McQuay ALS 141C Installation Manual

Installation, Operation and Maintenance Manual

Air-Cooled Screw Compressor Chiller

ALS 141C through 218C

60 Hertz

IOMM ALS-4

Group: Chiller

Part Number: 330145709

Date: August 2001

Supersedes: IOMM ALS-3

Table Of Contents

Introduction .............................. |

3 |

General Description................................... |

3 |

Nomenclature ............................................ |

3 |

Inspection .................................................. |

3 |

Installation and Start-up ........... |

3 |

Handling .................................................... |

4 |

Location..................................................... |

5 |

Service Access ........................................... |

5 |

Clearance Requirements ............................ |

6 |

Vibration Isolators ..................................... |

7 |

Lifting and Mounting Weights................... |

8 |

Water Piping .............................................. |

9 |

System Water Volume.............................. |

10 |

Variable Water Flow ................................ |

10 |

Evaporator Freeze Protection .................. |

11 |

Flow Switch............................................. |

11 |

Water Connections................................... |

12 |

Refrigerant Charge................................... |

12 |

Glycol Solutions ...................................... |

12 |

Remote Evaporator................. |

13 |

General .................................................... |

13 |

Performance Derate Factors .................... |

13 |

Refrigerant Piping.................................... |

14 |

Startup Procedures................................... |

17 |

Dimensions, Remote Evaporator ............. |

18 |

Water Flow and Pressure Drop19 |

|

Physical Data .......................... |

21 |

Compressor Staging................ |

22 |

Dimensional Data ................... |

23 |

Wind Baffles and Hail Guards24 |

|

Electrical Data ........................ |

26 |

Field Wiring............................................. |

26 |

Wire Sizing Ampacities ........................... |

27 |

Field Wiring Diagram............. |

35 |

Solid State Starters ................. |

36 |

Unit Layout and Principles of |

|

Operation ................................ |

43 |

Major Component Location..................... |

43 |

Control Center ......................................... |

43 |

Sequence of Operation ............................ |

44 |

Start-up and Shutdown ........... |

47 |

Seasonal Start-up ..................................... |

47 |

Temporary Shutdown............................... |

47 |

Start-up After Temporary Shutdown........ |

48 |

Extended (Seasonal) Shutdown ............... |

48 |

Start-up After Extended (Seasonal) |

|

Shutdown................................................. |

49 |

System Maintenance............... |

50 |

General .................................................... |

50 |

Compressor Maintenance ........................ |

50 |

Lubrication .............................................. |

50 |

Electrical Terminals................................. |

50 |

Condensers .............................................. |

50 |

Refrigerant Sightglass.............................. |

51 |

Lead-Lag ................................................. |

51 |

Preventative Maintenance Schedule ........ |

52 |

Service .................................... |

53 |

Compressor Solenoids ............................. |

53 |

Filter-Driers ............................................. |

53 |

Liquid Line Solenoid Valve..................... |

55 |

Electronic Expansion Valve..................... |

55 |

Electronic Expansion Valve Operation.... |

56 |

Evaporator ............................................... |

57 |

Charging Refrigerant ............................... |

57 |

Charging Oil ............................................ |

58 |

In-Warranty Return Material |

|

Procedure ................................ |

59 |

Standard Controls ................... |

60 |

Optional Controls .................................... |

64 |

Controls, Settings and Functions ............. |

65 |

Troubleshooting Chart............................. |

66 |

Periodic Maintenance Log....................... |

67 |

Our facility is ISO Certified

Initial Issue January 1998

"McQuay" is a registered trademarks of McQuay International2001 McQuay International

"Information covers the McQuay International products at the time of publication and we reserve the right to make changes in design and construction at anytime without notice"

2 |

IOMM ALS-4 |

Introduction

General Description

McQuay air-cooled water chillers are complete, self-contained automatic refrigerating units that include the latest in engineering components arranged to provide a compact and efficient unit. Each unit is completely assembled, factory wired, evacuated, charged, tested and comes complete and ready for installation, except for remote evaporator models. Each unit consists of multiple air-cooled condensers with integral subcooler sections, multiple accessible semi-hermetic single-screw compressors, solid-state starters, multiple circuit shell-and-tube evaporator, and complete refrigerant piping. Liquid line components included are manual liquid line shutoff valves, charging valves, filterdriers, liquid line solenoid valves, sightglass/moisture indicators, and electronic expansion valves. Compressor suction and discharge shutoff valves are included. Other features include compressor heaters, an evaporator heater for low ambient water freeze protection, automatic one time pumpdown of refrigerant circuit upon circuit shutdown, and an advanced fully integrated microprocessor control system.

Nomenclature

A L S - XXX C

Air-Cooled |

|

Liquid Oil Injected |

Design Vintage |

|

|

Rotary Screw Compressor |

Nominal Tons |

|

Inspection

When the equipment is received, all items should be carefully checked against the bill of lading to ensure a complete shipment. All units should be carefully inspected for damage upon arrival. All shipping damage must be reported to the carrier and a claim must be filed with the carrier. The unit’s serial plate should be checked before unloading the unit to be sure that it agrees with the power supply available. Physical damage to unit after acceptance is not the responsibility of McQuay International.

Note: Unit shipping and operating weights are available in the Physical Data Tables.

Installation and Start-up

Note: Installation and maintenance are to be performed only by qualified personnel who are familiar with local codes and regulations, and experienced with this type of equipment.

CAUTION

Sharp edges and coil surfaces are a potential injury hazard. Avoid contact with them.

Start-up by McQuayService is included on all units sold for installation within the USA and Canada and must be performed by them. Two week prior notification of start-up is required. The contractor should obtain a copy of the Start-up Scheduled Request Form from the sales representative or from the nearest office of McQuayService.

IOMM ALS-4 |

3 |

Handling

Care should be taken to avoid rough handling or shock due to impact or dropping the unit. Do not push or pull the unit from anything other than the base, and block the pushing vehicle away from the unit to prevent damage to the sheet metal cabinet and end frame (see Figure 1).

Never allow any part of the unit to fall during unloading or moving as this may result in serious damage.

To lift the unit, 2½ “ (64 mm) diameter lifting holes are provided in the base of the unit. Spreader bars and cables should be arranged to prevent damage to the condenser coils or unit cabinet (see Figure 2).

Figure 1, Suggested Pushing Method

Figure 2, Required Lifting Method

NOTES:

1.All 4 rigging points on a unit must be used. See Figure 5 through Figure 6 for location, and weight at lifting points for a specific size unit.

2.Crosswise and lengthwise spreader bars must be used to avoid damage to unit. Lifting cables from the unit mounting holes up must be vertical.

3.The number of condenser sections, and fans can vary from this diagram.

4 |

IOMM ALS-4 |

Location

Care should be taken in the location of the unit to provide proper airflow to the condenser. (See Figure 3 for required clearances).

Due to the vertical condenser coil design of the ALS chillers, it is recommended that the unit be oriented so that prevailing winds blow parallel to the unit length, thus minimizing the wind effect on condensing pressure and performance. It is recommended that wind baffles be installed if the unit is installed with no protection against prevailing winds.

Using less clearances than shown in Figure 3, will cause discharge air recirculation to the condenser and could have a significant and detrimental effect on unit performance. See the current version of McQuay Product Manual PM ALS for more detailed information on the subject of air recirculation.

