Operating and installation

instructions

SmartLine downdraft extractor

To avoid the risk of accidents or damage to the appliance it is essen-

tial to read these instructions before it is installed and used for the

first time.

en-GB M.-Nr. 11 480 260

Contents

Warning and Safety instructions...................................................................... 4

Caring for the environment .............................................................................. 14

Guide to the appliance...................................................................................... 15

Downdraft extractor............................................................................................. 15

Controls / Indicators............................................................................................ 16

Accessories supplied .......................................................................................... 17

Cleaning the SmartLine element for the first time ......................................... 18

Modes of operation ........................................................................................... 19

Tips on saving energy ...................................................................................... 20

Operation............................................................................................................ 21

Switching the downdraft extractor on ................................................................. 21

Setting/changing the power level........................................................................ 21

Switching the downdraft extractor off ................................................................. 21

Run-on time......................................................................................................... 21

Cleaning and care ............................................................................................. 22

Ceramic surface .................................................................................................. 23

Drip tray............................................................................................................... 23

Grease filter/extraction grille................................................................................ 24

Problem solving guide ...................................................................................... 26

Optional accessories ........................................................................................ 27

After sales service............................................................................................. 28

Contact in the event of a fault ............................................................................. 28

Data plate ............................................................................................................ 28

Warranty .............................................................................................................. 28

Installation.......................................................................................................... 29

Safety instructions for installation ....................................................................... 29

Installation examples........................................................................................... 30

Surface-mounted ................................................................................................ 31

Installation notes – surface-mounted.................................................................. 31

Worktop cutout – surface-mounted .................................................................... 34

Spacer bars – surface-mounted.......................................................................... 37

Installation dimensions–Surface-mounted........................................................ 38

Air duct dimensions – surface-mounted – worktop depth 600mm.................... 39

Air duct dimensions – surface-mounted – worktop depth greater than 600mm 42

Installation – surface-mounted............................................................................ 46

2

Contents

Flush-fit ............................................................................................................... 52

Installation notes – flush-fit ................................................................................. 52

Worktop cutout – flush-fit.................................................................................... 55

Spacer bars – flush-fit ......................................................................................... 58

Installation dimensions–Flush ........................................................................... 59

Air duct dimensions – flush-fit – worktop depth 600mm ................................... 60

Air duct dimensions – flush-fit – worktop depth greater than 600mm............... 63

Installation – flush-fit ........................................................................................... 67

Ducting ................................................................................................................ 73

Electrical connection ........................................................................................... 74

Product data sheets ......................................................................................... 76

3

Warning and Safety instructions

This downdraft extractor complies with all relevant safety requirements. Inappropriate use can, however, lead to personal injury and

material damage.

Please read these operating and installation instructions carefully

before using the downdraft extractor for the first time. They contain important information on safety, installation, use and maintenance. This prevents both personal injury and damage to the

downdraft extractor.

In accordance with standard IEC60335-1, Miele expressly and

strongly advises that you read and follow the instructions in the

chapter on installing the downdraft extractor as well as the safety

instructions and warnings.

Miele cannot be held liable for injury or damage caused by noncompliance with these instructions.

Keep these instructions in a safe place and pass them on to any

future owner.

For safe operation, please also refer to the operating and installation instructions for the SmartLine elements and hob units installed

adjacent to the downdraft extractor.

4

Warning and Safety instructions

Correct application

This downdraft extractor is intended for use in domestic house-

holds and similar working and residential environments.

The downdraft extractor is not suitable for outdoor use.

It must only be used as a domestic appliance to extract vapours

and remove odours from cooking.

All other types of use are not permitted.

This downdraft extractor can only be used by people with reduced

physical, sensory or mental capabilities or lack of experience and

knowledge if they are supervised whilst using it.

They may only use the downdraft extractor unsupervised if they have

been shown how to use it in a safe manner. They must be able to recognise and understand the consequences of incorrect operation.

5

Warning and Safety instructions

Safety with children

Children under 8 years of age must be kept away from the coun-

tertop extractor unless they are constantly supervised.

Children aged 8 and older may only use the countertop extractor

without supervision if they have been shown how to use it in a safe

manner. Children must be able to understand and recognise the possible dangers caused by incorrect operation.

Children must not be allowed to clean or maintain the downdraft

extractor unsupervised.

Children should be supervised in the vicinity of the downdraft ex-

tractor. Do not allow them to play with the downdraft extractor.

Danger of suffocation! Whilst playing, children may become en-

tangled in packaging material (such as plastic wrapping) or pull it

over their head with the risk of suffocation. Keep packaging material

away from children.

6

Warning and Safety instructions

Technical safety

Unauthorised installation, maintenance and repairs can cause

considerable danger for the user. Installation, maintenance and repairs must only be carried out by a Miele authorised technician.

The downdraft extractor must only be installed and operated in

combination with those SmartLine elements and hob units specified

by Miele.

Damage to the downdraft extractor can compromise your safety.

Check it for visible signs of damage. Do not use a damaged

downdraft extractor.

Reliable and safe operation of this downdraft extractor can only

be assured if it has been connected to the mains electricity supply.

The countertop extractor must not be connected to the inverter of

an autonomous power supply, e.g. a solar power system. When the

countertop extractor is switched on, power surges could result in a

safety switch-off. This could damage the electronic module.

The electrical safety of the downdraft extractor can only be guar-

anteed when continuity is complete between it and an effective

earthing system. It is most important that this basic safety requirement is present and tested regularly. If in doubt, the electrical installation should be checked by a qualified electrician.

Before connecting the downdraft extractor to the mains supply,

ensure that the connection data on the data plate (voltage and frequency) match the mains electricity supply. This data must correspond in order to avoid the risk of damage to the downdraft extractor.

Compare this data before connecting the appliance to the mains.

Consult a qualified electrician if in any doubt.

Multi-socket adapters and extension leads do not guarantee the

required safety of the appliance (fire hazard). Do not use these to

connect the downdraft extractor to the mains electricity supply.

7

Warning and Safety instructions

For safety reasons, this downdraft extractor may only be used

after it has been built in.

This downdraft extractor must not be installed and operated in

mobile installations (e.g. on a ship).

Any contact with live connections or tampering with the electrical

or mechanical components of the downdraft extractor will endanger

your safety and may lead to appliance malfunctions.

Only open the casing as described in the installation instructions and

in the “Cleaning and care” section of this booklet. Under no circumstances should any other parts of the casing be opened.

The manufacturer's warranty will be invalidated if the downdraft

extractor is not repaired by a Miele approved service technician.

Miele can only guarantee the safety of the appliance when genu-

ine original Miele replacement parts are used. Faulty components

must only be replaced by Miele spare parts.

The downdraft extractor is not intended for use with an external

timer switch or a remote control system.

If the plug is removed from the connection cable or if the cable is

supplied without a plug, the downdraft extractor must be connected

to the electrical supply by a suitably qualified electrician.

If the mains connection cable is damaged, it must be replaced

with a special mains connection cable by a qualified electrician (see

“Electrical connection” in the “Installation” chapter).

8

Warning and Safety instructions

During installation, maintenance and repair work, the downdraft

extractor must be completely disconnected from the mains electricity supply. It is only completely isolated from the electricity supply

when:

- the mains fuse has been disconnected or

- the screw-out fuses have been fully unscrewed or

- the plug (if present) is removed from the socket. To do this, pull

the plug not the mains connection cable.

