Page 1

CH-9101 Herisau/Switzerland

Phone ++41 71 353 85 85

Fax ++41 71 353 89 01

CompuServe 100031,3703

Internet http://www.metrohm.com

E-Mail sales@metrohm.ch

732 IC Detector

733 IC Separation Center

5.732.0012 Program

IC Detector732

+0.023 µS/cm 15.2 min

Full Scale 5.00 µS/cm

OVERLOAD

THERMOSTAT

FULL

PARAM

SCALE

IC Separation Center733

MetrohmMetrohm

METHOD

PUMP R/S

CONFIG

7

8 9

CONFIG

EVENT

PROGRAM

ZERO OFF

4

5 6

PRINT

REPORT

PLOT

1

2 3

MARK

PROG

R/S

0

.

SELECT CLEAR

QUIT ENTERZERO

-

/+

MetrohmMetrohm

FILL INJECT

A B

STEP

FILL INJECT

8.732.1033 Instructions for Use

1.10.1998 / dö

Page 2

Table of contents

Table of contents

1 Introduction............................................................................................1

1.1 Instrument description.............................................................................1

1.2 Parts and controls..................................................................................... 3

1.2.1 732 IC Detector .............................................................................3

1.2.2 733 IC Separation Center..............................................................5

1.3 Information on the Instructions for Use................................................8

1.3.1 Organization .................................................................................. 8

1.3.2 Notation and pictograms............................................................... 9

1.4 Safety notes .............................................................................................10

1.4.1 Electrical safety............................................................................10

1.4.2 General precautionary rules........................................................10

2 Installation ...........................................................................................11

2.1 Flow chart.................................................................................................11

2.2 Setting up the instruments....................................................................12

2.2.1 Packaging....................................................................................12

2.2.2 Check ..........................................................................................12

2.2.3 Location.......................................................................................12

2.2.4 Arrangement of the instruments..................................................12

2.3 Connection of 733 IC Separation Center.............................................13

2.3.1 733.0010/733.0X30 IC Separation Center................................... 13

2.3.2 733.0X20 IC Separation Center................................................... 14

2.3.3 Connection of syringe and suction tubing.................................. 16

2.3.4 Connection of the drain tube....................................................... 16

2.3.5 Connection of the 6.5324.000 Bottle rack (option) ..................... 16

2.4 Mains connection....................................................................................17

2.4.1 Setting the mains voltage............................................................ 17

2.4.2 Fuses........................................................................................... 18

2.4.3 Mains cable and mains connection ............................................18

2.4.4 On/off switching of the instruments ............................................18

2.5 Capillary connections.............................................................................19

2.5.1 Capillaries.................................................................................... 19

2.5.2 Steel connectors.......................................................................... 19

2.5.3 PEEK connectors ........................................................................20

2.6 Connection of 709 IC Pump...................................................................21

2.6.1 Electrical connection ................................................................... 21

2.6.2 Pulsation dampener .................................................................... 21

2.6.3 Filter unit PEEK............................................................................ 22

2.6.4 Filter unit Manufit ......................................................................... 23

2.6.5 Connection to injection valve with PEEK capillaries ...................24

2.6.6 Connection to injection valve with steel capillaries..................... 25

2.6.7 Passivation of the IC system.......................................................27

2.7 Precolumns..............................................................................................28

2.7.1 General information on precolumns............................................28

2.7.2 Precolumns with twin cartridge holder........................................28

2.7.3 Precolumns with cartridge head .................................................30

2.7.4 IC anion precolumn SUPERSEP ................................................. 31

732 IC Detector / 733 IC Separation Center

I

Page 3

Table of contents

3 Operating tutorial ........................................................................45

2.8 Separating columns and suppressor module.................................... 32

2.8.1 General information on separating columns .............................. 32

2.8.2 Selection of the sample loop ...................................................... 32

2.8.3 General information on suppressor module............................... 33

2.8.4 One-channel system without suppressor module...................... 35

2.8.5 Two-channel system without suppressor module...................... 35

2.8.6 One-channel system with suppressor module........................... 37

2.8.7 Leak testing and conditioning..................................................... 40

2.9 Connection of external devices............................................................ 41

2.9.1 Connection of a recorder ............................................................ 41

2.9.2 Connection of «IC Metrodata for Win95».................................... 41

2.9.3 Connection of the 750 Autosampler ........................................... 41

2.9.4 Connection of the 766 IC Sample Processor ............................. 41

2.9.5 Connection of the 791 VA Detector ............................................ 41

2.9.6 Connection of a printer ............................................................... 42

2.9.7 Connection of a PC..................................................................... 44

2.9.8 Connection of devices to the remote interface........................... 44

3.1 Requirements ..........................................................................................45

3.2 Preparations............................................................................................. 46

3.3 Putting into operation............................................................................ 48

3.4 Calibration................................................................................................ 59

3.5 Sample determination............................................................................ 62

3.6 Storing as a method............................................................................... 64

4 Operation ...............................................................................................67

4.1 Operating sequences............................................................................. 67

4.1.1 General flow chart ....................................................................... 67

4.1.2 Flow chart for basic settings....................................................... 68

4.1.3 Flow chart for putting into operation ........................................... 69

4.1.4 Flow chart for injection ................................................................ 70

4.2 Fundamentals of the operation ............................................................ 71

4.2.1 Display......................................................................................... 71

4.2.2 Overview of key functions ........................................................... 72

4.2.3 Instrument dialog ........................................................................ 77

4.2.4 Data entry.................................................................................... 79

4.2.5 Text entry..................................................................................... 80

4.3 Displays in the standby mode.............................................................. 81

4.3.1 Measured value and current time ............................................... 81

4.3.2 Status messages ........................................................................ 82

4.4 Basic settings.......................................................................................... 84

4.4.1 Setup........................................................................................... 84

4.4.2 Configuration, <CONFIG> key.................................................. 88

4.5 Measurement parameters...................................................................... 97

4.5.1 <PARAM> key ........................................................................... 97

4.5.2 <FULL SCALE> key................................................................. 102

II

732 IC Detector / 733 IC Separation Center

Page 4

Table of contents

4.6 Triggering of functions ........................................................................103

4.6.1 <FILL> keys .............................................................................103

4.6.2 <INJECT> keys........................................................................104

4.6.3 <ZERO> key ............................................................................ 105

4.6.4 <ZERO OFF> key ...................................................................106

4.6.5 <MARK> key............................................................................ 106

4.6.6 <PUMP R/S> key.....................................................................106

4.7 Programming .........................................................................................107

4.7.1 <PROGRAM> key.................................................................... 107

4.7.2 <PROG R/S> key..................................................................... 114

4.7.3 <EVENT> key........................................................................... 114

4.7.4 <METHOD> key ......................................................................117

4.8 Data output.............................................................................................119

4.8.1 <PRINT> key............................................................................ 119

4.8.2 <PLOT> key.............................................................................122

4.8.3 <REPORT> key........................................................................ 124

4.9 Examples of methods...........................................................................126

4.9.1 Cation determination with Metrosep Cation 1-2........................126

4.9.2 Anion determination with Metrosep Anion Dual 2.....................129

5 Notes – Maintenance – Faults ................................... 133

5.1 Practical notes on ion chromatography............................................133

5.1.1 Separating columns ..................................................................133

5.1.2 Pumps .......................................................................................134

5.1.3 Eluents.......................................................................................135

5.1.4 Suppressor module...................................................................136

5.1.5 Connections .............................................................................. 136

5.2 Maintenance and servicing..................................................................136

5.2.1 General information................................................................... 136

5.2.2 Passivation ................................................................................137

5.2.3 Recycling................................................................................... 137

5.2.4 Shutdown...................................................................................137

5.2.5 Changing separating columns..................................................138

5.2.6 Regeneration of the suppressor................................................140

5.2.7 Cleaning the suppressor........................................................... 141

5.2.8 Replacing the suppressor......................................................... 143

5.3 Faults and malfunctions ......................................................................145

5.3.1 Error messages .........................................................................145

5.3.2 Malfunctions and their rectification ...........................................148

5.4 Diagnostic tests.....................................................................................149

5.4.1 General...................................................................................... 149

5.4.2 Preparing instruments ............................................................... 150

5.4.3 Checking working memory (RAM) ............................................ 151

5.4.4 Check keypad ...........................................................................151

5.4.5 Check display............................................................................152

5.4.6 Check RS232 interface.............................................................. 153

5.4.7 Check remote interface.............................................................154

5.4.8 Internal hardware test................................................................ 155

5.4.9 Initialize data memory................................................................157

5.5 Validation / GLP.....................................................................................159

732 IC Detector / 733 IC Separation Center

III

Page 5

Table of contents

6 Interfaces .......................................................................................... 161

6.1 RS232 interfaces................................................................................... 161

6.1.1 General rules for remote control ............................................... 161

6.1.2 Call-up of objects...................................................................... 162

6.1.3 Triggers .....................................................................................163

6.1.4 Status messages ...................................................................... 164

6.1.5 Error messages......................................................................... 165

6.1.6 Remote control commands ...................................................... 166

6.1.7 Data transmission protocol....................................................... 177

6.1.8 Handshake................................................................................ 178

6.1.9 Pin assignment.......................................................................... 181

6.1.10 RS232 error rectification............................................................ 182

6.2 Remote interfaces.................................................................................183

6.2.1 "Remote" interface..................................................................... 183

6.2.2 "733 IC Separation Center" interface......................................... 185

6.3 Analog output........................................................................................ 187

6.4 External power supply for 733 IC Separation Center......................187

6.5 Valve interfaces..................................................................................... 188

7 Appendix ............................................................................................. 189

7.1 Technical data ....................................................................................... 189

7.1.1 732 IC Detector ......................................................................... 189

7.1.2 733 IC Separation Center.......................................................... 192

7.2 Standard equipment............................................................................. 193

7.2.1 732 IC Detector ......................................................................... 193

7.2.2 733 IC Separation Center.......................................................... 194

7.3 Optional accessories............................................................................ 196

7.3.1 Accessories for 733 IC Separation Center................................ 196

7.3.2 Separating columns and precolumns....................................... 198

7.3.3 Additional devices and cables.................................................. 202

7.4 Warranty and conformity.....................................................................204

7.4.1 Warranty .................................................................................... 204

7.4.2 EU Declaration of conformity .................................................... 205

7.4.3 Certificate of conformity and system validation........................ 207

7.5 Index........................................................................................................ 209

IV

732 IC Detector / 733 IC Separation Center

Page 6

Table of contents

List of figures

Fig. 1: Block diagram of the ion chromatography system ........................................... 2

Fig. 2: Front of the 732 IC Detector .............................................................................. 3

Fig. 3: Rear of the 732 IC Detector............................................................................... 4

Fig. 4: Front of the 733 IC Separation Center............................................................... 5

Fig. 5: Rear of the 733 IC Separation Center................................................................6

Fig. 6: Connection 732 – 2.733.0010/2.733.0X30 ...................................................... 13

Fig. 7: Connection 732 – 2.733.0X20 ......................................................................... 15

Fig. 8: Setting the mains voltage ................................................................................ 18

Fig. 9: Connectors for capillaries................................................................................ 20

Fig. 10: Connection of 709 IC Pump ............................................................................ 21

Fig. 11: 6.2821.100 Filter unit PEEK .............................................................................22

Fig. 12: 6.2821.000 Filter unit Manufit...........................................................................23

Fig. 13: Connection to injection valve with PEEK capillaries........................................25

Fig. 14: Connection to injection valve with steel capillaries .........................................26

Fig. 15: Installing precolumn cartridges ....................................................................... 29

Fig. 16: Interior of the 733.0010 IC Separation Center .................................................34

Fig. 17: Interior of the 733.0X30 IC Separation Center................................................. 36

Fig. 18: Connections at suppressor module................................................................38

Fig. 19: Ion chromatogram of the calibration ...............................................................61

Fig. 20: Ion chromatogram of the drinking water sample ............................................63

Fig. 21: Schematic representation of the instrument dialog......................................... 78

Fig. 22: Ion chromatogram for cation standard with Metrosep Cation 1-2 ................ 128

Fig. 23: Ion chromatogram for anion standard with Metrosep Anion Dual 2 ............. 131

Fig. 24: Assembling the suppressor........................................................................... 142

