Mcintosh MC 2500, MC 2255, MC 2250, MC 2155, MC 2120 catalog

...

The World Wide Leader

In State Of The Art

High Fidelity Technology

Engineered and Manufactured

in the United States of America

Mclntosh Laboratory Inc.

2 Chambers Street

Binghamton, New York, 13903-9990

Phone 607-723-3512

TABLE OF CONTENTS

Power Amplifiers:

MC 2500, MC 2255, MC 2250, MC 2155, MC 2120,

MC 502

PreAmplifiers:

C 33, C 29, C 27, C 504

Tuners:

MR 80, MR 78, MR 75 25-37

Tuner-Preamplifier:

MX 117 38-45

Receiver:

MAC4100 AM/FM Receiver 46-50

Preamplifier- Amplifier:

MA6200 51

Loudspeakers: 52-65

The Mclntosh Story 66-67

Equalizers:

MQ107, MQ 104 68

2-16

14-24

YOU SHOULD OWN

McIntosh

BECAUSE

• Mclntosh instruments are designed and manufactured for long life.

• Mclntosh instruments have always

been designed for long life with low

maintenance costs and high quality performance. Mclntosh instruments have been and are the

LABORATORY STANDARD

for the world.

• Until 1949 the performance requirements for a Mclntosh had

long been an engineering dream.

They became a reality with the introduction of the first Mclntosh

amplifier. Through all these years

Mclntosh has produced instru-

ments that have exceptionally long

life. Clinics held ail over North

America have shown that most of

the Mclntosh instruments ever

manufactured still meet or exceed

their original exacting specifications.

• Used McIntosh instruments have

the highest resale value. Retailers

report that customers are constantly searching for used Mclntosh in-

struments. A Mclntosh does not re-

main on the "Used" display long.

You'll get more when you trade-in

your Mclntosh assuring you of

maximum return on your invest-

ment,

• Mclntosh dedication, not only to

improvements, but also to fun-

damentals, has justified many

patents on basic circuit structures

as well as refinements.

• Doesn't it make good sense to deal

with a company that wants to do as

much for you as it possibly can?

FM Guide. . . 69-76

1

THE NEW

MCINTOSH AMPLIFIERS

Mclntosh leadership in research and bipolar

epitaxial transistor technology has produced

startling new advances in safe, cool,

superior performance and protection.

Mclntosh engineering continues to advance

power amplifier technology and protected performance. Experience and knowledge are the foundation on which the engineering superstructure is

built that supports the Mclntosh recognized reputation as Laboratory Standard for the world. A new

level of technology and a higher level of amplifier

performance is realized in the all new Mclntosh

Amplifiers.

LEADERSHIP

• Mclntosh life testing selects only components

that give the most trouble free performance. Added care in engineering, design and manufacturing

produces long product life at the peak of perfor-

mance.

LEADERSHIP

• Mclntosh POWER GUARD assures maximum amplifier power without clipping distortion.

LEADERSHIP

• Mclntosh engineers developed a unique output

circuit configuration that is temperature stable

and that delivers clean output power at any level

without a trace of crossover distortion.

LEADERSHIP

• Mclntosh Automatic System . Test provides

positive protection and extends the long trouble

free life of an amplifier. Each time an amplifier is

turned on, seven tests are completed that

measure and verify accurate performance.

LEADERSHIP

• Mclntosh Output Autotransformers deliver full

power output and multiple feedback loops assure

lowest distortion at all power levels and all

speaker impedances.

LEADERSHIP

• Mclntosh designed mute circuits give positive

protection from transients due to turn on, turn off

power supply voltage changes.

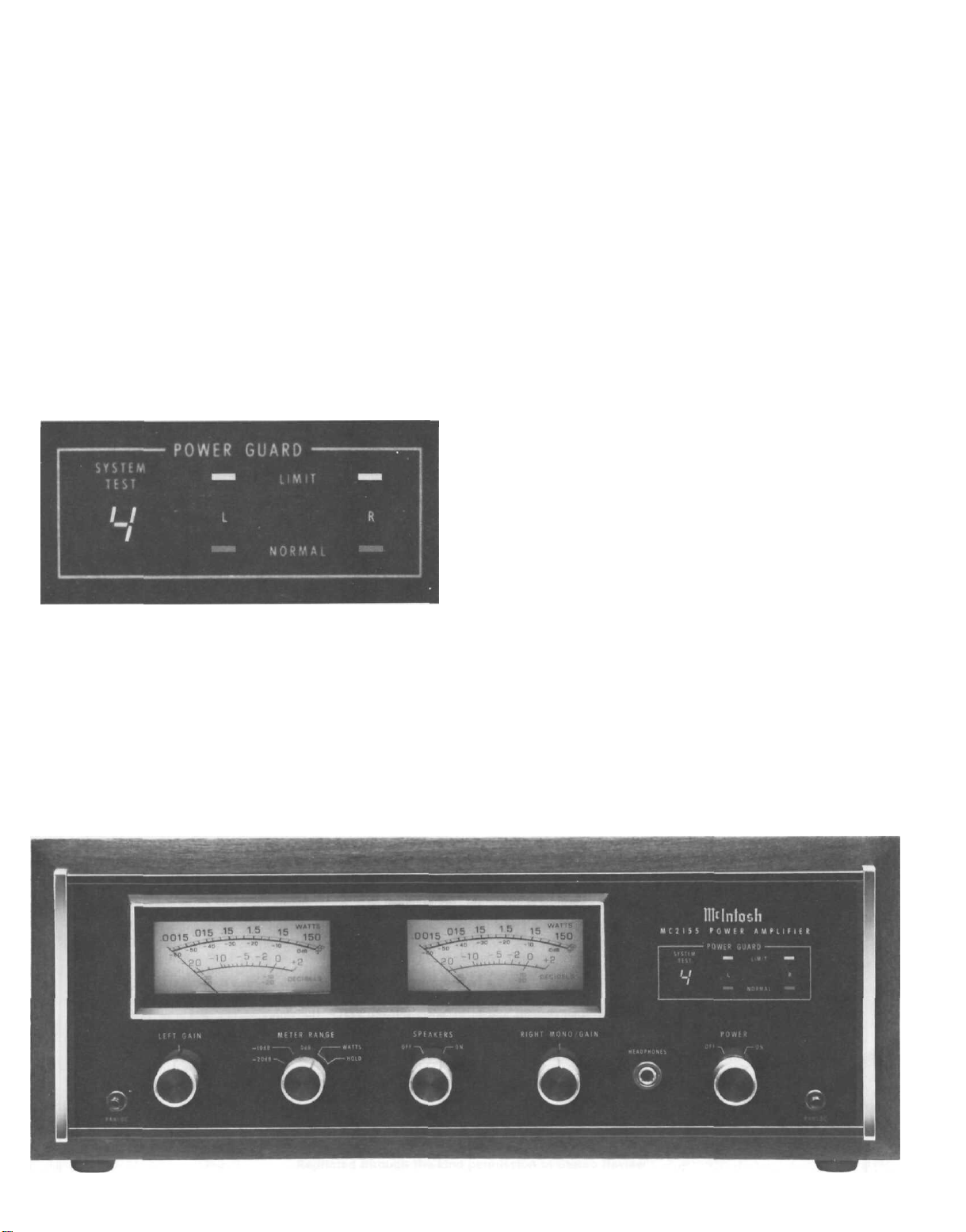

MC 2255 Shown in optional walnut veneer cabinet

2

YOU ARE PROTECTED FROM

LISTENING TO AMPLIFIER

PRODUCED DISTORTION

WITH MCINTOSH

POWER GUARD

Plus:

• Mclntosh Output Autotransformer delivers full

power output. Multiple feedback loops assure

lowest distortion at all power levels and all

speaker impedances

• Mclntosh engineers developed a unique output

stage circuit arrangement that is completely

temperature accurate, that delivers clean output

power at any level without crossover distortion

• Mclntosh life testing of components permits component selection for trouble-free performance; ad-

ded care in production engineering and manufacturing results in long product life

• Mclntosh designed "turn-on/mute" circuits pro-

vide positive protection from "turn-on transients"

and other potentially damaging noises

• Mclntosh POWER GUARD assures maximum

amplifier power without clipping distortion

Higher power demands on amplifiers have

presented music listeners with a form of unpleasntness in listening, amplifier overload (hard clipping)

that looks and acts like square waves. Clipping is

caused when the amplifier is asked to produce more

power output with low distortion than it can deliver.

Clipping of a complex wave form is largely composed of odd order harmonics and intermodulation products. High order odd harmonics and intermodula-

tion products are dissonant and are not musically

related to the signal being amplified. They are heard

as great and disappointing discordance and distor-

tion.

