EBS

Electronically controlled

Brake system

in motor coaches

System and function a l

description

1. Edition

© Copyright WABCO 2003

Vehicle Control Systems

An American Standard Company

8150004083

The right of amendment is reserved

Version 001/07.01

EBS

1. Introduction / Advantages of EBS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

2. System structure in buses

System structure 2-axle bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

WABCO EBS construction kit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

System variants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Wiring diagram 2-axle bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Wiring diagram 3-axle bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

3. Description of components

Brake signal transmitter 480 00. ... 0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

EBS central module 446 135 ... 0. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Proportional relay valve 480 202 ... 0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3/2 relay valve 480 205 ... 0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Axle modulator 480 103 ... 0. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

4. Description of EBS function

Table of Contents

Page

Function of the electro-pneumatic unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Function of pneumatic redundancy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Additional redundancy on the front axle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Rear axle redundancy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Electrical / electronic structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Control functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Backup functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Halt brake, brake hold and release aid. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

5. Error recognition and display

Error recognition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Error display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

6. EBS ”emergency modes” / EBS test types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

7. WABCO PC - Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Diagnostic equipment for WABCO EBS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Diagnostic Software EBS Euro. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

8. Parameter Setting

Parameter setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

2

Introduction / Advantages of EBS

EBS

1.

Introduction

The demands m ade on brakin g sy stems a re i ncre asing

steadily. Therefore, the development and introduction of

an electronic braking system (EBS) is a logical step.

EBS increases tr affic safety through reduced stoppi ng

distance and improved brake stability. The full diagnosis

and surveillance functions as well as the display of brake

lining wear offer an effective fleet logistics.

Advantages of EBS

EBS reduces service costs considerably.

q The electronic braking system has a lot of

functions. The aim is to maximise braking safety at

reduced costs, for instance by optimising wheel

brake lining wear.

q Setting pressure, according to wear criteria, to the

front and rear a xle results in uniform lining wear.

Overall wear is minimised by making the load on all

wheel brakes uniform. Moreover, servicing and

lining replacement are done at the same time. This

reduces down-time costs.

Increased brake safety

WABCO did not only take existing regulations into

consideration while developing EBS. Top priority was

given to safety and user advantages. This is why a

vehicle with EBS can clearly do more than is required by

law.

The high safety quality attributed to EBS is due to

several factors:

q Braking time is red uced through s horter respons e

time and pressure build-u p time of the brakes on

the front and rear axle(s).

q The improved ABS function increases vehicle

stability when brakes are activated.

q The components of the fr ont and rear ax le brak in g

system and brake lining wear are monitored

permanently.

q The integrated ASR function also provides

optimum vehicle s tability and traction during start

and acceleration.

q Depending on the vehicle utilisation profile and

other factors, this also means considerable savings

for the vehicle user. In terms of wheel brake service

costs alone, a firsthand owner will save more

money with an electr onically braked bus than with

a vehicle with a conventional braking system.

3

2.