732 IC Detector / 733 IC Separation Center

V

Page 7

Table of contents

List of numbered parts and controls

11 Display ................................................3

22 Main function keys ..............................3

33 Numeric keys ......................................3

44 Auxiliary function keys.........................3

55 Program status display ....................... 3

66 Auto-zero display ............................... 3

77 Thermostat display.............................. 3

88 Overload display .................................3

99 Mains switch ..................................4,18

1010 Serial number......................................4

1111 Analog output 0…1 V.......................... 4

1212 Analog output 0…10 mV.....................4

1313 Connection for detector block ............4

1414 Connection for

733 IC Separation Center....................4

1515 Connection for 709 IC Pump ..............4

1616 RS232 interface...................................4

1717 Remote interface.................................4

1818 Mains connection plug...................4,18

1919 Fuse holder ....................................4,18

2020 Door to interior ....................................5

2121 Connection for syringe........................ 5

2222 Feedthrough for aspirating tubing ......5

2323 „FILL“ for valve A................................. 5

2424 „INJECT“ for valve A ...........................5

2525 „FILL“ for valve B.................................5

2626 „INJECT“ for valve B ...........................5

2727 Connection/Feedthrough....................5

2828 Feedthrough........................................5

2929 Opening for detector cable B .............6

3030 Opening for outlet capillary B .............6

3131 Rear panel opening.............................6

3232 Opening for outlet capillary A..............6

3333 Opening for detector cable A..............6

3434 Knurled screw .....................................6

3535 Detachable rear panel.........................6

3636 Connection for 732 IC Detector A.......6

3737 Knurled screw .....................................6

3838 Terminal block for valve A................... 6

3939 Detachable rear panel.........................6

4040 Opening for inlet capillary A................6

4141 Rear panel opening.............................6

4242 Connection for drain tube ...................6

4343 Rear panel opening........................6,36

4444 Opening for inlet capillary B................ 6

4545 Connection for 732 IC Detector B....... 6

4646 Terminal block for valve B...................6

4747 Model plate .........................................6

4848 Connection for external supply...........6

4949 Ferrule ..........................................20,29

5050 Pressure screw.............................20,29

5151 Capillary ............................................20

5252 Compression fitting...........................20

5353 Connector with filter ..........................22

5454 Housing for filter unit......................... 22

5555 Connector .........................................22

5656 Inlet capillary ................................23,26

5757 Manufit pressure screw................ 23,29

5858 Counterpart end................................23

5959 PTFE gasket................................. 23,29

6060 4 Steel meshes ............................23,29

6161 Steel mesh holding end.................... 23

6262 Manufit housing ...........................23,29

6363 Outlet capillary .............................23,26

6464 Filter unit PEEK .................................25

6565 PEEK capillary.........................25,34,36

6666 Pulsation dampener................25,34,36

6767 Column connection

capillary..............................25,29,34,36

6868 Injection valve..........................25,34,36

6969 Filter unit Manufit............................... 26

7070 Coupling............................................ 26

7171 Steel capillary.................................... 26

7272 Outlet capillary ..................................29

7373 2 Steel meshes .................................29

7474 Precolumn cartridge..........................29

7575 Inlet capillary .....................................29

7676 IC separating column..............29,34,36

7777 Manufit pressure screw..................... 29

7878 Steel spacer ...................................... 29

7979 Steel connector for ferrule................. 29

8080 Manufit housing ................................29

8181 Detector block.............................. 34,36

8282 Inlet capillary for detector block...34,36

8383 Mounting rail ................................34,36

8484 Column holder .............................34,36

8585 Capillary for syringe .....................34,36

8686 Sample loop.................................34,36

8787 Inlet capillary for injector .............. 34,36

8888 PTFE aspirating tubing.................34,36

8989 Suppressor inlet capillary

for eluent ...................................... 36,38

9090 Suppressor inlet capillary

for H2SO4......................................36,38

9191 Suppressor outlet capillary

for H2SO4......................................36,38

9292 Suppressor outlet capillary

for H2O .........................................36,38

9393 Suppressor inlet capillary

for H2O .........................................36,38

9494 Suppressor outlet capillary

for eluent ...................................... 36,38

9595 Suppressor module ..........................36

9696 Coupling............................................ 36

9797 Screw nut ........................................ 142

9898 Connection piece............................ 142

9999 Suppressor rotor .............................142

100100 Suppressor holder .......................... 142

VI

732 IC Detector / 733 IC Separation Center

Page 8

1 Introduction

1.1 Instrument description

The 732 IC Detector is a conductivity detector especially designed for

ion chromatography with an extensive operating range and high sensitivity for the recording of chromatograms with and without chemical

suppression. The associated thermostattable detector block is normally

installed in the 733 IC Separation Center, but can also be used as a

separate detector. The two following versions are available:

• 2.732.0010 IC Detector with standard detector block

• 2.732.0110 IC Detector with metal-free detector block

The 732 IC Detector is operated using the keypad with operator guidance via the two-line LCD. In addition to setting of the measurement

parameters, time programs can be generated which can be used to initiate a large number of instrument functions for each of the maximum

20 program steps. Further, the same functions can be executed at a

specific time with 4 programmable "events".

1.1 Instrument description

The 732 IC Detector is equipped with various interfaces for communication purposes. Recorders, integrators or the «IC Metrodata for

Win95» chromatography data system can be connected to the analog

output (1 V or 10 mV) for the plotting and evaluation of chromatograms.

The two RS232 interfaces are used for the connection of a 709 IC

Pump, a printer or a PC for remote control of the IC system. Finally,

programmable signals at a "remote" interface can be employed to control any external devices which, in turn, can start functions at the IC

system.

The 733 IC Separation Center is a thermally and electronically isolated wet part which accommodates injectors, columns, detectors,

suppressor module and pulsation dampener and is controlled by the

732 IC Detector. The following versions are available:

• 2.733.0010 IC wet part with 1 injector for a one-channel system

with electronic suppression

• 2.733.0020 IC wet part with 2 injectors for a two-channel system

with electronic suppression

• 2.733.0120 IC wet part with 2 injectors for a two-channel system

with electronic suppression, metal-free

• 2.733.0030 IC wet part with 1 injector and 1 Metrohm

Suppressor Module MSM for a one-channel system

with chemical suppression

• 2.733.0130 IC wet part with 1 injector and 1 Metrohm

732 IC Detector / 733 IC Separation Center

Suppressor Module MSM for a one-channel system

with chemical suppression, metal-free

1

Page 9

1 Introduction

The 732 IC Detector and 733 IC Separation Center are the main components of a modular ion chromatography system that can be expanded to meet the wishes of the individual user (see Fig. 1). The

minimum configuration of the one-channel system also includes a 709

IC Pump, a separating column and a recorder. The two-channel system

requires at least a second 732 IC Detector and a second 709 IC Pump.

Printers, integrators, data recording devices, PC and autosamplers can

be attached to both systems. Further, practically all HPLC peripherals

and parts available on the market such as precolumns, additional

separating columns, additional detectors and other injection systems

can be seamlessly integrated in the system.

However, the individual IC units can also be freely combined with

common HPLC instruments. This offers the possibility of expanding

your system to a standalone ion chromatograph.

Two-channel systemOne-channel system

PC

IN IN

PL

752

750/766

S

754

W

IF

732

D

M

C

D

733

C

I

I

709 709

WW

S

W

PL

732

750/766

EE

Fig. 1: Block diagram of the ion chromatography system

PRPR

C Separating

column

D Detector PC PC 733 IC Separation Center

E Eluent PL Recorder 750 Autosampler

I Injector PR Printer 752 Pump Unit

IF Interface S Sample 754 Dialysis Unit

IN Integrator W Waste 766 IC Sample Processor

2

M

Suppressor module

(one-channel system only)

709

IC Pump

732

IC Detector

732 IC Detector / 733 IC Separation Center

Page 10

1.2 Parts and controls

1.2.1 732 IC Detector

88 11 22 33 44

IC Detector732

+0.023 µS/cm 15.2 min

Full Scale 5.00 µS/cm

OVERLOAD

THERMOSTAT

ZERO

PARAM

FULL

SCALE

PROG

R/S

CONFIG

7

ZERO OFF

4

PLOT

1

MARK

0

PUMP R/S

8 9

EVENT

5 6

REPORT

2 3

.

1.2 Parts and controls

METHOD

PROGRAM

PRINT

SELECT

-/+

QUIT ENTER

CLEAR

77 66 55

Fig. 2: Front of the 732 IC Detector

11 Display (LCD)

comprising 2 lines each of 24

characters

22 Main function keys

Auto-zero, Parameters, Full Scale,

Program start/stop

33 Numeric keys

Edit mode: Numeric keys

Basic mode: Function keys

44 Auxiliary function keys

Select, Clear, Quit, Enter

55 Program status display (LED)

LED dark: Program inactive

LED lit up: Program ready

LED flashes: Program running

66 Auto-zero display (LED)

LED dark: Auto-zero switched off

LED lit up: Auto-zero switched on

77 Thermostat display (LED)

LED dark: Heating switched off

LED lit up: Heating switched on

88 Overload display (LED)

LED lit up: Meas. signal >150%

of full-scale range

LED flashes: Meas. signal >180%

of full-scale range

732 IC Detector / 733 IC Separation Center

3

Page 11

1 Introduction

99

WARNING - Fire Hazard -

For continued protection replace only

with the same type and rating of fuse

Type 1.732.0010 Nr.

f=50-60 Hz

S=70 VA

100-120V:

220-240V:

S

Fuse

0,63A(T)

0,315A(T)

Output

0...1V 0...10mV

Remote

RS 232

Made by Metrohm Herisau Switzerland

1313121211111010

Detector Block

733 IC Separation Center

709 IC Pump

1919

1818 1717 1616 1515 1414

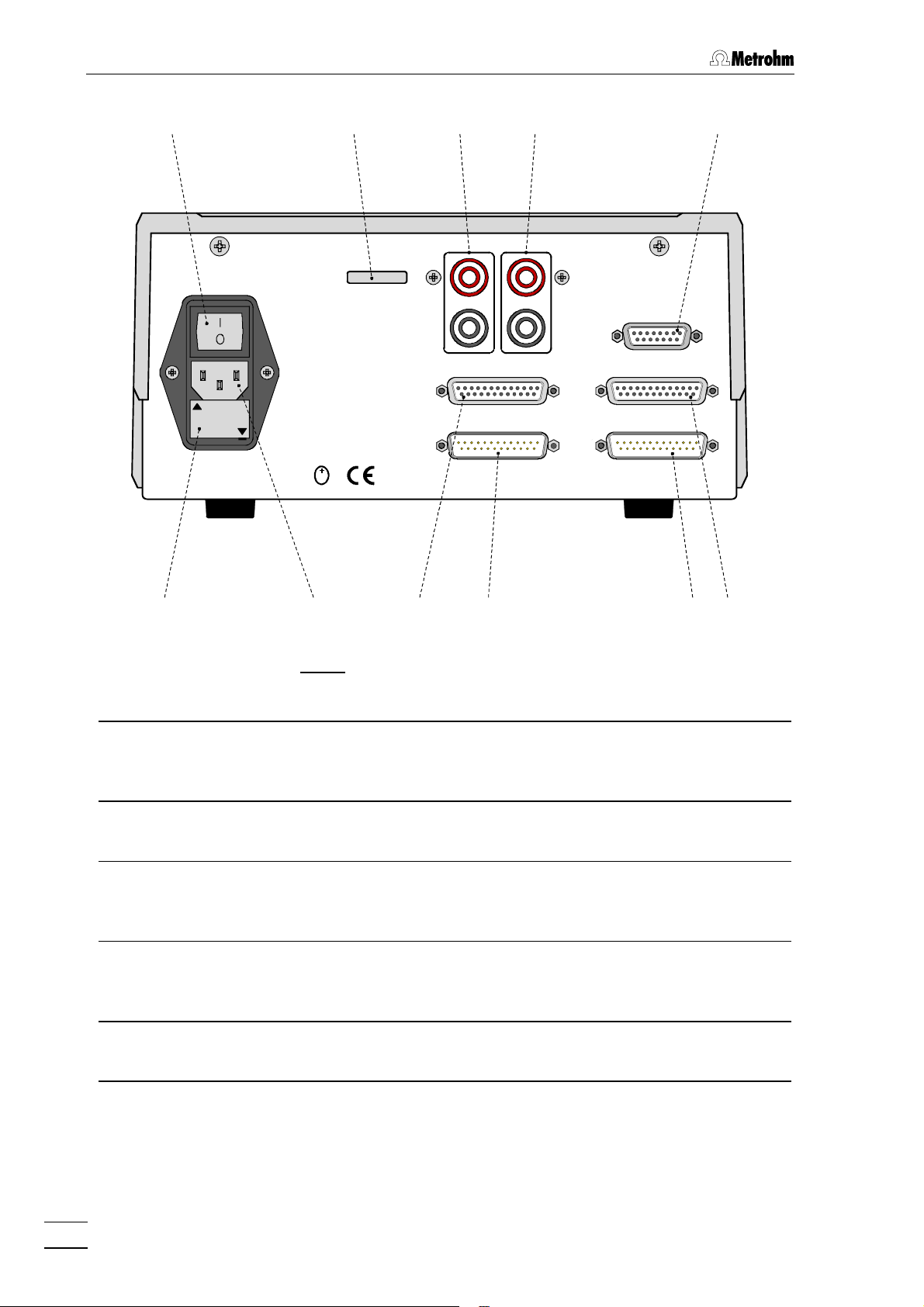

Fig. 3: Rear of the 732 IC Detector

99 Mains switch

switch to switch instrument on and off:

I = ON 0 = OFF

1515 Connection for 709 IC Pump

RS232 interface, can also be used for

connection of a printer

1010 Serial number 1616 RS232 interface

connection of a printer, PC, etc.

