Page 1

Application Bulletin 403/1 e

Installation ins truction for MVA-21: 894 Profession al CVS fully automat ed for CVS determinations

The «MVA-21» is a fully automated system for the

determination of suppressor and brightener in plating

solutions.

• PC controlled operation.

• Manual operations:

o Filling of the sample vials on the Sample

Processor with suppressor standard solution,

plating bath samples and rinsing solution.

• Automatic addition of 4 solutions: VMS, brightener

concentrate, suppressor conc entrat e and suppressor

standard or plating bath sample.

• Automatic rinsing of the measuring vessel.

• Method change during the determination series is

possible.

• Applications:

o Analysis of suppressor concentration in plating

baths with CVS.

o Analysis of brightener concentration in plating

baths with CVS.

Content

1. Instruments and accessories .......................................... 2

2. System setup .................................................................. 2

2.1. Electrical connections ......................................... 2

2.2. Tubing connections for rinsing and draining of the

measuring vessel ................................................ 3

2.3. Tubing connections for automatic dosing of

standard solutions and auxiliar y solution s ........... 4

3. viva Configuration ........................................................... 5

3.1. Devices – 894 Profesional CVS .......................... 5

3.2. Sensors/Electrodes ............................................. 5

3.3. Dosing units ........................................................ 5

3.4. Solutions ............................................................. 6

3.5. Devices – 858 Professional Sample Processor for

CVS ..................................................................... 6

3.6. Needle adjustment .............................................. 7

4. viva «Method» ................................................................ 8