Service Access

Each end of the unit must be accessible after installation for periodic service work. Compressors, filter-driers, and manual liquid line shutoff valves are accessible on each side of the unit adjacent to the control box. High pressure and low pressure transducers are mounted on the compressor. The cooler barrel heater thermostat is located on the cooler. Compressor microprocessor and most other operational and equipment protection controls are located in the unit control box. The solid-state starters with their internal electrical protection features are mounted on the base side rails adjacent to the compressor they serve.

On all ALS units the condenser fans and motors can be removed from the top of the unit. The complete fan/motor assembly can be removed for service. The fan blade and fan motor rain shield must be removed for access to wiring terminals at the top of the motor.

WARNING

Disconnect all power to the unit while servicing condenser fan motors.

Failure to do so may cause bodily injury or death.

Do not block access to the sides or ends of the unit with piping or conduit. These areas must be open for service access. Do not block any access to the control panel with a field mounted disconnect switch.

IOMM ALS-4 |

5 |

Clearance Requirements

Figure 3, Clearance Requirements, ALS 141-218

Notes:

1.Minimum side clearance between two units is 12 feet.

2.Unit must not be installed in a pit or enclosure that is deeper or taller than the height of the unit unless extra clearance is provided per note 4.

3.Minimum clearance on each side is 8 feet when installed in a pit no deeper than the unit height.

4.Minimum side clearance to a side wall or building taller than the unit height is 8 feet provided no solid wall above 6 feet is closer than 12 feet to the opposite side of the unit.

5.The evaporator can be removed from the side of the unit.

6.Do not mount electrical conduits, etc, above the side rail on either side if the unit.

7.There must be no obstruction of the fan discharge.

8.It is recommended that field supplied disconnect switches not be mounted on the unit.

6 |

IOMM ALS-4 |

Vibration Isolators

Vibration isolators are recommended for all roof mounted installations or wherever vibration transmission is a consideration. The following section "Lifting and Mounting Weights" contains the location of unit lifting holes and the load at each location. Mounting holes are also dimensioned and the bearing weight at each hole given.

The unit should be initially installed on shims or blocks at the illustrated "free height" of the isolator. Six inches for the McQuay isolators shown. When all piping, wiring, flushing, charging, etc is complete, the springs should be adjusted upward to load them and free the blocks which are then removed.

Installation of spring isolators requires flexible pipe connections and at least three fett of conduit flex tie-ins. Piping and conduit should be supported independently from the unit.

Figure 4, Spring Flex Isolators

Table 1, Spring Vibration Isolators, Part Numbers

|

|

Mounting Location (See Footprint Drawings Figure 5 or Figure 6 |

|

||||||

Model |

R1 |

|

R2 |

|

R3 |

R4 |

R5 |

|

R6 |

ALS 141-ALS 186 Isolator kit part |

number 350014880 |

|

|

|

|

|

|

||

Max Load |

2200 |

|

2200 |

|

2600 |

2600 |

1800 |

|

1800 |

Spring P/N |

022611901 |

|

022611901 |

|

022612000 |

02261200 |

022611800 |

|

022611800 |

Color |

Gray |

|

Gray |

|

White |

White |

Green |

|

Green |

Housing P/N |

022610300 |

|

022610300 |

|

022610300 |

022610300 |

022610300 |

|

022610300 |

|

|

|

|

|

|

|

|||

ALS 190-ALS 218 Isolator kit part number 350014881 |

|

|

|

|

|

||||

Max Load |

2600 |

|

2600 |

|

3000 |

3000 |

2200 |

|

2200 |

Spring P/N |

022612000 |

|

022612000 |

|

330202101 |

330202101 |

022611901 |

|

022611901 |

Color |

White |

|

White |

|

Gold |

Gold |

Gray |

|

Gray |

Housing P/N |

022610300 |

|

022610300 |

|

022610300 |

022610300 |

022610300 |

|

022610300 |

Notes:

1.The same isolators are used when the chiller is supplied with the optional copper finned condenser coils.

2.The spring is fully compressed at approximately 3900 lb. (1769 kg).

IOMM ALS-4 |

7 |

Lifting and Mounting Weights

Figure 5, ALS 141C – ALS 186C Lifting and Mounting Locations

NOTES:

1.2 ½ in. (63.5 mm) lifting holes at location "L" on side of base rail.

2.1 in. (25.4 mm) mounting holes at location "R" on bottom of base rail.

|

L2 |

L4 |

R2 |

R4 |

R6 |

36 (914) |

102 (2591) |

|

|

192 (4877) |

|

CONTROL BOX |

|

|

161 (4089) |

|

|

46 (1168) |

|

|

|

R5 |

|

R1 |

R3 |

83.4

(2118)

|

|

L1 |

|

|

L3 |

|

|

|

2 (51) |

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

Typical Spacing |

|

|

|

|

|

|

|

|

|

|

for Isolator |

|

|

|

|

|

|

|

|

|

|

Mounting (6) |

|

|

|

|

|

|

|

|

|

|

|

|

ALS |

Lifting Weight for Each Point |

Mounting Loads for Each Point |

Operating Wt |

|

|

Shipping Wt. |

Copper Fin |

|||

lb (kg) |

|

lb. (kg) |

|

|

|

|||||

Model |

L1 & L2 |

L3 & L4 |

R1 & R2 |

R3 & R4 |

R5 & R6 |

lb. (kg) |

|

|

lb. (kg) |

Add |

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

141 |

2585 (1171) |

2125 (963) |

1835 (831) |

1785 (809) |

1230 (557) |

9700 (4394) |

9420 (4267) |

1370 (620) |

||

|

|

|

|

|

|

|

|

|

|

|

150 |

2570 (1164) |

2205 (999) |

1830 (829) |

1805 (818) |

1305 (591) |

9880 (4476) |

9550 (4326) |

1370 (620) |

||

|

|

|

|

|

|

|

|

|

|

|

171 |

2570 (1164) |

2210 (1001) |

1830 (829) |

1810 (820) |

1305 (591) |

9890 (4472) |

9560 (4331) |

1370 (620) |

||

|

|

|

|

|

|

|

|

|

|

|

186 |

2575 (1166) |

2210 (1001) |

1830 (829) |

1810 (820) |

1310 (593) |

9900 (4485) |

9570 (4335) |

1370 (620) |

||

|

|

|

|

|

|

|

|

|

|

|

Figure 6, ALS 190C – ALS 218C Lifting and Mounting Locations

L2 L4

R2 |

R4 |

R6 |

36 (914)

123 (3124)

123 (3124)

224 (5690)

BOX

CONTROL

195 (4953)

195 (4953)

46 (1168)

46 (1168)

R1 |

R3 |

R5 |

83.4

(2118)

L1 |

L3 |

|

2 (51) |

|

|||

|

|

|

Typical Spacing |

|

|

|

for Isolator |

|

|

|

Mounting (6) |

ALS |

Lifting Weight for Each Point |

Mounting Loads for Each Point |

Operating Wt |

Shipping Wt. |

Copper Fin |

|||

lb (kg) |

|

lb. (kg) |

|

|||||

Model |

L1 & L2 |

L3 & L4 |

R1 & R2 |

R3 & R4 |

R5 & R6 |

lb. (kg) |

lb. (kg) |

Add |

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

190 |

2915 (1320) |

2230 (1010) |

2010 (910) |

2135 (967) |

1165 (527) |

10620 (4811) |

10290 (4661) |

1610 (730) |

|

|

|

|

|

|

|

|

|

200 |

2920 (1323) |

2230 (1010) |

2015 (913) |

2135 (967) |

1165 (527) |

10630 (4815) |

10300 (4666) |

1610 (730) |

|

|

|

|

|

|

|

|

|

206 |

2940 (1332) |

2310 (1046) |

2000 (906) |

2240 (1015) |

1240 (562) |

10960 (4965) |

10500 (4756) |

1610 (730) |

|

|

|

|

|

|

|

|

|

218 |

2960 (1341) |

2405 (1089) |

1985 (899) |

2425 (1098) |

1365 (618) |

11550 (5232) |

10730 (4861) |

1610 (730) |

|

|

|

|

|

|

|

|

|

8 |

IOMM ALS-4 |

Water Piping

Due to the variety of piping practices, it is advisable to follow the recommendations of local authorities. They can supply the installer with the proper building and safety codes required for a safe and proper installation.