EBS

System structure in buses

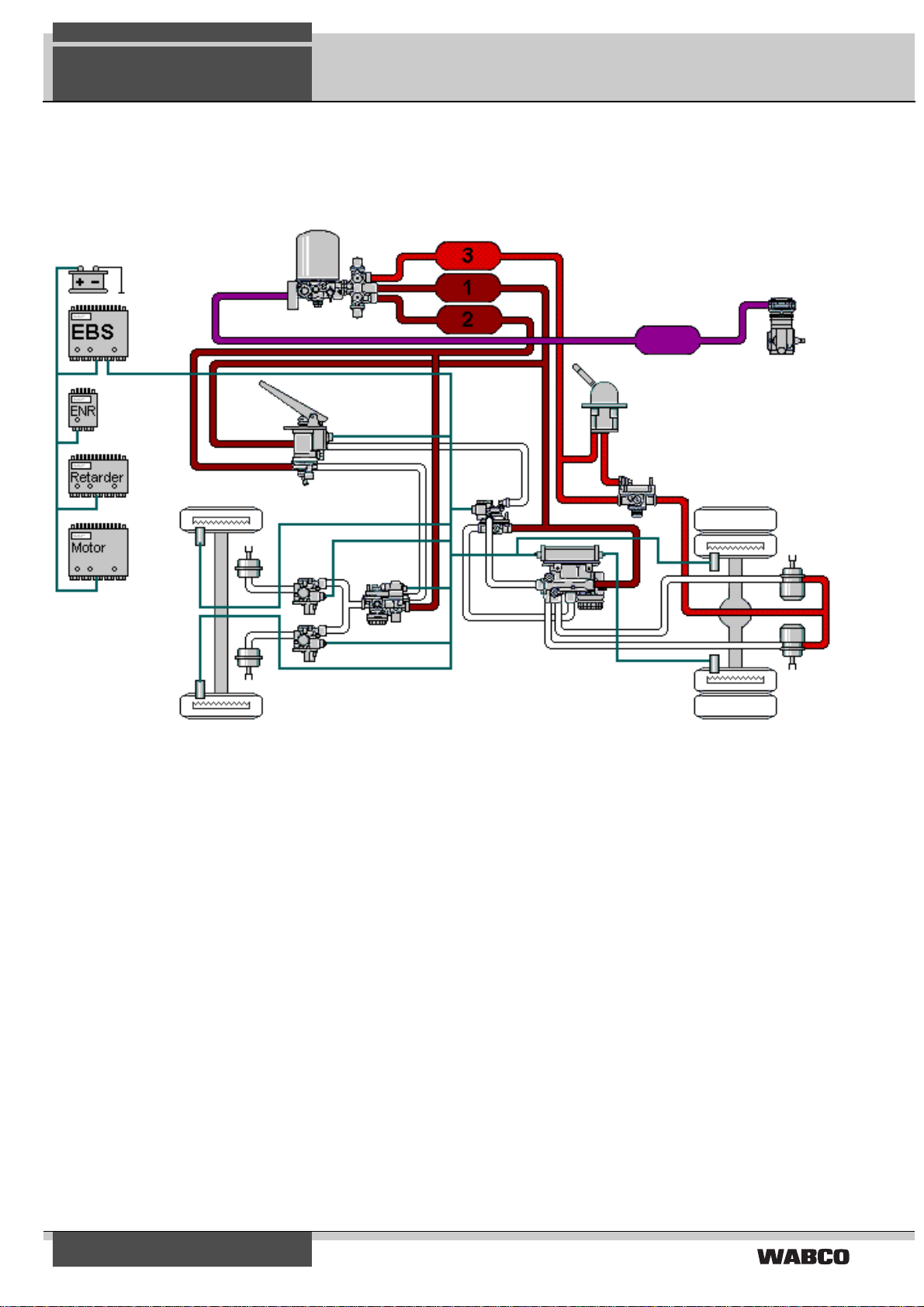

EBS braking system for buses with no attachment (4S/4M system )

9

1

7

4

10

11

2

6

3

5

12

13

8

14

Legend:

EBS components:

1 EBS central module

2 Brake signal transm itt er

3 Proportional relay valve

4 ABS solenoid valv e

5 Axle modulator

6 3/2 relay valve

7 ABS sensors

Other components:

8 Compressor

9 Air dryer

10 Four-circuit protection valve

11 Air reservoir

12 Ha nd br ake valv e

13 Relay valve FBA

14 Brake cylinder

4

System structure in buses

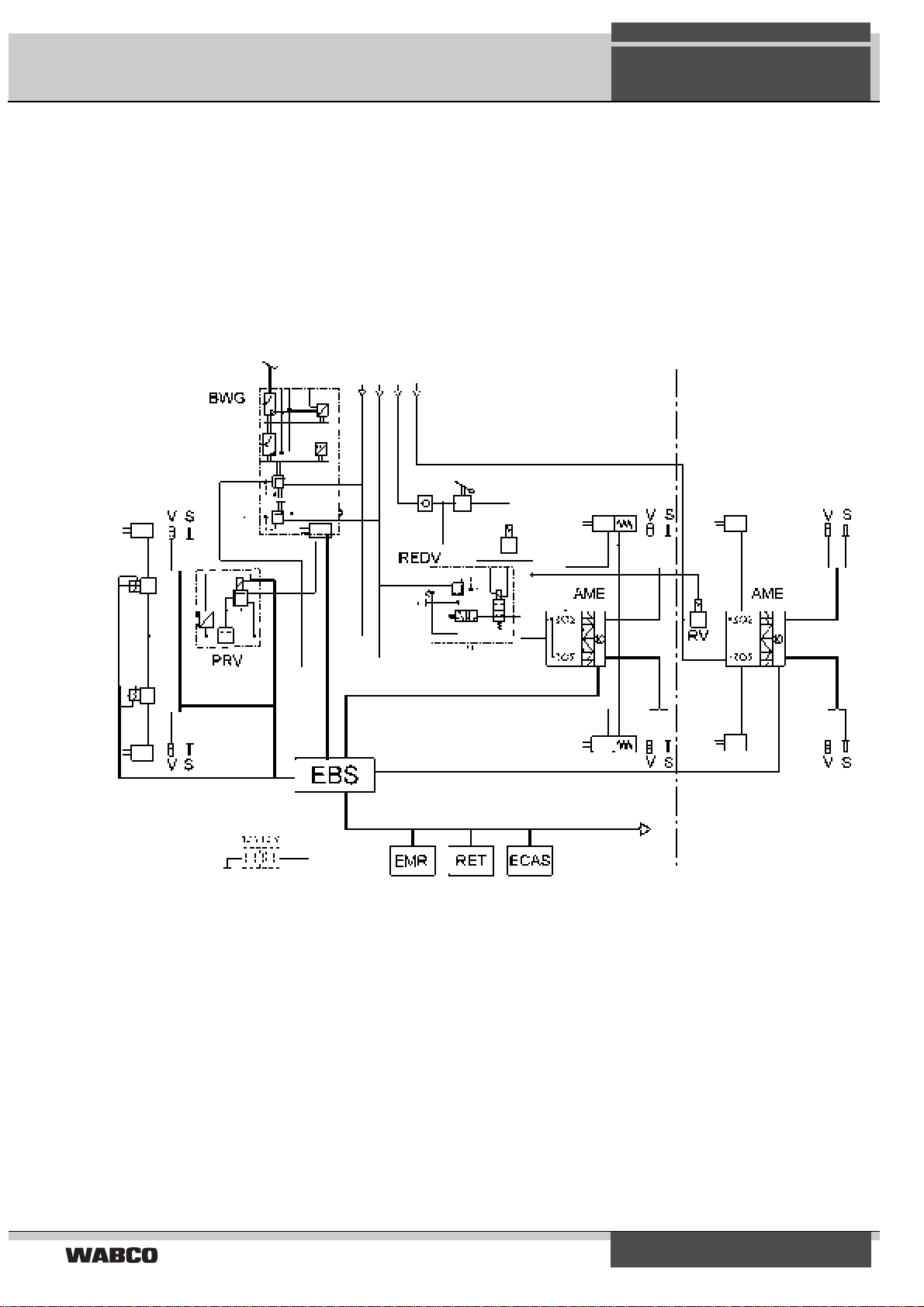

WABCO EBS construction kit

EBS

2.

The design and structure of WABCO EBS allow high

flexibility for vehicle manufacturers during system

construction.

In terms of range

q subsystem or full system

q addition and cut-off redundancy

supply

q electrical interfaces

the most complex demand s can, therefore, be met. To

meet the vital needs of the vehicle owner, WABCO

recommends an EBS with an individual pressure control

unit on the front and r ear axle, and which provides for

pneumatic redundancies in all brake circuits.

third axle

Battery

2P/1E-EBS

AME = Axle modulator

BWG = Brake signal transmitter

ECAS = Electronically Air Suspension System

EMR = Electronically engine control

PRV = Proportional relay valve

REDV = 3/2 relay valve (redundancy valve)

RET = Retarder

RV = Relay valve

S = Speed sensor

V = Wear indicator

The EBS described here consists of a dual-circuit, purely

pneumatic unit and a superimposed single-circuit,

electro-pneumatic unit. This configuration is described

as 2P/1E system.

