Page 1

THE

MclNTOSH

MC

2300

SOLID STATE STEREO POWER

AMPLIFIER

Price $1.25

Page 2

Page 3

The Mclntosh MC 2300 is a high quality, extremely high power, solid state stereo amplifier. Because of the high power available it is

necessary to emphasize some prudent and

safe operating conditions.

1. Never connect or disconnect inputs or

outputs while the amplifier is turned on.

Loudspeakers can be damaged or destroyed by the high power available from

the instrument.

2. Never operate the amplifier with the power

cord plugged into an auxiliary AC power

outlet on source equipment. The amplifier

draws near 14 amperes at full power and

damage to the source equipment can

occur.

3. Do not operate the instrument plugged

into an ordinary extension cord. Heavy

duty extension cords (14 ga. or heavier)

have adequate wire size and will not overheat.

4. Be cautious when lifting the instrument.

It weighs 128 pounds. Make certain that

what it is placed on can support the

weight.

Page 4

Your MC 2300 Stereo Power Amplifier

will give you many years of pleasant

and satisfactory performance. If

you have any questions concerning

the operation or maintenance of

this instrument, please contact:

CUSTOMER SERVICE

Mclntosh Laboratory Inc.

2 Chambers Street

Binghamton, New York 13903

Phone: 607-723-3512

Take Advantage of 3 years

of FREE Factory Service . . .

Fill in the Application NOW.

CONTENTS

GUARANTEE.... 1

INSTALLATION.... 3

HOW TO CONNECT....4,5

Stereophonic.... 6

Monophonic.... 7

FRONT PANEL INFORMATION.... 8

PERFORMANCE LIMITS.... 9

TYPICAL PERFORMANCE CHARTS....10

TECHNICAL DESCRIPTION....11

BLOCK DIAGRAM....16

Mclntosh Laboratory Incorporated guarantees this

Instrument to be capable of performance as advertised. We also guarantee the mechanical and electrical workmanship and components to be free of

defects for a period of 90 days from date of purchase. If such defects occur, Mclntosh Laboratory

An application for a FREE THREE YEAR FACTORY

SERVICE CONTRACT is included with this manual.

The terms of the contract are:

For Three Years from date of purchase —

1. Mclntosh will provide all parts, materials and

labor needed to return the measured performance

of the instrument to the original performance

limits free of any charge. The SERVICE CONTRACT does not cover any shipping costs to and

from the authorized service agency or the factory.

2. Any Mclntosh authorized service agency will re-

pair all Mclntosh instruments at normal service

rates. To receive the free service under the terms

of the SERVICE CONTRACT, the SERVICE CONTRACT CERTIFICATE must accompany the instrument when taken to the service agency.

3. Always have service done by a Mclntosh author-

ized service agency. If the instrument is modified

or damaged, as a result of unauthorized repair the

SERVICE CONTRACT will be cancelled. Damage

by improper use or mishandling is not covered by

the SERVICE CONTRACT.

Copyright © 1971 by Mclntosh Laboratory, Inc.

GUARANTEE

or one of its authorized agencies wilt repair the

defect at no cost to the purchaser. This guarantee

does not extend to components damaged by improper use nor does it extend to transportation to

and from the factory or service agency.

4. The SERVICE CONTRACT is issued to you as the

original purchaser. To protect you from misrepresentation this contract cannot be transferred to a

second owner.

5. The SERVICE CONTRACT is given to purchasers

who live In the 50 United States or Canada only.

6. For your protection Mclntosh selects Its dealers

carefully. Only one dealer in ten qualifies for a

Mclntosh franchise. To receive the SERVICE

CONTRACT your purchase must be made from a

Mclntosh franchised dealer.

7. Your completely filled In application for a SERVICE CONTRACT must be postmarked within 30

days of the date of purchase of the instrument.

8. To receive the SERVICE CONTRACT all information on the application must be filled in. The

SERVICE CONTRACT will be issued when the

completely filled in application is received at

Mclntosh Laboratory Incorporated in Binghamton,

New York. If the application is not received at

Mclntosh Laboratory, only the service offered

under the 90-day guarantee will apply.

2

Page 5

Installation

Installation of the MC 2300 requires careful thought

about three important factors. They are the electrical

power to operate the unit, the weight and the heat

generated when the MC 2300 is operating.