Basically, the piping should be designed with a minimum number of bends and changes in elevation to keep system cost down and performance up. It should contain:

1.Vibration eliminators to reduce vibration and noise transmission to the building.

2.Shutoff valves to isolate the unit from the piping system during unit servicing.

3.Manual or automatic air vent valves at the high points of the system. Drains at the low parts in the system. The evaporator should not be the highest point in the piping system.

4.Some means of maintaining adequate system water pressure (e.g., expansion tank or regulating valve).

5.Water temperature and pressure indicators located at the unit to aid in unit servicing.

6.A strainer or some means of removing foreign matter from the water before it enters the pump. The strainer should be placed far enough upstream to prevent cavitation at the pump inlet (consult pump manufacturer for recommendations). The use of a strainer will prolong pump life and help maintain high system performance levels.

WARNING

7.A strainer must also be placed in the supply water line just prior to the inlet of the evaporator. This will aid in preventing foreign material from entering the evaporator and causing damage or decreasing its performance. Care must also be exercised if welding pipe to the evaporator connections to prevent any weld slag from entering the vessel.

8. The shell-and-tube evaporator has a thermostat and heating cable to prevent freeze-up down to - 20° F (-28.8° C). It is suggested that the heating cable be wired to a separate 110V supply circuit. As shipped from the factory, it is factory wired to the control circuit. Any water piping to the unit must also be protected to prevent freezing.

9.If the unit is used as a replacement chiller on a previously existing piping system, the system should be thoroughly flushed prior to unit installation and then regular chilled water analysis and chemical water treatment is recommended immediately at equipment start-up.

10.The total water quantity in the system should be sufficient to prevent frequent "on-off" cycling. For air-conditioning systems, system gallons equal to 7 time the flow rate is recommended.

11.In the event glycol is added to the water system, as an afterthought for freeze protection, recognize that the refrigerant suction pressure will be lower, cooling performance less, and water side pressure drop greater. If the percentage of glycol is large, or if propylene is employed in lieu of ethylene glycol, the added pressure drop and loss of performance could be substantial.

12.For operations requiring the ice mode feature, logic in MicroTech will adjust the freezestat to a pressure equivalent to 13.5° F (7.5° C) below the leaving evaporator water temperature. However, if a different freezestat pressure value is desired, the freezestat can be manually changed through MicroTech. Refer to the current OM ALSMICRO for additional information.

CAUTION

If a separate disconnect is used for the 110V supply to the cooler heating cable, it should be clearly marked so that it is not accidentally shut off during cold seasons.

A preliminary leak check should be made prior to insulating the piping and filling the system,.

Piping insulation should include a vapor barrier to prevent moisture condensation and possible damage to the building structure. It is important to have the vapor barrier on the outside of the insulation to prevent condensation within the insulation on the cold surface of the pipe.

IOMM ALS-4 |

9 |

System Water Volume

It is important to have adequate water volume in the system to provide an opportunity for the chiller to sense a load change, adjust to the change and stabilize. As the expected load change becomes more rapid, a greater water volume is needed. The system water volume is the total amount of water in the evaporator, air handling products and associated piping. If the water volume is too low, operational problems can occur including rapid compressor cycling, rapid loading and unloading of compressors, erratic refrigerant flow in the chiller, improper motor cooling, shortened equipment life and other undesirable occurrences.

For normal comfort cooling applications where the cooling load changes relatively slowly, we recommend a minimum system volume of five minutes times the flow rate (gpm). For example, if the design chiller flow rate is 400 gpm, we recommend a minimum system volume of 2000 gallons (400 gpm x 5 minutes).

For process applications where the cooling load can change rapidly, additional system water volume is needed. A process example would be a quenching tank. The load would be very stable until the hot material is immersed in the water tank. Then, the load would increase drastically. For this type of application, system volume may need to be increased drastically.

Since there are many other factors that can influence performance, systems may successfully operate below these suggestions. However, as the water volume decreases below these suggestions, the possibility of problems increases.

Variable Water Flow

Variable water flow involves changing the water flow through the evaporator as the load changes. McQuay chillers are designed for this duty provided that the rate of change in water flow is slow and the minimum and maximum flow rates for the vessel are not exceeded.

The recommended change in water flow is listed in the table below. As the number of stages of control increase, the slower the permissible rate of change in flow rate becomes. The ALS control logic has timers that limit the rate of unloading or loading allowed. Slow changes allow the chiller the opportunity to sense a change, react to the change and stabilize preventing operational problems.

ALS Size |

Number of |

Unloading |

Maximum allowable % per |

|

Compressors |

Steps |

minute of flow change |

||

|

||||

141 to 218 |

2 |

8 |

10.0 |

For example, assume that an ALS with two compressors has a design flow of 500 gpm and the minimum vessel flow rate of 300 gpm. The allowable amount of flow change is 200 gpm. An ALS with two compressors has an allowable change rate of 10% of change per minute. Therefore, the maximum rate of change recommended would be 20 gpm/minute (200 X .10).

The water flow through the vessel must remain between the minimum and maximum values listed on Figure 13. If flow drops below the minimum allowable, large reductions in heat transfer can occur. If the flow exceeds the maximum rate, excessive pressure drop and tube erosion can occur.

10 |

IOMM ALS-4 |

Evaporator Freeze Protection

All evaporators come equipped with thermostatically controlled resistive element heater. When power is applied to terminals 13 and 16, the heat element will provide freeze protection down to - 20° F (-28.8° C). However, this should not be the only method of freeze protection. Unless the evaporator is flushed and drained as is described below in note 4, two or more of the remaining three recommendations must be followed as part of the system design:

1.Continuous circulation of water through the piping and the heat exchanger.

2.The inclusion of glycol solution in the chilled water circuit.

3.The addition of insulation and heat to the exposed piping.

4.Draining and flushing the chiller vessel with glycol during subfreezing weather. NOTE: The heater element must be disconnected and made inoperative any time there is no fluid in the evaporator. Failure to do so can cause the element to create excessive heat and to burn out.

It is the responsibility of the installing contractor and/or on-site maintenance personnel to insure that this additional protection is provided. Routine checks should be made to insure adequate freeze protection is maintained.

Failure to do so may result in damage to unit components. Freeze damage is not considered a warranty failure.

Freeze protection should also be extended to any water piping exposed to freezing temperatures.

