McQuay PEH050 Installation Manual

Installation, Operating and Maintenance Manual |

IOMM PEHPFH |

|

|

|

Group: Chiller |

|

|

|

Part Number: 736015417 |

|

|

|

Effective: February 1999 |

|

|

|

Supersedes: IM 306-4 |

|

IM 307-5 |

Single/Dual Compressor Centrifugal Chillers

PEH/PHH 050, 063, 079, 087, 100, 126

PFH/PJH 050, 063, 079, 087, 126

© 1997 McQuay International

Table of Contents |

|

Introduction .................................................................................................................... |

3 |

General Description.................................................................................................................................. |

3 |

Application................................................................................................................................................ |

3 |

Installation....................................................................................................................... |

4 |

Receiving and Handling ........................................................................................................................... |

4 |

Location and Mounting ............................................................................................................................ |

5 |

Water Piping.............................................................................................................................................. |

6 |

Oil Cooler Piping ..................................................................................................................................... |

8 |

Refrigerant Vent Piping............................................................................................................................ |

9 |

Electrical ................................................................................................................................................. |

11 |

Power Wiring.......................................................................................................................................... |

11 |

Control Wiring........................................................................................................................................ |

12 |

Prestart System Checklist....................................................................................................................... |

14 |

Operation....................................................................................................................... |

15 |

Operator Responsibilities....................................................................................................................... |

15 |

Nomenclature ......................................................................................................................................... |

15 |

MicroTech Control Panel....................................................................................................................... |

16 |

Capacity Control System........................................................................................................................ |

16 |

Lubrication System................................................................................................................................. |

19 |

Hot Gas Bypass....................................................................................................................................... |

20 |

Maintenance.................................................................................................................. |

21 |

Pressure/Temperature Chart................................................................................................................... |

21 |

Routine Maintenance.............................................................................................................................. |

21 |

Annual Shutdown ................................................................................................................................... |

24 |

Annual Startup........................................................................................................................................ |

25 |

Repair of System..................................................................................................................................... |

25 |

Maintenance Schedule................................................................................................. |

28 |

Service Programs ......................................................................................................... |

30 |

McQuay" is a registered trademark of McQuay International ©1997 McQuay International

"Illustrations cover the general appearance of McQuay International products at the time of publication and we reserve the right to make changes in design and construction at anytime without notice"

2 |

Centrifugal Chillers |

IOMM PEH/PFH |

Introduction

General Description

The McQuay Model PE Centrifugal Water Chillers are complete, self-contained, automatically controlled fluid chilling units. Each unit is completely assembled and factory tested before shipment.

In the PEH series, each unit contains one compressor connected to a condenser and evaporator. A sister model, the PHH Heat Recovery Chiller is similar to the PEH models except for the substitution of a split condenser (two water circuits) for heat recovery applications. The PHH models are equipped with a hot-gas bypass system for operation at light cooling loads. This hot gas system is standard on PHH units and optional for PEH models.

The PFH series are equipped with two compressors operating in parallel on a single evaporator and condenser. Model PJH series are the equivalent double bundle heat recovery units.

The chillers use refrigerant R-134a to reduce the size and weight of the package compared to negative pressure refrigerants and since R-134a operates at a positive pressure over the entire operation range, no purge system is required.

The controls are pre-wired, adjusted and tested. Only normal field connections such as piping, electrical and pump interlocks, etc. are required thereby simplifying installation and increasing reliability. All necessary safety and operating controls are factory installed in the control panel.

The basic sizes of units are the PEH/PHH/PFH/PJH 048, 050, 063, 076, 079, 087, 100 and 126. They provide a capacity range from 80 tons to 2500 tons. In this manual all references to the PEH models will equally apply to other models unless specifically referenced otherwise.

Application

The operation and maintenance procedures presented in this manual apply to the standard PEH family of chillers. Reference to the Installation Manual, IM 306 for these units should be made for details pertaining to receiving and handling, installation, piping and wiring, and preparation for initial startup.

All McQuay centrifugal chillers are factory tested prior to shipment and must be initially started at the job site by a factory trained McQuay service technician. Failure to follow this startup procedure may affect the equipment warranty.

The standard warranty on this equipment covers parts which prove defective in material or workmanship. Specific details of this warranty can be found in the warranty statement furnished with the equipment and also found at the end of this manual.