The MC 2300 draws 1400 watts or about 14 am-

peres when operated at full power. Do not use ordi-

nary extension cords of any type. Heavy duty extension cords (14 ga. or heavier) have adequate wire

size and will not overheat. Plug the AC power cord

directly into a wall outlet. Make certain that the AC

power outlet has at least 15 amperes capacity with

nothing else using the circuit. Do not plug the MC

2300 into an auxiliary AC power outlet on a preamplifier or other source equipment. If remote power

operation is required, an external relay arrangement

must be made.

Weight of the instrument is 128 pounds. Make

certain that the shelf on which it is to be mounted

can support that weight. If it is to be vertically

mounted, be certain the structure is capable of supporting the MC 2300.

Adequate ventilation extends the trouble-free life

of electronic instruments. It is generally found that

each 10° centigrade (18° F) rise in temperature reduces the life of electrical insulation by one half.

Adequate ventilation is an inexpensive and effective

means of preventing insulation breakdown that results from unnecessarily high operating temperatures. The direct benefit of adequate ventilation is

longer, trouble-free life. Provide a source for input

air and an outlet for the heated air. The heat generated in the operation of the MC 2300 is exhausted

from the unit by two low noise, long life fans.

Cooling input air is drawn into the MC 2300

through the ventilation holes on the sides of the

MC 2300. The air passes over the tranformers, output

heat sinks and transistors; and, is blown out the back

of the instrument by the two fans. It is recommended

that at least 2 inches of clear space be provided on

each side.

To permit the fans to operate best, provide at least

5 inches of space at the rear of the instrument. A

source for input air and a means to exhaust the

heated air is necessary so that the heated air does

not recirculate through the MC 2300.

To install the unit in a cabinet the aluminum side

rails with the feet attached must be removed. The

rails are attached to the front panel by 8 #10-32

machine screws and to each side by 4 small clips.

Remove both the front panel screws and the four

clips from each side for cabinet mounting. The opening to fit the unit is 17¼ by 10¼ inches.

RACK INSTALLATION

The MC 2300 may be mounted in a standard 19"

rack by removing the aluminum side rails. If a standard rack is used, the screws that held the aluminum

rails to the front panel are used to attach the MC

2300 to the rack. When rack mounted, the MC 2300

requires 10½ inches of panel space. Allow two

inches in front of the panel for the knobs. A depth of

17 inches plus ventilation space is required.

The MC 2300 can be slide mounted in a rack.

Tapped well nuts and internal structure bracing has

been added to both sides of the MC 2300 for use

with the Model CTS-116 side mounted slide assemblies manufactured by Chassis-Trak Inc., Indianapolis, Indiana.

3

Page 6

How to Connect

INPUT

Stereo or twin amplifier operation:

Use shielded cables to connect the signal from the

preamplifier or signal source to the power amplifier.

All connection are made on the back panel of the

MC 2300.

For stereo operation the LEFT OUTPUT of the preamplifier should be connected to the LEFT INPUT of

the power amplifier. The RIGHT OUTPUT of the pre-

amplifier should be connected to the RIGHT/MONO

input of the power amplifier. In stereo or twin amplifier operation the MODE SWITCH must be in the

stereo position.

For twin amplifier operation a separate signal

source can be connected to each input.

To minimize the possibility of hum the shielded

leads shall be run parallel or loosely twisted to-

gether. Locate the cables away from AC power cords.

Monophonic or Single Channel operation:

A shielded cable from the signal source is con-

nected to the RIGHT/MONO input of the MC 2300.

The MODE SWITCH on the back panel of the amplifier must be placed in the MONO position. In the

MONO position the output of the right channel input

amplifier is fed to both left and right power amplifiers.

The LEFT INPUT is disconnected. Only the signal fed

into the RIGHT/MONO input will be amplified. Should

the MODE SWITCH be left in the STEREO position

and the output transformers be strapped to a mono-

phonic load, one channel will attempt to drive the

other and cause high circulating currents and over-

heating. Be certain that the MC 2300 is never oper-

ated in the stereo mode with the outputs connected

for monophonic operation.