Figure 7, Typical Field Water Piping

Vent |

|

|

|

Outlet |

|

|

|

|

Vibration |

Flow |

Balancing Gate valve |

Valved |

Eliminator |

Switch |

valve |

pressure |

|

Protect all field piping |

|

gauge |

|

||

|

|

against freezing |

|

|

Vibration |

Water |

Gate valve |

|

Eliminator |

||

Drain |

strainer |

|

|

|

|

||

|

|

|

Flow Switch

A water flow switch must be mounted in the leaving water line to insure that there will be adequate water flow to the evaporator before the unit can start. This will safeguard against slugging the compressors on start-up. It also serves to shut down the unit in the event that water flow is interrupted to guard against evaporator freeze-up.

A flow switch is available from McQuay under ordering number 017503300. It is a "paddle" type switch and adaptable to any pipe size from 1" (25mm) to 8" (203mm) nominal.

Certain minimum flow rates are required to close the switch and are listed in Table 2. Installation should be as shown in Figure 8.

Electrical connections in the unit control center should be made at terminals 62 and 63. The normally open contacts of the flow switch should be wired between these two terminals. Flow switch contact quality must be suitable for 24 VAC, low current (16ma). Flow switch wire must be in separate conduit from any high voltage conductors (115 VAC and higher).

IOMM ALS-4 |

11 |

Figure 8, Flow Switch

Flow direction marked on switch

1" (25mm) NPT flow switch connection

Tee

1 1/4" (32mm) pipe |

1 1/4" (32mm) pipe |

dia. min. after switch |

dia. min. before switch |

Table 2, Switch Minimum Flow Rates

NOMINAL PIPE SIZE |

MINIMUM REQUIRED FLOW TO |

INCHES (MM) |

ACTIVATE SWITCH - GPM (LPS) |

5 (127) |

58.7 (3.7) |

6 (152) |

79.2 (5.0) |

8 (203) |

140 (8.8) |

Note: Water pressure differential switches are not recommended for outdoor applications.

Water Connections

Water piping to the cooler can be brought up through the bottom of the unit or through the side between the vertical supports. The dimensional drawings in Figure 14 give the necessary dimensions and locations for all piping connections. Evaporator piping connections face toward the left side of the unit when looking at the control panel.

Refrigerant Charge

All units are designed for use with HCFC-22 (and are compatible with some HCFC alternatives) and are shipped with a full operating charge. The operating charge for each unit is shown in the Physical Data Tables. Units ordered with a remote evaporator are shipped with a unit operating charge of refrigerant pumped down in the unit condensers. The McQuay authorized startup technician will top off the system charge at startup.

Glycol Solutions

When using glycol anti-freeze solutions the chiller's capacity, glycol solution flow rate, and pressure drop through the cooler may be calculated using the following formulas and tables.

Note: The procedure below does not specify the type of glycol. Use the derate factors found in Table 3 for corrections when using propylene glycol and those in Table 4 for ethylene glycol.

1.Capacity - Cooling capacity is reduced from that with plain water. To find the reduced value, multiply the chiller’s water system tonnage by the capacity correction factor to find the chiller’s capacity when using glycol.

2.Flow - To determine flow (or delta-T) knowing delta-T (or flow) and capacity:

GPM = (24)( tons) ( flow factor)

Delta − T

3.Pressure drop - To determine pressure drop through the cooler, when using glycol, enter the water pressure drop curve at the water flow rate. Multiply the water pressure drop found there by the "PD" factor to obtain corrected glycol pressure drop.

4.To determine glycol system kW, multiply the water system kW by the factor designated "Power".

Test coolant with a clean, accurate glycol solution hydrometer (similar to that found in service stations) to determine the freezing point. Obtain percent glycol from the freezing point table below. On glycol applications the supplier normally recommends that a minimum of 25% solution by weight be used for protection against corrosion.

12 |

IOMM ALS-4 |

CAUTION

Do not use automotive grade antifreeze. Industrial grade glycols must be used. Automotive antifreeze contains inhibitors that will cause plating on the copper tubes within the chiller evaporator. The type and handling of glycol used must be consistent with local codes.

Table 3, Propylene Glycol |

Table 4, Ethylene Glycol |

% |

FREEZE |

|

|

|

|

||

POINT. |

CAP |

POWER |

FLOW |

PD |

|||

P.G. |

|||||||

oF |

oC |

|

|

|

|

||

|

|

|

|

|

|||

10 |

26 |

-3 |

0.987 |

0.992 |

1.010 |

1.068 |

|

20 |

19 |

-7 |

0.975 |

0.985 |

1.028 |

1.147 |

|

30 |

9 |

-13 |

0.962 |

0.978 |

1.050 |

1.248 |

|

40 |

-5 |

-21 |

0.946 |

0.971 |

1.078 |

1.366 |

|

50 |

-27 |

-33 |

0.965 |

0.965 |

1.116 |

1.481 |

|

% |

FREEZE |

|

|

|

|

||

POINT. |

CAP |

POWER |

FLOW |

PD |

|||

E.G. |

|||||||

oF |

oC |

|

|

|

|

||

|

|

|

|

|

|||

10 |

26 |

-3 |

0.991 |

0.996 |

1.013 |

1.070 |

|

20 |

18 |

-8 |

0.982 |

0.992 |

1.040 |

1.129 |

|

30 |

7 |

-14 |

0.972 |

0.986 |

1.074 |

1.181 |

|

40 |

-7 |

-22 |

0.961 |

0.976 |

1.121 |

1.263 |

|

50 |

-28 |

-33 |

0.946 |

0.966 |

1.178 |

1.308 |

|

Remote Evaporator

General

The multiple compressor ALS air-cooled chillers are available with the evaporator shipped loose for remote mounting. This allows the main unit to be installed outdoors to save interior room and eliminates the need for anti-freeze solutions and heat tracing of chilled water lines since the chilled water system is indoors. There are some general guidelines to review before proceeding:

1.R-22 only.

2.Maximum line length of 50 ft (15 m) and Total Equivalent Length (TEL) of 120 ft (37 m).

3.Evaporator not more than 6 ft (1.8 m) above the compressor or 16 ft (5 m) below compressor.

4.No underground piping.

5.No hot gas bypass.

6.Units with remote evaporator are not included in the ARI Certification Program.

The remote evaporator is shipped separately, ready for quick and easy installation at the job site. All refrigerant accessories such as liquid-vapor line shut-off valves, replaceable core filter-driers, liquid line solenoid valves, electronic expansion valves, and sightglasses are already included on the ALS condensing unit. The evaporator is equipped with entering and leaving chilled water temperature sensor wells. The sensors are pre-wired to the ALS unit with 75 feet long sensor leads and must be field connected to the evaporator thermowells. Suction pressure transducers and temperature sensors must also be relocated to the evaporator. ALS units are factory charged with a full unit charge pumped down into the condensers. Field piping must be leak tested, evacuated and charged during installation. Do not exceed 150 psig test pressure unless the unit is blanked off from the piping.

Performance Derate Factors

All performance tables and adjustment factors found in the current version of the Air-Cooled Screw Chiller catalog (PM ALS-x) are applicable for remote evaporator installations. However, a performance derate must be applied to the R-22 performance data due to additional pressure drops in the suction and liquid lines which cause a loss of compressor performance. These derates are based on a suction line pressure drop equivalent of approximately 2°F (1°C) change in saturation temperature.