The single-circuit, electro-pneumatic unit comprises a

central electronic control device (central module), the

axle modulator with integrated electronic unit for the rear

axle, and, if necessary, the axle modulator for the th ird

axle, a brake signal transmitter with two integrated

halt brake

desired value sensors and brake switches, as w ell as a

proportional relay valve and two ABS valves for the front

axle.

In terms of structure, the dual-circuit pneumatic unit

basically corres ponds to that of a conventional brak ing

system. This unit serves as redundancy and only

becomes active in case of electro-pneumatic circuit

failure.

5

2.

EBS

System structure in buses

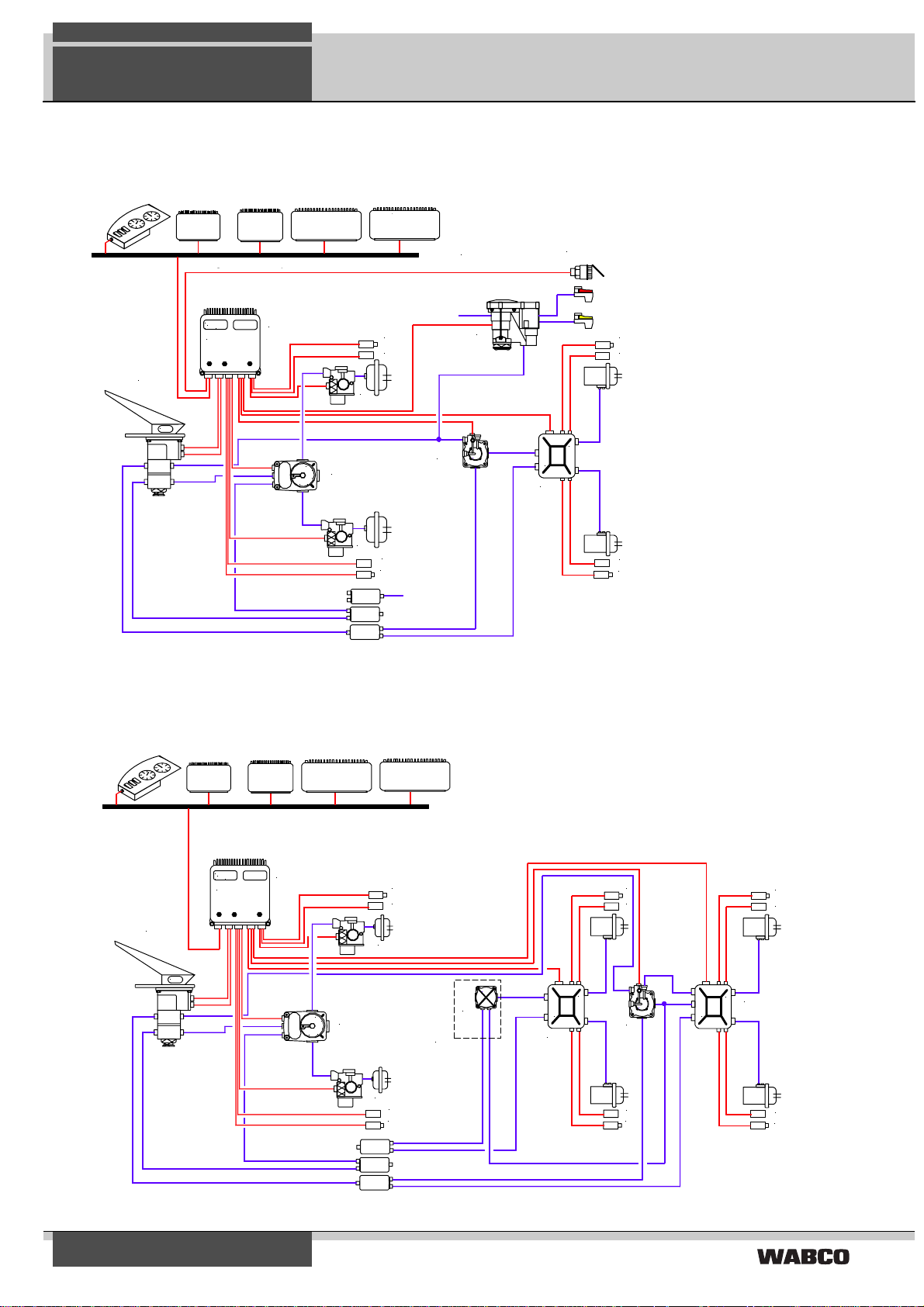

EBS 4S/4M in buses with optional trailer control

Niveau-

3

Level control

regelung

air reservoir

8

7

4

ISO 11992

Luftbehälter

9

Motor

Engine

Fahrzeugdatenbus SAE J 1939

vehicle data bus SAE J 1939

WABCO

446 130 XXX 0

EPB 4S/4M

WABCO

2

WABCO

IIII II IIII III

Retarder

Retarder

Getriebe

Gearbox

1

O

C

B

A

W

ISO 7638

6

WAB CO

WABCO

WABCO

1 Zentralsteuergerät EBS

2 Bremswertgeber

1 Central control unit EBS