4.1. Method run .......................................................... 8

4.2. Evaluation ........................................................... 9

5. Operation...................................................................... 10

5.1. Suppressor determinat ion seri es ...................... 10

5.2. Brightener determination series ........................ 11

6. Remarks ....................................................................... 12

6.1. Single additive setup ......................................... 12

6.2. Combination of applications .............................. 12

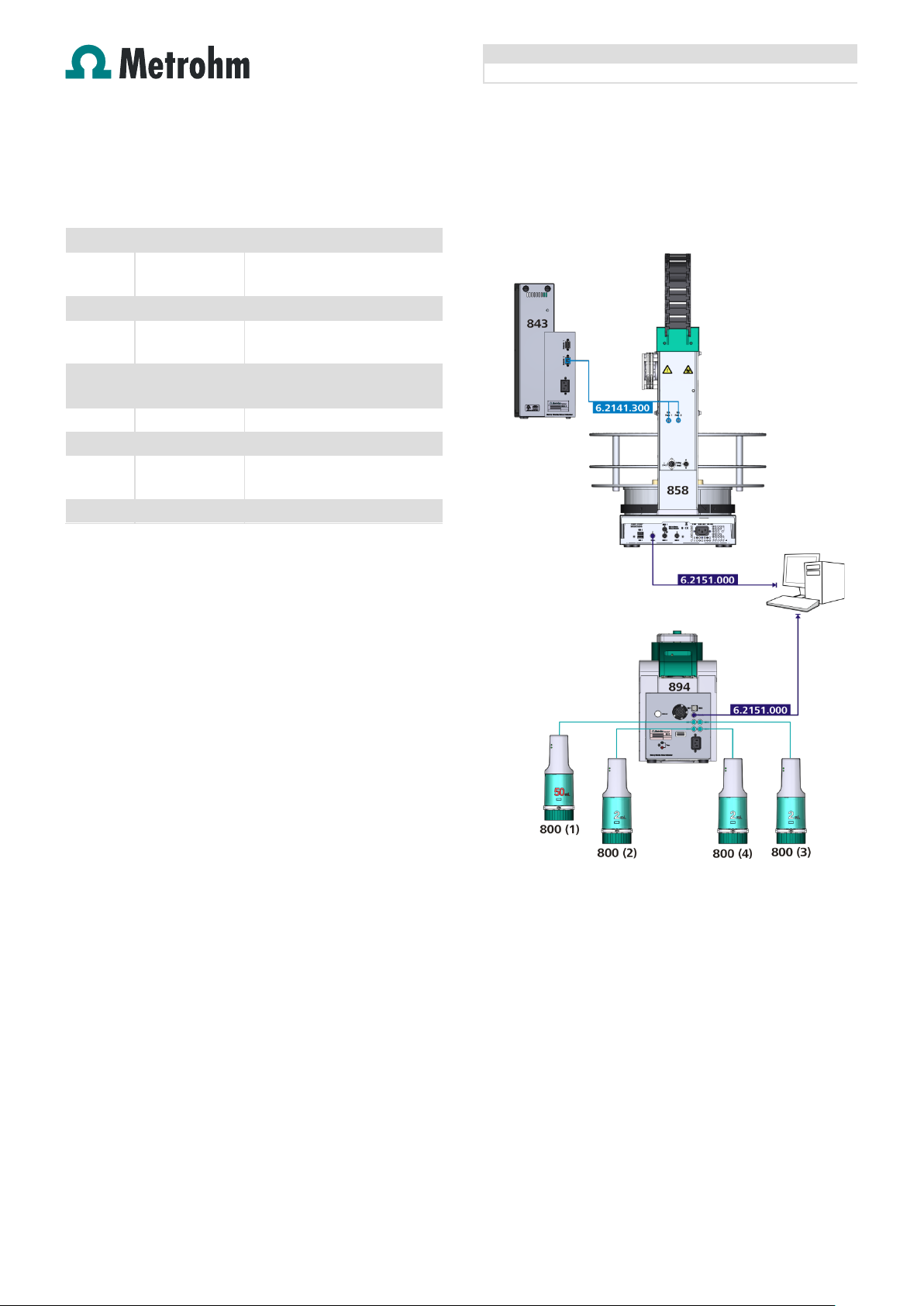

Fig 1 MVA-21

Page 1 of 12

6.3. Storing dosing units........................................... 12

6.4. Storing electrodes ............................................. 12

6.5. Waste container ................................................ 12

Page 2

Application Bulletin 403/1 e

Installation instruction for MVA-21

Professional CVS Systems

Sample Processor

1

6.2141.300

Remote cable

1

6.5339.0x0

CVS Electrodes kit

viva

1. Instruments and accessories

Quantity Article number

1 2.894.1210

2 2.800.0010 800 Dosino

1 2.843.0240

1 2.858.0110

1 6.5339.500

1 6.6065.10X

894 Professional CVS

semiautomated

Membrane Pump Station for

858 Professional CVS

Equipment with 2 Dosing

Units for VA/CVS

1.0

2. System setup

2.1. Electrical connections

Page 2 of 12

Fig 2 Electrical connections

Please note! The cable 6.2141.300 has to be connected to

«Remote 2» of the 843 Pump Station.