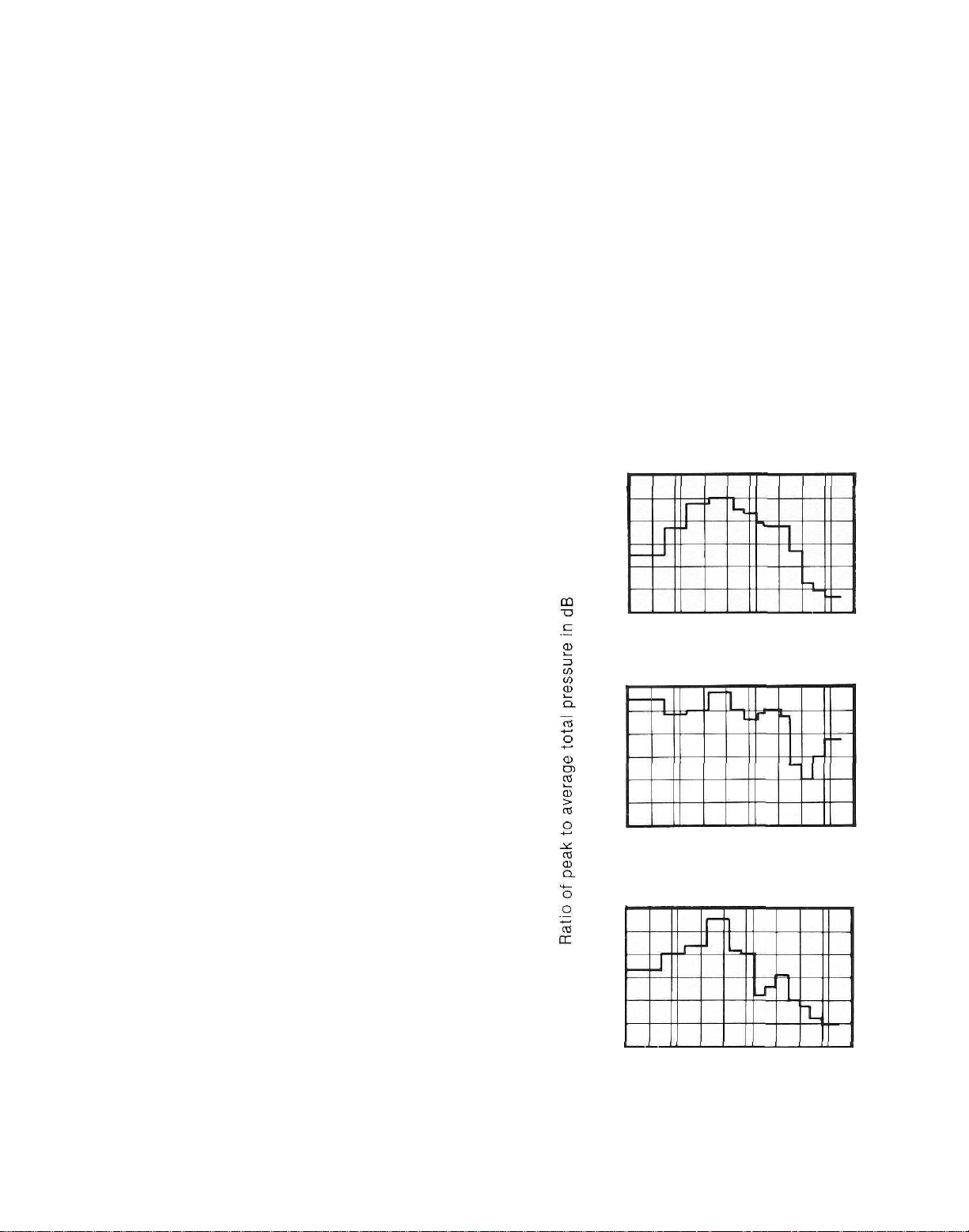

In most acoustical events we may listen to surprisingly low average power output but the peak

power requirements can be very high. Consider

these graphs of the power demanded of an amplifier

reproducing the piano, the pipe organ, and the bass

saxophone. The charts show that the peak power demand is almost 1000 times (30 dB) the average power

demand. Since it is necessary that these short inter-

val power spikes be reproduced with low distortion,

it means the average power output of the power

amplifier must be limited to 1/1000th of its capability

or the listener must accept the discordant distortion

of clipping.

Amplifiers when driven to clipping are capable of

delivering up to twice the heat load to the

loudspeaker. In addition, they can have more than

40% harmonic distortion. The extra heat energy content of the clipped signal will damage most

speakers. Mclntosh leadership in engineering has

developed a new circuit that...(1) dynamically

prevents power amplifiers from being overdriven in-

30

0

-30

20 100 1K 10K

30

0

-30

20 100 1K 10K

30

0

-30

20 100 1K 10K

to hard clipping. ..(2) which reduces the heat

developed in the loudspeakers. ..(3) assures that the

amplifier will produce its maximum output without

increased distortion. That circuit we call "POWER

GUARD."

PIANO

HERTZ

PIPE ORGAN

HERTZ

BASS SAXOPHONE

HERTZ

3

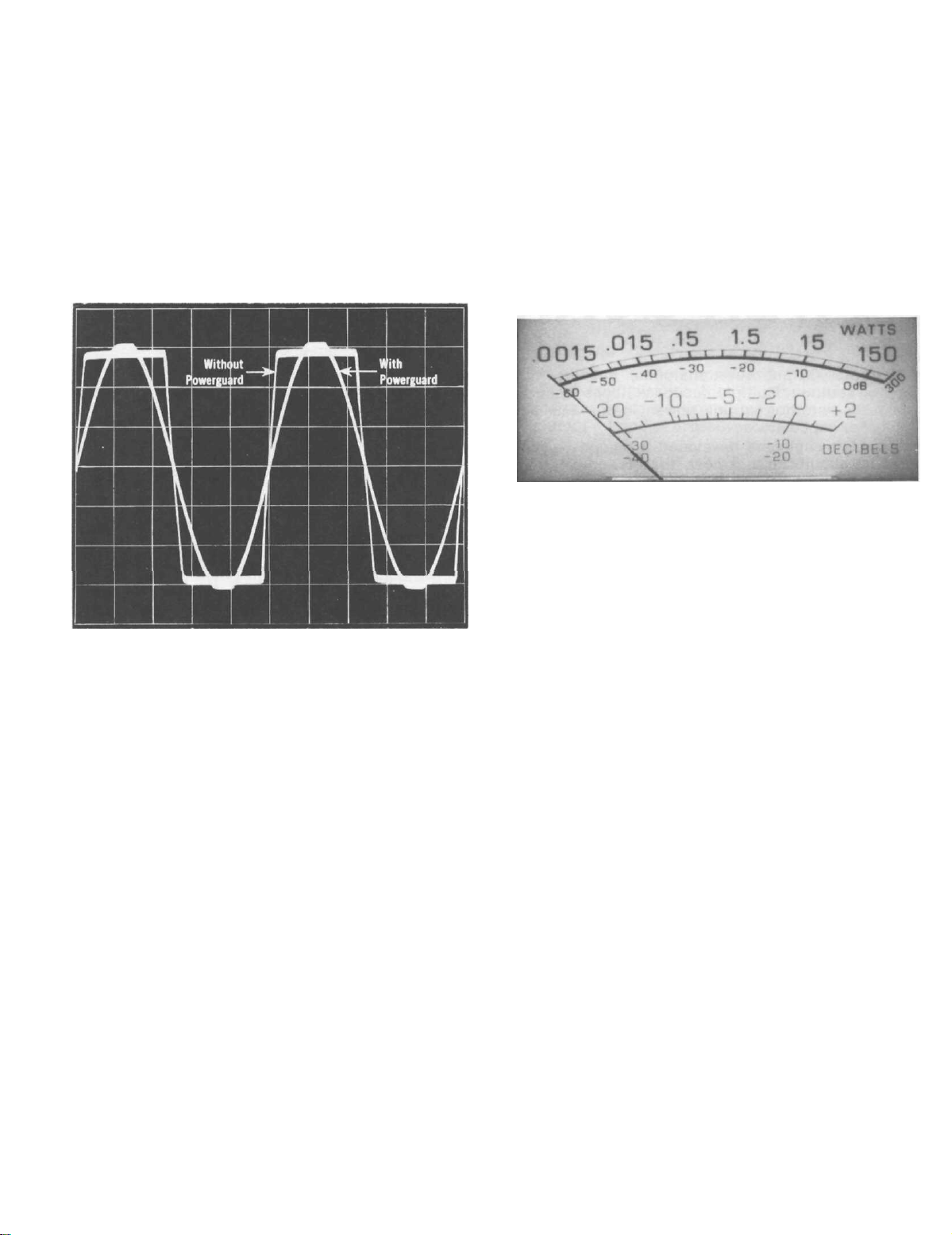

THE MCINTOSH POWER GUARD

The Power Guard waveform comparison circuit

detects minute amounts of waveform difference between the output signal and the input signal. A

sampling of the program material at the output of

the amplifier is constantly compared with the program material at the amplifier input. Should the differences reach 1%, Power Guard goes to work.

THE MCINTOSH POWER METERS

Mclntosh developed output monitoring meters

add to your operating flexibility. Ordinary meters are

incapable of indicating the short interval informa-

tion in a sound wave. The mass of the meter move-

ment is too great to respond to the instantaneous

changes in music program material. That short interval information can have a duration as brief as one-

half of one thousandth of a second. Even should the

meter be capable of the high velocity movement the

human eye could not perceive the information.

Oscillogram of output waveform with and without Power Guard.

Input overdriven for each trace 20 dB.

In only a fraction of a millisecond Power Guard

dynamically reduces input level to prevent amplifier

overload yet permits the amplifier to deliver its absolute maximum power output without extra distortion. In addition, the output of the "waveform comparator" activates the front panel NORMAL and

LIMIT indicators.

The Power Guard circuit provides a precise visual

indication when the amplifier has reached full power

output. Any time that the input circuit is fed excessive amounts of signal causing waveform differences through the amplifier of 0.5%, the output

mode indicators change from green NORMAL to red

LIMIT automatically and instantaneously. This warning persists long enough for positive visual indication of clipping for a pulse that is so infrequent or

short that it would be impossible to be seen even on

an oscilloscope. The indicators will illuminate on

clipping for a pulse as short in time as 100 microseconds. You are always assured that the power of your

amplifier is as clean and distortion free as it can be.

4

Mclntosh engineering pursued both problems

electrically by developing new electronic circuits

that cause the meters to respond to short interval information with an accuracy of 98%! To permit the

eye to see such high speed motion the electronic circuits that drive the meter pointer are time stretched

so the meter pointer position can register in the persistence of vision characteristics of the human eye.

The meters indicate directly in watts, or can be

made to hold the highest reading and continuously

update on higher power or can be switched to be

peak reading — peak locking decibel meters.

When used as a watt indicating meter all the information is direct reading, without conversions or

complicated mathematics. In addition, as direct

reading meters they are calibrated in average watts

for a sine wave signal but respond to signal peaks.

The meters indicate direct power in watts. They

are calibrated in average watts for a sine wave

signal but respond to signal peaks. So, a 200

average watt indication also means 400 instantaneous peak watts. The meters are voltage actuated and indicate power accurately when the

amplifier is operated into rated output load impedances.

Watts Hold, permits the meter to lock to and in-

dicate the highest power peak in a sequence of

peaks. The meter will be driven to maximum power

and electronically held there until a higher peak

passes through the amplifier. If no further peaks are

reached the meter needle will very slowly return to a

lower peak or to its rest position at a decay rate of 10

dB per minute.

The meters have extremely fast rise time, about

500 microseconds for 90% accuracy. A tone burst of

500 microseconds is almost inaudible even at full

power.

The meters are protected from damage in the

event of overloading in the wrong meter range.

AUTOMATIC TEST SYSTEM

The Automatic Test System provides positive protection and extends the long trouble free life of an

amplifier. Each time the amplifier is turned on an

Automatic Test System measures and verifies accurate performance at seven critical points in the

amplifier's circuits. The Automatic Test System

verification assures operational readiness before

operation starts and limits any damage should there

be component malfunction. Each time a test is

verified an LED number indicator shows which test

is being performed. An adjustable "beep" tone can

be heard with each test.

THE MCINTOSH OUTPUT CIRCUIT DESIGN

To achieve long trouble free life in an amplifier it

is essential to have cool operation. Cool operation

results from the careful design of the output circuit,

matching of the output circuit to the loudspeakers

with an autotransformer and a mechanical design

that permits the use of generous sized heat sinks

providing adequate ventilation without the use of

fans.

