Page 1

NIRS

Analyzer PRO

Manual

8.928.8004EN

Page 2

Page 3

Metrohm AG

CH-9100 Herisau

Switzerland

Phone +41 71 353 85 85

Fax +41 71 353 89 01

info@metrohm.com

www.metrohm.com

NIRS

Analyzer PRO

Manual

8.928.8004EN 03.2013 fpe

Page 4

Teachware

Metrohm AG

CH-9100 Herisau

teachware@metrohm.com

This documentation is protected by copyright. All rights reserved.

Although all the information given in this documentation has been checked with great care, errors

cannot be entirely excluded. Should you notice any mistakes please send us your comments using the

address given above.

Page 5

▪▪▪▪▪▪▪

Change Control

Version

Date

Summary of Changes

1.0

Dec. 2,

2012

Document first release, initiated change control

Change control on this document is as follows:

3

Page 6

▪▪▪▪▪▪▪

Table of contents

1 Introduction ................................................................................................................... 5

1.1 Information Disclaimer ................................................................................. 7

2 Hardware Familiarization .............................................................................................. 8

2.1 Lamp Housing .............................................................................................. 8

2.2 Optical Switch .............................................................................................. 8

2.3 Diode Array Spectrometer ............................................................................ 9

3 Specifications............................................................................................................... 11

3.1 Window Reflectance .................................................................................. 12

3.2 MicroBundle Fiber Optic Interface .............................................................. 12

3.3 Direct Light ................................................................................................ 13

4 Mounting Information ................................................................................................. 14

4.1 4.1 Mounting Frame, U-Bolts Secured to Mounting Flanges ...................... 14

4.2 Mounting by straps to blind plates ............................................................ 19

4.3 Weld Flange ............................................................................................... 20

5 Mounting Dimensions .................................................................................................. 22

6 Electrical Connection ................................................................................................... 23

7 Air Cooling Connection Kit........................................................................................... 30

8 Air Purge Connection (Used with “Spoon Probe”) ....................................................... 32

9 Fiber Optic Probe Mounting ........................................................................................ 34

10 Ethernet Connection .................................................................................. 35

11 Safety and Power-up .................................................................................. 37

12 Connection to Vision Software ................................................................... 38

13 Diagnostics ................................................................................................. 43

13.1 Window Reflection ..................................................................................... 43

13.1.1 Performance Test ................................................................................................. 43

13.1.2 Reference Standardization .................................................................................... 46

13.1.3 Wavelength Certification ...................................................................................... 50

13.2 MicroBundle Fiber Optic Sensing ............................................................... 52

13.2.1 Performance Test ................................................................................................. 52

13.2.2 Reference Standardization .................................................................................... 55

13.2.3 Wavelength Certification ...................................................................................... 59

13.3 Direct Light Sampling ................................................................................. 60

13.3.1 Performance Test ................................................................................................. 61

13.3.2 Reference Standardization (External Reference Correction) .................................... 64

14 Sampling .................................................................................................... 65

15 Standards and Approvals ........................................................................... 66

4

Page 7

▪▪▪▪▪▪▪

1 Introduction

Analyzer PRO is a rugged, compact Near-Infrared Process

Instrument, designed for the wavelength range from 1100-1650

nanometers. This is an excellent region for process analysis,

containing many second and third overtones of molecular

vibrations which can be measured.

The instrument is based upon high-resolution diode array

technology. The InGaAs diode array, with spectral dispersion of

1.1 nm/pixel, is a stable, intrinsically accurate method of NIR

absorbance measurement. It offers excellent peak shape

resolution, and contains no moving parts. Therefore, no

wavelength accuracy adjustment is needed, as there is no

measurable drift.

Sampling systems are as follows:

• Window Reflectance, where the sample passes in contact with the window on the side of the

instrument

• Reflectance Probe, using a 1” (25.4mm) diameter stainless steel probe

• Direct Light Reflectance, where the sample passes at a distance of 4-10 inches

(approximately 100-250mm) from the window

The analyzer is housed in a robust cabinet, designed for easy, reliable mounting at the desired

location in the production area. Mounting is simplified by use of industry-standard stainless steel

clamps, which facilitate installation and removal, as well as good positioning of the analyzer to the

sample.

The instrument may be mounted in any orientation, as long as the sample window is in the proper

location. The sample interface is normally placed at a point of production where the product is

pumped through a pipe, dryer, blender, or other feed mechanism. There should be no (or very few)

gaps or voids in the product flow, as these will cause measurement instability.

5

Page 8

▪▪▪▪▪▪▪

The Analyzer PRO vides non-destructive analysis of

chemical and pharmaceutical products directly in

the process line, without use of a bypass loop.

Because most materials can be measured directly,

with no need for sample dilution or preparation,

the material can be measured as produced, with

no loss of end product.

Operation of the Analyzer PRO is through

Metrohm Vision™ software, which is robust,

powerful, and easy to use. This validated software

package meets all 21 CFR Part 11 requirements,

and comes with a test script to prove compliance

for internal regulatory personnel. Combined with

normal customer procedures for network and user

access, all 21 CFR Part 11 requirements are met.

Vision provides excellent tools by which to develop an analytical model for sample prediction. The

NIR sample information is correlated with quantitative lab data from the primary analysis method,

and a predictive model is used to report values for ongoing sample analysis.

Communication between instrument and computer is by Ethernet line, using standard connectors.

Commands use a proprietary, encrypted language which is not susceptible to hacking, support of

viruses, or other means of hacking. Only authorized operators may communicate with the Analyzer

PRO instrument, and only by valid entry through Vision.

Measurements may be displayed in a control room area on the computer screen as they are reported

in the Routine Analysis section of Vision. Provision is made for digital electronic transfer to most

supported plant controller languages.

Use of the Analyzer PRO helps to optimize the use of raw materials by ongoing measurement in real

time. This permits adjustment and correction of the process to target values, eliminating or

minimizing waste product. The Analyzer PRO fits into Process Analytical Technology (PAT) planning,

in support of recent FDA process initiatives.

Precise instrument matching enhances method development, minimizes implementation efforts, and

ensures straightforward calibration model transferability between analyzers.

6

Page 9

▪▪▪▪▪▪▪

1.1 Information Disclaimer

This manual and the information herein are correct as of the time of publication, based upon the best

information available at the time. Configuration, options, and software information may change over

time, in keeping with the corporate philosophy of continuous improvement.

Metrohm NIRSystems and its distributors cannot be liable for changes to the customer process based

upon information contained in this manual which is subject to revision and update. Additionally, the

information and steps in this manual are not meant to serve as template standard operating

procedures for use in regulation industries. Customers should supply their own procedures for

internal users, based upon the specific samples, methods, and needs of the application.

Metrohm offers optional training and field support to assist in the technical aspects of calibration and

library development. The final responsibility lies with the user, who has access to calibration samples,

lab data, and other information required to build and maintain methods using this instrument.

7

Page 10

▪▪▪▪▪▪▪

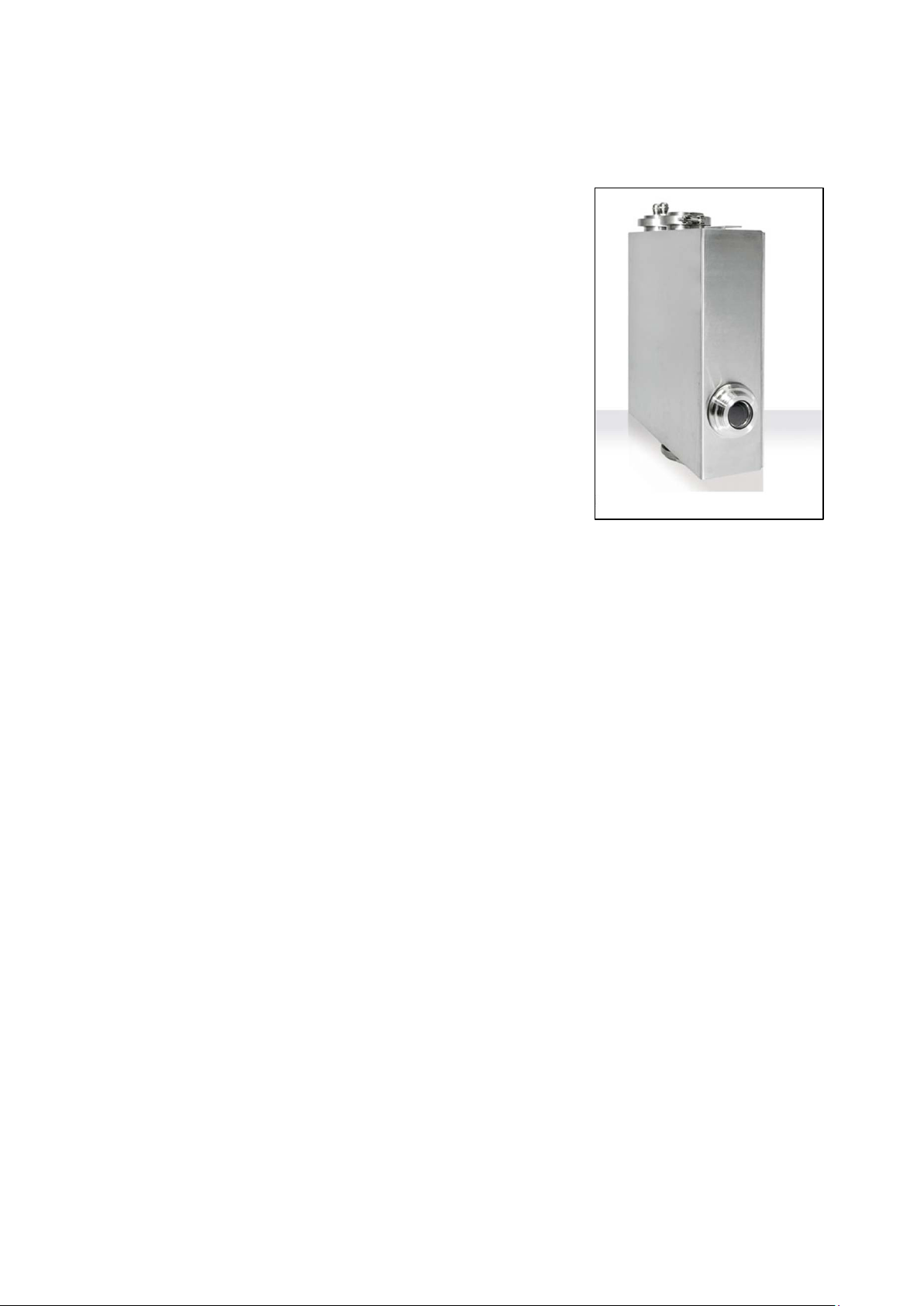

2 Hardware Familiarization

Analyzer PRO is built into a rugged, sealed stainless steel housing which is designed to withstand the

harsh production environment, including washdown.

Fiber optics are used with the Reflectance Probe design, and should always be protected from

damage and abuse. In particular, fiber bend radius should never be less than 6” (150mm). It is

strongly recommended that fibers be mounted in enclosed cable trays to minimize handling,

movement, and possible accidents.

The inside view of the instrument is as shown.

Primary components are as follows:

2.1 Lamp Housing

This contains two halogen lamps. Only one lamp is active at a time. If a lamp fails, the other is

automatically switched on, and a motor moves the Sample Illumination or “light-output” fiber to the

operating lamp. The Sample Illumination Fiber carries the light energy to the sampling point.

Note that the Lamp Housing also has a Reference Fiber for each lamp, which are routed to the

optical switch. These fibers are used to measure the background (reference) energy for each lamp.

The Optical Switch automatically moves to the correct position, based upon which lamp is in use.