Page 3

Application Bulletin 403/1 e

Installation instruction for MVA-21

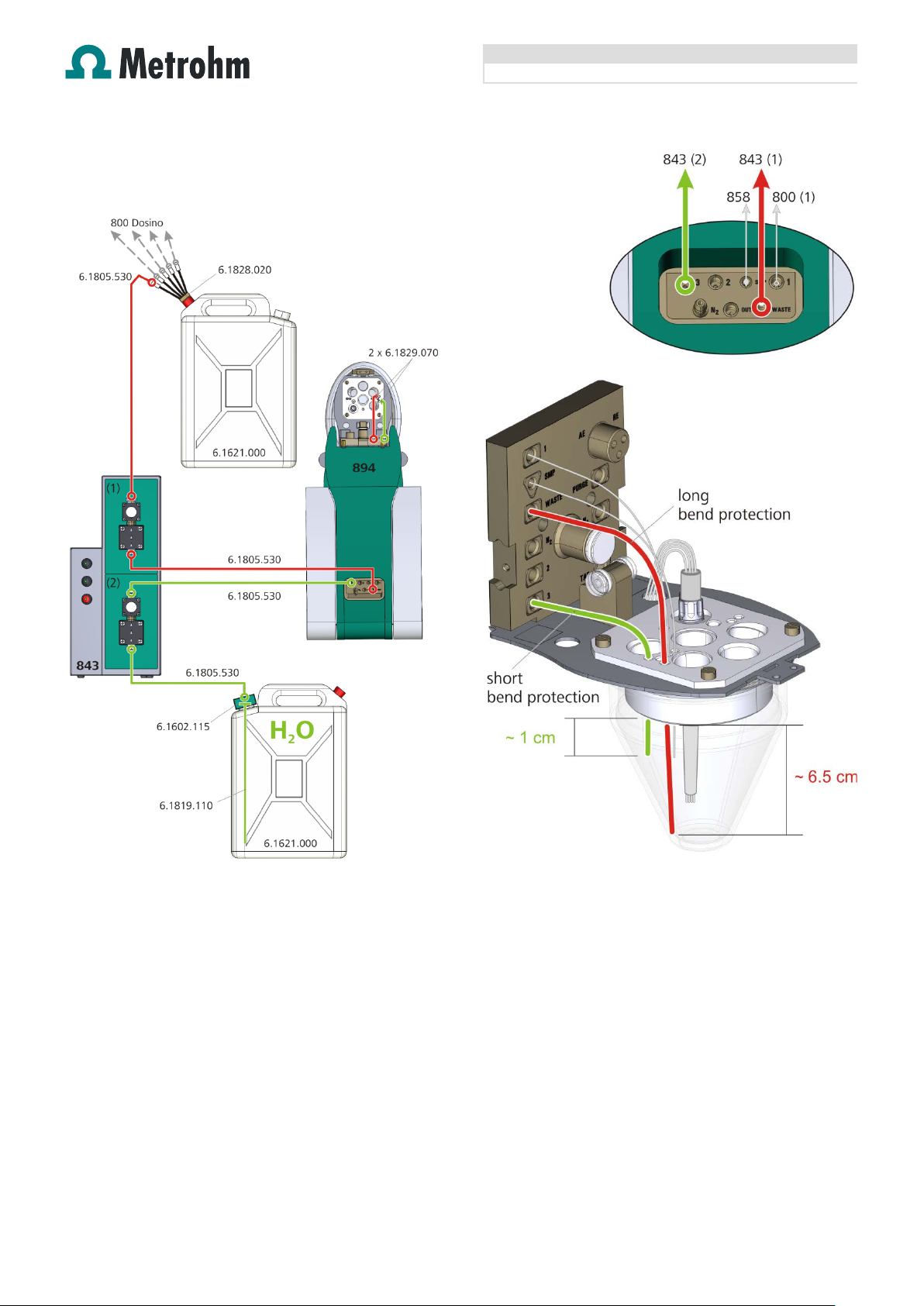

2.2. Tubing connections for rinsing and draining of

the measuring vessel

Fig 3: Tubing connections for rinsing and draining of the measuring

vessel

Page 3 of 12

Fig 4: Detailed view of the measuring head

Page 4

Application Bulletin 403/1 e

Installation instruction for MVA-21

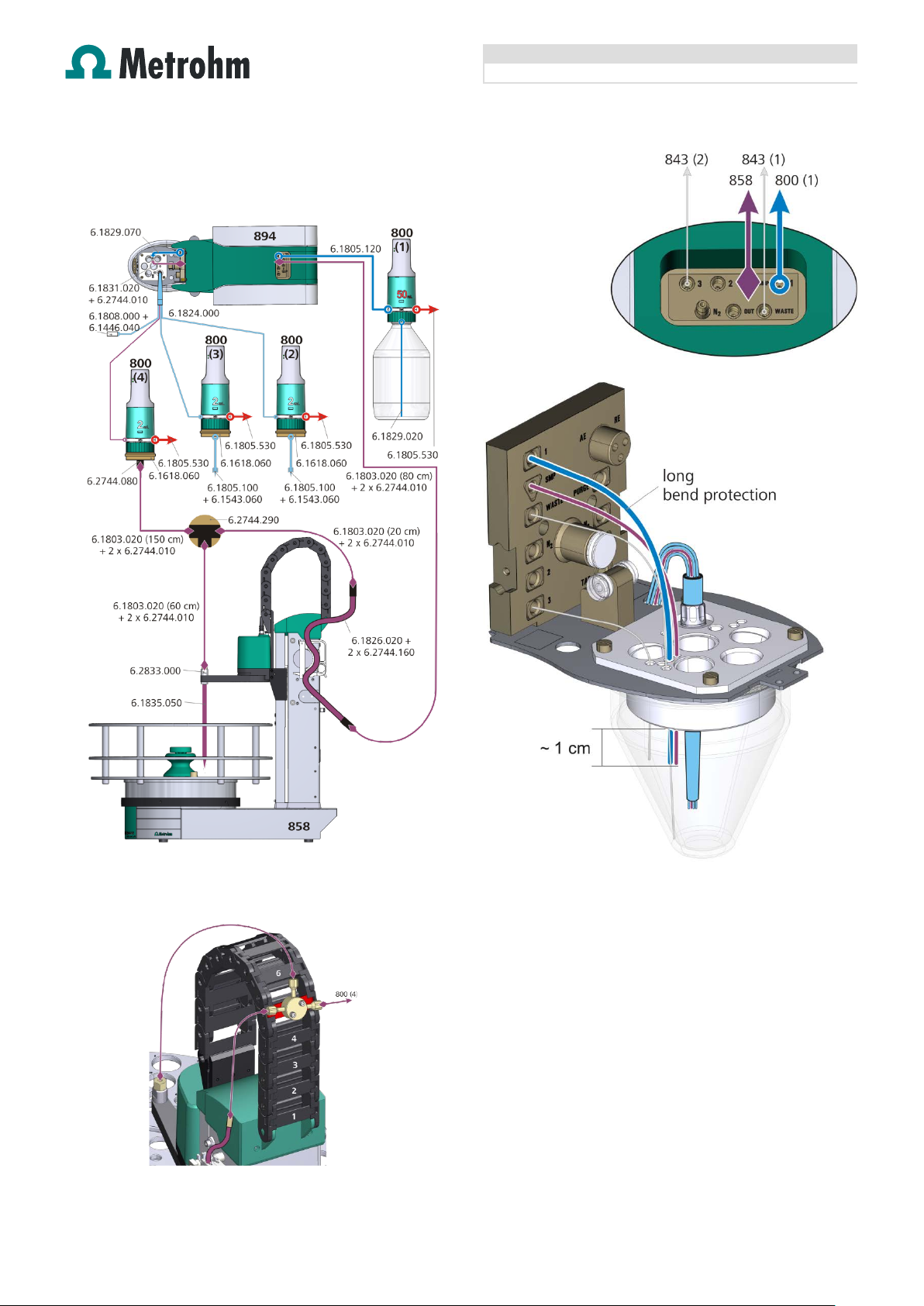

2.3. Tubing connections for automatic dosing of

standard solutions and auxiliary solutions

Fig 5: Tubing connections for automatic dosing of standard

solutions and auxiliary solutions

Fig 7: Detailed view of the measuring head

Fig 6: Detailed view to mount the T-connector

Page 4 of 12

Page 5

Application Bulletin 403/1 e

Installation instruction for MVA-21

8.103.8010xx

viva Tutorial CVS

referred to as Tutorial

Sensor name

Sensor type

Auxiliary electrode

Auxiliary electrode

RDE

RDE

Reference electrode

Reference electrode

3. viva Configuration

In addition to this application bulletin it is recommended to

have the following document availabl e.

Fig 8: Detailed view for the tubing connections of the dosing unit

waste port

3.1. Devices – 894 Professional CVS

The 894 Professional CVS is automatically recognized by

the viva software. When an instrument is connected for the

first time it needs to be entered in the viva «Configuration».

The corresponding dialogue will pop up automatically.

Device name* 894_1

* as used in the example method

For a step by step description please see the Tutorial

chapter «4.1.1 Configuring the instrument».

3.2. Sensors/Electrodes

With the software a set of electrodes is preinstalled in the

viva «Configuration». The following three electrodes have to

be present if the measuring command in the method is used

as specified in the viva method templates.