The bipolar eptaxial output transistors and the

Mclntosh output circuit allows the amplifier to

operate as cool as possible. When there is limited

program demand on the amplifier only the optimum

number of output devices operate. When there is no

signal no output device is conducting. Conservative

Mclntosh engineering keeps operating temperatures

low assuring long life.

The interleaved multifilar wound Mclntosh design-

ed autotransformer transfers all the power you paid

for to all impedance taps. You are not power penalized for operating at an output impedance of less than

8 ohms. The Mclntosh autotransformer does its outstanding job without adding phase shift, limiting frequency response or power output. The distortion

through the autoformer is 0.003% at 20 Hz and

unmeasurable at higher frequencies. In short, the

Mclntosh autotransformer is the ideal answer to a

difficult problem.

If in the testing an unacceptable voltage is encountered, the LED numeric designation locks to

isolate the faulty circuit. Faulty circuit identification

permits the service technician more efficient repair.

Without the Mclntosh Automatic Test System attempts to locate a fault by the probing and testing

needed, will often create additional problems by put-

ting undue mechanical and electrical stress on the

circuit components. The Automatic Test System protects your investment.

Heat sinks must be large and they must have adequate ventilation for effective cooling. For example

the MC 2255 has 1100 square inches (7.64 square

feet) of radiating surface. In addition, the chassis

has been designed to permit the maximum amount

of air to flow over the heat sinks to conduct away the

life limiting heat.

Mclntosh amplifiers provide the correct connection impedance to drive numbers of speakers simultaneously. For instance the 1 ohm output will drive

eight 8 ohm speakers and deliver full power without

overheating.

MC 2155 shown in optional walnut veneer cabinet.

5

test reports

"Reprinted with permission from the June 1982 issue of STEREO REVIEW magazine.

Copyright © 1982 Ziff-Davis Publishing Company. All rights reserved."

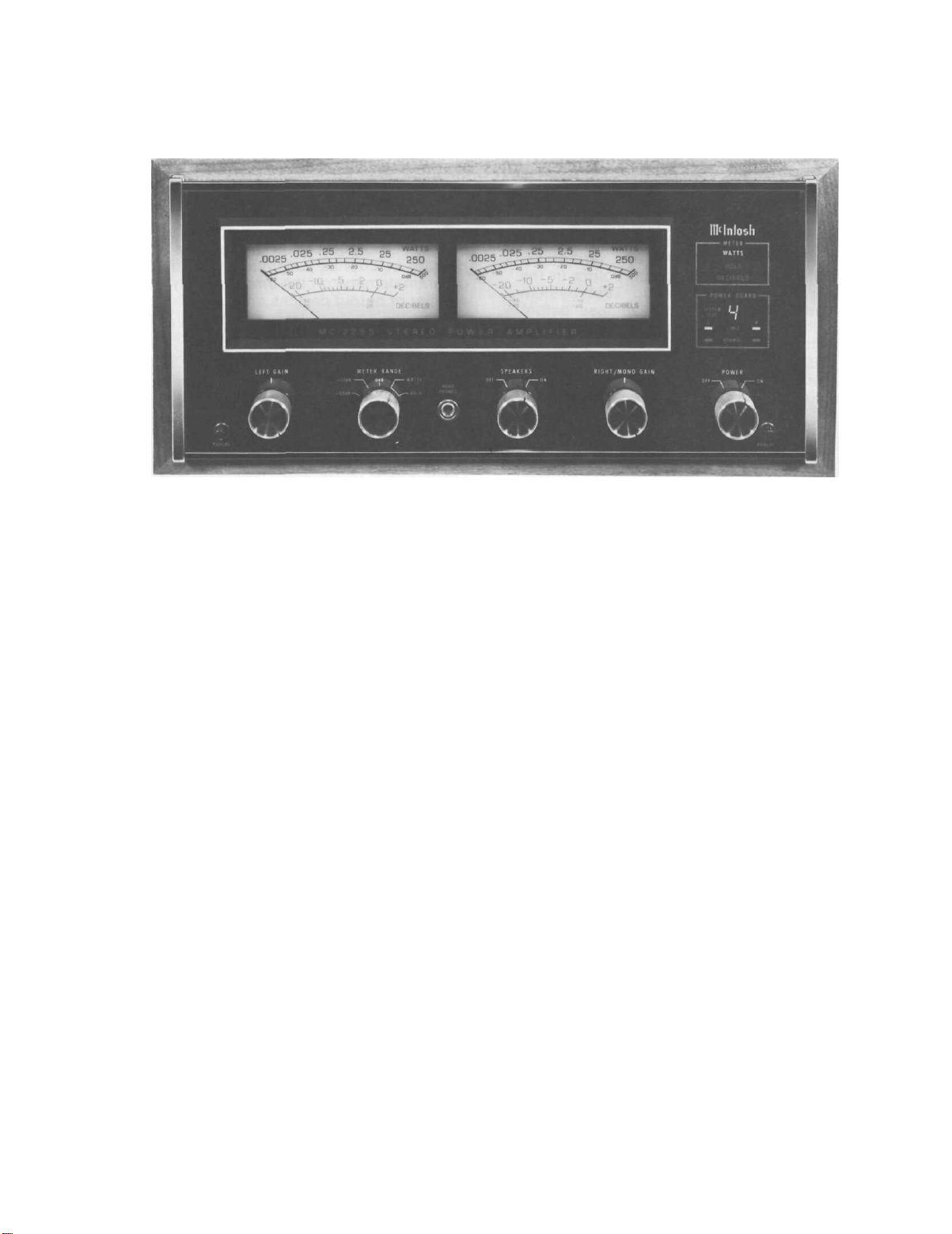

Mclntosh MC 2255 Power Amplifier

• Mclntosh MC 2255 Power Amplifier

• Power Rating: 250 watts per channel

• Size: 16¼ x 14¾ x 7¼ inches

• Weight: 82 pounds

• Price: $2,750

HE Mclntosh MC 2255 basic power am-

T

plifier is rated to deliver its output into

loads of 1, 2, 4, or 8 ohms, from 20 to

20,000 Hz, with no more than 0.02 per cent

harmonic or intermodulation distortion. Its

stereo outputs may be paralleled or bridged

to drive a mono load with a maximum output of 500 watts at 0.02 per cent distortion.

Depending on the connection used, the

mono load impedance can be from 0.5 to 16

ohms.

The unusual load capabilities of the MC

2255 derive from the use of large autotransformers to match the output transistors to

their loads. Like vacuum-tube amplifiers,

the MC 2255 has output terminals designated for 1, 2, 4, or 8 ohms. Thus, regard-

less of the speaker impedance, the output

transistors are optimally loaded and can deliver

their

full

power

without

and

excessive

driver

tortion or overheating.

The output stages of the MC 2255 operate in class-B, but a unique biasing system

completely eliminates the crossover distortion usually associated with class-B operation. This being the most efficient mode of

linear amplifier operation, the total power

consumption of the MC 2255 from the 120volt a.c. line is only 0.7 ampere at idle (or

normal playing volume) and 12 amperes at

full

output.

form a complete class-AB low-power amplifier which drives the front-panel headphone

The

input

dis-

stages

jack as well as the power stages. Switches

connect the input sections for mono operation.

In the

right-channel input drives both output sections

mode the other input section is used as a

phase inverter so that the outputs can be

driven 180 degrees out of phase.

The power stages are protected by a novel

Power Guard circuit that makes it impossible to clip the amplifier output by overdriving it. A waveform comparator monitors the

input and output signals of the amplifier,

and if the output waveform differs from the

input by an amount corresponding to about

0.5 per cent harmonic distortion, a red LIMIT light glows on the panel (there are separate lights for the two channels). Any further increase in the drive level causes the

signal to be attenuated ahead of the output

section. This prevents the output from ever

exceeding its linear operating range (according to McIntosh, the amplifier can be

overdriven by 20 dB before distortion

reaches 2 per cent).

Internally, the McIntosh MC 2255 is a

very complex amplifier, containing some

eighty-five transistors, forty-seven diodes,

and fourteen integrated circuits. Many of

its components are involved in the protective systems and in its novel self-test feature. Each time the amplifier is turned on,

an automatic seven-step test sequence

checks the key operating voltages for cor-

rectness. As each step is executed, the corresponding numeral lights up on a frontpanel display and a green light signals that

it has been passed. If any stage of the test is

not satisfactory, its number remains lit to

in

phase,

MONO/PARALLEL

and for the

MONO

mode

BRIDGE

the

indicate the problem area. Two different

test speeds can be selected, and one can

choose to have a "beep" sound after each

step or to have the tests proceed in silence.

Two large meters are calibrated logarithmically from less than 2.5 milliwatts to 500

watts output (because of the output transformers, these readings are equally applica-

ble to any of the load impedances for which

the amplifier is designed). Another scale

reads in decibels from -20 to + 2 (the latter corresponding to about 250 watts output). Knobs below the meters control LEFT

GAIN, RIGHT/MONO GAIN, METER RANGE

(-20 dB, -10 dB, 0 dB, WATTS, HOLD),

the SPEAKERS outputs, and POWER. The

HOLD position of the METER RANGE switch

causes the meters to retain their highest

readings. The meter-driving circuits allow

them to respond to very short program

peaks, although they are calibrated in aver-

age watts.

At the right side of the panel are the two

indicator groups.

shows the number of the SYSTEM TEST sequence step as it is executed, and pairs of

red and green LEDs show either that the

LIMIT

(of

or that the amplifier operation is NORMAL.

Above this group, a meter group illuminates

the words WATTS, HOLD, or DECIBELS, according

to the

switch.

On the rear of the chassis are two sets of

barrier terminal strips for the speaker outputs, a single unswitched a.c. outlet, and the

holder for the 15-ampere line fuse. A threeposition MODE switch selects STEREO, MONO

BRIDGE,

or

The

POWER GUARD

output power)

setting

of the

MONO PARALLEL

has

been exceeded

METER RANGE

operation. Next

display

6

STEREO REVIEW

test reports

to the two input phono jacks is a switch that

sets the input sensitivity to either 0.75 or 2.5

volts for full output depending upon the associated equipment. (The latter is the normally preferred setting for most setups.)

The MC 2255 is a handsome and rugged

amplifier, following a long-standing McIntosh tradition in its styling and construction. The pane! and most of the top metalwork are finished in black, with front accents of silver and softly lit blue-green meters. The chassis is chrome-plated. Also furnished with the amplifier are side brackets

and hardware for the McIntosh Panloc system for custom installations.

Mclntosh MC 2255

Power Amplifier

• Comment. Mclntosh (one of the oldest names in hi-fi, and perhaps the only

firm from its time to remain under the

original ownership) has earned an impressive reputation for their continued

support of their products, their exceptionally conservative design and specifications, and generally outstanding quality The MC 2255, the first McIntosh

product we have reviewed in many

years, is a perfect example of the continuation of those policies.

