McIntosh MP1100 Owner's Manual

McIntosh Laboratory, Inc. 2 Chambers Street Binghamton, New York 13903-2699 Phone: 607-723-3512 www.mcintoshlabs.com

MP1100

Phono Preamplifier

Owner’s Manual

Important Safety Information is supplied in a separate document “Important Additional Operation Information Guide”

Thank You

Your decision to own this McIntosh MP1100 Phono

Preamplifier ranks you at the very top among discriminating music listeners. You now have “The Best.”

The McIntosh dedication to “Quality,” is assurance

that you will receive many years of musical enjoyment

from this unit.

Please take a short time to read the information in

this manual. We want you to be as familiar as possible with all the features and functions of your new

McIntosh.

Please Take A Moment

The serial number, purchase date and McIntosh Dealer

name are important to you for possible insurance

claim or future service. The spaces below have been

provided for you to record that information:

Serial Number: _______________________________

Purchase Date: _______________________________

Dealer Name: ________________________________

Technical Assistance

If at any time you have questions about your McIntosh

product, contact your McIntosh Dealer who is familiar

with your McIntosh equipment and any other brands

that may be part of your system. If you or your Dealer

wish additional help concerning a suspected problem,

you can receive technical assistance for all McIntosh

products at:

McIntosh Laboratory, Inc.

2 Chambers Street

Binghamton, New York 13903

Phone: 607-723 -3512

Fax: 607-724-0549

Customer Service

If it is determined that your McIntosh product is in

need of repair, you can return it to your Dealer. You

can also return it to the McIntosh Laboratory Service

Department. For assistance on factory repair return

procedure, contact the McIntosh Service Department

at:

McIntosh Laboratory, Inc.

2 Chambers Street

Binghamton, New York 13903

Phone: 607-723 -3515

Fax: 607-723-1917

Table of Contents

Safety Instructions ..................................................... 2

(Separate Sheet) ................... Important Additional

Operation Information Guide

Thank You and Please Take a Moment ...................... 2

Technical Assistance and Customer Service ............. 2

Table of Contents ....................................................... 2

General Information .................................................. 3

Connector and Cable Information ............................. 3

Introduction ................................................................ 4

Performance Features ............................................. 4-5

Dimensions ................................................................ 6

Installation ................................................................. 7

Connections:

Rear Panel Connections .............................................. 8

Connecting Components ............................................. 9

Front Panel:

Front Panel Displays, Controls, Push-buttons .......... 10

Front Panel Information Displays Modes ..................11

Remote Control:

HR090 Remote Control Push-buttons ...................... 12

Setup:

How to Operate the Setup Mode .............................. 13

Default Settings, Firmware Version .......................... 13

Input Settings ....................................................... 13-14

Rename Input ............................................................ 14

Profile Store .............................................................. 15

Digital Output ........................................................... 16

Tube Lights ............................................................... 16

Power Mode .............................................................. 16

IR Sensor................................................................... 17

Factory Reset ............................................................ 17

Operation:

How to Operate the MP1100 ................................ 18-23

Trim Functions ..................................................... 18 -22

Mute, Trim and Output Meters ................................. 23

USB Input and Installing Software ...................... 24-26

Reset of Microprocessors .......................................... 25

Graphic Curves .................................................... 27-28

Rumble and Scratch Filter Curves ............................ 28

Additional Information:

Photo ......................................................................... 29

Specifications ............................................................ 30

Packing Instruction ................................................... 31

Copyright 2016 © by McIntosh Laboratory, Inc.

2

General Information and Connector Information

General Information

1. For additional connection information, refer to the

owner’s manual(s) for any component(s) connected

to the MP1100 Phono Preamplifier.

2. The Main AC Power going to the MP1100 and any

other McIntosh Component(s) should not be applied

until all the system components are connected

together. Failure to do so could result in malfunctioning of some or all of the system’s normal

operations. When the MP1100 and other McIntosh

Components are in their Standby Power Off Mode,

the Microprocessor’s Circuitry inside each component is active and communication is occurring

between them.

3. The Balanced and Unbalanced Outputs may be

used simultaneously, connected to different Preamplifiers or component recording device.

4. The MP1100 internal Analog to Digital Converter

Circuitry is designed to encode 2-channel PCM

(Pulse Code Modulation) Digital Signals. The

Coaxial and Optical Digital Audio Outputs are for

PCM Digital Signals.

5. Sound Intensity is measured in units called Deci-

bels and “dB” is the abbreviation.

6. When discarding the unit, comply with local rules

or regulations. Batteries should never be

thrown away or incinerated but disposed

of in accordance with the local regulations

concerning battery disposal.