1111 Analog output 0……1 V

red socket: live

black socket: common

1212 Analog output 0……10 mV

red socket: live

1717 Remote interface

remote I/O lines for connection of

external devices

1818 Mains connection plug

mains connection, see section 2.4

black socket: common

1313 Connection for detector block 1919 Fuse holder

changing the fuses, see section 2.4

1414 Connection for 733 IC Separation

Center

4

732 IC Detector / 733 IC Separation Center

Page 12

1.2.2 733 IC Separation Center

IC Separation Center733

1.2 Parts and controls

FILL INJECT

A B

STEP

FILL INJECT

21212020 2222 2424 2525 2626 27272323 2828

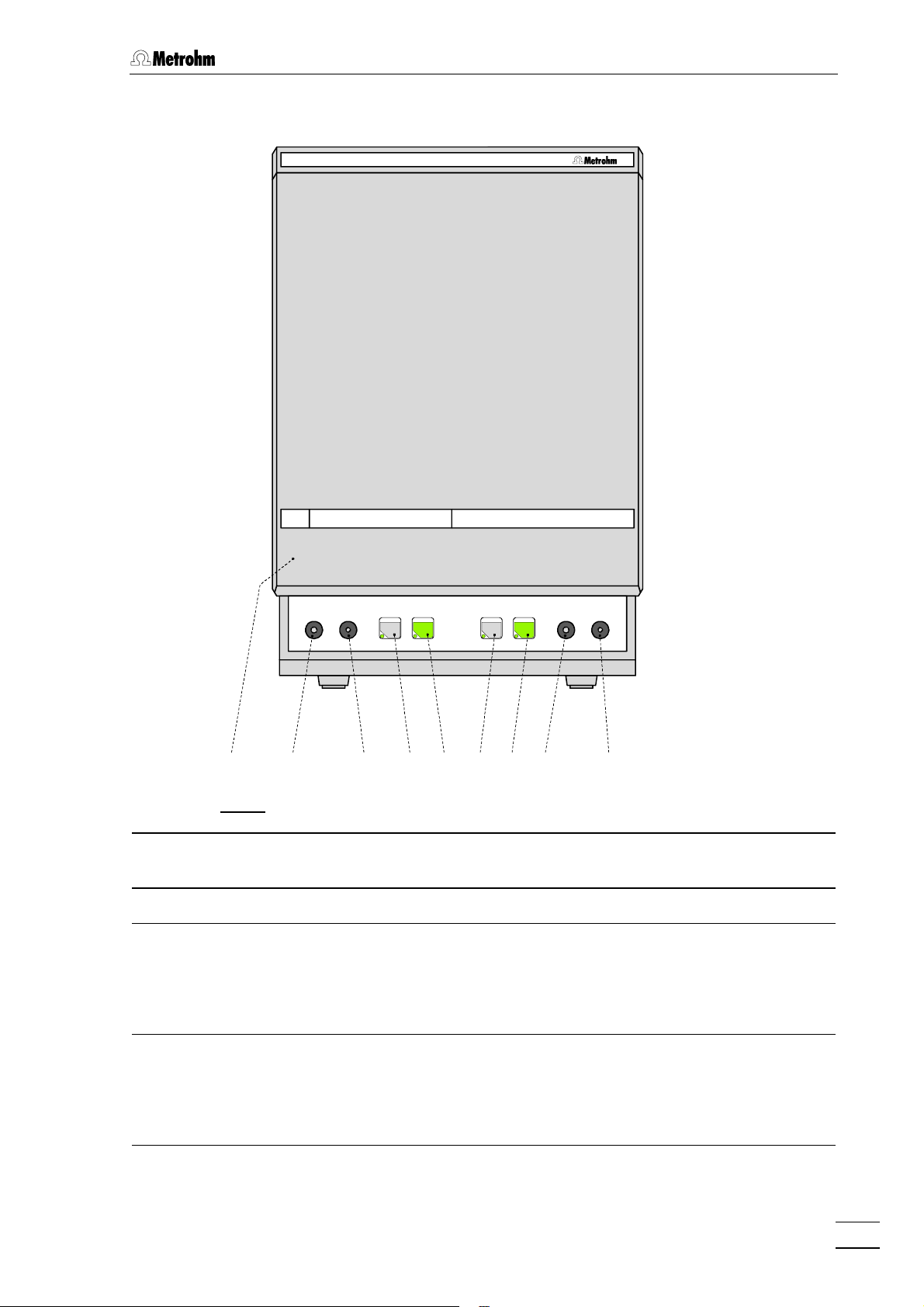

Fig. 4: Front of the 733 IC Separation Center

2020 Door to interior 2525 "FILL" key for valve B or "STEP" for

suppressor module

2121 Connection for 6.2816.020 Syringe 2626 "INJECT" key for valve B

2222 Feedthrough for aspirating tubing 2727 733.0010: Feedthrough for capillary

733.0X20: Connection for

6.2816.020 Syringe

733.0X30: Feedthrough for

suppressor inlet cap.

2323 "FILL" key for valve A 2828 733.0010: Feedthrough

733.0X20: Feedthrough for

aspirating tubing

733.0X30: Feedthrough for suppressor inlet capillary

2424 "INJECT" key for valve A

732 IC Detector / 733 IC Separation Center

5

Page 13

1 Introduction

2929 3030 3131 3232 3333

3434

3434

4848

4747

External

Power

24VDC/2A

5VDC/0,5A

Type: 1.733.00X0

Nr.: XX XXX

Pos.

Fill

Integr.

Ground

Start

Fill

Inject

RUN

COM

RUN

COM

732 IC Detector

3434

Waste AWaste B

3535

3434

B

Pos.

Fill

Integr.

Ground

Start

Fill

Inject

RUN

COM

Made by Metrohm Herisau Switzerland

732 IC Detector

RUN

COM

A

3636

3737

4646

4545

3737

3737

3838

Inlet AInlet B

3939

3737

4444 4343 4242 4141 4040

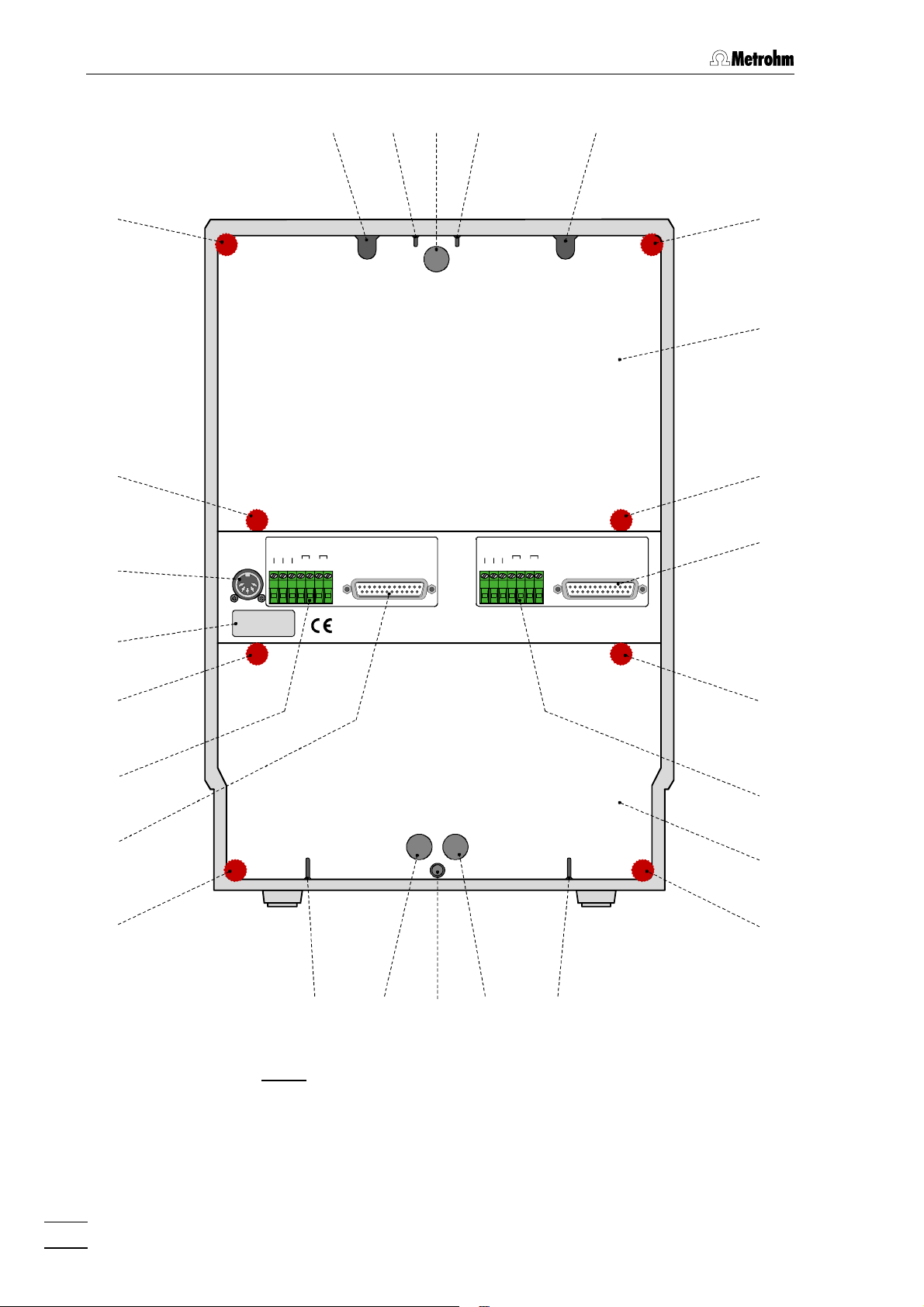

Fig. 5: Rear of the 733 IC Separation Center

6

732 IC Detector / 733 IC Separation Center

Page 14

1.2 Parts and controls

2929 Opening for detector cable B

opening for connecting cable

detector block B – 732

3030 Opening for outlet capillary B

discharge of the eluent of column B to

waste

3131 Rear panel opening

(closed with plastic stopper) for

additional supply and discharge lines

to and from the inner compartment

3232 Opening for outlet capillary A

discharge of the eluent of column A to

waste

3333 Opening for detector cable A

opening for connecting cable

detector block A – 732

3434 Knurled screw

for fastening the rear panel 3535

3939 Detachable rear panel

access to bottom part of inner

compartment

4040 Opening for inlet capillary A

supply of the eluent for column A

4141 Rear panel opening

(closed with plastic stopper) for

additional supply and discharge lines

to and from the inner compartment

4242 Connection for drain tube

for discharge of spilled liquid from the

inner compartment

4343 Rear panel opening

(closed with plastic stopper) for

additional supply and discharge lines

to and from the inner compartment

4444 Opening for inlet capillary B

supply of the eluent for column B

3535 Detachable rear panel

4545 Connection for 732 IC Detector B

access to top part of the inner

compartment

3636 Connection for 732 IC Detector A 4646 Terminal block for valve B

Ground, Fill, Inject:

inputs for control of the valve

Pos.Fill:

output signal on switching of the

valve to position "FILL"

Integr.Start:

output signal on switching of the

valve to position "INJECT"

3737 Knurled screw

for fastening rear panel 3939

3838 Terminal block for valve A

Ground, Fill, Inject:

inputs for control of the valve

Pos.Fill:

4747 Model plate

with serial number

4848 Connection for external supply

connection of power supply unit

(5 V, 0.5 A / 24 V, 2 A) in operation

without 732 IC Detector

output signal on switching of the

valve to position "FILL"

Integr.Start:

output signal on switching of the

valve to position "INJECT"

732 IC Detector / 733 IC Separation Center

7

Page 15

1 Introduction

1.3 Information on the Instructions for Use

Please read through these Instructions for Use carefully before you put

the 732 IC Detector and 733 IC Separation Center into operation. The

Instructions for Use contain information and warnings which must be

heeded the user to assure safe operation of the instruments.

1.3.1 Organization

These 8.732.1033 Instructions for Use for the 732 IC Detector and

733 IC Separation Center provide a comprehensive overview of the installation, startup procedure, operation, fault rectification and technical

specifications of these instruments. The Instructions for Use are organized as follows:

Section 1 Introduction

General description of instruments, parts and controls

and safety notes

Section 2 Installation

Installation of 732 IC Detector / 733 IC Separation Center, attachment of accessories and external devices

Section 3 Operating tutorial

Introduction to the operation using an example

Section 4 Operation

Detailed description of the operation and explanation of

functions of all keys

Section 5 Notes – Maintenance – Faults

Notes on ion chromatography, maintenance, fault rectification, diagnostic tests, validation

Section 6 Interfaces (green pages)

Description of RS232 interfaces, remote interfaces, valve

interface and analog output

Section 7 Appendix

Technical data, standard equipment, options, warranty,

declarations of conformity, index

To find the required information on the instruments, you will find it an

advantage to use either the Table of contents or the Index at the

back. The 8.732.1043 Quick Reference Guide is suitable for use as a

reference work for daily use as it explains the most important parameters and key functions.

As a supplement to the Instructions for Use, the Metrohm Monograph

8.732.2003 "Ion chromatography" is also supplied. This provides an

introduction to the theoretical fundamentals and general information on

separating columns and sample pretreatment. You will find detailed information on the separating columns available from Metrohm and on

special IC applications in the relevant "Application Bulletins", which

are available on request free of charge from your Metrohm agency.