9

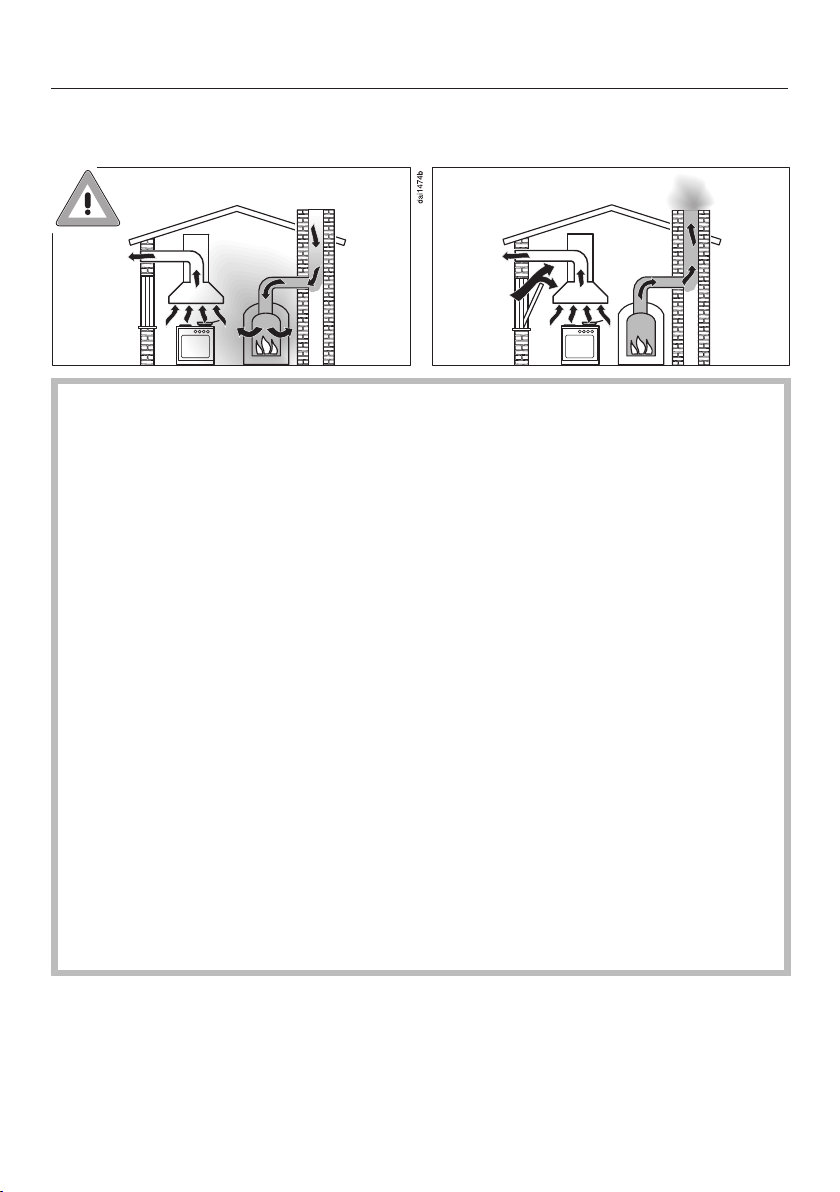

Warning and Safety instructions

Using at the same time as other heating appliances that depend on the air from the room

Danger of toxic fumes!

Great care should be taken when using the downdraft extractor in

the same room or the same area of the house as another heating

appliance that depends on the air from the room.

Such heating appliances draw in air from the room and duct exhaust gases out through a chimney or extraction ducting. They include gas, oil, wood and coal-fired boilers and heaters, continuous

flow or other water heaters, gas hobs and ovens.

The downdraft extractor draws in air from the kitchen and from

neighbouring rooms. This applies to the following modes of operation:

- extraction mode,

- recirculation mode with a recirculation box installed outside the

room.

If there is insufficient air, an underpressure will occur. The heating

appliance may be starved of oxygen. This impairs combustion.

Harmful gases could be drawn from the chimney or extraction

ducting back into the room.

This could have potentially fatal consequences!

10

Warning and Safety instructions

In order to ensure safe operation and to prevent gases given off by

the heating appliance from being drawn back into the room, when

the downdraft extractor and the heater are both operated simultaneously, an underpressure in the room of 0.04mbar (4Pa) is the

maximum permissible.

Sufficient ventilation can be maintained by air inlets which cannot

be blocked, e.g. in windows, doors and outside wall vents. The

diameter of the inlet openings must enable sufficient ventilation. A

ventilation brick alone is not generally sufficient to ensure safe

ventilation.

The overall ventilation condition of the dwelling must be taken into

account. If in any doubt, the advice of a competent builder, or for

gas, a qualified gas fitter should be sought.

If the downdraft extractor is being operated in recirculation mode,

where the air is directed back into the room in which it is located,

operating a heating appliance which depends on the room air at

the same time is not hazardous.

11

Warning and Safety instructions

Correct use

Open flames are a fire hazard.

Never use an open flame beside the downdraft extractor. To avoid

the danger of fire, do not flambé or grill over an open flame. When

switched on, the downdraft extractor could draw flames into the filter. Fat deposits could ignite, presenting a fire hazard.

Overheated oil and fat can ignite, causing fire damage to the

downdraft extractor.

When cooking with oil or fat, chip pans and deep fat fryers, etc, do

not leave the pots and pans unattended. Similarly, never leave an

open grill unattended when grilling.

Deposits of grease and dirt will prevent the downdraft extractor

from working properly.

Do not use the downdraft extractor without the grease filters in

place. Otherwise cooking vapours will not be cleaned.

Hot cooking vapours during cooking can cause the downdraft ex-

tractor to get hot.

Do not touch the casing or the grease filters until the downdraft extractor has cooled down.

Do not use the downdraft extractor for resting objects on.

Liquids can damage the downdraft extractor if they get into it.

Keep liquids away from the downdraft extractor.

Light objects can be drawn into the downdraft extractor and im-

pair its operation.

Do not place any light objects (e.g. paper towels) within close proximity of the downdraft extractor.

If you are operating a gas cooking element directly next to the

downdraft extractor, the FlameGuard must be placed between the

downdraft extractor and the element.

12

Warning and Safety instructions

Cleaning and care

The steam from a steam cleaning appliance could reach live elec-

trical components and cause a short circuit.

Do not use a steam cleaner to clean the downdraft extractor.

There is a risk of fire if the cooker hood is not cleaned as de-

scribed in these operating instructions.

Accessories

Only use genuine original Miele accessories and spare parts with

this appliance. Using accessories or spare parts from other manufacturers will invalidate the warranty and Miele cannot accept liability.

13

Caring for the environment

Disposal of the packing material

The packaging is designed to protect

the appliance from damage during

transportation. The packaging materials

used are selected from materials which

are environmentally friendly for disposal

and should be recycled.

Recycling the packaging reduces the

use of raw materials in the manufacturing process and also reduces the

amount of waste in landfill sites.

Disposing of your old appliance

Electrical and electronic appliances often contain valuable materials. They

also contain specific materials, compounds and components, which were

essential for their correct function and

safety. These could be hazardous to human health and to the environment if

disposed of with your domestic waste

or if handled incorrectly. Please do not,

therefore, dispose of your old appliance

with your household waste.

Please dispose of it at your local community waste collection / recycling

centre for electrical and electronic appliances, or contact your dealer or

Miele for advice. You are also responsible for deleting any personal data that

may be stored on the appliance being

disposed of. Please ensure that your

old appliance poses no risk to children

while being stored prior to disposal.

