the plinth.

^

Switch the machine on again and

reselect the programme.

If this switch trips again contact the

Miele Service Department.

43

Page 44

Correcting minor faults

After sales service

Important:

When a fault first occurs, please check

that the fault has not been caused by

incorrect operation. This will help avoid

an unnecessary service call-out. To do

this:

Turn the programme selector to the

^

STOP position f (the fault code goes

out).

Switch the machine off (press I-0).

^

Switch the machine on again and

^

reselect the programme.

If you still have difficulties or if a fault

code "F..." appears in the display,

please contact your authorised Service

Dealer or the Miele Service

Department. See back cover for

addresses.

Please quote the fault code as well as

the model type and number of your

machine which is given on the data

plate (see "Electrical connection").

44

Page 45

Installation

Please refer to the installation

diagram supplied with the machine.

Furniture and fittings installed

,

near the machine must be of a

commercial standard able to

withstand the effects of steam and

condensed water.

The machine must be installed correctly

and levelled.

Any unevenness in the floor level can

be compensated for and the height of

the machine raised or lowered by

adjusting the four screw feet.

The machine can be installed in the

following ways:

^ Free-standing.

^ Slot-in or at the end of a row:

The machine can be installed next to

other machines or furniture or in a

suitable niche. The niche must be at

least 60 cm wide and 60 cm deep.

^

Built-under:

The machine can be installed under a

continuous worktop or sink drainer.

The recess must be at least 60 cm

wide, 60 cm deep and 82 cm high.

If necessary, the machine lid can be

removed as follows:

Open the door.

^

^ Remove the fixing screws on the left

and right hand sides using a cross

slotted screwdriver.

^ Pull the machine lid approx. 5 mm

forwards, lift it upwards and remove

it.

Important for machines fitted with a

steam condenser (depending on mo

del):

To prevent damage by steam to the

worktop, the self adhesive protective

foil supplied (25 x 58 cm) must be

stuck in place underneath the worktop

near the steam condenser.

-

45

Page 46

Installation

Position and secure the machine

To ensure stability the machine must

first be aligned and then screwed to the

worktop.

Open the door. Secure the machine

^

to the front edge of the worktop using

screws through the holes on the left

and right hand sides of the front trim.

Do not use silicone sealant to seal

^

the gaps between the machine and

any neighbouring units as this would

hinder ventilation to the circulation

pump.

Depending on the requirements for

building under, the following kit

ordered from the Miele Spares Dept.:

Cover plate (protects the worktop)

The underside of the worktop is

protected against water damage by a

stainless steel plate.

can be

Decor frame and decor panel

(optional)

If you wish to fit a decor panel to the

machine this can only be done by a

Miele Service technician. Contact Miele

for details.

Decor panel dimensions:

Door panel H x W: 442/586 mm

Service panel H x W: 117/586 mm

46

Page 47

Electrical connection

All electrical work must be

,

carried out by a suitably qualified

and competent person in

accordance with local and national

safety regulations.

Connection should be made via a

^

suitable isolator, with an on-off switch

which should be easily accessible for

servicing work.

For extra safety it is advisable to

^

install a residual current device with a

trip current of 30 mA (in accordance

with DIN VDE 0664).

WARNING

THIS APPLIANCE MUST BE

EARTHED

^ Equipotential bonding should be

carried out.

Bonding connection

There is a screw connection point

marked with the earth symbol (

the back of the machine, to which the

earth lead must be connected.

^

For technical data see data plate or

wiring diagram supplied.

The machine must only be operated

with the voltage, frequency and fusing

shown on the data plate

.

8) at

The conversion diagram

with test certification (VDE, DVGW etc.)

is located on the rear of the machine,

and on the plinth (behind the service

panel).

The wiring diagram

inner side of the service panel.