OUTPUT

Stereo or twin amplifier operation:

To connect the left speaker first check the imped-

ance of the speaker which is usually identified on

the speaker itself or in the owner's manual. Connect

one lead from the common terminal of the speaker to

the LEFT CHANNEL OUTPUT terminal strip screw

COMmon. Connect the other terminal of the speaker

to the screw with the number corresponding to the

speaker impedance on the LEFT CHANNEL OUTPUT

terminal strip. The right channel speaker is con-

nected in the same manner on the RIGHT CHANNEL

OUTPUT terminal strip. For stereo or twin channel

operation it is not necessary to use the same impedance loudspeaker on each output. Connect each

channel for the impedance desired.

When multiple speakers are to be connected to

either or both outputs, the combined load impedance

must be calculated and the load connected to the

appropriate impedance tap. The following table will

aid in selecting the correct impedance match.

Load Load

impedance Connect impedance Connect

in ohms

0.4 to 0.9

0.9 to 1.8

1.8 to 3.6

If a load impedance is used that is lower than the

output impedance tap, then reduced power and possible distortion will result. If a load impedance is used

that is higher than the output impedance tap, then

neither the signal nor the amplifier will be harmed but

the voltage available is limited to that stated at that

tap.

For constant voltage line operation:

25 volts Connect to 2 ohms

70 volts Connect to 16 ohms

Make all speaker connections at the amplifier only.

For multiple speaker operation, parallel the leads

from the speakers to the amplifier.

Because of the high power available from the MC

2300, be sure to use large diameter speaker leads. In

all cases, the leads to and from the speaker should

be twin conductor or twisted together.

Use lamp cord, bell wire, or wire with similar type

of insulation to connect the speakers to the amplifier. For the normally short distances of under 20 feet

between the amplifier and speaker #18 wire or larger

can be used. For distances over 20 feet between the

amplifier and speaker use larger diameter wire. Se-

lect the correct size wire for the wire distance from

the chart.

It is recommended that the DC resistance of the

speaker leads not be over 5% of the load impedance.

Up to 10% can be tolerated. Resistance of the leads

should be computed for the length of wire both to

and from the speaker or speakers.

to

0.5

1

2

in ohms

3.6 to 7.2

7.2 to

14.4

14.4

to 28

to

4

8

16

4

Page 7

Monophonic or Single Channel operation:

When the MC 2300 is used as a monophonic or

single channel power amplifier the two channels are

combined to produce output up to 600 watts. The

output must be tied together at the appropriate load

impedance tap. In connecting a load to the MC 2300

for single channel operation connect the common

side of the load to the LEFT CHANNEL OUTPUT terminal marked COM., the other lead as below.

For monophonic constant voltage line operation:

If the output

voltage is:

25 volts

70 volts

The hot side

of the load is

connected to:

Left 2

Left 16

Connect a jumper

wire between

Left 2 and Right 2

Left 16 and Right 16

Make all speaker connections at the amplifier only.

For multiple speaker operation, parallel the leads

from the speakers to the amplifier.

If the speaker The hot side

or load of the line Is

Impedance Is: connected to:

0.25 ohms

0.5 ohms

2 ohms

4 ohms

8 ohms

Left 0.5

Left 1

Left 4

Left 8

Left 16

Connect a jumper

wire between:

Left 0.5 and Right 0.5

Left 1 and Right 1

Left 4

Left 8

Left 16

and Right 4

and Right 8

and Right 16

If the load impedance is between any of the above

figures seclect the best impedance match from this

chart:

Load Impedance

in ohms

0.4 to 0.9

0.9 to 1.8

1.8 to 3.6

WIRE GAUGE

Connect to

0.5

1

2

22

Load Impedance

in ohms

3.6 to 7.2

7.2 to

14.4

14.4

to 28

20

Connect to

4

8

16

18

Should the MODE SWITCH be left in the STEREO

position and the output transformers be strapped to

a monophonic load, one channel will attempt to drive

the other and cause circulating currents and over-

heating. Be certain that the MC 2300 is never oper-

ated in the stereo mode with the outputs connected

for monophonic operations.