7. For additional information on the MP1100

and other McIntosh Products please visit the McIntosh Web Site at www.mcintoshlabs.com.

Connector and Cable Information

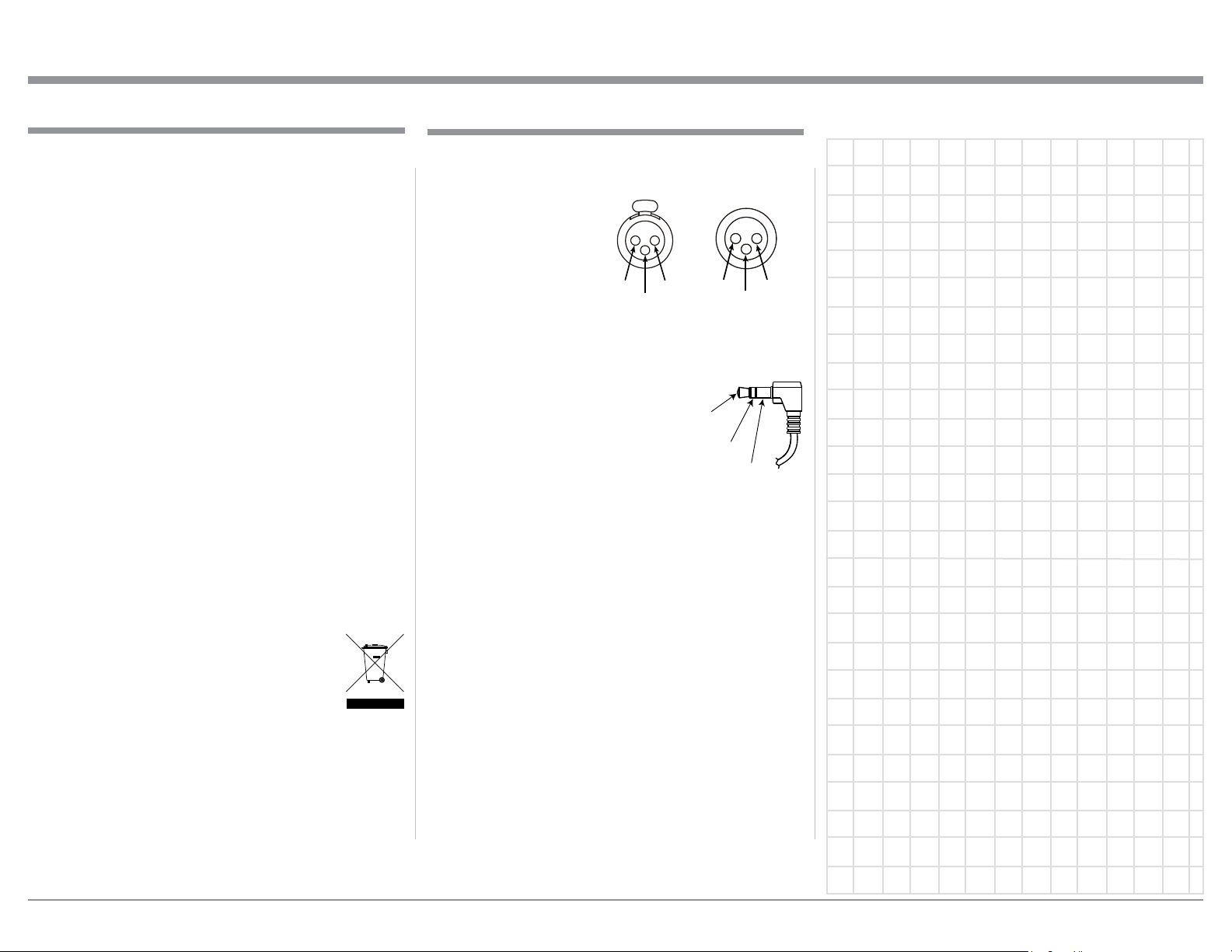

XLR Connectors

Below is the Pin configuration for the XLR Balanced

Output Connector on the MP1100. Refer to the diagram for connections:

PIN 1: Shield/Ground

PIN 2: + Output

PIN 3: - Output

PIN 2 PIN 1

PIN 3

Power Control (Trigger) Connectors

When the MP1100 TRIGger IN Connector receives a

Power Control On Signal (5 to 12 volts) it will make

that signal available at the TRIGger OUT Connector to control

other connected McIntosh Components. An additional connection

is for controlling the illumination

of the Output Meters on McIntosh

Components. A 3.5mm stereo mini phone plug is used

for connection to the Power Control (Trigger) Connectors on the MP1100.