8

732 IC Detector / 733 IC Separation Center

Page 16

1.3.2 Notation and pictograms

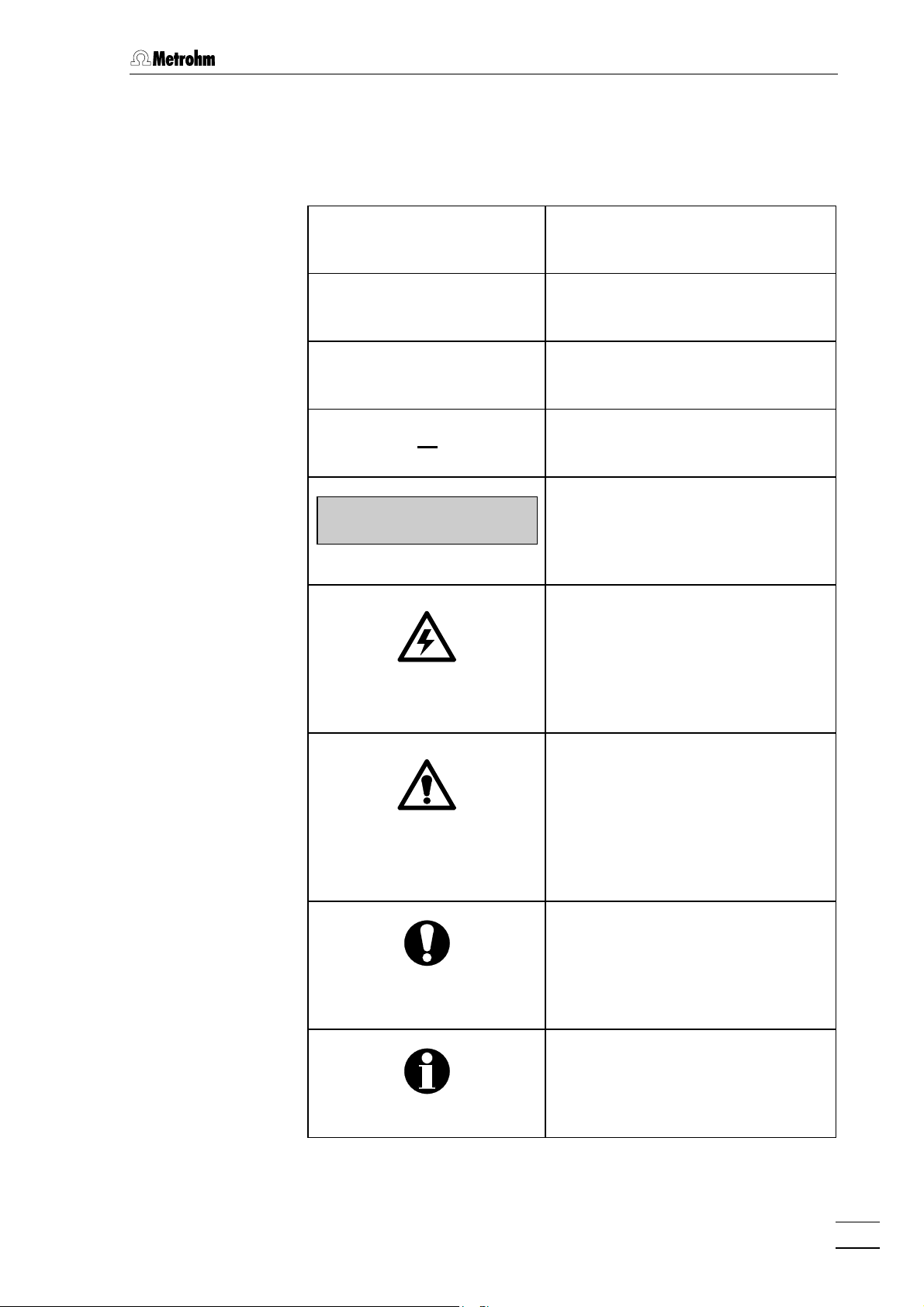

The following notations and pictograms (symbols) are used in these Instructions for Use:

<PARAM> Key

"Range" Parameter or entry value

3535 Part or control of 732/733

2222 Part or control of 709

1.3 Information on the Instructions for Use

>PARAM/detector

range: 1.00 mS/cm

Display

Text in display 11 of the 732 IC

Detector

Hazard

This symbol draws attention to a

possible danger to life or of injury if

the associated directions are not

followed correctly.

Warning

This symbol draws attention to

possible damage to instruments or

instrument parts if the associated

directions are not followed correctly.

Caution

This symbol marks important information. First read the associated

directions before you continue.

732 IC Detector / 733 IC Separation Center

Comment

This symbol marks additional information and tips.

9

Page 17

1 Introduction

1.4 Safety notes

1.4.1 Electrical safety

While electrical safety in the handling of the 732 IC Detector and 733

Separation Center is assured in the context of the specifications IEC

1010-1 (protection class 1, degree of protection IP40), the following

points should be noted:

• Mains connection

Setting of the mains voltage, checking the mains fuse and the

mains connection must be effected in accordance with the instruc-

tions in section 2.4.

• Opening the 732 IC Detector

If the 732 IC Detector is connected to the power supply, the instrument must not be opened nor must parts be removed from it, otherwise there is a danger of coming into contact with components which

are live. Hence, always disconnect the instrument from all voltage

sources before you open it and ensure that the mains cable is

disconnected from mains connection 18 18 !

• Opening the 733 IC Separation Center

Disconnect connecting cable to the 732 IC Detector from connector 1414 before you remove the middle housing panel with con-

nectors.

• Protection against static charges

Electronic components are sensitive to static charging and can be

destroyed by discharges. Before you touch any of the components

inside the 732 IC Detector or 733 IC Separation Center, you should

earth yourself and any tools you are using by touching an earthed

object (e.g. housing of the instrument or a radiator) to eliminate any

static charges which exist.

1.4.2 General precautionary rules

• Handling of solvents

Check all lines of the IC system periodically for possible leaks. Follow

the relevant instructions regarding the handling of flammable and/or

toxic solvents and their disposal.

10

732 IC Detector / 733 IC Separation Center

Page 18

2 Installation

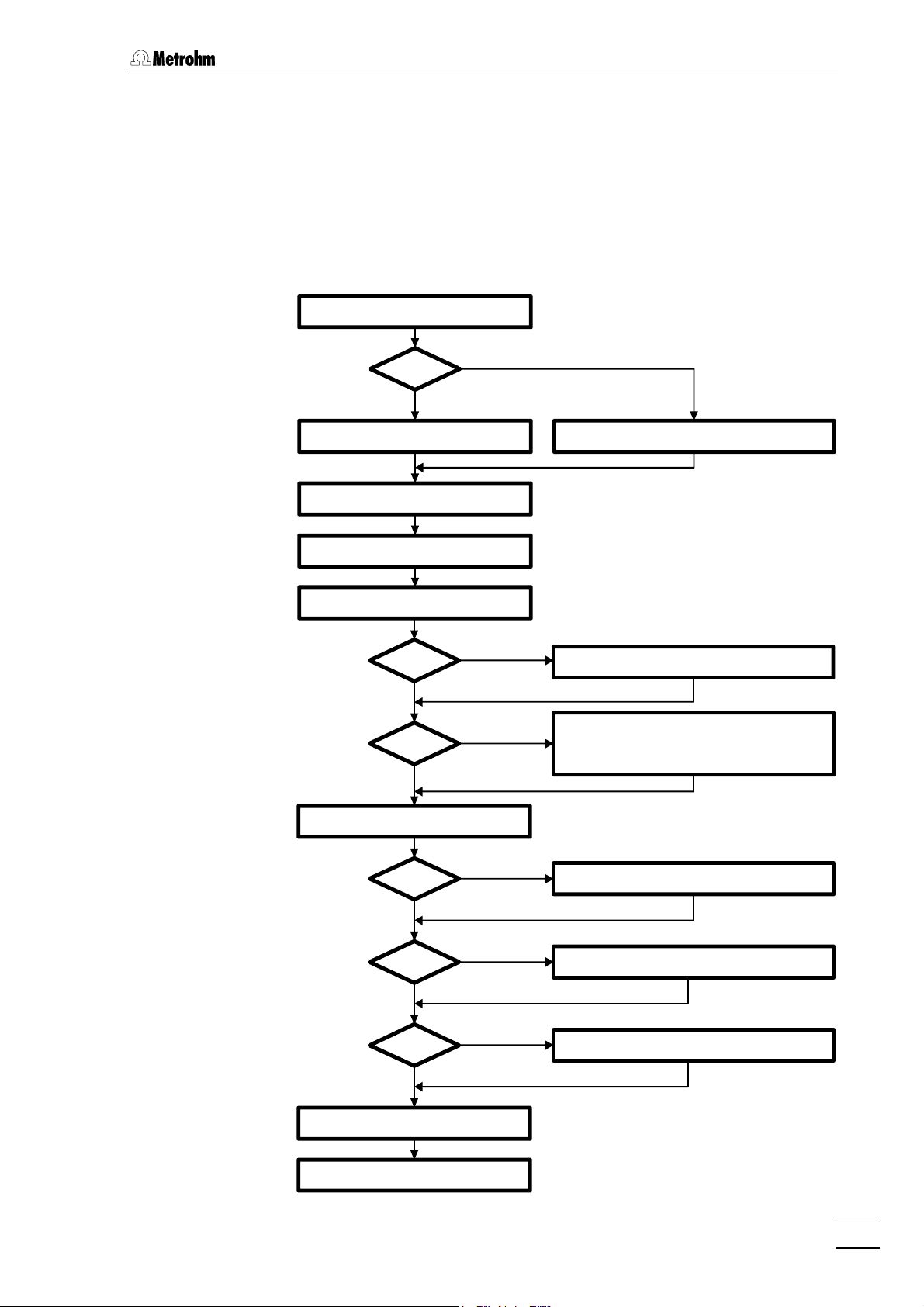

2.1 Flow chart

The following flow chart provides an overview of all installation work. You

will find more detailed information in the relevant sections.

2.1 Flow chart

Setting upSetting up

733.0X20733.0X20

NoNo

Connecting 733Connecting 733 sect. 2.3.1sect. 2.3.1 Connecting 733Connecting 733 sect. 2.3.2sect. 2.3.2

Installing accessoriesInstalling accessories sect. 2.3.3/4sect. 2.3.3/4

Mains connectionMains connection sect. 2.4sect. 2.4

Connecting 709 IC PumpConnecting 709 IC Pump sect. 2.6sect. 2.6

metal freemetal free

YesYes

PrecolumnPrecolumn

NoNo

sect. 2.2sect. 2.2

YesYes

NoNo

YesYes

PassivationPassivation sect. 2.6.7sect. 2.6.7

Precolumn with twin cartridge holderPrecolumn with twin cartridge holder sect. 2.7.2sect. 2.7.2

Precolumn with cartridge headPrecolumn with cartridge head sect. 2.7.3sect. 2.7.3

IC anion precolumn SUPERSEPIC anion precolumn SUPERSEP sect. 2.7.4sect. 2.7.4

Installing sample loopInstalling sample loop sect. 2.8.2sect. 2.8.2

ConditioningConditioning sect. 2.8.7sect. 2.8.7

Connecting external devicesConnecting external devices sect. 2.9sect. 2.9

732 IC Detector / 733 IC Separation Center

733.0010733.0010 Connecting separating columnConnecting separating column sect. 2.8.4sect. 2.8.4

NoNo

733.0X20733.0X20 Connecting separating columnConnecting separating column sect. 2.8.5sect. 2.8.5

NoNo

733.0X30733.0X30 Connecting sep. col. + suppressorConnecting sep. col. + suppressor sect. 2.8.6sect. 2.8.6

NoNo

YesYes

YesYes

YesYes

11

Page 19

2 Installation

2.2 Setting up the instruments

2.2.1 Packaging

The 732 IC Detector and 733 IC Separation Center are supplied

together with the separately packed accessories in special packagings

containing shock-absorbing foam linings designed to provide excellent

protection. The actual instruments are packed in an evacuated

polyethylene bag to prevent the ingress of dust. Please store all these

special packagings as only they assure transport of the instruments

free from damage.

2.2.2 Check

After receipt, immediately check whether the shipment is complete and

has arrived without damage (compare with delivery note and list of accessories in section 7.2). In the case of transport damage, see instructions in section 7.4.1 "Warranty".

2.2.3 Location

Position the instruments in the laboratory at a location convenient for

operation, free from vibrations and protected against a corrosive atmosphere and contamination by chemicals. The same applies to all

other components of the IC system.

To avoid disturbing temperature influences on the insulated column

compartment, the entire system including pump and eluent reservoir

must be protected against direct sunlight.