14

Downdraft extractor

Guide to the appliance

a

Extraction grille

b

Grease filter

c

Cover with control unit

d

Casing

e

Grease trap

f

Air duct

g

Fan

h

E-box

15

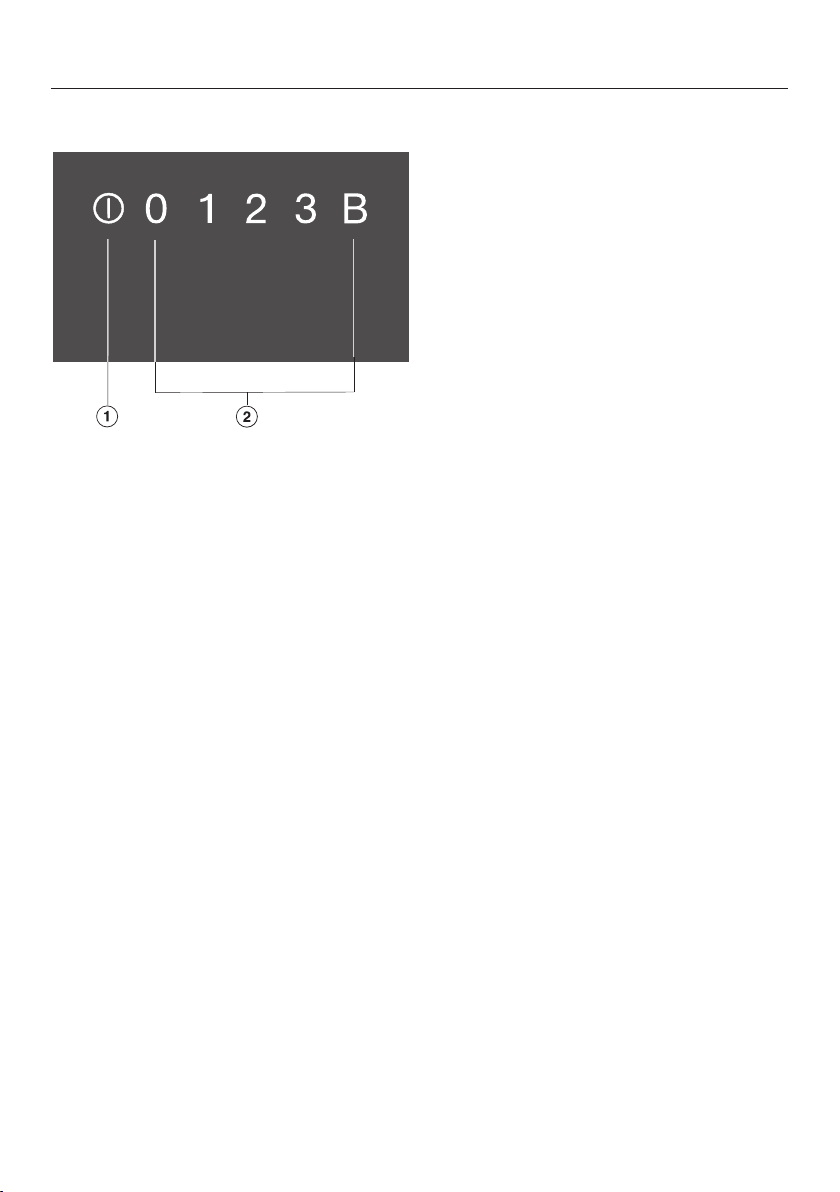

Guide to the appliance

Controls / Indicators

a

Switching the downdraft extractor on/off

b

Numerical keybank for setting the power level

16

Guide to the appliance

Accessories supplied

The accessories supplied with your appliance as well as a range of optional

ones are available to order from Miele

(see “Optional accessories”).

Extraction grille

17

Cleaning the SmartLine element for the first time

Please stick the extra data plate for

the appliance supplied with this documentation in the space provided in

the “After sales service” section of

this booklet.

Remove any protective wrapping and

stickers.

Clean the ceramic surface with a

damp cloth, and then wipe dry.

18

Depending on the model of the

downdraft extractor, the following options are available:

Extraction mode

The air is drawn in and cleaned by the

grease filter and directed outside.

Recirculation mode

(DUU 1000(-1) conversion kit required)

The air is drawn in and cleaned by the

grease filter. The air is then directed into

the recirculation box where it is also

cleaned by the charcoal filters. The

cleaned air is then recirculated back

into the kitchen.

Modes of operation

19

Tips on saving energy

This downdraft extractor operates very

efficiently and economically. The following will help you to save even more energy when using it:

- It is important to ensure that the kitchen is well ventilated during operation. In extraction mode if there is insufficient air flow, the downdraft extractor cannot operate efficiently and

this causes increased operating noise

levels.

- Always cook with the lowest possible

setting. This produces fewer cooking

vapours, so you can use a lower

power level and therefore benefit

from reduced energy consumption.

- Check the selected power level on

the downdraft extractor. A low power

level is usually sufficient. Only use the

Booster setting when necessary.

- When a large volume of cooking vapours are being produced, switch to

a high power level in good time. This

is more efficient than operating the

downdraft extractor for longer to try

to capture cooking vapours which

have already been distributed

throughout the kitchen.

- Switch the downdraft extractor off

after cooking.

- Clean or replace the filters at regular

intervals. Heavily soiled filters reduce

performance, increase the risk of fire

and are unhygienic.

20

Operation

Switching the downdraft extractor on

Insert the extraction grille.

Touch the sensor control.

The sensor controls light up.

If no further entry is made, the

downdraft extractor will switch itself

off after a few seconds.

Setting/changing the power level

For light to heavy cooking vapours and

odours, select from power levels 1 to 3.

For short periods of cooking food with

intensive vapours and a strong aroma,

e.g. when searing meat, select Booster

setting B.

Switching the downdraft extractor off

Touch the sensor control.

The sensor controls go out.

If the downdraft extractor is not

switched off, it will switch itself off

12hours after the last automatic operation.

Run-on time

In order to rid kitchen air of steam and

odours, the downdraft extractor continues to run for 5minutes on the power

level that was set last. The power level

is gradually reduced during the run-on

time. The current power level pulsates

during the run-on time.

Touch the desired power level.

Booster

The maximum duration for the Booster

is 10minutes.

To switch it off early, set a different

power level.

Tip: To help release vapours effectively

with pans over 15cm high, place a

wooden spoon between the lid and the

pot.

21

Cleaning and care

Danger of burning due to hot

surfaces.

The surfaces will be hot after cook-

ing.

Switch the countertop extractor and

the cooking elements off.

Allow the surfaces to cool down be-

fore cleaning the countertop extractor.

Risk of damage due to moisture

ingress.

The steam from a steam cleaning ap-

pliance could reach live electrical

components and cause a short circuit.

Do not use a steam cleaner to clean

the countertop extractor.

All surfaces could be discoloured or

damaged if unsuitable cleaning

agents are used. All surfaces are

susceptible to scratching.

Remove all cleaning agent residues

immediately.

Never use abrasive sponges or

cleaning agents.

Allow the SmartLine element to cool

down before cleaning.

Clean the SmartLine element and ac-

cessories after each use.

Dry the SmartLine element thoroughly

after every cleaning to avoid limescale residue.