AC POWER

The MC 2300 is designed to operate on 117 to 130

volts 50/60 Hz. Do not use ordinary extension cords

of any type. Heavy duty extension cords (14 ga. or

heavier) have adequate wire size and will not overheat. Plug the the AC power cord directly into a wall

outlet. Make certain that the AC power outlet has at

least 15 ampere capacity with nothing else using the

circuit. Do not plug the MC 2300 into an auxiliary AC

power outlet on a preamplifier or other source equip-

ment unless it is known there is adequate current

capacity. If remote power operation is required, an

external relay arrangement must be made.

16

14

12

10

8

6

0

50

75

100 150 200

LENGTH IN FEET OF TWO-CONDUCTOR SPEAKER WIRE

250

300

5

Page 8

STEREOPHONIC CONNECTIONS

PROGRAM SOURCE

TO 120 VAC

DO NOT CONNECT LINE

CORD INTO PREAMPLIFIER

AC OUTLETS.

IF REMOTE POWER

CONTROL IS NEEDED

USE AN EXTERNAL

RELAY.

LEFT SPEAKER ML 4 C

6

RIGHT SPEAKER ML 4 C

Page 9

MONOPHONIC CONNECTIONS

PROGRAM SOURCE

To 120 VAC

DO NOT CONNECT LINE

AC OUTLETS.

IF REMOTE POWER

CONTROL tS NEEDED USE

AN EXTERNAL RELAY.

ML 4 C LOUDSPEAKER

MODE SWITCH

MONO

7

STERE0

Page 10

Front Panel Information

LEFT GAIN

The left gain control is used to control gain or volume

of the left channel. Clockwise rotation increases gain.

RIGHT/MONO GAIN

In stereo the RIGHT/MONO GAIN control determines the gain or volume of the right channel only.

Clockwise rotation increases gain. If the MC 2300 is

connected as a monophonic or single channel ampli-

fier, the gain or volume is controlled by the RIGHT/

MONO GAIN control.

Both controls have a standard volume control

taper. The numerals around the controls are provided

for reference. They do not represent relative output

versus rotation.

METER RANGE

The meter switch has four positions. The first position is OFF. With switch in the OFF position there is

no indication on the meters.

0: In this position of the meter range switch, the

amplifier will deliver 300 watts when the meter indicates + 3 dB, with meter indication of "0," the

amplifier delivers 150 watts, with a meter indication

of —3 dB, the amplifier delivers 75 watts.

—10: In this position of the meter range switch,

the amplifier will deliver 15 watts output when the

meter indicates "0."

—20: In this position of the meter range switch,

the amplifier will deliver 1.5 watt when the meter

indicates "0."

Two meters monitor and indicate the output power

in each channel. The meters indicate peak power output of the monitored channel. To assure more accurate indications of peak power, Mclntosh's peak locking circuits stretch the peak reading of rapid changing information long enough to give adequate visual

perception. Ordinary meters lack the capability of indicating the short interval of power in a sound wave.

The mass of the meter movement is too great to respond to the nearly instantaneous changes in music

program material. Mclntosh has developed circuits

that permit the meters of the MC 2300 to respond to

the short interval power in a sound wave to an accuracy of 98%.

Monitoring of the output power is done at the primary or input of the autoformer resulting in true

power readings regardless of output impedance

selected.

The graph represents the relationship between the

meter reading and power output for all three meter

ranges:

POWER

The power switch turns the MC 2300 on or off. If

you wish to control the on/off operation of the amplifier remotely, use a control relay in series with the

power line and leave the power switch in the ON

position. Do not plug the MC 2300 into any of the

auxiliary AC power outlets of the preamplifier or

other associated equipment unless that equipment

has power capacity for handling 1400 watts (14 amperes).

8

Page 11

Performance Limits

PERFORMANCE GUARANTEE

Performance Limits are the maximum deviation

from perfection permitted for a Mclntosh instrument.

We promise you that the MC 2300 you buy must be

capable of performance at or exceeding these limits

or you qet your money back. Mclntosh is the only

POWER OUTPUT

STEREO: 300 watts continuous, both channels op-

erating; which is:

12.2 volts RMS across 0.5 ohm

17.3 volts RMS across 1 ohm

24.5 volts RMS across 2 ohms

34.6 volts RMS across 4 ohms

49.0 volts RMS across 8 ohms

69.3 volts RMS across 16 ohms

MONO: 600 watts continuous; which is:

12.2 volts RMS across 0.25 ohm

17.3 volts RMS across 0.5 ohm

24.5 volts RMS across 1 ohm

36.6 volts RMS across 2 ohms

49.0 volts RMS across 4 ohms

69.3 volts RMS across 8 ohms

HARMONIC DISTORTION

Stereo:

Less than 0.25% at 300 watts output from 20 Hz

to 20,000 Hz both channels operating. Typical per-

formance is less than 0.1% at rated power. Distortion decreases as output power is reduced.