2.2 Optical Switch

The Optical Switch receives the light reflected back from the sample, which has been modified by

interaction with the sample material. The other inputs to the Optical Switch are the two Reference

fibers from Lamps #1 and #2, along with a “Dark Signal” reference. The Optical Switch, under control

of the on-board electronics, measures the energy returning from the sample, compares this with the

energy level sent to the sample, and scales the signal to create an absorbance spectrum over the

8

Page 11

▪▪▪▪▪▪▪

wavelength range from 1100-1650 nm. (The optical switch may be heard moving when instrument

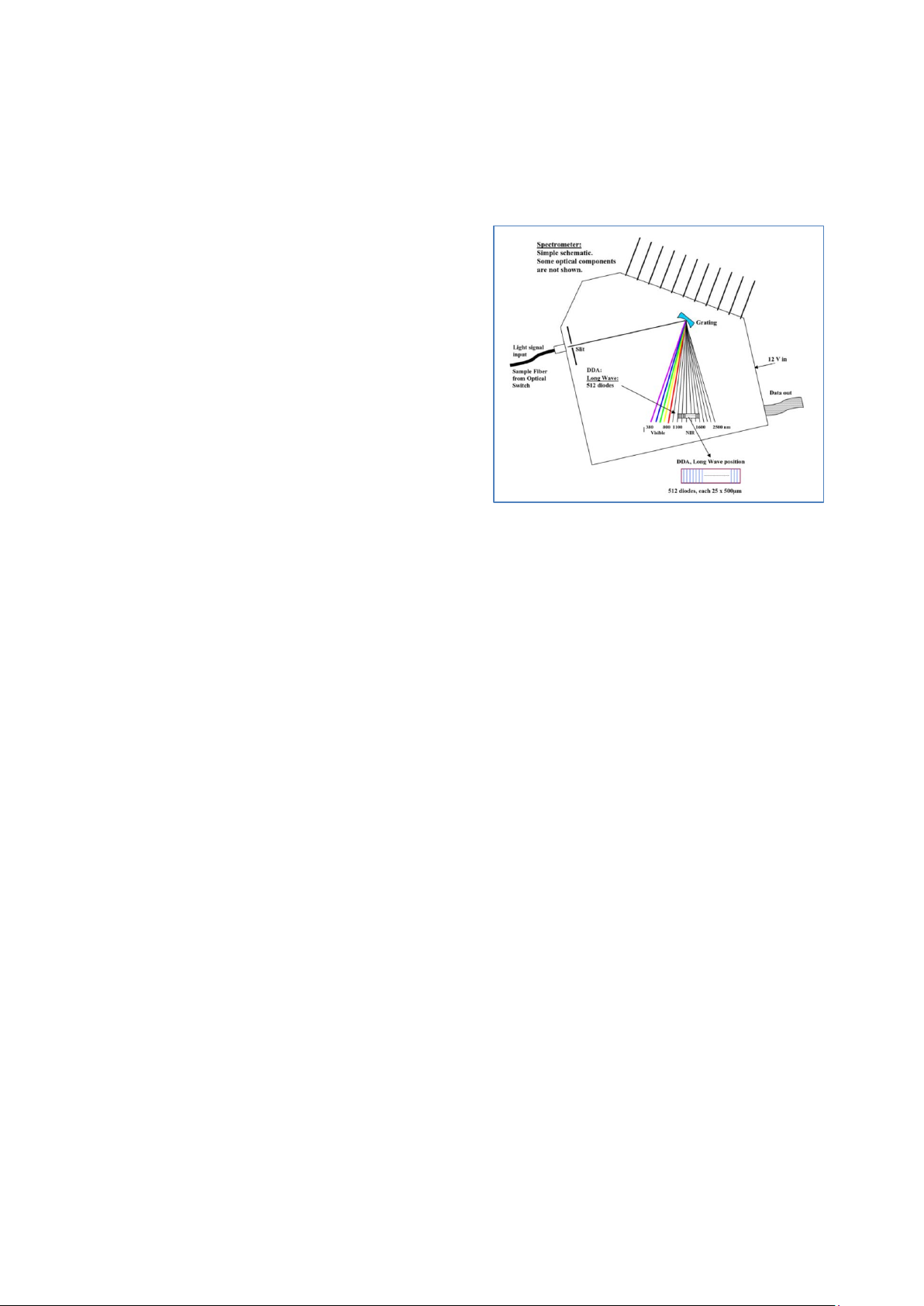

The diode-array spectrometer is composed of 512

scans are taken, if the ambient noise level is low enough.)

2.3 Diode Array Spectrometer

discrete InGAs detector diodes. It has no moving

parts.

The wavelength accuracy is intrinsically stable, and

requires no adjustment. Temperature is maintained

internally to assure consistent and accurate

response.

NOTE: There are no user-serviceable parts in the

Diode Array Assembly. Do not attempt to open,

disassemble, or service this unit. Any attempt at

service or opening will immediately void the

warranty.

Power Supply

This takes the incoming AC Mains voltage and steps it down to 24 VDC, as used by the instrument.

Cooling Fan

The fan circulates air internally to maintain consistent, controlled temperature to the spectrometer

and all internal components. This assures repeatable optical response.

Sampling Point

This may be either a Window Reflectance system (as shown here), a Fiber Optic Probe, or Direct

Light. The internal instrument interface is the same for all styles. A fiber optic bundle carries the light

to the sample. A small bundle carries the returning energy from the sample to the Optical Switch.

AC Mains Block

This is explained in the section on electrical Connection. All connections should be made in

compliance with local codes, by a qualified electrician. Always use safety lockout procedures when

performing electrical wiring.

Ethernet RJ-45 Connector

The Ethernet cable is plugged in on the instrument motherboard.

Control PCB

Instrument functions are controlled from this PC board. There are no user-serviceable items or

procedures in connection with this board.

9

Page 12

▪▪▪▪▪▪▪

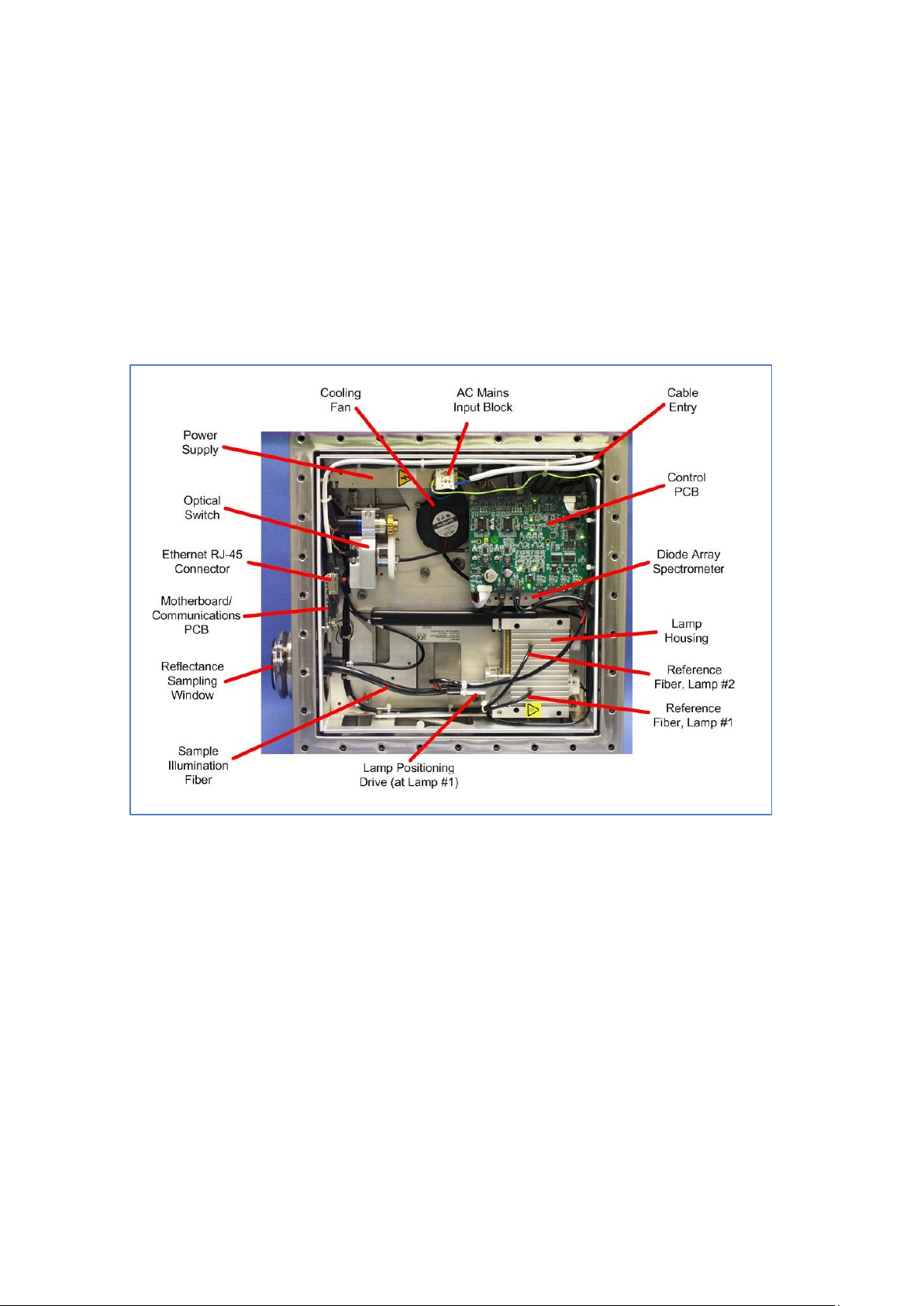

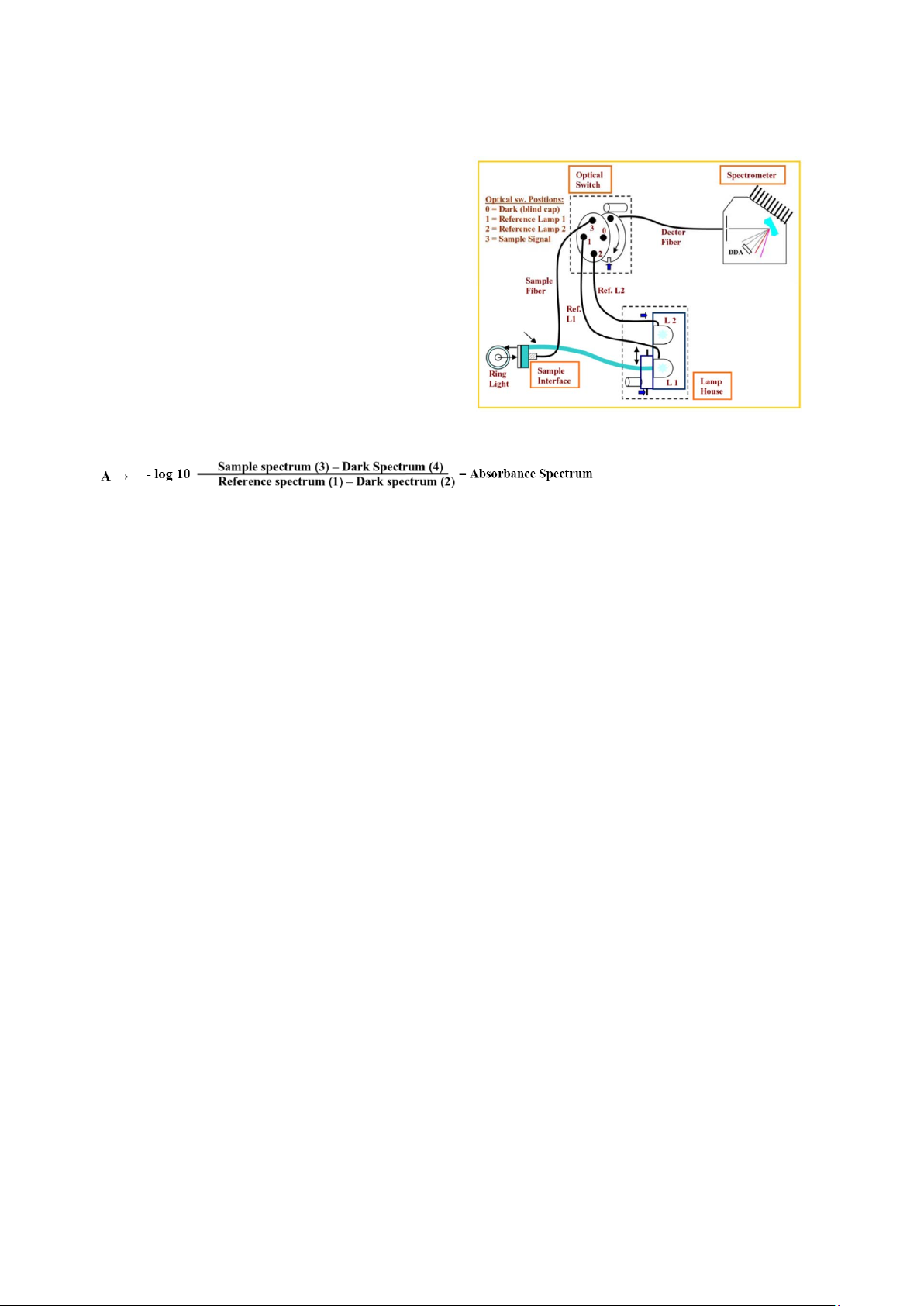

The internal light paths of the Analyzer PRO are

Block Diagram

shown.