Unsuitable cleaning agents

To avoid damaging the surfaces of the

appliance, do not use:

- washing-up liquid

- cleaning agents containing soda, alkalines, ammonia, acids or chlorides

- cleaning agents containing descaling

agents

- stain and rust removers

- abrasive cleaning agents, e.g.

powder cleaners and cream cleaners

- solvent-based cleaning agents

- dishwasher cleaner

- oven sprays

- glass cleaning agents

22

- hard, abrasive brushes or sponges

(e.g. pot scourers) or sponges which

have been previously used and still

contain abrasive cleaning agents

- melamine eraser blocks

Cleaning and care

Ceramic surface

Risk of damage by pointed ob-

jects.

The seal between the SmartLine ele-

ment and the worktop could suffer

damage.

Do not use pointed objects for cleaning.

Not all soiling and residues can be

removed using a solution of washing-up liquid. An invisible film can

develop that can lead to discolouration of the glass ceramic surface.

This discolouration cannot be removed.

Clean the ceramic surface regularly

with a proprietary ceramic glass

cleaning agent.

Remove any coarse soiling with a

damp cloth and more stubborn soiling with a shielded scraper blade

suitable for use on glass.

Then clean the ceramic glass surface

with the Miele ceramic and stainless

steel hob cleaner (see “optional accessories”) or with a proprietary

ceramic glass cleaner applied with

kitchen paper or a clean cloth. Please

follow the cleaning agent manufacturer's instructions.

Drip tray

Clean the drip tray if liquids have boiled

over or spilled into the downdraft extractor.

Remove and clean the grease filter as

described in the “Grease filter” section.

Hold the drip tray and open the

2clips (1x front, 1x rear). Carefully remove the tray from the casing, making sure it is kept horizontal.

Pour out the liquid.

Clean and dry the drip tray.

Clean and dry the accessible inside

of the downdraft extractor.

Fasten the drip tray back onto the

casing.

Replace the grease filter and the

cover on top.

Clean the ceramic surface with a

damp cloth, and then wipe dry. Ensure that all cleaning agent residues

are removed.

Spots caused by limescale and water

residues can be removed using

Miele's ceramic and stainless steel

hob cleaner.

23

Cleaning and care

Grease filter/extraction grille

The extraction grille and the reusable

metal grease filter in the vapour extraction fan collect solid matter from kitchen vapours (grease, dust, etc.) and

therefore prevent soiling of the

downdraft extractor. Accumulated

grease solidifies over a longer period of

time and makes cleaning more difficult.

The grease filter should therefore be

cleaned at least every 3–4weeks.

Risk of fire due to soiled grease

filter.

Grease collected in the grease filter

can ignite.

Clean the grease filter regularly.

Removing the grease filter

Remove the FlameGuard if neces-

sary.

Lift up the extraction grille.

Carefully remove the grease filter. En-

sure that you do not tilt the grease filter.

Pour out any liquid which has collec-

ted at the bottom of the grease filter.

Cleaning the extraction grille and the grease filter by hand

Clean the extraction grille and the

grease filter with a soft nylon brush in

a mild solution of hot water and a

little washing-up liquid. Do not use

concentrated washing-up liquid.

Cleaning the extraction grille and the grease filter in the dishwasher

Place the extraction grille upright in

the lower basket.

Place the grease filter with its base

facing upwards in the lower basket.

Ensure the spray arm is not obstructed.

Use a standard household dish-

washer detergent.

Select a dishwasher programme with

a maximum wash temperature of:

- 55°C for the extraction grille

- 65°C for the grease filter

Depending on the detergent used,

cleaning the grease filter in a dishwasher can cause permanent discolouration to the internal surfaces of the

filter. However, this will not affect the

functioning of the grease filter in any

way.

24

Fitting the grease filter

Fit the grease filter so that the straight

side of the grease filter is on the side

that connects to the air duct.

Example: connector for air duct on the

left

Interior of the casing

When removing the grease filter for

cleaning, also clean off any accessible oil or fat build-up from the casing. Doing so will prevent a fire hazard.

Cleaning and care

25

Problem solving guide

Many malfunctions and faults that can occur in daily operation can be easily

remedied. Time and money will be saved because a service call will not be

needed.

The following guide may help you to find the reason for a malfunction or a fault,

and to correct it.

Problem Cause and remedy

The SmartLine element

cannot be switched on.

The power levels 1 to B

light up one after the

other.

There is no power to the SmartLine element.

Check whether the mains fuse has tripped. Con-

tact an electrician or Miele Service (for the minimum fuse rating, see data plate).

There may be a technical fault.

Disconnect the SmartLine element from the mains

electricity supply for approx. 1 minute by

– tripping the relevant mains fuse or screwing the

fuse out completely, or

– switching off the residual current protection

device.

If, after resetting the trip switch in the mains fuse

box or the residual current protection device, the

SmartLine element will still not switch on, contact

a qualified electrician or Miele Service.

An automatic reset is performed after an interruption to the power supply.

26

Optional accessories

Miele offer a comprehensive range of

useful accessories as well as cleaning

and conditioning products for your

Miele appliances.

These products can be ordered through

the Miele Webshop.

They can also be ordered from Miele

(see end of this booklet for contact details) or from your Miele dealer.

FlameGuard

For installing between the downdraft

extractor and a gas cooking element

Ceramic and stainless steel

hob cleaner 250ml

Removes heavy soiling, limescale deposits and aluminium residues

Microfibre cloth

Removes finger marks and light soiling

27

After sales service

Contact in the event of a fault

In the event of any faults which you cannot remedy yourself, please contact your

Miele dealer or the Miele Customer Service Department.

You can book a Miele Customer Service Department call-out online at

www.miele.com/service.

Contact information for the Miele Customer Service Department can be found at

the end of this document.

Please quote the model identifier and serial number of your appliance (Fabr./SN/

Nr.) when contacting the Miele Customer Service Department. This information

can be found on the data plate.

Please note that telephone calls may be monitored and recorded for training purposes and that a call-out charge will be applied to service visits where the problem

could have been resolved as described in this booklet.

Data plate

Stick the extra data plate supplied with the appliance here. Make sure that the

model number matches the one specified on the back cover of this document.

Warranty

For information on the appliance warranty specific to your country please contact

Miele. See back cover for address.

In the UK, your appliance warranty is valid for 2 years from the date of purchase.

However, you must activate your cover by calling 0330 160 6640 or registering online at www.miele.co.uk.

28

*INSTALLATION*

Installation

Safety instructions for installation

Damage risk from incorrect installation.

Incorrect installation can cause damage to the SmartLine element.

The SmartLine element must only be installed by a qualified person.

Damage from falling objects.

Take care not to damage the SmartLine element when fitting wall units above it.

Fit the wall units before the SmartLine element.

After installation, the mains connection cable of the SmartLine

element must not come into contact with any moving kitchen component (e.g. a drawer) or be subject to mechanical loads which could

damage it.

Combination with gas appliances

Only Miele CS 7xxx gas appliances may be installed next to the

downdraft extractor.

Observe carefully the safety clearances listed on the following

pages.

Exhaust ducting must be of non-inflammable material. Suitable

material is available from Miele specialist dealers or the Miele Spares

Dept.

The appliance must not be connected to a chimney or flue which

is in use. Neither should it be connected to ducting which ventilates

rooms with fireplaces.

If exhaust air is to be extracted into a chimney or ventilation duct

no longer used for other purposes, seek professional advice.

29

*INSTALLATION*

Installation

Installation examples

Recirculation mode

Extraction mode

30

*INSTALLATION*

Installation

Surface-mounted

Installation notes – surface-mounted

Sealing between the SmartLine Element and the worktop

The SmartLine element and worktop

may be damaged if the element

needs to be removed after it has

been sealed with a sealant.

Do not use any sealant between the

SmartLine element and the worktop.