PIN 1

Power

Control

Meter

Illumination

Control

PIN 3

Ground

PIN 2

3

Introduction

The McIntosh MP1100 Phono Preamplifier is one of

the finest Phono Preamplifiers ever created and has

the ability for connections to components with analog

and digital inputs. The MP1100 reproduction is sonically transparent and absolutely accurate. The McIntosh Sound is “The Sound of the Music Itself.”

Performance Features

• Electromagnetic Input Switching

Digital Logic Circuits drive Electromagnetic Switches

on Inputs and operating functions for reliable, noiseless, distortion free switching.

• Selectable Phono Cartridge Loading

Adjustable Capacitance and Resistance Loading are

available for both Moving Coil and Moving Magnet

Phono Cartridges. Resistance Loading is selectable

from values of 25 ohms to 47,000 ohms. Capacitance

Loading is selectable from values of 50 picofarads to

400 picofarads.

• Balanced and Unbalanced Outputs

The Balanced Outputs allow connection using long

cable lengths without a loss in sound quality. The

MP1100 also has unbalanced Output connections for

compatibility with a wide range of audio components.

• Dual Mono Design

The circuitry for both channels is totally separate,

physically isolated and shielded which helps to assure

total channel isolation.

• Selectable Equalizer

In addition to normal RIAA Equalization Standard,

the MP1100 provides the ability to select four alternative Equalization Settings of LP, AES, NAB or 78.

This helps to assure a desired tonal balance when

playing a wide variety of phonograph records made

before the RIAA Equalization Standard was employed.

• Vacuum Tube Phono Amplification

The MP1100 utilizes Vacuum Tube Amplification

Circuitry for the Phono Inputs. The circuits use the

latest designs providing the lowest possible noise and

distortion.

• Fully Balanced Circuitry

The MP1100 utilizes the very latest in Fully Balanced

Circuitry from the Input Connectors all the way to the

Output Connectors for the lowest possible noise and

distortion.

• Moving Coil and Moving Magnet Phono Inputs

The MP1100 has three precision Phono Preamplifier

Circuits with unbalanced and balanced connections.

They have the ability to be configured for Moving

Coil or Moving Magnet Cartridges. The close tolerance resistors and capacitors used in the Equalization Circuitry provide an extremely flat frequency

response.

• Rumble and Scratch Filters

Selectable Rumble and Scratch Filters can improve the

quality of sound when playing back older vinyl recodings.

• Digital Audio Outputs

The Digital Outputs encode PCM Signals from the

selected Input (Phono and Line). Coaxial and Optical

Outputs process Digital Signals at 96kHz or 192kHz

with 24-Bit resolution. The Digital Outputs have two

different output level settings and the Digital Circuitry

can be switched Off providing true analog only signal

processing.

• USB Digital Audio Output

The USB Digital Output provides Digital Signals at

96kHz or 192kHz with 24-Bit resolution from the

selected Input.

• Alphanumeric Fluorescent Display

The Front Panel Information Display indicates the

Source Selection, Cartridge Loading, Equalizer and

Setup Mode Selections. The display intensity is adjustable.

• Illuminated Output Meters

The Illuminated Output Meters are peak responding,

and indicate the output of the MP1100 Phono Preamplifier.

• Special Power Supply

The Multi Regulated Power Supply and a special

R-Core Power Transformer ensure stable noise free

operation even though the power line varies.

• Remote Control with External Sensor Input

The Remote Control provides control of the MP1100

operating functions. The External Sensor Input provides Remote Control when the MP1100 is located

behind closed doors or in another room.

4

• Power Control Connections

The Power Control (PWR CTRL) TRIGger INput

Connection provides convenient Turn-On/Off of the

MP1100 when connected to a McIntosh Component

with Power Control TRIGger OUT. The MP1100

TRIGger OUT Connection provides Turn-On/Off

operation when connected with other McIntosh Audio

Components.

• LED Front Panel Illumination

The even Illumination of the Front Panel is accomplished by multiple extra long life Light Emitting

Diodes (LEDs) arranged with a special orientation.

• Glass Front Panel and Super Mirror Chassis

Finish

The famous McIntosh Illuminated Glass Front Panel

and the Lower Chassis are Stainless Steel with a

Mirror Finish. The Upper Chassis and Top Cover is

hairline brushed black Titanium Stainless Steel Finish.

This will ensure the pristine beauty of the MP1100

will be retained for many years to come.