Cooling towers used with McQuay model PE centrifugal chillers are normally selected for maximum condenser inlet water temperatures between 75°F and 90°F (24°C and 32°C). Lower entering water temperatures are desirable from the standpoint of energy reduction but a minimum does exist. For recommendations for optimum entering water temperature and cooling tower fan control, consult McQuay Product Manual PM PEH/PFH, Applications Section.

IOMM PEH/PFH |

Centrifugal Chillers |

3 |

Installation

Receiving and Handling

The unit should be inspected immediately after receipt for possible damage.

All McQuay centrifugal water chillers are shipped FOB factory and all claims for handling and shipping damage are the responsibility of the consignee.

Insulation corners from the evaporator's rigging hole locations is shipped loose and should be glued in place after the unit is finally placed. Neoprene vibration pads are also shipped loose. Check to be sure that these items are delivered with the unit.

Leave the shipping skid in place until the unit is in its final position. This will aid in handling the equipment.

Extreme care should be used when rigging the equipment to prevent damage to the control center, or refrigerant piping. See certified dimension sheets for the center of gravity of the unit.

The unit can be lifted by fastening the rigging hooks to the four corners of the unit where the rigging eyes are located (see Figure 1). Spreader bars should be used between the rigging lines to prevent damage to the control center and motor terminal boxes on PFH dual compressor units.

Figure 1, Unit Components

Control Panel

Evaporator

Relief Valve

Evaporator

Expansion Valve |

Condenser Dual |

|

Relief Valves |

||

|

Condenser

Liquid Line

Shutoff Valve

4 |

Centrifugal Chillers |

IOMM PEH/PFH |

Figure 2, Major Component Location

Vent Line from Oil Sump

Oil Pressure Regulator

Suction

Shutoff Valve

(Duals Only)

Rigging

Eyes

Evaporator

Outlet

Evaporator

Inlet (Note)

Condenser

Outlet

Condenser

Inlet

Lubricant to Lub Control

Box for Unloader

Lubrication

Control Box

(2) Dual

Relief Values

Lubricant Outlet

to Cooler

Mounting Holes

(2) Each Corner

Oil Sump,

Pump, Heater

Discharge

Check Valve

Motor

Cooling Inlet

Motor

Terminal Box

Rigging

Eyes

|

Motor Cooling |

Condenser |

Outlet Filter-Drier |

Note

The PFH126 Dual Compressor Chiller shown has the evaporator inlet in the bottom. All other single and dual compressor units have the evaporator inlet on top.

Location and Mounting

The unit should be mounted on a level concrete or steel base and should be located so as to provide service clearance at one end of the unit for possible removal of evaporator tubes and/or condenser tubes. Clearances required are 18 feet (5.5 meters) for units with 16 foot (4.9 meters) long shells, 16 feet (4.9 meters) for units with 14-foot (4.3 meters) long shells, 14 feet (4.3 meters) for units with 12-foot (3.7 meters) long shells, and 10 feet (3 meters) for units with 8-foot (2.4 meters) long shells. Evaporator/condenser tubes are rolled into the tube sheets to permit replacement if necessary. Clearance at all other points, including the top, is 3 feet (1 meter).

The shipped loose neoprene vibration pads should be located under the corners of the unit (unless the job specifications state otherwise).

IOMM PEH/PFH |

Centrifugal Chillers |

5 |

Units are shipped with refrigerant and oil valves closed to isolate these fluids for shipment. Valves must remain closed until start-up by McQuay technician.

Water Piping

Water Pumps

Make sure that the floor or structural support is adequate to support the full operating weight of the complete unit.

Rubber Shearflex pads, or "Isomode," are supplied with the unit for use under each corner of the base members. The unit must be level.

It will not be necessary to bolt the unit to the mounting slab or framework; but should this be desirable, 1 1/8" (28.5 mm) mounting holes are provided in the unit support at the four corners and under the compressor base on the side-mounted compressor units.

Note

Avoid the use of 3600/3000 rpm (two-pole motor) pump motors.

It is not uncommon to find these pumps operate with objectionable noise and vibration.

It is also possible to build up a frequency beat due to the slight difference in the operating rpm of the pump motor and the McQuay centrifugal motor. McQuay encourages the use of 1750/1460 rpm or four-pole pump motors whenever possible.

Evaporator and Condenser Water Piping

All PEH and PFH evaporators and condensers come equipped with groove-type nozzles for Victaulic couplings (also suitable for welding) or flange connections. The installing contractor must provide matching mechanical connections of the sizes given in the system dimension and capacity tables.