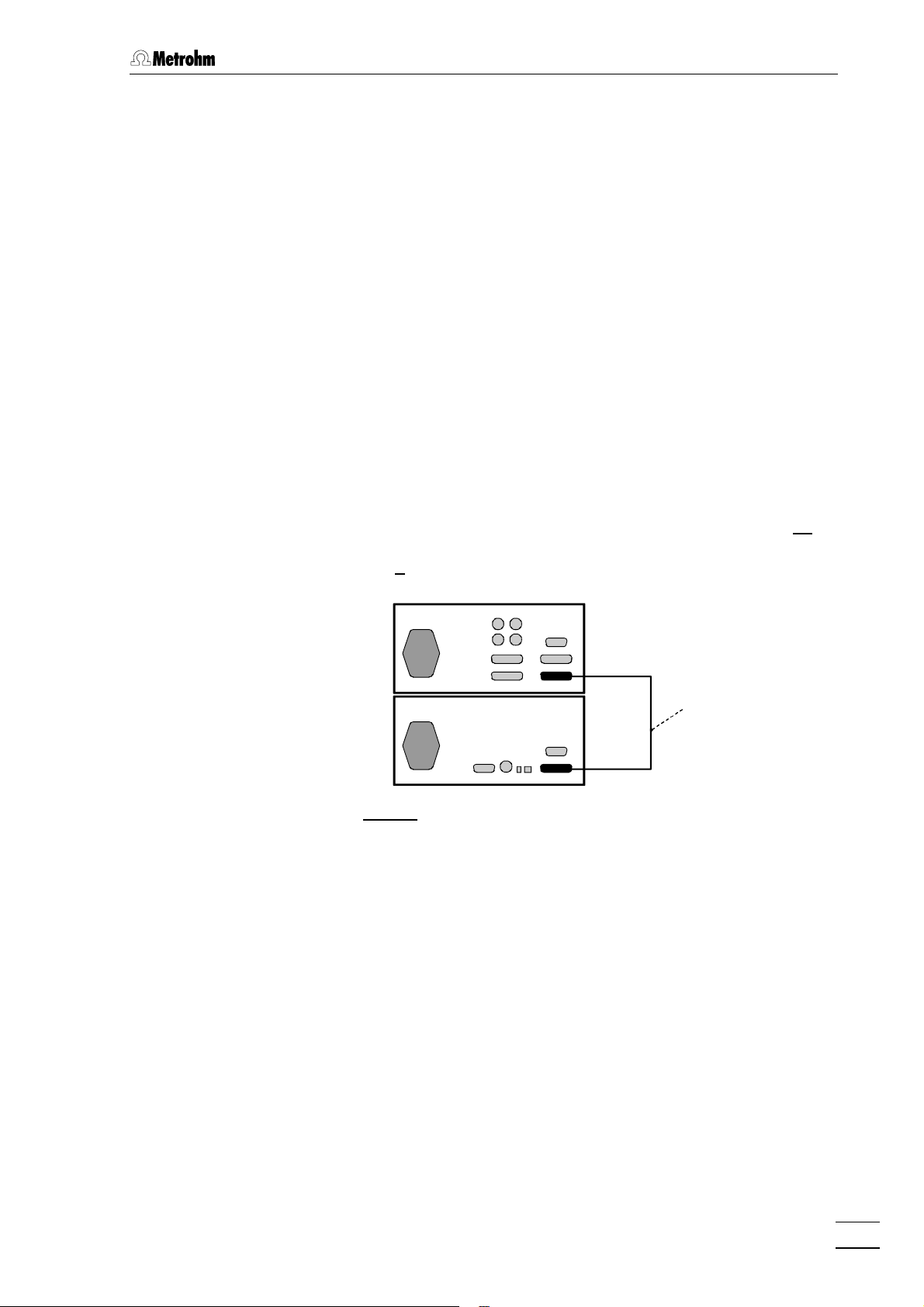

2.2.4 Arrangement of the instruments

In one-channel operation, the 709 IC Pump, 733 IC Separation Center

and 732 IC Detector are best stacked on top of one another in this order.

In two-channel operation (2.733.0X20 IC Separation Center), the optimum arrangement (1, 2 or 3 towers) depends on the laboratory space

available. However, the 709 IC Pumps should be set up at the very

bottom and the 732 IC Detectors at the very top.

12

To ensure that the arrangement of pumps and detectors for the two

channels A and B is clearly apparent in two-channel operation, it is

advantageous to mark the instruments. The 6.2248.000 Magnetic

plate is enclosed with the 732 IC Detector for this purpose. It can be

cut to the desired size, labeled (e.g. with "A" or "B") and affixed to the

appropriate instrument.

732 IC Detector / 733 IC Separation Center

Page 20

2.3 Connection of 733 IC Separation Center

2.3 Connection of 733 IC Separation Center

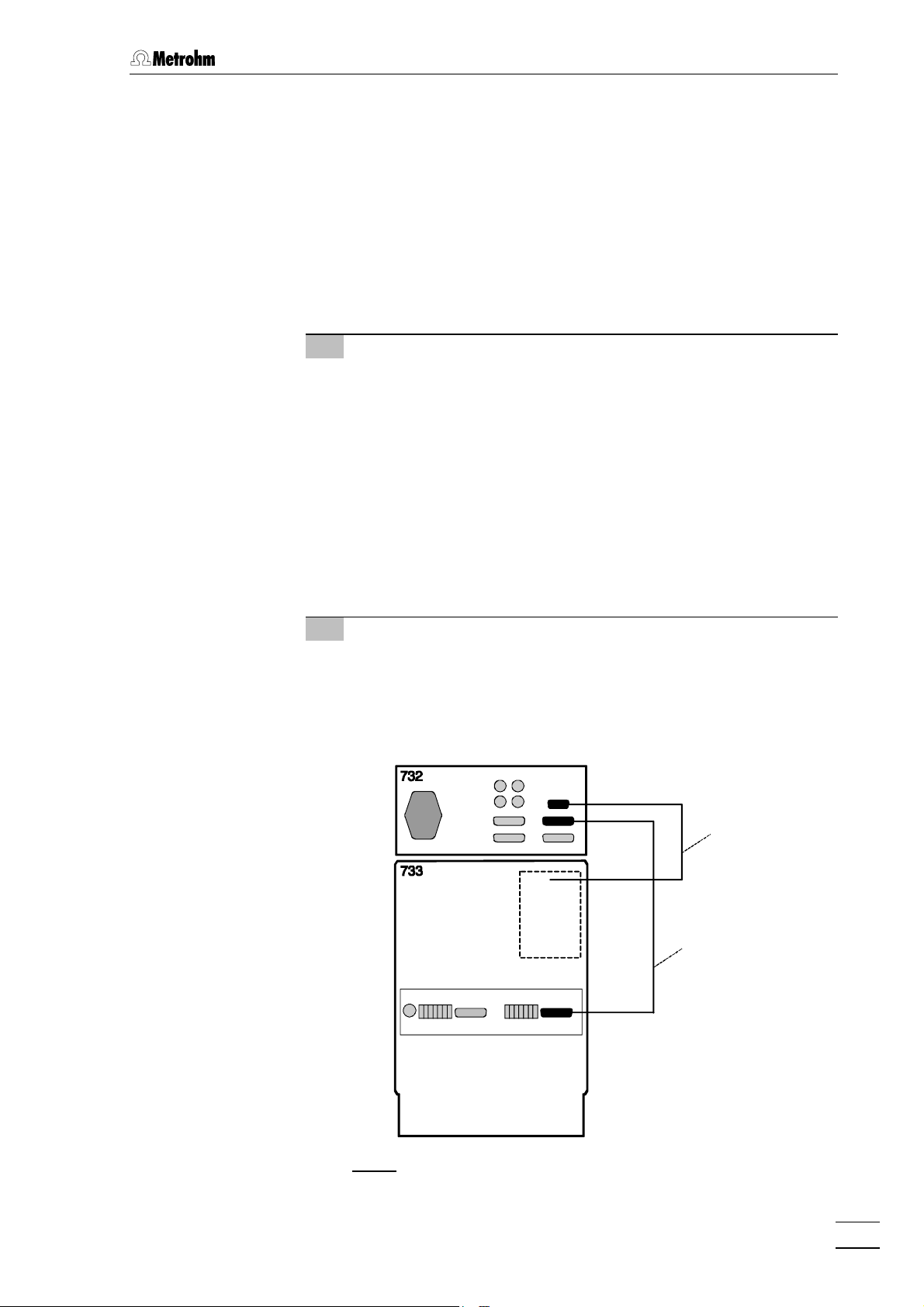

2.3.1 2.733.0010/2.733.0X30 IC Separation Center

The instrument versions 2.733.0010 and 2.733.0030 of the IC Separation Center are operated with a 732 IC Detector whose standard

equipment also includes the 1.732.0100 Detector block. For the

metal-free 2.733.0130 instrument version the metal-free 1.732.0110

Detector block must be used. It is best to proceed as follows when

connecting the two instruments and the detector block:

1 Install detector block

• Unscrew the four knurled screws 3434 from the top rear panel

3535 of the 733 IC Separation Center and remove rear panel

(see Fig. 5).

• Position detector block from the back in the space provided

in the 733 IC Separation Center on the right and push fully to

the front (see Fig. 16).

• Insert the cable permanently attached to the detector block in

opening 3333 and the outlet capillary in opening 3232 "Waste A" of

the rear panel 3535.

• Replace rear panel 3535 and screw to the 733 IC Separation

Center using the four knurled screws 3434.

2 Connect detector block

• Plug the gray connecting cable permanently attached to the

detector block into connection 1313 "Detector Block" of the 732

IC Detector and fasten to the instrument by tightening the

screws in the cable connector (see Fig. 6).

Cable from

detector block

6.2125.090

RUN

COM

Fig. 6: Connection 732 – 2.733.0010/2.733.0X30

732 IC Detector / 733 IC Separation Center

13

Page 21

2 Installation

3 Connect waste container

• Lead the outlet capillary of the detector block to a sufficiently

large waste container and fix in place.

4 Connect 732 to 733

• Plug one end of the 6.2125.090 Connecting cable into con-

nection 1414 "733 IC Separation Center” of the 732 IC Detector

and fasten to the instrument by tightening the screws in the

cable connector (see Fig. 6).

• Plug the other end of the 6.2125.090 Connecting cable into

connection 3636 "732 IC Detector" of the 733 IC Separation

Center and fasten to the instrument by tightening the screws

in the cable connector (see Fig. 6).

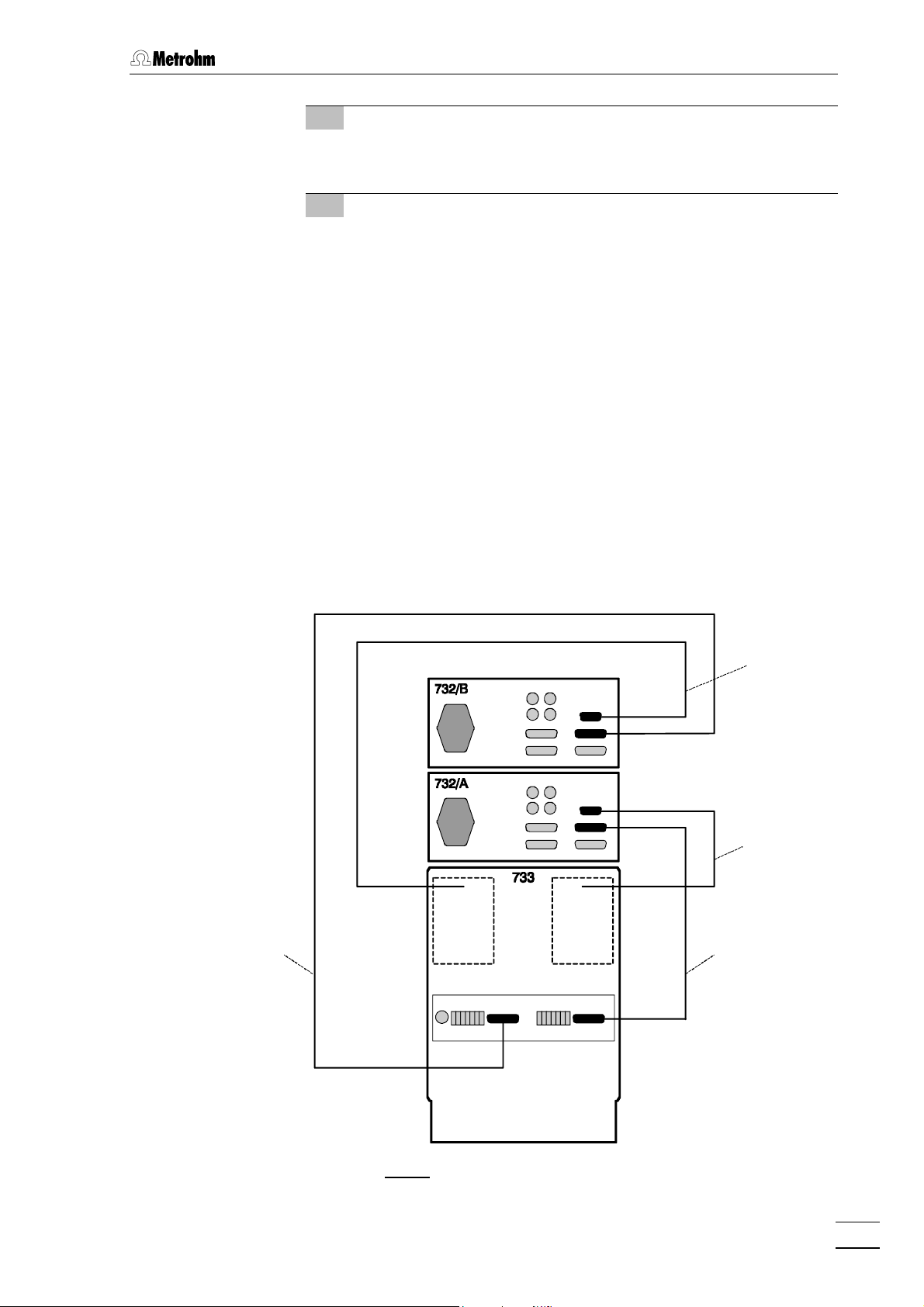

2.3.2 2.733.0X20 IC Separation Center

For operation of the 2.733.0020 or the metal-free 2.733.0120 instrument

version of the 733 Separation Center, two 1.732.0100 or metal-free

1.732.0110 IC Detectors are needed. It is best to proceed as follows

when connecting the instruments and the two detector blocks:

1 Install detector blocks

• Unscrew the four knurled screws 3434 from the top rear panel

3535 of the 733 IC Separation Center and remove rear panel

(see Fig. 5).