Introduction and Performance Features

5

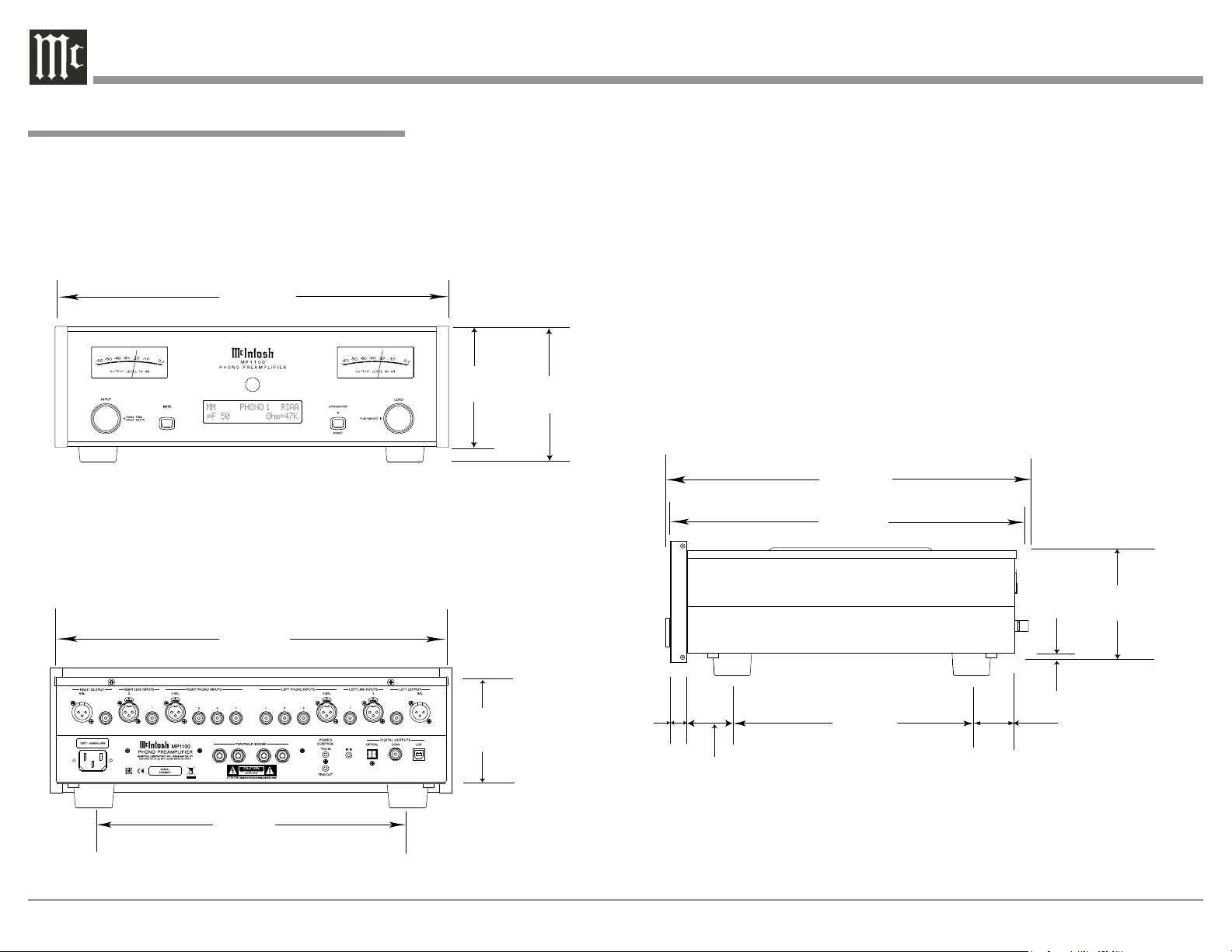

Dimensions

The following dimensions can assist in determining

the best location for your MP1100. There is additional

information on the next page pertaining to installing

the MP1100 into cabinets.