The sample is illuminated with white light. The

resulting signal is sent back (through the optical

switch) to the Diode Array Spectrometer for

analysis.

Both dark and light reference signals are used to

set the scale of absorbance. Vision uses the

resulting information to produce sample spectra.

The formula (shown only for information) is as

follows:

10

Page 13

▪▪▪▪▪▪▪

3 Specifications

Overall Analyzer PRO instrument specifications are as follows:

Item Specification

Ambient Temperature

Ambient Humidity 10-90% Relative Humidity, non-condensing

Electrical Supply 100-240 VAC, 50-60 Hz, 2.0 A, 150 W

Protection IP69k according to IEC 60529 and DIN 40050 part 9, NT ELEC 023

Dimensions

Weight 33.0 pounds (15 Kg)

Pressurized Air Cooling

(Ambient Temperature 4565 Degrees C)

Pressurized Air – Spoon

Probe

Network Connections Local Area Network (LAN) – Ethernet, RJ-45 connection

23 to 104° F (-5 to 40° C)

With Air Cooling: 23 to 149° F (-5 to 65° C)

Width: 17.0” (42 cm)

Height: 17.0” (42 cm)

Depth: 5.0” (13 cm)

Cooling air flow rate minimum 5 Liters/min

>99.9% water free

>99.9% free of oil and fine particles down to 0.3 micrometers

Purge air: 3-5 bar

Sample Temperature,

Reflectance Window

Sample Temperature,

Spoon Probe

Computer Requirements See Vision computer requirements

Wavelength Range 1100-1650 nm

Analysis Time:

Wavelength Accuracy 0.5 nm

Wavelength Precision < 0.02 nm

Wavelength Stability < 0.01 nm/°C

Specifications for each type of sample interface follow:

302 degrees F (150° C)

248 degrees F (120° C)

5 – 50 ms / integration time; depends upon sample. Typical result

time: 3-15 sec.

11

Page 14

▪▪▪▪▪▪▪

3.1 Window Reflectance

In-line analysis of paste, granulates, slurry, powdered products and similar materials in pipes or fluid

transport systems can be performed without need for bypass streams. The sample material must pass

over the sample interface window.

The window reflection interface may easily be installed into the production line using standard GEA

Tuchenhagen flowcell mountings, or by welding an interface flange into the wall of the

pipe/transport system. GEA Tuchenhagen is well known for innovative, hygienic components for

operation in the process stream.

• Temperature: 150°C (302°F)

• Pressure: Vacuum > 1 Torr (approximately 1 mm Hg), Pressure < 3000 PSI

• Lens: Sapphire; diameter 45 mm (1.8”), thickness 12 mm (0.5”), with

EPDM O-ring seal for reliable, temperature resistant sealing

• Pipe flowcells: Fits directly into GEA Tuchenhagen Varinline Access units (DN40 to

DN150 with 68 mm [2.7”] opening). This mounting method facilitates

implementation of CIP (clean in place) and SIP (sterilize in place) methods.

• Transport System: Stainless steel welding flange

3.2 MicroBundle Fiber Optic Interface

Direct in-line measurement with microbundle fiber optic probe interface, optimized for process

streams of clear to opaque liquids, slurries, suspensions, and powders. The analyzer may be

configured with a reflectance or immersion probe based upon sample type.

316 Stainless Steel or Hastalloy Probes (custom materials also available)

• Micro Interactance Reflectance Probe

• Micro Interactance Immersion Probe

• Micro Interactance Reflectance with purge on collection tip

(requires clean air or nitrogen for purge)

• Optimized Micro Reflectance (45-degree) Probe with 3 meters of fiber

(Angled face for optimized sample collection)

Window: Sapphire

Temperature: 300°C (572°F)

Pressure: 5000 PSI (344 Bar)

12

Diameter: 1” (25.4 mm) Standard

Length: 12” (305 mm) Standard

Installation: 1” Swagelok® crimp fitting

Cleaning: Wash in water, hot or cold depending upon product

Fiber: Interactance Micro Fiber Optic Bundle (3m) with Metal or Nylon Cladding,

SMA connection to the Analyzer PRO

Page 15

▪▪▪▪▪▪▪

3.3 Direct Light

In-line analysis of products where direct contact with the product is not technically feasible, such as

product transported on a conveyor belt or similar means of movement.

Lens: Sapphire; diameter 45 mm (1.8”), thickness 12 mm (0.5”), with EPDM O-ring

seal for reliable, temperature resistant sealing

Distance: 100-250 mm to sample surface (4 to 10”)

Scanning Area: 20 - 85 mm (0.8 to 3.3”) diameter, depending upon distance to sample

13

Page 16

▪▪▪▪▪▪▪

4 Mounting Information

Analyzer PRO is provided with an innovative, rugged integral flange-mounting system that permits

easy installation and service. There are two mounting flanges, top and bottom, to which are

mounted “blind plates” using a rugged, industry-standard tri-clamping mechanism. This approach

eliminates bolt holes or other entry points for contaminants.

The mounting flanges are sized to attach directly to 3” (76.2 mm) diameter stainless steel piping,

which is widely used in sanitary installation areas. To mount using pipe, determine where the window

or fiber will be positioned, and install pipes in the corresponding positions for supporting and

mounting the enclosure. The pipes should have the proper flange ends to accept the clamps to lock

the Analyzer PRO instrument in place.

Two alternative methods are shown. This first is preferred in most cases.

4.1 4.1 Mounting Frame, U-Bolts Secured to Mounting Flanges

Many installations will be performed using a fabricated mounting frame which can be bolted to a

solid surface in the plant. This mounting method should be well-planned, so the sample window (or

fiber optic probe) is in the right location upon final installation. In this case a Analyzer PRO Fiber Optic

Probe system is being installed.

This sequence shows mounting the frame to the Analyzer PRO instrument first, then bolting the

frame (with Analyzer PRO installed) to the mounting bolts.

We advise using a cart or frame to support the instrument during mounting, to avoid damage. Use

lab jacks as shown, to make height adjustment easy. Protect the fiber optic cable, as well as the

power and communications cables. Do not kink, bend, or otherwise stress the fiber optic cable in any

way, as this may damage the internal fibers and cause loss of energy.

Safety NOTE: Please follow all site safety rules regarding lifting and physical exertion while mounting

the Analyzer PRO.

In addition, use of a rolling cart provides an easy way to protect the fiber optic cable, power cable,

and communications cable – they are carefully coiled on the lower shelf of the cart, to avoid damage.