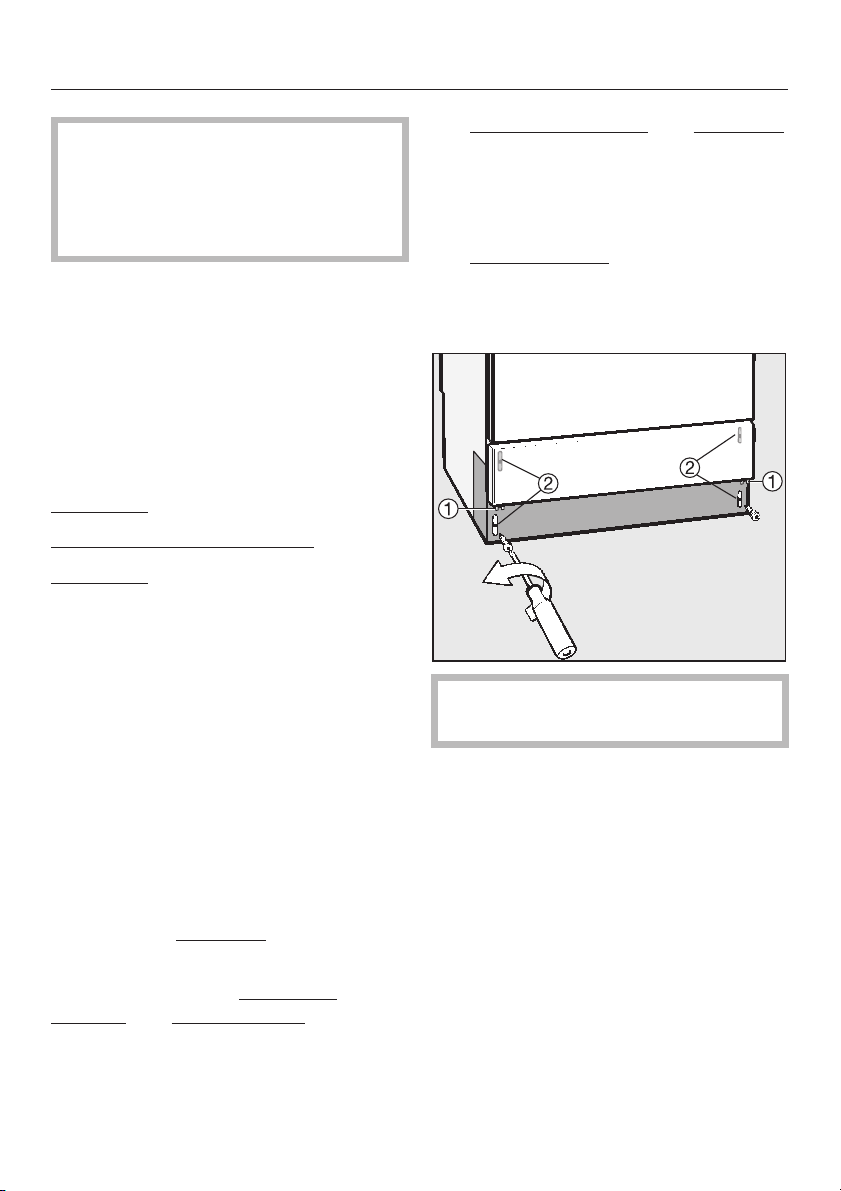

To remove the service panel and

plinth:

,

Disconnect the machine from the

mains electricity supply.

^

Remove fixing screws a from the

service panel.

^

Take hold of the service panel at both

sides and pull upwards.

^

Unscrew plinth facing (screws b).

^

Remove the plastic protective cap.

and data plate

is secured to the

This machine can be converted in

accordance with the conversion

diagram and wiring diagram supplied.

47

Page 48

Electrical connection

To re-assemble:

Refit the plastic protective cap, plinth

^

facing and service panel in the

reverse order to which they were

removed.

See also the installation diagram

supplied.

48

Page 49

Plumbing

Connection to the water inlet

Water in the machine must not

,

be used as drinking water.

The machine must be connected to

^

the water supply in accordance with

local and national water authority

regulations.

This machine is constructed to

^

comply with German water

regulations (DVGW), and may be

connected to a suitable supply

without an extra non-return valve if

national regulations permit.

^ The water pressure (flow rate) must

be a minimum of 0.5 bar (50 kPa).

If the water pressure (flow rate) is

below 2 bar (200 kPa), the filling time

is automatically extended.

The max. permitted static pressure is

10 bar (1000 kPa).

If the water pressure is not in the

range of 0.5 to 10 bar (50-1000 kPa),

the p / 6 indicator light may come

on and the fault code "F..E" will show

in the display. Please contact the

Miele Service Department.

should also be connected to a cold

water stopcock.

Stopcocks with 3/4 BSP male thread

^

are to be provided on site. They

should be easily accessible so that

the water supply can be turned off

when the machine is not in use.

The DN 10 inlet hoses are approx.

^

1.7 m long terminating in a 3/4 inch

female thread. On no account must

the inlet filters be removed.

Large surface area filters are

^

enclosed in the kit supplied with the

machine for installing between the

stopcock and the inlet hose

(see illustration in "Cleaning and Care

- Water inlet").

^

The machine is supplied as standard

for connection to a cold (coded blue)

and

a hot (coded red) water supply

up to a max. temperature of 70 °C.

The inlet hoses should be connected

to the stopcocks for the hot and cold

water supplies. The steam condenser

inlet hose (without waterproof

connector) should be connected to

the cold water stopcock.

If there is no hot water connection,

the hot water inlet hose marked red

,

The inlet hoses must not be

shortened or damaged in any way

(see illustration).

See also the installation diagram

supplied.

49

Page 50

Plumbing

Drainage

This machine is fitted with two drainage

hoses. One hose is designated for dirty

water; the other for water emitted by the

steam condenser.

The drainage system is fitted with a

non-return valve which prevents dirty

water from flowing back into the

machine via the drain hose.

The machine should preferably be

^

connected to a separate

system on-site.

If separate drainage is not available,

contact your Miele application

specialist for professional advice.

The on-site drain connection point

should be sited between 0.3 m and 1

m above the lower edge of the

machine.

If it is lower than 0.3 m, lay the hose

in a curve at a height of at least

0.3 m.

The drainage system must be able to

take a minimum drainage flow of 16

l/min.

drainage

^

The drain hoses are approx. 1.4 m

long, flexible and have an internal

diameter of 22 mm. They must not be

shortened.

Hose clips are supplied for securing

them in position.

^

Longer drain hoses (up to 4 m long)

are available to order from the Miele

Spare Parts Dept.

^

The drainage system must not

exceed 4 metres.

See also the installation diagram

supplied.

50

Page 51

Height: 85 (82) cm

Width: 60 cm

Depth: 60 cm

Voltage: see data plate

Rated load: see data plate

Fuse rating: see data plate

Mains connection cable: approx. 1.8 m

Water pressure (flow rate): 50 - 1000 kPa

(0.5 - 10 bar) pressure

Cold / hot water inlet connections: up to max. 70 °C

Delivery head: min. 0.3 m, max. 1 m

Drainage length: max. 4 m

Inlet hose: approx. 1.7 m

Drain hose: approx. 1.4 m

Steam condenser: approx. 2 l/min

Noise level in dB (A):

Sound level LpA Free standing: <70

Built under: <70

Technical data

Test marks: DVGW (German association of gas and

water engineers)

51

Page 52

Alteration rights reserved / 1004

M.-Nr. 06 134 790 / 00

This paper consists of cellulose which has been bleached without the use of chlorine.

Loading...

Loading...