In the following chapters it will be

Page 5 of 12

3.3. Dosing units

An 807 Dosing Unit attached to an 800 Dosino which is

connected to the 894 Professional CVS is automatically

recognized by the viva software. When the Dosing Unit is

connected for the first time it needs to be entered in the viva

«Configuration». The corresponding dialogue will pop up

automatically. For a step by step description please see the

Tutorial chapter «5.1.3 Configuring dosing units».

3.3.1. Dosing unit at 800 Dosino (1)

Dosing Unit name as used in the viva method templates.

800 Dosino (MSB 1) 894/D1 50mL VMS

Parameters for preparation

Dosing port Prep/empty Dosing port 2

Page 6

Application Bulletin 403/1 e

Installation instruction for MVA-21

Port

Length

Diameter

Dosing port 1

Port 1

138 cm

2 mm

Dosing port 2

Port 3

0 cm

2 mm

800 Dosino (MSB 2)

894/D2 2mL Brightener

800 Dosino (MSB 3)

894/D3 2mL Suppressor

Dosing rate Fill port

Maximum

mL/L

Dosing rate special port

Maximum

mL/L

Port

Length

Diameter

Rotating direction

automatic

800 Dosino (MSB 4)

894/D4 2mL Std or sample

Dosing rate Fill port

4.0

mL/L

Dosing rate special port

maximum

mL/L

Fill port

Port 2

230 cm

1 mm

Special port

Port 4

0 cm

2 mm

Rotating direction

automatic

Solution name

Dosing Unit

Suppressor concentrate

894/D3 2mL Suppressor

Std or sample

894/D4 2mL Std or sample

Device name*

858 Professional Sample Processor 1

Axial distance

166.0

mm

Dosing rate port 1 Maximum mL/L

Dosing rate port 2 Maximum mL/L

Dosing rate Fill port Maximum mL/L

Dosing rate special port Maximum mL/L

Tubing parameters

Fill port Port 2 25 cm 2 mm

Special port Port 4 0 cm 2 mm

Valve disk

Rotating direction automatic

3.3.2. Dosing unit at 800 Dosino (2) and 800 Dosino (3)

Dosing Unit name as used in the viva method templates.

Parameters for preparation

Dosing port Prep/empty Dosing port 2

Dosing rate port 1 2.0 mL/L

Dosing rate port 2 maximum mL/L

Tubing parameters

Dosing port 1 Port 1 80 cm 0.3 mm

Dosing port 2 Port 3 0 cm 2 mm

Fill port Port 2 55 cm 2 mm

Special port Port 4 0 cm 2 mm

Valve disk

Tubing parameters

Port Length Diameter

Dosing port 1 Port 1 80 cm 0.3 mm

Dosing port 2 Port 3 0 cm 2 mm

Valve disk

3.4. Solutions

Solutions that should automatically be dosed have to be

defined in the viva «Configuration» and need to be

assigned to the Dosing Unit which is used for the dosing.

The following table shows the solution names and assigned

Dosing Units as used in the viva method templates.

VMS 894/D1 50mL VMS

Brightener concentrate 894/D2 2mL Brightener

SOLUTION TYPE for «VMS» and «Suppressor concentrate»

has to be AUXILIARY SOLUTION, for «Brightener concentrate»

and «Std or sample» it is S

TANDARD SOLUTION.

For a step by step description please see the Tutorial

chapter «5.1.4 Define solutions».

3.5. Devices – 858 Professional Sample Processor for CVS

The «858 Professional Sample Processor for CVS» is

automatically recognized by the viva software. When an

instrument is connected for the first time it needs to be

entered in the viva «Configuration». The corresponding

dialogue will pop up automatically.

3.3.3. Dosing unit at 800 Dosino (4)

Dosing Unit name as used in the viva method templates.

Parameters for preparation

Dosing port Prep/empty Dosing port 2

Dosing rate port 1 2.0 mL/L

Dosing rate port 2 maximum mL/L

Page 6 of 12

* as used in the example method

For a step by step description please see the Tutorial

chapter «6.1.1 Configuring the instrument».