For R-22 applications:

Capacity = Tons (kW) x 0.97 |

Power = Compressor kW x 0.99 |

IOMM ALS-4 |

13 |

Refrigerant Piping

General

Careful design of the refrigerant piping is necessary for efficient system operation. The refrigerant piping should be designed for a low refrigerant pressure drop to obtain maximum capacity and efficiency while maintaining adequate velocity. Lines should slope in the direction of flow to assure good oil return to the compressors. Cost considerations favor keeping line sizes as small as possible while not exceeding acceptable pressure drops in order to maintain unit performance.

NOTE

All refrigerant piping must be reviewed and approved by McQuay Application Engineers prior to order entry and will be verified by McQuay startup technicians.

Equivalent Line Lengths

Recommended refrigerant line sizes are based on equivalent line lengths of straight pipe, that is, a combination of straight pipe, fittings and valves. The pressure drop through valves and fittings is determined by establishing the equivalent straight length of pipe of the same size with the same friction loss. The "Total Equivalent Length" is the sum of the "Lineal Line Length" and the appropriate "Valve and Fitting Losses in Equivalent Feet of Pipe for Field Supplied Piping" given in Table 5

Table 5, Fitting Equivalent Feet of Pipe

Line Size (in.) |

Angle Valve |

Globe Valve |

90° Std. Radius Elbow |

90° Long Radius Elbow |

1 1/8 |

12 |

29 |

2.6 |

1.7 |

1 3/8 |

15 |

38 |

3.3 |

2.3 |

1 5/8 |

18 |

43 |

4.0 |

2.6 |

2 1/8 |

24 |

55 |

5.0 |

3.3 |

2 5/8 |

29 |

69 |

6.0 |

4.1 |

3 1/8 |

35 |

84 |

7.5 |

5.0 |

Location and Arrangement

Refrigerant lines should be as short and direct as possible to minimize tubing and fittings. Long radius elbows must be used (except for traps) to minimize the pressure drops. Traps should be as short as possible to minimize oil accumulation. Refrigerant piping should be arranged so that normal inspection of the equipment is not hindered. Adequate clearance should be provided between refrigerant piping and adjacent walls for insulation. Piping should be run so that it does not interfere with compressor service access, passages or obstruct headroom, windows and doors. Suction line hangers must be sized and located to support the weight of the piping in accordance with good piping practice.

Horizontal portions of the suction lines must be downward sloping toward the compressors. Slope all piping in the direction of flow. Vertical portions of the suction lines must be sized for oil return at minimum compressor load.

Note: Double section risers must not be utilized on any circuit. Traps must be provided as shown on Figure 9 and Figure 10.

Suction Line Sizing

Pressure drop in the suction line reduces system capacity and efficiency because it forces the compressor to operate at lower suction pressure. The suction line should be sized for a pressure drop approximately equivalent of 2°F (1° C) change in saturation temperature. For suction line sizing see Table 7 and Table 8. For applications with the evaporator below the ALS unit, the vertical section of the suction lines must be sized to return oil to the compressors at the minimum compressor capacity step.

14 |

IOMM ALS-4 |

Example of Suction Line Size Calculation

ALS150C condensing unit with refrigerant R-22

Evaporator located 5 feet below the ALS compressor

Lineal length of horizontal suction line is 25 feet

Suction line requires 7 long radius (90°) elbows; 3 in the horizontal, 4 in the riser

From Table 6, the nominal circuit capacities for circuit 1 and 2 are 65 and 80 tons respectively

Total lineal suction line length = 30 feet each circuit (25 feet horizontal plus 5 feet vertical riser). For the first try, assume that the total equivalent suction line length is twice the lineal suction line length.

Therefore the estimated total equivalent suction line length = 60 feet

From Table 7 and Table 8, For nominal circuit capacities of 65 & 80 tons and total equivalent line length of 60 ft, the suction line size = 2 5/8" for horizontal lines and 2 1/8" for vertical lines.

From Table 5, Fitting loss for 2 5/8" long radius (90°) elbow = 4.1 ft, and 3.3 ft for the 2 1/8 elbows.

Therefore fitting loss in equivalent feet of pipe for (3) 2 5/8" long radius (90°) elbow = 12.3 ft, and 13.2 ft for (4) 2 1/8" elbows.

Therefore the actual equivalent suction line length = 30 + 12.3 + 13.2 = 55.5 feet

From and Table 8, For nominal circuit capacities of 65 & 80 tons and equivalent line length of 55.5 ft the suction line size is correct.

Table 6, ALS 141C-420C Nominal Circuit Capacities

ALS Model |

Circuit 1 |

Circuit 2 |

|

Tons (kW) |

Tons (kW) |

||

|

|||

141 |

65 (229) |

65 (229) |

|

150 |

65 (229) |

80 (262) |

|

171 |

80 (262) |

80 (262) |

|

186 |

80 (262) |

95 (334) |

|

190 |

80 (262) |

95 (334) |

|

200 |

95 (334) |

95 (334) |

|

206 |

95 (334) |

95 (334) |

|

218 |

95 (334) |

95 (334) |

Table 7, Vertical Upflow Suction Line Sizes

Nominal Circuit |

Vertical Upflow Suction Lines |

||

Capacity |

|||

Equivalent Line Length Ft (m) |

Suction Line Size (in.) |

||

Tons (kW) |

|||

65 (229) |

40 (12) |

2 1/8 |

|

75 (23) |

2 1/8 |

||

|

|||

80 (262) |

40 (12) |

2 1/8 |

|

75 (23) |

2 1/8 |

||

|

|||

95 (334) |

40 (12) |

2 5/8 |

|

75 (23) |

2 5/8 |

||

|

|||

Table 8, Horizontal and Vertical Downflow Suction Line Sizes

Nominal Circuit |

Vertical Downflow and Horizontal Suction Lines |

|

Capacity |

Equivalent Line Length Ft (m) |

Suction Line Size, in. |

Tons (kW) |

||

65 (229) |

40 (12) |

2 5/8 |

75 (23) |

2 5/8 |

|

|

115 (35) |

2 5/8 |

80 (262) |

40 (12) |

2 5/8 |

75 (23) |

2 5/8 |

|

|

115 (35) |

3 1/8 |

95 (334) |

40 (12) |

2 5/8 |

75 (23) |

3 1/8 |

|

|

115 (35) |

3 1/8 |

IOMM ALS-4 |

15 |

Liquid-Vapor Lines

The liquid-vapor line from the ALS condensing unit to the evaporator liquid connection is not a conventional liquid line since it carries both liquid and vapor. The compressors on the ALS units utilize a liquid cooled motor and an economizer. Therefore the expansion valve which feeds the full flow of liquid refrigerant into the compressor for motor cooling is mounted in the liquid line between the condenser sub-cooling coil and the compressor inlet, not at the evaporator inlet. The liquid-vapor line to the evaporator is a low-pressure line downstream of the expansion valve and the size is slightly larger than a normal liquid line. For liquid line sizing see Table 9 and Table 10.