In its circuitry and operating features,

the MC 2255 is quite unlike any other

basic power amplifier we have seen. By

using autotransformers to match the

load impedance to the transistor requirements, McIntosh has made an amplifier

capable of delivering its full potential

performance into almost any load impedance it might encounter. That performance, as our tests have shown, is absolutely first-rate. It is difficult to imagine any home installation needing more

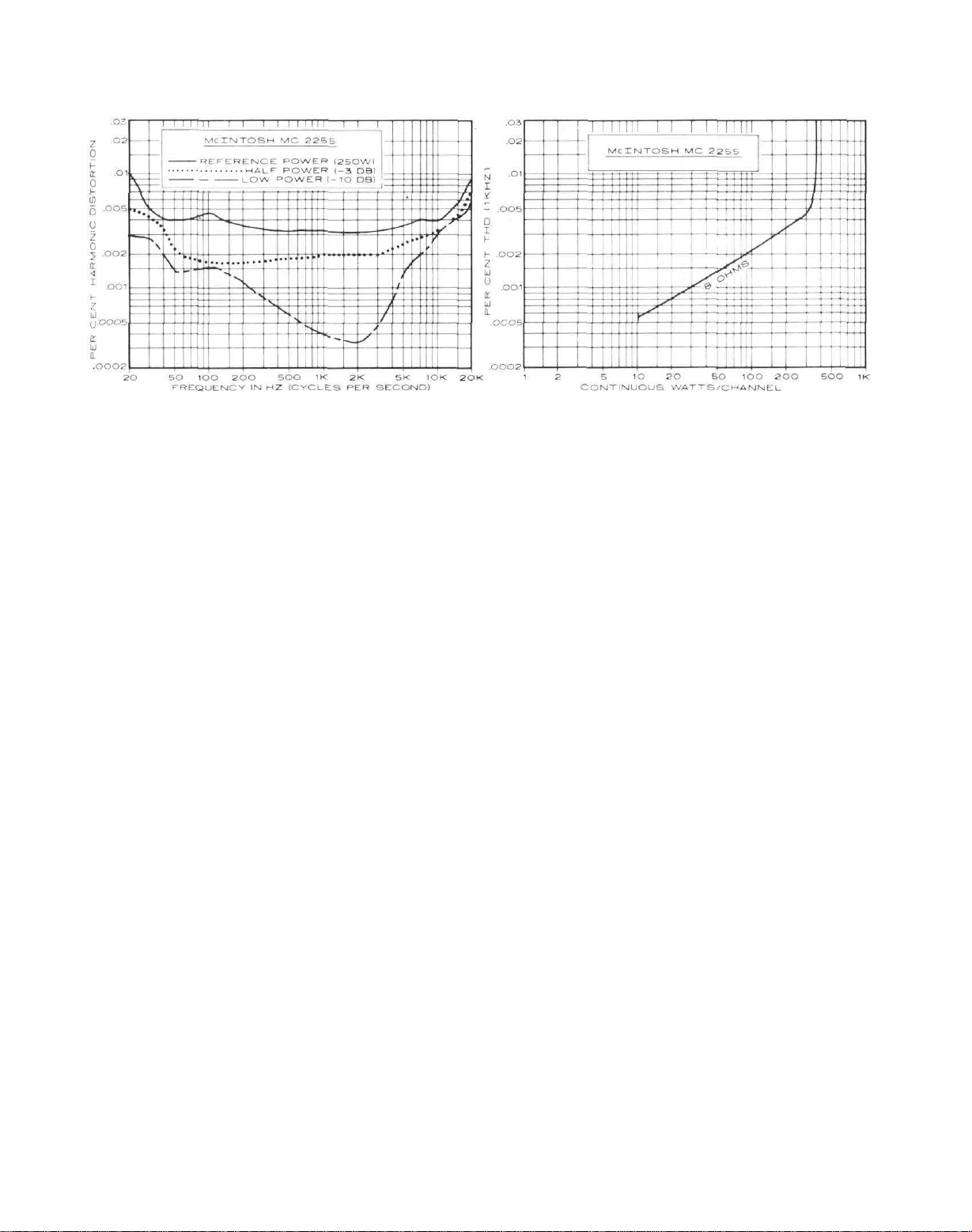

• Laboratory Measurements. Preconditioning the MC 2255 at one-third rated

power made the heat sinks very hot, but the

rest of the amplifier remained comfortably

cool throughout our tests. In normal opera-

tion the MC 2255 is no more than faintly

warm and has no need of a cooling fan or

any unusual ventilation precautions

With both channels driving 8-ohm loads

at 1,000 Hz the distortion was undetectable

(well below the noise level) until we reached

10 watts output, when it measured 0.00056

per cent. It increased very gradually with

higher power to 0.0032 per cent at 250

watts and 0.0045 per cent at 300 watts. The

power than the MC 2255 delivers with

such apparent ease. Its noise, distortion,

stability, and any other quality one

might name are quite literally "state of

the

art."

The Power Guard system is most ef-

fective in making it impossible to hardclip the output of the amplifier. Regard-

less of how hard it is driven, it simply

cannot develop an audible amount of

distortion on musical program material

(2 per cent is well below the probable

threshold of audibility of distortion in a

music system being driven to 350-plus

watts). This feature should also mean a

greatly reduced likelihood of blowing

out a speaker, since clipping is a com-

mon cause of tweeter damage. For the

nontechnical user, the self-test feature is

mostly a "security blanket," although

we can appreciate that it would also simplify troubleshooting and servicing.

LEARLY, no effort has been spared in

c

the design and construction of this am-

plifier. This sort of perfectionism carries

a considerable price, both in dollars and

pounds (avoirdupois, not sterling!). Considering the probable long life of the MC

2255, that price does not seem at all

unreasonable

-Julian

D.

Hirscti

maximum power (corresponding to "clip-

ping power," except that the waveform

could not be made to clip) was about 357

watts, with distortion reading 0.24 per cent

at the limiting point. The output into 4

ohms (using the appropriate output terminals) was also 357 watts, and we were able

to develop 420 watts per channel into 2-ohm

loads.

At the rated 250 watts output into 8

ohms, the maximum distortion was 0.01 per

cent at 20 Hz. Over most of the audio range

it was about 0.004 per cent, rising to 0.009

per cent at 20,000 Hz. At lower power outputs the distortion was substantially lower.

The amplifier sensitivity (using the 2.5-volt

switch setting) was 0.15 volt for a 1-watt

reference output, and the A-weighted noise

and hum level was 86 dB below 1 watt. The

frequency response of the amplifier was

within +0. - 0 1 dB from 20 to 20,000 Hz

and was down 0.9 dB at 5 Hz and 3 dB at

150

kHz.

The amplifier rise time was about 3 mi-

croseconds, and its IHF slew factor was

about 10 The IHF intermodulation distortion, measured with 18- and 19-kHz signals, was — 94 dB for the second-order component at 1,000 Hz and -67 dB for each of

the third-order products at 17 and 20 kHz,

all being referred to a 250-watt level.

The clipping headroom of the amplifier

was 1.55 dB for 4- and 8-ohrn loads and

2.55 dB for 2-ohm loads. The dynamic power output was 455 to 466 watts, depending

on the load impedance, giving dynamicheadroom ratings of 2.65, 2.7, and 2.5 dB

for loads of 8, 4, and 2 ohms, respectively.

The meters read quite accurately (about

0.2 dB high at full power) and responded to

very brief transient signals. They are driven

from the class-AB input amplifier instead

of from the output stages as in most amplifiers, so the meter readings are unaffected

by switching off the speakers. We found the

headphone volume to be only marginally

useful with 600-ohm phones. It was adequate with conventional-impedance phones.

Reprinted through the kind permission of Stereo Review

STEREO REVIEW

7

Output Transformers

in Transistor

Power Amplifiers

by Sidney Corderman*

Output transformers can make transistor power amplifiers more reliable,

more flexible, and more powerful. At

the same time output transformers

offer the best continuous protection

to loudspeakers against the hazards of

avalanche failure of output transistor

devices.

Time has shown that output transformers make transistor amplifiers

operate cool and safe. The output

transformerless amplifier (OTL)

becomes less exciting when amplifiers

must give long, consistent and predictable operation.

Let's take a look at transformers in

general at their past and present

use in amplifiers - - - and at why

Mclntosh Laboratory continues to be

the leader in the amplifier field with

the use of transformers.

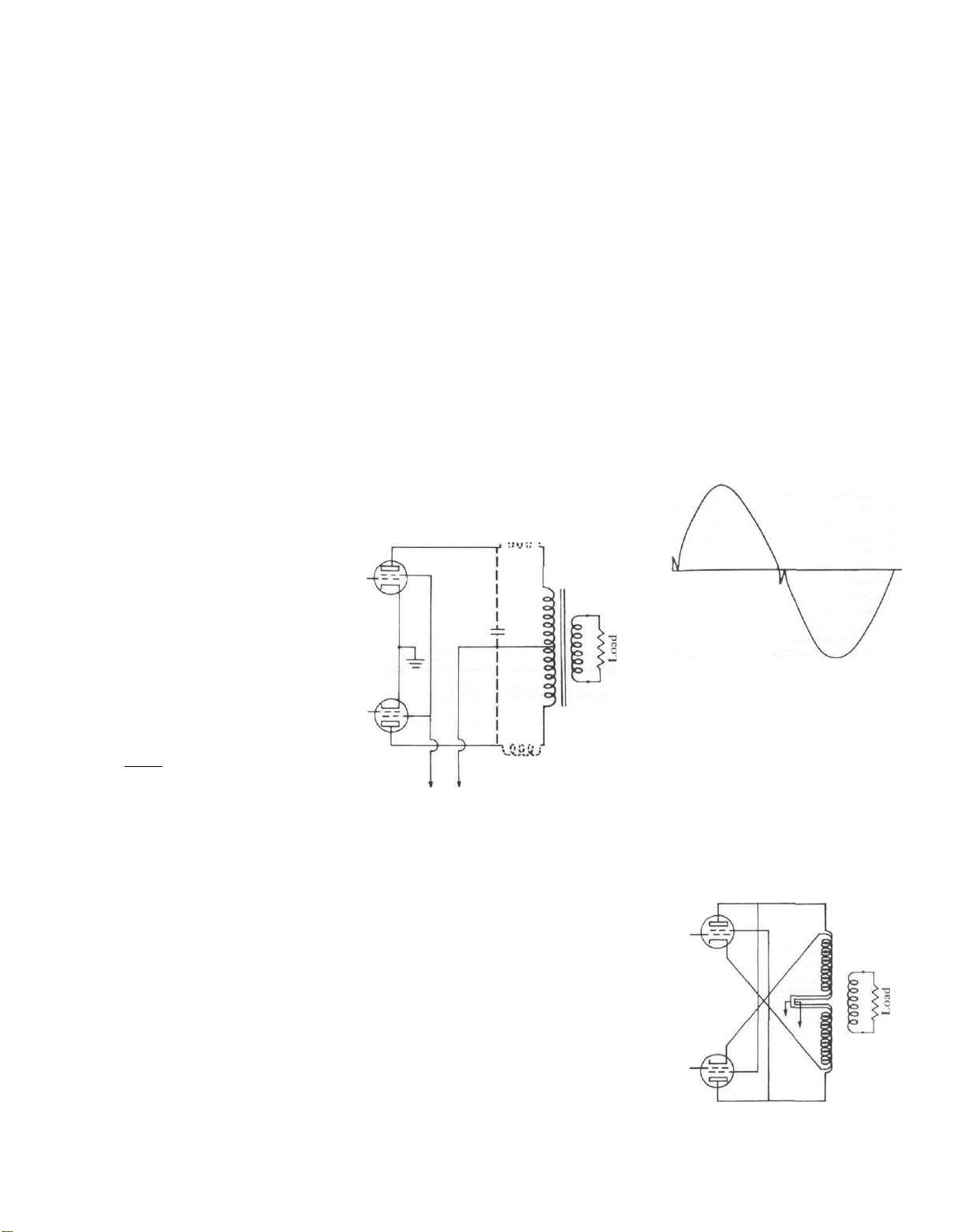

Remember Vacuum Tube Amplifiers?