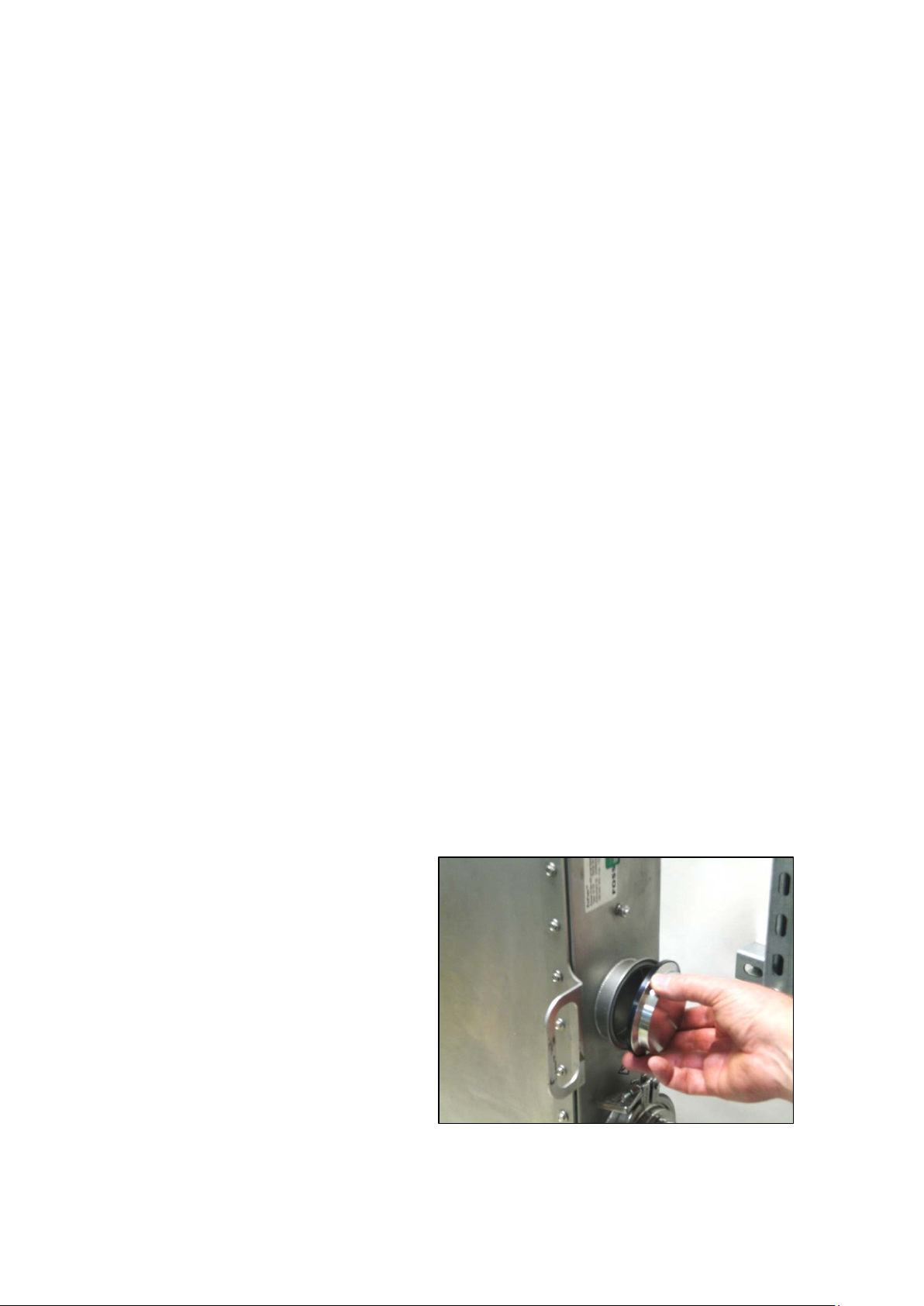

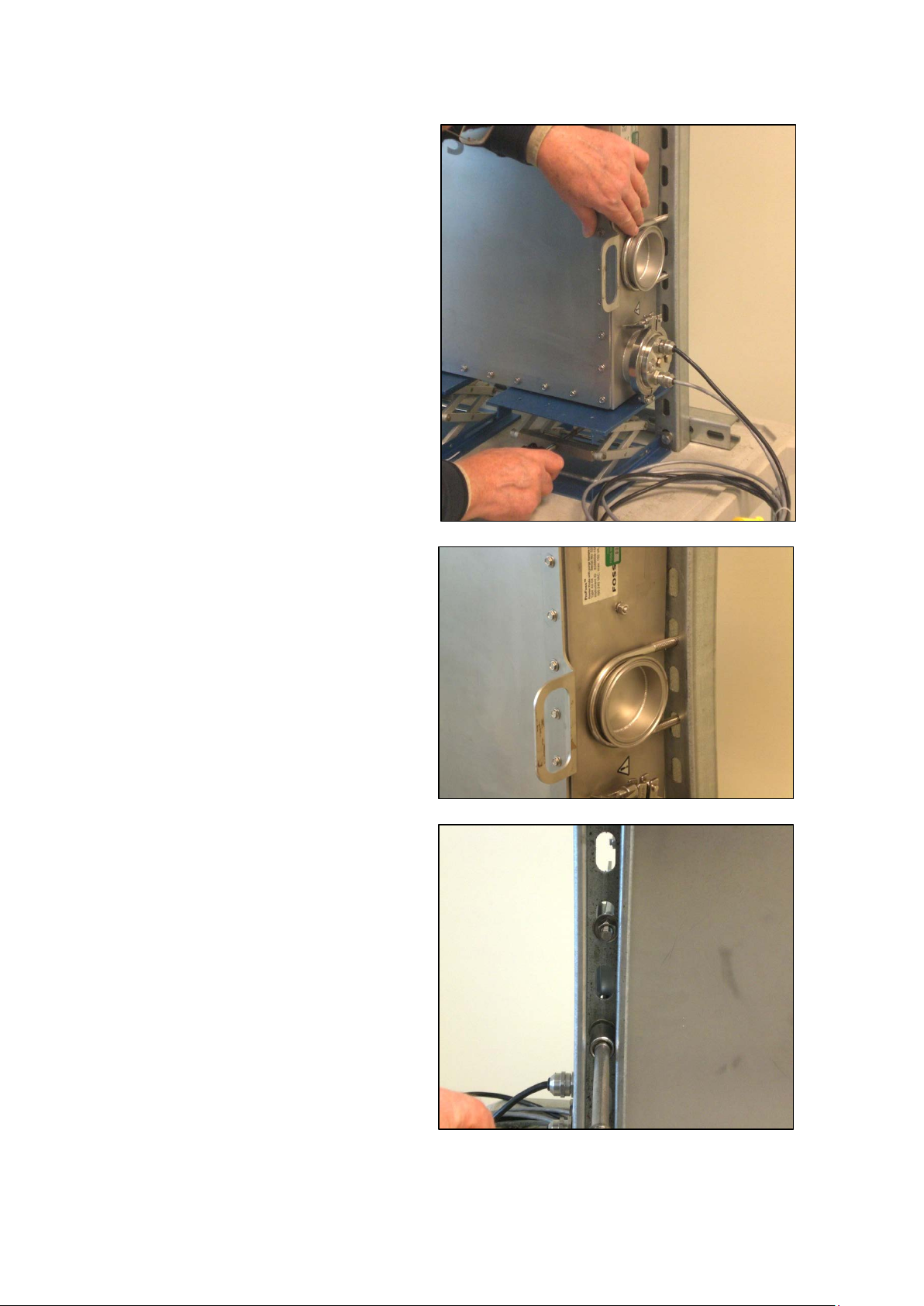

1. Remove the locking clamps and blind

mounting plate from each mounting

flange. Remove the gasket as well.

Keep all these parts in a safe place, in

case they are needed at some point in

the future.

14

Page 17

▪▪▪▪▪▪▪

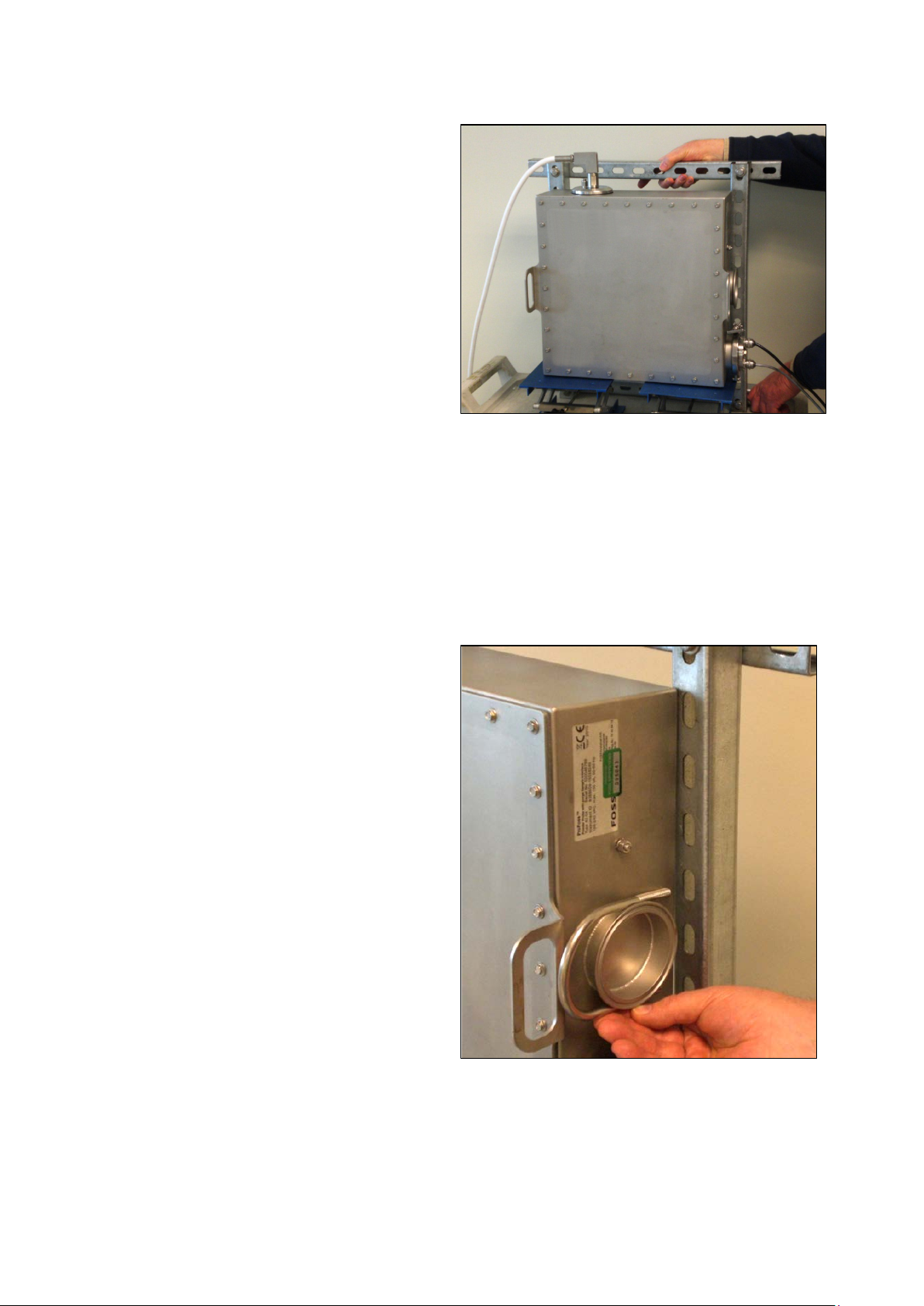

2. Fabricate the mounting frame as

shown. It may be larger if required. In

Note that the Analyzer PRO instrument is on a cart for positioning. We use lab jacks to

3. Use 3” (76.2 mm) inside-diameter

this installation we purchased pre-cut

channel from McMaster Carr. We used

four (4) lengths of Steel Strut Channel,

Slotted, 1-5/8” x 1-5/8”, zinc-plated, 2

foot length, part number 3310T53.

The brackets each measure 24” (610

mm) in length. The upright brackets

are bolted so the centerline of the

slotted holes is 17.25” (about 439 mm)

apart. Use 3/8” (or 10mm) bolts.

The brackets should be capable of

supporting the full Analyzer PRO

weight, plus an ample safety margin.

We suggest a minimum capacity be

100 pounds, or roughly 45 kilograms.

raise it to the final mounting height, to avoid difficult lifting. The installer is shown

checking the size and slot pattern for fit.

stainless U-Bolts with extended-length

legs, like that shown.

(This is a McMaster-Carr ExtendedLength Type 316 SS U-Bolt 3/8”-16

Thread, part number 29605T7 -- as of

time of publication.)

Remove the nuts from the U-Bolt and

gently place it over the flange as

shown. Verify that the mounting

height is correct, and that the U-Bolt

will be in the correct position to bolt

onto the brackets. Use additional

wooden blocks to reach the proper

mounting height. Check both sides.

15

Page 18

▪▪▪▪▪▪▪

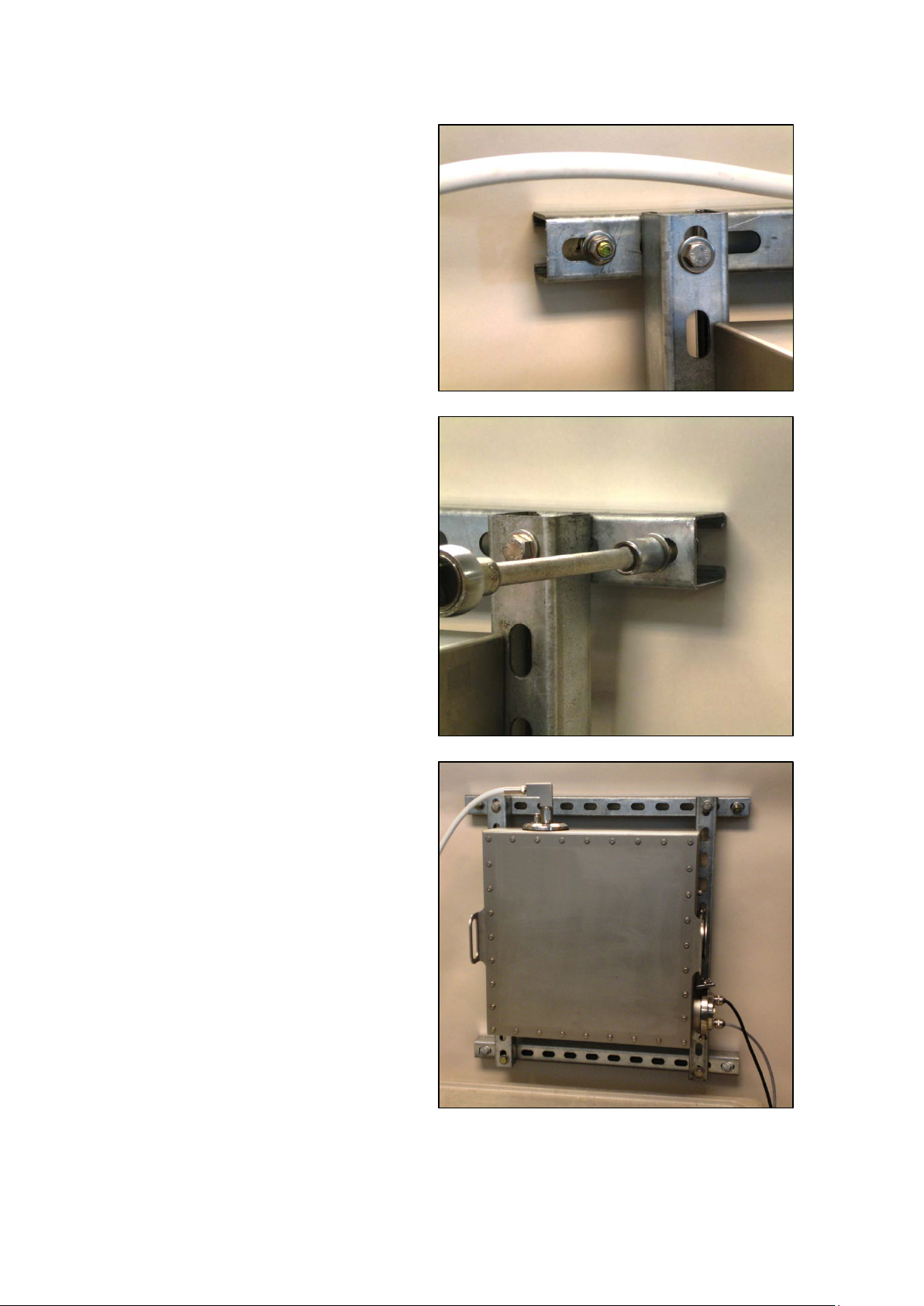

4. Adjust height with the lab jacks, so the

5. When the height is correct, push the

U-Bolts align properly with the frame

slots. Adjust each side equally, to keep

the Analyzer PRO aligned with the

bracket.

U-Bolt through the slots.

Do this on both sides of the Analyzer

PRO instrument, in preparation for

securing with washers and nuts.

6. Install large washers, lock washers,

and nuts on the ends of the U-Bolts.

Do not tighten until all four sets of

washers and nuts are in place.

When all four sets of hardware are in

place, gently tighten each nut, using

care not to distort the U-Bolts or

frame.

16

If preferred, nylon-insert locking nuts

may be used in place of normal lock

washers and hex nuts.

Page 19

▪▪▪▪▪▪▪

7. The Analyzer PRO instrument is now

securely mounted to the fabricated

8. Mounting studs should be placed in

9. Roll the cart so the mounting frame is

frame. It is ready to be mounted to the

final process location.

Verify that all hardware is secure.

Protect the fiber (if so equipped) as

well as the power and

communications cables.

Carefully move the Analyzer PRO

instrument and mounting frame to the

final location.

the correct positions to hold the frame

in place.