3.5.1. Tower

Tower parameters

Max. stroke path 130 mm

Min. beaker radius Off

Lift rate 25 mm/s mm/s

Page 7

Application Bulletin 403/1 e

Installation instruction for MVA-21

Rack name

6.2141.450

Shift rate

20

°/s

defined

Rinse position

0

mm

Shift position

0

mm

Rinse position

Not available

Shift position

Not available

Special position

Not available

Swing head

Swing position 0 mm

Rinse position 0 mm

External position Not used

3.5.2. Rack

3.5.3. Rack data Rack parameters

Beaker radius samples off mm

Beaker sensor off

Rack offset 0 °

Lift positions – Tower 1

Work position

User

mm

Special position 0 mm

Lift positions – Tower 2

Work position Not available

Special beakers

Not used

3.5.4. Needle adjustment

The work position of the pipetting needle 6.1835.050 has to

be adjusted in a way that the lower end of the needle is

positioned max. 1 mm above the bottom of the sample vial.

This is essential to guarantee a complete transfer of the

sample from the sample vial on the rack of the 858

Professional Sample Processor into the measuring vessel of

the 894 Professional CVS.

0.5 … 1 mm

Fig 9: Needle adjustment

Procedure to adjust the needle position in viva

1. Insert an empty sample vial to the desired sample

position on the rack (posit ion 5 7 to 126).

2. Click on the Manual symbol.

3. Select Tower 1 (Sample changers – 858 Professional

Sample Processor).

4. Open tab «Move».

5. Enter the position of the empty sample vial in the field

«Target position».

6. Click Start to move the needle to the chosen rack

position.

7. Enter 125 mm in the field «Target position» in the

section «Lift position».

8. Click Start to lower the needle to the chosen target

position. To adjust the needle like shown above, use

the arrow up and down buttons to lower the

needle stepwise.

Page 7 of 12

Page 8

Application Bulletin 403/1 e

Installation instruction for MVA-21

9. Once the needle is properly adjusted select the tab

«Assign position».

10. The new value can be seen in the section «Lift position

– Current position».

11. Select the option «Work position for Tower» in the

section Lift position.

12. Click on «Assign» in the section Lift position .

13. Leave the Manual control with a click on the «Close»

button.

4. viva «Method»

4.1. Method run

viva software includes three method templates for CVS

analysis with an automated system.

• Brightener determination (CVS, MLAT), automated

• Conditioning (Cu VMS), automated

• Suppressor determination (CVS, DT), automated

The templates already establish t h e bas ic s eq u e nc es fo r the

different applications, the use of 800 Dosinos for automatic

dosing as well as the calculation of the result and the

application of a sample changer and pumps to process a

sample series. However certain commands and settings

have to be adapted to the used hardware and the

requirements of the specific application.

For a step by step description please see the Tutorial

chapter «6.2 Methods for the automated determination».

The following commands have to be adapted:

4.1.1. Measuring commands

Such as

4.1.2. Dosing commands

Such as:

• Define the volume of solution that should be dosed

when this command is due.

Such as:

• Define the volume of solution that should be dosed

when this command is due.

• Assign the Dosing Unit that should be used to run this

command.

Such as:

• On the tab «General/Hardware» assign the 894

Professional CVS instrument to which the 800 Dosino is

connected.

4.1.3. Automation commands

Such as:

• Assign the 858 Professional Sample Processor that

should be used to run this command.

4.1.4. Transferring sample

This only applies for the brightener determination by MLAT!

To guarantee a complete transfer of the sample from the

sample vial on the rack of the 858 Professional Sample

Processor into the measuring vessel of the 894 Professional

CVS the peristaltic pump time has to be adjusted in

the TRACK

– PERISTALTIC PUMP in the command PUMP –

PERISTALTIC PUMP ON.

• Assign the 894 Professional CVS instrument to be used

on the tab «General/Hardware».

• Adapt the measuring parameters on the tabs «Pre-

treatment», «Sweep», «Post-treatment» and

«Potentiostat» according to the requirements of the

application. These parameters can be found in separate

application documentation.

Page 8 of 12

Fig 10: Method snippet TRACK – PERISTALTIC PUMP

Page 9

Application Bulletin 403/1 e

Installation instruction for MVA-21

Cell volume

50 mL

100 mL

4.1.5. Rinsing measuring vessel

After each sample the measuring vessel need to be rinsed

with deionized water. The rinsing and draining times depend

on the total volume used in the determination.