The seal under the edge of the top

part of the appliance provides a sufficient seal for the worktop.

Tiled worktop

Grout lines and the hatched area underneath the SmartLine element frame

must be smooth and even. If they are

not, the SmartLine element will not sit

flush with the worktop and the sealing

strip underneath the top part of the appliance will not provide a good seal

between the appliance and the worktop.

Sealing strip

Dismantling the SmartLine element

for service purposes may damage

the sealing strip underneath the edge

of the SmartLine element.

Always replace the sealing strip before reinstalling the SmartLine element.

31

*INSTALLATION*

Installation

Installing several SmartLine elements

The gaps between the individual SmartLine elements are sealed with a silicone

sealant that is heat-resistant to at least

160°C. With flush-fit installation, the

gap between the SmartLine element(s)

and the worktop must also be sealed

with a silicone sealant that is heat-resistant to at least 160°C.

After installation, the SmartLine elements must be easily accessible from

below, so that the bottom half of the

casing can be removed for maintenance. If the SmartLine elements are not

accessible from below, the sealant must

be removed so that they can be removed.

Worktop depth

The downdraft extractor can be installed with the connector for the air

duct on either the right or the left-hand

side.

Minimum worktop depth for

- Right connector 600mm

- Left connector 665mm

32

*INSTALLATION*

Installation

Connecting sleeve

The connecting sleeve makes it easier

to perform servicing and repair work.

The position of the connecting sleeve is

determined by the worktop depth.

Connecting sleeve – worktop depth

600mm

1 Duct piece at least 100mm long

2 Duct piece, rest of duct, adapted to

the height of the base unit

Connecting sleeve – worktop deeper

than 600mm

1 Connection angle in the direction of

the worktop

2 Duct piece, adapted to the height of

the base unit

33

*INSTALLATION*

Installation

Worktop cutout – surface-mounted

Information for calculating the cutout

The elements overlap the worktop by 10mm.

When installing several elements, a distance of 2mm must be observed between

the individual elements.

Calculating cutout dimensionB

1 element = Width of the element minus 10mm on the right, minus 10mm on the

left

Several elements = Total width of the elements plus 2mm distance between the

elements, minus 10mm on the right, minus 10mm on the left.

Some examples are illustrated below.

34

*INSTALLATION*

Installation with a downdraft extractor

Combination examples Numberxwidth [mm] Dimen-

Cooking ele-

Downdraft ex-

ments

1x378 1x120

tractor

Installation

sionB

[mm]

+1

480

2x378 1x120

1x378

2x120

1x620

3x378 2x120

2x378

2x120

1x620

4x378 2x120

1x620 2x120

860

1224

1362

1604

1742

844

+1

+1

+1

+1

+1

+1

35

*INSTALLATION*

Installation

Installation without a downdraft extractor

Combination examples Numberxwidth [mm] DimensionB

Cooking elements

1x378

[mm]

358

+1

2x378

1x378

1x620

3x378

2x378

1x620

4x378

738

980

1118

1360

1498

+1

+1

+1

+1

+1

36

*INSTALLATION*

Installation

Spacer bars – surface-mounted

When installing several SmartLine elements, an additional spacer bar must be fitted in between the individual elements.

The clips supplied with the spacer bars are only required for installing a

CSDA700xFL.

Installing 3elements and 2spacer bars

Spacer bars for the downdraft extractor – surface-mounted

a

Brackets

37

*INSTALLATION*

Installation

Installation dimensions–Surface-mounted

All dimensions are given in mm.

a

Front

b

Fan (in the plinth on the floor)

c

Air duct

d

E-box

38

*INSTALLATION*

Air duct dimensions – surface-mounted – worktop depth

600mm

Side view

Installation

39

*INSTALLATION*

Installation

a

For maintenance work it must be possible to remove the rear cabinet wall.

The cabinet wall and an adjoining room wall or a piece of furniture must be at

least 110mm apart to ensure sufficient room for the ducting.

b

After installation the removable drip tray must be accessible from below.

2quick-release catches have to be opened to remove the tray.

c

Duct length must be adapted to the height of the base unit.

Standard delivery 500mm

Installing the connecting sleeve, see “Installation – Installation notes – surfacemounted”.

d

Plinth fan

Front view

40

*INSTALLATION*

View from above

Installation

41

*INSTALLATION*

Installation

Air duct dimensions – surface-mounted – worktop depth greater

than 600mm

View from the side – right air duct connection

42

*INSTALLATION*

a

For maintenance work it must be possible to remove the rear cabinet wall.

The cabinet wall and an adjoining room wall or a piece of furniture must be at

least 110mm apart to ensure sufficient room for the ducting.

b

Duct connecter, adapted to the worktop depth

c

After installation the removable drip tray must be accessible from below.

2quick-release catches have to be opened to remove the tray.

d

Duct length must be adapted to the height of the base unit.

Standard delivery 500mm

Installing the connecting sleeve, see “Installation – Installation notes – surfacemounted”.

e

Plinth fan

x Dimension of which the worktop is deeper than 600mm.

View from the front – right air duct connection

Installation

43

*INSTALLATION*

Installation

View from above – right air duct connection

44

*INSTALLATION*

If you want to install the air duct to the left of the downdraft extractor, the worktop must be at least 665mm deep.

View from the front – left air duct connection

Installation

View from above – left air duct connection

45

*INSTALLATION*

Installation

Installation – surface-mounted

If the worktop is more than 24mm

deep, it must be cut out underneath

on the building-in side on the right or

left hand side.

a

Worktop

b

Maximum 24mm

c

12mm

Securing the brackets

1bracket (supplied with the spacer bar)

must be secured centrally to the right or

left-hand side of the cutout.

Wooden worktops

Fit the bracket so that it sits flush

with the top edge of the worktop

cutout.

Secure the bracket with the

3.5x25mm wood screws supplied.

Natural stone worktops

You will need heavy-duty doublesided tape (not supplied) to secure the

bracket.

46

Stick the tape along the top edge of

the worktop cutout.

Fit the bracket so that it sits flush

with the top edge of the worktop

cutout.

Press the bracket firmly into position.

*INSTALLATION*

Installation

Preparing the worktop

Create the worktop cutout. Remem-

ber to maintain the minimum safety

distances (see “Installation – Safety

distances”).

Seal any cut surfaces on wooden

worktops with a special varnish, sil-

icone sealant or resin to prevent the

wood from swelling as a result of

moisture ingress. The sealant must

be heat-resistant.

Make sure that the sealant does not

come into contact with the top of the

worktop.

Fitting the spacer bars

Use the middle screw holes if one of the

following SmartLine elements is installed to the right or left of the spacer

bar: CS7611, CS 7641, CS7101(-1),

CS7102(-1)

Wooden worktops

Position the spacer bars flush onto

the upper edge of the cutout.

Secure the spacer bars with the

3.5x25mm wood screws supplied.

Natural stone worktops

You will need heavy-duty doublesided tape (not supplied) to secure the

spacer bars.

Stick the tape along the top edge of

the worktop cutout.

Position the spacer bars flush onto

the upper edge of the cutout.

Press the spacer bars firmly into

place.

47

*INSTALLATION*

Installation

Installing the downdraft extractor

The downdraft extractor can be installed with the connector for the air

duct on either the right or the left-hand

side.

Remove the grease trap from the cas-

ing.

a

Connector for air duct on the right

b

Connector for air duct on the left

Stick the sealing strip supplied under

the edge of the cover. Do not apply

the sealing strip under tension.

Fit the clips onto the spacer bars.

Guide the control cable downwards

between the spacer bars.