Mono:

Less than 0.25% at 600 watts output from 20 Hz to

20,000 Hz. Typical performance is less than 0.1%

at rated power. Distortion decreases as output

power is reduced.

INTERMODULATION DISTORTION

Stereo:

Less than 0.25% if instantaneous peak power is

600 watts or less per channel with both channels

operating for any combination of frequencies 20

Hz to 20,000 Hz.

Mono:

Less than 0.25% if instantaneous peak power is

1200 watts or less for any combination of fre-

quencies 20 Hz to 20,000 Hz.

FREQUENCY RANGE

Stereo:

20 Hz to 20,000 Hz, +0 - 0.5 dB at rated power;

1, 4, 8 or 16 ohms

20 Hz to 20,000 Hz, +0-1.0 dB at rated power;

0.5 and 2 ohms

12 Hz to 35,000 Hz, +0 - 1.5 dB at one-half rated

power

Mono:

20 Hz to 20,000 Hz, +0 - 0.5 dB at rated power;

0.5, 2, 4 or 8 ohms

20 Hz to

20,000

Hz,

0.25, and 1.0 ohms

+0-1.0

dB at

rated power;

12 Hz to 35,000 Hz, +0 - 1.5 dB at one-half rated

power

NOISE AND HUM

90 dB below rated output

OUTPUT POWER MONITOR METER

Meter is calibrated to read +3 db when ampli-

fier produces 300 RMS watts or 600 peak watts.

Meter range switch is provided to increase meter

sensitivity by 10 dB or 20 dB.

Meter features special circuit to respond to peak

values of complex input signal. Calibration accuracy

at 0 dB is ±2% at all frequencies; meter range accuracy is ±5%.

OUTPUT IMPEDANCE

Stereo: 0.5, 1, 2, 4, 8, and 16 ohms

Mono: 0.25, 0.5, 1, 2, 4, and 8 ohms

OUTPUT VOLTAGES

25 volts, stereo and mono; 70 volts, stereo and

mono

DAMPING FACTOR

27 at 0.5 ohm output, 50 at 1 ohm output, 29 at 2

ohm output, 21 at 4 ohm output, 14 at 8 ohm output.

INPUT IMPEDANCE

200,000 ohms

INPUT SENSITIVITY

0.5 volts input required to produce rated output.

Level control provided for input voltages up to 30

volts.

POWER REQUIREMENTS

120 volts, 50/60 Hz, 160 watts at zero signal out-

put. 1400 watts at rated output.

SEMICONDUCTOR COMPLEMENT

46 Silicon transistors, 22 Silicon rectifiers and

diodes

MECHANICAL INFORMATION

SIZE: Front pane! measures 19 inches wide (48.26

cm) by 10½ inches high (26.67 cm). Chassis measures 17 inches wide (43.18 cm) by 10 inches high

(25.4 cm) by 17 inches deep (43.18 cm), including

connectors. Clearance in front of mounting panel including knobs 2 inches (5.08 cm)

FINISH: Front panel is anodized gold and black.

Chassis is black baked enamel.

MOUNTING: Standard 19" (48.26 cm )rack mounting.

WEIGHT: 128 pounds (58.06 kg) net, 143 pounds

(64.86 kg) in shipping carton.

SPECIAL FEATURES: The amplifier is completely

stable when connected to any loudspeaker system

and to any reactive loads. The MC 2300 has special

circuits to prevent damage by short circuit or open

circuit of the output loads, or by any amount of output impedance mis-match.

Thermal cutouts are mounted on the output transistor heat sinks to provide protection in the event of

inadequate ventilation.