If the method templates are used, the rinsing and draining

times are defined in the corresponding PUMP

commands in

the TRACK –RINSE and TRACK – DRAIN. The number of

rinsing cycles is defined in the command LOOP – LOOP

RINSING in the TRACK – RINSING CYCLES.

Fig 11: Method snippet TRACK – RINSING CYCLE

Examples for rinsing and draining times:

Number of rinsing cycles 2 2

Draining time [s] 35 50

Rinsing time [s] 9 18

Please note! The device assigned to the commands PUMP

– PUMP RINSE und PUPM – PUMP DRAIN need to be the

858 Professional Sample Processor, since the 843 Pump

Station is connected to and controlled from the sample

changer.

4.1.6. Rinsing transfer tubing

This only applies for the brightener determination by MLAT!

After each sample the transfer tubing from the 858

Professional Sample Processor to the measuring vessel of

the 894 Profess ional CVS nee d to be rinse d with deioni zed

water. The rinsing solution is placed in a vial on the rack of

the 858 Professional Sample Processor. The position of the

rinsing solution relative to the sample position is defined in

the TRACK

command MOVE

– GO TO RINSING POSITION in the

– MOVE RINSING POSITION.

Fig 12: Method snippet TRACK – GO TO RINSING POSITION

The position of the rinsing solution is defined as «sa mple

position + 28». This means the outer circle on the rack

6.2041.450 is used for the sample the inner circle for the

rinsing solution

The transfer time for the rinsing solution corresponds to the

sample transfer time defined in the TRACK

PUMP

in the command PUMP – PERISTALTIC PUMP ON.

– PERISTALTIC

4.2. Evaluation

Settings regarding evaluation and documentation of the

determination are located in the «Evaluation» part of the

method. The templates already include all necessary

settings to determine brightener or suppressor concentration

in an acid copper bath. If modifications however should be

necessary, here is where important parameters are found:

4.2.1. Substances

In the «Substances» part settings for peak recognition and

baseline parameters are defined.

4.2.2. Standards

In the «Standards» part the concentration of the used

standard solution is defined.

4.2.3. Calibration

In the «Calibration» part the calibration method, such as DT

or MLAT, is defined as well as the regression type.

Page 9 of 12

Page 10

Application Bulletin 403/1 e

Installation instruction for MVA-21

4.2.4. Results

In the «Results» part on the tab «Results» the substance is

selected for which the concentration should be calculated

and displayed.

5. Operation

5.1. Suppressor determination series

5.1.1. Manual operation

• Dosing Unit «894/D1 50mL VMS» connected to Dosino

1 has to be prepared with VMS.

• Suppressor standard solutions and plating bath

samples are placed on position 57 to 111 of the sample

rack using the sample vials for 11 mL (6.2743.057).

• On the position after the last sample a vial with pure

water is placed to rinse Dosino 4 after the end of the

suppressor sample series.

5.1.2. Workplace

• In the «Run» window on the tab «Determination series»

create a sample table

Fig 14: Example sample table for suppressor determination

• To run a calibration with a standard solution select

sample type STANDARD. For a determination the sample

type S

AMPLE has to be selected.

• No «Sample amount» needs to be defined in the

sample table, since addition volumes for the standard

and the sample are defined in the method

commands ADD

STD and ADD SAMPLE DT.

Fig 13: Example positions of solutions on the sample rack

6.2041.450 for suppressor determination

5.1.3. Course of events

• The execution of calibration and determination by

dilution titration is controlled by the 894 Professional

CVS and viva.

a) T he measurin g ves sel is empti ed using the 843

Pump Station.

b) Dosing Unit «894/D4 2mL Std or sample»

connected to Dosino 4 is automatically rinsed and

prepared with suppressor standard or sample from

the vial on the rack of the sample changer.

c) The measuring vessel is rinsed using the 843

Pump Station.

d) Dosino 1 automatically adds the VMS and Dosino

4 is used for the automatic addition of suppressor

standard or plating bath sample.

e) At the end of each determination the measuring

vessel, is automatically emptied and rinsed using

the 843 Pump Station.