We installed 3/8” studs in the

mounting area as shown. These are

21.75” (552mm ) apart, which

corresponds with the slot holes in our

mounting frame. The lower studs are

mounted 22” (560mm) below, at the

same width.

These studs should be capable of

supporting the weight of the Analyzer

PRO instrument and frame, with a

large margin of safety. Be sure to

measure for the frame used, and

directly in front of the mounting studs.

Using the lab jacks, raise the Analyzer

PRO instrument (on the mounting

frame as shown) to the correct

position. When the studs align with

the mounting frame, gently ease the

mounting frame over the studs as

shown.

17

Page 20

▪▪▪▪▪▪▪

10. Install a large washer, a lock washer,

11. When all four sets of washers and nuts

12. When all hardware is tight, the lab

and a hex nut onto each stud.

Do not tighten until all four sets of

hardware are in place.

Continue to protect the fiber optic

cable, as shown here.

are threaded on, begin tightening each

set. Do not damage or distort the

mounting frame.

If nylon-insert nuts are preferred, those

may be used in place of standard hex

nuts.

jacks may be lowered and removed.

This may be done gently, to verify that

the mountings support the weight,

and that all hardware is properly

tightened.

This photo shows the final mounting,

with all bolts installed and tightened.

As before, continue to protect the

fiber optic cable, as well as the power

and communications cables. The cart is

still shown at the bottom of this

photo, immediately after removing lab

jacks. The cables are on the bottom

shelf, ready for the next stages of

installation.

18

Page 21

▪▪▪▪▪▪▪

4.2 Mounting by straps to blind plates

The blind plates are 15mm stainless steel,

The mounting flange of the instrument is shown at

and are equipped with a special gasket to

properly affix the blind plate to the flange on

the instrument.

The blind plates may be welded or machined

in any way to properly affix and support the

instrument in the desired position.

Do not distort or weaken the blind plates, as

they support the full weight of the Analyzer

PRO. Weight is 33 pounds, or 15 Kg.

the top.

The “blind plate” and gasket are shown at right.

The clamp is a “Tri-Clover” style. It is an ISO Clamp,

76.1mm. This style of clamp is used in sanitary

installations, and is known for ruggedness as well as

ease of installation and removal.

Do not attempt to drill mounting holes through the

cabinet or cover, as this will compromise the

protective sealing of the instrument enclosure. Any

holes drilled in the cabinet will invalidate the

instrument warranty.

Before mounting, determine the optimal desired position of the sampling window, and arrange for

the blind plate positions to correspond to that desired sampling position. (With a fiber optic probe

this position may be less critical.)

Before mounting the instrument, verify that the blind plates are in the correct locations, and that the

fabricated mounting arrangement will support the full weight of the instrument. When mounted, the

distance from the outside flat of the top blind plate, to the outside flat of the bottom blind plate is

19.25” (384mm). Leave some provision for movement of the mounting brackets (such as slotted

holes) to ease mounting and final positioning. At least ¼” (6mm) of movement is recommended. The

gaskets have a molded ridge on each surface, and the mounting must accommodate this ridge

during assembly.

The blind plate, gasket, and mounting flange should be securely clamped in place, top and bottom.

There should be no play in the clamp or mounting mechanism. This method of mounting provides for

easy mounting and dismounting, if required. The cover, secured by 32 bolts and sealed by a

compressive gasket, has two handles which allow lifting. Please wear protective gloves when lifting.

19

Page 22

▪▪▪▪▪▪▪

This photo shows one installation on a process

The Weld flange uses the standard sanitary

pipe.

The Analyzer PRO instrument is supported by

metal straps from a support above the

instrument, using the mounting flanges. In this

case the blind plates were drilled to accept the

mounting bolt. Because the mounting flange

openings are sealed, there is no risk of

contaminants getting inside the Analyzer PRO

enclosure.

This photo was taken before the cables were

secured with tie wraps.

When the mouning is finished, secure the power cable and commmunications cable to prevent

damage. Be careful where they exit the Analyzer PRO, as a very tight bend here may cause cable

damage. It is wist to protect the cables from any passing traffic or possbile impact.

4.3 Weld Flange

The Weld Flange may be used to mount the instrument to ports where sample material is moving in a

continuous manner, and sampling will be consistent. Additional supports using the mounting plates

are required to hold the weight of the Analyzer PRO. While this flange may be welded, may

customers prefer to bolt it in place. Either method is acceptable, as long as sampling is not impeded.

sample interface and offers a large diameter

surface that can be welded onto the process.

The Analyzer PRO is then connected to this

flange.

Additional supports using the mounting plates

are required to hold the weight of the Analyzer

PRO.

Sample windows must be clean before final

installation.

20

Page 23

▪▪▪▪▪▪▪

This photo shows an installation on a chute,

where the product falls by gravity onto the

This shows the weld flange mounted on the

sample window, thus providing a suitable

measurement.

The Weld Flange is bolted to a plate which

mounts in the duct. The plate may be removed

if needed, and replaced with a blank plate. This

allows cleaning and minor maintenance,

without stopping the line for more than a brief

interval.

Note that the Analyzer PRO is supported by

straps on each side, which support the weight.

The Weld Flange does not support the weight

of the instrument.

Analyzer PRO. The Tri-clamp is used to secure

the instrument in place on the weld flange.

NOTE: The Weld Flange provides positioning of

the sample window only. It does not support

the weight of the Analyzer PRO instrument.

21

Page 24

▪▪▪▪▪▪▪

This view shows the

The front view shows

Flange mounting

5 Mounting Dimensions

The Analyzer PRO dimensions are as shown. Note that the dimensions are in “hard Metric”. The inch

conversions are very close, but will be less exact.

distance to the viewing

window, as measured

from the side.

Note the mounting

flanges shown on either

side of the drawing –

these are detailed below.

overall dimensions, as

well as the height to

each flange.

The critical dimensions

are those to the

sampling point – the

sample window must be

in the correct position to

take spectra of the

sample.

Be sure to leave room for

electrical connection.

dimensions are shown.

Leave room for

attachment of Tri-clamps

by installation personnel.

22

Page 25

▪▪▪▪▪▪▪

6 Electrical Connection

The electrical connector flange also uses a removable plate

Connections are marked as follows:

The Analyzer PRO is shipped with a temporary AC mains electrical cable in place, suitable for initial

testing. Cord length is just over two meters. The installer need only terminate the AC mains power

cable as required to meet local codes and installation requirements.

For permanent installation, a suitable cable must be installed. This cable should be three-conductor,

round cross-section, 3.0mm nominal diameter, and must meet all electrical, temperature, and

installation requirements for the area where mounting will be performed.

and quick connect clamp. The plate has two cable entry

glands for the power line and the other for the LAN cable.

The instrument is supplied with fitted cables for both with

3 meters length enabling the Analyzer PRO to be installed

easily in a laboratory environment for start-up training on

the operation of the analyzer.

An additional two plugged threaded holes (G1/8 thread)

are present on the plate for the addition of the air cooling

kit.

An illuminated button is also present. Functions will be

discussed.

Electrical specifications are as follows:

Electrical Supply 100-240 VAC, 50-60 Hz, 2.0 A, 150 W

Protection IP69k according to IEC 60529 and DIN 40050 part 9, NT ELEC 023

Symbol Meaning N. America Europe

L Line White Brown

N Neutral Black Blue

Ground Green

Green/

Yellow

AC Mains connections and Ethernet Connection

enter the Analyzer PRO through the fitting shown.

This fitting provides for gasketed, sealed entry of

cables.

The cables have round cross-section to assure good sealing in the clamping ferrules. When the AC

23

Page 26

▪▪▪▪▪▪▪

1. Remove power from the instrument.

2. Unplug or disconnect existing,

3. Remove the 32 screws holding the cover

mains cable is replaced, the same type of cross-section of cable must be used to assure a good seal.

The cables are carefully routed to prevent interference with operation of the Analyzer PRO.

When replacing the temporary AC mains cable, follow this procedure:

Both poles must be broken.

Use safety lock-out procedures if

applicable.

temporary AC mains cable.

in place on the instrument. Use a 7 mm

socket or nut driver.

NOTE: If using a powered removal tool,

set the torque on a low setting, to avoid

stressing the screws. Start at a low

torque, then increase enough to remove

the screws easily. Use a similar torque

when re-installing the screws. Avoid

cross-threading.

24

Page 27

▪▪▪▪▪▪▪

4. Press each tab above the wire to be

removed, and pull the wire directly

5. Gently loosen the cable gland over the

6. Remove the Tri-clamp holding the cable

7. Continue to loosen the gland nut until it

outward.

NOTE: Verify that power is off before

performing this operation.

existing AC mains cable. Use a 22 mm

(approx 7/8”) open-end wrench.

NOTE: This nut is easy to loosen before

removal of Tri-clamp. Do not fully

remove the nut at this point.

input header. Save clamp for re-use.

separates from the cable seal.

25

Page 28

▪▪▪▪▪▪▪

8. Slide the gland nut and sealing ferrule

9. Prepare a “fish” line which will be used

11. Note the position of the nut, seal and o-

back from the threaded area.

to pull the new cable into the enclosure.

This line will be used to pull the new

cable back into the correct position.

10. Gently pull the old cable out of the

threaded header, guiding the fish line as

needed.

Do not pull the line all the way out – the

far end should remain where it can be

used to pull the new line into the

instrument enclosure.

This view shows the fish line after

pulling. Remove tape and old cable.

ring on the existing cable. Remove each

one and prepare to install on the new

cable.

26

Page 29

▪▪▪▪▪▪▪

12. Install the parts as shown on the new

cable. This cable is a “North American”

13. Secure the new cable to the fish line,

15. Run the new cable to the AC power

type of cable, with white, black and

green conductors.

and prepare to gently pull the new cable

into the instrument.

14. Pull the fish line inside the instrument,

while feeding the new cable gently

through the threaded opening, and up

through the corner of the instrument

cabinet.

block. Push down on each tab and

install the correct wires as shown, all the

way into the aperture.

After installation, give each wire a

gentle tug to assure that it is seated

properly. If the cable “pulls out”, verify

that the cable end is not distorted, and

try again.

27

Page 30

▪▪▪▪▪▪▪

16. Be sure the black o-ring is installed into

17. Thread the gland nut and hand-tighten.

18. Using the same 22 mm wrench, tighten

19. Tie-wrap the new cable to the Ethernet

the groove on the sealing ring as

shown.

the gland nut to compress the seal

properly. Do not crush the cable. When

tight, the cable should not “give” when

tugged slightly.

cable internally, to secure it from

moving under vibration. Cut off the

loose end.

28

Page 31

▪▪▪▪▪▪▪

20. If not using a “fish”, the wire can be fed

directly. Note that the cable is fed

The AC Mains connection point is shown, with

When complete, check all connections and seals. Check power to be sure it operates properly. Re-

This photo shows a close-up view of the wiring

through a corner of the mounting

enclosure, and is easier to feed in one

direction than the other.

We recommend feeding the new AC

mains cable through the triangular

corner opening – and then into the

large round opening -- where it can

easily be located and pulled through.

European color coding. Always follow all

applicable local codes to assure safe, reliable

connection.

As a reminder, connections are as follows:

Symbol Meaning N. America Europe

L Line White Brown

Ground Green

N Neutral Black Blue

install instrument cover.

entry point.

Note the LED on the flange. This LED is not

related to AC power.

This LED will be steady green (not blinking)

when the instrument is ready. When scanning,

the LED will blink green. This will also be

mentioned in the sampling section of this

manual.

Green/

Yellow

29

Page 32

▪▪▪▪▪▪▪

Preparation for Installation:

Mounting the air tubing:

7 Air Cooling Connection Kit

Compressed Air Cooling Kit (60038416), installation

The optional air cooling kit for high ambient temperatures over 45 °C includes quick-connect fittings

that are placed in the two plugged holes. Tubing is also supplied, along with an air filter set with

regulator to remove water and oil from the compressed air supply.

Adjust the air supply volume until the temperature is below this value

This kit includes three Air Fittings, a 30 cm (11.8 inch) piece of air tubing, and 20 m (65 feet) of extra

tubing.

1. Loosen the tri clamp and pull out the round plate with the

two blind plugs.

2. Remove the two blind plugs and mount the air fittings

instead.

3. Mount the third air fitting on the inside of the plate. Use the

hole closest to the bottom of the cabinet. This is now the air

input.

4. Some of the first kits included a Silencer (Ceramic cylinder

on a short brass tube) for the exhaust. This must NOT be

mounted; it may cause a too high pressure inside the box.