Important Notes on Welding

1.If welding is to be performed on the mechanical or flange connections, the solid-state temperature sensor and thermostat bulbs must be removed from the wells to prevent damage to those components.

2.The unit must be properly grounded or severe damage to the MicroTech Controller may occur.

Small water pressure test valves or pipe plugs are provided at both the inlets and outlets of the vessel heads. The test valves permit the water flow pressure drops to be checked. The pressure drops and flow rates for the various evaporators and condensers are shown in McQuay Product Manual PM PEH/PFH. Refer to the nameplate on the vessel shell for identification.

Evaporator inlet and outlet water connections have been reversed over time with design changes in the vessel. Be sure that water inlet and outlet connections match certified drawings and stenciled nozzle markings. The condenser is connected with the coolest water entering at the bottom to maximize subcooling.

Note

When common piping is used in connection with a heating system, care should be taken to insure that water flowing through the evaporator cannot exceed 110°F which can cause the relief valve to discharge refrigerant or damage controls.

The piping should be supported to reduce the weight and strain on the fittings and connections. Piping should also be adequately insulated. A cleanable 20-mesh water strainer should be installed at both

6 |

Centrifugal Chillers |

IOMM PEH/PFH |

inlets. Sufficient shutoff valves should be installed to permit draining the water from the evaporator or condenser without draining the complete system.

Flow Switch

A water flow switch must be mounted in either the entering or leaving water line to insure that there will be adequate water flow to the evaporator before the unit can start. This will safeguard against slugging the compressors on start-up. It also serves to shut down the unit in the event that water flow is interrupted to guard against evaporator freeze-up.

A flow switch is available from McQuay under Part Number 017503300. It is a "paddle" type switch and adaptable to any pipe size from 25mm to 203mm.

Consult the manufacturer's data for the minimum flow rates required to close the switch. Installation should be as shown in Figure 3.

Figure 3, Flow Switch Mounting

Flow direction marked on switch

25mm (1") NPT flow switch connection

Tee

32mm (1 1/4") pipe dia. min. after switch

32mm (1 1/4") pipe dia. min. after switch

Electrical connections in the unit control center should be made at terminals 62 and 63. The normally open contacts of the flow switch should be wired between these two terminals. Flow switch contact quality must be suitable for 24 VAC, low current (16ma). Flow switch wire must be in separate conduit from any high voltage conductors (115 VAC and higher).

CAUTION

Freeze Notice: Neither the evaporator nor the condenser is self-draining; both must be blown out.

The piping should also include thermometers at the inlet and outlet connections and air vents at the high points.

The water heads can be interchanged (end for end) so that the water connections can be made at either end of the unit. If this is done, new head gaskets must be used.

In cases where the water pump noise may be objectionable, rubber isolation sections are recommended at both the inlet and outlet of the pump. In most cases, it will not be necessary to provide vibration eliminator sections in the condenser inlet and outlet water lines; but where noise and vibration are critical (for example, where a pipe chase goes through walls adjoining living quarters in an apartment building), they may be required.

Where a cooling tower is used to supply condenser water, a flow balancing valve is required. Some form of water flow modulation may also be required if tower water becomes too cold.