9

Page 12

Typical

HARMONIC DISTORTION vs. POWER OUTPUT

Performance

Charts

.5

.4

.3

.2

.1

0

.1

POWER BANDWIDTH

400

360

320

280

240

200

160

120

80

40

0

10

INTERMODULATION DISTORTION

1

POWER OUTPUT IN AVERAGE WATTS

100

FREQUENCY HERTZ

10

1000

100

10K

1K

100 K

.7

.6

.5

.4

.3

.2

.1

0

.1

1

POWER OUTPUT IN EQUIVALENT AVERAGE WATTS

10

100

1000

10

Page 13

Technical Description

Each channel of the MC 2300 can be divided into

five different sections. These sections are (1) input

amplifier, (2) power amplifier circuit, (3) limiter circuit, (4) meter circuit and (5) power supplies.

INPUT AMPLIFIER

The MC 2300 will deliver rated output from an input signal of 0.5 volts. The input control reduces the

amount of signal into the input amplifier as the setting is reduced. By the correct setting of the control

input signals on the order of 30 volts can be applied

to the input of the MC 2300 without overdriving the

input. At the input amplifier two NPN transistors, Q2

and Q4, are connected in a differential amplifier arrangement. The two inputs to the differential amplifier

are the input signal and the feedback signal from the

output of the input amplifier. The use of a differential

amplifier provides the most efficient use of larger

amounts of negative feedback to maintain low noise

and distortion. The combined output of the differential amplifier feeds a common emitter voltage amplifier Q6. The output of the Q6 is coupled via a large

value capacitor to the power circuit and to the feedback input of the differential amplifier. A large value

capacitor is used to assure good low frequency reproduction and to assure that no DC is coupled to

the power amplifier circuits. From the collector of

Q6 the resistors R20 and R18 form a dividing network

which determines the amount of negative feedback

fed to the differential amplifier. The path provides

both AC and DC feedback. A small trimming capacitor parallels R20 to increase the amount of feedback

at frequencies above 50,000 Hz. This increased feedback reduces the noise level of the input section

where the signal to noise level is more critical, it also

rolls off the frequency response above 50,000 Hz.

Resistors R9 and R10 with C5 C6 form a filter chain

to filter the ± 21 volts used to supply the input amplifier. Left and right channels operate identically.

The output of the left and right input amplifiers is fed

to the mono/stereo switch.

OPERATION OF MONO/STEREO SWITCH

If the MODE switch is in the STEREO position

each input amplifier is directly connected to its respective power amplifier. In the MONO position the

output of the right channel input amplifier is fed to

both left and right power amplifiers, the LEFT INPUT

is disconnected. For stereo or twin channel operation the MC 2300 has two independent amplifying

sections. Consequently, each amplifier output can be

loaded with any desired impedance load. For MONO

operation the two power amplifier output sections

are connected together for parallel operation. The

output load therefore must be connected to the output of each channel strapped together in parallel.

Should the MODE switch be left in the STEREO

position and the output transformers be strapped to

a mono load, one channel will attempt to drive the

other and cause high circulating currents and over-

heating. Be certain that the MC 2300 is never oper-

ated in the stereo mode with the outputs strapped

in parallel.

POWER AMPLIFIER

At the right input channel power amplifier input,

two PNP transistors (Q102 and Q104) are connected

in a differential amplifier configuration. As in the

11

Page 14

12

Page 15

input amplifier the two signals to the differential

amplifier are the normal power amplifier input signal and the negative feedback signal from the power

amplifier output. The combined output of the differential amplifier feeds transistor Q106 which is a

common emitter Class A linear voltage amplifier. The

output of Q106 is directly coupled to the bases of

transistors Q112 and Q118 which are NPN and PNP

complementary medium power driver transistors. The

driver stages furnish the current required to the

bases of the output transistors Q116 thru Q138. Output transistors Q116, 120, and 124, 128, 132, 136 con-

trol the positive portion of the output signal while

transistors Q118, 122, 126, 130, 134, 138 control the

negative half of the output signal. These 12 output

transistors work together forming a series push-pull

output capable of delivering extremely high currents.

The output transistors are mounted on oversized

black anodized heat sinks. Two long life quiet running fans draw air over the heat sinks and out the

rear of the unit. With all covers in place the MC 2300

will run relatively cool even under full load conditions. Resistor R112 completes the DC negative feedback path to the differential input while the resistors

R112 and R106 form a voltage divider network for

the AC negative feedback.