Until the early 1960's, McIntosh

and just about everyone else in the

high fidelity component manufacturing business produced vacuum tube

power amplifiers exclusively. The

familiar push-pull circuit of Fig. 1

reigned supreme. In that circuit we

had a pair of tetrode or pentrode tubes

with their high output impedance try-

ing to deliver power to low impedance

loudspeaker systems. A transformer

was needed to provide the necessary

impedance match between them. But

there were problems in trying to

achieve an optimum transfer of power

between tubes and speakers. Typically,

using a pair of 6L6 output tubes in

push pull, we had a tube load imped-

ance of 4000 ohms trying to deliver

Fig. 1 — Typical push — pull output circuit

(see story tor dashed line information)

power to, say, an 8 ohm speaker load.

The impedance ratio was 500 to 1,

and the necessary transformer had to

have a turns ratio of around 23 to 1

(turns ratio varies as the square root of

the impedance ratio). The required

turns ratio created problems at both

ends of the audio frequency spectrum.

Leakage inductance and shunt capacitance (represented as dashed lines in

Fig. 1) caused high frequency roll-off.

The primary inductance of the transformer together with its inherent nonlinear characteristics placed limits on

low-frequency response. And the

energy stored in the unwanted leakage

inductance caused notch distortion, as

illustrated in Fig. 2.

Fig. 2 - Notch distortion in a typical Class B

The McIntosh Unity Coupled Circuit

Long before the advent of transistorized power amplifiers, McIntosh

found an effective way to solve these

problems. We called it the Unity Coupled Circuit. The basic configuration

is illustrated in the diagram of Fig. 3.

Fig. 3 — McIntosh "notch free" low

distortion Unity Coupled Circuit

output circuit

*

Vice President of Research and Development, McIntosh Laboratory Inc.

8

The impedance ratio required between

primary and secondary has been reduced by a factor of four-to-one compared with the conventional arrangement. It is now 125 to 1 (1000/8).

The turns ratio is therefore only half

of what it was before. Leakage inductance is therefore much lower, and so

is the shunt capacitance across the

windings. The use of a bifilar winding

technique completely eliminates the

leakage inductance problem of cou-

pling between the sections of the primary windings. It was the development of the Unity Coupled Circuit

by McIntosh (the circuit is patented)

way back in 1947 that enabled us to

produce amplifiers which were a whole

order of magnitude lower in distor-

tion than the competition of those

days. Typically, we were able to produce power output circuits with total

harmonic distortion of under 1.0%

even before the distortion-reducing

negative feedback loop was added.

With just 20 dB of feedback applied,

the THD was further reduced to under

0.1%!

What About Transistor Amplifiers

The audio industry welcomed the

power output transistor as the solution

to all its problems. After a few falter-

ing starts (early germanium power

output transistors were notoriously

unreliable and easily destroyed by high

operating temperatures), silicon power

transistors became the standard power

device in power amplifiers.

Since power output transistors exhibit a low output impedance, it was

possible to design output circuits to

match 8-ohm loads directly—without

the need for a matching audio output

transformer. Indeed, most OTL amplifiers, when coupled to 8-ohm resistive

loads for test purposes, can deliver full

rated power to those loads for long

periods of time without overheating or

exceeding safe thermal dissipation

limits. The trouble is that we don't

listen to resistors we listen to loudspeakers. It will come as no surprise to

you to learn that speakers having a

"nominal" impedance of 8 ohms often

measure lower and higher impedance

values at different audio frequencies.

Then, too, consider the fact that many

popular speaker systems have nominal

impedances of 4 ohms, and the imped-

ance of 4 ohm speakers can easily dip

down to as low as 2 ohms at certain

frequencies. What happens to an OTL

amplifier with such low impedances

connected to it? In theory, if an out-

put stage is designed to match an 8

ohm impedance, its power "output

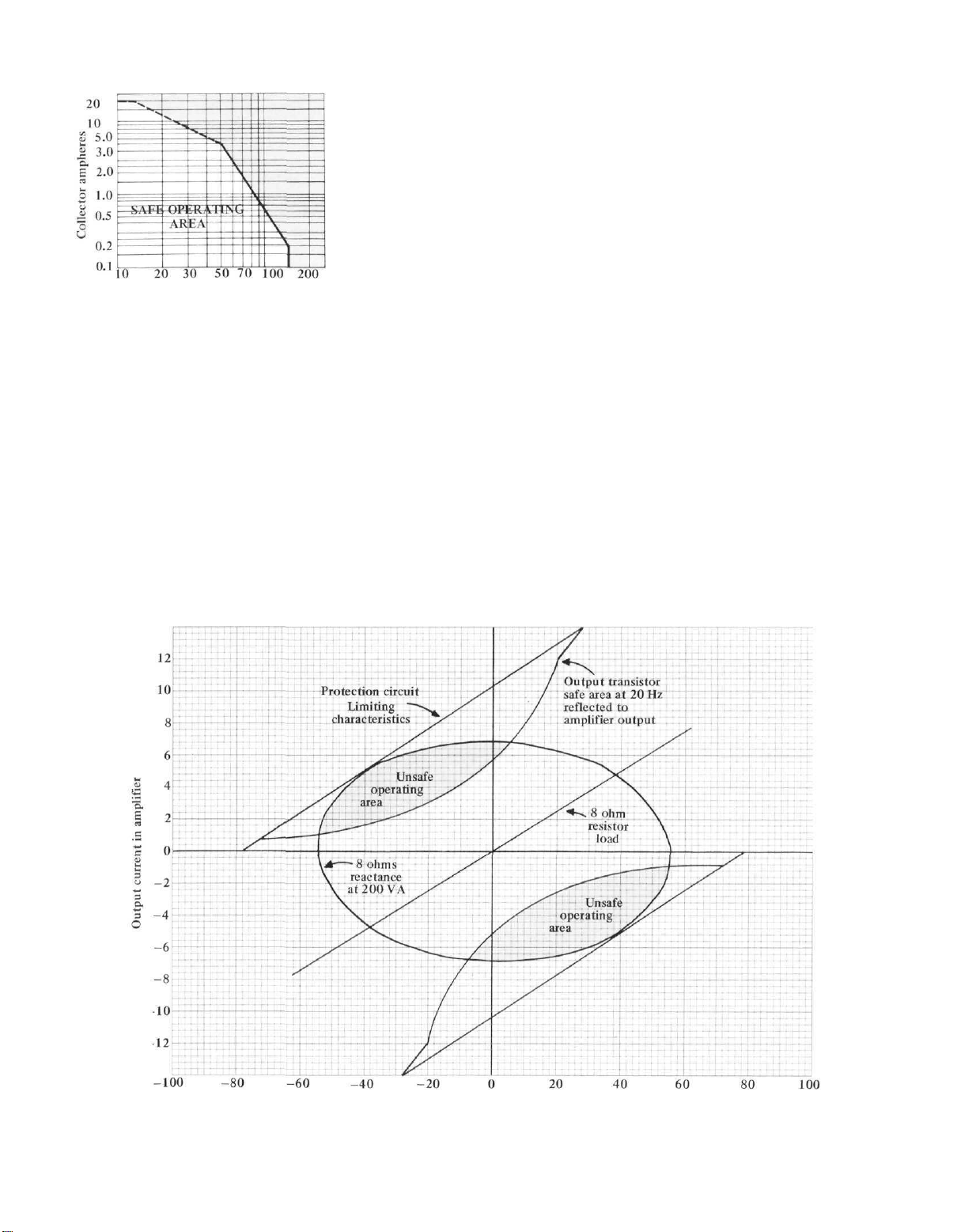

capability should double when it's

connected to a 4 ohm impedance. But

as this mismatch occurs, thermal dissipation increases rapidly. In fact,

operating into a 4 ohm load, heat dissipation is double what it would be

when operating at 8 ohms, as illustrated in Fig. 4. Unfortunately, if the

amplifier was designed for 8-ohm oper-

ation, its thermal dissipation limits

were designed with some safety factor

Heat dissipation

capacity required to

meet FTC rating

at 8 ohms.

Load impedance in ohms (1000%=Heat

produced at rated output into 8 ohms.)

Fig. 4 - Heat produced by transformerless

amplifier at various load impedance

for 8 ohm operation, so as to meet the

new FTC preconditioning requirements. These call for the amplifier to

be able to deliver one-third rated

power at rated impedance for one

hour. But, as you can see from Fig. 4,

the safety margin is not nearly great

enough to permit operation at 4-ohms

—or 2-ohms-or 1-ohm impedances.

Remember, too, that many amplifiers

and receivers have provisions for connection of more than one pair of

speakers for use in different listening

rooms, so that even if 8-ohm speakers

are selected, using double pairs of

them results in a 4-ohm net nominal

impedance even before allowing for

downward variations in impedance

at specific frequencies in the audio

spectrum. So, unless manufacturers are

willing to resort to disproportionately

massive heat sinks, cooling fans or

combinations of both, designing power

amplifiers that can deliver their maxi-

mum powers at both 8 ohms and im-

pedances of 4 ohms and lower becomes physically impractical in the

case of the OTL amplifiers.