IOMM PEH/PFH |

Centrifugal Chillers |

7 |

Oil Cooler Piping

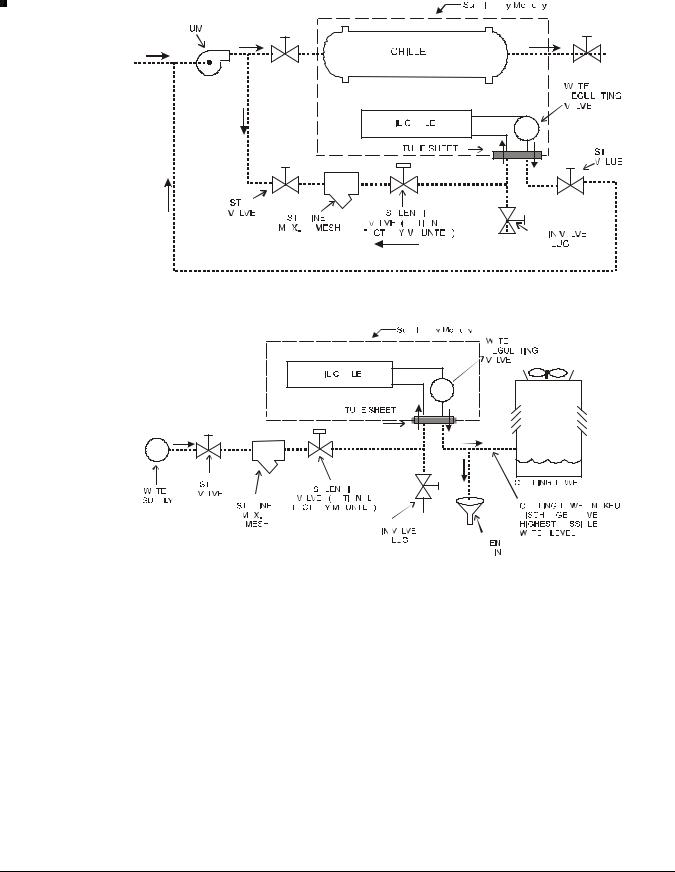

Figure 4, Oil Cooler Water Piping Across Chilled Water Pump

Figure 5, Oil Cooler with City Water or Other Supply

PEH-048/050 and PFH-048/050 units are equipped with internal self-contained refrigerant-cooled oil coolers and require no field piping for the coolers.

PEH 063, 079, 087, 100 and 126 single compressor units have a factory mounted water-cooled oil cooler, and a temperature controlled water regulating valve with the cooling water piping extended to the condenser tube sheet. Accessories must be installed as shown Figure 4. The solenoid stop valve can be factory installed as an option.

PFH 063, 079, 087, and 126 dual compressor units are equipped as above but the solenoid valves are factory installed at each cooler as standard. The water piping for the two oil coolers cooling is factory piped to a common connection at the tube sheet.

Field water piping to the inlet and outlet connections must be installed according to good piping practices and should include stop valves to isolate the cooler for servicing. A 1" minimum cleanable filter (40 mesh maximum), a solenoid stop valve wired in accordance with the field connection control diagram (also available as a factory installed option,), and drain valve or plug should also be field installed. The water supply for the oil cooler may be either from the chilled water circuit (preferred and recommended) or from an independent source such as city water (see Figure 5).

8 |

Centrifugal Chillers |

IOMM PEH/PFH |

The use of condenser water for oil cooling is not recommended. When using chilled water it is important that the water pressure drop through the oil cooler be less than the drop across the evaporator or insufficient oil cooler flow will result. This is normally no problem except on single pass evaporators in which case the oil cooler water should be piped across the chilled water pump to provide the maximum possible head and flow.

The water flow through the oil cooler will be adjusted by the regulating valve so that the temperature of oil supplied to the compressor bearings (leaving the oil cooler) is between 80°F (27°C) and 110°F (43°C).

When supplied with city water, the oil piping should discharge through a trap into an open drain to prevent draining the cooler by siphoning. The discharged city water may also be used for cooling tower makeup by discharging it into the tower sump above the highest possible water level.

Refrigerant Vent Piping

As a safety precaution, each system is equipped with pressure relief valves located on the condenser, evaporator, and oil sump vessel for the purpose of relieving excessive refrigerant pressure to the atmosphere. Most codes require that relief valves be vented to the outside, and this is desirable installation practice for all installations.

Note

Remove plastic shipping plugs (if installed) from the inside of the valves prior to making pipe connections. Whenever vent piping is installed, the lines should be run in accordance with local code requirements; where local codes do not apply, ANSI/ASHRAE Standard 15-1994 code recommendations should be followed.

The condenser design incorporates two relief valves (one set) with a three-way shutoff valve separating the two valves (see Figure 6). One valve remains/in the system at all times and the second valve acts as a standby.

If one relief valve of the two-valve set fails, the shutoff valve may be used to isolate the faulty relief valve, while the other valve provides pressure protection.

Figure 6, Condenser Relief Valve Set,

Relief Valve # 1

Stem In: # 1 Open

Stem Out: # 2 Open Always Front or Back Seat

Relief Valve # 2

3-Way Valve

When piping the vent line to a dual valve set, it may be sized for one relief valve and piped to both valves. On large capacity condenser designs, two separate sets of dual relief valves are used. The vent line must be sized to the total of two valves but piped to all four.