3 Prop. Relaisventil

2 Brake signal transmitter

4 ABS Magnetregelventil

3 Proportional Relay valve

5 Achsmodulator

4 ABS Solenoid Control valve

6 Anhängersteuerventil

5 Axle modulator

7 Splus Stabsensoren

6 Trailer control valve

8 Verschleißsensoren

9 Redundanzventil

8

7

rod sensor

7 S

plus

8 Wear indicators

9 3/2 relay valve (redundancy valve

)

5

EBS 6S/6M in articulated buses

Engine Gearbox

Motor

Fahrzeugdatenbus SAE J 1939

vehicle data bus SAE J 1939

2

WABCO

WABCO

446 130 XXX 0

EPB 4S/4M

IIII II IIII III

WABCO

Retarder

Retarder

1

O

W

Getriebe

C

B

3

A

4

4

7

8

Anhänger-

trailer control

steuerventil

valve

Niveau-

Level control

regelung

8

7

Optional

7

8

1 Central control unit EBS

2 Brake signal transmitter

3 Proportional Relay valve

4 ABS Solenoid Control valve

5 Axle modulator

6 3/2 relay valve (redundancy valve

7 S

plus

8 Wear indicators

9 Relay valve

WABCO

9

WABCO

WABCO

5

1 Zentralsteuergerät EBS

2 Bremswertgeber

3 Prop. Relaisventil

4 ABS Magnetregelventil

5 Achsmodulator

Redundancy valve

6 redundanzventil

rod sensor

7 Splus Stabsensoren

8 Verschleißsensoren

9 Relaisventil

8

7

WABCO

6

)