Fit the cover onto the spacer bars.

48

Fasten the casing from the inside with

the screws on the right and left

sides (3 in each case).

Fasten the grease trap.

Mount the air duct.

If the vent ducting does not sit se-

curely up against the exhaust duct,

stick the sealing strip supplied to it.

*INSTALLATION*

Installation

Ensure that the air duct is not under

mechanical tension after installation.

E-box

a

Mains connection cable

b

Connection to window contact

c

Electrical connection socket for the

fan operating voltage cable

d

Electrical connection socket for the

fan control cable

e

Electrical connection socket for the

control unit cable

49

*INSTALLATION*

Installation

Connection to window contact, if required

The window contact connection

is live!

Danger of electric shock!

Disconnect the countertop extractor

from the mains before connecting

the switching system.

The connection cable of the switching system must only be connected

by a suitably qualified and competent electrician.

The connection cable of the switching system must comply with type

H03VV-F 2x0.75mm2 and must not

exceed 2.0m in length.

The switching system must be

equipped with a potential-free contact suitable for 230V, 1A. The extractor is switched off when the

switch is open.

Only use DIPT-approved and tested

radio switching systems (e.g. window

contact switches, pressure switches)

and have them approved by authorised specialists (e.g. building regulations inspector).

The switching system must be suitable for use with a BLDC motor.

You will need the appropriate external switching system documents

to safely connect and operate the

switch.

50

*INSTALLATION*

Installation

Loosen the lug and pull the plug out.

Loosen the strain relief screw and

unlock the casing on both sides.

Open the casing.

Remove the stopper.

Exchange the bridge for the con-

nection cable of the switching sys-

tem.

Close the casing.

Connecting the e-box

Connect the operating voltage and

fan control cables to the e-box and

the fan.

Connect the control unit cable to the

e-box.

The socket positions are designed in

such a way that they cannot be mixed

up.

Connect the downdraft extractor to

the mains.

Check that the downdraft extractor

works.

Sealing the gaps

Seal the gaps between the individual

SmartLine elements, and between the

flush-mounted SmartLine elements

and the worktop, with a silicone sealant that is heat-resistant to at least

160°C.

Unsuitable sealant can damage natural stone.

For natural stone worktops and natural stone tiles, only use silicone

sealant that is specially formulated

for natural stone.

Please follow the manufacturer's instructions.

Tighten the strain relief screw.

Reinsert the plug.

51

*INSTALLATION*

Installation

Flush-fit

Installation notes – flush-fit

Flush-fit installation is only possible in

natural stone (granite, marble), solid

wood and tiled worktops. For installation in worktops made of other materials, please consult the relevant manufacturer as to whether their worktops

are suitable for flush-fit installation.

The internal width of the base unit underneath the appliance must be at

least as wide as the inner worktop

cutout (see “Installation – Building-in

dimensions – flush-fit”), so that the

SmartLine element is easily accessible

from underneath after installation and

the bottom half of the casing can be

removed for maintenance. If the element is not freely accessible from below after installation, the sealant must

be removed so that the element can

be removed.

Natural stone worktops

The SmartLine element is set directly in

the cutout.

Solid wood worktops, tiled worktops,

glass worktops

The SmartLine element is set on a

wooden frame inside the cutout. The

frame must be provided on site, and is

not supplied with the appliance.

Sealing strip

Dismantling the SmartLine element

for service purposes may damage

the sealing strip underneath the edge

of the SmartLine element.

Always replace the sealing strip before reinstalling the SmartLine element.

52

*INSTALLATION*

Installation

Installing several SmartLine elements

The gaps between the individual SmartLine elements are sealed with a silicone

sealant that is heat-resistant to at least

160°C. With flush-fit installation, the

gap between the SmartLine element(s)

and the worktop must also be sealed

with a silicone sealant that is heat-resistant to at least 160°C.

After installation, the SmartLine elements must be easily accessible from

below, so that the bottom half of the

casing can be removed for maintenance. If the SmartLine elements are not

accessible from below, the sealant must

be removed so that they can be removed.

Worktop depth

The downdraft extractor can be installed with the connector for the air

duct on either the right or the left-hand

side.

Minimum worktop depth for

- Right connector 600mm

- Left connector 665mm

53

*INSTALLATION*

Installation

Connecting sleeve

The connecting sleeve makes it easier

to perform servicing and repair work.

The position of the connecting sleeve is

determined by the worktop depth.

Connecting sleeve – worktop depth

600mm

1 Duct piece at least 100mm long

2 Duct piece, rest of duct, adapted to

the height of the base unit

Connecting sleeve – worktop deeper

than 600mm

1 Connection angle in the direction of

the worktop

2 Duct piece, adapted to the height of

the base unit

54

*INSTALLATION*

Worktop cutout – flush-fit

Installation

Natural stone worktop Wooden worktop

0.5

+

* 7

mm with CS7611FL

Information for calculating the cutout

The elements overlap the worktop by 10mm.

When installing several elements, a distance of 2mm must be observed between

the individual elements.

Calculating cutout dimensionA

1 element = Width of the element plus 2mm on the right, plus 2mm on the left.

Several elements = Total width of the elements plus 2mm distance between the

elements, plus 2mm on the right, plus 2mm on the left

Calculating cutout dimensionB = Cutout dimension A minus 12mm on the right,

minus 12mm on the left.

Some examples are illustrated below.

55

*INSTALLATION*

Installation

Installation with a downdraft extractor

Combination examples Numberxwidth [mm] Dimen-

Cooking ele-

ments

Downdraft

extractor

1x378 1x120

2x378 1x120

1x378

2x120

sionA

[mm]

504

884

1248

+1

+1

+1

1x620

3x378 2x120

2x378

2x120

1386

1628

+1

+1

1x620

4x378 2x120

1x620 2x120

1766

868

+1

+1

Dimen-

sionB

[mm]

+1

480

+1

860

+1

1224

+1

1362

+1

1604

+1

1742

+1

844

56

*INSTALLATION*

Installation without a downdraft extractor

Installation

Combination examples

Numberxwidth

[mm]

Cooking elements

1x378

2x378

1x378

1x620

3x378

2x378

1x620

4x378

DimensionA

[mm]

+1

382

+1

762

+1

1004

+1

1142

+1

1384

+1

1522

DimensionB

[mm]

+1

358

+1

738

+1

980

+1

1118

+1

1360

+1

1498

57

*INSTALLATION*

Installation

Spacer bars – flush-fit

When installing several SmartLine elements, an additional spacer bar must be fitted in between the individual elements.

The clips supplied with the spacer bars are only required for installing a

CSDA700xFL.

Installing 3elements and 2spacer bars

Spacer bars for the downdraft extractor – flush-fit

a

Brackets

58

*INSTALLATION*

Installation dimensions–Flush

All dimensions are given in mm.

Installation

a

Front

b

Fan (in the plinth on the floor)

c

Stepped cutout (for detailed illustrations, see “Installation – Worktop

cutout – flush-fit”)

d

12mm wooden frame (not supplied,

for detailed illustrations, see “Installation – Worktop cutout – flush-fit”)

e

Air duct

f

E-box

59

*INSTALLATION*

Installation

Air duct dimensions – flush-fit – worktop depth 600mm

Side view

a

For maintenance work it must be possible to remove the rear cabinet wall.

The cabinet wall and an adjoining room wall or a piece of furniture must be at

least 110mm apart to ensure sufficient room for the ducting.

60

*INSTALLATION*

Installation

b

After installation the removable drip tray must be accessible from below.