5. Cut the tube to length with a clean cut.

6. Push the end of the tube into the fitting until it makes a

tight seal.

7. To remove the tube, press down the collar of the fitting

while gently pulling the tube.

Connecting the units:

8. Mount the 30 cm tube in the air input fitting on the inside of the round plate. Lead it into the

instrument, under the Mounting Tray so that the outlet is close to the opposite wall. If

needed, adjust the length of the tube.

9. Mount the plate on the instrument again, and tighten the Tri-clamp.

10. Mount a suitable length of tubing to the air out (exhaust) air fitting on the Analyzer PRO. Lead

the tube to terminate at a point where the exhaust flow of air is not objectionable to nearby

personnel.

11. ATEX rated areas may require termination of the exhaust tube to another room or outside.

Check with the customer’s Safety personnel, or the on-site ATEX-responsible person.

12. Mount a tube from the regulator to the air input on the Analyzer PRO.

30

Page 33

▪▪▪▪▪▪▪

13. Pull the knob on the regulator and turn it fully counter clockwise in order to set the pressure

to zero.

14. Connect the factory air to the water separator.

15. Slowly increase the pressure until a smooth flow is felt from the exhaust tube.

Normally a setting of app. 0.02 MPa (0.2 bar) is about right. The objective is to keep the temperature

somewhat below 65 °C.

31

Page 34

▪▪▪▪▪▪▪

The “Spoon Probe” is typically used in fluid bed

The air inlet at the base of the probe is shown.

8 Air Purge Connection (Used with “Spoon Probe”)

Air purge may be used with the MicroBundle “Spoon Probe’ which uses air purging to remove

accumulated sample from the window area, under control of the software.

Part number 60039031 must be used. Install the kit as explained above. The Analyzer PRO

MicroBundle Fiber version comes with the solenoid air control valve and fittings already mounted.

Connect the output from the regulator to the air input on the instrument.

One way valves are mounted in the air in and air out connections inside the instrument: Observe the

“in” and “out” arrow marks next to the fittings.

1. Connect the air tube from the powder probe to the air out fitting.

2. Connect the air from the regulator to the air in fitting.

Adjust the pressure for effective emptying of the spoon after measurement. Pressure range 0,3 – 0,5

MPa (3 – 5 bar, 43.5 to 72.5 PSI).

The probe is designed for a standard 1” Swagelok® crimp fitting.

dryers and other locations where sample is

conveyed in a manner where it may accumulate

on the probe and be sampled periodically.

After sampling, purge air is activated through

the purge holes, and the sample is cleared from

the sampling area, in preparation for the next

sample.

The fitting is a ¼” NPT Swagelok SS-400-1-1

fitting, or equivalent. (Qty. 1)

It is critical to remember that the supply lines

must be sized much larger that the final deliver

line to the probe. Internal friction on a long

supply line will limit the amount of gas available

to the probe, if the line is too small. The tubing

to the probe itself is ¼” (about 6mm) however

the supply lines may have to be much larger to

accommodate the full flow required.

A ground ring is provided, as samples may build up static electricity. The probe should be properly

grounded using this ring.

32

Page 35

▪▪▪▪▪▪▪

This photo shows a typical accumulation of

sample on the face of the spoon probe. This

The photo shows the internal control for the air

The user is responsible for chemical compatibility with

photo was taken in a fluid bed dryer, in

between purge cycles.

As sample accumulates, the instrument will take

a sample scan and produce sample spectra for

analysis. The scan timing must sometimes be

adjusted to the flow rate, to assure that enough

sample has accumulated.

When the purge air system is activated, the

pressure through the purge holes “blasts” the

sample from the face of the probe. While a

slight film may be left on the probe window,

this is not enough to skew spectra, and can be

ignored.

purge. This valve is controlled by Vision. A setup

screen allows setting of intervals and timing.

This shows a typical setup, though yours will

vary.

IMPORTANT NOTE:

The purge gas provided to the probe must be instrument grade, to avoid coating the probe window

with foreign substances.

Specifically, if air is provided, it should be from an “oil-less” source, and should be clean, dry, and

filtered. “Instrument-grade” air, or pure nitrogen, are two possible types of purge gas that may be

used.

the process, cleanliness of the purge gas, temperature

variation, pressure, and control over flow.

33

Page 36

▪▪▪▪▪▪▪

As a rule, it is always best to mount the exposed cable

9 Fiber Optic Probe Mounting

The MicroBundle fiber optic probe will come installed to the Analyzer PRO. It will be tested in the

final configuration, to assure good operation.

It is very important to protect the fiber optic cable, to prevent damage. While the cable can be

replaced, this is quite expensive and should be avoided. Careful mounting and handling are

important. Never let a fiber optic cable hang where it can be snagged by equipment, crushed, or

otherwise damaged.

Fiber optic cables, if not protected, are susceptible to various types of damage. These include:

Abrasion of the protective covering

Repetitive flexing of unsupported cable lengths

Breakage of fibers by tight bends

Compression of the fiber bundle

Physical damage from equipment operating in the area

Inadvertent damage from untrained personnel

The minimum bend radius of the fiber bundle is approximately 12 inches, or 30 mm. Do not bend

tighter than this.

Always handle the fiber gently, and do not let it be compressed, abraded, or twisted.

in a cable tray, or other means of protecting the cable

from damage.

There are various suppliers of cable trays. The one

shown is manufactured by Panduit. Please find a

supplier in your area, and protect the fiber optic cable

in a suitable cable tray.

34

Page 37

▪▪▪▪▪▪▪

10 Ethernet Connection

The cable type is as follows:

Patch cable:

The Analyzer PRO is shipped with a two-meter length of Ethernet communication cable, wired into

the instrument and tie-wrapped in place. Do not remove the tie wraps or attempt to change the

cable. The cable should last the life of the Analyzer PRO Instrument.

• Category 5e, SF/UTP Patch 4P

• IEC 61156-6 LSHT

(or equivalent)

The exposed end of the Ethernet cable has an

RJ-45 plug like that shown in the photo at right.

The exposed end should be connected to the

LAN, and the connection should be shielded

from wash-down, dirt, vibration, and

tampering.

It is advisable to place the Analyzer PRO within

the same “network neighborhood” as the

computer on which Vision is installed. They

should be under the same network “subnet

mask”.

Because network setups vary dramatically from company to company, Metrohm cannot provide

troubleshooting for a specific network. That is the responsibility of company IT and Network Support

personnel.

As a rule, if the Analyzer PRO can communicate locally (whether through a local router or other

means) then it is capable of network communication through a Local Area Network (LAN). Wide Area

Networks (WAN) may pose problems due to different subnet masks, security issues, or firewalls

between different parts of the network. Please consult your local support personnel for help with

these issues.

It is very important to know if the connection cable is a “patch” or “crossover” type of cable. While

the cables are usually marked in some manner, one way to verify is to view the ends of the cable

together.

When held with both ends as shown,

conductors up, both ends of a patch cable will

appear identical.

The “solid” orange, blue, green and brown will

be in the same positions on each jack.

The striped wires may appear white, as in this

photo, or the stripes may appear more clearly.

35

Page 38

▪▪▪▪▪▪▪

Crossover Cable:

When held with both ends as shown,

conductors up, the wire patterns are different.

Note the left plug – the order of solid wires is

orange, blue, green, and brown.

On the right plug, the order of solid wires is

green, brown, orange, and blue.

On a crossover cable, the pairs are designed to

“cross over” the signal when devices are

hooked directly to each other, instead of

through a network switch.

Devices area available with can plug into a cable and change the cable type from crossover to patch,

or the other direction. In the latest networks, the type of cable may not matter, as the system sense

the signal and corrects the pin signals as required. This is called “automatic MDI/MDI-X

configuration”.

Because of the many variations in network design, capability, permissions, and administration, a full

discussion is not possible in this manual. The field is very dynamic, and we recommend consultation

with network personnel on these issues if problems arise.

36

Page 39

▪▪▪▪▪▪▪

11 Safety and Power-up

It is allowable to release the mounting clamps

When dismounting the Analyzer PRO, avoid

The Analyzer PRO is designed for safe operation in a process environment, and is well-sealed against

dust, dirt, and wash-down. Do not open the housing or loosen any cable glands, as this may

compromise the sealing of the unit.

which secure the unit, as the housing is sealed

behind where the clamps mount. If removing the

clamps, always use adequate safety precautions

to prevent personal injury, or damage to the

Analyzer PRO instrument.

Do not ever open the Analyzer PRO instrument

with power applied, as hazardous voltages are

present inside the instrument. Personal injury

may result from contact with live power. Always

use lockout procedures to avoid personal injury.

stressing or damaging the electrical lines in any

way. As the instrument is moved, be sure there is

adequate slack in the AC mains (power) and

communications cables. If necessary, these may

be disconnected at the external connecting

points for each.

37

Page 40

▪▪▪▪▪▪▪

1. Click on the Start icon, then click on

3. Vision prompts the user to create a new

12 Connection to Vision Software

Analyzer PRO is designed to operate with Vision software. Vision requires a User ID and password for

entry as a security measure. Each user must operate within a “Project” inside Vision. The procedure

for creating a Project will be shown. Inside the Project, Vision uses a Data Collection Method (DCM)

to communicate with the Analyzer PRO.

Please follow this procedure to connect:

Vision in the menu as shown.

Alternatively, if a Vision icon appears on

the desktop, double-click it to open

Vision.

2. The Vision log-in box is shown. Type in

the default User ID “NIRS” and then the

default password, “NIRS”.

Click “OK”. Vision will open.

Project. Enter the name of the Project,

using a logical name such as that

shown, or a name related to the

product being analyzed.

The name can be up to 16 characters,

with no spaces. It may not contain

characters like “/”, “+”, “*”, or other

such characters. The name will be

shown in lower-case.

Location may be left empty, and Vision

will place the Project database in the

default Vision directory.

38

Click “OK”.

Page 41

▪▪▪▪▪▪▪

4. Vision asks to create a Project database

as shown. If this location is acceptable,

5. Vision opens a screen for configuration

6. Select and highlight the instrument with

7. Vision prompts for connection to the

click “OK”.

As a rule it is best to use the default

location, unless there is an over-riding

reason to use another location.

of data sources. This enables

communication with the instrument

through Vision.

Highlight “NIRSystems DDA Analyzer

PRO Instrument Driver” and click

“Configure”.

the correct chassis ID number.

If there is only one instrument on the

network, it will be shown by default, as

shown at right.

Click “OK” to return to the previous

screen. Then click “OK” again. This sets

the communication channel to the

Analyzer PRO instrument.

instrument. Click on “Acquire new Data”

to connect.

39

Page 42

▪▪▪▪▪▪▪

8. The Analyzer PRO instrument

9. When finished, the screen

runs an automatic selfchecking routine, which

appears as shown. No operator

input is required.

indicates successful testing.

Click on “Close” to proceed.

10. Vision requests a valid Data Collection

Method (DCM) in this screen. Since no

DCM has been created yet, click on

“New”.