A high value resistor, R118, in series with a high

voltage power supply acts as a current source for the

driver transistors Q112 and Q114. The dual diode

D104 and resistor R27 set the standing current for all

of the output transistors to achieve Class B operation.

Driver transistor Q112 is physically mounted atop the

dual junction diode D104 causing the junction voltage drop to decrease as the diode is heated. This

change in voltage causes the standing current to re-

main constant regardless of the operating temperatures.

13

Page 16

LIMITER CIRCUIT

In the power amplifier circuit the amount of signal

output has a linear relationship with the input signal.

In the event of a short circuit or severe impedance

mismatch the limiter circuit will protect the output

transistors against failure. The Mclntosh patented

Sentry Monitoring circuit constantly monitors the output signal and instantly reacts to prevent overload to

the output transistors. At signal levels up to rated output the limiter circuit is a high impedance circuit in

all modes and has no effect upon the output signal.

If the power output exceeds the design limits the

limiter circuit becomes low impedance and reduces

the signal to the output transistors.

Both positive and negative halves of the output are

monitored independently and the circuit operation

is similar for both halves. The amount of current flowing through an output transistor is monitored by sensing the voltage measured across the emitter (positive) or collector (negative) resistor relative to the

output buss. This voltage is applied to the base of the

limiter transistor Q107 (positive) and/or Q109 (negative) via the voltage dividing network R121, 129 (positive) and/or R123, R131 (negative). When the current

flowing in the output attempts to exceed the design

limits then the voltage at the base of the limiter transistors causes those transistors to conduct making a

portion of the signal to the base of the driver transistors Q111 (positive) and Q113 (negative) to be

drained off.

METER CIRCUIT

Ordinary meters lack the capability of indicating

the short interval of power in a sound wave. The mass

of the meter movement is too great to respond to the

nearly instantaneous changes in music program material. Mclntosh has developed circuits that permit

the meters of the MC 2300 to respond to the short

interval power in a sound wave to an accuracy of

98%.

Monitoring of the output power is done at the primary or input of the autoformer. Sampling the output

power in this portion of the circuit gives true power

readings regardless of output impedance selected.

To be able to read power peaks that are sustained

for such extremely short durations, Mclntosh engineers developed circuits that accelerated the upswing of the meter and caused the needle to be held

at the peak reading long enough for the human eye

to perceive the indication of the needle. The Mclntosh meter circuit is a dynamic peak locking meter

circuit that does both things. (Patented)

Diode D203 and resistor R217 tied to the negative

supply place a bias on the emitter of transitor Q201

to hold the transistor just at the threshold of conduction. Diode D201 passes only the positive portions of

the input signal to the base of Q201 charging the capacitor C201. Since the transistor Q201 is on the

edge of conduction the slightest positive swing of input signal causes conduction to begin. The largest

capacitor C203 in the emitter circuit will appear as a

direct short at first to the negative supply thereby accelerating the needle of the meter upscale. At the

peak of the signal the needle will stop its upswing.

When the meter needle reaches peak and the input

signal starts a downswing, the capacitor C201 starts

to lose its charge by the RC time constant of C201,

R209. For that amount of time a positive charge is

supplied to the base of Q201 causing it to conduct for

a longer length of time. The RC combination R215,

14

Page 17

C203 act as a meter upswing accelerator while the

RC combination R209, C201 act as a pulse or time

stretching aid. Variable resistor R213 is used to adjust the meter to read exactly " + 3" at 300 watts

RMS. All components of the meter circuit have been

selected and designed to have maximum flat response at the frequency extremes. A reading of a

given power is correct regardless of the frequency

of the signal. The MC 2300 contains two independent

meters and meter circuits. Both meter circuits operate the same and are completely independent except

for meter range setting. The meter range switch does

not alter the sensitivity of the meter circuit but attenu-

ates, by the correct ratio, the amount of input signal

to the meter circuit.

POWER SUPPLIES

To deliver rated power at frequency extremes, de-

sign of a power amplifier supply must have good

regulation and ample reserve. At lower frequencies

the power supply capacitors must be of sufficient

size to deliver full voltage, cycle after cycle, with no

increase in ripple. At higher frequencies power tran-

sistors require more power. The power supply must

be able to furnish the additional power without sacrificing regulation or overheating. In all cases the

power furnished to one channel should have no effect

upon the performance of second channel. Any effect

would cause cross talk and poor channel separation.