• Position first detector block A from the back in the space

provided in the 733 IC Separation Center on the right and

push fully to the front (see Fig. 16).

• Position second detector block B from the back in the space

provided in the 733 IC Separation Center on the left and push

fully to the front (see Fig. 16).

• Insert the cable permanently attached to detector block A in

opening 3333 and the outlet capillary in opening 32 32 "Waste A"

of the rear panel 3535.

• Insert the cable permanently attached to detector block B in

opening 2929 and the outlet capillary in opening 3030 "Waste B"

of the rear panel 3535.

• Replace rear panel 3535 and fasten to 733 IC Separation Center

with the four knurled screws 3434.

2 Connect detector blocks

• Plug the gray connecting cable permanently attached to

detector block A into connection 1313 "Detector block" of the

first 732 IC Detector and fasten to the instrument by tightening the screws in the cable connector (see Fig. 7).

• Plug the gray connecting cable permanently attached to

detector block B into connection 1313 "Detector Block" of the

second 732 IC Detector Block and fasten to the instrument by

tightening the screws in the cable connector.

14

732 IC Detector / 733 IC Separation Center

Page 22

2.3 Connection of 733 IC Separation Center

3 Connect waste container

• Lead the outlet capillaries of the two detector blocks to a

sufficiently large waste container and fix in place.

4 Connect 732 to 733

• Plug one end of the 6.2125.090 Connecting cable into con-

nection 1414 "733 IC Separation Center“ of the first 732 IC De-

tector and fasten to the instrument by tightening the screws

in the cable connector (see Fig. 7).

• Plug other end of the 6.2125.090 Connecting cable into

connection 3636 "732 IC Detector" of the 733 IC Separation

Center and fasten to the instrument by tightening the screws

in the cable connector.

• Plug one end of the 6.2125.090 Connecting cable into con-

nection 1414 "733 IC Separation Center" of the second 732 IC

Detector and fasten to the instrument by tightening the

screws in the cable connector.

• Plug the other end of the 6.2125.090 Connecting cable into

connection 4545 "732 IC Detector" of the 733 IC Separation

Center and fasten to the instrument by tightening the screws

in the cable connector.

Cable from

detector block

Cable from

detector block

6.2125.0906.2125.090

COM

RUN

732 IC Detector / 733 IC Separation Center

Fig. 7: Connection 732 – 2.733.0X20

15

Page 23

2 Installation

2.3.3 Connection of syringe and aspirating tubing

For manual filling of the sample loops mounted on the injection valves,

the 6.2816.020 Syringe and the PTFE aspirating tubing already screwed

to the valve are needed. These accessories are mounted or adjusted as

follows:

1 Connect syringe

• Push 6.2816.020 Syringe (without needle) as far as it will go

into connection socket 2121 (for valve A) or 2727 (for valve B)

(see Fig. 4).

2 Adjust aspirating tubing

• Loosen the rotary nipple screwed onto the interior side of

connection 2222 or 2828.

• Pull PTFE aspirating tubing 8888 (see Fig. 16 and Fig. 17) by

hand out of connection 2222 or 2828 as far as desired.

• Retighten rotary nipple on the interior side of connection 2222

or 2828 to fix the aspirating tubing in place.

2.3.4 Connection of the drain tube

The 733 IC Separation Center has a connection at the rear to which a

drain tube for discharged liquids can be attached. Proceed as follows:

1 Connect drain tube

• Mount 6.1816.00 Silicone tubing on connection nipple 4242

(see Fig. 5).

2 Lead drain tube to collecting vessel

• Lead the other end of the drain tube to a suitable collecting

vessel and fix in place.

2.3.5 Connection of the 6.5324.000 Bottle rack (option)

The optional available 6.5324.000 Bottle rack for supply vessels can be

placed on top of the IC system tower. The accessories include the

supply vessels for eluent (2 L), regeneration solution (1 L) and rinsing

solution (1 L). For the connection of the supply capillaries leading to the

709 IC Pump and the suppressor module, see the instructions given on

the enclosed leaflet.

16

732 IC Detector / 733 IC Separation Center

Page 24

2.4 Mains connection

Follow the instructions below for connecting to the power supply. If

the instrument is operated with a mains voltage set wrongly and/or

wrong mains fuse, there is a danger of fire!

2.4.1 Setting the mains voltage

Before switching on the 732 IC Detector for the first time, check that the

mains voltage set on the instrument (see Fig. 8) matches the local

mains voltage. If this is not the case, you must reset the mains voltage

on the instrument as follows:

1 Disconnect mains cable

Disconnect mains cable from mains connection plug 1818 of the

732 IC Detector.

2.4 Mains connection

2 Remove fuse holder

Using a screwdriver, loosen fuse holder 1919 below the mains

connection plug 1818 and take out completely.

3 Check and change fuse if necessary

Carefully take the fuse installed for the desired mains voltage out

of fuse holder 1919 and check its specifications (the position of the

fuse in the fuse holder is marked by the white arrow imprinted

next to the mains voltage range):

100……120 V 0.63 A (slow-blow) Metrohm No. U.600.0014

220……240 V 0.315 A (slow-blow) Metrohm No. U.600.0011

4 Insert fuse

Change fuse if necessary and reinsert in fuse holder 1919.

5 Install fuse holder

Depending on the desired mains voltage, insert fuse holder 1919 in

the 732 IC Detector so that the corresponding mains voltage

range can be read normally and the adjacent white arrow points

to the white bar imprinted below the fuse holder (see Fig. 8).

732 IC Detector / 733 IC Separation Center

17

Page 25

2 Installation

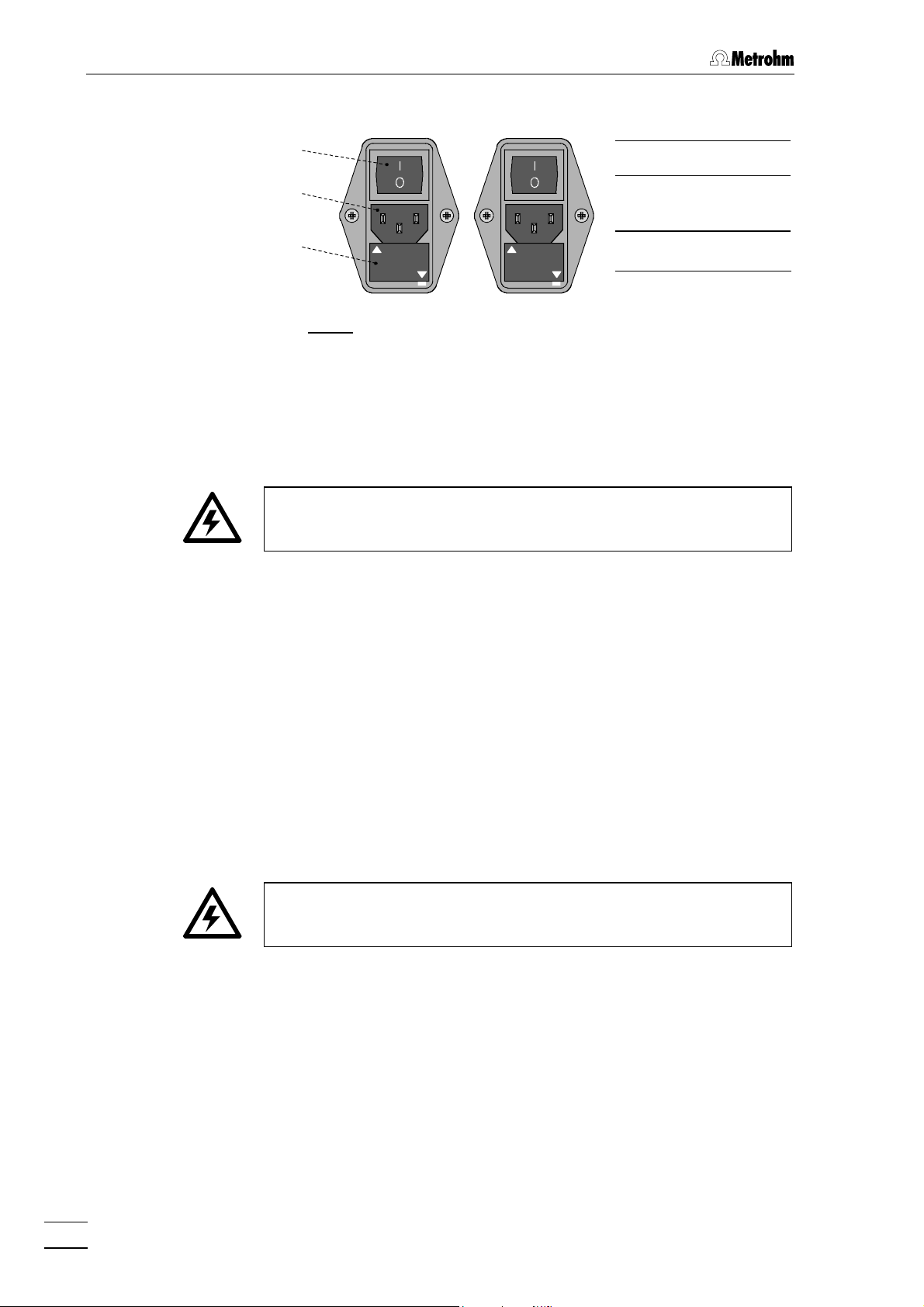

100 – 120 V220 – 240 V

2.4.2 Fuses

99

1818

99 Mains switch

1818 Mains con-

nection plug

1919

220 -- 240 V

100 -- 120 V

100 -- 120 V

220 -- 240 V

1919 Fuse holder

Fig. 8: Setting the mains voltage

One of the two fuses 0.63 A/slow-blow for 100…120 V or 0.315 A/slowblow for 220…240 V is installed in fuse holder 1919 of the 732 IC Detector

as standard.

Ensure that the instrument is never put into operation with fuses of

another type, otherwise there is danger of fire!

For checking or changing fuses, process as described in section 2.4.1.

2.4.3 Mains cable and mains connection

Mains cable

The instrument is supplied with one of three mains cables

• 6.2122.020 with plug SEV 12 (Switzerland, …)

• 6.2122.040 with plug CEE(7), VII (Germany, …)

• 6.2133.070 with plug NEMA 5-15 (USA, …)

which are three-cored and fitted with a plug with an earthing pin. If a

different plug has to be fitted, the yellow/green lead (IEC standard)

must be connected to protective earth (protection class 1).

Any break in the earthing inside or outside the instrument can make it

a hazard!

Mains connection

Plug the mains cable into mains connection plug 1818 of the 732 IC De-

tector (see Fig. 8).

2.4.4 On/off switching of the instruments

18

The 732 IC Detector is switched on and off using mains switch 99. When

the instrument is switched on, display 11 lights up.

732 IC Detector / 733 IC Separation Center

Page 26

2.5 Capillary connections

2.5.1 Capillaries

Some of the connections under high pressure between the feed pump

and the detector block must be set up by the user. For metal-free sys-

tems, the 6.1831.010 PEEK capillary (i.d. = 0.25 mm, e.d. = 1/16",

length = 3 m) must be used.

For non metal-free systems, the 6.1831.010 PEEK capillary can also

be used in the pressure range of 0…25 MPa (0…250 bar); on the other

hand, in the pressure range of 25…50 MPa (250…500 bar), which is

permissible only together with the non metal-free 2.709.0010 version of

the 709 IC Pump, the 6.2620.020 Steel capillary (i.d. = 0.25 mm,

e.d. = 1/16", length = 3 m) must be used.

With PEEK capillaries the connection is made preferably with the

6.2744.010 PEEK connectors, with steel capillaries, the connection is

made preferably with 6.2620.000 and 6.2620.010 steel connectors (see

section 2.5.2 and section 2.5.3).

2.5 Capillary connections

Capillaries fitted with new connectors must have a perfectly flat cut

surface. For PEEK capillaries it is best to use the 6.2621.080 Capil-

lary tubing cutter, for steel capillaries the 6.2621.040 Capillary

tubing cutter (both available as an option).

2.5.2 Steel connectors

For the connection of steel capillaries, the steel connectors 6.2620.010

Ferrule and 6.2620.000 Pressure screw available as an option can

be used. Proceed as follows:

1 Mount connectors

Slide a pressure screw 5050 (6.2620.000) and a ferrule 4949

(6.2620.010) over the end of the capillary 5151 to be fastened as

shown in Fig. 9.

2 Insert capillary in connection

Push capillary end into the corresponding connection as far as it

will go (to avoid dead volume).

3 Tighten compression fitting

Tighten pressure screw 5050 with the open-end spanner 1/4"

(6.2621.050) supplied.

For the connection of capillaries to the injection valves, use only the

special steel connections contained in a plastic bag affixed to the

valve (or as an alternative the 6.2744.010 PEEK compression fittings).

If other steel connectors are used (e.g. 6.2620.000 and 6.2620.010),

the valve connection may be damaged!