40

Page 43

▪▪▪▪▪▪▪

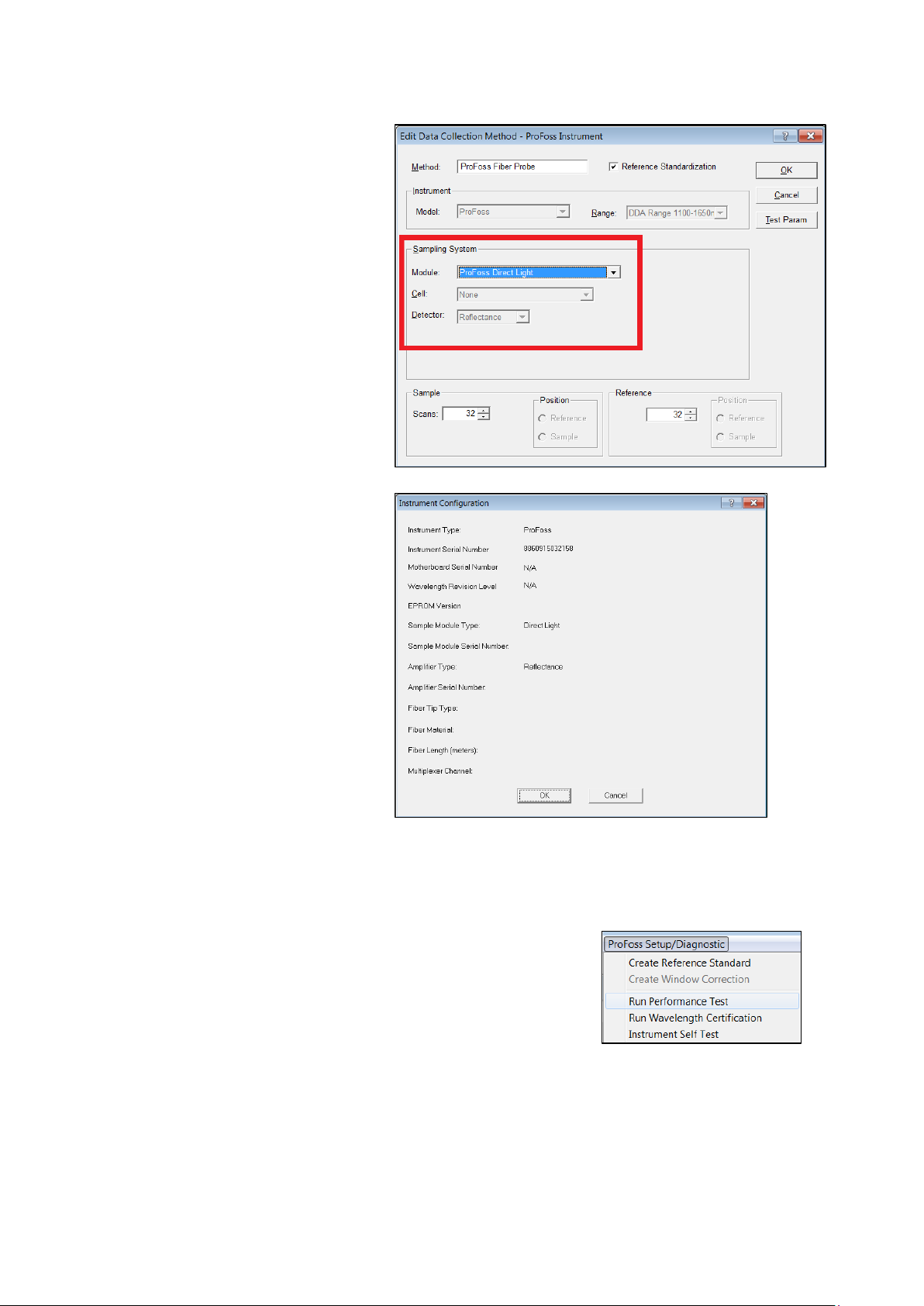

11. The Profess Analyzer

sends its

12. Vision displays the selection box for the DCM.

13. Vision checks to verify that the instrument is

configuration to the

Data Collection

Method – this is a

“Window Reflection”

system, as shown in

the Sampling system

“Module” box.

The wavelength

range is 1100-1650

nanometers.

Reference

Standardization is a

default for this model,

and the box is

checked.

The “Method” name is empty when the DCM is displayed. Enter a name for the method. The

name used here is “Window Refl”. Spaces are allowed in the DCM name.

Click “OK” when finished.

Click on the method just created, then click on

“OK”.

You may hear some clicking noises from the

Analyzer PRO instrument as it executes internal

checks. These noises are normal.

stable. If the Analyzer PRO was just turned on,

this may take some time, depending on ambient

temperature.

Once the instrument is stabilized, this box is

removed from the screen.

41

Page 44

▪▪▪▪▪▪▪

14. Vision displays the instrument

15. When the system is ready to run, the

Please proceed to the section on Analyzer PRO Diagnostics.

configuration, so the user may confirm

that this is the correct instrument.

This information is used to create a path

in the Diagnostic Database.

Diagnostics menu will become active.

42

Page 45

▪▪▪▪▪▪▪

13 Diagnostics

1. Please verify that the

Diagnostics are provided to assure ongoing performance of the Analyzer PRO instrument. Upon each

connection to the instrument, Self-Test is performed automatically. The instrument monitors itself,

and will alert the operator in the event of malfunction.

It is wise to institute ongoing testing to monitor instrument performance and operation. The

frequency for this testing depends upon application and usage, and should be set by the System

Manager and other personnel who are preparing the system for use. This team of people will have

the best information on frequency of use, and the need for ongoing testing.

The tests are quite similar for each instrument configuration; however there are small differences in

how the standards are presented. Therefore this manual gives specific directions for each

configuration. Find the configuration that will be used, and follow the directions accordingly.

Tests are described below.

13.1 Window Reflection

First, verify that the Data Collection Method is correctly set up.

Sampling System appears as

shown below, in the area

marked by the box.

There is no need to set “Cell”

or Detector” as these

selections default to the

proper settings.

2. Click on OK if setting up the DCM, then select it in the “Select Data Collection Method”

window as shown in the previous section of this manual.

If using the View DCM command, simply click on “Close”.

13.1.1 Performance Test

It is wise to run Performance Test to verify that the instrument is fully warmed up and operating

correctly. Follow these steps:

43

Page 46

▪▪▪▪▪▪▪

1. Click on “Analyzer PRO Setup/Diagnostic”, then “Run

2. Vision displays the Instrument

Performance Test”.

Configuration box. This information

is used to set up the Diagnostic

Database entries for this instrument.

If correct, click on “OK”.

This box is shown upon each initial

connection, and is not shown on

subsequent diagnostic tests, as long

as the instrument has remained

connected to Vision.

3. Vision asks which fiber should be used for the

test. The test defaults to the Sample fiber. Do not

click yet.

4. When testing the sample channel, always place

the R80 standard on the sample window. Click

on “Sample” to start the test.

Because of the large spot size, it is not necessary

to orient the sample in any particular direction.

Simply center it over the window as shown.

NOTE: We advise removing the standards when

not in use. The intense light beam can warm the

standards considerably, which will change their

photometric response. Please place the standards

on the window only for current testing, and

remove them promptly when finished.

44

Page 47

▪▪▪▪▪▪▪

5. When the test is finished,

the split-screen display will

6. The tabulated results show

appear as shown. (The test

normally takes 9-10 minutes

in this configuration.)

Double-click in the lower

right quadrant to see the

tabulated results.

these items:

• Scan: 10 is the default value

• EOC: Errors on communication this will be “0” nearly all the time.

• P-P: Peak to Peak noise

• Minimum: Magnitude of lowest-going noise peak

• Wavelength: Location of negative peak

• Maximum: Magnitude of highest-going noise peak

• Bias: Baseline offset of noise scans

• RMS: Root-mean-square value of P-P

• Gain: Not used on this instrument

45

Page 48

▪▪▪▪▪▪▪

7. The “OpQual” tab gives

8. If a printed copy is needed, click on “Print Report”.

1. Click on “Analyzer PRO Setup/Diagnostic”, then “Create

acceptance specifications,

along with actual results

and a “Yes/No” indicator to

test status.

A copy is automatically saved to the Vision Diagnostic

Database. Click on “Close Report” when finished.

NOTE: We advise removing the standards from the sample window when not in use. The intense

light beam can warm the standards considerably, which will change their photometric response.

Please place the standards on the window only for current testing, and remove them promptly when

finished.

13.1.2 Reference Standardization

Reference Standardization is a method to set the photometric scale of the instrument to a known,

repeatable level. Ideally, the instrument reference scale should be set so that 100% reflectance is

equivalent to zero (0) Absorbance. This facilitates transfer of models from one instrument to another

of the same optical sampling geometry.

In practice, it is quite difficult to set the scale exactly, due to issues of cleanliness, temperature, and

atmospheric influences. Fortunately, NIR instruments normally use mathematical and chemometric

modeling methods that compensate for minor photometric scale differences between instruments.

Reference Standard”.

This test is required to set the photometric scale to a known

absorbance value.

46

Page 49

▪▪▪▪▪▪▪

2. Vision shows this selection box, marked

“Select ERC Correction File”.

3. Vision prompts the user to place the 80%

4. Click “OK” when the standard is in

5. Vision takes a scan of the

The term “ERC” stands for “External

Reference Correction”, which is another

term for Reference Standardization.

Essentially, this is a method to

mathematically correct the instrument

reference to the equivalent of 100%

reflectance.

From the CD or DVD drive, highlight the

RSS1xxxx file, then click “Open”.

reflectance standard (R801xxxx) from the

XC-1000 set over the sample window.

position.

internal instrument reference

path. This may take several

minutes. Some clicking of the

optical switch assembly will be

audible. Messages are shown at

the lower left corner of the

Vision screen indicating actions.

Click “OK” to have Vision plot

the file spectrum of the Certified

80% Reflectance Reference

standard, from the CD.

47

Page 50

▪▪▪▪▪▪▪

6. Vision shows the spectrum of the

7. Vision plots the correction

9. Vision asks to upload the new

certified 80% Reflectance

Standard spectrum, plotted from

1100-1650nm.

Chick “OK” to plot the spectrum

of the correction.

spectrum in dark green. This

correction spectrum will be

applied to the internal reference.

Click “OK” to apply the

correction.

8. Vision applies the correction,

shown in purple.

Click “Yes” to save the ERC to

the Diagnostic Database.

ERC (Reference Standardization)

to the Analyzer PRO instrument.

Click “Yes” to proceed.

48

Page 51

▪▪▪▪▪▪▪

10. Vision loads the ERC (Reference

Standardization) file to the

11. This enlarged plot shows the full

instrument.

Click “Print Report” if verification

is needed. Click “Close Report”

when finished.

Reference Standardization.

Further explanation may help the

user understand what is taking

place.

The magenta plot at the top is a

raw absorbance spectrum of the

R80 standard, as measured

though the instrument fiber

paths.

The absorbance level is too high,

due to fiber absorbance. This will

be corrected using the certified

spectrum of the R80 from the

CD.

The dark green spectrum is correction required to read the certified 80% standard correctly on this

instrument. By applying this correction, a true spectrum of the R80 will be displayed on this

instrument.

The purple spectrum is the resulting, corrected spectrum of the R80 standard, after correction.

There is another mathematical correction which is applied, but that is not shown during Reference

Standardization. The difference between the spectrum of the R80 standard and 100% reflectance is

known, and is also applied to the reference as sample spectra are acquired. The net result is that

sample spectra appear as if taken against a perfect 100% reflective background. Since this is done on

each Analyzer PRO instrument, spectra and models should transfer with minimal baseline correction

required.

When correcting the reference, there will always be slight correction differences due to fiber position,

placement of the standard, temperature, dust, and other factors. Normally the correction will be

good to within several hundredths of an absorbance unit, as illustrated above. Math treatments are

used to correct for the resulting minor baseline effects.