Front View of the MP1100

17-1/2"

44.4cm

Dimensions

Rear View of the MP1100

17-1/8"

43.5cm

13 -1/4"

33.7cm

5-3/8"

13.7cm

4-5/8"

11.8cm

6"

15.2cm

13/16"

2.1cm

2"

5.1cm

Side View of the MP1100

15-7/8"

40.3cm

14-1/2"

36.8cm

10-9/16"

26.8cm

3/16"

0.48cm

1-15/16"

4.9cm

4-13/16"

12.22cm

6

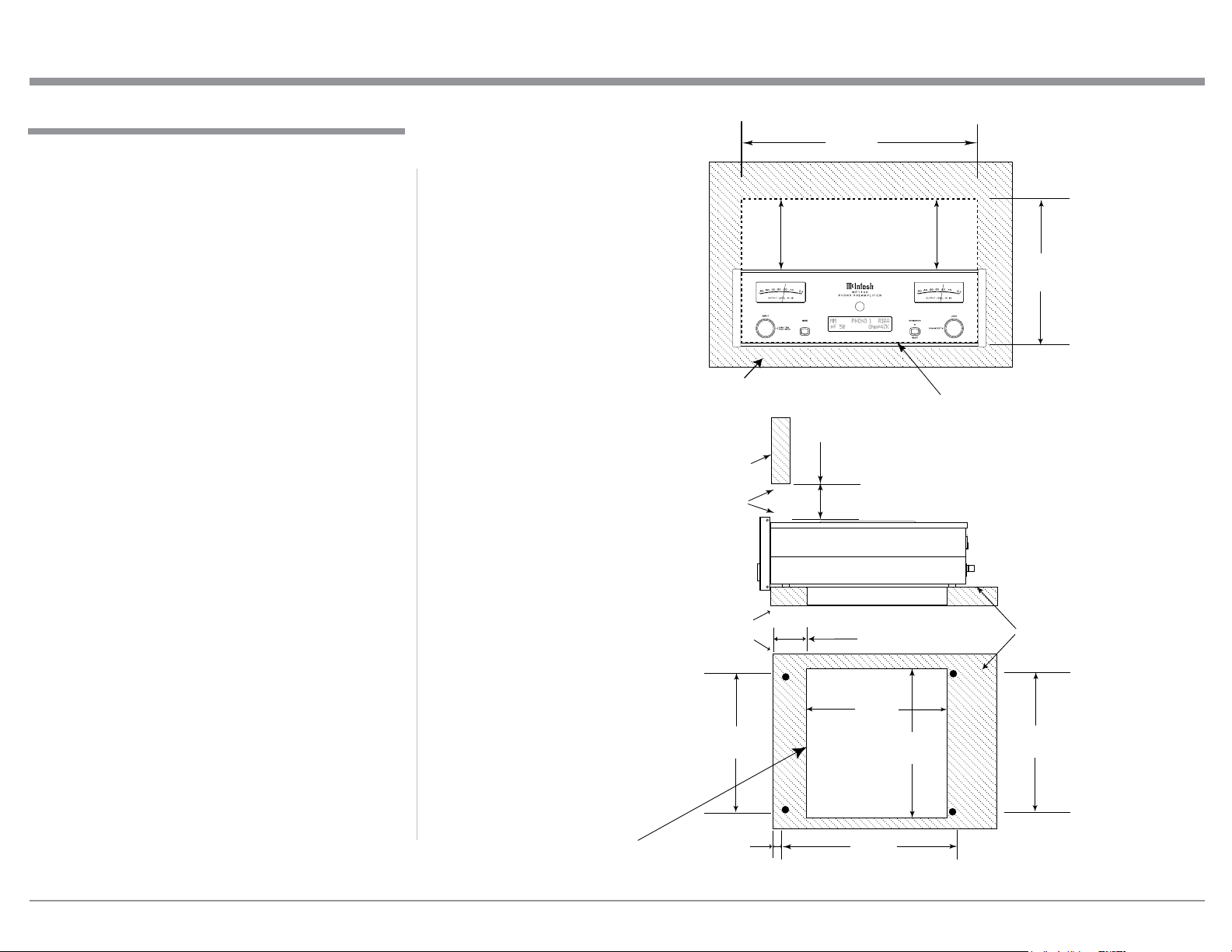

Installation

Installation

The MP1100 can be placed upright on a table or

shelf, standing on its four feet. It also can be custom

installed in a piece of furniture or cabinet of your

choice. The four feet may be removed from the bottom

of the MP1100 when it is custom installed as outlined below. The four feet together with the mounting

screws should be retained for possible future use if the

MP1100 is removed from the custom installation and

used free standing. The required panel cutout, ventilation cutout and unit dimensions are shown.

Always provide adequate ventilation for your

MP1100. Cool operation ensures the longest possible

operating life for any electronic instrument. Do not

install the MP1100 directly above a heat generating

component such as a high powered amplifier. If all

the components are installed in a single cabinet, a

quiet running ventilation fan can be a definite asset in

maintaining all the system components at the coolest

possible operating temperature.

A custom cabinet installation should provide the

following minimum spacing dimensions for cool

operation.