8

7

WABCO

5

WABCO

4

7

8

7

8

7

8

6

System structure in buses

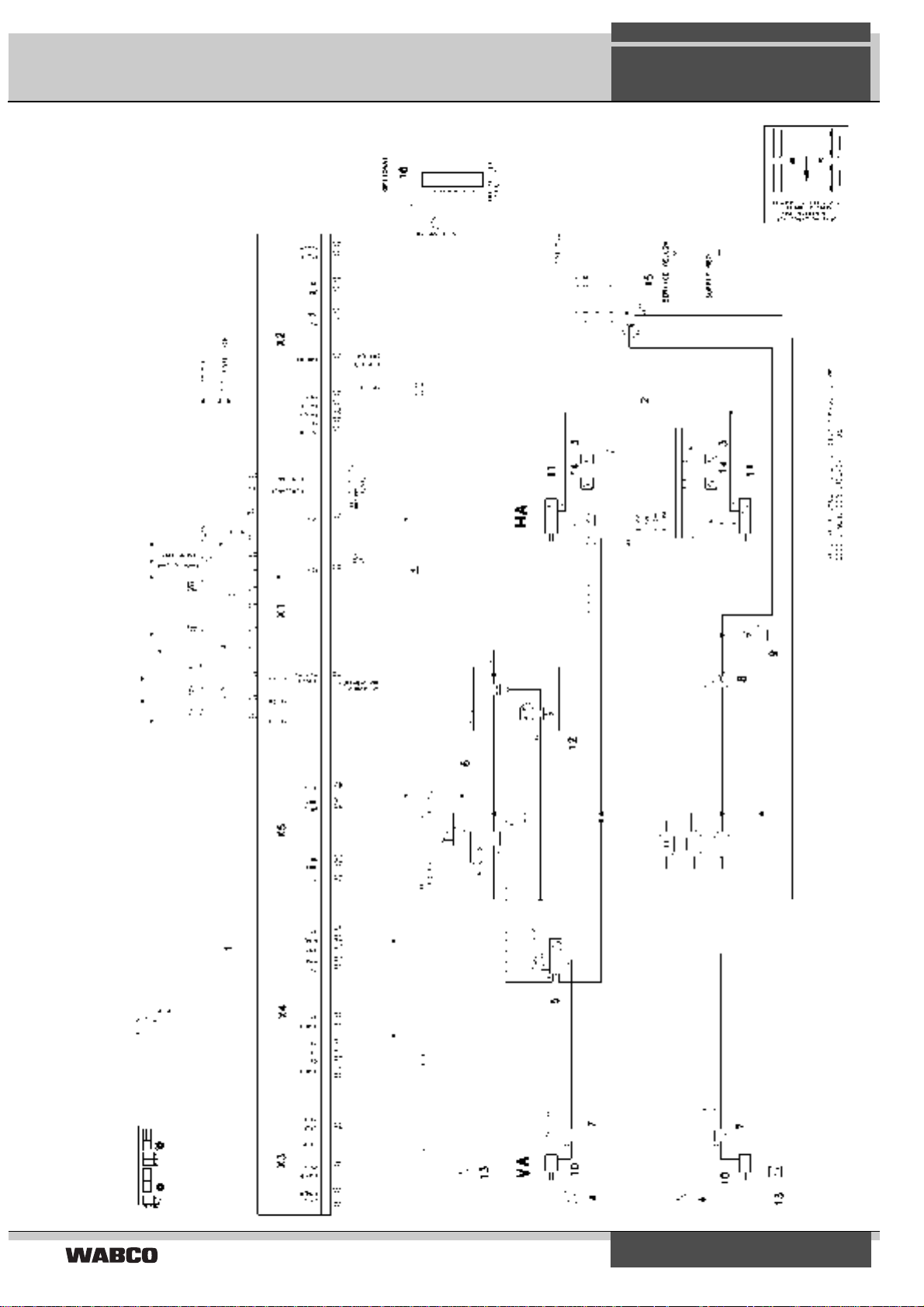

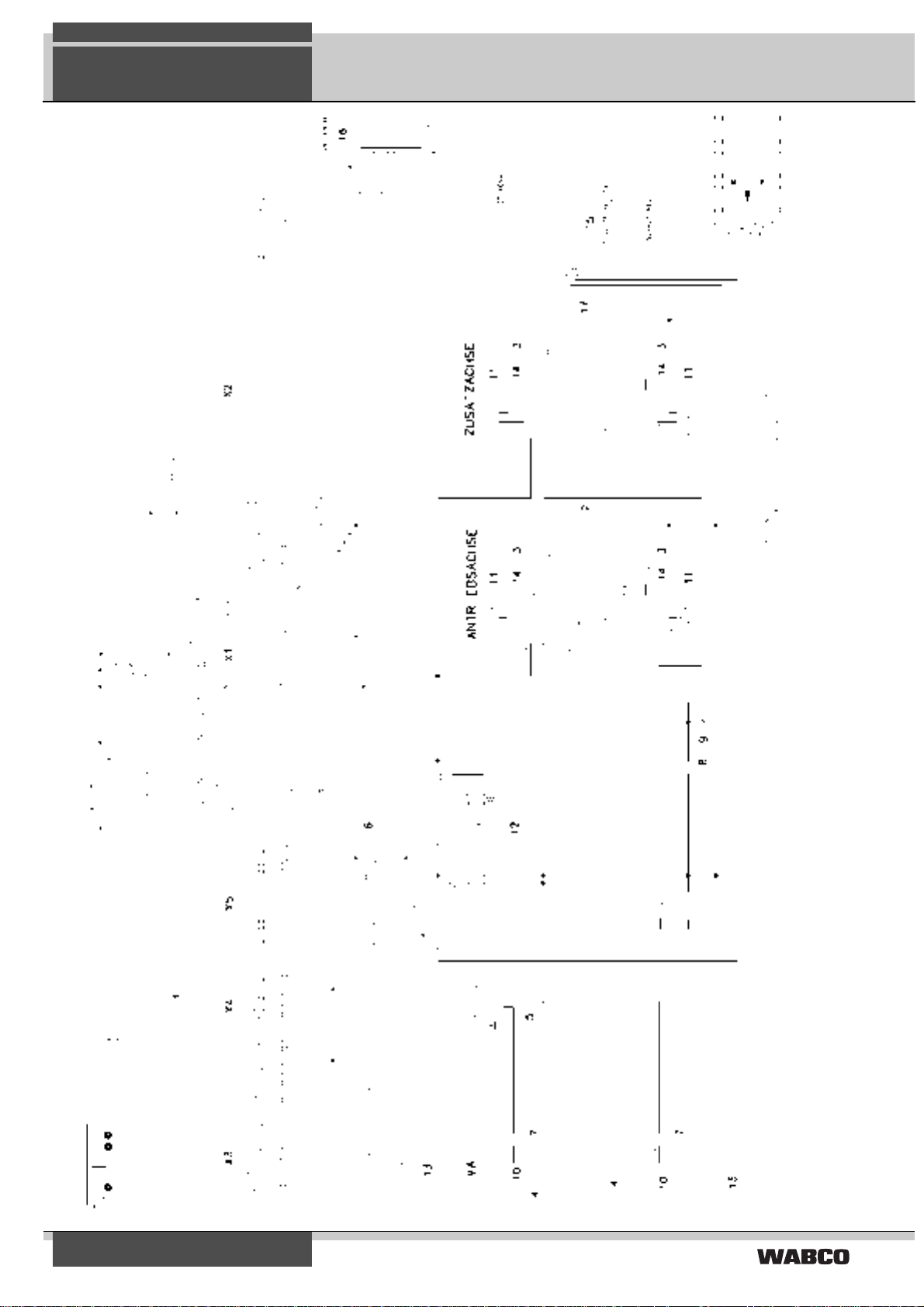

Wiring diagram 841 801 701 0: Dual-axle bus (4S/4M)

EBS

2.

7

2.

EBS

System structure in buses

Wiring diagram 841 801 702 0: Three-axle bus (6S/6M)