In stereo use a stereo power amplifier must act as

two separate amplifiers whether their power signals

are common or separate. This design goal is fully

achieved in the MC 2300.

In the Mclntosh MC 2300 two high current supplies

are used. Each high current supply furnishes the

positive and negative forty volts required in the power

output circuits. The four 39,000 microfarad capacitors store ample power (over 120 joules) for fre-

quencies in the low range. The power transformer

has been designed to run relatively cool at full power

output. Bridge rectifiers D301 and D302 are used in

both high current supplies for most efficient conversion of power.

A high voltage lower current supply is designed to

furnish power to the lower level and driver circuits.

Full wave recification and considerable filtering assure clean signal amplification with no added hum or

noise.

A resettable circuit breaker in the primary of the

power transformer and two heat sensing switches

S302, S303 protect the amplifier against overload

and/or overheat.

15

Page 18

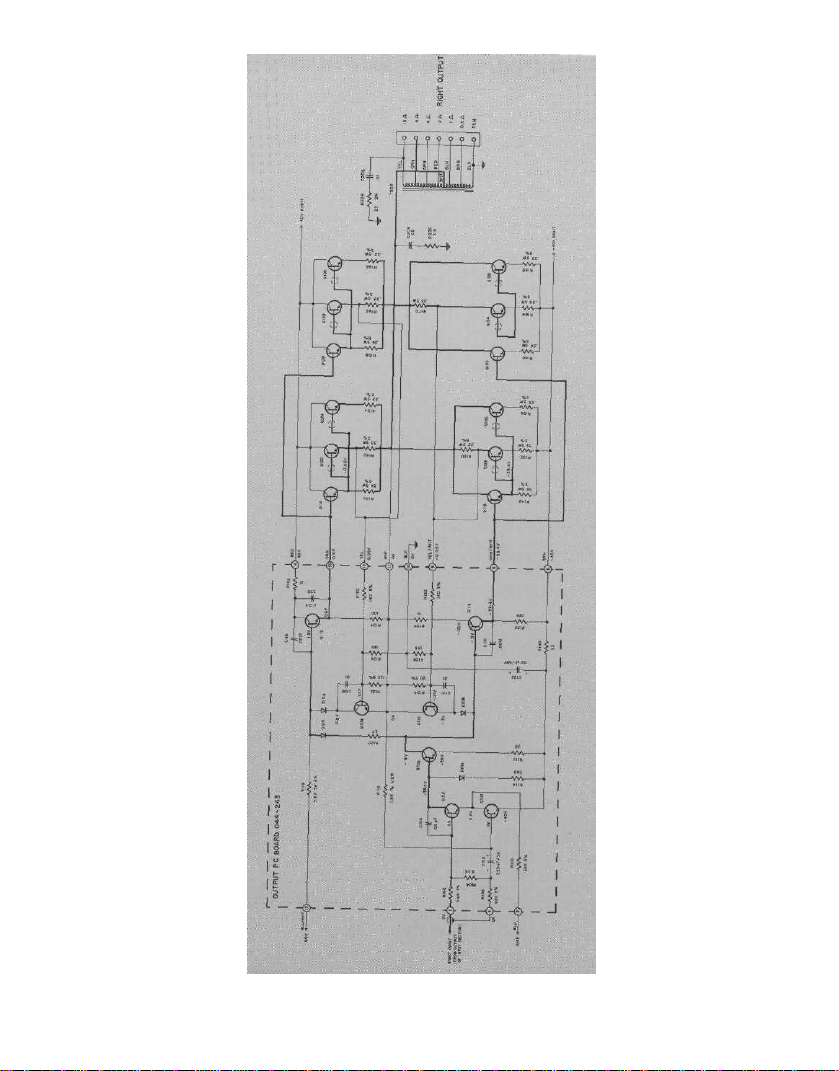

Block Diagram

16

Page 19

Page 20

MCINTOSH LABORATORY INC.

2 CHAMBERS ST., BINGHAMTON, N. Y. 13903

607-723-3512

Design subject to change without notice.

Printed in U.S.A.

038-662

Loading...

Loading...