732 IC Detector / 733 IC Separation Center

19

Page 27

2 Installation

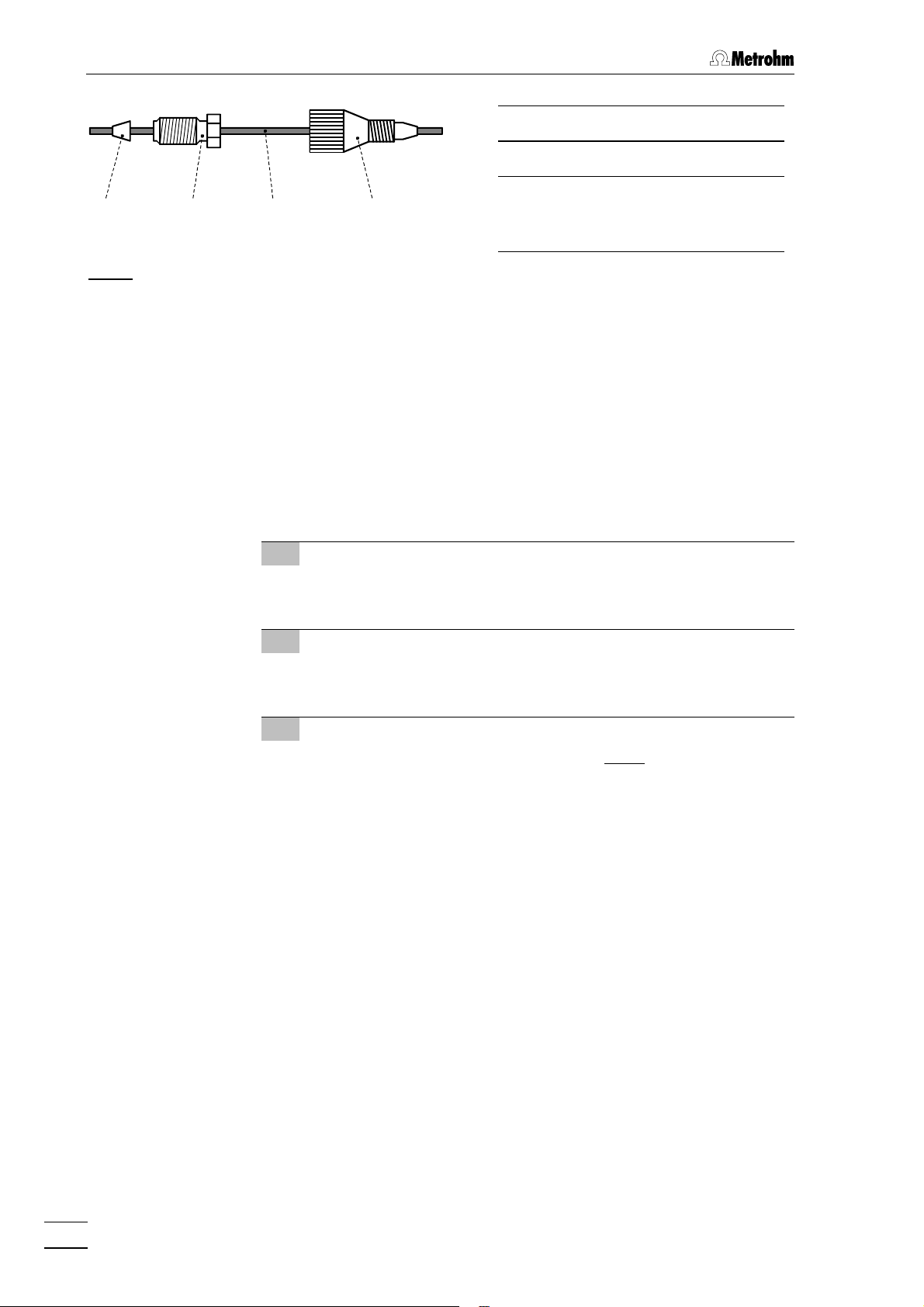

50504949 5151 5252

4949 Ferrule (6.2620.010)

5050 Pressure screw (6.2620.000)

5151 Capillary

6.2620.020 Steel capillary or

6.1831.010 PEEK capillary

Fig. 9: Connectors for capillaries

2.5.3 PEEK connectors

For the connection of 6.1822.010 PEEK capillaries (i.D. = 0.3 mm) or

6.1822.010 PTFE microcapillaries, the 6.2744.010 PEEK compres-

sion fittings are used. Proceed as follows:

1 Mount compression fitting

Slide a compression fitting 5252 (6.2744.010) over the end of the

capillary 5151 to be fastened as shown in Fig. 9.

2 Insert capillary in connection

Push capillary end in the corresponding connection as far as it

will go (to avoid dead volume).

5252 Compression fitting

(6.2744.010)

3 Tighten compression fitting

Tighten compression fitting 5252 by hand (never use tools).

20

732 IC Detector / 733 IC Separation Center

Page 28

2.6 Connection of 709 IC Pump

2.6.1 Electrical connection

For operation of the 732 IC Detector and 733 IC Separation Center you

can use any commercial HPLC pump. However, as the attainable sensitivity depends to a large extent on the quality of the pump, Metrohm

advises use of the 709 IC Pump, which has been specially developed

for the demands of ion chromatography and has minimal pump pulsation and an outstanding flow constancy.

Startup and operation of the 709 IC Pump are described in the 709

Instructions for Use. The eluent, which must be degassed and filtered

(cf. section 5.1.3), is selected on the basis of the separating column installed in the 733 IC Separation Center and the current separation

problem (see 8.732.2003 IC Monograph).

The connection of the 709 IC Pump at the connection 1515 of the 732

IC Detector is shown in Fig. 10. For this you can use the 6.2125.060

Cable available as an option or another RS cable specified as a "null

modem" cable. To ensure proper functioning of the communication

between the 732 IC Detector and 709 IC Pump, the sliding switch 3636 on

the IC pump must be set to "RS 232" and the external control switched

on with key 88 <EXT.> (see 709 Instructions for Use).

2.6 Connection of 709 IC Pump

732

709

Fig. 10: Connection of 709 IC Pump

2.6.2 Pulsation dampener

To protect the column material against pressure drops caused by the

injector, the use of a pulsation dampener connected between the pump

and the injection valve of the 733 IC Separation Center is recommended. The optional 6.2620.150 Pulsation dampener MF (see sec-

tion 7.3.1) is very well suited to this purpose.

6.2125.060

The metal-free 6.2620.150 Pulsation Dampener is supplied fully assembled and has two connections for capillaries, for which either the

connectors supplied or two 6.2744.010 PEEK compression fittings can

be used. The flow direction is arbitrary. The pulsation dampener is positioned in the interior of the 733 IC Separation Center on the base below the injection valve (see Fig. 16 and Fig. 17).

732 IC Detector / 733 IC Separation Center

21

Page 29

2 Installation

2.6.3 Filter unit PEEK

The 6.2821.100 Filter unit PEEK (see Fig. 11) supplied with the 709

IC Pump is installed between the 709 IC Pump and the injection valve

at the 733 IC Separation Center. This filter unit serves to avoid contamination of the piston seals of the 709 IC Pump by abrasive particles and

can be used in the pressure range 0…25 MPa (0…250 bar).

The two filter units PEEK supplied with the 2.733.0X30 IC Separation

Center (with suppressor) are installed between the 752 Pump Unit and

the inlet capillaries for regeneration and rinsing solution. These filter

units serve to protect the suppressor module from foreign particles and

bacterial growth.

The 6.2821.100 Filter unit PEEK consists of the housing 5454 and the two

connectors 5353 (with filter) and 5555 (without filter) screwed into the hous-

ing 5454. For the connection of capillaries 5151 PEEK compression fittings

5252 (6.2744.010) must be used. New connectors 5353 with filter are available as an option with the ordering number 6.2821.110 (set of 10).

For the connection of the filter unit, please note the flow direction

arrow printed on the housing.

5151 5252 5353 5454 5555 5252 5151

Fig. 11: 6.2821.100 Filter unit PEEK

5151 Capillary

6.1831.010 PEEK capillary

5252 Compression fitting (6.2744.010) 5555 Connector without filter

5353 Connector with filter (6.2824.110)

Part of 6.2824.100 Filter unit

22

5454 Housing for filter unit

Part of 6.2824.100 Filter unit

Part of 6.2824.100 Filter unit

732 IC Detector / 733 IC Separation Center

Page 30

2.6.4 Filter unit Manufit

The optional 6.2821.000 Filter unit Manufit (see section 7.3.1) is installed between the 709 IC Pump and the injection valve at the 733 IC

Separation Center. The filter unit serves to avoid contamination of the

piston seals by abrasive particles and can be used in the pressure

range 0…50 MPa (0…500 bar) for non metal-free systems together

with steel capillaries. It is installed as follows (see Fig. 12):

1 Prepare Manufit housing

• Insert outlet capillary 6363 with steel mesh holding end 6161 into

Manufit housing 6262.

• Insert the 4 steel meshes 6060 provided into the steel mesh

holding end 6161.

• Press the PTFE gasket 5959 into the steel mesh holding end

6161.

2 Prepare Manufit pressure screw

• Insert inlet capillary 5656 with counterpart end 5858 into Manufit

pressure screw 5757.

2.6 Connection of 709 IC Pump

5656

5757

5858

5959

6060

6161

3 Assembly

• Fit the two capillary end pieces 5858 and 6161 together.

• Screw Manufit pressure screw 5757 and Manufit housing 6262

firmly together.

To replace contaminated steel meshes, proceed in the reverse order.

IC Pump

709

5656 Inlet capillary

5757 Manufit pressure screw

5858 Counterpart end

5959 PTFE Gasket (6.2821.010)

6060 Steel meshes (6.2821.020)

6161 Steel mesh holding end

6262

IC Separation

6363

Fig. 12: 6.2821.000 Filter unit Manufit

732 IC Detector / 733 IC Separation Center

Center 733

6262 Manufit housing

6363 Outlet capillary

23

Page 31

2 Installation

2.6.5 Connection to injection valve with PEEK capillaries

For metal-free systems and for non metal-free systems in the pressure

range 0…25 MPa (0…250 bar) we recommend to use 6.1831.010

PEEK capillaries, a 6.2620.150 Pulsation dampener (see section 2.6.2)

and a 6.2821.100 Filter unit PEEK (see section 2.6.3) to connect the

709 IC Pump and the injection valve of the 733 IC Separation Center.

Proceed as follows:

For the connection of capillaries to the injection valve, use only the

6.2744.010 PEEK compression fittings. If other steel connectors are

used (e.g. 6.2620.000 and 6.2620.010), the valve connection may be

damaged!

1 Connection to 709 IC Pump

• Cut connection capillary 2222 (6.1831.010 PEEK capillary) to

the required length and equip with the necessary connectors.

• Attach one end of connection capillary 2222 to connection 2323 of

the 709 IC Pump (see 709 Instructions for Use).

• Attach the other end of connection capillary 2222 to the con-

nector 5353 (with filter) of the filter unit 6464 (see Fig. 13).

• Attach the PEEK capillary 6565 cut to the required length and

equipped with connectors to the connector 5555 of the filter unit

6464.

2 Installation of the capillary in the IC Separation

Center

• Unscrew the four knurled screws 3737 of the bottom rear panel

3939 of the 733 IC Separation Center and remove rear panel

(see Fig. 5).

• Insert PEEK capillary 6565 from the back into the inner com-

partment of the IC Separation Center.

• Install rear panel 3939 so that the capillary is positioned in

opening 4040 „Inlet A“ or 4444 „Inlet B“ and screw on with the four

knurled screws 3737.

3 Connection to injection valve

• Connect PEEK capillary 6565 to pulsation dampener 6666 (see

section 2.6.2). Using another PEEK capillary 6565, connect pul-

sation dampener 6767 to connection "5" of injection valve 6868.

4 Mount column connection capillary

• Connect column connection capillary 6767 (ca. 20 cm of

6.1831.010 PEEK capillary) to connection "4" of injection valve

6868.