Allow at least 6 inches (15.2cm) above the top, 2

inches (5.1cm) below the bottom and 1 inch (2.5cm)

on each side of the Preamplifier, so that airf low is not

obstructed. Allow 18-1/2 inches (47.0m) depth behind

the front panel. Allow 1-7/16 inch (3.7cm) in front of

the mounting panel for knob clearance. Be sure to cut

out a ventilation hole in the mounting shelf according

to the dimensions in the drawing.

MP1100 Front Panel

Custom Cabinet Cutout

MP1100 Side View

in Custom Cabinet

MP1100 Bottom View

in Custom Cabinet

Cabinet Front Panel

Cabinet

Front

Panel

Opening

for Ventilation

Support

Shelf

15-1/16"

38.3cm

17-3/16"

43.66cm

Opening for Ventilation

Cutout Opening for Custom Mounting

6"

15.2cm

Cutout Opening

for Ventilation

7/8"

2-

7.3cm

8-1/8"

23.2cm

Cutout

Opening

for

Ventilation

13-1/8"

33.3cm

10-3/4"

27.3cm

Chassis

Spacers

15-1/16"

39.6cm

Note: Center the cutout Horizontally

on the unit. For purposes of

clarity, the above illustration

is not drawn to scale.

1-1/8"

2.9cm

12-5/16"

31.3cm

7

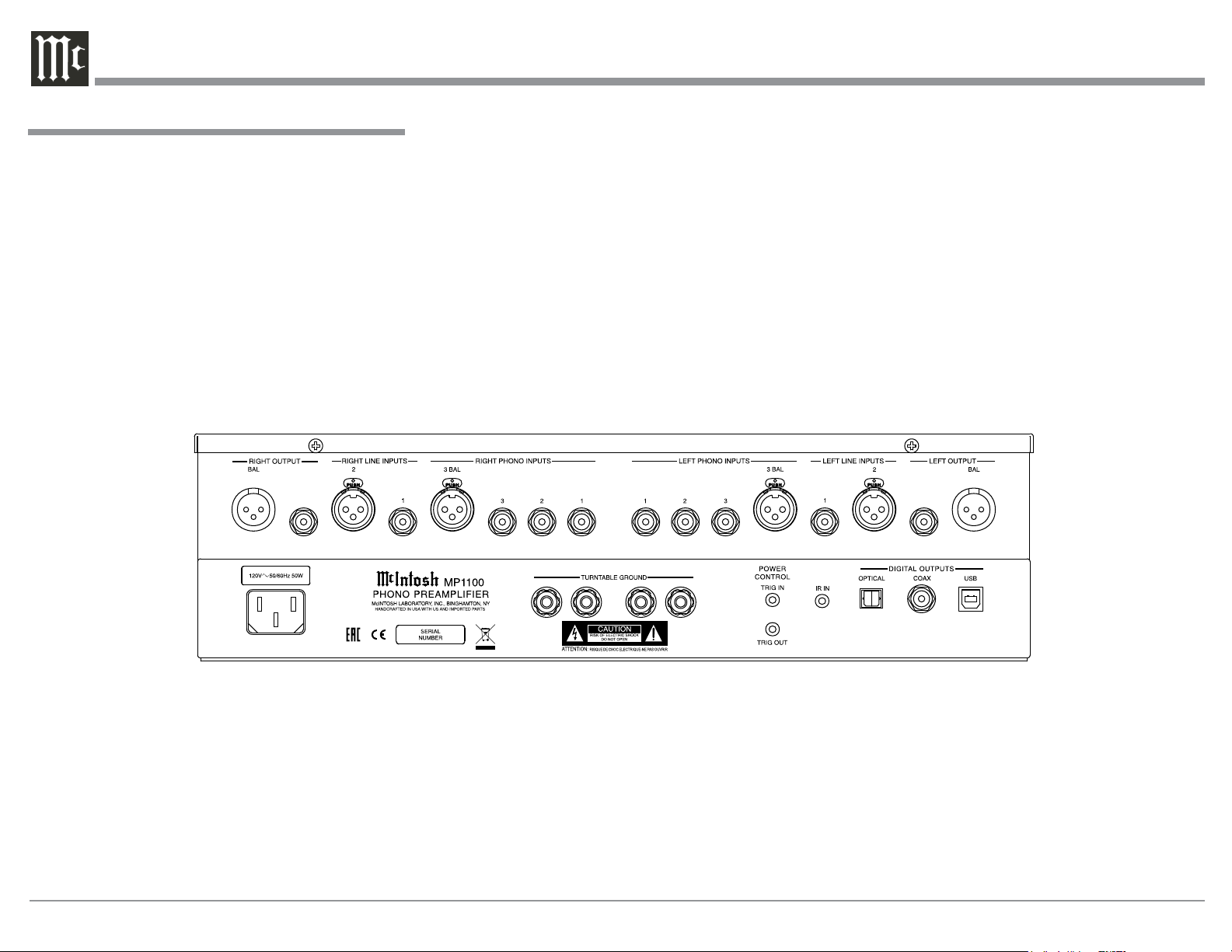

Rear Panel Connections

The identification of Rear Panel Connections for the

MP1100 Phono Preamplifier is located on a separate

folded sheet contained in the Owner’s Manual Packet.