IOMM PEH/PFH |

Centrifugal Chillers |

9 |

Relief Valves

Relief valve connection sizes and quantity are shown to the right. Relief valves must be piped to the outside of the building in accordance with ANSI/ASHRAE 15. Twin relief valves mounted on a transfer valve are used on the condenser so that one relief valve can be shut off and removed leaving the other in operation. Where 4 valves are shown, they consist of two valves mounted on two transfer valves. Only two relief valves of the four are active at any time.

|

Relief Valve |

|

Evaporator Code |

Connection |

Number |

E1608 Thru E2616 |

1” FPT |

1 |

E3016 Thru E4216 |

1” FPT |

2 |

E4820 Thru E4824 |

1” FPT |

2 |

Condenser Code |

|

|

C1608 thru C3016 |

1” FPT |

2 |

C3616 Thru C4216 |

1” FPT |

4 |

C4820 Thru C4824 |

1” FPT |

4 |

Vent piping is sized for only one valve of the set since only one can be in operation at a time. In no case would a combination of evaporator and condenser sizes require more refrigerant than the pumpdown capacity of the condenser. Condenser pumpdown capacities are based upon ANSI/ASHRAE Standard 15 recommendations of 90% full at 90°F (32°C).

Relief Valve Pipe Sizing

Relief valve pipe sizing is based on the discharge capacity for the given evaporator or condenser and the length of piping to be run. Discharge capacity for HFC-134a vessels is calculated as follows:

C = 0133. xDxL

Where: C=Minimum discharge capacity, lbs of air/min

D=Vessel diameter, in.

L=Vessel length, ft.

Example: E3016 Evaporator, HFC-134a Refrigerant, 75 equivalent feet of piping

C = 0133. x30x16 = 63.8 Lbs of air / min

From the table below, 75 feet of piping for 63.8 lb. of air/min. at 180 psig valve setting requires a 2" diameter pipe.

Discharge Capacity, lbs of Air/Min

EQUIVALENT |

|

|

|

DIAMETER STANDARD WALL IRON PIPE |

|

|

|

||||||

LENGTH OF |

1” (25mm) |

1.25” (32mm) |

1.5” (38mm) |

2” (50mm) |

|

2.5” (64mm) |

3” (76mm) |

||||||

DISCHARGE |

|

|

|

RELIEF VALVE PRESSURE SETTNG |

|

|

|

|

|||||

PIPING, FT. (m) |

180 |

225 |

180 |

225 |

180 |

225 |

180 |

225 |

|

180 |

225 |

180 |

225 |

50 (15.2) |

21.4 |

26.8 |

42.8 |

53.6 |

62.7 |

78.4 |

117.0 |

146.3 |

|

182.2 |

227.7 |

315.4 |

393.7 |

75 (22.9) |

17.5 |

21.9 |

35.0 |

43.8 |

51.5 |

64.4 |

95.4 |

119.3 |

|

150.5 |

188.1 |

257.4 |

321.8 |

100 (30.5) |

15.2 |

19.1 |

30.2 |

27.8 |

44.3 |

55.4 |

82.6 |

103.3 |

|

129.6 |

162.0 |

222.5 |

278.1 |

150 (45.7) |

12.4 |

15.6 |

24.7 |

30.9 |

36.0 |

45.0 |

67.3 |

84.2 |

|

105.1 |

131.9 |

182.2 |

227.7 |

200 (61.0) |

10.6 |

13.6 |

21.4 |

26.8 |

31.4 |

39.3 |

58.4 |

73.1 |

|

91.1 |

113.9 |

157.7 |

197.1 |

300 (91.4) |

8.8 |

11.1 |

17.5 |

21.9 |

25.5 |

32.0 |

47.6 |

59.6 |

|

75.6 |

94.5 |

128.5 |

160.7 |

Note: Standard relief valve settings; R-134a, evaporator=180 psig, condenser=225 psig

Note: Per ASHRAE Standard 15, the pipe size may not be less than the relief device, meaning a minimum 1" diameter pipe is required. The discharge from more than one relief valve may be run into a common header, the area of which shall not be less than the sum of the areas of the connected pipes. For further details, refer to ASHRAE Standard 15. The common header can be calculated by the formula:

D |

|

æ |

D |

2 |

+ D |

2 |

.. . . D |

2 |

ö 0.5 |

C o m m o n |

= ç |

|

2 |

n |

÷ |

||||

|

è |

1 |

|

|

ø |

||||

10 |

Centrifugal Chillers |

IOMM PEH/PFH |

Loading...

Loading...