2quick-release catches have to be opened to remove the tray.

c

Duct length must be adapted to the height of the base unit.

Standard delivery 500mm

Installing the connecting sleeve, see “Installation – Installation notes – flush-fit”.

d

Plinth fan

Front view

61

*INSTALLATION*

Installation

View from above

62

*INSTALLATION*

Air duct dimensions – flush-fit – worktop depth greater than

600mm

View from the side – right air duct connection

Installation

63

*INSTALLATION*

Installation

a

For maintenance work it must be possible to remove the rear cabinet wall.

The cabinet wall and an adjoining room wall or a piece of furniture must be at

least 110mm apart to ensure sufficient room for the ducting.

b

Duct connecter, adapted to the worktop depth

c

After installation the removable drip tray must be accessible from below.

2quick-release catches have to be opened to remove the tray.

d

Duct length must be adapted to the height of the base unit.

Standard delivery 500mm

Installing the connecting sleeve, see “Installation – Installation notes – flush-fit”.

e

Plinth fan

x Dimension of which the worktop is deeper than 600mm.

View from the front – right air duct connection

64

*INSTALLATION*

View from above – right air duct connection

Installation

65

*INSTALLATION*

Installation

If you want to install the air duct to the left of the downdraft extractor, the worktop must be at least 665mm deep.

View from the front – left air duct connection

View from above – left air duct connection

66

*INSTALLATION*

Installation

Installation – flush-fit

If the worktop is more than 28mm

deep, it must be cut out underneath

on the building-in side on the right or

left hand side.

a

Worktop

b

Maximum 24mm

c

12mm

Securing the brackets

1bracket (supplied with the spacer bar)

must be secured centrally to the right or

left-hand side of the cutout.

Wooden worktops

Fit the bracket so that it sits flush

with the top edge of the lower step of

the stepped cutout.

Secure the bracket with the

3.5x25mm wood screws supplied.

Natural stone worktops

You will need heavy-duty doublesided tape (not supplied) to secure the

bracket.

Stick the tape onto the upper edge of

the lower step of the stepped cutout.

Fit the bracket so that it sits flush

with the top edge of the lower step of

the stepped cutout.

Press the bracket firmly into position.

67

*INSTALLATION*

Installation

Preparing the worktop

Create the worktop cutout. Remem-

ber to maintain the minimum safety

distances (see “Installation – Safety

distances”).

Seal any cut surfaces on wooden

worktops with a special varnish, sil-

icone sealant or resin to prevent the

wood from swelling as a result of

moisture ingress. The sealant must

be heat-resistant.

Make sure that the sealant does not

come into contact with the top of the

worktop.

For wooden worktops, secure the

wooden frame 5.5mm below the up-

per edge of the worktop.

For CS7611FL, the wooden frame

must be secured 7mm under the up-

per edge of the worktop.

Fitting the spacer bars

Use the middle screw holes if one of the

following SmartLine elements is installed to the right or left of the spacer

bar: CS7611, CS 7641, CS7101(-1),

CS7102(-1)

Wooden worktops

Position the spacer bars flush onto

the lower step of the stepped cutout.

Secure the spacer bars with the

3.5x25mm wood screws supplied.

Natural stone worktops

You will need heavy-duty doublesided tape (not supplied) to secure the

spacer bars.

68

Stick the tape onto the lower step of

the stepped cutout.

Position the spacer bars flush onto

the lower step of the stepped cutout.

Press the spacer bars firmly into

place.

*INSTALLATION*

Installing the downdraft extractor

The downdraft extractor can be installed with the connector for the air

duct on either the right or the left-hand

side.

Installation

Remove the grease trap from the cas-

ing.

a

Connector for air duct on the right

b

Connector for air duct on the left

Stick the sealing strip supplied under

the edge of the cover. Do not apply

the sealing strip under tension.

Fit the clips onto the spacer bars.

Guide the control cable downwards

between the spacer bars.

Fit the cover onto the spacer bars.

Fasten the casing from the inside with

the screws on the right and left

sides (3 in each case).

Fasten the grease trap.

Mount the air duct.

If the vent ducting does not sit se-

curely up against the exhaust duct,

stick the sealing strip supplied to it.

69

*INSTALLATION*

Installation

Ensure that the air duct is not under

mechanical tension after installation.

E-box

a

Mains connection cable

b

Connection to window contact

c

Electrical connection socket for the

fan operating voltage cable

d

Electrical connection socket for the

fan control cable

e

Electrical connection socket for the

control unit cable

70

*INSTALLATION*

Connection to window contact, if required

The window contact connection

is live!

Danger of electric shock!

Disconnect the countertop extractor

from the mains before connecting

the switching system.

The connection cable of the switching system must only be connected

by a suitably qualified and competent electrician.

The connection cable of the switching system must comply with type

H03VV-F 2x0.75mm2 and must not

exceed 2.0m in length.

The switching system must be

equipped with a potential-free contact suitable for 230V, 1A. The extractor is switched off when the

switch is open.

Only use DIPT-approved and tested

radio switching systems (e.g. window

contact switches, pressure switches)

and have them approved by authorised specialists (e.g. building regulations inspector).

The switching system must be suitable for use with a BLDC motor.

You will need the appropriate external switching system documents

to safely connect and operate the

switch.

Installation

71

*INSTALLATION*

Installation

Loosen the lug and pull the plug out.

Loosen the strain relief screw and

unlock the casing on both sides.

Open the casing.

Remove the stopper.

Exchange the bridge for the con-

nection cable of the switching sys-

tem.

Close the casing.

Connecting the e-box

Connect the operating voltage and

fan control cables to the e-box and

the fan.

Connect the control unit cable to the

e-box.

The socket positions are designed in

such a way that they cannot be mixed

up.

Connect the downdraft extractor to

the mains.

Check that the downdraft extractor

works.

Sealing the gaps

Seal the gaps between the individual

SmartLine elements, and between the

flush-mounted SmartLine elements

and the worktop, with a silicone sealant that is heat-resistant to at least

160°C.

Unsuitable sealant can damage natural stone.

For natural stone worktops and natural stone tiles, only use silicone

sealant that is specially formulated

for natural stone.

Please follow the manufacturer's instructions.

Tighten the strain relief screw.

Reinsert the plug.

72

*INSTALLATION*

Ducting

If the downdraft extractor is used

at the same time as a heating appliance that relies on oxygen from the

same room, there is a risk of toxic

fumes.

It is essential that the “Warning and

Safety” instructions are observed.

The downdraft extractor should be

installed according to local and national building regulations. Seek approval from the building inspector

where necessary.

The downdraft extractor has an exhaust

connection of 222x89mm.

Use smooth pipes or flexible ducting

made from non-flammable materials

for vent ducting.

To achieve the most efficient air ex-

traction with the lowest noise levels,

please note the following:

Installation

If the exhaust air is to be ducted into

a flue, the ducting must be directed in

the flow direction of the flue.

If ducting is to be laid horizontally it

must be laid with a downwards sloping gradient. This is to ensure that

condensate cannot drain back into

the extractor.

If the vent ducting is to run through

rooms, ceiling space, etc. there may

be great variations in temperature

between the different areas. The

problem of condensation will need to

be addressed. The vent ducting will

need to be suitably insulated.

- The cross-section of the vent ducting

must not be smaller than the crosssection of the exhaust connection

(see “Appliance dimensions”).

- The vent ducting should be as short

and straight as possible.

- Only use wide radius bends.

- The vent ducting must not be kinked

or compressed.

- Ensure that all connections are

strong and airtight.