Refer to separate sheet “Mc1B” for the Rear Panel

Connections.

Rear Panel Connections

MP1100 Phono Preamplifer Rear Panel

8

Connecting Components

The MP1100 has the ability to automatically switch

power On/Off from Components via the PWR CTRL

(Power Control) TRIGger connections. Follow the

connection instructions below, together with the

MP1100 Input/Output/Control Connection Diagram

located on a separate folded sheet “Mc1A” contained

in the Owner’s Manual Packet. The connections are

an example of a typical audio system. Your system

may vary from this, however the actual components

would be connected in a similar manner. For additional information refer to “Connector and Cable Information” on page 3.

Power Control (Trigger) Connections:

1. Connect a Control Cable from the MP1100 Power

Control TRIGger Out Jack to the Power Control In

on the Turntable 1.

2. Optionally, connect a Control Cable from the

Turntable 1 Power Control Out Jack to the Power

Control In on the Turntable 2.

3. Optionally, connect a Control Cable from the

Main Audio Preamplifier Power Control Out to

the MP1100 Power Control TRIGger IN.

Note: This optional Power Control Connection will

allow the MP1100 to automatically switch ON

and OFF when the Main Audio Preamplifier is

On or Off.

4. Connect any additional Components in a similar

manner, as outlined in steps 1 and 2.

Audio Connections:

5. Connect Audio Cables from the MP1100 PHONO

1 INPUT Jacks (Left and Right) to Turntable 1

(Left and Right) Output Jacks.

Note: If Turntable 1 has Balanced XLR Output Con-

nectors and has a Phono Cartridge installed

(with Balanced Output Connections), connect

XLR Audio Cables to the MP1100 PHONO 3

INPUT BALanced Connectors.

6. Optionally, connect Audio Cables from the

MP1100 PHONO 2 INPUT Jacks (Left and Right)

to Turntable 2 (Left and Right) Output Jacks.

Note: If Turntable 2 has Balanced XLR Output Con-

nectors and has a Phono Cartridge installed

(with Balanced Output Connections), connect

XLR Audio Cables to the MP1100 PHONO 3

INPUT BALanced Connectors.

7. Connect an additional Turntable in a similar manner, as outlined in steps 5 and 6.

8. Connect an Audio Cable from the MP1100 LINE

1 INPUT (Left and Right) Jacks to the Integrated

Amplifier REC Output Jacks.

Note: If the component has Balanced Output Con-

nections use the MP1100 LINE 2 BALanced

INPUT.

9. Connect any additional Components in a similar

manner, as outlined in step 8.

Optional USB Connection:

10. Connect a USB cable with (Type A to Type B)

connectors from the MP1100 USB DIGITAL

OUTPUT connector to an available USB connector on the computer.

Analog Output Connection:

11. Connect XLR audio cables from the MP1100

BALanced OUTPUT (Left and Right) to the Analog only Preamplifier Balanced Input 5 (Left and

Rig ht).

Note: If the Preamplifier has Unbalanced Inputs then

connect the MP1100 unbalanced Output Jacks

to the Preamplifier unbalanced Input Jacks.

Optional Digital Output Connection:

12. Connect a Digital Coaxial Cable from the MP1100

COAXial DIGITAL AUDIO OUTPUT Jack to

the Digital only Preamplifier Digital Audio Input

Coaxial 2 Jack.

Connecting Components

Note: If the Preamplifier has Optical Inputs then

connect the MP1100 Optical Output Connector

to the Preamplifier Optical Input Connector.

Ground Connections:

13. Connect the Ground Cable coming from the

Turntable(s) to the MP1100 TURNTABLE

GROUND Binding Post(s).

AC Power Cord Connections:

14. Connect the MP1100 to a live AC Outlet using the

supplied Power Supply Cord.