8

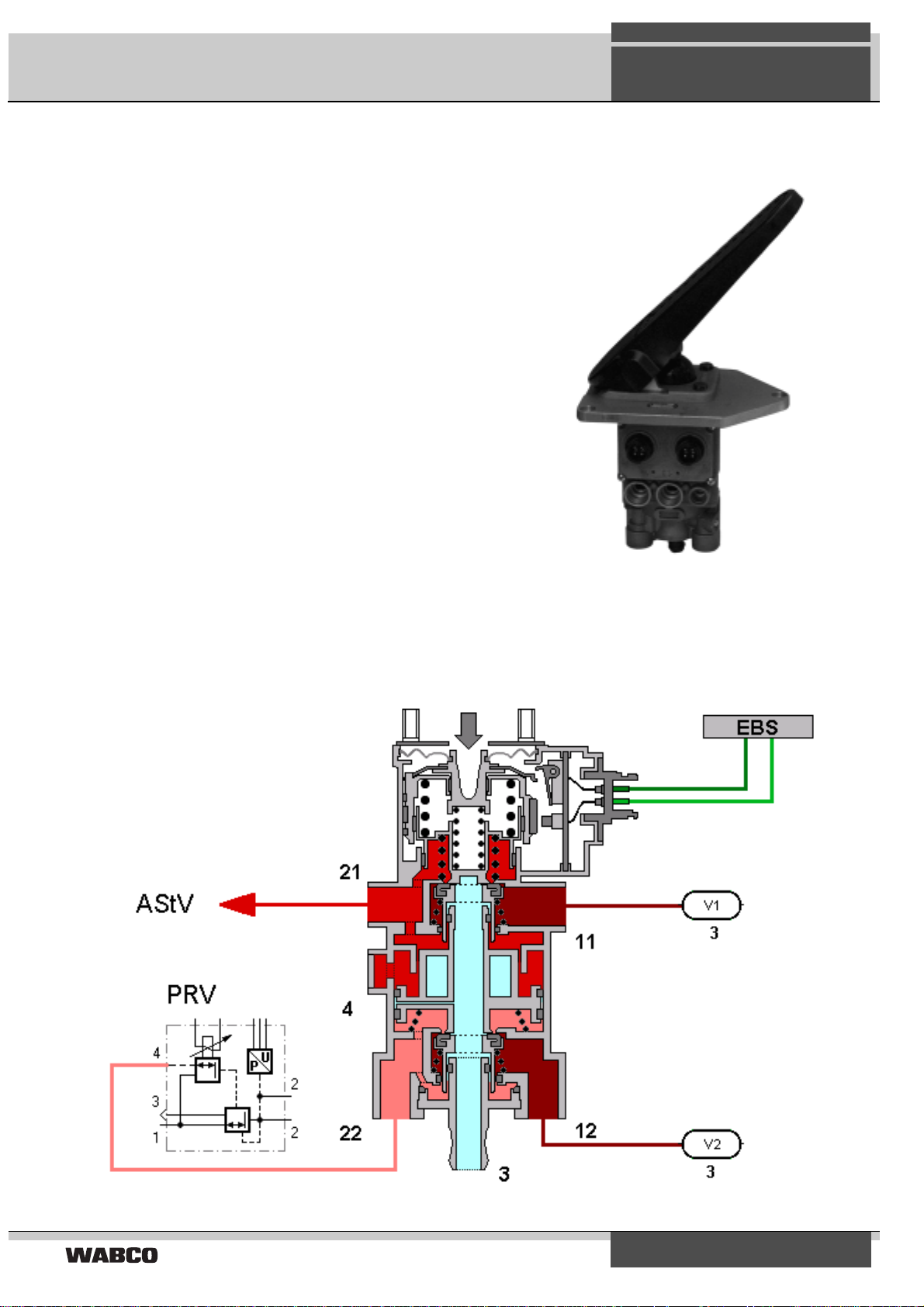

Description of components

Brake signal transmitter 480 001/ 002 ... 0

The brake signal transmitter is used to produce electrical

and pneumatic sign als, and to increase and decr ease

the air pressure of th e electronically con trolled braking

system. The device has a dual-c ircuit pneumatic and a

dual-circuit electrical structure. Actuation start is recorded electronically by a double s witch. T he operati ng tappet’s route is controlle d and transmitted as pulse-width

modulated electrical signal. Further pneumatic redundancy pressure is delivered in circuits 1 and 2. The

pressure in the seco nd circuit is retained slight ly in the

process. In case of (electrical or pneumatic) failure of a

circuit, the other circuits remain functional.

Depending on bus type , the brake signal transmitter is

actuated via a running pl ate (480 002 ... 0) 0) or via a

push pedal using the tappet (480 001 ... 0).

EBS

3.

How it works:

9

3.

EBS

Description of components

EBS central module 446 135 ... 0

The central module is used to control and monitor the

electronically controlled braking system. It determines

the vehicle’s nominal delay from the signals received by

the brake signal tr ansm itter. The nominal del ay and the

wheel velocity measured by the speed sensors are input

signal for the electro-pneumatic control unit, which uses

it to calculate nomina l pres sur e v alu es for the fr o nt axle

and rear axle(s). The front axle’s nominal pressure value

is then compared with the measured actual val ue, and

any existing deviations corrected with the help of the

proportional relay valve. Moreover, the wheel velocity is

evaluated so that in case of locking, an ABS control can

be carried out by modulating the braking pressure in the

brake cylinders. The central module exchanges EBS

system bus related data with the axle modulators.

The central module communicates with other systems

(engine control un it, retarder, display unit, etc.) via the

vehicle data bus in accordance with SAE J 1939.

KOM-integrated central unit:

10

Loading...

Loading...