49

Page 52

▪▪▪▪▪▪▪

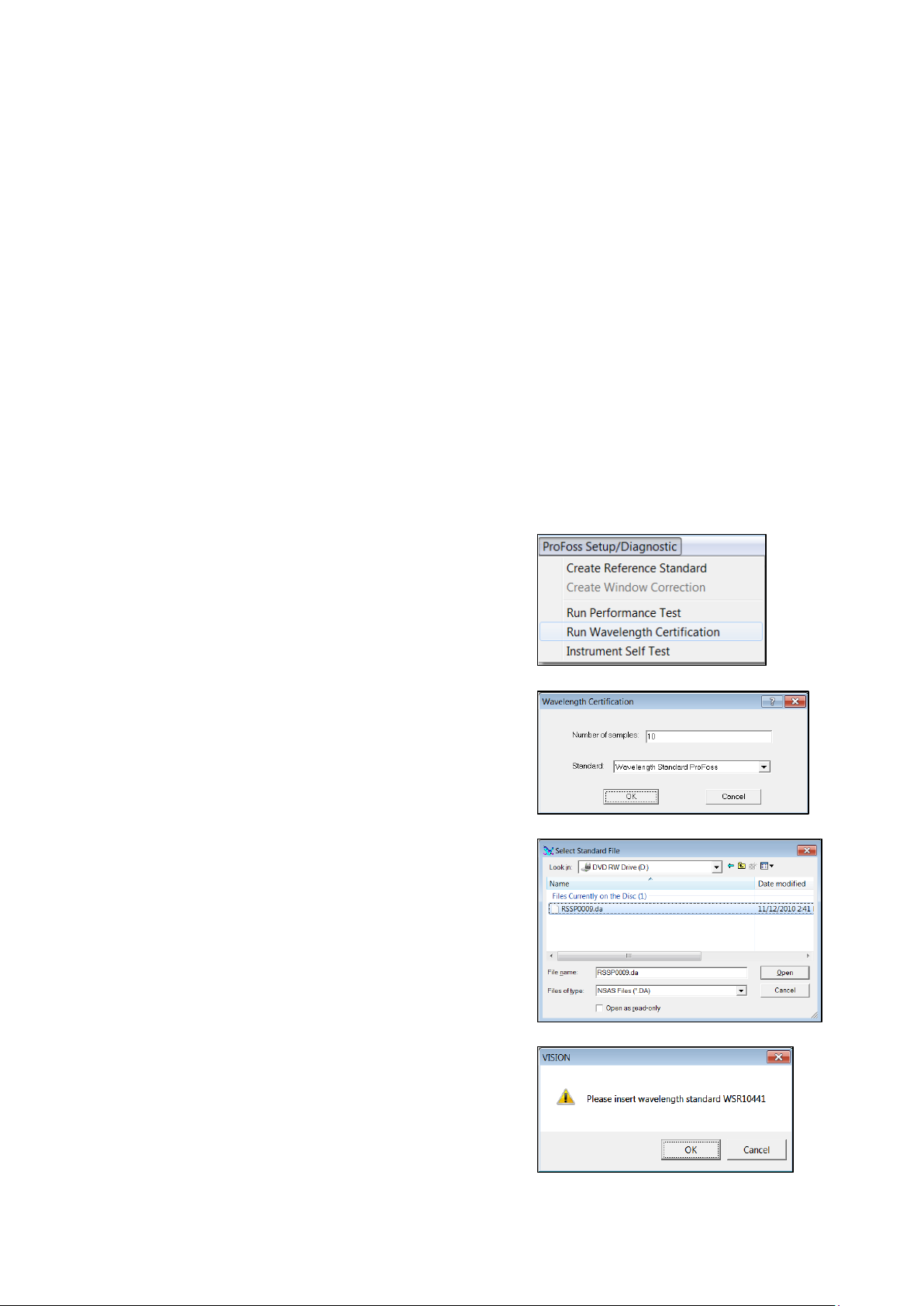

1. Click on “Analyzer PRO Setup/Diagnostic”, then “Run

2. The default number of scans is 10. The default

3. The Standards set contains a mini-CD

5. Vision requests that the user place the

6. Verify that the serial number of the standard is

13.1.3 Wavelength Certification

This test verifies that the wavelength scale of the Analyzer PRO meets parameters specified by the

U.S. National Institute of Standards and Technology (N.I.S.T.) for NIR wavelength response using rareearth standards.

Wavelength Certification”.

selection is “Wavelength Standard Analyzer PRO”.

Click “OK”.

with the standards file on it. Click on this

file, then click “Open”.

Vision initiates the test.

4. Vision begins taking an instrument reference spectrum.

wavelength standard onto the sample window.

Do not click “OK” yet.

50

the same as that shown in the Vision prompt box.

Click “OK” when ready. Vision will start the test.

Page 53

▪▪▪▪▪▪▪

7. This test runs in

about two

8. There are four

N.I.S.T. uncertainty is applied for rare-earth-type wavelength standards, shown as a

9. If a printed copy is needed, click on “Print Report”.

minutes. Splitscreen results

appear as

shown.

Double-click on

the lower right

quadrant to see

full tabulated

results.

wavelength

peaks used,

which serve to

characterize the

full wavelength

scale of the

instrument.

tolerance of +/-1.0 nm.

The Pass result is shown at the bottom of this report for each wavelength peak tested.

A copy is automatically saved to the Vision Diagnostic Database.

Click on “Close Report” when finished.

NOTE: We advise removing the standards from the sample window when not in use. The intense

light beam can warm the standards considerably, which will change their wavelength response.

Please place the standards on the window only for current testing, and remove them promptly when

finished.

51

Page 54

▪▪▪▪▪▪▪

1. Please verify that the Sampling

For testing purposes, we suggest the probe end be securely

13.2 MicroBundle Fiber Optic Sensing

First, verify that the Data Collection Method is correctly set up.

System appears as shown below,

in the area marked by the box.

Note that the drop-down menu

shows three different types of

probes which may be used. We

will use the Interactance

Reflectance Probe with Purge.

This probe is normally configured

with a “Purge” time and a “Settle”

time set in the DCM. The exact

settings will depend upon a

number of application factors,

and are quite product-specific.

Some experimentation may be

required to find the best

combinations.

For our purposes now, we will leave the purge and settle settings at “0”.

2. Click on OK if setting up the DCM, then select it in the “Select Data Collection Method”

window as shown in the previous section of this manual.

If using the View DCM command, simply click on “Close”.

13.2.1 Performance Test

It is wise to run Performance Test to verify that the instrument is fully warmed up and operating

correctly.

clamped in place.

This photo shows a common testing clamp, which attaches to

the side of a cart in the laboratory. Using this method, the fiber

optic probe can be placed upright, and the reflectance

standard cells are held securely in place by gravity. This avoids

any gaps, or inaccuracy caused by too much compression.

The clamp is a Double-Buret Clamp, part number 05-779Q,

available from Fisher Scientific. At the time of writing, the price

is less than $60 US.

Follow these steps to run Performance Test:

52

Page 55

▪▪▪▪▪▪▪

1. Click on “Analyzer PRO Setup/Diagnostic”, then “Run

Performance Test”.

2. Vision displays the Instrument

This shows the correct placement of the reflectance reference on the

Configuration box. This information is used

to set up the Diagnostic Database entries

for this instrument.

If correct, click on “OK”.

This box is shown upon each initial

connection, and is not shown on

subsequent diagnostic tests, as long as the

instrument has remained connected to

Vision.

3. Vision asks which fiber should be used for the test.

The test defaults to the Sample fiber. (Do not click

yet.)

Be sure Reflectance probe – the one used for

calibration – is on the fiber, and the reflectance

standard is in place as shown in the photo.

probe.

NOTE: the label may be on the top plate, instead of on the side.

Let gravity hold the reference in place – do not apply pressure, as this

could compress the reference material and change its reflectivity.

As a precaution, always keep the probe window and the reflectance

reference very clean. Do not allow dust, dirt, or liquids to contaminate

the surface. Consistent spectral performance depends upon clean

surfaces.

4. Click on “Sample” to start the test.

53

Page 56

▪▪▪▪▪▪▪

5. When the test is finished, the

6. The tabulated results show these

items:

split-screen display will

appear as shown. (The test

normally takes 9-10 minutes

in this configuration.)

Double-click in the lower

right quadrant to see the

tabulated results.

• Scan: 10 is the default value.

• EOC: Errors on communication – this will be “0” nearly all the time.

• P-P: Peak to Peak noise

• Minimum: Magnitude of lowest-going noise peak

• Wavelength: Location of negative peak

• Maximum: Magnitude of highest-going noise peak

• Bias: Baseline offset of noise scans

• RMS: Root-mean-square value of P-P

• Gain: Not used on this instrument

54

Page 57

▪▪▪▪▪▪▪

6. If a printed copy is needed, click on “Print Report”.

A copy is automatically saved to the Vision Diagnostic

1. Click on “Analyzer PRO Setup/Diagnostic”, then “Create

2. Vision shows this selection box, marked

Database. Click on “Close Report” when finished.

NOTE: We advise removing the standards from the sample window when not in use. The intense

light beam can warm the standards considerably, which will change their photometric response.

Please place the standards on the window only for current testing, and remove them promptly when

finished.

13.2.2 Reference Standardization

Reference Standardization is a method to set the photometric scale of the instrument to a known,

repeatable absorbance level. Ideally, the instrument reference scale should be set so that 100%

reflectance is equivalent to zero (0) Absorbance. This facilitates transfer of models from one

instrument to another of the same optical sampling geometry.

In practice, it is challenging to set the scale exactly, due to issues of cleanliness, temperature, and

atmospheric influences. However, the scale can be set closely. Fortunately, NIR instruments normally

use mathematical and chemometric modeling methods that compensate for minor photometric scale

differences between instruments.

Reference Standard”.

This test is required to set the photometric scale to a known

absorbance value.

“Select ERC Correction File”.

The term “ERC” stands for “External

Reference Correction”, which is another

term for Reference Standardization.

Essentially, this is a method to

mathematically correct the instrument

reference to the equivalent of 100%

reflectance.

Select the RSSP file, then click “Open”.

55

Page 58

▪▪▪▪▪▪▪

3. Vision takes a scan of the

4. Vision plots the stored

internal instrument

reference path.

Click “OK” to have Vision

plot the file spectrum of

the Certified 99%

Reflectance Reference

standard, from the CD.

file of the Certified 99%

Reflectance Reference

standard.

Position the Certified

99% Reflectance

Reference on the probe

end, and click “OK”.

5. Vision prepares to scan

the Certified 99%

Reflectance Reference.

Click “OK”. This may take

several minutes to

complete.

56

Page 59

▪▪▪▪▪▪▪

6. Vision plots the spectrum

of the internal instrument

7. Vision calculates the

8. Vision asks to save the

reference in magenta.

Note that the wavelength

scale is that of the

instrument, 11001650nm. This is normal.

The overall plot is scaled

from 400-2500 nm, the

useful range of the

Certified 99%

Reflectance Standard.

Click on “OK” to

proceed.

correction needed to

adjust the instrument

reference as required.

This is shown in green.

Click “OK” to apply the

correction.

correction (called the

“ERC”) to the Diagnostic

Database. Click “OK”.

57

Page 60

▪▪▪▪▪▪▪

9. Vision asks to upload the

10. When finished, Vision

The plots on this diagram

ERC to the instrument for

use when taking spectra.

Click “OK”.

indicates that the

correction was properly

loaded to the instrument.

If a printed copy is

needed, click on “Print

Report”.

bear further explanation to

help the user understand

what is taking place.

The magenta plot at the

bottom is a raw

absorbance spectrum of

the internal reference fiber

of the instrument. This

should not be used as a

reference in this form, for

two reasons:

First, the absorbance is negative, which means the reference would appear artificially brighter than

samples. Second, the spectral shape is not a flat line, and would impart unwanted artifacts into the

sample spectrum. Correction is required.

The cyan (light blue) spectrum is the Certified 99% Reflectance Standard, as measured on a

controlled, calibrated master spectrophotometer. This is close to 100% reflectance, though not

exactly. By measuring on the master instrument, the difference between the instrument reference

fiber and the Certified 99% Reflectance Standard is calculated, and is stored for correction purposes.

The correction between the Certified 99% Reflectance Standard and the instrument reference fiber is

applied. This correction is the green spectrum at the top of the plot. When this correction is applied,

the resulting spectrum is the purple line, overlaying the cyan plot of the Certified 99% Reflectance

Reference.

Vision also applies the mathematical correction required to make the instrument reference read at

58

Page 61

▪▪▪▪▪▪▪

the 100% reflectance level, though this is not shown on the correction plot. By applying this

1. Click on “Analyzer PRO Setup/Diagnostic”, then

3. The XC-2400 Standards set contains a mini-CD

4. Vision requests that the user place the

mathematical correction, sample spectra appear as if taken using an ideal 100% reflective

background reference.

When correcting the reference, there will always be slight correction differences due to fiber position,

placement of the standard, temperature, dust, and other factors. Normally the correction will be

good to within several hundredths of an absorbance unit, as illustrated above. Math treatments are

used to correct for the resulting minor baseline effects.

NOTE: We advise removing the standards from the sample window when not in use. The intense

light beam can warm the standards considerably, which will change their photometric response.

Please place the standards on the window only for current testing, and remove them promptly when

finished.

13.2.3 Wavelength Certification

This test verifies that the wavelength scale of the Analyzer PRO meets parameters specified by the

U.S. National Institute of Standards and Technology (N.I.S.T.) for NIR wavelength response using rareearth standards.

“Run Wavelength Certification”.

2. The default number of scans is 10. The default

selection is “Wavelength Standard Analyzer PRO”.

Click “OK”.

with the standards file on it. Click on this file,

then click “Open”.

Vision initiates the test.

wavelength standard onto the probe.

Do not click “OK” yet.

59

Page 62

▪▪▪▪▪▪▪

5. Verify that the serial number of the standard is the

6. This test runs in

7. If a printed copy is needed, click on “Print Report”.

same as that shown in the Vision prompt box. (A tie

wrap may be present to hold the cup in place.)

Click “OK” when ready. Vision will start the test.

about two

minutes.

Tabular results

appear as

shown.

There are four