9

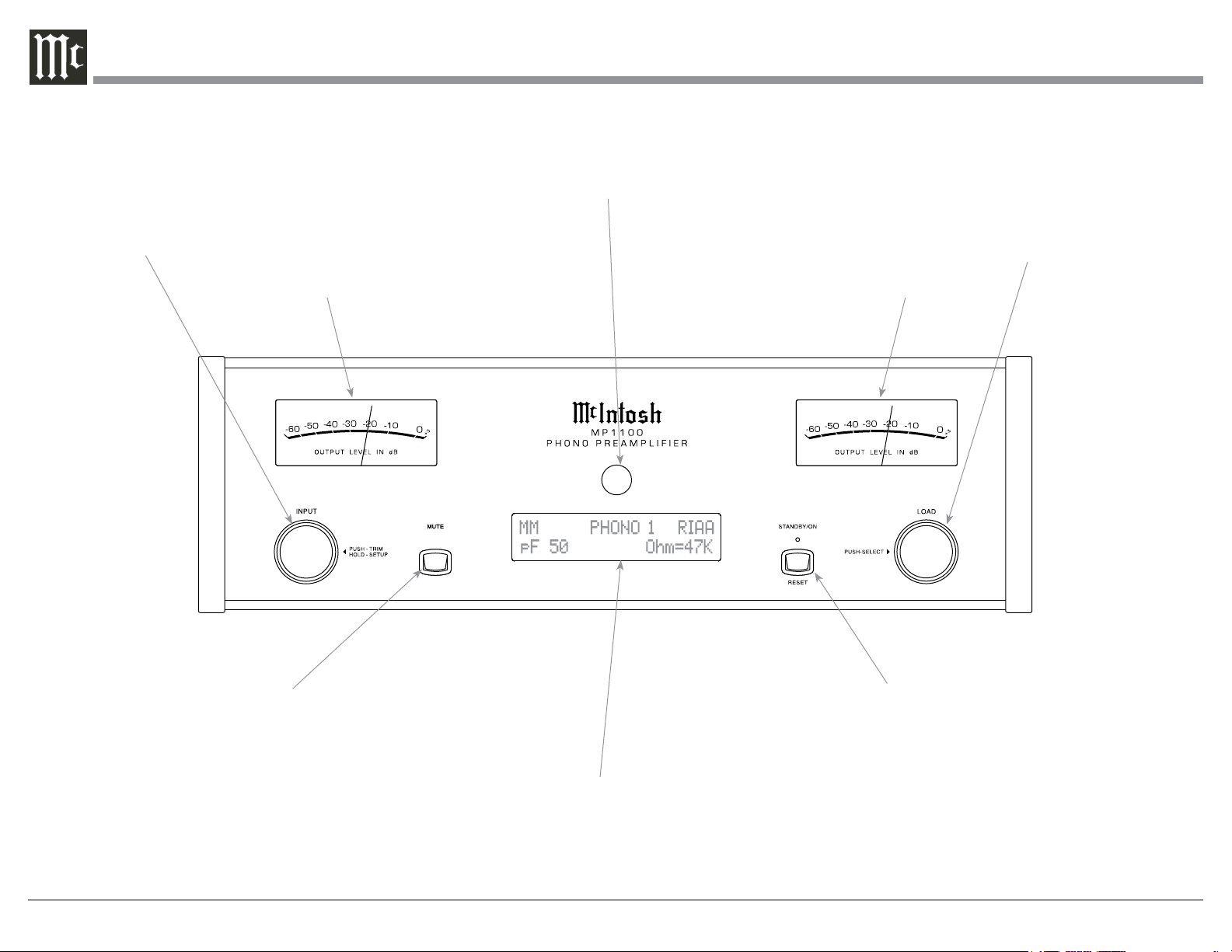

Front Panel Displays, Controls and Push-buttons

INPUT Control used to

select a source for listening

and recording. The control is

also used to enter the TRIM

or SETUP Modes and select

the various functions

Meter indicates the

Left Channel Output

of the Preamplifier

IR Sensor receives

commands from a

Remote Control

Meter indicates the

Right Channel Output

of the Preamplifier

LOAD Control used to

select the Resistance value

in Ohms and Capacitance

value in Picofarads that is

added to the Input Signal

Path for a flat Frequency

Response from the connected MM or MC Phono

Cartridge

10

MUTE Push-button mutes

the audio from the Loudspeakers and Headphones

STANDBY/ON Push-button

with indicator, switches the

MP1100 ON or OFF (Standby)

and resets the microprocessors

INFORMATION DISPLAY indicates the Sources, Resistive value in Ohms and Capacitance value in Picofarads,

other Audio Settings, Operational Functions and Setup

Mode Settings

Loading...

Loading...