Table 9, Vertical Upflow Liquid-Vapor Line Sizes

Nominal Circuit |

Vertical Upflow Liquid-Vapor Lines |

|

Capacity |

Equivalent Line Length |

Liquid-Vapor Line Size |

Tons (kW) |

Ft (m) |

o.d (in.) |

65 (229) |

40 (12) |

1 3/8 |

75 (23) |

1 3/8 |

|

80 (262) |

40 (12) |

1 3/8 |

75 (23) |

1 3/8 |

|

95 (334) |

40 (12) |

1 5/8 |

75 (23) |

1 5/8 |

|

Table 10, Horizontal and Vertical Downflow Liquid-Vapor Line Sizes

Nominal Circuit |

Vertical Downflow and Horizontal Liquid-Vapor Lines |

|

Capacity |

Equivalent Line Length |

Liquid-Vapor Line Size |

Tons (kW) |

Ft (m) |

o.d (in.) |

65 (229) |

40 (12) |

1 3/8 |

75 (23) |

1 3/8 |

|

|

115 (35) |

1 3/8 |

80 (262) |

40 (12) |

1 3/8 |

75 (23) |

1 5/8 |

|

|

115 (35) |

1 5/8 |

95 (334) |

40 (12) |

1 5/8 |

75 (23) |

1 5/8 |

|

|

115 (35) |

1 5/8 |

Figure 9, Evaporator Above ALS Unit

Evaporator

Trap

ALS Unit

Suction Line

Figure 10, Evaporator Below ALS Unit

ALS Unit

Suction Line

Evaporator

Trap

NOTE: Keep the trap width at a minimum to avoid trapping excessive oil.

16 |

IOMM ALS-4 |

Insulation

All piping joints and fittings must be thoroughly leak tested before insulation is applied. Suction lines must be insulated and should not be installed underground. Suction line insulation must be selected to

prevent condensation under local ambient conditions with the lines at 40°F to 50°F (4.4° C to 10° C) operating temperatures. The liquid-vapor lines will operate at 40°F to 60°F (4.4° C to 15.6° C) and must also be insulated to prevent sweating and heat gain.

Startup Procedures

NOTE: McQuayService or a factory authorized McQuay service agent must do initial start-up and commissioning.

Filter Driers

Following an initial 24 hour operation the pressure drop across the replaceable core filter-drier should be checked. If this pressure drop exceeds the values given in Table 11 at the various load conditions the filter drier cores must be replaced. Also if the moisture indicating sight glass shows a wet system condition after 24 hours of operation the filter cores must be changed. This should remove any contaminants introduced during field piping. The filter drier cores must also be changed anytime the system is opened for servicing.

Table 11, Filter Drier Pressure Drop

Percent Circuit |

Maximum Recommended Pressure Drop Across Filter Drier |

Loading (%) |

psig (kPa) |

100 |

7 (48.3) |

75 |

5 (34.5) |

50 |

3 (20.7) |

25 |

3 (20.7) |

Refrigerant and Oil Charge

The relative position of the ALS unit and the evaporator and the distance between them plays a critical role in determining suction and liquid line sizes and the field refrigerant and oil charges. ALS units with the remote evaporator option are shipped with a unit operating charge of refrigerant and oil. It will be necessary to evacuate the evaporator and field installed line and top off the charge See Table 12 for refrigerant charge for suction and liquid-vapor lines. McQuay Service will supply and add additional oil as required. The correct oil is Planetelf ACD68AW, McQuay Part No. 735030439 (5 gal.), 735030438 (1 gal.).

Charging Procedure

The calculated refrigerant charge must be added through the factory supplied charging valve located on the liquid-vapor line coming out of the compressor. Sufficient charge must be added to clear the liquid line sight glass located at the outlet of the condenser. Add an extra 10 lb. of refrigerant after the sight glass is clear.

Table 12, Refrigerant Charge for Suction and Liquid-Vapor Lines

Lineal Tubing |

Suction Line Refrigerant Charge |

Liquid-Vapor Line Refrigerant Charge |

||||

Length |

lb (kg) |

|

|

lb (kg) |

||

ft (m) |

Line (in.) |

|

R-22 |

Line (in.) |

|

R-22 |

10 (3) |

2 1/8 |

|

0.33 (0.15) |

1 3/8 |

|

3.6 (1.6) |

2 5/8 |

|

0.51 (0.23) |

1 5/8 |

|

5.0 (2.3) |

|

|

3 1/8 |

|

0.71 (0.32) |

|

|

|

20 (6) |

2 1/8 |

|

0.66 (0.30) |

1 3/8 |

|

7.2 (3.3) |

2 5/8 |

|

1.02 (0.46) |

1 5/8 |

|

10.0 (4.5) |

|

|

3 1/8 |

|

1.42 (0.64) |

|

|

|

30 (9) |

2 1/8 |

|

0.99 (0.45) |

1 3/8 |

|

10.8 (4.9) |

2 5/8 |

|

1.53 (0.69) |

1 5/8 |

|

15.0 (6.8) |

|

|

3 1/8 |

|

2.13 (0.96) |

|

|

|

40 (12) |

2 1/8 |

|

1.32 (0.60) |

1 3/8 |

|

14.4 (6.5) |

2 5/8 |

|

2.04 (0.92) |

1 5/8 |

|

20.0 (9.0) |

|

|

3 1/8 |

|

2.84 (1.29) |

|

|

|

Notes: See next page

IOMM ALS-4 |

17 |

1.The only approved oil is that identified on the label attached to the compressors. All POE oils are hygroscopic and care should be exercised in handling the oil to avoid absorption and retention of moisture.

2.Do not leave the oil container open for more than a minute while charging oil. Do not use oil that has not been properly sealed and stored.

3.Charge must never be added through the compressor suction line

Dimensions

Use the ALS dimension drawings Figure 14 for the ALS with remote evaporator. The refrigerant connections are located approximately where the refrigerant connections to the unit mounted evaporator are on a packaged chiller. The remote evaporator dimensions are Figure 11 Figure 12.