Remember that any constriction of

the air flow will reduce extraction

performance and increase operating

noise.

a

Sealing tape

Stick the sealing strip supplied to the

fan connection.

73

*INSTALLATION*

Installation

Electrical connection

We recommend that you connect the

SmartLine element to the mains via a

suitable switched electrical socket. This

makes it easier to perform servicing

work. The socket must be easily accessible after the SmartLine element

has been installed.

Danger of injury!

Installation, repairs and other work

by unqualified persons could be dangerous. Miele cannot be held liable

for unauthorised work.

Miele cannot be held liable for damage or injury caused by the lack of or

inadequacy of an on-site earthing

system (e.g. electric shock).

If the plug is removed from the connection cable or if the cable is supplied without a plug, the SmartLine

element must be connected to the

electrical supply by a suitably qualified electrician.

If the socket is no longer accessible,

or if a hard-wired connection is

planned, an additional means of disconnection must be provided for all

poles. Suitable means of disconnection include switches with an all-pole

contact gap of at least 3mm. These

include miniature circuit breakers,

fuses and contactors. The required

connection data is given on the data

plate. Please ensure this information

matches the mains supply.

After installation, ensure that all electrical components are shielded and

cannot be accessed by users.

Total power rating

See data plate

Connection data

The connection data is quoted on the

data plate. Please ensure these match

the household mains supply.

Residual current device

For extra safety, it is advisable to protect the SmartLine element with a suitable residual current device (RCD) with

a trip range of 30mA.

74

*INSTALLATION*

Installation

Disconnecting from the mains

Risk of electric shock.

There is a risk of electric shock if the

appliance is connected to the mains

supply during repair or service work.

After disconnection, ensure the appliance cannot be switched back on

by mistake.

To disconnect the appliance from the

mains power supply, do one of the following depending on installation:

Safety fuses

Completely remove fuses.

Automatic circuit breakers

Press the (red) test button until the

middle (black) button springs out.

Built-in circuit breakers

Circuit breakers at least type B or C:

Switch the lever from 1 (on) to 0 (off).

Replacing the mains connection cable

Risk of electric shock.

Incorrect connection to the power

supply may result in an electric

shock.

The mains cable must only be replaced by a qualified electrician.

When replacing the mains cable only

use cable type H05VV-F with a suitable cross section. A suitable connection cable is available to order from

Miele.

Residual current device (RCD)

Switch the main switch from 1 (on) to

0 (off) or press the test button.

75

Product data sheets

The following data sheets apply to the models described in this operating instruction manual.

Data sheet for household cooker hoods

In acc. with delegated regulation (EU) No. 65/2014 and regulation (EU) No.

66/2014

MIELE

Model name/identifier CSDA 7001 FL

Annual Energy Consumption (AEC

Energy efficiency class A++

Energy efficiency index (EEI

Fluid Dynamic Efficiency (FDE

Fluid Dynamic Efficiency class

A (most efficient) to G (least efficient) A

Lighting Efficiency (LE

Lighting Efficiency class

A (most efficient) to G (least efficient) -

Grease Filtering Efficiency 93,3%

Grease Filtering Efficiency class

A (most efficient) to G (least efficient) B

Airflow at best efficiency point

Air flow (min. speed)

Air flow (max. speed)

Air flow (intensive or boost setting)

Max. air flow (Q

Air pressure at best efficiency point 448 Pa

Airborne acoustical A-weighted sound power emissions (min. speed) 39 dB

Airborne acoustical A-weighted sound power emissions (max. speed) 65 dB

Airborne acoustical A-weighted sound power emissions (intensive or

boost setting)

Electrical power input at best efficiency point 100,6 W

Power consumption in off mode (Po) W

Power consumption in standby mode (Ps) 0,30 W

Nominal power of lighting system 0,0 W

Average illumination of the lighting system on the cooking surface 0 Ix

Time increase factor 0,7

max

)

hood

) lx/W

hood

) 25,3 kWh/year

hood

) 35,8

) 36,4

hood

294,5 m3/h

145 m3/h

460 m3/h

560 m3/h

560 m3/h

69 dB

76

United Kingdom

Miele Co. Ltd., Fairacres, Marcham Road, Abingdon, Oxon, OX14 1TW

Tel: 0330 160 6600, Internet: www.miele.co.uk/service, E-mail: info@miele.co.uk

Australia

Miele Australia Pty. Ltd.

ACN 005 635 398

ABN 96 005 635 398

1 Gilbert Park Drive

Knoxfield, VIC 3180

Tel: 1300 464 353

Internet: www.miele.com.au

Miele Electrical Appliances Co., Ltd.

1-3 Floor, No. 82 Shi Men Yi Road

Jing' an District

200040 Shanghai, PRC

Tel: +86 21 6157 3500

Fax: +86 21 6157 3511

E-mail: info@miele.cn,

Internet: www.miele.cn

China Mainland

Miele (Hong Kong) Ltd.

41/F - 4101, Manhattan Place

23 Wang Tai Road

Kowloon Bay, Hong Kong

Tel: (852) 2610 1025

Fax: (852) 3579 1404

Email:

customerservices@miele.com.hk

Website: www.miele.hk

Hong Kong, China

Miele India Pvt. Ltd.

Ground Floor, Copia Corporate Suites

Plot No. 9, Jasola

New Delhi - 110025

Tel: 011-46 900 000

Fax: 011-46 900 001

E-mail: customercare@miele.in

Internet: www.miele.in

India

Miele Ireland Ltd.

2024 Bianconi Avenue

Citywest Business Campus

Dublin 24

Tel: (01) 461 07 10

Fax: (01) 461 07 97

E-Mail: info@miele.ie

Internet: www.miele.ie

Ireland

Malaysia

Miele Sdn Bhd

Suite 12-2, Level 12

Menara Sapura Kencana

Petroleum

Solaris Dutamas No. 1

Jalan Dutamas 1

50480 Kuala Lumpur, Malaysia

Phone: +603-6209-0288

Fax: +603-6205-3768

Miele New Zealand Limited

IRD 98 463 631

8 College Hill

Freemans Bay, Auckland 1011

New Zealand

Tel: 0800 464 353

Internet: www.miele.co.nz

New Zealand

Miele Pte. Ltd.

29 Media Circle

#11-04 ALICE@Mediapolis

Singapore 138565

sTel: +65 6735 1191

Fax: +65 6735 1161

E-Mail: info@miele.com.sg

Internet: www.miele.sg

Singapore

Miele (Pty) Ltd.

63 Peter Place

Bryanston 2194

P.O. Box 69434

Bryanston 2021

Tel: (011) 875 9000

Fax: (011) 875 9035

E-mail: info@miele.co.za

Internet: www.miele.co.za

South Africa

Miele Appliances Ltd.

Showroom 1

Eiffel 1 Building

P.O. Box 114782 - Dubai

Tel. +971 4 3044 999

Fax. +971 4 3418 852

800-MIELE (64353)

E-Mail: info@miele.ae

Website: www.miele.ae

United Arab Emirates

Manufacturer:

Miele & Cie. KG, Carl-Miele-Straße 29, 33332 Gütersloh, Germany

Thailand

Miele Appliances Ltd.

BHIRAJ TOWER at EmQuartier

43rd Floor Unit 4301-4303

689 Sukhumvit Road

North Klongton Sub-District

Vadhana District

Bangkok 10110, Thailand

Sheikh Zayed Road, Umm Al Sheif

CSDA7001 FL

M.-Nr. 11 480 260 / 02en-GB

Loading...

Loading...