Next sample starts again from a).

• Recalibration within a determination series is possible.

• At the end of a determination series Dosino 4 is

automatically prepared with rinsing solution.

Page 10 of 12

Page 11

Application Bulletin 403/1 e

Installation instruction for MVA-21

5.2. Brightener determination series

5.2.1. Manual operation

• Dosing Unit «894/D1 50mL VMS» connected to Dosino

1 has to be prepared with VMS.

• Dosing Unit «894/D2 2mL Brightener» connected to

Dosino 2 has to be prepared with brightener

concentrate.

• Dosing Unit «894/D3 2mL Suppres sor» con nec ted to

Dosino 3 has to be prepared with suppressor

concentrate.

• Plating bath samples are placed on position 1 to 28 of

the sample rack using the sample vials for 50 mL

(6.2747.010). ). The exact sample volume needed for

the determination has to be pipetted into the vial.

• Rinsing solutions are placed on position 29 to 56 of the

sample rack using the sample vials for 50 mL

(6.2747.010). Usually the same volume of distilled

water is used for rinsing like it was used for the sample.

The rinsing solution has to be placed on the inner circle

on the neighboring position of the sample (Sample

position + 28).

5.2.2. Workplace

• In the «Run» window on the tab «Determination series»

create a sample table

Fig 16: Example sample table

• As sample type SAMPLE has to be selected.

• For «Sample amount» the volume pipetted into the vial

has to be entered.

5.2.3. Course of events

• The execution the determination by modified linear

approximation technique is controlled by the 894

Professional CVS and viva.

a) T he measurin g ves sel is empti ed using the 843

Pump Station.

b) The intercept solution is automatically prepared at

the beginning of each determination, by dosing

VMS from Dosino 1 and suppressor concentrate

from Dosino 3.

c) After the determination of the intercept value, the

plating bath sample is transferred from the sample

rack to the measuring vessel by means of the

build-in peristaltic pump of the 858 Profes sional

Sample Processor. The sample is added on top of

the intercept solution.

d) Standard addition is carried out automatically with

brightener concentrate from Dosino 2.

e) At the end of each determination the measur ing

vessel is emptied using the 843 Pump Station.

f) The transfer tubing from the sample changer to the

measuring vessel is rinsed with the rinsing solution

placed on the rack of the sample changer.

g) After the transfer tubing is rinsed the measuring

vessel is automatically emptied and rinsed using

the 843 Pump Station.

Next sample starts again from a).

Fig 15: Example positions of solutions on the sample rack

6.2041.450

Page 11 of 12

Page 12

Application Bulletin 403/1 e

Installation instruction for MVA-21

6. Remarks

6.1. Single additive setup

If the system is only used for suppressor or brightener

determination the unused port at the T connector

(6.2744.290) has to be closed with a threaded stopper

(6.2744.060).

6.2. Combination of applications

The determination of suppressor by dilution titration (DT)

and the determination of brightener by modified linear

approximation technique (MLAT) can also be combined in

one series.

6.3. Storing dosing units

When the dosing units are not used (during the night, over

the weekend) the dosing cylinder has to be rinsed with

water. Otherwise elemental copper can be formed or

additives can precipitate between the valve disk and the

distributor disk or in the tubings. A blockage can damage

the 800 Dosino. Emptying the cylinder and filling it with

water is sufficient to prevent a blockage.

6.4. Storing electrodes

When the electrodes are not used (during the night, over the

weekend) the electrodes should be thoroughly rinsed.

Working and auxiliary electrode can either be stored in

deionized water or dry. The reference electrode should be

stored separately in a vial filled with deionized water (KCl

solution, in case KCl is used as bridge electrolyte), so that

the reference electrode immerses at least to the rim of the

electrolyte vessel.

6.5. Waste container

The waste container must not be closed completely. For

pressure balancing in the waste container, keep at least one

opening unsealed. Overpressure would lead to a

malfunction of the drain pump.

Page 12 of 12

Loading...

Loading...