Dimensions, Remote Evaporator

Figure 11, Evaporator for ALS 141 - ALS 200

|

ALS |

Evaporator |

|

Water |

|

Refrigerant |

|

|

Unit Weights |

lb. (kg) |

R-22 Operating Charge |

lb. (kg) |

|||||||

|

|

Volume |

|

|

Volume |

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

Model |

Model |

|

|

|

|

Operating |

|

|

Shipping |

Circuit 1 |

Circuit 2 |

|||||||

|

|

gal. (l) |

|

|

cu. ft. (L) |

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

141 |

CDE350332801 |

34 (128) |

|

|

1.4 (40.0) |

|

934 (424) |

|

|

635 (288) |

34 (15.4) |

34 (15.4) |

||||||

|

150-200 |

CDE350332901 |

40 (150) |

|

|

1.8 (52.4) |

|

1127 (512) |

|

|

758 (343) |

45 (20.4) |

45 (20.4) |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

ALS |

Overall Dimensions in. (mm) |

|

|

|

|

|

|

|

|

|

|

|

|

Conn. |

||||

|

Model |

Length "K" |

|

Height "A" |

|

"B" |

|

"C" |

|

"D" |

"H" |

"J" |

|

|

"G" |

||||

|

141 |

94.6 (2403) |

|

17.8 (452) |

|

|

11.0 (279) |

|

10.2 (259) |

|

|

12.8 (325) |

6.4 (163) |

85.2 (2164) |

|

5 (152) |

|||

|

150-200 |

95.5 (2426) |

|

18.4 (467) |

|

|

12.0 (305) |

|

10.2 (259) |

|

|

14.0 (356) |

6.8 (173) |

84.0 (2134) |

|

8 (203) |

|||

18 |

IOMM ALS-4 |

Figure 12, Evaporator for ALS 206 - ALS 218

ALS |

Evaporator |

Water Volume |

Refrig Volume |

Weights lb. (kg) |

R-22 Opn Charge lb. (kg) |

|||||||

Model |

Model |

gal. (l) |

cu. ft. (l) |

Operating |

Shipping |

Circuit 1 |

|

Circuit 2 |

||||

206 |

CDE350281651 |

55 (208) |

|

2.4 (67.9) |

|

1464 (665) |

943 (428) |

57 (25.8) |

|

57 (25.8) |

||

218 |

CDE350282101 |

98 (373) |

|

2.8 (79.2) |

|

2028 (921) |

1121 (509) |

68 (30.9) |

|

68 (30.9) |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

ALS |

|

|

|

Dimensional Data |

|

|

|

|

|

|

||

Model |

A |

C |

|

D |

|

H |

|

|

J |

|

|

K |

206 |

21.3 (542) |

12.1 (307) |

|

16.0 (406) |

|

6.9 (176) |

|

84.5 (2149) |

|

96.7 (2459) |

||

218 |

23.6 (601) |

12.4 (315) |

|

20.0 (508) |

|

9.2 (235) |

|

86.6 (2202) |

|

99.7 (2533) |

||

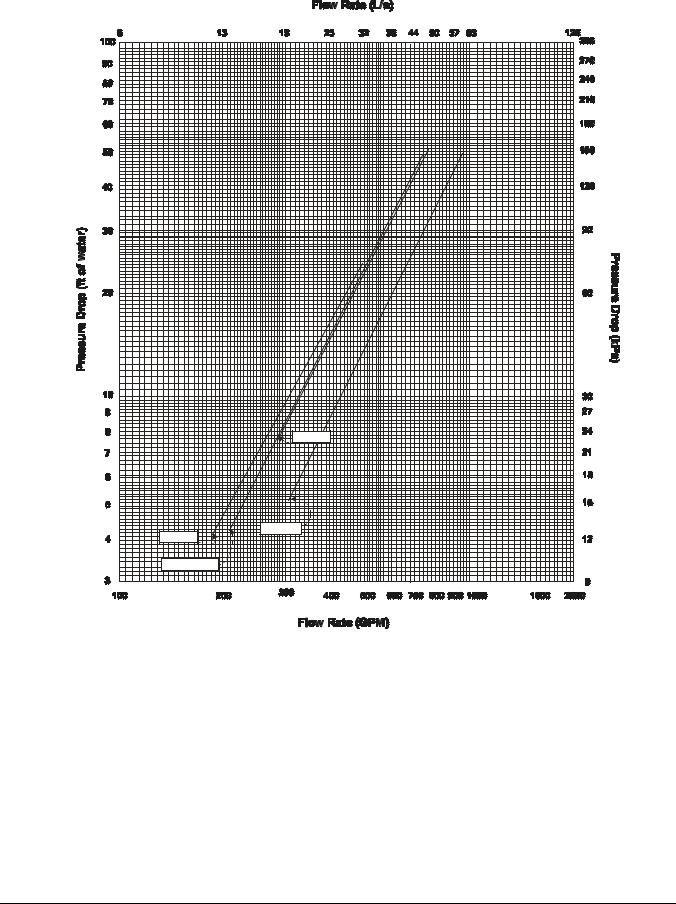

Water Flow and Pressure Drop

The chilled water flow through the evaporator should be adjusted to meet specified conditions. The flow rates must fall between the minimum and maximum values shown in. Flow rates below the minimum values shown will result in laminar flow that will reduce efficiency, cause erratic operation of the electronic expansion valve and could cause low temperature cutouts. On the other hand flow rates exceeding the maximum values shown can cause erosion on the evaporator water connections and tubes.

Measure the chilled water pressure drop through the evaporator at field installed pressure taps. It is important not to include valve or strainer pressure drop in these readings.