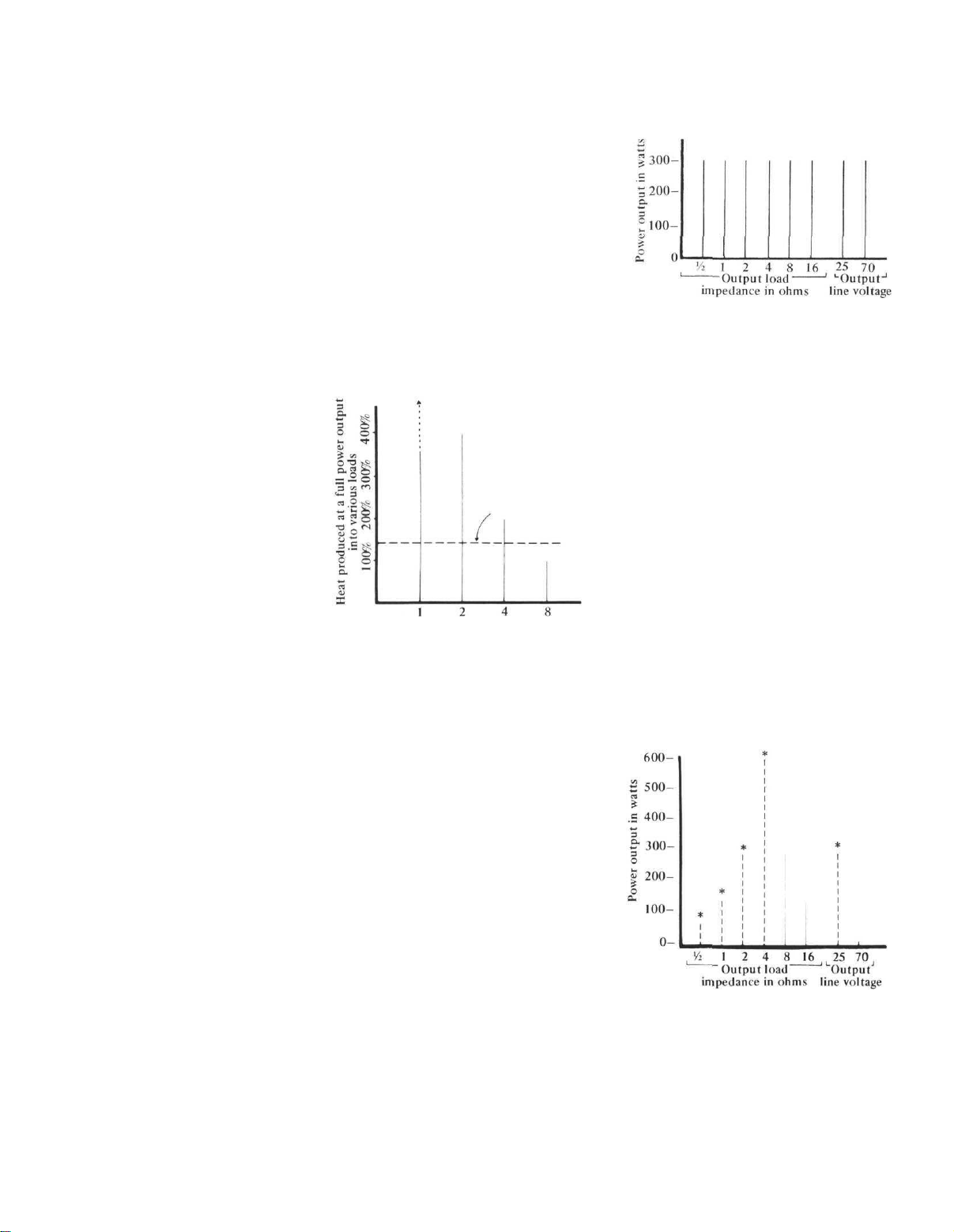

Fig. 6 - Performance of MC 2300

The Answer-Output Transformers!

If a transistorized amplifier were

equipped with an output transformer,

you could move up or down in load

impedance and maintain full power

ratings without over-dissipating anything, since the amplifier's output

stages would always be working into

an ideal load.

To many hi-fi enthusiasts, output

transformers tend to create visions of

compromised design. That is just not

the case today. Technology in materials and transformer design methods

have advanced significantly in recent

years and, remember, we're dealing

with low impedance devices-not tubes.

It's no longer necessary to translate

impedances from a "plate circuit" to a

speaker-a step down of several hun-

(* - - - Continuous operation not possible

due to overheating. Protection circuit is assumed to current limit when load falls below 4 ohms, in actuality the output into 4

ohms and lower impedances will fall below

the values shown.)

Fig. 7 - Performance of non McIntosh

transformerless amplifier rated for

300 watts in 8 ohm load

9

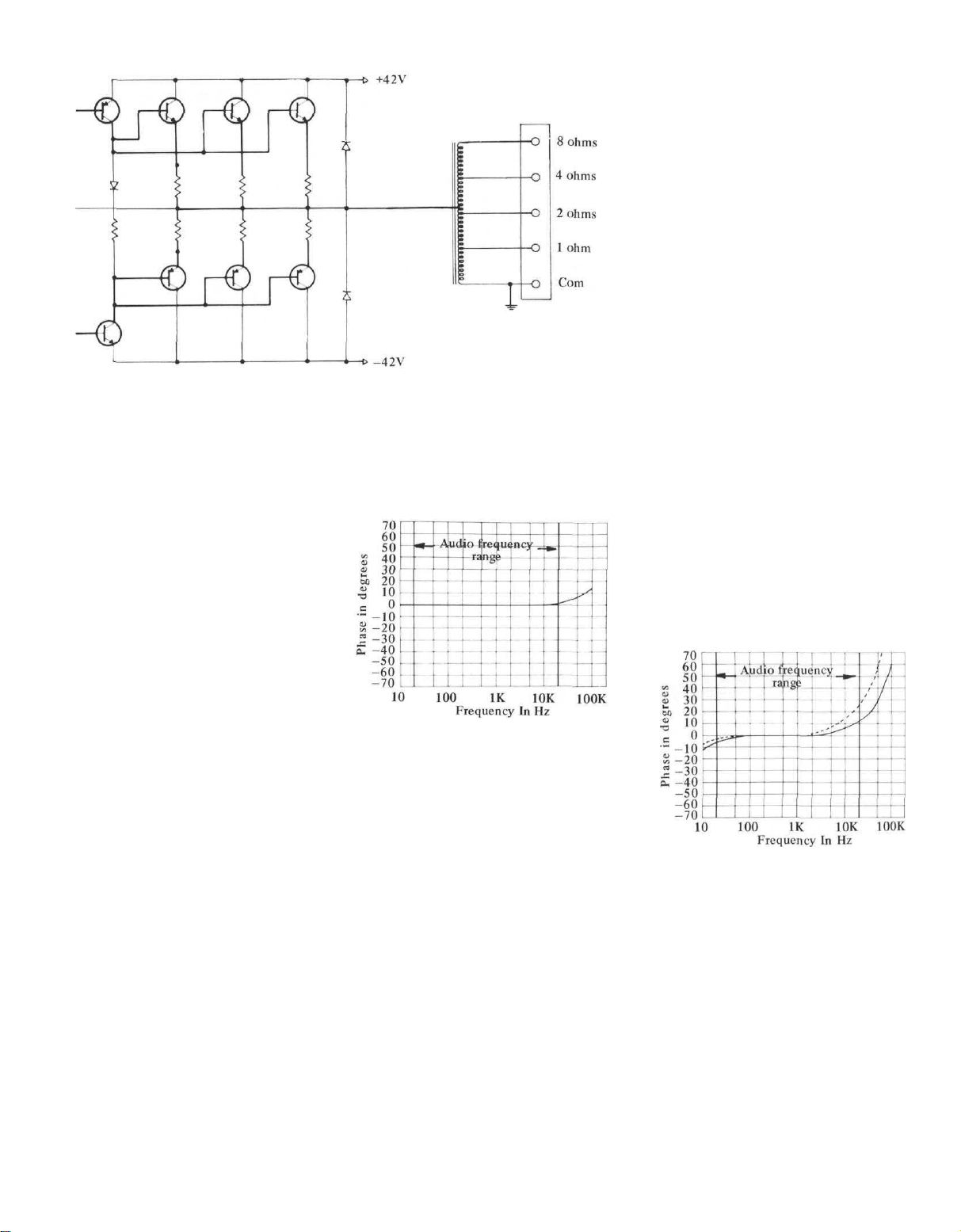

Fig. 5 - McIntosh MC 2205 output stage and transformer

dred to one. With transistor output

stages, a ratio of only about 4 to 1 is

required. In tube amplifiers, extremely

good balance in the push-pull primary

was required if notch distortion was to

be avoided. Now, using a single ended

push-pull transistor output stage the

transformer can be driven in a single

ended fashion. One end of the winding

Is returned to ground potential. With

the transformer at ground, no isolation

is required between the input and output and therefore a simple auto-

transformer can be used.

Fig. 5 shows a typical arrange-

ment used in our new MC 2205 amplifier. The output stages are designed to

work optimally into a load impedance

of 2.1 ohms and it becomes a simple

matter to "tap into" the auto-trans-

former for that precise impedance

match. Taps for 1 ohm, 2 ohm, 4 ohm

and 8 ohm operation are arranged so

that the output transistors continue to

work into their optimum impedance.

The result: full power output at any of

these impedances, with no possibility

of thermal over-dissipation.

Our popular MC 2300 amplifier

also uses an auto-transformer and

Fig. 6 shows how that amplifier is able

to deliver its full rated power (300

watts RMS per channel) into any

impedance from 0.5 ohms to 16 ohms,

as well as to 25 volt and 70 volt multispeaker system taps on the transformer. If we compare these results with

those obtained with a similarly rated

Fig. 8A - Typical of phase shift in

McIntosh auto-transformer at 8 ohms

OTL amplifier (Fig. 7) we see that at

all but 8 and 16 ohms, continuous

operation at theoretical maximum

power is impossible because of overheating and protection circuit limiting. Operation at 16 ohms, though

possible, is limited to a maximum

power output of 150 watts, in this

case, while operation into a 70-volt

line is impossible because of limitations in power supply voltages.

What About Phase Shift?

Critics opposed to the use of transformers in output circuits of audio

amplifiers arc quick to point out that

"transformers introduce phase shift"

at the low and high frequency extremes. As a matter of fact, a properly

designed transformer (and we'll get

into some of the factors that are involved in designing McIntosh output

transformers in a moment) can introduce about 3 degrees of phase shift at

20 kHz (Fig. 8A), which is certainly

insignificant. The typical volume control used on amplifiers (both those

that are OTL and those equipped with

transformers) introduce more shift

than that— about 20 degrees in fact

(Fig. 8B). Since an output transformer

is driven from an extremely low impedance, there is actually more lowfrequency phase shift caused by the

usual input coupling capacitor at these

low frequencies than by the trans-

former.