24

732 IC Detector / 733 IC Separation Center

Page 32

2.6 Connection of 709 IC Pump

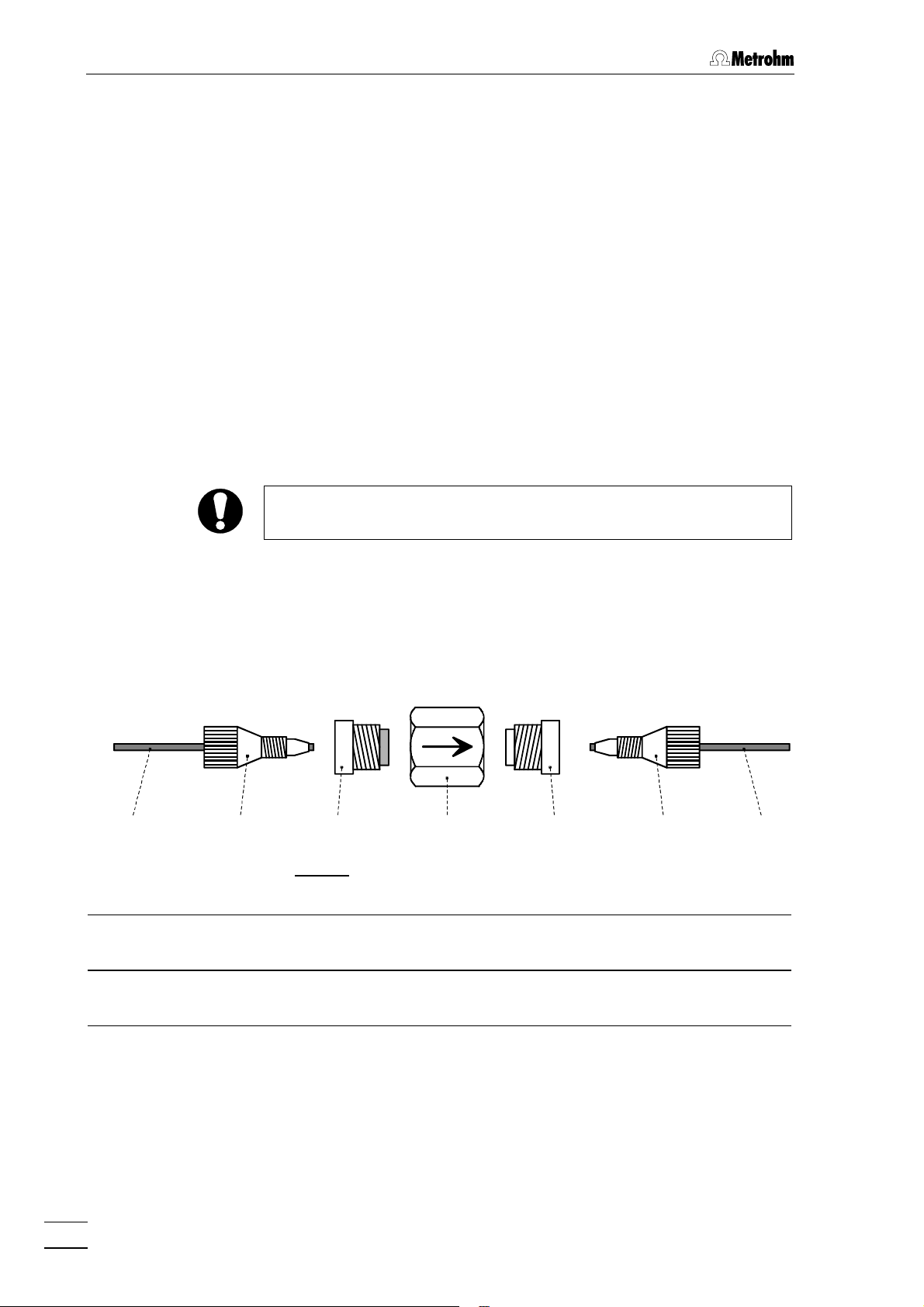

2222 6464 6565

709

6666 65656767 6868

733

Fig. 13: Connection to injection valve with PEEK capillaries

2222 Connection capillary

6666 Pulsation dampener (6.2620.150)

6.1831.010 PEEK capillary

6464 Filter unit PEEK (6.2824.100) 6767 Column connection capillary

6.1831.010 PEEK capillary

6565 PEEK capillary (6.1831.010) 6868 Injection valve

2.6.6 Connection to injection valve with steel capillaries

For the pressure range 25…50 mPa (250…500 bar) we recommend to

use 6.2620.020 Steel capillaries, a 6.2620.150 Pulsation dampener (see

section 2.6.2) and a 6.2821.000 Filter unit Manufit (see section 2.6.4) to

connect the 709 IC Pump and the injection valve of the 733 IC Separation Center. Proceed as follows:

For the connection of capillaries to the injection valve, use only the

special steel connectors contained in a plastic bag affixed to the

valve. If other steel connectors are used (e.g. 6.2620.000 and

6.2620.010), the valve connection may be damaged!

1 Connection to 709 IC Pump

• Attach inlet capillary 5656 of the Manufit filter unit 6969 to connec-

tion 2323 of the 709 IC Pump (see 709 Instructions for Use).

• Attach outlet capillary 6363 of the filter unit Manufit 6969 using

coupling 7070 to a steel capillary 7171 cut to the required length

(see Fig. 14).

732 IC Detector / 733 IC Separation Center

25

Page 33

2 Installation

2 Installation of the capillary in the IC Separation

Center

• Unscrew the four knurled screws 3737 of the bottom rear panel

3939 of the 733 IC Separation Center and remove rear panel

(see Fig. 5).

• Insert steel capillary 7171 from the back into the inner com-

partment of the IC Separation Center.

• Install rear panel 3939 so that the capillary is positioned in

opening 4040 „Inlet A“ or 4444 „Inlet B“ and screw on with the four

knurled screws 3737.

3 Connection to injection valve

• Connect steel capillary 7171 to pulsation dampener 6666 (see

section 2.6.2). Using another steel capillary 7171, connect pul-

sation dampener 6666 to connection "5" of injection valve 6868.

4 Mount column connection capillary

• Connect column connection capillary 6767 (ca. 20 cm of

6.1831.010 PEEK capillary) to connection "4" of injection valve

6868.

5656 7070

709

Fig. 14: Connection to injection valve with steel capillaries

5656 Inlet capillary

of Filter unit Manufit 6969

6363 Outlet capillary

of Filter unit Manufit 6969

6666 Pulsation dampener (6.2620.150) 7070 Coupling (6.2620.060)

6767 Column connection capillary

6.2620.020 Steel capillary

6868 Injection valve

6969 Filter unit Manufit (6.2821.000)

7171 Steel capillary (6.2620.020)

71716969 6363 7171 6666 6767 6868

733

26

732 IC Detector / 733 IC Separation Center

Page 34

2.6.7 Passivation of the IC system

With non metal-free IC systems, the entire IC system (without precolumn, separating column and suppressor module) must be passivated

with nitric acid before being put into operation for the first time. Proceed

as follows:

1 Connect detector block to injection valve

• Connect column connection capillary 6767 using a 6.2620.060

Coupling directly to inlet capillary 8282 of the detector block

(see Fig. 16).

2 Set injection valve to "INJECT"

• Switch on 732 IC Detector using mains switch 99.

• Press key 2424 or 2626 <INJECT> on 733 IC Separation Center.

The green LED in the key should light up to show that the injection valve is in the position "INJECT".

2.6 Connection of 709 IC Pump

3 Rinse with HNO

3

• Immerse aspirating capillary of the 709 IC Pump in c(HNO3)

= 0.2 mol/L.

• Set a flow rate of 1 mL/min on the 709 IC Pump.

• Switch on 709 IC Pump and rinse IC system for ca. 10 min.

During this time, check all capillaries and their connections

between the 709 IC Pump and the detector block for escaping liquid. Should liquid escape at any position, the appropriate compression fitting must be tightened more or changed.

• Switch off 709 IC Pump.

4 Rinse with dist. H2O

• Immerse aspirating capillary of the 709 IC Pump in distilled or

demineralised water.

• Switch on 709 IC Pump and rinse the IC system for ca.

10 min.

• Switch off 709 IC Pump.

5 Rinse with eluent

• Immerse aspirating capillary of the 709 IC Pump in the eluent

which will be needed for the separating column used later.

• Switch on 709 IC Pump and rinse IC system until the absolute

conductivity shown on the 732 Detector is stable.

• Switch off 709 IC Pump.

6 Remove coupling

732 IC Detector / 733 IC Separation Center

• Remove 6.2620.060 Coupling between column outlet capillary 7171 and inlet capillary 8282 (see Fig. 16). The IC system is

now ready for the installation of precolumns, separating columns and suppressor module.

27

Page 35

2 Installation

2.7 Precolumns

2.7.1 General information on precolumns

The use of easily exchangeable precolumns protects the separating

columns and prolongs their lifetime. The precolumns available from

Metrohm (see section 7.3.2) are either real precolumns or precolumn

cartridges, which are used together with the 6.2821.050 Twin cartridge

holder or a 6.2821.040 Cartridge head.

New IC precolumns are normally filled with solution and sealed at

both ends. Before the precolumn is installed in the system, it must be

ensured that this solution is freely miscible with the eluent used

(check manufacturer's specifications).

2.7.2 Precolumns with twin cartridge holder

The precolumn cartridges are installed in the 6.2821.050 Twin cartridge

holder as follows (see Fig. 15):

1 Install cartridge

• Insert inlet capillary 7575 with end piece for precolumn cartridge

in Manufit housing 6262.

• Insert outlet capillary 7272 with end piece for precolumn car-

tridge in Manufit pressure screw 5757.

• Remove end caps from the precolumn cartridge 7474 (the steel

mesh 7373 and gaskets 5959 are already inserted in the car-

tridge).

• Fit the two capillary end pieces onto the precolumn cartridge

7474 (comply with the flow direction if specified on the column).

• Screw Manufit pressure screw 5757 and Manufit housing 6262

firmly together.

2 Connect precolumn

• Fit connectors to inlet capillary 7575 of the assembled precol-

umn (see section 2.5).

• Connect inlet capillary 7575 either using 6.2620.060 Coupling to

the column connection capillary 6767 mounted on the injection

valve (see section 2.6.4) or directly to connection "4“ of injection valve A or B.

• Shorten outlet capillary 7272 of the precolumn to ca. 5 cm and

mount the connectors (see section 2.5).

28

3 Rinse the precolumn

• Place a beaker beneath outlet capillary 7272.

• Switch on 709 IC Pump, rinse precolumn for ca. 10 min with

eluent and then switch off 709 IC Pump.

732 IC Detector / 733 IC Separation Center

Page 36

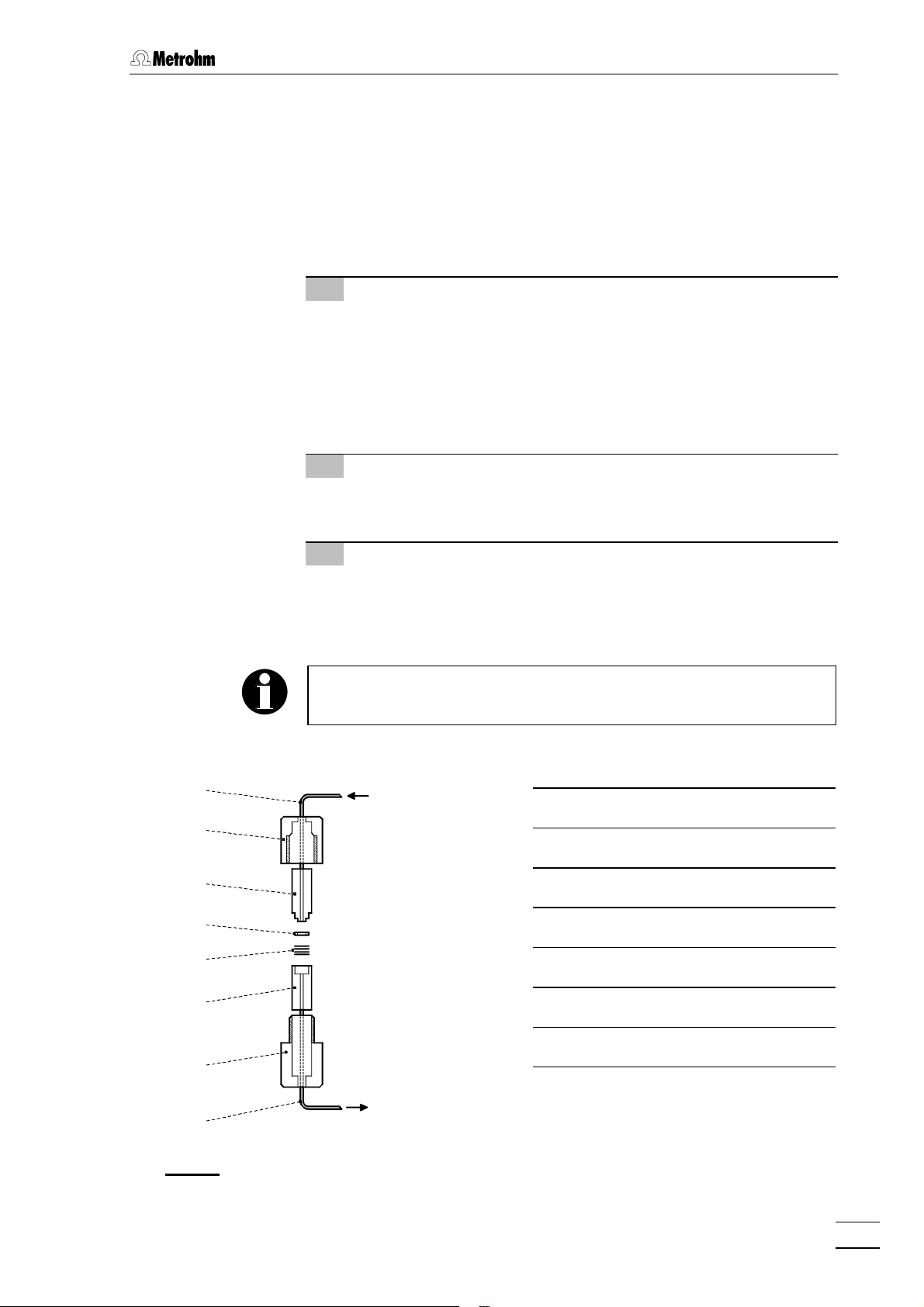

2.7 Precolumns

Cartridge head

Twin cartridge holder

7272

5757

5959

7373

7474

7373

5959

with 6.2821.050

Säule

with 6.2821.040