IOMM ALS-4 |

19 |

Figure 13, Evaporator Pressure Drops

ALS 206 |

ALS 218 |

ALS 141 |

ALS 150-200 |

Table 13, Minimum/Nominal/Maximum Flow Rates

ALS |

Minimum |

Pressure |

Nominal |

Pressure |

Maximum |

Pressure |

|

Unit |

|||||||

Flow gpm |

Drop ft. |

Flow gpm |

Drop ft. |

Flow gpm |

Drop ft. |

||

Size |

|||||||

|

|

|

|

|

|

||

141 |

187 |

4.0 |

298.8 |

9.5 |

498 |

24.2 |

|

150 |

209 |

4.2 |

335.3 |

10.5 |

559 |

28.5 |

|

171 |

234 |

5.2 |

373.9 |

13.0 |

623 |

35.3 |

|

186 |

255 |

6.1 |

408.0 |

15.4 |

680 |

41.9 |

|

190 |

260 |

6.4 |

415.4 |

16.0 |

692 |

43.4 |

|

200 |

276 |

7.2 |

442.1 |

18.0 |

737 |

49.0 |

|

206 |

285 |

7.5 |

456.7 |

18.7 |

761 |

50.4 |

|

218 |

307 |

5.0 |

490.6 |

13.1 |

818 |

36.8 |

20 |

IOMM ALS-4 |

Physical Data

Table 14, Physical Data, ALS 141C – ALS 186C

DATA |

|

|

|

ALS MODEL NUMBER |

|

|

|

|

|

|

141C |

150C |

171C |

186C |

|||||||

|

Ckt 1 |

Ckt 2 |

Ckt 1 |

Ckt 2 |

Ckt 1 |

|

Ckt 2 |

Ckt 1 |

|

Ckt 2 |

BASIC DATA |

|

|

|

|

|

|

|

|

|

|

Unit Cap. @ ARI Conditions, tons (kW) |

124.5 (436) |

139.7 (489) |

155.8 (545) |

170 (595) |

||||||

Unit Operating Charge R-22, lbs (kg) |

140 (63.5) |

140 (63.5) |

140 (63.5) |

150 (68.1) |

150 (68.1) |

150 (68.1) |

150 (68.1) |

160 (72.6) |

||

Cabinet Dimensions |

228.7 x 83.4 x 92.5 |

228.7 x 83.4 x 92.5 |

228.7 x 83.4 x 92.5 |

228.7 x 83.4 x 92.5 |

||||||

L x W x H, in. (mm) |

(5809 x 2118 x 2350) |

(5809 x 2118 x 2350) |

(5809 x 2118 x 2350) |

(5809 x 2118 x 2350) |

||||||

Unit Operating Weight, lbs. (kg) |

9700 (4395) |

9880 (4475) |

9890 (4480) |

9900 (4485) |

||||||

Unit Shipping Weight, lbs (kg) |

9420 (4270) |

9550 (4325) |

9560 (4330) |

9570 (4335) |

||||||

COMPRESSORS, SCREW, SEMI-HERMETIC |

|

|

|

|

|

|

|

|

|

|

Nominal Capacity, tons (kW) |

65 (230) |

65 (230) |

65 (230) |

80 (280) |

80 (280) |

80 (280) |

80 (280) |

95 (335) |

||

CONDENSERS, HIGH EFFICIENCY FIN AND TUBE TYPE WITH INTEGRAL SUBCOOLER |

|

|

|

|

|

|

||||

Coil Face Area, ft2. (m2) |

115.6 (10.7) |

115.6 (10.7) |

115.6 (10.7) |

115.6 (10.7) |

115.6 (10.7) |

115.6 (10.7) |

115.6 (10.7) |

115.6 (10.7) |

||

Finned Height x Finned Length |

80 x 208 |

80 x 208 |

80 x 208 |

80 x 208 |

80 x 208 |

|

80 x 208 |

80 x 208 |

|

80 x 208 |

ft. (mm) |

(2032 x 5283) |

(2032 x 5283) |

(2032 x 5283) |

(2032 x 5283) |

(2032 x 5283) |

|

(2032 x 5283) |

(2032 x 5283) |

|

(2032 x 5283) |

Fins Per Inch x Rows Deep |

16 x 3 |

16 x 3 |

16 x 3 |

16 x 3 |

16 x 3 |

|

16 x 3 |

16 x 3 |

|

16 x 3 |

CONDENSER FANS, DIRECT DRIVE PROPELLER TYPE |

|

|

|

|

|

|

|

|

||

No. of Fans -- Fan Diameter, in. (mm) |

10 - 28 (711) |

10 - 28 (711) |

12 - 28 (711) |

12 - 28 (711) |

||||||

No. of Motors -- hp (kW) |

10 - 1.5 (1.1) |

10 - 1.5 (1.1) |

12 - 1.5 (1.1) |

12 - 1.5 (1.1) |

||||||

Fan & Motor RPM, 60Hz |

1140 |

1140 |

1140 |

1140 |

||||||

60 Hz Fan Tip Speed, fpm |

8357 |

8357 |

8357 |

8357 |

||||||

60 Hz Total Unit Airflow, cfm |

90200 |

90200 |

108240 |

108240 |

||||||

EVAPORATOR, DIRECT EXPANSION |

|

|

|

|

|

|

|

|

|

|

Shell Dia.- Length |

12.75 – 94.6 |

14.0 – 95.5 |

14.0 – 95.5 |

14.0 – 95.5 |

||||||

in.(mm) - in. (mm) |

(324 - 2403) |

(356 - 2425) |

(356 - 2425) |

(356 - 2425) |

||||||

Evaporator R-22 Charge lbs (kg) |

34 (15.4) |

34 (15.4) |

45 (20.4) |

45 (20.4) |

45 (20.4) |

|

45 (20.4) |

45 (20.4) |

|

45 (20.4) |

Water Volume, gallons (liters) |

34 |

(129) |

40 |

(151) |

40 (151) |

40 (151) |

||||

Max. Water Pressure, psi (kPa) |

152 (1048) |

152 (1048) |

152 (1048) |

152 (1048) |

||||||

Max. Refrigerant Pressure, psi (kPa) |

300 (2068) |

300 (2068) |

300 (2068) |

300 (2068) |

||||||

Table 15, Physical Data, ALS 190C – ALS 218C

DATA |

|

|

|

|

ALS MODEL NUMBER |

|

|

|

|

|

|

190C |

200C |

206C |

218C |

||||||||

|

Ckt 1 |

Ckt 2 |

Ckt 1 |

|

Ckt 2 |

Ckt 1 |

|

Ckt 2 |

Ckt 1 |

Ckt 2 |

|

BASIC DATA |

|

|

|

|

|

|

|

|

|

|

|

Unit Cap. @ ARI Conditions, tons (kW) |

173.1 (606) |

184.2 (645) |

190.3 (666) |

204.4 (715) |

|||||||

Unit Operating Charge R-22, lbs (kg) |

170 (77.0) |

180 (81.5) |

180 (81.5) |

180 (81.5) |

185 (83.8) |

185 (83.8) |

210 (95.1) |

|

210 (95.1) |

||

Cabinet Dimensions, |

263.4 x 83.4 x 92.5 |

263.4 x 83.4 x 92.5 |

263.4 x 83.4 x 92.5 |

263.4 x 83.4 x 92.5 |

|||||||

L x W x H, in. (mm) |

(6690 x 2118 x 2350) |

(6690 x 2118 x 2350) |

(6690 x 2118 x 2350) |

(6690 x 2118 x 2350) |

|||||||

Unit Operating Weight, lbs. (kg) |

10620 (4810) |

10630 (4815) |

10960 (4965) |

11550 (5230) |

|||||||

Unit Shipping Weight, lbs (kg) |

10290 (4660) |

10300 (4665) |

10500 (4755) |

10730 (4860) |

|||||||

COMPRESSORS, SCREW, SEMI-HERMETIC |

|

|

|

|

|

|

|

|

|

|

|

Nominal Capacity, tons (kW) |

80 (280) |

95 (335) |

95 (335) |

95 (335) |

95 (335) |

95 (335) |

95 (335) |

|

95 (335) |

||

CONDENSERS, HIGH EFFICIENCY FIN AND TUBE TYPE WITH INTEGRAL SUBCOOLER |

|

|

|

|

|

|

|||||

Coil Face Area, ft2. (m2) |

135.0 (12.5) |

135.0 (12.5) |

135.0 (12.5) |

135.0 (12.5) |

135.0 (12.5) |

135.0 (12.5) |

135.0 (12.5) |

|

135.0 (12.5) |

||

Finned Height x Finned Length |

80 x 243 |

80 x 243 |

80 x 243 |

|

80 x 243 |

80 x 243 |

|

80 x 243 |

80 x 243 |

80 x 243 |

|

ft. (mm) |

(2032 x 6172) |

(2032 x 6172) |

(2032 x 6172) |

|

(2032 x 6172) |

(2032 x 6172) |

(2032 x 6172) |

(2032 x 6172) |

(2032 x 6172) |

||

Fins Per Inch x Rows Deep |

16 x 3 |

16 x 3 |

16 x 3 |

|

16 x 3 |

16 x 3 |

|

16 x 3 |

16 x 3 |

16 x 3 |

|

CONDENSER FANS, DIRECT DRIVE PROPELLER TYPE |

|

|

|

|

|

|

|

|

|

||

No. of Fans -- Fan Diameter, in. (mm) |

14 - 28 (711) |

14 - 28 (711) |

14 - 28 (711) |

14 - 28 (711) |

|||||||

No. of Motors -- hp (kW) |

14 - 1.5 (1.1) |

14 - 1.5 (1.1) |

14 - 1.5 (1.1) |

14 - 2.0 (1.5) |

|||||||

Fan & Motor RPM, 60Hz |

1140 |

1140 |

1140 |

1140 |

|||||||

60 Hz Fan Tip Speed, fpm |

8357 |

8357 |

8357 |

8357 |

|||||||

60 Hz Total Unit Airflow, cfm |

126280 |

126280 |

126280 |

138908 |

|||||||

EVAPORATOR, DIRECT EXPANSION |

|

|

|

|

|

|

|

|

|

|

|

Shell Dia. -- Length |

14.0 – 95.5 |

14.0 – 95.5 |

16.0 – 96.8 |

20.0 – 99.7 |

|||||||

in.(mm) - in. (mm) |

(356 - 2425) |

(356 - 2425) |

(406 - 2459) |

(508 - 2532) |

|||||||

Evaporator R-22 Charge lbs (kg) |

45 (20.4) |

45 (20.4) |

45 (20.4) |

|

45 (20.4) |

57 (25.8) |

|

57 (25.8) |

68 (30.8) |

|

68 (30.8) |

Water Volume, gallons (liters) |

40 |

(151) |

40 (151) |

55 (208) |

98 (371) |

||||||

Max. Water Pressure, psi (kPa) |

152 (1048) |

152 (1048) |

152 (1048) |

152 (1048) |

|||||||

Max. Refrigerant Pressure, psi (kPa) |

300 (2068) |

300 (2068) |

300 (2068) |

300 (2068) |

|||||||

IOMM ALS-4 |

21 |

Loading...

Loading...