So, why haven't more manufacturers used output transformers on solidstate amplifiers? Possibly they are not

aware of the technology, but more

likely they don't want to spend the

extra cost. A good transformer is an

expensive component. It is heavy,

takes up a fair amount of space and

contradicts the audiophile's notion

that transistorized equipment must be

small and lightweight. Be that as it

may, the FTC regulations suggest that

output transformers are the only logical solution to rating audio amplifiers

honestly at 4, 8, 16 or any other

impedance required.

1 watt, 8 ohms

— Volume Control Clockwise

— Volume Control 12 o'clock

Fig. 8B - Typical phase shift

in a complete Mclntosh amplifier

Not Just Any Transformer!

At Mclntosh, we wind all our own

output auto-transformers. Of course,

we could purchase them from any one

of a number of transformer companies

who do nothing but wind transformers

(our power transformers are, in fact,

purchased from other suppliers), but

we have long since found that trans-

formers can't always be made successfully "according to the book". A great

deal of experimentation is required before a new design of a transformer can

10

be mated to a specific amplifier circuit. We went through dozens of developmental samples in the case of our

new MC 2205 amplifier. What we

ended up with it shown schematically

in the diagram of Fig. 9. The transformer is trifilar wound to provide

coupling between sections. It takes 23

individual windings to make this output transformer. There are five different winding sections, all five of which

are connected in parallel. We use

grain oriented silicon steel core laminations because that kind of core means

less iron-and less iron in turn means

tighter coupling. It also means lower

winding resistance for a given size

wire. The grain oriented silicon steel

means that it has a higher magnetic

saturation point-about 17 kilogauss

versus 12 to 13 kilogausses for the

non-oriented variety. There is therefore less core loss, or, to put it simply,

we end up with a more efficient transformer-one which couples more of

the available amplifier power to the

speaker loads. To further improve coupling, we don't use any interlayer in-

sulating paper in a power transformer

that might pose a breakdown problem.

But since our polyurethane insulated

Fig. 9 - MC 2205 output

auto-transformer schematic diagram

wire is rated at 4000 volts per mil (and

since the highest voltage we're talking

about for an audio transformer is

about 56 volts), this really is no prob-

lem at all. All of our output trans-

formers arc potted with material

which has especially high thermal

conductivity. Besides helping to keep

operating temperatures within the

transformer down, this compound reduces lamination buzz to inaudible

levels. We figure you'd rather listen to

your speakers than to our transformers!

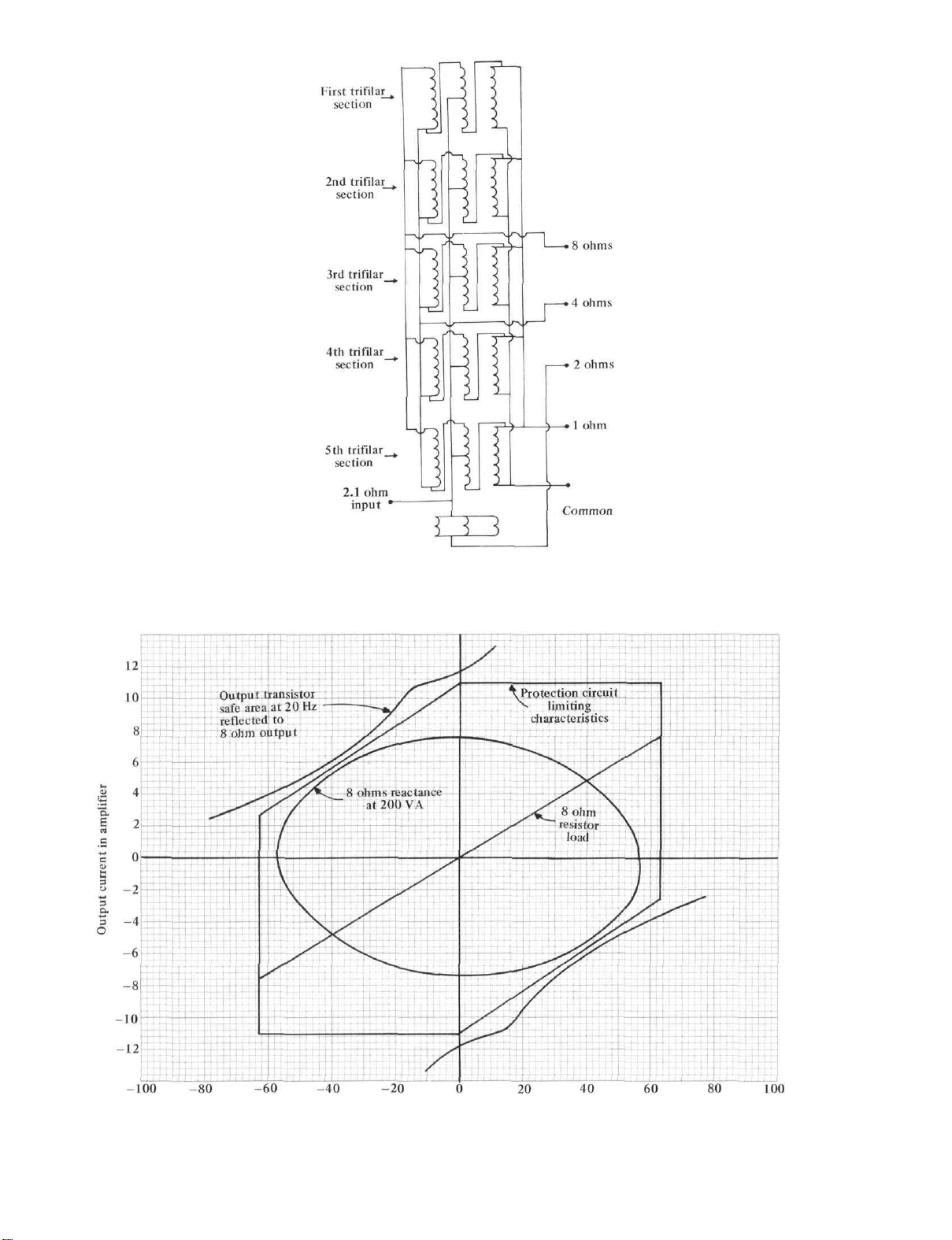

Our Transformers Are Only Part

of The Story

Whether an amplifier uses an out-

put transformer or not, its output de-

vices must be designed to work into an

optimum load so that maximum cur-

rent delivered by the output transis-

tors never exceeds the safe operating

area specified for the transistor. Fig.

11 shows current versus voltage limita-

tions for the epibase type of output

transistor used in our MC 2205 ampli-

fier. If all amplifier loads were purely

resistive, staying within the safe oper-

ating area would be relatively simple,

but the fact is that speakers often pre-

Output volts

Fig. 10-Load and limiting data of

the McIntosh MC 2205 measured at 8 ohm output

11

Collector volts

Fig. 11 - Current versus voltage

limitation epibase type

output transistor

fiers. In Fig. 10 we have combined the

safe operating diagram of Fig. 10 with

load and limiting characteristics at the

8-ohm tap of our MC 2205. As you

can see, even when the load is totally

reactive, every possible voltage and

current condition falls within the

safe operating area of the output de-

vices used. Compare this diagram with

Fig. 12 derived from data concerning

the output transistors used in a currently available high-powered amplifier.

Note that inadequate protection is

provided for reactive loads.

To Sum It All Up

The points we've tried to make are

relatively few, but they spell the differ-

ence between a McIntosh output-

transformer equipped amplifier and

every other kind of amplifier around.

1. A transformer equipped amplifier will deliver rated power at any impedance for which a transformer tap

is provided.

2. An OTL amplifier designed for

8-ohm operation cannot operate safely

(according to the FTC rules) when

driving lower impedances (4 ohms,

2 ohms, etc.), yet such loads commonly occur either because of speaker im-

pedance variations with frequency or

because of paralleling of multiple

speaker systems across one channel

of an amplifier.

3. The new FTC power rule regarding audio amplifiers has forced many

manufacturers to omit 4-ohm ratings even though 4-ohm speakers arc in

common use. McIntosh transformerequipped audio

amplifiers

deliver

full

power at any impedance for which a

transformer output tap is provided.

4. Because of their design, McIntosh

transformers introduce less series leakage inductance than is commonly encountered with OTL amplifiers which

require a series inductance between

the output circuit and the speaker connection for amplifier stability. At the

8 ohm tap of our MC 2205, leakage inductance is a low 3.5 microhenries.

This represents an impedance of only

2.2 ohms at a frequency of 100 kHz.

5. Properly designed output transformers impose no limitations on frequency response. At the 8-ohm tap of

the MC 2205, response is down 0.3 dB

at 50 kHz. With a 4-ohm toad con-

nected, response is down 0.1 dB at

50

kHz.

6. Phase response of the MC 2205

amplifier, using its specially designed

output transformer, is accurate to

within 9 degrees at the 8 ohm tap at

a frequency of 50 kHz and undergoes

zero degrees of phase shift at 20 Hz.

At the 4-ohm tap, phase shift at 50 kHz

is only 7.2 degrees.

Next time anyone gets into an argument with you concerning the attributes of an OTL amplifier versus a

McIntosh transformer-equipped amplifier, you might let your adversary read

this story.

12

Output volts

a non McIntosh high-powered transformerless amplifier measured at 8 ohms output.

Fig. 12 — Load and limiting data of

You are Mclntosh protected

six ways with the new

Mclntosh amplifiers.

PROTECTION

1. The patented Mclntosh Sentry Monitoring circuit

constantly monitors the output signal. At signal

levels up to rated output this circuit has high impedance and has no effect upon the output. If the

power output exceeds design maximum, the Sentry

Monitoring circuit operates to limit the signal to the

output transistors. In the event of a short circuit

across the amplifier output or severe impedance

mismatch the Sentry Monitoring circuit will protect

the output transistors from failure. Both positive and

negative halves of the output signal are monitored

independently.

PROTECTION

2. Should the temperature of the heat sinks rise

above normal through restricted ventilation or other

causes, the AC Power is disconnected by an

automatic heat sensing relay. The AC power will be

restored when the temperature returns to normal.

PROTECTION

3. Any loudspeaker damaging DC component in the

output circuit, from whatever cause, is shunted to

ground through the Mclntosh autotransformer. You

and your speakers are protected completely from

this kind of amplifier failure.

PROTECTION

4. Mclntosh gives you a money back guarantee of

performance. Your Mclntosh instrument must be

capable of meeting its published performance limits

or you get your money back. No other manufacturer

offers you this money back guarantee of performance.

PROTECTION

5. The Mclntosh 3 Year Service Contract protects

you from the cost of repair for three full years

because Mclntosh will provide the service materials

and labor needed to return the measured performance to the original performance limits. The SERVICE CONTRACT does not cover any shipping costs

to and from the authorized service agency or the factory.

PROTECTION

6. The Automatic Test System provides positive pro-

tection and extends the long trouble free life of an

amplifier. Each time the amplifier is turned on seven

tests measure and verify accurate performance.

Automatic Test System protects by verifying circuit

readiness before operation starts. Each time a test

is verified a numeric indicator turns on to indicate

the test being performed. If in the test countdown an

unacceptable voltage is encountered, the numeric

designation locks to isolate the faulty circuit.

13

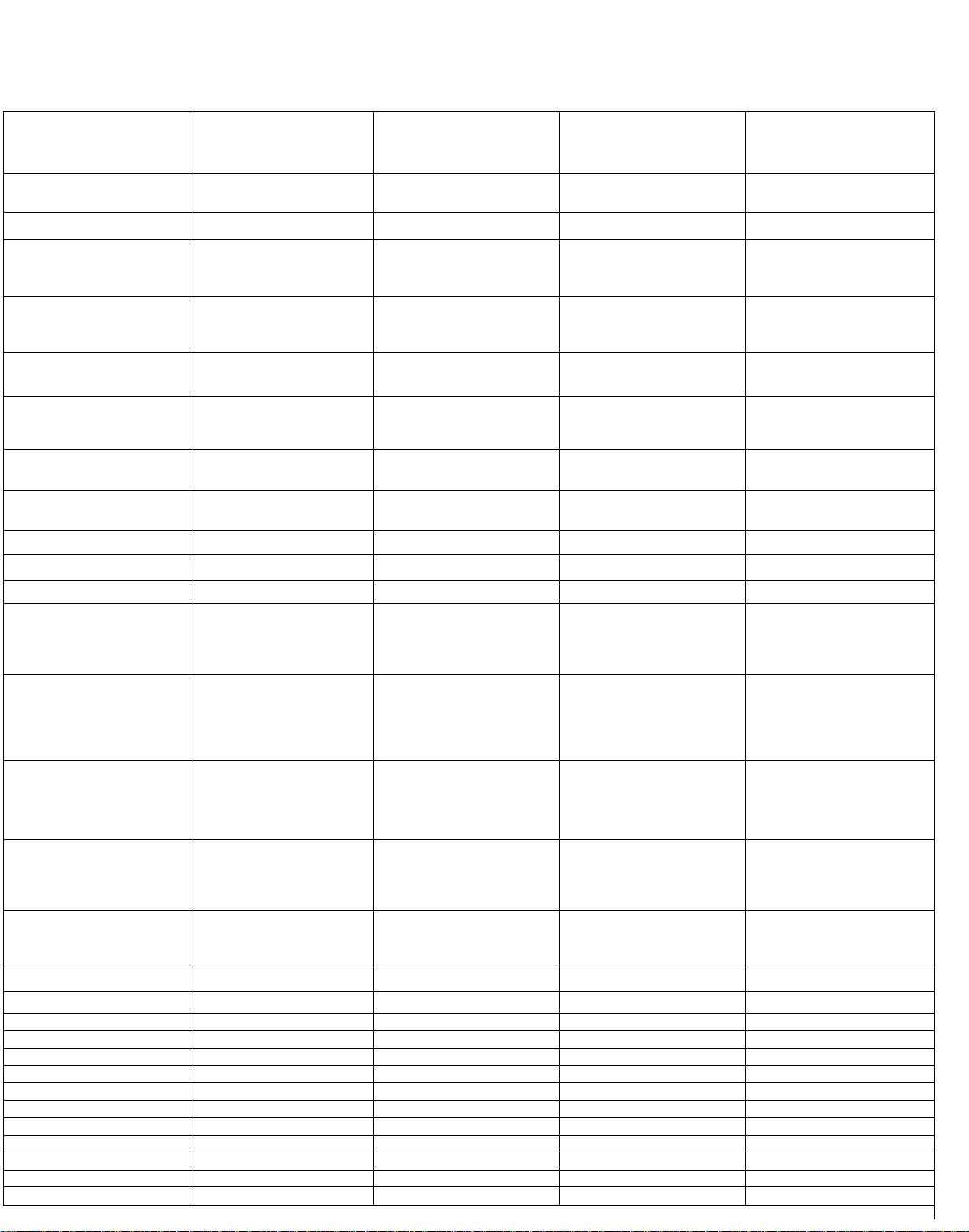

PERFORMANCE GUARANTEED

Performance limits are the maximum

deviation from perfection permitted for a

Mclntosh instrument. We promise you that

when you purchase a new Mclntosh product from a Franchised Mclntosh dealer it

will be capable of performance at or exceeding these limits or you can return the

unit and get your money back. Mclntosh is

the only manufacturer that makes this

statement.

POWER AMPLI

POWER OUTPUT STEREO

Minimum Watts,

Both Channels Operating

POWER OUTPUT MONO

Minimum Watts

POWER BAND WIDTH

TOTAL HARMONIC DISTORTION

Maximum, 250 mW to Rated

Power, 20 Hz to 20 kHz

OUTPUT LOAD IMPEDANCE

Stereo

Mono

INTERMODULATION DISTORTION

Maximum, 250 mW to Rated Power

FREQUENCY RESPONSE

20 Hz to 20 kHz

(at 1 Watt)

NOISE AND HUM

Below Rated Output

OUTPUT VOLTAGES FOR

DISTRIBUTION SYSTEMS

DAMPING FACTOR

INPUT IMPEDANCE

INPUT SENSITIVITY

POWER REQUIREMENT

AC Line Voltage - Frequency

Watts at No Signal

Watts at Rated Output

SEMICONDUCTOR COMPLEMENT

Transistors

Diodes

Integrated Circuits

SIZE

Panel Height

Panel Width

Depth

FINISH

MC 2500

500 Watts Per

Channel

1000 Watts

20 Hz to 20 kHz

0.02%

1, 2, 4, 8 W

1/2,

1, 2, 4, 8, 16 W

0.02%

+ 0.

-0.25

dB

-95 dB

25 Volts

greater than 30

50.000 W

0.75 or 2.5 Volts

120V, 50-60 Hz

75 Watts

1800 Watts

91

35

6

10-1/2" (26.7cm)

19" (48.3cm)

17" (43.2cm)

Gold and Black

Panel, Black

Knobs

Mclntosh audio power ratings are stated

in accordance with the Federal Trade

Commission Regulation of November 4,

1974 concerning power output claims for

amplifiers used in home entertainment

products.

14

WEIGHT

Net

In Carton

HEAT SINK AREA

SPECIAL FEATURES

Power Guard

Output Autoformers

Automatic Test System

Output Meters: Calibrated in Watts

Output Meters: Calibrated in dB

Thermal Turn-Off

Sentry Monitor

D.C. Speaker Protection

Output Limit Indicator

Panloc Mounting

Cooling: Convection

129#(58.5kg}

144#(65.3kg)

1990

sq. in.

X

N/A

X

X

X

X

X

X

N/A

N/A

FIER PERFORMANCE LIMITS

MC 2255

250 Watts Per

Channel

500 Watts

20 Hz to 20 kHz

0.02%

1, 2, 4, 8 W

1/2,

1, 2, 4, 8, 16 W

0.02%

+ 0,

-0.25

-95 dB

25 Volts

greater than 30

50,000 W

0.75 or 2.5 Volts

dB

MC 2250

250 Watts Per

Channel

500 Watts

20 Hz to 20 kHz

0.02%

1, 2, 4, 8 W

1/2,

1, 2, 4, 8, 16 W

0.02%

+ 0,

-0.25

-95 dB

25 Volts

greater than 30

50,000 W

0.75 or 2.5 Volts

dB

MC

2155

150 Watts Per

Channel

300 Watts

20 Hz to 20 kHz

0.02%

1, 2, 4, 8 W

1/2,

1, 2, 4, 8, 16 W

0.02%

+ 0,

-0.25

dB

-95 dB

25 Volts

greater than 30

50,000 Si

0.75 or 2.5 Volts

MC

2120

120 Watts Per

Channel

240 Watts

20 Hz to 20 kHz

0.1%

2, 4, 8, 16 W

1, 2, 4, 8 W

0.1%

+ 0,

-0.25

dB

-95 dB

25 Volts

14 to 50

100,000 W

0.75 or 2.5 Volts

MC 502

75 W/Chan. 2.7 to 4 W

50W/Chan. 8 W

150 Watts

into 8 Ohms

20 Hz to 20 kHz

0.02%

2.7 to 8 W

8 W

0.02%

+ 0,

-0.25

-95 dB

25 Volts (Stereo Only)

75,000 W

0.75 or 2.5 Volts

dB

>50

120V, 50-60 Hz

70 Watts

1440 Watts

85

47

14

7-1/8" (18.1cm)

16-3/16" (41.1cm)

14-1/2" (36.8cm)

Black Glass Panel,

Gold/Teal Nomen-

clature, Gold and

Black Knobs

82# (37.2kg)

96# (43.5kg)

1080

sq. in.

X

X

X

X

X

X

X

X

X

X

X

120V, 50-60 Hz

84 Watts

1440 Watts

76

37

9

6-31/32" (17.7cm)

16" (40.6cm)

14-1/2" (36.8cm)

Gold Panel

Gold and Black

Knobs

80# (36.3kg)

94# (42.6kg)

1080

sq. in.

X

X

X

N/A

N/A

X

X

X

X

N/A

X

120V, 50-60 Hz

84 Watts

720 Watts

81

47

14

5-7/16" (13.8cm)

16" (40.6cm)

14-1/2" (36.8cm)

Black Glass Panel,

Gold/Teal Nomen-

clature, Gold and

Black Knobs

65# (29.5kg)

77# (35kg)

772 sq. in.

X

X

X

X

X

X

X

X

X

X

X

120V, 50-60 Hz

50 Watts

460 Watts

39

24

2

5-7/32" (13.3cm)

16" (40.6cm)

14-1/2" (36.8cm)

Gold Panel,

Gold and Black

Knobs

57# (26kg)

70# (32kg)

772 sq. in.

X

X

N/A

N/A

N/A

X

X

X

X

N/A

X

120, 50-60 Hz

20 Watts

400 Watts

39

20

4

3-5/8" (9.2cm)

16" (40.6cm)

14-1/2" (36.8cm)

Black Glass Panel,

Gold/Teal Nomen-

clature, Gold and

Black Knobs

27# (12kg)

38#(17kg)

513 sq. in.

X

N/A

N/A

N/A

N/A

X

X

X

X

X

X

" 5

Loading...

Loading...